Page 1

EDSIPCx7

.N+_

Ä.N+_ä

L−force Controls

System Manual

Industrial PC

Embedded Line (EL), Command Station (CS), Cabinet PC (CPC), L−force

Controller 3241 C

System structure and configuration

l

Page 2

0Fig. 0Tab. 0

Page 3

Contents i

1 About this documentation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Terminology used 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Notes used 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety information 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Product description 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Application as directed 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 "Industrial PC" system 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Overview of designs 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Embedded Line 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Command Station 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Cabinet PC 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Embedded Line (EL, MP) design 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Command Station (CS) design 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Cabinet PC (CPC) design 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.1 3241 C 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.2 CPC 2800 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.3 CPC 5100 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.4 CPC 9100 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Options 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.1 Overview 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.2 ACU UPS control unit 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 Accessories 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8.1 Overview 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 Software 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.1 Operating system (accessories) 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.2 Other software types 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.3 Fan monitoring with "Smart Cool" and "FAN Service" (option) 31. . . . . . .

4 Index 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDSIPCx7 EN 4.1

l 3

Page 4

1

About this documentation

Document history

1 About this documentation

Contents

This documentation provides you with information about the intended use of the

Industrial PC.

The present manual is part of the "PC−based automation" manual collection which you can

find on the DVDs of the same name.

Target group

This documentation is directed at qualified skilled personnel according to IEC 60364.

Qualified skilled personnel are persons who have the required qualifications to carry out

all activities involved in installing, mounting, commissioning, and operating the product.

Validity

These instructions are valid for

ƒ Embedded Line EL 1800 − EL 9800 (TC)

ƒ Monitor Panel MP 800 − 9000 DVI

ƒ Command Station CS 5800 − 9800 (TC)

ƒ Command Station CS 5000 − 9000 DVI

ƒ Cabinet PC CPC 2800, CPC 5100, CPC 9100

1.1 Document history

ƒ Cabinet PC 3241 C

Material number Version Description

.N+_ 4.1 11/2013 TD29 Description of MC cards moved in separate

13433000 4.0 03/2013 TD29 General revision

13370131 3.0 02/2011 TD29 Amended by description of MC−ISI communication

13348653 2.0 10/2010 TD31 Change of generation from x700 series to x800

13300002 1.0 06/2009 TD14 First edition

operating instruction

card

series

I Tip!

Information and auxiliary devices related to the Lenze products can be found

in the download area at

http://www.Lenze.com

4

l

EDSIPCx7 EN 4.1

Page 5

About this documentation

Conventions used

1

1.2 Conventions used

This documentation uses the following conventions to distinguish between different

types of information:

Spelling of numbers

Decimal separator

Text

Program name » « PC software

Icons

Page reference ^ Reference to another page with additional

Documentation reference , Reference to another documentation with

1.3 Terminology used

Point In general, the decimal point is used.

For instance: 1234.56

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: ^ 16 = see page 16

additional information

For example: , EDKxxx = see

documentation EDKxxx

Term Meaning

IPC Industrial PC

CPC Cabinet PC; control cabinet PC with decentralised

display/operating unit (MP, Thin Client)

CS Command Station; stand−alone operator station

EL Embedded Line PC; for installation in control cabinets, machine

panelling, or other mounting cutouts

MP Monitor panel; external display

Thin Client Device for representing and operating applications which are

located on a remote host computer (e.g. CPC).

PLC Programmable Logic Controller

EDSIPCx7 EN 4.1

l

5

Page 6

1

About this documentation

Notes used

1.4 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

} Danger!

Pictograph and signal word Meaning

{ Danger!

} Danger!

( Stop!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

) Note!

I Tip!

,

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

6

l

EDSIPCx7 EN 4.1

Page 7

2 Safety instructions

2.1 General safety information

Scope

The following general safety instructions apply to all Lenze drive and automation

components.

The product−specific safety and application notes given in this documentation must be

observed!

For your own safety

} Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets!

Safety instructions

General safety information

2

ƒ Lenze drive and automation components ...

... must only be used for the intended purpose.

... must never be operated if damaged.

... must never be subjected to technical modifications.

... must never be operated unless completely assembled.

... must never be operated without the covers/guards.

... can − depending on their degree of protection − have live, movable or rotating parts

during or after operation. Surfaces can be hot.

ƒ All specifications of the corresponding enclosed documentation must be observed.

This is vital for a safe and trouble−free operation and for achieving the specified product

features.

The procedural notes and circuit details provided in this document are proposals which

the user must check for suitability for his application. The manufacturer does not

accept any liability for the suitability of the specified procedures and circuit proposals.

ƒ Only qualified skilled personnel are permitted to work with or on Lenze drive and

automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and operation of

the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent regulations, directives

and laws applicable at the place of use.

EDSIPCx7 EN 4.1

Transport, storage

ƒ Transport and storage in a dry, low−vibration environment without aggressive

atmosphere; preferably in the packaging provided by the manufacturer.

– Protect against dust and shocks

– Comply with climatic conditions according to the technical data.

.

l

7

Page 8

2

Safety instructions

General safety information

Mechanical installation

ƒ Install the product according to the regulations of the corresponding

documentation. In particular observe the section "Operating conditions" in the

chapter "Technical data".

ƒ Provide for a careful handling and avoid mechanical overload. During handling

neither bend components, nor change the insulation distances.

ƒ The product contains electrostatic sensitive devices which can easily be damaged by

short circuit or static discharge (ESD). Thus, electronic components and contacts

must not be touched unless ESD measures are taken beforehand.

Electrical installation

ƒ Carry out the electrical installation according to the relevant regulations (e. g. cable

cross−sections, fusing, connection to the PE conductor). Additional notes are

included in the documentation.

ƒ When working on live products, observe the applicable national regulations for the

prevention of accidents (e.g. BGV 3).

ƒ The documentation contains notes for the EMC−compliant installation (shielding,

earthing, arrangement of filters and installation of the cables). The manufacturer of

the system or machine is responsible for the compliance with the limit values

required in connection with EMC legislation.

ƒ For compliance with the limit values for radio interference emission at the site of

installation, the components − if specified in the technical data − have to be mounted

in housings (e. g. control cabinets). The housings have to enable an EMC−compliant

installation. In particular observe that for example control cabinet doors preferably

have a circumferential metallic connection to the housing. Reduce openings or

cutouts through the housing to a minimum.

ƒ Only plug in or remove pluggable terminals in the deenergised state!

Commissioning

ƒ If required, you have to equip the system with additional monitoring and protective

devices in accordance with the respective valid safety regulations (e. g. law on

technical equipment, regulations for the prevention of accidents).

Maintenance and servicing

ƒ The components are maintenance−free if the required operating conditions are

observed.

ƒ If the cooling air is polluted, the cooling surfaces may be contaminated or the air

vents may be blocked. Under these operating conditions, the cooling surfaces and air

vents must be cleaned at regular intervals. Never use sharp objects for this purpose!

ƒ After the system has been disconnected from the supply voltage, live components

and power connections must not be touched immediately because capacitors may

be charged. Please observe the corresponding notes on the device.

8

l

EDSIPCx7 EN 4.1

Page 9

Safety instructions

General safety information

Disposal

ƒ Recycle metals and plastic materials. Ensure professional disposal of assembled

PCBs.

ƒ This device contains a battery. According to European legislation you are obliged to

dispose of batteries separately via the take−back systems specified.

2

EDSIPCx7 EN 4.1

l

9

Page 10

3

Product description

Application as directed

3 Product description

3.1 Application as directed

Lenze Industrial PCs (IPCs) are used as directed if they are exclusively used for the

implementation of operator concepts or the presentation of information in common

industrial and commercial areas. A different use, or one beyond these purposes, is not

permissible.

A use that is not intended also includes a use harbouring fatal risks or dangers which,

without the provision of exceptionally high safety measures, may result in death, injury or

damage to material assets.

Lenze Industrial PCs must not be used ...

ƒ in private areas.

ƒ in potentially explosive atmospheres.

ƒ in areas with harmful gases, oils, acids, radiation, etc.

ƒ in applications where vibration and impact loads occur, exceeding the requirements

of EN 50178.

ƒ for performing safety functions, for instance

– in air traffic control / in flight−control systems

– for the monitoring/control of nuclear reactions

– for the monitoring/control of means of mass transport

– for the monitoring/control of medical systems

– for the monitoring/control of weapon systems

Higher−level safety systems must be used to guarantee the protection of persons and

material assets!

10

l

EDSIPCx7 EN 4.1

Page 11

3.2 "Industrial PC" system

The "Industrial PC" system by Lenze offers a broad platform for the creation of devices

configured in a customised manner providing corresponding hardware components for

the respective application case. For the corresponding hardware components like CPU,

ROM, RAM, etc. please refer to the current IPC catalogue.

According to the requirements of the customer application, the operator devices can be

selected from a variety of possibilities (screen size/operator panels). The consistently

implemented platform strategy with defined interfaces with regard to electronics and

mechanics allows for various combinations of the modules. Like this, the suitable system

can be implemented for virtually every application.

Apart from the standard devices there is a number of accessory components which provide

for the integration of the individually adapted Industrial PC into a variety of different

system environments.

For the Industrial PCs as component also the following complete automation systems are

offered:

Product description

"Industrial PC" system

3

ƒ Control technology

Logic & Motion with CANopen and EtherCAT (^ "Control technology" system manual)

ƒ Visualisation technology

Scalable visualisation system with CANopen, PROFIBUS, PROFINET, and Ethernet (^

"Visualisation technology" system manual)

The IPC platform is complemented by cost−optimised HMIs which are offered in fixed

configurations and which, to a limited extent, also perform automation functions. This

EL100 series is designed for the installation in control cabinet doors and is solely different

with regard to the design of the touch−sensitive touchscreen (see operating instructions

for the HMI EL100/EL100−ECO).

EDSIPCx7 EN 4.1

l

11

Page 12

3

Product description

"Industrial PC" system

Centralised and decentralised solutions

Depending on the requirements with regard to the installation of the Industrial PC, both

centralised Panel PC solutions and decentralised (separate) solutions can be selected.

Centralised solutions:The Panel PCs of the "Embedded Line (EL)" and "Command Station

(CS)" series are compact devices and combine display, operation, and electronics in a

common housing.

Fig. 3−1 Centralised Panel PC solution

Decentralised solutions:The decentralised solutions comprise separate units: the

Industrial PC of the "Cabinet PC (CPC)" series, which is preferably placed in a protected

manner in the control cabinet, and the operating unit on site (monitor panel MP or CS−DVI).

This solution has advantages with regard to cabling, operating conditions, and

accessibility.

12

Fig. 3−2 Decentralised Panel PC solution

l

EDSIPCx7 EN 4.1

Page 13

Product description

"Industrial PC" system

Customised solutions

Different industry sectors and ambient conditions bring about extremely differing

requirements with regard to the design of IPCs and operator panels, which due to their

complexity cannot always be implemented by means of standard components. In these

cases Lenze is the solution partner for customised developments.

Typical developments are:

ƒ Customised decoration foil for a consistent Corporate Design

ƒ Extension with components (mouse−pad, RFID, speakers, scanner,)

ƒ Individual software adaptations

ƒ Stainless steel operator devices with minimised clearances in IP65, IP66 or IP69K.

3

EDSIPCx7 EN 4.1

l

13

Page 14

3

Product description

Overview of designs

3.3 Overview of designs

By a consequently implemented platform strategy Industrial PCs can be individually

assembled and nearly optionally scaled with regard to power, display size, and function. By

this, three different designs are provided from which the customised platform for the

automation solution can be selected in each case.

In the Embedded Line and Command Station types apart from the Industrial PCs also Thin

Clients (EL 1800 − 9800 TC, CS 5800 − 9800 TC) and monitor panels (MP 800 − 9000 DVI,

CS 5000 − 9000 DVI) are available.

Design Embedded Line Command Station Cabinet PC Cabinet PC

Type EL 1800 − 9800

EL 1800 − 9800 TC

MP 800 − 9000 DVI

CS 5800 − 9800

CS 5800 − 9800 TC

CS 5000 − 9000 DVI

CPC 2800

CPC 5100

CPC 9100

3241 C

Mounting /

installation

Enclosure Front: IP65, rear

Screen

Product benefits l Compact,

In mounting cutout

of machine

panelling / control

cabinets

side: IP20

TFT display with touch sensors

26.4 cm ... 48.3 cm

(10.4" ... 19")

mechanically

robust panel PC

l Fanless

operation is

possible as an

option

l Decentralised

design possible

l Expansible via

MC card

Stand−alone on a support

arm or wall

IP65 IP20 IP20

38.1 cm ... 48.3 cm

(15" ... 19")

l Stand−alone, robust,

command station

protected against dust

and splash water to all

sides

l Flat design housing

with rear mounting

frame

l Support arm mounting

or wall mounting

l Decentralised design

possible

l Expansible via MC card

In the control

cabinet on a wall

Externally Externally

l Compact,

mechanically

robust control

cabinet PC

l Decentralised

design

l Expansible via

MC card

cabinet on DIN rail

l Compact,

l Decentralised

l Expansible via

l Expansible via

In the control

mechanically

robust control

cabinet PC

design

MC card

I/O compound

modules

14

l

EDSIPCx7 EN 4.1

Page 15

Product description

Overview of designs

Embedded Line

3

3.3.1 Embedded Line

Industrial PCs of the "Embedded Line (EL)" type are panel PCs for the installation in control

cabinets, machine panelling, or other mounting cutouts. They are provided with bolts and

clamping screws on the rear side for easy mounting and a safe sealing also in rough

industrial environments.

Apart from the Industrial PCs 1800 − EL 9800, also mere displays (monitor panels and Thin

Clients) are available in this design, which can be connected as a monitor to a Cabinet PC.

Thin Clients (TC): A Thin Client terminal serves to represent and operate applications on a

remotely installed host computer via a network connection. For data transmission the

Microsoft® RDP (Remote Desktop Protocol) is used. As host computer a Windows® XP

system for an operating section or a Windows® server operating system for several

operating sections is used. All processes are carried out on the connected server, the Thin

Client only providing for the display of the graphics or of the input systems for operating

the application. The computing power of the client can therefore be kept accordingly low.

Monitor panel (MP): A monitor panel is an operator terminal to use remote Industrial PCs

as a built−in variant or stand−alone terminal. Like the Embedded Line devices, they feature

corresponding front modules.

Type EL 1800 − 9800 EL 1800 − 9800 TC MP 800 − 9000 DVI

Function IPC Thin Client Monitor panel

Screen diagonal

Current supply DC24 V ±25%

Uninterruptible power

system (UPS)

Cooling With or without fan Without fan

MC card slots 2 2 −

MC card ^ 29 − −

Configurable Yes No No

Interfaces

Enclosure

Front

Rear side

Backup

26.4 cm (10.4"), 30.5 cm (12.1"), 38.1 cm (15") or

If Windows® CE 6.0 is

used: backup and restore

48.3 cm (19" inches)

Optionally via ACU UPS control unit −

3 x USB type A

1 x USB type A front panel (opt.)

1 x PS/2

1 x RS232

1 x LAN (10/100 Mbps)

IP65

IP20

− −

tool V2

20.3 cm (8"), 26.4 cm

(10.4"), 30.5 cm (12.1"),

38.1 cm (15") or 48.3 cm

(19" inches)

2 x USB type A

1 x USB type A front panel

(opt.)

1 x USB type B

1 x DVI

EDSIPCx7 EN 4.1

l

15

Page 16

3

Product description

Overview of designs

Command Station

3.3.2 Command Station

A Command Station (CS) is a stand−alone operator station which is protected against dust

and splash water at each side. The flat housing features a mounting frame on the rear side,

which can be mounted on a support arm or a wall. For the flexible implementation of

individual operating concepts the system offers numerous options and extension

consoles.

Apart from the Industrial PCs CS 5800 − 9800, also mere monitor panels and Thin Clients

are available in this design, which can be connected as a monitor to a Cabinet PC.

Thin Clients (TC): A Thin Client terminal serves to represent and operate applications on a

remotely installed host computer via a network connection. For data transmission the

Microsoft® RDP (Remote Desktop Protocol) is used. As host computer a Windows® XP

system for an operating section or a Windows® server operating system for several

operating sections is used. All processes are carried out on the connected server, the Thin

Client only providing for the display of the graphics or of the input systems for operating

the application. The computing power of the client can therefore be kept accordingly low.

Monitor panel (DVI): A monitor panel is an operator terminal to use remote Industrial PCs

as a built−in variant or stand−alone terminal. Like the command station devices, they

feature corresponding front modules and add−on components.

Type CS 5800 − 9800 CS 5800 − 9800 TC CS 5000 − 9000 DVI

Function IPC Thin Client Monitor panel

Screen diagonal 38.1 cm (15") or 48.3 cm (19")

Current supply DC 24 V ±25%

Uninterruptible power

system (UPS)

Cooling With fan

MC card slots 1 1 −

MC card ^ 29 − −

Configurable Yes No No

Interfaces

Enclosure IP65

Backup

used: backup and restore

Optionally via ACU UPS control unit −

3 x USB type A

1 x USB type A front panel (opt.)

1 x/2 x USB type A in mounting frame (opt.)

1 x PS/2

1 x RS232

1 x LAN (10/100 Mbps)

If Windows® CE 6.0 is

− −

tool V2

2 x USB type A

1 x USB type A front panel

(opt.)

1 x USB type B

1 x DVI

1 x LAN (10/100 Mbps)

16

l

EDSIPCx7 EN 4.1

Page 17

Product description

Overview of designs

Cabinet PC

3

3.3.3 Cabinet PC

The decentralised solutions comprise separate units, the Industrial PC which is preferably

placed in a protected manner in the control cabinet, and the operating unit on site. This

solution has advantages with regard to cabling, operating conditions, and accessibility.

The following can be used as a screen:

ƒ A standard monitor.

ƒ A Monitor panel of the "Command Station" or "Embedded Line" type.

With the DVI/USB extender accessories the distance between the IPC and the monitor

panel can be up to 35 m.

ƒ A Thin Client Panel of the "Command Station" or "Embedded Line" type for

representing and operating applications which are located on a remotely installed

host computer (IPC).

The Thin Client and host computer communicate via an Ethernet connection. Like this

greater distances can be covered than with an external monitor panel. Since all

processes run on the host computer and the Thin Client solely serves to display

information and to transfer entries, the CPU performance can be selected accordingly

low.

Type 3241 C CPC 2800 CPC 5100 CPC 9100

Function IPC

Current supply DC 24 V ±25% AC 115 V ... 230 V

Uninterruptible

power system (UPS)

Mounting

Cooling Without fan With or without fan With fan

MC card slots 1 2 −

MC card ^ 29 ^ 29 −

Configurable No Yes

Interfaces

Enclosure IP20 IP20 (front IP54)

Backup

Optionally via ACU UPS control unit Optionally via UPS−331

Within control

cabinet on DIN rail

3 x USB type A

1 x DVI (no VGA)

2 x LAN

(10/100 Mbps)

1 x LAN (1 Gbps)

If Windows® CE is

used: backup and

restore tool V3

Within control cabinet on a wall

3 x USB type A

1 x PS/2

1 x RS232

1 x DVI

1 x LAN

(10/100 Mbps)

If Windows® CE is

used: backup and

restore tool V2

8 x USB type A

(10/100 Mbps)

2 x PS/2

1 x RS232

1 x DVI

2 x LAN

RAID 0, 1, 5, 10

Within 19"

mounting rack

10 x USB type A

2 x PS/2

1 x RS232

1 x DVI

2 x LAN

(10/100 Mbps)

EDSIPCx7 EN 4.1

l

17

Page 18

3

Product description

Embedded Line (EL, MP) design

3.4 Embedded Line (EL, MP) design

Elements

4

3

10

PS/2

LAN

8

2

USB

5

Power

Fail

Status

6

F1

F2

+

7

F3

-

RS232

CF Card

MC Card

Reset

ACU UPS

24 V DC

0 1

Pos. Description

0 Panel PC / Thin Client / monitor panel (here EL 5800 Panel PC)

1 Front face USB port (option)

2 Screw clamp fixings

3 DVD drive (option); not for monitor panel (MP 800− 9000 DVI)

4 PC or monitor control for the monitor panel (MP 800− 9000 DVI)

5 Front face control and display elements

Overview

Panel PC EL EL 1800 / EL 1800s / EL 2800 / EL 5800 / EL 9800

Thin Client EL EL 1800 TC / EL 1800s TC / EL 2800 TC / EL 5800 TC / EL 9800 TC

Monitor Panel MP 800 DVI / MP 1000 DVI / MP 1000s DVI / MP 2000 DVI / MP 5000 DVI / MP 9000 DVI

l EL 1800 (TC): VGA touchscreen 26.4 cm (10,4")

EL 1800s (TC): SVGA touchscreen 26.4 cm (10,4")

EL 2800 (TC): SVGA touchscreen 30.5 cm (12,1")

EL 5800 (TC): XGA touchscreen 38.1 cm (15")

EL 9800 (TC): SXGA touchscreen 48.3 cm (19")

Power

Fail

Status

F1

F2

+

F3

-

l MP 800 DVI: VGA touchscreen 20.3 cm (8")

MP 10000 DVI: VGA touchscreen 26.4 cm (10,4")

MP 1000s0 DVI: SVGA touchscreen 26.4 cm (10,4")

MP 20000 DVI: SVGA touchscreen 30.5 cm (12,1")

MP 50000 DVI: XGA touchscreen 38.1 cm (15")

MP 90000 DVI: SXGA touchscreen 48.3 cm (19")

l 3 freely assignable function keys

ELx7xx−001

18

CS57x0−026

l

EDSIPCx7 EN 4.1

Page 19

Product description

Embedded Line (EL, MP) design

Panel PC EL 5820

Thin Client EL 5820 TC

Monitor Panel MP 5020 DVI

l XGA touchscreen 38.1 cm (15")

S1

S2

S3

S4

S5

S6

S7

+

Power

Fail

Status

-

F4

F3F2

F1

Esc

F11 F12F6F5 F7 F8 F9 F10

S8

S9

S10

S11

S12

S13

S14

Enter

ELx7xx−002

Panel PC EL 1850 / EL 1850s / EL 2850 / EL 5850

Thin Client EL 1850 TC / EL 1850s TC / EL 2850 TC / EL 5850 TC

Monitor Panel MP 1050 DVI / MP 1050s DVI / MP 2050 DVI / MP 5050 DVI

A

BCD

-

8

9

7

E

FGH

+6

4

5

I

JKL

3

1

2

*

M

N O P

,

.

0

/

Power

PgUp

Fail

Status

Home

End

PgDn

EscDelIns

Bs

Menu

AltCtrl

Shift

Space

Alpha

Q+R

S T

-

F1 F2 F5

F3 F4

WVU

F7F6

F11F10YXF9F8 F12

Enter

@\Z

CS57x0−028

l 12 freely assignable function keys

l 14 freely assignable special keys

l EL 1850 (TC): VGA touchscreen 26.4 cm (10.4")

EL 1750s (TC): SVGA touchscreen 26.4 cm (10.4")

EL 2850 (TC): SVGA touchscreen 30.5 cm (12.1")

EL 5850 (TC): XGA touchscreen 38.1 cm (15")

l MP 1050 DVI: VGA touchscreen 26.4 cm (10.4")

MP 1050s DVI: SVGA touchscreen 26.4 cm (10.4")

MP 2050 DVI: SVGA touchscreen 30.5 cm (12.1")

MP 5050 DVI: XGA touchscreen 38.1 cm (15")

l 12 freely assignable function keys

l Keypad, control keys, Alpha level switch−over

3

Panel PC EL 5870

Thin Client EL 5870 TC

Monitor Panel MP 5070 DVI

+

-

F4

F3F1 F2

F5

EWQ

T

R

@

€

D

SA

F

XY

GHJ

VC

OI P ÜUZ

LK

;

M

NB

,

μ

F9F8F6 F7 F10

:

.

l XGA touchscreen 38.1 cm (15")

l 12 freely assignable function keys

/

(

)

-

879

&

$

+

546

§

"

!

123

*

=

>

,

|

<

/

0

Power

Fail

Status

Bs

Entf

Bild

Einfg

AltGr

Bild

Pos1

Ende

AltStrg

F12

Esc

F11

*

~

+

Enter

Ä

Ö

\?ß

_

Space

-

CS57x0−029

l MF2 keyboard

EDSIPCx7 EN 4.1

l

19

Page 20

3

Status

F1

Fail

+

-

F3

F2

Power

Product description

Command Station (CS) design

3.5 Command Station (CS) design

Elements

0

1

8

23

9

CF Card

5

6

MC Card

ACU UPS

24 V DC

7

Pos. Description

0 Command Station (IPC, here CS 5800)

Command Station TC (Thin Client)

Command Station DVI (monitor panel)

1 Mounting frame with VESA−100 adapter surface

2 PC or monitor control for the monitor panel

3 Screen

4 Front face control and display elements

5 Front face USB port (option)

6 Mounting frame connecting plate (option)

PS/2

LAN

4

USB

RS232

Reset

CS57x0−001

Overview

Command Station CS 5800 / CS 9800

Command Station CS 5800 TC / CS 9800 TC

Command Station CS 5000 DVI / CS 9000 DVI

Power

Fail

Status

F1

F2

+

F3

-

l CS 5800 (TC): XGA touchscreen 38.1 cm (15")

CS 9800 (TC): SXGA touchscreen 48.3 cm (19")

l CS 5000 DVI: XGA touchscreen 38.1 cm (15")

CS 9000 DVI: SXGA touchscreen 48.3 cm (19")

l 3 freely assignable function keys

CS57x0−026

20

l

EDSIPCx7 EN 4.1

Page 21

Command Station CS 5810

Command Station CS 5810 TC

Command Station CS 5010 DVI

Product description

3

Command Station (CS) design

l XGA touchscreen 38.1 cm (15")

l 3 freely assignable function keys

l Up to 7 freely assignable switching elements

(^ LEERER MERKER)

l Emergency−off switch

Power

Fail

Status

F1

F2

+

F3

-

CS57x0−027

Command Station CS 5850

Command Station CS 5850 TC

Command Station CS 5050 DVI

Q+R

S T

-

F1 F2 F5

F3 F4

WVU

F7F6

Command Station CS 5870

Command Station CS 5870 TC

Command Station CS 5070 DVI

F11F10YXF9F8 F12

@\Z

A

BCD

8

7

E

FGH

4

5

I

JKL

1

2

M

N O P

.

0

PgUp

Home

PgDn

Bs

Shift

Alpha

/

(

879

$

546

"

!

123

=

,

0

Bs

l XGA touchscreen 38.1 cm (15")

-

9

+6

3

*

,

/

Power

Fail

Status

End

EscDelIns

Menu

AltCtrl

Space

Enter

CS57x0−028

l 12 freely assignable function keys

l Keypad, control keys, Alpha level switch−over

l XGA touchscreen 38.1 cm (15")

l 12 freely assignable function keys

)

-

&

+

§

*

>

|

<

/

Power

Fail

Status

l MF2 keyboard

EDSIPCx7 EN 4.1

Entf

Bild

Einfg

AltGr

Bild

Pos1

+

-

F4

F3F1 F2

F5

EWQ

T

R

@

€

D

SA

GHJ

F

XY

VC

F9F8F6 F7 F10

F11

*

OI P ÜUZ

~

+

Enter

Ä

LK

Ö

\?ß

_

;

:

M

NB

μ

Space

,

-

.

Ende

AltStrg

F12

Esc

CS57x0−029

l

21

Page 22

3

Strg

Alt

|

<

>

N

H

G

B

V

S

A

Y

X

F

D

C

K

J

M

_

-

;

:

, .

'

#

AltGr

Strg

Ö

L

Ä

Q

@

€

E

I

/

[

]

)

^

°

$

&

!

65

4

1

"

§

9

8{7

3 ³

2 ²

F6 F7

F4F3F3 F5

EscF1F1F2F2

(

ZTRWU

Rollen

Druck

Entf

Pos.

`

=

?

´

\ß}

0

F8

F9

F12

F10

F11

~

+

*

Einfg

P

O

Ü

Product description

Command Station (CS) design

Add−on components (accessories)

Operator console CSB 7

l Up to 7 freely assignable switching elements that

can be used in any combination

l Emergency−off switch

l Internal cabling for Command Station with

Combicon plug

CS57x0−030

Operator console CSB 14

l Up to 14 freely assignable switching elements that

can be used in any combination

l Emergency−off switch

l Internal cabling for Command Station with

Combicon plug

CS57x0−031

Keyboard CSB MF2 E

l MF2 keyboard with long−throw keys in stainless

steel finish

Rollen

Esc

3 ³

2 ²

Strg

Alt

Druck

F12

F10

F11

Pos.

Einfg

Entf

AltGr

Strg

l Internal cabling for Command Station with USB

plug

l Design types:

– with NUM block

– with touch pad

l Available languages:

– German, English, French

– Others on request

CS57x0−033

Add−on components with combinations of operator console and keyboard are available.

The operator consoles can be assembled with RAFI control/display elements of the RAFIX

22 FS type (printed circuit board mounting). The design is adapted to the visual appearance

of the Command Station.

Control/Display elements of type RAFIX 22 FS

l Square−law flange, dark grey

l Flat front ring, silver metallic

l Lighting by very bright LED

l Colour of fascia panel white, yellow, green, red, or blue

l Key−operated switch with two keys; different versions available

l Emergengy stop pushbutton

– With potential−free contacts

– With unlabelled yellow sticker (Æ60 mm, in accordance with DIN EN ISO

13850)

CSB−002

22

l

EDSIPCx7 EN 4.1

Page 23

3.6 Cabinet PC (CPC) design

3.6.1 3241 C

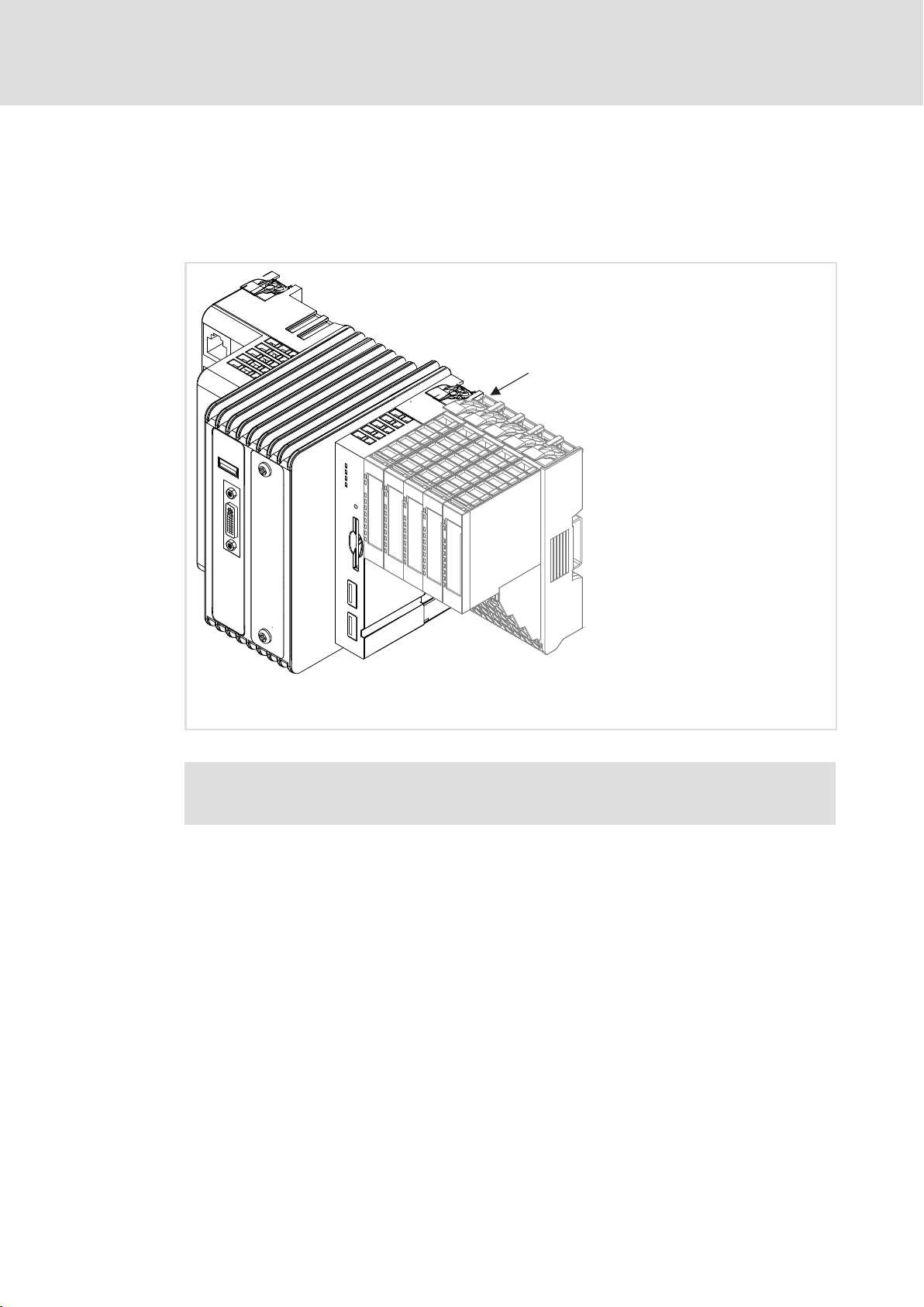

System overview

Product description

Cabinet PC (CPC) design

EPM-S701

3

3241 C

IPC 3241 C

Fig. 3−3 IPC 3241 C with connected I/O system 1000 (grey)

I/O System 1000

, For information on the I/O system 1000, please refer to the system manual

"I/O system 1000".

32xxC_005

EDSIPCx7 EN 4.1

l

23

Page 24

3

Product description

Cabinet PC (CPC) design

3241 C

Elements

1

1

0

2

4

3

5

6

Pos. Description

0 IPC 3241 C

1 Locking lever (DIN rail)

2 Backplane bus contacts

3 Guide for DIN rail with thermal connection via GapPad strips

4 Status LEDs

5 Reset button

6 Contact cover

32xxC−001

24

l

EDSIPCx7 EN 4.1

Page 25

Product description

Cabinet PC (CPC) design

CPC 2800

3

3.6.2 CPC 2800

Elements

1

2

3

0

0

4

5

6

7

8

9

:

;

Pos. Description

0 Control cabinet PC

1 DVD drive (optional)

2 PS/2

3 LAN (Ethernet)

4 Status LEDs

Error (red):

l Is lit if a power supply failure has occurred;

HD (yellow):

l Indicates access to a storage medium.

Power (green):

l Is lit when the supply voltage is present.

l Flashes (

l Is blinking (

l Is blinking (

UPS.

l Is blinking (

empty or missing).

l Blinks 4 x per second if the ACCU−PACK causes a short circuit or if the CAPS−PACK is completely

discharged.

5 USB

6 RS 232

7 CF Card

8 MC Card

9 ACU UPS

: 24 V DC

; DVI

−

) in the case of a hardware error.

−−−−−−−

−−−−−

) when the ACU UPS (optional) is being charged.

−

−−−−−−

) when there is a supply voltage failure and the device is being supplied by the ACU

−−

−−−

) when the supply voltage of the ACU UPS is too low (e.g. rechargeable battery is

−

CPC2700−001

EDSIPCx7 EN 4.1

l

25

Page 26

3

X2

X1

Product description

Cabinet PC (CPC) design

CPC 5100

3.6.3 CPC 5100

Elements

0

1

2

I

0

:

3

KEYB

4

5

6

7

8

MOUSE

X1

VGA

COM1

USB

X2

STANDBY

POWER

USB

LAN

HD

AUDIO

MIC

INOUT

CTRL

RESET

SLOTABCDEFG

;

<

=

>

?

@

9

Pos. Description

0 Control cabinet PC

1 Mains connection 115 ... 230 V AC

2 Mains switch

3 From left to right:

l Keyboard connection (PS/2)

l Mouse connection (PS/2)

4 From left to right:

l Analog monitor connection (VGA)

l Serial interface (COM1)

5 8 x USB−A

2 x Ethernet (RJ45)

6 From left to right:

l Microphone

l Audio line−out

l Audio line−in

7 Digital monitor connection (DVI on PCIe expansion card)

8 5 x PCI slot

9 PCIe x4 slot (in x16 socket)

: Optionally assigned interfaces

; DVD drive (option)

< Stand−by pushbutton

= Reset pushbutton

> From the top to the bottom:

l Power LED (is lit if mains voltage is applied)

l HD−LED (is lit if the hard disk is accessed)

l CTRL−LED (green: housing fan in operation; red: housing fan out of service)

? PE terminal screw (protective conductor)

@ Labelling field for the terminal and slot assignment

CPC5100−001

26

l

EDSIPCx7 EN 4.1

Page 27

Product description

I

0

Cabinet PC (CPC) design

CPC 9100

3

3.6.4 CPC 9100

Elements

IN

LAN

COM1

MOUSE

VGA

KEYB

012 45 6 78 9 :

3

. ;

Pos. Description

0 Control cabinet PC

1 Mains connection 115 ... 230 V AC

2 Mains switch

3 UPS control cable (only for power supply unit with integrated UPS)

4 from bottom to top:

l Keyboard connection (PS/2)

l Mouse connection (PS/2)

5 from bottom to top:

l Analog monitor connection (VGA)

l Serial interface (COM1)

6 8 x USB−A

2 x Ethernet (RJ45)

7 from bottom to top:

l Microphone

l Audio line−out

l Audio line−in

8 Digital monitor connection (DVI to PCIe expansion card)

9 5 x PCI slot

: 1 x optional PCIe x4 slot (in x16 socket)

; 3 x optionally assigned 5.25" bays (e.g. for DVD drives, hard disks in removable rack, battery packs for

UPS)

< 2 x USB−A

= No function

> from left to right:

l Power LED (is illuminated when mains voltage is applied)

l HD−LED (is illuminated when hard disk is accessed)

l Fan−LED (no function)

? Reset pushbutton

@ Power pushbutton

. Device fan (hot−swappable)

OUT

AUDIO

USB

USB

MIC

=

?

>

<@

CPC9100−001

EDSIPCx7 EN 4.1

l

27

Page 28

3

Product description

Options

Overview

3.7 Options

3.7.1 Overview

Option For the use with Function

ACU UPS control unit l CS 5800 ... CS 9800

3.7.2 ACU UPS control unit

Description

The optional ACU UPS control unit in connection with a battery or capacitor pack adds a

UPS functionality to the Industrial PC of the EL 1800−9800, CS 5800−9800, CPC 2800, and

3241 C series.

The ACU UPS control unit is either pre−equipped by the factory or can be refitted by the

Lenze Service staff.

l EL 1800 ... EL 9800

l CPC 2800

l 3241 C

For expansion of the IPC by

UPS functionality

Features of the ACU UPS control unit

with battery pack (ACCU PACK) with capacitor pack (CAPS PACK)

l Bridges a short−term mains failure or mains

fluctuations and shuts down the PC.

l Software−based configuration

l ^ Documentation for the battery pack

l Data backup in the event of mains failure.

l Not suitable for Windows XP and Windows

Embedded Standard 2009.

l Software−based configuration

l ^ Documentation for the capacitor pack

EPC50

A

C

C

U

-

P

a

c

k

ACU

0

S

3

Before

instruction

opening,

manual.

read

the

1

USV

2

FAN3

FAN2

CR2450

19

BLIGHT

USB-μCON

T4A

F1

POWER

20

1

2

ACCU

RESET

4

0 2700 battery pack or 2701 capacitor pack (accessories)

1 Connection cable (included in delivery of battery pack/capacitor pack)

2 Port on industrial PC

3 ACU UPS control unit

4 Baseboard

CS57x0−042

28

l

EDSIPCx7 EN 4.1

Page 29

3.8 Accessories

3.8.1 Overview

Accessories Function For the use with

MC−CAN2 For connection to a CAN fieldbus;

MC−ETC For connection to a EtherCAT

MC−ETH For connection to a Ethernet

MC−ISI For the connection to RS 232,

MC−PBM For connection to a PROFIBUS

MC−PBS For connection to a PROFIBUS

MC−PNC For connection to a PROFINET

MC−PND For connection to a PROFINET

DVI/USB extender For the decentralised configuration

the card features 2 independent

CAN interfaces

network

network

RS 422, or RS 485; the card has 2

independent serial interfaces

system as master

system as slave

system as control system (controller

interface connection)

system as device (device interface

connection)

between the computer unit and the

operating/display unit

Product description

Accessories

Overview

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l IPC 3241 C

l IPC CPC 2800

l IPC CS 5800 − 9800

l IPC EL 1800 − 9800

l Monitor panel MP 800 − 9000 DVI

l Monitor panel CS 5000 − 9000 DVI

l IPC 3241 C

l IPC CPC 2800

l IPC CPC 5100

l IPC CPC 9100

3

EDSIPCx7 EN 4.1

, For further information please see the corresponding separate manuals.

l

29

Page 30

3

Product description

Software

Operating system (accessories)

3.9 Software

3.9.1 Operating system (accessories)

Industrial PC Operating

EL 1800 − 9800

CS 5800 − 9800

CPC 2800, CPC 5100,

CPC 9100

EL 1800 − 9800

CS 5800 − 9800

3241 C

EL 1800 − 9800

CS 5800 − 9800

CPC 2800

1) The Industrial PC must be equipped with a hard disk.

, For further information please see the corresponding separate manuals.

3.9.2 Other software types

Industrial PC Software Description

EL 1800 − 9800 TC

CS 5800 − 9800 TC

3241 C Backup and restore

Devices with Windows CE

6.0:

EL 1800 − 9800

CS 5800 − 9800

CPC 2800

system

Windows XP

Multilanguage

Windows

Embedded

Standard 2009

Windows CEâ 6

Prof.

â

ââ

â

Thin Client connection

manager

tool V3

Backup and restore

tool V2

Description Storage medium

l Professional with SP3

l Pre−installed languages: English, German,

French, Spanish, Portuguese (Brazil),

Chinese (P.R. of China)

l Component version of Windows XP

Professional, where the necessary

software components and drivers are

factory−set.

l Pre−installed languages: English, German

l For the different processor types adapted

image files are available.

l Real−time capable operating system with

low resource requirements

l For the different processor types adapted

installations are available (not for Coreä

Duo).

l Terminal Client Manager for configuring the

connection to the server and the desired programs.

l These tools provide the possibility of copying the flash

memory to a USB stick. A restore can be carried out by

inserting the USB stick and switching on the voltage, or

by means of a tool. An option to manage the archives

can be configured.

l By carrying out a restore as described above, the

replacement device can be set to a state identical to

the one the original device had during the backup.

l For further information please refer to the backup and

restore tool manual

â

l Hard disk

l Hard disk

l Compact Flash

card

l Only 3241 C: on

flash memory of

the device

l Compact Flash

card

1)

30

, For further information please see the corresponding separate manuals.

l

EDSIPCx7 EN 4.1

Page 31

Product description

Fan monitoring with "Smart Cool" and "FAN Service" (option)

3.9.3 Fan monitoring with "Smart Cool" and "FAN Service" (option)

The "Smart Cool" and "Fan service" softwares can be used for the following IPCs:

ƒ EL 1800 − 9800

ƒ CS 5800 − 9800

ƒ CPC 2800

"Smart Cool"

Forced−ventilated industrial PCs are always provided with a temperature monitoring

system which is controlled via the "Smart Cool" software.

A thermal sensor measures the temperature inside the housing of the industrial PC. When

a preset temperature is exceeded, the fans of the industrial PC are switched on by "Smart

Cool". When the temperature has dropped again, "Smart Cool" switches off the fans.

A default setting depending on the installed PC components determines which fans in the

industrial PC are to be controlled by the software and at which temperature the fans are

to be switched on.

3

The software starts automatically together with the operating system and runs in the

background.

You can open the user interface of "Smart Cool" via the identically−named entry in the

system control. The user interface provides option boxes for selecting one of the following

states:

"Smart Cool" state: Temperature monitoring is active and operates as described above

(default setting).

"FAN on" state: All fans of the industrial PC are running continuously.

The assigned state remains selected even after a restart.

"FAN service"

The "FAN service" is installed together with "Smart Cool". It monitors the fans of the

Industrial PC and reports (Windows window) or logs (log file) the following system states:

ƒ Fan failure

ƒ Defective or empty buffer battery

The "FAN service" runs in the background and has no user interface.

Location of the "LogFanService.txt" log file:

ƒ Windows Embedded Standard 2009 and Windows XP Multilanguage in the "Smart

Cool" program folder

(e.g. "x:\Programs\Lenze\SmartCool\)

EDSIPCx7 EN 4.1

ƒ For Windows CE in the folder "x:\Storage\DeviceScanner\"

) Note!

In order to prevent the log file size from getting too large, its data are

transferred to the "LogFanService.bak" file as soon as the file size exceeds

100 kB.

l

31

Page 32

Index4

4 Index

3241 C, 23

A

ACU UPS control unit, 28

Application as directed, 10

B

Battery pack, 28

C

Cabinet PC

− 3241 C, 23

− CPC 2800, 25

− CPC 5100, 26

− CPC 9100, 27

− design, 17

− features, 14

Capacitor pack, 28

Command Station, 20, 23

− design, 16

− features, 14

Control elements, CSB 7/14, 22

CPC 2800, 25

CPC 5100, 26

CPC 9100, 27

D

Definition of notes used, 6

Definitions, 5

Design

− Command Station, 20, 23

− Embedded Line, 18

− overview, 14

Designs

− Cabinet PC, 17

− Command Station, 16

− Embedded Line, 15

Device

− control/display elements, CSB 7/14, 22

− Overview, 24

− overview, 18, 20, 25, 26, 27

Display elements, CSB 7/14, 22

Disposal, 9

E

Embedded Line, 18

− design, 15

− features, 14

F

Fan monitoring, 31

FAN Service, 31

I

I/O system 1000, 23

Industrial PC system, 11

M

Monitor panel, 17

N

Notes, definition, 6

O

Operating system, 30

Overview, 18, 20, 24, 25, 26, 27

P

Product description, 10

− application as directed, 10

S

Safety instructions, 7

− application as directed, 10

− definition, 6

− layout, 6

Smart Cool, 31

Software

− fan monitoring, 31

− Operating system, 30

T

Thin Client Panel, 17

U

UPS, 28

32

l

EDSIPCx7 EN 4.1

Page 33

V

Validity, documentation, 4

Index 4

EDSIPCx7 EN 4.1

l

33

Page 34

F

(

Ê

ü

© 11/2013

Lenze Automation GmbH

Hans−Lenze−Str. 1

D−31855 Aerzen

Germany

+49(0)51 54 /82−0

+49(0)51 54 /82 − 28 00

Lenze@Lenze.de

www.Lenze.com

Service Lenze Service GmbH

Breslauer Straße 3

D−32699 Extertal

Germany

(

Ê

008000/ 2446877 (24 h helpline)

+49(0)5154/ 82−11 12

Service@Lenze.de

EDSIPCx7 § .N+_ § EN § 4.1 § TD29

10987654321

Q

Loading...

Loading...