Page 1

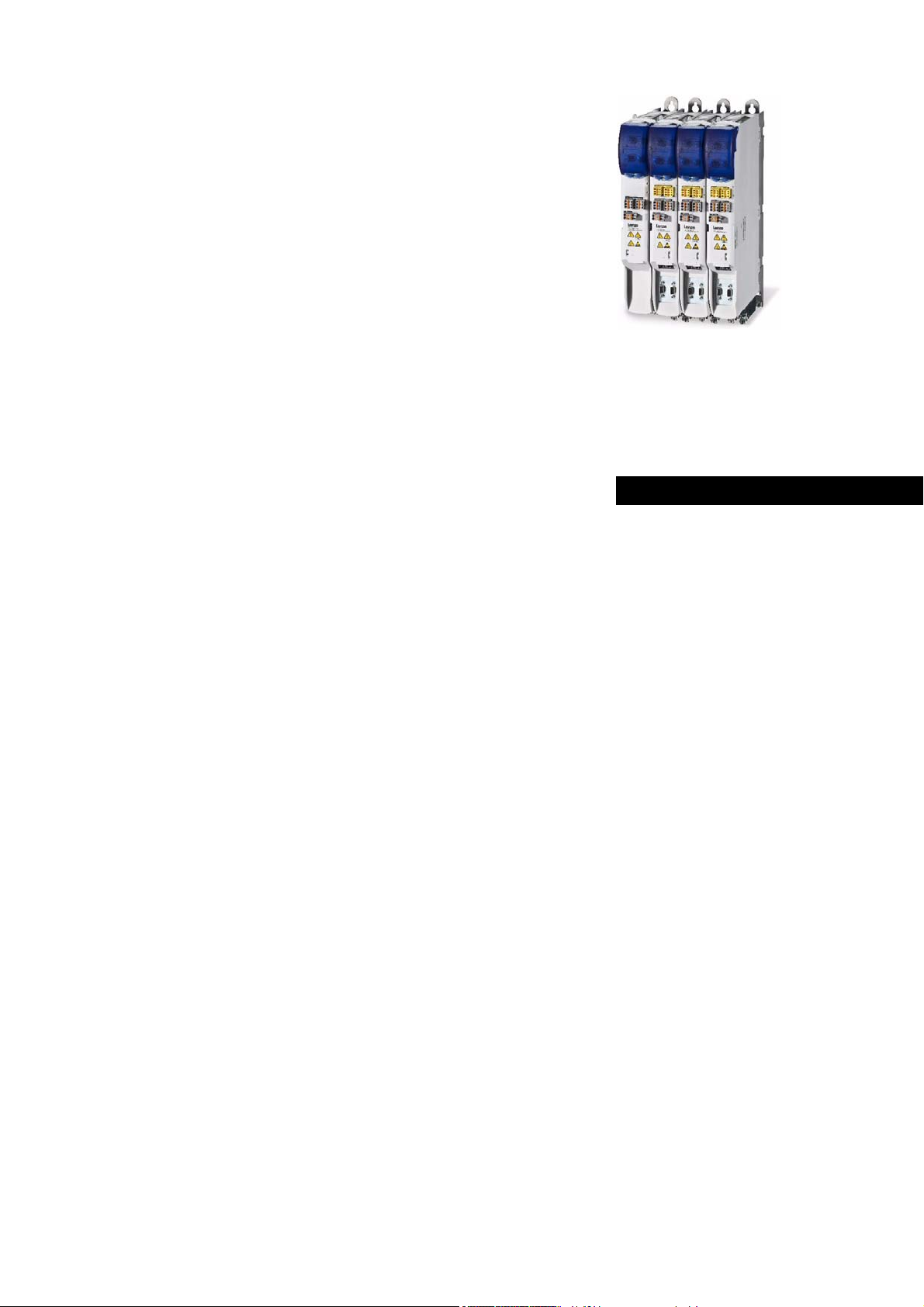

Inverter

i700

i700 servo inverter _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

E70ACM...

Reference manual EN

Ä.J(yä

13410788

L

Page 2

Contents

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

1.1 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

1.2 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

1.3 Definition of notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

1.4 Structure of the parameter descriptions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

2 Parameter handling _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

2.1 Parameter transfer during initialisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

2.2 Storage parameter set (par001.*) and total parameter set (par000.*) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 19

2.2.1 Saving a parameter set from the i700 to a file (export) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

2.2.2 Loading the stored parameter set to the i700 (import) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

2.2.3 Monitoring of the parameter import (error report) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

2.3 Cyclic redundancy check (CRC) - parameter set comparison on the basis of the checksum _ _ _ _ _ 21

0x2030 - Parameter set: Validity check (CRC)

3 Communication with the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

3.1 Acceleration of the system (initialisation) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

3.2 Process data (cyclic PDO transfer) and PDO mapping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

3.2.1 Synchronisation with "Distributed clocks" (DC) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

3.3 Parameter data transfer (SDO communication) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

3.3.1 Object directory _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

3.3.2 SDO abort codes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

3.3.3 ESI: EtherCAT Slave Information file (device description) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

3.4 Activating the control via PDO _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 28

0x2824 | 0x3024 - Device control via PDO: Activation

3.5 Lenze control and status word _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 28

0x2830 | 0x3030 - Lenze control word

0x2831 | 0x3031 - Lenze status word

0x2833 | 0x3033 - Lenze statusword 2

3.6 Ethernet over EtherCAT (EoE) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

3.6.1 System architecture _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

3.6.2 Supported protocols and services _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

3.6.3 Display of EoE-specific information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

0x2020 - EoE information

3.6.4 GCI-SDO communication (TCP port 9410) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

3.6.4.1 Structure of the EtherCAT data telegram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

3.6.4.2 Assignment of user data areas P0 ... P4 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 36

3.6.4.3 Error codes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

3.6.4.4 Telegram example 1:

Querying the heatsink temperature (read request) _ _ _ _ _ _ _ _ _ _ _ _ _ 38

3.6.4.5 Telegram example 2:

Querying the software version of the i700 (read request) _ _ _ _ _ _ _ _ _ _ 40

3.6.4.6 Telegram example 3:

Setting the LV warning threshold in the i700 (write request) _ _ _ _ _ _ _ _ 42

4 Device settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

4.1 Behaviour in case of error _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

0x10F1 - ECAT: Behaviour in case of error

4.2 Device identification data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 46

0x2000 - Device: Data

0x2001 - Device: Name

4.3 Function "Optical device recognition" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 46

0x2021 - Device: Optical recognition

4.4 Device commands _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

0x2022 - Device command

2 Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Page 3

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.5 Monitoring of the DC-bus voltage _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

0x2540 - Device: Voltage values

4.6 Real-time information (distributed clock) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 50

0x2580 - ECAT DC: Real-time information

5 Motor control & motor settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 52

5.1 Required commissioning steps (short overview) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

5.1.1 Servo control for synchronous motor (SM) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

5.1.2 Servo control for asynchronous motor (ASM) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

5.1.3 V/f characteristic control for asynchronous motor (ASM) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 56

5.2 Commissioning functions (short overview) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 57

0x2822 | 0x3022 - Axis command

0x2823 | 0x3023 - Axis command: Progress

0x2825 | 0x3025 - Axis: Operating mode

0x2832 | 0x3032 - Identification: Status word

5.2.1 Enable/inhibit operation via control word _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 59

5.2.2 Saving changed parameters safe against mains failure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 60

5.3 Wiring check by means of manual test modes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 61

0x2835 | 0x3035 - Manual test mode: Settings

5.3.1 Manual test mode "voltage/frequency" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 62

5.3.2 Manual test mode "current/frequency" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 63

5.4 Manual control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 65

0x2836 | 0x3036 - Manual jog: Settings

5.5 Setting the control mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 69

0x2C00 | 0x3400 - Motor control

5.6 Accepting/adapting plant parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 70

5.7 Compensating for inverter influence on output voltage _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 71

0x2DE0 | 0x35E0 - Advanced settings

0x2947 | 0x3147 - Inverter characteristic: Voltage grid points (y)

5.8 Setting the motor parameters for the servo control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 75

5.8.1 Lenze motor: Easy loading of motor data from the catalogue via the »PLC-Designer« _ _ 75

5.8.2 Motors of other manufacturers or no catalogue data available: Three possibilities to create the

setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 75

0x2C08 | 0x3408 - motor: Setting method - motor parameters

5.8.2.1 Enter motor nameplate data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 76

5.8.2.2 Set motor parameters manually _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 76

5.8.2.3 Determine motor parameters automatically via "motor parameter identification"

78

5.8.3 Motor parameters (object descriptions) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 81

0x2C01 | 0x3401 - Motor: Common parameters

0x2C02 | 0x3402 - Motor (ASM): Parameter

0x2C03 | 0x3403 - Motor (SM): Parameter

0x6075 | 0x6875 - Motor rated current

0x6076 | 0x6876 - Motor rated torque

5.9 Setting the feedback system for the servo control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 85

5.9.1 General settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 86

0x2C45 | 0x3445 - open circuit in the feedback system: Response

0x2C46 | 0x3446 - feedback system: Specifiable number of revolutions

0x2C5F | 0x345F - Feedback system: Parameter CRC

5.9.2 Settings for "resolver" version _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 87

0x2C43 | 0x3443 - Resolver: Number of pole pairs

0x2C44 | 0x3444 - Resolver error compensation: Parameter

5.9.3 Settings for "encoder" version _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 89

0x2C40 | 0x3440 - Encoder: Type

0x2C42 | 0x3442 - Encoder: Parameter

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05 3

Page 4

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.9.4 Additional settings for SinCos absolute value encoders with HIPERFACE® protocol _ _ _ 91

0x2C41 | 0x3441 - Hiperface: Parameter

5.9.5 Detection of changed settings of the feedback system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 94

5.10 Synchronous motor (SM): Pole position identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 95

5.10.1 Monitoring of the pole position identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 96

0x2C60 | 0x3460 - Monitoring of pole position identification: Response

5.10.2 Pole position identification PPI (360°) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 96

0x2C61 | 0x3461 - Pole position identification PPI (360°)

5.10.3 Pole position identification PPI (min. movement) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 99

0x2C62 | 0x3462 - Pole position identification PPI (min. movement)

5.10.4 Pole position identification PPI (without movement) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 102

0x2C63 | 0x3463 - pole position identification PLI (without movement)

5.11 Setting control loops _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 105

5.11.1 Setting and optimising the current controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 105

0x2941 | 0x3141 - Current controller: Feedforward control

0x2942 | 0x3142 - Current controller: Parameter

0x2943 | 0x3143 - Motor: Current setpoint - filter time

5.11.1.1 Manual test mode "Current pulse" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 108

5.11.2 Determining the total moment of inertia _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 111

0x2910 | 0x3110 - Moments of inertia

5.11.3 Setting the speed controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 113

0x2900 | 0x3100 - Speed controller: Parameter

0x2901 | 0x3101 - Speed controller: Gain - adaptation

0x2902 | 0x3102 - Speed controller: Load starting value

0x2903 | 0x3103 - Speed: Speed setpoint - filter time

0x2904 | 0x3104 - Speed: Actual speed - filter time

5.11.4 Setting the position controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 116

5.11.5 Setting the field controller (ASM) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 118

5.11.6 Setting the field weakening controller (ASM) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 119

5.11.7 Field weakening operation - synchronous motor (SM) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 121

5.12 Fine adjustment des motor model _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 122

5.12.1 Correction of the stator leakage inductance (Lss)... _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 122

5.12.2 Synchronous motor (SM): Compensating for temperature and current influences _ _ _ 128

5.12.3 Asynchronous motor (ASM): Identifying the Lh saturation characteristic _ _ _ _ _ _ _ _ _ 129

5.12.4 Estimating the optimal magnetising current _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 131

0x2980 | 0x3180 - Position controller: Gain

0x2981 | 0x3181 - Position controller: Gain - adaptation

0x2982 | 0x3182 - Position controller: Output signal limitation

0x2983 | 0x3183 - Position: Select a new actual position

0x2984 | 0x3184 - Determine target position: Mode

0x29C0 | 0x31C0 - Field controller: Parameter

0x29E0 | 0x31E0 - Field weakening controller: Parameter

0x29E1 | 0x31E1 - field: Field set value limitation

0x29E2 | 0x31E2 - DC link circuit voltage: Filter time

0x29E3 | 0x31E3 - motor: Actual voltage - filter time

0x29E4 | 0x31E4 - Voltage reserve range

0x2C04 | 0x3404 - Motor: Lss saturation characteristic - inductance grid points (y)

0x2C05 | 0x3405 - Motor: Lss saturation charcteristic - reference for current grid points (x)

5.12.1.1 Example for determining the saturation characteristic _ _ _ _ _ _ _ _ _ _ _ 125

0x2C06 | 0x3406 - Motor (SM): Magnet characteristic (current) - grid points

0x2C07 | 0x3407 - Motor (ASM): Lh saturation characteristic - inductance grid points (y)

4 Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Page 5

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.13 Parameterising filter elements in the setpoint path _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 132

5.13.1 Jerk limitation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 132

0x2945 | 0x3145 - Torque: Setpoint jerk limitation

5.13.2 Notch filters (band-stop filters) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 132

0x2944 | 0x3144 - Torque: Notch filter setpoint torque

5.14 Parameterising the V/f characteristic control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 136

5.14.1 Defining the V/f characteristic shape _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 137

0x2B00 | 0x3300 - VFC: V/f characteristic - shape

0x2B01 | 0x3301 - VFC: V/f characteristic - define reference point

0x2B02 | 0x3302 - VFC: User-definable V/f characteristic - frequency grid points (x)

0x2B03 | 0x3303 - VFC: User-definable V/f characteristic - voltage grid points (y)

5.14.2 Activating the voltage vector control (lmin controller) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 140

0x2B04 | 0x3304 - VFC: Voltage vector control - setpoint current

0x2B05 | 0x3305 - VFC: Voltage vector control parameter

5.14.3 Setting the voltage boost _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 141

0x2B06 | 0x3306 - VFC: Voltage boost

5.14.4 Setting the load adjustment _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 142

0x2B07 | 0x3307 - VFC: Load adjustment parameter

5.14.5 Defining the behaviour at the current limit (Imax controller) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 143

0x2B08 | 0x3308 - VFC: Imax controller - Parameter

5.14.6 Setting the slip compensation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 145

0x2B09 | 0x3309 - VFC: Slip compensation - Parameter

5.14.7 Setting the oscillation damping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 146

0x2B0A | 0x330A - VFC: Oscillation damping - Parameter

5.14.8 Optimising pull-out slip limitation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 148

0x2B0C | 0x330C - VFC: Override point of field weakening

5.14.9 Display parameter _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 148

0x2B0B | 0x330B - VFC: Setpoint frequency

5.14.10 "Flying restart" function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 149

0x2BA0 | 0x33A0 - Flying restart: Activate

0x2BA1 | 0x33A1 - Flying restart: Current

0x2BA2 | 0x33A2 - Flying restart: Start frequency

0x2BA3 | 0x33A3 - Flying restart: Integration time

0x2BA4 | 0x33A4 - Flying restart: Min. deviation

0x2BA5 | 0x33A5 - Flying restart: Delay time

0x2BA6 | 0x33A6 - Flying restart: Result

5.15 "DC-injection braking" function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 153

0x2B80 | 0x3380 - DC-injection braking: Current

5.16 "Short-circuit braking" function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 154

5.17 Setting the switching frequency _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 155

0x2939 | 0x3139 - Switching frequency

5.18 Frequency and speed limitations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 156

6 Holding brake control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 157

6.1 Operating modes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 157

6.1.1 Triggering via control word via external control (Lenze setting) _ _ _ _ _ _ _ _ _ _ _ _ _ _ 158

6.1.2 Triggering via state machine of device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 158

6.1.3 No brake connected _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 159

6.2 Display of the holding brake status _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 159

6.3 Basic signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 159

6.4 Settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 161

0x2820 | 0x3020 - brake control: settings

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05 5

Page 6

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 CiA402 device profile _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 163

7.1 Supported drive modes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 165

7.2 Applied units and scaling for position and velocity _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 165

7.3 General CiA402 parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 166

0x60FD | 0x68FD - Digital inputs

0x6404 | 0x6C04 - Motor manufacturer

0x6502 | 0x6D02 - Supported drive modes

0x67FF | 0x6FFF - Device profile number

7.4 Device control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 168

0x6040 | 0x6840 - CiA402 controlword

0x6041 | 0x6841 - Statusword

0x605A | 0x685A - Quick stop option code

0x6060 | 0x6860 - Modes of operation

0x6061 | 0x6861 - Modes of operation display

0x6085 | 0x6885 - Quick stop deceleration

7.4.1 Commands for the device status control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 171

7.4.1.1 Shutdown _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 172

7.4.1.2 Switch on _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 173

7.4.1.3 Enable operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 174

7.4.1.4 Activate quick stop _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 175

7.4.1.5 Disable operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 176

7.4.1.6 Disable voltage _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 177

7.4.1.7 Fault reset _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 178

7.4.2 Device states _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 179

7.4.2.1 Not ready to switch on _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 181

7.4.2.2 Switch on disabled _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 182

7.4.2.3 Ready to switch on _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 183

7.4.3 Selection of the operating mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 189

7.5 Parameters for the scaling of physical values _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 190

0x607E | 0x687E - Polarity

0x6080 | 0x6880 - Max. motor speed

0x608F | 0x688F - Position encoder resolution

0x6090 | 0x6890 - Velocity encoder resolution

7.6 Parameters for actuation of the position control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 192

0x6062 | 0x6862 - Position demand value

0x6063 | 0x6863 - Position actual internal value

0x6064 | 0x6864 - Position actual value

0x6065 | 0x6865 - Following error window

0x6066 | 0x6866 - Following error time out

0x6067 | 0x6867 - Position window

0x6068 | 0x6868 - Position window time

0x60F4 | 0x68F4 - Following error actual value

0x60FA | 0x68FA - Control effort

0x60FC | 0x68FC - Position demand internal value

7.4.2.4 Switched on _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 184

7.4.2.5 Operation enabled _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 185

7.4.2.6 Quick stop is active _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 186

7.4.2.7 Fault reaction active _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 187

7.4.2.8 Fault _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 188

6 Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Page 7

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.7 Velocity mode (vl) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 195

7.7.1 Default mapping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 195

7.7.2 Object description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 196

0x6042 | 0x6842 - vl target velocity

0x6043 | 0x6843 - vl velocity demand

0x6044 | 0x6844 - vl velocity actual value

0x6046 | 0x6846 - vl velocity min max amount

0x6048 | 0x6848 - vl velocity acceleration

0x6049 | 0x6849 - vl velocity deceleration

7.7.3 Signal flow (servo control) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 198

7.7.4 Signal flow (V/f characteristic control) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 200

7.8 Cyclic sync position mode (csp) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 202

7.8.1 Default mapping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 203

7.8.2 Object description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 204

0x607A | 0x687A - Target position

0x60C0 | 0x68C0 - Interpolation sub mode select

0x60C2 | 0x68C2 - Interpolation time period

0x60E0 | 0x68E0 - Positive torque limit value

0x60E1 | 0x68E1 - Negative torque limit value

7.8.3 Signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 206

7.8.4 Control commands & status information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 208

7.9 Cyclic sync velocity mode (csv) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 209

7.9.1 Default mapping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 210

7.9.2 Object description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 211

0x606C | 0x686C - Velocity actual value

0x60B1 | 0x68B1 - Velocity offset

0x60FF | 0x68FF - Target velocity

7.9.3 Signal flow (servo control) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 212

7.9.4 Signal flow (V/f characteristic control) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 214

7.9.5 Control commands & status information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 216

7.10 Cyclic sync torque mode (cst) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 217

7.10.1 Default mapping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 218

7.10.2 Object description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 219

0x2946 | 0x3146 - Cyclic sync torque mode: Speed limitation

0x6071 | 0x6871 - Torque demand

0x6072 | 0x6872 - Max torque

0x6073 | 0x6873 - Max current

0x6074 | 0x6874 - Torque demand

0x6077 | 0x6877 - Torque actual value

0x6078 | 0x6878 - Current actual value

0x6079 | 0x6879 - DC link circuit voltage

0x60B2 | 0x68B2 - Torque offset

7.10.3 Signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 223

7.10.4 Control commands & status information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 225

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05 7

Page 8

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.11 Touch probe (TP) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 226

7.11.1 Default mapping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 227

7.11.2 General functional principle _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 228

7.11.3 Filtering the touch probe signal _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 229

0x2500 - Touch probe (TP): Debounce time

7.11.4 Compensation of runtime delays _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 229

0x2D00 | 0x3500 - Touch probe (TP): Dead time compensation

7.11.5 Touch probe function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 231

0x60B8 | 0x68B8 - Touch probe function

7.11.6 Touch probe status _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 232

0x60B9 | 0x68B9 - Touch probe status

7.11.7 Time stamps and positions detected _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 233

0x2D01 | 0x3501 - Touch probe (TP): Time stamp

0x60BA | 0x68BA - Touch probe pos1 pos value

0x60BB | 0x68BB - Touch probe pos1 neg value

0x60BC | 0x68BC - Touch probe pos2 pos value

0x60BD | 0x68BD - Touch probe pos2 neg value

8 Monitoring functions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 235

8.1 24-V supply voltage monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 235

8.2 Monitoring of the power section and device utilisation (Ixt) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 236

0x2D40 | 0x3540 - Ixt utilisation

8.3 Monitoring of the heatsink temperature _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 239

0x2D84 | 0x3584 - Heatsink temperature

8.4 Monitoring of the motor utilisation (I²xt) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 241

0x2D4E | 0x354E - Motor utilisation (I²xt): Motor overload warning threshold

0x2D4F | 0x354F - Motor utilisation (I²xt): Actual utilisation

0x2D50 | 0x3550 - motor utilisation (I²xt): Motor overload error

0x2D4C | 0x354C - Motor utilisation (I²xt): Parameter for the thermal model

0x2D4D | 0x354D - Motor utilisation (I²xt): User-definable characteristic

8.4.1 Example of how to enter the characteristic for standard and servo motors _ _ _ _ _ _ _ 246

8.4.2 UL 508-compliant I²xt motor overload monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 248

8.5 Motor temperature monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 250

0x2D49 | 0x3549 - Motor temperature monitoring: Parameters

8.5.1 Spec. charact. curve for motor temperature sensor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 252

8.6 Motor speed monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 253

0x2D44 | 0x3544 - Motor speed monitoring

8.7 Motor phase failure monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 254

0x2D45 | 0x3545 - Motor phase failure detection

8.7.1 Limits of the motor phase failure monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 255

8.7.2 Monitoring 2: In the "enable operation" state transition _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 256

8.7.3 Monitoring 1: In "operation enabled" status _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 256

8.7.4 Monitoring with regard to short circuit and earth fault _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 257

8.8 Monitoring of the ultimate motor current _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 258

0x2D46 | 0x3546 - Monitoring: Ultimate motor current

8 Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Page 9

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9 Diagnostics & error management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 259

9.1 LED status displays _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 260

9.2 Indication of fault and warning (error code) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 261

0x603F | 0x683F - Error code

0x284F | 0x304F - Current fault

9.2.1 Response of the device in the event of an error _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 262

0x605E | 0x685E - Response to error

0x2826 | 0x3026 - Quick stop: Duration in the event of a fault

9.2.2 Resetting the error/fault _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 264

0x2840 | 0x3040 - Delay time: Reset error

0x2841 | 0x3041 - Reset error

9.3 History buffer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 265

0x10F3 - Diagnostics: History buffer

9.4 CiA402 error codes / error messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 267

Error code 0x0000: No error

Error code 0x2320: Short circuit or earth leakage on motor side

Error code 0x2340: Short circuit on motor side

Error code 0x2351: Motor utilisation (I²xt) > [value] %

Error code 0x2380: Fault - utilisation of the power section (Ixt) too high

Error code 0x2381: Warning - Utilisation of the power section (Ixt) too high

Error code 0x2382: Fault - device utilisation (Ixt) too high

Error code 0x2383: Warning - device utilisation (Ixt) too high

Error code 0x2384: Ultimate motor current reached

Error code 0x2385: Output current > [value] A (maximum device current)

Error code 0x2386: Clamp is active

Error code 0x2387: Clamp responded too often

Error code 0x3210: DC link circuit - overvoltage [value] V

Error code 0x3220: DC link circuit - undervoltage [value] V

Error code 0x4210: Module temperature too high, [value]

Error code 0x4280: Internal fault - module temperature monitoring

Error code 0x4310: Motor temperature too high, [value]

Error code 0x4380: Motor temperature sensor

Error code 0x5112: 24-V supply

Error code 0x6010: Watchdog reset

Error code 0x6310: Incorrect parameter set download

Error code 0x6320: Parameter error in object [value]

Error code 0x7121: PLI - motor blocked

Error code 0x7303: Error in feedback system

Error code 0x7380: Hiperface communication error

Error code 0x7381: Hiperface: Invalid absolute value - motor speed too high

Error code 0x8180: ECAT DC - synchronisation required

Error code 0x8181: EtherCAT communication

Error code 0x8280: Sync Manager - address [value]

Error code 0x8281: Sync Manager - actual size [value]

Error code 0x8282: Sync Manager - settings [value]

Error code 0x8283: PDO Mapping: Object unknown (index [value])

Error code 0x8284: No PDO mapping object (index [value])

Error code 0x8285: Too many mapped objects (max. number = [value])

Error code 0x8286: PDO mapping - error

Error code 0x8700: Sync controller

Error code 0x8701: Time-out during synchronisation with EtherCAT Sync signal

Error code 0xFF00: Fatal internal error

Error code 0xFF01: Fatal internal communication error, cycle [value]

Error code 0xFF02: Brake

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05 9

Page 10

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Error code 0xFF03: Fatal internal error - overflow task [value]

Error code 0xFF04: PLI - motor movement too large

Error code 0xFF05: STO inhibited

Error code 0xFF06: Max. speed reached

Error code 0xFF07: Impermissible during identification or in the test mode

Error code 0xFF08: Impossible during identification

Error code 0xFF09: Motor phase failure

Error code 0xFF0A: Motor phase failure - phase U

Error code 0xFF0B: Motor phase failure - phase V

Error code 0xFF0C: Motor phase failure - phase W

Error code 0xFF0D: No resolver connected --> command cannot be executed.

Error code 0xFF0E: Speed too low --> command cannot be executed.

Error code 0xFF0F: No resolver connected --> command cannot be executed.

Error code 0xFF10: Time-out

Error code 0xFF11: Numerical problem

Error code 0xFF12: Inverter error too big

Error code 0xFF13: Identification aborted

Error code 0xFF14: Not allowed in state 'operation enabled' or 'quick stop active'

Error code 0xFF15: No Hiperface absolute value encoder connected --> command cannot be executed

Error code 0xFF16: Connected Hiperface absolute value encoder is not supported

Error code 0xFF17: Connected Hiperface absolute value encoder is not supported --> command cannot be executed

Error code 0xFF18: Communication timeout in the manual control mode

Error code 0xFF19: Internal error during identification

9.5 Identification data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 280

0x1000 - Device: Type

0x1001 - Error memory

0x1008 - ECAT: Manufacturer's device name

0x1009 - Device: Hardware version

0x100A - Device: Software version

0x1018 - ECAT: Identification data

9.6 Diagnostics parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 281

0x10F8 - ECAT DC: Current time

0x2D81 | 0x3581 - Counter: Operating time

0x2D82 | 0x3582 - motor: Actual voltage - Veff, phase-phase

0x2D83 | 0x3583 - Motor: Phase currents

0x2D8A | 0x358A - Speed monitoring: Actual speed error

10 Service/internal _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 283

0x2DD0 | 0x35D0 - field: Values

0x2DD1 | 0x35D1 - motor: Currents

0x2DD2 | 0x35D2 - Position: Target position interpolated

0x2DD3 | 0x35D3 - Target speeds

0x2DD4 | 0x35D4 - Speed controller: Output signal

0x2DD5 | 0x35D5 - torque: Target torque

0x2DD6 | 0x35D6 - Torque: Filter cascade

0x2DD7 | 0x35D7 - Voltage values

0x2DDC | 0x35DC - Slip: Actual slip

0x2DDD | 0x35DD - Device: Actual output frequency

0x2DDE | 0x35DE - motor: Actual position of rotor angle

0x2DDF | 0x35DF - Axis: Device data

10.1 Firmware update _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 288

10 Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Page 11

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11 Appendix _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 289

11.1 Table of attributes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 289

11.2 Structure of the parameter set file _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 310

11.2.1 File header _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 310

11.2.2 Data header _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 311

11.3 Communication objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 313

0x1600 - RPDO-->Axis A: Cyclic sync position mode (csp)

0x1601 - RPDO-->Axis A: Cyclic sync torque mode (cst)

0x1602 - RPDO-->Axis A: Cyclic sync velocity mode (csv)

0x1603 - RPDO-->Axis A: Velocity mode (vl)

0x1604 - RPDO-->Axis A: Touch probe (TP)

0x1605 - RPDO-->Axis A: Freely configurable (user)

0x1606 - RPDO-->Axis A: Torque limits

0x1607 - RPDO --> Axis A: Speed Limits

0x1610 - RPDO-->Axis B: Cyclic sync position mode (csp)

0x1611 - RPDO-->Axis B: Cyclic sync torque mode (cst)

0x1612 - RPDO-->Axis B: Cyclic sync velocity mode (csv)

0x1613 - RPDO-->Axis B: Velocity mode (vl)

0x1614 - RPDO-->Axis B: Touch probe (TP)

0x1615 - RPDO-->Axis B: Freely configurable (user)

0x1616 - RPDO-->Axis B: Torque limits

0x1617 - RPDO --> Axis B: Speed limits

0x1A00 - Axis A-->TPDO: Cyclic sync position mode (csp)

0x1A01 - Axis A-->TPDO: Cyclic sync torque mode (cst)

0x1A02 - Axis A-->TPDO: Cyclic sync velocity mode (csv)

0x1A03 - Axis A-->TPDO: Velocity mode (vl)

0x1A04 - Axis A-->TPDO: Touch probe (TP)

0x1A05 - Axis A-->TPDO: Freely configurable (user)

0x1A06 - Axis A-->TPDO: Additional status information

0x1A10 - Axis B-->TPDO: Cyclic sync position mode (csp)

0x1A11 - Axis B-->TPDO: Cyclic sync torque mode (cst)

0x1A12 - Axis B-->TPDO: Cyclic sync velocity mode (csv)

0x1A13 - Axis B-->TPDO: Velocity mode (vl)

0x1A14 - Axis B-->TPDO: Touch probe (TP)

0x1A15 - Axis B-->TPDO: Freely configurable (user)

0x1A16 - Axis B-->TPDO: Additional status information

0x1C00 - Sync Manager: Communication type

0x1C12 - Sync Manager 2 (RPDO-->Device): PDO mapping

0x1C13 - Sync Manager 3 (RPDO-->Device): PDO mapping

0x1C32 - Sync Manager 2 (RPDO-->Device): Parameter

0x1C33 - Sync Manager 3 (Device-->TPDO): Parameter

11.4 Licences _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 324

Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 325

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 336

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05 11

Page 12

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

Danger!

The controller is a source of danger which may lead to death or severe injury of persons.

To protect yourself and others against these dangers, observe the safety instructions

before switching on the controller.

Please read the safety instructions in the mounting instructions and in the hardware

manual for the i700 servo inverter. Both instructions are included in the scope of supply

of the drive controller.

Target group

This documentation addresses to all persons who want to parameterise, configure, and diagnose

the i700 servo inverter.

Validity

The information in this documentation are valid for the following standard devices:

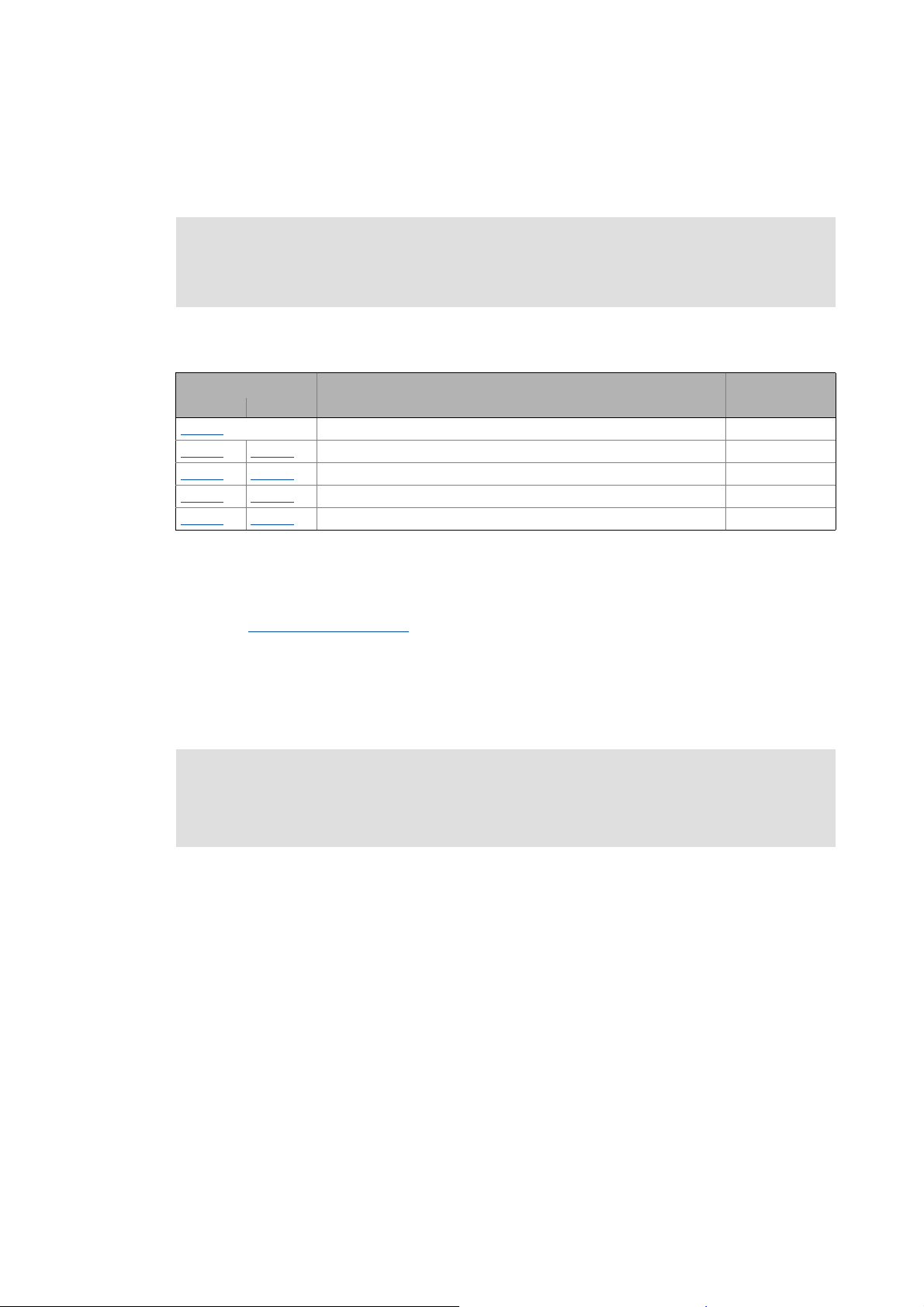

Product series Type designation From software version

i700 servo inverter E70ACM... 01.00

Screenshots/application examples

All screenshots in this documentation are application examples. Depending on the firmware

version of the i700 servo inverter and the software version of the engineering tools installed (»PLC

Designer« or »EASY Starter«), the screenshots in this documentation may deviate from the screen

representation.

Document history

Version Description

1.5 03/2014 TD05 Extensions & corrections; Adaptation to software version V01.06

1.4 10/2013 TD05 Extensions & corrections;

Adaptation to software versions V01.04 and V01.05

1.3 03/2013 TD05 Extensions & corrections; Adaptation to software version V01.03

1.2 10/2012 TD05 Extensions & corrections; Adaptation to software version V01.02

1.1 07/2012 TD05 First edition

Tip!

Information and tools regarding the Lenze products can be found in the Internet:

http://www.lenze.com

12 Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Download

Page 13

1 About this documentation

1.1 Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.1 Conventions used

This documentation uses the following conventions to distinguish between different types of

information:

Type of information Writing Examples/notes

Spelling of numbers

Decimal separator Point The decimal point is always used.

Example: 1234.56

Hexadecimal number 0x For hexadecimal numbers, the prefix "0x" is used.

Example: 0x60F4

Binary number 0b For binary numbers, the prefix "0b" is used.

Example: 0b00010111

Text

Version information Blue text colour All information that only applies to a certain controller

Program name » « The Lenze »PLC Designer« PC software...

Window italics The Message window ... / The Options dialog box...

Variable name Set bEnable to TRUE to...

Control element bold The OK button... / The Copy command... / The Properties

Sequence of menu

commands

Shortcut <bold> Press <F1> to open the online help.

Program code Courier

Keyword Courier bold

software version or higher is identified accordingly in this

documentation.

Example: This function extension is available from software

version V3.0!

tab... / The Name input field...

If the execution of a function requires several commands,

the individual commands are separated by an arrow: Select

Open to...

File

If a command requires a combination of keys, a "+" is placed

between the key symbols:

Use <Shift>+<ESC> to...

IF var1 < var2 THEN

a = a + 1

END IF

Hyperlink underlined

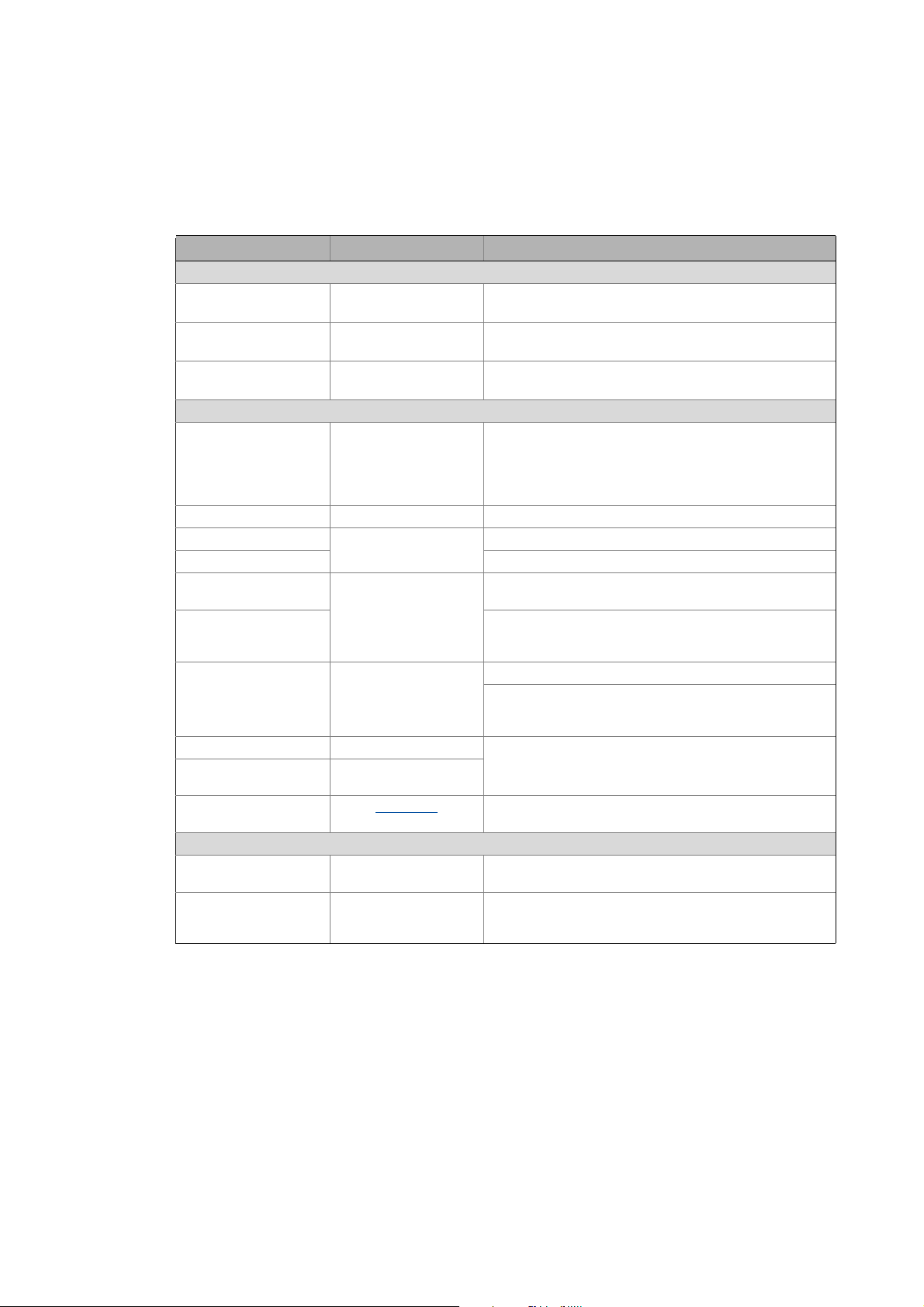

Icons

Page reference ( 13) Optically highlighted reference to another page. In this

Step-by-step instructions

Optically highlighted reference to another topic. In this

documentation it is activated by mouse-click.

documentation it is activated by mouse-click.

Step-by-step instructions are indicated by a pictograph.

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05 13

Page 14

1 About this documentation

1.2 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2 Terminology used

Term Meaning

Engineering Tools Software solutions for simple engineering at all stages

»EASY Navigator« – Ensures easy operator guidance

• All practical Lenze engineering tools at a glance

• Tools can be selected quickly

• Clearly arranged, simplifying the engineering process from the start

»EASY Starter« – Simple tool for service technicians

• Especially developed for the commissioning and maintenance of Lenze

devices

• Graphical user interface with few buttons

• Simple online diagnostics, parameterisation and commissioning

• No risk of accidentally changing the application

• Ready applications can be loaded to the device

»PLC Designer« – for process programming

• Creation of individual programs

• Programming of Logic & Motion in accordance with IEC 61131-3 (IL, LAD,

FBD, ST, SFC, and CFC editor), is based on CoDeSys V3

• Certified function blocks according to PLCopen Part 1 + 2

• Graphical DIN 66025 editor (G-code) with DXF import

• Integrated visualisation for an easy process representation

• All important pieces of information at a glance during commissioning

Lenze Controller The Lenze Controller (abbreviated: "Controller") is the central component of the

Engineering PC Use the Engineering PC and the engineering tools installed to configure and

HIPERFACE® HIPERFACE® stands for High Performance Interface and is a universal interface between

Object "Container" for one or several parameters which can be used to parameterise or monitor

Index For the purpose of addressing, each object is provided with a unique index.

Subindex If an object contains several parameters, the individual parameters are stored under

Touch probe A "Touch probe" is an event which can for instance be actuated in an edge-controlled

automation system which (by means of the runtime software) controls the Logic and

Motion functionalities.

The Lenze Controller communicates with the field devices via the fieldbus.

parameterise the system.

The Engineering PC communicates with the Lenze Controller via Ethernet.

EtherCAT® is a real-time capable Ethernet system with top performance.

EtherCAT® is a registered trademark and patented technology licensed by Beckhoff

Automation GmbH, Germany.

motor feedback system and inverter.

HIPERFACE® is a registered trademark of the SICK STEGMANN GmbH.

the i700 servo inverter.

In this documentation the index is represented as a hexadecimal value and is identified

by a prefixed "0x", e.g. "0x1000".

"subindexes".

In this documentation the colon is used as a separator between the index and the

subindex, e.g. "0x1018:1".

manner via a digital input to detect an actual value (that changes quickly) at the time of

activation and to process it further within the program afterwards.

14

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Page 15

1 About this documentation

1.3 Definition of notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

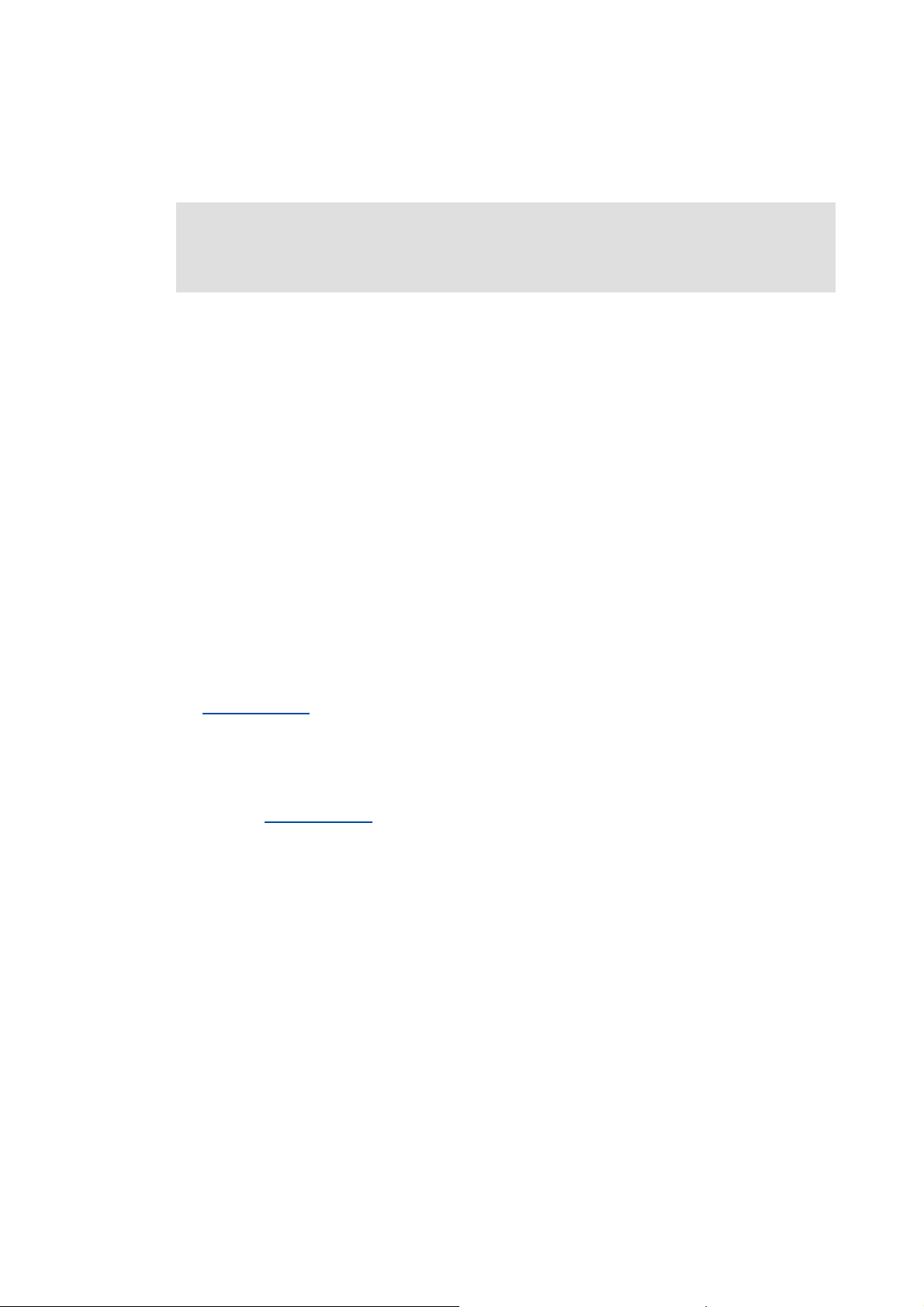

1.3 Definition of notes used

The following signal words and symbols are used in this documentation to indicate dangers and

important information:

Safety instructions

Layout of the safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

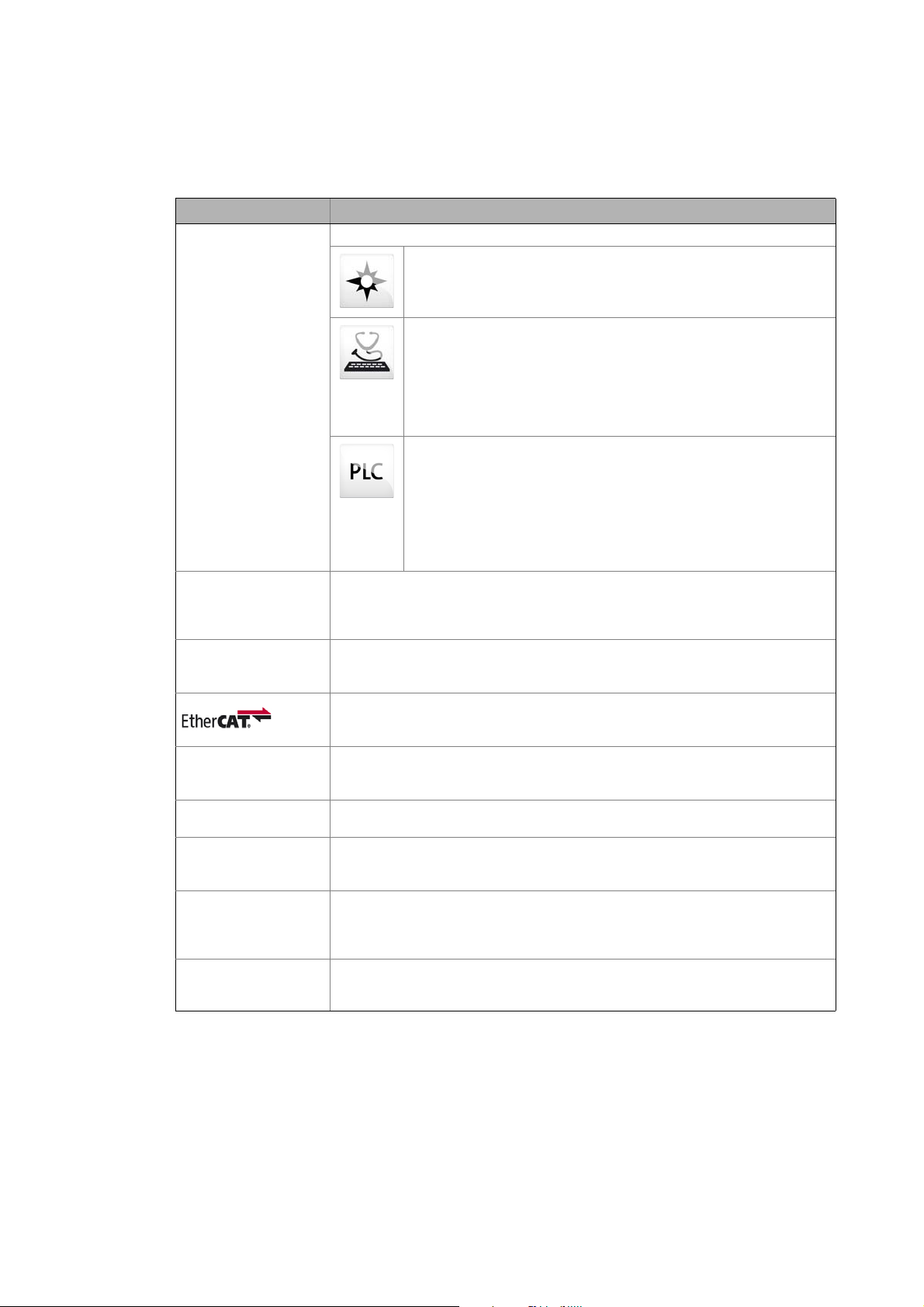

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for simple handling

Reference to another document

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05 15

Page 16

1 About this documentation

1.4 Structure of the parameter descriptions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.4 Structure of the parameter descriptions

All parameters which you can use to parameterise or monitor the i700 servo inverter are stored

within "objects".

• For the purpose of addressing, each object is provided with a unique index. In this

documentation the index is represented as a hexadecimal value and is identified by a prefixed

"0x", e.g. "0x1000".

• If an object contains several parameters, they are stored in "subindexes". In this documentation

the colon is used as a separator between the index and the subindex, e.g. "0x1018:1".

Note!

This documentation is valid for the i700 servo inverter in the single axis version (single

inverter) and also as double axis (double inverter).

For parameters referring to one axis, both indexes (for axis A and axis B) are listed in the

parameter description. For a single axis, only the first index is relevant in this case.

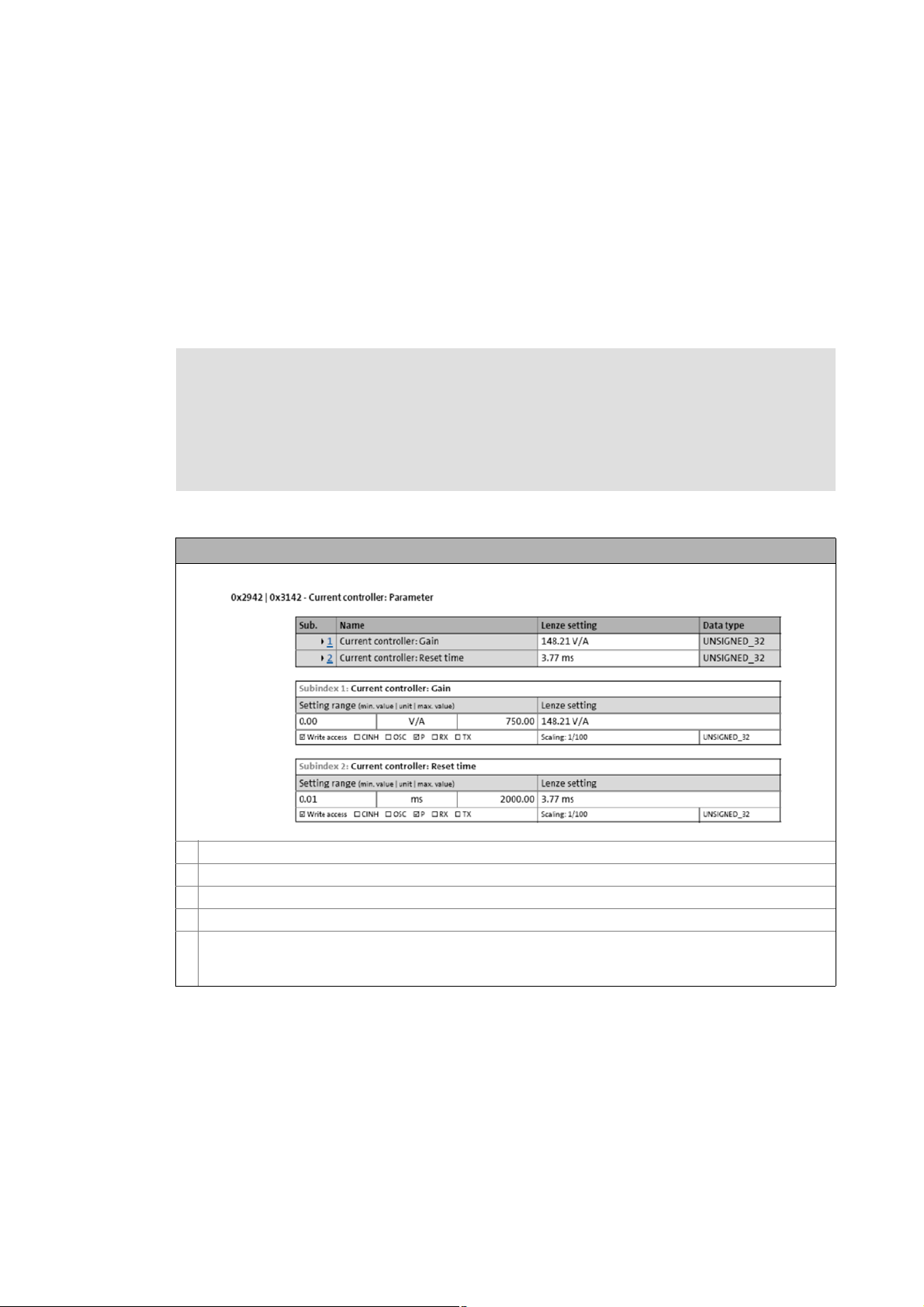

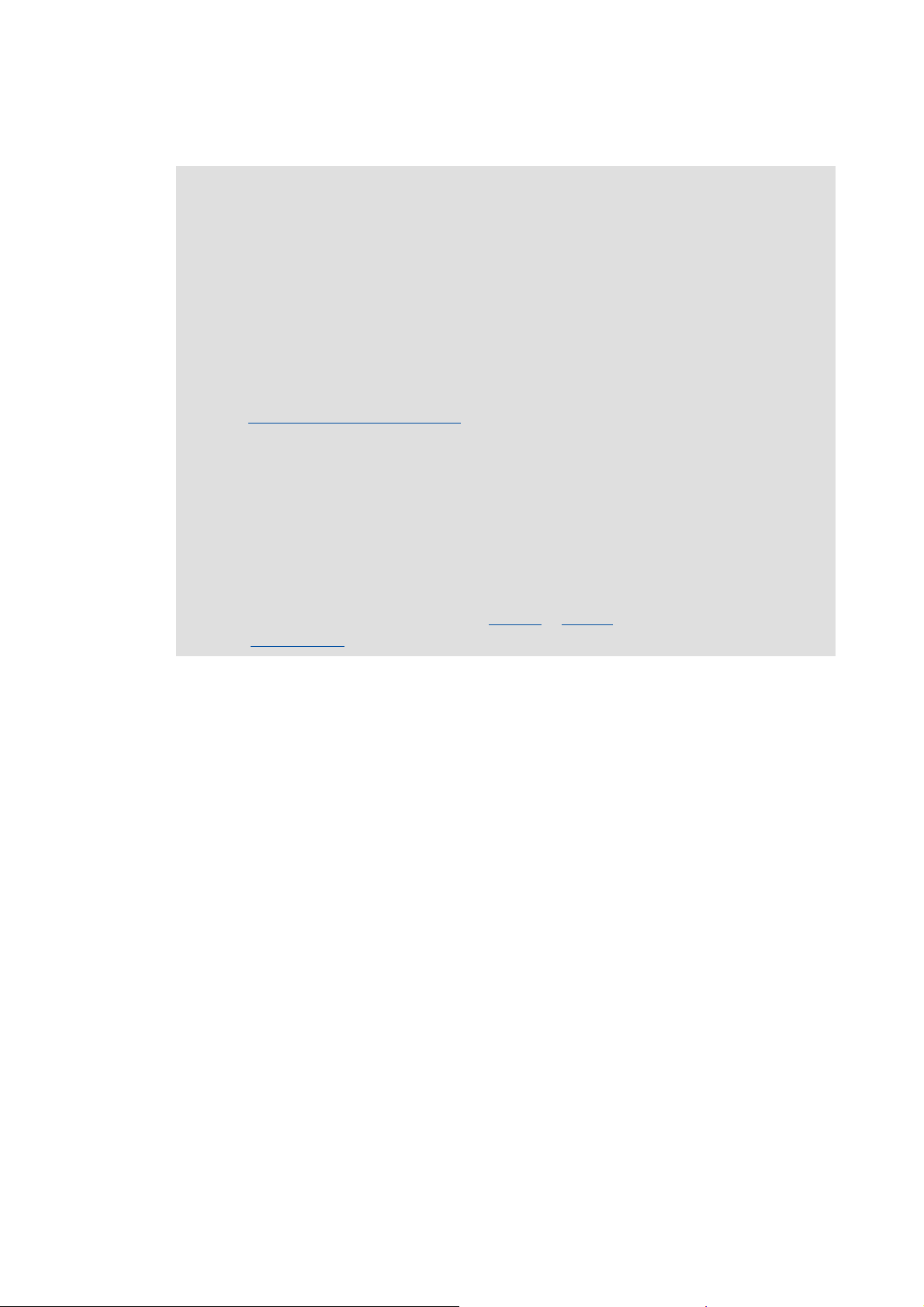

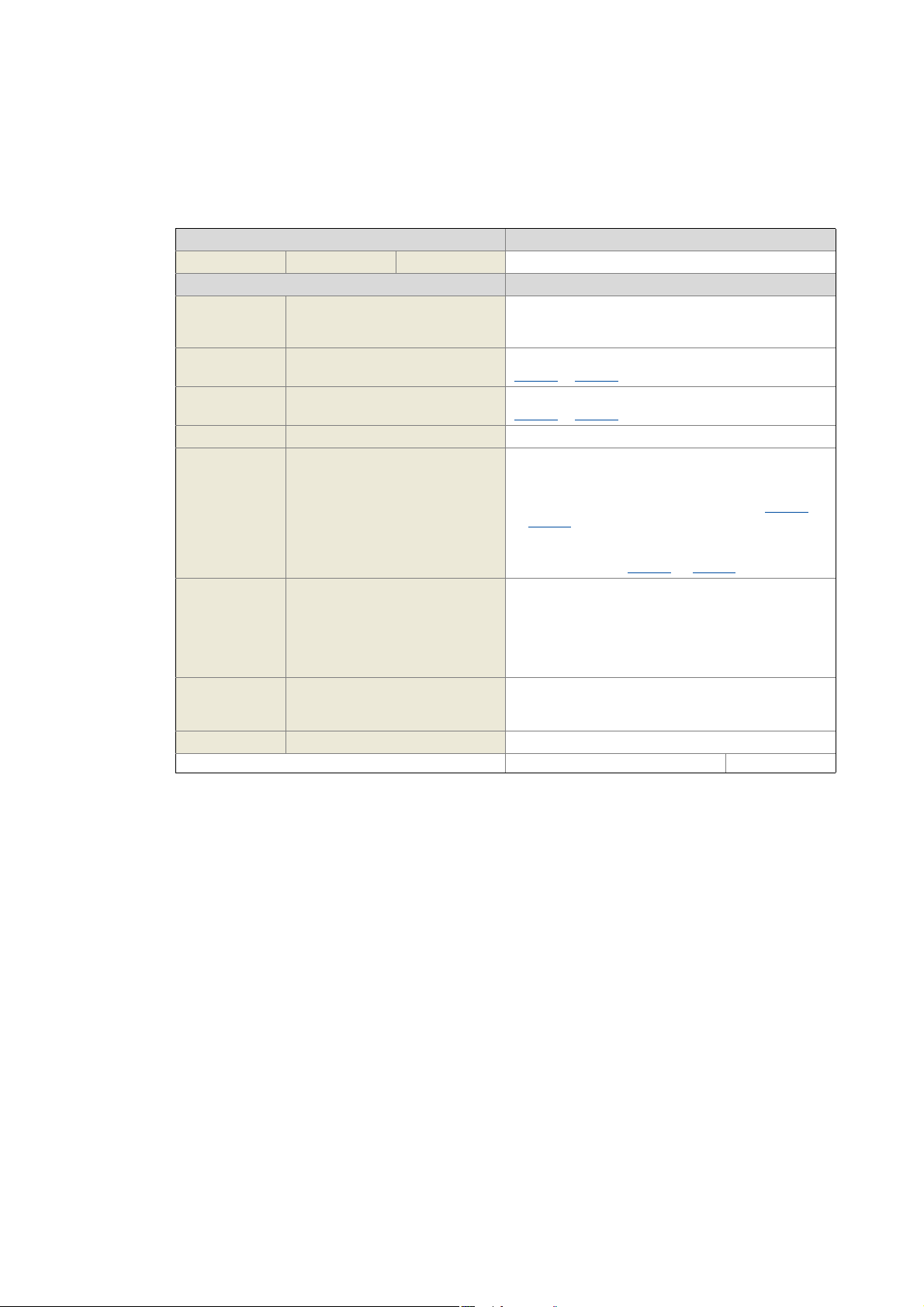

Each parameter description is structured according to the following pattern:

Example: Structure of the parameter descriptions in this documentation

Object index for axis A

Object index for axis B (only relevant for double axis)

Parameter or object name

If the object contains several parameters: Overview table with list of all subindexes

Table with detailed information about the corresponding parameter:

• Explanations & references (optional)

• Display options/possible settings, Lenze setting, attributes (for the meaning see the following table)

16

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Page 17

1 About this documentation

1.4 Structure of the parameter descriptions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

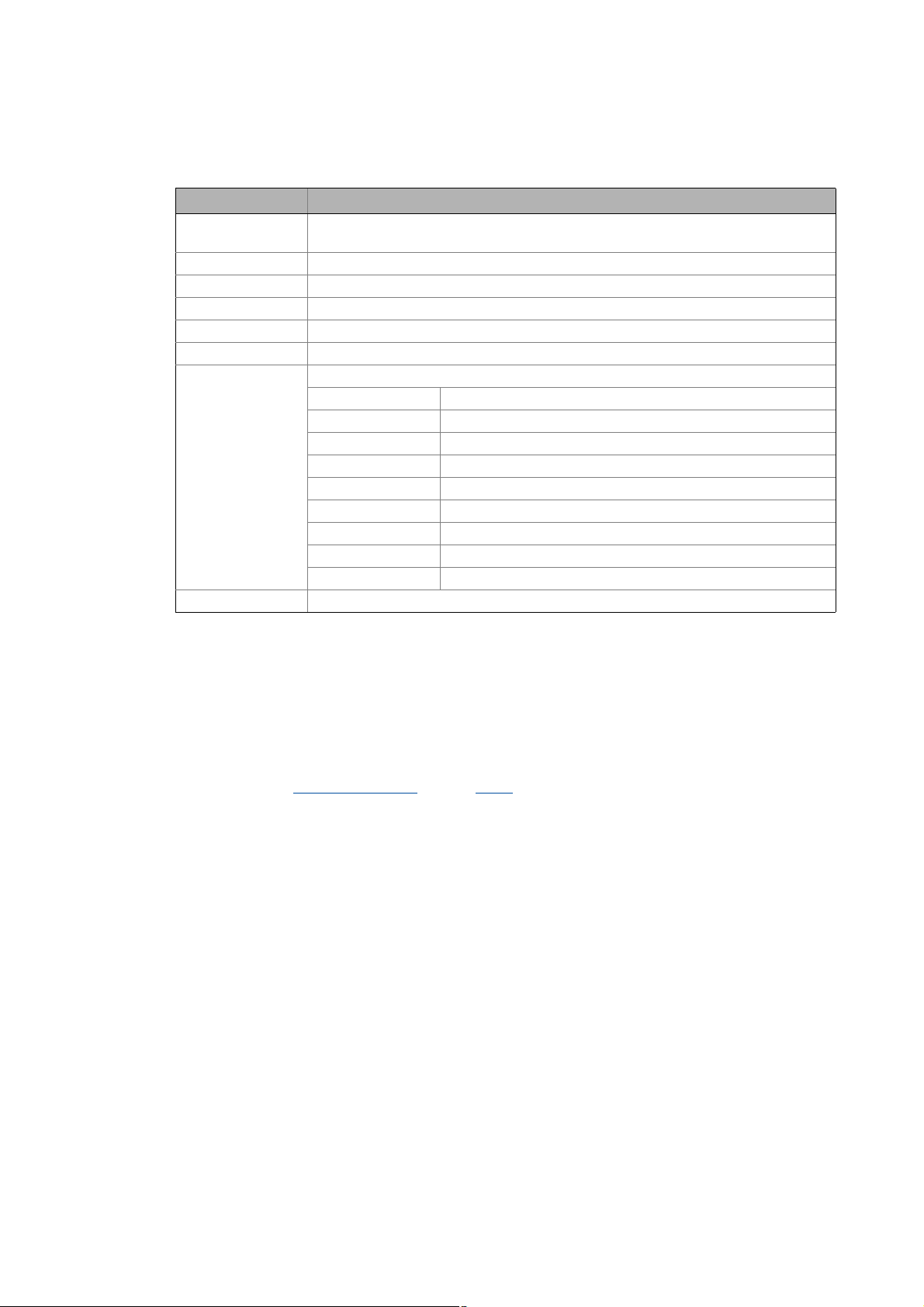

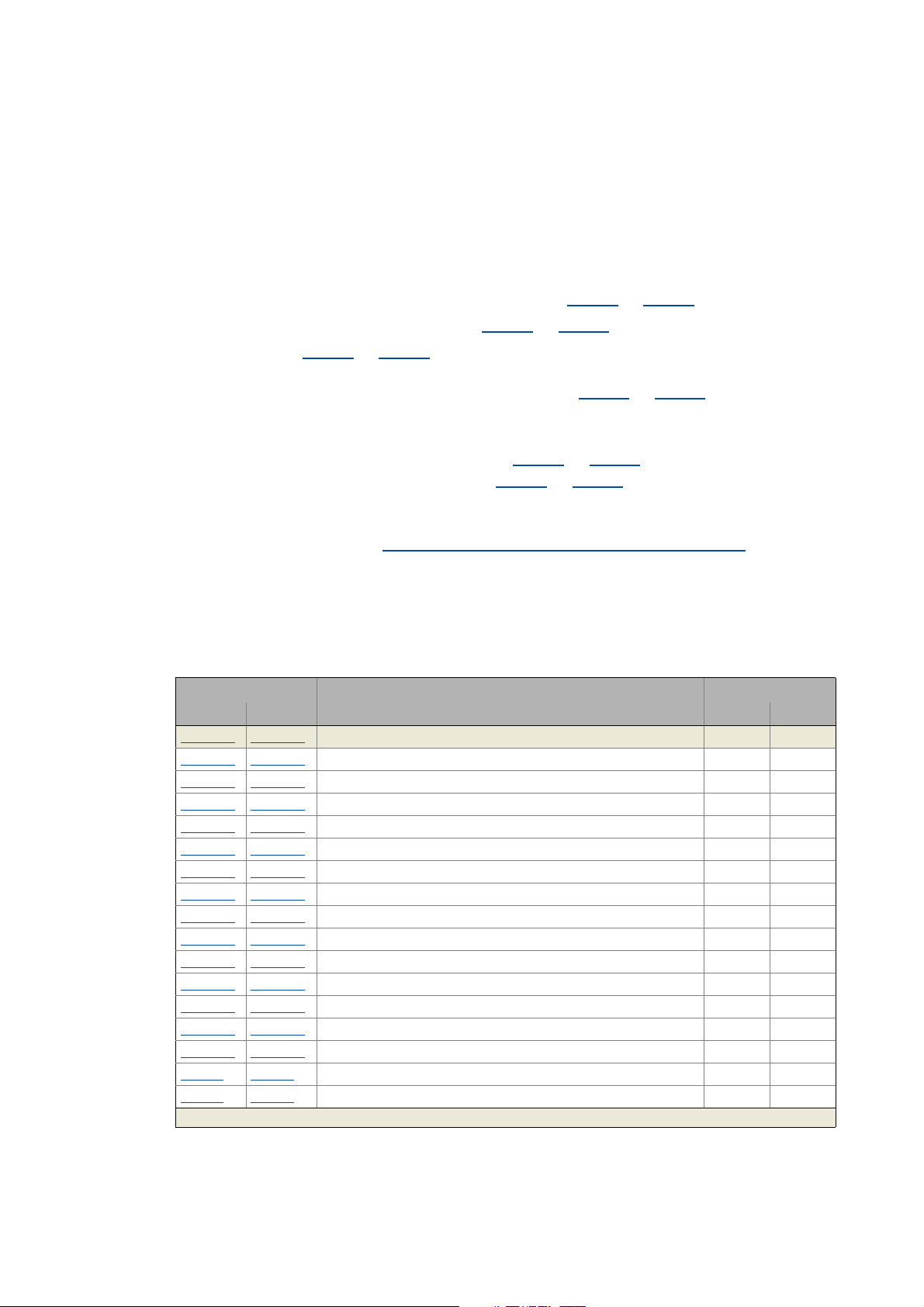

Parameter attributes

Name Meaning

Write access = Parameter can be written to.

= Parameter can only be read.

CINH = Parameter can only be written to if controller inhibit is set.

OSC = Parameter can be recorded by means of the oscilloscope function.

P = Parameter can be persisted.

Tx = Parameter can be mapped into the TPDO.

Rx = Parameter can be mapped into the RPDO.

Data type Data type of the parameter:

INTEGER_8 1 byte, with sign

INTEGER_16 2 bytes with sign

INTEGER_32 4 bytes with sign

UNSIGNED_8 1 byte without sign

UNSIGNED_16 2 bytes without sign

UNSIGNED_32 4 bytes without sign

UNSIGNED_64 8 bytes without sign

STRING(xx) ASCII string (with character length xx)

ARRAY [] OF... ARRAY

Scaling Scaling of the parameter

Tip!

To find a specific object or parameter in this documentation, you can use the following

navigation helps:

• At the beginning of each main chapter, all objects which are described in the respective

chapter are listed in a table.

•In the Table of attributes

reference to the detailed description.

and the Index, all objects/parameters are listed with a

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05 17

Page 18

2 Parameter handling

2.1 Parameter transfer during initialisation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Parameter handling

2.1 Parameter transfer during initialisation

During the acceleration of the system, the controller and the controllers exchange configuration

data (e.g. bus cycle and PDO mapping). With regard to this, observe the following particular features

for the i700 servo inverter:

Parameter download

The i700 servo inverter itself does not

settings deviating from the i700 servo inverter "Lenze setting" (default) are maintained centrally in

the controller and are stored there permanently (persistently). During the initialisation at run-up,

only these deviations are transferred to the i700 servo inverter by the controller. Like this it is

ensured that the i700 servo inverter works with the parameter settings provided for it.

Firmware download (optional)

store parameter settings safe against mains failure. All

If required, the firmware of the i700 servo inverter can be stored together with the »PLC Designer«

project. During the run-up, the controller then checks whether the firmware version in the i700

servo inverter complies with the firmware version stored in the project for this device. If this is not

the case, the controller loads the firmware version stored in the project to the i700 servo inverter.

Like this, it can be ensured for "Device replacement" service work that the replacement device also

works with the same firmware version as the original device.

18

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Page 19

2 Parameter handling

2.2 Storage parameter set (par001.*) and total parameter set (par000.*)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.2 Storage parameter set (par001.*) and total parameter set (par000.*)

For the storage of the i700 servo inverter parameters, two different parameter sets are provided,

which are stored in different parameter set files in the higher-level controller:

Storage parameter set (par001.i7psf)

• Only contains the parameters of the i700 servo inverter which are writable and identified with

the "P" attribute (persistent).

• Parameters can be read out from the i700 servo inverter and saved to the file. Conversely, the

parameters stored can be written to the i700 servo inverter again.

• Recommended for storage and archiving of the controllers settings.

Total parameter set (par000.i7psf)

• Contains all parameters of the i700 servo inverter, including the mere display parameters which

vary permanently during operation.

• The total parameter set can only be read from the i700 servo inverter.

• Use for purposes of service and diagnostics.

The structure of the parameter set file is described in the appendix.

Structure of the parameter set file ( 310)

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05 19

Page 20

2 Parameter handling

2.2 Storage parameter set (par001.*) and total parameter set (par000.*)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.2.1 Saving a parameter set from the i700 to a file (export)

Reading out and storing the parameters from the i700 servo inverter is initiated and controlled from

the higher-level controller. For reading out a parameter set, the corresponding parameter values are

summarised in a parameter set file (par001.* or par000.*) in the i700 servo inverter and are then

transferred as a file to the controller via EtherCAT.

2.2.2 Loading the stored parameter set to the i700 (import)

Loading a stored parameter set file to the i700 servo inverter is initiated and controlled from the

higher-level controller, just like in the case of the read-out. The storage parameter set file is

transferred to the i700 servo inverter as a file via EtherCAT, and the parameter settings are loaded

(imported).

For logical reasons, it is only possible to transfer "storage parameter set files" (par001.*) to the i700

servo inverter. Display parameters are updated under normal operating conditions and do not need

to be loaded.

Note!

In the case of Lenze controllers, the parameter set files are transferred as "files" via GCI

("Generic Communication Interface").

• GCI is a Lenze-specific application protocol which uses CoE ("CANopen over

EtherCAT").

• Other control manufacturers may also use FoE ("File Access over EtherCAT") for the

transfer.

2.2.3 Monitoring of the parameter import (error report)

When the parameter import has been completed, the "parErr.i7psf" error report file is created. This

file is recreated automatically during every import.

On the basis of the error report it can be determined whether errors have occurred during the

parameter import:

• Parameters that have been transferred with errors are listed there together with their index,

subindex, and error code (SDO abort code).

• If no errors have occurred, this data area of the file is blank. However, the headers including the

checksum are available and valid nevertheless.

20

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Page 21

2 Parameter handling

2.3 Cyclic redundancy check (CRC) - parameter set comparison on the basis of the checksum

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.3 Cyclic redundancy check (CRC) - parameter set comparison on the basis of the checksum

Each parameter set features an individual checksum (CRC32), which is composed of the settings of

all storable indexes (P-flag) of the parameter set. When a setting changes, there is also a change in

the checksum.

Cyclic redundancy check (CRC):

By comparison of the checksums of parameter sets it can be determined very quickly whether

parameter sets are identical or not. In particular, it is thus determined for the i700 servo inverter

whether the parameter set stored in the controller is identical to that in the i700 servo inverter and

therefore does not have to be loaded again.

0x2030 - Parameter set: Validity check (CRC)

Checksum for quick comparison of the storage parameter set (par001.i7psf)

• If the checksum shown here is identical to the checksum of the parameter set file stored in the Lenze Controller,

it is not necessary to write the parameter set file to the i700 servo inverter.

• If the checksums are different, however, there are deviations between the parameter set available in the Lenze

Controller and that in the i700 servo inverter.

• The checksum cannot be used for comparison of the total parameter set (par000.i7psf).

Display area (min. value | unit | max. value) Initialisation

0 4294967295

Write access CINH OSC P RX TX UNSIGNED_32

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05 21

Page 22

3 Communication with the controller

3.1 Acceleration of the system (initialisation)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 Communication with the controller

"EtherCAT control technology" communication manual

Here you will find detailed information on the EtherCAT configuration and

commissioning of Lenze devices in the EtherCAT network.

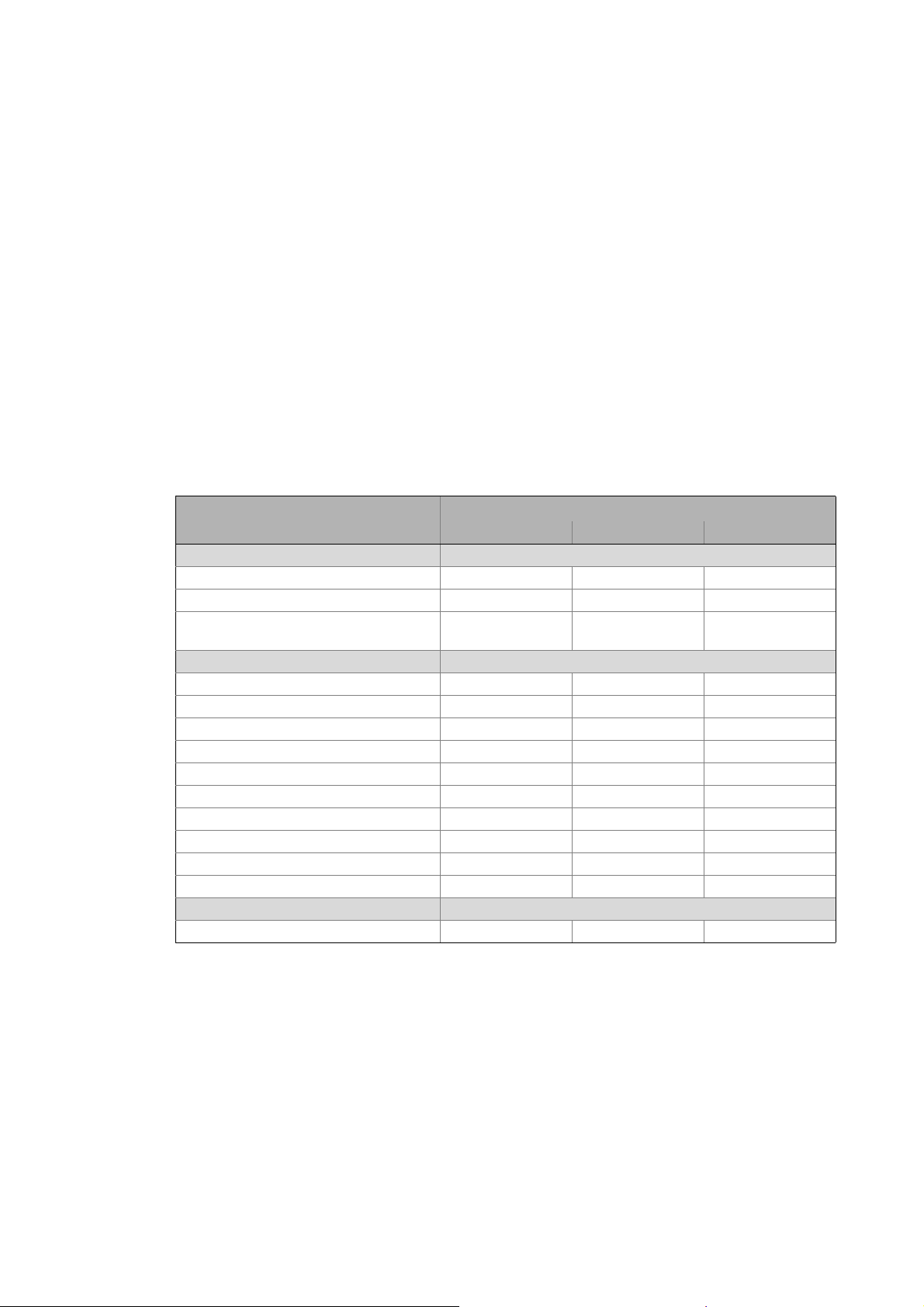

Objects described in this chapter

Object Name Data type

Axis A Axis B

0x2020 EoE information RECORD

0x2824

0x2830

0x2831

0x2833

0x3024 Device control via PDO: Activation UNSIGNED_8

0x3030 Lenze control word UNSIGNED_16

0x3031 Lenze status word UNSIGNED_16

0x3033 Lenze statusword 2 UNSIGNED_16

Tip!

The communication objects important for the integration of the controller with external

control are described in the appendix.

Communication objects

( 313)

3.1 Acceleration of the system (initialisation)

Stop!

Before switching on the i700 servo inverter for the first time, check the entire wiring with

regard to completeness, short circuit, and earth fault.

To establish communication, the i700 servo inverter must be supplied with voltage. During the

acceleration of the system, the controller and the drive exchange configuration data.

The controller transmits the following configuration data to the i700 servo inverter:

•Bus cycle

• This is the basic cycle within which the EtherCAT bus is actuated. The bus cycle is given as a

multiple of 125 μs.

• The bus cycle equals the communication cycle within which the process data are exchanged

cyclically. New process data are only accepted and generated in the Servo-Inverter i700

maximally every 250 μs.

22

• Parameter set determined during commissioning.

• Among other things, it includes information about feedforward control values, the mains

voltage and the switching frequency as well as controller parameters adapted to the motor

module which are used for the motor control.

• Configuration of the process data transmitted cyclically via EtherCAT (PDO mapping)

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Page 23

3 Communication with the controller

3.1 Acceleration of the system (initialisation)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Note!

If no data for the initialisation of the controller are transmitted, the i700 servo inverter

uses the "Lenze setting" for the parameters.

Power up/Power down

In the case of "Power up" and "Power down", no undefined states can occur that cause

damage to the device or motor movements which are not requested or not braked.

In the case of a voltage failure/dip, there is no immediate response by the i700 servo

inverter. The functionality is to be maintained for as long as possible.

24-V supply voltage monitoring

Persistent data storage

A complete, persistent storage of the drive configuration which remains the same even

though the controller is switched off from time to time is carried out in the higher-level

controller instead of in the i700 servo inverter. Hence, the controller needs to transmit

the configuration data again to the i700 servo inverter after a power up.

( 235)

However, in the case of a power down, the following device data are stored persistently

in the i700 servo inverter:

• Power-on and elapsed-hour meter (0x2D81

• History buffer

( 265)

or 0x3581 for axis B)

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05 23

Page 24

3 Communication with the controller

3.2 Process data (cyclic PDO transfer) and PDO mapping

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.2 Process data (cyclic PDO transfer) and PDO mapping

"EtherCAT control technology" communication manual

Here you will find some detailed information on the configuration of the process data

objects (PDO mapping) with the »PLC Designer«.

Cyclic process data are transferred cyclically between the controller (master) and the controllers

(slaves) as so-called Process Data Objects (PDOs).

• The i700 servo inverter supports the following bus cycle times of the EtherCAT:

0.125 ms*

0.250 ms

0.500 ms

1.000 ms

... (only integer multiple of 1 ms)

10.000 ms (max. cycle time)

* Note: With a bus cycle time of 0.125 ms, the process data is updated only every 0.250 ms, as

this is the fastest control cycle for the setpoint and actual value transfer.

• The processing time of a process date through the drive is t=max[bus cycle, 0.250 ms]. If the

entire chain from the control via the drive back to the control is considered, a process data needs

2 bus cycles in addition (for Lenze C3200) . Thus, the turnaround time for a PDO can be indicated

with 3 bus cycles.

• For the process data communication, the i700 servo inverter supports the mapping of max. 32

process data objects (PDOs) with a total max. size of 100 bytes per direction of transmission.

• A fixed PDO mapping preconfigured by Lenze is available for every CiA402 operating mode

supported by the i700 servo inverter. Every PDO mapping includes of several objects from the

Object directory

• For every axis, further fixed, preconfigured PDO mappings can be used for touch probe

functionality.

• In addition to the fixed, preconfigured PDO mappings, freely configurable PDO mappings are

available for every axis which can be used for individual PDO mapping. A maximum of 8 objects

from the Object directory

.

can be configured per direction of transmission.

24

• The configuration of the PDOs actually transmitted between the controller and the i700 servo

inverter is carried out via the »PLC Designer«.

• Experience shows that most i700 servo inverters are operated in one of the available CiA402

operating modes (csp, csv, cst or vl). We therefore recommend to use and activate the fixed

PDO mapping preconfigured by Lenze for the selected operating mode. In doing so all

parameters that usually need to be replaced during a cyclic PDO transfer can be accessed.

• If you wish to use touch probe functionality in addition, optionally and additionally activate

the fixed, preconfigured PDO mapping for touch probe functionality.

• Moreover, the PDO mappings that can be freely configured by the user can be optionally

activated. However, we recommend to use these freely configurable PDO mappings in special

cases only, if no standard PDO mapping is suitable for the case of application at hand. Special

thought should be given to the aspect of traceability in case of service.

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Page 25

3 Communication with the controller

3.2 Process data (cyclic PDO transfer) and PDO mapping

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

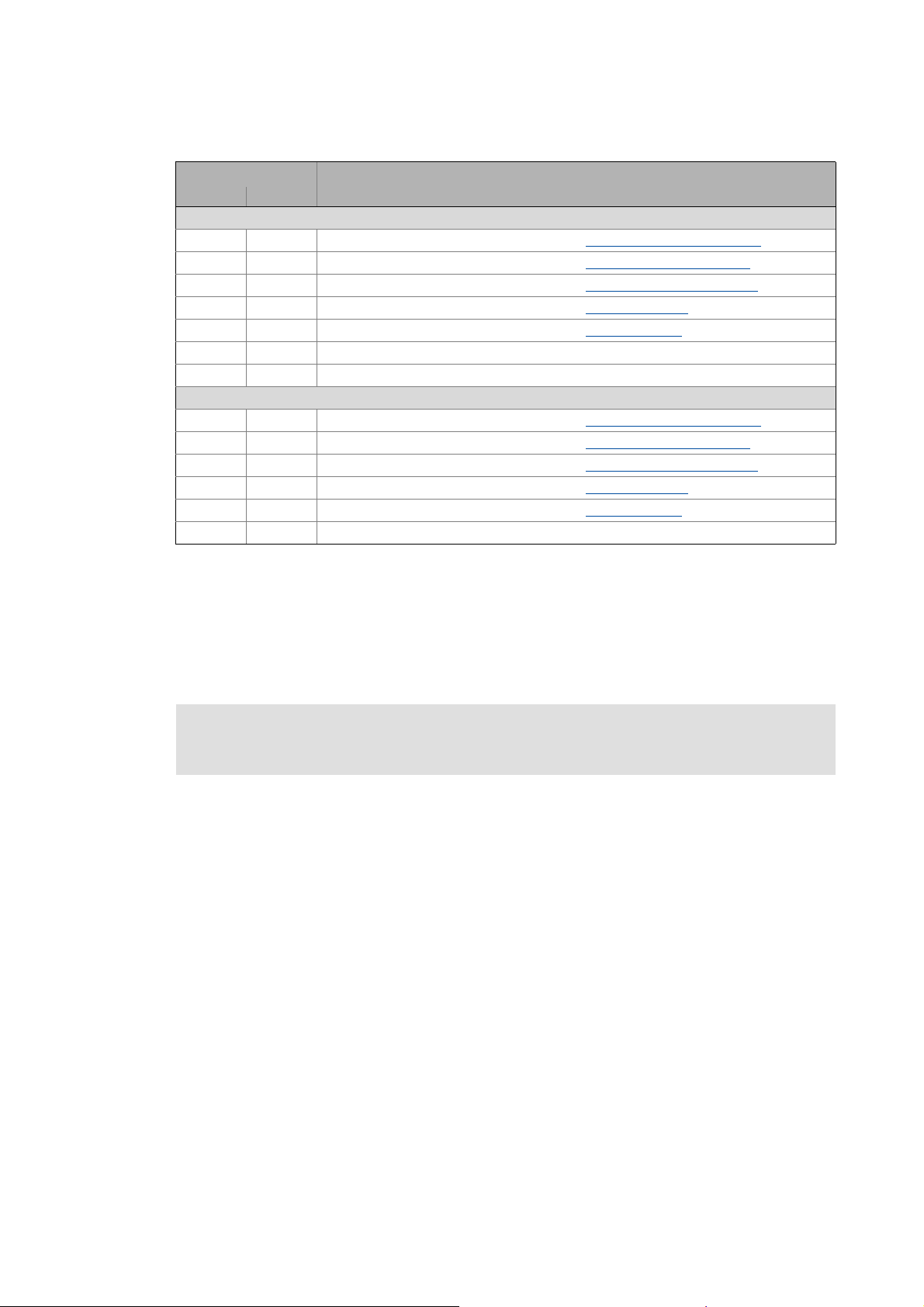

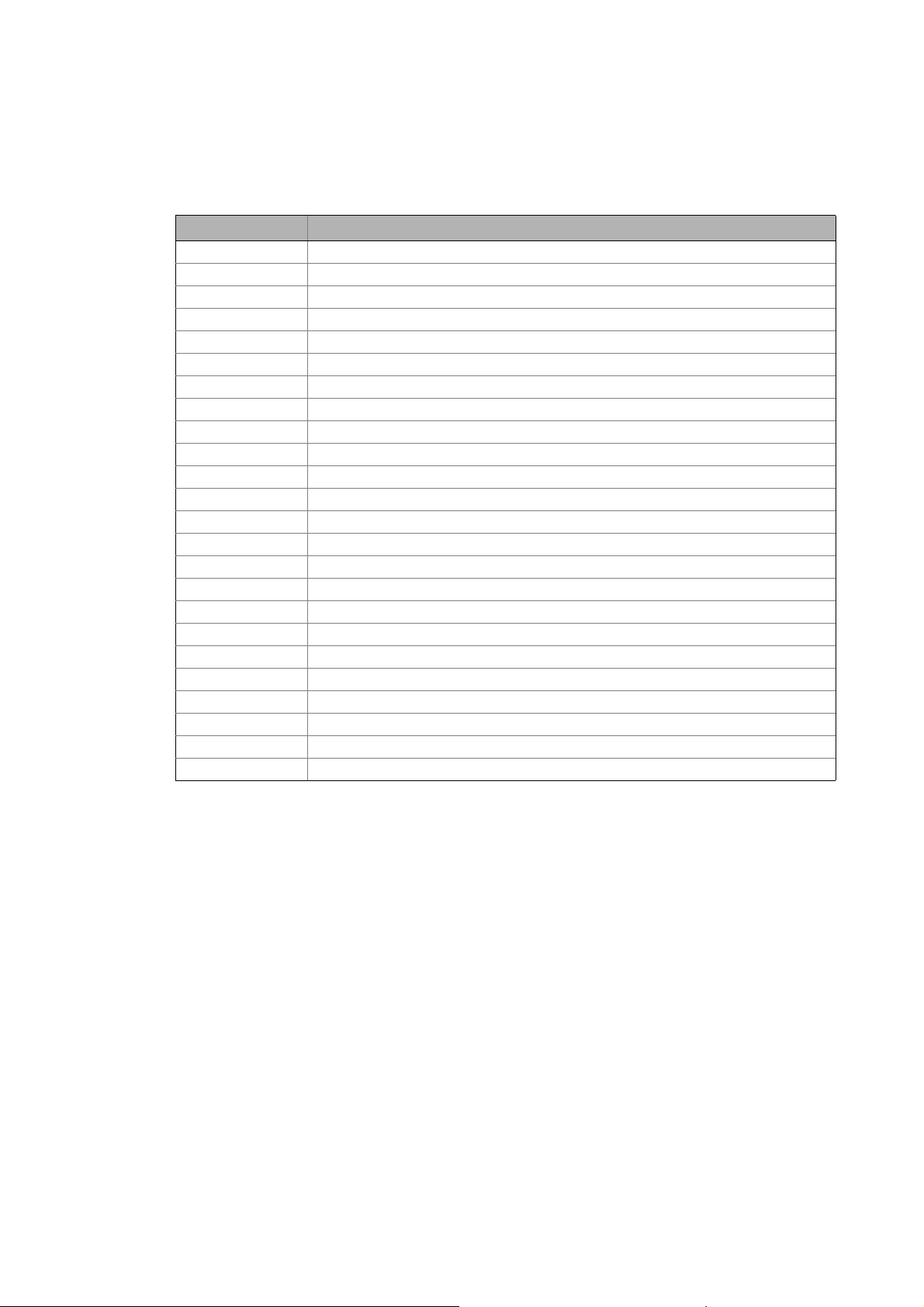

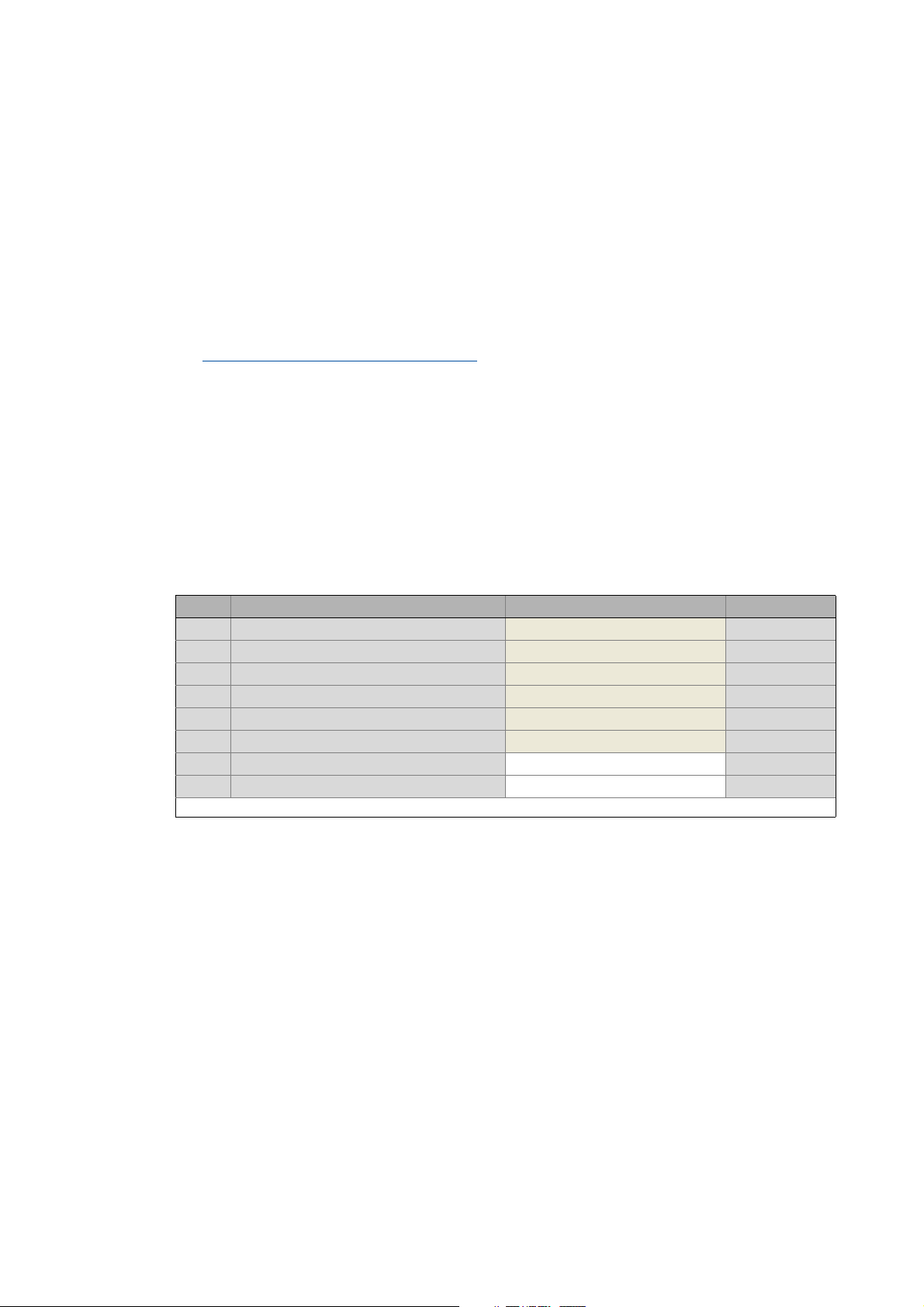

Object Info

Axis A Axis B

RPDO mapping – configuration of the process data (setpoints) from the controller to the i700 servo inverter

0x1600 0x1610 Fixed, preconfigured PDO mapping object for "Cyclic sync position mode (csp)

0x1601 0x1611 Fixed, preconfigured PDO mapping object for "Cyclic sync torque mode (cst)

0x1602 0x1612 Fixed, preconfigured PDO mapping object for "Cyclic sync velocity mode (csv)

0x1603 0x1613 Fixed, preconfigured PDO mapping object for "Velocity mode (vl)

0x1604 0x1614 Fixed, preconfigured PDO mapping object for "Touch probe (TP)

0x1605 0x1615 Freely configurable PDO mapping object

0x1606 0x1616 Fixed, preconfigured PDO mapping object for torque limit values

TPDO mapping – configuration of process data (actual values) from the i700 servo inverter to the controller

0x1A00 0x1A10 Fixed, preconfigured PDO mapping object for "Cyclic sync position mode (csp)

0x1A01 0x1A11 Fixed, preconfigured PDO mapping object for "Cyclic sync torque mode (cst)

0x1A02 0x1A12 Fixed, preconfigured PDO mapping object for "Cyclic sync velocity mode (csv)

0x1A03 0x1A13 Fixed, preconfigured PDO mapping object for "Velocity mode (vl)

0x1A04 0x1A14 Fixed, preconfigured PDO mapping object for "Touch probe (TP)

0x1A05 0x1A15 Freely configurable PDO mapping object

"

"

"

"

"

"

"

"

"

"

3.2.1 Synchronisation with "Distributed clocks" (DC)

The "Distributed clocks" (DC) function enables an exact time adjustment for applications where

several auxiliary axes carry out a coordinated movement at the same time. The data is accepted

synchronously with the PLC program. In the case of the DC synchronisation, all slaves are

synchronised with a reference clock, called the "DC master".

"EtherCAT control technology" communication manual

Here you will find some detailed information about DC synchronisation.

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05 25

Page 26

3 Communication with the controller

3.3 Parameter data transfer (SDO communication)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.3 Parameter data transfer (SDO communication)

In addition to the cyclic process data transfer, parameter data can be transferred as so-called SDOs

(Service Data Objects) in a non-cyclic manner within an individual datagram between the controller

(master) and the controllers (slaves).

• SDO communication is implemented according to the EtherCAT-CoE protocol, using a mailbox.

• SDO communication enables read or write access to all indices contained in the object directory

of the i700 servo inverter.

• The turnaround time for an SDO (request by the control, transport via the bus, processing in the

drive, transport of the response back to the control) is between 1ms and 100ms plus 2*bus

cycle time (typically 10 ms).

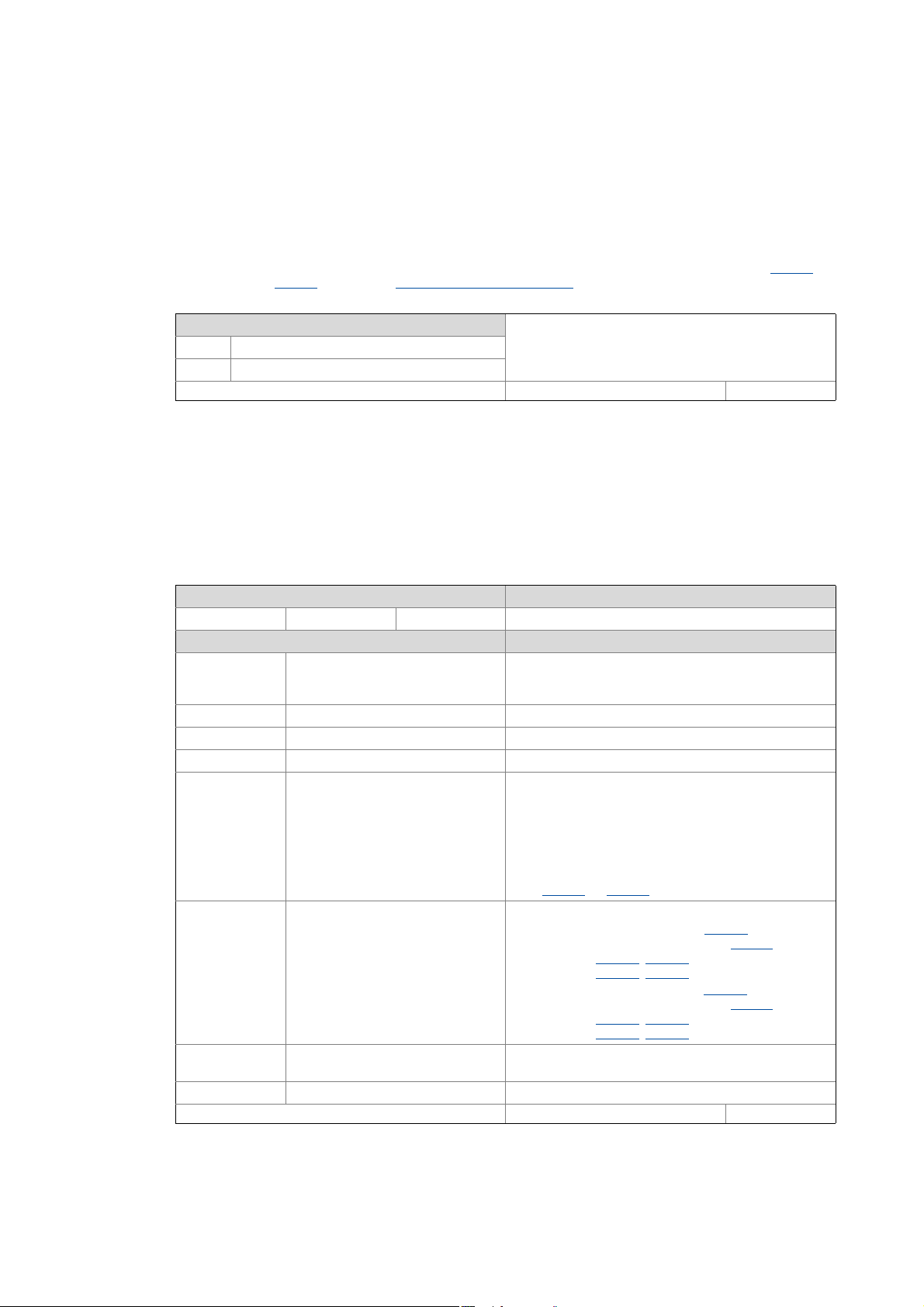

3.3.1 Object directory

The object directory contains the specific indices for all axes. The object directory is structured

according to specifications of the EtherCAT Technology Group (ETG):

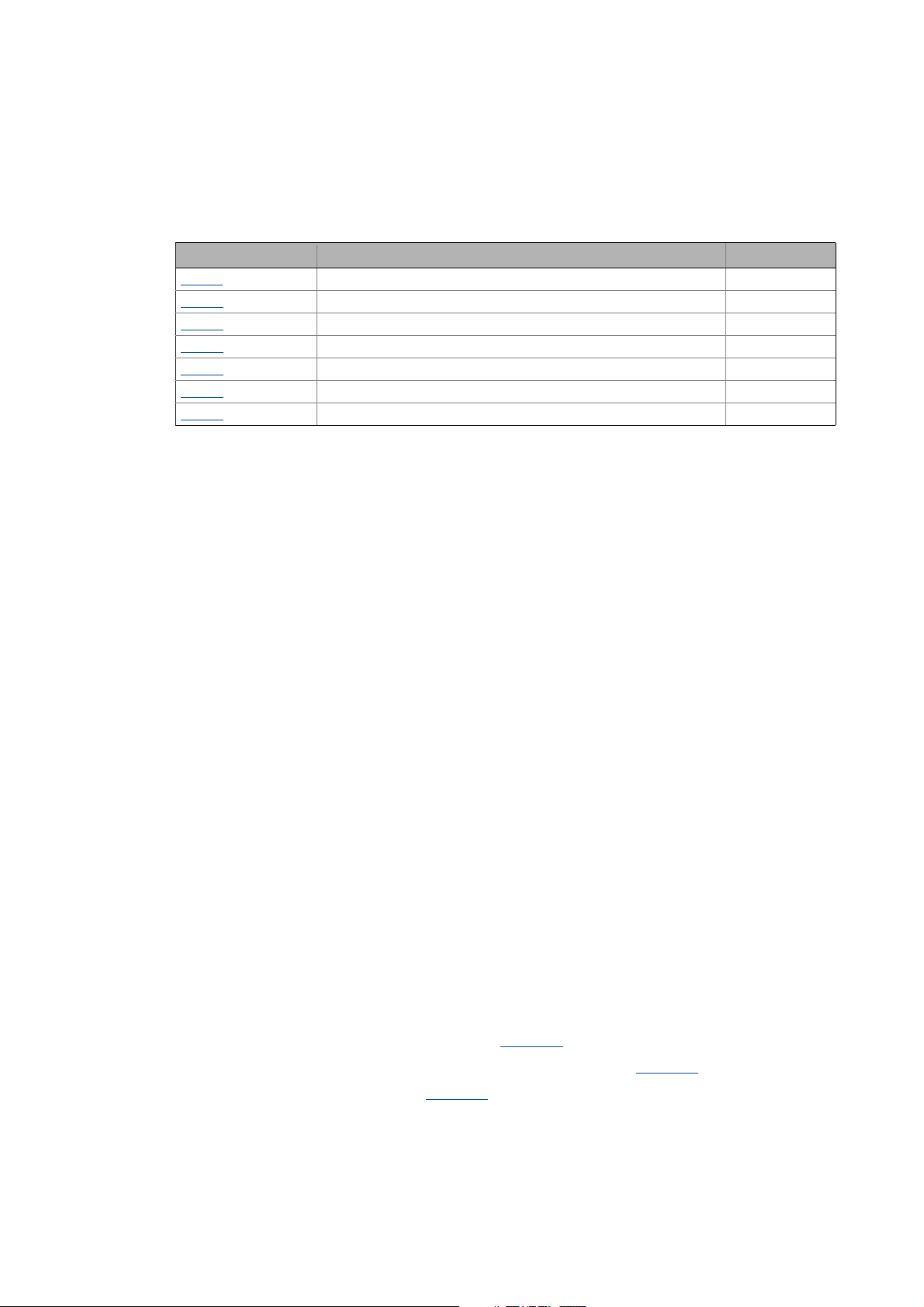

Range Index area

Device Axis A Axis B

Communication Area 0x1000 - 0x1FFF

Identification data 0x1000 - 0x1018 - -

Sync manager 0x1C00 - 0x1C33 - -

PDO mapping - 0x1600 - 0x1606

0x1A00 - 0x1A05

Manufacturer specific area 0x2000 - 0x5FFF

Device settings 0x2000 - 0x27FF - -

Axis identification - 0x2800 - 0x281F 0x3000 - 0x301F

Axis control - 0x2820 - 0x283F 0x3020 - 0x303F

Error management - 0x2840 - 0x28FF 0x3040 - 0x30FF

Motor control & motor settings - 0x2900 - 0x2CFF 0x3100 - 0x34FF

Touch probe - 0x2D00 - 0x2D3F 0x3500 - 0x353F

Monitoring functions - 0x2D40 - 0x2D7F 0x3540 - 0x357F

Diagnostics - 0x2D80 - 0x2DBF 0x3580 - 0x35BF

Service/internal - 0x2DC0 - 0x2E3F 0x35C0 - 0x363F

Reserved - 0x2E40 - 0x2FFF 0x3640 - 0x37FF

CiA402 profile specific area 0x6000 - 0xDFFF

Device profile CiA402 - 0x6000 - 0x67FF 0x6800 - 0x6FFF

0x1610 - 0x1616

0x1A10 - 0x1A15

26

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Page 27

3 Communication with the controller

3.3 Parameter data transfer (SDO communication)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

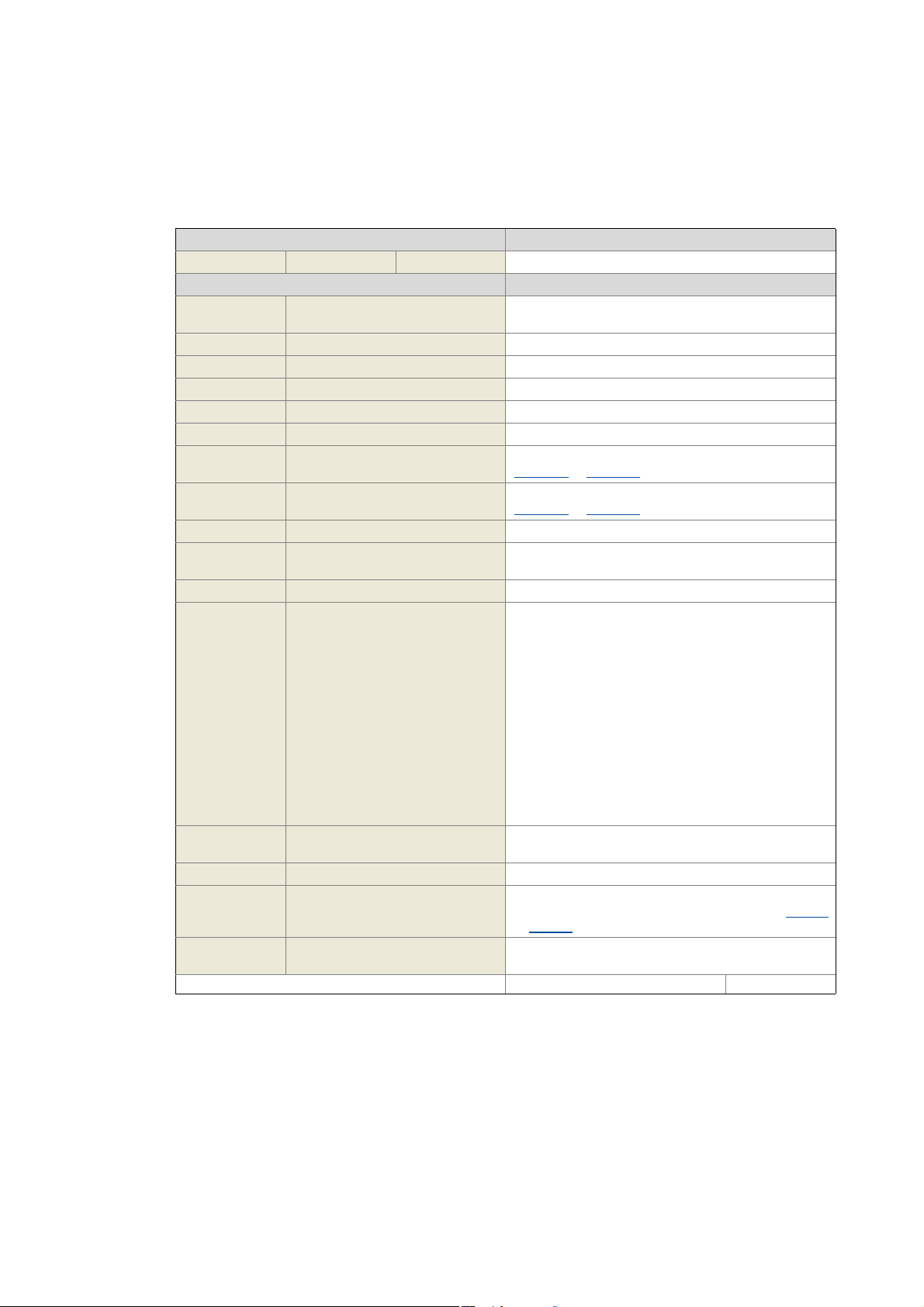

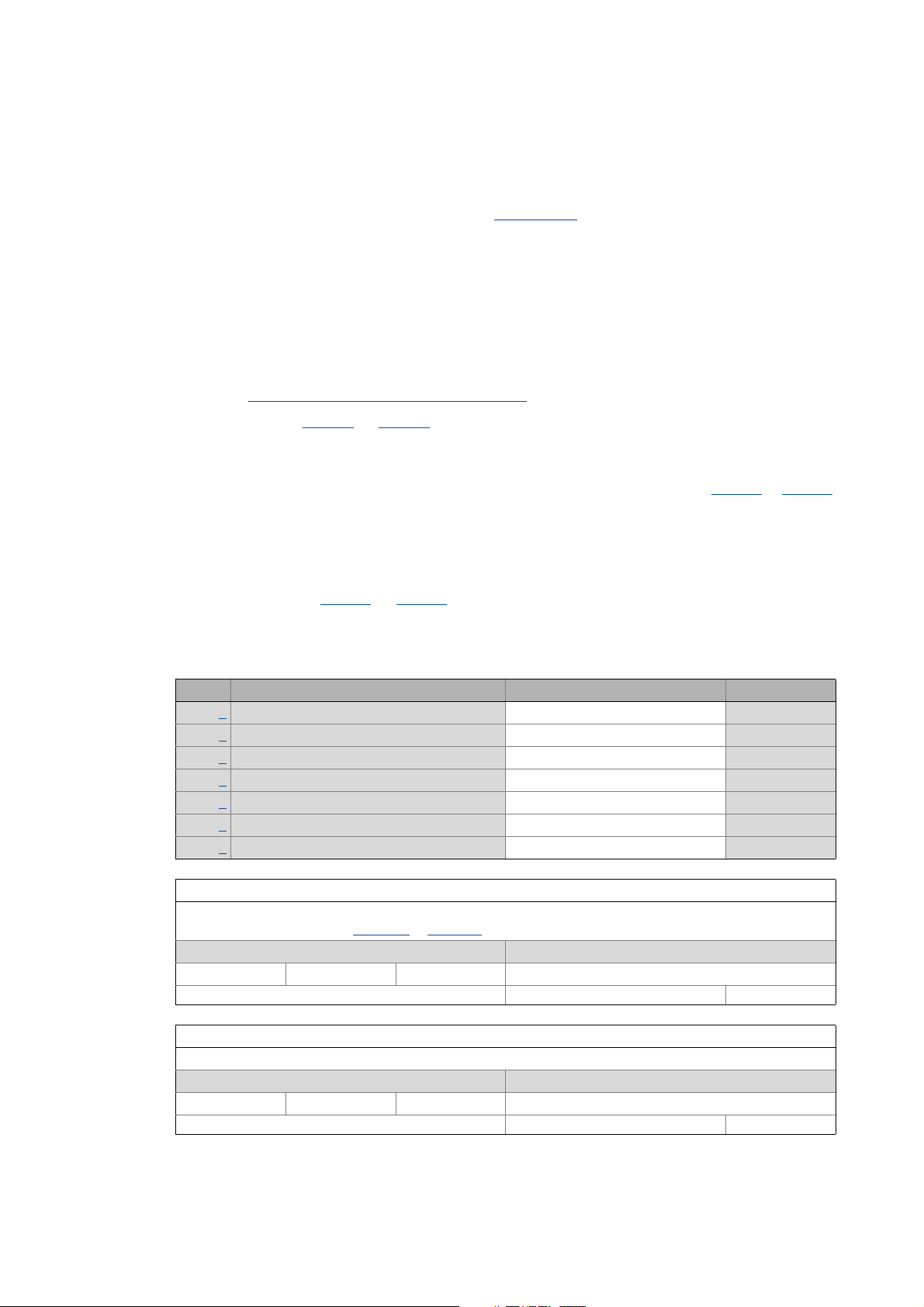

3.3.2 SDO abort codes

If an SDO request is evaluated negatively, a corresponding abort code is output:

SDO abort code Description

0x0000 0000 No error

0x0503 0000 The status of the toggle bit has not changed.

0x0504 0000 SDO protocol time-out

0x0504 0005 The space in the main memory is not sufficient.

0x0601 0000 Access to object not supported.

0x0601 0001 Read access to a write-protected object.

0x0601 0002 Write access to a write-protected object.

0x0602 0000 Object is not listed in the object directory.

0x0604 0041 Object cannot be mapped into the PDO.

0x0604 0042 The number and/or length of the mapped objects would exceed the PDO length.

0x0604 0043 General parameter incompatibility

0x0604 0047 General internal device incompatibility

0x0606 0000 Access has failed because of hardware errors.

0x0607 0010 Wrong data type or parameter length.

0x0607 0012 Wrong data type (parameter length is too large).

0x0607 0013 Wrong data type (parameter length is too small).

0x0609 0011 Subindex does not exist.

0x0609 0030 The value range for parameters is too large (only for write access).

0x0609 0031 The parameter value is too high.

0x0609 0032 The parameter value is too low.

0x0800 0000 General error

0x0800 0020 Data cannot be transferred or saved to the application.

0x0800 0021 Data cannot be transferred or saved to the application because of local control.

0x0800 0022 Data cannot be transferred/saved to the application because of current device state.

3.3.3 ESI: EtherCAT Slave Information file (device description)

The EtherCAT Slave Information file (EtherCAT Device Description file) contains all information

about the device (operating modes, parameters, …).

• The EtherCAT Slave Information file is integrated by the EtherCAT network configuration tool in

order to be able to configure and commission the devices.

• Part of the information contained in the EtherCAT Slave Information file can be uploaded online

by the EtherCAT master by accessing the EtherCAT EEPROM of the device. The description of the

object directory can also be identified online.

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05 27

Page 28

3 Communication with the controller

3.4 Activating the control via PDO

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.4 Activating the control via PDO

0x2824 | 0x3024 - Device control via PDO: Activation

This object serves to switch off all RPDOs (from the device's point of view) so that the device is exclusively controlled

via SDOs.

• This is, for instance, required for manual enable of commissioning functions and test modes via the (0x6040

control word 0x6840

Selection list (Lenze setting printed in bold)

0Off

1Activate

Write access CINH OSC P RX TX UNSIGNED_8

for axis B). Enable/inhibit via control word

3.5 Lenze control and status word

0x2830 | 0x3030 - Lenze control word

Via the Lenze control word, the control functions can be influenced.

Setting range (min. value | unit | max. value) Lenze setting

0x0000 0xFFFF 0x0000

Value is bit-coded: ( =bit set) Info

Write access CINH OSC P RX TX UNSIGNED_16

Bit 0 Flying restart: Completed Via this bit, the control reports the acceptance of the

Bit 1 Flying restart: Blocked "1" ≡ Block flying restart process

Bit 2 Reserved

Bit 3 Reserved

Bit 4 Speed controller: Load I component "1" ≡ Set starting value of the torque

Bit 5 Position: Traverse to new actual

Bit 6 Activate DC-injection braking or

Bits 7-15 Reserved

position

short-circuit braking

speed found to the "Flying restart" function. The flying

restart process is now completed.

• In case of servo control, this corresponds to the I

component of the speed controller, in case of V/f

operation to the modulation of the slip

compensation.

• As long as this bit is set to "1", the I component and

the slip compensation are set to the starting value set

in 0x2902

"1" ≡ Set/relatively shift actual position

• Axis A: Set the actual position (0x6064

consideration of the set resolution (0x608F

value set in 0x2983

value set in 0x2983

• Axis B: Set the actual position (0x6864

consideration of the set resolution (0x688F

value set in 0x3183

value set in 0x3183

"1" ≡ Trigger DC-injection braking for asynchronous

motor or short-circuit braking for synchronous motor

(or 0x3102 for axis B).

) under

) to the

(0x2984 = 0), or shift it by the

(0x2984 = 1).

) under

) to the

(0x3184 = 0), or shift it by the

(0x3184 = 1).

28

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

Page 29

3 Communication with the controller

3.5 Lenze control and status word

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

0x2831 | 0x3031 - Lenze status word

In the Lenze status word, messages are combined that go beyond the CiA specification.

Display area (min. value | unit | max. value) Initialisation

0x0000 0xFFFF

Value is bit-coded: Info

Bit 0 Position controller: In limitation Position mode: Output of the position controller in

Bit 1 Speed: Limited speed setpoint 1 Input of speed controller 1 in limitation

Bit 2 Speed controller: In limitation Output of speed controller 1 in limitation

Bit 3 Torque: Limited target torque Target torque in limitation

Bit 4 Motor: Limited current setpoint Setpoint current in limitation

Bit 5 Speed: Limited speed setpoint 2 Torque mode: Input of speed controller 2 in limitation

Bit 6 Upper speed limit is active Torque mode: Speed is limited to the upper speed limit

Bit 7 Lower speed limit is active Torque mode: Speed is limited to the lower speed limit