Page 1

g500 H45 ... H450 | 45 Nm ... 450 Nm

Helical gearboxes / Helical gearboxes with

three−phase AC motors

Mounting Instructions

EN

.NjN

Ä.NjNä

Page 2

Please read these instructions before you start working!

Follow the enclosed safety instructions.

0Abb. 0Tab. 0

Page 3

Contents i

1 About this documentation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Terminology used 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Notes used 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety instructions for drive components 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Product description 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Important notes 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Identification 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Nameplate 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Transport weights 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Mechanical installation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Important notes 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Transport equipment for gearbox 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Preparation 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 General information about the assembly of drive systems 13. . . . . . . . . . .

4.3.2 Gearboxes with breathers 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 Condensation drain hole of the motor 14. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Mounting 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Mounting gearboxes with solid shafts 15. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Attachment of motors to gearboxes with bearing housing

(input design N) 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 Coupling hubs 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Electrical installation 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Commissioning and operation 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Important notes 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Before switching on 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 During operation 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EN

7 Maintenance 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Important notes 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Maintenance intervals 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Maintenance operations 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Motors 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Repair 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Disposal 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Troubleshooting and fault elimination 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lenze ¯ MA 12.0012 ¯ 1.0

3

Page 4

About this documentation1

1 About this documentation

Contents

¯ This documentation serves for safety−relevant operations on and with the

gearboxes. It contains safety instructions which must be observed.

¯ All personnel working on and with the gearboxes must have the documentation

available during the work and observe the information and notes relevant for

them.

¯ The documentation must always be complete and in a perfectly readable state.

Target group

This documentation is directed at qualified skilled personnel according to IEC 60364.

Qualified skilled personnel are persons who have the required qualifications to carry out

all activities involved in installing, mounting, commissioning, and operating the

product.

EN

Tip!

Information and auxiliary devices related to the Lenze products can be

found in the download area at

http://www.Lenze.com

4

Lenze ¯ MA 12.0012 ¯ 1.0

Page 5

About this documentation

1.1 Document history

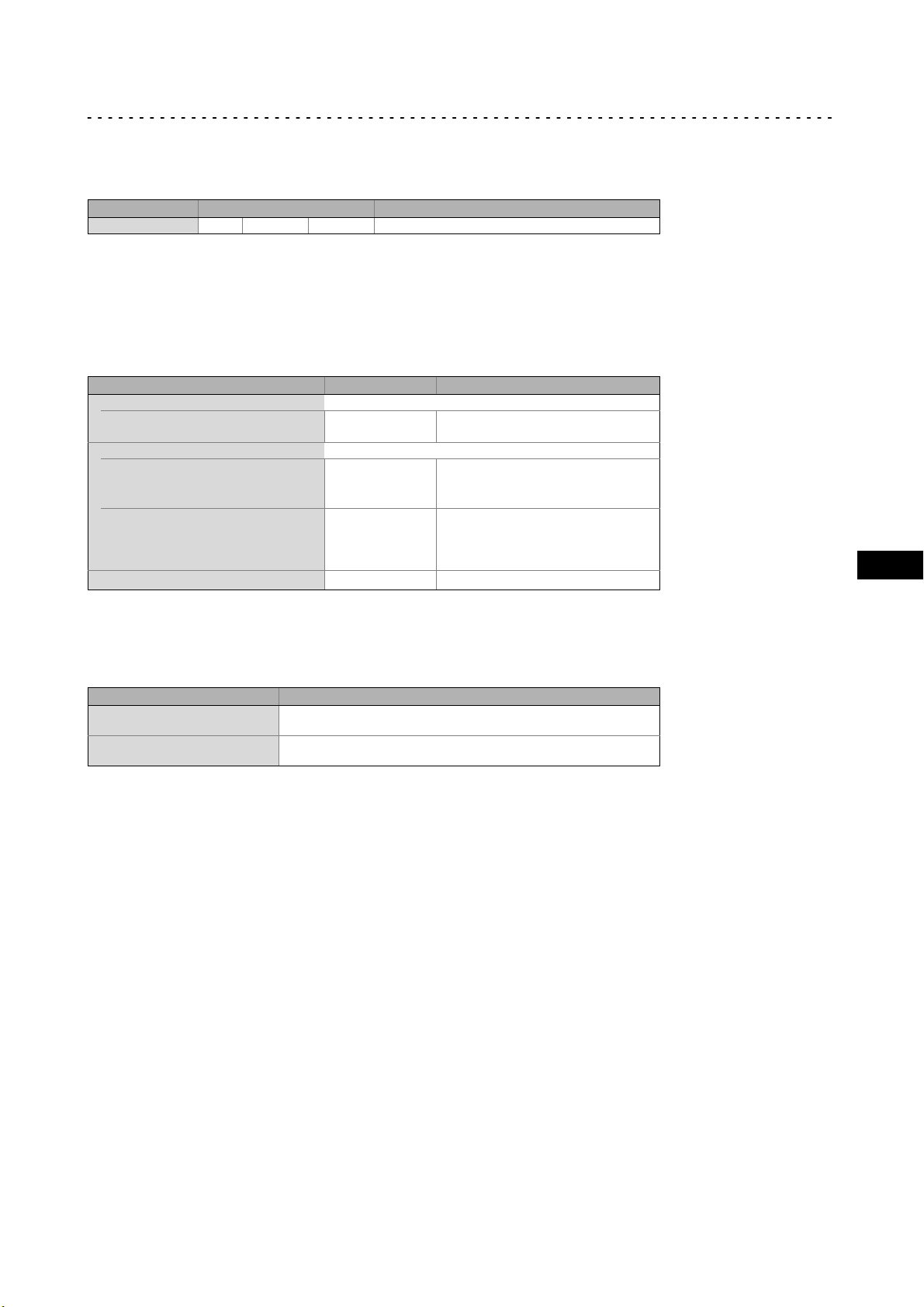

Material number Version Description

.NjN 1.0 12/2013 TD09 First edition for the pilot series

1.2 Conventions used

This documentation uses the following conventions to distinguish different types of

information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator Point In general, the decimal point is used.

Icons

Page reference

Documentation reference

Wildcard

For instance: 1234.56

Reference to another page with

additional information

For instance: 16 = see page 16

Reference to another documentation

with additional information

For example: EDKxxx = see

documentation EDKxxx

Wildcard for options, selection data

1

Document history

EN

1.3 Terminology used

Term In the following text used for

Gearboxes Gearboxes of the g500 product family

Drive system Drive systems with g500 gearboxes and other Lenze drive

components

1.4 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Lenze ¯ MA 12.0012 ¯ 1.0

5

Page 6

EN

1

Safety instructions

Structure of safety instructions:

About this documentation

Notes used

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent

dangerous situations)

Pictograph and signal word Meaning

Danger of personal injury through dangerous electrical

voltage.

Danger!

Danger!

Stop!

Application notes

Reference to an imminent danger that may result in death

or serious personal injury if the corresponding measures are

not taken.

Danger of personal injury through a general source of

danger.

Reference to an imminent danger that may result in death

or serious personal injury if the corresponding measures are

not taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Pictograph and signal word Meaning

Note!

Tip!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

6

Lenze ¯ MA 12.0012 ¯ 1.0

Page 7

Safety instructions

General safety instructions for drive components

2 Safety instructions

2.1 General safety instructions for drive components

Danger!

Disregarding the following basic safety measures may lead to severe

personal injury and damage to material assets!

¯ Store in dry, low−vibration environment without aggressive atmosphere; if

possible in the manufacturer’s packaging.

– Protect against dust and impacts.

– Observe the climatic conditions according to the technical data, catalogue.

¯ Lenze drive and automation components ...

... must only be used as intended.

... must never be commissioned despite noticeable damage.

... must never be technically changed.

... must never be commissioned in an incompletely mounted state.

... must never be operated without the required covers.

... may have live, moving or rotary parts during and after operation − corresponding

to their type of protection. Surfaces may be hot.

... must not be operated with great vibrations ....

... must not be operated in the resonance range of a system

¯ All specifications of the corresponding enclosed documentation must be

observed.

This is vital for a safe and trouble−free operation and for achieving the specified

product features.

2

EN

¯ Only qualified skilled personnel are permitted to work with or on Lenze drive and

automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and operation of

the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent regulations,

directives and laws applicable at the place of use.

Lenze ¯ MA 12.0012 ¯ 1.0

7

Page 8

3

3 Product description

3.1 Important notes

¯ The most important technical data are indicated on the nameplate (structure and

¯ The product catalogues contain further technical data.

3.2 Identification

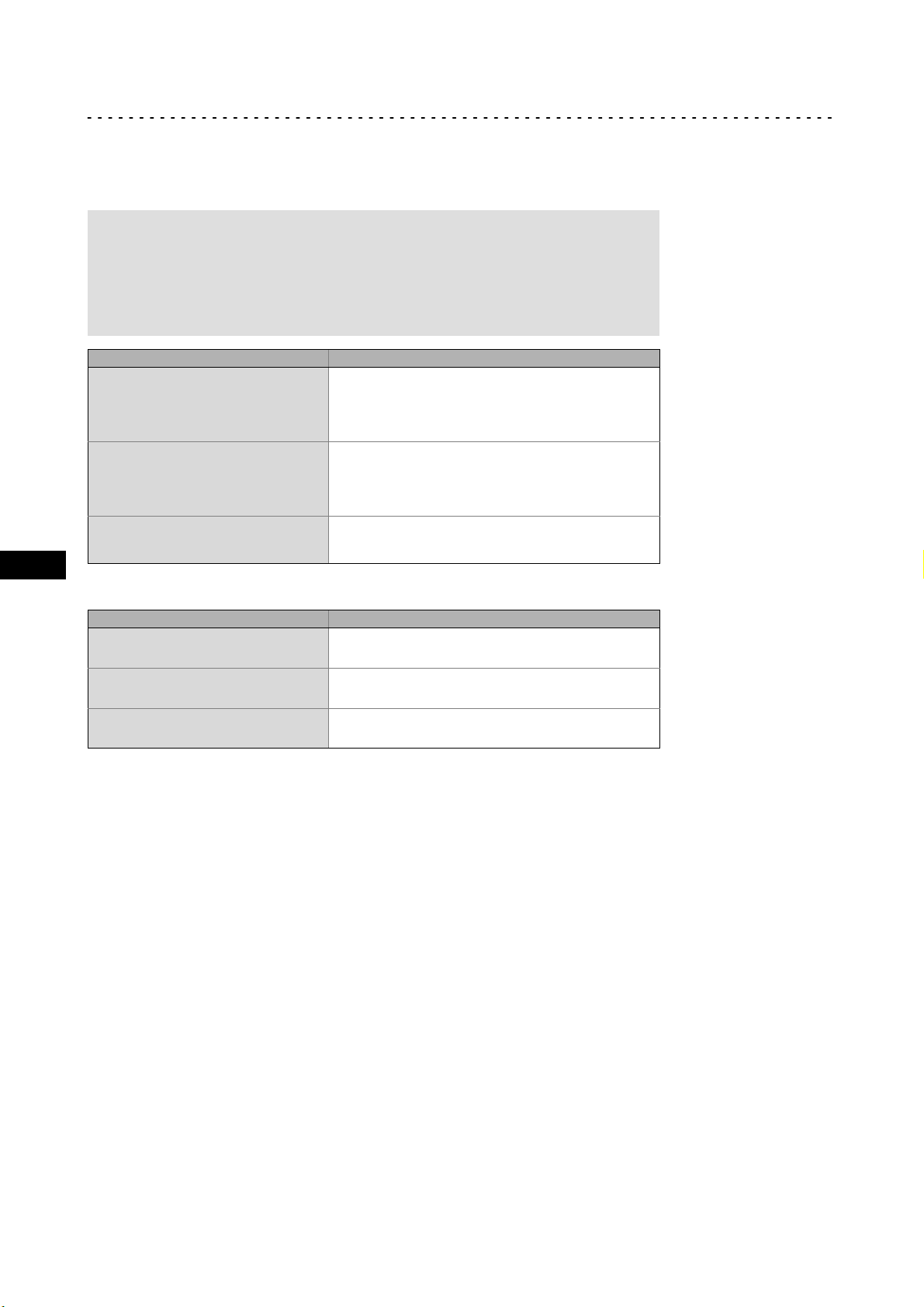

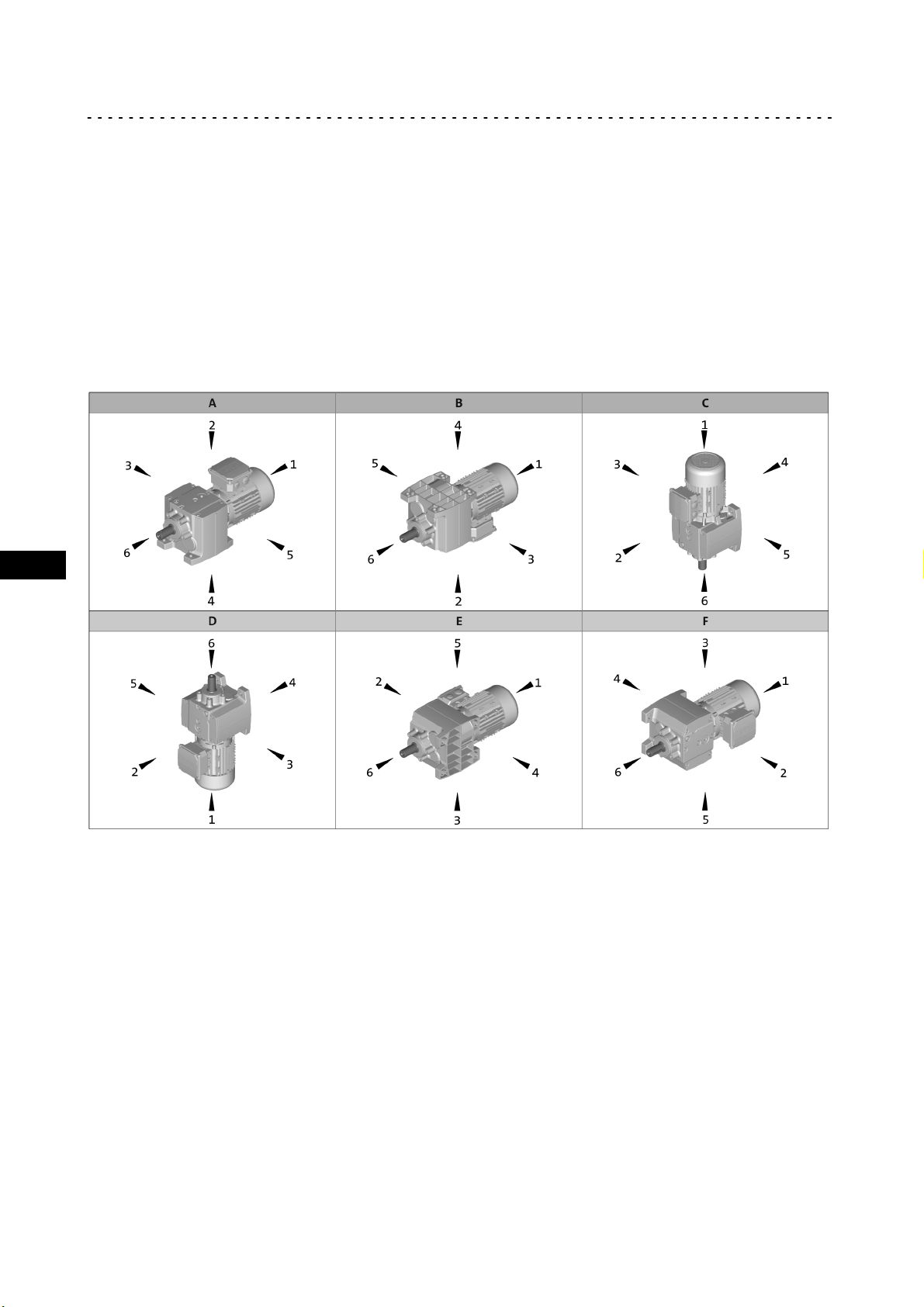

Mounting position (A−F) and position of system modules (1−6)

Product description

Important notes

contents 9 to 11).

EN

Hollow shaft: 0 without flange: 0

Solid shaft: 3, 5, 8 (3+5) Flange: 3, 5, 8 (3+5)

Hollow shaft with shrink disc: 3, 5 Terminal box/

Motec:

2, 3, 4, 5

8

Lenze ¯ MA 12.0012 ¯ 1.0

Page 9

3.2.1 Nameplate

Geared motor

Note!

In the geared motor version the nameplate is attached to the motor.

Product description

Identification

Nameplate

3

Example

g500−X−001.iso

EN

g500−X−001.iso

Lenze ¯ MA 12.0012 ¯ 1.0

9

Page 10

EN

3

Product description

Identification

Pos. Contents

1 Manufacturer / production location

2 Motor type / standard

3 Gearbox type

4 Motor type

5 Technical data

6 Mounting position / position of the system blocks

7 Lubricant amount and type of lubricant

8 Brake data (if fitted)

9 Feedback /pulse encoder or resolver data (if fitted)

10 Manufacture data

11 Bar code

12 Year / week of manufacture

13 Operating mode

14

Temperature class

Enclosure

Motor protection

15 Valid conformities,

approvals and certificates

16 Rated data for

various frequencies

18 Frequencies and corresponding motor data

19

Standard version: Voltage tolerance range "Range A"

UL version: UL file number

20 Additional customer data

21 UL category (e.g. inverter duty motor)

22 Efficiency and part load efficiency

23 Energy efficiency (logo)

27 Permissible ambient temperature range

29 Standstill current (ampere locked rotor ALR)

30 Weight (optional)

Ratio

Rated torque

Rated speed

Rated frequency

Brake

Braking torque

AC/DC brake voltage

Electrical power input

Order number

Material number

Serial number

CE identification

CCC identification

UL mark

UL energy efficiency mark

Hz = frequency

kW = motor power

V = motor voltage

A = motor current

r/min. = motor speed

h = Motor efficiency: at a rated power of

100%

cos j = motor power factor

C 86 = Motor code for controller

parameterisation (code 0086)

10

Lenze ¯ MA 12.0012 ¯ 1.0

Page 11

Gearbox

N version Example

Pos. Contents

1 Manufacturer / production location

2 Gearbox and motor type

3 Year / week of manufacture

4 Mounting position / position of the system blocks

5 Rated torque

Rated speed/rated frequency

6 Lubricant amount / type of lubricant

7 Ratio

8 Material number / serial number

9 Bar code

10 Order number

11 Operating factor (indicated when <1.0)

12 Additional customer data

13 Permissible ambient temperature range

Product description

Transport weights

G500−X−002.iso

3

EN

3.3 Transport weights

Motor frame size

063 071 080 090 100 112 132

Gearbox size

H45 < 10 < 10

H100 < 10 <15 <20 <25

H140 <15 <15 <20 <25

H210 <15 <20 <20 <25 <35

H320 <15 <20 <25 <30 <35

H450 <20 <25 <25 <35 <40 <60 <80

Tab. 1 Weights in kg

Lenze ¯ MA 12.0012 ¯ 1.0

11

Page 12

4

4 Mechanical installation

4.1 Important notes

¯ Use load carrying equipment for transport!

¯ Before the transport

Mechanical installation

Important notes

– check that all components are safely mounted,

– fasten all transport aids (eye bolts or support plates).

Danger!

Danger due to toppling or falling loads!

¯ The payload of the hoists and load handling devices must at least

correspond to the weight of the load.

¯ The load must be secured in such a way that it cannot topple or fall

down.

¯ Do not stay under a pending load!

EN

4.2 Transport equipment for gearbox

Danger!

The motors attached to the gearbox are partially equipped with eyebolts.

These are exclusively determined for mounting/dismounting the motor

to the gearbox and must not be used for the complete geared motor!

Please see the position of the transport threads in the following figures. Gearboxes from

size H210 are in series equipped with a transport thread for eye bolts according to DIN

580 in the gearbox cover. In case of smaller drives, the thread in the output shaft can be

used. The eye bolt is not included in the scope of supply!

H45−H140 H210−H450

1.

2.

Fig. 1 Eye bolt position

12

Lenze ¯ MA 12.0012 ¯ 1.0

Page 13

Mechanical installation

Preparation

General information about the assembly of drive systems

4

Gearbox type/size Thread max. payload Eye bolt according to

DIN 580

g500−H45 M6 80

g500−H100 M6 80

g500−H140 M8 140

g500−H210 M8 140

g500−H320 M10 230

g500−H450 M12 340

Tab. 2 Load carrying capacity of eye bolt in kg

Danger!

Completely screw in transport aids (such as eye bolts or bearing plates),

they must be flat and applied over their entire surface!

If possible, the transport aids (such as eye bolts or bearing plates) must

be stressed vertically in the direction of the screw axis! Angular tension or

tension to the sides reduces the payload! Observe the information

provided in the DIN 580!

Use additional appropriate lifting aids, if required, to achieve a direction

of loading which is as vertical as possible (highest payload). Secure lifting

aids against shifting!

Stop!

Observe load carrying capacity!

Staying under floating load is prohibited!

EN

4.3 Preparation

Note!

Thoroughly remove anticorrosion agents from output shafts and flange

faces.

4.3.1 General information about the assembly of drive systems

Stop!

The lubricant fill quantity of the gearboxes is matched to the mounting

position. The mounting position indicated on the nameplate must be

observed to avoid damage to the gearbox.

Lenze ¯ MA 12.0012 ¯ 1.0

13

Page 14

4

4.3.2 Gearboxes with breathers

Mechanical installation

Preparation

Gearboxes with breathers

Stop!

Do not place gearbox onto breather valve!

No ventilation measures are required for the gearboxes H45, H100 and H140.

Gearboxes which are delivered with a ventilation unit are equipped with a label on the

gearbox.

Remove the transport locking device on the vent valve before the first commissioning.

EN

Note!

Loosely enclosed vent valves must be mounted in accordance with the

4.3.3 Condensation drain hole of the motor

mounting position, ( 23).

Note!

Lenze delivers motors with condensation drain holes with sealed

condensation drain holes. The holes are sealed with a plastic plug or a

locking screw. This does not affect the type of protection and the motor is

protected against the ingress of foreign substances during transport and

operation. Further information, ( 28).

GT−GNG−13285760.iso/dms

14

Lenze ¯ MA 12.0012 ¯ 1.0

Page 15

Mechanical installation

Mounting gearboxes with solid shafts

4.4 Mounting

4.4.1 Mounting gearboxes with solid shafts

¯ Draw the transmission elements onto the output shaft only by using the

centering thread.

Stop!

Shocks and blows to the shafts damage the roller bearings.

4.4.2 Attachment of motors to gearboxes with bearing housing (input design N)

4

Mounting

g500−H_000.iso

Fig. 2 Input side design N

Spider / gear rim 1 Locking screw

Coupling hub 2 Keyway

Drive size

1A 11 23 23 M4 1.5 M3 1.34 * M3 1.34

1B 14 40 25 M5 2.0 M6 10.5 B5 x 5 x 16 M4 2.9

2B 11 23 23 M4 1.5 M3 1.34 * M3 1.34

1C 19 40 25

2C 14 40 25

4C 14 40 25

6C 11 40 25 −−− −−− * −−− −−−

7C 19 40 25

1D 24 60 30

2D 19 60 30 B6 x 6 x 18

1E 28 60 30

2E 24 60 30

3E 19 60 30 B6 x 6 x 18

4E 24 50 50 *

Tab. 3 Attachment of motors to gearboxes with mounting flange

Motor shaft Assembly

D

max. l

[ mm ]

* Use original key for the motor

1)

Key for standard hub and clamping hub

[ mm ]

dimension

M

[ mm ]

Standard hub

Locking screw

Thread

[ mm ]

M5 2.0

M5 2.0

Tightenin

g torque

[ Nm ]

Clamping hub Key

Thread

[ mm ]

Tightenin

g torque

[ Nm ]

M6 10.5

M6 10.5

1)

Clamping ring hub

DIN

6885/1

[ mm ]

B6 x 6 x 16

B5 x 5 x 163C 14 40 25

B6 x 6 x 16 M4 2.9

B8 x 7 x 18

B8 x 7 x 18

Thread

[ mm ]

M4 2.9

M5 6

Tightenin

g torque

[ Nm ]

EN

Lenze ¯ MA 12.0012 ¯ 1.0

15

Page 16

4

4.4.3 Coupling hubs

General

Mechanical installation

Mounting

Coupling hubs

Note!

Standard hubs, clamping hubs and clamping ring hubs are

maintenance−free.We recommend checking the star−shaped spider and

system components when inspecting the drive.

Mounting the standard hub / clamping hub

1. Fit motor key (2).

– Fit enclosed key for drive sizes C, E, F.

2. Push the coupling hub over the motor shaft, mounting dimension m (see Fig. 2

and Tab. 3) must be observed.

EN

3. Secure coupling hub against axial movement using the fixing screw or clamping

screw (1).

4. Lay spider in the coupling claw on the gearbox side.

5. Align claws of the motor−side coupling hub with its counterpart.

6. Slowly push on motor, and bolt on to the gearbox flange.

16

Lenze ¯ MA 12.0012 ¯ 1.0

Page 17

Mounting the clamping ring hub

2

Fig. 3 Coupling

1 Clamping ring hub

2 Clamping ring

3 Clamping screws (DIN912)

Note!

The motor shaft must be designed with fit k6.

Mechanical installation

Mounting

Coupling hubs

1

3

4

1. Grease the contact surfaces of the motor shaft using a thin−bodied oil, e. g.

Castrol 4 in 1" or Klüber Quitsch Ex"!

Stop!

Do not use oil or grease with molybdenum−disulphide or high−pressure

additives, or grease pastes!

2. Push the coupling hub over the motor shaft, mounting dimension m" (see Fig. 2

and Tab. 3) must be observed.

3. Align the hub and tighten the clamping screws until they have contact.

4. Tighten the clamping screws evenly and crosswise with gradually rising torque

until the indicated tightening torque (see Tab. 3) is reached at all clamping screws.

In the intermediate steps, this procedure should also be repeated until the

indicated tightening torque is reached at all clamping screws.

5. Lay spider in the coupling claw on the gearbox side.

6. Align claws of the motor−side coupling hub with its counterpart.

7. Slowly push on motor, and bolt on to the gearbox flange.

EN

Lenze ¯ MA 12.0012 ¯ 1.0

17

Page 18

4

Dismounting the clamping ring hub

1. Loosen the clamping screws evenly one after the other.

Mechanical installation

Mounting

Coupling hubs

Stop!

Each screw must only be loosened by half a revolution per pass! Unscrew

all clamping screws by 3 − 4 threads.

2. Remove the screws next to the forcing threads and screw them into the other

threads until they have contact.

3. Tighten the screws in the forcing threads crosswise and step−by−step so that the

clamping ring is loosened.

4. Clean and grease all contact surfaces including threads and head of the clamping

screws before reassembly.

EN

18

Lenze ¯ MA 12.0012 ¯ 1.0

Page 19

5 Electrical installation

Danger!

Electrical connections must only be carried out by skilled personnel!

Electrical installation 5

EN

Lenze ¯ MA 12.0012 ¯ 1.0

19

Page 20

6

6 Commissioning and operation

6.1 Important notes

Commissioning and operation

Important notes

Stop!

The drive may only be commissioned by skilled personnel!

¯ Take safety measures prior to any operation:

– Disconnect the machine from the mains, ensure standstill of the drive system

and avoid any machine movement.

6.2 Before switching on

Please check:

¯ Drive function - machine function assignment

¯ The direction of rotation of the drive shaft

EN

2−stage 3−stage

¯ Does the drive appear undamaged?

¯ Is the mechanical fixing o.k.?

¯ Is the electrical connection correct?

¯ Are all rotating parts and surfaces that may become hot protected against

contact?

¯ For gearboxes with breathing:

– Has the transport locking device been removed?

20

Lenze ¯ MA 12.0012 ¯ 1.0

Page 21

Commissioning and operation

6.3 During operation

During operation, check the drive periodically and take special care of:

¯ changes compared to normal operation, like

– unusual noise, stronger vibrations or increased temperatures,

– leakages,

– loose fixing elements,

– the condition of the electrical cables.

¯ In case of faults:

– shut down the drive,

– check the troubleshooting table.

If the fault cannot be remedied, please contact the Lenze customer service.

6

During operation

EN

Lenze ¯ MA 12.0012 ¯ 1.0

21

Page 22

7

7 Maintenance

7.1 Important notes

Maintenance

Important notes

Note!

¯ Gearboxes below 200 Nm are lubricated for life.

¯ The mechanical power transmission system is maintenance−free.

7.2 Maintenance intervals

¯ In case of gearboxes > 200 Nm, the lubricant must regularly be replaced.

– The type of lubricant is indicated on the nameplate. Replace the lubricant only

with the same type of lubricant.

– The lubricant maintenance interval depends on the lubricant temperature, see

Fig. 4.

EN

Stop!

With drive systems: observe the maintenance intervals for the other drive

components!

100

90

80

0

70

1000

1

Fig. 4 Lubricant diagram

Oil sump temperature [°C]

Oil life/changing intervals [operating

hours h]

7.3 Maintenance operations

3

16000 h

10000

2

25000 h

Synthetic oil CLP HC/CLP PG

Mineral oil CLP

100000

GT−GNG−002.iso/dms

Gearboxes and geared motors are ready to use on delivery and filled by Lenze with the

lubricant type and lubricant quantity indicated on the nameplate. The first filling

corresponds to the mounting position and design indicated on the nameplate.

22

Lenze ¯ MA 12.0012 ¯ 1.0

Page 23

Breather position, oil filling screw and drain plug

A B

+

+

C D

Maintenance

Maintenance operations

+

+

7

+

+

E F

+

+

Filler Drain

+

+

EN

H210

+

H320; H450

Breather element Check

Oil−level inspection

Check the oil level by means of the displayed dipsticks. Manufacture them according to

the mounting position.

Lenze ¯ MA 12.0012 ¯ 1.0

23

Page 24

7

Model: Dipsticks for g500−H210

Maintenance

Maintenance operations

A

B

EN

C

D

F

E

24

Lenze ¯ MA 12.0012 ¯ 1.0

Page 25

Model: Dipsticks for g500−H320

A

Maintenance

Maintenance operations

E

7

B

EN

C

F

D

Lenze ¯ MA 12.0012 ¯ 1.0

25

Page 26

7

Model: Dipsticks for g500−H450

Maintenance

Maintenance operations

EN

A

E

B

C

26

F

D

Lenze ¯ MA 12.0012 ¯ 1.0

Page 27

Maintenance

Maintenance operations

Changing lubricant

Stop!

¯ Gearbox should be warm.

¯ Secure drive system and machine from inadvertent movement and

mains connection.

The type of lubricant indicated on the nameplate by the following manufacturers is

approved.

Shell Klüber Fuchs

1. Place receptacle under oil drain plug.

7

2. Remove breathing / oil filler plug.

3. Completely drain lubricant by removing the oil drain plug.

4. Reinsert drain plug (if necessary, replace seal).

5. Fill in lubricant through filler hole (quantities see nameplate).

6. Screw in breathing / oil filler plug.

7. Dispose of waste oil according to the applicable regulations.

EN

Lenze ¯ MA 12.0012 ¯ 1.0

27

Page 28

7

7.3.1 Motors

Drain condensation

Depending on the mounting position, the condensation drain holes are always at the

bottom of the motor!

¯ For condensate drainage

Maintenance

Repair

Motors

– the motor must be deenergised;

– the plugs (screws) must be removed.

Stop!

To restore the enclosure, re−insert the plugs (screws) after condensate

drainage. If the condensation drain holes are not sealed again, the IP

enclosure of the motor will be reduced. For horinzontal motor shafts to

IP23 and for vertical motor shafts to IP20.

EN

Fig. 5 Motor with condensation drain holes

Condensation drain holes

7.4 Repair

¯ We recommend that all repairs are carried out by the Lenze customer service.

28

Lenze ¯ MA 12.0012 ¯ 1.0

Page 29

Maintenance

7.5 Disposal

Protect the environment! Packing material can be recycled. Dispose of your separated

resources according to the waste disposal regulations or via a waste management

company.

The following table provides recommendations for an environmentally friendly

disposal of the machine and its components.

What? Where?

Transport

material

Lubricants Oil, grease

Components Housing:

Pallets Return to the manufacturer or

Packaging material Cardboard box to waste paper

Detergents and solvents

Paint residues

Cast iron, aluminium,

Bearings, gear wheel shafts:

Seals, electronic scrap

copper

Steel

Hazardous waste

forwarder

Plastics to plastics recycling or

residual waste

Reuse or dispose of wood wool

Dispose according to current

regulations

Separate valuable substances

and dispose

7

Disposal

EN

Lenze ¯ MA 12.0012 ¯ 1.0

29

Page 30

EN

Troubleshooting and fault elimination8

8 Troubleshooting and fault elimination

If any malfunctions should occur during operation of the drive system, please check the

possible causes using the following table. If the fault cannot be eliminated by one of the

listed measures, please contact the Lenze Service.

Fault Possible cause Remedy

Drive does not turn

Motor runs, gearbox does

not

Unusual running noises

Excessive temperature

Loose fixing elements Vibrations Avoid vibrations

Shrink disc connection is

spinning

Voltage supply interrupted Check connection

Faulty electrical connection Check that supply voltage

Excessive load Reduce load

Coupling components are missing or

defective

Gearbox is defective Inform Lenze Service

Clutch disengaged Engage the clutch

Overload Reduce load

Damage to the gearbox or motor Inform Lenze Service

Overload Reduce load

Inadequate heat dissipation Improve cooling air flow

Lack of lubricant Top up lubricant according to

¯ Correct screw tightening torque has not

been reached

– Insufficient number of passes, not all

screws are tightened correctly.

¯ Machine shaft and hollow shaft bore

not sufficiently degreased

¯ Wrong component part dimensions

– Fits, roughnesses

¯ Yield point of machine shaft material is

too low

– Re > 300 N/mm2 required

¯ Friction factors are too low

– Coefficients of friction m ³ 0.15

required

¯ The shrink disc itself has been

degreased so that the screws and the

bevels are dry. Due to incorrect friction

factors, the shrink disc cannot be

tightened correctly.

matches nameplate data

Check drive−machine

assignment

Check mounting

Check drive−machine

assignment

Check drive−machine

assignment

Clean gearbox / motor

regulations

Specifications for assembly,

dimensions and material not

observed

30

Lenze ¯ MA 12.0012 ¯ 1.0

Page 31

Notes !

EN

Lenze ¯ MA 12.0012 ¯ 1.0

31

Page 32

© 12/2013 | MA 12.0012 | .NjN | 1.0 | TD09

Lenze Drives GmbH

Postfach 10 13 52

D−31763 Hameln

Germany

+49515482−0

+49515482−2800

Lenze@Lenze.com

www.Lenze.com

Lenze Service GmbH

Breslauer Straße 3

D−32699 Extertal

Germany

0080002446877 (24 h helpline)

+49515482−1396

Service@Lenze.com

10987654321

Loading...

Loading...