Page 1

USER’S MANUAL

MODELS:

SS504A SS508A

SS604A SS608A

SS604A-3P SS608A-3P

SS610A SS612A-3P

SSi1004A SSi1008A

SSi1010A SSi1012A-3P

Page 2

SimpleServo 500/600/i1000 User Manual Rev 3.4

Copyright ©2001 by AC Technology Corporation

All rights reserved. No part of this manual may be reproduced or transmitted in any form without written

permission from AC Technology Corporation. The information and technical data in this manual are

subject to change without notice. AC Technology Corporation and its Divisions make no warranty of any

kind with respect to this material, including, but not limited to, the implied warranties of its merchantability

and fitness for a given purpose. AC Technology Corporation and its Divisions assume no responsibility for

any errors that may appear in this manual and make no commitment to update or to keep current the

information in this manual.

MotionView, SimpleServo, and all related indicia are either registered trademarks or trademarks of AC

Technology Corporation in the United States and other countries.

This document printed in the United States of America.

2

Page 3

SimpleServo 500/600/i1000 User Manual Rev 3.4

TABLE OF CONTENTS

1 GENERAL INFORMATION ................................................................................................................7

2 SPECIFICATIONS ..............................................................................................................................8

2.1 Electrical Characteristics............................................................................................................................8

2.2 Environment.................................................................................................................................................8

2.3 Dimensions and Weight .............................................................................................................................9

2.4 Operating Modes SS500/600 drives ........................................................................................................9

2.5 Operating Modes SSi1000 drives.............................................................................................................9

2.6 SSi1000 drives features...........................................................................................................................10

2.7 Connections and I/O.................................................................................................................................11

3 DIMENSIONS.................................................................................................................................... 12

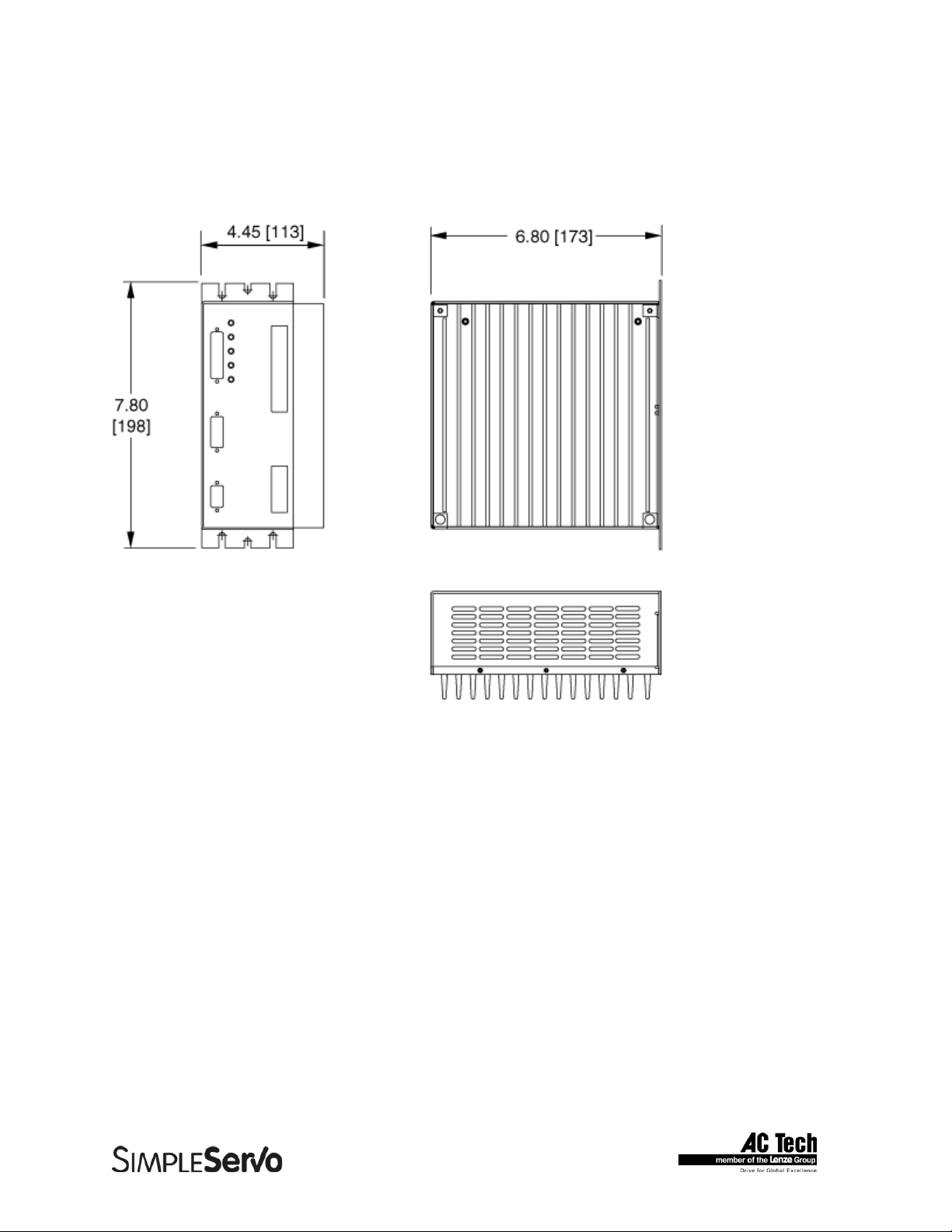

3.1 SS500 Series Dimensions.......................................................................................................................12

3.2 SS604/SS608/SSi1004/SSi1008 Series Dimensions..........................................................................13

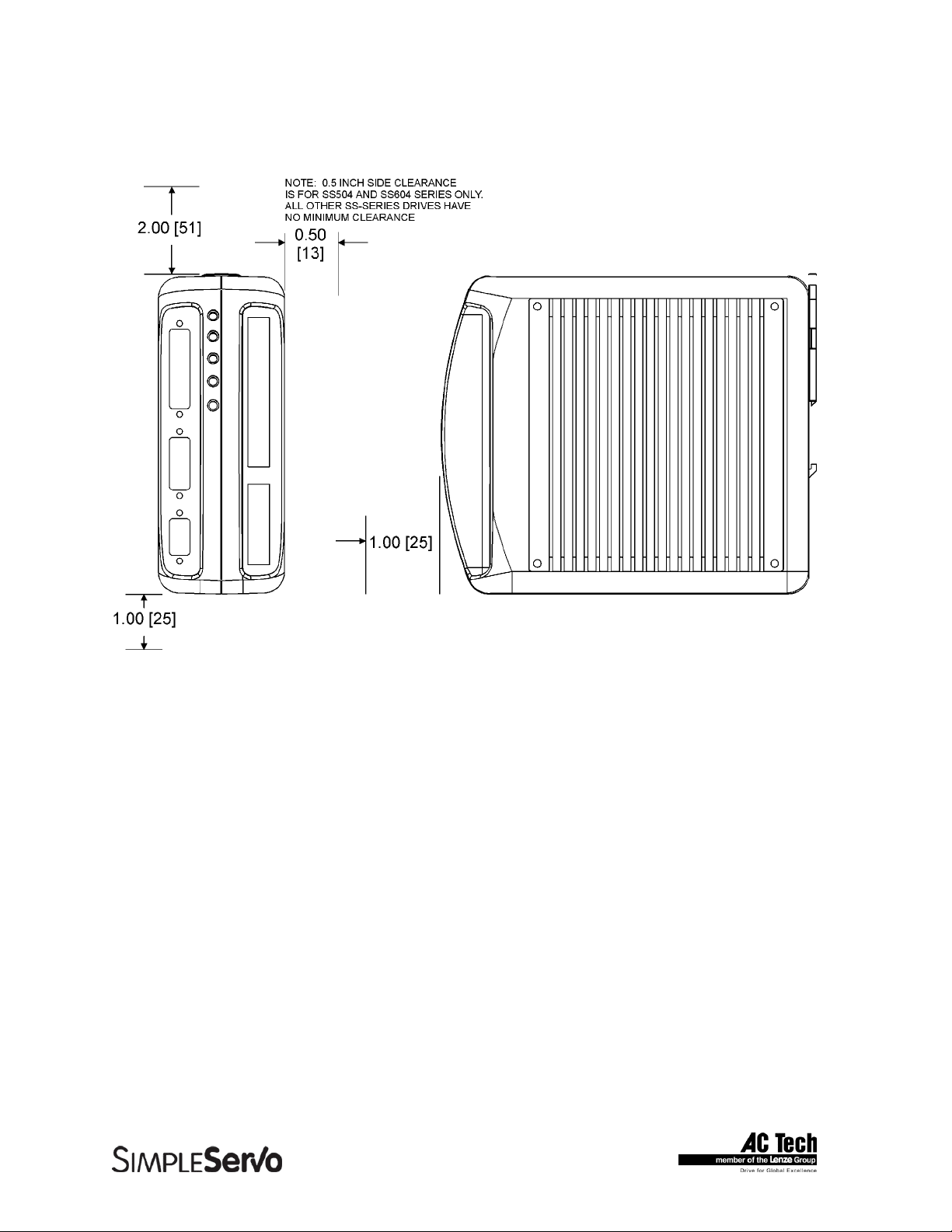

3.3 SS610/SS612-3P/SSi1010/SSi1012-3P Dimensions with Heat Sink Fan Kit Installed..................14

3.4 Suggested Clearance for Cooling Air Circulation (All Models)...........................................................15

4 INSTALLATION ................................................................................................................................16

4.1 Start Up.......................................................................................................................................................17

4.2 Mounting.....................................................................................................................................................17

4.3 Wiring.......................................................................................................................................................... 17

4.4 Shielding and grounding ..........................................................................................................................18

4.4.1 General guidelines .................................................................................................................... 18

4.4.2 EMI Protection ...........................................................................................................................18

4.4.3 Enclosure.................................................................................................................................... 18

4.5 Line filtering................................................................................................................................................18

4.6 Heat sinking ...............................................................................................................................................19

4.7 Line fusing..................................................................................................................................................19

5 SIMPLESERVO CONNECTIONS..................................................................................................... 20

5.1 External Connectors .................................................................................................................................20

5.1.1 TB501 - Power, Motor, and Fuse Connections ....................................................................20

5.1.2 TB502 - Analog/Digital I/O Terminal Block............................................................................ 21

5.1.3 Encoder feedback .....................................................................................................................23

5.1.4 TB504 - Motor Feedback Input ...............................................................................................23

5.1.5 TB505 - Serial Communications Port..................................................................................... 25

5.1.6 TB506 - Controller Interface (SS500/600 drives) ................................................................. 26

5.1.7 TB506 - Encoder repeat and analog input connections (SSi1000 drives)........................27

5.1.8 Connectors and Wiring Notes .................................................................................................28

5.2 Digital I/O details (SS500/600 drives)....................................................................................................29

5.2.1 Step and Direction/ Master Encoder Inputs ..........................................................................29

5.2.2 Digital outputs ............................................................................................................................ 29

5.2.3 Digital inputs ..............................................................................................................................30

5.3 Digital I/O details (SSi1000 drives).........................................................................................................32

5.3.1 Digital inputs ..............................................................................................................................32

5.3.2 Digital outputs ............................................................................................................................ 32

5.4 Analog I/O details......................................................................................................................................35

5.4.1 Analog reference input .............................................................................................................35

5.4.2 Analog output............................................................................................................................. 35

5.5 Communication interfaces (SS500/600 drives) ....................................................................................35

5.6 Communication interfaces (SSi1000 drives).........................................................................................35

5.6.1 RS232 interface......................................................................................................................... 35

5.6.2 RS485 interface......................................................................................................................... 36

5.6.3 Ethernet interface...................................................................................................................... 37

3

Page 4

SimpleServo 500/600/i1000 User Manual Rev 3.4

5.7 Motor Selection .........................................................................................................................................38

5.7.1 Setting Up motor .......................................................................................................................38

5.8 Using custom motor..................................................................................................................................39

5.8.1 Setting custom motor parameters...........................................................................................39

5.8.2 Autophasing ...............................................................................................................................40

5.8.3 Custom Motor Data Entry ........................................................................................................40

6 SS500/600 PROGRAMMABLE FEATURES AND PARAMETERS ................................................45

6.1 Motor Group...............................................................................................................................................45

6.2 Parameters Group ...................................................................................................................................45

6.2.1 Drive operating modes .............................................................................................................45

6.2.2 Current Limit ..............................................................................................................................47

6.2.3 Peak current limit.......................................................................................................................47

6.2.4 Analog input scale( Current scale) .........................................................................................47

6.2.5 Analog input scale (Velocity scale)......................................................................................... 48

6.2.6 ACCEL/DECEL Limits (Velocity mode only) .........................................................................48

6.2.7 Reference (Velocity mode only)............................................................................................. 48

6.2.8 Reset Option .............................................................................................................................. 48

6.2.9 Steps per Revolution (Step and Direction mode only).........................................................48

6.2.10 Step input type (Step and Direction mode only) .................................................................. 48

6.3 I/O Group....................................................................................................................................................49

6.3.1 Programmable digital input...................................................................................................... 49

6.3.2 Programmable digital output....................................................................................................49

6.3.3 Analog output............................................................................................................................. 49

6.3.4 Analog output current scale (Volt/amps) ..............................................................................49

6.3.5 Analog output velocity scale (mV/RPM) ................................................................................ 50

6.3.6 Analog input offset parameter .................................................................................................50

6.3.7 Analog input dead band ...........................................................................................................50

6.3.8 Adjust analog voltage offset ....................................................................................................50

6.4 Velocity Limits Group................................................................................................................................50

6.5 Position limits.............................................................................................................................................50

6.6 Compensation group ................................................................................................................................51

6.6.1 Velocity Loop Filter ...................................................................................................................51

6.6.2 Position Loop Filter ...................................................................................................................51

6.7 Faults Group ..............................................................................................................................................52

6.8 Tools Group ...............................................................................................................................................52

6.8.1 Run Panel................................................................................................................................... 52

6.8.2 Drive monitor.............................................................................................................................. 52

6.8.3 Oscilloscope tool .......................................................................................................................52

7 SSI10XX PROGRAMMABLE FEATURES AND PARAMETERS ...................................................53

7.1 Motor folder................................................................................................................................................53

7.2 Parameters.................................................................................................................................................53

7.2.1 Drive mode................................................................................................................................. 53

7.2.2 Current Limit ..............................................................................................................................53

7.2.3 Peak Current Limit .................................................................................................................... 53

7.2.4 Autoboot .....................................................................................................................................53

7.2.5 Feedback loss detection ..........................................................................................................53

7.2.6 RS485 configuration .................................................................................................................53

7.2.7 Group ID .....................................................................................................................................54

7.2.8 IP properties (command button) ............................................................................................. 54

7.3 I/O................................................................................................................................................................54

7.3.1 Outputs 1,2,3,4 functions........................................................................................................54

7.3.2 Hard limit switches action. .......................................................................................................54

7.4 Limits...........................................................................................................................................................54

7.4.1 Position Limits............................................................................................................................ 54

4

Page 5

SimpleServo 500/600/i1000 User Manual Rev 3.4

7.5 Compensation ...........................................................................................................................................55

7.5.1 Velocity Loop filter.....................................................................................................................55

7.5.2 Position Loop filter.....................................................................................................................55

7.6 Indexer Program .......................................................................................................................................56

7.7 Security.......................................................................................................................................................56

7.8 Faults Group ..............................................................................................................................................56

7.9 Tools ...........................................................................................................................................................56

7.9.1 Drive monitor.............................................................................................................................. 56

7.9.2 Oscilloscope tool .......................................................................................................................56

8 DIAGNOSTICS .................................................................................................................................57

8.1 Diagnostic LED’s....................................................................................................................................... 57

8.1.1 Front panel LEDs ......................................................................................................................57

8.1.2 Bottom side LEDs .....................................................................................................................57

8.2 Faults ..........................................................................................................................................................58

8.2.1 Fault Event .................................................................................................................................58

8.2.2 Fault Reset................................................................................................................................. 58

9 OPERATION .....................................................................................................................................59

9.1 Minimum Connections..............................................................................................................................59

9.2 Configure the SS500/600 SimpleServo drives .....................................................................................59

9.3 Configure SSi1000 SimpleServo drives ................................................................................................60

9.4 Enabling the SS500/600 drives. .............................................................................................................62

9.5 Enabling SSi1000 drives..........................................................................................................................63

9.6 Tuning in velocity mode ...........................................................................................................................64

9.7 Tuning in position PVFF mode................................................................................................................65

9.8 Tuning in position P+V mode. .................................................................................................................66

10 SAMPLE MOTOR RESPONSES FOR VARIOUS GAIN SETTINGS .............................................. 67

10.1 Motor response to gain settings (Velocity mode).................................................................................67

10.1.1 Low P-gain.................................................................................................................................67

10.1.2 Right P-gain...............................................................................................................................68

10.1.3 I-gain too high ...........................................................................................................................69

10.1.4 Correct P-gain and I-gain........................................................................................................ 70

10.2 Motor response to gain settings (Position Mode).................................................................................71

10.2.1 PVFF mode P-gain / D-gain relationship. Non-optimal setting.......................................... 71

10.2.2 PVFF mode P-gain / D-gain relationship. Optimal setting. ................................................72

10.2.3 VFF gain effect .........................................................................................................................73

11 SYSTEM CONNECTION EXAMPLES .............................................................................................75

11.1 System with external motion controller..................................................................................................75

11.2 Simple Torque and Velocity System ......................................................................................................76

11.3 Position Follower.......................................................................................................................................78

11.4 Indexer connections options for position follower ................................................................................79

12 TROUBLESHOOTING...................................................................................................................... 80

13 WARRANTY AND OTHER INFO ..................................................................................................... 82

5

Page 6

SimpleServo 500/600/i1000 User Manual Rev 3.4

Safety Warnings

• The symbol shown at left indicates an important safety consideration. Please read this

manual carefully before performing any of the procedures contained herein. Failure to follow

these instructions may result in equipment damage, fire, severe injury, or fatality.

• Have a qualified electrical maintenance technician install, adjust and service this equipment.

Follow the National Electrical Code and all other applicable electrical and safety codes,

including the provisions of the Occupational Safety and Health Act (OSHA), when installing

equipment.

• The symbol shown at left indicates additional information, shortcuts, or tips that do not affect

the safe operation of the drive.

• Reduce the chance of an electrical fire, shock, or explosion by proper grounding, overcurrent protection, thermal protection, and enclosure. Follow sound maintenance procedures.

• It is possible for a drive to run at full speed as a result of a component failure. Please

ensure that a master switch has been placed in the AC line to stop the drive in an

emergency.

WARNING!

Hazard of electrical shock! Circuit potentials are at 115 VAC or 230 VAC above earth

ground. Avoid direct contact with the printed circuit board or with circuit elements to prevent

the risk of serious injury or fatality. Disconnect incoming power and wait 60 seconds before

servicing drive. Capacitors retain charge after power is removed.

6

Page 7

SimpleServo 500/600/i1000 User Manual Rev 3.4

1 General Information

• The AC Tech SimpleServo family of servo amplifiers is an economical solution to today’s complex

motion-control needs. The SimpleServo combines a Digital Signal Processor (DSP), controller, heat

sink and power supply in one standalone, DIN-rail mountable or panel-mounted unit. The

SimpleServo can be operated as a stand-alone unit or as a digital amplifier.

• The SimpleServo controls brushless motors with a high switching (carrier) frequency for virtually silent

operation. Most servo motors used today require high precision control and a smooth, sinusoidally

commutated signal. An on-board DSP provides commutation by generating the three-phase sine

wave, using feedback information from an optical encoder.

• The SimpleServo will accept feedback from an encoder that includes Hall sensor feedback

information. It accepts commands from a variety of sources, including analog voltage, PWM and

internal reference signals. The control will operate in current (torque) mode, velocity mode, or position

(step and direction) mode. Upon initial start up, the motor is commutated using the hall sensors—for

the first two or three mechanical degrees of motor rotation—to map the encoder; the Hall-effect

information is unnecessary thereafter.

• The SimpleServo’s built-in RS-232 serial communications port and SimpleServo control program,

MotionView™, make programming extremely simple. In fact, you could be up and running in less than

thirty minutes! Each SimpleServo unit is an amplifier, power supply, controller and heat sink

integrated into a single standalone package. The SimpleServo will only accept an encoder with Hall

or an encoder with hall-commutation tracks encoded on the feedback device.

7

Page 8

SimpleServo 500/600/i1000 User Manual Rev 3.4

2 Specifications

2.1 Electrical Characteristics

Drive

SSX04 6A 4 8 90 – 240

SSX08 12A 8 14 90 – 240

SSX10 15A 10 20 90 – 240

SSX12-3P 19A 12 20 90 – 240

Notes:

“-3P” = 3-phase input power models

* Phase RMS current. Peak current allowed for up to 2 Sec.

Applies to all models:

AC Output Voltage Range (Sinusoidal, Three-Phase) 0–240 VAC RMS

Minimum Output Voltage Range 0 – 340 VAC

Acceleration Time Range (Zero to Max Speed) 0.1 – 5000000 Rpm/sec

Deceleration Time Range (Max Speed to Zero) 0.1 – 5000000 Rpm/sec

Speed Regulation (typical) ± 1 RPM

Input Impedance (+REF to COM and +REF to -REF) 47 kohms

Power Device Switching Frequency (sinusoidal commutation) 16 kHz

Encoder power supply (max) +5 VDC @ 300 mA

Maximum encoder feedback frequency 2.1 MHz

2.2 Environment

Vibration

SS500 Series 0.1 G (all frequencies)

SS600 and SS1000 Series 0.5G max (20 – 50 Hz)

0.1G max (>50 Hz)

Ambient Operating Temperature Range 0 to 40ºC

Ambient Storage Temperature Range -10 to 70ºC

Humidity 5 – 90% non-condensing

Altitude 1500 m/5000 ft (derate by 1% per 300m

Maximum

Continuous

Current (AC in)

(1000 ft) above 1500m (5000 ft))

Continuous

Phase

Current

(AC Amps)

Peak*

Current

(AC Amps)

Input Voltage

(±10%, 50-60 Hz)

(VAC)

8

Page 9

SimpleServo 500/600/i1000 User Manual Rev 3.4

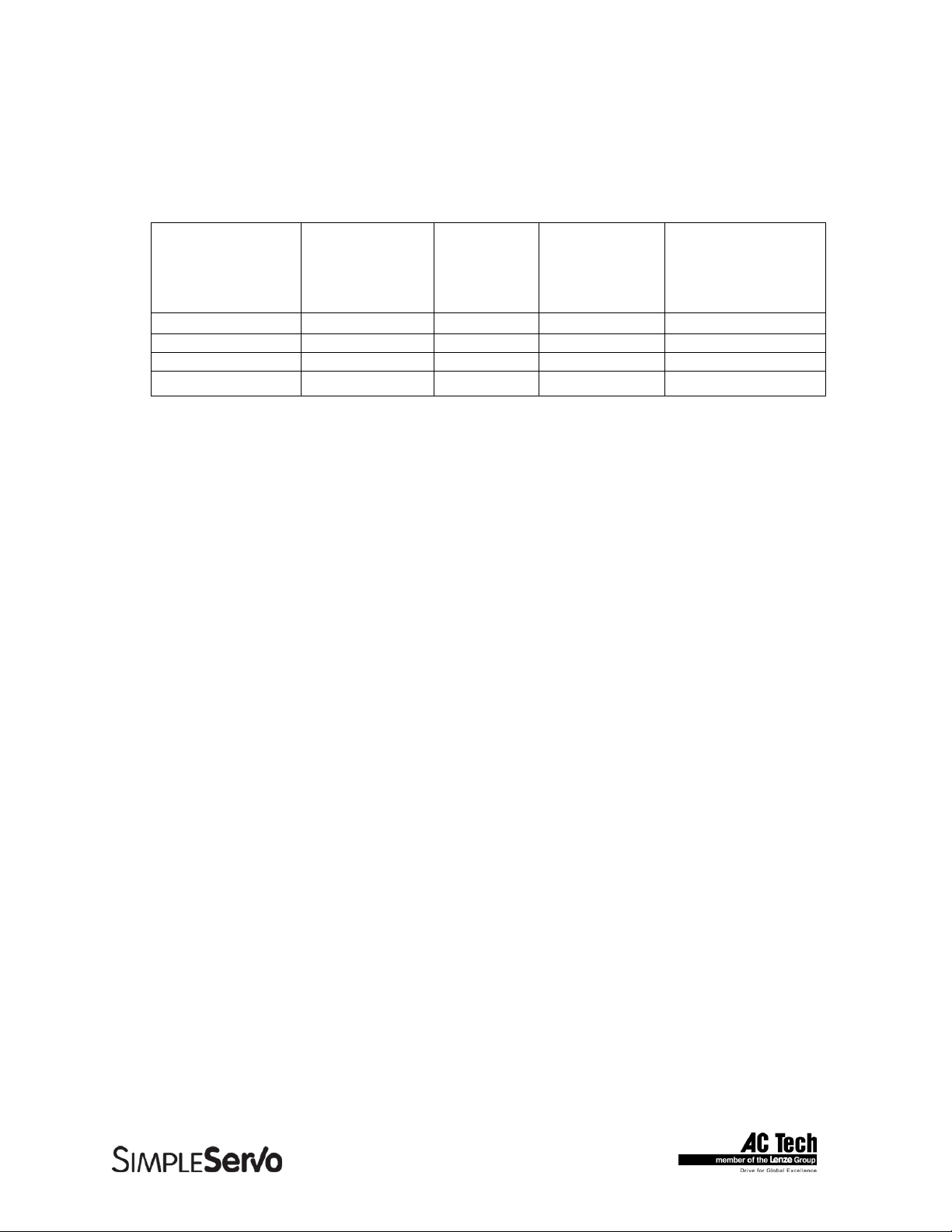

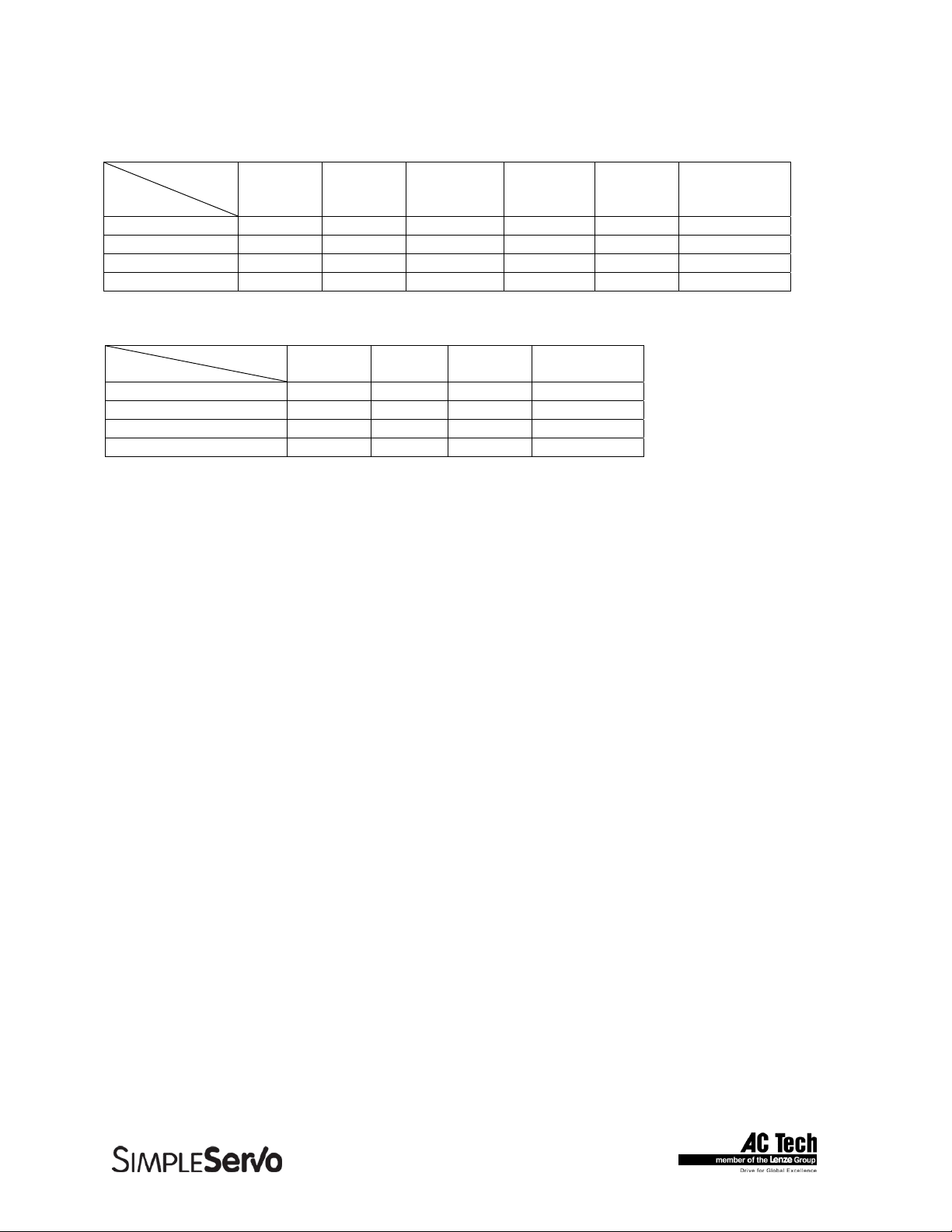

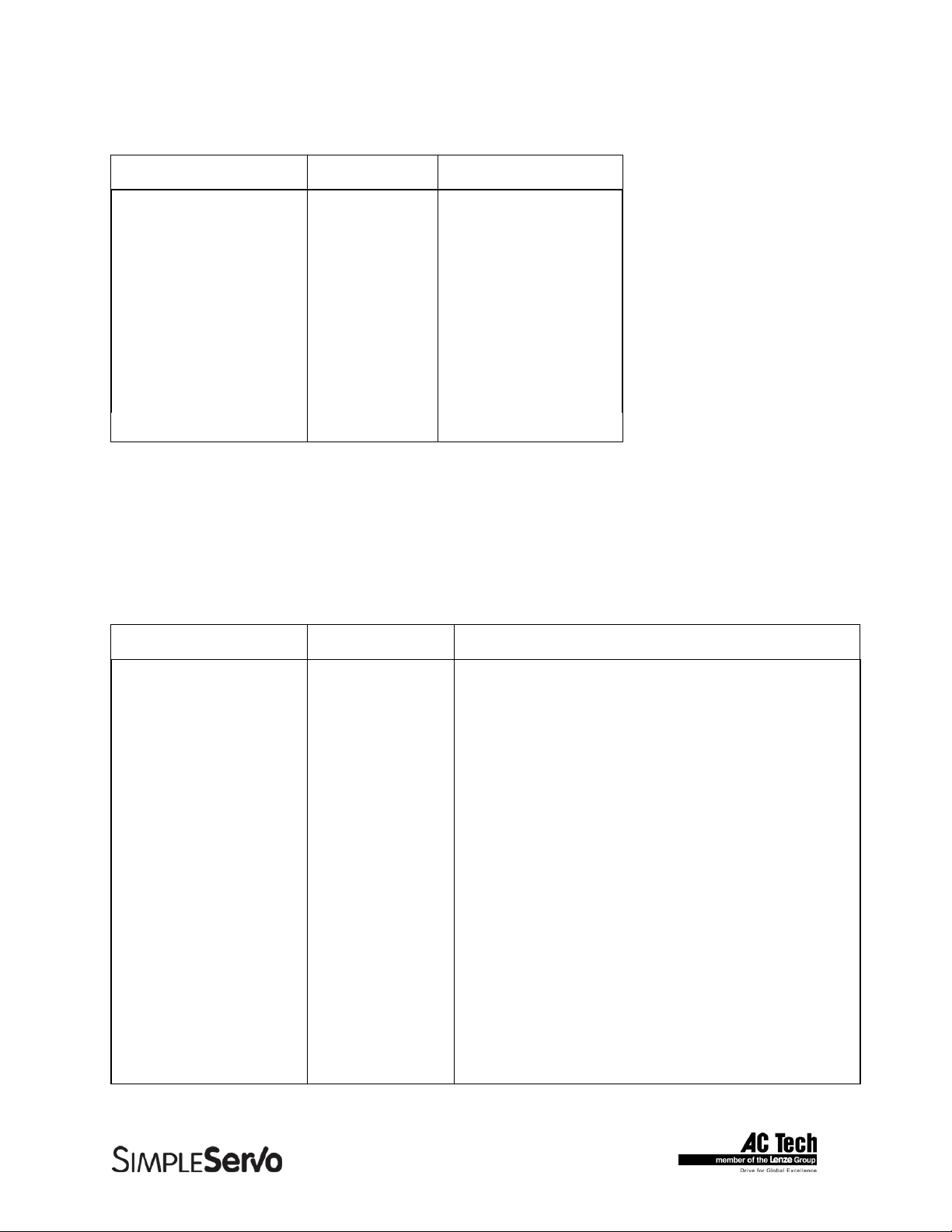

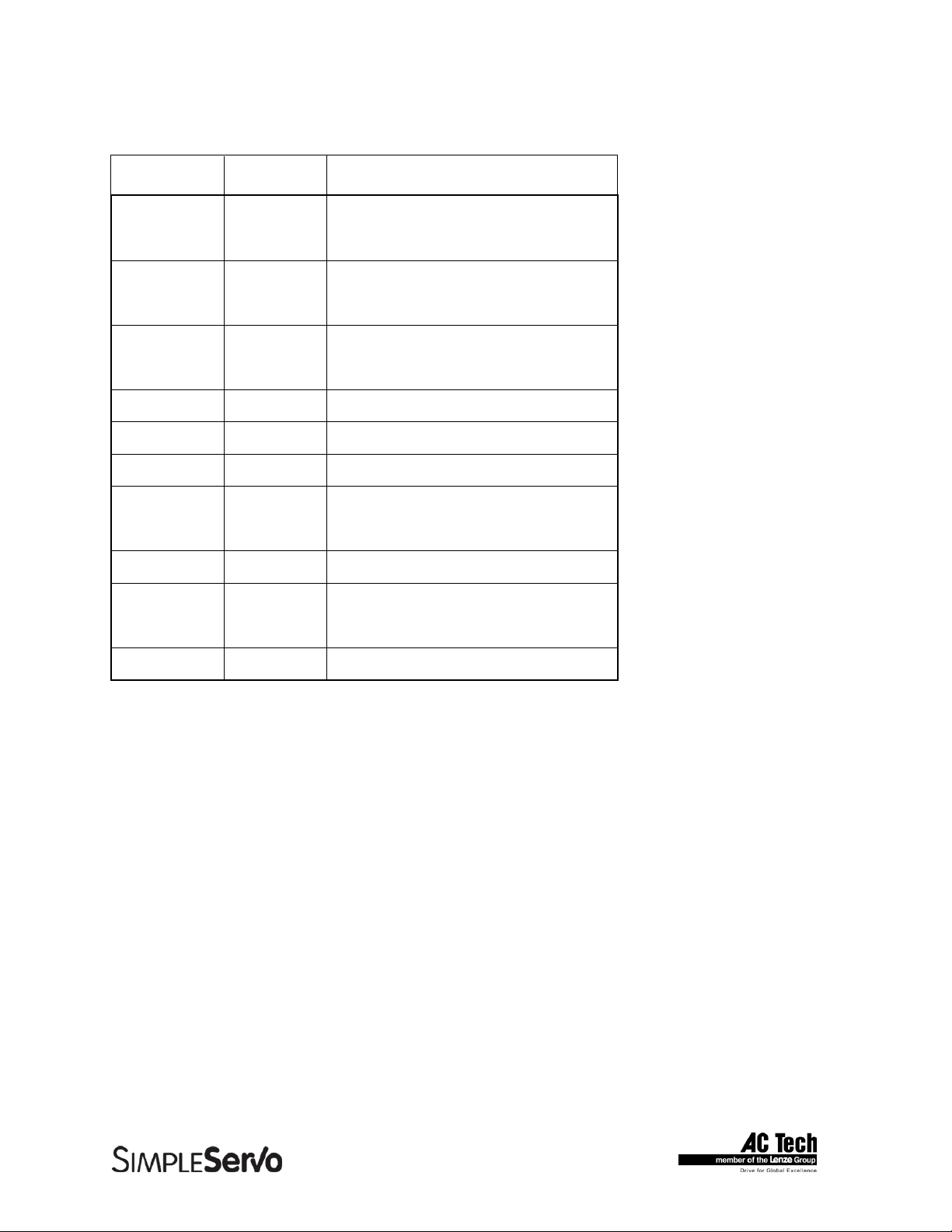

2.3 Dimensions and Weight

Model

Dimension

Height (inches) 6.50 7.80 6.50 7.80 7.80 7.80

Width (inches) 2.60 2.60 3.80 3.70 4.50 4.50

Depth (inches) 7.50 6.80 7.50 6.80 6.80 6.80

Weight (lbs) 2.5 4.0 3.5 5.0 5.6 5.6

Model

Dimension

Height (inches) 7.80 7.80 7.80 7.80

Width (inches) 2.60 3.70 4.50 4.50

Depth (inches) 6.80 6.80 6.80 6.80

Weight (lbs) 4.0 5.0 5.6 5.6

SS504A SS604A SS508A SS608A SS610A SS612-3P

SSi1004 SSi1008 SSi1010 SSi1012-3P

2.4 Operating Modes SS500/600 drives

• Torque

Reference 0 ± 10 VDC or 0 to 10 VDC, scalable

Torque Range 100:1

Current-Loop Bandwidth up to 3 kHz

• Velocity

Reference 0 ± 10 VDC or 0 to 10 VDC

Accuracy ± 1 RPM

Velocity-Loop Bandwidth up to 400 Hz

Speed Range up to 5000:1 ppr encoder

• Position

Reference Step and direction signals or Master Encoder full quadrature signal (software

selectable).

Minimum Pulse Width 250 nanoseconds

Reference Max frequency 2 MHz

Position-Loop Bandwidth Up to 400 Hz

Accuracy ±1 encoder count

2.5 Operating Modes SSi1000 drives

• Position PIVFF, Position P+V (inner velocity loop)

• Gearing

• Velocity

9

Page 10

SimpleServo 500/600/i1000 User Manual Rev 3.4

2.6 SSi1000 drives features

Indexing

Index resolution 64 bit

Index (position) range from -2

Index generation control Language statements or Host Interface commands

Indexing Incremental, absolute, registered and segmented moves

Motion Queue 32 levels deep

Acceleration/deceleration Linear or S-curved

Move profiles Trapezoidal, Triangular, S-curved

Gearing mode Dedicated inputs for quadrature master encoder reference,

Programmable “on the fly” Gear Ratio and Master Encoder

Scanned events period 256 uS

Registration 2uS reaction time. Current position capture.

User Program

User programming language Statements based.

Program control All major construction: DO-WHILE, WHILE, IF-THEN-ELSE

GOTO, GOSUB. Subroutines supported.

Types supported Typeless. All operands are 64 bit. 32.32 format

Operands representation Floating point.

Translation Multipass compiler

Program Object Bytecode

Execution Java-like virtual bytecode machine

Host Interface support

31

to 231 User Units

PPR via interface or User Program.

Velocity mode Velocity reference, Accel, Decel programmable on the fly via

interface or User Program

Events

Scanned events event on any valid logic expression. Expression can include any

internal System and User variables , I/O states , Flags, arithmetic

and logical expression results.

Tools for program Full featured IDE integrated in MotionView software. Single

Development Step execution capability, Breakpoints, status and variable

WATCH on the fly debug window.

Host Interface transports RS232/485 addressable (32 devices on network), 10/100

Ethernet.

Host Interface commands Unified Set for all interface transports. Could be executed

concurrently with User Program statements.

10

Page 11

SimpleServo 500/600/i1000 User Manual Rev 3.4

Variables

Internal format 64 bit

Number of User Variables 64

Variables resolution 64 bit

System variables resolution 64 bit

Arithmetic and logic functions

Arithmetic functions Addition, Subtraction, Multiplication, Division

Logic and bitwise functions AND, OR, XOR, NOT

2.7 Connections and I/O

All models

RS232 serial interface Standard 9-pin D-shell (DCE)

Encoder Feedback Standard 15-pin D-shell

Encoder buffered repeat in 25-pin D-shell

Power 8-pin removable terminal block (9-pin for 3-P models)

SS500/600 drives

Digital Inputs 1 dedicated (ENABLE), 1 programmable.

Digital Outputs 1 dedicated (READY) , 1 programmable.

Analog Inputs 1 differential analog input. Full range +/- 10V single ended

and +/- 5V differential .Analog input is used for Torque or Velocity reference.

Analog Outputs 1 single ended analog output. +/- 10 V full scale range. Analog output can

be assigned to various drive’s signals.

I/O Controller 15-pin removable terminal block or 25-pin D-shell

Standard 25-pin D-shell

SSi10XX drives

Digital Inputs 5-24V rated 12 digital optically isolated inputs separated into 4 groups.

Each group has common terminal for the group. 2 of 12 inputs are suitable

for connection of master encoder with up to 2 MHz signals’ rate.

Digital Outputs 4 +1 dedicated optically isolated digital outputs. 20mA capability suitable for

24V system control voltages. Both collector and emitter available for each

output at the terminal.

Dedicated output assigned for “READY” function.

Analog Inputs 1 differential analog input. Full range +/- 10V single ended and +/- 5V

differential. Analog Input can be read via System Variable “AIN”.

Analog Outputs 1 single ended analog output. +/- 10 V full scale range. Analog output can

be set by User Program (System Variable AOUT) or via Host Interface.

I/O Connections 25-pin D-shell for digital I/O and 15-pin removable terminal block for analog

input/output connections.

Interfaces

RS-485 4-pin removable terminal block

Ethernet 10/100 RJ-45 modular jack (if equipped)

Windows® Software: MotionViewTM (Windows 95, 98, NT,2000)

11

Page 12

SimpleServo 500/600/i1000 User Manual Rev 3.4

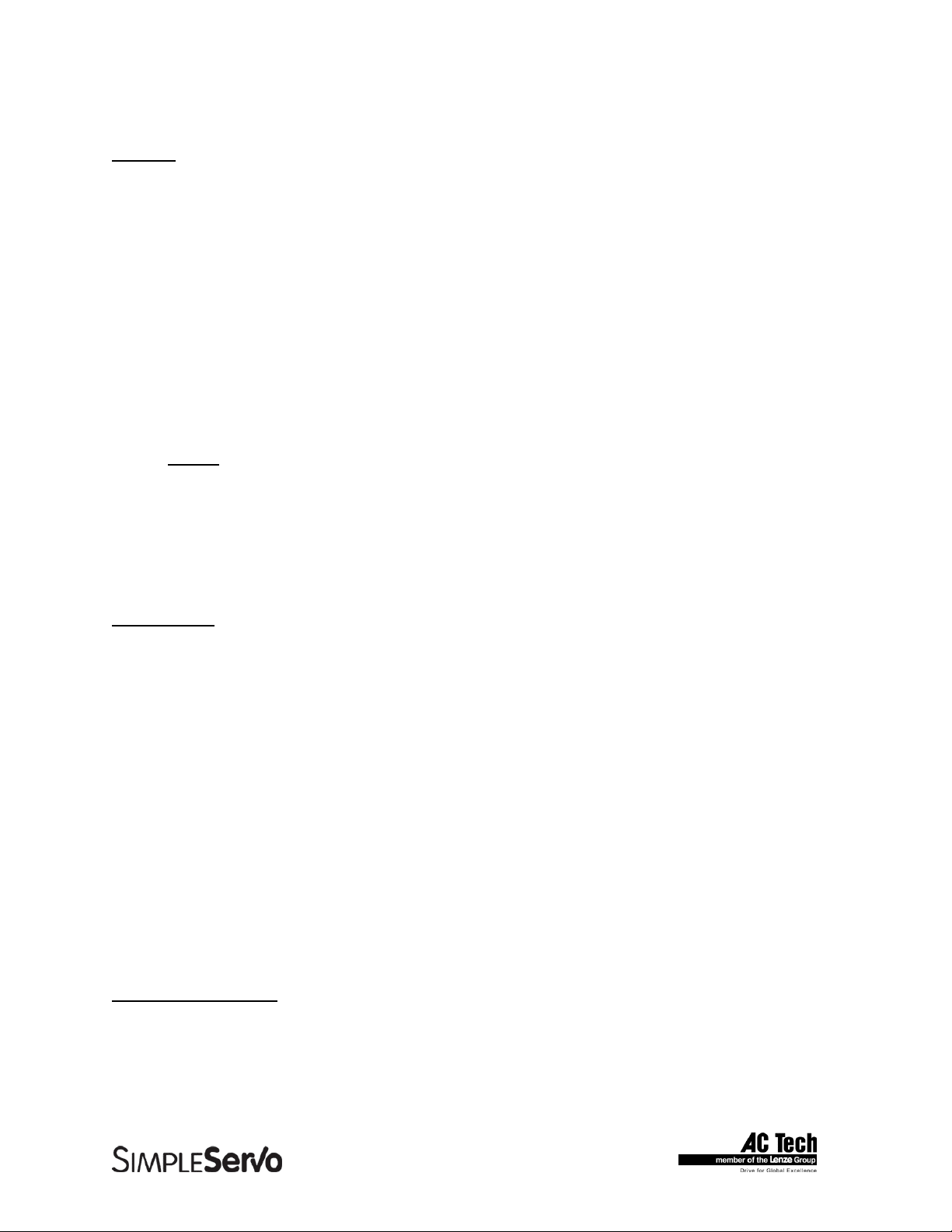

3 Dimensions

3.1 SS500 Series Dimensions

DIMENSION “A”

MODEL DIMENSION

SS504 2.60 [66] (NO HEATSINK NECESSARY)

SS508 3.80 [97]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

12

Page 13

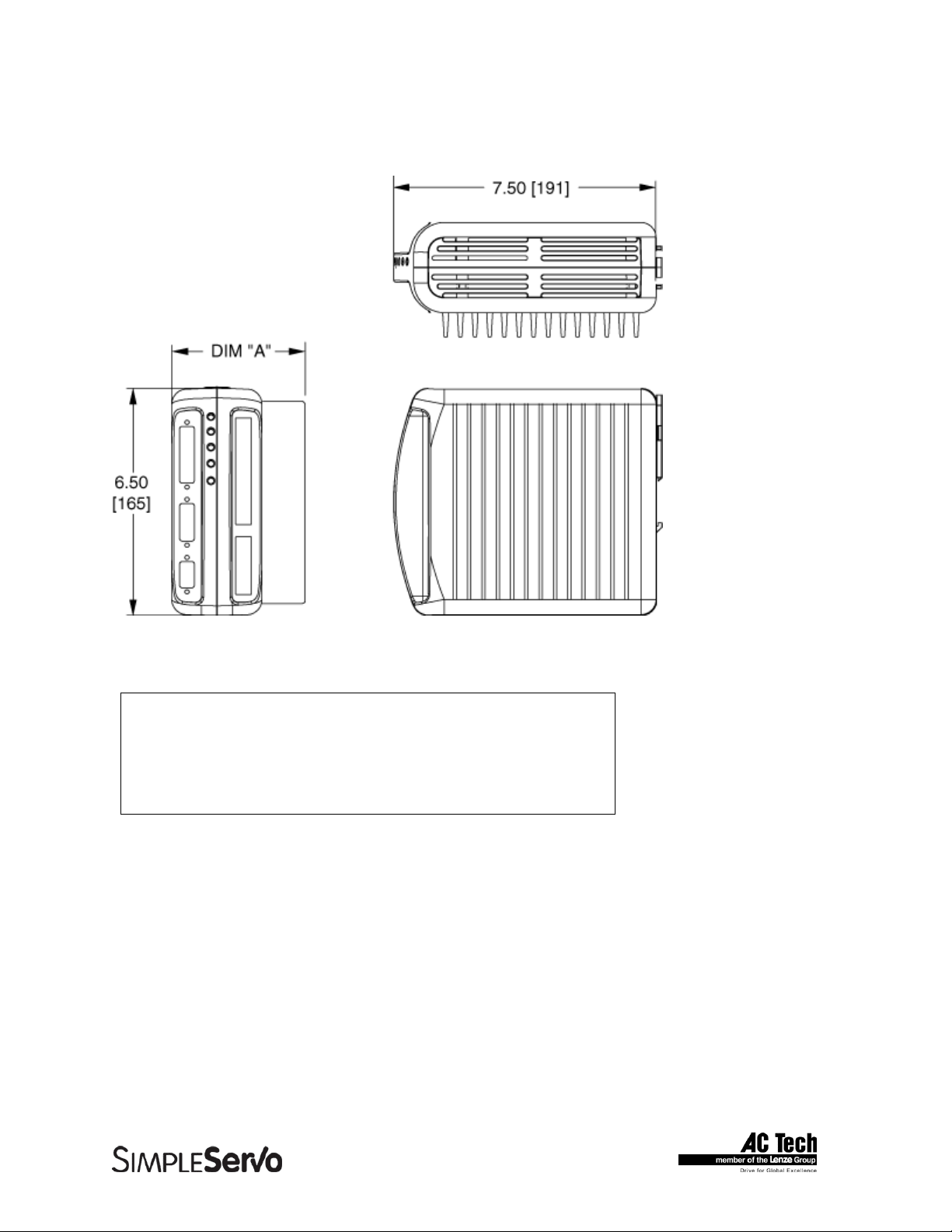

SimpleServo 500/600/i1000 User Manual Rev 3.4

3.2 SS604/SS608/SSi1004/SSi1008 Series Dimensions

DIMENSION “A”

MODEL DIMENSION

SS604/ssi1004 2.60 [66]

SS608/ssi1008 3.54 [94]

ALL DIMENSIONS IN INCHES [MILLIMETERS]

13

Page 14

SimpleServo 500/600/i1000 User Manual Rev 3.4

3.3 SS610/SS612-3P/SSi1010/SSi1012-3P Dimensions with Heat Sink

Fan Kit Installed

ALL DIMENSIONS IN INCHES [MILLIMETERS]

14

Page 15

SimpleServo 500/600/i1000 User Manual Rev 3.4

3.4 Suggested Clearance for Cooling Air Circulation (All Models)

15

Page 16

SimpleServo 500/600/i1000 User Manual Rev 3.4

4 Installation

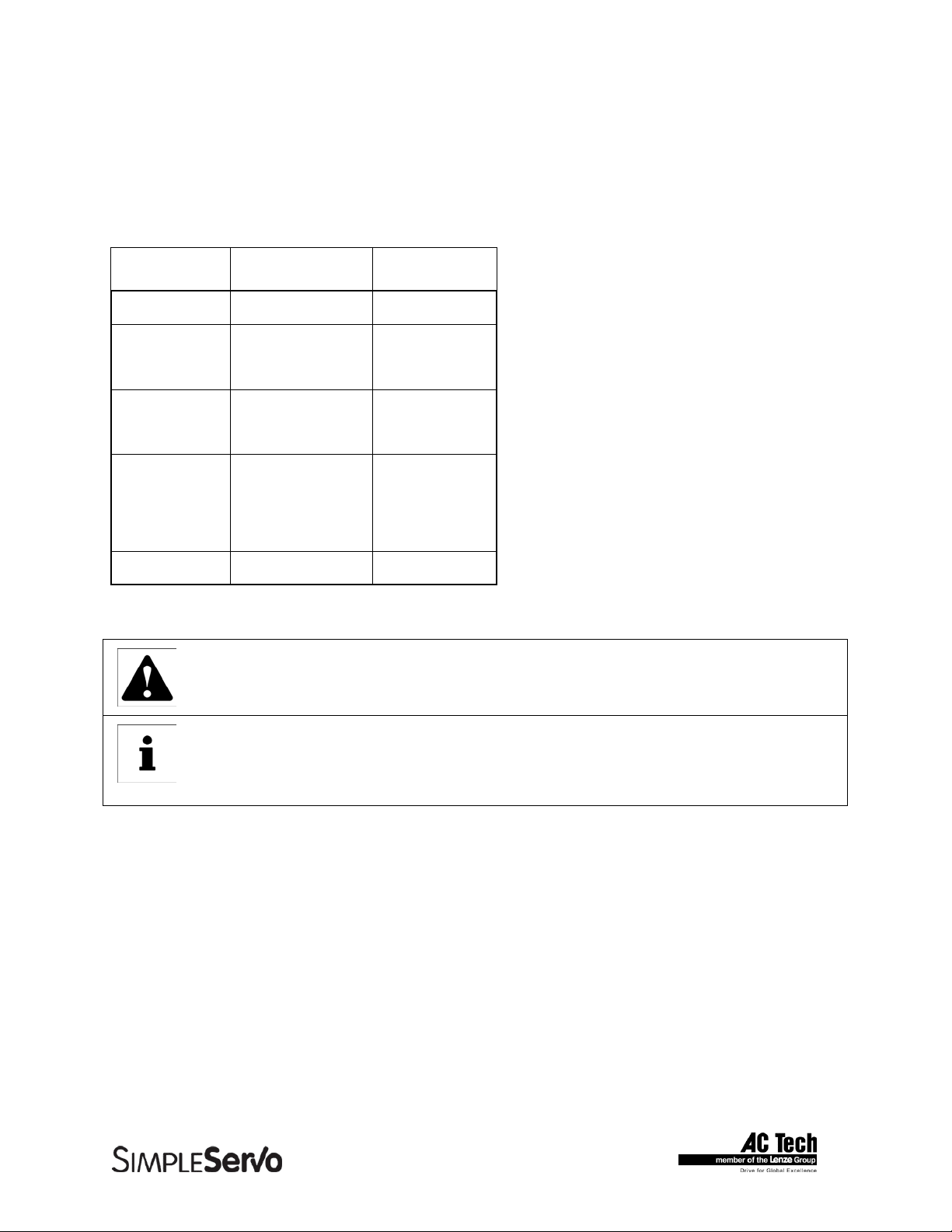

WARNING!

• Hazard of electrical shock! Circuit potentials are at 115 VAC or 230 VAC above earth

ground. Avoid direct contact with the printed circuit board or with circuit elements to prevent

the risk of serious injury or fatality. Disconnect incoming power and wait 60 seconds before

servicing drive. Capacitors retain charge after power is removed.

• The SimpleServo must be mounted vertically for safe operation at the maximum current

rating.

• Printed circuit board components are sensitive to electrostatic fields. Avoid contact with the

printed circuit board directly. Hold the SimpleServo by the case only.

• Protect the control from dirt, filings, airborne particles, moisture, and accidental contact.

Provide sufficient room for access to the terminal block.

• Mount the control away from other heat sources. Operate within the specified ambient

operating temperature range. Additional cooling with an external fan may be recommended

in certain applications.

• Avoid excessive vibration to prevent intermittent connections

• DO NOT connect incoming power to the output motor terminals (U, V, W)! Severe damage

to the SimpleServo will result.

• Do not disconnect any of the motor leads from the SimpleServo unless power is removed or

the control is disabled. Opening any one motor lead may cause failure.

• The DIN-rail mounting tab is designed to bear only the weight of the SimpleServo and heat

sink. Make sure enough slack exists in the wire routing to ensure that the cables do not tug

or pull downward against the DIN-rail mounting tab.

16

Page 17

SimpleServo 500/600/i1000 User Manual Rev 3.4

4.1 Start Up

Step-By-Step StartUp instructions are covered in Section 9 “Operation”.

4.2 Mounting

Note: It may be necessary to add shock-absorbing “bumpers” to the back of the SS500.

1. Mount the SimpleServo vertically in the panel as shown in Figure 5.

2. Ensure that a 30 mm (1.2 inch) DIN rail is installed horizontally in the rear of the panel prior to

mounting the SS500.

3. Ensure that the upper mounting tab on the back of the SS500 is in the UP position.

4. Hook the SS500’S lower mounting tab under the DIN rail as shown in Figure 4a. The tab fit

should be snug.

5. Rotate the SS500 upward, flush against the DIN rail, ensuring that the lower mounting tab

remains engaged by the DIN rail.

6. Once the SS500 is flush against the DIN rail, push down on the mounting tab atop the drive

(Figure 4b). The mounting tab will latch onto the top of the DIN rail.

Install the bumpers as follows:

1. Peel off the adhesive cover from the clear bumper. Apply to the DIN rail tab of the SimpleServo

(the moveable tab on the rear of the control that clamps onto the top of the DIN rail).

2. Mount the drive as indicated above.

3. Peel off the adhesive cover from the black bumper. Lift the bottom of the control (while it is still

clamped to the DIN rail) to open a slightly larger air gap between the SimpleServo and the

enclosure.

4. Apply the black bumper to the back of the SimpleServo (the side facing the enclosure)

approximately one inch above the bottom. Release the drive. It should come to rest on the newly

applied black bumper.

4.3 Wiring

WARNING!

• Hazard of electrical shock! Circuit potentials are at 115 VAC or 230 VAC above earth

ground. Avoid direct contact with the printed circuit board or with circuit elements to prevent

the risk of serious injury or fatality. Disconnect incoming power and wait 60 seconds before

servicing drive. Capacitors retain charge after power is removed.

• Under no circumstances should power and control wiring be bundled together. Induced

voltage can cause unpredictable behavior in any electronic device, including motor controls.

Use 18-28 AWG wire for reference and analog signal wiring. Use 12-16 AWG wire for AC line (L1 and L2)

and motor (Phase U, V and W) wiring.

17

Page 18

SimpleServo 500/600/i1000 User Manual Rev 3.4

4.4 Shielding and grounding

4.4.1 General guidelines

AC Technology Corporation recommends the use of single-point grounding (SPG) for panel-mounted

controls. Serial grounding (a “daisy chain”) is not recommended. The SPG for all enclosures must be tied

to earth ground at the same point. The system ground and equipment grounds for all panel-mounted

enclosures must be individually connected to the SPG for that panel using 14 AWG (5.5 mm) or larger

wire. Refer to Figure 6 for wiring guidelines.

In order to minimize EMI, the chassis must be grounded to the mounting panel (Figure 6). Use 14 AWG

(1.6 mm) or larger wire to join the enclosure to earth ground. A lockwasher must be installed between the

enclosure and ground terminal. To ensure maximum contact between the terminal and enclosure, remove

paint in a minimum radius of 0.25 in (6 mm) around the screw hole of the enclosure.

AC Technology Corporation recommends the use of the special SimpleServo cables provided by AC

Technology Corporation. If you specify cables other than those provided by AC Technology Corporation,

please make sure all cables are shielded and properly grounded.

It may be necessary to earth ground the shielded cable (Figure 6). Ground the shield at the SimpleServo

end and at the motor end.

If the SimpleServo continues to pick up noise after grounding the shield, it may be necessary to add an

AC line filtering devices and/or an output filter (between drive and servo motor).

4.4.2 EMI Protection

Electromagnetic interference (EMI) is an important concern for users of digital servo control systems. EMI

will cause control systems to behave in unexpected and sometimes dangerous ways. Therefore, reducing

EMI is of primary concern not only for servo control manufacturers such as AC Technology Corporation,

but the user as well. Proper shielding, grounding and installation practices are critical to EMI reduction.

4.4.3 Enclosure

The panel in which the SimpleServo is mounted must be made of metal, and must be grounded using the

SPG method outlined above.

Proper wire routing inside the panel is critical; power and logic leads must be routed in different avenues

inside the panel .

If you use drives that output over 8 amps, you must ensure that the panel contains sufficient clearance

above and below for the cooling fan to circulate air. Refer to Figure 3 for minimum suggested cooling air

clearance.

4.5 Line filtering

In addition to EMI/RFI safeguards inherent in the SimpleServo design, external filtering may be required.

High frequency energy can be coupled between the circuits via radiation or conduction. The AC power

wiring is one of the most important paths for both types of coupling mechanisms. There are many AC line

filter manufacturers whose filters can be successively integrated. AC Tech recommends Schaffner filters

based on our test results.

18

Page 19

SimpleServo 500/600/i1000 User Manual Rev 3.4

In order to comply with EN50081-1 and EN50082-2, the following filters must be installed within 20cm of

the drive power inputs:

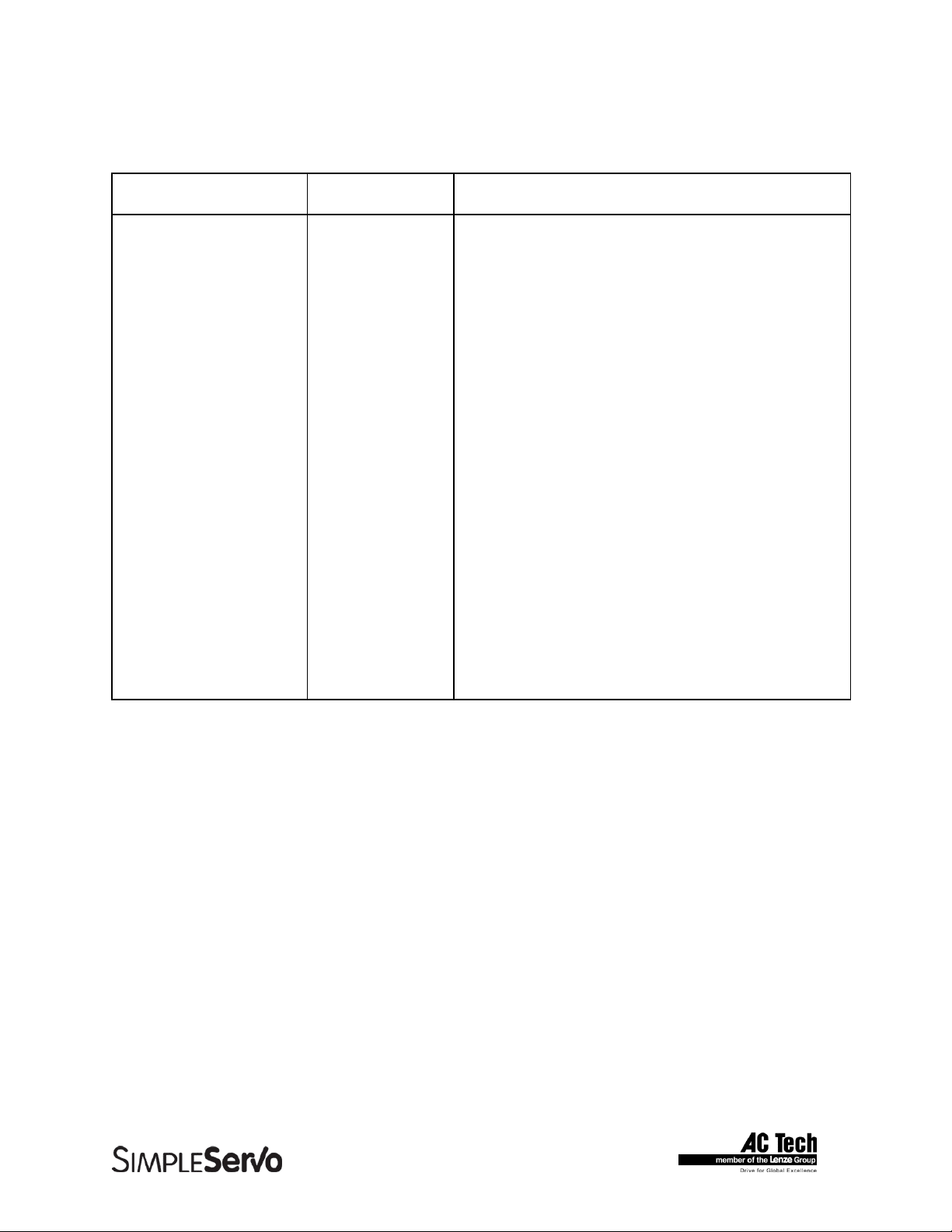

TABLE 1 LINE FILTER PART NUMBERS

SimpleServo P/N Schaffner AC filter P/N

SS504 FN350-8

SS508 FN350-12

SS608(-3P) FN350-12 (FN351-8

1

)

SS1008(-3P) FN350-12 (FN351-81)

SS610 FN350-20

SS1010 FN350-20

SS612-3P FN351-16

1

SS1012-3P FN351-161

1

For 3-phase (-3P) models

Line filters should be placed inside the shielded panel. Connect the filter to the incoming power lines

immediately after the safety mains and before any critical control components (Figure 6). Wire the AC line

filter as close as possible to the SimpleServo. If you add separate fuses, add them after the AC line filter.

Note

The ground connection from the filter must be wired to solid earth ground, not machine

ground.

If the end-user is using a CE-approved motor, the AC filter combined with the recommended SimpleServo

motor and encoder cables, is all that is necessary to meet the EMC directives listed herein. The end user

must use the comparable filter (see table above), to comply with CE specifications. The OEM may choose

to provide alternative filtering that encompasses the SimpleServo and other electronics within the same

panel. The OEM has this liberty because CE is a machinery directive.

4.6 Heat sinking

SimpleServos contain sufficient heat sinking in their basic configuration. There is no need for additional

heat sinking. However, drives that output more than 8 amps incorporate a heat sink cooling fan; you must

ensure that there is sufficient clearance for the cooling fan to circulate air (Figure 3). As a minimum, you

must allow an air gap of 1 inch above and below the drive.

4.7 Line fusing

External line fuses must be installed on all SimpleServos. Connect the external line fuse in series with the

AC line voltage input. Table 3 lists the recommended line fuse sizes. Use fast acting fuses rated for 250

VAC or higher, and approximately 200% of the maximum phase current.

TABLE 2 RECOMMENDED LINE FUSE SIZES

Model Number Line Fuse Size (AC Amps)

SSX04

SSX08

SSX12

15

25

30

19

Page 20

SimpleServo 500/600/i1000 User Manual Rev 3.4

5 SimpleServo Connections

The standard SimpleServo control contains five connectors: two quick-connect terminal blocks and three

subminiature type “D” connectors. These connectors provide power, communications and external

feedback to the motor, SimpleServo control, and host controller (Figure 8). Prefabricated cable

assemblies may be purchased from AC Technology Corporation to facilitate wiring the control, motor and

host computer. Contact your SimpleServo Sales Representative for assistance.

5.1 External Connectors

5.1.1 TB501 - Power, Motor, and Fuse Connections

TB501 is an 8-pin quick-connect terminal block used for motor, power and fuse connections. Refer to

Table 3 for connector pin assignments. Where referenced in the table below, refer to Connector Wiring

Notes for more information.

WARNING!

• Hazard of electrical shock! Circuit potentials are at 115 VAC or 230 VAC above earth

ground. Avoid direct contact with the printed circuit board or with circuit elements to prevent

the risk of serious injury or fatality. Disconnect incoming power and wait 60 seconds before

servicing drive. Capacitors retain charge after power is removed.

• DO NOT connect incoming power to the output motor terminals (U, V, W)! Severe damage

to the SimpleServo will result.

All conductors must be enclosed in one shield and jacket around them. The shield on the amplifier end

must be terminated at TB501 pin 6 (chassis ground); the other end should be properly terminated at the

motor shield. To satisfy CE requirements, AC Technology Corporation recommends that you purchase

SimpleServo cables for both the motor and AC line. Contact your SimpleServo representative for

assistance.

Wire size

If current draw is less than 8 amps: 16 AWG (1.0 mm) or 14 AWG (1.6 mm)

If current draw is greater than 8 amps but less than 12 amps: 14 AWG (1.6 mm) or 12 AWG (2.6 mm)

If current draw is greater than 12 amps: 12 AWG (2.6 mm)

TABLE 3 TB501 PIN ASSIGNMENTS (single phase models)

Terminal Block Pin # Name Function

1 W (T) Motor Power Out

2 V (S) Motor Power Out

3 U (R) Motor Power Out

4 DUMP+ Dump resistor out

5 DUMP- Dump resistor out

6 GND Chassis ground

7 L1 AC Power In

8 L2 AC Power In

20

Page 21

SimpleServo 500/600/i1000 User Manual Rev 3.4

TABLE 4 TB501 PIN ASSIGNMENTS (3 phase models)

Terminal Block Pin # Name Function

1 W (T) Motor Power Out

2 V (S) Motor Power Out

3 U (R) Motor Power Out

4 DUMP+ Dump resistor out

5 DUMP- Dump resistor out

6 GND Chassis ground

7 L1 AC Power In

8 L2 AC Power In

9 L3 AC Power In

5.1.2 TB502 - Analog/Digital I/O Terminal Block

TB502 is a 15-pin quick-connect terminal block used for analog and digital I/O functions in standalone

mode.

TABLE 5 TB502 PIN ASSIGNMENTS (all models except SSi10XX)

Terminal Block Pin# Name Function

1 -REF -10V (5mA)

2 IN- Positive (+) of analog signal input

3 IN+ Negative (-) of analog signal input

4 +REF +10V (5mA)

5 AGND Analog ground (attach shield from signal source here)

6 MA+/Step+ Step+ (or master encoder channel A+) input1

7 MA-/Step- Step- (or master encoder channel A-) input1

8 MB+/Dir+ DIR+ (or master encoder channel B+) input

9 MB-/Dir- DIR- (or master encoder channel B-) input

10 Analog Output Programmable analog output

11 AUX INPUT Programmable digital input

12 EN Enable Input2

13 OUT_RDY Ready output O.C.

14 OUT_AUX Programmable Output O.C.

15 GND Logic common

21

Page 22

SimpleServo 500/600/i1000 User Manual Rev 3.4

TABLE 6 TB502 PIN ASSIGNMENTS (SSi10XX only)

Terminal Block Pin # Name Function

1 -Vcc -Vcc (5mA)

2 REF- Negative reference input (differential)

3 REF+ Positive reference input (differential)

4 +Vcc -Vcc (5mA)

5 AGND Analog ground (attach shield from signal source here)

6 SPARE

7 SPARE

8 SPARE

9 SPARE

10 Analog output Programmable analog output

11 SPARE

12 SPARE

13 SPARE

14 SPARE

15 GND Logic common

22

Page 23

SimpleServo 500/600/i1000 User Manual Rev 3.4

5.1.3 Encoder feedback

An encoder needs to have power supplied to it. Both front-end controllers and the SimpleServo each

have a +5 VDC supply voltage that may be used to power the encoder. The SimpleServo contains patentpending automated switching circuitry, which will power the encoder from a front-end controller if it is

present (through the ENC+ pin). If no supply voltage is present at the ENC+ pin, the SimpleServo will

switch its internal power (+5 VDC supply) to the encoder.

WARNING!

Use only +5 VDC encoders. Do not connect any other type of encoder to the SimpleServo

reference voltage terminals. When using a front-end controller, it is critical that the +5 VDC

supply on the front-end controller NOT be connected to the +5 VDC supply on the

SimpleServo, as this will result in damage to the SimpleServo.

Note

• SimpleServo inputs are compatible with single-ended or open-collector type of hall sensors.

If you have these type of hall sensors just connect them to “HA+”, “HB+”, “HC+” and leave

“HA-,HB-,HC-“ inputs unconnected. You don’t need to supply pull-up resistors in case the

hall sensors are open-collector. Necessary pull-up circuits are already provided inside

SimpleServo amplifier.

• Encoder connections must be full differential. SimpleServo doesn’t support single-ended or

open-collector type outputs for encoder.

• An encoder resolution of 2000 PPR or higher is recommended for optimum performance.

5.1.4 TB504 - Motor Feedback Input

TB504 is a 15-pin DB connector that contains connections for Hall effect sensors and encoder feedback.

Refer to Table 5 for connector pin assignments. Encoder inputs on TB504 have 26LS32 or compatible

differential receivers for increased noise immunity. Inputs have all necessary filtering and line balancing

components so no external noise suppression networks are needed.

All conductors must be enclosed in one shield and jacket around them. AC Technology Corporation

recommends that each and every pair (for example, EA+ and EA-) be twisted. In order to satisfy CE

requirements, use of an OEM cable is recommended. Contact your SimpleServo representative for

assistance.

The SimpleServo buffers encoder feedback through TB504 to TB506. Encoder channel A on TB506, for

example, is buffered channel A pin of TB504 inside the SimpleServo. The Hall sensors from the motor

must be wired to the 15-pin connector.

23

Page 24

SimpleServo 500/600/i1000 User Manual Rev 3.4

TABLE 7 TB504 PIN ASSIGNMENTS

"D"-Sub Pin # Name Function3

1 EA+ Encoder Channel A

2 EA- Encoder Channel A Not4

3 EB+ Encoder Channel B

4 EB- Encoder Channel B Not

5 EZ+ Encoder Channel Z

6 EZ- Encoder Channel Z Not

7 GND Drive Common/Encoder Ground

8 SHLD Shield

9 PWR Encoder supply (+5VDC)

10 HA- Hall Sensor A-

11 HA+ Hall Sensor A+

12 HB+ Hall Sensor B+

13 HC+ Hall Sensor C+

14 HB- Hall Sensor B-

15 HC- Hall Sensor C-

24

Page 25

SimpleServo 500/600/i1000 User Manual Rev 3.4

5.1.5 TB505 - Serial Communications Port

TB505 is a 9-pin D-sub connector that is used to communicate with a host computer via standard RS232

interface. This port is present on all SimpleServo drives. All levels must be RS-232C compliant.

TB505 Pin Assignments (all models)

"D"-Sub Pin # Name Function

1 Reserved

2 TX RS232 TX

3 RX RS232 RX

4 Reserved

5 GND Common

6 Reserved

7 Reserved

8 Reserved

9 Reserved

WARNING!

Do not make any connection to Reserved pins!

Note

If you purchase serial cables from a third party, you must use a pass-through cable, not NullModem (not crossover).

25

Page 26

SimpleServo 500/600/i1000 User Manual Rev 3.4

5.1.6 TB506 - Controller Interface (SS500/600 drives)

TB506 is a 25-pin DB connector for interfacing to front-end controllers. It is strongly recommended that

you use OEM cables to aid in satisfying CE requirements. Contact your SimpleServo representative for

assistance.

TABLE 8 TB506 PIN ASSIGNMENTS

"D"-Sub Pin # Name Function3

1 EA+ Encoder Channel A

2 EA- Encoder Channel A Not4

3 EB+ Encoder Channel B

4 EB- Encoder Channel B Not

5 EZ+ Encoder Channel Z

6 EZ- Encoder Channel Z Not

7 GND Drive Common

8 SHLD Shield

9 ENC+ Positive Terminal of Encoder Power (+)5

10 N/C Spare

11 MA+/Step+ Master Encoder A+ / Step input+1

12 MA-/Step- Master Encoder A- / Step input-1

13 MB+/Dir+ Master Encoder B+ / Direction input +

14 MB-/Dir- Master Encoder B- / Direction input -

15 READY-C Output Ready OC. Collector

16 READY-E Output Ready OC. Emitter

17 ENABLE+ Enable Input +2

18 ENABLE- Enable Input -2

19 AUX-C Programmable output OC. Collector

20 AUX-E Programmable output OC Emitter

21 EXTPOWER +5 V (20mA max)

22 GND Drive Common

23 IN+ Positive (+) of Analog signal input

24 IN - Negative (-) of Analog signal input

25 Analog Ground Reference Signal Ground/Analog Shield

26

Page 27

SimpleServo 500/600/i1000 User Manual Rev 3.4

5.1.7 TB506 - Encoder repeat and analog input connections (SSi1000 drives)

TB506 is a 25-pin DB connector that includes buffered motor encoder repeat and analog input

connections.

TABLE 9 TB506 PIN ASSIGNMENTS

"D"-Sub Pin # Name Function3

1 EA+ Encoder Channel A

2 EA- Encoder Channel A Not4

3 EB+ Encoder Channel B

4 EB- Encoder Channel B Not

5 EZ+ Encoder Channel Z

6 EZ- Encoder Channel Z Not

7 GND Drive Common

8 SHLD Shield

9 SPARE

10 SPARE

11 SPARE

12 SPARE

13 SPARE

14 SPARE

15 SPARE

16 SPARE

17 SPARE

18 SPARE

19 SPARE

20 SPARE

21 SPARE

22 GND Logic Common

23 IN+ Positive (+) of Analog signal input

24 IN - Negative (-) of Analog signal input

25 Analog Ground Reference Signal Ground/Analog Shield

27

Page 28

SimpleServo 500/600/i1000 User Manual Rev 3.4

5.1.8 Connectors and Wiring Notes

Note 1

An external pulse train signal (for “step”) supplied by an external device, such as a PLC or stepper

indexer, can control the speed and position of the servomotor. The speed of the motor is controlled by the

frequency of the step signal, while the number of pulses that are supplied to the SimpleServo determines

the position of the servomotor. “DIR” input controls direction of the motion.

Note 2 (SS500/600 drives only)

The enable (EN) pin, TB502 pin 12 or TB506 pin 17/18, must be wired to one of the output terminals on

the front-end controller, i.e., if the controller is present, it must supervise the enable function on the

SimpleServo. The SimpleServo will accept open-collector outputs for use as a switch, TTL or CMOS

outputs (5V) programmed for active low operation.

Note 3

Each of the encoder output pins on TB506 is buffered pass-through. The encoder channel A pin on

TB504, for example, is buffered and routed to the encoder channel A pin on TB506 inside the

SimpleServo. If you require encoder information, wire your controller to TB506. The encoder and Hall

sensor feedback from the motor must be wired to the 15-pin Type D receptacle (connector) through the

feedback cable.

Note 4

The complement of A is sometimes written as not A. The B, C and Z encoder channels are annotated in a

similar fashion.

Note 5

WARNING!

Use only +5 VDC encoders. Do not connect any other type of encoder to the SimpleServo

reference voltage terminals. When using a front-end controller, it is critical that the +5 VDC

supply on the front-end controller NOT be connected to the +5 VDC supply on the

SimpleServo, as this will result in damage to the SimpleServo.

The encoder needs to have power supplied to it. A front-end controller, as well as the SimpleServo, has a

+5 VDC supply voltage that may be used to power the encoder. The SimpleServo contains patentpending automated switching circuitry which will power the encoder from a front-end controller if it is

present (through the ENC+ pin). If no supply voltage is present at the ENC+ pin, the SimpleServo will

switch its internal power (+5 VDC supply) to the encoder.

28

Page 29

SimpleServo 500/600/i1000 User Manual Rev 3.4

5.2 Digital I/O details (SS500/600 drives)

5.2.1 Step and Direction/ Master Encoder Inputs

TB506-11,12,13,14 and TB502-6,7,8,9

You can connect a master encoder with quadrature outputs or a step and direction pair of signals to

control position in step/direction operating mode. These inputs are optically isolated from the rest of

the drive circuits and from each other. Both inputs can operate from any voltage source in the range of

5 to 24 VDC and do not require additional series resistors for normal operation. See figure below.

Master encoder/step and direction input circuit.

You can connect a single ended or differential signal to the inputs. You can also connect sinking or

sourcing outputs to these inputs. See application note in Section 12 of this manual for the connection

guidelines. The function of these inputs “Master Encoder” or “Step and Direction” is software

selectable. Use MotionView set up program to choose desirable function.

5.2.2 Digital outputs

There are two digital outputs “READY” and “OUT AUX” available in different output configurations.

On TB506:

“READY”(TB506-15, 16) “AUX-C and AUX-E” (TB506-19, 20).

Outputs are fully isolated from the rest of the drive circuits (“dry contact”). See figure below for its

electrical diagram.

29

Page 30

SimpleServo 500/600/i1000 User Manual Rev 3.4

On TB502:

“AUX” output

• Zero speed

• In speed window

• Current limit

• Run Time Fault

“OUT_RDY” (TB502-13), “OUT_AUX” (TB502-14).

Functions the same as “READY” and “AUX” have open-collector sinking outputs (sinking only)

referenced to drive logic common. See figure below for the electrical diagram.

Both versions of these outputs (On TB506 and TB502) have the same logic.

“READY” output

Activated when the drive is ready and enabled. It is reset to an inactive state when the drive is

disabled, not operational or any fault is detected.

Programmable output. Activated when any of the selected conditions are true. These

conditions are software selectable. Use MotionView to select the condition assigned to this

programmable output. Only one condition at a time can be selected for output. Possible

choices are:

5.2.3 Digital inputs

“ENABLE+ & ENABLE-” (TB506-17, 18).

Optically isolated input. Compatible with 5 -24V voltage source or open-collector sinking

output. For connection guidelines, refer to the application note in Section 12. See figure

below for electrical diagram.

30

Page 31

SimpleServo 500/600/i1000 User Manual Rev 3.4

AUX INPUT (TB502-11), “EN” (TB502-12)

“EN” Functions same as “ENABLE+ / ENABLE-”

This is a single-ended input, compatible with 5V TTL, open-collector sinking output, and switch

or relay contacts. The input is referenced to drive logic common. These inputs are active low,

i.e., connecting it to drive logic common or supplying logic “0” referenced to drive logic

common activates this input. For connection guidelines see application note in Section 12.

See figure below for electrical diagram.

“EN”, “ENABLE+ ENABLE- ”

Drive enable input. Activating this input enables the drive.

“AUX INPUT”

Programmable input: Function of this input is software selectable. Use MotionView program to

select the function for this input. Possible choices are:

• External fault

• Stop

• Reverse

31

Page 32

SimpleServo 500/600/i1000 User Manual Rev 3.4

5.3 Digital I/O details (SSi1000 drives)

SSi10XX indexing drives have 25-pin D-sub digital I/O connector. Digital I/O supplement on these

drives consists of 12 inputs and 5 outputs. All I/O optically isolated from rest of the drive’s circuitry.

5.3.1 Digital inputs

SSi drives have 12 digital inputs which are separated on 4 groups. Each group has its own common

for inputs in the group. All inputs are optically isolated and suitable for 5–24 VDC input control voltage.

Some of the inputs can be configured to carry out special functions. Refer to Table 7 for digital inputs

function reference. All inputs have same electrical characteristics and the same input circuitry

arrangements.

5.3.1.1 Special functions

Inputs C1,C2. Master Encoder connections

Inputs C1 and C2 are suitable for Master Encoder connection for Gear Mode usage. Inputs C1 and C2

are capable of handling signals with of up to 2 MHz rate. Refer to Programmer’s Manual for details.

Inputs A1,A2. Limit switches connection.

These inputs can be used for Limit switches connections. These two inputs will perform different

actions upon activation if programmed to do so. When programmed for <Not assigned> they function

as normal inputs. Refer to Section 7.3.2 for details.

Input A3. Enable

A3 input can be programmed for ENABLE function. When this input is programmed for ENABLE

function it must be active before ENABLE statement is issued otherwise fault will be generated. If this

input gets deactivated while drive is enabled drive will stop and generate fault. When input is not

programmed for a special function, it functions as a normal input.

Input C3. Registartion sensor input.

This input can be used for registration sensor connection. Upon activation of the input, current actual

position is recorded and is available for User Program. This input also used in all registration move

commands. Refer to Programmer’s Manual for details.

5.3.2 Digital outputs

SSi drives have 5 digital outputs numbered 1 to 5. Outputs 1 - 4 can be configured as general-purpose

outputs, or can be configured for special functions (selection made via MotionView program in I/O

folder Section 7.3.1 of this manual). Output #5 is dedicated as “READY”, which is ON when SSi is

enabled and OFF when SSi is disabled or at fault. Output #5 is not accessible via User Program or

Host Interface.

All outputs are optically isolated from SSi circuitry and each other and are open collector type. They

have 30mA load capability. Both Collector and Emitter of each output are available for customer

connection.

32

Page 33

SimpleServo 500/600/i1000 User Manual Rev 3.4

TABLE 10 TB507 PIN ASSIGNMENTS

Pin

number

Function Aux function Pin

number

Function Aux function

1 Input A1 Left limit 14 Output 1 C

2 Input A2 Right limit 15 Output 1 E

3 Input A3 Enable 16 Output 2 C

4 Input A4 17 Output 2 E

5 Common for A

18 Output 3 C

section

6 Input B1 19 Output 3 E

7 Input B2 20 Output 4 C

8 Input B3 21 Output 4 E

9 Input B4 22 Output 5 C Ready C

10 Common for B

23 Output 5 E Ready E

section

11 Common for C

24 Input C4

section

12 Input C2 ME B 25 Input C3 Registration

13 Input C1 ME A

33

Page 34

SimpleServo 500/600/i1000 User Manual Rev 3.4

Inputs A1-A4 COM

A1

A2

A3

A4

Inputs B1-B4 COM

B1

B2

B3

B4

Inputs C1-C4 COM

1

2

3

4

5

6

7

8 9

1

2

3

4

5

6

7

8 9

16

15

14

13

12

11

10

SSi drive's

circuitry

16

15

14

13

12

11

10

1

2

3

4

5

6

7

8 9

1

2 3

16

15

14

13

12

11

10

4

OUT1+

OUT1-

OUT2+

OUT2-

OUT3+

OUT3-

OUT4+

OUT4-

READY+

READY-

C3

C3

C3

C4

1

2

3

4 5

1

2

3

4 5

8

7

6

8

7

6

U3

SSi drives I/O arrangements

34

Page 35

SimpleServo 500/600/i1000 User Manual Rev 3.4

5.4 Analog I/O details

5.4.1 Analog reference input

IN+, IN- (TB506-23, 24 or TB502-2,3)

Analog differential input. This input will accept +/-10V single-ended voltage on IN+ or IN- input or

+/-5V differential voltage between IN+ and IN-. Both connections must be referenced to Analog

Common (TB506-25 or TB502-5) of the drive. This input is used to control speed or torque of the

motor in velocity or torque mode (SS500/600 only).The total reference voltage as seen by the drive is

the voltage difference between IN+ and IN-. If used in single-ended mode one of the inputs must be

connected to voltage source while the other one must be connected to Analog Common. If used in

differential mode, the voltage source is connected across IN+ and IN- inputs and driving circuit

common (if any) needs to be connected to drive Analog Common terminal.

Reference as seen by drive:

Vref = (VIN+) - (VIN-)

Note

In SSi1000 drives, Vref is available by reading System Variable “AIN”.

5.4.2 Analog output

Analog out. (TB502-10)

Analog output is single ended –10/+10V span signal which can represent different quantities of the

drive (SS500/600 only). For SS500/600 drives MotionView SetUp program can be used to select

signal source for the analog output as well as its scaling. SSi1000 indexing drives can set analog

output directly from User program (Sysytem Variable “AOUT”) or via Host Interface command. Load

capability of that output is 10mA.

5.5 Communication interfaces (SS500/600 drives)

Drives are equipped with RS232 communication interface. Communication speed is fixed at 38,400

baud.

5.6 Communication interfaces (SSi1000 drives)

In addition to standard RS232 interface SSi indexing drives have RS485 and Ethernet communication

interfaces. Communication speed for RS232/485 can be 115200 or 38400 baud and DIP-SWITCH

DS501 #6 selectable.

5.6.1 RS232 interface

This interface is available on SSi drives for communication with Host computer. The SSi RS232 is

addressable, with the address set by DIP-SWITCH DS501. See “RS485 interface” paragraph below to

see how address should be set. The SSi RS232 has a unique re-transmitting feature. If you send

commands using RS232 interface to the drive with a different address, the drive will retransmit this

command to the RS485 network so the other drive might pick it up. This allows the possibility of

connecting a network of SSi drives to a Host computer via RS232 on one of the drives in the network.

There is no special adjustments or setups needed to start using this feature.

35

Page 36

SimpleServo 500/600/i1000 User Manual Rev 3.4

5.6.2 RS485 interface

RS485 interface is available at the 4 pins screw terminal connector TB508. Up to 32 drives can be

daisy chained by connecting their “+” and “-“ terminals using twisted pair wire. Connect termination

resistor between “+” and “-“ terminals of the last drive in network. See figure below for connection.

TABLE 11 TB508 RS485 CONNECTOR

PIN # Function

1 RS485 Data +

2 RS485 Data +

3 RS485 Data 4 RS485 Data -

RS485 Network connection. Use twisted pair wire with optional shield. Connect shield to the

earth ground (optional).

Network Master (Computer or PLC)

RS485 Data +

RS485 Data -

120

Last Drive in the network

terminated with resistor

Additional Drives (Up to 32 total)

36

Page 37

SimpleServo 500/600/i1000 User Manual Rev 3.4

DIP-SWITCH DS501 has its first 5 switches for address assignment and switch #6 for baud rate

selection. Two speeds are possible: 38,400 and 115,200 baud. As mentioned previously, up to 32

drives can be connected to a single network. Each drive on the network has to have its own unique

address set via DIP-SWITCH. Pulling switch UP sets it ON and pulling switch DOWN sets it OFF. The

drive address will be a sum of all ON switch values. For example, if switches 1,2, and 5 are ON and

the rest of the switches are OFF, the resulting address will be 1(#1)+2(#2)+16(#5) = 19.

TABLE 12 DIP-SWITCH DS501

Dip-switch # Value

1 1

2 2

3 4

4 8

5 16

6 OFF = 115200, ON = 38400 baud

To assign an address of 10, the sum of the switch values must be equivalent to 10. In this case,

switches 2 and 4 would need to be set to ON (2 + 8 =10).

Diagnostic LED. (green)

There are two LEDs near RS485 connector. Green LED lights up when data is sent to or from drive

over the RS485 interface. Refer to Section 9.1.2 for more information on the LEDs.

5.6.3 Ethernet interface.

SSi drives support standard 10/100 Ethernet connection via modular RJ-45 jack and CAT-5 standard

twisted pair network cable used in computer equipment. The RJ-45 socket has two integrated LEDs

showing network status. Green LED lights up when physical connection is present and yellow LED

lights up when SSi sends or receives data over the Ethernet.

SSi drives support both manual and automatic IP parameters assignment. Automatic (DHCP)

assignment of IP properties is possible if there is a DHCP server on the network. This is the default

setting. You can quickly connect drive(s) to floor/corporate network and configure it for further

operation. In manual mode you need to supply the IP address, Subnet mask, and Default gateway.

Default gateway address is needed only if drives are located on different subnets. If drives are on the

same network and there is no gateway supply to this field address of the host computer or address on

the same subnet but not used by any of the devices.

37

Page 38

SimpleServo 500/600/i1000 User Manual Rev 3.4

5.7 Motor Selection

SimpleServo drives are compatible with many servo motors, both AC Technology Corporation motors

and motors from the other manufacturers. We have tested many motors with the SimpleServo and put

their parameters in a database for customer convenience. If you opted for the motor which is in the

database you do not need to provide any motor data to set up motor for the use. However if your

motor is not in the database you can still use it but need to provide some electrical and mechanical

data to make a custom motor profile. The auto-phasing feature of SimpleServo allows you to correctly

determine relation between phase voltage and hall sensor signals, eliminating the need to use a multichannel oscilloscope.

5.7.1 Setting Up motor

MotionView Motor Group on the left tree shows currently selected motor. You can click “CLICK HERE

TO CHANGE” to view selected motor parameters or select new motor.

MotionView’s <Motor Group> folder and its contents

Note

If drive is ENABLED, a new motor cannot be set. You can only set a new motor when the

drive is DISABLED.

38

Page 39

SimpleServo 500/600/i1000 User Manual Rev 3.4

To View selected motor parameters or make a new motor selection:

• Click “CLICK HERE TO CHANGE”. Selection dialog opens. (See figure above). If you are

just viewing motor parameters click Cancel on Motor Parameters dialog when done. This

will dismiss dialog and return back to MotionView.

• Select motor Vendor from the right list box and desired motor from the left list box.

• If you want to use custom motor instead of available motors from supplied database then

go to Selecting custom motor topic below.

• Finally click OK button to dismiss dialog and return to Motion View main program.

5.8 Using custom motor

• You can load custom motor from file or you can create new custom motor.

• To create custom motor click Create custom and follow instruction in topic Setting custom

motor parameters below.

• To load custom motor click <Open custom> button then select motor file and click OK to

dismiss file dialog.

• Click OK to return to Motion View program or Cancel to abandon changes.

5.8.1 Setting custom motor parameters

WARNING!

Use extreme caution when entering custom parameters! Incorrect settings may cause

damage to the drive or motor! If you are unsure of the settings, refer to the materials that

were distributed with your motor, or contact the motor manufacturer for assistance.

1. Enter custom motor data in the motor parameters dialog fields. Complete all sections of

dialog: Electrical, Mechanical, Feedback. See Section 6.8.3 for explanation of motor

parameters and how to enter them.

Note

If you don’t know, or are unsure of, the motor halls order and encoder channels A and B

relationship, leave “B leads A for CW”, “Halls order” and “inverted” fields as they are. You

can execute autophasing (see below) to set them correctly.

2. Enter motor model text in Motor Model edit box. Do not enter Motor ID. For custom motors it is

0 and will be assigned automatically when you save motor data to file.

3. Click Save to File button and enter filename without extension. Default extension .cmt will be

given when you click OK on file dialog box.

Note

Saving the file is necessary even if you are going to use the autophasing feature and still

don’t know all of the final parameters. After autophasing is completed you will have a

chance to save the corrected motor file again before loading it to memory.

4. Click OK to dismiss Motor Parameters dialog.

5. MotionView will ask if you want autophase your custom motor. If you answer “No” motor data

will be loaded immediately to the drive’s memory. If you answer “Yes” motor dialog will be

dismissed and drive will start autophasing sequence. Refer to topic below for autophasing

information.

6. If you answered “Yes” when prompted for autophasing after autophasing is completed you will

be returned to the same motor selection dialog box. At this time fields “B leads A for CW” ,

“Halls order” and “inverted” fields will be assigned correct values. Click “Save File” to save

custom motor file and then “OK” to dismiss dialog and load data to drive memory.

39

Page 40

SimpleServo 500/600/i1000 User Manual Rev 3.4

5.8.2 Autophasing

Autophasing is the feature of the SimpleServo drives that helps determine some important motor

parameters when using a motor which is not in the MotionView database. Autophasing will determine

Hall order sequence, Hall sensor polarity and encoder channel relationship (B leads A or A leads B for

CW rotation).

To perform autophasing:

1. Complete steps in Section 5.8.1 “Setting custom motor parameters” above. If the motor file

you are trying to autophase already exists on your hard drive, simply load it per “Selecting

custom motor” section above.

2. Make sure that the motor’s shaft is not connected to any mechanical load and can freely

rotate.

3. Make sure that the drive is disabled.

4. Do not edit field “Hall order” and check boxes “inverted”, ”B leads A for CW” because their

values are ignored for autophasing.

5. Click OK to dismiss motor selection dialog. MotionView responds with the question “Do you

want to perform autophasing?”

6. Click OK. Safety reminder dialog appears. Click “Proceed” and wait until autophasing is

completed.

7. If there was a problem with motor connection and/or hall sensor connection, MotionView will

respond with an error message. Correct wiring problem(s) and repeat steps 1 – 6.

8. If autophasing is completed with no error then MotionView will return to motor dialog box and

parameter fields “Hall order” and check boxes “inverted”, ”B leads A for CW” will be filled with

correct values.

9. Click “Save File” to save motor file to disk (you can use the same filename as you use to save

initial data in step 1) and click OK to send motor data to the drive.

5.8.3 Custom Motor Data Entry

Motor Parameters dialog has three sections (frames) dividing motor parameters on groups:, Electrical

constants, Mechanical constants, and Feedback. When creating custom motor entry you must supply

all parameters listed in these sections. All entries are mandatory except inertia (Jm) parameter. You

may enter 0 if you are not sure of a value.

Electrical constants.

• Motor Torque Constant (Kt).

Be careful with the units! This must be set in Newton-Meters per Amp RMS (N-m/A). The torque

constant for many motors will be given in different English units such as pound-inches per Amp

(lb-in/A) or ounce-inches per Amp (oz-in/A). You will need to convert these English units to metric.

To convert lb-in/A to N-m/A, multiply by 0.1130.