Page 1

BA 12.0030

Show/Hide Bookmarks

.ð.$

Ä.".$ä

Operating Instructions

G-motion

GPA servo planetary geared motors

Page 2

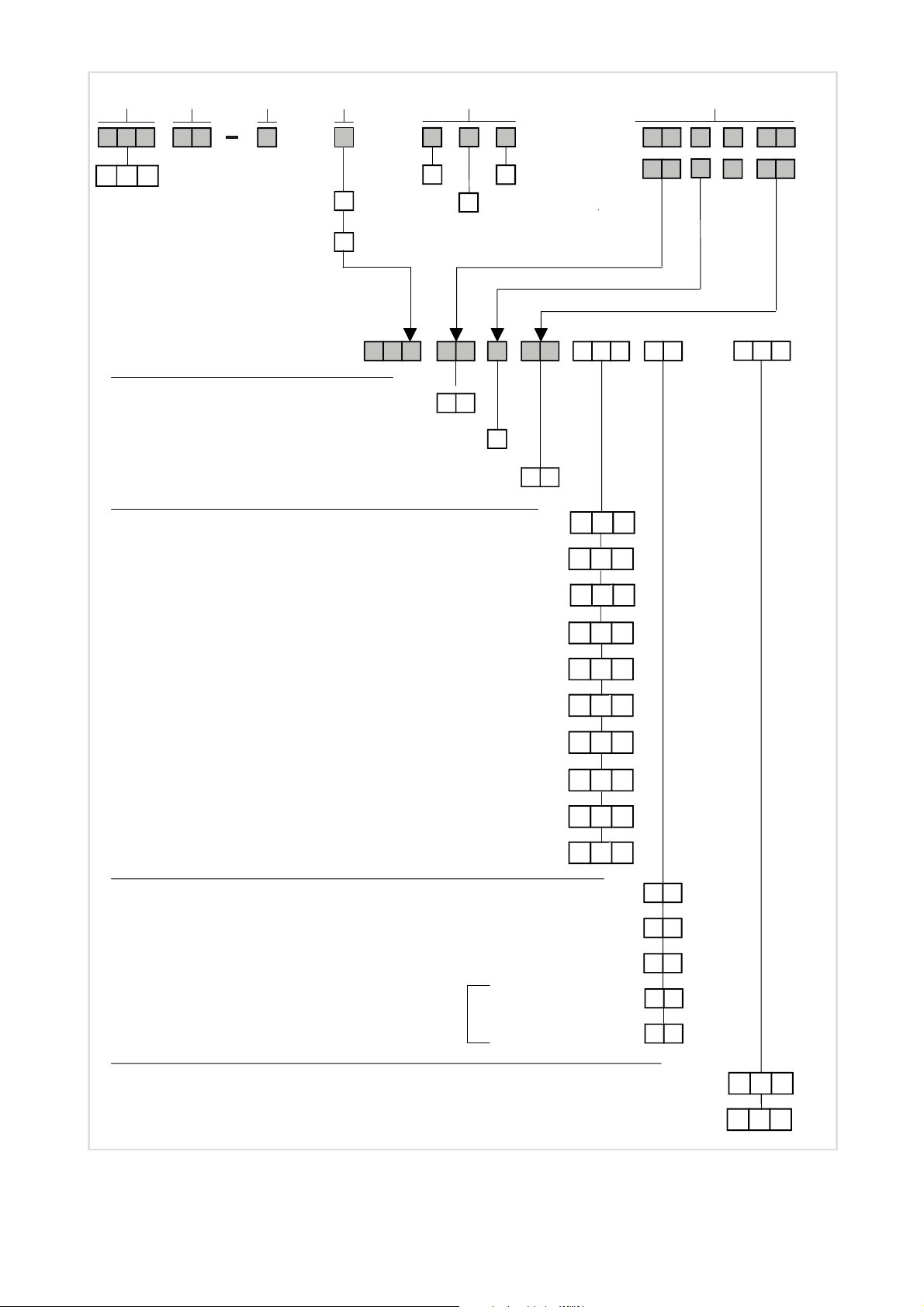

Product key

Show/Hide Bookmarks

Gearbox

type

GP A

Gearbox

size

Planetary gearbox

servo motor,

asynchronous, externally

ventilated

Servomotor, synchronous,

externally ventilated

Step

number

Expanded servomotor key

Square measure

Length of coil module

Tacho generator and phase angle sensor

Square measure (example: 142 mm)

Input design

Solid shaft

smooth

A

Output design Drive size

G

Without foot mounting with centering

C

S

MC

14

Length ofcoil module

Rated speed, value100/min (example: 2000 min

Square flange(through

N

holes)

l

-1

)

20

Resolver p=1

R OS

C

1

()

C024

l

...

Brake

Sin-Cos-Absolute value encoder Singleturn, Hiperface, SCS70

Sin-Cos-Absolute value encoder Multiturn, Hiperface, SCM70

Sin-Cos-Absolute value encoder Singleturn, Hiperface, SRS50

Sin-Cos-Absolute value encoder Multiturn, Hiperface, SRM50

Sin-Cos-Absolutevalue encoder Singleturn, EnDat,ECN 1313

Sin-Cos-Absolutevalue encoder Multiturn, EnDat, EQN 1325

Sin-Cos-Absolutevalue encoder Multiturn, EnDat, EQI 1329

Incrementalencoder TTL, 2048, ITD 21

Incrementalencoder TTL, 2048, CDD 50

PM brake 24 VDC uprated

not for

UL design,UR approval

PM-brake DC 205V uprated

S C S

S C M

S SR

S R M

E C N

E NQ

EIQ

T 2 0

C D D

Without brake

PM brake 24 VDC

PM-brake DC 205V

B0

P1

P2

P5

P6

Cooling

2

Separately ventilated with fan

Separately ventilated with fan

BA 12.0030 EN 2.0

S 00

F 1 0

Page 3

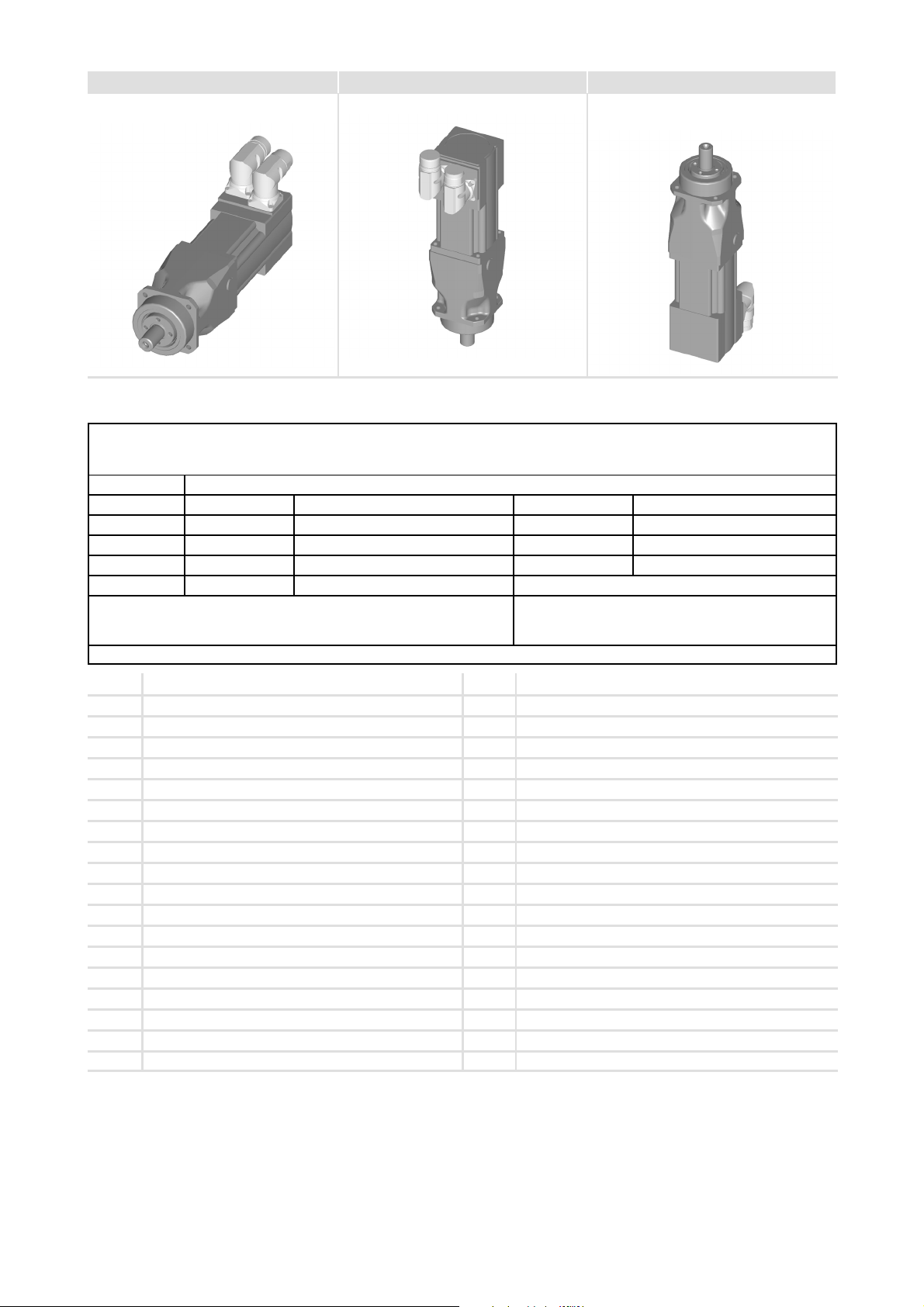

GPA mounting positions A, C, D

Show/Hide Bookmarks

A C D

Nameplate (sample)

3~MOT GPA00-1SGCN-09FN38

330 V 1.2 kW n

2.5 A # 1.6 HP $ c=2.1 % M

max. 5.9 A ( 250 Hz ) Cooling type S00 I CLP 150 000A

I.CL.F IP 55 Fan data

Ta 30 °C C86:1314 U

Brake !!

Brake

SN 15005432100065566 ## IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII $$

Manufacturer Lubricant type

Assembly plant Position of system modules / mounting position

UL file no. Insulation class

CE designation Enclosure

Motor type Fan data

Gearbox type Ambient operating temperature

Rated voltage Code for motor parameterisation

Motor driving power Induced voltage

Input speed ID number

! Rated output torque of geared motor !! Brake data

" Output speed "" Encoder data

# Rated current ## Serial number

$ Motor driving power $$ Bar code

% Load capacity

& Rated output torque of gearbox

' Ratio

( Maximum current

) Rated frequency

I Cooling type S00

V A Nm

Hans-Lenze-Strasse 1

D-31855 Aerzen

http://www.Lenze.com

3750 min-1 M212 Nm ! n

1eck

in

V Item 00452320

UL

File no.

25 Nm & i=4 '

2GN

Encoder

""

Feedback

RS 0

N

2eck

Made in

Germany

938 min-1"

BA 12.0030 EN 2.0

3

Page 4

What is new?/ What has been changed in the Operating Instruction?

Show/Hide Bookmarks

Material number Edition Important Contents

00 491 027 1.0 05/04 TD09 1st edition First printing

13 011 303 2.0 08/04 TD09 1st edition Completion of the product key

Completion of the chart transport weights

© 2004

Lenze Drive Systems GmbH,Hans-Lenze-Straße 1,31855 Aerzen

No part of this documentation may be reproduced or made accessible to third parties without written consent by

Systems GmbH

All information given in this documentation has been selected carefully and complies with the hardware and software d escribed.

Nevertheless, deviations cannot be ruled out. We do not take any responsibility or liability for damages which might possibly occur.

Necessary corrections will be included in subsequent editions.

4

.

Lenze Drive

BA 12.0030 EN 2.0

Page 5

Contents i

Show/Hide Bookmarks

1 Preface and general information 6............................................

1.1 About these Operating Instructions 6.....................................

1.2 Terminology used 6....................................................

1.3 Scope of supply 6......................................................

1.4 Lenze drive systems 7...................................................

1.5 Legal regulations 7.....................................................

2Safety 8...................................................................

2.1 Personnel responsible for safety 8........................................

2.2 General safety information 8............................................

2.3 Definition of notes used 9...............................................

3 Technical data 10............................................................

3.1 Product features 10.....................................................

3.2 Transport weights 11....................................................

3.3 General data/operating conditions 12......................................

3.3.1 Temperatures 12................................................

3.3.2 Ambient conditions 12...........................................

4 Mechanische Installation 13...................................................

4.1 Storage 13.............................................................

4.2 Mounting 13...........................................................

4.2.1 Preparation 13..................................................

4.2.2 General information about the assembly of drive systems 14...........

4.2.3 Assembly of transmission elements on solid shafts 14................

5 Electrical installation 15.......................................................

5.1 Motor connection 15............................................

6 Commissioning and operation 16...............................................

6.1 Before switching on 16..................................................

6.2 During operation 16.....................................................

7 Maintenance 17.............................................................

7.1 Maintenance intervals 17................................................

7.1.1 Replacing the lubricant 18........................................

7.1.2 Lubricant quantity 19............................................

8 Troubleshooting and fault elimination 20.......................................

9Disposal 21..................................................................

10 Appendix 22................................................................

10.1 Manufacturer’s Certification 22...........................................

BA 12.0030 EN 2.0

5

Page 6

1

Show/Hide Bookmarks

Preface and general information

About these Operating Instructions

1 Preface and general information

1.1 About these Operating Instructions

ƒ These Operating Instructions are intended for safety-relevant operations on and

with the gearboxes G. They contain safety instructions which must be observed.

ƒ All personnel working on and with the gearboxes G must have the Operating

Instructions available and observe the information and notes relevant for them.

ƒ The Operating Instructions must always be complete and perfectly readable.

1.2 Terminology used

Term In the following text used for

Gearboxes Gearbox of product family G

Drive system Drive system with gearboxes G and other Lenze drive components

1.3 Scope of supply

ƒ The drive systems are combined individually according to a modular design. The

scope of supply can be obtained from the pertinent papers.

ƒ After receipt of the supply, check immediately whether it corresponds with the

accompanying papers. Lenze does not grant any warranty for subsequent claims.

Claim for

– visible transport damages immediately to the forwarder.

– visible deficiencies / incompleteness immediately to the responsible Lenze

subsidiary / agency.

6

BA 12.0030 EN 2.0

Page 7

1.4 Lenze drive systems

Show/Hide Bookmarks

Labelling

Lenze drive systems are uniquely designated by the content of their nameplates.

Manufacturer

Lenze Drive Systems GmbH

Hans-Lenze-Straße 1

31855 Aerzen

Application as directed

ƒLenzedrivesystems

– are intended for use in machinery and plant,

– must only be used for the purposes ordered and confirmed,

– must only be operated under the ambient conditions prescribed in these

Operating Instructions,

– must not be operated beyond their corresponding power limits.

Preface and general information

Lenze drive systems

1

Any other use shall be deemed inappropriate!

1.5 Legal regulations

Liability

ƒ The information, data, and notes in the Operating Instructions met on the state of

theartatthetimeofprinting.Claimsreferringtodrivesystemswhichhavealready

been supplied cannot be derived from the information, illustrations, and

descriptions.

ƒ We do not accept any liability for damage and operating interference caused by:

– inappropriate use,

– unauthorised modifications to the drive system,

– improper working on and with the drive system,

– operating faults,

– disregarding the Operating Instructions.

Warranty

ƒ Conditions of warranty: see terms of sale and delivery of Lenze Drive Systems GmbH.

BA 12.0030 EN 2.0

ƒ Warranty claims must be made to Lenze immediately after detecting the deficiency

or fault.

ƒ The warranty is void where liability claims cannot be made.

7

Page 8

2

Show/Hide Bookmarks

Safety

Personnel responsible for safety

2Safety

2.1 Personnel responsible for safety

Operator

ƒ An operator is any natural or legal person who uses the drive system or on behalf of

whom the drive system is used.

ƒ The operator or his safety officer must ensure

– that all relevant regulations, instructions and legislation are observed.

– that only qualified personnel work with and on the drive system.

– that the personnel have the Operating Instructions available for all corresponding

operations.

– that non-qualified personnel are prohibited from working with and on the drive

system.

Skilled personnel

Skilled personnel are persons who - because of their education, experience, instructions,

and knowledge about corresponding standards and regulations, rules for the prevention

of accidents, and operating conditions - are authorised by the person responsible for the

safety ofthe plant toperform the requiredactions and whoare able tor ecognise potential

hazards.

(See IEC 364, definition of skilled personnel)

2.2 General safety information

ƒ This safety information is not claimed to be complete. In case of questions and

problems, please contact your Lenze representative.

ƒ At the time of delivery the drive system meets the state of the art and ensures

basically safe operation.

ƒ The drive system is a source of danger for persons, for the drive system itself, and for

other material assets of the operator, if

– unqualified personnel works with and on the drive system,

– the drive system is used inappropriately.

ƒ The drive systems must be designed such that they perform their functions after

proper installation and with application as directed in fault-free operation and that

they do not cause hazar ds for persons. This also applies for their interaction with the

complete plant.

8

ƒ Makesurebyappropriatemeasuresthatincaseoffailureofthedrivesystemno

material damage is caused.

ƒ Operate the drive system only when it is in a proper state.

ƒ Retrofittings, modifications, or redesigns of the drive system are basically

prohibited. Lenze must be contacted in all cases.

BA 12.0030 EN 2.0

Page 9

2.3 Definition of notes used

Show/Hide Bookmarks

The following signal words and symbols are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Safety

Definition of notes used

2

Pictograph and signal word Meaning

Application notes

Pictograph and signal word Meaning

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Danger of personal injury through dangerous electrical

voltage.

Danger!

Danger!

Stop!

Note!

Reference to an imminent danger that may result in death or

serious personal injury if the correspondingmeasures are not

taken.

Danger of personal injury through a general source of danger

Reference to an imminent danger that may result in death or

serious personal injury if the correspondingmeasures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Important note to ensure trouble-free operation

X

H

BA 12.0030 EN 2.0

Tip!

Useful tip for simple handling

Reference to another documentation

9

Page 10

3

Show/Hide Bookmarks

Technical data

Product features

3 Technical data

ƒ The most important technical data are indicated on the nameplate (for Design and

Contentsseepage3).

ƒ Additional technical data are listed in the product catalogues.

3.1 Product features

Design

Drive systems have a modular design.

They consist of:

ƒ Speed reduction gearboxes

–Planetarygearbox

ƒ Motors

– Servomotor

ƒ Frequency inverters

Mode of operation

ƒ Torque and speed conversion

ƒ The reaction torque must be supported by the flange mounting in a suitable way.

10

BA 12.0030 EN 2.0

Page 11

3.2 Transport weights

Show/Hide Bookmarks

Geared servo motor Drive size (square measure)

GPA - SGCN 06 09 12 14 19

GPA 00 - 1 < 6 <10

GPA 01 - 1 <8 <12 <19

GPA 02 - 1 <15 <22 <37

GPA 03 - 1 <30 <45 <59

GPA 04 - 1 <75

GPA 05 - 1 <90

GPA 00 - 2 <7

GPA 01 - 2 <9 <13

GPA 02 - 2 <17 <24

GPA 03 - 2 <36 <51

GPA 04 - 2 <84

GPA 05 - 2 < 112

Technical data

Transport weights

3

Geared servo motor Drive size (square measure)

GPA - AGCN 10 13 14 17 19 21

GPA 00 - 1 < 10

GPA 01 - 1 <11 <17

GPA 02 - 1 <14 <20 <25 <35

GPA 03 - 1 <28 <33 <43 <68 <81

GPA 04 - 1 <84 <96

GPA 05 - 1 <99 < 111

GPA 00 - 2 <11

GPA 01 - 2 <12 <18

GPA 02 - 2 <23 <28 <37

GPA 03 - 2 <74

GPA 04 - 2 <92 < 105

GPA 05 - 2 < 120 < 132

Tab. 1 Transport weight in [kg]

BA 12.0030 EN 2.0

11

Page 12

3

Show/Hide Bookmarks

3.3 General data/operating conditions

3.3.1 Temperatures

3.3.2 Ambient conditions

Technical data

General data/operating conditions

Temperatures

The permissible temperature range is determined by the following:

ƒ The lubricant specifications in connection with the expected oil temperatures in

operation (see chapter 7.1 and nameplate).

ƒ The thermal class of the motor considering the motor temperature expected during

operation (see nameplate and/or Operating Instructions of the motor).

The operating temperature is determined by the powerloss, the ambient temperature and

the cooling system!

ƒ Gearboxes are protected against dust and spray water.

ƒ Motors according to their enclosure (see nameplate and/or Operating Instructions of

the motor).

ƒ Ambient media - especially chemically aggressive - can destroy shaft seals and

coatings (plastic). Abrasive media endanger shaft seals.

12

BA 12.0030 EN 2.0

Page 13

4 Mechanische Installation

Show/Hide Bookmarks

Mechanical installation

Storage

4

4.1 Storage

If you do not install the gearbox immediately, ensure appropriate conditions of storage.

ƒUptooneyear:

ƒOverayear:

4.2 Mounting

4.2.1 Preparation

Danger!

Only transport the drive with transport equipment or hoists which are suitable

for this load (see transport weights, chapter 3.2). Ensure a safe fixing. Avoid

shocks!

The motors attached to the gearbox are partially equipped with eyebolts.

These are exclusivelydetermined for motor/gearbox mounting and

dismounting and must not be used for the complete geared motor!

– Without special measures in dry and dust-free rooms and protected from sunlight.

– Requires consultation with the plant.

Stop!

Thoroughly remove anticorrosion agents from output shafts and flange faces.

BA 12.0030 EN 2.0

13

Page 14

4

Show/Hide Bookmarks

4.2.2 General information about the assembly of drive systems

Mechanical installation

Mounting

General information about the assembly of drive systems

ƒ Take safety measures prior to any operation:

– Disconnect the machine from the mains, ensure standstill of the machine and

avoid any machine movement.

– Check the proper state of the drive system. Never install and set up damaged drive

systems.

– Check the combination of drive function and machine functions. Check the

direction of rotation.

ƒ The mounting surfaces must be even, without torsion, and free from vibration.

ƒ Align the drive system on the mounting surfaces exactly with the machine shaft to

be driven.

– Ensure that the assembly is without torsion, to avoid additional load.

– Compensate for minor misalignments by using suitable flexible couplings.

ƒ Support the reaction torque appropriately.

ƒ Fixings of accessories and attachments must be secured against loosening. We

recommend that screw connections are glued.

4.2.3 Assembly of transmission elements on solid shafts

ƒ Draw the transmission elements onto the output shaft only by using the centering

Stop!

The lubricant fill quantity of the gearboxes is matched to the mounting

position. The mounting position indicated on the nameplate must be observed

to avoid damage to the gearbox.

thread.

Stop!

Shocks and blows to the shafts damage the roller bearings.

14

BA 12.0030 EN 2.0

Page 15

5 Electrical installation

Show/Hide Bookmarks

Electrical installation 5

5.1 Motor connection

To correctly connect the motor options, please observe:

ƒ the notes in the terminal box of the motor

ƒ the notes in the Operating Instructions of the motor

ƒ the technical data on the motor nameplate.

Danger!

Electrical connections must only be made by skilled personnel!

BA 12.0030 EN 2.0

15

Page 16

6

Show/Hide Bookmarks

Commissioning

Before switching on

6 Commissioning and operation

6.1 Before switching on

Check:

ƒ Is the mechanical fixing o.k.?

ƒ Are the electrical connections o.k.?

ƒ Are all rotating parts and surfaces, w hich may become hot, protected against

6.2 During operation

ƒ During operation, check the drive periodically and take special care of:

Stop!

The drive may only be commissioned by skilled personnel!

contact?

– unusual noises or temperatures,

–leakages,

– loose fixing elements,

– the condition of the electrical cables.

ƒ If any interference should occur , proceed according to the troubleshooting list in

chapter 8. If the interference cannot be eliminated, please contact the Lenze Service.

16

BA 12.0030 EN 2.0

Page 17

7 Maintenance

g

g

Show/Hide Bookmarks

Gearboxes and geared motors from Lenze are filled with a drive-specific and

design-specific lubricant filling at delivery. The mounting position and design are decisive

at ordering for the required lubricant quantity.

Maintenance

Maintenance intervals

7

7.1 Maintenance intervals

ƒ The mechanical power transmission system is free of maintenance.

ƒ Shaft seals:

ƒ Lubricating intervals:

Note!

When changing the lubricant, Lenze recommends also changing the grease

packing of the bearings and replacing the radial shaft seal rings!

– The service life depends on the ambient conditions.

– Replace seals in case of leakage to avoid consequential damage.

– Gearboxes of type GPA are lubricated for life and hermetically sealed. In normal

operation, a lubricant change is not required.

– With extremely severe operation, we recommend changing the lubricant every

10,000 operating hours.

– The type of lubricant is indicated on the nameplate. Replace the lubricant only by

thesametype.

Stop!

For drive systems: Also observe the maintenance intervals for the other drive

components!

BA 12.0030 EN 2.0

Lubricants Changing intervals

Type Specification Ambient

CLP PAO 150 Oil on synthetic basis

(polyglycol)

temperature

-20 °C...40 °C Do not mix with

Note

mineral oils!

10,000 operating hours, no longer

than three years

(oil temperature 70...100 °C)

17

Page 18

7

Show/Hide Bookmarks

7.1.1 Replacing the lubricant

Maintenance

Maintenance intervals

Replacing the lubricant

1. Drain lubricant by removing the oil drain/filler plug.

2. Fill recommended lubricant in the specified amount.

3. Insert oil drain/filler plug with new seal.

4. Dispose of waste oil according to applicable regulations.

Stop!

ƒ

Gearbox should be warm.

ƒ

Secure drive system and machine from inadvertent movement and mains

connection.

Fig. 1 Position of oil filler/drain plug

Oil filler/drain plug

Recommended lubricant

Manufacturer Mobil Optimol

Type Mobil SHC 629 Optigear Synthetic A 150

18

BA 12.0030 EN 2.0

Page 19

7.1.2 Lubricant quantity

Show/Hide Bookmarks

Maintenance

Maintenance intervals

Lubricant quantity

7

Gearbox

GPA 00 - 1 22 25 35

GPA 01 - 1 35 55 75

GPA 02 - 1 80 130 160

GPA 03 - 1 130 210 300

GPA 04 - 1 220 350 500

GPA 05 - 1 300 600 700

GPA 00 - 2 35 42 50

GPA 01 - 2 45 80 90

GPA 02 - 2 100 175 190

GPA 03 - 2 160 310 410

GPA 04 - 2 270 700 720

GPA 05 - 2 420 1200 1350

Tab. 2 Lubricant quantity in [ml]

Mounting position

A C D

BA 12.0030 EN 2.0

19

Page 20

Troubleshooting and fault elimination8

Show/Hide Bookmarks

8 Troubleshooting and fault elimination

If any malfunctions should occur during operation of the drive system, please check the

possible causes using the following table. If the fault cannot be eliminated by one of the

listed measures, please contact the Lenze Service.

Fault Possible cause Remedy

Drive is at standstill Voltage supply interrupted Check connection

Wrong electrical connection Check if nameplate matches voltage supply

Excessive load Reduce load

Motor running, gearbox at

standstill

Unusual noise Overload Reduce load

Excessive temperature Overload Reduce load

Loose fixing elements Vibrations Avoid vibrations

Fixing elements are missing or

defective

Gearbox is defective Contact Lenze Service

Damage in the gearbox or

motor

Insufficient heat dissipation Improve cooling air supply

Insufficient lubricant Refill lubricant as specified

Check drive - machine combination

Check attachment

Check drive - machine combination

Contact Lenze Service

Check drive - machine combination

Clean gearbox / motor

20

BA 12.0030 EN 2.0

Page 21

9Disposal

Show/Hide Bookmarks

Protect the environment! Packaging material can be recycled.

What? Where?

Transport material Pallets Return to the manufacturer or forwarder

Lubricants Oil, grease Dispose according to current regulations

Components Housing: Grey cast

Disposal 9

Packaging material Cardboard box to waste paper

Plastics to plastics recycling or residual

waste

Reuse or dispose of wood wool

Separate valuable substances and dispose

Bearings, gear wheel shafts: Steel

Seals: Hazardous waste

BA 12.0030 EN 2.0

21

Page 22

10

Show/Hide Bookmarks

Appendix

Manufacturer’s Certification

10 Appendix

10.1 Manufacturer’s Certification

Herewith we declare that the products stated below are determined for assembly in a machine

or for assembling a machine with other components. The commissioning of the machine is

prohibited as long as it has been ascertained that it meets the EC Directive 98/37/EC.

Product Type designation

Low-profile gearboxes and geared motors GFL

Helical gearboxes and geared motors GST, 12.6

Helical bevelgearboxes and geared motors GKS, 12.5

Bevel gearboxes and geared motors GKR

Bevel gear units and geared motors with coupling GKK

Helical worm gearboxes and geared motors GSS, 52.1

Planetary geared motors GPA

Variable speed belt drives and geared motors G-K

11.1, 11.2, 11.4

Variable speed drives and geared motors G-D

11.7

Shaft-mounted gearboxes 12.4

Worm gearboxes and geared motors 52.3, 52.4, 52.5

Lenze Drive Systems GmbH

P.O.box101352

D-31763 Hameln

Site: Bösingfeld

Breslauer Straße 3

D-32699 Extertal

Phone (051 54) 82-0

Fax (051 54) 82-1575

Applied standards and regulations:

EN 292 part 1

EN 292 part 2

Hameln, March 30, 2004

(Dr.-Ing. Etienne Nitidem)

Head of Research and Development Department for Electromechanics

22

BA 12.0030 EN 2.0

Page 23

N

Show/Hide Bookmarks

Lenze Drive Systems GmbH

Hans-Lenze-Straße 1

31855 Aerzen

Germany

Service 0080002446877(24hhelpline)

¬

Service +49 (0) 51 54 82-1112

E-Mail Lenze@Lenze.de

Internet www.Lenze.com

BA 12.0030 2.0 09/2004 TD09

2004

+49(0)515482-0

10987654321

Loading...

Loading...