Page 1

g500

G50AB045 ... G50BB320 |

45 Nm ... 20000 Nm

Bevel gearbox / Bevel gearbox

with three−phase AC motor

Mounting Instructions

EN

.Xqô

Ä.Xqôä

l

Page 2

, Please read these instructions before you start working!

Follow the enclosed safety instructions.

0Abb. 0Tab. 0

Page 3

Contents i

1 About this documentation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Terminology used 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Notes used 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety instructions for drive components 8. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Application as directed 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Foreseeable misuse 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Residual hazards 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Product description 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Important notes 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Identification 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Nameplate 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Gearbox code 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Mechanical installation 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Important notes 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Transport 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Preparation 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 General information about the assembly of drive systems 22. . . . . . . . . . .

4.3.2 Gearboxes with breathers 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 Gearbox with compensation container

(preferably for mounting pos. "C") 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4 Mounting the gearboxes 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5 Maximum permissible load at the motor adapter 26. . . . . . . . . . . . . . . . . .

4.3.6 Mounting of motors to gearboxes with an adapter and a

flexible coupling 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.7 Coupling hubs 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.8 Mounting of motors to gearboxes with a short adapter with a

plug−in hollow shaft with a keyway (drive−end version B or H) 33. . . . . . . .

4.3.9 Attachment of gearboxes with hollow shafts and keyway 34. . . . . . . . . . .

4.3.10 Mounting the shrink disc with a rotating cover 38. . . . . . . . . . . . . . . . . . . .

4.3.11 Mounting the fixed cover 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.12 Mounting the hoseproof hollow shaft cover 42. . . . . . . . . . . . . . . . . . . . . .

4.3.13 Torque plate assembly 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Electrical installation 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Motor connection 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Motor options 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lenze ¯ MA 12.0014 ¯ 5.1

3

Page 4

Contentsi

6 Commissioning and operation 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Important notes 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Before switching on 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Initial commissioning 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 During operation 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Maintenance 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Important notes 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Maintenance intervals 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Maintenance operations 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Position of the lubricant monitoring elements 50. . . . . . . . . . . . . . . . . . . .

7.3.2 Table of lubricants 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.3 Checking the oil level 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.4 Changing the oil 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.5 Lubricate roller bearings 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.6 Drain condensation 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Repair 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Troubleshooting and fault elimination 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Lenze ¯ MA 12.0014 ¯ 5.1

Page 5

About this documentation 1

1 About this documentation

Contents

¯ This documentation serves for safety−relevant operations on and with the

gearboxes. It contains safety instructions which must be observed.

¯ All personnel working on and with the gearboxes must have the documentation

available during the work and observe the information and notes relevant for

them.

¯ The documentation must always be complete and in a perfectly readable state.

¯ The information in this documentation can be supplemented by further

documents, if necessary, e.g. information regarding the motors mounted,

additional components on the gearbox or motor, or with regard to gearboxes and

motors in ATEX design.

Target group

This documentation is directed at qualified skilled personnel according to IEC 60364.

Qualified skilled personnel are persons who have the required qualifications to carry out

all activities involved in installing, mounting, commissioning, and operating the

product.

I Tip!

Information and tools concerning the Lenze products can be found in the

download area at

www.lenze.com

Lenze ¯ MA 12.0014 ¯ 5.1

5

Page 6

1

About this documentation

Document history

1.1 Document history

Material number Version Description

13457390 1.0 02/2014 TD29 First edition for the pilot series

.Xqô 5.1 09/2018 TD29 "Maintenance" chapter: g500−B240 − lubricated for

.Xqô 5.1 09/2018 TD29 Complete revision including the cast iron gearboxes

13535365 4.0 05/2017 TD09 Drawing exchanged in the chapter "Disassembly of

13553160

.Xqô 5.1 09/2018 TD29 Error corrections

5.0 06/2018 TD15 Array of products extended

life

Table new: load carrying capacity of the eye bolt

gearbox with hollow shaft"

Auxiliary tool table supplemented

Important note corrected in the Maintenance

chapter

Ambient temperatures changed in the lubricant

table

1.2 Conventions used

This documentation uses the following conventions to distinguish different types of

information:

Type of information Writing Example/notes

Numeric notation

Decimal Standard notation Example: 1234

Decimal separator Point The decimal point is always used.

Icons

Page reference

Documentation reference

Wildcard

^

,

L

For example: 1234.56

Reference to another page with additional

information

For instance:

Reference to another documentation with

additional information

Example:

Wildcard for options, selection data

^ 16 = see page 16

, EDKxxx = see EDKxxx documentation

1.3 Terminology used

Term In the following text used for

Gearboxes Gearboxes of the g500 product family

Drive system Drive systems with g500 gearboxes and other Lenze drive

components

6

Lenze ¯ MA 12.0014 ¯ 5.1

Page 7

About this documentation

1.4 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Layout of the safety instructions:

} Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent

dangerous situations)

Pictograph and signal word Meaning

Danger of personal injury through dangerous electrical

voltage

{ Danger!

} Danger!

( Stop!

Reference to an imminent danger that may result in death

or serious personal injury if the corresponding measures are

not taken.

Danger of personal injury through a general source of

danger

Reference to an imminent danger that may result in death

or serious personal injury if the corresponding measures are

not taken.

Danger of property damage

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

1

Notes used

Application notes

Pictograph and signal word Meaning

) Note!

I Tip!

,

Important note to ensure trouble−free operation

Useful tip for easy handling

Reference to another document

Lenze ¯ MA 12.0014 ¯ 5.1

7

Page 8

2

2 Safety instructions

2.1 General safety instructions for drive components

(in compliance with Low−Voltage Directive 2014/35/EU)

At the time of dispatch, the drive components are in line with the latest state of the art

and can be regarded as operationally safe.

Scope

The following general safety instructions apply to all Lenze drive and automation

components.

The product−specific safety and application notes given in this documentation must be

observed!

General hazards

Safety instructions

General safety instructions for drive components

} Danger!

Disregarding the following basic safety measures may lead to severe

personal injury and damage to material assets!

¯ Lenze drive and automation components ...

... must only be used for the intended purpose.

... must never be operated if damaged.

... must never be subjected to technical modifications.

... must never be operated unless completely assembled.

... must never be operated without the covers/guards.

... can − depending on their degree of protection − have live, movable or rotating parts

during or after operation. Surfaces can be hot.

... must not be actuated if the drive system shows vibration accelerations > 2g

(20m/s

... must not be actuated in the resonance range of a system or the Lenze drive system.

¯ All specifications of the corresponding enclosed documentation must be

observed.

This is vital for safe and trouble−free operation and for achieving the specified

product features.

¯ Only qualified skilled personnel are permitted to work with or on Lenze drive and

automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and operation of

the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent regulations,

directives and laws applicable at the place of use.

2

).

8

Lenze ¯ MA 12.0014 ¯ 5.1

Page 9

Safety instructions

General safety instructions for drive components

Temperatures

The permissible temperature range is determined by the following:

¯ The lubricant specifications in connection with the expected oil temperatures in

operation (see chapter 7.2 and nameplate).

¯ The thermal class of the motor considering the motor temperature expected

during operation (see nameplate and/or operating instructions of the motor).

¯ Protect geared motors against direct solar radiation. Avoid heat concentration

beneath covers.

The operating temperature is determined by the power loss, the ambient temperature

and the cooling system!

( Stop!

With mineral oil, the upper temperature limit for continuous operation is

80°C, with synthetic oil and shaft sealing rings made of FP (Viton) it is

100°C. If these temperatures are exceeded, measures are necessary to

reduce the temperature, (¶ 66).

2

} Danger!

Depending on the operating conditions, surfaces may be hot, provide

protection against accidental contact.

Ambient media

¯ Gearboxes are protected against dust and spray water.

¯ Motors according to their enclosure (see nameplate and/or operating instructions

for the motor).

¯ Ambient media − especially chemically aggressive − can destroy shaft seals and

coatings (plastic). Abrasive media endanger shaft seals.

¯ The installation site of the drive must be free of shocks and vibration.

¯ Protect geared motors against direct solar radiation. Avoid heat concentration

beneath covers.

¯ Dirt of dust deposits impede the heat dissipation (cooling).

Transport

Before transport

¯ check that all component parts are safely mounted;

¯ check that all component parts with a loose fastening are secured or removed;

¯ tighten all transport aids (eye bolts or support plates).

Use an appropriate means of transport and lifting equipment! (¶ 19)

Lenze ¯ MA 12.0014 ¯ 5.1

9

Page 10

2

Storage

If you do not install the gearbox immediately, provide for proper storage conditions.

¯ Generally

¯ Up to one year:

Safety instructions

General safety instructions for drive components

– Store gearboxes indoors in a dry, clean (low−dust) and sunlight−protected

environment.

– The storage location must be free from vibrations and shocks (V

in order to prevent roller bearing standstill damage.

– Temperature changes with condensate formation are to be avoided.

– Do not activate ventilation unit, in order to prevent air exchange with the

ambient air.

– Store gearboxes with a ventilation unit with the vent plug on top.

– Shafts and uncoated surfaces are delivered in a protected against rust status.

Aftertreatment is required where the corrosion protection has been damaged.

– Remove the plug for motors with condensation drain holes (option)(¶ 21).

< 0.2 mm/s)

eff

¯ More than one year, up to two years:

– Apply a long−term corrosion preventive (e.g. Anticorit BW 366 from the Fuchs

company) to the shafts and uncoated surfaces before storing the motor away.

– Install gearbox in mounting position A.

– Fill gearbox up to the top vent hole / oil hole with the oil grade specified (see

nameplate). Then mount the locking screw and ventilation unit (do not activate)

again.

Corrosion protection

Lenze offers paints with different resistance characteristics for drive systems. Since the

resistance may be reduced when the paint coat is damaged, defects in paint work (e.g.

through transport or assembly) must be removed professionally to reach the required

corrosion resistance.

) Note!

Increased surface and corrosion protection can be achieved by using

adapted coating systems.

Mechanical installation

¯ Provide for careful handling and avoid mechanical overload. During handling

neither bend components, nor change the insulation distances.

10

Lenze ¯ MA 12.0014 ¯ 5.1

Page 11

Safety instructions

General safety instructions for drive components

Electrical installation

¯ Carry out the electrical installation according to the relevant regulations (e. g.

cable cross−sections, fusing, connection to the PE conductor). Additional notes are

included in the documentation.

¯ The Instructions contain notes concerning wiring according to EMC regulations

(shielding, earthing, filters and cable routing). The compliance with limit values

required by the EMC legislation is the responsibility of the manufacturer of the

machine or system.

Warning: The inverters are automation components which can be used in industrial

environment according to EN 61000−6−4. These products may cause radio

interference in residential areas. If this happens, the operator may need to take

appropriate action.

¯ Only plug in or remove pluggable terminals in the deenergised state!

Commissioning

¯ If required, you have to equip the system with additional monitoring and

protective devices in accordance with the respective valid safety regulations (e. g.

law on technical equipment, regulations for the prevention of accidents).

2

¯ Before commissioning remove transport locking devices and keep them for later

transports.

Geared motors for deep−freeze applications

¯ Geared motors for deep−freeze applications are specially optimised to operation

at very low temperatures. Observe that for operation outside the temperature

range specified (e.g. during commissioning) increased wear or even failures may

occur.

¯ We recommend loading the gearbox with a maximum of 50 % of the rated output

torque if it is outside the specified temperature range during commissioning.

Disposal

Sort individual parts according to their properties. Dispose of them as specified by the

current national regulations.

Lenze ¯ MA 12.0014 ¯ 5.1

11

Page 12

2

2.2 Application as directed

All products which this documentation applies to are no household appliances but are

exclusively intended as components for re−utilisation for commercial use or

professional use in terms of IEC/EN 61000−3−2. They meet the requirements of the

Low−Voltage Directive 2014/35/EU and the requirements of the harmonised standards

of the IEC/EN 60034 series.

Only use the products under the operating conditions and power limits specified in this

documentation.

Do not use the brakes installed as fail−safe brakes. It cannot be ruled out that the braking

torque is reduced by disruptive factors which cannot be influenced.

¯ Drives

Any other use shall be deemed inappropriate!

Safety instructions

Application as directed

– ... must only be operated under the operating conditions and power limits

specified in this documentation.

– ... comply with the protection requirements of the EU Low−Voltage Directive.

12

Lenze ¯ MA 12.0014 ¯ 5.1

Page 13

2.3 Foreseeable misuse

Impermissible applications:

¯ In a potentially explosive atmosphere

– Exception: special ATEX design

¯ In aggressive environments (acids, gases, vapours, dusts, or oils).

¯ Under water or in liquids

¯ Under radiation

Safety instructions

Foreseeable misuse

2

Lenze ¯ MA 12.0014 ¯ 5.1

13

Page 14

2

2.4 Residual hazards

Protection of persons

¯ Risk of burns!

Safety instructions

Residual hazards

– Hot surfaces up to 140 °C during operation! Provide protection against contact.

¯ Highfrequency voltages can be capacitively transferred to the motor housing

through the inverter supply.

– Earth motor housing carefully.

¯ Risk of injury due to rotating shaft!

– Before working on the drive system, ensure that the motor is at a standstill.

¯ Danger of unintentional starting or electrical shocks!

– Connections must only be made when the equipment is deenergised and the

motor is at standstill.

– Installed brakes are no fail−safe brakes.

¯ Dangerous voltages at the power terminals, even if the plug is removed: residual

voltage >60 V!

Motor protection

¯ Installed thermal detectors are no full protection for the machine.

– If required, limit the maximum current, parameterise the controller such that it

will be switched off after some seconds of operation with I > I

there is the danger of blocking.

, especially if

N

– Installed overload protection does not prevent an overload under any

conditions.

¯ Installed brakes are no fail−safe brakes.

– The torque can be reduced due to disruptive factors that cannot be influenced,

e.g. by ingressing oil due to a defect shaft sealing ring on the A side.

¯ Fuses are no motor protection.

– Use current−dependent motor protection switches at average operating

frequency.

– Use installed thermal detectors at high operating frequency.

¯ In the case of permanent−magnet motors, too high torques cause

demagnetisation.

– The maximum torques according to catalogue must not be exceeded.

¯ If deviations from normal operation occur, e.g. increased temperature, noise,

vibration, determine the cause and, if necessary, contact the manufacturer. If in

doubt, switch off the motor.

¯ Design with plug:

– Never disconnect plug when energised! Otherwise, the plug can be destroyed.

– Switch off power supply and inhibit controller prior to disconnecting the plug.

Fire protection

¯ Fire hazard

– Prevent contact with flammable substances.

14

Lenze ¯ MA 12.0014 ¯ 5.1

Page 15

3 Product description

3.1 Important notes

¯ The most important technical data is given on the nameplate.

¯ The product catalogues contain further technical data.

Product description

Important notes

3

Lenze ¯ MA 12.0014 ¯ 5.1

15

Page 16

3

Product description

Identification

Nameplate

3.2 Identification

3.2.1 Nameplate

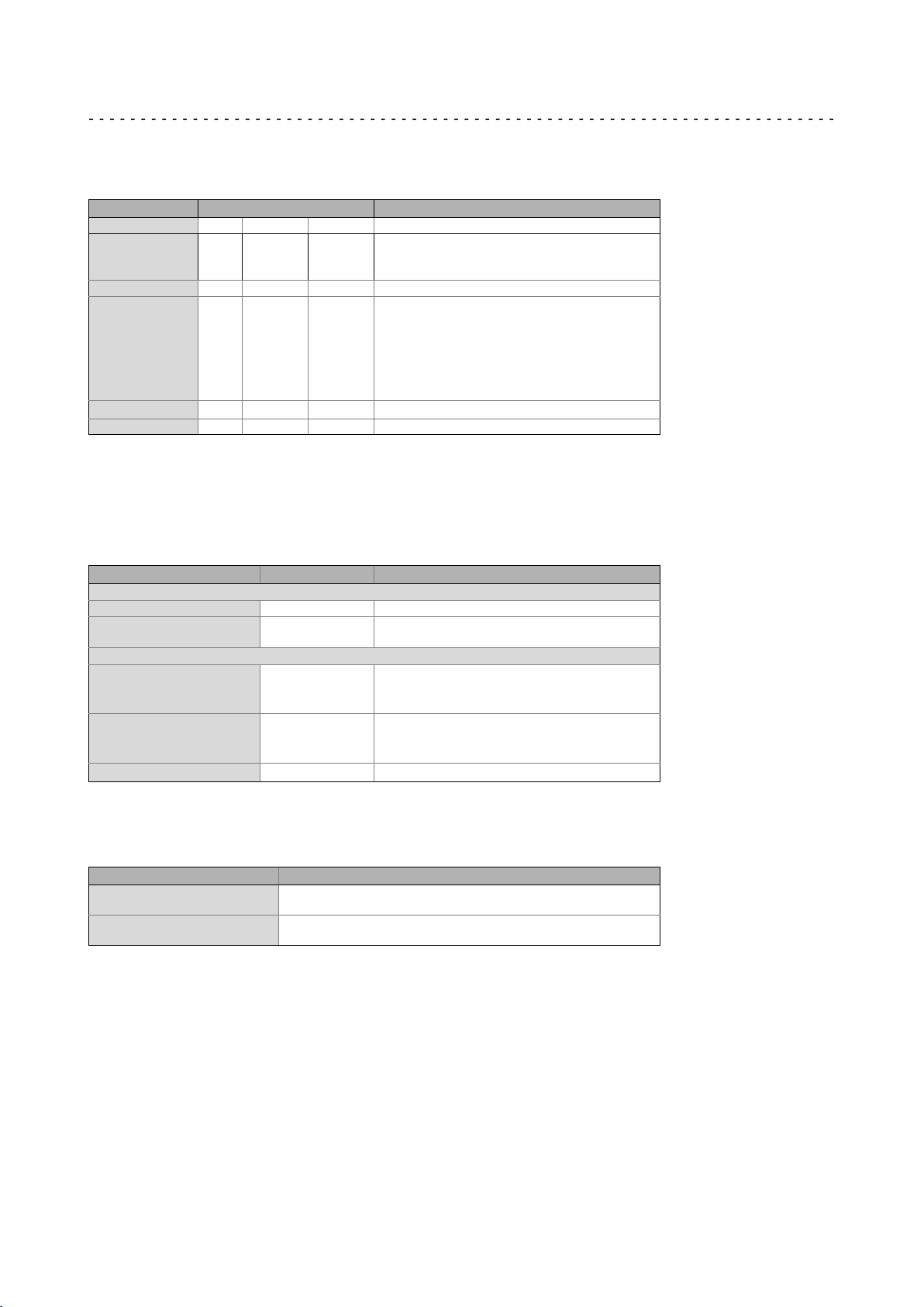

Geared motor with a directly mounted motor (layout A)

L

2

3

4

5.1

5.3

6

8.1

9

10.2

11

8.2

7.1

1

21

18

17

5.2

5.4

7.2

8.3

10.3

15

Hz

kW

V

A

r/min

h %

cos j

C86

20.1

16.1

16.2

16.4

16.4

16.5

16.5

16.3

16.7

16.6

22

Geared motor with a directly mounted motor (layout B, with QR code)

L

2

14.1

3

4

5.1

5.3

6

8.1

8.2

20.1

11

10.2

9

1

5.4

7.1

8.3

10.3

21

5.2

30

7.2

33.1

43

14.3

18

17

33.2

15

r/min

h %

cos j

C86

13

Hz

16.1

16.2

kW

16.4

16.4

16.5

16.5

16.3

16.7

16.6

22

23

V

A

26

15

19

23

13

14.1

14.2

14.3

27

14.2

Gearbox with motor adapter

L

3

5.1

11

1

6

10.2

18

5.4

5.3

7.2

10.3

30

20.1

17

27

4

5.2

7.1

Three−phase AC motor for motor adapter

L

2

4

21

8.1

9

10.2

11

8.2

14.2

10.3

1

14.1

23

15

26

22

13

8.3

14.3

27

20.1

18

Hz

kW

r/min

V

A

cos j

h %

16.1

16.2

16.3

*

-

*

-

16.4

16.4

16.5

16.5

16.6

16.7

16

Lenze ¯ MA 12.0014 ¯ 5.1

Page 17

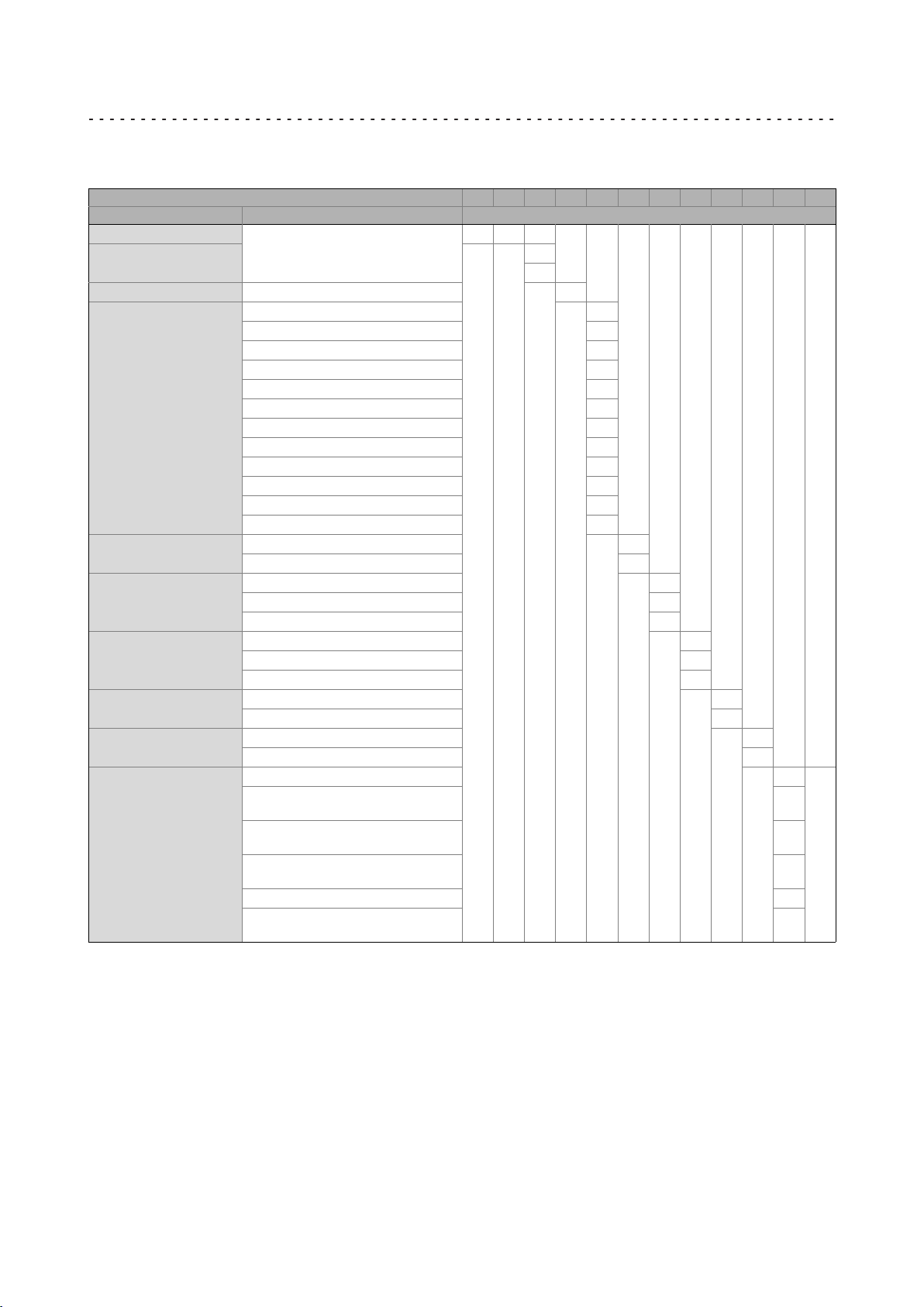

Pos. Contents

1 Manufacturer / production location

2 Type of motor / standard

3 Gearbox type

4 Motor type

5 Technical data

5 5.1 Ratio

5 5.2 Rated torque

5 5.3 Rated speed

5 5.4 Rated frequency

5 5.5 Rated voltage

5 5.6 Rated current

5 5.7 Maximum current

5 5.8 Rated power [kW]

5 5.9 Rated power [HP]

5 5.10 Continuous standstill torque

6 Position of system modules / mounting position

7 Lubricant details

7 7.1 Lubricant amount

7 7.2 Lubricant type

8 Brake data

8 8.1 Type

8 8.2 AC/DC brake voltage

8 8.3 Braking torque, electrical power input

9 Feedback / pulse encoder or resolver data

10 Production data

10 10.2 Material number

10 10.3 Serial number

11 Bar code

13 Information with regard to the operating mode

14 Additional motor specifications

14 14.1 Temperature class

14 14.2 Enclosure

14 14.3 Motor protection

15 Applicable conformities, approvals and certificates

16 Rated data for various frequencies

16 16.1 Hz = frequency

16 16.2 kW = motor power

16 16.3 rpm = motor speed

16 16.4 V = motor voltage

16 16.5 A = motor current

16 16.6 cos j = motor power factor

16 16.7 h = motor efficiency: at a rated power of 100%

17 Application factor / load capacity

18 Year of manufacture / week of manufacture

19 UL file number

20 Customer data

20 20.1 Additional customer data

21 UL category (e.g. inverter duty motor)

22 C86 = motor code for inverter parameterisation (code 0086)

23 Efficiency class

26 CC number Department of Energy (optional)

27 Permissible ambient temperature (e.g. Ta £ 40°C)

30 Weight

33 Encoder data

33.1 Encoder type

33.2 Encoder voltage

43 Internal key: QR code

Product description

Identification

Nameplate

3

Lenze ¯ MA 12.0014 ¯ 5.1

17

Page 18

3

Product description

Gearbox code

3.2.2 Gearbox code

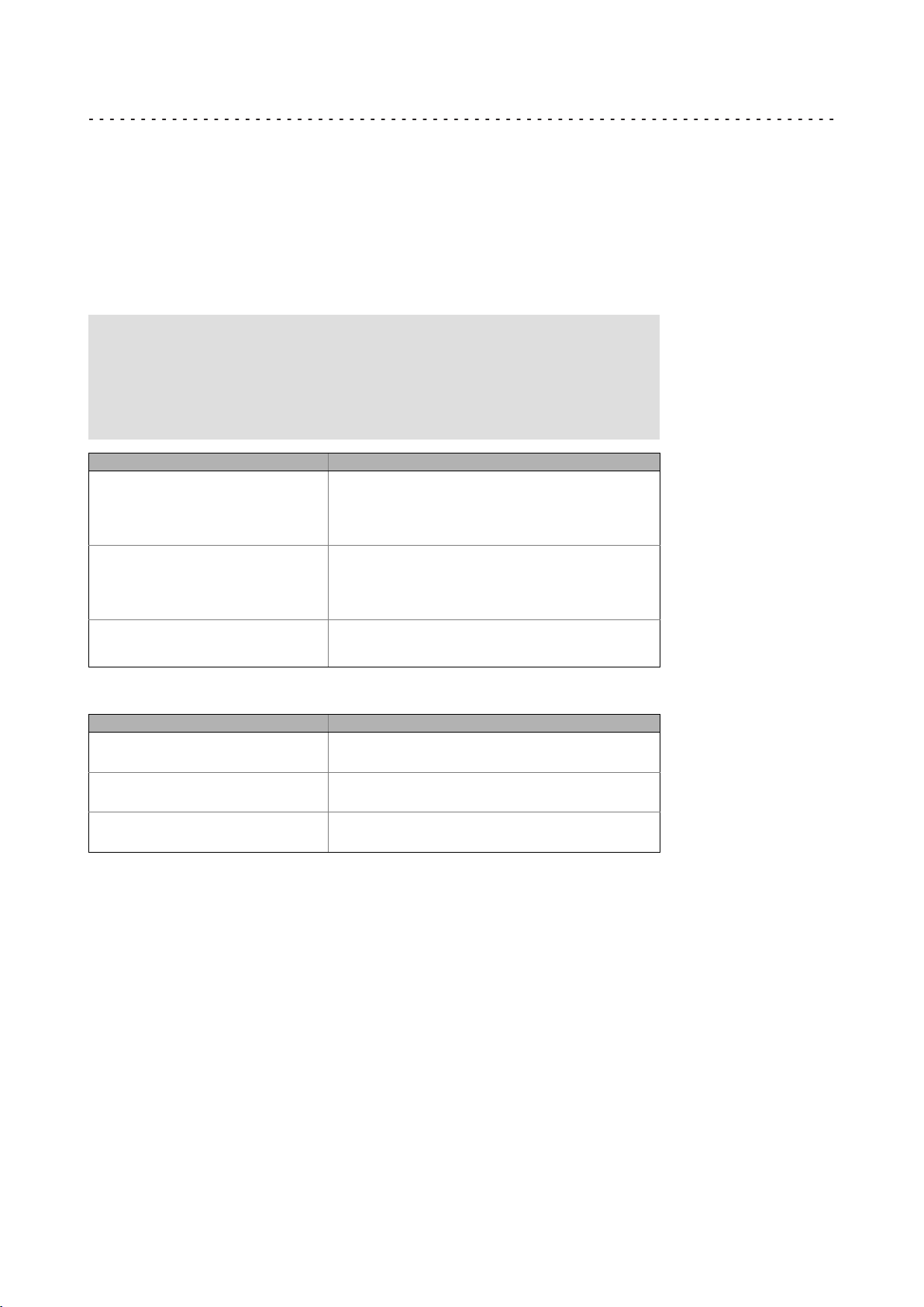

Example G 50 A B 045 M H B R 2 N 2E

Meaning Variant Gearbox code

Product family G 50

Generation A

B

Gearbox type Bevel gearbox B

Output torque 45 Nm 045

110 Nm 111

240 Nm 124

450 Nm 145

600 Nm 160

820 Nm 182

1500 Nm 215

2700 Nm 227

4300 Nm 243

8000 Nm 280

13000 Nm 313

20000 Nm 320

Type of construction Geared motor M

Gearbox N

Shaft type Solid shaft with featherkey V

Hollow shaft with keyway H

Hollow shaft with shrink disk S

Housing type Foot mounting + centering A

Flange mounting Without flange R

Number of stages 2−stage 2

Drive size Without adapter (integrated motor) C

Foot mounting B

Centering C

Flange with through holes K

3−stage 3

NEMA adapter with a jaw coupling

with a keyway

NEMA adapter with a plug−in hollow

shaft with a keyway

IEC adapter with a plug−in hollow shaft

with a keyway

IEC adapter with a jaw coupling N

IEC adapter with a jaw coupling with a

keyway

A

00

...

B

82

H

1A

...

2K

T

18

Lenze ¯ MA 12.0014 ¯ 5.1

Page 19

4 Mechanical installation

1.

2.

4.1 Important notes

¯ Use load carrying equipment for transport!

¯ Before the transport

– check that all components are safely mounted,

– fasten all transport aids (eye bolts or support plates).

} Danger!

Danger due to toppling or falling loads!

¯ The payload of the hoists and load handling devices must at least

correspond to the weight of the load.

¯ Secure the load handling device so that it won’t slip from its position.

¯ The load must be secured in such a way that it cannot topple or fall

down.

¯ Do not stay under a pending load!

Mechanical installation

Important notes

4

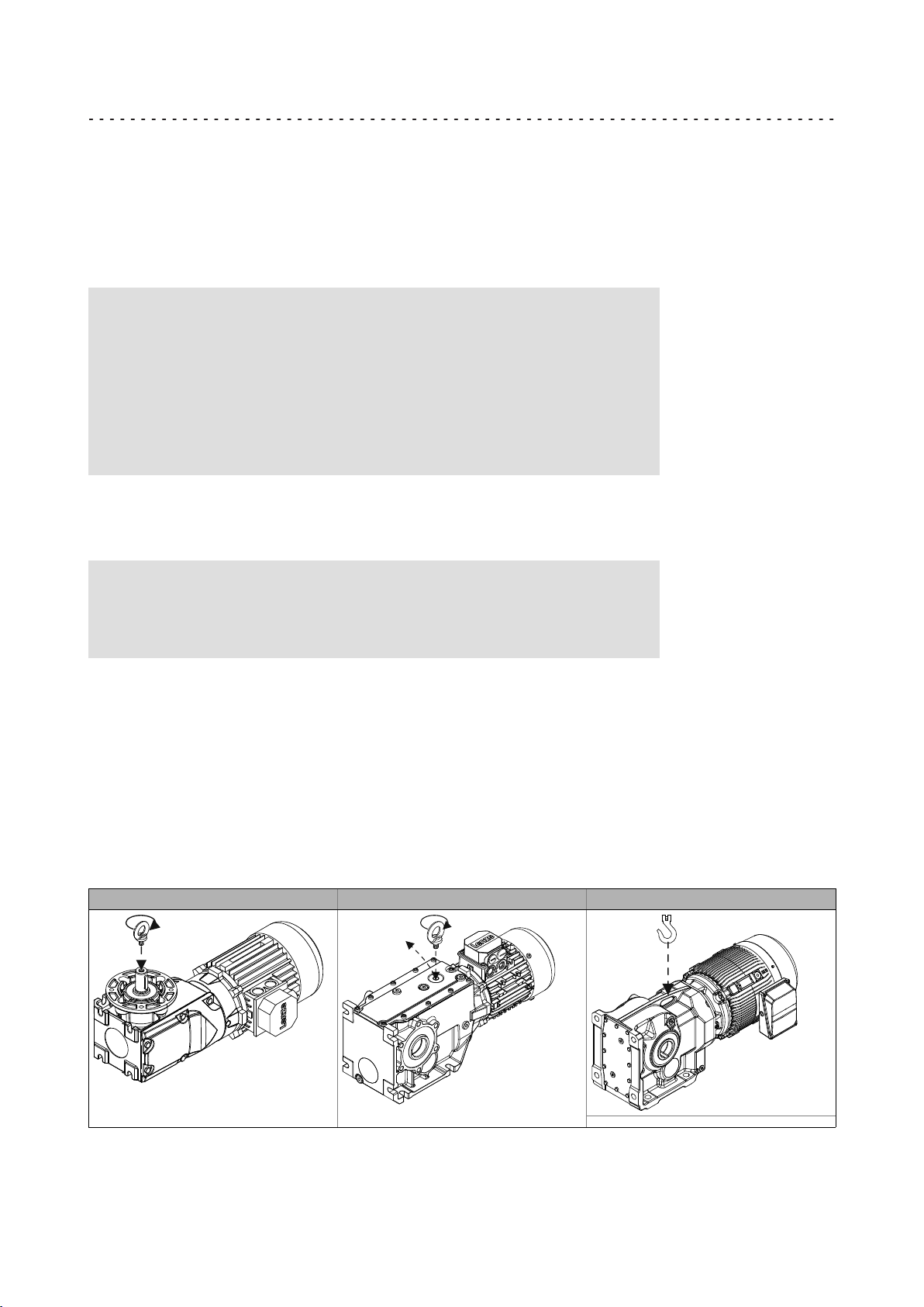

4.2 Transport

} Danger!

The motors attached to the gearbox are partially equipped with eyebolts.

They are exclusively determined for mounting/dismounting the motor to

the gearbox and must not be used for the complete geared motor!

The position of the transport holes can be gathered from the illustrations shown in the

following. As a standard, the G50BB145 ... G50BB243 size gearbox is provided with

transport holes for eye bolts complying with DIN 580 in the gearbox cover. The eye bolt

is not included in the scope of supply!

For the smaller drives with solid shafts, the output shaft thread can be used or the drive

is transported using a securing rope. The rope should be wrapped around the round area

between the motor−gearbox interface.

The gearboxes of sizes G50BB280 ... G50BB320 can be lifted at the ear that is cast on to

the housing.

G50A0B45 ... G50BB124 G50BB145 ... G50BB243 G50BB280 ... G50BB320

Fig. 1 Positioning of the eye bolt for transporting the complete drive system

Lenze ¯ MA 12.0014 ¯ 5.1

19

Page 20

4

Mechanical installation

Transport

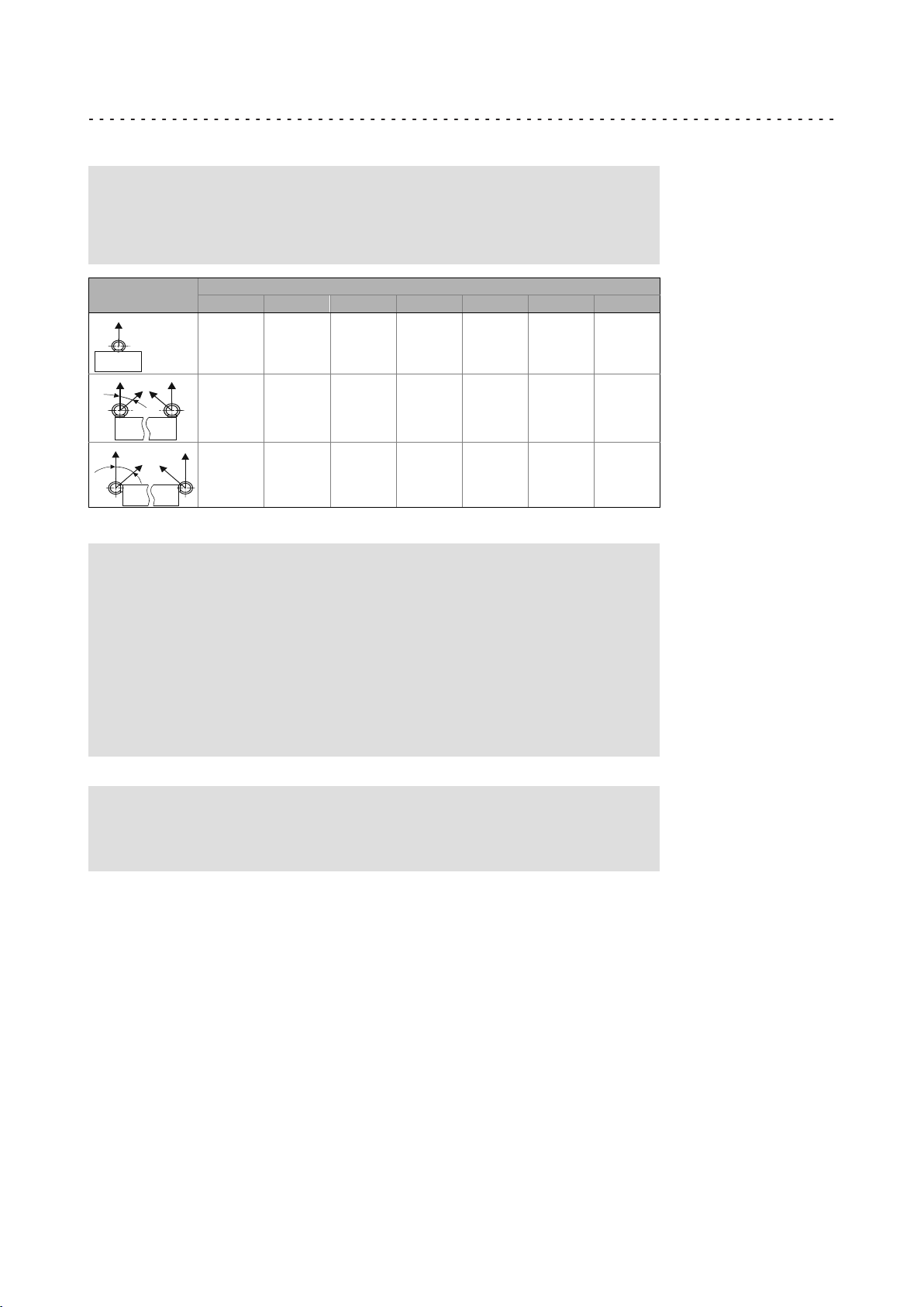

) Note!

As standard, threads are delivered with plug screws. The plug can be

easily removed, e.g. by using a screwdriver blade. For the thread size and

load carrying capacity of the eye bolt, please see Tab. 1.

Eye bolt position

£45°

£45°

Tab. 1 Load carrying capacity of each eye bolt in kg

M6 M8 M10 M12 M16 M20 M24

80 140 230 340 700 1200 1800

−−−−− 100 170 240 500 860 1290

−−−−− 70 115 170 350 600 900

} Danger!

Completely screw in transport aids (such as eye bolts or bearing plates),

they must be flat and applied over their entire surface!

If possible, the transport aids (such as eye bolts or bearing plates) must

be stressed vertically in the direction of the screw axis! Angular tension or

tension to the sides reduces the payload! Observe the information

provided in DIN 580!

Use additional appropriate lifting aids, if required, to achieve a direction

of loading which is as vertical as possible (highest payload). Secure lifting

aids against shifting!

Thread

( Stop!

Observe load carrying capacity!

Standing beneath floating loads is prohibited!

20

Lenze ¯ MA 12.0014 ¯ 5.1

Page 21

Mechanical installation

4.3 Preparation

¯ Protect shaft sealing rings against contact with solvents!

¯ Thoroughly remove anticorrosion agents from the output shaft and from flange

faces.

¯ Repair paintwork damage.

¯ In some cases, due to lack of space, stud bolts with nuts must be used instead of

head screws. In these cases, contact Lenze, if necessary.

Tighten all screw connections with the torques given and lock them with standard

screw locking adhesive!

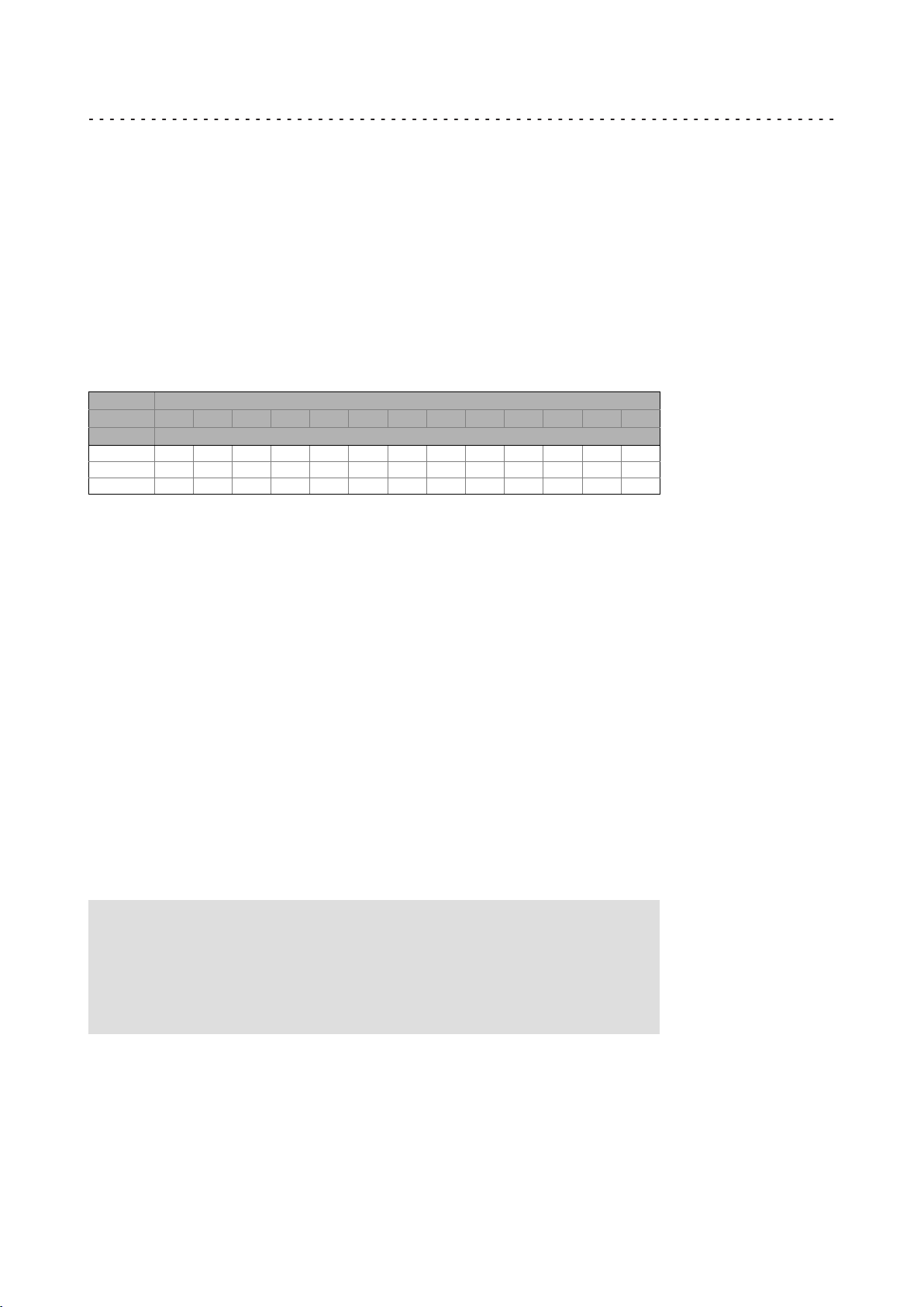

Thread

M3 M4 M5 M6 M8 M10 M12 M16 M20 M24 M27 M30 M36

Strength Tightening torque [Nm]

4.8 0.7 1.4 2.8 4.8 12 23 − − − − − − −

8.8 1.3 3.0 5.9 10.1 24.6 48 84 206 415 714 1050 1428 2482

10.9 1.9 4.6 8.6 14.9 36.1 71 123 302 592 1017 1496 2033 3535

Tab. 2 Tightening torques for friction factor m = 0.12; tolerance of the tightening torque ±10 %

Please note: increase the tightening torque by 10% for screwed connections with flat

gaskets.

4

Preparation

Correcting the lubricant amount

If the oil quantity in the gearbox has been increased for longtime storage ((¶ 10)), the

oil must be drained completely and then must be refilled for the mounting position

provided. The following steps must be complied with:

1. Place receptacle under oil drain plug.

2. Remove breathing / oil filler plug.

3. Completely drain lubricant.

4. Screw in oil drain plug.

5. Fill in amount of oil for the mounting position provided (according to nameplate).

6. Screw in ventilation / oil filler plug.

Condensation drain hole

) Note!

Lenze delivers motors with condensation drain holes with sealed

condensation drain holes. The holes are sealed with a plastic plug or a

locking screw. This does not affect the type of protection and the motor is

protected against the ingress of foreign substances during transport and

operation. Further information, (¶ 64).

Lenze ¯ MA 12.0014 ¯ 5.1

21

Page 22

4

4.3.1 General information about the assembly of drive systems

Mechanical installation

Preparation

General information about the assembly of drive systems

( Stop!

The lubricant fill quantity of the gearboxes is matched to the mounting

position. The mounting position indicated on the nameplate must be

observed to avoid damage to the gearbox.

¯ Take safety measures prior to any operation:

– Disconnect the machine from the mains, ensure standstill of the drive system

and avoid any machine movement.

– Check faultless state of the drive system. Never install and commission

damaged drive systems.

– Check drive function - machine function assignment. Check direction of rotation

(¶ 46).

¯ The mounting areas / the foundation:

– must be plane, torsionally rigid, and free from vibrations,

– must be suited to absorb the forces and torques generated during operation,

– should have vibration−absorbing properties.

¯ Align drive system on mounting surfaces exactly with the machine shaft to be

driven.

– Be sure to carry out mounting in a manner free from distortion, in order to avoid

additional loads.

– Even out slight inaccuracies by the use of suitable flexible couplings.

¯ Support reaction torque by suitable measures.

¯ Be absolutely sure to secure fastening fixtures of accessories and built−on

accessories against unintended loosening. We recommend:

– the use of screws with a minimum property class of 8.8.

– with steel or cast iron output flanges, in particular for applications with an

alternating load, the use of screws with a strength of 10.9 with correspondingly

high tightening torques.

– Secure screwed connections with medium strength using screw locking

adhesive.

22

Lenze ¯ MA 12.0014 ¯ 5.1

Page 23

Mechanical installation

Gearboxes with breathers

4.3.2 Gearboxes with breathers

( Stop!

Do not place gearbox onto breather valve!

The G50BB045 ... G50BB124 gearboxes do not require any ventilation measures.

Gearboxes that are delivered with a ventilation unit are provided with a label.

Remove the transport locking device on the vent valve before initial commissioning.

4

Preparation

) Note!

Loosely enclosed vent valves must be mounted in accordance with the

mounting position, (¶ 50).

GT−GNG−13285760.iso/dms

Lenze ¯ MA 12.0014 ¯ 5.1

23

Page 24

4

4.3.3 Gearbox with compensation container (preferably for mounting pos. "C")

Temperature fluctuations generate changes in the lubricant volume. A compensation

reservoir serves to compensate for the change in volume in each case.

The compensation reservoir is supplied as a mounting set. Before commissioning, the

oil vent plug must be replaced with the reservoir.

Mounting and dismounting: , mounting instructions for the compensation reservoir

Mechanical installation

Preparation

Gearbox with compensation container

( Stop!

For transporting the geared motor, the compensation reservoir must be

removed and the gearbox must be locked by means of a locking screw.

( Stop!

Leaky pipe to the oil compensation reservoir

The pipe of the oil compensation reservoir is subjected to a natural

ageing process.

Possible consequences:

¯ Environmental impact

Protective measures:

¯ Make sure that the pipe does not show any signs of cracks or leakage.

¯ Do not commission a leaky pipe.

¯ If the pipe shows any signs of damage, replace it.

) Note!

With unfavourable combinations of a small ratio and a high input speed,

the use of a compensation reservoir may also be advisable in other

mounting positions.

24

Lenze ¯ MA 12.0014 ¯ 5.1

Page 25

Mechanical installation

Mounting the gearboxes

4.3.4 Mounting the gearboxes

( Stop!

Shocks and impacts on the shaft damage the roller bearings.

¯ Draw the transmission elements onto the output shaft only by using the

centering thread.

¯ Align the gearbox shaft and transmission elements in an accurate fashion in order

to prevent tensioning.

¯ Mount belt pulleys, sprockets, or gear wheels as closely as possible to the gearbox

in order to keep the bending load of the shaft and the bearing forces at a

minimum level.

Gearbox with output flange

¯ Especially with regard to applications with an alternating load, Lenze

recommends...:

– the use of anaerobic adhesive between the gearbox flange and mounting area

in order to increase the friction fit;

– with steel or cast iron output flanges, the use of screws with a strength of 10.9

with correspondingly high tightening torques.

4

Preparation

Lenze ¯ MA 12.0014 ¯ 5.1

25

Page 26

4

Mechanical installation

Preparation

Maximum permissible load at the motor adapter

4.3.5 Maximum permissible load at the motor adapter

( Stop!

¯ The loads generated by the motor mounted must be checked!

¯ The forces F

not be exceeded!

mentioned (see following tables) at the adapter must

M

For the effective force F

, static forces (e.g. weight) and dynamic forces (e.g.

M

acceleration forces, for example caused by vibrations or start−up processes) have to be

taken into consideration.

Furthermore the loading case of the force FM has to be taken into consideration:

Loading case k

Static 1

Dynamic−pulsating 0.8

Dynamic−alternating 0.6

loading case

The position of the motor‘s centre of gravity, including all motor options, must be

calculated. If the distance of the centre of gravity L

is greater, the permissible force

Tab

must be reduced as follows.

L

F

Mperm

+ k

loading_case

@ F

MTab

@

Tab

L

v k

loading_case

@ F

MTab

If forces act from several directions, e.g. in the case of a moving horizontal travelling

drive, the acting forces have to be added vectorially (e.g. vertical force due to weight plus

horizontal acceleration force).

F

corresponds to the maximum value of the forces added vectorially!

Mperm

L

F

M

If the permissible force F

is exceeded, the motor has to be supported in a suitable,

Mperm

distortion−free fashion!

Drive size

IEC NEMA

xA/2B

1B − 80 450 600 800 800

xC 5C 115 450 600 800 800

xD 5D 115 450 660 1000 1500

N

xE 5E 145 −−−−− 660 1000 1500

xF − 145 −−−−− −−−−− −−−−− 1500

xG 5G 190 −−−−− −−−−− −−−−− −−−−−

xH xH 250 −−−−− −−−−− −−−−− −−−−−

A

Distance L

of the motor

A 80 350 350 350 350

Tab

B110

G50BB111

[mm] Maximum permissible force F

Gearbox type

B240

G50BB124

B450

G50BB145

26

M Tab

B600

G50BB160

[N]

Lenze ¯ MA 12.0014 ¯ 5.1

Page 27

Mechanical installation

Preparation

Maximum permissible load at the motor adapter

4

Drive size

IEC NEMA

xA/2B

1B − 80 800 800 −−−−− −−−−−

xC 5C 115 800 800 −−−−− −−−−−

xD 5D 115 1500 1500 1500 1500

N

xE 5E 145 1500 1500 1500 1500

xF − 145 1500 1500 1500 1500

xG 5G 190 1700 1700 1700 1700

xH xH 250 −−−−− 2600 3500 3500

Drive size

IEC NEMA

51

55 18 145 2220 2210 −

55 − 145 2500 2490 2450

61 21 190 4490 4480 4420

65 25 250 5230 5230 5230

H

T

66 28 250 4500 4500 4500

70 − 300 3720 3720 3720

76 32 300 6980 7100 7100

81 36 400 6200 6880 6880

82 − 400 − 11400 11400

A

A

B

Distance L

of the motor

− 80 350 −−−−− −−−−− −−−−−

Distance L

of the motor

14 115 1540 − −

Tab

B820

G50BB182

[mm] Maximum permissible force F

Tab

B8000

G50BB280

[mm] Maximum permissible force F

Gearbox type

B1500

G50BB215

Gearbox type

B13000

G50BB313

B2700

G50BB227

B20000

G50BB320

[N]

M Tab

M Tab

B4300

G50BB243

[N]

Lenze ¯ MA 12.0014 ¯ 5.1

27

Page 28

4

Mechanical installation

Preparation

Mounting of motors to gearboxes with an adapter

4.3.6 Mounting of motors to gearboxes with an adapter and a flexible coupling

When mounting a motor to an adapter, be sure to observe a fully circumferential

contact of the flange faces, thus ensuring that there is no aperture to the interior of the

adapter.

With higher degrees of protection or when there is a risk of dirt or humidity entering,

additionally seal the contact surfaces with a suitable sealant.

m

1

2

d

ø

l

m

Spider / gear rim 1 Locking screw

0

Coupling hub 2 Keyway

1

B14/ FT

B5/FF

g500−H_X−002.iso

28

Lenze ¯ MA 12.0014 ¯ 5.1

Page 29

Adapter for IEC motors

Mechanical installation

Preparation

Mounting of motors to gearboxes with an adapter

4

Drive size

IEC

N1A 11 23 23 M4 1.5 M3 1.34

N1B 14 40 25 M5 2.0 M6 10.5 B5 x 5 x 16 M4 3.0

N2B 11 23 23 M4 1.5 M3 1.34

N1C 19 40 25

N2C 14 40 25

N3C 14 40 25

N4C 14 40 25

N6C 11 40 25 −−− −−−

N7C 19 40 25

N1D 24 60 30

N2D 19 60 30 B6 x 6 x 18

N1E 28 60 30

N2E 24 60 30

N3E 19 60 30 B6 x 6 x 18

N4E 24 50 50

N1F 28 60 30

N2F 24 60 30

N3F 24 50 50

N1G 38 80 80

N3G 38 80 80

N1H 42 110 110

N2H 48 110 110

N3H 38 80 80

T51 24 50 50

T55 28 60 60

T55 28 60 60

T61 38 80 60

T65 42 110 111

T66 48 110 109

T70 55 110 110

T76 60 140 140

2)

T81

T82 75 140 136

Motor shaft Assembly

dimension

d

max. l

[mm]

1)

2)

[mm]

65 140 140

Featherkey with a standard hub and clamping hub

T81 only valid for motor frame size 250, 4−pole

m

[mm]

Standard hub

Locking screw

Thread Tightening

torque

[Nm]

M5 2.0

M5 2.0

M8 10

M5 2.0

M8 10

M10 17

Clamping hub Featherk

Thread Tightening

torque

6885/1

[Nm]

B6 x 6 x 16

M6 10.5

M6 10.5

M8 25N2G 28 60 60

B5 x 5 x 16

B6 x 6 x 16 M4 3.0

B8 x 7 x 18

B8 x 7 x 18

B8 x 7 x 18

ey

DIN

[mm]

Clamping ring hub

1)

Thread Tightening

*

*

*

*

M3 1.34

M3 1.34

M4 3.0

−−− −−−

M5 6

*

M10 69 M8 35

−−− −−−

*

−−− −−−

torque

[Nm]

Adapter for NEMA motors

Drive size

NEMA

A5B

A5C

A5D 22.225 54 54.0

A5E 28.575 67 66.7

A5G 34.925

A5H 41.275 102.0

A6H 47.625 112 111.1

A14 22.225 57.15 53

A18 28.575 69.85 66.5

A21 34.925 85.725 79

A25 41.275 101.6 95

A28 47.625 117.475 111

A32 53.975 133.35 127

A36 60.325 149.225 143

Motor shaft Assembly

dimension

d

max. l

[mm]

15.875 54 40.0

[mm]

102

m

[mm]

101.5

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

Tab. 3 Attachment of motors to gearboxes with adapter

* Use original featherkey of the motor

1) Featherkey for standard hub and clamping hub

2) Measured from the seating face of the motor flange

Lenze ¯ MA 12.0014 ¯ 5.1

Standard hub

Locking screw

Thread Tightening

M5 2.0 M6 10.5

M8 10

M5 2.0

M8 10

M10 17

torque

[Nm]

Clamping hub Featherk

ey

Thread Tightening

torque

[Nm]

M8 25

M10 69 M8 35

−−− −−−

DIN

6885/1

[mm]

B4.76 x 4.76

x 20

Clamping ring hub

1)

Thread Tightening

M4 3

M5 6

*

*

−−− −−−

torque

[Nm]

29

Page 30

4

4.3.7 Coupling hubs

General

Mechanical installation

Preparation

Coupling hubs

) Note!

Standard hubs, clamping hubs and clamping ring hubs are

maintenance−free.

We recommend carrying out a visual inspection of the star−shaped

spider/ring gear and the system parts within the inspection intervals.

) Note!

Tighten all screws to the coupling hubs and the motor fastening of

gearboxes in ATEX design with an intermediate strength screw retention.

Mounting the standard hub / clamping hub

1. Fit motor keyway (2).

– With some sizes a shorter featherkey is supplied, which is to be mounted. The

sizes concerned by this are shown on (¶ 29)

2. With a clamping hub:

– slightly loosen the clamping screw

– Fit coupling hub on the motor shaft using a center hole thread (do not mount by

hammer strokes, in order to avoid damage to the roller bearings in the motor).

– Observe mounting dimension m of the coupling hub (¶ 28).

3. Secure coupling hub against axial movement using the fixing screw or clamping

screw (1).

4. Lay spider in the coupling claw on the gearbox side.

– The mounting process can be facilitated by lightly greasing or oiling the ring

gear sides or the hub sides. For this purpose, only use mineral oil−based

lubricants without additives, silicone−based lubricants, or vaseline.

5. Align claws of the motor−side coupling hub with its counterpart.

6. Slowly push on motor, and bolt on to the gearbox flange.

30

Lenze ¯ MA 12.0014 ¯ 5.1

Page 31

Mounting the clamping ring hub

2

Fig. 2 Coupling

1 Clamping ring hub

2 Clamping ring

3 Clamping screws (DIN912)

Mechanical installation

Preparation

Coupling hubs

1

3

4

) Note!

The motor shaft must be designed with fit k6.

1. Slightly oil contact surfaces of the motor shaft using low−viscosity lubricating oil

such as Castrol 4 in 1" or Klüber Quietsch Ex".

( Stop!

Do not use oils and greases with molybdenum disulphide or extreme

pressure additives such as lubricating grease pastes!

2. Slightly loosen clamping screws in the coupling hub.

– Fit coupling hub on the motor shaft using a center hole thread (do not mount by

hammer strokes, in order to avoid damage to the roller bearings in the motor).

– Observe mounting dimension m of the coupling hub (see Tab. 3).

3. Align hub and slightly tighten clamping screws until they are fitting closely.

4. Tighten the clamping screws evenly crosswise in several steps until the indicated

tightening torque is reached (see Tab. 3).

5. Lay spider in the coupling claw on the gearbox side.

– The mounting process can be facilitated by lightly greasing or oiling the ring

gear sides or the hub sides. For this purpose, only use mineral oil−based

lubricants without additives, silicone−based lubricants, or vaseline.

6. Align claws of the motor−side coupling hub with its counterpart.

7. Slowly push on motor, and bolt on to the gearbox flange.

Lenze ¯ MA 12.0014 ¯ 5.1

31

Page 32

4

Dismounting the clamping ring hub

1. Loosen the clamping screws evenly one after the other.

Mechanical installation

Preparation

Coupling hubs

( Stop!

Each screw must only be loosened by half a revolution per pass! Unscrew

all clamping screws by 3 − 4 threads.

2. Remove the screws next to the forcing threads and screw them into the other

threads until they have contact.

3. Tighten the screws in the forcing threads crosswise and step−by−step so that the

clamping ring is loosened.

4. Clean and grease all contact surfaces including threads and head of the clamping

screws before reassembly.

32

Lenze ¯ MA 12.0014 ¯ 5.1

Page 33

Mechanical installation

Preparation

Mounting of motors to gearboxes with a short adapter with a plug−in hollow shaft with a keyway

4.3.8 Mounting of motors to gearboxes with a short adapter with a plug−in

hollow shaft with a keyway (drive−end version B or H)

Ød

l

0

4

1

ü

û

g500−X−010

Fig. 3 Motors on gearboxes with a short adapter with a plug−in hollow shaft with a keyway

1 Plastic ring

2 Hollow shaft

A Correct

B Incorrect

) Note!

Ensure that the plastic ring is not twisted and that it is in the correct

position.

The plastic ring prevents fretting corrosion. It does not have to be

greased.

1. Check whether the dimensions of the motor shaft and the featherkey match the

hollow shaft bore and keyway.

2. Check whether the drill depth in the hollow drive shaft for the motor shaft is

sufficient. For this purpose, compare the drill depth from the flange face with the

distance of motor shaft front side to the motor flange.

3. Check whether the opening of the plastic ring to the keyway in the hollow shaft is

aligned correctly and correct it, if necessary.

4. Align the featherkey in the motor shaft to the keyway in the hollow shaft.

5. Position the motor shaft centrically to the hollow drive shaft and then insert it

into the hollow drive shaft carefully, only exerting little force, in order to avoid

damaging the ball bearings in the bell housing and the motor. By no means join

the parts by hammer strokes!

6. Screw the motor and gearbox flange together, securing the fixing screws using

medium−strength screw locking adhesive.

Lenze ¯ MA 12.0014 ¯ 5.1

33

Page 34

4

4.3.9 Attachment of gearboxes with hollow shafts and keyway

1. If necessary, remove anti−corrosion coating in the hollow shaft and on the

2. Check the seat and edges of the hollow shaft and the machine shaft for damage.

3. Apply a fitting grease (Fig. 4) to the shaft and into the hollow shaft bore.

4. Mount gearbox with hollow shaft on the machine shaft to be driven, ensuring

Mechanical installation

Preparation

Attachment of gearboxes with hollow shafts and keyway

machine shaft.

Rework, if necessary. Ensure good concentricity of the machine shaft in order to

avoid unnecessary additional forces caused by tensioning.

exact alignment. In the mounting process, lead forces only across the hollow shaft

and not across the housing.

Paste gegen

Passungsrost

2.

3.

1.

4.

Fig. 4 Application of fitting grease against fretting corrosion

( Stop!

Take up forces only via the hollow shaft, and not via gearbox housing.

5. Secure the gearbox axially:

– The hollow shaft has snap ring grooves for axial securing. Parts used to fix the

shaft are not included in the scope of supply.

g500−B−MoPa−001

K12.0611

34

Lenze ¯ MA 12.0014 ¯ 5.1

Page 35

Mechanical installation

Attachment of gearboxes with hollow shafts and keyway

Auxiliary tool (recommended dimensions)

H7

Æ d

18

20

25

30

35 M12 7

40

45

50

55

60

65

70

80

90

100

120

Tab. 4 Dimensions in [mm]

6. Cover rotating screw heads, interfering edges, slots or similar items safe against

contact.

d

2

M6 4

M10

M16

M20

M24

c

10

11

13

13

14

16

20

24

24

7

5

6

8

9

4

Preparation

Lenze ¯ MA 12.0014 ¯ 5.1

35

Page 36

4

Mechanical installation

Preparation

Attachment of gearboxes with hollow shafts and keyway

Dismounting

( Stop!

¯ Before dismantling the machine shaft, mount an adequately

dimensioned load handling device at the gearbox.

¯ Ensure pretensioning of the drive mechanism, preventing the gearbox

from falling into the drive mechanism when it is loosened from the

plug−in shaft.

¯ When removing the hollow shaft via the housing, impermissibly great

forces may be generated.

¯ Tensioning of the hollow shaft causes a bearing failure and damage of

the gearbox housing.

1. Undo axial gearbox locking in the hollow shaft.

2. Remove/extract the gearbox from the motor shaft using an appropriate auxiliary

tool (Fig. 5).

Fig. 5 Disassembly of gearboxes with hollow shaft, with auxiliary tool

Auxiliary tool (recommended dimensions)

H7

Æ d

30 7.8 8 3 2 29.8 M10 18 33 5.5

35 *

35

40 11.8 12 4 −−− 39.8 M16 −−− 43 6

45 13.8 12 4 −−− 44.8 M16 −−− 48.5 7

50 13.8 12 5 −−− 49.8 M16 −−− 53.5 7

55 15.8 16 5 −−− 54.8 M20 −−− 59 7.5

60 17.8 16 5 −−− 59.8 M20 −−− 64.1 8

70 19.8 16 5 −−− 69.8 M20 −−− 74.1 8

80 21.8 20 5 −−− 79.8 M20 −−− 85.1 9

90 24.8 10 10 −−− 89.8 M20 72 95 11

100 27.8 15 10 −−− 99.8 M24 80 106 12

120 31.8 15 10 −−− 119.8 M24 80 127 15

Tab. 5 Dimensions in mm

b ±0.1 c

9.8 7 3 5 34.8 M12 20 38 6

9.8 12 3 −−− 34.8 M12 −−− 38 6

* Auxiliary tool for gearbox size G50BB124

8

c

9

c

10

d1 ±0.1 d

2

d

3

t −0.1 t

1

36

Lenze ¯ MA 12.0014 ¯ 5.1

Page 37

) Note!

l

l

2

l

1

l

2

In the case of the bevel gearbox the hollow shafts are released to rotate

freely in the central part, i.e. the hole diameter is greater by 0.1 mm in

this area! Provide for a sufficient length of the machine shaft so that the

machine shaft is guided on both sides.

Mechanical installation

Preparation

Attachment of gearboxes with hollow shafts and keyway

4

Gearbox

Code Type

G50AB045 g500−B45 85 22 100

G50BB111 g500−B110 105 25 120

G50BB124 g500−B240 127 25 143

G50BB145 g500−B450 117 50 150

G50BB160 g500−B600 133 57 170

G50BB182 g500−B820 143 60 180

G50BB215 g500−B1500 163 70 210

G50BB227 g500−B2700 188 80 240

G50BB243 g500−B4300 234 100 300

G50BB280 g500−B8000 260 135 350

G50BB313 g500−B13000 310 150 410

G50BB320 g500−B20000 380 180 500

Tab. 6 Dimensions in mm

l1 min l

2

l max.

Lenze ¯ MA 12.0014 ¯ 5.1

37

Page 38

4

4.3.10 Mounting the shrink disc with a rotating cover

Mechanical installation

Preparation

Mounting the shrink disc with a rotating cover

( Stop!

¯ Do not disassemble new shrink disc.

¯ Never tighten clamping screws before the machine shaft has been

inserted, since otherwise the hollow shaft may undergo plastic

deformation.

¯ During operation, the shrink disc has to be covered so that it is safe

against contact by implementing suitable measures (e.g. cover).

¯ Degrease hollow shaft bore and machine shaft!

Depending on the design, the shrink discs may be equipped with a rotating cover

(pos. 1).

) Note!

This cover is fitted to the shrink disc on delivery.

1

1.

Fig. 6 Cover of the clamping screws

1 Protection cover

2 Clamping screws

1. Remove protective cap (1), if available.

2. Check machine shaft:

– Diameter in fit tolerance h6

– Material yield point Re > = 360 MPa

– E−module approx. 210000 MPa

– Surface roughness R

– Concentricity in order to prevent unnecessary additional forces caused by

tensioning.

£ 15 mm

z

2

1

8.

g500−B−001 des/dms

3. Thoroughly clean and degrease hollow shaft bore and machine shaft.

) Note!

Thoroughly degrease the bore over the entire hollow shaft length to

make sure that remainders of the anticorrosion agent will not be carried

off into the area of the shrink disc when pushing on the machine shaft.

4. Slightly loosen clamping screws (2) one after the other, do not unscrew!

5. Push drive onto machine shaft.

38

Lenze ¯ MA 12.0014 ¯ 5.1

Page 39

Mechanical installation

Mounting the shrink disc with a rotating cover

6. Slightly tighten clamping screws manually.

7. Tighten clamping screws (2) one after the other (see Fig. 7) in several passes, with

rising torque, evenly until the indicated screw−tightening torque (see Tab. 7 ) is

reached at all screws.

GT−GNG−003.iso/dms

Fig. 7 Explanation: "one after the other"

I Tip!

Several (in general more than 5 ) passes are necessary until the full

tightening torque is reached at all screws!

4

Preparation

The shrink disc is mounted correctly and fixed when the faces of the outer ring and the

inner ring are aligned (Fig. 8). Minimum misalignments are permissible.

GT−GNG−001.iso

Fig. 8 Hollow shaft with shrink disk

3 Outer ring

4 Inner ring

Hollow shaft bore [mm] 20 25 30 35 40

Clamping screw thread M6 M5 M6 M6 M8 M6 M8 M6 M8

Width across flats

1)

[mm]

SW

Torque [ Nm ] 12 6 14 14 30 14 30 14 34

Hollow shaft bore [mm] 50 65 75 80 95 105 125

Clamping screw thread M8 M10 M10 M10 M12 M14 M14

Width across flats

1)

[mm]

SW

Torque [ Nm ] 34 70 70 70 121 193 193

Tab. 7 Tightening torque for the clamping screws

1)

Width across flats of the shrink disc clamping screws

10 8 10 10 13 10 13 10 13

13 17 17 17 19 22 22

0

free of grease

Lenze ¯ MA 12.0014 ¯ 5.1

39

Page 40

4

Mechanical installation

Preparation

Mounting the shrink disc with a rotating cover

) Note!

If a different tightening torque is indicated on the shrink disc, this

tightening torque has priority over the value indicated in the table.

8. Push protective cap (1, Fig. 6) onto the shrink disc.

I Tip!

For finding out the cause of non−reached torques of the shrink disc

connection, please go through the troubleshooting list in chapter 8.

Dismounting

} Danger!

Loose drive components or drive components falling down may cause

injury to persons or damage to the machine. Secure the drive

components before disassembly.

1. Remove protective cap (1).

2. Loosen clamping screws (2) evenly one after the other each by ¼ revolution in

several passes. Do not unscrew clamping screws completely to prevent accidents!

3. Press off outer ring (see Fig. 8), if necessary. For this, loosen the outer ring using

the forcing threads and some clamping screws (number corresponding to the

forcing threads in the inner ring). For loosening the outer ring, screw in the screws

evenly to prevent canting. Press off the outer ring until loosened completely.

4. Remove the drive from the machine shaft.

( Stop!

Dismantle the shrink disc only for cleaning purposes. Afterwards, grease

bevel surfaces and screws using a solid lubricant with a friction factor of

m = 0.04.

¯ Suitable lubricants on molybdenum−disulphide lubricant (MoS2) basis are, e.g.:

– Molykote G Rapid (company Dow Corning)

– Molykote BR2 Plus (company Dow Corning)

– Molykombin UMFT1 (company Klüber Lubrication)

Usually, disassembly problems only occur if:

¯ the connection is spinning due to overload or a too low friction factor and fretting

corrosion has occurred,

¯ the shrink disc has been tightened too much leading to a plastic deformation of

components,

¯ the components are corroded.

40

Lenze ¯ MA 12.0014 ¯ 5.1

Page 41

X

X

4.3.11 Mounting the fixed cover

) Note!

This cover can be ordered optionally and will then be loosely enclosed

with the shipment, or it is already mounted to the gearbox.

Gearbox size: B45/G50BA045 ... B820/G50BB182

With these sizes, the protective cap is clipped on.

Mechanical installation

Preparation

Mounting the fixed cover

4

Gearbox size: B1500/G50BB215 ... B20000/G50BB320

With these sizes, the cover is screwed together with the housing.

Gearbox size: B1500/G50BB215 ... B4300/G50BB243

With these sizes, additional reducing bushs are screwed into the gearbox housing

thread.

x

x

1

3

2

1 Protection cover 3 Reducing bush

2 Cheese head screw

1. Screw reducing bushes (3) into the flange so that they are flush using a

screwdriver.

2. Fasten the protective cap (1) over the reducing bushes (3) on the flange using

cheese head screws (2).

Lenze ¯ MA 12.0014 ¯ 5.1

41

Page 42

4

4.3.12 Mounting the hoseproof hollow shaft cover

With the g500−B gearbox, the hoseproof hollow shaft cover is bolted down directly in

the housing.

Mechanical installation

Preparation

Mounting the hoseproof hollow shaft cover

A

A

1 Protection cover 4 Seal

2 Cheese head screw

1. Place seal (4) between the flange and the protection cover (1).

2. Fasten the protection cover (1) on the housing flange using cheese head screws

(2).

A-A

X

X

4

2

1

42

Lenze ¯ MA 12.0014 ¯ 5.1

Page 43

4.3.13 Torque plate assembly

( Stop!

Impermissible load caused by incorrect mounting:

¯ The socket of the torque plate must be mounted on both sides.

¯ When mounted, the socket must have axial clearance.

Mechanical installation

Preparation

Torque plate assembly

4

Fig. 9 Mounting of the torque plate at the base

The torque plate on the pitch circle can be mounted in various positions depending on

the pitch of the bore belt.

Fig. 10 Mounting of the pitch circle torque plate

) Note!

In the case of a knee lever design, transfer the force at right angles to the

torque plate, if possible (90°±20°).

Mounting

1. Clean the contact surfaces between the housing and torque plate.

2. Tighten the screws according to the torque specified, (¶ 21)

Lenze ¯ MA 12.0014 ¯ 5.1

43

Page 44

5

5 Electrical installation

Electrical installation

Motor connection

{ Danger!

Hazardous electrical voltage

The electrical installation has to be carried out by skilled personnel in

compliance with electrotechnical regulations and standards.

5.1 Motor connection

To correctly connect the motor, please observe:

¯ the notes in the terminal box of the motor

¯ the notes in the Operating Instructions of the motor

¯ the technical data on the motor nameplate.

5.2 Motor options

To correctly connect the motor options, e. g. brakes or feedback systems, please observe:

¯ the notes in the corresponding terminal box

¯ the notes in the corresponding operating instructions

¯ the technical data on the corresponding motor nameplate.

44

Lenze ¯ MA 12.0014 ¯ 5.1

Page 45

Commissioning and operation

6 Commissioning and operation

6.1 Important notes

( Stop!

The drive may only be commissioned by skilled personnel!

¯ Before commissioning remove transport locking devices and keep them for later

transports.

¯ Take safety measures prior to any operation:

– Disconnect the machine from the mains, ensure standstill of the drive system

and avoid any machine movement.

6.2 Before switching on

Check:

6

Important notes

¯ The oil level of the gearbox after previous long−term storage!

¯ That the drive does not show any visible signs of damage.

¯ Is the mechanical fixing o.k.?

¯ Has the electrical connection been implemented correctly?

¯ Are all rotating parts and surfaces that may become hot protected against

contact?

¯ For gearboxes with ventilation:

– Has the transport locking device been removed?

( Stop!

At drive speeds below 200 rpm the amount of lubricant may need to be

increased. Consultation with Lenze is required.

6.3 Initial commissioning

In order to ensure trouble−free operation, carry out checks during initial commissioning.

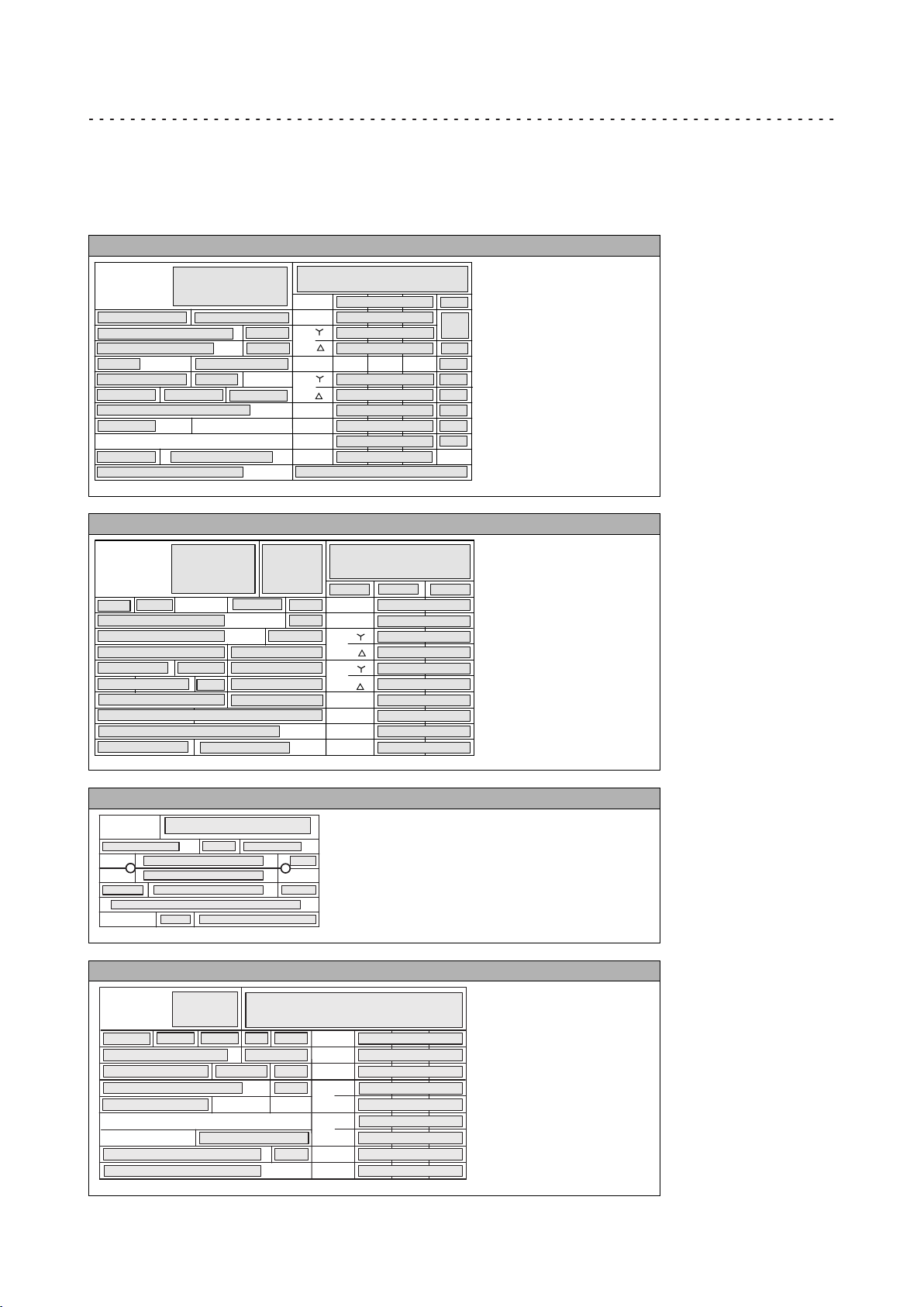

When Check

At initial start−up Rotating direction of the drive shaft ()

Continuously Monitor geared motor with regard to noticeable noise, vibrations,

and changes

After 3 hours under rated load Measure housing temperature (Tab. 9) at the hottest point. The value

measured at the same time serves as a reference value for later

measurements. If necessary, implement required measures if

temperatures are rising too high, ^ 46

Fastening elements, locking screws, and covers

Leakages: small quantities of escaping lubricant

After the first day Check oil level, ^ 59

Tab. 8 Measures at initial commissioning

Lenze ¯ MA 12.0014 ¯ 5.1

45

Page 46

6

Please check the following:

¯ Drive function - machine function assignment

¯ The direction of rotation of the drive shaft

All sizes except for G50BB124, 3−stage Only G50BB124, 3−stage

Fig. 11 Rotating direction of drive shaft

Commissioning and operation

During operation

6.4 During operation

¯ Warming

If operating conditions are unfavourable (e.g. high input speed, small ratio, vertical

mounting position, high ambient temperature, ...), the gearboxes may heat up more.

Temperature Measures

> 70 °C Apply covers and warning labels

> 80 °C Gearboxes with mineral oil (CLP) or for standard shaft sealing ring,

> 100 °C Gearboxes with synthetic oil (CLP HC) and FKM shaft sealing ring

Tab. 9 Housing temperature

During operation, check the drive periodically and take special care of:

¯ changes compared to normal operation, like

¯ Use synthetic oil,

¯ Provide for better cooling,

¯ It may be necessary to contact Lenze

¯ Provide for better cooling,

¯ It may be necessary to contact Lenze

– unusual noise, stronger vibrations or increased temperatures,

– leakages,

– loose fixing elements,

– the condition of the electrical cables.

¯ In the event of faults:

– shut down the drive,

– check the troubleshooting table.

If the fault cannot be remedied, please contact the Lenze customer service.

46

Lenze ¯ MA 12.0014 ¯ 5.1

Page 47

Maintenance

7 Maintenance

7.1 Important notes

) Note!

¯ Gearboxes below 250 Nm are lubricated for life.

¯ The mechanical power transmission system is maintenance−free.

¯ Before commissioning remove transport locking devices and keep them for later

transports.

¯ Take safety measures prior to any operation:

– Disconnect the machine from the mains, ensure standstill of the drive system

and avoid any machine movement.

7.2 Maintenance intervals

7

Important notes

( Stop!

For drive systems: Also observe the maintenance intervals for the other

drive components!

Dust deposits prevent heat to be emitted and cause a high housing temperature. The

gearboxes/geared motors must be purified of dirt and dust at regular intervals.

¯ In the case of gearboxes that are not lubricated for life, the lubricant must be

replaced at regular intervals.

– The type of lubricant is indicated on the nameplate. Replace the lubricant only

with the same type of lubricant.

– The lubricant change depends on the lubricant temperature, see Fig. 12.

1. Measure the lubricant temperature at the drain plug,

2. Add 10 °C,

3. Read the changing interval from the diagram.

Lenze ¯ MA 12.0014 ¯ 5.1

47

Page 48

7

Maintenance

Maintenance intervals

110

100

90

80

70

A

60

1000

B

Fig. 12 Lubricant diagram

Oil sump temperature [°C]

0

Oil life/changing intervals [operating

1

hours h]

10000

C

D

50000

Synthetic oil CLP HC/CLP PG

2

Mineral oil CLP

3

¯ Shaft seals and roller bearings:

– The service life depends on the operating conditions.

– Replace seals in case of leakage to avoid consequential damage.

Time interval Measures Description of the operations

On the first day, then every

month

Every 6 months

Annually Check vent valve Check whether air can pass through the

After 3h, then every 2 years Check fastening elements Check mounting of the gearbox (foot, flange

According to diagram; at

the latest as specified in

the lubricant table

Visual inspection Inspection regarding unusual operating noises,

Leakage test If leakages are found, eliminate their cause, see

Clean gearbox Remove dirt and dust deposits. To be inspected

Check rubber buffer Check rubber buffer of the torque plate and

Relubricate bell housings

of the roller bearing

Check pipe of the oil

expansion tank

Oil change Carry out oil change ^ 62 for type and amount

Replace roller bearing

grease filling

vibrations and impermissibly high

temperatures

"Troubleshooting" section

more frequently in the case of heavy dirt

accumulation

replace it in the event of visible wear or

damage

For bell housings with lubricating nipples:

relubricate roller bearing in bell housing using a

grease gun. Grease: Klüber Microlube GLY 92,

quantity approx. 5 grams

Replace pipe when it shows signs of leakage or

after 4 years

breather element. If it shows blockages, replace

it

and shrink disk mounting).

of lubricant see nameplate

When an oil change is carried out, the roller

bearing grease filling should also be replaced

^ 63

48

Lenze ¯ MA 12.0014 ¯ 5.1

Page 49

Maintenance

Maintenance operations

7.3 Maintenance operations

Gearboxes and geared motors are ready to use on delivery and filled by Lenze with the

lubricant type and lubricant quantity indicated on the nameplate. The first filling

corresponds to the mounting position and design indicated on the nameplate.

) Note!

Gearboxes of sizes G50AB045 ... G50BB124 are lubricated for life. Due to

the lower thermal load, no lubricant change and therefore no

arrangements for ventilation are required.

The G50BB124 gearbox can be optionally equipped with breather

elements.

7

Lenze ¯ MA 12.0014 ¯ 5.1

49

Page 50

7

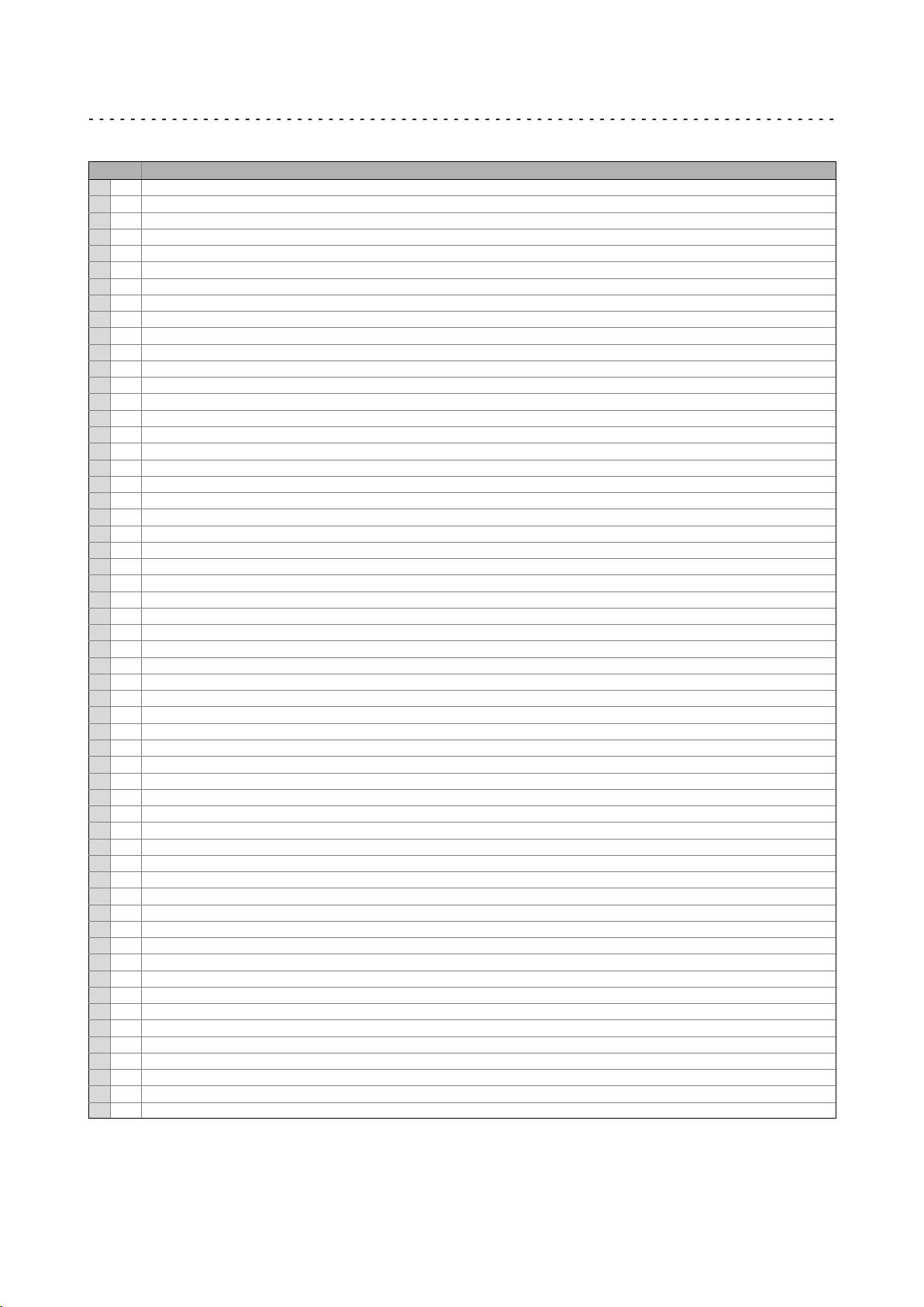

7.3.1 Position of the lubricant monitoring elements

G50BB124

Mounting position A Mounting position B Mounting position C

Maintenance

Maintenance operations

Position of the lubricant monitoring elements

+

+

+

50

Filling Drain

Breathing Control

Lenze ¯ MA 12.0014 ¯ 5.1

Page 51

Maintenance

Maintenance operations

Position of the lubricant monitoring elements

Mounting position D Mounting position E Mounting position F

+

7

Filling Drain

Breathing Control

The shown oil bores are optional for gearbox size g500−B240!

Lenze ¯ MA 12.0014 ¯ 5.1

51

Page 52

7

G50BB145

Mounting position A Mounting position B Mounting position C

Maintenance

Maintenance operations

Position of the lubricant monitoring elements

+

+

+

52

Filling Drain

Breathing Control

Lenze ¯ MA 12.0014 ¯ 5.1

Page 53

Maintenance

Maintenance operations

Position of the lubricant monitoring elements

Mounting position D Mounting position E Mounting position F

7

+

+

+

Filling Drain

Breathing Control

Lenze ¯ MA 12.0014 ¯ 5.1

53

Page 54

7

Maintenance

Maintenance operations

Position of the lubricant monitoring elements

G50BB160 ... G50BB243

Mounting position A Mounting position B Mounting position C

+

+

+

+

G50BB160

G50BB182

G50BB215

+

G50BB227

G50BB243

54

Filler Drain

Breather element Check

Lenze ¯ MA 12.0014 ¯ 5.1

Page 55

Maintenance

Maintenance operations

Position of the lubricant monitoring elements

Mounting position D Mounting position E Mounting position F

+

+

+

G50BB227

G50BB243

7

+

G50BB215

G50BB160

G50BB182

G50BB227

G50BB243

G50BB215

Filler Drain

Breather element Check

G50BB215

+

G50BB160

G50BB185

G50BB215

Lenze ¯ MA 12.0014 ¯ 5.1

55

Page 56

7

G50BB280 ... G50BB320

Mounting position A Mounting position B Mounting position C

Maintenance

Maintenance operations

Position of the lubricant monitoring elements

+

*

+

+

*

*

56

*

*

Filling Drain

Breathing Control

Borehole on both sides

*

Lenze ¯ MA 12.0014 ¯ 5.1

Page 57

Maintenance

Maintenance operations

Position of the lubricant monitoring elements

Mounting position D Mounting position E Mounting position F

7

+

+

+

*

Filling Drain

Breathing Control

*

Lenze ¯ MA 12.0014 ¯ 5.1

Borehole on both sides

57

Page 58

7

Maintenance

Maintenance operations

Table of lubricants

7.3.2 Table of lubricants

Lenze recommends the use of the following lubricants.

If you carry out an oil change, use the same type of oil as specified on the nameplate. The

oil changing intervals are reference values for normal ambient conditions and a

maximum oil temperature of 70 °C. Difficult operating conditions (e.g. high

temperatures, aggressive ambient media) require shorter intervals.

Lubricant Ambient

CLP 220 0 °C ... + 40 °C Mineral oil with