Page 1

BA 12.0023−EN

.IPQ

Ä.IPQä

L−force Geared Motors

Operating Instructions

GLL

GST, GFL, GKS/GKL, GKR, GSS

Gearbox

l

Page 2

, Please read these instructions before you start working!

Follow the enclosed safety instructions.

0Fig. 0Tab. 0

2

l

BA 12.0023−EN 7.0

Page 3

Contents i

1 About this documentation 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Terminology used 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Notes used 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety instructions for drive components 9 . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Application as directed 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Improper use 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Residual hazards 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Temperatures 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Ambient conditions 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Product description 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Identification 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Product features 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Nameplate 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Product key 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Transport weights 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Technical data 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 General data and operating conditions 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Mechanical installation 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Transport equipment for gearbox 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Storage 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Specified directions of rotation 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Mounting 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Preparation 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 General information about the assembly of drive systems 31 . . . . . . . . . . .

5.4.3 Assembly of transmission elements on solid shafts 31 . . . . . . . . . . . . . . . .

5.4.4 Attachment of motors to gearboxes with bearing housing

(input design N) 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.5 Coupling hubs 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.6 Attachment of gearboxes with hollow shafts and keyway 35 . . . . . . . . . .

5.4.7 Mounting the shrink disc with a rotating cover 37 . . . . . . . . . . . . . . . . . . . .

5.4.8 Mounting the fixed cover 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.9 Mounting the hoseproof hollow shaft cover 42 . . . . . . . . . . . . . . . . . . . . . .

5.4.10 Gearboxes with breathers 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.11 Breather position, oil filling screw and drain plug 44 . . . . . . . . . . . . . . . . . .

5.4.12 Gearbox with compensation container for mounting position C 55 . . . . .

BA 12.0023−EN 7.0

l 3

Page 4

Contentsi

5 Electrical installation 57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Motor connection 57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Motor options 57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Commissioning and operation 58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Before switching on 58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 During operation 58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Maintenance 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Maintenance intervals 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Maintenance operations 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 Opening the condensation drain hole 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 Lubricate roller bearings 62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.3 Table of lubricants 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.4 Replacing the lubricant 66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.5 Lubricant quantity 66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.6 Amount of lubricant for combined mounting positions 72 . . . . . . . . . . . . .

8.3 Repair 73 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Disposal 73 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Spare parts list, geared motors 74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 Spare parts list, gearbox and gearbox with variable speed drive 75 . . . . . . . . . . . . .

7.7 Order form 76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Troubleshooting and fault elimination 77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l 4

BA 12.0023−EN 7.0

Page 5

1 About this documentation

Contents

ƒ These Operating Instructions are intended for safety−relevant operations on and

with the gearboxes GLL. They contain safety instructions which must be observed.

ƒ All personnel working on and with the gearboxes GLL must have the Operating

Instructions available and observe the information and notes relevant for them.

ƒ The Operating Instructions must always be complete and perfectly readable.

I Tip!

Information and auxiliary devices related to the Lenze products can be found

in the download area at

http://www.Lenze.com

About this documentation 1

Validity

These instructions are valid for the following gearbox types:

Type Name

GST

GFL

GKS/GKL

GKR

GSS

Helical gearbox

Shaft−mounted helical gearbox

Helical−bevel gearbox

Bevel gearbox

Helical−worm gearbox

Target group

This documentation is directed at qualified skilled personnel according to IEC 60364.

Qualified skilled personnel are persons who have the required qualifications to carry out

all activities involved in installing, mounting, commissioning, and operating the product.

BA 12.0023−EN 7.0

l

5

Page 6

1

About this documentation

Document history

1.1 Document history

Material number Version Description

00 390 375 1.0 11/1995 TD09 1st edition for pilot series

00 393 076 1.0 03/1997 TD09 Completely revised

00 393 076 1.0 04/2000 TD09 Addendum to Ch. 5.4.1 Preparatory work

Updated illustrations for Ch. 5.4.10 Gearbox with breather

00 407 986 1.0 12/2000 TD09 Completely revised

Revised product key and position of system blocks

Supplement with gearbox 03

Ch. 5.4.12 Gearbox with compensation container in mounting position C

Ch. Spare parts list compensation container

Changes of lubricant quantities

00 425 604 1.0 08/2001 TD09 Ch. 5.4.8 Assembly of shrink disk cover: new

Ch. 5.4.9 Assembly of hoseproof hollow shaft cover: new

Supplement with GKR 05

00 425 604 2.0 11/2001 TD09 Changes of lubricant quantities

00 460 708 1.0 12/2002 TD09 Changes of nameplates

Supplement with GKR 06

Change of company’s name

00 460 708 2.0 02/2003 TD09 Supplement − Warning in Ch. 5

00 476 711 2.1 10/2003 TD09 Changes: Product key and position of system blocks

Supplement with Ch. 8.2.2, Roller bearing grease and Ch. 8.2.3, Lubricant table

13124908 3.0 11/2005 TD09 New "geared motor" nameplate included.

Revision of the lubricant table

13166718 4.0 08/2006 TD09 Revision of the nameplate marking

New nameplate: CSA/UL version

Supplement with Ch. Mounting the shrink disc with a rotating cover

Revision of the Ch. Position of the breathing, oil filler plug and oil drain plug

Addition of the drive sizes: 3F; 4E; 6C and 7C

13290892 5.0 03/2009 TD09 Complete revision

13321528 6.0 10/2009 TD09 Conversion from G−motion to L−force Geared Motors

Supplement − Ch. Condensation drain hole

.IPQ 7.0 11/2011 TD09 Update of the lubricant table

Changed lubricant quantities for GST

Transport weights extended

Table of the roller bearing greases extended

6

l

BA 12.0023−EN 7.0

Page 7

About this documentation

Conventions used

1

1.2 Conventions used

This documentation uses the following conventions to distinguish different types of

information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator Point In general, the decimal point is used.

Icons

Page reference ^ Reference to another page with additional

Document reference , Reference to another documentation

1.3 Terminology used

Term In the following text used for

Gearboxes Gearbox of product family GLL

For instance: 1234.56

information

For instance: ^ 16 = see page 16

providing additional information

E.g.: , Software manual ...

Drive system Drive system with gearboxes GLL and other Lenze drive components

BA 12.0023−EN 7.0

l

7

Page 8

1

1.4 Notes used

About this documentation

Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

} Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

{ Danger!

} Danger!

( Stop!

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

) Note!

I Tip!

,

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

8

l

BA 12.0023−EN 7.0

Page 9

General safety instructions for drive components

2 Safety instructions

2.1 General safety instructions for drive components

(in accordance with Low−Voltage Directive 2006/95/EC)

At the time of dispatch, the drive components are in line with the latest state of the art and

can be regarded as operationally safe.

Scope

The following safety instructions generally apply to Lenze drive components.

The product−specific safety and application notes given in this documentation must be

observed!

General hazards

Safety instructions

2

} Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets!

ƒ Lenze drive components ...

... must only be used as directed.

... must never be commissioned in the event of visible damage.

... must never be technically changed.

... must never be commissioned before assembly has been completed.

... must never be operated without required covers.

... can include live and rotating parts − depending on their type of protection − during

and after operation. Surfaces can be hot.

ƒ All specifications of the corresponding enclosed documentation must be observed.

This is vital for a safe and trouble−free operation and for achieving the specified product

features.

ƒ Only qualified, skilled personnel is permitted to work on and with Lenze drive

components.

According to IEC 60364 / CENELEC HD 384, these are persons who ...

... are familiar with the installation, mounting, commissioning, and operation of the

product.

... have the qualifications required for their occupation.

... know and are able to apply all national regulations for the preventions of accidents,

directives and laws applicable on site.

BA 12.0023−EN 7.0

l

9

Page 10

2

Safety instructions

General safety instructions for drive components

Transport, storage

ƒ Transport and storage in a dry, low−vibration environment without aggressive

atmosphere; preferably in the packaging provided by the manufacturer.

– Protect against dust and shocks.

– Comply with climatic conditions according to the technical data.

ƒ Before transport

– Check that all transport locking devices are mounted.

– Tighten all transport aids.

) Note!

Do not apply extra loads to the product as the transport aids (such as eye bolts

or bearing plates) are designed for the weight of the motor only (refer to the

catalogue for the weight).

} Danger!

Completely screw in transport aids (such as eye bolts or bearing plates), they

must be flat and applied over their entire surface!

If possible, the transport aids (such as eye bolts or bearing plates) must be

stressed vertically in the direction of the screw axis! Angular tension or tension

to the sides reduces the payload! Observe the information provided in the

DIN 580!

Use additional appropriate lifting aids, if required, to achieve a direction of

loading which is as vertical as possible (highest payload). Secure lifting aids

against shifting!

If you do not install the motor immediately, ensure proper storage conditions.

ƒ Up to one year:

– Shafts and uncoated surfaces are delivered in a protected against rust status.

Aftertreatment is required where the corrosion protection has been damaged.

– Remove the plug for motors with condensation drain holes (special version).

ƒ More than one year, up to two years:

– Apply a long−term corrosion preventive (e.g. Anticorit BW 366 from the Fuchs

company) to the shafts and uncoated surfaces before storing the motor away.

10

( Stop!

Observe load carrying capacity!

Staying under floating load is prohibited!

l

BA 12.0023−EN 7.0

Page 11

Safety instructions

General safety instructions for drive components

Corrosion protection

Lenze offers paints with different resistance characteristics for drive systems. Since the

resistance may be reduced when the paint coat is damaged, defects in paint work (e.g.

through transport or assembly) must be removed professionally to reach the required

corrosion resistance.

Mechanical installation

ƒ Provide for a careful handling and avoid mechanical overload. During handling

neither bend components, nor change the insulation distances.

Electrical installation

ƒ Carry out the electrical installation according to the relevant regulations (e. g. cable

cross−sections, fusing, connection to the PE conductor). Additional notes are

included in the documentation.

ƒ The documentation contains notes for the EMC−compliant installation (shielding,

earthing, arrangement of filters and installation of the cables). The manufacturer of

the system or machine is responsible for the compliance with the limit values

required in connection with EMC legislation.

2

ƒ Only plug in or remove pluggable terminals in the deenergised state!

Commissioning

ƒ If required, you have to equip the system with additional monitoring and protective

devices in accordance with the respective valid safety regulations (e. g. law on

technical equipment, regulations for the prevention of accidents).

ƒ Before commissioning remove transport locking devices and keep them for later

transports.

BA 12.0023−EN 7.0

l

11

Page 12

2

2.2 Application as directed

Safety instructions

Application as directed

Low−voltage machines are no household appliances, they are designed as components for

industrial or professional use in terms of IEC/EN 61000−3−2 only.

They comply with the harmonised standards of the series IEC/EN60034.

Low−voltage machines are components for installation into machines as defined in the

Machinery Directive 2006/42/EC. Commissioning is prohibited until the conformity of the

end product with this directive has been established (follow i. a. IEC/EN 60204−1).

It is only permissible to use low−voltage machines with IP23 protection or less outdoors if

special protective measures are taken.

The integrated brakes must not be used as safety brakes. It cannot be ruled out that

interference factors which cannot be influenced cause a brake torque reduction.

ƒ Drives

– ... must only be operated under the operating conditions and power limits

specified in this documentation.

– ... comply with the protection requirements of the EC Low−Voltage Directive.

Any other use shall be deemed inappropriate!

2.3 Improper use

ƒ Do not operate the motors

– ... in explosion−protected areas

– ... in aggressive environments (acid, gas, vapour, dust, oil)

– ... in water

– ... in radiation environments

) Note!

Increased surface and corrosion protection can be achieved by using adapted

coating systems.

12

l

BA 12.0023−EN 7.0

Page 13

2.4 Residual hazards

Protection of persons

ƒ The motor surfaces can become very hot. Danger of burns when touching!

– Provide protection against accidental contact, if necessary.

ƒ High−frequency voltages can be capacitively transferred to the motor housing

through the inverter supply.

– Carefully earth the motor housing.

ƒ Danger of unintentional starting or electrical shocks

– Connections must only be made when the equipment is deenergised and the

motor is at standstill.

– Built−in brakes are not fail−safe brakes.

Motor protection

ƒ Integrated temperature sensors do not provide full protection for the machine.

– Limit the maximum current if necessary. Select parameter settings for the

controller which ensure a switch−off if operated at I > I

particularly if a danger of blocking exists.

– The integrated overload protection function does not prevent overloading under

all circumstances.

Safety instructions

Residual hazards

after a couple of seconds,

r

2

ƒ Built−in brakes are not fail−safe brakes .

– Torque reduction is possible through disruptive factors which cannot be

influenced, e.g. through oil ingress due to a defective shaft sealing ring at the A

end.

ƒ Fuses do not protect the motor.

– Use current−dependent motor protection switches for average operating

frequency.

– Use built−in thermal detectors at high operating frequency.

ƒ Excessive torques lead to a break of the motor shaft or demagnetisation.

– Do not exceed the maximum torques according to the catalogue.

ƒ Lateral forces from the motor shaft are possible.

– Perfectly align shafts of motor and driving machine to each other.

ƒ If deviations from normal operation occur, e.g. increased temperature, noise,

vibration, determine the cause and, if necessary, contact the manufacturer. If in

doubt, switch off the motor.

Fire protection

ƒ Fire hazard

– Avoid contact with inflammable substances.

BA 12.0023−EN 7.0

l

13

Page 14

2

2.4.1 Temperatures

Safety instructions

Residual hazards

Temperatures

The permissible temperature range is determined by the following:

ƒ The lubricant specifications in connection with the expected oil temperatures in

operation (see chapter 8.1 and nameplate).

ƒ The thermal class of the motor considering the motor temperature expected during

operation (see nameplate and/or Operating Instructions of the motor).

The operating temperature is determined by the power loss, the ambient temperature and

the cooling system!

( Stop!

With mineral oil, the upper temperature limit for continuous operation is 80°C,

with synthetic oil and shaft sealing rings made of FP (Viton) 100°C. If these

temperatures are exceeded, measures are necessary to reduce the

temperature, see chapter 9.

} Danger!

Depending on the operating conditions, surfaces may be hot, provide

protection against accidental contact.

2.4.2 Ambient conditions

ƒ Gearboxes are protected against dust and spray water.

ƒ Motors according to their enclosure (see nameplate and/or Operating Instructions

for the motor).

ƒ Ambient media − especially chemically aggressive − can destroy shaft seals and

coatings (plastic). Abrasive media endanger shaft seals.

ƒ The installation site of the drive must be free of shocks and vibration.

ƒ Dirt of dust deposits impede the heat dissipation (cooling).

14

l

BA 12.0023−EN 7.0

Page 15

3 Product description

ƒ The most important technical data are given on the nameplate (structure and

contents ^ page 19 to 21).

ƒ The product catalogues contain further technical data.

3.1 Identification

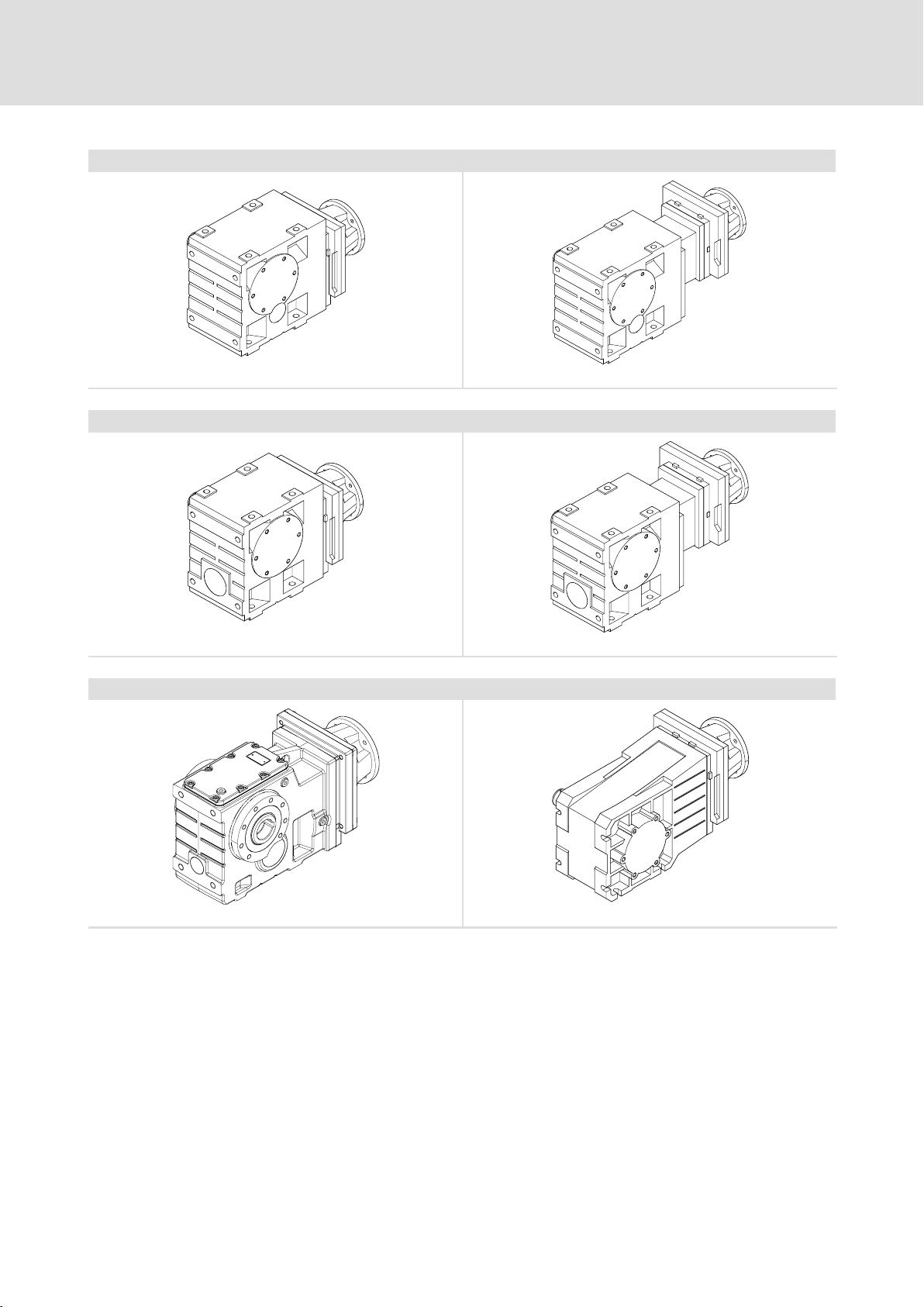

GST

Product description

Identification

3

1−stage 2−stage 3−stage

GFL

2−stage 3−stage

BA 12.0023−EN 7.0

l

15

Page 16

3

Product description

Identification

GKS

3−stage 4−stage

GSS

2−stage 3−stage

GKL GKR

3−stage 2−stage

16

l

BA 12.0023−EN 7.0

Page 17

3.2 Product features

Design

Drive systems have a modular design.

They consist of:

ƒ Reduction gearboxes

– Helical gearboxes

– Shaft−mounted helical gearboxes

– Helical−worm gearboxes

– Helical−bevel gearboxes

– Bevel gearbox

ƒ Variable speed drives

ƒ Motors

Product description

Product features

3

Mode of operation

ƒ Torque and speed conversion

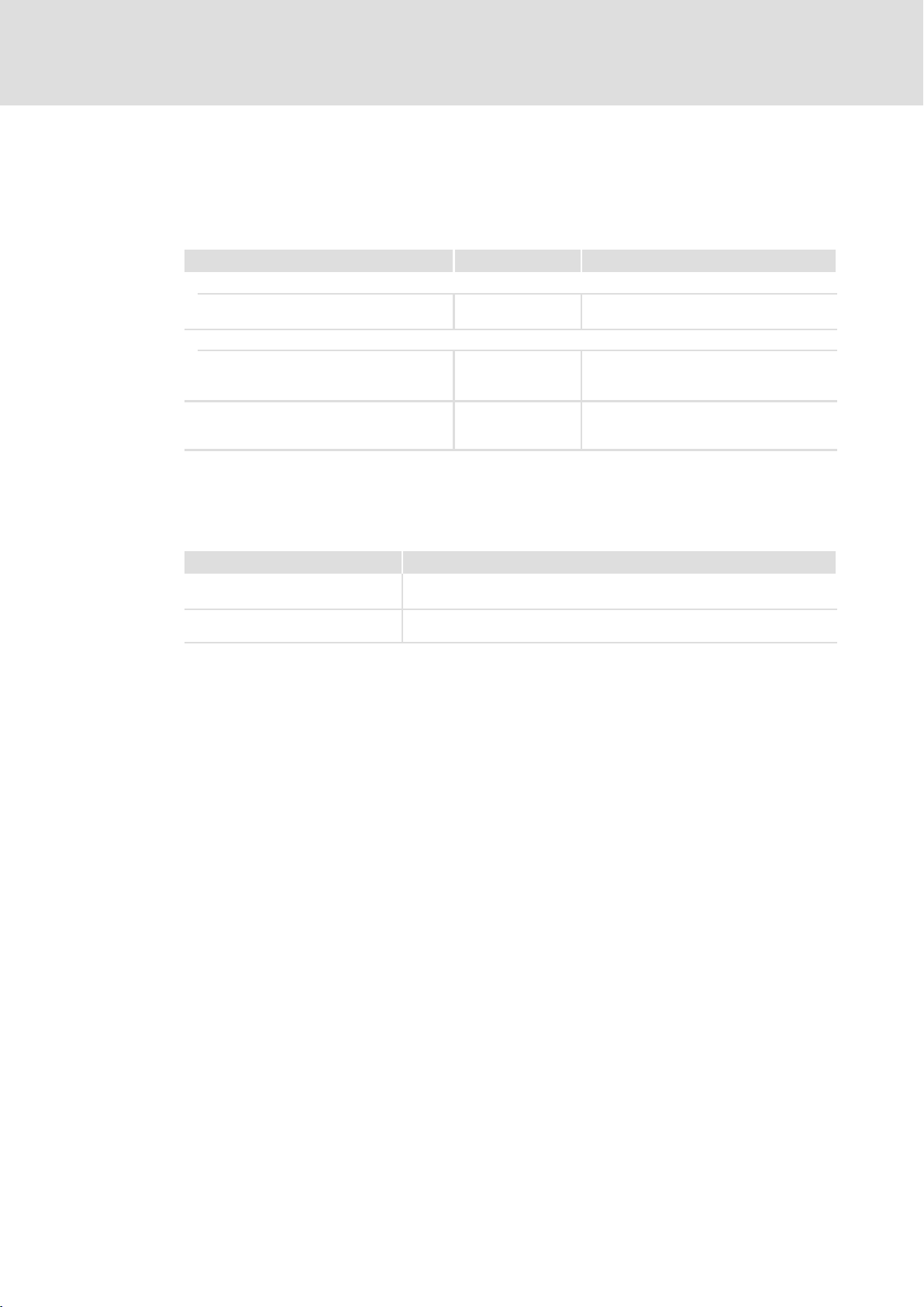

Product family Pre−stage 1st stage 2nd stage 3rd stage

Helical gearbox

Shaft−mounted helical gearbox −−−

Helical−bevel gearbox

Bevel gearbox −−− −−−

Helical−worm gearbox Helical Worm −−−

ƒ The torque reaction must be supported in a suitable manner.

Helical

Helical

Helical

Bevel

−−−

Helical

BA 12.0023−EN 7.0

l

17

Page 18

3

Product description

Product features

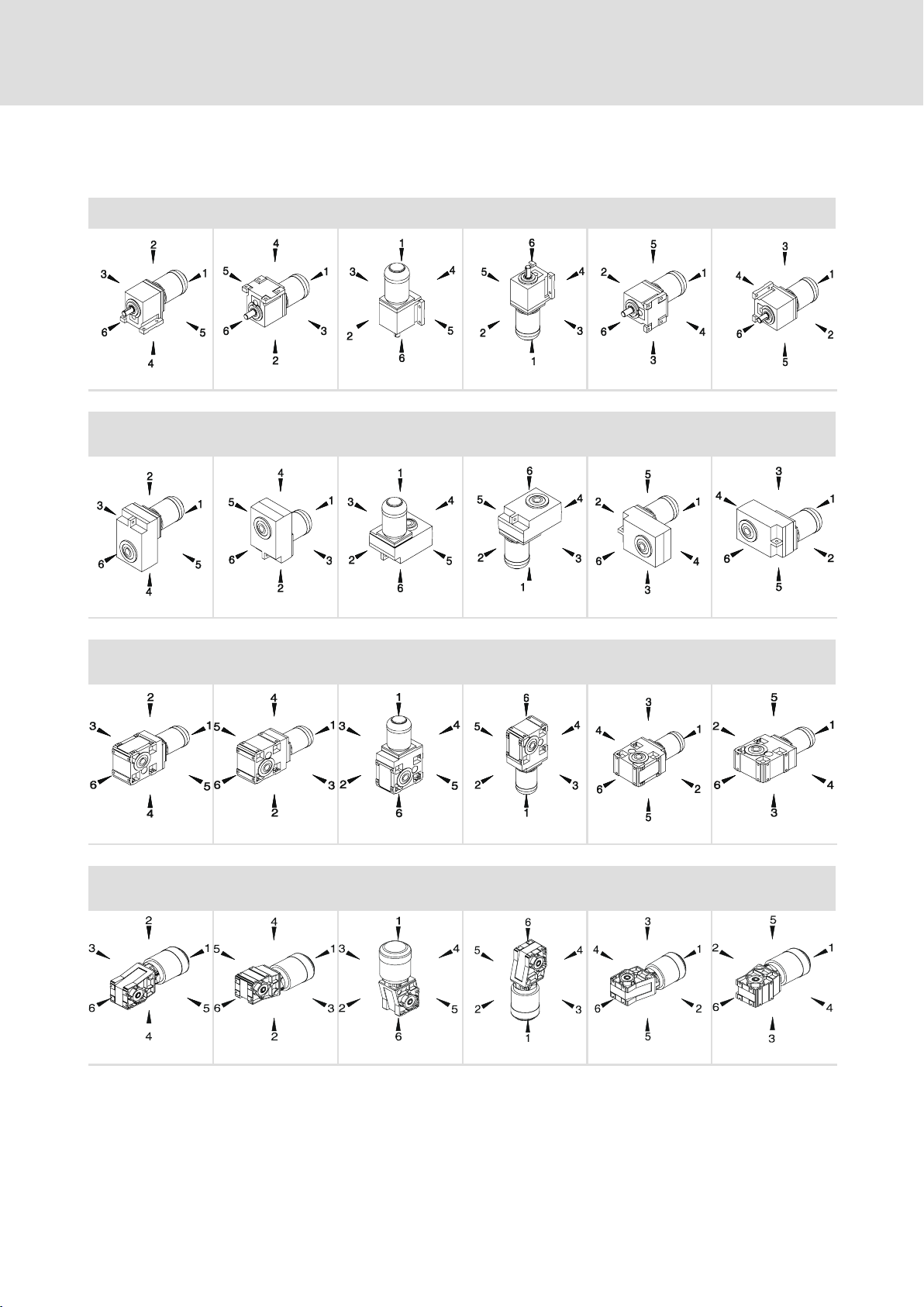

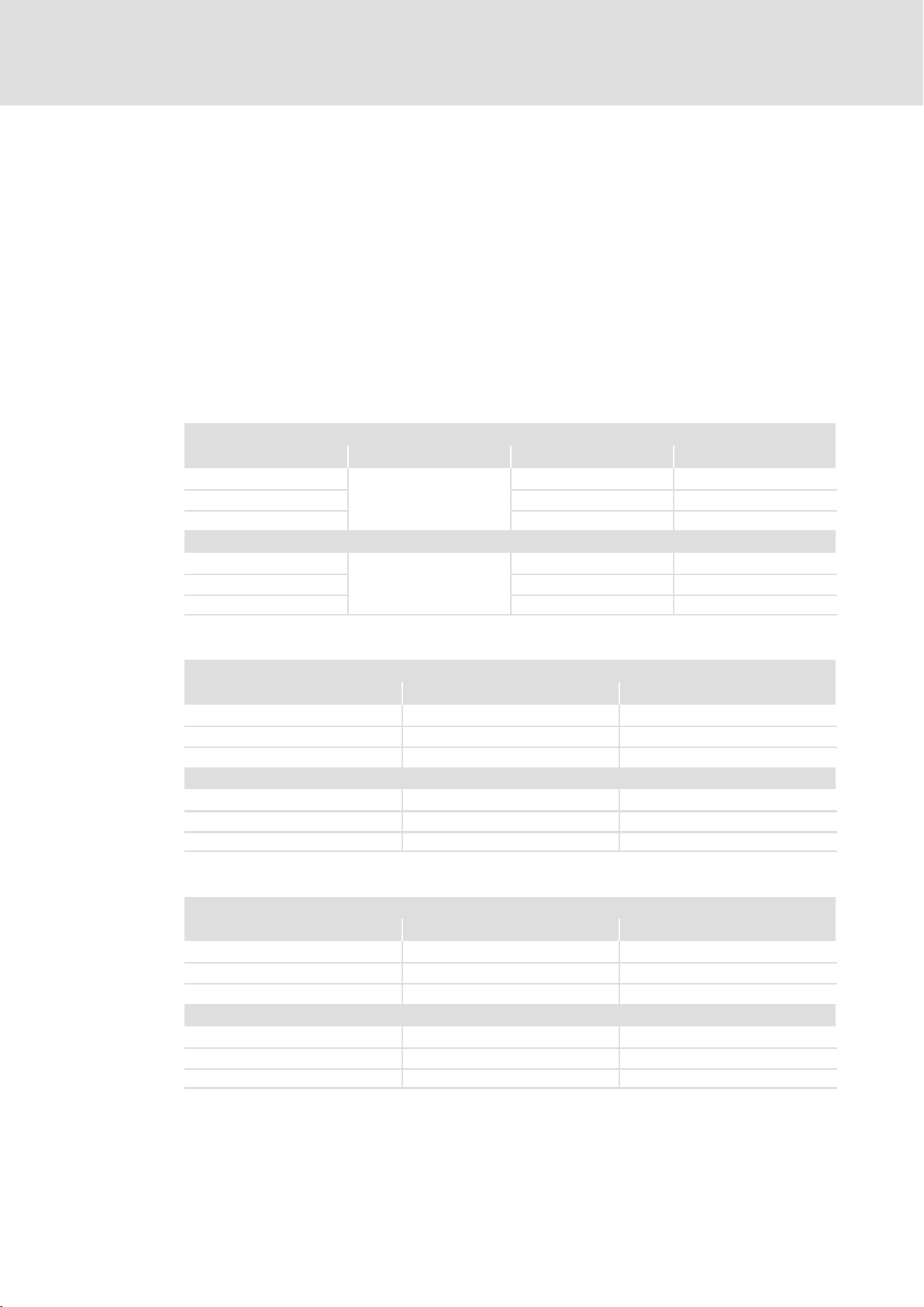

Mounting position (A−F) and position of system modules (1−6)

GST

Terminal box, Motec, connector: 2, 3, 4, 5

Without terminal box, Motec, connector: 0

A B C D E F

GFL

Solid shaft: 6

Hollow shaft: 0

Hollow shaft with shrink disc: 1, 6

Foot: 3, 4

Without foot: 0

Terminal box, Motec, connector: 2, 3, 4, 5

Without terminal box, Motec, connector: 0

A B C D E F

GKS/GSS/GKL

Solid shaft: 3, 5, 8 (3+5)

Hollow shaft: 0

Hollow shaft with shrink disc: 3, 5

Flange: 3, 5, 8 (3+5)

Without flange: 0

Terminal box, Motec, connector: 2, 3, 4, 5

Without terminal box, Motec, connector: 0

A B C D E F

GKR

Solid shaft: 3, 5, 8 (3+5)

Hollow shaft: 0

Hollow shaft with shrink disc: 3, 5

Flange: 3, 5, 8 (3+5)

Without flange: 0

Terminal box, Motec, connector: 2, 3, 4, 5

Without terminal box, Motec, connector: 0

A B C D E F

18

l

BA 12.0023−EN 7.0

Page 19

Product description

Product features

Nameplate

3

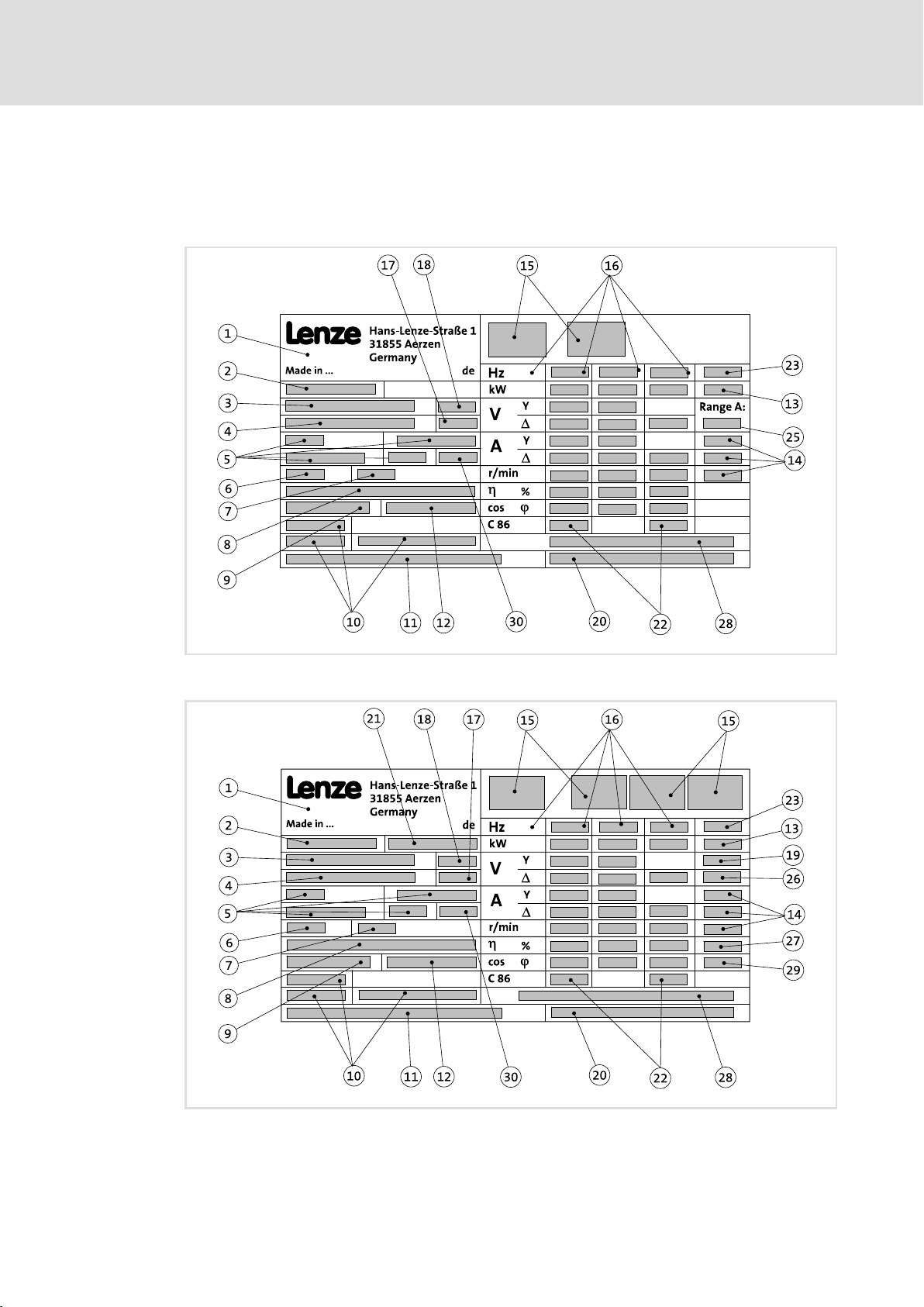

3.2.1 Nameplate

Geared motor

Standard version

CSA/UL version

Nameplate GNG−001.iso

BA 12.0023−EN 7.0

l

Nameplate GNG−002.iso

19

Page 20

3

Product description

Product features

Nameplate

Pos. Contents

1 Manufacturer / production location

2 Motor type / standard

3 Gearbox type

4 Motor type

5 Technical data

6 Mounting position / position of the system blocks

7 Lubricant

8 Brake data (if fitted)

9 Feedback / pulse encoder or resolver data (if fitted), see product key ^ 23

10 Manufacture data

11 Bar code

12 Rectifier designation

13 Information on operating mode

14 Additional motor

specifications

15 Valid conformities,

approvals and certificates

16 Rated data for

various frequencies

17 Application factor (given if < 1.0) / load capacity

18 Year / week of manufacture

19 UL file number

20 Additional customer data

21 Inverter duty motor

22 Motor code for controller parameterisation (code 0086)

23 Efficiency class

24 Maximum ambient temperature

25 Grade A = voltage tolerance range according to range A according to IEC/EN 60034−1

26 CC number of the Department of Energy (optional)

27 Ta £ 40°C

28 Partial load efficiencies for 50Hz operation at a rated power of 50% and 75%

29 ALR

30 Weight

Ratio

Rated torque

Rated speed

Rated frequency

Type

AC/DC brake voltage

Braking torque, electrical power input

Order number

Material number; Serial number

Temperature class

Enclosure

Motor protection

CE identification; CCC identification

cURus logo / UL file number

UL energy efficiency logo

Hz = frequency

kW = motor power

r/min. = motor speed

V = motor voltage

A = motor current

h = Motor efficiency: at a rated power of 100%

cos j = motor power factor

20

l

BA 12.0023−EN 7.0

Page 21

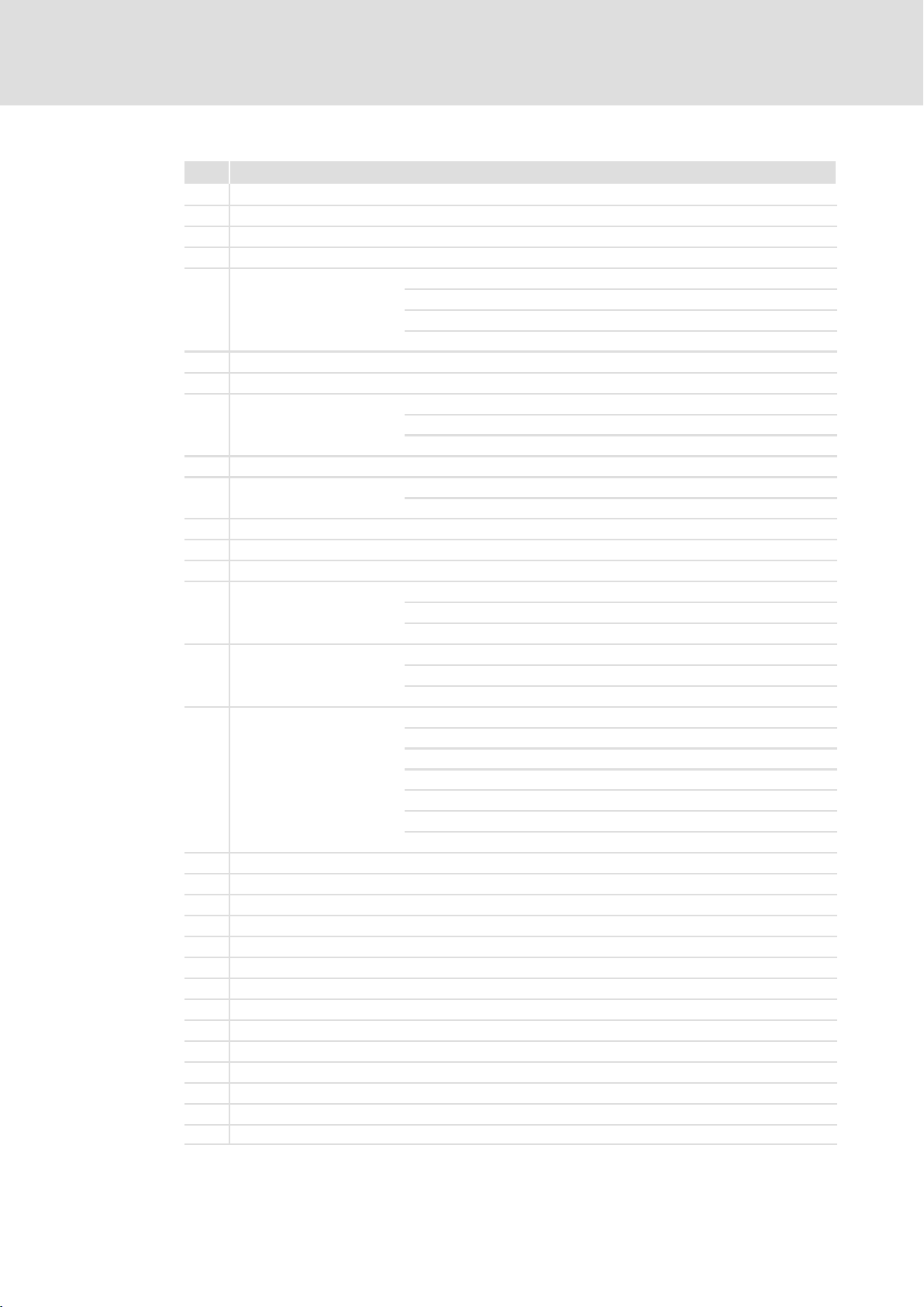

Examples

Three−phase AC motor with square flange for direct gearbox attachment

Standard version CSA/UL version

Typenschild−GNG−003.iso/dms Typenschild−GNG−003.iso/dms

Product description

Product features

3

Gearbox

N and W version M and N version with motor K (compact unit) and D (Disco) − version

Typenschild GST−004.iso Typenschild GST−005.iso Typenschild GKS−006.iso

Version N and W version M and N version with motor

Pos.

1 Production site / country; www.Lenze.com

2 Gearbox type Gearbox and motor type

3 Year of manufacture/ week of manufacture

4 Mounting position / position of the system modules

5 Rated torque/rated speed Rated torque

Rated speed/rated frequency

Application factor (data if < 1.0)

6 Lubricant

7 Ratio

8 Material number / serial number

9 Bar code

10 Order number

11 Additional information

12 Additional customer data

K (compact unit) and D (Disco) − version

Operating frequency

Rated torque/rated speed

BA 12.0023−EN 7.0

l

21

Page 22

3

Product description

Product features

Product key

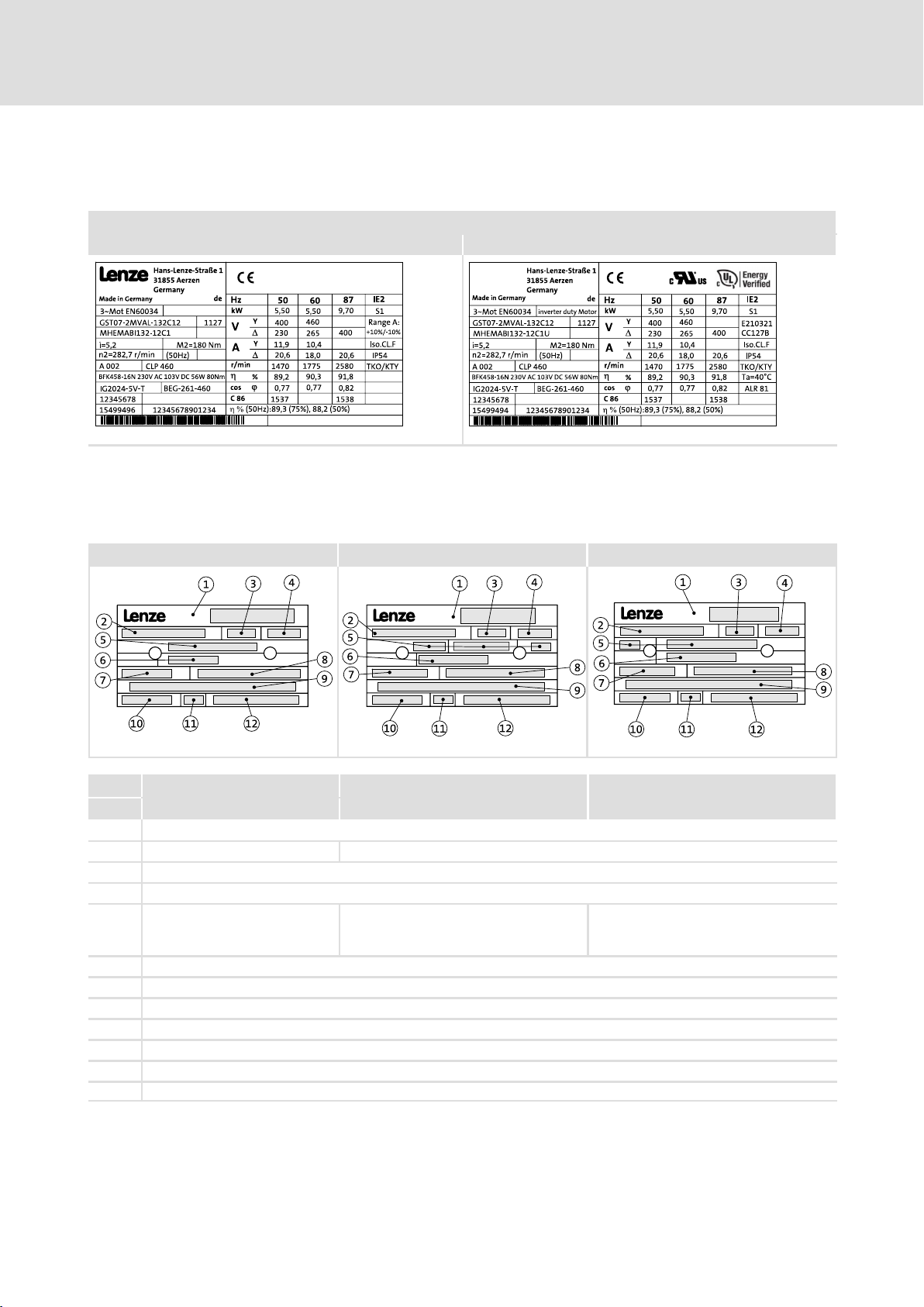

3.2.2 Product key

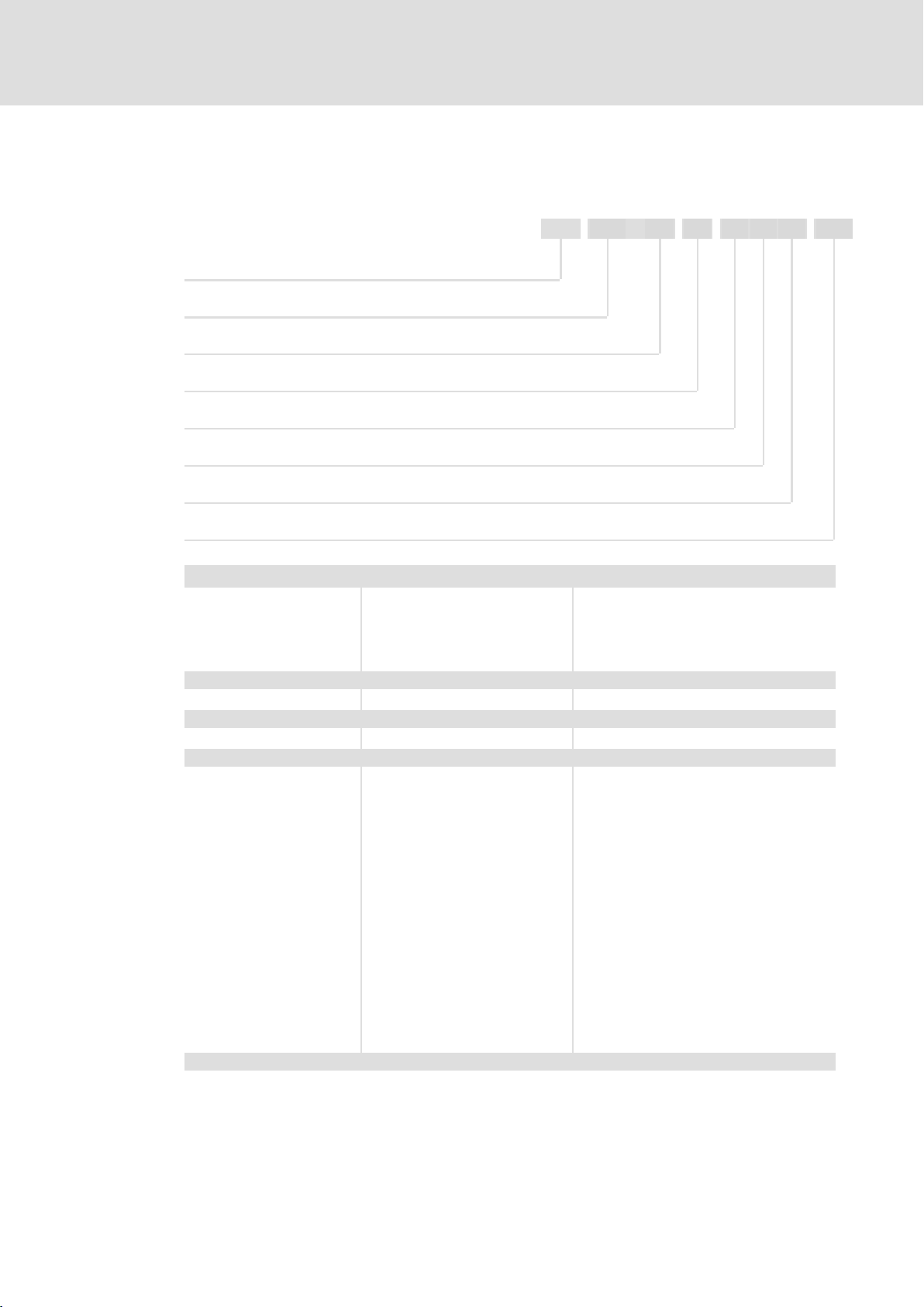

Geared motors

0

1

2

3

4

5

6

7

Legend for product key

0 Gearbox type GST

GFL

GKS/GKL

GKR

GSS

LLL LL − L L L L L L

Helical gearbox

Shaft−mounted helical gearbox

Helical−bevel gearbox

Bevel gearbox

Helical−worm gearbox

1 Gearbox size

2 Number of stages

3 Input design A

D

E

G

I

K

M

N

P

Q

R

S

T

U

W

Servo motor, asynchronous, totally enclosed

fan−cooled

Disco variable speed drive

Three−phase AC motor with Motec

SDS three−phase AC motor

Servo motor, asynchronous, internal cooling

Compact unit

Three−phase AC motor

Gearbox with bearing flange for IEC

standard motors or NEMA

DC permanent magnet motor 13.12x/SGS

DC motor, smooth housing, MGFQU/MGFQK

DC motor, ribbed housing, MGFRK

Servo motor, synchronous, totally enclosed

fan−cooled

DC shunt motor 13.5xx

Three−phase AC motor 13.71x/13.75x

Gearbox with free drive shaft

22

l

BA 12.0023−EN 7.0

Page 23

Legend for product key

Output design

4

5 A

6 R

Product description

3

Product features

Product key

G

V

H

S

B

C

D

K

l

Solid shaft, smooth (without keyway)

Solid shaft (with keyway)

Hollow shaft

Hollow shaft with shrink disk

Foot mounting, with centering

Foot mounting, without centering

Without foot, with centering

Without foot, without centering

Without flange

With flange (through holes)

With flange (threaded holes)

7 Drive size

Examples

Feedback system

Resolver / encoder

0

1

2

3

Legend

0 Type

RS

IG

IK

AS

AM

1 Number

0

1

2, 3, 4...

32, 512,

1024,

2048, ...

2 Voltage

5 V, 9 V,

15 V,

24 V, ...

3 Interface or signal level

Standard with safety function

T

H

H

E

S

Resolver

Incremental encoder

Incremental encoder with commutation signal

Singleturn absolute value encoder

Multiturn absolute value encoder

2−pole resolver for servo motors

2−pole resolver for three−phase AC motors

Number of pole pairs for resolvers

Number of steps / increments per revolution

Medium supply voltage

TTL

HTL for incremental encoders

Hiperface for absolute value encoders

EnDat

sin/cos 1 V

Motor

Mounting flange/free input shaft

Mech. variable speed drive

ss

U

K

K

F

V

071C32

1C

071−1202C

LLLLL

TTL

HTL (for incremental encoders)

Hiperface (for absolute value encoders)

EnDat

sin/cos 1 V

ss

BA 12.0023−EN 7.0

l

23

Page 24

3

Product description

Transport weights

3.3 Transport weights

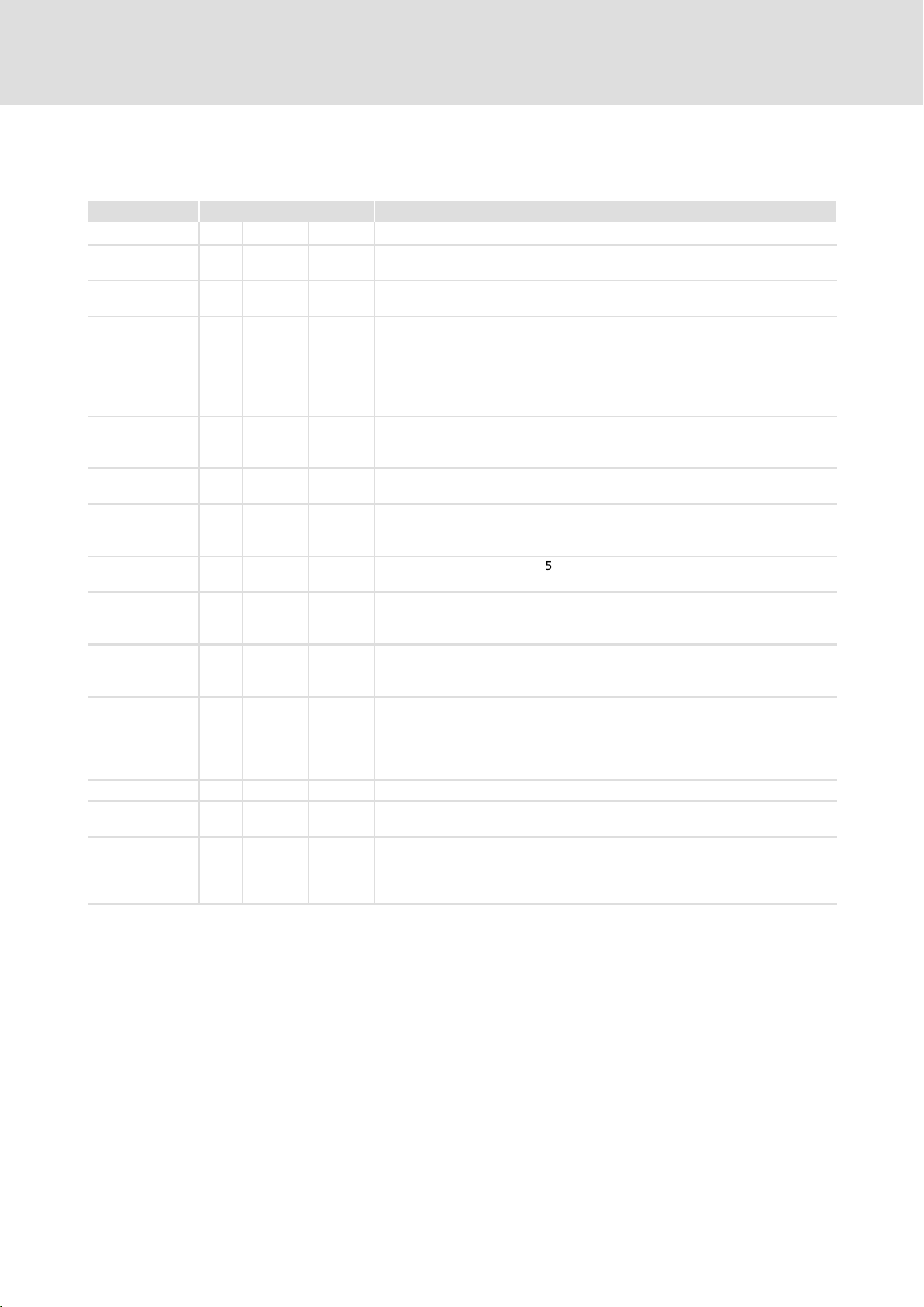

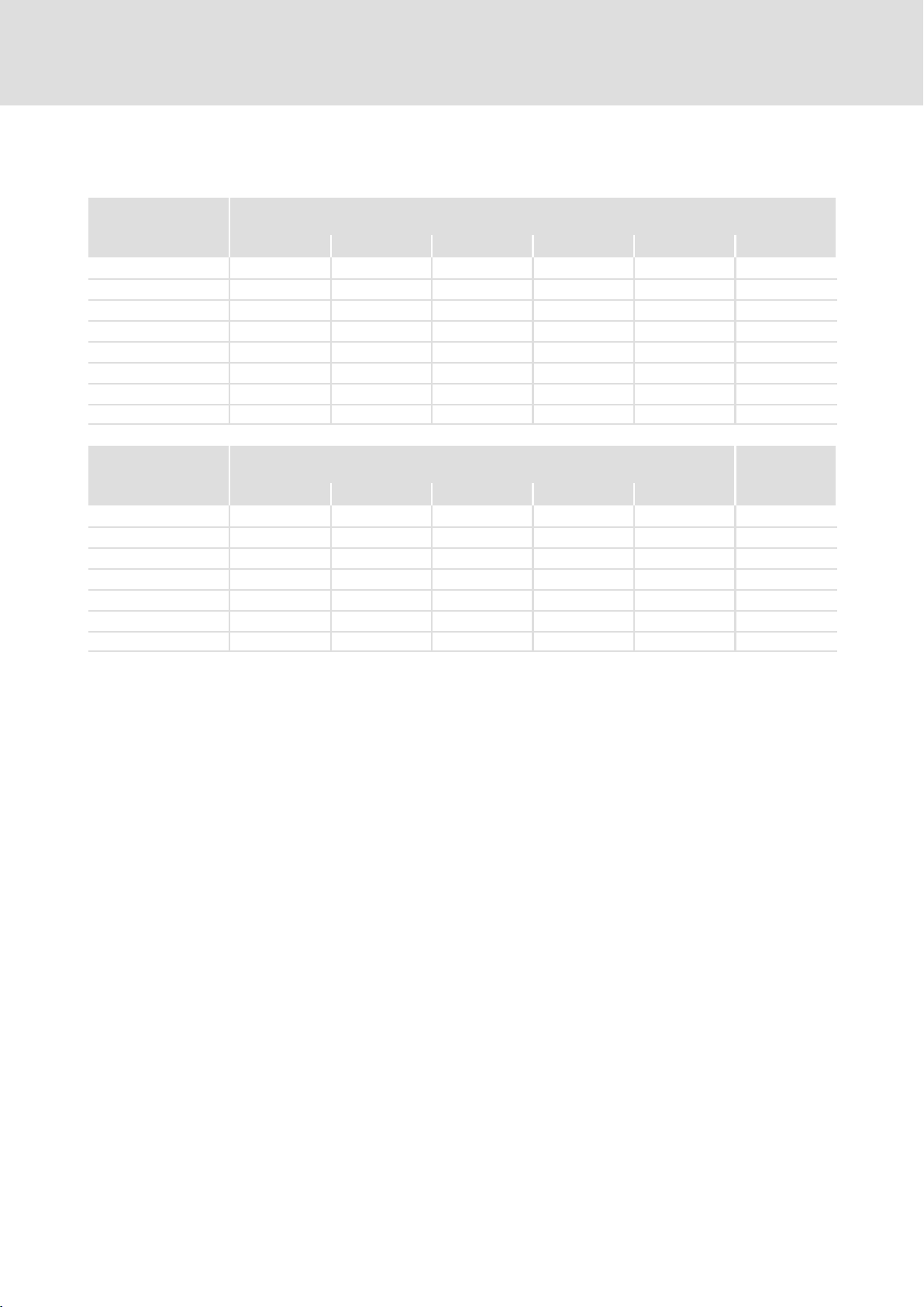

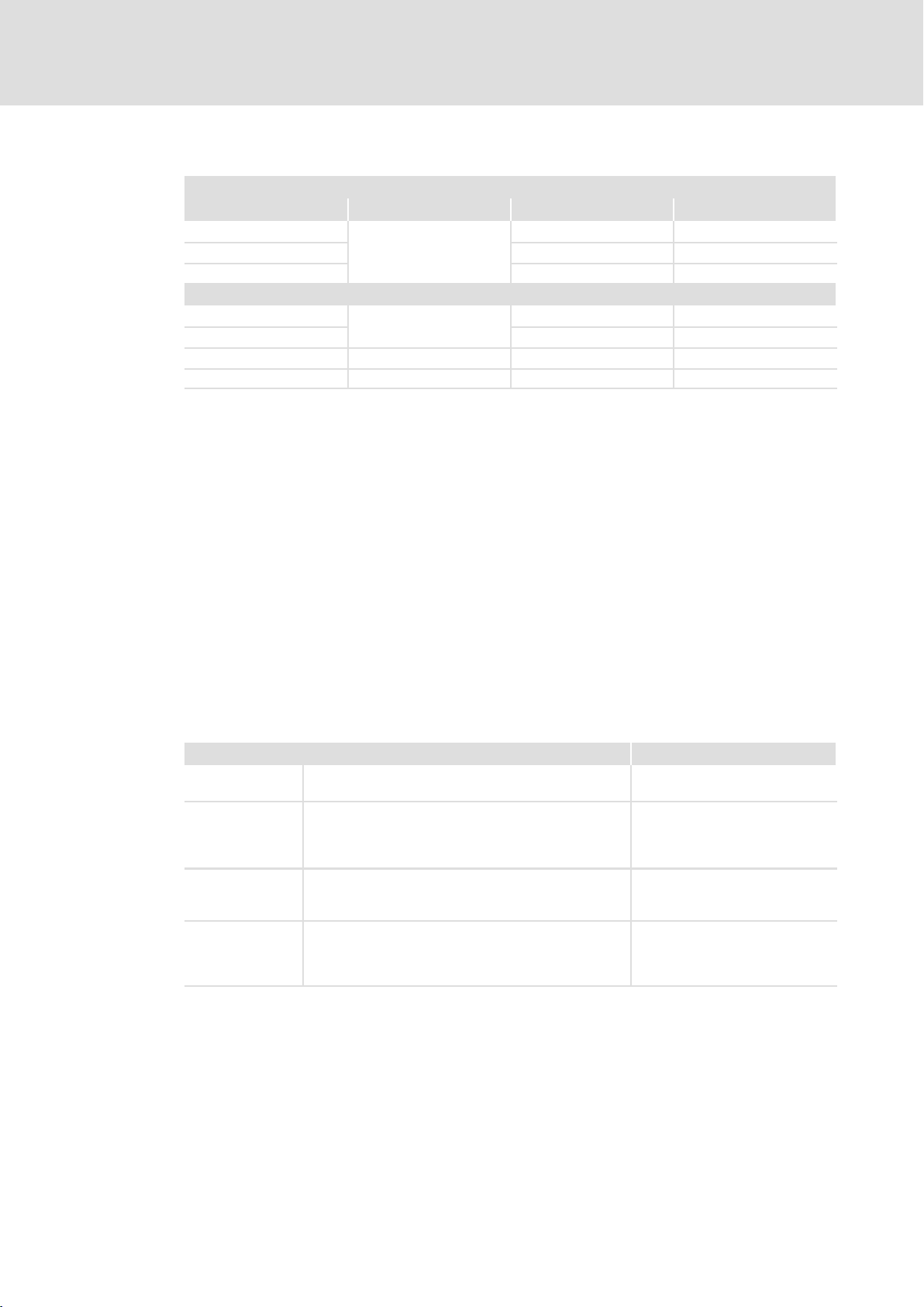

Gearbox size

063−LL 071−LL 080−LL 090−LL 100−LL 112−LL

GLL03 < 10 < 10

GLL04 < 30 < 30 < 40 < 50

GLL05 < 50 < 50 < 60 < 60 < 70

GLL06 < 70 < 70 < 80 < 90 < 100 < 125

GLL07 < 125 < 125 < 150 < 150 < 175

GLL09 < 200 < 200 < 225 < 225 < 250

GLL11 < 350 < 375 < 375 < 400

GLL14 < 625 < 650 < 650

Gearbox size

132−LL 160−LL 180−LL 200−LL 225−LL

GLL04 < 30

GLL05 < 50

GLL06 < 150 < 70

GLL07 < 200 < 250 < 150

GLL09 < 275 < 325 < 475 < 550 < 250

GLL11 < 425 < 450 < 600 < 700 < 850 < 400

GLL14 < 700 < 750 < 850 < 950 < 1100 < 625

Tab. 1 Transport weights in [kg]; values may differ from table value

Geared motors

Motor frame sizes

Geared motors

Motor frame sizes

Gearboxes

24

l

BA 12.0023−EN 7.0

Page 25

General data and operating conditions

4 Technical data

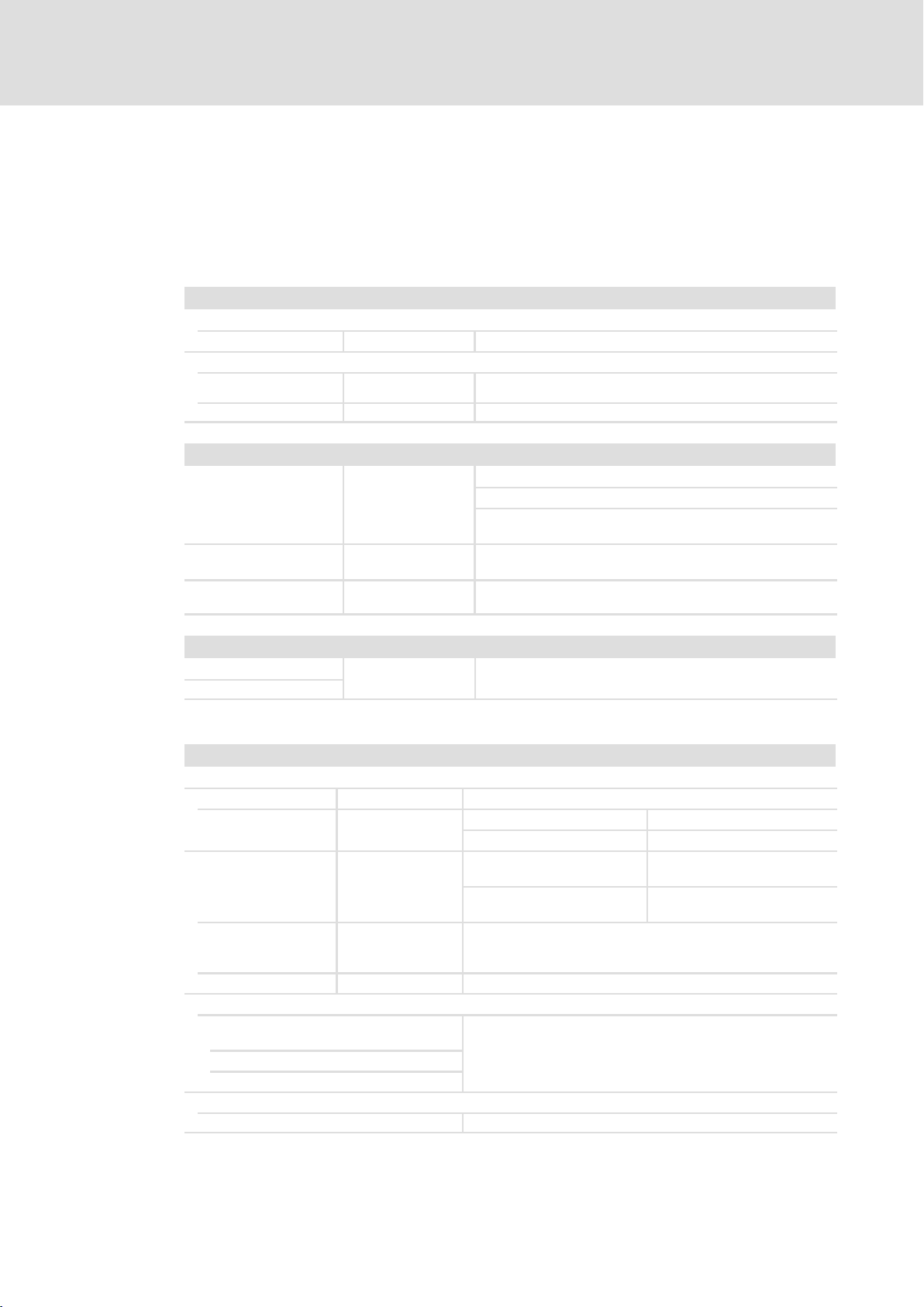

4.1 General data and operating conditions

General data

Conformity and approval

Conformity

CE

Approvals

M

CCC

Protection of persons and equipment

Degree of protection IEC/EN 60034−5

Thermal class F (155 °C)

Permissible voltage According to limiting curve A of the pulse voltage from

2006/95/EC Low−Voltage Directive

File No. E210321

IEC/EN 60034−1

Technical data

See nameplate

Degrees of protection only apply to horizontal installation

All unused plug−in connections must be sealed with

protective caps or dummy connectors.

Exceedance of the temperature limit weakens or destroys the

insulation

IEC / TS 60034−25 (image 14)

4

EMC

Noise emission

Noise immunity

IEC/EN 61800−3

Depending on the controller, see documentation for the

controller.

Operating conditions

Ambient conditions

Climatic

Transport IEC/EN 60721−3−2 2K3 (−20 ... +70 °C)

Storage IEC/EN 60721−3−1

Operation IEC/EN 60721−3−3

Site altitude < 1000 m amsl − without power reduction

Humidity Average relative humidity 85 %, without condensation

Electrical

Motor connection dependent on the

controller

Length of motor cable

Length of cable for speed feedback

Mechanical

IEC/EN60721−3−3 3M6

1K3 (−20 ... +60 °C) < 3 months

1K3 (−20 ... +40 °C) > 3 months

Without brake −15 °C ... +40 °C

With brake −10 °C ... +40 °C

> +40 °C With power reduction see,

> 1000 m amsl < 4000m amsl with power reduction, see

catalogue

See inverter instructions

Without power reduction

catalogue

BA 12.0023−EN 7.0

l

25

Page 26

5

Mechanical installation

Transport equipment for gearbox

5 Mechanical installation

} Danger!

Only transport the drive with transport equipment or hoists which are suitable

for this load (see transport weights, chapter LEERER MERKER). Ensure a safe

fixing. Avoid shocks!

The motors attached to the gearbox are partially equipped with eyebolts.

These are exclusively determined for motor/gearbox mounting and

dismounting and must not be used for the complete geared motor!

5.1 Transport equipment for gearbox

As of size 05, Lenze GST, GKS and GSS gearboxes are as standard available with a transport

thread for eye bolts according to DIN 580. The thread position can be seen from the below

figures. The eye bolts are not contained in the delivery package.

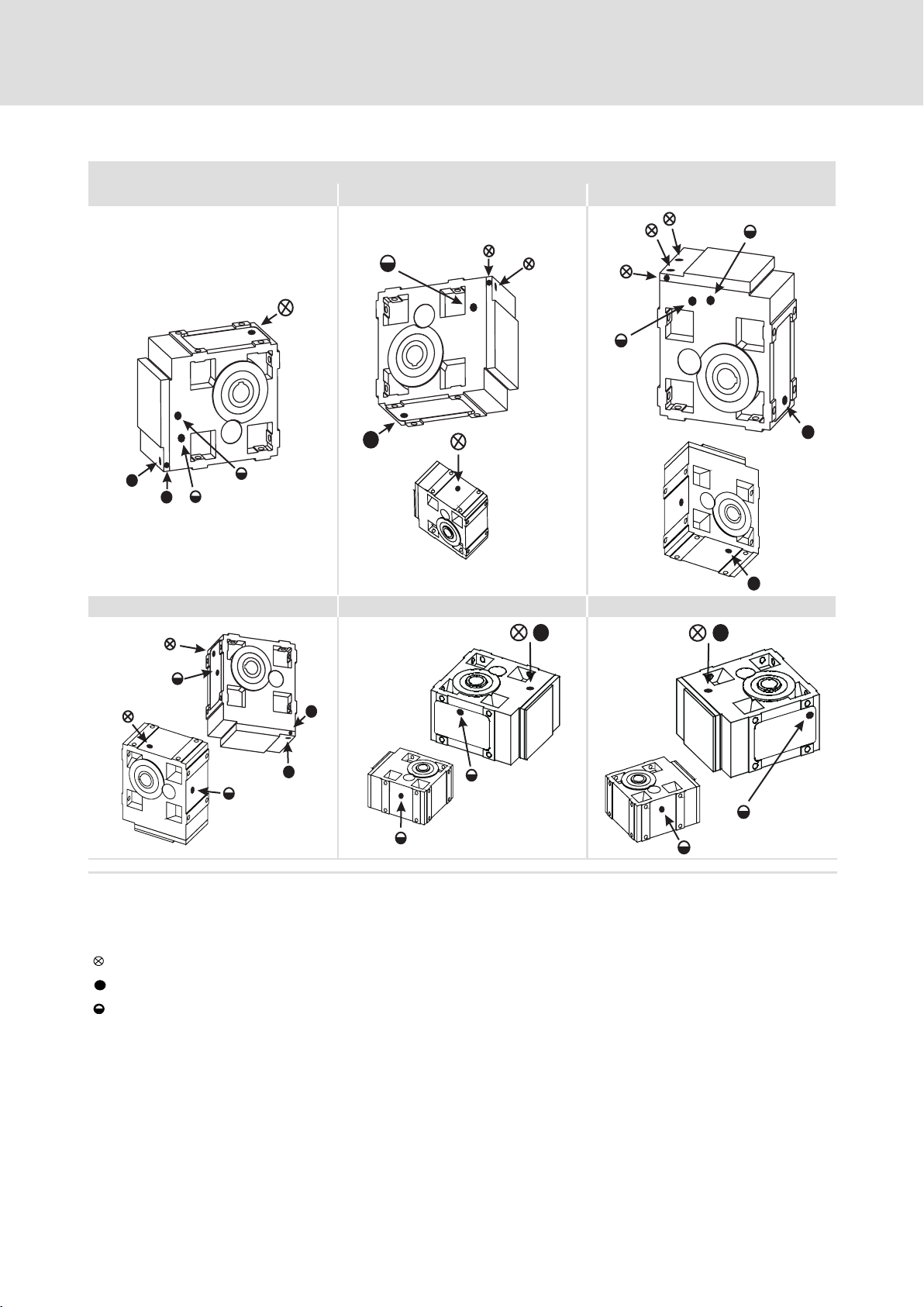

GSTXX−1 GSTXX−2/3 GSSXX−2/3 and GKSXX−3/4

Fig. 1 Eye bolt position

) Note!

As standard, threads are delivered with plug screws. The plug can be easily

removed, e.g. by using a screwdriver blade. For the thread size and load

carrying capacity of the eye bolt, please see Tab. 2.

26

l

BA 12.0023−EN 7.0

Page 27

Mechanical installation

Transport equipment for gearbox

5

Gearbox size Thread

05 M8 140 100

06 M8 140 100

07 M12 340 240

09 M16 700 500

11 M20 1200 860

14 M20 1200 860

Tab. 2 Load carrying capacity of eye bolt in kg

max. load carrying capacity of eye bolt to DIN 580

single−strand two−strand (45°)

} Danger!

Completely screw in transport aids (such as eye bolts or bearing plates), they

must be flat and applied over their entire surface!

If possible, the transport aids (such as eye bolts or bearing plates) must be

stressed vertically in the direction of the screw axis! Angular tension or tension

to the sides reduces the payload! Observe the information provided in the

DIN 580!

Use additional appropriate lifting aids, if required, to achieve a direction of

loading which is as vertical as possible (highest payload). Secure lifting aids

against shifting!

45°

GT−GNG−005.iso/dms

( Stop!

Observe load carrying capacity!

Staying under floating load is prohibited!

BA 12.0023−EN 7.0

l

27

Page 28

5

5.2 Storage

Mechanical installation

Storage

If you do not install the gearbox immediately, ensure appropriate conditions of storage.

ƒ Generally

– Store gearbox in dry, clean (dust−free) and sunlight−protected indoor rooms.

– The storage location must be free of vibration and shocks (V

avoid roller bearing downtime damage.

– Temperature changes with condensate formation must be avoided.

– Do not activate breather element to prevent air exchange with ambient air.

ƒ Up to one year:

– Store the gearbox with breather such that the breather screw is located at the top.

– Shafts and bright surfaces are delivered with protection against corrosion. Spots

with defective corrosion protection must be re−treated.

– On motors with condensation drain holes (option), the plug screw must be

removed (see chapter 5.4.1).

< 0.2 mm/s) to

eff

ƒ Over one year, up to two years:

– Before storage, shafts and bright surfaces must be provided with a long−term

anticorrosive agent (e.g. Anticorit BW 366 from the company Fuchs).

– Set up gearbox in mounting position A.

– Fill gearbox with oil grade filled in (see nameplate) up to the top breather / oil

bore. Then mount plug screw or breather element (do not activate) again.

28

l

BA 12.0023−EN 7.0

Page 29

5.3 Specified directions of rotation

GST GFL

GKR GKS/GKL GSS

Mechanical installation

Specified directions of rotation

GT−GNG−GST−008.iso/dms GT−GNG−GFL−005.iso/dms

5

GT−GNG−GKR−006.iso/dms GT−GNG−GKS/GKL−004−iso/dms GT−GNG−GSS−007.iso/dms

Fig. 2 Direction of rotation of drive

BA 12.0023−EN 7.0

l

29

Page 30

5

5.4 Mounting

5.4.1 Preparation

Mechanical installation

Mounting

Preparation

( Stop!

Thoroughly remove anticorrosion agents from output shafts and flange faces.

Correcting the oil quantity

If the oil quantity has been increased in the gearbox for long−term storage (see chapter

5.2), the oil must be completely drained and then filled in again for the corresponding

mounting position. The following steps must be observed:

1. Place receptacle under oil drain plug.

2. Remove ventilation / oil filler plug.

3. Completely drain lubricant.

4. Screw in oil drain plug.

5. Fill in oil quantity for the corresponding mounting position (^ 66).

6. Screw in ventilation / oil filler plug.

Condensation drain hole

) Note!

Lenze delivers motors with condensation drain holes with sealed condensation

drain holes. The holes are sealed with a plastic plug or a plug screw. This does

not impair the enclosure and the motor is protected against ingress of foreign

particles during transport and operation. For further information, please see

chapter 8.2.1.

30

l

BA 12.0023−EN 7.0

Page 31

Mechanical installation

Mounting

General information about the assembly of drive systems

5

5.4.2 General information about the assembly of drive systems

( Stop!

The lubricant fill quantity of the gearboxes is matched to the mounting

position. The mounting position indicated on the nameplate must be observed

to avoid damage to the gearbox.

ƒ Take safety measures prior to any operation:

– Disconnect the machine from the mains, ensure standstill of the drive system and

avoid any machine movement.

– Check the proper state of the drive system. Never install and set up damaged drive

systems.

– Check the combination of drive function and machine functions. Check the

direction of rotation (see 5.3).

ƒ The mounting surfaces must be even, without torsion, and free from vibration.

ƒ Align the drive system on the mounting surfaces exactly with the machine shaft to

be driven.

– Ensure that the assembly is without torsion to avoid additional load.

– Compensate for minor misalignments by using suitable flexible couplings.

ƒ Support the reaction torque appropriately.

ƒ Fixings of accessories and attachments must be secured against loosening.

We recommend that screw connections are glued.

5.4.3 Assembly of transmission elements on solid shafts

ƒ Draw the transmission elements onto the output shaft only by using the centering

thread.

( Stop!

Shocks and blows to the shafts damage the roller bearings.

BA 12.0023−EN 7.0

l

31

Page 32

5

Mechanical installation

Mounting

Attachment of motors to gearboxes with bearing housing

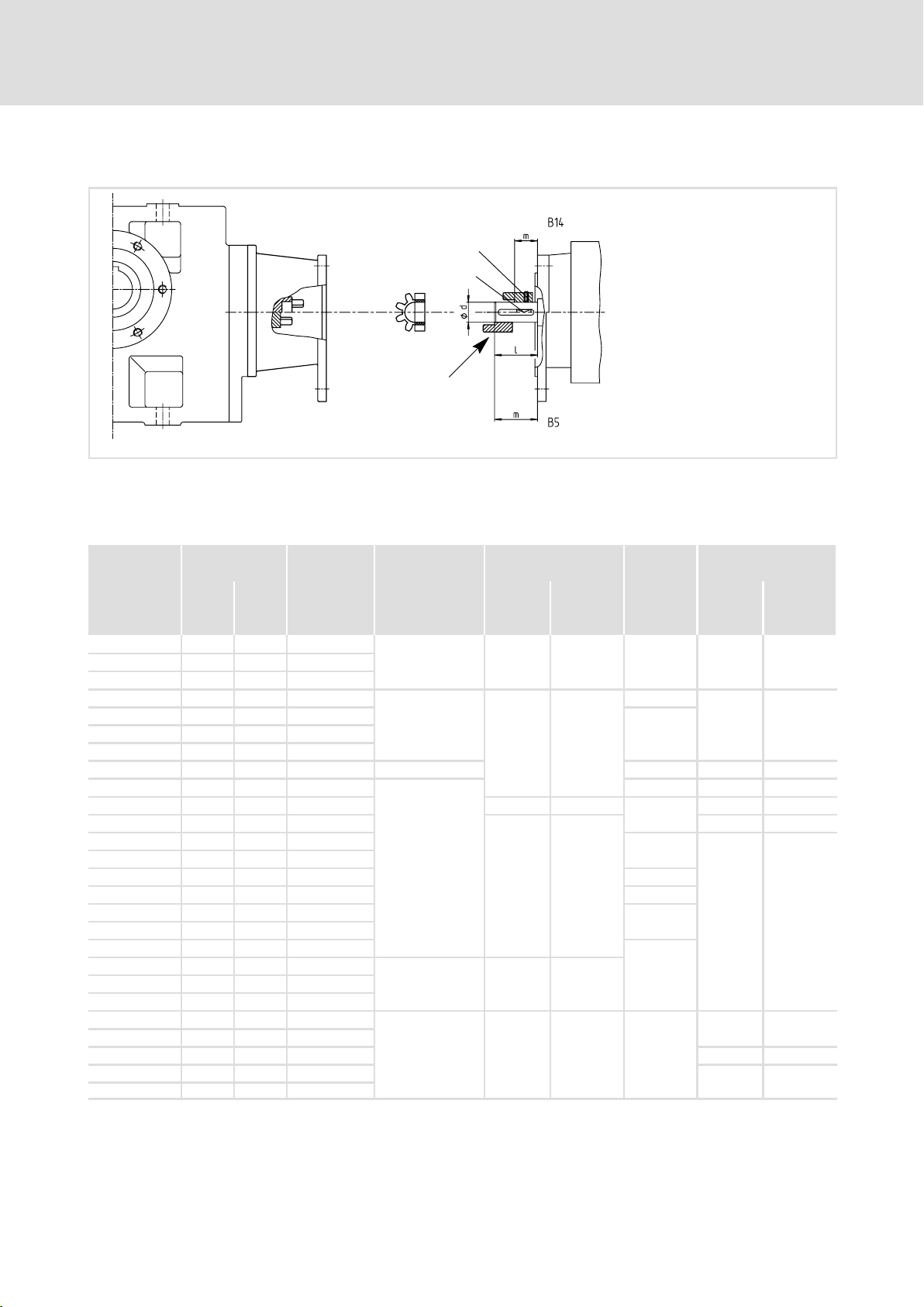

5.4.4 Attachment of motors to gearboxes with bearing housing (input design N)

1

0

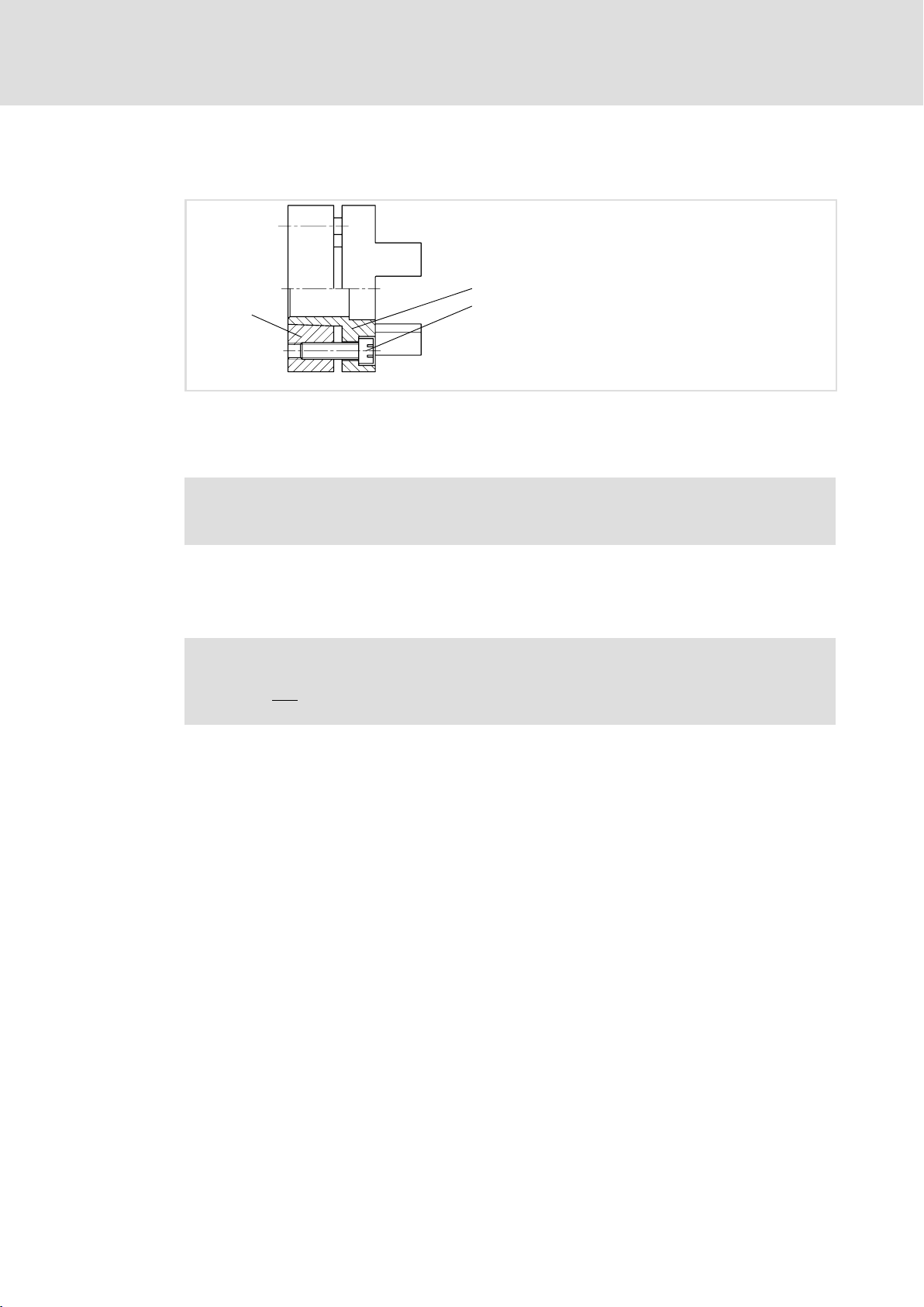

Fig. 3 Input side design N

0 Spider / gear rim 1 Locking screw

1 Coupling hub 2 Keyway

2

1

K12.0621

Drive size

Motor shaft Assembly

dimension

D

max. l

M

Standard hub

Locking screw

Thread

Clamping hub Key

Thread

Tightening

torque

[ mm ]

1A 11 23 23

1B 14 30 30

2B 11 23 23

1C 19 40 25

2C 14 40 25

3C 14 40 25

4C 14 40 25

6C 11 40 25 −−− * −−− −−−

7C 19 40 25

1D 24 50 50 M4 2.9

2D 19 40−50 50

1E 28 30−60 30

2E 24 30−60 30

3E 19 30−60 30 B6 x 6 x 18

4E 24 50 50 *

1F 28 30−60 30

2F 24 30−60 30

3F 24 50 50

1G 38 80 80

2G 28 60 60

3G 38 80 80

1H 42 110 110

2 h 48 110 110

3H 38 80 80 M8 35

1K 55 110 110

2K 60 140 140

[ mm ]

[ mm ]

[ mm ]

M4 M3 1.34 * M3 1.34

M5

M5

M6 M8 25

M8 M10 69 *

[ mm ]

M6 10.5

M6 10.5

[ Nm ]

1)

Clamping ring hub

DIN

6885/1

[ mm ]

B6 x 6 x 16

B5 x 5 x 16

B6 x 6 x 16 M4 2.9

*

B8 x 7 x 18

B8 x 7 x 18

*

Thread

Tightening

[ mm ]

M4 2.9

−−− −−−

M4 2.9

M5 6

−−− −−−

−−− −−−

torque

[ Nm ]

Tab. 3 Attachment of motors to gearboxes with mounting flange

* Use original key for the motor

1)

Key for standard hub and clamping hub

32

l

BA 12.0023−EN 7.0

Page 33

Mechanical installation

Mounting

Coupling hubs

5

5.4.5 Coupling hubs

General

) Note!

Standard hubs, clamping hubs and clamping ring hubs are

maintenance−free.We recommend checking the star−shaped spider and

system components when inspecting the drive.

5.4.5.1 Assembly of standard hub / clamping hub

1. Fit motor key (2).

– Fit enclosed key for drive sizes LC, LE, LF.

2. Push the coupling hub over the motor shaft, mounting dimension m (see Fig. 3 and

Tab. 3) must be observed.

3. Secure coupling hub against axial movement using the fixing screw or clamping

screw (1).

4. Lay spider in the coupling claw on the gearbox side.

5. Align claws of the motor−side coupling hub with its counterpart.

6. Slowly push on motor, and bolt on to the gearbox flange.

BA 12.0023−EN 7.0

l

33

Page 34

5

5.4.5.2 Assembly of clamping ring hub

Mechanical installation

Mounting

Coupling hubs

2

Fig. 4 Coupling

1 Clamping ring hub

2 Clamping ring

3 Clamping screws (DIN912)

1

3

) Note!

The motor shaft must be designed with fit k6.

1. Grease the contact surfaces of the motor shaft using a thin−bodied oil, e. g. Castrol

4 in 1" or Klüber Quitsch Ex"!

( Stop!

Do not use oil or grease with molybdenum−disulphide or high−pressure

additives, or grease pastes!

2. Push the coupling hub over the motor shaft, mounting dimension m" (see Fig. 3

and Tab. 3) must be observed.

3. Align the hub and tighten the clamping screws until they have contact.

4. Tighten the clamping screws evenly and crosswise with gradually rising torque until

the indicated tightening torque (see Tab. 3) is reached at all clamping screws. In the

intermediate steps, this procedure should also be repeated until the indicated

tightening torque is reached at all clamping screws.

5. Lay spider in the coupling claw on the gearbox side.

6. Align claws of the motor−side coupling hub with its counterpart.

34

7. Slowly push on motor, and bolt on to the gearbox flange.

l

BA 12.0023−EN 7.0

Page 35

Attachment of gearboxes with hollow shafts and keyway

5.4.5.3 Disassembly of clamping ring hub

1. Loosen the clamping screws evenly one after the other.

( Stop!

Each screw must only be loosened by half a revolution per pass! Unscrew all

clamping screws by 3 − 4 threads.

2. Remove the screws next to the forcing threads and screw them into the other

threads until they have contact.

3. Tighten the screws in the forcing threads crosswise and step−by−step so that the

clamping ring is loosened.

4. Clean and grease all contact surfaces including threads and head of the clamping

screws before reassembly.

Mechanical installation

Mounting

5

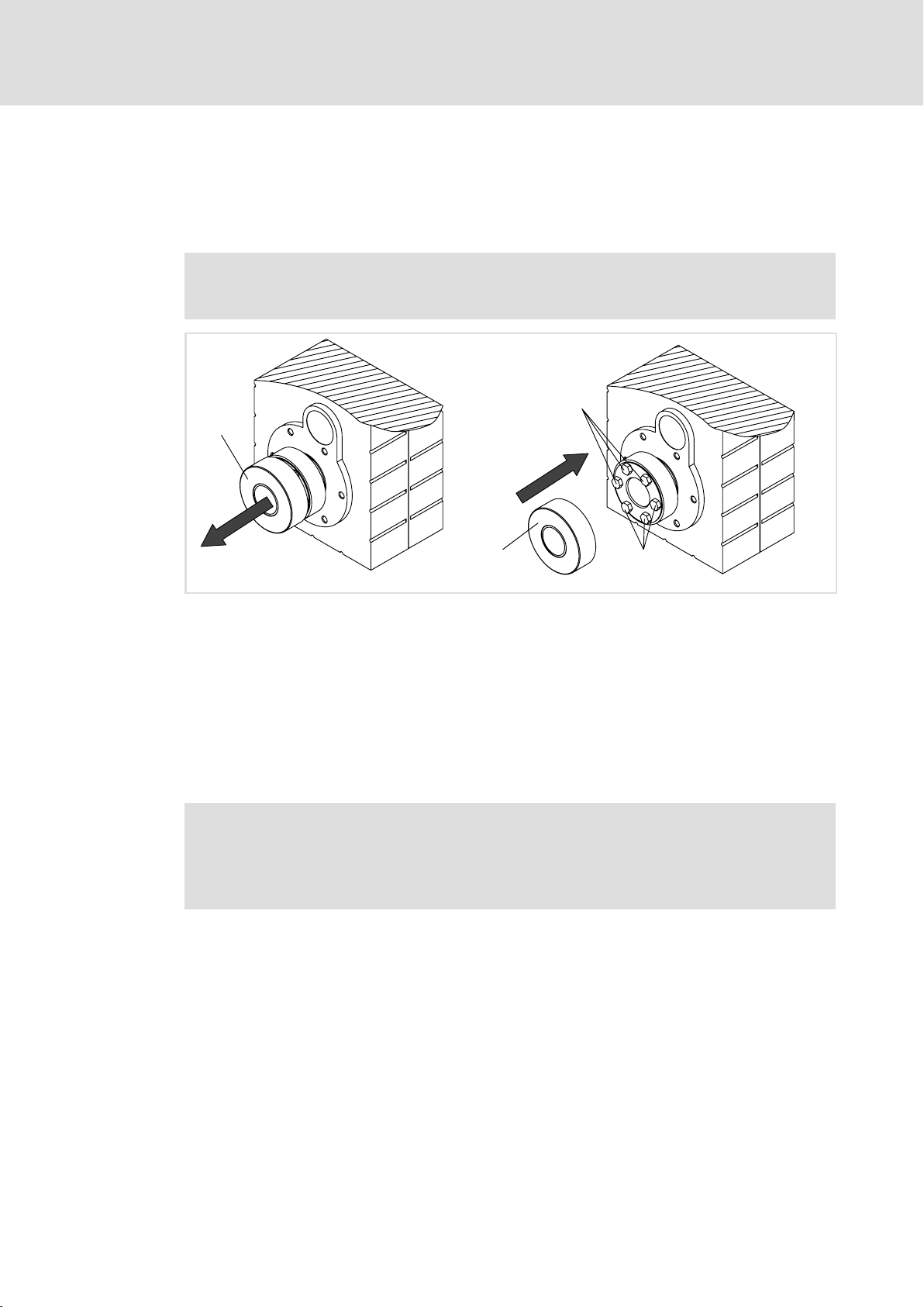

5.4.6 Attachment of gearboxes with hollow shafts and keyway

Mounting

1. Draw the gearbox with hollow shaft onto the machine shaft to be driven:

– Apply the supplied assembly paste (Fig. 5) on the shaft and in the hollow shaft

bore.

GT−GNG−GKR−011.iso GT−GNG−GKR−011_a.iso

Fig. 5 Application of assembly paste against fretting corrosion (included in the scope of supply)

BA 12.0023−EN 7.0

( Stop!

Take up forces only via the hollow shaft, and not via gearbox housing.

2. Secure the gearbox axially:

– The hollow shaft has snap ring grooves for axial securing. Parts used to fix the

shaft are not included in the scope of supply.

l

35

Page 36

5

Mechanical installation

Mounting

Attachment of gearboxes with hollow shafts and keyway

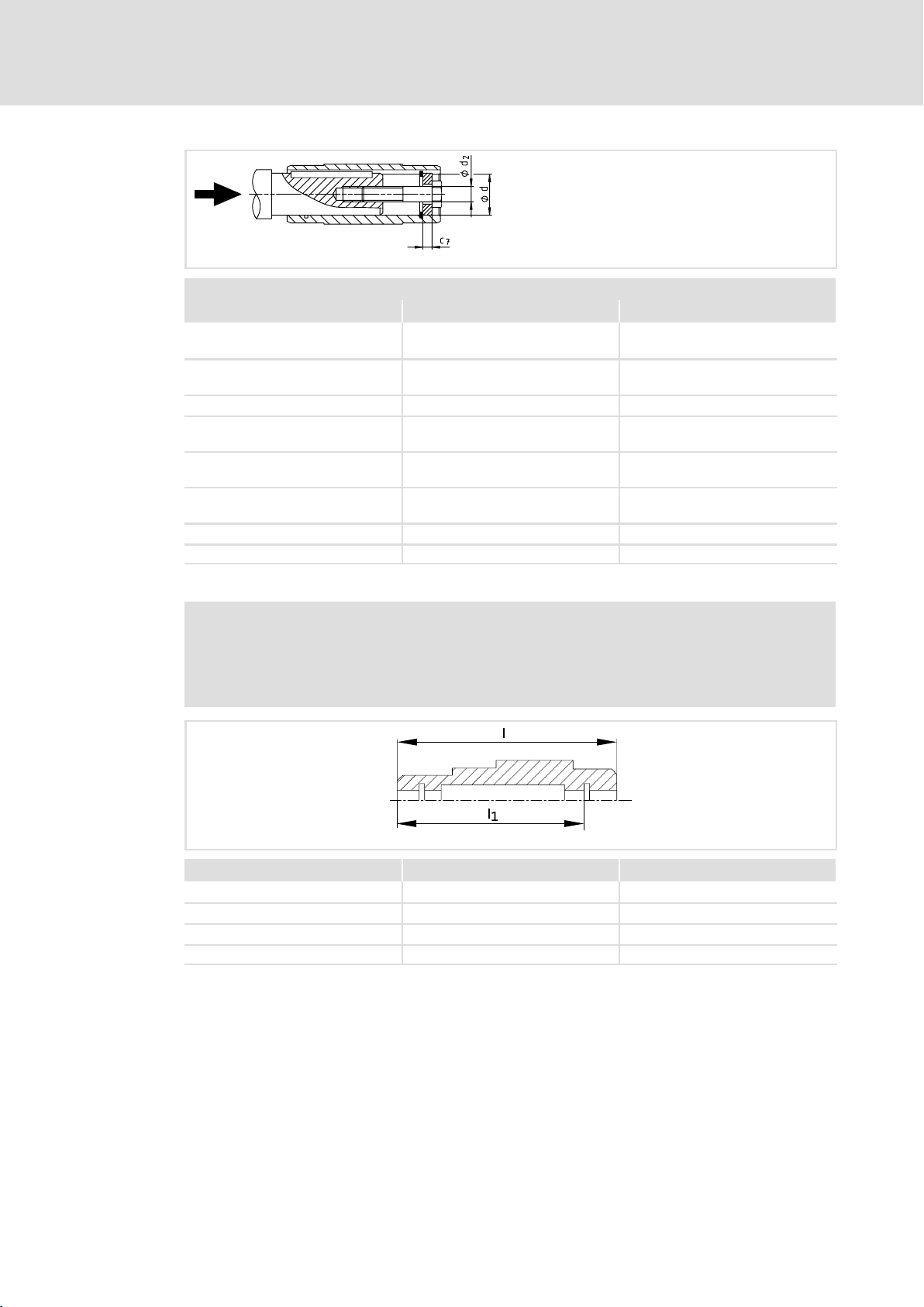

K12.0611

Auxiliary tool (recommended dimensions)

H7

Æ d

18

20

25

30

35 M12 7

40

45

50

55

60

70

80 M20 16

100 M24 24

Tab. 4 Dimensions in [mm]

d

2

M6 4

M10 5

M16 8

M16

M20

M20 13

10

11

14

c

7

6

9

) Note!

With bevel gearbox GKR, the hollow shafts are turned free in the middle of the

hollow shaft, i.e. the bore diameter is 0.1 mm higher here! A sufficient length

of the machine shaft must be observed.

GKR size l1 min l max.

03 85 100

04 105 120

05 127 143

06 150 170

Tab. 5 Dimensions in mm

36

l

BA 12.0023−EN 7.0

Page 37

Mechanical installation

Mounting

Mounting the shrink disc with a rotating cover

Dismounting

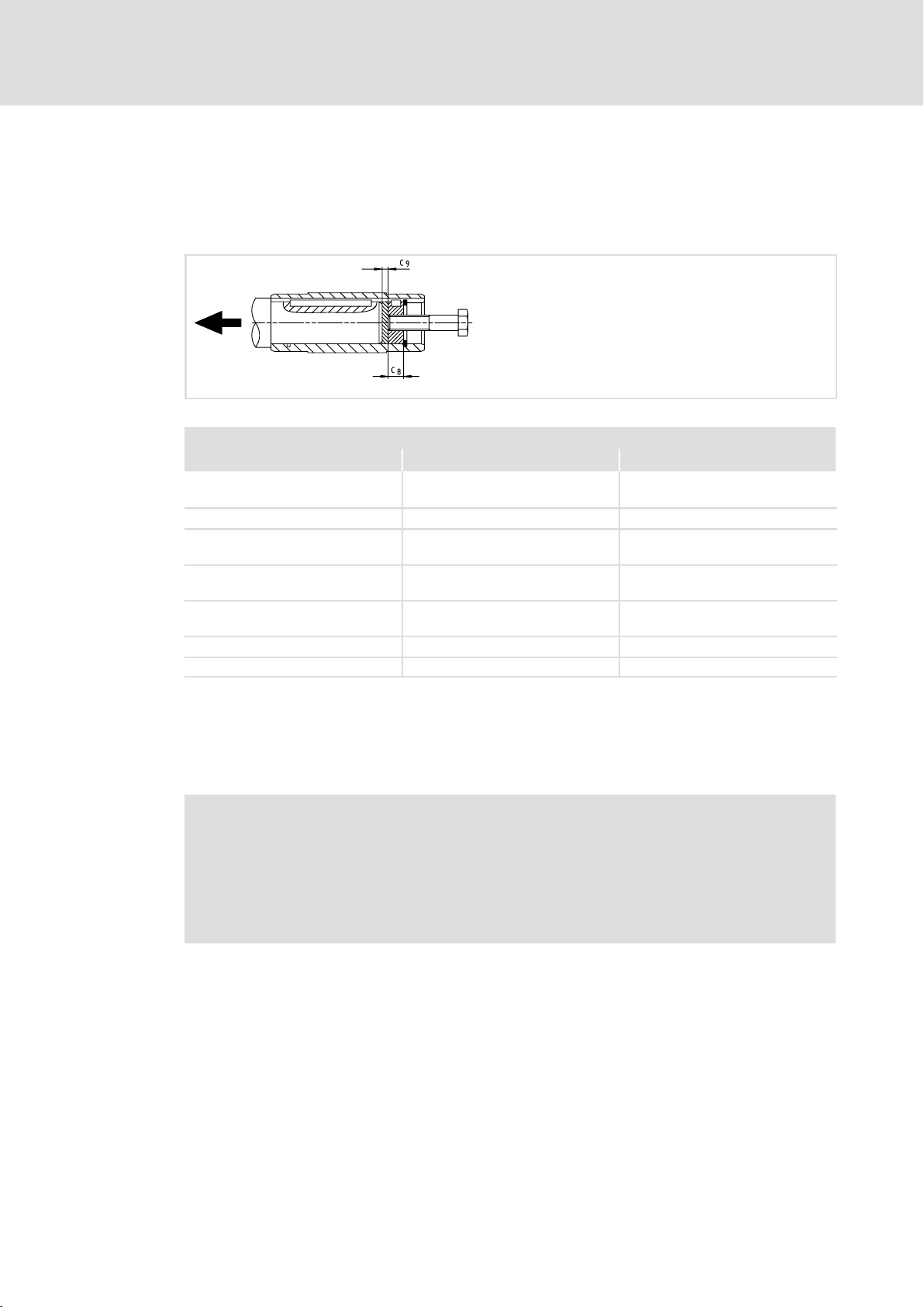

1. Undo axial gearbox locking in the hollow shaft.

2. Remove/extract the gearbox from the motor shaft using an appropriate auxiliary

tool (Fig. 6).

Fig. 6 Dismantling of gearboxes with hollow shaft using the auxiliary tool, not for GKR

Auxiliary tool (recommended dimensions)

H7

Æ d

25

30

35 12 3

40

45

50

55

60

70

80 20 6

100 24 8

Tab. 6 Dimensions in [mm]

c

8

10 3

16 4

16

20

20 5

c

9

5

5

K12.0611

5.4.7 Mounting the shrink disc with a rotating cover

( Stop!

Do not dismantle new shrink disc.

Never tighten clamping screws before the machine shaft is pushed in.

Otherwise the hollow shaft may be deformed plastically. Protect the shrink

disc against contact while in operation by appropriate measures (e.g. cover).

Degrease hollow shaft bore and machine shaft!

BA 12.0023−EN 7.0

l

37

Page 38

5

5.4.7.1 Mounting the shrink disc

Mechanical installation

Mounting

Mounting the shrink disc with a rotating cover

Depending on the design, the shrink discs may be equipped with a rotating cover

(protective cap, pos. 1).

) Note!

This cover is fitted to the shrink disc on delivery.

1

1.

2

5.

1

Fig. 7

1 Protection cover

2 Clamping screws

1. Remove protective cap (1), if available.

2. Check machine shaft

– Diameter in fit tolerance h6

– Surface roughness Rz £ 15 mm

3. Thoroughly clean and degrease hollow shaft bore and machine shaft.

2

) Note!

Thoroughly degrease the bore over the entire hollow shaft length to make

sure that remainders of the anticorrosion agent will not be carried off into the

area of the shrink disc when pushing on the machine shaft.

4. Slightly loosen clamping screws (2) one after the other, do not unscrew!

5. Push drive onto machine shaft.

6. Slightly tighten clamping screws manually.

KL_GFL06_001−dms

38

7. Tighten clamping screws (2) one after the other (see Fig. 8) in several passes, with

rising torque, evenly until the indicated screw−tightening torque (see Tab. 7 ) is

reached at all screws.

l

BA 12.0023−EN 7.0

Page 39

Mechanical installation

Mounting

Mounting the shrink disc with a rotating cover

GT−GNG−003.iso/dms

Fig. 8 Explanation: "one after the other"

I Tip!

Several (in general more than 5 ) passes are necessary until the full tightening

torque is reached at all screws!

The shrink disc is mounted correctly and fixed when the faces of the outer ring and the

inner ring are aligned (Fig. 9). Minimum misalignments are permissible.

5

GT−GNG−001.iso

Fig. 9 Hollow shaft with shrink disk

3 Outer ring 0 free of grease

4 Inner ring

Hollow shaft bore [mm]

Torque [ Nm ] 12 30 30 30 30 30 59 70 59 100

Tab. 7 Tightening torque for the clamping screws

20 25 30 35 40 50 60 65 80 100

) Note!

If a different tightening torque is indicated on the shrink disc, this tightening

torque has priority over the value indicated in the table.

8. Push protective cap (1, Fig. 7) onto the shrink disc.

I Tip!

For finding out the cause of non−reached torques of the shrink disc connection,

please go through the troubleshooting list in chapter 9.

BA 12.0023−EN 7.0

l

39

Page 40

5

Mechanical installation

Mounting

Mounting the shrink disc with a rotating cover

Dismounting

} Danger!

Loose drive components or drive components falling down may cause injury to

persons or damage to the machine. Secure the drive components before

disassembly.

1. Remove protective cap (1).

2. Loosen clamping screws (2) evenly one after the other each by ¼ revolution in

several passes. Do not unscrew clamping screws completely to prevent accidents!

3. Press off outer ring (see Fig. 9), if necessary. For this, loosen the outer ring using the

forcing threads and some clamping screws (number corresponding to the forcing

threads in the inner ring). For loosening the outer ring, screw in the screws evenly to

prevent canting. Press off the outer ring until loosened completely.

4. Remove the drive from the machine shaft.

( Stop!

Dismantle the shrink disc only for cleaning purposes. Afterwards, grease bevel

surfaces and screws using a solid lubricant with a friction factor of m = 0.04.

ƒ Suitable lubricants on molybdenum−disulphide lubricant (MoS2) basis are, e.g.:

– Molykote G Rapid (company Dow Corning)

– Molykote BR2 Plus (company Dow Corning)

– Molykombin UMFT1 (company Klüber Lubrication)

Usually, disassembly problems only occur if:

ƒ the connection is spinning due to overload or a too low friction factor and fretting

corrosion has occurred,

ƒ the shrink disc has been tightened too much leading to a plastic deformation of

components,

ƒ the components are corroded.

40

l

BA 12.0023−EN 7.0

Page 41

Mechanical installation

Mounting

Mounting the fixed cover

5

5.4.8 Mounting the fixed cover

for size 09, 11 and 14

) Note!

This cover is supplied loose on delivery!

3x120°

Fig. 10

1 Protection cover

2 Cheese head screw

3 Thread reducing sleeve

x

x

1

3

2

1. Screw the three reducing bushes (3) into the flange with a screwdriver so they are

flush and staggered by 120°.

2. Fasten the protective cap (1) over the reducing bushes (3) on the flange using three

cheese head screws (2).

BA 12.0023−EN 7.0

l

41

Page 42

5

Mechanical installation

Mounting

Mounting the hoseproof hollow shaft cover

5.4.9 Mounting the hoseproof hollow shaft cover

for size 09, 11 and 14

3x120°

Fig. 11

1 Protection cover

2 Cheese head screw

3 Thread reducing sleeve

4 Seal

4

1

3

2

1. Screw the three reducing bushes (3) into the flange with a screwdriver so they are

flush and staggered by 120°.

2. Fit seal (4) between flange and protective cap (1).

3. Fasten the protective cap (1) over the reducing bushes (3) on the flange using three

cheese head screws (2).

42

l

BA 12.0023−EN 7.0

Page 43

5.4.10 Gearboxes with breathers

( Stop!

Do not place gearbox onto breather valve!

When using gearbox sizes 03, 04 and 05 (except for GSS 05) it is not necessary to provide

special breathing measures.

Breather elements are mounted for gearbox sizes 06 to 14 and GSS 05. In special cases, they

may be done without. When using gearbox sizes 09 to 14 in mounting position C, we

recommend the use of an oil compensation container (chapter 5.4.12).

Gearboxes supplied with a breather element bear a corresponding label on the gearbox.

Remove shipping bracket on breather valve.

Mechanical installation

Mounting

Gearboxes with breathers

5

GT−GNG−13285760.iso/dms

For mounting positions differing from the standard mounting positions A − F, the breather

function must be checked. Mount breather elements supplied loose (differing from the

standard) as described in chapter 5.4.11. Gearboxes which can be mounted in different

positions (see chapter 8.2.6) are supplied without breather element.

Ensure ventilation before initial commissioning!

( Stop!

ƒ Rotate gearbox to the mounting position shown on the nameplate (see

nameplate, page 19− 21 and chapter 5.4.11).

ƒ With gearbox types GSTLL−3, GFLLL−3, GSSLL−3 and GKSLL−4, the

pre−stage is separately ventilated! (Exception: size 06)

BA 12.0023−EN 7.0

l

43

Page 44

5

Mechanical installation

Mounting

Breather position, oil filling screw and drain plug

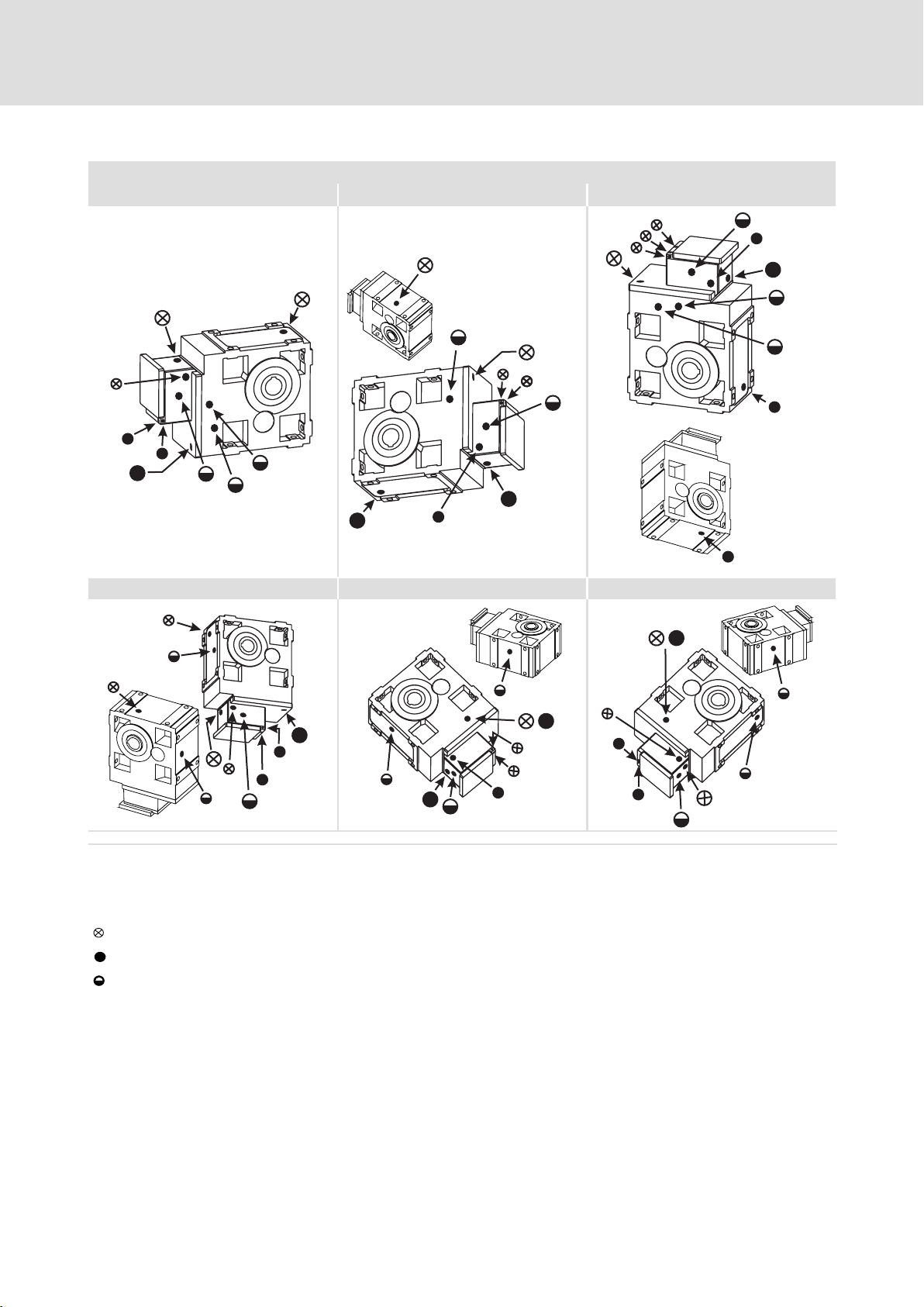

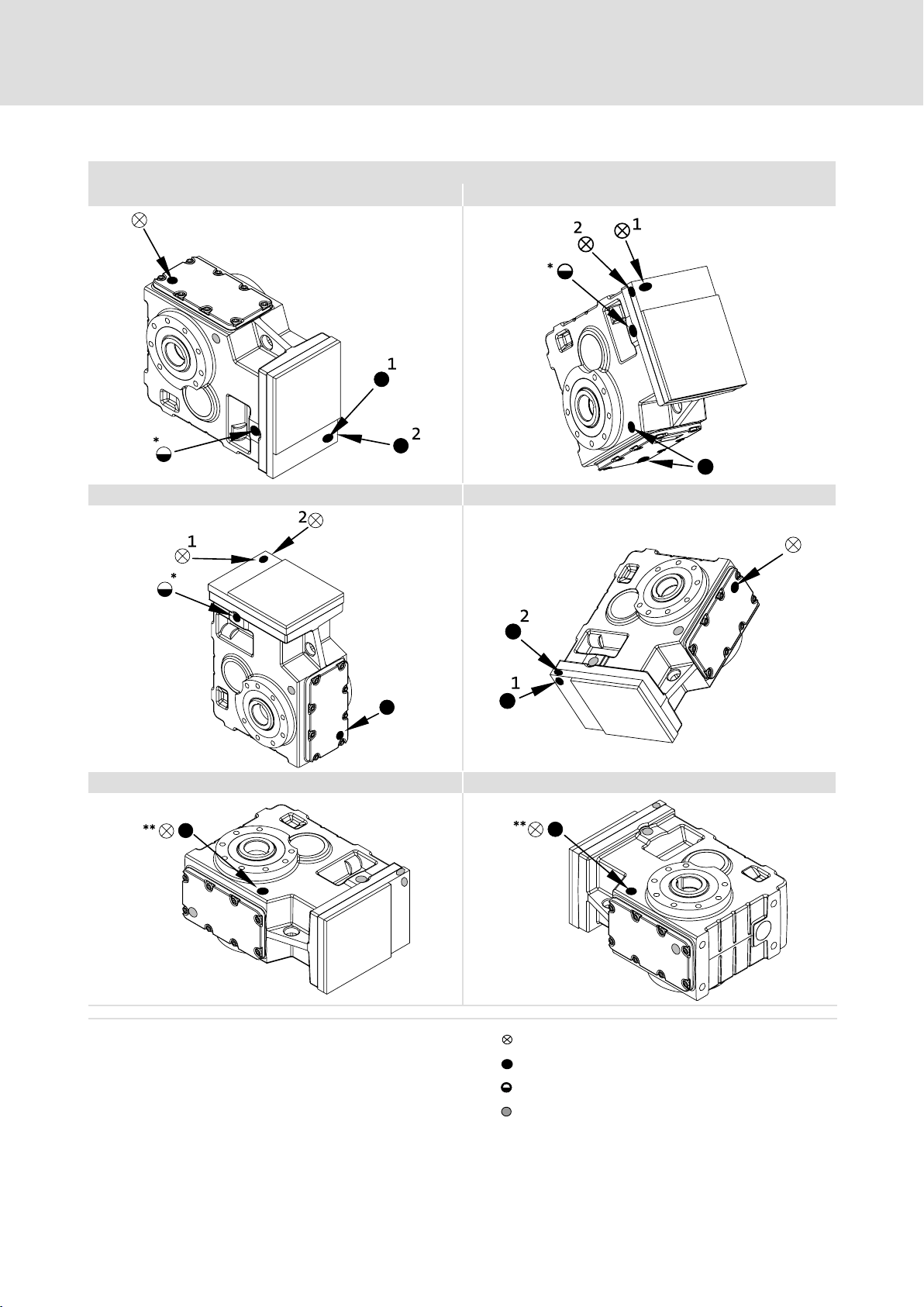

5.4.11 Breather position, oil filling screw and drain plug

Helical gearbox GST 05 ... 09−1

A B

C D

E F

A...F Mounting positions Oil drain plug

*

**

on both sides Oil−control plug

opposite Pos. 1 Standard

Breathing / oil filler plug Pos. 2 only

with:

GST05−1A 080C22

GT−GNG−GST−1−001_A−F.iso/dms

44

l

BA 12.0023−EN 7.0

Page 45

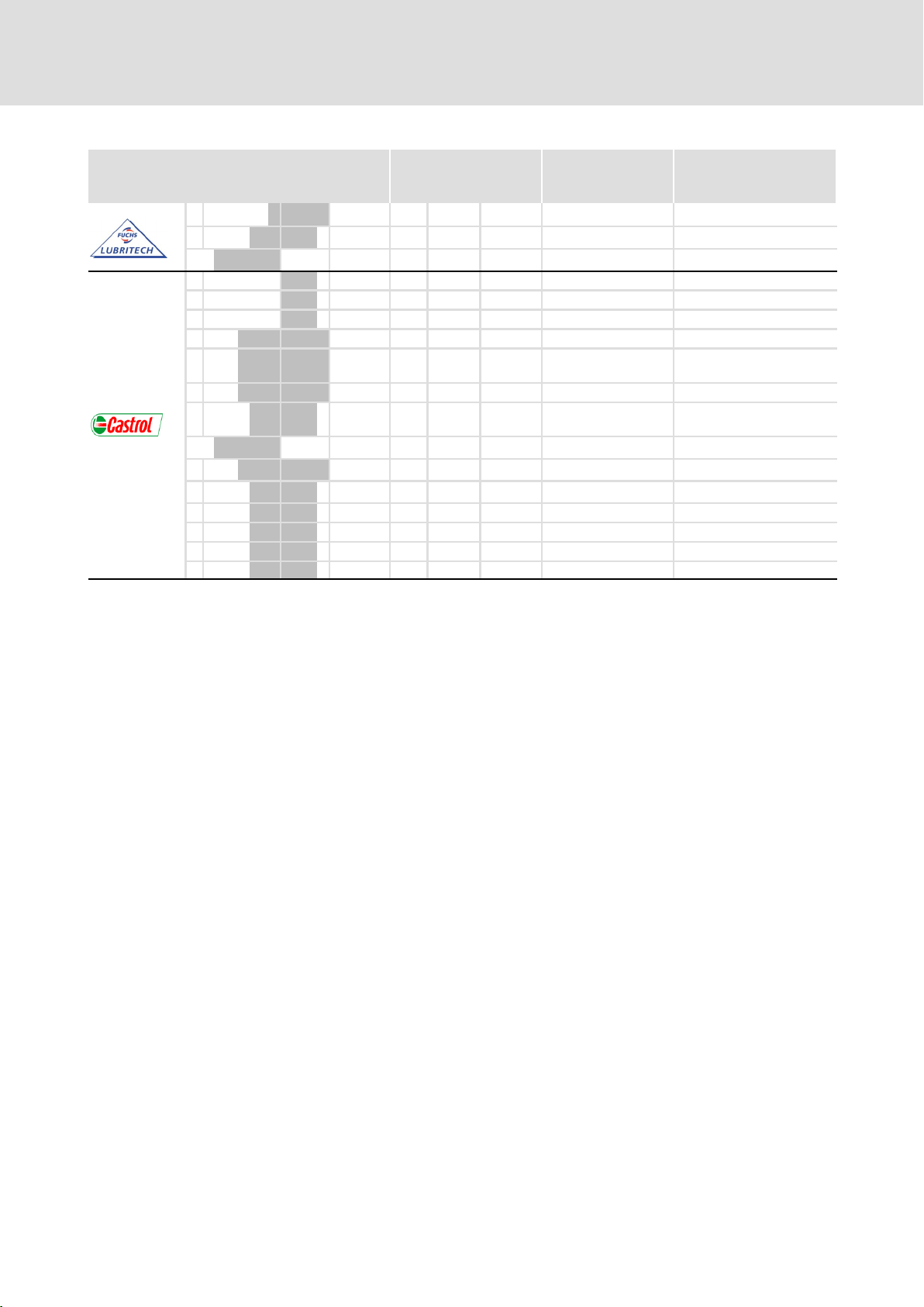

Breather position, oil filling screw and drain plug

Helical gearbox GST 05 ... 14−2, foot mounting

A B

C D

Mechanical installation

Mounting

5

E F

A...F Mounting positions Pos. 1 Standard

*

**

on both sides

opposite GST05−2M VLL 100CLL

Breathing / oil filler plug GST06−2M VLL 112CLL

Oil drain plug GST07−2M VLL 160CLL

Oil−control plug

Pos. 2 only

with:

GST05−2M VLL 090CLL

GT−GNG−GST−2−001_A−F.iso/dms

BA 12.0023−EN 7.0

l

45

Page 46

5

Mechanical installation

Mounting

Breather position, oil filling screw and drain plug

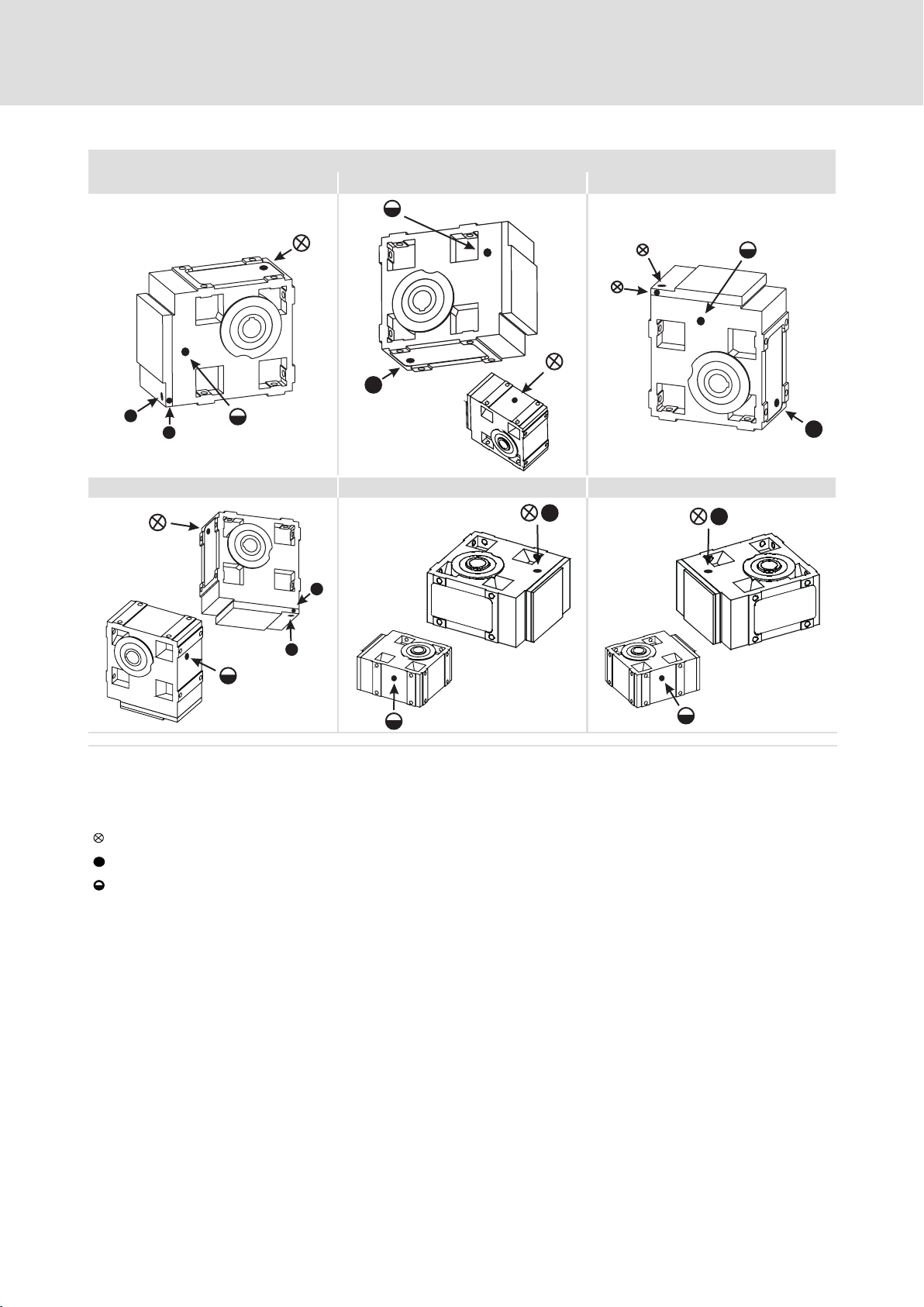

Helical gearbox GST 06...14−3

A B

C D

E F

A...F Mounting positions Oil−control plug

* on both sides Pos. 1 Standard

**

opposite

Breathing / oil filler plug GST05−3M VLL 100CLL

Oil drain plug GST06−3M VLL 112CLL

Pos. 2 only

with:

GST05−3M VLL 090CLL

GT−GNG−GST−3−001_A−F.iso/dms

46

l

BA 12.0023−EN 7.0

Page 47

Mechanical installation

Breather position, oil filling screw and drain plug

Shaft−mounted helical gearbox GFL 05 ... 14−2

A B C

2

1

1

2

D E F

Mounting

2

5

1

GFL09...14

2

2

1

1

A...F Mounting positions Pos. 1 Standard

*

**

on both sides

opposite GFL05−2M LLL 100CLL

Pos. 2 only

with:

GFL05−2M LLL 090CLL

Breathing / oil filler plug GFL06−2M LLL 112CLL

Oil drain plug GFL07−2M LLL 160CLL

Oil−control plug

1

2

GT−GNG−GFL−2−001.iso/dms

BA 12.0023−EN 7.0

l

47

Page 48

5

Mechanical installation

Mounting

Breather position, oil filling screw and drain plug

Shaft−mounted helical gearbox GFL 06 ... 14−3

A B C

2

GFL06...14

GFL05

1

GFL05

1

2

GFL14

GFL06...14

*

GFL05

1

2

D E F

2

GFL06...14

*

1

2

1

GFL05

*

GFL06...14

GFL05

A...F Mounting positions Pos. 1 Standard

*

**

on both sides

opposite GFL07−3M LLL 100CLL

Pos. 2 only

with:

GFL07−3M LLL 090CLL

Breathing / oil filler plug GFL09−3M LLL 112CLL

Oil drain plug

Oil−control plug

GFL06...14

1

2

GFL05

*

GT−GNG−GFL−3−001.iso/dms

48

l

BA 12.0023−EN 7.0

Page 49

Mechanical installation

Breather position, oil filling screw and drain plug

Helical bevel gearbox GKS 05...14−3

A B C

GKS09...14

2

*

* GKS05...07

1

2

* GKS09...14

1

1

2

* GKS09...14

5

Mounting

GKS09...14

* GKS05...07

GKS05...07

D E F

GKS05...07

GKS09...14

GKS09...14

GKS05...07

2

1

GKS05...07

GKS09...14

**

A...F Mounting positions Pos. 1 Standard

*

**

on both sides

opposite GKS05−3M LLL 100CLL

Pos. 2 only

with:

GKS05−3M LLL 090CLL

Breathing / oil filler plug GKS06−3M LLL 112CLL

Oil drain plug GKS07−3M LLL 160CLL

Oil−control plug

GKS09...14

**

GKS09...14

GKS05...07

GT−GNG−GKS−3−001_A−F.iso/dms

BA 12.0023−EN 7.0

l

49

Page 50

5

Mechanical installation

Mounting

Breather position, oil filling screw and drain plug

Helical bevel gearbox GKS 05 ... 14−4

A B C

GKS05...07

GKS09...14

*

2

1

**

GKS05

1

1

*

GKS06...14

GKS14

1

2

* GKS06...14

** GKS05

* GKS05...07

* GKS09...14

GKS05...07

2

*

GKS06...14

* GKS05...07

* GKS09...14

** GKS05

D E F

GKS05...07

GKS09...14

GKS09...14

GKS05

GKS05...07

**

* GKS06...14

2

1

GKS09...14

GKS06...14

GKS05...07

**

2

1

**

GKS05

A...F Mounting positions Pos. 1 Standard

*

**

on both sides

opposite GKS07−4M LLL 100CLL

Pos. 2 only

with:

GKS07−4M LLL 090CLL

Breathing / oil filler plug GKS09−4M LLL 112CLL

Oil drain plug

Oil−control plug

GKS05

GKS09...14

**

GKS05...07

1

GKS09...14

2

GKS06...14

GT−GNG−GKS−4−001_A−F.iso/dms

50

l

BA 12.0023−EN 7.0

Page 51

Mechanical installation

Breather position, oil filling screw and drain plug

Helical−worm gearbox GSS 05 ... 07−2

A B C

*

5

Mounting

1

D E F

2

*

**

2

1

1

2

*

**

A...F Mounting positions Pos. 1 Standard

*

**

on both sides

opposite GSS05−2M LLL 100CLL

Breathing / oil filler plug GSS06−2M LLL 112CLL

Oil drain plug GSS07−2M LLL 160CLL

Oil−control plug

Pos. 2 only

with:

GSS05−2M LLL 090CLL

GT−GNG−GSS−2−001_A−F.iso/dms

BA 12.0023−EN 7.0

l

51

Page 52

5

Mechanical installation

Mounting

Breather position, oil filling screw and drain plug

Helical−worm gearbox GSS 05...07−3

A B C

*

2

**

GSS05

1

2

*

GSS06/07

** GSS05

1

*

GSS06/07

D E F

**

2

1

**

GSS05

GSS05

**

2

1

* GSS06/07

GSS06/07

GSS05

1

2

**

1

2

GSS06/07

* GSS06/07

** GSS05

*

GT−GNG−GSS−3−001_A−F.iso/dms

A...F Mounting positions Pos. 1 Standard

*

**

on both sides

opposite GSS07−3M LLL 100CLL

Pos. 2 only

with:

GSS07−3M LLL 090CLL

Breathing / oil filler plug

Oil drain plug

Oil−control plug

52

l

BA 12.0023−EN 7.0

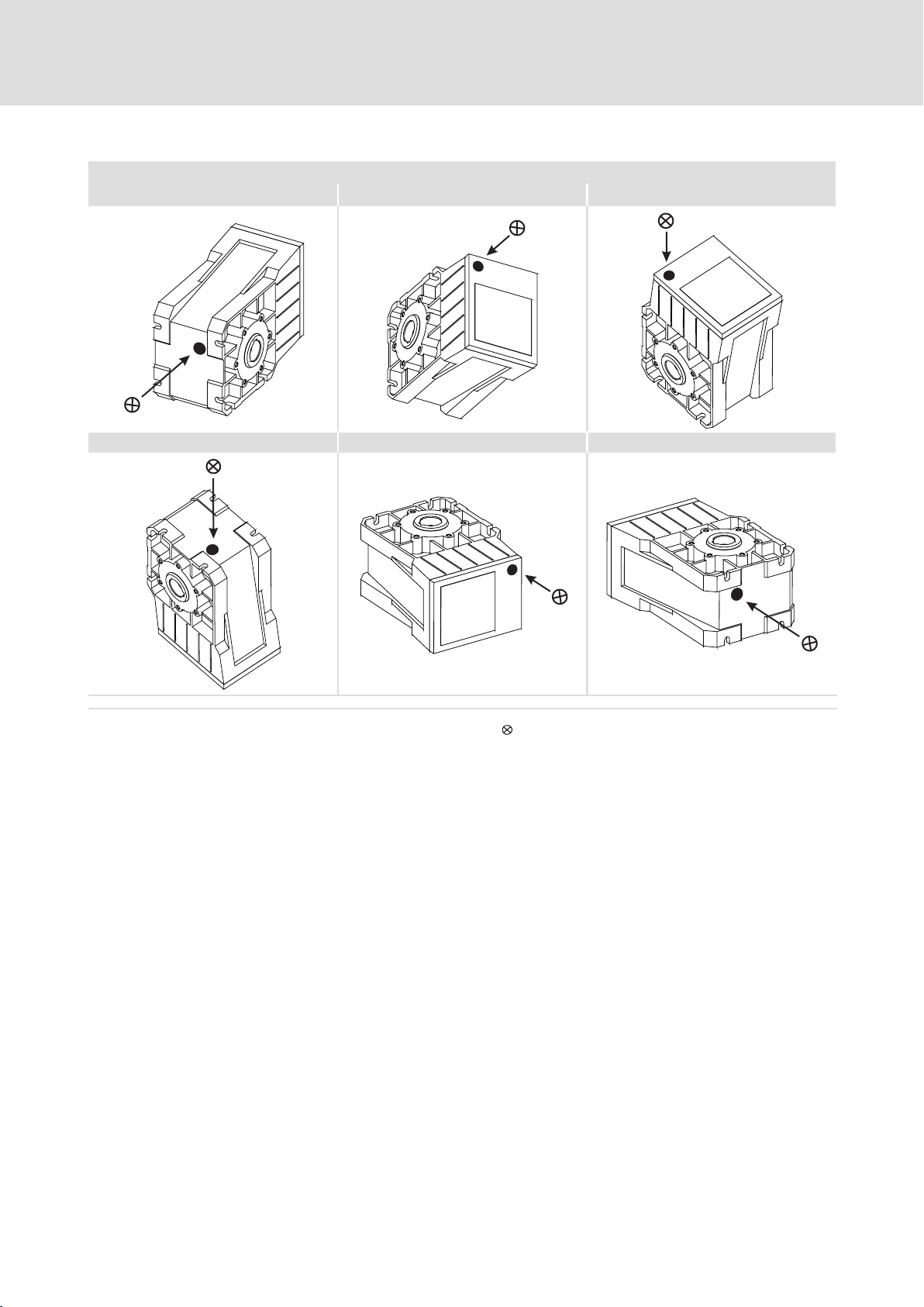

Page 53

Mechanical installation

Breather position, oil filling screw and drain plug

Bevel gearbox GKR

A B C

D E F

5

Mounting

A...F Mounting positions Breathing / oil filler plug

GT−GNG−GKR−2−001_A−F.iso/dms

BA 12.0023−EN 7.0

l

53

Page 54

5

Mechanical installation

Mounting

Breather position, oil filling screw and drain plug

Helical−bevel gearbox GKL 07...09−3

A B

C D

E F

A...F Mounting positions Breathing / oil filler plug

*

**

Pos. 1 or 2 depending on version

on both sides Oil drain plug

opposite Oil−control plug

Sealing plug without function

GT−GNG−GKL−001.iso/dms

54

l

BA 12.0023−EN 7.0

Page 55

Mechanical installation

Mounting

Gearbox with compensation container for mounting position C

5

5.4.12 Gearbox with compensation container for mounting position C

GST GFL

Fig. 12 Position of the compensation container in mounting position C

1 Intermediate cover 9 Plug screw

GKS

K12.0956

5.4.12.1 Component parts list

Fig. 13 Component−parts list − compensation container

1 Intermediate cover 5 Cover

2 Fixing screw 6 Breather element

3 Sealing rings 7 Hexagon nut

4 Housing 8 Seal

K12.0956

BA 12.0023−EN 7.0

l

55

Page 56

5

Mechanical installation

Mounting

Gearbox with compensation container for mounting position C

Mounting

1. Mount gearbox in mounting position C (motor on top).

2. Remove the plug (9) from the intermediate cover (1).

3. Mount housing (4) using seal (3) and fixing screw (2) to intermediate cover (1)

(instead of the plug (9)).

4. Use hexagon nut (7) to bolt the breather element (6) to the cover (5).

5. Mount cover (5) and seal (8) to the housing (4).

( Stop!

For transport the compensation reservoir must be removed and the plug must

seal the gearbox (pos. 9).

56

l

BA 12.0023−EN 7.0

Page 57

6 Electrical installation

{ Danger!

Electrical connections must only be carried out by skilled personnel!

6.1 Motor connection

To correctly connect the motor, please observe:

ƒ the notes in the terminal box of the motor

ƒ the notes in the Operating Instructions of the motor

ƒ the technical data on the motor nameplate.

Electrical installation

Motor connection

6

6.2 Motor options

To correctly connect the motor options, e. g. brakes or feedback systems, please observe:

ƒ the notes in the corresponding terminal box

ƒ the notes in the corresponding operating instructions

ƒ the technical data on the corresponding motor nameplate.

BA 12.0023−EN 7.0

l

57

Page 58

7

Commissioning and operation

Before switching on

7 Commissioning and operation

( Stop!

The drive may only be commissioned by skilled personnel!

7.1 Before switching on

Please check:

ƒ Does the drive appear undamaged?

ƒ Is the mechanical fixing o.k.?

ƒ Has the electrical connection been carried out properly?

ƒ Are all rotating parts and surfaces that may become hot protected against contact?

ƒ If the oil level of the drive has been increased due to storage purposes (¶ 28), it

must be reduced again to the height permissible for the intended mounting

position.

ƒ For gearboxes with breathing:

– Has the transport locking device been removed?

ƒ For gearboxes with backstop:

– Will the motor start to rotate in the correct direction? (¶ 29)

7.2 During operation

) Note!

The helical−worm gearboxes reach their full performance only after a short

running−in period of 24...48 hours at rated torque!

During operation, check the drive periodically and take special care of:

ƒ Deviations from normal operation such as

– abnormal noises, stronger vibrations, or increased temperatures

– leakages,

– loose fixing elements,

– the condition of the electrical cables.

58

ƒ If any interference should occur, you have to stop the drive and go through the steps

for troubleshooting and fault elimination (chapter 9). If the interference cannot be

eliminated, please contact the Lenze Service.

l

BA 12.0023−EN 7.0

Page 59

8 Maintenance

Lenze gearboxes and geared motors are filled with a drive and design−specific lubricant

filling upon delivery. This original filling corresponds to the lubricant listed in the column

of the respective gearbox type from Lenze. The important factors for the lubricant filling

on ordering are the mounting position and the design.

) Note!

Gearboxes of size 03 and 04 are lubricated for life. Because of the minimum

thermal load it is not necessary to replace the lubricant.

8.1 Maintenance intervals

ƒ The mechanical power transmission system is free of maintenance.

Maintenance

Maintenance intervals

8

ƒ Gearboxes as of size 05 (pre−stages as of size 06) require regular lubricant

replacement.

– The type of lubricant is indicated on the nameplate. Replace the lubricant only

with the same type.

– The lubricant maintenance interval depends on the oil temperature, see Fig. 14.

ƒ Shaft seals and roller bearings:

– The service life depends on the operating conditions.

– Replace seals in case of leakage to avoid consequential damage.

) Note!

When changing the lubricant, Lenze recommends also changing the grease

packing of the bearings and replacing the rotary shaft seals!

( Stop!

For drive systems: Also observe the maintenance intervals for the other drive

components!

BA 12.0023−EN 7.0

l

59

Page 60

8

Maintenance

Maintenance intervals

Lubricants

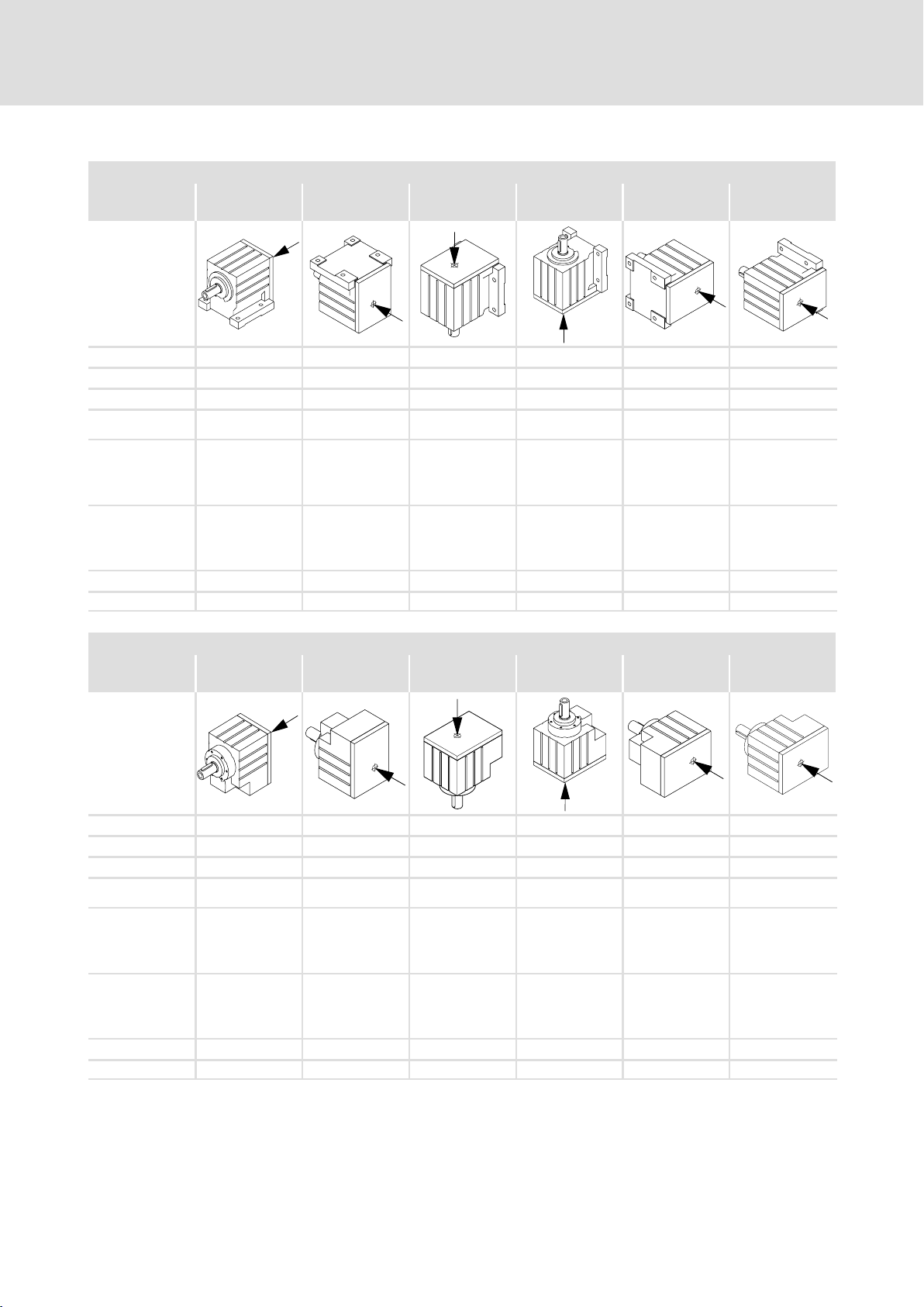

Type Specification Ambient temperature Note

CLP 460 Oil on mineral basis with

CLP PG 460 Oil on synthetic basis

CLP HC 220 USDA H1 Food−compatible oil on

CLP HC 320

CLP HC 220

CLP HC 46 Oil on synthetic basis

CLP PG 220 USDA H1 Food−compatible oil on

Tab. 8 Overview of lubricant change

additives

(polyglycol)

synthetic basis

Oil on synthetic basis

(synthetic hydrocarbon)

(synthetic hydrocarbon)

synthetic basis

0 °C ... + 40 °C

−20 °C ... + 40 °C Do not mix with mineral

oil!

−20 °C ... + 40 °C Approval acc. to USDA−H1

−25 °C ... + 50 °C Can be mixed with

residual mineral oil

−40 °C...0 °C Good cold−flow behaviour

20 °C ... + 40 °C Approval acc. to USDA−H1

) Note!

In case of ambient temperatures <−20°C or >+40°C, please contact Lenze!

Observe increased starting torques at low temperatures!

60

Fig. 14

0 Oil sump temperature [°C] 2 Synthetic oil CLP HC/CLP PG

1 Oil life/changing intervals

[operating hours h]

3 Mineral oil CLP

l

GT−GNG−002.iso/dms

BA 12.0023−EN 7.0

Page 61

Maintenance

Maintenance operations

Opening the condensation drain hole

8

8.2 Maintenance operations

8.2.1 Opening the condensation drain hole

) Note!

ƒ Depending on the mounting position, the condensation drain holes are

always at the bottom of the motor!

ƒ For condensate drainage

– the motor must be deenergised;

– the plugs (screws) must be removed.

( Stop!

To restore the enclosure, re−insert the plugs (screws) after condensate

drainage. If the condensation drain holes are not sealed again, the IP enclosure

of the motor will be reduced. For horinzontal motor shafts to IP23 and for

vertical motor shafts to IP20.

The required maintenance intervals strongly depend on the corresponding ambient and

operating conditions. Initially, the condensation drain holes should be opened more

frequently (at least once a week) to obtain experimental values for the condensate

quantity arising.

0

Fig. 15 Motor with condensation drain holes

0 Condensation drain holes

BA 12.0023−EN 7.0

l

61

Page 62

8

Maintenance

Maintenance operations

Lubricate roller bearings

8.2.2 Lubricate roller bearings

The roller bearings on motors and gearboxes from Lenze are filled with the greases listed

below:

Gearbox roller bearing

GST, GFL, GKS, GKR, GKL

Gearbox roller bearing

GSS

Motor roller bearing

Special grease for gearbox roller bearing

Low−temperature oils,

observe critical starting

performance at low

temperatures

Biodegradable oil

(lubricant for forestry,

agriculture and water

economy)

Ambient temperature Manufacturer Type

−30...+50°C

−30...+80°C

−40...+60°C

−30...+80°C

−15...+60°C

−30 °C ... +70 °C

−40 °C ... +80 °C

−40...+80°C Klüber Asonic GHY 72

−40...+50°C Fuchs Plantogel 0120S

Fuchs

Klüber

Klüber

Klüber

Klüber

Lubcon

Klüber

Renolit H 443

Petamo 133 N

Microlube GHY 72

Petamo GHY 133 N

Klüberplex BE 11−462

Thermoplex 2TML

Asonic GHY 72

The following lubricant quantities are required:

ƒ For fast−running bearings (motor and drive end of gearbox): fill approx. one−third of

the hollow space between rolling bodies with grease.

ƒ For slow−running bearings (in gearbox and driven side of gearbox): fill approx.

two−thirds of the hollow space between roller bearings with grease.

62

l

BA 12.0023−EN 7.0

Page 63

Maintenance

Maintenance operations

Table of lubricants

8

8.2.3 Table of lubricants

) Note!

Please note that the recommendation of a lubricant/grease or its listing in a

Lenze lubricant table does not mean that Lenze is liable for these lubricants or

damages resulting from incompatibilities of materials used.

The lubricants listed in the lubricant table are permissible for Lenze drives. Specialty

lubricants must be used, for example, for long−term storage or special operating

conditions. These corresponding lubricants are available at a surcharge.

Observe the following legend of the lubricant table for the selection of lubricants!

CLP Þ Mineral oil

CLP PG Þ Polyglycol oil

CLP PAO Þ Synthetic hydrocarbon or poly−alpha−olefin oil

CLP E Þ Diester oil (water pollution class 1)

1) Þ No test results are currently available about the performance of listed lubricants for

2) Þ Polyglycol oils cannot be mixed with other oil types

3) Þ For ambient temperatures higher than 40°C please contact the manufacturer for exact

4) Þ Observe critical starting behaviour for low temperatures! For temperatures lower than

5) Þ Ambient temperature range

ä

`

d

Þ Food−grade lubricant

Þ Biodegradable lubricant (lubricant for forestry, agriculture and water supply and

Þ Low−temperature oils, observe critical starting performance at low temperatures!

worm gearbox lubrication. If these oils are used, the permissible torque must be reduced

to 80% of the catalogue values.

ambient conditions!

−25°C special measures for the motor storage and NBR shaft seals are necessary!

distribution)

BA 12.0023−EN 7.0

l

63

Page 64

8

Maintenance

Maintenance operations

Table of lubricants

Shell

Ambient temperature [°C]

−50 0 +50

0 +40 CLP VG 460

−25 +50

−20 +40 CLP PG VG 220

−20 +40 CLP PG VG 460

−20 +50

0 +40 CLP VG 460

−25 +50

−20 +40 CLP PG VG 460 Klübersynth GH 6−460

−20 +40 CLP PG VG 220 Klübersynth GH 6−220

−30 0

−40 0

−20 +40

−20 +50

0 +40 CLP VG 460 Renolin CLP 460

−25 +50

−20 +40 CLP PG VG 460 Renolin PG 460

−20 +40

0 +40 CLP VG 460 AGIP BLASIA 460

−25 +50

−20 +40 CLP PG VG 460 AGIP BLASIA S 460

0 +40 CLP VG 460 Energol GR−XP 460

−25 +50

−20 +40 CLP PG VG 220 Enersyn SG−XP 220

−20 +40 CLP PG VG 460 Enersyn SG−XP 460

0 +40 CLP VG 460

−25 +50

−10 +50

−10 +40

−20 +40

−20 +40

0 +40 CLP VG 460 Carter EP 460

−25 +50

4)

4)

3)

3)

3)

3)

3)

3)

3)

3)

3)

DIN 51517−3: CLP

ISO 12925−1: CKC/CKD

CLP HC VG 320

CLP E VG 320

`

CLP HC VG 320

CLP PG VG 32 Klübersynth GH 6−32

d

CLP HC VG 46

d

CLP HC VG 220

ä

CLP E VG 320

`

CLP HC VG 320

CLP E VG 320 Plantogear 320 S Plantogear 320

`

CLP HC VG 320 AGIP BLASIA SX 320

CLP HC VG 320 Enersyn EP−XF 320

CLP HC VG 320

CLP HC VG 460 Mobil SHC Cibus 460

ä