Page 1

M... MCA19, MCA21

Asynchronous servo motors with spring−applied

brake mounted on the B−bearing side

Supplement to Operating Instructions

EN

.Z!z

Ä.Z!zä

Page 2

Please read these instructions before you start working!

Follow the safety instructions enclosed.

Important notes

This supplement is only valid together with the general motor operating instructions, see Internet!

Invalid chapters of the motor operating instructions: none

Additions to the "Maintenance and repair" section:

Stop!

When replacing the brake, complete rotor or the hub, the spare part from the

corresponding Lenze repair kit must always be used.

Characteristics and maintenance of the BFK457−16 R and BFK458−18 spring−applied brakes.

Encoder dismounting and mounting.

0Abb. 0Tab. 0

Page 3

Contents i

1 Mechanical installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Important notes 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Spring−applied brake − holding brake 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Characteristics 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 BFK457−16R design − non−adjustable 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 BFK458−18 design − adjustable 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Maintenance/repair 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Spring−applied brake − holding brake 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Wear on spring−applied brakes 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Maintenance 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 Dismounting the MCA19 and 21 fan cover 9. . . . . . . . . . . . . . . . . . . . . . . .

2.1.4 BFK457−16R air gap 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.5 Checking and re−adjusting the BFK458−18 air gap 11. . . . . . . . . . . . . . . . . .

2.2 Replacing the brake 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Dismounting the MCA 19 and 21 encoder 12. . . . . . . . . . . . . . . . . . . . . . . . .

2.3 BFK457−16R 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Dismounting and mounting 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 BFK458−18 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Dismounting and mounting 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Encoder mounting 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lenze ¯ MA 33.0012 ¯ 1.0

3

Page 4

1

1 Mechanical installation

1.1 Important notes

The brake that is mounted here is specially adapted to the use on the MCA 19 and 21.

Mechanical installation

Important notes

Stop!

If the wear air gap of a spring−applied brake is reached, the brake will no

longer be released. In this case, the complete rotor of the brake must be

replaced.

Note!

¯ BFK457−16R: It is not possible to re−adjust the brake. The complete

rotor must be replaced.

¯ BFK458−18: When the wear limit has been reached, the brake must be

re−adjusted, or the complete rotor must be replaced.

Safety system

Stop!

If a safety encoder is used, all maintenance and installation work must be

performed at the Lenze site.

Otherwise any warranty will expire and Lenze GmbH will not accept any

liability for consequential damage.

The IG2048−5V−V3

not be dismounted and mounted. This service work is performed by Lenze.

safety encoder can be mounted on the brakes described here and must

4

Lenze ¯ MA 33.0012 ¯ 1.0

Page 5

1.2 Spring−applied brake − holding brake

1.2.1 Characteristics

Mechanical installation

Spring−applied brake − holding brake

Characteristics

1

Motor type Type of brake

MCA19 BFK457−16R 0.3 0.6 −−− −−− −−− 24.6 4

MCA21 BFK458−18 0.4 0.6 3.0 10.0 13.0 24.6 6

s

Lrated

+0.1 / −0.05

[mm] [mm] [mm] min. [mm] max. [mm] [Nm] No. of pieces

s

Lmax.

holding brake

Max.

adjustment,

permissible

wear path

Rotor thickness Tightening

torque of the

fixing screws

Fixing screws

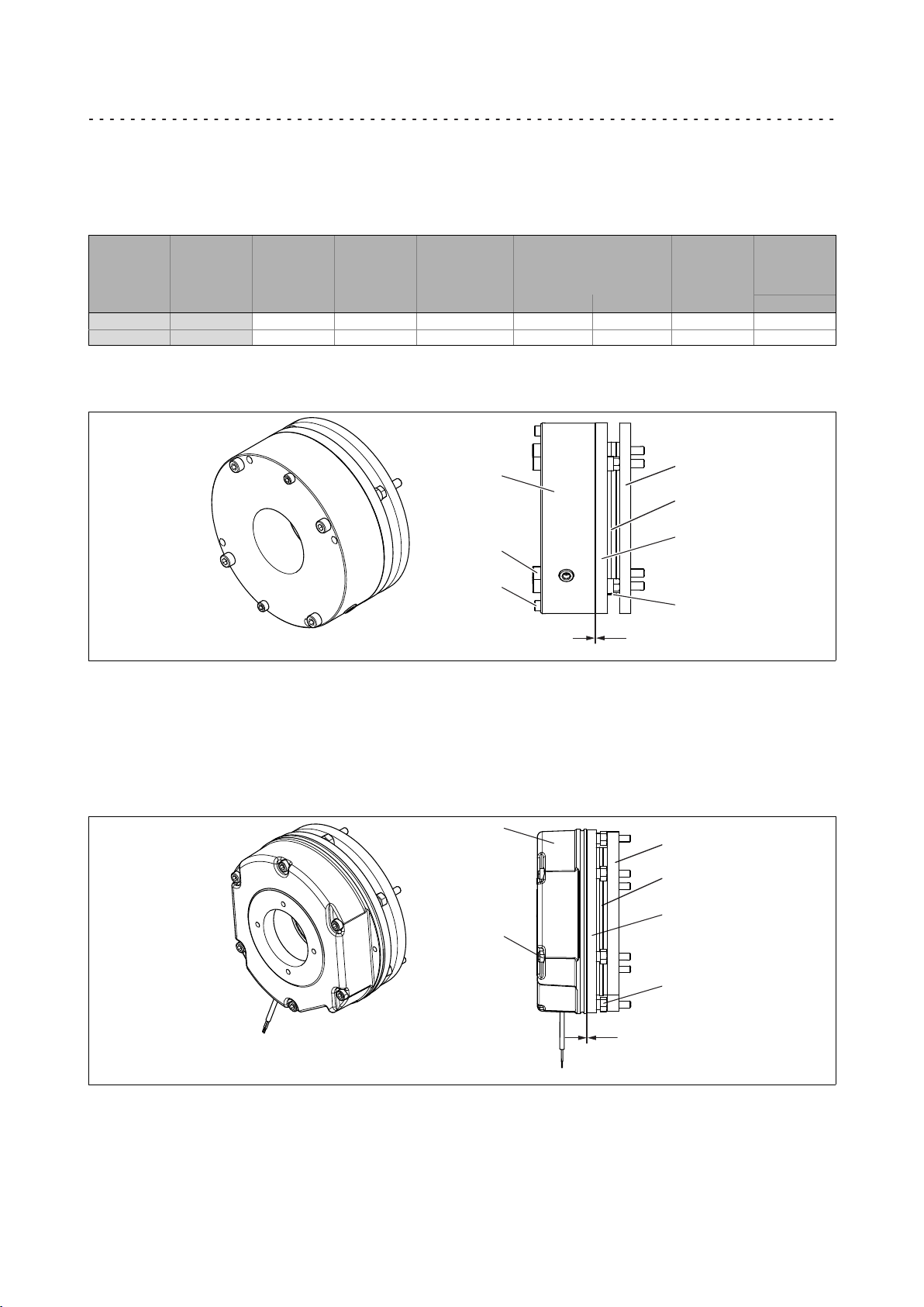

1.2.2 BFK457−16R design − non−adjustable

1

5

3

2

6

7

4

s

L

Fig. 1 Design of an INTORQ BFK457−16 Compact spring−applied brake, fully mounted rotor and flange

1 Stator 3 Rotor with friction lining 6 Fixing screws

2 Armature plate 4 Spacer bush 7 Screws of the emergency manual

5 Flange s

release

Air gap

L

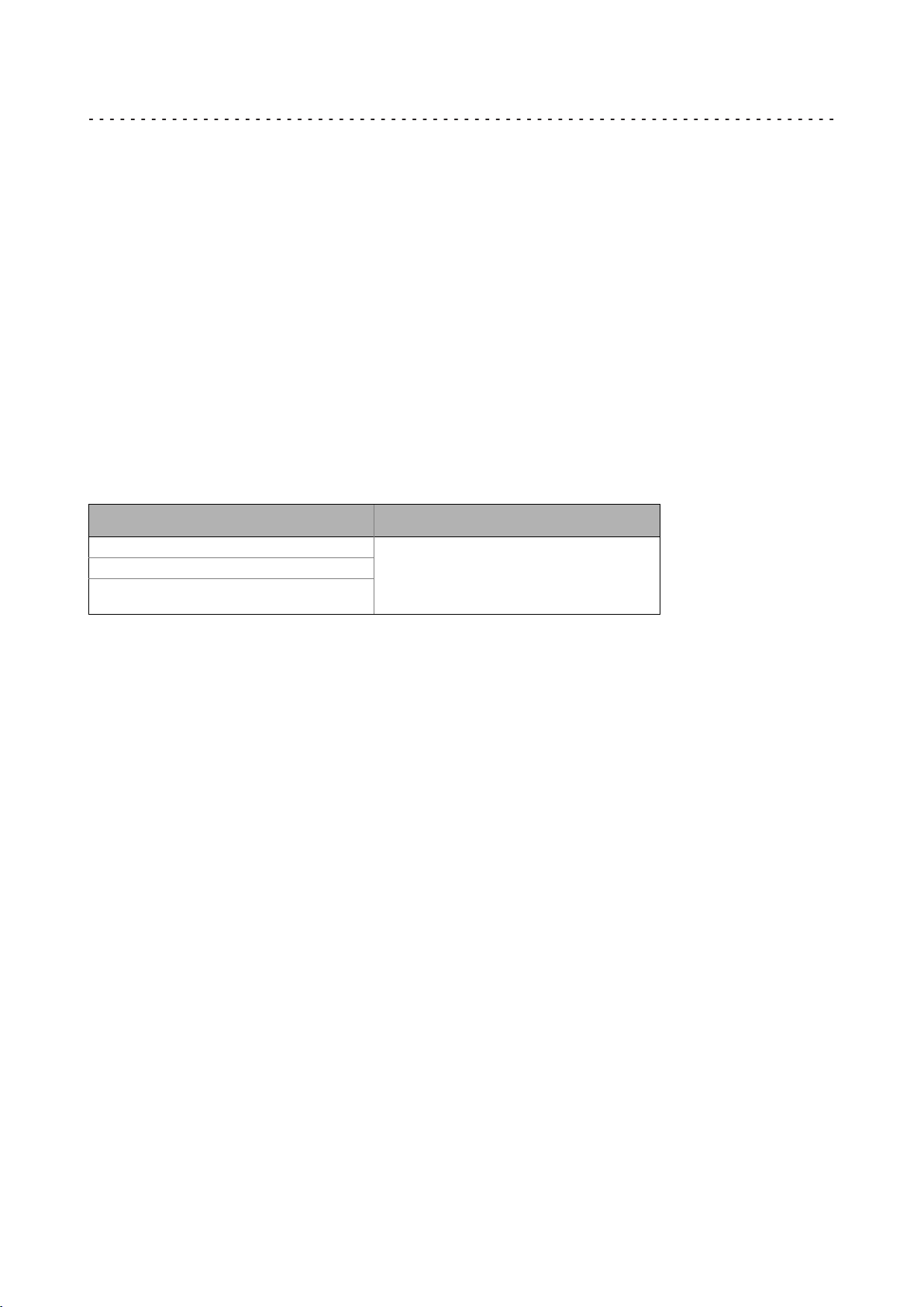

1.2.3 BFK458−18 design − adjustable

1

5

3

2

6

8

s

L

Fig. 2 Design of an INTORQ BFK458 spring−applied brake: basic module E (complete stator) + rotor + hub + flange

1 Stator 3 Rotor with friction lining 6 Fixing screws

2 Armature plate 5 Flange 8 Sleeve bolts

s

Air gap

L

Lenze ¯ MA 33.0012 ¯ 1.0

5

Page 6

2

Maintenance/repair

Spring−applied brake − holding brake

2 Maintenance/repair

2.1 Spring−applied brake − holding brake

The brakes need to be checked on a regular basis to ensure safe and trouble−free

operation.

The necessary maintenance intervals primarily depend on the stress to which the brake

is subjected in an application. When a maintenance interval is being calculated, all

causes of wear must be taken into account (see notes "Wear on spring−applied brakes").

In the case of brakes which are subjected to low levels of stress, e.g. holding brakes with

emergency stop function, regular inspections at a fixed time interval are recommended.

In order to reduce the amount of work involved in maintenance, perform the inspection

at the same time as other maintenance work carried out cyclically on the machine if

possible.

If the brakes are not properly serviced, operating faults, production outages or damage

to machinery can occur. A maintenance concept adapted to the operating conditions

and the stresses to which the brakes are subjected must therefore be drawn up for every

application. For brakes, the maintenance intervals and servicing work listed in the

following table are necessary.

Maintenance interval for holding brake with

emergency stop

At least every 2 years

After 1 million cycles at the latest

Shorter intervals in the case of frequent emergency

stops!

Maintenance work

Inspection of the brake integrated in the motor:

¯ Check ventilation function and

activation/deactivation

¯ Measure air gap (re−adjust air gap, if necessary),

2.1.4

6

Lenze ¯ MA 33.0012 ¯ 1.0

Page 7

2.1.1 Wear on spring−applied brakes

Causes of wear

Component Effect Influencing factors Cause

Friction lining Wear on the friction lining Applied friction energy

Number of start−stop

cycles

Armature plate and

flange

Teeth of the brake

rotor

Armature plate

bracket

Springs Fatigue failure of the

Running−in of armature

plate and flange

Teeth wear (primarily at

the rotor end)

Armature plate, cap screws

and bolts are deflected

springs

Applied friction energy Friction between the brake

Number of start−stop

cycles,

Level of the braking

torque,

Dynamics of the

application,

Speed fins in operation

Number of start−stop

cycles,

Level of braking torque

Number of switching

operations of the brake

Braking during operation

(impermissible, holding

brakes!)

Emergency stops

Overlapping wear when

the drive starts and stops

Active braking by the drive

motor with the help of the

brake (quick stop)

Starting wear if motor is

mounted in a position

with the shaft vertical,

even if the brake is open

lining and the armature

plate or flange e.g. during

emergency braking or

service brake operation

Relative movement and

impacts between brake

rotor and brake hub

Load changes and impacts

due to reversal error

during interaction

between armature plate,

cap screws and guide bolts

Axial load cycle and

shearing stress on the

springs due to radial

reversing error of the

armature plate

Maintenance/repair

Spring−applied brake − holding brake

Wear on spring−applied brakes

2

Inspection of the individual parts

With a mounted brake ¯ Check release function and control

¯ Measure air gap (re−adjust, if necessary)

¯ Measure rotor thickness (replace rotor, if necessary)

¯ Thermal damage of armature plate or flange (tarnished

dark blue)

With a dismounted brake ¯ Check clearance of the rotor gear teeth (replace rotors that are damaged

by vibration)

¯ Damage by vibration of the torque support at the sleeve bolts, cylindrical

pins, and armature plate

¯ Check springs for damage

¯ Check armature plate and flange or end shield

– Max. run−in depth = rated air gap of the design size

Lenze ¯ MA 33.0012 ¯ 1.0

7

Page 8

2

2.1.2 Maintenance

Maintenance/repair

Spring−applied brake − holding brake

Maintenance

Stop!

The brakes must not be actuated without blowers.

Danger!

¯ Only work on the drive system when it is in a deenergised state!

¯ Hot motor surfaces of up to 140 °C. Observe cooling times!

¯ Remove loads acting on motors or secure loads acting on the drive!

Note!

Always fully replace brakes with defective armature plates, cylinder head

screws, springs or counter friction faces.

¯ The brakes used are not fail−safe because interference factors which

cannot be influenced (e.g. oil ingress) may lead to a reduction in

torque.

¯ When the rotor has been replaced, the original braking torque is only

attained after the friction surfaces have run in. After the rotor

replacement, increased initial wear will occur if the armature plate and

counter friction faces are not run in.

Tools required

Type Torque key

BFK457−16

BFK458−18 20 to 100 6 x 1/2"

Use for hexagon socket

Measuring

range [Nm]

20 to 100 6 x 1/2"

screws

Width across

flats [mm]

square

square

Open−jawed spanner width

across flats [mm]

Sleeve bolts Two−flat

lever

*

−−−−− −−−−− −−−−−

15 10 13 x 1/2"

Box spanner

mounting on

the outside

Width across

flats [mm]

square

for flange

Feeler gauge

8

Lenze ¯ MA 33.0012 ¯ 1.0

Page 9

Maintenance/repair

1

2

Spring−applied brake − holding brake

Dismounting the MCA19 and 21 fan cover

2.1.3 Dismounting the MCA19 and 21 fan cover

The brake is mounted to the N−end shield of the motor. Remove the fan cover to

check, maintain, or set the brake.

1. Disconnect the mains plug (1) of the fan.

2. Loosen the four screws (2) with which the fan is fitted onto the non−drive end

shield and remove the fan.

2

Lenze ¯ MA 33.0012 ¯ 1.0

9

Page 10

2

2.1.4 BFK457−16R air gap

Maintenance/repair

BFK457−16R air gap

Dismounting the MCA19 and 21 fan cover

Stop!

¯ The motor must not run whilst the air gap is checked.

¯ Do not insert feeler gauge further than 10 mm between the armature

plate (2) and stator (1)!

1

2

6

1 Complete stator 6 Fixing screw

2 Armature plate

1. Check air gap near the fixing screws (6) between the armature plate (2) and the

stator (1) using a feeler gauge and compare the values to the data "s

table, 5.

If the value measured, "s

replaced ( 12).

1

Air gap

À

Lrated

", is outside the tolerance ( 5), the rotor must be

Lrated

" in the

10

Lenze ¯ MA 33.0012 ¯ 1.0

Page 11

Checking and re−adjusting the BFK458−18 air gap

-

+

2.1.5 Checking and re−adjusting the BFK458−18 air gap

Stop!

¯ The motor must not run whilst the air gap is checked.

¯ Do not insert feeler gauge further than 10 mm between the armature

plate (2) and stator (1)!

1

Maintenance/repair

Dismounting the MCA19 and 21 fan cover

2

9

2

1

6

1 Complete stator 6 Fixing screw

2 Armature plate 9 Sleeve bolt

1. Check air gap near the fixing screws (6) between the armature plate (2) and the

stator (1) using a feeler gauge and compare the values to the data "s

table, 5.

If the value measured, "s

must be re−adjusted!

2. Slightly loosen the six fixing screws (6).

3. Slightly adjust the sleeve bolts (9) by rotation using the open−jawed spanner.

", is outside the tolerance of "s

Lrated

Lrated

Lrated

" ( 5), the air gap

Air gap

À

" in the

– If the air gap is too large, into the complete stator (1).

– If the air gap is too small, out of the complete stator (1).

– 1/6 revolution changes the air gap by approx. 0.15 mm

4. Tighten the fixing screws (6) with 24.6 Nm.

5. Repeat the air gap check and re−adjust the air gap again, if necessary, or replace

the brake.

Lenze ¯ MA 33.0012 ¯ 1.0

11

Page 12

2

2.2 Replacing the brake

2.2.1 Dismounting the MCA 19 and 21 encoder

Maintenance/repair

Replacing the brake

Dismounting the MCA 19 and 21 encoder

Stop!

If a safety encoder is used, all maintenance and installation work must be

performed at the Lenze site.

Otherwise any warranty will expire and Lenze GmbH will not accept any

liability for consequential damage.

Tools required

¯ Allen key width across flats 1.5

¯ Open−jawed spanner width across flats 7

¯ Open−jawed spanner width across flats 13

Danger!

Risk of injury!

There may be sharp edges on the metal sheet of the torque plate.

10.6/10.7

1 Complete stator 10.1 M8 nut 10.4 Stud bolts

6 Fixing screws 10.2 M4 nut 10.6 Protective plate

10 Encoder 10.3 Threaded bolt 10.7 Torque plate

1. Loosen brake cable in the terminal box.

10.2

1

10.1

6

10.3

10

10.4

2. Loosen two stud bolts (10.4) on the motor shaft. In the case of an incremental

encoder, loosen the clamping hub.

3. Unscrew the upper M4 nut (10.2) of the torque plate (10.6) of the encoder.

4. Carefully slide the encoder (10) off the motor shaft and make sure that you do not

loose the protective plate (10.7) of the torque plate.

5. Loosen the M8 nut (10.1) of the threaded bolt (10.3). The threaded bolt remains in

the end shield.

6. Now the brake can be dismounted.

12

Lenze ¯ MA 33.0012 ¯ 1.0

Page 13

2.3 BFK457−16R

2.3.1 Dismounting and mounting

Stop!

When replacing the brake, the complete rotor or the hub, the spare part

from the corresponding Lenze repair kit must always be used. It can be

ordered from the Lenze Service, specifying the motor serial number and

the motor material number.

11

8

5

12

3

2

1

6

Maintenance/repair

BFK457−16R

Dismounting and mounting

2

1 Complete stator 6 Fixing screws 11 Motor end shield

5 Flange 8 Hub

1. Loosen brake cable.

2. Evenly loosen and fully unscrew the four fixing screws (6).

3. Remove stator (1) with complete rotor from end shield (11). Observe brake cable!

4. Check toothing of the hub (2). If it shows signs of wear, it has to be replaced.

Lenze ¯ MA 33.0012 ¯ 1.0

13

Page 14

2

Dismounting and mounting the hub

7.2

Maintenance/repair

BFK457−16R

Dismounting and mounting

11

9

12

7.1

8

7.1

Circlip/retaining ring

7.2 9 Keyway 12 Motor shaft

1. Remove circlip (7.2)

In order to provide for more stability (alternating load), the hub is additionally glued to

the shaft.

2. The hub (8) must be heated to 150 − 160 °C and then removed from the shaft by

means of an extractor. (If necessary, have this work carried out by the Lenze

Service staff).

3. Remove circlip (7.1)

4. The seat of the hub must be cleaned, ensuring that an adhesive bond between the

shaft and hub can be re−established afterwards.

5. Fit a circlip (7.1) in order to provide for horizontal fixation and fit the featherkey

(9) onto the shaft.

6. Heat the hub (8) to 120°C and slide it onto the shaft while it is warm.

8 Hub 11 Motor end shield

– With an alternating load, we recommend securing the hub on the shaft using a

high−strength adhesive (Loctite 603 or Weicon 306−03).

7. Fit the circlip (7.2) onto the hub.

14

Lenze ¯ MA 33.0012 ¯ 1.0

Page 15

Stop!

Check the condition of the brake flange (5) and armature plate (2)!

¯ In the case of heavy scoring, the parts must be replaced.

¯ Both parts must be free from grease and oil!

3

2

1

13

6

Maintenance/repair

BFK457−16R

Dismounting and mounting

11

8

5

12

2

1 Complete stator 5 Flange 11 Motor end shield

2 Armature plate 6 Fixing screws 12 Shaft

3 Complete rotor 8 Hub 13 M6 cylinder head screw

1. Slide the new rotor (3) with the toothed intermediate ring onto the hub and check

whether it can be shifted manually.

2. Align and position the drill holes of the brake flange (5) towards the threaded

holes in the non−drive end shield (11).

3. Fit the complete stator with rotor (1) and tighten it with 24.6 Nm using the four

fixing screws (6).

4. Remove two M6 cylinder head screws (13) for the emergency manual

release/transport locking device, thus enabling the armature plate (2) to move

freely.

5. Measure the air gap between the stator (1) and armature plate (2)

(0.3 +0.1/−0.05 mm).

6. Reconnect the brake cable.

7. Perform a functional check of the brake. When the power is switched on, the air

gap between the magnet housing and the armature plate must be SL = 0, i.e. the

rotor must be enabled to move freely.

Stop!

Ensure that the screws of the emergency manual release/transport

locking device have been removed!

Lenze ¯ MA 33.0012 ¯ 1.0

15

Page 16

2

2.4 BFK458−18

2.4.1 Dismounting and mounting

Maintenance/repair

BFK458−18

Dismounting and mounting

Stop!

When replacing the brake, complete rotor or the hub, the spare part from

the corresponding Lenze repair kit must always be used. It can be ordered

from the Lenze Service, specifying the motor serial number and the motor

material number.

11

5

10.3

8

3

2

10.1

1

6

1 Complete stator 5 Flange 10.1 M8 nut

2 Armature plate 6 Fixing screws 10.3 Threaded bolt

3 Complete rotor 8 Hub 11 Motor end shield

1. Loosen brake cable.

2. Loosen the five fixing screws (6) and the nut (10.1) evenly and fully uncrew them.

The threaded bolt (10.3) remains in the motor end shield as a guide.

3. Remove complete stator (1) from the motor end shield (11). Observe brake cable!

4. Remove complete rotor (3) from the hub (8).

5. Check toothing of the hub (8). If it shows signs of wear, it has to be replaced.

16

Lenze ¯ MA 33.0012 ¯ 1.0

Page 17

Dismounting and mounting the hub

11

9

12

7.1

8

7.2

Maintenance/repair

BFK458−18

Dismounting and mounting

2

7.1

Circlip/retaining ring

7.2 9 Keyway 12 Motor shaft

1. Remove circlip (7.2)

In order to provide for more stability (alternating load), the hub is additionally glued to

the shaft.

2. The hub (8) must be heated to 150 − 160 °C and then removed from the shaft by

means of an extractor. (If necessary, have this work carried out by the Lenze

Service staff).

3. Remove circlip (7.1)

4. The seat of the hub must be cleaned, ensuring that an adhesive bond between the

shaft and hub can be re−established afterwards.

5. Fit a circlip (7.1) in order to provide for horizontal fixation and fit the featherkey

(9) onto the shaft.

6. Heat the hub (8) to 120°C and slide it onto the shaft while it is warm.

8 Hub 11 Motor end shield

– With an alternating load, we recommend securing the hub on the shaft using a

high−strength adhesive (Loctite 603 or Weicon 306−03).

7. Fit the circlip (7.2) onto the hub.

Lenze ¯ MA 33.0012 ¯ 1.0

17

Page 18

2

Maintenance/repair

BFK458−18

Dismounting and mounting

Stop!

Check the condition of the brake flange (5) and armature plate (2)!

¯ In the case of heavy scoring, the parts must be replaced.

¯ Both parts must be free from grease and oil!

2

1

6

11

5

8

3

1 Complete stator 5 Flange 11 Motor end shield

2 Armature plate 6 Fixing screws

3 Complete rotor 8 Hub

1. Slide the new rotor (3) with the toothed intermediate ring onto the hub and check

whether it can be shifted manually.

2. Align and position the drill holes of the brake flange (5) towards the threaded

holes in the non−drive end shield (11).

3. Fit the stator (1) and tighten it with 24.6 Nm using the six fixing screws (6).

4. Measure the air gap between the stator and armature plate (2)

(0.4 +0.1/−0.05 mm).

5. Reconnect the brake cable.

6. Perform a functional check of the brake. When the voltage is switched on, the air

gap between the magnet housing and the armature plate must be SL = 0, i.e. the

rotor must be enabled to move freely.

18

Lenze ¯ MA 33.0012 ¯ 1.0

Page 19

2.4.2 Encoder mounting

Maintenance/repair

BFK458−18

Encoder mounting

2

10.6/10.7

1 Complete stator 10.1 M8 nut 10.4 Stud bolts 12 Motor shaft

6 Fixing screws 10.2 M4 nut 10.6 Protective plate

10 Encoder 10.3 Threaded bolt 10.7 Torque plate

10.2

10.1

10.3

10.4

1

6

12

10

Stop!

After having dismounted and mounted the encoder, it is absolutely

necessary to perform a reference run. If this step is ignored, collision

damage may be the consequence.

6

1. After the brake has been mounted successfully, screw the threaded bolt (10.3)

into the non−drive end shield first and then counter it using the M8 nut (10.1),

tightening torque = 24.6 Nm.

2. Carefully slide the encoder (10) onto the shaft (12), fitting the torque plate (10.7)

with the protective plate (10.6) onto the threaded bolt (10.3). Then tighten the

two stud bolts on the motor shaft (10.4) with 1.5 Nm and secure them by means

of medium−strength screw glue or locking varnish.

3. Mount the upper M4 nut (10.2) in order to axially secure the torque plate and

tighten it with 3 Nm, clamping the torque plate against the lower M4 nut (10.2).

Stop!

The torque plate must be tension−free and has to be positioned at right

angles to the motor−encoder shaft. Otherwise the service life of the

encoder bearings may be reduced!

Lenze ¯ MA 33.0012 ¯ 1.0

19

Page 20

© 01/2019 | MA 33.0012 | .Z!z | 1.0 | TD09

Lenze Drives GmbH

Postfach 10 13 52, 31763 Hameln

Breslauer Straße 3, 32699 Extertal

GERMANY

HR Lemgo B 6478

+49515482−0

+49515482−2800

sales.de@lenze.com

www.lenze.com

Lenze Service GmbH

Breslauer Straße 3, D−32699 Extertal

Germany

0080002446877 (24 h helpline)

+49515482−1112

service.de@lenze.com

10987654321

Loading...

Loading...