Page 1

EDSPLCLIB01

13384444

Ä.GMMä

L-force Controls

Software Manual

Function library "LenzeIO1000Drv"

for Lenze software »Drive PLC Developer Studio« and »PLC Designer«

L

Page 2

Function library "LenzeIo1000Drv"

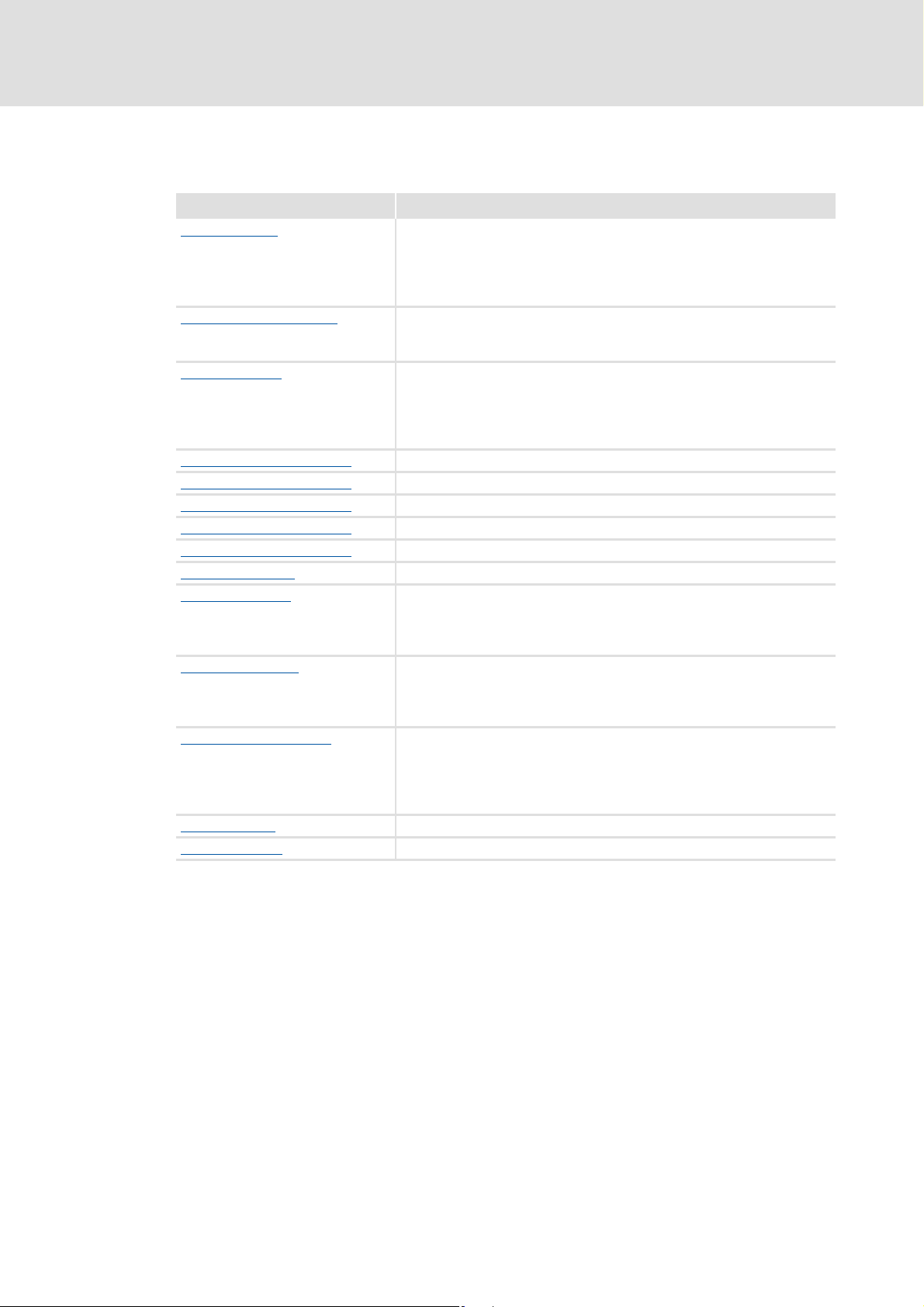

Contents

Contents

1 About this documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Conventions used

1.2 Definition of notes used

2 System requirements

3 Project planning concept

3.1 Parameterisation and process data blocks

3.2 Initialisation of the CAN driver

3.3 Minimum configuration

4 Function blocks

4.1 L_io1000ParAiDc - Parameterise analog inputs

4.2 L_io1000ParAiTemperature - Parameterise temperature measurement

4.3 L_io1000ParAoDc - Parameterise analog outputs

4.4 L_io1000ParCounterEPMS600 - Parameterise counter

4.5 L_io1000ParCounterEPMS601 - Parameterise counter

4.6 L_io1000ParCounterEPMS602 - Parameterise counter

4.7 L_io1000ParCounterEPMS603 - Parameterise counter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.8 L_io1000ParCounterEPMS604 - Parameterise encoder evaluation

4.9 L_io1000ParRestore - Load default setting in I/O system

4.10 L_io1000ParPDO15 - Communication settings PDO1 ... PDO5

4.11 L_io1000ParPDO610 - Communication settings PDO6 ... PDO10

4.12 L_io1000ParComGuarding - Parameterising monitoring functions

4.13 L_io1000Data15 - Process data transfer PDO1 ... PDO5

4.14 L_io1000Data610 - process data transfer PDO6 ... PDO10

5 Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Your opinion is important to us

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

. . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . . . . . . . . 58

2 L DMS 1.0 EN - 07/2011 - TD05

Page 3

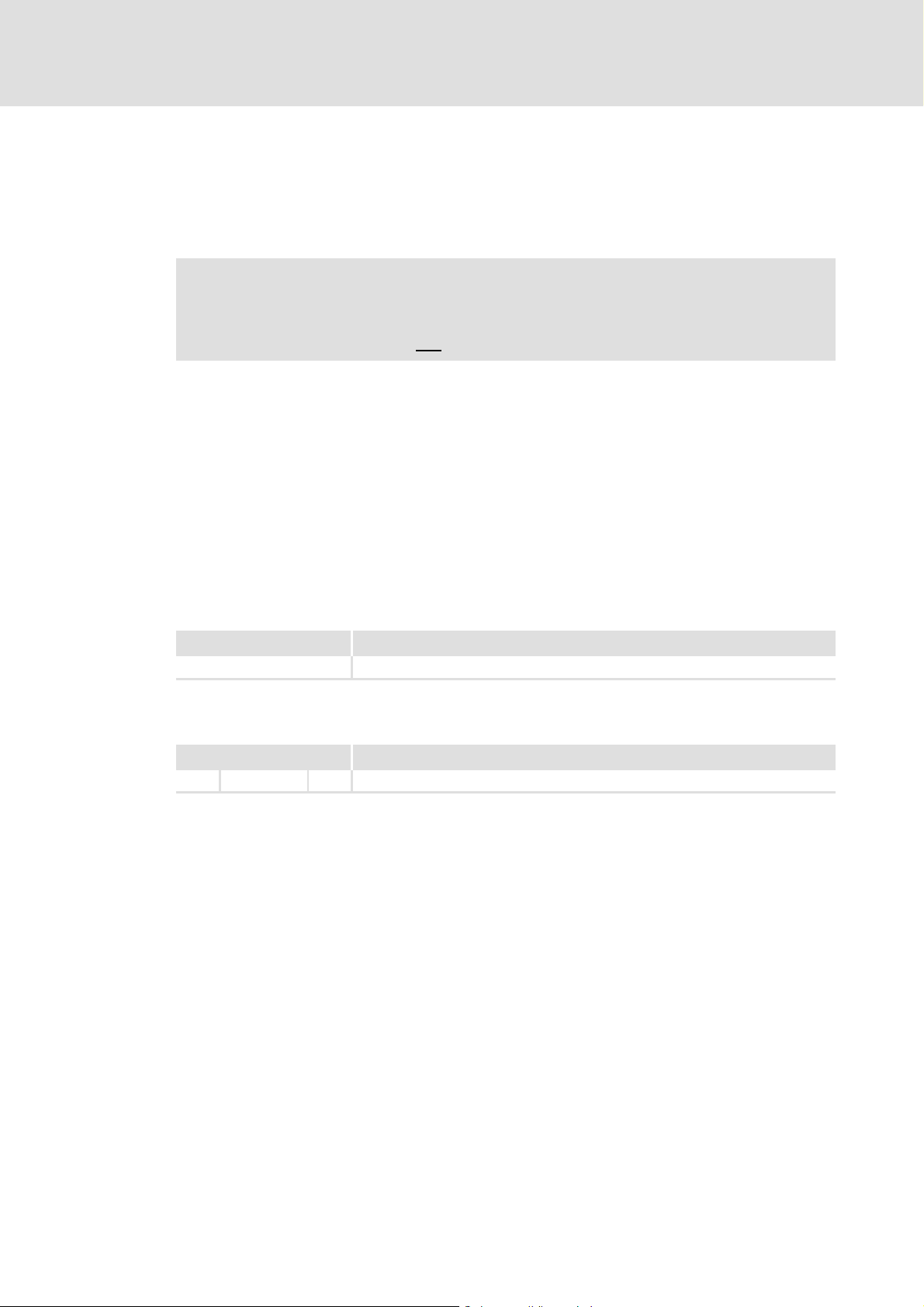

1 About this documentation

This documentation describes the function blocks that are contained in the

"LenzeIo1000Drv" function library. These function blocks enable the access of Lenze PLC

products (e.g. 9400

ServoPLC) to the decentralised I/O system 1000.

Note!

The "LenzeIo1000Drv" is exclusively suitable for Lenze-PLCs the project planning

environment of which is not

Functional survey

Loading of the default setting of the L-force I/O system 1000

Parameter setting of the I/O compound modules (analog inputs and outputs,

temperature measurement, counters, encoder evaluation, pulse width modulation)

Function library "LenzeIo1000Drv"

About this documentation

provided with an *.eds import!

Setting of the communication-relevant parameters in the I/O system

Coordination of the process communication between PLC and I/O system

Validity information

The information given in this documentation is valid for the following function library:

Function library From version

LenzeIo1000DrvVxx.lib V1.0

Document history

Version Description

1.0 07/2011 TD05 First edition for LenzeIo1000DrvV10.lib

Tip!

The "LenzeIo1000DrvVxx.lib" library version can be queried via the following global

constants:

• C_wLenzeIo1000DrvVersionER: Enabled major version

• C_wLenzeIo1000DrvVersionEL: Enabled minor version

• C_wLenzeIo1000DrvVersionIR: Internal minor version

• C_wLenzeIo1000DrvVersionBN: Internal build number

DMS 1.0 EN - 07/2011 - TD05 L 3

Page 4

Function library "LenzeIo1000Drv"

About this documentation

Conventions used

1.1 Conventions used

This documentation uses the following conventions to distinguish between different types

of information:

Type of information Writing Examples/notes

Numbers

Decimal separator Point The decimal point is always used.

Text

Program name » « The Lenze PC software »PLC Designer«...

Window Italics The Message window ... / The Options dialog box...

Variable identifier By setting bEnable to TRUE...

Control element Bold The OK button... / The copy command... / The

Sequence of menu

commands

Shortcut <Bold> Press <F1> to open the online help.

Program code Courier

Keyword Courier bold

Example: 1234.56

Properties tab... / The Name input field...

If several commands must be used in sequence to

carry out a function, then the individual commands

are separated by an arrow: Select File

If a key combination is required for a command, a "+"

is inserted between the key identifiers: Use

<Shift>+<ESC>...

IF var1 < var2 THEN

a = a + 1

END IF

Open to...

Hyperlink Underlined

Symbols

Page reference ( 4) Optically highlighted reference to another page. It is

Step-by-step instructions

Optically highlighted reference to another topic. It is

activated with a mouse click in this online

documentation.

activated with a mouse click in this online

documentation.

Step-by-step instructions are indicated by a

pictograph.

4 L DMS 1.0 EN - 07/2011 - TD05

Page 5

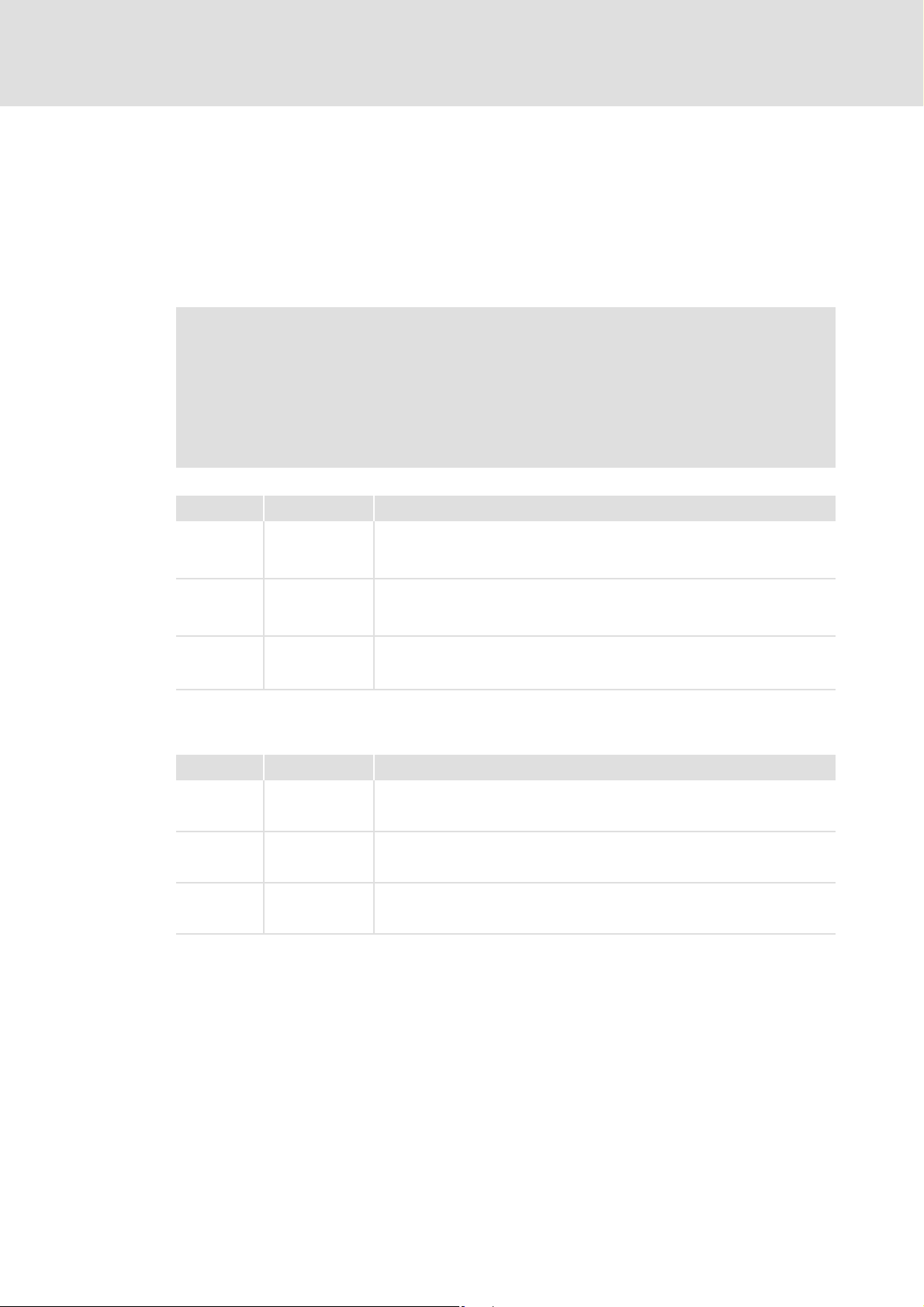

1.2 Definition of notes used

The following signal words and symbols are used in this documentation to indicate

dangers and important information:

Safety instructions

Layout of the safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Function library "LenzeIo1000Drv"

About this documentation

Definition of notes used

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for simple handling

Reference to another document

DMS 1.0 EN - 07/2011 - TD05 L 5

Page 6

Function library "LenzeIo1000Drv"

System requirements

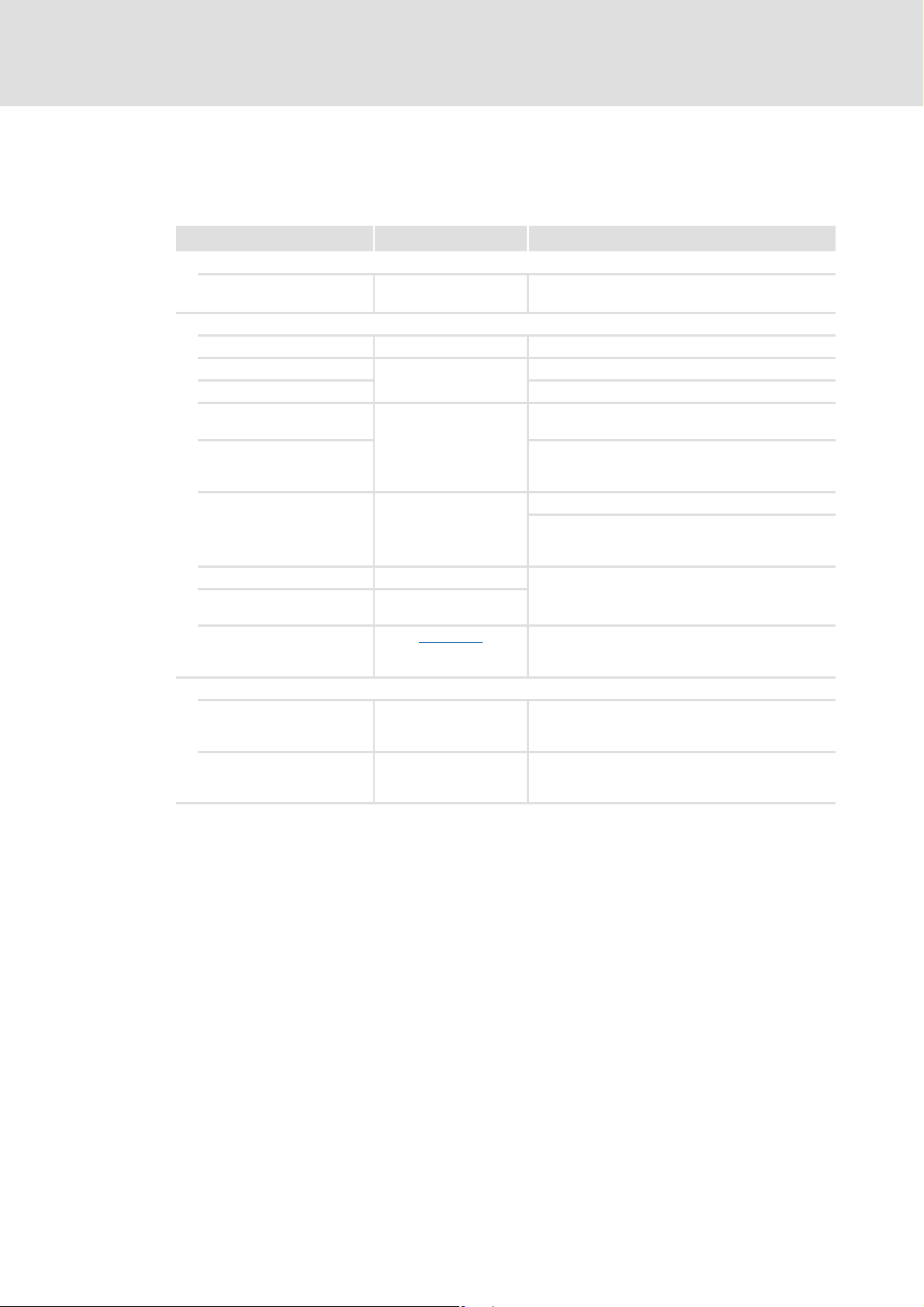

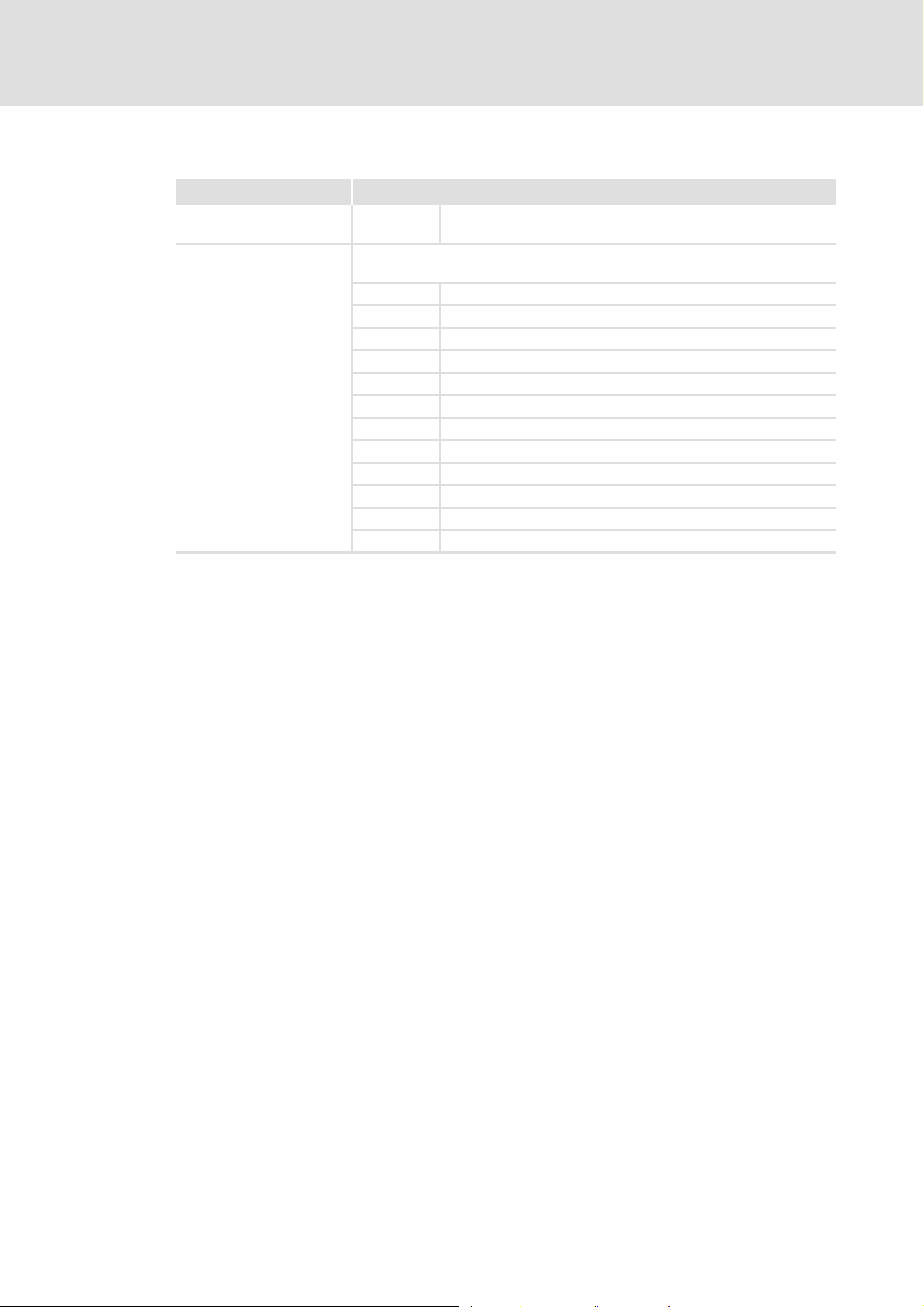

2 System requirements

Software

The function library can be used with the following Lenze software:

Product Type designation Version

Drive PLC Developer Studio ESP-DDS2-x 2.x

PLC Designer V2 2.2 or higher

PLC Designer V3 ESPEVPDxxxxxx 3.x

Supported target systems

Product range Type designation Hardware version From software version

Drive PLC EPL-10200 1A or higher 2.x

9300 Servo PLC EVS93xx-EI

EVS93xx-ET

ECS ECSxA 1B or higher 7.x

9400 ServoPLC E94AxPExxxx 2A or higher 2.x

2M or higher 2.x

Required libraries for use in »Drive PLC Developer Studio«

with Drive PLC/9300 Servo PLC/ECS:

Unless already available, insert the following libraries into the library management (menu

WindowLibrary management):

CANopenSdoDrvV10.lib

LenzeTICan9300V10.lib

LenzeIo1000DrvV10.lib

LenzeConversionBoxV10.lib (optional)

Note!

Before the "LenzeTICan9300V10.lib" library is inserted into the library manager,

the CAN_Management system block must be implemented into the Control

configuration.

If the CAN_Management system block is missing or implemented subsequently,

a compilation error may be caused during the project compilation.

Remedy:

implement the CAN_Management system block and re-insert the library into

the library manager.

Remove "LenzeTICan9300V10.lib" library from the library manager,

6 L DMS 1.0 EN - 07/2011 - TD05

Page 7

Function library "LenzeIo1000Drv"

System requirements

Required libraries for use in the »PLC Designer« with 9400 ServoPLC:

Unless already available, insert the following libraries into the library management (menu

WindowLibrary management):

LenzeCanOpenSdoDrvV10.lib

LenzeTICan9400V10.lib

LenzeIo1000DrvV10.lib

LenzeConversionBoxV10.lib (optional)

DMS 1.0 EN - 07/2011 - TD05 L 7

Page 8

Function library "LenzeIo1000Drv"

Project planning concept

Parameterisation and process data blocks

3 Project planning concept

The user is provided with suitable function blocks by the "LenzeIo1000Drvlib" library to

enable support of the decentralised I/O system through Lenze PLC products These function

blocks are implemented in an IEC 61131 program and serve both for parameterising the I/

O system and for process data processing. They provide digital and analog input and

output information of the I/O system. Configurations of the user via user codes are not

required.

3.1 Parameterisation and process data blocks

The "LenzeIo1000Drvlib" library contains two types of function blocks:

1. Parameterisation blocks

2. Process data blocks

Parameterisation blocks

Parameterisation blocks allow the modification of index information in the decentralised

I/O system and the transmission of specified data. These data are transmitted only once to

the I/O system during the initialisation phase..

The parameterisation blocks for modules and monitoring functions are required for

individual parameter setting of analog modules, communication monitoring, etc.

The parameterisation blocks communication settings (L_io1000ParPDO15

L_io1000ParPDO610

) are mandatory for data exchange between PLC and I/O system.

and

Note!

In case of parameterisation blocks with the same bus node address at the

byNodeAdr input, the bExecute inputs must not be set to TRUE at the same time.

The parameter setting of the modules and the communication settings of a bus

coupler have to be started successively.

Process data blocks

Process data blocks are required for transmitting and receiving I/O data between PLC and

I/O system. The process data blocks L_io1000Data15

evaluate and process the current process data information of the inputs of the I/O system

in the PLC program. Information and data of the PLC control can be transmitted to the

process via the output modules of the I/O system.

and L_io1000Data610 serve to

8 L DMS 1.0 EN - 07/2011 - TD05

Page 9

3.2 Initialisation of the CAN driver

The "LenzeIo1000Drv.lib" function library for the L-force I/O system 1000 is based on a

library for transmitting and receiving CAN objects. Depending on the PLC version, the "CAN

on board" or an optional fieldbus card can be used as communication channel.

9400 ServoPLC

For using the "LenzeCanMsg.lib" library, an initialisation of the CAN driver with L_CanInit

function block call is required. This function block must only be called once. Thus, best use

the "PLC_START" system event for calling this function.

The L_CanInit function block outputs information on the communication channel used via

its dwHandle output. This information must be provided to the blocks of the

"LenzeIo1000Drv.Lib" via the dwHandle input.

Drive PLC, 9300 Servo PLC, ECS

For using the "LenzeCanDrv.lib" library, an initialisation of the CAN driver with the

L_CanInit function call is required. This function must only be called once. Thus, best use

the system POU "PLC_ColdStart" for calling this function.

Function library "LenzeIo1000Drv"

Project planning concept

Initialisation of the CAN driver

The L_CanInit function returns information on the communication channel used via the

dwHandle variable. This information must be provided to the blocks of the

"LenzeIo1000Drv.Lib" via the dwHandle input.

DMS 1.0 EN - 07/2011 - TD05 L 9

Page 10

Function library "LenzeIo1000Drv"

Project planning concept

Minimum configuration

3.3 Minimum configuration

For implementing the I/O system, a minimum configuration must be carried out. It consists

of a parameterisation block L_io1000ParPDO15

relationships and a process data block L_io1000Data15

information.

The parameterisation block must be connected to the process data block as follows:

for parameterising the communication

for evaluation the input/output

The parameterisation block does not have to be executed in the same task as the

process data block. In this case, the outputs of the parameterisation block must be

connected to the inputs of the process data block.

10 L DMS 1.0 EN - 07/2011 - TD05

Page 11

4 Function blocks

Function block Function

L_io1000ParAiDc

L_io1000ParAiTemperature

L_io1000ParAoDc

L_io1000ParCounterEPMS600

L_io1000ParCounterEPMS601

L_io1000ParCounterEPMS602

L_io1000ParCounterEPMS603

L_io1000ParCounterEPMS604

L_io1000ParRestore

L_io1000ParPDO15

L_io1000ParPDO610

L_io1000ParComGuarding

L_io1000Data15

L_io1000Data610 Process data transfer PDO6 ... PDO10

Function library "LenzeIo1000Drv"

Function blocks

Parameterise I/O compound modules "analog inputs":

• EPM-S400

• EPM-S401

• EPM-S402

• EPM-S403

Parameterise I/O compound modules "temperature measurement":

• EPM-S404

• EPM-S405

Parameterise I/O compound modules "Analog outputs":

• EPM-S500

• EPM-S501

• EPM-S502

• EPM-S503

Parameterise I/O compound modules EPM-S600 (counter)

Parameterise I/O compound modules EPM-S601 (counter)

Parameterise I/O compound modules EPM-S602 (counter)

Parameterise I/O compound modules EPM-S603 (counter)

Parameterise I/O compound module EPM-S604 (encoder evaluation)

Load default setting in I/O system

Communication settings PDO1 ... PDO5:

• Identifier

• Transmission mode

• Cycle time/blocking time

Communication settings PDO6 ... PDO10:

• Identifier

• Transmission mode

• Cycle time/blocking time

Parameterise monitoring functions:

•NodeGuarding

•Heartbeat

• Switching performance of the output channels in the event of an error

• Timeout monitoring

Process data transfer PDO1 ... PDO5

DMS 1.0 EN - 07/2011 - TD05 L 11

Page 12

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParAiDc - Parameterise analog inputs

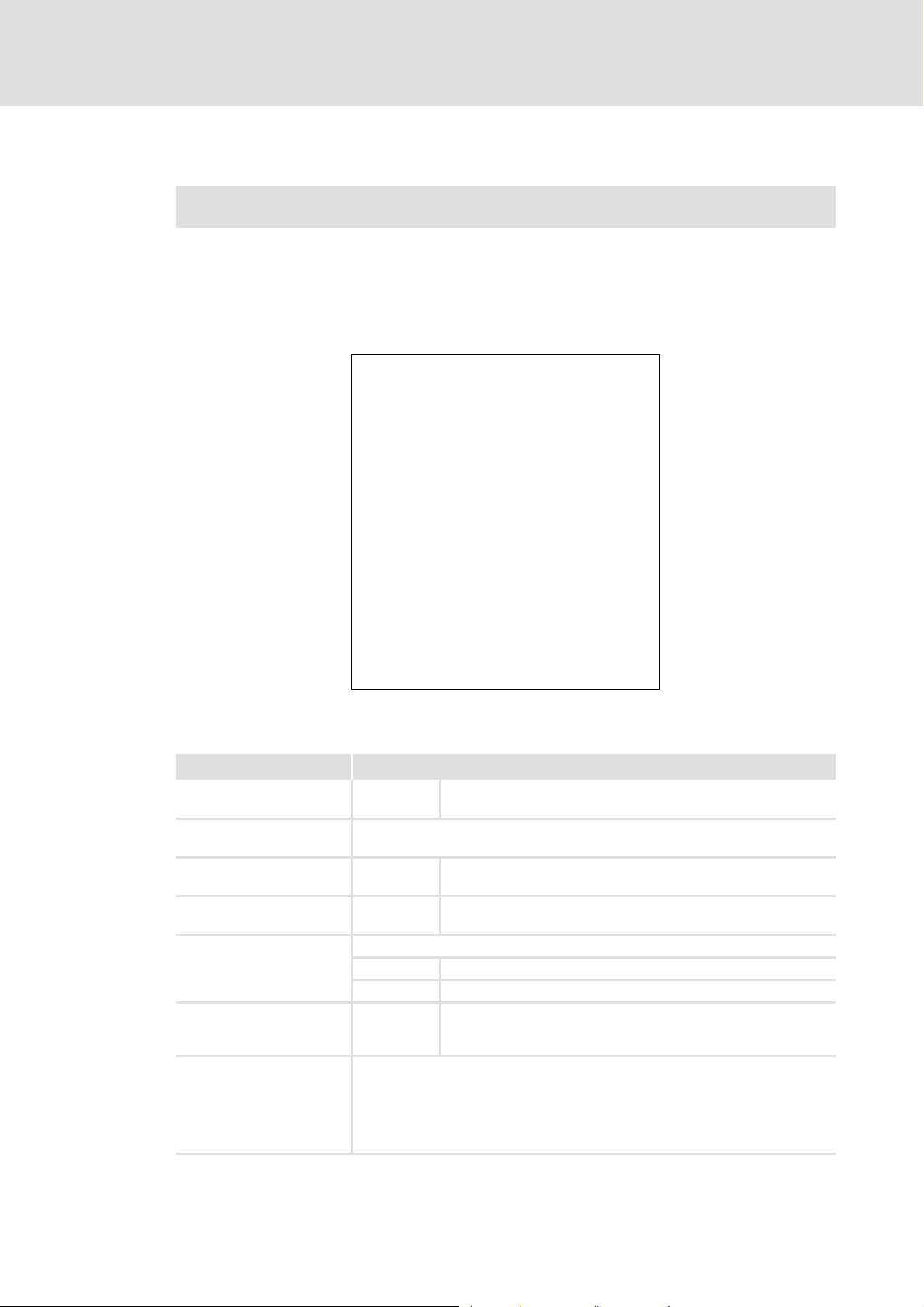

4.1 L_io1000ParAiDc - Parameterise analog inputs

Call possible in: ; Cyclic task

Interrupt task

; Time-controlled task (INTERVAL)

Event-controlled task (EVENT)

This FB serves to parameterise the analog input modules EPM-S400, EPM-S401, EPM-S402

and EPM-S403.

A FALSE/TRUE edge at the bExecute input starts the parameter setting.

The dnState output shows the transmission status.

L_io1000ParAiDc

⎯ bExecute bDone ⎯

⎯ dwHandle dnState ⎯

⎯ byNodeAdr

⎯ byAnalogModuleNo

⎯ byNoOfChannels

⎯ byFunction_CH1

⎯ byFunction_CH2

⎯ byFunction_CH3

⎯ byFunction_CH4

Inputs

Identifier/data type Information/possible settings

bExecute

dwHandle

DWORD

byNodeAdr

byAnalogModuleNo

byNoOfChannels

byFunction_CH1 ... _CH4

FALSEÊTRUE Start parameter setting of the analog input module

BOOL

• 9400 ServoPLC: Handle created by FB L_CanInit

• Drive PLC, 9300 Servo PLC, ECS: 10

1 ... 127 CAN node address of the I/O system

BYTE

1 ... 64 Number of the analog input module

BYTE

Number of channels of the I/O system

BYTE

Function channel 1 ... 4

BYTE

• see system manual "I/O system 1000":

EPM-S400: Chapter 7.8.1

EPM-S401: Chapter 7.8.2

EPM-S402: Chapter 7.8.3

EPM-S403: Chapter 7.8.4

2 EPM-S400, EPM-S402

4 EPM-S401, EPM-S403

12 L DMS 1.0 EN - 07/2011 - TD05

Page 13

Outputs

Identifier/data type Value/meaning

bDone

dnState

BOOL

Status of parameter setting

DINT

• When the function has been executed successfully, the value "0" is output.

TRUE Parameter setting completed successfully

-1003 byNodeAdr input is not in valid range

-1004 Wrong value at byAnalogModuleNo input

-1005 Wrong value at byNoOfChannels input

-2000 Error while executing the internal block for writing CAN indices

-2002 Wrong value at the dwHandle input

-2003 Wrong value at the byNodeAdr input

-2006 Writing of a wrong CAN index

-2007 Timeout while writing a CAN index of the I/O system

-2100 Error while writing a parameter of the I/O system

-2101 Output buffer is full

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParAiDc - Parameterise analog inputs

1 Parameter setting started

0 Parameter setting completed successfully

DMS 1.0 EN - 07/2011 - TD05 L 13

Page 14

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParAiTemperature - Parameterise temperature measurement

4.2 L_io1000ParAiTemperature - Parameterise temperature measurement

Call possible in: ; Cyclic task

Interrupt task

; Time-controlled task (INTERVAL)

Event-controlled task (EVENT)

This FB serves to parameterise the analog input modules EPM-S404 and EPM-S405.

A FALSE/TRUE edge at the bExecute input starts the parameter setting.

The dnState output shows the transmission status.

L_io1000ParAiTemperature

⎯ bExecute bDone ⎯

⎯ dwHandle dnState ⎯

⎯ byNodeAdr

⎯ byAnalogModuleNo

⎯ byNoOfChannels

⎯ bDiagnosticAlarm

⎯ byTemperatureSystem

⎯ byFilter

⎯ bWireBreakDetection_CH1

⎯ byFunction_CH1

⎯ bySampling_CH1

⎯ bLimitAlarm_CH1

⎯ nUpperLimit_CH1

⎯ nLowerLimit_CH1

⎯ bWireBreakDetection_CH2

⎯ byFunction_CH2

⎯ bySampling_CH2

⎯ bLimitAlarm_CH2

⎯ nUpperLimit_CH2

⎯ nLowerLimit_CH2

⎯ bWireBreakDetection_CH3

⎯ byFunction_CH3

⎯ bySampling_CH3

⎯ bLimitAlarm_CH3

⎯ nUpperLimit_CH3

⎯ nLowerLimit_CH3

⎯ bWireBreakDetection_CH4

⎯ byFunction_CH4

⎯ bySampling_CH4

⎯ bLimitAlarm_CH4

⎯ nUpperLimit_CH4

⎯ nLowerLimit_CH4

14 L DMS 1.0 EN - 07/2011 - TD05

Page 15

L_io1000ParAiTemperature - Parameterise temperature measurement

Inputs

Identifier/data type Information/possible settings

bExecute

dwHandle

DWORD

byNodeAdr

byAnalogModuleNo

byNoOfChannels

bDiagnosticAlarm

byTemperatureSystem

byFilter

bWireBreakDetection

_CH1 ... _CH4

byFunction_CH1 ... _CH4

bySampling_CH1 ... _CH4

bLimitAlarm_CH1 ... _CH4

nUpperLimit_CH1 ... _CH4

nLowerLimit_CH1 ... _CH4

FALSEÊTRUE Start parameter setting of the analog input module

BOOL

• 9400 ServoPLC: Handle created by FB L_CanInit

• Drive PLC, 9300 Servo PLC, ECS: 10

1 ... 127 CAN node address of the I/O system

BYTE

1 ... 64 Number of the analog input module

BYTE

Number of channels of the I/O system

BYTE

BOOL

Temperature system

BYTE

Activate interference frequency suppression

BYTE

BOOL

Function channel 1 ... 4

BYTE

• see system manual "I/O system 1000":

EPM-S404: Chapter 7.9.1

EPM-S405: Chapter 7.9.2

Conversion time channel 1 ... 4

BYTE

• see system manual "I/O system 1000":

EPM-S404: Chapter 7.9.1

EPM-S405: Chapter 7.9.2

BOOL

Upper limit value channel 1 ... 4

BYTE

Lower limit value channel 1 ... 4

BYTE

2 EPM-S405

4 EPM-S404

TRUE Enable diagnostic alarm

0°C

1°F

2K

160Hz

250Hz

TRUE Activate open circuit detection channel 1 ... 4

TRUE Activate limit value monitoring channel 1 ... 4

Function library "LenzeIo1000Drv"

Function blocks

DMS 1.0 EN - 07/2011 - TD05 L 15

Page 16

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParAiTemperature - Parameterise temperature measurement

Outputs

Identifier/data type Value/meaning

bDone

dnState

BOOL

Status of parameter setting

DINT

• When the function has been executed successfully, the value "0" is output.

TRUE Parameter setting completed successfully

1 Parameter setting started

0 Parameter setting completed successfully

-1003 byNodeAdr input is not in valid range

-1004 Wrong value at byAnalogModuleNo input

-1005 Wrong value at byNoOfChannels input

-1007 Wrong value at byTemperatureSystem input

-1009 Wrong value at byFilter input

-2000 Error while executing the internal block for writing CAN indices

-2002 Wrong value at the dwHandle input

-2003 Wrong value at the byNodeAdr input

-2006 Writing of a wrong CAN index

-2007 Timeout while writing a CAN index of the I/O system

-2100 Error while writing a parameter of the I/O system

-2101 Output buffer is full

16 L DMS 1.0 EN - 07/2011 - TD05

Page 17

Function library "LenzeIo1000Drv"

L_io1000ParAoDc - Parameterise analog outputs

4.3 L_io1000ParAoDc - Parameterise analog outputs

Function blocks

Call possible in: ; Cyclic task

Interrupt task

; Time-controlled task (INTERVAL)

Event-controlled task (EVENT)

This FB serves to parameterise the analog output modules EPM-S500, EPM-S501, EPMS502 and EPM-S503.

A FALSE/TRUE edge at the bExecute input starts the parameter setting.

The dnState output shows the transmission status.

L_io1000ParAoDc

⎯ bExecute bDone ⎯

⎯ dwHandle dnState ⎯

⎯ byNodeAdr

⎯ byAnalogModuleNo

⎯ byNoOfChannels

⎯ bShortCircuitDetection_CH1

⎯ byFunction_CH1

⎯ bShortCircuitDetection_CH2

⎯ byFunction_CH2

⎯ bShortCircuitDetection_CH3

⎯ byFunction_CH3

⎯ bShortCircuitDetection_CH4

⎯ byFunction_CH4

Inputs

Identifier/data type Information/possible settings

bExecute

dwHandle

DWORD

byNodeAdr

byAnalogModuleNo

byNoOfChannels

bShortCircuitDetection

_CH1 ... _CH4

byFunction_CH1 ... _CH4

FALSEÊTRUE Start parameter setting of the analog output module

BOOL

• 9400 ServoPLC: Handle created by FB L_CanInit

• Drive PLC, 9300 Servo PLC, ECS: 10

1 ... 127 CAN node address of the I/O system

BYTE

1 ... 64 Number of the analog output module

BYTE

Number of channels of the I/O system

BYTE

BOOL

Function channel 1 ... 4

BYTE

• see system manual "I/O system 1000":

EPM-S500: Chapter 7.8.5

EPM-S501: Chapter 7.8.6

EPM-S502: Chapter 7.8.7

EPM-S503: Chapter 7.8.8

2 EPM-S500, EPM-S502

4 EPM-S501, EPM-S503

TRUE Activate short circuit detection channel 1 ... 4

DMS 1.0 EN - 07/2011 - TD05 L 17

Page 18

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParAoDc - Parameterise analog outputs

Outputs

Identifier/data type Value/meaning

bDone

dnState

BOOL

Status of parameter setting

DINT

• When the function has been executed successfully, the value "0" is output.

TRUE Parameter setting completed successfully

1 Parameter setting started

0 Parameter setting completed successfully

-1003 byNodeAdr input is not in valid range

-1004 Wrong value at byAnalogModuleNo input

-1005 Wrong value at byNoOfChannels input

-2000 Error while executing the internal block for writing CAN indices

-2002 Wrong value at the dwHandle input

-2003 Wrong value at the byNodeAdr input

-2006 Writing of a wrong CAN index

-2007 Timeout while writing a CAN index of the I/O system

-2100 Error while writing a parameter of the I/O system

-2101 Output buffer is full

18 L DMS 1.0 EN - 07/2011 - TD05

Page 19

Function library "LenzeIo1000Drv"

L_io1000ParCounterEPMS600 - Parameterise counter

4.4 L_io1000ParCounterEPMS600 - Parameterise counter

Function blocks

Call possible in: ; Cyclic task

Interrupt task

; Time-controlled task (INTERVAL)

Event-controlled task (EVENT)

This FB serves to parameterise the EPM-S600 counter module.

A FALSE/TRUE edge at the bExecute input starts the parameter setting.

The dnState output shows the transmission status.

L_io1000ParCounterEPMS600

⎯ bExecute bDone ⎯

⎯ dwHandle dnState ⎯

⎯ byNodeAdr

⎯ byAnalogModuleNo

⎯ bDiagnosticAlarm

⎯ byInputFrequencyTrackA

⎯ byInputFrequencyTrackB

⎯ byInputFrequencyLatch

⎯ byInputFrequencyGate

⎯ byInputFrequencyReset

⎯ byAlarmFunction

⎯ byCounterFunction

⎯ bySignalSelection

⎯ bActivateHardwareGate

⎯ bInternalGateInterrupt

⎯ byCompareFunction

⎯ bInvertDirectionTrackB

⎯ byResetFunction

⎯ dwLoadValue

⎯ dwEndValue

⎯ byHysteresis

⎯ byPulse

Inputs

Identifier/data type Information/possible settings

bExecute

dwHandle

DWORD

byNodeAdr

byAnalogModuleNo

bDiagnosticAlarm

DMS 1.0 EN - 07/2011 - TD05 L 19

FALSEÊTRUE Start parameter setting of the analog output module

BOOL

• 9400 ServoPLC: Handle created by FB L_CanInit

• Drive PLC, 9300 Servo PLC, ECS: 10

1 ... 127 CAN node address of the I/O system

BYTE

1 ... 64 Number of the analog output module

BYTE

TRUE Enable diagnostic alarm

BOOL

Page 20

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParCounterEPMS600 - Parameterise counter

Identifier/data type Information/possible settings

byInputFrequencyTrackA

byInputFrequencyTrackB

byInputFrequencyLatch

byInputFrequencyGate

byInputFrequencyReset

Input filter of digital input 1 "A"/"pulse"

BYTE

Input filter of digital input 5 "B"/"direction"

BYTE

Input filter of digital input 4 "latch"

BYTE

Input filter of digital input 8 "hardware gate"

BYTE

Input filter of digital input 7 "reset"

BYTE

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

20 L DMS 1.0 EN - 07/2011 - TD05

Page 21

Function library "LenzeIo1000Drv"

L_io1000ParCounterEPMS600 - Parameterise counter

Identifier/data type Information/possible settings

byAlarmFunction

byCounterFunction

bySignalSelection

bActivateHardwareGate

bInternalGateInterrupt

byCompareFunction

bInvertDirectionTrackB

byResetFunction

Process alarm

BYTE

A process alarm can be triggered in case of the following events:

bits0 Open hardware gate

bits1 Closed hardware gate

Bit 2 Counter limit overflow

bits3 Counter limit underflow

bits4 Comparison value reached

Bit 5 Final value reached

Bit 6 Latch value reached

Bit 7 Reserved

Counting function

BYTE

Signal evaluation

BYTE

Activation of hardware gate

BOOL

Gate function (internal gate)

BOOL

Comparison operation

BYTE

BOOL

Reset function

BYTE

0 Continuous counting

1 Single counting, main counting direction is forward

2 Single counting, main counting direction is backward

3 Single counting, no main counting direction

4 Periodic counting, main counting direction is forward

5 Periodic counting, main counting direction is backward

6 Periodic counting, no main counting direction

0 Counter deactivated

• The other parameter data for the counter are ignored.

1 Rotary transducer 1-fold (at A and B)

2 Rotary transducer 2-fold (at A and B)

3 Rotary transducer 4-fold (at A and B)

4 Direction (pulse at A and direction at B)

FALSE Hardware gate deactivated

• Counter starts by setting the software gate.

TRUE Hardware gate activated

• HIGH level at the gate input activates the hardware gate.

• Counter starts if hardware and software gate are set.

FALSE Cancel (counting process restarts from the load value)

TRUE Interrupt (counting process is continued with counter content)

0 Output never switches

1 Output switches if count value ≥ comparison value.

2 Output switches if count value ≤ comparison value.

3 Output switches if count value = comparison value.

TRUE Invert counting direction track B

0 Deactivated

1HIGH level

2 Rising edge

3 one-time rising edge

Function blocks

DMS 1.0 EN - 07/2011 - TD05 L 21

Page 22

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParCounterEPMS600 - Parameterise counter

Identifier/data type Information/possible settings

dwLoadValue

DWORD

dwEndValue

DWORD

byHysteresis

byPulse

Outputs

Identifier/data type Value/meaning

bDone

dnState

Load value

Final value

Hysteresis

BYTE

Pulse duration

BYTE

TRUE Parameter setting completed successfully

BOOL

Status of parameter setting

DINT

• When the function has been executed successfully, the value "0" is output.

1 Parameter setting started

0 Parameter setting completed successfully

-1003 byNodeAdr input is not in valid range

-1004 Wrong value at byAnalogModuleNo input

-1007 Wrong value at byInputFrequencyTrackA input

-1008 Wrong value at byInputFrequencyTrackB input

-1009 Wrong value at byInputFrequencyLatch input

-1010 Wrong value at byInputFrequencyGate input

-1011 Wrong value at byInputFrequencyReset input

-1012 Wrong value at byAlarmFunction input

-1013 Wrong value at byCounterFunction input

-1014 Wrong value at bySignalSelection input

-1017 Wrong value at byCompareFunction input

-1019 Wrong value at byResetFunction input

-2000 Error while executing the internal block for writing CAN indices

-2002 Wrong value at the dwHandle input

-2003 Wrong value at the byNodeAdr input

-2006 Writing of a wrong CAN index

-2007 Timeout while writing a CAN index of the I/O system

-2100 Error while writing a parameter of the I/O system

-2101 Output buffer is full

22 L DMS 1.0 EN - 07/2011 - TD05

Page 23

Function library "LenzeIo1000Drv"

L_io1000ParCounterEPMS601 - Parameterise counter

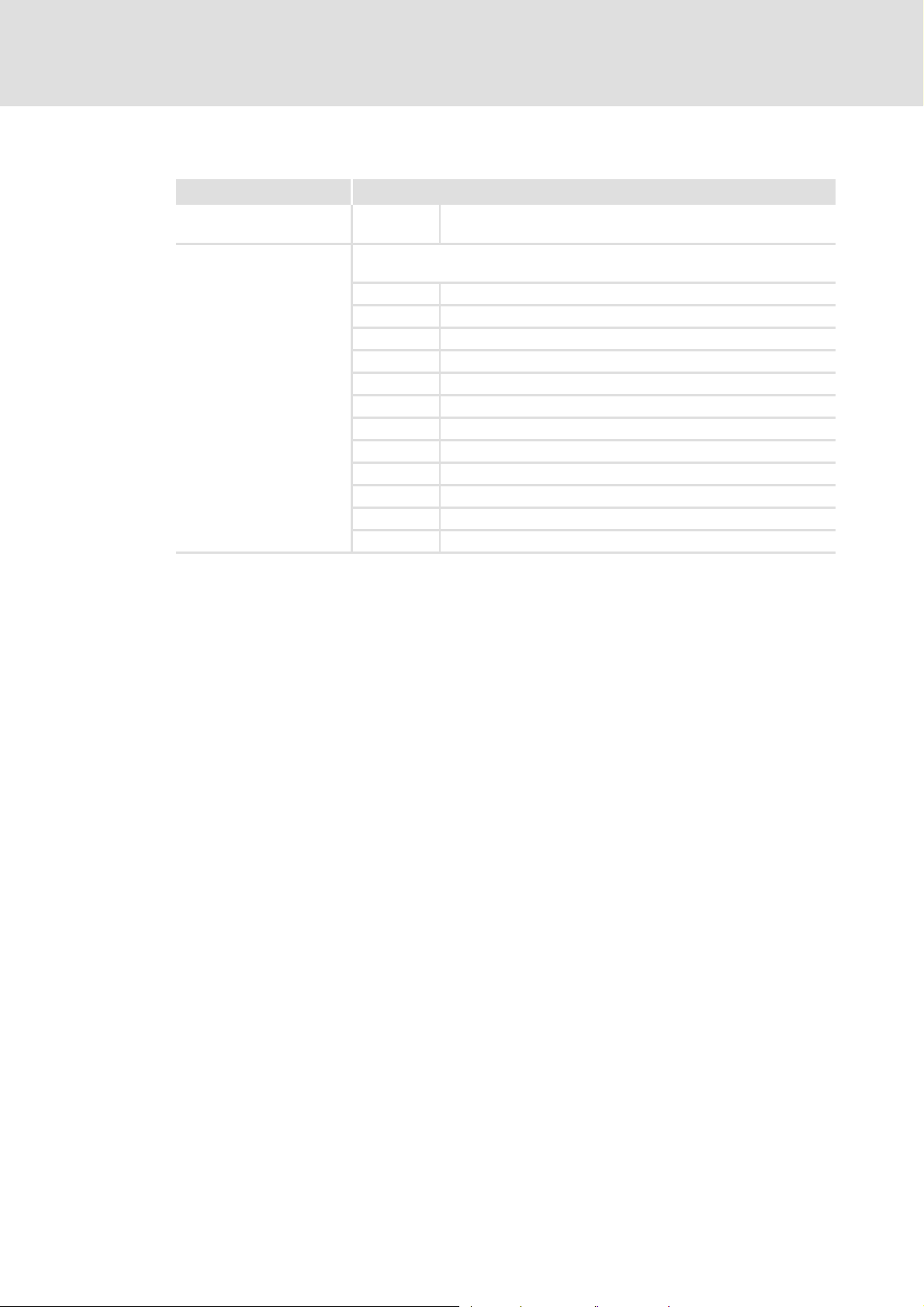

4.5 L_io1000ParCounterEPMS601 - Parameterise counter

Function blocks

Call possible in: ; Cyclic task

Interrupt task

; Time-controlled task (INTERVAL)

Event-controlled task (EVENT)

This FB serves to parameterise the EPM-S601 counter module.

A FALSE/TRUE edge at the bExecute input starts the parameter setting.

The dnState output shows the transmission status.

L_io1000ParCounterEPMS601

⎯ bExecute bDone ⎯

⎯ dwHandle dnState ⎯

⎯ byNodeAdr

⎯ byAnalogModuleNo

⎯ bDiagnosticAlarm

⎯ byCnt0InputFrequencyTrackA

⎯ byCnt0InputFrequencyTrackB

⎯ byCnt0AlarmFunction

⎯ byCnt0CounterFunction

⎯ byCnt0SignalSelection

⎯ bCnt0InternalGateInterrupt

⎯ byCnt0CompareFunction

⎯ bCnt0InvertDirectionTrackB

⎯ dwCnt0SetValue

⎯ dwCnt0LoadValue

⎯ dwCnt0EndValue

⎯ byCnt0Hysteresis

⎯ byCnt1InputFrequencyTrackA

⎯ byCnt1InputFrequencyTrackB

⎯ byCnt1AlarmFunction

⎯ byCnt1CounterFunction

⎯ byCnt1SignalSelection

⎯ bCnt1InternalGateInterrupt

⎯ byCnt1CompareFunction

⎯ bCnt1InvertDirectionTrackB

⎯ dwCnt1SetValue

⎯ dwCnt1LoadValue

⎯ dwCnt1EndValue

⎯ byCnt1Hysteresis

DMS 1.0 EN - 07/2011 - TD05 L 23

Page 24

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParCounterEPMS601 - Parameterise counter

Inputs

Identifier/data type Information/possible settings

bExecute

dwHandle

DWORD

byNodeAdr

byAnalogModuleNo

bDiagnosticAlarm

byCnt0

InputFrequencyTrackA

byCnt0

InputFrequencyTrackB

byCnt0AlarmFunction

byCnt0CounterFunction

FALSEÊTRUE Start parameter setting of the analog output module

BOOL

• 9400 ServoPLC: Handle created by FB L_CanInit

• Drive PLC, 9300 Servo PLC, ECS: 10

1 ... 127 CAN node address of the I/O system

BYTE

1 ... 64 Number of the analog output module

BYTE

TRUE Enable diagnostic alarm

BOOL

Counter 1: Input filter of digital input 1, "A1"/"pulse"

BYTE

Counter 1: Input filter of digital input 5, "B1"/"direction"

BYTE

Counter 1: Process alarm

BYTE

A process alarm can be triggered in case of the following events:

Counter 1: Counting function

BYTE

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

bits0 Reserved

bits1 Reserved

Bit 2 Counter limit overflow

bits3 Counter limit underflow

bits4 Comparison value reached

Bit 5 Final value reached

Bit 6 Reserved

Bit 7 Reserved

0 Continuous counting

1 Single counting, main counting direction is forward

2 Single counting, main counting direction is backward

3 Single counting, no main counting direction

4 Periodic counting, main counting direction is forward

5 Periodic counting, main counting directin is backward

6 Periodic counting, no main counting direction

24 L DMS 1.0 EN - 07/2011 - TD05

Page 25

Function library "LenzeIo1000Drv"

L_io1000ParCounterEPMS601 - Parameterise counter

Identifier/data type Information/possible settings

byCnt0SignalSelection

bCnt0InternalGateInterrupt

byCnt0CompareFunction

bCnt0InvertDirectionTrackB

dwCnt0SetValue

DWORD

dwCnt0LoadValue

DWORD

dwCnt0EndValue

DWORD

byCnt0Hysteresis

byCnt1

InputFrequencyTrackA

byCnt1

InputFrequencyTrackB

Counter 1: Signal evaluation

BYTE

Counter 1: Gate function (internal gate)

BOOL

Counter 1: Comparison operation

BYTE

BOOL

Counter 1: Set value

Counter 1: Load value

Counter 1: Final value

Counter 1: Hysteresis

BYTE

Counter 2: Input filter of digital input 4, "A2"/"pulse"

BYTE

Counter 1: Input filter of digital input 8, "B2"/"direction"

BYTE

0 Counter deactivated

• The other parameter data for the counter are ignored.

1 Rotary transducer 1-fold (at A and B)

2 Rotary transducer 2-fold (at A and B)

3 Rotary transducer 4-fold (at A and B)

4 Direction (pulse at A and direction at B)

FALSE Cancel (counting process restarts from the load value)

TRUE Interrupt (counting process is continued with counter content)

0 Comparison bit is never set

1 Comparison bit is set if count value ≥ comparison value.

2 Comparison bit is set if count value ≤ comparison value.

3 Comparison bit is set if count value = comparison value.

TRUE Counter 1: Invert counting direction track B

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

Function blocks

DMS 1.0 EN - 07/2011 - TD05 L 25

Page 26

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParCounterEPMS601 - Parameterise counter

Identifier/data type Information/possible settings

byCnt1AlarmFunction

byCnt1CounterFunction

byCnt1SignalSelection

bCnt1InternalGateInterrupt

byCnt1CompareFunction

bCnt1InvertDirectionTrackB

dwCnt1SetValue

DWORD

dwCnt1LoadValue

DWORD

dwCnt1EndValue

DWORD

byCnt1Hysteresis

Counter 2: Process alarm

BYTE

A process alarm can be triggered in case of the following events:

bits0 Reserved

bits1 Reserved

Bit 2 Counter limit overflow

bits3 Counter limit underflow

bits4 Comparison value reached

Bit 5 Final value reached

Bit 6 Reserved

Bit 7 Reserved

Counter 2: Counting function

BYTE

Counter 2: Signal evaluation

BYTE

Counter 2: Gate function (internal gate)

BOOL

Counter 2: Comparison operation

BYTE

BOOL

Counter 2: Set value

Counter 2: Load value

Counter 2: Final value

Counter 2: Hysteresis

BYTE

0 Continuous counting

1 Single counting, main counting direction is forward

2 Single counting, main counting direction is backward

3 Single counting, no main counting direction

4 Periodic counting, main counting direction is forward

5 Periodic counting, main counting direction is backward

6 Periodic counting, no main counting direction

0 Counter deactivated

1 Rotary transducer 1-fold (at A and B)

2 Rotary transducer 2-fold (at A and B)

3 Rotary transducer 4-fold (at A and B)

4 Direction (pulse at A and direction at B)

FALSE Cancel (counting process restarts from the load value)

TRUE Interrupt (counting process is continued with counter content)

0 Comparison bit is never set

1 Comparison bit is set if count value ≥ comparison value.

2 Comparison bit is set if count value ≤ comparison value.

3 Comparison bit is set if count value = comparison value.

TRUE Counter 2: Invert counting direction track B

• The other parameter data for the counter are ignored.

26 L DMS 1.0 EN - 07/2011 - TD05

Page 27

Outputs

Identifier/data type Value/meaning

bDone

dnState

BOOL

Status of parameter setting

DINT

• When the function has been executed successfully, the value "0" is output.

TRUE Parameter setting completed successfully

-1003 byNodeAdr input is not in valid range

-1004 Wrong value at byAnalogModuleNo input

-1007 Wrong value at byCnt0InputFrequencyTrackA input

-1008 Wrong value at byCnt0InputFrequencyTrackB input

-1009 Wrong value at byCnt0AlarmFunction input

-1010 Wrong value at byCnt0CounterFunction input

-1011 Wrong value at byCnt0SignalSelection input

-1013 Wrong value at byCnt0CompareFunction input

-1019 Wrong value at byCnt1InputFrequencyTrackA input

-1020 Wrong value at byCnt1InputFrequencyTrackB input

-1021 Wrong value at byCnt1AlarmFunction input

-1022 Wrong value at byCnt1CounterFunction input

-1023 Wrong value at byCnt1SignalSelection input

-1025 Wrong value at byCnt1CompareFunction input

-2000 Error while executing the internal block for writing CAN indices

-2002 Wrong value at the dwHandle input

-2003 Wrong value at the byNodeAdr input

-2006 Writing of a wrong CAN index

-2007 Timeout while writing a CAN index of the I/O system

-2100 Error while writing a parameter of the I/O system

-2101 Output buffer is full

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParCounterEPMS601 - Parameterise counter

1 Parameter setting started

0 Parameter setting completed successfully

DMS 1.0 EN - 07/2011 - TD05 L 27

Page 28

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParCounterEPMS602 - Parameterise counter

4.6 L_io1000ParCounterEPMS602 - Parameterise counter

Call possible in: ; Cyclic task

Interrupt task

; Time-controlled task (INTERVAL)

Event-controlled task (EVENT)

This FB serves to parameterise the EPM-S602 counter module.

A FALSE/TRUE edge at the bExecute input starts the parameter setting.

The dnState output shows the transmission status.

L_io1000ParCounterEPMS602

⎯ bExecute bDone ⎯

⎯ dwHandle dnState ⎯

⎯ byNodeAdr

⎯ byAnalogModuleNo

⎯ bDiagnosticAlarm

⎯ byInputFrequencyTrackA

⎯ byInputFrequencyTrackB

⎯ byInputFrequencyReset

⎯ byAlarmFunction

⎯ byCounterFunction

⎯ bySignalSelection

⎯ bInternalGateInterrupt

⎯ byCompareFunction

⎯ bInvertDirectionTrackB

⎯ byResetFunction

⎯ dwLoadValue

⎯ dwEndValue

⎯ byHysteresis

Inputs

Identifier/data type Information/possible settings

bExecute

dwHandle

DWORD

byNodeAdr

byAnalogModuleNo

bDiagnosticAlarm

FALSEÊTRUE Start parameter setting of the analog output module

BOOL

• 9400 ServoPLC: Handle created by FB L_CanInit

• Drive PLC, 9300 Servo PLC, ECS: 10

1 ... 127 CAN node address of the I/O system

BYTE

1 ... 64 Number of the analog output module

BYTE

TRUE Enable diagnostic alarm

BOOL

28 L DMS 1.0 EN - 07/2011 - TD05

Page 29

Function library "LenzeIo1000Drv"

L_io1000ParCounterEPMS602 - Parameterise counter

Identifier/data type Information/possible settings

byInputFrequencyTrackA

byInputFrequencyTrackB

byInputFrequencyReset

byAlarmFunction

byCounterFunction

Input filter of digital input 1 and 5, "A"/"pulse"

BYTE

Input filter of digital input 4 and 8, "B"/"direction"

BYTE

Input filter of digital input 6 and 7, "reset"

BYTE

Process alarm

BYTE

A process alarm can be triggered in case of the following events:

Counting function

BYTE

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

bits0 Reserved

bits1 Reserved

Bit 2 Counter limit overflow

bits3 Counter limit underflow

bits4 Comparison value reached

Bit 5 Final value reached

Bit 6 Reserved

Bit 7 Reserved

0 Continuous counting

1 Single counting, main counting direction is forward

2 Single counting, main counting direction is backward

3 Single counting, no main counting direction

4 Periodic counting, main counting direction is forward

5 Periodic counting, main counting direction is backward

6 Periodic counting, no main counting direction

Function blocks

DMS 1.0 EN - 07/2011 - TD05 L 29

Page 30

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParCounterEPMS602 - Parameterise counter

Identifier/data type Information/possible settings

bySignalSelection

bInternalGateInterrupt

byCompareFunktion

bInvertDirectionTrackB

byResetFunktion

dwLoadValue

DWORD

dwEndValue

DWORD

byHysteresis

Signal evaluation

BYTE

Gate function (internal gate)

BOOL

BYTE

BOOL

BYTE

BYTE

FALSE Cancel (counting process restarts from the load value)

TRUE Interrupt (counting process is continued with counter content)

Comparison operation

TRUE Invert counting direction track B

Reset function

Load value

Final value

Hysteresis

0 Counter deactivated

1 Rotary transducer 1-fold (at A and B)

2 Rotary transducer 2-fold (at A and B)

3 Rotary transducer 4-fold (at A and B)

4 Direction (pulse at A and direction at B)

0 Comparison bit is never set

1 Comparison bit is set if count value ≥ comparison value.

2 Comparison bit is set if count value ≤ comparison value.

3 Comparison bit is set if count value = comparison value.

0 Deactivated

1HIGH level

2 Rising edge

3 one-time rising edge

• The other parameter data for the counter are ignored.

30 L DMS 1.0 EN - 07/2011 - TD05

Page 31

Outputs

Identifier/data type Value/meaning

bDone

dnState

BOOL

Status of parameter setting

DINT

• When the function has been executed successfully, the value "0" is output.

TRUE Parameter setting completed successfully

-1003 byNodeAdr input is not in valid range

-1004 Wrong value at byAnalogModuleNo input

-1007 Wrong value at byInputFrequencyTrackA input

-1008 Wrong value at byInputFrequencyTrackB input

-1009 Wrong value at byInputFrequencyReset input

-1010 Wrong value at byAlarmFunction input

-1011 Wrong value at byCounterFunction input

-1012 Wrong value at bySignalSelection input

-1014 Wrong value at byCompareFunction input

-1016 Wrong value at byResetFunction input

-1019 Channel 2: Lower limit is higher than upper limit

-1025 Channel 3: Lower limit is higher than upper limit

-1031 Channel 4: Lower limit is higher than upper limit

-2000 Error while executing the internal block for writing CAN indices

-2002 Wrong value at the dwHandle input

-2003 Wrong value at the byNodeAdr input

-2006 Writing of a wrong CAN index

-2007 Timeout while writing a CAN index of the I/O system

-2100 Error while writing a parameter of the I/O system

-2101 Output buffer is full

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParCounterEPMS602 - Parameterise counter

1 Parameter setting started

0 Parameter setting completed successfully

DMS 1.0 EN - 07/2011 - TD05 L 31

Page 32

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParCounterEPMS603 - Parameterise counter

4.7 L_io1000ParCounterEPMS603 - Parameterise counter

Call possible in: ; Cyclic task

Interrupt task

; Time-controlled task (INTERVAL)

Event-controlled task (EVENT)

This FB serves to parameterise the EPM-S603 counter module.

A FALSE/TRUE edge at the bExecute input starts the parameter setting.

The dnState output shows the transmission status.

L_io1000ParCounterEPMS603

⎯ bExecute bDone ⎯

⎯ dwHandle dnState ⎯

⎯ byNodeAdr

⎯ byAnalogModuleNo

⎯ byCnt0InputFrequencyTrackA

⎯ byCnt0InputFrequencyTrackB

⎯ byCnt0SignalSelection

⎯ bCnt0InvertDirectionTrackB

⎯ byCnt1InputFrequencyTrackA

⎯ byCnt1InputFrequencyTrackB

⎯ byCnt1SignalSelection

⎯ bCnt1InvertDirectionTrackB

Inputs

Identifier/data type Information/possible settings

bExecute

dwHandle

DWORD

byNodeAdr

byAnalogModuleNo

byCnt0

InputFrequencyTrackA

FALSEÊTRUE Start parameter setting of the analog output module

BOOL

• 9400 ServoPLC: Handle created by FB L_CanInit

• Drive PLC, 9300 Servo PLC, ECS: 10

1 ... 127 CAN node address of the I/O system

BYTE

1 ... 64 Number of the analog output module

BYTE

Counter 1: Input filter of digital input 1, "A1"/"pulse"

BYTE

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

32 L DMS 1.0 EN - 07/2011 - TD05

Page 33

Function library "LenzeIo1000Drv"

L_io1000ParCounterEPMS603 - Parameterise counter

Identifier/data type Information/possible settings

byCnt0

InputFrequencyTrackB

byCnt0SignalSelection

bCnt0InvertDirectionTrackB

byCnt1

InputFrequencyTrackA

byCnt1

InputFrequencyTrackB

byCnt1SignalSelection

bCnt1InvertDirectionTrackB

Counter 1: Input filter of digital input 5, "B1"/"direction"

BYTE

Counter 1: Signal evaluation

BYTE

BOOL

Counter 2: Input filter of digital input 4, "A2"/"pulse"

BYTE

Counter 1: Input filter of digital input 8, "B2"/"direction"

BYTE

Counter 2: Signal evaluation

BYTE

BOOL

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

0 Counter deactivated

• The other parameter data for the counter are ignored.

1 Rotary transducer 1-fold (at A and B)

2 Rotary transducer 2-fold (at A and B)

3 Rotary transducer 4-fold (at A and B)

4 Direction (pulse at A and direction at B)

TRUE Counter 1: Invert counting direction track B

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

2 100 kHz

3 60 kHz

4 30 kHz

6 10 kHz

75 kHz

82 kHz

91 kHz

0 Counter deactivated

• The other parameter data for the counter are ignored.

1 Rotary transducer 1-fold (at A and B)

2 Rotary transducer 2-fold (at A and B)

3 Rotary transducer 4-fold (at A and B)

4 Direction (pulse at A and direction at B)

TRUE Counter 2: Invert counting direction track B

Function blocks

DMS 1.0 EN - 07/2011 - TD05 L 33

Page 34

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParCounterEPMS603 - Parameterise counter

Outputs

Identifier/data type Value/meaning

bDone

BOOL

dnState

Status of parameter setting

DINT

• When the function has been executed successfully, the value "0" is output.

TRUE Parameter setting completed successfully

1 Parameter setting started

0 Parameter setting completed successfully

-1003 byNodeAdr input is not in valid range

-1004 Wrong value at byAnalogModuleNo input

-1006 Wrong value at byCnt0InputFrequencyTrackA input

-1007 Wrong value at byCnt0InputFrequencyTrackB input

-1008 Wrong value at byCnt0SignalSelection input

-1010 Wrong value at byCnt1InputFrequencyTrackA input

-1011 Wrong value at byCnt1InputFrequencyTrackB input

-1012 Wrong value at byCnt1SignalSelection input

-2000 Error while executing the internal block for writing CAN indices

-2002 Wrong value at the dwHandle input

-2003 Wrong value at the byNodeAdr input

-2006 Writing of a wrong CAN index

-2007 Timeout while writing a CAN index of the I/O system

-2100 Error while writing a parameter of the I/O system

-2101 Output buffer is full

34 L DMS 1.0 EN - 07/2011 - TD05

Page 35

Function library "LenzeIo1000Drv"

L_io1000ParCounterEPMS604 - Parameterise encoder evaluation

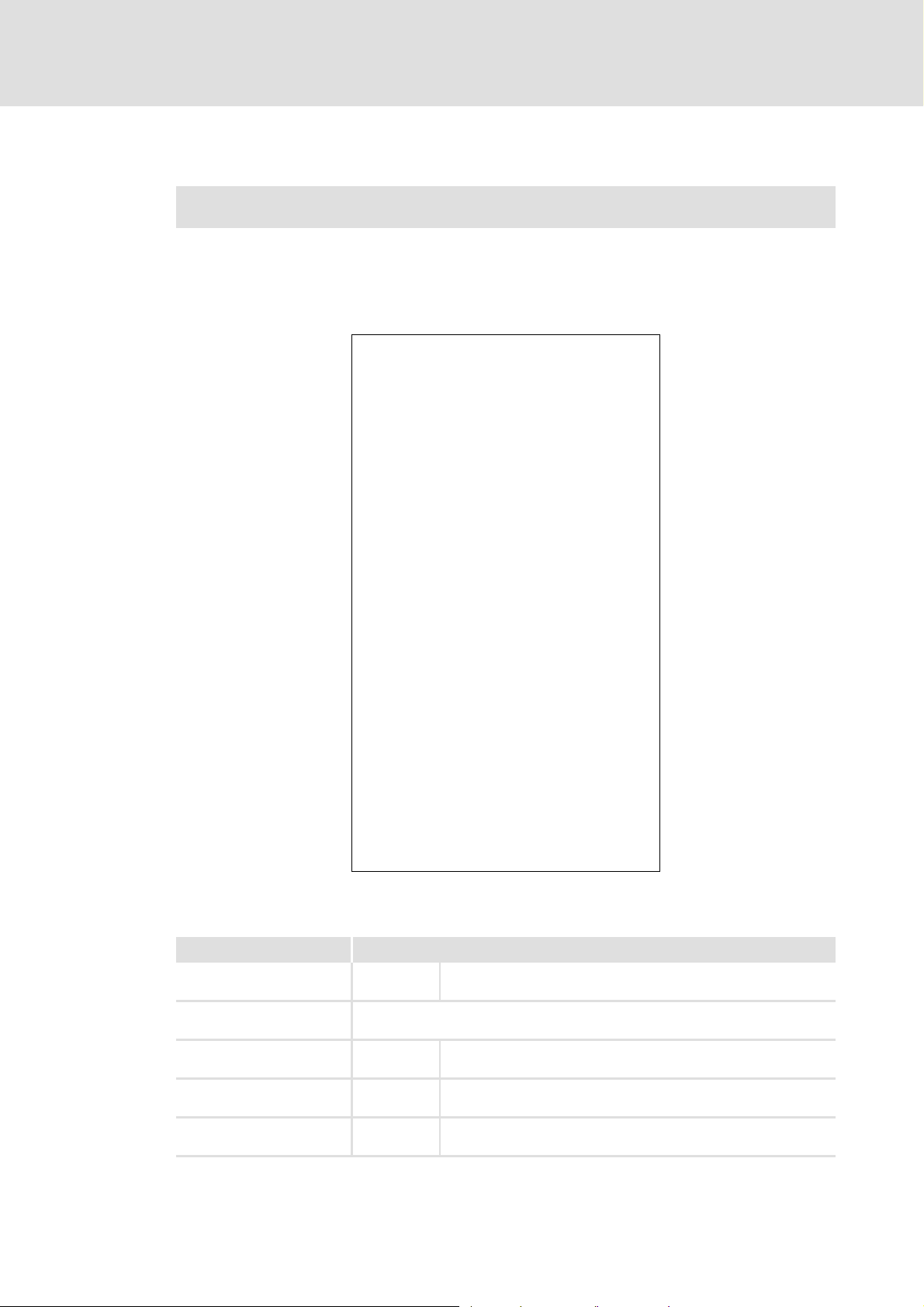

4.8 L_io1000ParCounterEPMS604 - Parameterise encoder evaluation

Function blocks

Call possible in: ; Cyclic task

Interrupt task

; Time-controlled task (INTERVAL)

Event-controlled task (EVENT)

This FB serves to parameterise the I/O compound module EPM-S604. The module is an SSI

interface for direct connection to an SSI encoder.

A FALSE/TRUE edge at the bExecute input starts the parameter setting.

The dnState output shows the transmission status.

L_io1000ParCounterEPMS604

⎯ bExecute bDone ⎯

⎯ dwHandle dnState ⎯

⎯ byNodeAdr

⎯ byAnalogModuleNo

⎯ bDiagnosticAlarm

⎯ byDeadTime

⎯ byBaudrate

⎯ dwScaling

⎯ byBitLength

⎯ bMasterMode

⎯ bMsbFirst

⎯ bRisingEdgeSignal

⎯ bGrayCode

⎯ bSSIFunctionEnabled

Inputs

Identifier/data type Information/possible settings

bExecute

dwHandle

DWORD

byNodeAdr

byAnalogModuleNo

bDiagnosticAlarm

FALSEÊTRUE Start parameter setting of the analog output module

BOOL

• 9400 ServoPLC: Handle created by FB L_CanInit

• Drive PLC, 9300 Servo PLC, ECS: 10

1 ... 127 CAN node address of the I/O system

BYTE

1 ... 64 Number of the analog output module

BYTE

TRUE Enable diagnostic alarm

BOOL

DMS 1.0 EN - 07/2011 - TD05 L 35

Page 36

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParCounterEPMS604 - Parameterise encoder evaluation

Identifier/data type Information/possible settings

byDeadTime

byBaudrate

dwScaling

DWORD

byBitLength

bMasterMode

bMsbFirst

bRisingEdgeSignal

bGrayCode

bSSIFunctionEnabled

BYTE

BYTE

BYTE

BOOL

BOOL

BOOL

BOOL

BOOL

TimeOut

11 μs

22 μs

34 μs

48 μs

5 16 μs

6 32 μs

7 48 μs

8 64 μs

Baud rate

1 2000 kHz

2 1500 kHz

3 1000 kHz

4 500 kHz

5 250 kHz

6 125 kHz

Scaling

Bit length

FALSE Listen-in operation

TRUE Master operation

FALSE LSB is transmitted first

TRUE MSB is transmitted first

FALSE Falling edge

TRUE Rising edge

FALSE Standard code

TRUE Gray code

TRUE SSI function enabled

36 L DMS 1.0 EN - 07/2011 - TD05

Page 37

L_io1000ParCounterEPMS604 - Parameterise encoder evaluation

Outputs

Identifier/data type Value/meaning

bDone

dnState

BOOL

Status of parameter setting

DINT

• When the function has been executed successfully, the value "0" is output.

TRUE Parameter setting completed successfully

-1003 byNodeAdr input is not in valid range

-1004 Wrong value at byAnalogModuleNo input

-1007 Wrong value at byDeadTime input

-1008 Wrong value at byBaudrate input

-1010 Wrong value at byBitLength input

-2000 Error while executing the internal block for writing CAN indices

-2002 Wrong value at the dwHandle input

-2003 Wrong value at the byNodeAdr input

-2006 Writing of a wrong CAN index

-2007 Timeout while writing a CAN index of the I/O system

-2100 Error while writing a parameter of the I/O system

-2101 Output buffer is full

Function library "LenzeIo1000Drv"

Function blocks

1 Parameter setting started

0 Parameter setting completed successfully

DMS 1.0 EN - 07/2011 - TD05 L 37

Page 38

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParRestore - Load default setting in I/O system

4.9 L_io1000ParRestore - Load default setting in I/O system

Call possible in: ; Cyclic task

Interrupt task

; Time-controlled task (INTERVAL)

Event-controlled task (EVENT)

This FB serves to load the default setting into the I/O system.

A FALSE/TRUE edge at the bExecute input causes the command to be sent to the I/O

system.

The dnState output shows the transmission status.

Note!

If the PLC has the task to completely parameterise the I/O system, this FB must

be called first (before any other parameter blocks).

L_io1000ParRestore

⎯ bExecute bDone ⎯

⎯ dwHandle dnState ⎯

⎯ byNodeAdr

Inputs

Identifier/data type Information/possible settings

bExecute

dwHandle

DWORD

byNodeAdr

FALSEÊTRUE Load default setting in I/O system

BOOL

• 9400 ServoPLC: Handle created by FB L_CanInit

• Drive PLC, 9300 Servo PLC, ECS: 10

1 ... 127 CAN node address of the I/O system

BYTE

Outputs

Identifier/data type Value/meaning

bDone

BOOL

dnState

38 L DMS 1.0 EN - 07/2011 - TD05

Status

DINT

TRUE Default setting has been loaded into the I/O system

-1000 Error while executing the internal block for writing CAN indices

-1002 Wrong value at the dwHandle input

-1003 byNodeAdr input is not in valid range

-1006 Writing of a wrong CAN index

-1007 Timeout while writing a CAN index of the I/O system

-1100 Error while writing a parameter of the I/O system

-1101 Output buffer is full

Page 39

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParRestore - Load default setting in I/O system

Sequence

For accepting the reset communication setting, the NMT command "Reset Node" is sent to

the I/O system. The I/O system re-initialises and returns a boot-up telegram as soon as it is

in the "Pre-Operational" status again. Only if the FB receives this boot-up telegram, loading

of the default setting is completed.

Note!

After sending the NMT command "Reset Node" to the I/O system, the FB has to

receive the boot-up telegram within 10 s, otherwise a timeout error will be

output at the dnState output.

DMS 1.0 EN - 07/2011 - TD05 L 39

Page 40

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParPDO15 - Communication settings PDO1 ... PDO5

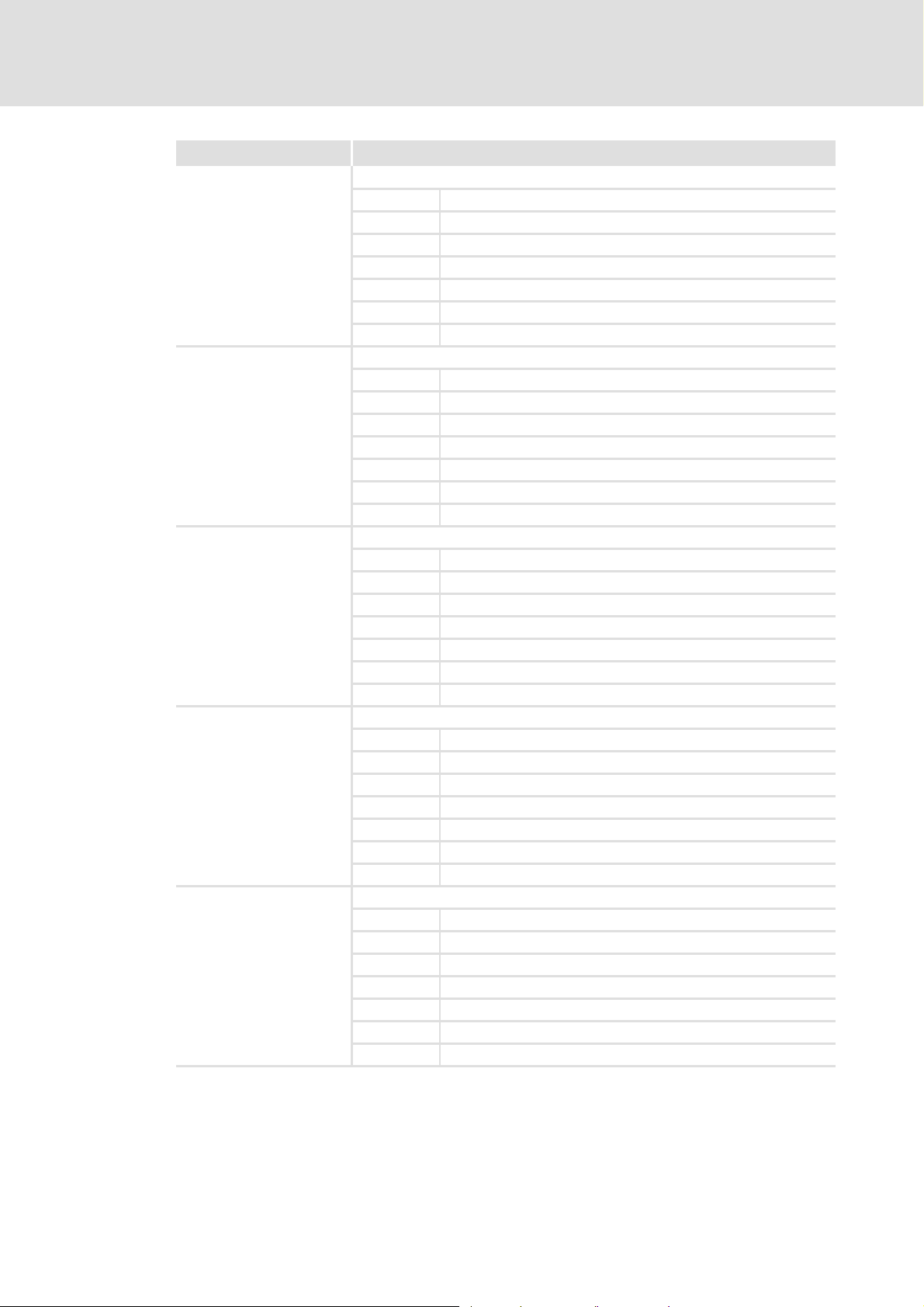

4.10 L_io1000ParPDO15 - Communication settings PDO1 ... PDO5

Call possible in: ; Cyclic task

Interrupt task

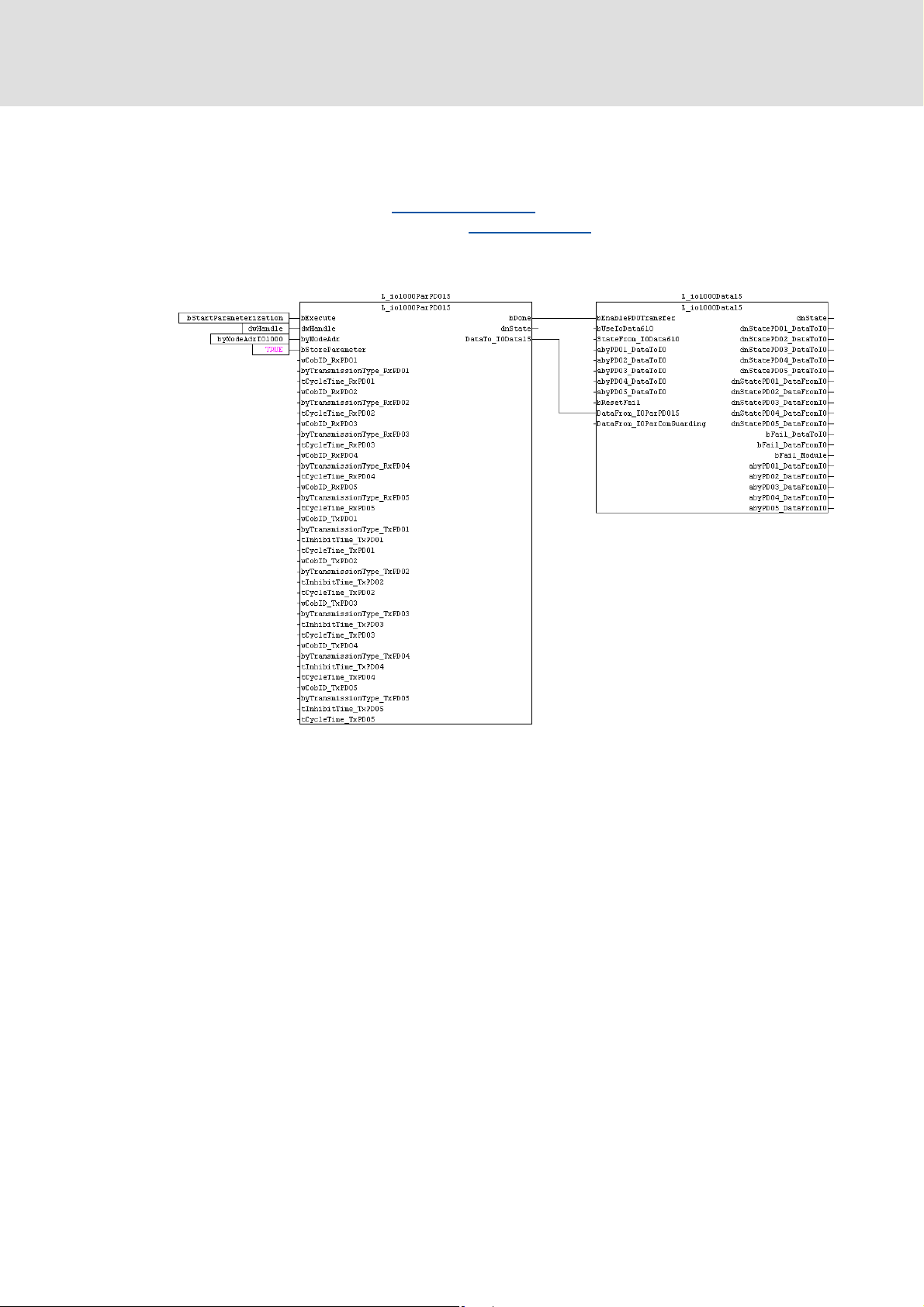

This FB serves to set communication-relevant parameters for data exchange between PLC

and I/O system via the process data objects PDO1 ... PDO5.

Via 3 or 4 input values, a transmit/receive object is parameterised.

The DataTo_IOData15 output serves to transmit fixed-structure information to the

L_io1000Data15

A FALSE/TRUE edge at the bExecute input starts the parameter setting.

The dnState output shows the parameter setting status.

process data block.

; Time-controlled task (INTERVAL)

Event-controlled task (EVENT)

Note!

• In order to completely parameterise the I/O system 1000, the

parameterisation blocks can be linked (bDone output connected to bExecute

input of the next FB) or executed successively in a sequencer.

• If only a maximum of 5 PDOs are required for communication, the

FB L_io1000ParPDO15 should be executed last in the sequencer as this FB

serves to save the parameter set of the parameter set.

• Deactivate all PDOs that are not required for communication. This saves

runtime resources of the PLC.

40 L DMS 1.0 EN - 07/2011 - TD05

Page 41

Function library "LenzeIo1000Drv"

L_io1000ParPDO15 - Communication settings PDO1 ... PDO5

L_io1000ParPDO15

⎯ bExecute bDone ⎯

⎯ dwHandle dnState ⎯

⎯ byNodeAdr DataTo_IOData15 ⎯

⎯ bStoreParameter

⎯ wCobID_RxPDO1

⎯ byTransmissionType_RxPDO1

⎯ tCycleTime_RxPDO1

⎯ wCobID_RxPDO2

⎯ byTransmissionType_RxPDO2

⎯ tCycleTime_RxPDO2

⎯ wCobID_RxPDO3

⎯ byTransmissionType_RxPDO3

⎯ tCycleTime_RxPDO3

⎯ wCobID_RxPDO4

⎯ byTransmissionType_RxPDO4

⎯ tCycleTime_RxPDO4

⎯ wCobID_RxPDO5

⎯ byTransmissionType_RxPDO5

⎯ tCycleTime_RxPDO5

⎯ wCobID_TxPDO1

⎯ byTransmissionType_TxPDO1

⎯ tInhibitTime_TxPDO1

⎯ tCycleTime_TxPDO1

⎯ wCobID_TxPDO2

⎯ byTransmissionType_TxPDO2

⎯ tInhibitTime_TxPDO2

⎯ tCycleTime_TxPDO2

⎯ wCobID_TxPDO3

⎯ byTransmissionType_TxPDO3

⎯ tInhibitTime_TxPDO3

⎯ tCycleTime_TxPDO3

⎯ wCobID_TxPDO4

⎯ byTransmissionType_TxPDO4

⎯ tInhibitTime_TxPDO4

⎯ tCycleTime_TxPDO4

⎯ wCobID_TxPDO5

⎯ byTransmissionType_TxPDO5

⎯ tInhibitTime_TxPDO5

⎯ tCycleTime_TxPDO5

Function blocks

DMS 1.0 EN - 07/2011 - TD05 L 41

Page 42

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParPDO15 - Communication settings PDO1 ... PDO5

Inputs

Identifier/data type Information/possible settings

bExecute

dwHandle

DWORD

byNodeAdr

bStoreParameter

wCobID...

_RxPDO1 ... _RxPDO5

_TxPDO1 ... _TxPDO5

WORD

byTransmissionType...

_RxPDO1 ... _RxPDO5

_TxPDO1 ... _TxPDO5

tCycleTime...

_RxPDO1 ... _RxPDO5

_TxPDO1 ... _TxPDO5

tInhibitTime...

_TxPDO1 ... _TxPDO5

FALSEÊTRUE Start parameter setting

BOOL

• 9400 ServoPLC: Handle created by FB L_CanInit

• Drive PLC, 9300 Servo PLC, ECS: 10

1 ... 127 CAN node address of the I/O system

BYTE

TRUE Save parameter set at the end of the parameterisation process.

BOOL

Identifier

for PDO1 ... PDO5 (PLC I/O system)

for PDO1 ... PDO5 (I/O system PLC)

Transmission mode

for PDO1 ... PDO5 (PLC I/O system)

for PDO1 ... PDO5 (I/O system PLC)

BYTE

Cycle time

for PDO1 ... PDO5 (PLC I/O system)

for PDO1 ... PDO5 (I/O system PLC)

TIME

TIME

0 ... 65535 Cycle time in [ms]

Blocking time

for PDO1 ... PDO5 (I/O system PLC)

0 ... 65535 Blocking time in [ms]

Then the NMT command "Reset Node" is sent to the I/O system.

0 Automatic allocation of the identifiers

> 0 Value of the set identifier

0 Event-controlled

1 Time-controlled

2 Event-controlled with higher-level cycle time

3 PDO deactivated

( 45)

42 L DMS 1.0 EN - 07/2011 - TD05

Page 43

L_io1000ParPDO15 - Communication settings PDO1 ... PDO5

Outputs

Identifier/data type Value/meaning

bDone

dnState

BOOL

Status of parameter setting

DINT

• When the function has been executed successfully, the value "0" is output.

TRUE Parameter setting completed successfully

-1000 Error while executing the function block

-1003 byNodeAdr input is not in valid range

-1005 Wrong value at wCobID_RxPDO1 input

-1006 Wrong value at byTransmissionType_RxPDO1 input

-1007 Cycle time at tCycleTime_RxPDO1 input > 65535 ms

-1008 Wrong value at wCobID_RxPDO2 input

-1009 Wrong value at byTransmissionType_RxPDO2 input

-1010 Cycle time at tCycleTime_RxPDO2 input > 65535 ms

-1011 Wrong value at wCobID_RxPDO3 input

-1012 Wrong value at byTransmissionType_RxPDO3 input

-1013 Cycle time at tCycleTime_RxPDO3 input > 65535 ms

-1014 Wrong value at wCobID_RxPDO4 input

-1015 Wrong value at byTransmissionType_RxPDO4 input

-1016 Cycle time at tCycleTime_RxPDO4 input > 65535 ms

-1017 Wrong value at wCobID_RxPDO5 input

-1018 Wrong value at byTransmissionType_RxPDO5 input

-1019 Cycle time at tCycleTime_RxPDO5 input > 65535 ms

-1020 Wrong value at wCobID_TxPDO1 input

-1021 Wrong value at byTransmissionType_TxPDO1 input

-1022 Blocking time at tInhibitTime_TxPDO1 input > 65535 ms

-1023 Cycle time at tCycleTime_TxPDO1 input > 65535 ms

-1024 Wrong value at wCobID_TxPDO2 input

-1025 Wrong value at byTransmissionType_TxPDO2 input

-1026 Blocking time at tInhibitTime_TxPDO2 input > 65535 ms

-1027 Cycle time at tCycleTime_TxPDO2 input > 65535 ms

Function library "LenzeIo1000Drv"

Function blocks

1 Parameter setting started

0 Parameter setting completed successfully

DMS 1.0 EN - 07/2011 - TD05 L 43

Page 44

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParPDO15 - Communication settings PDO1 ... PDO5

Identifier/data type Value/meaning

dnState

DataTo_IOData15

io1000_ParPDO15

Status of parameter setting (continuation)

DINT

-1028 Wrong value at wCobID_TxPDO3 input

-1029 Wrong value at byTransmissionType_TxPDO3 input

-1030 Blocking time at tInhibitTime_TxPDO3 input > 65535 ms

-1031 Cycle time at tCycleTime_TxPDO3 input > 65535 ms

-1032 Wrong value at wCobID_TxPDO4 input

-1033 Wrong value at byTransmissionType_TxPDO4 input

-1034 Blocking time at tInhibitTime_TxPDO4 input > 65535 ms

-1035 Cycle time at tCycleTime_TxPDO4 input > 65535 ms

-1036 Wrong value at wCobID_TxPDO5 input

-1037 Wrong value at byTransmissionType_TxPDO5 input

-1038 Blocking time at tInhibitTime_TxPDO5 input > 65535 ms

-1039 Cycle time at tCycleTime_TxPDO5 input > 65535 ms

-1100 Error when sending the reset node telegram to the I/O system

-1101 Error when receiving the boot-up telegram from the I/O system

-1102 Timeout when receiving the boot-up telegram from the I/O system

-1103 Error when sending the start remote node telegram to the I/O

system

-2000 Error while executing the internal block for writing CAN indices

-2002 Wrong value at the dwHandle input

-2003 Wrong value at the byNodeAdr input

-2006 Writing of a wrong CAN index

-2007 Timeout while writing a CAN index of the I/O system

-2100 Error while writing a parameter of the I/O system

-2101 Output buffer is full

Communication-relevant parameters for the process data objects PDO1 ... PDO5

• Output for transmitting the structure data to the L_io1000Data15 process data

block.

44 L DMS 1.0 EN - 07/2011 - TD05

Page 45

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParPDO15 - Communication settings PDO1 ... PDO5

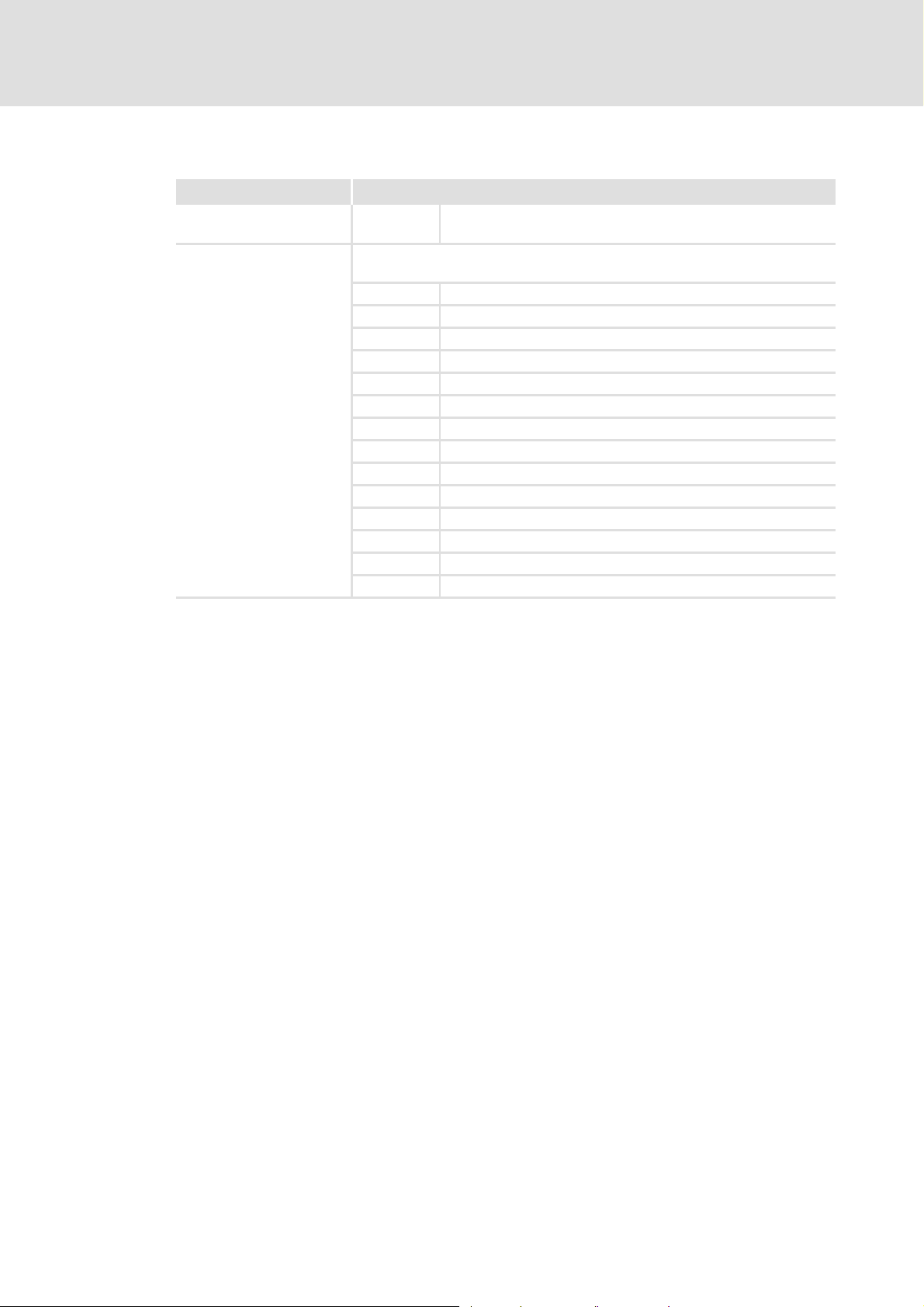

Automatic allocation of the identifiers

For the process data objects PDO1 ... PDO5, the identifiers can be automatically allocated

as a function of the node address. If an automatic allocation is required, the value "0" has

to be applied at the corresponding wCobID_... input. In this case, the identifier is calculated

as follows:

Identifier (COB-ID) = basic identifier + node address (node ID)

The basic identifiers are defined block-internally:

Process data object Basic identifier

RxPDOs (PLC I/O system) TxPDOs (I/O system PLC)

PDO1 835 836

PDO2 840 841

PDO3 845 846

PDO4 850 851

PDO5 855 856

Example for RxPDO1 and node address 3: Identifier = 835 + 3 = 838

If a value higher than "0" is given at the wCobID_... input, the applied value is used as

identifier for the corresponding PDO instead.

Note!

If several I/O systems (stations) at the system bus are parameterised via the

FB L_io1000ParPDO15 with standard values, an identifier collision may occur

between the individual PDOs of these stations. Hence, check the identifiers used.

Saving the parameter set in the I/O system safe against mains failure

If the bStoreParameter input is set to TRUE, the parameter set of the I/O system will be

saved safe against mains failure at the end of the parameterisation process.

For accepting the communication setting, the NMT command "Reset Node" is sent to the

I/O system. The I/O system re-initialises and returns a boot-up telegram as soon is it is in

the "Pre-Operational" status again. After the boot-up telegram has been received, the

bDone output of the FB is set to TRUE.

Note!

• Only Global Drive (e.g. Drive PLC): For sending the NMT telegram, the

controller has to be in the "Operational" CAN status. Hence, the controller has

to be parameterised as CAN master.

• After sending the NMT command "Reset Node" to the I/O system, the FB has

to receive the boot-up telegram within 10 s, otherwise a timeout error will be

output at the dnState output.

DMS 1.0 EN - 07/2011 - TD05 L 45

Page 46

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParPDO610 - Communication settings PDO6 ... PDO10

4.11 L_io1000ParPDO610 - Communication settings PDO6 ... PDO10

Call possible in: ; Cyclic task

Interrupt task

This FB serves to set communication-relevant parameters for data exchange between PLC

and I/O system via the process data objects PDO6 ... PDO10.

Via 3 or 4 input values, a transmit/receive object is parameterised.

The DataTo_IOData610 output serves to transmit fixed-structure information to the

L_io1000Data610

A FALSE/TRUE edge at the bExecute input starts the parameter setting.

The dnState output shows the parameter setting status.

process data block.

; Time-controlled task (INTERVAL)

Event-controlled task (EVENT)

Note!

• In order to completely parameterise the I/O system 1000, the

parameterisation blocks can be linked (bDone output connected to bExecute

input of the next FB) or executed successively in a sequencer.

• If only a maximum of 5 PDOs are required for communication, the

FB L_io1000ParPDO610 should be executed last in the sequencer as this FB

serves to save the parameter set of the parameter set.

• Deactivate all PDOs that are not required for communication. This saves

runtime resources of the PLC.

46 L DMS 1.0 EN - 07/2011 - TD05

Page 47

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParPDO610 - Communication settings PDO6 ... PDO10

L_io1000ParPDO610

⎯ bExecute bDone ⎯

⎯ dwHandle dnState ⎯

⎯ byNodeAdr DataTo_IOData610 ⎯

⎯ bStoreParameter

⎯ wCobID_RxPDO6

⎯ byTransmissionType_RxPDO6

⎯ tCycleTime_RxPDO6

⎯ wCobID_RxPDO7

⎯ byTransmissionType_RxPDO7

⎯ tCycleTime_RxPDO7

⎯ wCobID_RxPDO8

⎯ byTransmissionType_RxPDO8

⎯ tCycleTime_RxPDO8

⎯ wCobID_RxPDO9

⎯ byTransmissionType_RxPDO9

⎯ tCycleTime_RxPDO9

⎯ wCobID_RxPDO10

⎯ byTransmissionType_RxPDO10

⎯ tCycleTime_RxPDO10

⎯ wCobID_TxPDO6

⎯ byTransmissionType_TxPDO6

⎯ tInhibitTime_TxPDO6

⎯ tCycleTime_TxPDO6

⎯ wCobID_TxPDO7

⎯ byTransmissionType_TxPDO7

⎯ tInhibitTime_TxPDO7

⎯ tCycleTime_TxPDO7

⎯ wCobID_TxPDO8

⎯ byTransmissionType_TxPDO8

⎯ tInhibitTime_TxPDO8

⎯ tCycleTime_TxPDO8

⎯ wCobID_TxPDO9

⎯ byTransmissionType_TxPDO9

⎯ tInhibitTime_TxPDO9

⎯ tCycleTime_TxPDO9

⎯ wCobID_TxPDO10

⎯ byTransmissionType_TxPDO10

⎯ tInhibitTime_TxPDO10

⎯ tCycleTime_TxPDO10

DMS 1.0 EN - 07/2011 - TD05 L 47

Page 48

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParPDO610 - Communication settings PDO6 ... PDO10

Inputs

Identifier/data type Information/possible settings

bExecute

dwHandle

DWORD

byNodeAdr

bStoreParameter

wCobID...

_RxPDO6 ... _RxPDO10

_TxPDO6 ... _TxPDO10

WORD

byTransmissionType...

_RxPDO6 ... _RxPDO10

_TxPDO6 ... _TxPDO10

tCycleTime...

_RxPDO6 ... _RxPDO10

_TxPDO6 ... _TxPDO10

tInhibitTime...

_TxPDO6 ... _TxPDO10

FALSEÊTRUE Start parameter setting

BOOL

• 9400 ServoPLC: Handle created by FB L_CanInit

• Drive PLC, 9300 Servo PLC, ECS: 10

1 ... 127 CAN node address of the I/O system

BYTE

TRUE Save parameter set at the end of the parameterisation process.

BOOL

Identifier

for PDO6 ... PDO10 (PLC I/O system)

for PDO6 ... PDO10 (I/O system PLC)

Transmission mode

for PDO6 ... PDO10 (PLC I/O system)

for PDO6 ... PDO10 (I/O system PLC)

BYTE

Cycle time

for PDO6 ... PDO10 (PLC I/O system)

for PDO6 ... PDO10 (I/O system PLC)

TIME

TIME

0 ... 65535 Cycle time in [ms]

Blocking time

for PDO6 ... PDO10 (I/O system PLC)

0 ... 65535 Blocking time in [ms]

Then the NMT command "Reset Node" is sent to the I/O system.

0 Automatic allocation of the identifiers

> 0 Value of the set identifier

0 Event-controlled

1 Time-controlled

2 Event-controlled with higher-level cycle time

3 PDO deactivated

( 51)

48 L DMS 1.0 EN - 07/2011 - TD05

Page 49

L_io1000ParPDO610 - Communication settings PDO6 ... PDO10

Outputs

Identifier/data type Value/meaning

bDone

dnState

BOOL

Status of parameter setting

DINT

• When the function has been executed successfully, the value "0" is output.

TRUE Parameter setting completed successfully

-1000 Error while executing the function block

-1003 byNodeAdr input is not in valid range

-1005 Wrong value at wCobID_RxPDO6 input

-1006 Wrong value at byTransmissionType_RxPDO6 input

-1007 Cycle time at tCycleTime_RxPDO6 input > 65535 ms

-1008 Wrong value at wCobID_RxPDO7 input

-1009 Wrong value at byTransmissionType_RxPDO7 input

-1010 Cycle time at tCycleTime_RxPDO7 input > 65535 ms

-1011 Wrong value at wCobID_RxPDO8 input

-1012 Wrong value at byTransmissionType_RxPDO8 input

-1013 Cycle time at tCycleTime_RxPDO8 input > 65535 ms

-1014 Wrong value at wCobID_RxPDO9 input

-1015 Wrong value at byTransmissionType_RxPDO9 input

-1016 Cycle time at tCycleTime_RxPDO9 input > 65535 ms

-1017 Wrong value at wCobID_RxPDO10 input

-1018 Wrong value at byTransmissionType_RxPDO10 input

-1019 Cycle time at tCycleTime_RxPDO10 input > 65535 ms

-1020 Wrong value at wCobID_TxPDO6 input

-1021 Wrong value at byTransmissionType_TxPDO6 input

-1022 Blocking time at tInhibitTime_TxPDO6 input > 65535 ms

-1023 Cycle time at tCycleTime_TxPDO6 input > 65535 ms

-1024 Wrong value at wCobID_TxPDO7 input

-1025 Wrong value at byTransmissionType_TxPDO7 input

-1026 Blocking time at tInhibitTime_TxPDO7 input > 65535 ms

-1027 Cycle time at tCycleTime_TxPDO7 input > 65535 ms

Function library "LenzeIo1000Drv"

Function blocks

1 Parameter setting started

0 Parameter setting completed successfully

DMS 1.0 EN - 07/2011 - TD05 L 49

Page 50

Function library "LenzeIo1000Drv"

Function blocks

L_io1000ParPDO610 - Communication settings PDO6 ... PDO10

Identifier/data type Value/meaning

dnState

DataTo_IOData610

io1000_ParPDO610

Status of parameter setting (continuation)

DINT

-1028 Wrong value at wCobID_TxPDO8 input

-1029 Wrong value at byTransmissionType_TxPDO8 input

-1030 Blocking time at tInhibitTime_TxPDO8 input > 65535 ms

-1031 Cycle time at tCycleTime_TxPDO8 input > 65535 ms

-1032 Wrong value at wCobID_TxPDO9 input

-1033 Wrong value at byTransmissionType_TxPDO9 input

-1034 Blocking time at tInhibitTime_TxPDO9 input > 65535 ms

-1035 Cycle time at tCycleTime_TxPDO9 input > 65535 ms

-1036 Wrong value at wCobID_TxPDO10 input

-1037 Wrong value at byTransmissionType_TxPDO10 input

-1038 Blocking time at tInhibitTime_TxPDO10 input > 65535 ms

-1039 Cycle time at tCycleTime_TxPDO10 input > 65535 ms

-1100 Error when sending the reset node telegram to the I/O system

-1101 Error when receiving the boot-up telegram from the I/O system

-1102 Timeout when receiving the boot-up telegram from the I/O system

-1103 Error when sending the start remote node telegram to the I/O

system

-2000 Error while executing the internal block for writing CAN indices

-2002 Wrong value at the dwHandle input

-2003 Wrong value at the byNodeAdr input

-2006 Writing of a wrong CAN index

-2007 Timeout while writing a CAN index of the I/O system

-2100 Error while writing a parameter of the I/O system

-2101 Output buffer is full

Communication-relevant parameters for the process data objects PDO6 ... PDO10