Page 1

MCH Series Drives

LonWorks Communications Guide

Page 2

About These Instructions

This documentation applies to the use of an MCH Series Variable Frequency Drive with LonWorks protocol and

should be used in conjunction with the MCH Series Installation and Operation Manual (Document MH01) that

shipped with the drive. These documents should be read in their entirety as they contain important technical data

and describe the installation and operation of the drive.

LON®, LonTalk® and LonWorks® are registered trademarks of the Echelon Corporation, San Jose CA 95126,

http://www.echelon.com; support@echelon.com.

Anybus® and ABS-S® are registered trademarks of HMS Industrial Networks AB, Sweden, USA, Germany and

other countries, http://www.anybus.com.

Modbus ™ is a registered trademark of Schneider Electric, founder of Modbus-IDA, http://www.modbus-IDA.org.

© 2003 AC Technology Corporation

No part of this documentation may be copied or made available to third parties without the explicit written approval

of AC Technology Corporation. All information given in this documentation has been carefully selected and tested

for compliance with the hardware and software described. Nevertheless, discrepancies cannot be ruled out. AC

Tech does not accept any responsibility nor liability for damages that may occur. Any necessary corrections will be

implemented in subsequent editions.

Page 3

Contents

1 Safety Information .............................................................................................................1

1.1 Warnings, Cautions and Notes ..............................................................................1

1.1.1 General ....................................................................................................1

1.1.2 Application ...............................................................................................1

1.1.3 Installation ...............................................................................................1

1.1.4 Electrical Connection ................................................................................2

1.1.5 Operation .................................................................................................2

2 Introduction .......................................................................................................................3

2.1 Hardware Description ...........................................................................................3

2.2 LED Status Indicators ............................................................................................4

2.3 Serial Communications Wiring ..............................................................................5

3 Drive Setup and Programming ...........................................................................................6

3.1 Added Programming Parameters ..........................................................................6

3.2 Bus Configuration Parameters ...............................................................................7

3.3 Omitted Parameters and Selections ......................................................................9

3.4 Modified Parameters and Selections .....................................................................9

3.5 Serial Communication Setup .................................................................................10

4 MCH LonWorks® Network Variables .................................................................................12

4.1 LonWorks® Network Variable Map .......................................................................12

4.2 Supported Input Network Variables .......................................................................13

4.3 Supported Output Network Variables .....................................................................15

4.4 Supported Configuration Network Variables ..........................................................19

4.5 LonWorks XIF Files ...............................................................................................23

i RG-MHLON

Page 4

1 Safety Information

1.1 Warnings, Cautions and Notes

1.1.1 General

Some parts of Lenze controllers (frequency inverters, servo inverters, DC controllers) can be live, moving

and rotating. Some surfaces can be hot.

Non-authorized removal of the required cover, inappropriate use, and incorrect installation or operation

creates the risk of severe injury to personnel or damage to equipment.

All operations concerning transport, installation, and commissioning as well as maintenance must be

carried out by qualified, skilled personnel (IEC 364 and CENELEC HD 384 or DIN VDE 0100 and IEC report

664 or DIN VDE0110 and national regulations for the prevention of accidents must be observed).

According to this basic safety information, qualified skilled personnel are persons who are familiar with

the installation, assembly, commissioning, and operation of the product and who have the qualifications

necessary for their occupation.

1.1.2 Application

Safety Information

Drive controllers are components designed for installation in electrical systems or machinery. They are

not to be used as appliances. They are intended exclusively for professional and commercial purposes

according to EN 61000-3-2. The documentation includes information on compliance with EN 61000-3-2.

When installing the drive controllers in machines, commissioning (i.e. the starting of operation as directed)

is prohibited until it is proven that the machine complies with the regulations of the EC Directive 98/37/EC

(Machinery Directive); EN 60204 must be observed.

Commissioning (i.e. starting drive as directed) is only allowed when there is compliance to the EMC Directive

(89/336/EEC).

The drive controllers meet the requirements of the Low Voltage Directive 73/23/EEC. The harmonised

standards of the series EN 50178/DIN VDE 0160 apply to the controllers.

The availability of controllers is restricted according to EN 61800-3. These products can cause

radio interference in residential areas. In the case of radio interference, special measures may be

necessary for drive controllers.

1.1.3 Installation

Ensure proper handling and avoid excessive mechanical stress. Do not bend any components and do not

change any insulation distances during transport or handling. Do not touch any electronic components

and contacts. Controllers contain electrostatically sensitive components, which can easily be damaged by

inappropriate handling. Do not damage or destroy any electrical components since this might endanger

your health! When installing the drive ensure optimal airflow by observing all clearance distances in the

drive's user manual. Do not expose the drive to excessive: vibration, temperature, humidity, sunlight, dust,

pollutants, corrosive chemicals or other hazardous environments.

1 RG-MHLON

Page 5

Safety Information

1.1.4 Electrical Connection

When working on live drive controllers, applicable national regulations for the prevention of accidents (e.g.

VBG 4) must be observed.

The electrical installation must be carried out in accordance with the appropriate regulations (e.g.

cable cross-sections, fuses, PE connection). Additional information can be obtained from the regulatory

documentation.

The regulatory documentation contains information about installation in compliance with EMC (shielding,

grounding, filters and cables). These notes must also be observed for CE-marked controllers.

The manufacturer of the system or machine is responsible for compliance with the required limit values

demanded by EMC legislation.

1.1.5 Operation

Systems including controllers must be equipped with additional monitoring and protection devices according

to the corresponding standards (e.g. technical equipment, regulations for prevention of accidents, etc.).

You are allowed to adapt the controller to your application as described in the documentation.

DANGER!

• After the controller has been disconnected from the supply voltage, do not touch the live

components and power connection until the capacitors have discharged. Please observe the

corresponding notes on the controller.

• Do not continuously cycle input power to the controller more than once every three minutes.

• Close all protective covers and doors during operation.

WARNING!

Network control permits automatic starting and stopping of the inverter drive. The system design

must incorporate adequate protection to prevent personnel from accessing moving equipment

while power is applied to the drive system.

Table 1: Pictographs used in these instructions

Pictograph Signal word Meaning Consequences if ignored

DANGER!

WARNING!

STOP!

NOTE

Warning of Hazardous Electrical

Voltage.

Impending or possible danger

for persons

Possible damage to equipment Damage to drive system or its surroundings

Useful tip: If observed, it will

make using the drive easier

Reference to an imminent danger that may

result in death or serious personal injury if the

corresponding measures are not taken.

Death or injury

RG-MHLON 2

Page 6

2 Introduction

This document explains how to connect an MCH Drive to a LonWorks® network. It is intended as a serial

communications supplement only and will not discuss normal drive operations. For more information

regarding normal drive setup and functionality, refer to the MCH Installation and Operation Manual (MH01).

LonWorks® technology is a complete platform for implementing control network systems. These networks

consist of intelligent control devices or nodes that interact with their environment and communicate with

each other using a common, message based protocol (LonTalk®). A LonWorks® network can consist of

up to 32,385 nodes divided into 255 subnets (127 nodes/subnet).

2.1 Hardware Description

To connect to a LonWorks® network, the MCH Drive utilizes an Anybus-S® Drive Profile Embedded

Interface Card that supports Version 1.1 of the LonMark® 6010 Functional Profile for Variable Speed Motor

Drives. This Anybus-S LonWorks (ABS-LON®) module is located inside of the bypass or option box that is

attached to the MCH Drive.

The ABS-LON® module communicates according to the LonTalk® protocol. This means that it can

communicate with all LonWorks® nodes that comply with this protocol, but it does not necessarily mean

that all services available in the LonTalk® protocol are supported.

Introduction

The ABS-LON® module uses the FTT-10A (Free Topology Twisted Pair) transceiver from Echelon Corporation.

This is the most commonly used twisted-pair media in building automation and this architecture supports

star, bus and loop wiring. The FTT-10A transceiver connects to a twisted pair cable with a baud rate of 78

kbit/s. The FTT-10A transceiver appears as a high impedance to the network when unpowered, and does

not interfere with network communications when powered down.

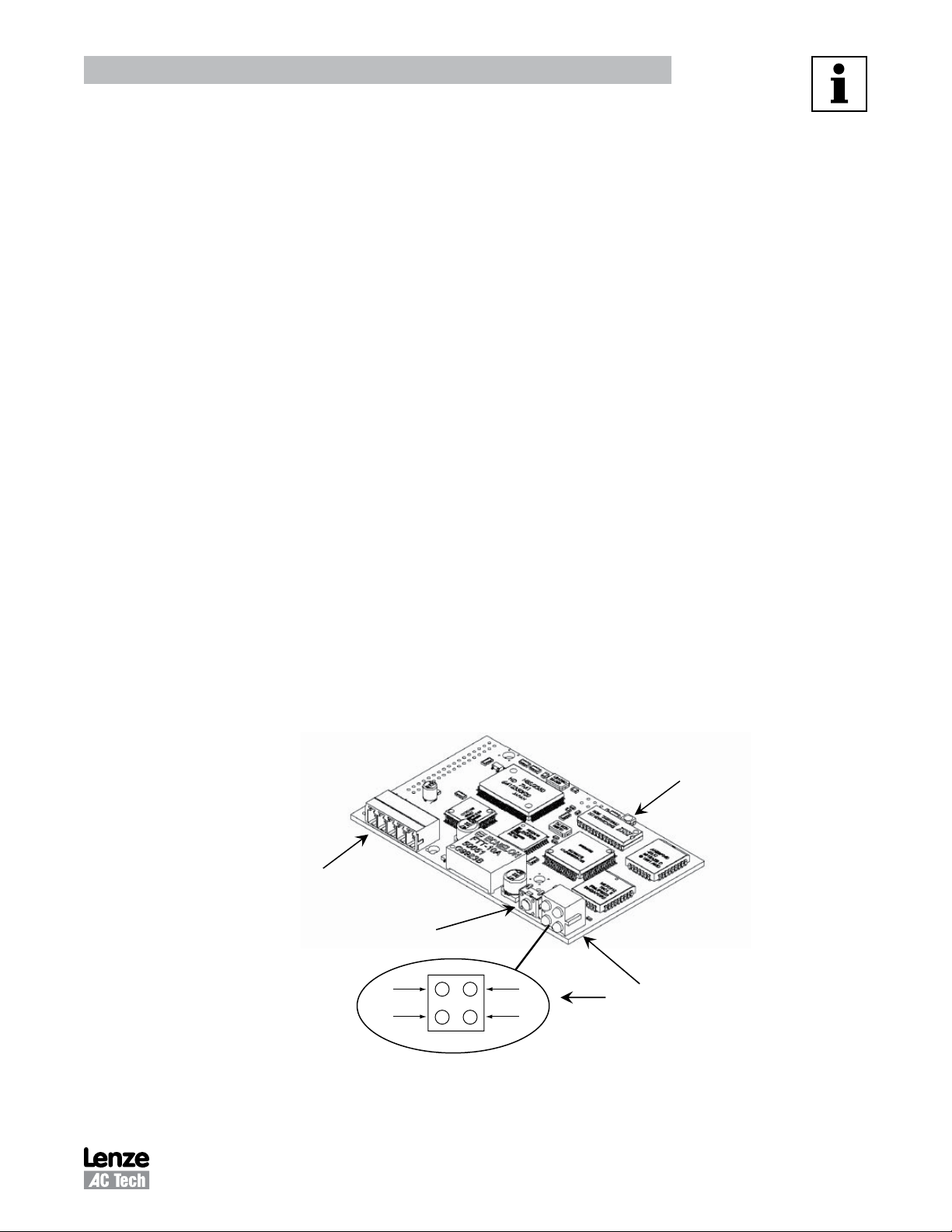

Figure 1 identifies the components of the communications module intended for user interaction.

Watchdog LED

Socket for LonWorks

Bus Connector

Service Pin Pushbutton

1

4

2

3

LED Status Indicators

Figure 1: MCH LonWorks® Comm Module

3 RG-MHLON

Page 7

Drive Setup & Programming

2.2 LED Status Indicators

LED 1 - Drive Communication

This LED indicates the communication status between the comm module and the drive.

LED State Indicates:

Steady Green Link OK

Steady Red Link lost, permanent

Flashing Red Link lost, temporary

LED 2 - Service

This LED indicates the node configuration and application status.

LED State Indicates:

Steady OFF Node configured and installed in network

Steady Green Node not configured, has no application; Error detected by Neuron Self Test routine

Flashing Green Node not configured and not installed in network but node has an application

LED 3 - Wink

This LED indicates receipt of a wink command.

LED State Indicates:

Flashing Red

Steady OFF Normal state

Wink command received on LonWorks

® network

LED 4 - Network Status

This LED indicates the communication status between the module and the LonWorks® network.

LED State Indicates:

Steady OFF No power

Flashing Red Receive heartbeat timeout occurred; Fieldbus communication loss indicated to host: RX_FAIL

Steady Green Module and network are communicating correctly

Watchdog LED (WD)

This LED indicates module, drive and software status.

LED State Indicates:

Flashing Green 1Hz Module initialized and running properly

Flashing Green 2Hz Module not initialized

Flashing Red 1Hz Hardware check fault

Flashing Red 4Hz Drive initialization failed

Steady Orange Software download enabled

RG-MHLON 4

Page 8

Drive Setup & Programming

2.3 Serial Communications Wiring

Figure 2 illustrates one method of wiring the MCH Series LonWorks® Bus Connector with an optional

switch to provide remote operation of the service pin.

Optional Switch MCH LonWorks Bus Connector

(For remote

operation of

)

service pin

Figure 2: Wiring the MCH LonWorks® Bus Connector

Net A, Net B This is the 2-wire LonWorks bus designed according to the LonMark® design guidelines.

The bus is of non-polarization character and supports line-powered networks.

Service Pin This pin is used for the (optional) remote functionality of the Service Pin pushbutton. Refer

to Figure 2 for an illustration on how to wire this.

1

Shield

2

Ground

3

Remote Service Pin

4

Net A

5

Net B

Ground This pin is used for the remote Service Pin functionality. Refer to Figure 2.

Shield This pin should be connected to the shield of the LonWorks cable, in cases where such

cable is to be used. The pin is connected to the Ground terminal (2) on the communications

module through an RC-filter.

5 RG-MHLON

Page 9

Drive Setup & Programming

3 Drive Setup and Programming

Most drive parameters (including those required for serial communications) are not accessible through the

LonWorks® interface. They can only be accessed by entering the Programming Mode of the drive itself.

Refer to the MCH Installation and Operation Manual (MH01) for more information. The parameter information

in manual MH01 is based on the standard MCH Series Modbus™ Drive. The differences between the drive

programming parameters described in the manual and those that exist in the MCH Series LonWorks®

Drive are explained in sections 3.1-3.4 herein.

3.1 Added Programming Parameters

60 SERIAL TIMEOUT This parameter makes the serial watchdog timeout period selectable.

(Section 3.5)

86 MOTOR RATED SPEED This parameter allows the user to enter the nominal speed of the motor

in RPM. This value is required for LON parameter nvoSpeedActRpm to

function properly. This parameter has a minimum value of 1 RPM and a

maximum value of 65000 RPM. The default is 1800 RPM.

89 MOTOR RATED FREQUENCY This parameter allows the user to enter the nominal frequency of the

motor in Hz. This value is required for many LON parameters (including

nviDrvSpeedStpt and nvoDrvSpeed) to function properly. This parameter

has a minimum value of 0.00 Hz and a maximum value of 650.00 Hz. The

default is 60.00 Hz.

125 APP REVISION This parameter allows the user to view the version of the application

software installed in the ABS_LON module. This parameter is used for

troubleshooting and to establish compatibility between the drive software

and the ABS_LON module. If this parameter is displaying a value of 0104

or 9999, contact AC Tech.

126 CPI REVISION This parameter allows the user to view the version of the common profile

interface software installed in the ABS_LON module. This parameter is

used for troubleshooting and to establish compatibility between the drive

software and the ABS_LON module. If this parameter is displaying a value

of 0124 or 9999, contact AC Tech.

127 CFG REVISION This parameter allows the user to view the version of the AC Tech

configuration software installed in the ABS_LON module. This parameter

is used for troubleshooting and to establish compatibility between the

drive software and the ABS_LON module. If this parameter is displaying a

value of 0001 or 9999, contact AC Tech.

RG-MHLON 6

Page 10

Drive Setup & Programming

3.2 Bus Configuration Parameters

The Bus configuration parameters are only used to provide additional information about the installation

state of the drive. As the address information usually is assigned from the network side in a LonWorks

network, in the programming mode of the drive, these parameters are read-only.

100 NODE STATE This parameter contains the current state of the network interface. Configured

Online is the normal run-time mode and means that the drive is commissioned

and online. Soft/Bypass/Hard Offline means the node is not participating actively

on the network.

Value Node State

0

1

2

3

4

5

6

7

Unknown State

Unconfigured

Applicationless

Configured Online

Configured Offline

Soft Offline

Configured Bypass Offline

Hard Offline, Bypass Offline

101 NEURON ID [5] Byte 6 of the unique Neuron ID (MSB)

102 NEURON ID [4] Byte 5 of the unique Neuron ID

103 NEURON ID [3] Byte 4 of the unique Neuron ID

104 NEURON ID [2] Byte 3 of the unique Neuron ID

105 NEURON ID [1] Byte 2 of the unique Neuron ID

106 NEURON ID [0] Byte 1 of the unique Neuron ID (LSB)

107 NODE ADDRESS 1 Indicates the ID of the node within this subnet. A value of 0 means that it is not

assigned.

108 NODE SUBNET 1 Indicates to which subnet this node belongs. A value of 0 means that it is not

assigned.

7 RG-MHLON

Page 11

Drive Setup & Programming

Each domain in a LonWorks network has a unique ID of 0, 1, 3 or 6 bytes in length. If the ID is shorter than

6 bytes, it is left justified in the following parameters (109-114).

109 DOMAIN ID 1 [5] Byte 6 of the domain ID (MSB)

110 DOMAIN ID 1 [4] Byte 5 of the domain ID

111 DOMAIN ID 1 [3 Byte 4 of the domain ID

112 DOMAIN ID 1 [2] Byte 3 of the domain ID

113 DOMAIN ID 1 [1] Byte 2 of the domain ID

114 DOMAIN ID 1 [0] Byte 1 of the domain ID (LSB)

115 NODE ADDRESS 2 Indicates the ID of the node within this subnet. A value of 0 means that it is not

assigned.

116 NODE SUBNET 2 Indicates to which subnet this node belongs. A value of 0 means that it is not

assigned.

Each domain in a LonWorks network has a unique ID of 0,1,3 or 6 bytes in length. If the ID is shorter than

6 bytes, it is left justified in the following parameters (117-122).

117 DOMAIN ID 2 [5] Byte 6 of the domain ID (MSB)

118 DOMAIN ID 2 [4] Byte 5 of the domain ID

119 DOMAIN ID 2 [3] Byte 4 of the domain ID

120 DOMAIN ID 2 [2] Byte 3 of the domain ID

121 DOMAIN ID 2 [1] Byte 2 of the domain ID

122 DOMAIN ID 2 [0] Byte 1 of the domain ID (LSB)

123 XMIT ERRORS The number of CRC errors detected during packet reception. These may be due

to collisions or noise on the transceiver input.

124 TRANS TIMEOUTS The number of times that the node failed to receive expected acknowledgements

or responses after retrying the configured number of times. These may be due

to destination nodes being inaccessible on the network, transmission failures

because of noise on the channel, or if any destination node has insufficient

buffers or receive transaction records.

RG-MHLON 8

Page 12

Drive Setup & Programming

3.3 Omitted Parameters and Selections

36 SLEEP THRESHOLD Sleep Mode functionality has not been added to the MCH Series LonWorks®

37 SLEEP DELAY

38 SLEEP BANDWIDTH

41 ANALOG INPUT FILTER

52 TB14 OUT The following options have not been added to these parameters in the MCH

53 TB15 OUT

54 RELAY INV MIN/MAX A

58 SERIAL ADDRESS The ABS_LON module only communicates with one MCH Drive so there is

drive so these drive parameters do not exist.

Series LonWorks® drive:

MIN ALARM

INV MIN ALARM

MAX ALARM

INV MAX ALARM

no need for the drive to have a unique serial address and this parameter has

been removed.

3.4 Modified Parameters and Selections

8 ACCEL This parameter defines the time that it will take for the drive to ramp the motor up

from 0.00Hz to Drive Parameter #11 (Max Frequency).

9 DECEL This parameter defines the time that it will take for the drive to ramp the motor down

from Drive Parameter #11 (Max Frequency) to 0.00Hz.

24 AUTO SOURCE The default selection for this parameter is KEYPAD. This setting is required if the

drive speed is to be modified over the LonWorks® network.

32 HZ MULTIPLIER The default setting for this parameter is 30.00.

56 SERIAL LOSS The selections for this parameter are FAULT (default) and PRESET#3. The functionality

of this parameter is described in Section 3.5 Serial Communications Setup.

9 RG-MHLON

Page 13

Drive Setup & Programming

3.5 Serial Communication Setup

The factory default values of the drive parameters have been set to allow immediate serial communications

(without serial stop/start and serial speed commands). For serial speed and/or serial start/stop control,

modify the setting of Drive Parameter #30 (Control). The drive parameters that are required for serial

communications, including Drive Parameter #30, are described herein.

24 AUTO SOURCE This parameter must be set to KEYPAD for the drive speed or setpoint to be modified

over the network.

30 CONTROL This parameter should be set to accommodate the specific application intent:

NORMAL Serial start/stop and serial speed commands are invalid.

NORM NO HAND Same as NORMAL except the HAND/OFF/AUTO, herein referred to

SERIAL SPEED Serial start commands are invalid. Serial speed commands are

S SPD/NO HAND Same as SERIAL SPEED except H/O/A is limited to settings of OFF

as H/O/A, is limited to settings of OFF and AUTO.

valid in AUTO.

and AUTO.

SERIAL AUTO Serial start/stop and serial speed commands are valid in AUTO.

This setting forces the drive to be started via the serial link when

in AUTO.

S AUTO/NO HND Same as SERIAL AUTO except H/O/A is limited to settings of OFF

and AUTO.

The STOP command issued when LonWorks (LON) parameter nviEmrgOvrd is set to EMERG_SHUTDOWN

is accepted regardless of the H/O/A switch position.

RG-MHLON 10

Page 14

Drive Setup & Programming

56 SERIAL LOSS This parameter sets the action to be taken in the event that the LON has modified

the speed command or started the drive and a serial watchdog timeout occurs. The

options for this parameter are FAULT (default) and PRESET#3.

If FAULT is selected and the drive is running when a serial watchdog timeout occurs

the drive will trip into a SERIAL FAULT stopping the drive and taking it out of serial

control. A fault reset command (issued via LON parameter nviResetFault), a keypad

stop or a terminal stop is required to clear the fault.

If PRESET#3 is selected and a timeout occurs the drive will continue to run at the

speed defined in Drive Parameter #3 (PRESET #3). If the drive is stopped (KSTOP,

RSTOP, SSTOP or FAULT) or a valid speed command is received from the LON, the

drive will return to its normal speed reference.

When Drive Parameter #30 (CONTROL) is set to SERIAL SPEED, the speed reference

MUST be the drive keypad (-KEY or -MKB) for the serial loss action to take effect.

When CONTROL is set to SERIAL AUTO the serial loss action will take effect with any

speed reference.

This parameter also defines the action to be taken in the event that the drive is

placed OFFLINE or a Receive Heartbeat timeout (RX_FAIL) occurs.

57 SERIAL This parameter needs to be set to either WITH TIMER (default) or W/O TIMER for the

drive to communicate through the serial link. Serial communications will not work if

this parameter is set to DISABLED.

60 SERIAL TIMEOUT This parameter makes the serial watchdog timeout period selectable. It has a

minimum value of 10 seconds and maximum value of 255 seconds. The default is

30 seconds. If no action is to be taken when a serial watchdog timeout occurs, Drive

Parameter #57 (Serial) should be set to W/O TIMER. This will disable the watchdog

timer. Otherwise Drive Parameter #57 (Serial) should be set to WITH TIMER. The

action to be taken when a timeout occurs is then determined by Drive Parameter

#56 (Serial Loss).

NOTE: Receive heartbeat timeouts and OFFLINE occurrences are not affected by the

setting of Parameter 60.

11 RG-MHLON

Page 15

LonWorks Network Variables

4 MCH LonWorks® Network Variables

The MCH LonWorks® Network Variables (nv) are divided into three types: input, output and configuration.

Sections 4.2 - 4.5 describe each of these variable types and the individual supported variables within each.

4.1 LonWorks® Network Variable Map

Figure 3 is a visual map of the supported LonWorks® network variables for the MCH Series drive.

Variable Speed Motor Drive: 6010

nviDrvSpeedStpt

nv1

SNVT_switch

nviDrvSpeedScale

nv2

SNVT_lev_percent

nviResetFault

nv8

SNVT_switch

nviEmergOverride

nv9

SNVT_hvac_emerg

nviDigOutput1 (Not supported)

nv10

SNVT_switch

nviDigOutput2 (Not supported)

nv11

SNVT_switch

nviAnlgOutput (Not supported)

nv12

SNVT_lev_percent

Mandatory

Configuration Properties

nc17 - nciLocation

nc50 - nciMaxSpeed (mandatory)

nc53 - nciMinSpeed (mandatory)

nc48 - nciRcvHrtBt

nc49 - nciSndHrtBt (mandatory)

nc52 - nciMinOutTm

nc158 - nciNmlSpeed (mandatory)

nc159 - nciNmlFreq (mandatory)

nc160 - nciRampUpTm (mandatory)

nc161 - nciRampDownTm (mandatory)

nc162 - nciDrvSpeedScale

Manufacturer-Defined

Network

Variables

Optional

Network

Variables

Network

Variables

nvoDrvSpeed

nv4

SNVT_lev_percent

nvoDrvCurnt

nv3

SNVT_amp

nvoDrvVolt

nv5

SNVT_volt

nvoDrvPwr (Not supported)

nv6

SNVT_power_kilo

nvoDrvRunHours

nv7

SNVT_time_hour

nvoSpeedActRpm

nv12

SNVT_count_inc

nvoTorqueAct (Not supported)

nv12

SNVT lev percent

nvoDrvTemp (Not supported)

nv12

SNVT_temp_p

nvoFreqAct

nv12

SNVT_freq_hz

nvoDrvStatus

nv12

SNVT_count

nvoRunning

nv12

SNVT_switch

nvoFaulted

nv12

SNVT_switch

nvoPIDAct (Not supported)

nv12

SNVT_lev_percent

nvoEmergOvrStat

nv12

SNVT_hvac_emerg

nvoDigInput1 (Not supported)

nv12

SNVT_switch

nvoDigInput2 (Not supported)

nv12

SNVT_switch

nvoAnlgInput (Not supported)

nv12

SNVT_lev_percent

nvoParValue

nv12

SNVT_count

Manufacturer-Defined Configuration Properties

ncMFR1 - nciStopMode (UCPT)

ncMFR2 - nciStopLevel (UCPT)

ncMFR3 - nciPIDGain (UCPT) (Not supported)

ncMFR4 - nciPIDIntTime (UCPT) (Not supported)

ncMFR5 - nciPidDerTime (UCPT) (Not supported)

ncMFR6 - nciParValue (UCPT)

ncMFR7 - nciParRead (UCPT)

ncMFR8 - nciParWrite (UCPT)

Figure 3: LonWorks® Network Variable Map for MCH Series Drives

RG-MHLON 12

Page 16

LonWorks Network Variables

4.2 Supported Input Network Variables

NviObjRequest

Definition Network input SNVT_obj_request nviObjRequest;

Explanation This input is used to enable control commands and updates from the network. The

status of the node is reported in nvoObjStatus.

Valid range:

Object Request Function

RQ_UPDATE_STATUS Updates nvoObjStatus

RQ_CLEAR_STATUS Clears nvoObjStatus

RQ_CLEAR_ALARM Resets a drive fault

RQ_REPORT_MASK Reports supported requests in nvoObjStatus

RQ_NORMAL The normal request. Sets object to default state

RQ_DISABLE Stops the drive with the selected stop mode and disables

RQ_ENABLE Enables the drive for operation and enables the object

the operation and object

Commands not listed above will be reported as invalid_request in nvoObjStatus.

NviDrvSpeedStpt

Definition Network input SNVT_switch nviDrvSpeedStpt.

Explanation This input network variable provides a low-resolution speed setpoint. It may also

Valid Range:

use the receive heartbeat function. The speed setpoint is the result of multiplication

of nviDrvSpeedStpt and nviDrvSpeedScl.

State Valid Range

0 Stop the drive

1 Start the drive

-1 (0xff) Auto (Invalid)

Value (% Nominal) Internal Value

-100.0% to -0.5% -200 to -1

0.0% 0

0.5% to 100.0% 1 to 200

Default value The default value is AUTO (state = 0xFF). This value will be adopted at power-up.

This network variable input may use the Receive Heartbeat function if the Receive

Heartbeat function is setup for use. The actual value of drive speed also depends

on the setting of nviDrvSpdScl.

13 RG-MHLON

Page 17

NviDrvSpdScl

Definition Network input SNVT_lev_percent nviDrvSpeedScale

Explanation This input network variable provides scaling for nviDrvSpeedStpt (0.005%

For example, if the value of nviDrvSpeedStpt is 100% and nviDrvSpdScl value

For example if nviDrvSpeedStpt value is 100% and nviDrvSpdScl value is -150%,

Valid Range -163.840% to 0.00 % or 0.00% to +163.835%

The value 0x7FFF represents invalid data.

Default Value Defined by nciDrvSpdScl.

LonWorks Network Variables

resolution).

is 150%, then the actual speed setpoint value is 150% meaning that the drive

should run at 1.5 times nominal speed in the forward direction. A negative value

for nviDrvSpdScl sets the drive direction to reverse.

then actual speed setpoint value is -150%, meaning that he drive should run at

1.5 times nominal speed in the reverse direction.

NviResetFault

Definition Network input SNVT_switch nviResetFault

Explanation This input network variable provides a mechanism to clear a fault status in the

Valid Range:

On a transition from 0 to 1, this input network variable clears the fault condition in the drive.

Default Value The drive will power-up in the ‘Reset Fault Ready’ state.

drive.

State Value Command

0 0.0% Reset Fault Ready

1 100.0% Reset Fault

Following a fault reset, this variable must be set back to 0 to enable the next fault

reset.

RG-MHLON 14

Page 18

NviEmrgOvrd

Definition Network input SNVT_hvac_emerg nviEmrgOvrd

Explanation HVAC Emergency Mode. This input network variable provides the ability to stop the

Valid Range:

Default Value EMERG_NORMAL

LonWorks Network Variables

motor in case of an emergency.

Setting Function

EMERG_NORMAL Not emergency mode, motor control enabled

EMERG_PRESSURIZE No functionality in this implementation

EMERG_DEPRESSURIZE No functionality in this implementation

EMERG_PURGE No functionality in this implementation

EMERG_SHUTDOWN Emergency shutdown mode. Stops motor

EMERG_FIRE No functionality in this implementation

EMERG_NUL Value not available

4.3 Supported Output Network Variables

NvoObjStatus

Definition Network output SNVT_obj_status nvoObjStatus

Explanation This nvo reports the node object status.

Valid Range:

Bit Setting Function

Invalid_id Invalid node ID requested

report_mask Reporting supported fields

Disabled (20) RQ_DISABLED is active

electrical_fault (5) Same as the faulted bit in nvoDrvStatus

In_alarm Same as the alarm bit in nvoDrvStatus

NvoDrvSpeed

Definition Network output SNVT_lev_percent nvoDrvSpeed

Explanation This output network variable provides the speed of the drive as a percentage of the

nominal speed.

Valid Range -163.830% to 0.000 % or 0.000% to +163.830%.

The value 0x7FFF represents invalid data.

Default Value 0.000%.

15 RG-MHLON

Page 19

NvoDrvCurnt

NOTE: This parameter is not supported in drives with software version MC11101 or MC11102.

Definition Network output SNVT_amp nvoDrvCurnt

Explanation This output network variable provides the drive output current in Amps.

Valid Range 0.0 to 3276.7 A

Default Value 0.0 A

NvoDrvRunHours

NOTE: This parameter is not supported in drives with software version MC11101 or MC11102.

Definition Network output SNVT_time_hour nvoDrvRunHours

Explanation This output network variable provides total operation time of the motor in hours.

Valid Range 0 to 65535 hours

LonWorks Network Variables

Default Value 0 hours

NvoDrvVolt

NOTE: This parameter is not supported in drives with software version MC11101 or MC11102.

Definition Network output SNVT_volt nvoDrvVolt

Explanation This output network variable provides the drive output voltage in Volts.

Valid Range 0 – 700 V

Default Value 0 V

NvoSpeedActRpm

Definition Network output SNVT_count_inc nvoSpeedActRpm

Explanation This output network variable provides the speed of the drive in RPM’s

Valid Range -32768 to 0 or 0 to 32767

Default Value 0 RPM

RG-MHLON 16

Page 20

NvoFreqAct

Definition Network output SNVT_freq_hz nvoFreqAct

Explanation This output network variable provides the speed of the drive in Hz.

Valid Range 0.0 - 120.00 Hz

Default Value 0.00 Hz

NvoDrvStatus

Definition Network output SNVT_state nvoDrvStatus

Explanation This output network variable provides the status of the drive.

Valid Range

LonWorks Network Variables

Bit Name Description

0 FWD The drive is currently running the motor in forward motion

1 REV The drive is currently running the motor in reverse motion

2 NETCTRL The network is the active source for start/stop control

3 NETREF The network is the active source for the speed reference

4 RTSO Not used

5 FAULT The drive is currently faulted

6 ALARM Not used

7 REF The drive is running the motor at the speed defined by the

speed reference of the active control source (i.e. actual drive

speed = commanded drive speed)

8 FORN Not used

9 ZERO SPEED The drive is running at zero speed

10 LIMIT Not used

11 ACC The drive is currently ramping up to its commanded speed

12 DEC The drive is currently ramping down to its commanded speed

13-15 Not used Not used

Default Value 0

17 RG-MHLON

Page 21

NvoRunning

Definition Network output SNVT_switch nvoRunning

Explanation This output indicates whether or not the motor is running.

Valid Range:

Default Value 0

NvoFaulted

Definition Network output SNVT_switch nvoFaulted

Explanation This output indicates whether or not the drive is currently faulted.

Valid Range:

LonWorks Network Variables

State Value Command

0 0.0% The motor is not running

1 100.0% The motor is running

State Value Command

0 0.0% The drive is not faulted

1 100.0% The drive is faulted

Default Value 0

NvoEmrgOvrd Stat

Definition Network output SNVT_hvac_emerg nvoEmrgOvrdStat

Explanation Feedback for the nviEmrgOvrd

Valid Range:

Default Value EMERG_NORMAL

NvoParValue

Definition Network output SNVT_count nvoParValue

Explanation This variable contains the data read at the parameter set by nciParRead.

Valid Range 1 - 46

Value Function

EMERG_NORMAL Not emergency mode, motor control enabled

EMERG_SHUTDOWN Emergency shutdown mode. Motor stopped.

Default Value 0

RG-MHLON 18

Page 22

LonWorks Network Variables

4.4 Supported Configuration Network Variables

NciSndHrtBt

Definition Network config input SNVT_time_sec nciSndHrtBt

Explanation This input configuration network variable provides the maximum send time for the

variable nvoDrvSpeed.

Valid Range 0.0 to 6553.5 sec

The value 0 disables the Send Heartbeat mechanism.

The value 0xFFFF represents invalid data.

Default Value 0 sec (disabled)

NciRcvHrtBt

Definition Network config input SNVT_time_sec nciRcvHrtBt

Explanation This configuration property is used to control the maximum time that elapses after

the last update to input network variables nviDrvSpeedStpt or nviDrvSpdScl. If

a timeout occurs, the module indicates an RX_FAIL condition to the drive which

induces the Serial Loss action described in Section 3.5.

Valid Range 0.0 to 6553.5 sec

The value 0xFFFF represents invalid data.

The value 0 disables the Receive Heartbeat mechanism.

Default Value 0 sec (disabled)

NciMinOutTm

Definition Network config input SNVT_time_sec nciMinOutTm

Explanation This input configuration network variable controls the minimum period of time that

Valid Range 0.0 to 6553.5 sec

The value 0xFFFF represents invalid data.

The value 0 disables transmission limiting.

Default Value 0.0 sec (disabled)

expires before the network output variables can be propagated (resent).

19 RG-MHLON

Page 23

nciNmlSpeed

Definition Network config input SNVT_rpm nciNmlSpeed

Explanation This configuration property is used to provide the nominal speed of the motor.

Valid Range 1 to 65000 RPM

The value 0xFFFF represents invalid data.

Default Value 1800 RPM

nciNmlFreq

Definition Network config input SNVT_freq_hz nciNmlFreq

Explanation This configuration property is used to provide the nominal frequency of the motor.

Valid Range 0.0 - 650.00 Hz

Default Value 60.00 Hz

LonWorks Network Variables

nciMinSpeed

Definition Network config input SNVT_lev_percent nciMinSpeed

Explanation This configuration property is used to define the minimum speed of a motor. Its

-163.840% <= minimum speed <= maximum speed <= 163.835%

Valid Range -163.840% to 0.000 % or 0.000% to +163.835%

The value 0x7FFF represents invalid data.

Default Value 0.830%

nciMaxSpeed

Definition Network config input SNVT_lev_percent nciMaxSpeed

Explanation This configuration property is used to define the maximum speed of a motor. Its

value is entered as a percentage of nominal speed, as defined by the Nominal

Speed (nciNmlSpeed) configuration value. The value of the minimum speed must

be validated against the value of the maximum speed as follows:

value is entered as a percent of nominal speed, as defined by the Nominal Speed

(nciNmlSpeed) configuration value. The value of the maximum speed must be

validated against the value of the minimum speed as follows:

-163.840% <= minimum speed <= maximum speed <= 163.835%

Valid Range -163.840% to 0.000 % or 0.000% to +163.835%

The value 0x7FFF represents invalid data.

Default Value 100.000%

RG-MHLON 20

Page 24

nciRampUpTm

Definition Network config input SNVT_time_sec nciRampUpTm

Explanation This configuration property is used to set the ramp up time of the drive (i.e. the time

Valid Range 0.1 to 3600.0 sec

(Refer to MCH Installation and Operation Manual for the actual minimum boundary)

The value 0xFFFF represents invalid data.

Default Value 30.0 sec

nciRampDownTm

Definition Network config input SNVT_time_sec nciRampDownTm

Explanation This configuration property is used to set the ramp down time of the drive (i.e.

LonWorks Network Variables

that it will take for the drive to ramp the motor from 0.00Hz to Max Frequency).

the time that it will take for the drive to ramp the motor from Max Frequency to

0.00Hz).

Valid Range 0.3 to 3600.0 sec

(Refer to MCH Installation and Operation Manual for the actual minimum boundary)

The value 0xFFFF represents invalid data.

Default Value 30.0 sec

nciLocation

Definition Network config input SNVT_str_asc nciLocation

Explanation This configuration property can optionally be used to provide more descriptive

Valid Range 31 characters

Default Value Empty spaces

nciDrvSpdScl

Definition Network config input SNVT_lev_percent nciDrvSpeedScale

Explanation Default value for nviDrvSpdScl.

physical location information than can be provided by the Neuron Chip’s 6-byte

location string. The location relates to the object and not to the node.

Valid Range -163.840% to 0.000 % or 0.000% to +163.835%

The value 0x7FFF represents invalid data.

Default Value 100.000%

21 RG-MHLON

Page 25

nciStopMode

Definition Network config input SNVT_switch nciStopMode

Explanation This input network variable is used to choose between coast and ramp stop.

Valid Range:

Default Value 0

nciStopLevel

Definition Network config input SNVT_lev_percent nciStopLevel

Explanation This is the stop level for the drive when it is in ramp to stop mode. When the drive

LonWorks Network Variables

State Value Command

0 0.0% Coast to stop

1 100.0% Ramp to stop

is ramping to a stop and reaches this level, a coast to stop is performed. The value

is relative to nvoDrvSpeed ( i.e. a value of 5% corresponds to a nvoDrvSpeed value

of 5%).

Valid Range -163.840% to 0.00 % or 0.00% to +163.835%

The value 0x7FFF represents invalid data.

Default Value 5.000 %

nciParValue

Definition Network config input SNVT_count_inc nciParValue

Explanation This nci is used as a value input for the user selected parameter nciParWrite.

Valid Range 1 - 46

Default Value 0

nciParRead

Definition Network config input SNVT_count nciParRead

Explanation Chooses the parameter value to be read from the drive.

Valid Range 1 - 46

Default Value 0

RG-MHLON 22

Page 26

LonWorks Network Variables

nciParWrite

Definition Network config input SNVT_count nciParWrite

Explanation Chooses the parameter value to be written to the drive.

Valid Range 1 - 46

Default Value 0

4.5 LonWorks XIF Files

The LonMark external interface (or XIF) file is used to set up a LonWorks network with an MCH Series drive

that has not yet been commissioned. These files are available for download in the Technical Library of the

Lenze-AC Tech website.

Use Drive Parameter #63 to retrieve the software version of your MCH drive. Drives with software versions

MC11103 and later, and MC121xx use the 21312203.XIF file. If your MCH drive has an earlier software

version (MC11101 or MC11102), then contact technical support for the appropriate XIF file.

4.6 Reference and Links

MCH Series Variable Frequency Drives visit:

http://www.lenze-actech.com

LonWorks and Echelon Corporation visit:

http://www.echelon.com

LonMark Functional Profiles (including 6010) visit:

http://www.lonmark.org

ANYBUS-S Drive Profile Embedded Interface Cards, LonMark 6010 Functional Profile visit:

http://www.anybus.com/products/abs.shtml

23 RG-MHLON

Page 27

AC Technology Corporation

630 Douglas Street • Uxbridge MA 01569 • USA

Sales: 800-217-9100 •Service: 508-278-9100

www.lenze-actech.com

RG-MHLON-e3

Loading...

Loading...