Page 1

g700

g700−P20 ... g700−P800 | 5 Nm ...

800 Nm

Planetary gearboxes with servo

Mounting Instructions

EN

.O10

Ä.O10ä

Page 2

First read this documentation and the documentation of the motor before you start

working.

Observe the safety instructions contained therein.

0Abb. 0Tab. 0

Page 3

Contents i

1 About this documentation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Terminology used 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Notes used 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety instructions for drive components 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Product description 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Important notes 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Identification 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Nameplate 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Transport weights 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Mechanical installation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Important notes 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Means of transport for gearboxes 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Preparation 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Mounting 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Important notes 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Electrical connection 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Commissioning and operation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Important notes 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Before switching on 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 During operation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Maintenance 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Important notes 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Repair 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Disposal 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Troubleshooting and fault elimination 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EN

Lenze ¯ MA 12.0015 ¯ 1.0

3

Page 4

1

About this documentation

Document history

1 About this documentation

Contents

¯ This documentation serves for safety−relevant operations on and with the

gearboxes. It contains safety instructions which must be observed.

¯ All personnel working on and with the gearboxes must have the documentation

available during the work and observe the information and notes relevant for

them.

¯ The documentation must always be complete and in a perfectly readable state.

Target group

This documentation is directed at qualified skilled personnel according to IEC 60364.

Qualified skilled personnel are persons who have the required qualifications to carry out

all activities involved in installing, mounting, commissioning, and operating the

product.

EN

Tip!

Information and auxiliary devices related to the Lenze products can be

found in the download area at

http://www.Lenze.com

1.1 Document history

Material number Version Description

.O10 1.0 03/2014 TD09 First edition for the pilot series

1.2 Conventions used

This documentation uses the following conventions to distinguish different types of

information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator Point In general, the decimal point is used.

Icons

Page reference

Documentation reference

Wildcard

For instance: 1234.56

Reference to another page with

additional information

For instance:

Reference to another documentation

with additional information

For example:

documentation EDKxxx

Wildcard for options, selection data

16 = see page 16

EDKxxx = see

4

Lenze ¯ MA 12.0015 ¯ 1.0

Page 5

1.3 Terminology used

Term In the following text used for

Gearboxes Gearbox of the product family g700

About this documentation

Terminology used

1

Drive system Drive systems with g700 gearboxes and other Lenze drive

1.4 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

components

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent

dangerous situations)

Pictograph and signal word Meaning

Danger of personal injury through dangerous electrical

voltage.

Danger!

Danger!

Stop!

Reference to an imminent danger that may result in death

or serious personal injury if the corresponding measures are

not taken.

Danger of personal injury through a general source of

danger.

Reference to an imminent danger that may result in death

or serious personal injury if the corresponding measures are

not taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

EN

Application notes

Pictograph and signal word Meaning

Note!

Tip!

Lenze ¯ MA 12.0015 ¯ 1.0

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

5

Page 6

EN

2

2 Safety instructions

2.1 General safety instructions for drive components

Safety instructions

General safety instructions for drive components

Danger!

Disregarding the following basic safety measures may lead to severe

personal injury and damage to material assets!

¯ Store in dry, low−vibration environment without aggressive atmosphere; if

possible in the manufacturer’s packaging.

– Protect against dust and impacts.

– Observe the climatic conditions according to the technical data, catalogue.

¯ Lenze drive and automation components ...

... must only be used as intended.

... must never be commissioned despite noticeable damage.

... must never be technically changed.

... must never be commissioned in an incompletely mounted state.

... must never be operated without the required covers.

... may have live, moving or rotary parts during and after operation − corresponding

to their type of protection. Surfaces may be hot.

... must not be operated with great vibrations ....

... must not be operated in the resonance range of a system

¯ All specifications of the corresponding enclosed documentation must be

observed.

This is vital for a safe and trouble−free operation and for achieving the specified

product features.

¯ Only qualified skilled personnel are permitted to work with or on Lenze drive and

automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and operation of

the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent regulations,

directives and laws applicable at the place of use.

6

Lenze ¯ MA 12.0015 ¯ 1.0

Page 7

3 Product description

3.1 Important notes

¯ The most important technical data is given on the nameplate.

¯ The product catalogues contain further technical data.

3.2 Identification

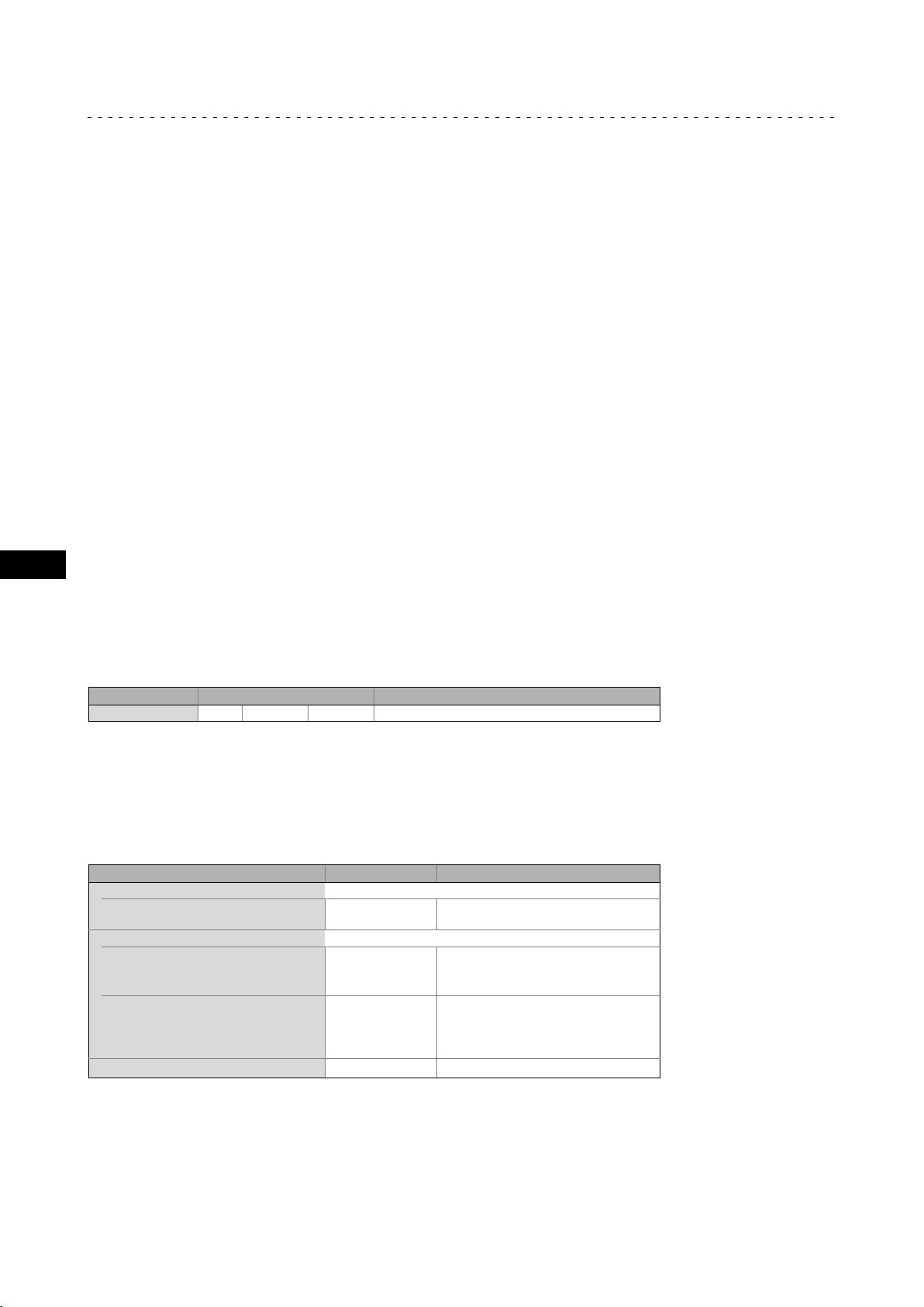

3.2.1 Nameplate

Geared motor

Note!

In the geared motor version the nameplate is attached to the motor.

Standard version

Product description

Important notes

3

5.1+5.6

5.2+5.6

5.3+5.7

5.4

5.5

1

Hans-Lenze-Straße 1

2

8

9

L

D-31855 Aerzen

GERMANY

3

6

12

14

7

Made in

Germany

4

19

E210321

13

15

En60034

11

Pos. Contents

1 Manufacturer / production location

2 Motor type / standard

3 Gearbox type

4 Motor type

5 Technical data

gearboxes

6 Rated output torque − geared motor

7 Lubricant

8 Brake data (if fitted)

9 Feedback / pulse encoder or resolver data (if fitted), motor documentation product key

10 Manufacture data

11 Bar code

12 Rated output torque − gearbox

13 Permissible ambient temperature

14 Additional motor specifications

15 Valid conformities, approvals and

certificates

16 Technical data

motor

17 Weight

18 Year / week of manufacture

19 UL file number

5.1 Rated voltage 5.5 Ratio

5.2 Rated frequency 5.6 Drive power

5.3 Rated current 5.7 Induced voltage

5.4 Maximum current

Type

AC/DC brake voltage

Braking torque, electrical power input

Material number

Serial number

Temperature class

Enclosure

CE identification

16.1 Motor speed [rpm]

16.2 Perm. output speed for S1 operation [Hz]

16.3 Motor code for controller parameterisation (code 0086)

16.4 Temperature monitoring

16.1

16.2

16.3

16.4

10

EN

g700−xxx.des

Lenze ¯ MA 12.0015 ¯ 1.0

7

Page 8

3

Product description

Transport weights

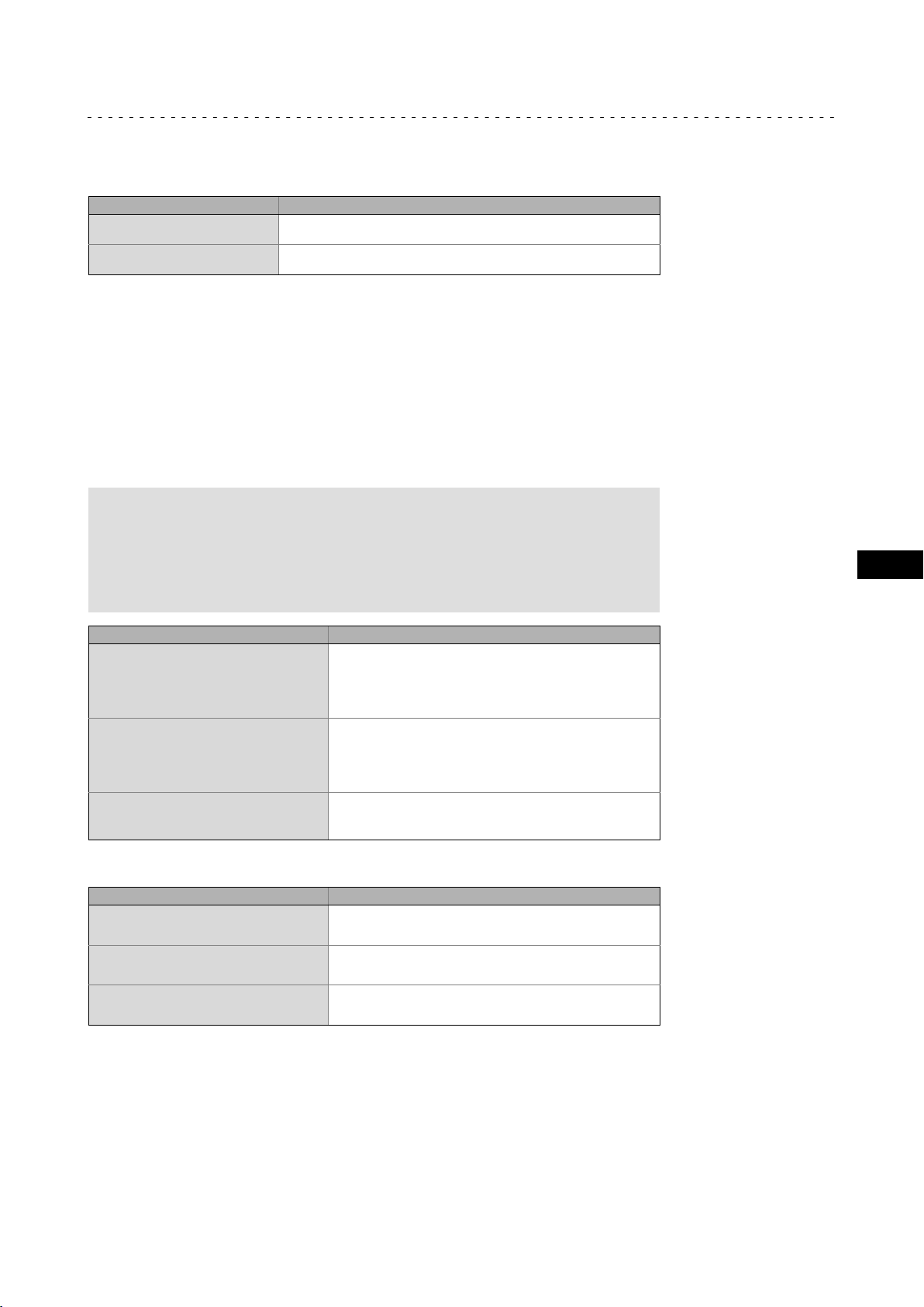

Example

Example: g700 with motor

Hans-Lenze-Straße 1

L

3~MOT

225 V~

270 Hz

1.3 A

max. 5.4 A

i = 5.0

Bremse

Brake

Geber

Feedback

D-31855 Aerzen

GERMANY

G70AP020MVCL1N

0.25 kW

0.34 HP

U 170 V

in

IP 54

BEM34-132

V A Nm

RS

M 3 Nm

2

M 15 Nm

2,GN

I.CL.F

Made in

Germany

MCS06C41-RS0B0-A11N-ST5S00N-R0SU

Ta 30°C

Id.-Nr. 15696914

SN 156969141000017071234

E210321

n 810 r/min

1eto

n 4050 r/min

2,th

C86: 1310

KTY

En60034

Ä123454678ä936

EN

3.3 Transport weights

g700 with MCA/MCS

Motor frame size

06 09 10 12 13 14 17 19

Gearbox size

g700−P20 < 3.0

g700−P44 < 4.5 < 7.0

g700−P130 < 6.0 < 11.0 < 10.0 < 13.0

g700−P260 < 13.0 < 18.0 < 17.0 < 25.0 < 22.0 < 31.0 < 36.0

g700−P800 < 37.0 < 13.0 < 51.0 < 48.0 < 70.0

Tab. 1 Weights in kg

8

Lenze ¯ MA 12.0015 ¯ 1.0

Page 9

Mechanical installation

4 Mechanical installation

4.1 Important notes

¯ Use load carrying equipment for transport!

¯ Before the transport

– check that all components are safely mounted,

– fasten all transport aids (eye bolts or support plates).

¯ Transport the drive only with means of transport or hoists with a sufficient load

capacity.

¯ Ensure secure fastening.

¯ Prevent shocks!

Danger!

Danger due to toppling or falling loads!

¯ The payload of the hoists and load handling devices must at least

correspond to the weight of the load.

¯ The load must be secured in such a way that it cannot topple or fall

down.

¯ Do not stay under a pending load!

4

Important notes

EN

4.2 Means of transport for gearboxes

Danger!

The motors attached to the gearbox are partially equipped with eyebolts.

These are exclusively determined for mounting/dismounting the motor

to the gearbox and must not be used for the complete geared motor!

Stop!

Observe load carrying capacity!

Staying under floating load is prohibited!

Lenze ¯ MA 12.0015 ¯ 1.0

9

Page 10

4

4.3 Preparation

Mechanical installation

Preparation

Important notes

Note!

Thoroughly remove anticorrosion agents from output shafts and flange

faces.

4.4 Mounting

4.4.1 Important notes

Stop!

Shocks and impacts on the shaft damage the roller bearings.

EN

4.5 Electrical connection

Danger!

Electrical connections must only be carried out by skilled personnel!

Note!

The notes for the electrical connection can be found in...

¯ in the terminal box (in case of motors with terminal box).

¯ in the connection plan (in case of motors with plugs).

10

Lenze ¯ MA 12.0015 ¯ 1.0

Page 11

Commissioning and operation

5 Commissioning and operation

5.1 Important notes

Stop!

The drive may only be commissioned by skilled personnel!

¯ Take safety measures prior to any operation:

– Disconnect the machine from the mains, ensure standstill of the drive system

and avoid any machine movement.

5.2 Before switching on

Please check:

¯ Drive function - machine function assignment

5

Important notes

¯ The direction of rotation of the drive shaft

g700 with servo motor

¯ Does the drive appear undamaged?

¯ Is the mechanical fixing o.k.?

¯ Is the electrical connection correct?

¯ Are all rotating parts and surfaces that may become hot protected against

contact?

5.3 During operation

EN

During operation, check the drive periodically and take special care of:

¯ changes compared to normal operation, like

– unusual noise, stronger vibrations or increased temperatures,

– leakages,

– loose fixing elements,

– the condition of the electrical cables.

¯ In case of faults:

– shut down the drive,

– check the troubleshooting table.

If the fault cannot be remedied, please contact the Lenze customer service.

Lenze ¯ MA 12.0015 ¯ 1.0

11

Page 12

6

Maintenance

Important notes

6 Maintenance

6.1 Important notes

Note!

¯ The gearboxes are lubricated for life.

¯ The mechanical power transmission system is maintenance−free.

6.2 Repair

¯ We recommend that all repairs are carried out by the Lenze customer service.

6.3 Disposal

Protect the environment! Packing material can be recycled. Dispose of your separated

resources according to the waste disposal regulations or via a waste management

company.

EN

The following table provides recommendations for an environmentally friendly

disposal of the machine and its components.

What? Where?

Transport

material

Lubricants Oil, grease

Components Housing:

Pallets Return to the manufacturer or

Packaging material Cardboard box to waste paper

Detergents and solvents

Paint residues

Cast iron, aluminium,

Bearings, gear wheel shafts:

Seals, electronic scrap

copper

Steel

Hazardous waste

forwarder

Plastics to plastics recycling or

residual waste

Reuse or dispose of wood wool

Dispose according to current

regulations

Separate valuable substances

and dispose

12

Lenze ¯ MA 12.0015 ¯ 1.0

Page 13

Troubleshooting and fault elimination 7

7 Troubleshooting and fault elimination

If any malfunctions should occur during operation of the drive system, please check the

possible causes using the following table. If the fault cannot be eliminated by one of the

listed measures, please contact the Lenze Service.

Fault Possible cause Remedy

Drive does not turn

Motor runs, gearbox does

not

Unusual running noises

Excessive temperature

Loose fixing elements Vibrations Avoid vibrations

Motor too hot

Can only be evaluated by

measuring the surface

temperature:

¯ Non−ventilated motors

> 140 °C

¯ Externally ventilated or

self−ventilated motors

> 110 °C

Motor suddenly stops and

does not restart

Incorrect direction of

rotation of the motor,

correct display on the

controller

Motor rotates normally but

does not reach the expected

torque

Motor turns in one direction

at maximum speed in an

uncontrolled manner

Motor rotates slowly in one

direction and cannot be

influenced by the controller

Voltage supply interrupted Check connection

Incorrect electrical

connection

Excessive load Reduce load

Gearbox is defective Inform Lenze Service

Overload Reduce load

Damage in the gearbox or

motor

Overload Reduce load

Inadequate heat dissipation Improve cooling air flow

Preheated cooling air Ensure a sufficient supply of fresh cooling

Overload, with normal

mains voltage the current is

too high and the speed too

low

Rated operating mode

exceeded (S1 to S8 IEC/EN

60034−1)

Loose contact in supply cable

(temporary single−phase

operation!)

Fuse has blown

(single−phasing!)

Overload of the drive ¯ Check load and, if necessary, reduce by

Heat dissipation impeded by

deposits

Overload monitoring of the

inverter is activated

Motor cable polarity is

reversed

Polarity of encoder cable

reversed

Motor cable interchanged

cyclically

Motor cable interchanged

cyclically

Polarity of encoder cable

reversed

Polarity of motor cable and

encoder cable reversed

Check if nameplate matches voltage supply

Check drive−machine assignment

Check drive−machine assignment

Contact Lenze Service

Check drive−machine assignment

Clean gearbox / motor

air

Use larger drive (determined by power

measurement)

Adjust rated operating mode to the

specified operating conditions.

Determination of correct drive by expert or

Lenze customer service

Tighten loose contact

Replace fuse

means of longer ramp−up times

¯ Check winding temperature

Clean surface and cooling fins of the drives

¯ Check controller settings

¯ Reduce load caused by longer

acceleration times

Check the polarity and correct

Connect the phases at the motor cable

connection correctly

Check motor connector and, if necessary,

correct

Check encoder connection and, if necessary,

correct

Check the polarity and correct

EN

Lenze ¯ MA 12.0015 ¯ 1.0

13

Page 14

Troubleshooting and fault elimination7

Irregular running

Vibrations

Running noises

RemedyPossible causeFault

Insufficient shielding of

motor or resolver cable

Drive controller gain too

large

Insufficiently balanced

coupling elements or

machine

Inadequate alignment of

drive train

Loose fixing screws Check and tighten screw connections

Foreign particles inside the

motor

Bearing damage

Checking shielding and earth connection

Adjust the gains of the controllers (see Drive

controller operating instructions)

Rebalance

Realign machine unit, check foundation if

necessary

Repair by manufacturer if necessary

EN

14

Lenze ¯ MA 12.0015 ¯ 1.0

Page 15

Notes !

EN

Lenze ¯ MA 12.0015 ¯ 1.0

15

Page 16

© 03/2014 | MA 12.0015 | .O10 | 1.0 | TD09

Lenze Drives GmbH

Postfach 10 13 52

D−31763 Hameln

Germany

+49515482−0

+49515482−2800

Lenze@Lenze.com

www.Lenze.com

Lenze Service GmbH

Breslauer Straße 3

D−32699 Extertal

Germany

0080002446877 (24 h helpline)

+49515482−1396

Service@Lenze.com

10987654321

Loading...

Loading...