Page 1

LDCDS−EL100

.LRN

Ä.LRNä

Operating Instructions

HMI with Windowsâ CE

EL 1xx ECO, EL 1xx ECO PLC, EL 1xx CAN, EL 1xx PLC, EL 1xx MPI

HMI for visualisation / with control technology

Page 2

Please read these instructions before you start working!

Follow the enclosed safety instructions.

Page 3

Contents i

1 About this documentation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Validity information 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Target group 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Document history 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Terminology used 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Conventions used 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 Notes used 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety instructions 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Product−specific safety instructions 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Safety instructions for the installation according to UL 13. . . . . . . . . . . . . . . . . . . . .

3 Product description 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Application as directed 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Scope of supply 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Overview 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 EL 1xx CAN/PLC/MPI 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 EL 1xx ECO (PLC) 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Technical data 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

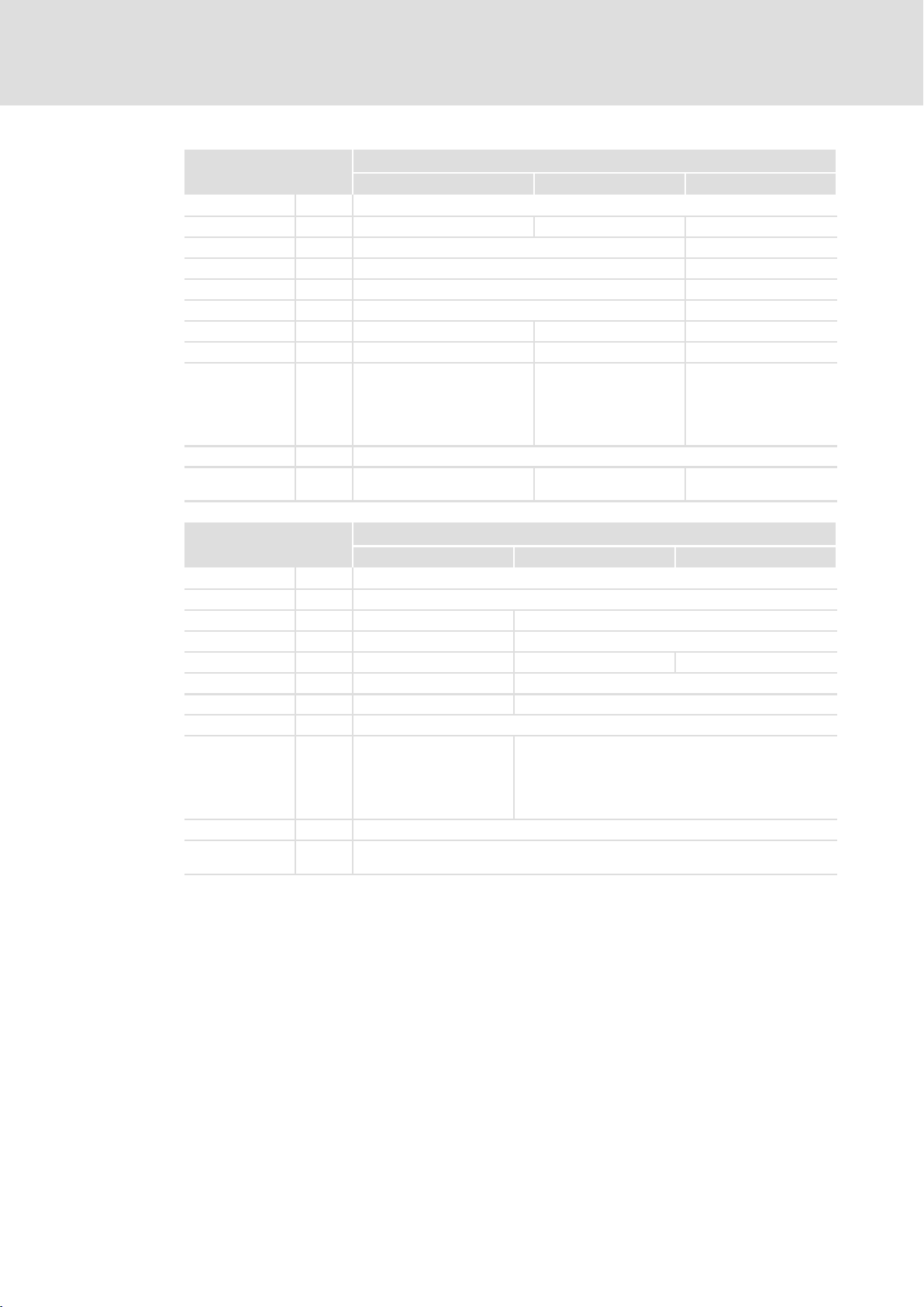

4.1 General data and operating conditions 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

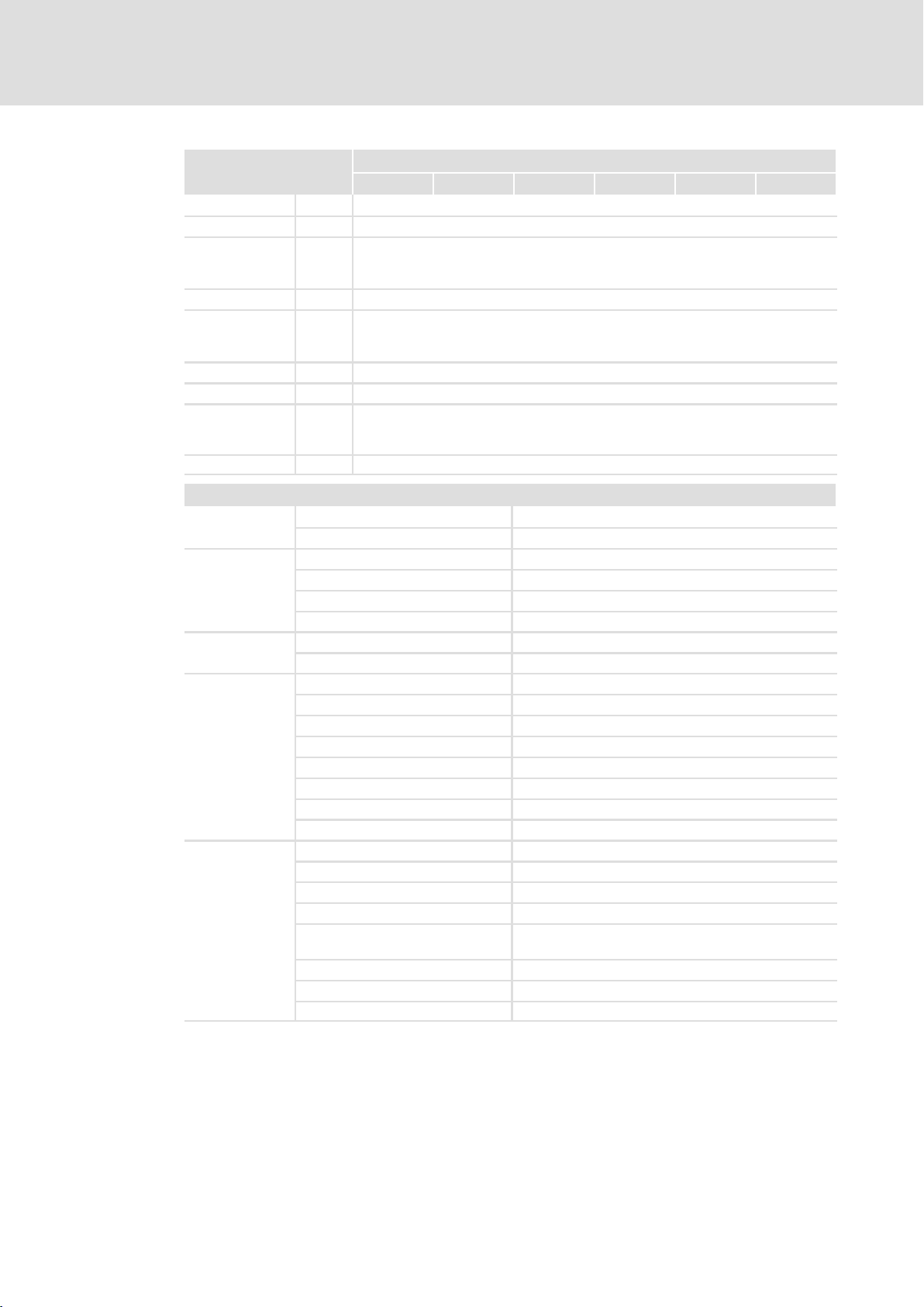

4.2 Electrical data 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 EL 1xx CAN/PLC/MPI 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 EL 1xx ECO (PLC) 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Mechanical data 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

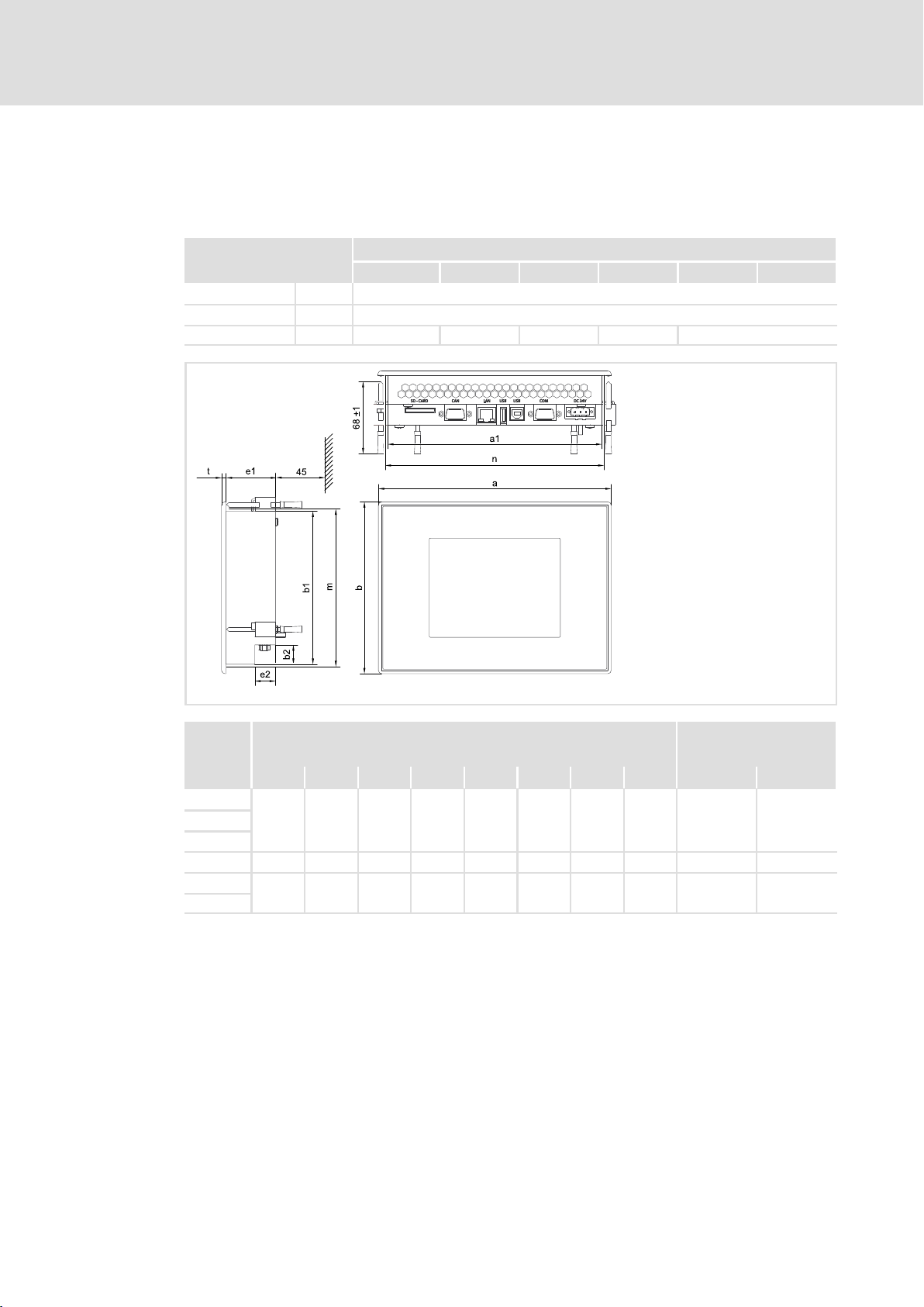

4.3.1 EL 1xx CAN/PLC/MPI 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

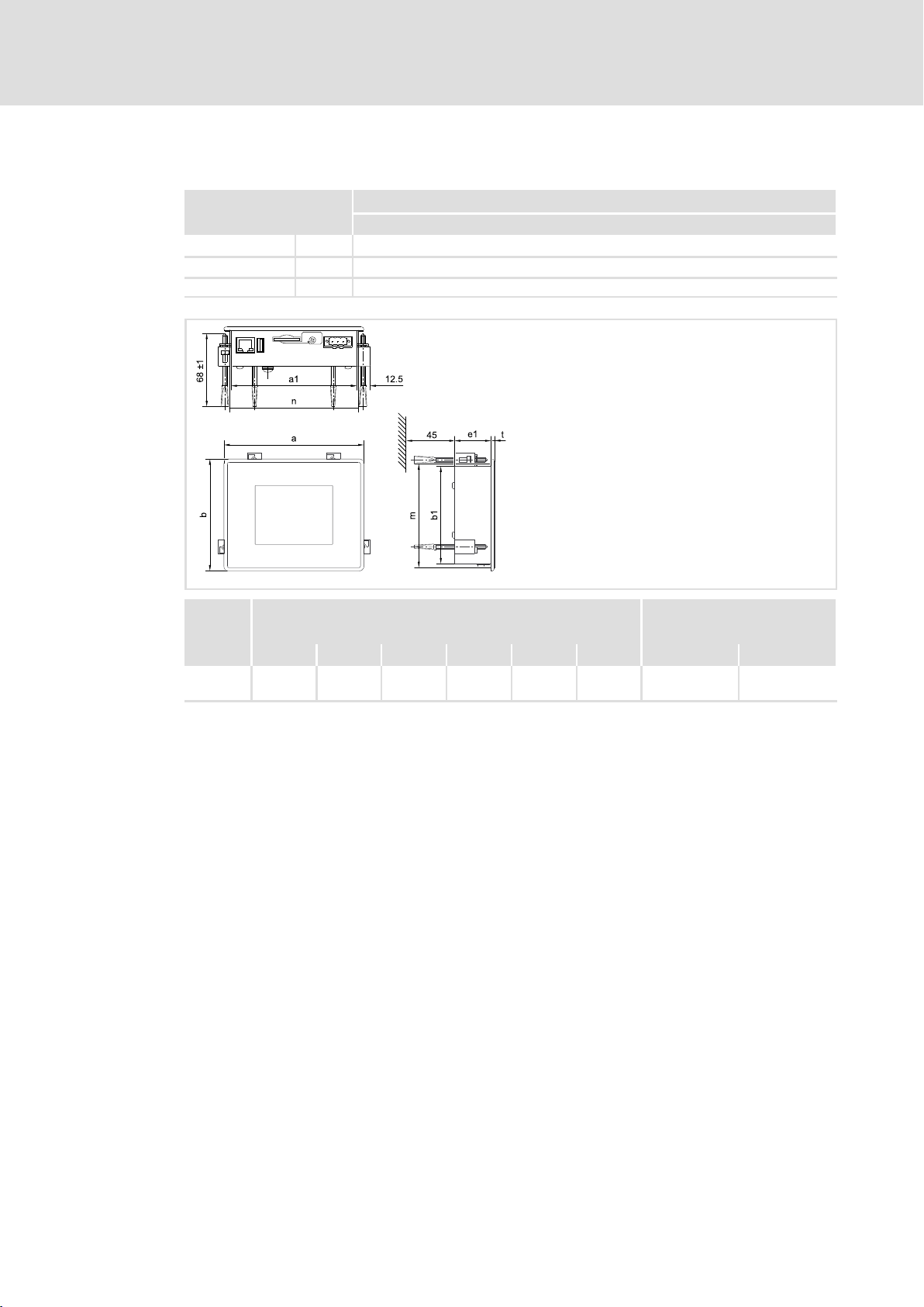

4.3.2 EL 1xx ECO (PLC) 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Mechanical installation 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Important notes 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

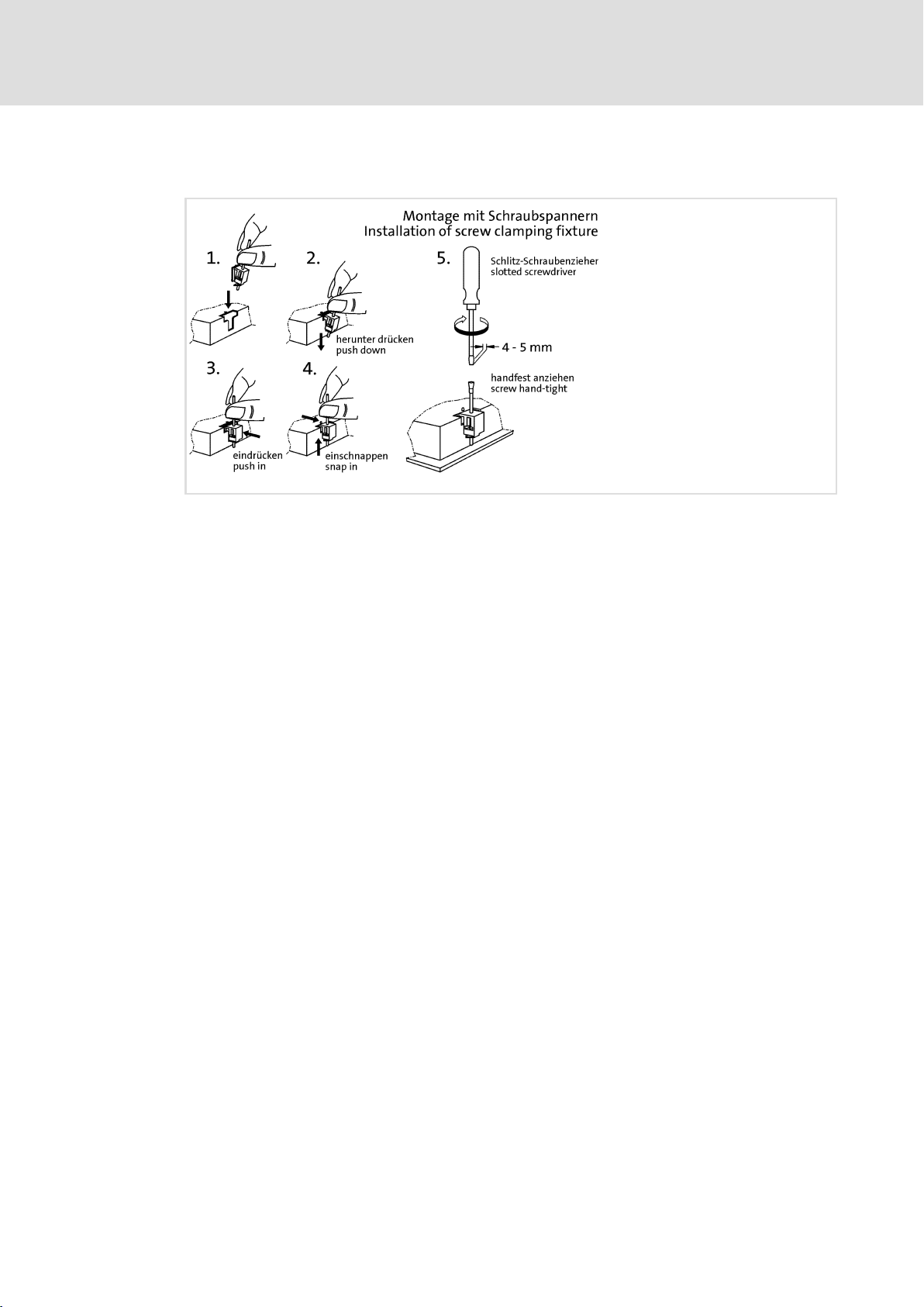

5.2 Mounting steps 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Electrical installation 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Important notes 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Wiring according to EMC 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Wiring 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 EL 1xx CAN/PLC/MPI 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 EL 1xx ECO (PLC) 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LDCDS−EL100 EN 9.0

3

Page 4

Contentsi

7 Commissioning 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Connecting external devices 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Initial switch−on 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Establish Ethernet connection 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Configure Ethernet interface 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 Activate communication between EL 1xx and VisiWinNetâ Smart 40. . .

7.4 Establish CAN fieldbus connection 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.1 Configure CAN interface 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Establish MPI connection 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 UPS functionality 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7 Installing fonts 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Operation 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

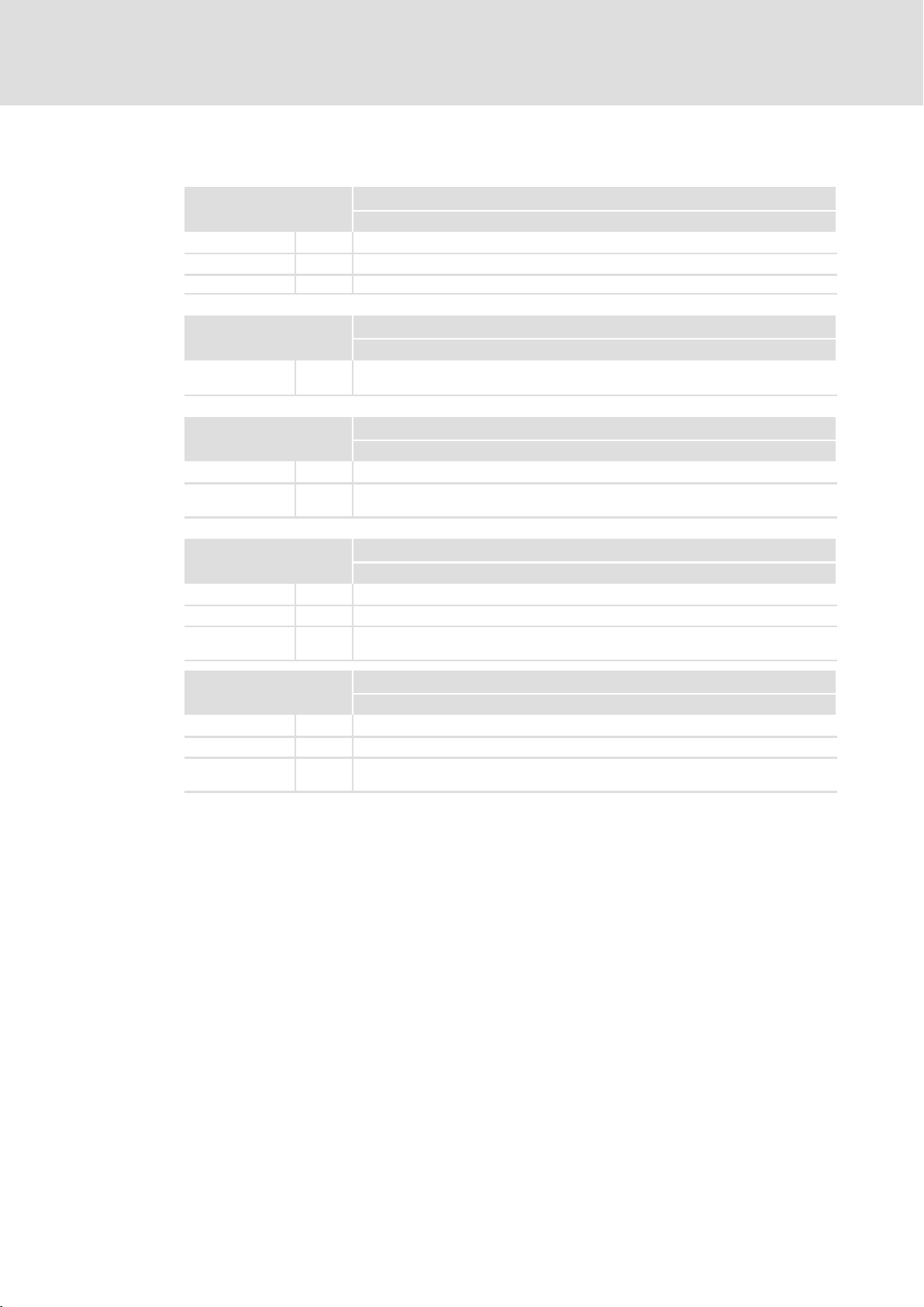

8.1 Operating system components 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Control Panel Applets 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

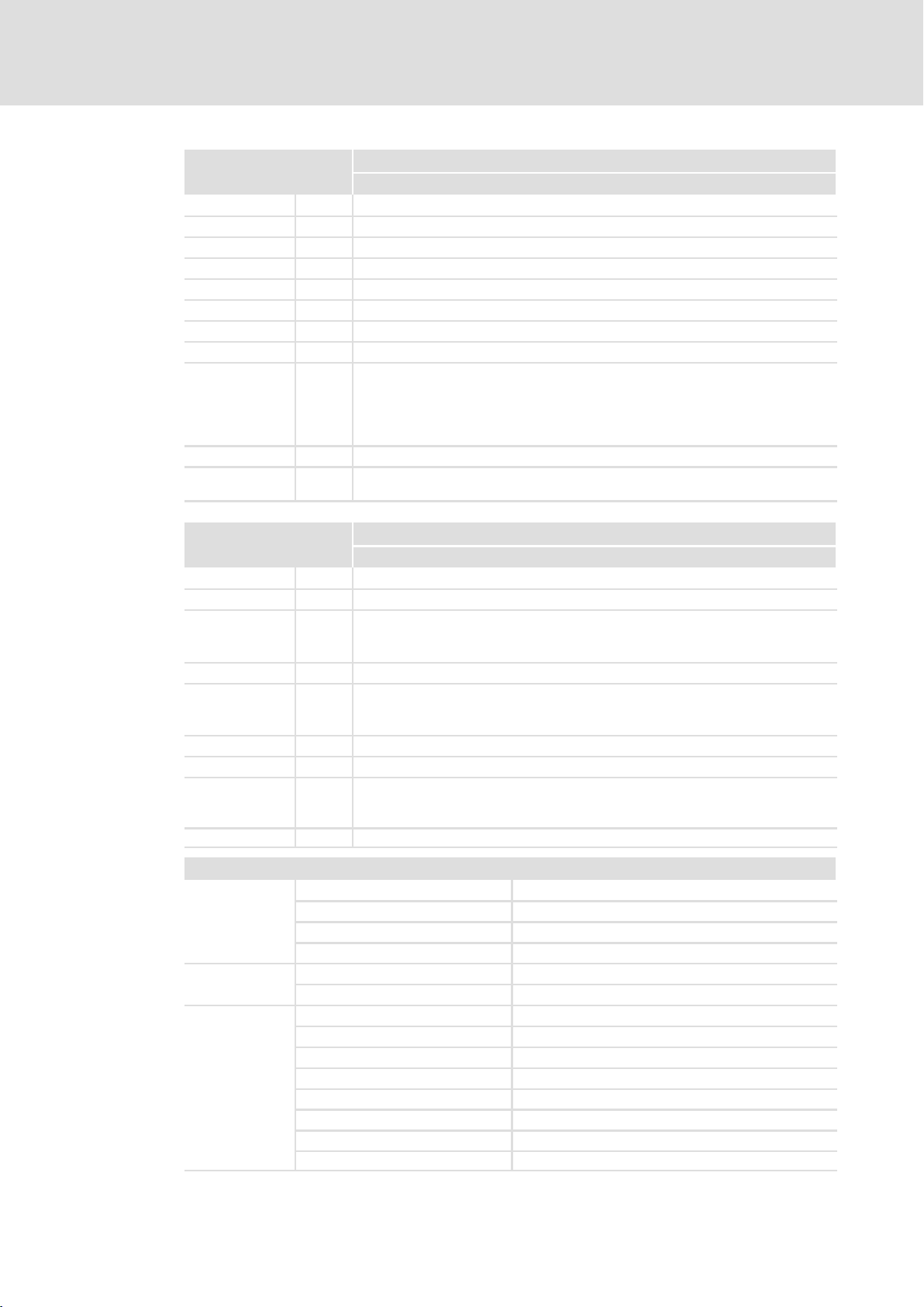

8.2.1 StartUp 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 Registry 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.3 VisiWinNETâ 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.4 Display 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.5 Server 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.6 Fieldbus 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.7 MPI Configuration 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.8 CAN Gateway 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Creating a PLC sample program 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 General information on PLC programming 55. . . . . . . . . . . . . . . . . . . . . . .

8.3.2 Start PLC Designer 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.3 Create PLC program 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.4 Create sym file 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.5 Transfer program to HMI 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.6 Start program on HMI 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.7 Build up CAN communication with distributed I/O module 64. . . . . . . . .

8.4 Access EL 1xx via server functionality 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 Enable Server Access 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.2 FTP Server − Transmit Data 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.3 Web Server (SysAdmin) − Manage Processes, Files, Registry 74. . . . . . . . . .

8.4.4 Telnet Server − Manage files at the Windows Command Prompt 75. . . . .

8.4.5 VNC−Server − Operate the EL 1xx by remote control via Internet or LAN 76

8.4.6 RAS Server − Operate your EL 1xx by remote control via telephone line 77

4

LDCDS−EL100 EN 9.0

Page 5

Contents i

8.5 Communicating via the CAN gateway function 78. . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.1 Important notes 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.2 Establishing communication using the system bus configurator 78. . . . . .

8.5.3 Establishing communication using the Global Drive Control (GDC) 82. . .

8.5.4 Establishing communication using the L−force Engineer 84. . . . . . . . . . . .

8.5.5 Establishing communication using the Drive PLC Developer

Studio (DDS) 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Maintenance 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 General notes 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Regular checks 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Cleaning 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Battery replacement 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Index 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LDCDS−EL100 EN 9.0

5

Page 6

1

About this documentation

Validity information

0Fig. 0Tab. 0

1 About this documentation

1.1 Validity information

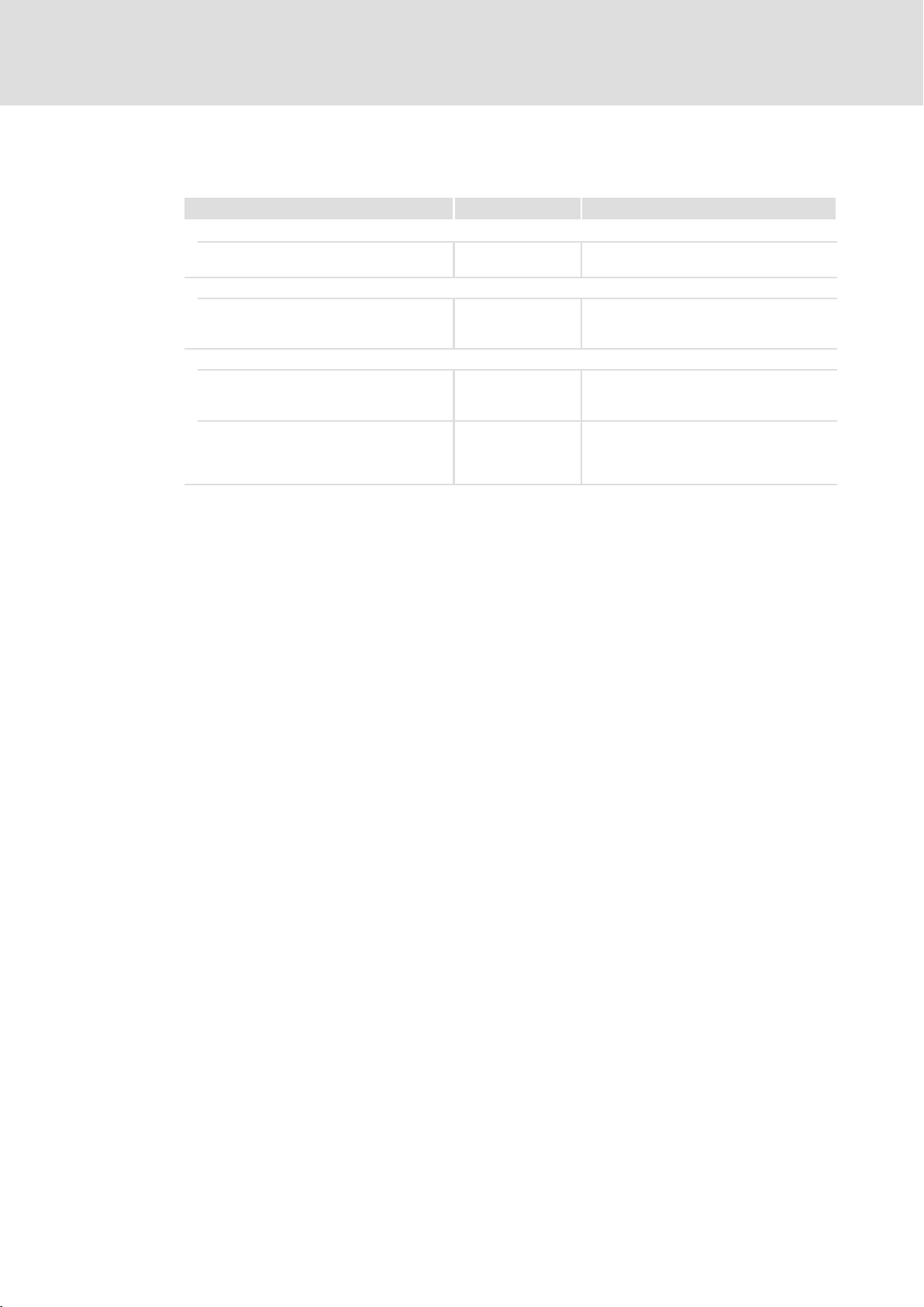

These instructions are valid for

HMI with CAN interface HMI with CAN interface, integrated

EL 103 ECO EL 103 ECO PLC −

EL 105M CAN EL 105m PLC EL 105M MPI

EL 105 CAN EL 105 PLC EL 105 MPI

EL 106 CAN EL 106 PLC EL 106 MPI

EL 108 CAN EL 108 PLC EL 108 MPI

EL 110 CAN EL 110 PLC EL 110 MPI

EL 110s CAN EL 110s PLC EL 110s MPI

The nameplate is on the back of the device.

1.2 Target group

This documentation is directed at qualified skilled personnel according to IEC 60364.

Qualified skilled personnel are persons who have the required qualifications to carry out

all activities involved in installing, mounting, commissioning, and operating the product.

PLC and UPS

HMI with MPI interface

6

LDCDS−EL100 EN 9.0

Page 7

1.3 Document history

Material number Version Description

.LRN 9.0 11/2013 TD29 Safety instructions for the installation according to

13398591 8.0 01/2012 TD29 New chapter "Install fonts"

13349601 7.1 07/2011 TD29 Pin assignment SUB−D plug corrected

13349601 7.0 06/2011 TD29 UL approval and other revisions

13346004 6.0 08/2010 TD29 Corrected CAN connection drawing for EL 103 ECO

13327978 5.0 05/2010 TD29 Amended by description of type EL 103 ECO;

13273430 4.0 01/2009 TD29 Amended by description of type EL 112

13236340 3.0 04/2008 TD29 Description of type EL 110s and all types with

13227672 2.0 11/2007 TD29 The "Commissioning" chapter has been expanded by

13200039 1.0 03/2007 TD29 First edition

About this documentation

Document history

UL added and other revisions

description of type EL 112 deleted; adapted BA

according to the new specifications regarding the

Lenze classification and the new specifications of

the units of measurement regulation

integrated PLC has been added

descriptions on server functionalities

1

Tip!

Information and auxiliary devices related to the Lenze products can be found

in the download area at

http://www.Lenze.com

1.4 Terminology used

Term In the following text used for

EL 1xx HMI of the EL 100 or EL 100 ECO series

HMI Human Machine Interface

MPI Interface for the SIMATIC S7 automation system from Siemens AG

SD/SDHC card Memory card in the SD/SDHC format

Touchscreen Touch screen terminal

LDCDS−EL100 EN 9.0

7

Page 8

1

About this documentation

Conventions used

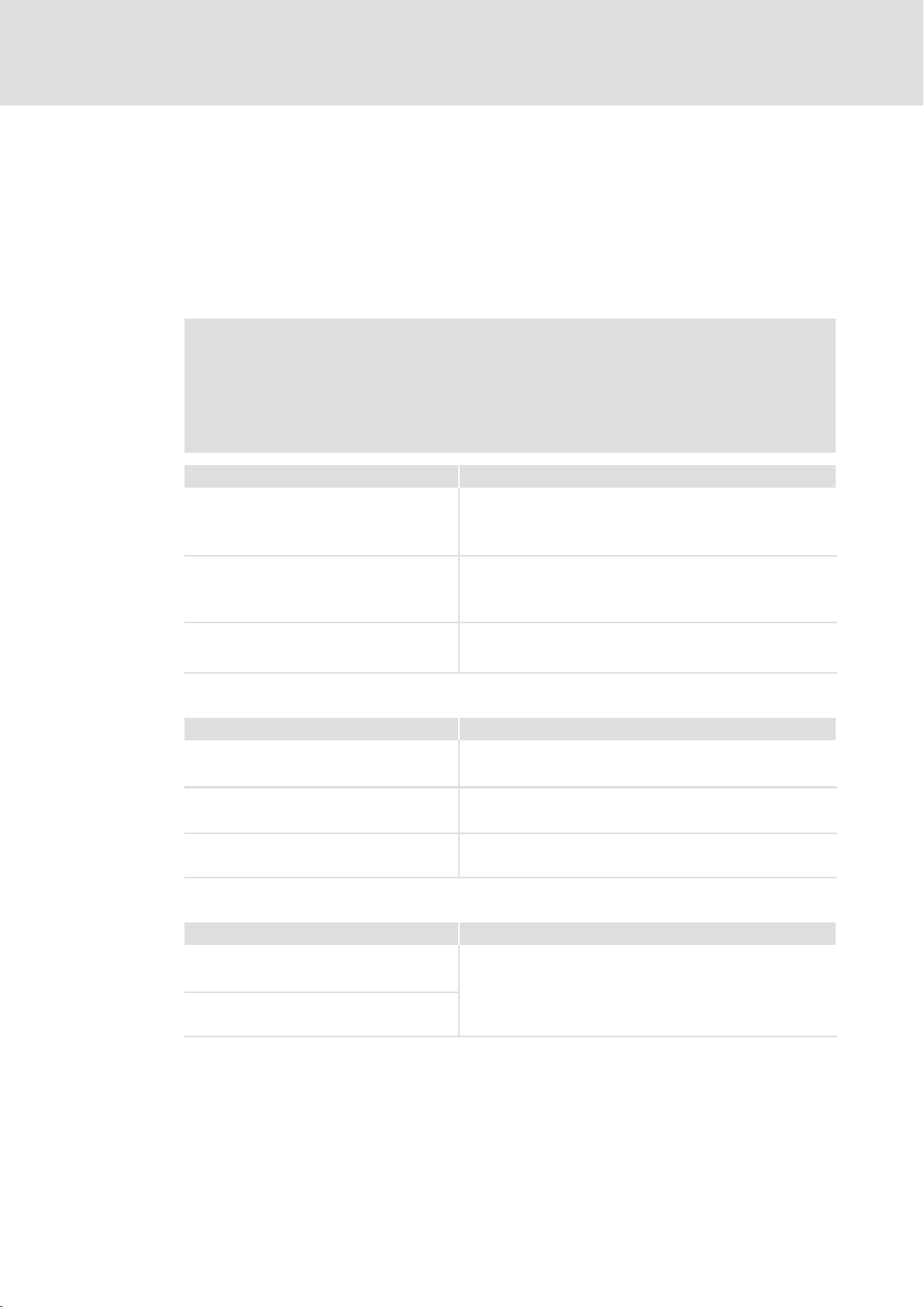

1.5 Conventions used

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator

Text

Program name » « PC software

Icons

Page reference Reference to another page with additional

Documentation reference Reference to another documentation with

Point In general, the decimal point is used.

For instance: 1234.56

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: 16 = see page 16

additional information

For example: EDKxxx = see

documentation EDKxxx

8

LDCDS−EL100 EN 9.0

Page 9

About this documentation

Notes used

1

1.6 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

Danger!

Danger!

Stop!

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

Note!

Tip!

Special safety instructions and application notes

Pictograph and signal word Meaning

Warnings!

Warnings!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

Safety note or application note for the operation according to

UL or CSA requirements.

The measures are required to meet the requirements according

to UL or CSA.

LDCDS−EL100 EN 9.0

9

Page 10

2

Safety instructions

General safety instructions

2 Safety instructions

2.1 General safety instructions

Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets!

ƒ Lenze drive and automation components ...

... must only be used for the intended purpose.

... must never be operated if damaged.

... must never be subjected to technical modifications.

... must never be operated unless completely assembled.

... must never be operated without the covers/guards.

... can − depending on their degree of protection − have live, movable or rotating parts

during or after operation. Surfaces can be hot.

ƒ For Lenze drive components ...

... only use permitted accessories.

... only use original manufacturer spare parts.

ƒ All specifications of the corresponding enclosed documentation must be observed.

This is vital for a safe and trouble−free operation and for achieving the specified product

features.

The procedural notes and circuit details provided in this document are proposals which

the user must check for suitability for his application. The manufacturer does not

accept any liability for the suitability of the specified procedures and circuit proposals.

ƒ Only qualified skilled personnel are permitted to work with or on Lenze drive and

automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and operation of

the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent regulations, directives

and laws applicable at the place of use.

Transport, storage

ƒ Transport and storage in a dry, low−vibration environment without aggressive

atmosphere; preferably in the packaging provided by the manufacturer.

– Protect against dust and shocks.

– Comply with climatic conditions according to the technical data.

10

LDCDS−EL100 EN 9.0

Page 11

Safety instructions

General safety instructions

Mechanical installation

ƒ Install the product according to the regulations of the corresponding

documentation. In particular observe the section "Operating conditions" in the

chapter "Technical data".

ƒ Provide for a careful handling and avoid mechanical overload. During handling

neither bend components, nor change the insulation distances.

ƒ The product contains electrostatic sensitive devices which can easily be damaged by

short circuit or static discharge (ESD). Thus, electronic components and contacts

must not be touched unless ESD measures are taken beforehand.

Electrical installation

ƒ Carry out the electrical installation according to the relevant regulations (e. g. cable

cross−sections, fusing, connection to the PE conductor). Additional notes are

included in the documentation.

ƒ When working on live products, observe the applicable national regulations for the

prevention of accidents (e.g. BGV 3).

2

ƒ The documentation contains information about EMC−compliant installation

(shielding, earthing, arrangement of filters and laying cables). The system or

machine manufacturer is responsible for compliance with the limit values required

by EMC legislation.

Warning: The controllers are products which can be used in category C2 drive systems

as per EN 61800−3. These products may cause radio interference in residential areas. If

this happens, the operator may need to take appropriate action.

ƒ For compliance with the limit values for radio interference emission at the site of

installation, the components − if specified in the technical data − have to be mounted

in housings (e. g. control cabinets). The housings have to enable an EMC−compliant

installation. In particular observe that for example control cabinet doors preferably

have a circumferential metallic connection to the housing. Reduce openings or

cutouts through the housing to a minimum.

ƒ Only plug in or remove pluggable terminals in the deenergised state!

Commissioning

ƒ If required, you have to equip the system with additional monitoring and protective

devices in accordance with the respective valid safety regulations (e. g. law on

technical equipment, regulations for the prevention of accidents).

Maintenance and servicing

LDCDS−EL100 EN 9.0

ƒ The components are maintenance−free if the required operating conditions are

observed.

ƒ If the cooling air is polluted, the cooling surfaces may be contaminated or the air

vents may be blocked. Under these operating conditions, the cooling surfaces and air

vents must be cleaned at regular intervals. Never use sharp objects for this purpose!

ƒ After the system has been disconnected from the supply voltage, live components

and power connections must not be touched immediately because capacitors may

be charged. Please observe the corresponding notes on the device.

11

Page 12

2

2.2 Product−specific safety instructions

Safety instructions

Product−specific safety instructions

Disposal

ƒ Recycle metals and plastic materials. Ensure professional disposal of assembled

PCBs.

ƒ This device contains a battery. According to European legislation you are obliged to

dispose of batteries separately via the take−back systems specified.

ƒ Before working on the HMI, the supply connector must be unplugged. This is

particularly important before opening the enclosure and connecting/removing

connectors.

ƒ The voltage input is not internally fused and may be destroyed if the input voltage is

too high. Observe the maximally permissible input voltage and professionally fuse

the device on the input side against voltage fluctuations and peaks.

ƒ During installation, see that the maximally permissible ambient temperature is not

exceeded. Corresponding measures for active or passive cooling must be taken if

required.

ƒ The HMI is a device of class A and can cause radio interference in residential areas. In

this case, the operator may have to take special measures. Any costs arising from

these measures have to be paid by the operator.

ƒ In the case of an error, send the HMI to the manufacturer. The address is provided on

the return envelope of this documentation. Please use the original packaging if you

return the HMI!

12

LDCDS−EL100 EN 9.0

Page 13

Safety instructions

Safety instructions for the installation according to UL

2

2.3 Safety instructions for the installation according to UL

Approval

Underwriter Laboratories (UL), UL508 and CSA C22.2 No. 142−M1987, (UL File Number

E236341)

Ratings

ƒ Input 24 V DC, 12 W

ƒ Max. Ambient Temperature 50 °C

ƒ Enclosure ratings:

– Front Panel Mounted UL Type 1, 2 and 5 Enclosure

– Except:

EL108 STD: Front Panel Mounted Type 1 Enclosure

EL108 KSTG: Panel mounted Type 1 Enclosure

Warnings!

Field Wiring Markings

Wiring Terminal MSTB 2,5/3−STF−5,08:

ƒ Use 60/75°C copper wire only.

ƒ AWG 18 ... AWG 12 (0.82 mm

ƒ Torque 5...7 lb−in (0.5 ... 0.6 Nm)

Device

ƒ For use in surrounding air temperature 50 °C.

ƒ Use in a pollution degree 2 environment.

ƒ For use on a flat surface of a Type 1, 2 and 5 enclosure.

– Except:

EL108 STD: Front Panel Mounted Type 1 Enclosure

EL108 KSTG: Panel mounted Type 1 Enclosure

ƒ EL 108 KSTG:

The device shall be supplied by an isolating source protected by a fuse with

max. rating 8 A.

Battery

ƒ Replace battery with any from the list below, part No. CR 2450 only. Use of

another battery may present a risk of fire or explosion.

Recommended CR2450 (R/C, BBVC2) types:

Renata Part.no. CR2450N, Sony Corp. part no. CR2450B, Toshiba part no.

CR2450, Varta part no. CR2450, Matsushita part no. CR2450

ƒ Battery may explode if mistreated. Do not recharge, disassemble, dispose of

in fire or heat above 100 °C (212 °F).

ƒ Dispose of used battery according to the regulation of recycling or waste.

2

... 3.3 mm2)

LDCDS−EL100 EN 9.0

13

Page 14

2

Safety instructions

Safety instructions for the installation according to UL

Homologation

Underwriter Laboratories (UL), UL508 et CSA C22.2 n° 142−M1987, (n° de dossier UL

E236341)

Caractéristiques assignées

ƒ Entrée 24 V CC, 12 W

ƒ Température ambiante maximale : 50 °C

ƒ Classification du coffret de protection :

– Montage sur panneau avant, coffret UL de type 1, 2 et 5

– Exception :

EL108 STD : coffret de type 1 monté sur le panneau avant

EL108 KSTG : coffret de type 1 monté sur panneau

Warnings!

Marquage du câblage à pied d’oeuvre

Bornier de câblage MSTB 2,5/3−STF−5,08 :

ƒ Utiliser exclusivement des conducteurs en cuivre 60/75°C.

ƒ AWG 18 ... AWG 12 (0,82 mm

ƒ Couple de 5 à 7 lb−in (0,5 ... 0,6 Nm)

Appareil

ƒ Destiné à une utilisation à une température ambiante maximale de 50 °C.

ƒ Destiné à une utilisation dans un environnement caractérisé par le degré de

pollution 2.

ƒ Conçu pour une utilisation sur une surface plane, coffret de type 1, 2 et 5.

– Exception :

EL108 STD : coffret de type 1 monté sur le panneau avant

EL108 KSTG : coffret de type 1 monté sur panneau

ƒ EL 108 KSTG :

L’équipement doit être alimenté par une source de tension avec isolation

galvanique protégée par un fusible de 8 A maximum.

Batterie

ƒ Remplacer la batterie par l’un des types répertoriés dans la liste ci−dessous,

n° de référence CR 2450 uniquement. L’utilisation d’une autre batterie

présente un risque d’incendie ou d’explosion.

Types CR2450 recommandés (R/C, BBVC2) :

Renata référence CR2450N, Sony Corp. référence CR2450B, Toshiba

référence CR2450, Varta référence CR2450, Matsushita référence CR2450

ƒ Toute utilisation non conforme de la batterie entraîne un risque d’explosion.

Ne pas recharger, démonter, jeter au feu ni exposer la batterie à une chaleur

supérieure à 100 °C (212 °F).

ƒ Eliminer la batterie conformément à la réglementation en vigueur en

matière de recyclage ou de traitement des déchets.

2

... 3,3 mm2)

14

LDCDS−EL100 EN 9.0

Page 15

3 Product description

3.1 Application as directed

HMIs of the EL 1xx series

ƒ are Human Machine Interfaces (HMIs) for the implementation of operating concepts

or the provision of information in common industrial and commercial areas.

ƒ must only be operated if the operating conditions specified in these operating

instructions are met.

ƒ are no household appliances. They are components intended to be used exclusively

for commercial purposes.

Systems with HMI devices

ƒ The user is responsible for the compliance of his application with the EC Directives.

Any other use shall be deemed inappropriate!

Product description

Application as directed

3

A use that is not intended also includes a use harbouring fatal risks or dangers which,

without the provision of exceptionally high safety measures, may result in death, injury or

damage to material assets.

The HMI must in particular not be used ...

ƒ in private areas.

ƒ in potentially explosive atmosphere.

ƒ in areas with harmful gases, oils, acids, radiation, etc.

ƒ for performing safety functions, for instance

– in air traffic control / in flight−control systems

– for the monitoring/control of nuclear reactions

– for the monitoring/control of means of mass transport

– for the monitoring/control of medical systems

– for the monitoring/control of weapons systems

Higher−level safety systems must be used to guarantee the protection of persons and

material assets!

Note!

The touchscreen does not comply with the Ergonomics Directive ZH 1/618.

Therefore, it is only designed for short−time inputs and monitoring functions.

For longer inputs, connect an external keyboard.

LDCDS−EL100 EN 9.0

15

Page 16

3

Product description

Scope of supply

EL 1xx CAN/PLC/MPI

3.2 Scope of supply

Number Description

1 HMI

Screw clamp fixings

4

for EL 103 ECO (PLC)

4

for EL 105(m) CAN/PLC/MPI

4

for EL 106 CAN/PLC/MPI

6

for EL 108 CAN/PLC/MPI

8

for EL 110(s) CAN/PLC/MPI

1 Mounting instructions

1 DVD "PC−based Automation"

3.3 Overview

3.3.1 EL 1xx CAN/PLC/MPI

EL100−001

Pos. Description

HMI

Screw clamp fixings

PE connection

SD/SDHC card slot

CAN or MPI port

Ethernet port

USB−A port

USB−B port

Serial RS232 interface

Connection supply

16

LDCDS−EL100 EN 9.0

Page 17

Product description

Overview

EL 1xx ECO (PLC)

3

3.3.2 EL 1xx ECO (PLC)

Pos. Description

HMI

Screw clamp fixings

PE connection

SD/SDHC card slot

CAN interface

Ethernet port

USB−A port

Connection supply

SD/SDHC card protection (eject protection)

EL100e−001

LDCDS−EL100 EN 9.0

17

Page 18

4

Technical data

General data and operating conditions

4 Technical data

4.1 General data and operating conditions

Conformity and approval

Conformity

CE

Approbation

UL UL 508

Other

RoHS − Products lead−free in accordance with CE Directive

EN 61000−6−1 (−3),

VDE 0839−6−1 (−3)

EN 61000−6−2 (−4),

VDE 0839−6−2 (−4)

EN 55022

EN 55024 Equipment of information technology

CSA C22.2

2002 residential area

2006 industrial premises

Programmable Controllers (File−No. E236341)

2011/65/EU

Protection of persons and equipment

Safety VDE0805 (EN60950),

Type of protection IP65 (front) / IP20 (back)

Class of protection 3

Ambient conditions

Climatic

Temperature

Storage/Transport 0 ... +60 °C

Operation

EL 1xx ECO

EL 1xx CAN/MPI

EL 1xx ECO PLC

EL 1xx PLC

Relative humidity 10 ... 90 %, no condensation

Site altitude

Storage/Transport < 12.000 m amsl

Operation < 3.000 m amsl

Vibration test according to EN 61131−2 (programmable controllers)

Vibration EN 60068−2−6 1 g

Shock EN 60068−2−27 15 g

VDE0870, UL

Type 1, 2 and 5 enclosure

0 ... +50 °C

5 ... +45 °C

18

Mounting conditions

Mounting place

Mounting position Terminals at the bottom

Control cabinet door

LDCDS−EL100 EN 9.0

Page 19

Technical data

Electrical data

EL 1xx CAN/PLC/MPI

4

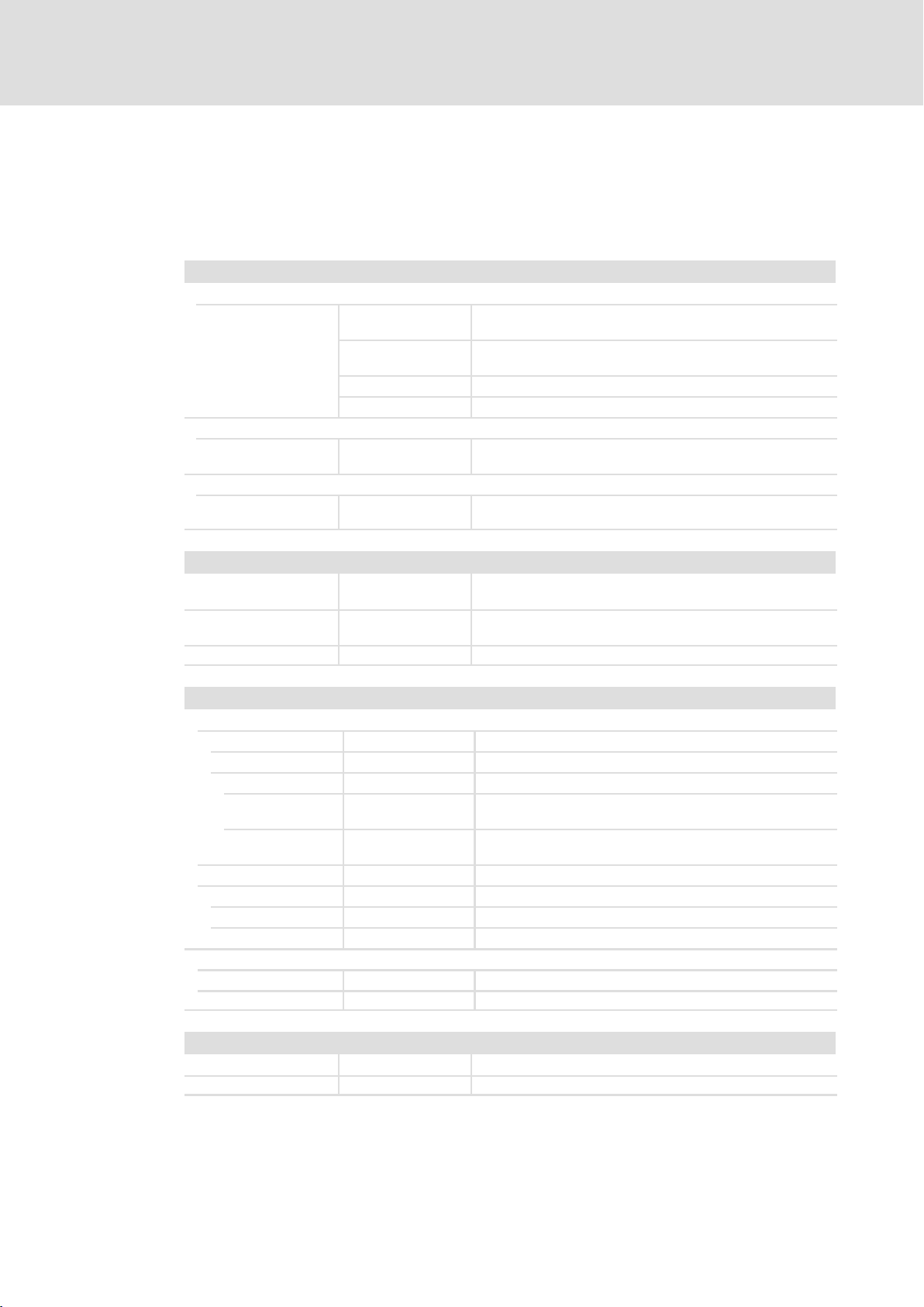

4.2 Electrical data

4.2.1 EL 1xx CAN/PLC/MPI

Supply

Voltage [V] DC 24 (+18 ... 30)

Current at 24 V [A] 0.25 0.3 0.3 0.5 0.5

Power at 24 V [W] 6.0 7.2 7.2 12.0 12.0

Buffer for real−time clock

dated

Battery

Service life

CPU and operating system

CPU type Intelâ Xscale PXA 270

Operating

system

[year] 7 (at 25 °C)

Type EL xxx

105m 105 106 108 110 110s

Typ EL xxx

105m 105 106 108 110 110s

Typ EL xxx

105m 105 106 108 110 110s

Windowsâ CE 5.0

Memory

105m 105 106 108 110 110s

RAM [MB] 64

Flash [MB] 32

Exchangeable

disk storage

Memory

105m 105 106 108 110 110s

RAM [MB] 128

Flash [MB] 64

Exchangeable

disk storage

1)

Due to the great variety of SD/SDHC cards available on the market, compatibility cannot be ensured. We do not

know about any restrictions.

Typ EL xxx CAN/MPI

SD/SDHC card slot

Typ EL xxx PLC

SD/SDHC card slot

1)

1)

LDCDS−EL100 EN 9.0

19

Page 20

4

Technical data

Electrical data

EL 1xx CAN/PLC/MPI

Screen

105m 105 106

Type Touch screen, resistive

Colours 16 grey tones 64 K 64 K

Display diagonal [cm] 14.5 (5.7") 16.3 (6.4")

Visible size [mm] 115 x 86 131 x 98

Resolution [pixels] 320 x 240 640 x 480

Pixel size [mm] 0.33 x 0.33 0.07 x 0.07

Contrast − 400:1 400:1

Brightness [cd/m2] 180 250 250

Angle of view

right

bottom

Illumination Cathode−ray tube, adjustable

Service life at

25°C

Screen (continued)

Type Touch screen, resistive

Colours 64 K

Display diagonal [cm] 20.3 (8") 26.4 (10.4")

Visible size [mm] 162 x 122 216 x 163

Resolution [pixels] 640 x 480 640 x 480 600 x 800

Pixel size [mm] 0.25 x 0.25 0.33 x 0.33

Contrast 250:1 300:1

Brightness [cd/m2] 400

Angle of view

right

bottom

Illumination Cathode−ray tube, adjustable

Service life at

25°C

[°] −

left

top

[h] 40000 45000 50000

[°] 65

left

top

[h] 50000

−

−

−

108 110 110s

65

55

65

Typ EL xxx

60

60

40

50

Typ EL xxx

65

65

50

60

60

60

40

50

20

LDCDS−EL100 EN 9.0

Page 21

Technical data

Electrical data

EL 1xx CAN/PLC/MPI

4

PLC functions

(EN 61131−3)

Editor AWL, FUP, KOP, ST, AS, CFC

Program code [kB] 2048

Data memory

Variables

Global Var.

Memory location [kB] 4

Process image

Input

Output

Retain data [kB] 128

UPS Integrated to save retain data to the flash memory

Target

L−force Logic

EL1xx

Task runtime [ms] ³10

Ports

COM 1

LAN

USB

1)

CAN

1)

MPI

1

* optionally CAN or MPI

[kB]

[kB]

[kB]

[kB]

Type

Connection SUB−D, 9−pole, connector

Type Ethernet

Protocol TCP/IP

Baud rate 10/100 Mbits

Connection RJ45, socket

Type 2.0 (1.1−compatible)

Connection Type A and type B, socket

Type CAN, ISO11898

Protocol Lenze system bus CAN

Topology Line, terminated on both sides with 120 W

Node Master or slave

Number of nodes Max. 63

Baud rate See CAN communication manual

Bus length See CAN communication manual

Connection SUB−D, 9−pole, connector

Type RS485

Protocol MPI

Topology Line, terminated on both sides with 200 W

Node Master

Number of nodes Max. 32 per segment

Baud rate 19.2 kBaud ... 12 MBaud

Bus length Max. 50 m

Connection SUB−D, 9−pole, connector

105m 105 106 108 110 110s

Typ EL xxx PLC

1024

512

4

4

V1.x

RS232

Max. 127 with RS485 repeaters

LDCDS−EL100 EN 9.0

21

Page 22

4

Technical data

Electrical data

EL 1xx ECO (PLC)

4.2.2 EL 1xx ECO (PLC)

Supply

Voltage [V] DC 24 (+18 ... 30)

Current at 24 V [A] 0.21

Power at 24 V [W] 5.0

Buffer for real−time clock

dated

Capacitor

Max. buffer time

CPU and operating system

CPU type IntelR Xscale PXA 270

Operating

system

Memory

RAM [MB] 64

Flash [MB] 32

Exchangeable

disk storage

Memory

RAM [MB] 64

Flash [MB] 32

Exchangeable

disk storage

1)

Due to the great variety of SD/SDHC cards available on the market, compatibility cannot be ensured. We do not

know about any restrictions.

[week]

Type EL xxx ECO

103

Typ EL xxx ECO

103

2

Typ EL xxx ECO

103

WindowsR CE 5.0

Typ EL xxx ECO CAN

103

SD/SDHC card slot

Typ EL xxx ECO PLC

103

SD/SDHC card slot

1)

1)

22

LDCDS−EL100 EN 9.0

Page 23

Technical data

Electrical data

EL 1xx ECO (PLC)

4

Screen

Type Touch screen, resistive

Colours 64 K

Display diagonal [cm] 8.9 (3.5")

Visible size [mm] 70 x 53

Resolution [pixels] 320 x 240

Pixel size [mm] 0.7 x 0.22

Contrast 400:1

Brightness [cd/m2] 300

Angle of view

right

bottom

Illumination LED

Service life at

25°C

PLC functions

(EN 61131−3)

Editor AWL, FUP, KOP, ST, AS, CFC

Program code [kB] 256

Data memory

Variables

Global Var.

Memory location [kB] 4

Process image

Input

Output

Retain data [kB] 16

UPS Integrated to save retain data to the flash memory

Target

L−force Logic

EL1xx

Task runtime [ms] ³100

[°] 65

left

top

[h] −

[kB]

[kB]

[kB]

[kB]

Typ EL xxx ECO

103

65

50

60

Typ EL xxx ECO PLC

103

64

64

1

1

V2.x

LDCDS−EL100 EN 9.0

Ports

LAN

USB

CAN

Type

Protocol TCP/IP

Baud rate 10/100 Mbits

Connection RJ45, socket

Type 2.0 (1.1−compatible)

Connection Type A, socket

Type CAN, ISO11898

Protocol Lenze system bus CAN

Topology Line, terminated on both sides with 120 W

Node Master or slave

Number of nodes Max. 63

Baud rate See CAN communication manual

Bus length See CAN communication manual

Connection SUB−D, 9−pole, connector

Ethernet

23

Page 24

4

Technical data

Mechanical data

EL 1xx CAN/PLC/MPI

4.3 Mechanical data

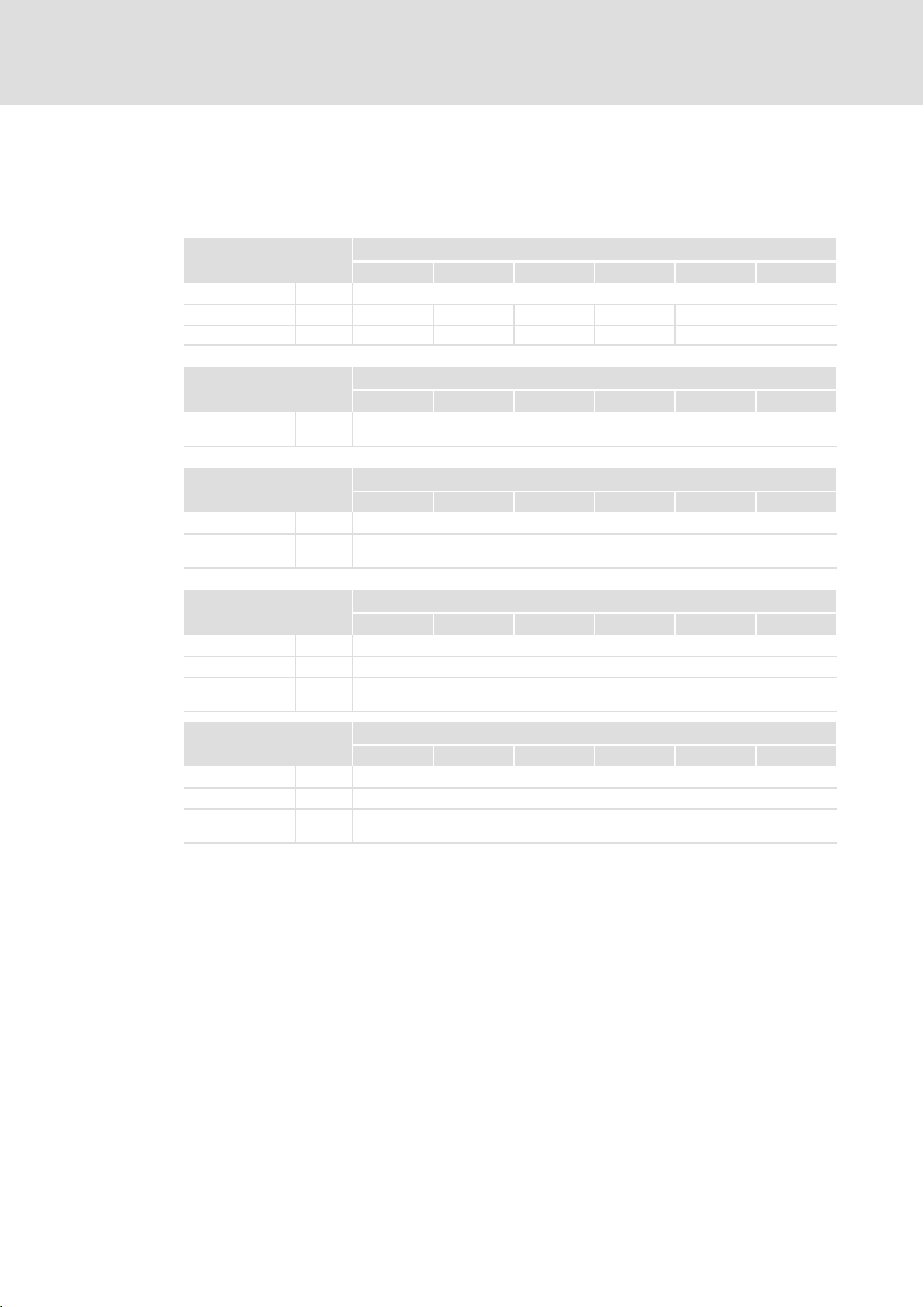

4.3.1 EL 1xx CAN/PLC/MPI

Design and weight

Front Aluminium with polyester film to DIN 42115

Cover Sheet steel, galvanised

Weight [kg] 1.1 1.1 1.2 1.5 2.0

Type EL xxx

105m 105 106 108 110 110s

EL100−002

Type

a a1 b b1 b2 e1 e2 t n ±0.5 m ±0.5

EL 105

EL 105M

EL 106

EL 108 250 220 180 156.5 33.7 46 18 4 224 160.5

EL 110

EL 110s

210

275 257 220 201 75.5 46 18 4 261 205

193 155 138 17.5 43.6 17.6 4 197 142

Dimensions Mounting cutout

[mm] [mm]

24

LDCDS−EL100 EN 9.0

Page 25

4.3.2 EL 1xx ECO (PLC)

Technical data

Mechanical data

EL 1xx ECO (PLC)

4

Design and weight

Front Aluminium with polyester film to DIN 42115

Cover Sheet steel, galvanised

Weight [kg] 0.4

Type

EL 103

ECO

a a1 b b1 e1 t n ±0.5 m ±0.5

130 116.5 104 90.5 33.6 3 120 94

Dimensions Mounting cutout

[mm] [mm]

Type EL xxx ECO

103

EL100e−002

LDCDS−EL100 EN 9.0

25

Page 26

5

Mechanical installation

Important notes

5 Mechanical installation

5.1 Important notes

The installation must be carried out by qualified, skilled personnel familiar with the

applicable national standards.

Stop!

Sensitive front frame gasket

During mounting, the gasket of the front frame is exposed and can be

damaged.

Possible consequences:

ƒ The degree of protection provided by the enclosure mentioned in the

technical data is not attained.

Protective measures:

ƒ Handle the gasket with care during mounting.

ƒ Protect the gasket against ultraviolet rays.

ƒ Each time before you mount the device, check whether the gasket is intact.

Stop!

Sensitive touchscreen surface

The touchscreen foil is very sensitive to external forces and can be damaged by

improper handling.

Possible consequences:

ƒ The touchscreen foil becomes damaged, scratched or dull.

Protective measures:

ƒ Avoid contact of the touchscreen foil with pointed or hard objects.

ƒ Always use a touch pen or your fingers to operate the touchscreen. Never

use objects such as ballpoint pens, pencils, etc.

ƒ When removing dirt and fingerprints, observe the notes given in the chapter

"Cleaning" ( 90).

Note!

When selecting the place where the PC is to be installed, pay attention to an

ergonomic positioning of the screen and to the incidence of light which might

cause reflections on the screen.

26

LDCDS−EL100 EN 9.0

Page 27

5.2 Mounting steps

Mechanical installation

Mounting steps

5

EL100−004

How to assemble the HMI:

1. Cut the mounting cutout out of the control cabinet door.

2. Assemble the upper screw clamping fixtures (see figure).

3. Check if the gasket under the front panel is located correctly.

4. Insert the device into the mounting cutout, secure it by hand against falling down

and tighten the assembled screw clamping fixtures hand−tight.

5. Secure the device by hand, assemble the remaining screw clamping fixtures and

tighten them hand−tight.

6. Check if the device is securely located in the mounting cutout and if the front panel

gasket is located correctly.

– If necessary, loosen the screw clamping fixtures, re−align the device or gasket and

tighten the screw clamping fixtures hand−tight.

– If the gasket is not located correctly, protection class IP65 is not reached on the

front of the device!

LDCDS−EL100 EN 9.0

27

Page 28

6

Electrical installation

Important notes

6 Electrical installation

6.1 Important notes

The installation must be carried out by qualified, skilled personnel familiar with the

applicable national standards.

Stop!

Short circuit and static discharge

The device contains components which are endangered in the case of short

circuit or static discharge.

Possible consequences:

ƒ The device or parts of it will be destroyed.

Protective measures:

ƒ Always switch off the voltage supply when working on the device. This

particularly applies:

– Before connecting / disconnecting connectors.

– Before plugging in / plugging out modules.

ƒ All persons handling printed circuit boards have to take account of ESD

measures.

ƒ Contacts of plug connectors must not be touched.

ƒ Printed circuit boards may be touched only at places free from electrical

contacts and may be placed only on appropriate materials (e.g. on ESD

packaging or conductive foam material).

ƒ Printed circuit boards may only be transported and stored in ESD packaging.

28

LDCDS−EL100 EN 9.0

Page 29

6.2 Wiring according to EMC

Electrical installation

Wiring according to EMC

6

General notes l The electromagnetic compatibility of the system depends on the type and accuracy of the

installation. Please especially note the following:

– Structure

– Shielding

– Earthing

l In the case of a differing installation it is required for evaluating the conformity to the EMC

Directive to check the system with regard to compliance with the EMC limit values. This for

instance applies to:

– The use of unshielded cables

l The end user is responsible for compliance with the EMC Directive.

– If you observe the following measures, you can be sure that no EMC problems will occur

during operation and that the EMC Directive or the EMC law is met.

– If devices which do not meet the CE requirement with regard to noise immunity

EN 61000−4−2 are actuated near the system, these devices can be affected

electromagnetically by the system.

Structure l Connect device to the earthed mounting plate:

– Mounting plates with an electroconductive surface (zinc−coated or stainless steel) allow for

continuous contacting.

– Coated plates are not suitable for an EMC−compliant installation.

l If you use several mounting plates:

– Connect mounting plates to each other on a large surface and in a conductive manner (e.g.

by means of copper strips).

l When installing the cables, observe a spatial separation of signal and mains cables.

l Route the cables as near to the reference potential as possible. Freely suspended cables act

like aerials.

Shielding l Preferably only use cables with a braid.

l The coverage of the shield should be more than 80%.

l In the case of data lines for a serial coupling, always use metallic or metallised plugs. Connect

the shield of the data line on the connector shell.

Earthing l Earth all metallically conductive components by the use of corresponding cables from a

central earthing point (PE rail).

l Comply with the minimum cross−sections defined in the safety instructions:

– With regard to EMC, however, not the cable cross−section, but the surface of the cable and

of the extensive contacting is decisive.

LDCDS−EL100 EN 9.0

29

Page 30

6

Electrical installation

Wiring

EL 1xx CAN/PLC/MPI

6.3 Wiring

6.3.1 EL 1xx CAN/PLC/MPI

Mains connection

Note!

ƒ Observe the max. permissible input voltage.

Professionally fuse the device on the input side against voltage fluctuations

and voltage peaks.

ƒ The HMI boots up as soon as the supply voltage is applied.

After the operating system has been shut down, the HMI switches off

automatically. For restarting, the supply voltage has to be disconnected for a

short time.

0V U

Description Connection type Cable type

DC 24 V connection

IPC001

PE connection Threaded bolt M4

IPC001

3−pole Phoenix Combicon

socket

cross−section max. 2.5 mm

with Phoenix Combicon plug,

MSTB 2.5 / 3−STF−5.08

Separate earthing conductor

(min. 2.5 mm

Cable (conductor

2

) with ring

cable lug

EL100−005

2

)

30

LDCDS−EL100 EN 9.0

Page 31

Serial interface

Description Connection type Cable type

1

6

RS232 connection

Pin 1: DCD

Pin 2: RxD

Pin 3: TxD

Pin 4: DTR

Pin 5: GND

Pin 6: DSR

Pin 7: RTS

Pin 8: CTS

Pin 9: RI

IPC001

Ethernet interface

Description Connection type Cable type

Ethernet connection

10/100 Mbps

Green LED (SPEED):

Yellow LED (LINK/ACTIVITY):

IPC001

on = 100 MBPS

off = 10 Mbps

on or blinking = LINK

/ACTIVITY

off = no LINK

Electrical installation

EL 1xx CAN/PLC/MPI

9−pin Sub−D plug

RJ45 socket

Control cable, shielded, with

Network cable CAT5 S/UTP or

CAT5e S/FTP (recommended),

cable length: max. 100 m

6

Wiring

9−pin Sub−D socket

Note!

If the RJ45 plug connection is exposed to oscillating or vibrating stress:

ƒ Use a strain relief in the immediate vicinity of the RJ45 socket.

ƒ Select the contact surface on which the device is mounted as fixing point of

the strain relief.

ƒ Comply with the related minimum bending radius of the cable used.

USB interface

IPC001

USB

DVI/USB−010

Description Connection type Cable type

USB 2.0 host connection

Max. load: 5 V/500 mA

USB device connection USB−B socket USB cable with USB−B plug

USB−A socket USB cable with USB−A plug

LDCDS−EL100 EN 9.0

31

Page 32

6

Electrical installation

Wiring

EL 1xx CAN/PLC/MPI

CAN interface

Note!

ƒ Only connect terminals of the same signal type.

ƒ For further information with regard to the CAN bus system please refer to

the CAN Communication Manual.

A

1

CAN

CG

LO HI CG

RR

A1 Node 1

A2 Node 2

An Node n

CG CAN−GND

LO CAN−LOW

HI CAN−HIGH

R 120 W−bus terminating resistor

A

2

CAN

LO HI CG

A

CAN

LO HI

n

We recommend the use of CAN cables in accordance with ISO 11898−2:

CAN cable in accordance with ISO 11898−2

Cable type Paired with shielding

Impedance 120 W (95 ... 140 W)

Cable resistance/cross−section

Cable length £ 300 m £ 70 mW/m / 0.25 0.34 mm2 (AWG22)

Cable length 301 1000 m £ 40 mW/m / 0.5 mm2 (AWG20)

Signal propagation delay £ 5 ns/m

Description Connection type Cable type

1

6

CAN bus connection

Pin 1: Not assigned

Pin 2: CAN−LOW (LO)

Pin 3: CAN−GND (CG)

Pin 4 ... 6: Not assigned

Pin 7: CAN−HIGH (HI)

Pin 8 ... 9: Not assigned

IPC001

9−pole Sub−D plug

CAN cable acc. to ISO 11898−2

with 9−pole Sub−D socket

EL100−009

32

LDCDS−EL100 EN 9.0

Page 33

MPI interface

Note!

ƒ For more information on the MPI port, please see the Siemens S7 System

Manual.

Electrical installation

Wiring

EL 1xx CAN/PLC/MPI

6

EL1xx

66

P5V

390 390

33

RxD/TxD-P RxD/TxD-P

RxD/TxD-N RxD/TxD-N

220 220

88

390 390

55

M5V M5V

++

S7

P5V

Note!

Only use cables complying with the listed specifications of the PROFIBUS user

organisation.

Field Values

Specific resistance 135 ... 165 W/km, (f = 3 ... 20 MHz)

Capacitance per unit length £ 30 nF/km

Loop resistance < 110 W/km

Core diameter > 0.64 mm

Core cross−section > 0.34 mm

Cores Twisted double, insulated and shielded

Description Connection type Cable type

1

MPI connection

Pin 1 ... 2: Not assigned

Pin 3: RxD/TxD−P (B)

6

Pin 4: RTS

Pin 5: M5V

Pin 6: P5V

Pin 7: Not assigned

Pin 8: RxD/TxD−N (A)

Pin 9: Not assigned

IPC001

2

9−pole Sub−D socket

According to specification of

EL100−019

the Siemens company

LDCDS−EL100 EN 9.0

Cable fixing and strain relief

Realise external strain relief.

33

Page 34

6

Electrical installation

Wiring

EL 1xx ECO (PLC)

6.3.2 EL 1xx ECO (PLC)

Mains connection

0V U

IPC001

Description Connection type Cable type

Cable (conductor

cross−section max. 2.5 mm

with Phoenix Combicon plug,

MSTB 2.5 / 3−STF−5.08

DC 24 V connection

3−pole Phoenix Combicon

socket

EL100e−005

2

)

PE connection Screw M4

IPC001

Ethernet interface

Description Connection type Cable type

Ethernet connection

10/100 Mbps

Green LED (SPEED):

Yellow LED (LINK/ACTIVITY):

IPC001

Note!

If the RJ45 plug connection is exposed to oscillating or vibrating stress:

ƒ Use a strain relief in the immediate vicinity of the RJ45 socket.

ƒ Select the contact surface on which the device is mounted as fixing point of

the strain relief.

ƒ Comply with the related minimum bending radius of the cable used.

on = 100 MBPS

off = 10 Mbps

on or blinking = LINK

/ACTIVITY

off = no LINK

RJ45 socket

Separate earthing conductor

(min. 2.5 mm

Network cable CAT5 S/UTP or

CAT5e S/FTP (recommended),

cable length: max. 100 m

2

) with ring

cable lug

34

LDCDS−EL100 EN 9.0

Page 35

USB interface

IPC001

CAN interface

Note!

ƒ Only connect terminals of the same signal type.

ƒ For further information with regard to the CAN bus system please refer to

the CAN Communication Manual.

Electrical installation

Wiring

EL 1xx ECO (PLC)

Description Connection type Cable type

USB 2.0 host connection

Max. load: 5 V/500 mA

USB−A socket USB cable with USB−A plug

6

A

1

CAN

CG

LO HI CG

RR

A1 Node 1

A2 Node 2

An Node n

CG CAN−GND

LO CAN−LOW

HI CAN−HIGH

R 120 W−bus terminating resistor

A

2

CAN

LO HI CG

A

CAN

LO HI

n

We recommend the use of CAN cables in accordance with ISO 11898−2:

CAN cable in accordance with ISO 11898−2

Cable type Paired with shielding

Impedance 120 W (95 ... 140 W)

Cable resistance/cross−section

Cable length £ 300 m £ 70 mW/m / 0.25 0.34 mm2 (AWG22)

Cable length 301 1000 m £ 40 mW/m / 0.5 mm2 (AWG20)

Signal propagation delay £ 5 ns/m

EL100−009

LDCDS−EL100 EN 9.0

35

Page 36

6

Electrical installation

Wiring

EL 1xx ECO (PLC)

Description Connection type Cable type

CAN bus connection

Pin 1: CAN−GND (CG)

Pin 2: CAN−LOW (LO)

Pin 3: CAN−SHIELD

Pin 4: CAN−HIGH (HI)

Pin 5: Not assigned

EL100−011

5−pole Phoenix Combicon

socket

CAN cable acc. to ISO 11898−2

with Phoenix Combicon plug,

MSTB 2.5 / 5−STF−5.08

CAN cable shield connection via cable clamp on the back of the device:

EL100−033

Cable fixing and strain relief

Fix the cable bundles on the back of the EL 103 using cable ties.

EL100−034

36

LDCDS−EL100 EN 9.0

Page 37

7 Commissioning

7.1 Connecting external devices

The HMI can communicate with other devices via different interfaces, e.g. to exchange

data or transfer projects:

EL 1xx PC

LAN LAN

1)

USB-B

USB-A

Commissioning

Connecting external devices

7

1)

COM1

USB-A

SD/SDHC

2)

CAN

2)

MPI

1)

Not for EL 1xx ECO (PLC)

2)

Optionally CAN or MPI (EL 1xx ECO: CAN only)

EL 1xx « PC Ethernet connection, e.g. via cross−link cable

EL 1xx « PC USB connection device−host (the Microsoft

EL 1xx « PC Serial connection via serial cross−link cable

USB stick, external keyboard/mouse

SD/SDHC card

EL 1xx « PC CAN bus connection with 2177IB (CAN to USB−A) or 2173IB (CAN to LPT

EL 1xx « S7 MPI connection

2177IB

2173IB

installed on the PC.)

interface) PC bus adapter

COM

USB-A

LPT

Simatic S7

MPI

â

"ActiveSync" software must be

EL100−016

LDCDS−EL100 EN 9.0

37

Page 38

7

7.2 Initial switch−on

Commissioning

Initial switch−on

How to proceed:

1. Check the whole wiring for completeness and correct installation.

For comprehensive inputs, we recommend to connect an external keyboard and mouse

to the USB port.

2. Switch on the voltage supply of the EL 1xx.

– The EL 1xx boots up, the operating system is started.

– If the EL 1xx is protected by a password, it will be queried.

– If the Show Explorer control field in the StartUp Control Panel Applet is marked

( 47), the Windows CE desktop will be displayed.

– If an autostart of the Remote Access Manager is specified in the VisiWinNET

Control Panel Applet ( 49), it will be started.

– If an autostart is specified for a project in the VisiWinNET

( 49), it will be started.

â

Control Panel Applet

â

7.3 Establish Ethernet connection

The EL 1xx can be connected to a LAN or to a PC directly (peer−to−peer) via Ethernet

interface.

38

LDCDS−EL100 EN 9.0

Page 39

7.3.1 Configure Ethernet interface

Prerequisite:

ƒ The EL 1xx is physically connected to the fieldbus via Ethernet interface.

– Network (with router): via Ethernet cable

– Peer−to−peer (without router): via crossed Ethernet cable (cross−over)

ƒ The EL 1xx is switched−on.

How to proceed:

1. Click Start ® Settings ® Network and Dial−up Connections on your EL 1xx.

2. Click the Dm9CE1 connection and configure the following dialogue via network

interface.

Commissioning

Establish Ethernet connection

Configure Ethernet interface

7

3. Click OK.

Note!

Modifications are not stored automatically in the Registry. This means that

they will be lost after a restart.

If you wish to make permanent modifications, proceed as follows:

ƒ Click Start ® Settings ® Control Panel ® Registry on your EL 1xx.

ƒ Click Save.

4. If an IP address assignment via DHCP Server was specified when configuring the

interface (only available for networks with router), restart the EL 1xx.

5. Double−click the network symbol down right in the status bar and check the

settings.

EL100−021

LDCDS−EL100 EN 9.0

39

Page 40

7

7.3.2 Activate communication between EL 1xx and VisiWinNetâ Smart

Commissioning

Establish Ethernet connection

Activate communication between EL 1xx and VisiWinNet

â

Smart

The following settings are required if you wish to transmit a VisiWinNET

the EL 1xx via Ethernet. They are not required to establish a general TCP/IP connection.

How to proceed:

â

Smart project to

Note!

If an autostart of the Remote Access Manager is specified in the VisiWinNET

Control Panel Applet ( 49), the VisiWinNET Remote Access dialogue is

displayed automatically after starting the HMI.

Proceed as follows if that dialogue is not displayed:

ƒ Start ® Programs ® Windows Explorer

ƒ Folder Flashdisk/VisiWinNET

ƒ Double−click the VisiWinNET.RemoteAccessManager Application.

1. Activate the Commandhandler Registry in the VisiWinNET Remote Access Dialogue.

â

2. If the TCP/IP control field is selected and the status is displayed as Running,

communication has been enabled. Elsewise, proceed as follows:

3. Select the TCP/IP control field.

4. Click Start.

The status changes to Running. TCP/IP communication has been enabled.

5. Click Save to store this setting.

See VisiWinNET

information on project transmission.

â

Smart software manual, Getting Started, for further

EL100−020

40

LDCDS−EL100 EN 9.0

Page 41

7.4 Establish CAN fieldbus connection

An EL 1xx CAN or EL 1xx ECO can be connected to a CAN fieldbus system via CAN interface.

7.4.1 Configure CAN interface

Prerequisite:

ƒ The EL 1xx is physically connected to the fieldbus via CAN interface.

ƒ The EL 1xx is switched−on.

How to proceed:

1. Click Start ® Settings ® Control Panel ® Fieldbus on the EL 1xx and configure the

CAN interface in the following dialogue.

Commissioning

Establish CAN fieldbus connection

Configure CAN interface

7

EL 1xx CAN Device Node: The EL 1xx node address within a CAN fieldbus network.

Baud Rate: Transmission speed of the fieldbus. The baud rate must be identical for

each fieldbus node within the same network. The fieldbus parameters are set

according to the baud rate.

2. Click Save.

EL100−028

LDCDS−EL100 EN 9.0

41

Page 42

7

7.5 Establish MPI connection

Commissioning

Establish MPI connection

An EL1xx MPI is able to communicate with a S7 PLC via MPI (Multi Point Interface).

Prerequisite:

ƒ The EL 1xx is physically connected to the fieldbus via MPI interface.

ƒ The EL 1xx is switched−on.

How to proceed:

1. Click Start ® Settings.® Control Panel.® MPI Configuration on your EL 1xx.

The MPI Configuration Dialogue will be opened.

EL100−029

HSA: Set the highest MPI address (Highest Station Address) here. The highest MPI

address must be identical within an MPI network!

TS (This Station): Set the local MPI address for the EL 1xx here.

Baud Rate: Transmission speed of the MPI network. The baud rate must be identical

for each MPI node within the same network. The MPI parameters are set according to

the baud rate.

Default Net Parameters: Default Net Parameters specified due to the baud rate. We

recommend not to modify them.

Status: The status of the MPI interface is displayed as "Offline", "Online" or "Error" in

the status bar.

2. Click OK.

Note!

Modifications are not stored automatically in the Registry. This means that

they will be lost after a restart. If you wish to make permanent modifications,

proceed as follows:

ƒ Click Start ® Settings ® Control Panel ® Registry.

ƒ Click Save.

42

LDCDS−EL100 EN 9.0

Page 43

7.6 UPS functionality

An "EL 1xx PLC" is equipped with an internal UPS which − in the event of a supply voltage

failure − keeps the EL 1xx alive until the values of the retain variables have been saved

fail−safe.

Note!

The PLC program indicates retain variables by the keyword RETAIN. The value

of these variables remains unchanged both after an uncontrolled and a normal

PLC exit. After restarting the PLC, the values will be available again.

An application example is a unit counter in a production plant which is to

continue counting after a restart.

After a supply voltage failure, the following steps will be carried out automatically:

1. To bridge voltage fluctuations, the system waits for a defined time and sees if the

supply voltage is applied again (delay time = 500 ms).

If the supply voltage is applied again within this time, the system continues operation

as usual.

Commissioning

UPS functionality

7

2. Otherwise, the background light of the display is switched off, the run−time

system/controller is stopped and the CAN telegram only transmits zeros.

3. All retain variables are saved within the buffer time of 2 seconds.

4. After the buffer time, the system checks cyclically whether the supply voltage is

applied again.

When the supply voltage is applied again, the system is restarted.

Otherwise, the system continues running until the buffer capacitors have drained.

LDCDS−EL100 EN 9.0

43

Page 44

7

7.7 Installing fonts

Commissioning

Installing fonts

If you want to use additional fonts, for instance containing Asian characters, on the EL 1xx,

you can implement them by means of the "AddFont.exe" tool.

Note!

Please observe the size of the font files, in particular for Asian fonts. To begin

with, check whether the files still fit into the internal flash memory of the

EL 1xx or if they have to be swapped out to an SD/SDHC card.

How to proceed:

1. Depending on the memory location, create the following directory for the additional

fonts:

Internal flash memory: \Flashdisk\Fonts

SD/SDHC card: \Storage\Fonts

2. Copy the "Addfont.exe" file from the "L−force PC−based Automation" DVD to this

directory.

3. Also copy the font files to this directory.

4. Extend the "\Flashdisk\Autostart.txt" file according to the following example:

;=============================================================

; use API addfont in Flashdisk\Fonts!!!!!

; Example: ;\Storage\Fonts\AddFont.exe Storage\Fonts\

;==============================================================

\Flashdisk\Fonts\AddFont.exe Flashdisk\Fonts\

5. Save the "Autostart.txt" file.

6. Restart the EL 1xx.

44

LDCDS−EL100 EN 9.0

Page 45

8 Operation

8.1 Operating system components

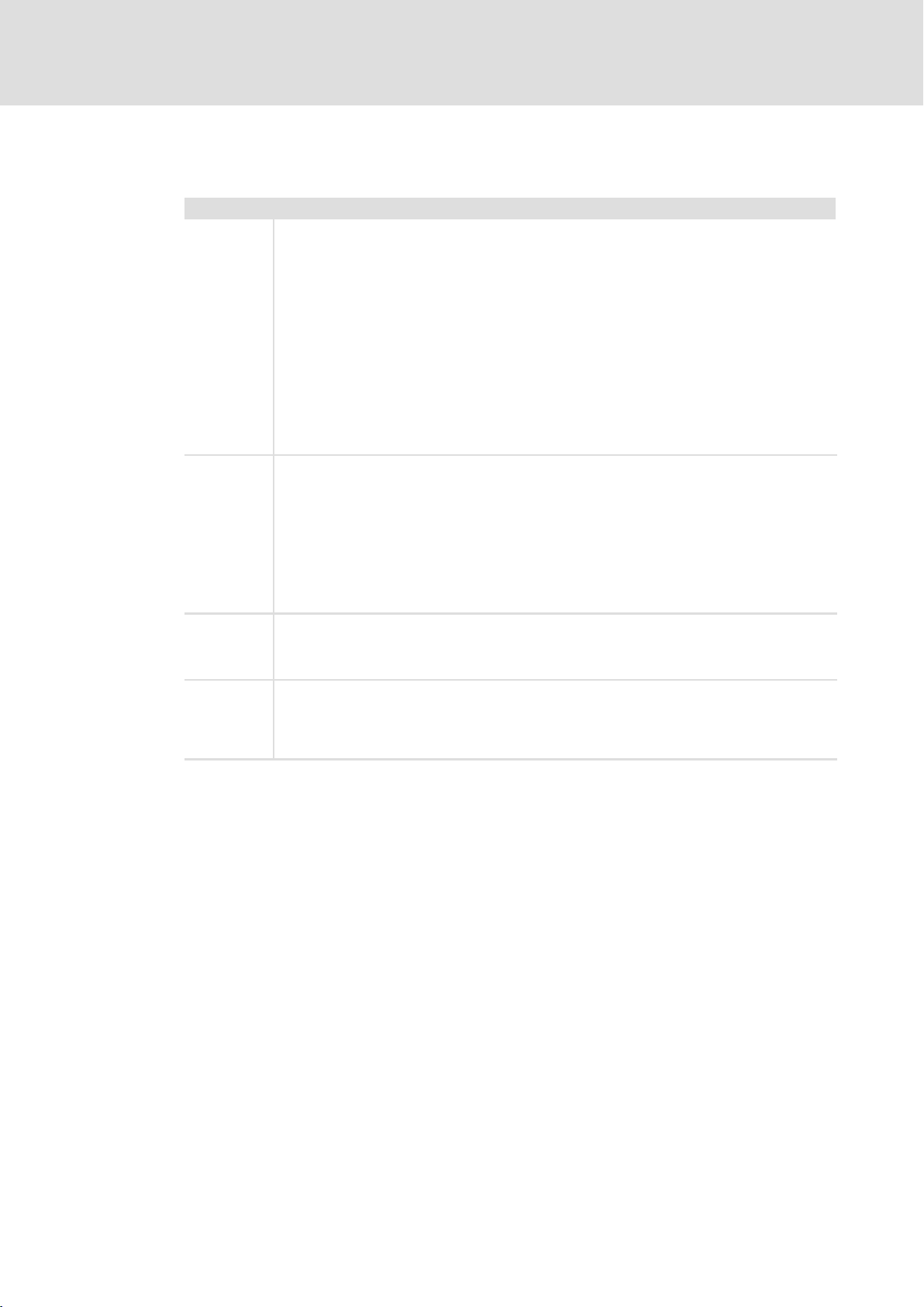

The following table shows the components of the optional versions of the Windows

operating system.

Component Description Version

Web Server X X

Remote Desktop (VNC) X X

FTP Server X X

RAS Server − X

Telnet X X

Active Sync File Transfer X X

Internet Explorer 6.0 − X

Registry Editor X X

Word Pad − X

Mouse Pointer X X

USB Keyboard Driver X X

HP Printer Driver (PCL) X X

HMI Start Manager X X

File Viewer Excel/Image/PDF/PowerPoint/Word

.NET Compact Framework 2.0 X X

USB Support X X

Touch Driver X X

TCP/IP X X

CAN Driver, Control Panel Applet X X

MPI Driver, Control Panel Applet X X

Soft Keyboard Software Input Panel X X

Control Panels X X

Network Tools Ping, Tracert, Netstat, Net X X

Visual Studio Communication

Components

Operation

Operating system components

Core ProPlus

− X

Viewer

ConmanClient2, Clientshutdown X X

8

R

CE

LDCDS−EL100 EN 9.0

45

Page 46

8

8.2 Control Panel Applets

Operation

Control Panel Applets

The Control Panel Applets adjusted or advanced by LENZE are described in the following.

Note!

A description of the standard WindowsR CE applets can be found in the

Windows

R

CE literature.

EL100−022

How to open the Control Panel:

1. Click Start ® Settings ® Control Panel on your EL 1xx.

The Control Panel window will be opened.

46

LDCDS−EL100 EN 9.0

Page 47

8.2.1 StartUp

Show Explorer: After the booting, the Windows CE desktop (Explorer) will be started if this

control field has been selected. Programs and settings cannot be accessed if this control

field has not been selected.

Note!

VNC Server Autostart: After the booting, the VNC Server will be started automatically if

this control field has been selected.

Operation

Control Panel Applets

StartUp

A disabled desktop can only be re−enabled via USB keyboard:

ƒ Press Shift + F4 on the keyboard. The Control Panel will be opened.

ƒ Open StartUP dialogue.

ƒ Select Show Explorer control field.

ƒ Click OK.

ƒ Restart the EL 1xx. The desktop will be re−enabled after a restart.

8

EL100−023

Note!

The VNC Server is not protected by a factory−set password. If the connection is

not required, the server should be disabled to prevent unauthorised access.

Alternatively, establish a password−protected connection.

An active VNC connection means additional load for the system. Hence, we

recommend to start the VNC Server manually via your Web Server if need be

instead of selecting the "Autostart" control field ( 76).

Start: Start VNC Server manually.

Password: Assign password for a password−protected connection (max. 15 characters).

LDCDS−EL100 EN 9.0

47

Page 48

8

8.2.2 Registry

Operation

Control Panel Applets

Registry

Note!

The modifications of some Applets are automatically stored in the Registry

when you click OK (message "Saving").

The modifications of other Applets are not stored automatically in the

Registry, which means that they are lost after a restart. If you wish to make

permanent modifications to these Applets, proceed as follows:

ƒ Click Start ® Settings ® Control Panel ® Registry on your EL1xx.

ƒ Click Save.

EL100−024

Registry Editor: Opens the Registry Editor.

Save: Saves the Registry.

Restart Device: Restarts the EL 1xx.

Clean: After a restart, the Registry is reset to the default setting if this control field has been

selected.

48

LDCDS−EL100 EN 9.0

Page 49

Operation

Control Panel Applets

VisiWinNET

8

â

8.2.3 VisiWinNET

Startup Project: Display of the VisiWinNETâ start project entered in the registry. The EL 1xx

can be searched for installed projects via the Search button. (Note: The search function is

only able to find those projects whose file extension (".vwn") exclusively consists of lower

case letters.)

Search Path: Path that is searched for VisiWinNET

accelerated via this preselection if the data carrier is very large or full.

Autostart: Startup Project will be started automatically when the system is started.

Search: VisiWinNET

Remote Access Manager "Autostart": When the system is started, the VisiWinNET

Connection Manager will be started automatically if this control field has been selected.

â

EL100−025

â

projects. The search process can be

â

project search.

â

OK: The settings are saved. The registration is stored.

8.2.4 Display

Brightness: Changing the brightness of the display. (For EL 105m without function.)

Contrast: Changing the contrast of the EL 105m display. (For all other devices without

function.)

Display rotation: The "−90" and "+90" buttons can be used to rotate the EL 1xx screen in

90−degree steps.

EL100−026

LDCDS−EL100 EN 9.0

49

Page 50

8

8.2.5 Server

8.2.6 Fieldbus

Operation

Control Panel Applets

Server

Find more information later in this chapter ( 72).

EL100−027

EL100−028

This Applet is only relevant for an EL1xx CAN. It has no function in an EL1xx MPI.

EL1xx CAN Device Node: EL1xx node address within a CAN fieldbus network.

Baud Rate: Transmission speed of the fieldbus. The baud rate must be identical for each

fieldbus node within the same network. The fieldbus parameters are set according to the

baud rate.

50

LDCDS−EL100 EN 9.0

Page 51

8.2.7 MPI Configuration

This Applet is only relevant for an EL 1xx MPI.

HSA: Set the highest MPI address (Highest Station Address) here. The highest MPI address

must be identical within an MPI network!

TS (This Station): Set the local MPI address for the EL 1xx here.

Baud Rate: Transmission speed of the MPI network. The baud rate must be identical for

each MPI node within the same network. The MPI parameters are set according to the baud

rate.

Operation

Control Panel Applets

MPI Configuration

8

EL100−029

Default Net Parameters: Default Net Parameters specified due to the baud rate. We

recommend not to modify them.

Status: The status of the MPI interface is displayed as "Offline", "Online" or "Error" in the

status bar.

See VisiWinNET

8.2.8 CAN Gateway

The CAN gateway function is used to implement data transmission from an Ethernet

network to the Lenze "CAN system bus" fieldbus. The following functions are supported:

ƒ Data transmission via SDO

ƒ Parameter data exchange

ƒ Program download from PC to Lenze drive components

Communication between the PC and the Lenze drive components connected to the CAN

system bus is possible via the following programs:

ƒ DriveServer, Global Drive Control, Global Drive Loader

ƒ Global Drive PLC Developer−Studio

ƒ L−force Engineer

â

Smart software manual for further information.

LDCDS−EL100 EN 9.0

Note!

The CAN gateway function is only supported if CAN communication software

from version 2.2.2.0 is installed on the PC.

Further information is provided elsewhere in this manual ( 78).

51

Page 52

8

Operation

Control Panel Applets

CAN Gateway

"State" register

EL100−032

Gateway: Start and stop gateway function

Bus state: Current state of the CAN system bus (BUS−ON or BUS−OFF)

Bus load (%): Current bus load

Error state: Current error

Client connections: Number of connected Ethernet nodes

Status message interpretation (bus state and error state):

BUS−ON and OK: CAN communication is alright.

BUS−ON and ERROR: The warning limit of the CAN controller has been reached or exceeded

(too many error frames). CAN communication is still possible.

BUS−OFF and ERROR: The CAN controller has reached the BUS−OFF state. CAN

communication is not possible. A reset of the device is required.

"Ethernet" register

EL100−033

52

Adapter name: Select the adapter here whose settings are to be displayed.

MAC address, IP address, Subnet mask: Settings from the "Network and Dial−up

Connections for Ethernet" applet.

LDCDS−EL100 EN 9.0

Page 53

Operation

Control Panel Applets

CAN Gateway

"CAN" register

EL100−034

Parameter channel: The parameter channel for data transmission is selected here if the

drive component has more than one parameter channel.

Selection Selectable address range

0 1 ... 127 (parameter channel 1 acc. to CANopen)

1 1 ... 63 (parameter channel 1 acc. to Lenze system bus (CAN))

2 64 ... 127 (parameter channel 2 acc. to Lenze system bus (CAN))

8

The address of e.g. parameter data channel 2 can be calculated as follows:

Address of parameter data channel 2 = Address of parameter data channel 1 + offset 64.

By selecting a value of "0", the bus is "CanOpen" compliant. There is no restriction to the

address range.

SDO timeout [ms]: The time set here defines the time slot a CAN node has to respond to

a request. If there is no response within the set time, the requesting component will

assume that the node is unavailable.

Busscan timeout [ms]: During a bus scan, the system is waiting for the nodes to respond.

On the one hand, the busscan timeout must be large enough to provide all nodes with

sufficient time to respond. On the other hand, the search will be slowing down if the

busscan timeout is too large.

Busscan delay [ms]: Under a heavy CAN bus load, searching the CAN bus for connected

nodes may cause faults. A delay time between the transmission messages can be set to

avoid this situation, thereby causing the search to take more time to finish.

LDCDS−EL100 EN 9.0

53

Page 54

8

Operation

Control Panel Applets

CAN Gateway

"Logging" register

This register displays errors that may be pending.

EL100−050

Autostart: If this option is selected, the CAN gateway is automatically activated when the

device is started. Alternatively, the CAN gateway must be activated manually on the

"State" register.

54

LDCDS−EL100 EN 9.0

Page 55

General information on PLC programming

8.3 Creating a PLC sample program

The following description is only valid for types with integrated PLC (EL 1xx PLC).

In the following sections you will find a description of the basics for creating a PLC program

using the Lenze PLC Designer. For more information about the PLC Designer, please see the

online help for the PLC Designer.

The example describes how to program a simple counter, how to create a .sym file and how

to transfer the program to the PLC of the EL 100 PLC.

To follow the steps described in the following sections, the "PLC Designer" software must

have been installed on your system.

8.3.1 General information on PLC programming

Please observe the following when configuring your EL 1xx:

ƒ The variable type LREAL does not exist.

Operation

Creating a PLC sample program

8

ƒ For direct addresses (%I / Q / M), a natural alignment must be used; i.e.

– BYTEs to any addresses

– 16−bit values (WORD, INT) to even addresses

– 32−bit values (DWORD, DINT) to addresses divisible by 4

ƒ Avoid floating−point operations because they will be emulated and therefore take

much longer than on an X86 with FPU.

ƒ Avoid task runtimes < 100 ms because short task runtimes have disadvantages

regarding visualisation (long reversing times).

LDCDS−EL100 EN 9.0

55

Page 56

8

8.3.2 Start PLC Designer

Operation

Creating a PLC sample program

Start PLC Designer

How to proceed:

1. With a standard installation, the PLC Designer is started via Start Lenze PLC

Designer Vx.x.x.x PLC Designer.

8.3.3 Create PLC program

How to proceed:

1. Open the menu File in the PLC Designer menu bar and select the menu item New.

The "Target Settings" dialogue will be opened.

2. Select the target system depending on the HMI used from the Configuration

selection list:

EL 1xx: L−force Logic EL1xx v1.09

EL 1xx ECO: L−force Logic EL1xx v2.06

If the target system is not available in the Configuration selection list, you can

download it from the download area of the Lenze homepage (www.lenze.com).

3. Click OK to close the dialogue.

The "Target settings" dialogue will be expanded.

56

LDCDS−EL100 EN 9.0

Page 57

Operation

Creating a PLC sample program

Create PLC program

4. Enable the General register and select the Download symbol file control field.

This enables data exchange between the visualistion and the PLC.

5. Click OK to close the dialogue.

The "New POU" dialogue will be opened.

6. Select the ST (structured text) control field.

8

7. Click OK to close the dialogue.

The "PLC_PRG (PRG−ST)" programming window will be opened.

In the next step, we will declare a local variable.

LDCDS−EL100 EN 9.0

57

Page 58

8

Operation

Creating a PLC sample program

Create PLC program

8. Enter the word "Count" in the lower half of the divided "PLC_PRG (PRG−ST)"

programming window.

9. Press [Enter]

The "Declare Variable" dialogue will be opened.