Page 1

EDB2131UB

Show/Hide Bookmarks

00408822

Operating Instructions

PROFIBUS-DP

24VDC

+-

2131

Fieldbus module type 2131

PROFIBUS

Page 2

These Operating Instructions are valid for fieldbus modules with the following nameplate data:

Show/Hide Bookmarks

2131 IB. 0x. 0x. PROFIBU S

Together with the unit series as from thenameplate data:

820X E. 2x. 1x. (8201- 8204)

820X E./C. 2x. 1x. Vxxx (8201- 8204)

821X E. 2x. 2x. (8211- 8218)

821X E./C. 2x. 2x. Vxxx (8211- 8218)

822X E. 1x. 1x. (8221- 8225)

822X E. 1x. 1x. Vxxx (8221- 8227)

824X E. 1x. 1x. (8241- 8246)

824X E./C. 1x. 1x. Vxxx (8241- 8246)

82EV V A 0x 8200 v ector

82EV 1x 0x 8200 vector

93XX E. 2x. 1x. (9321 - 9333)

93XX E./C. 2x. 1x. Vxxx (9321- 9333)

Type

Design:

E = Enclosure I P20

IB = Module

Hardware level and index

Softw are levelandind ex

Variant

Explanation

Important:

TheseOperatingInstructionsareonlyvalidincombinationwiththeOperatingInstructions of the

controller 82XX, 8200 vector or 93XX.

.

1996 Lenze GmbH&Co KG

Without written approval of Lenze Lenze GmbH&Co KG no part of these Instructions must be copiedor given to third parties.

Allindicationsgivenin these Operating instructions havebeen selected carefully andcomply withthe hardware and software described. Nevertheless,

deviation scannot beruled ou t .We donottake anyresponsibility orliabilityfordamageswhichmightpossiblyoccur. Requ ired correctionswill be madein

the follo w ing editions.

Version 1.0 06/99

Page 3

Contents

Show/Hide Bookmarks

1 Preface and general information 1-1...........................................

1.1 How to use these Operating Instructions 1-1................................................

1.1.1 T erminology used 1-1.........................................................

1.1.2 What is new? 1-1............................................................

1.2 Scope of supply 1-1..................................................................

1.2.1 Legalregulations 1-2..........................................................

2 Safety information 2-1......................................................

2.1 Persons responsible for safety 2-1.......................................................

2.2 Generalsafety information 2-1..........................................................

2.3 Layout of the safety information 2-2......................................................

3 Technical data 3-1.........................................................

3.1 Featur es of the 2131 fieldbus module 3-1..................................................

3.2 General data / application conditions 3-1..................................................

3.3 Rated data 3-2......................................................................

3.4 Dimensions 3-2.....................................................................

3.5 P r o toco l data 3-2....................................................................

3.6 Communication times 3-3.............................................................

3.6.1 Data-transfer time 3-3.........................................................

3.6.2 Processing time in the controller 3-3..............................................

3.6.3 Number of participants 3-4.....................................................

4 Installation 4-1............................................................

4.1 Connections of the fieldbus module 2131 4-1...............................................

4.1.1 Ov erview 4-1................................................................

4.1.2 9 pole SubD pin connector 4-2...................................................

4.1.3 Plug-in terminal for 2 pole male plug (external supply voltage) 4-2........................

4.2 Mechanical installation 4-3.............................................................

4.3 Electrical installation 4-3..............................................................

4.3.1 V oltage supply 4-3............................................................

4.3.2 Wiring to a host 4-4...........................................................

5 Commissioning 5-1........................................................

5.1 Configuration of the host system for communication with the 2131 fieldbus module. 5-1...............

5.1.1 Settings with COM -ET200 DOS 5-1................................................

5.1.2 Settings with COM -ET200 W IN 5-1................................................

5.1.3 Programexample 5-2.........................................................

5.2 Com missioningof the 2131 fieldbus module 5-2.............................................

5.2.1 Dr ive control via PROFIBUS 5-2..................................................

5.2.2 Enable controller 5-3..........................................................

5.3 Diagnostics 5-4.....................................................................

5.4 Sp ecial features with 82XX ,8200 vector and93XX 5-4........................................

BA2131EN

i

Page 4

Contents

Show/Hide Bookmarks

6 Parame ter setting 6-1......................................................

6.1 Parameters 6-1.....................................................................

6.1.1 Lenze parameters 6-1.........................................................

6.1.2 DRIVECOM parameters 6-2.....................................................

6.1.3 Op erating mode C0001 6-3.....................................................

6.1.4 Bus address/station address 6-3.................................................

6.1.5 Baud rate 6-4...............................................................

6.1.6 Master settings 6-4...........................................................

6.2 PROFIBUS-DP configuration 6-4.........................................................

6.3 PROFIBUS-DP parameter-setting channel 6-5...............................................

6.3.1 Structure ofthe DPparameter-settingchannel 6-5....................................

6.3.2 Parameter communicationwiththe controller 6-7.....................................

6.3.3 Example1: Write parameter 6-8..................................................

6.3.4 Example2: Write parameter 6-9..................................................

6.4 P r o cess data 6-9....................................................................

6.4.1 P r o cess-data assign ments for 82XX 6-10............................................

6.4.2 P r o cess-data assign ment for 8200 vector 6-10........................................

6.4.3 Process-data assignment for 93X X 6-11.............................................

6.5 Co ntroller status 6-13.................................................................

6.5.1 Standard unit control 6-13.......................................................

6.5.2 DRI V ECOM unit control 6-14......................................................

6.5.3 Control word 6-17.............................................................

6.5.4 Status word 6-20..............................................................

6.6 Lenze-specificparameters 6-22..........................................................

6.6.1 On ly82XX: Lenze param eter Operating Mod e (L-C0001) 6-22.............................

6.6.2 Param eter L-C0142 6-22........................................................

7 Troubleshooting and fault elimination 7-1.......................................

7.1 Controller is inhibited 7-2..............................................................

7.2 Check PROFIBUS 7-4.................................................................

7.3 Activate the fieldbus module 7-5.........................................................

7.4 Fault reset (TRIP ) 7-6.................................................................

8 Appendix 8-1.............................................................

8.1 A ccessories 8-1.....................................................................

8.2 List of abbreviations 8-2...............................................................

8.3 Glossary 8-3.......................................................................

8.4 Tableofkeywords 8-4................................................................

ii

BA2131EN

Page 5

Preface and general inf ormation

o

rforv

o

y

)Contr

o

(LA

R00A

A

)

liabilityfordeficienciesclaimed

subse

quently

a)ControllermasterfiletoDINE19245part3(

L_AR00A

A.GSD

)

pgy

S

imat

ic-S5COM-ET200V5.X(LE00AAA

X.200

)

Show/Hide Bookmarks

1 Preface and general information

1.1 How to use these Operating Instructions

l

These Operating Instructions are intended for safety-relevant operations on and with the 2131

fieldbus module. They contain safety information which must be observed.

l

All personnel working on and with the 2131 fieldbus module must have these Operating

Instructions available and observe the information and notes relevant for them.

l

The Operating Instructions must always be complete and perfectly readable.

TheseOperating Instructionsinform about the mostimportant technicaldata and the installationof

the 2131 fieldbus module. Theyare only valid in combination with theOperating Instructions of the

corresponding controller.

1.1.1 Terminology used

Controller In the following, the term ”controller” is used for ”93XX servo inverters” or ”82XX frequeny inverters”.

Drive system In the following, the term ”drive system” is used for drive systems with fieldbus modules or other Lenze drive

Fieldbus module In the following text, the term ”fieldbus module” is used for the fieldbus module type 2131 PROFIBU S .

Cxxx/y Sub code y of code Cxxx(z.B. C0410/3 = subcod e 3 of code C0410)

L-Cxxx/y Lenze code

Xk/y Terminal stripXk/termin aly (z.B. X 3 /2 8= termin al28 on terminal stripX3)

(xx-yyy) Crossreference (chapter - page)

1.1.2 What is new?

Ident. no. Edition of Important Contents

394 179 27/01/1997 Format change to DINA4

408822 01/06/1999 r ep laces 394 179

1.2 Scope of supply

Scope of supply Important

l

1 2131 fieldbus module with housing (enclosure IP20)

l

1M3fixingscrew

l

1two-pole male connect

l

1 diskette with:

–

–a

– b)Con troller type files for

llermasterfile toDIN E 19245part3

Simatic-S5 COM-ET 200V4.X(LE00A ATD.200)

components.

ltage suppl

l

Adaptation to 8200 vector (all chapters)

Afterthe delivered received,check immediately whetherthe items

supplied match the accompanying papers. Lenze does not accept any

Claim

l

.GS D

visible transport damage immediately to the forwarder

l

visible deficiencies/incompleteness immediately to your Lenze

representative.

.

BA2131EN

– c)Example program for Simatic-S5 (2130IB ST.S 5D)

l

1 Short Instructions

1-1

Page 6

Preface and general inf ormation

g

p

Show/Hide Bookmarks

1.2.1 Legal regulations

Labelling

Application as

directed

Liability

Warranty

Disposal

Nameplate CE mark Manufacturer

Lenze 2131 fieldbus modules are

unambiguously identified by their nameplates.

2131 fie l dbus module

l

Operate the fieldbus module only under the conditions prescribed in these Operating Instructions.

l

The fieldbus module is an additional module and can be optionally attached to the Lenze controller series 820X, 821X, 822X, 8200 vector

and 93XX. The 2131 fieldbus module links these Lenze controllers with the standardized serial communication system PROFIBUS-DP .

l

The fieldbus module must be attached and electrically connected so that it complies with its function and does not cause any hazards when

attached andoperated as instruc ted.

l

Observe all notes given in chapter „Safety information“

l

Please observe all information given in these Operating Instructions.This means:

– Read these Operating Instructions carefully before you start to work with the system.

– These Operating Instructions must always be available during operation of the fieldbus module.

Any other use shall be deemed inappropriate!

l

The information, data, and notes in these instructions met the state of the art at the time of printing. Claims referring to drive systems

which have already been supplied cannot be derived from the information, illustrations, anddescriptionsgiven in these Operating

Instructions.

l

The specifications, processes, and circuitry described in these Operating Instructions are for guidance only and must be adapted to your

own specific application. Lenze does not take responsibility for the suitabilityof the processand circuit proposals.

l

The indications given in these Operating Instructions describe the features of the product without warranting them.

l

Lenze doesnot accept any liabilityfor damag eandoperatinginterference causedby:

– disregarding these Instructions

– unauthorized modifications to the controller

– operatingerrors

– improper working on and with the controller

l

W arranty conditions: see Sales and Delivery Conditions of Lenze GmbH &Co KG.

l

Warranty claimsmust be made to Lenze immediatelyafter detectingthe deficiency orfault.

l

The warranty is vo idin all cases where liability claim scannot be made.

Material recycle dispose

Metal

Plastic

Assembled PCBs Short Instructions/Operating Instructions

Conforms to the EC Low Voltage Directive Lenze GmbH &Co KG

.

2-1)

(

-

-

-

P o stfach101352

D-31763 Hameln

-

-

-

1-2

BA2131EN

Page 7

Safety information

Show/Hide Bookmarks

2 Safety information

2.1 Persons respon sible for safety

Operator

l

An operator is any natural or legal person who uses the drive system or on behalf of whom the drive system is used.

l

The operator or his safety personnel is obliged

– to ensure the compliance with all relevant regulations, instructions and legislation.

– to ensure that onlyskilled personnel works on and with the2102I Bfieldbus module.

– to ensure that the personnel has the Operating Instructions available for all corresponding works.

– to ensure that all unqualified personnel are prohibited from working on and with the drive system.

Qualified personnel

Qualified personnel are persons who - because of their education, experience, instructions, and knowledge about corresponding standards and regulations, rules for

the prevention of accidents, and operating conditions - are authorized by the person responsible for the safety of the plant to perform the required actions and who are

able to recognize potential hazards.

(Definition for qualified personnel to VDE105 or IEC 364)

2.2 General safety information

l

These safety notes do claim to be complete. In case of questions and problems please contact your Lenze representative.

l

At the time of delivery the fieldbus module meets the state of the art and ensures basically safe operation.

l

The indications given in these Operating Instructions refer to the stated hardware and software versions of the fieldbus modules.

l

The fieldbus module is hazardous if:

– unqualified personnel works on and with the fieldbus module.

– the fieldbus module is used inappropriately.

l

The processing notes and circuit sections shown in these Operating Instructions are proposals which cannot be transferred to other applications without being

tested andchecked.

l

Ensure by appropriate measures that neither personal injury nor damage to property may occur in the event of failure of the fieldbus module.

l

The drive system must only be operated when no faults occur.

l

Retrofittings, modifications, or redesigns are basically prohibited.Lenze must be contacted in all cases.

l

The fieldbus module is electrical equipment intended for use in industrial high-power plants. The fieldbus module must be tightly screwed to the corresponding

controller duringoperation. Inaddition, all measuresdescribedin the OperatingInstructionsof theusedcontroller must be taken. Example: Fasten covers to ensure

protection against contact.

BA2131EN

2-1

Page 8

Safety information

Show/Hide Bookmarks

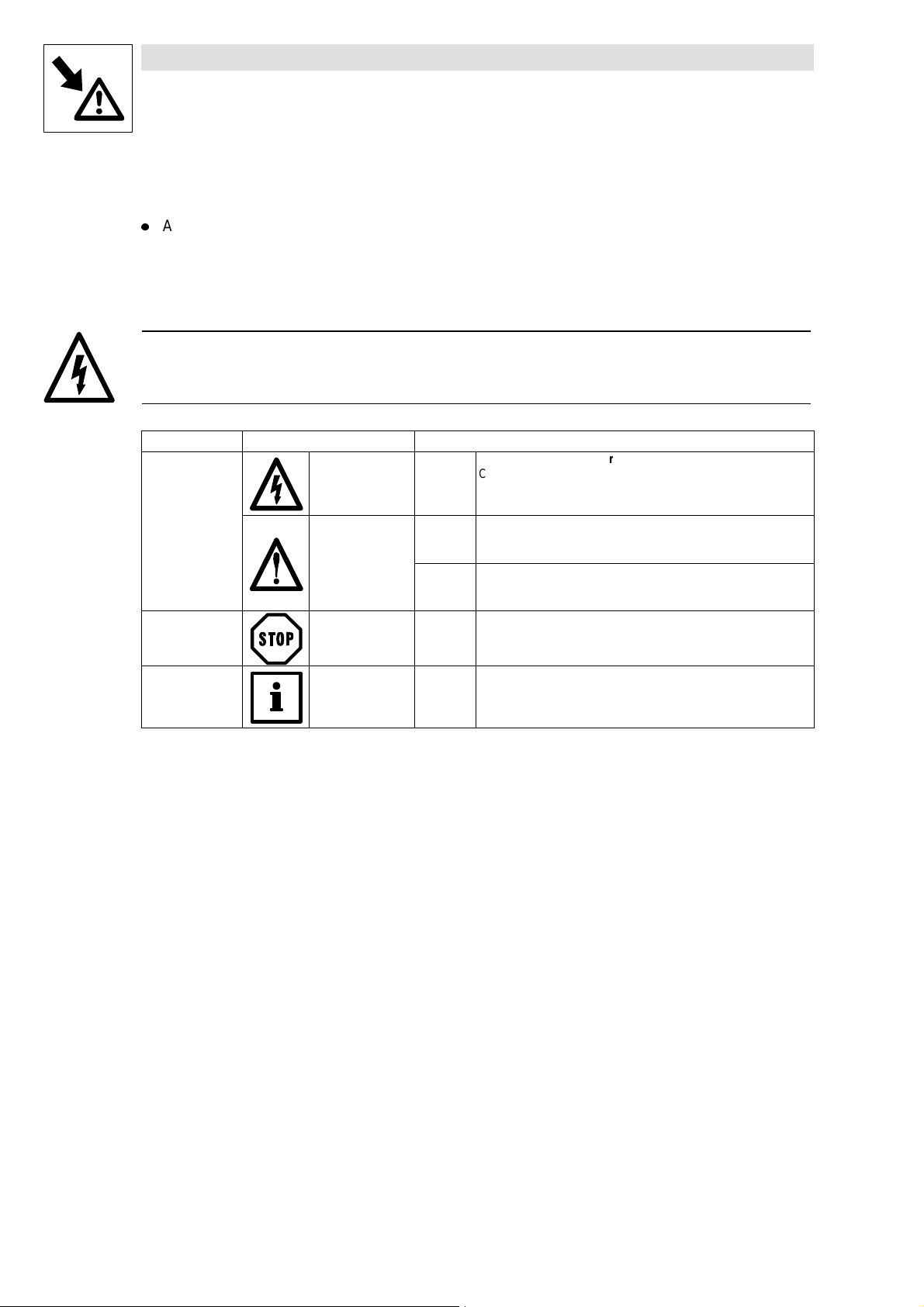

2.3 Layout of the safety information

l

All safety information has a uniform layout:

– The icon characterizes the type of danger.

– The signal word characterizes the severity of danger.

– The note text describes the danger and gives information how to prevent dangerous

situations.

Signal word

Note

Icons used Signalwords

Warning of

damage to

persons

Warning of

hazardous electrical

voltage

Danger! Warns of impending dangeU.

Consequences if disregarded:

Death orsevere injuries.

W arning of a general

danger

Warning of

damage to

material

Other notes Tip! This note designates general, useful notes.

Warning! Warns of potential,very hazardous situations.

Possible consequences if disregarded:

Death orsevere injuries.

Caution! Wa rns of potential,hazardous situations.

Possible consequences if disregarded:

Light or minor injuries.

Stop! Warns of potential damage to material.

Possible consequences if disregarded:

Damage of the controller/drive system or its environment

If you observe it, handling of the controller/drive system is made

easier.

.

2-2

BA2131EN

Page 9

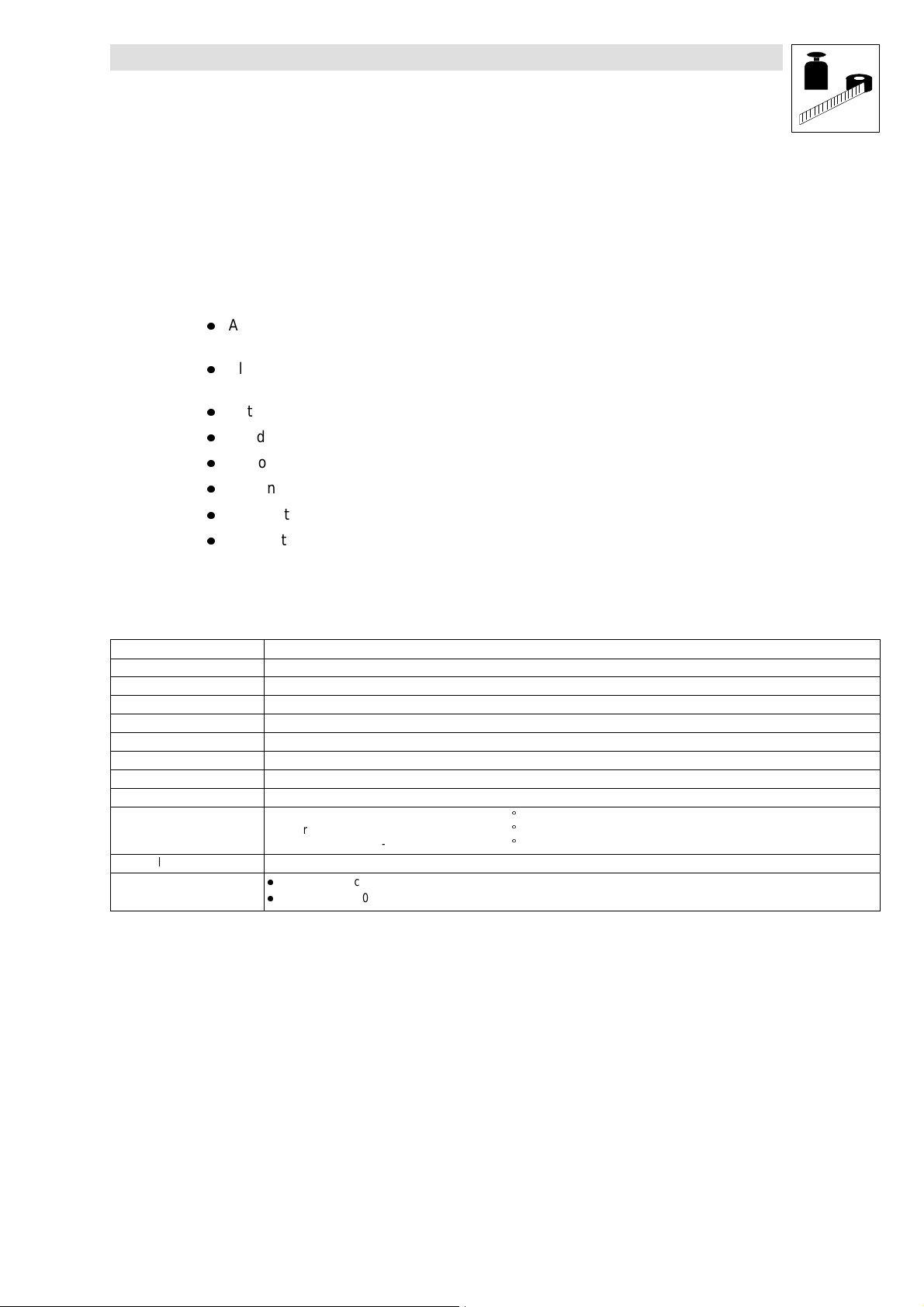

3 Technical data

Show/Hide Bookmarks

3.1 Features of the 2131 fieldbus module

The 2131 fieldbus module has the following features:

l

Attachable additional module for Lenze controller series 820X, 821X, 8200 vector, 822X and

93XX

l

Slave interface module for the communication system PROFIBUS with the communication

profile PROFIBUS-DP (DIN19245 part 1 and part 3)

l

Automatic baud ratedetection

l

Baud rate between 9.6 kbaud and 12 Mbaud

l

Optionally 4or 6 byteproces data

l

Optional parameter-setting channel

l

Access to all Lenze parameters

l

Application profile: DRIVECOM Profil 20

Tec hnical data

3.2 General data / application conditions

Field Values

Order designation 33.2131IB

Communcation medium RS485

Network topology Line

Max. cable length 1200 m (depending on the desired baudrate and the cable type used)

PROFI BUSparticipants Slave

Communication profile PROFIBUS-D P(DIN19245 part 1 and part 3)

Drive profile DRI V ECOMprofile 20

Baud rate 9.6 kbit/s to 12000 kbit/s

Ambient temperature during operation: 0 to 50C

Permissible humidity Class 3K3 to EN50178 (w ithout condensation, average relative humidity 85%)

24-V-DC-

V oltage supply

Transport: -25 to 70

Storage: -25 to 55

l

820X / 8200 vector (ob serve chapter4.3.1): onlyextern al supply

l

821X / 822X / 8200 vector (ob serve chapter 4.3.1) / 93XX : internal or external supply

C

C

BA2131EN

3-1

Page 10

Tec hnical data

Show/Hide Bookmarks

3.3 Rated data

Field Values

Communication medium RS485

V oltage supply 24 VDC10 %; max 60 mA

Insulation voltage - bus systems:

to PE 50 VAC

for external supply (terminal 39/59) 0 V AC (no electrical isolation)

topower stage 820X: 270 VAC (s in gle basic insulation )

to the control terminals 820X: 0 V AC (no electrical isolation)

for the external bus systems 0 V AC (n oelectrical isolation)

Degree of pollution V DE 0110 part 2 pollu tio ndegree 2

821X: 270 VAC (s in gle basic insulation )

8200 vector: 270 V AC (double basic insulation)

822X: 270 VAC (double basic insulation)

93XX: 270 V AC (double basic insulation)

8200 vector (withinternal supply) :

0 V AC (n oelectrical isolation)

821X: 50 VAC

(E lectrical isolation)

8200 vector (withexternal supply):

100 VAC ( single basicinsulation)

822X: 270 VAC (s in gle basic insulation )

93XX: 270 V AC (single basic insulation )

3.4 Dimensions

62

75

2131

Fig. 3-1 Dimensions of the 2131 fieldbus module (all dimensions in mm)

3.5 Protocol data

Field Values

Maximum number of controllers without repeater: 31

Process-data words (PCD ) :

DP user-data length:

withrepeater: 125

l

2 words (32 bit)

l

3 words (48 bit)

l

2 words (32 bit)

l

3 words (48 bit)

l

Parameter-setting channel + 2 words (64 + 32 bit)

l

Parameter-setting channel + 3 words (64 + 48 bit)

18

28

3-2

BA2131EN

Page 11

3.6 Communication times

Show/Hide Bookmarks

The communication times depend on:

l

the data transfer time

l

theprocessing time in thecontroller

3.6.1 Data - transfer time

The data-transfer time depends on:

l

thebaud rate

l

theuser-datalength

You will find more information about the data-transfer time in the documentation for your host

system.

3.6.2 Processing time in the controller

Tec hnical data

Processing time 820X

For the 820X series several processing steps are required, which are processed cyclically.

A processing cycle consists of:

l

Writing of control word or setpoint, if the value has changed

l

Alternating reading of status word and actual value

l

Processing of parameter access if thereis a service

Ifthe timetolerances caused bythe cyclic readingof thestatus word/actual value aretoo large, the

alternating reading of thestatusword and the actual value can besuppressed. Thisiscontrolled by

the bit 15 (PE inhibit)of the DRIVECO M control word:

l

PEinhibit = 0:

Status and actual-value update active

l

PEinhibit = 1:

Status and actual value update not active

A suppression of the processing of parameter access is not necessary, since this is controlled by

theuser.

BA2131EN

3-3

Page 12

Tec hnical data

Show/Hide Bookmarks

In the following table you will find a list of the processing times:

Processing step Max. processing t ime in ms

PE-inhibit = 0 Tolerance PE-inhibit = 1 Tolerance

Read parameter 55 +48 55 +8

Control word or

setpoint

Control word and

setpoint

Write parameter 108 +32 - Status word and

actual value

Note:

A change of the setpoint signal results in writing the control word.

Processing time 821X / 8200 vector / 822X

The parameter data and process data are independent of each other.

l

Parameter data: 30 ms + 20 ms tolerance

l

Proces data: approx. 3ms + 2 ms tolerance

27 +48 27 +8

54 +56 54 +16

200 +40 200 -

Processing time 93XX

The parameter data and process data are independent of each other.

l

Parameter data: approx. 30 ms + 20 ms tolerance (typical)

– The processing time can be longer for some codes (see the 9300 Manual).

l

Process data: approx. 3 ms + 2 ms tolerance

3.6.3 Number of participants

l

Standard: 32 particpants (including host system)

l

With repeaters: 127 participants (including host systems)

You canbuild up line and tree topologies bymeans of repeaters. The maximum total expansion of

the bus system depends on:

l

the baud rate used

l

the number of repeaters

More detailed information can be obtained from thedocumentation for thecontrol system.

3-4

BA2131EN

Page 13

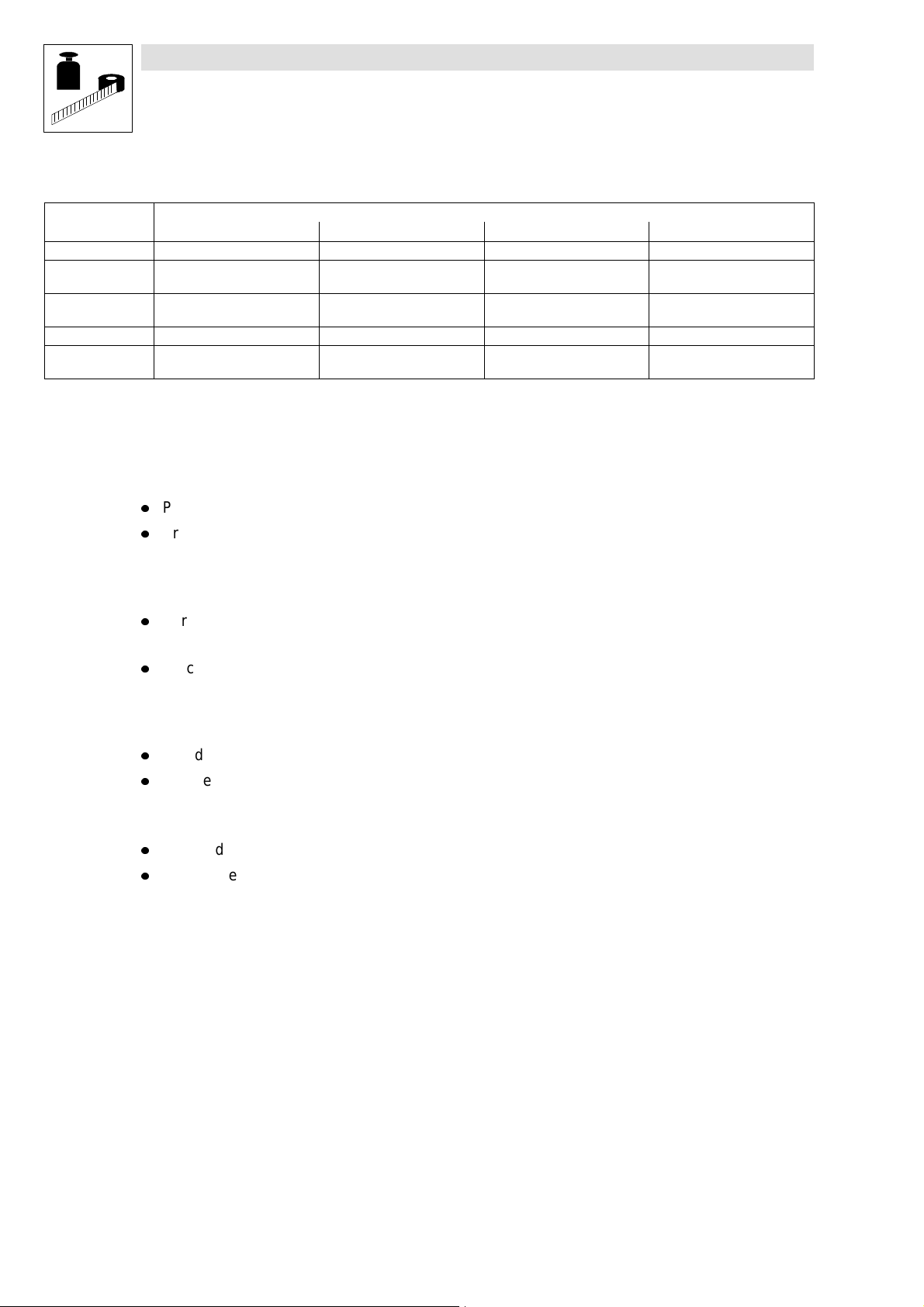

4 Installation

Show/Hide Bookmarks

4.1 Connections of the fieldbus modul e 2131

4.1.1 Overview

Installation

2131

8200 vector

82XX

Fig. 4-1 Controllers with fieldbus module 2131

2131

2131

93XX

BA2131EN

4-1

Page 14

Installation

5

8

7

6

Show/Hide Bookmarks

132

132

5

5

4

4

24 V D C

24 V D C

+ -

+ -

6

6

8

8

Fig. 4-2 2131 fieldbus module

7

7

2131

2131

2131pfb001

Pos. Name/Meaning

1 Green bus LED the voltage supply of the fieldbus module 2131

ON:

ON: 2131 fieldbus module is supplied with voltage and is connected to the controller .

OFF:

2131 fieldbus module is not supplied with voltage; controller or external voltage supply is

switched off.

BLINKIN G:

2131 fieldbus module is supplied with voltage but is not connected to the controller

(c ontroller is switchedoff, in initialization or not available) .

2 Yellow bus LED for the communication of the fieldbus module 2131

ON:

2131 fieldbus module is initialized but does not communicate with the PROFIBUS-DP from

the master.

OFF:

2131 fieldbus module is not initialized yet.

BLINKIN G:

PRO FIBUS-DP communication is active

3 Green drive LED (DRIVE)

Operating status of the 82XXor 93XX controllers. (See Operating Instructions of the

controller.)

4 Red drive LED (DRIVE)

Operating status of the 82XXor 93XX controllers. (See Operating Instructions of the

controller.)

5 PROFIBUS-DP connection

9 pole SubD pin connector (see chapter 4.1.2)

6 Connection for external voltage supply (24 V DC10%)

External voltage supply for the 2131 fieldbus module (see chapter4.1.3).

Always required for 820X ! For others as option.

7 Fix in gscrew for the 2131 fieldbus module

8 Only required for820X, 821X: additional PEscreen cable, whichavoids EMC related

communication interferences in especially noisy environments.

4.1.2 9 pole SubD pin connector

View Pin Name Explanation

1 PE Earth

2 free -

9

6

5

4

3 RxD/TxD-P Data transfer B

3

4 RTS R equest To Send

2

5 M5V2 Data reference potential

1

6 P5V2 5VDC

7 free 8 RxD/TxD-P Data transfer A

9 free -

1) Total current approx.60 mA

1)

4.1.3 Plug-in termina l for 2 pole male plug (external supply voltage)

Name Input/output Explanation

+ I nput External voltage supply +24 VDC/á10 %, 60 mA

- Input GND; reference for external supply

4-2

BA2131EN

Page 15

4.2 Mechanical installation

Show/Hide Bookmarks

l

Ifa keypad is attached to the front of the controller, removeit.

l

Plug the 2131 fieldbus module in the corresponding interface of the controller and fasten it

withthefixingscrew (

(4-2) ,Fig.4-2,pos.7).

4.3 Electrical installation

Note!

Thecommunciation of controllers820Xand 821X maybe interfered by electromagnetic radiation.

Installation

If necessary, use an additional PE screen cable (

4.3.1 Voltage supply

If required, supply the 2131 fieldbus module via the plug-in contacts 1/2 ( (

withaseparatevoltagesupply24VDC/10 %.

The821X,8200vector ,822x and 93XXshould always bedrivenwithout aseparate voltage supply.

The controllers 820X (8201¤8204)always require a separte voltage supply!

Use a separate supply unit for the external voltage supply (24 V)of the 2131 fieldbus module.

Use separate supply units for longer distances between the control cabinets.

The following chapter describes how to connect the 2131 fieldbus module to the bus system, see

chapter 4.3.2.

Note!

Internal voltage supply of the fieldbus module connected to a 8200 vector

Controllerswithan extended AIFinterface (front of the 8200 vector)can be internally supplied.The

part of the drawing highlighted with grey shows the jumper position.

In Lenze setting, the fieldbus module is not

For internal voltage supply, put the jumper in the position indicated below.

(4-2) ,Fig.4-2,pos.9).

internally supplied.

4-2) ,Fig.4-2,pos.6)

BA2131EN

Lenze setting

(only external voltage supply)

Internal voltage supply

4-3

Page 16

Installation

Show/Hide Bookmarks

4.3.2 Wiring t o a host

Warning!

An additional potential isolation must be installed if

l

a 820X, 821X or 8200 vector controller will be connected to a host

and

l

a safe electrical isolation (double basic insulation) to VDE0160 is required.

For this,you canuse an interfacemodulefor the host with an additional electricalisolation (seethe

corresponding manufacturer’s information).

For wiring, t he electrical isolation of t he supply voltage must be taken into ac count. The supply

voltage is assigned to the same potential as the data bus.

4-4

BA2131EN

Page 17

Wiring features:

Show/Hide Bookmarks

Features:

Communication medium RS485

Network topology without repeater: line

withrepeater: line ortree

Possible number of controllers without repeater: 32

withrepeater: 127

Max imum cable length 1200 m (d epen ding on the baud rate and the cable ty pe used)

Maximum baud rate 9.6-12000 kbit/s

The connection of the bus system PROF IBUS-DP is shown in the survey drawing. The required

accessories (e.g. connection cables) are listed in chapter 8.1.

Installation

82XX

Fig. 4-3 PROFIBUS with RS485 wiring (without repeater)

1Host

2 Bus-connector (

3Buscable(

4-6)

4-6)

93XX

8200 vector

2

3

1

BA2131EN

Wiring

Warning!

l

If the 2131 fieldbus module is no longer supplied with voltage, the bus system will continue

operation. However , the connected controller can no longer be accessed from the host.

l

If single bus participants are to be disconnected, it must be ensured that the bus terminators

at the physical cable ends remain active.

l

Only use cables which correspond to the listed specifications (see chapter 8.1).

l

Observe the bus connector drawing. (

l

Connect the controller using the bus connector.

Note: The bus system will not be interrupted if the bus connector is pulled off the controller.

l

Connect a bus terminator to the physical bus ends. The bus terminator is integrated into the

bus connector and can be activated via a switch.

l

Observe the wiring notes and thedocumentation for the control system.

4-6)

4-5

Page 18

Installation

Show/Hide Bookmarks

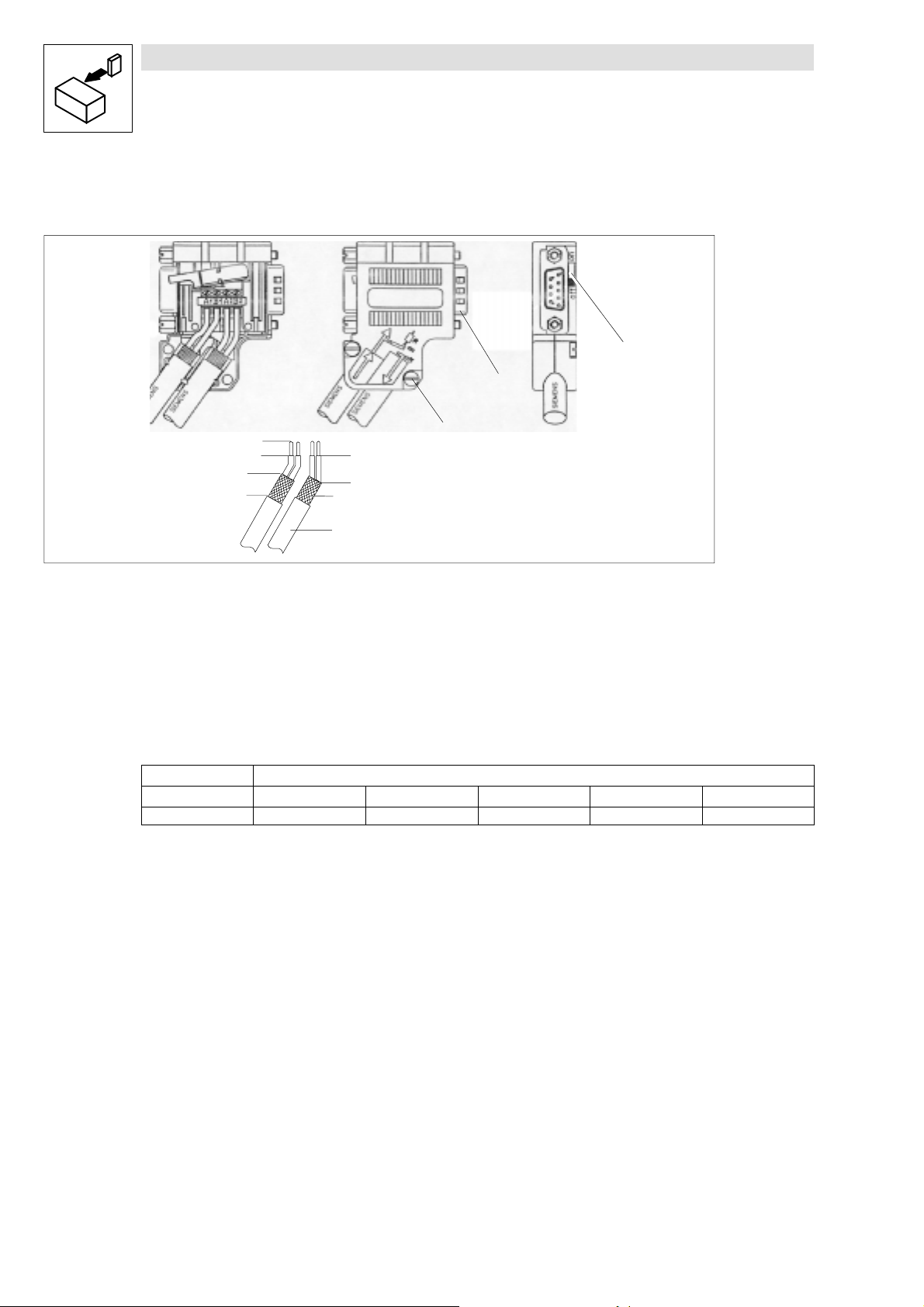

Bus cable

Connection of the bus cable in the bus connector (Siemens)

1

3

Enter approx. 5 mm

Enter approx. 11 mm

Fig. 4-4 Connection of the bus cable in the bus connector

19-poleSubDplug

2 Housing screw

3 Terminator

4 Cable screen (bare fit

5Buscable

(here

not connected)

inmetalguide required)

Enter approx. 16 mm

4

5

Length of the bus cable

The length of the bus cable depends on the baud rate:

9.6 - 93.75 187.5 500 1500 12000

Length [m] 1200 1000 400 200 100

2

Baud rate [k bit/s]

4-6

BA2131EN

Page 19

Installation

Show/Hide Bookmarks

BA2131EN

4-7

Page 20

Commissioning

Show/Hide Bookmarks

5 Commissioning

Stop!

l

Beforeswitching on the mains voltage check the wiring for completeness, short circuit and

earth fault.

l

Keep t o t he switch-on sequence!

(Chapter 5.1 to chapter 5.2.2)

5.1 Configuration of the host system for communication with the

2131 fieldbus module.

TheLenzecontrollers arePROFIBUS-DPparticipantsin conformitywithstandards.Communication

with the Simatic-S5 is possible, provided that the following Siemens hardware and software

components are available:

l

S5-interface module IM308-B or IM308-C

l

Programming software COM-ET 200

The COM-ET200 software is available in a DOS version (COM-E T200 DOS) and in a Windows

version (COM-ET200 WIN). The following two sections explain the specific controller settings for

both versions. The third section gives a program example which is to support the commissioning.

5.1.1 Settings with COM-ET200 DOS

Inthe following, wedescribe howto configurea Lenzecontroller forthe program packageCOM-ET

200 DOS:

1. Copy the file LE00AATD.200 from the diskette to the COM-ET200 directory .

2. Fill in the boxes of the menus indicated then:

Menu: ET200 system parameter

Bus profile: DP standard

Menu: Configure

Station type: Lenze 2131 Vxx

Configuration: User data with DP parameter-setting channel

0. = 115; 1. = 113 oder

0. = 115; 1. = 114

User data without DP parameter-setting channel

0. = 113 or

0. = 114

5.1.2 Settings with COM-ET200 WIN

In the following we describe how to configure a Lenze controller for the program package

COM-ET200 WIN:

1. Copy the file LE00AAAX.200 from the diskette to the COM-ET200 directory.

2. Select the 2131 fieldbus module via the slave family DRIVE S.

BA2131EN

5-1

Page 21

Commissioning

Show/Hide Bookmarks

3. Fill in the boxes of the following menu as indicated:

Menu: Configure

Station type: Lenze 2131 Vxx

Configuration: User data with DP parameter-setting channel

User data without DP parameter-setting channel

5.1.3 Program example

You will find a program example (file: 2130IBST.S5D) in STEP 5 on the attached diskette which

supports your commissioning. The program example comprisesthe followingfunction modules:

l

FB182: Process-data communication:

This is a simplified

drive control where the

standard functions of the Lenze drivecontrollers are mapped to the DRIVECO M-ProfilDRIV ECOM profile.

l

FB183: Parameter-data communication:

Thus function module supports the

DP parameter-setting channel. All

DRIV ECOM and Lenze parameters

can be written and read.

0. = 115; 1. = 113 oder

0. = 115; 1. = 114

0. = 113 or

0. = 114

5.2 Commissioni ng of the 2131 fieldbus module

1. Switch on the controller and, if necessary, the external supply of the 2131 fieldbus module.

The green bus LED for the supply voltage (see page 4-1; Fig. 4-1pos. 1) must be on.

The LED which displays the operating state of the controller must be on.

If the LEDs are not on, see chapter 7 “Troubleshooting and fault elimination“.

2. Set the station address (C0009)for each controller via the keypad or the host (seechapter

6.1.4, page 6-3).

If several controllers are interconnected in a network, it must be possible that the host

addresses each controller uniquely. Every controller therefore needs an address.

3. You can now communicate with the drive.

4. The control terminal 28 (ctrl. enable = controller enable)is always active and must be set to

HIGH level during operation (see Operating Instruction of the corresponding controller).

Otherwise, the controller cannot be enabled.

5.2.1 Drive control via PROFIBUS

82XX

1. For drive control with PROF I BUS, change the Lenze parameter operating mode (L-C0001)

from 0 to 3. (S eechapter 6.6.1). This change can be carried out using the 8201BB keypad or

thePROFIBUS.

Examples for PROFIBUS Write (L-C0001=3)

– Index = 5FFE

(results from 5FFF

hex

(L-C0001)

hex

; see Lenze code addressing (

hex

6-1)

5-2

BA2131EN

Page 22

Commissioning

Show/Hide Bookmarks

–Subindex:0

– V alue: 30000

2. Terminal 28 (controller enable)is always active and must be set to HIGH level during

PROFIBUSoperation (see the corresponding Operating Instructions).

– Otherwise the controller cannot be enabled by the PROFIBUS (DRIVECOM controller status

“OPERATION ENABLED“) .

– With 821X, 8200 vector and 822X the QSP function (quick stop)is always active. If QSP is

assigned to an input terminal (factory setting: not assigned), this terminal must be at HIGH

level during PROF I BUS operation (see the corresponding Operating Instructions).

The controller now accept s c ontrol and parameterdata from the PROFIBUS.

93XX

1. For drive control via PROFIBUS set the Lenze parameter Signal Configuration (L-C0005) to a

value xxx3. This change can be carried out via the 9371BB keypad or directly via PROFIBUS.

Note!

Werecommend the signal configuration C0005 = 1013 (speed control) for first commissioning.

(results from 3x104; see chapter 6.1.1)

dec

Examples for PROFIBUS Write (L-C0005=1013):

– Index = 5FFA

(results from 5FFF

hex

(L-C0005)

hex

; see Lenze code addressing (

hex

6-1)

–Subindex:0

– V alue: 10 130 000

(results from 1013x104; see chapter 6.1.1)

dec

2. Set the parameter L-C0142 to 0.

3. Terminal 28 (ctrl. enable = controller enable)is always active and must be set to HIGH level

during PROFIBUSoperation (see the Operating Instructions of the controller). Otherwise the

controller cannot be enabled by the PROFIBUS (DRIVECOM controller status “OPER ATION

ENABLED“).

– With the signal configuration L-C0005=1013, the QSP function (quick stop) and the

CW/CCW changeover are assigned to the digital input terminals E1 and E2, and thus they

are always active. During PROFIBUS operation, E1 must be on HIGH level (see Operating

Instructions 93XX).

Note!

With thesignal configuration L-C0005=xx13, terminal A1 is switched as voltage output.Therefore,

only the following terminals must be connected via cable:

l

X5.A1 with X5.28 (ctrl. enable)

l

X5.A1withX5.E1(CW/QSP)

The controller now accept s c ontrol and parameterdata from the PROFIBUS.

5.2.2 Enable controller

BA2131EN

As standard, the controller is enabled as follows:

1. Select a speed setpoint with a value unequal 0 (see chapter 6.4.1 “Process-data assignment“

(6-10) .

2. Change to the status “READYFORSWIT CHON“.

Value = 0000 0000 0111 1110

bin

(007E

). in the DRIVE CO M control word.

hex

5-3

Page 23

Commissioning

Show/Hide Bookmarks

3. Wait for the status “READY FOR SWITCH ON“.

Value for DRIVECOM status word = xxxx xxxx x01x 0001

4. Change to the status “OPER ATION ENABLED“.

Value = 0000 0000 0111 1111

5. Wait for “OPERATION ENABLED“.

See also chapter 6.5.2 “DRIVECOM unit control“, page 6-14ff.

5.3 Diagnostics

If the initialization to the controller is not completed when using an external supply voltage for the

module (e.g. controller not switched on), the bit “static diagnostics” willbe set (station status byte

2, bit 1).

Thismeansthatthemodule cannotprovidevaliduserdata.Themastermustthenstop theuserdata

transfer and request diagnostics data until the bit “static diagnostics“ will not be set any longer.

bin

(007F

bin.

)in the DRIVECOM control word.

hex

5.4 Special featur es with 82XX, 8200 vector and 93XX

Please note

l

For safe operation it is absolutely necessary to observe the notes for the controllers given in this chapter.

l

Please observe the corresponding Operating Instructions of the controllers.

820X

821X, 822X

8200 vector

93XX

l

Parameter setting (codes except process data) is only possible when the controller is inhibited (DR IV ECO Mcontroller status unequal

“OPERA TIO NENABLED“). Parameters are accepted when the controller is enabled, but they are not saved.

l

A TRIPmust only be reset through PR OFIBUS:

If the contro ller isset tothe statusTRI Pwhile being operated with PROFIBUS con trol (L-C0001 = 3) and if the TRI Pis reset through terminal

28, the drive can start for a short time. When resetting a fault via PROFIBUS, this does not occur.

l

After the command “TR IP reset“ the 820Xcontroller is basically initialized. Duringthis time the controller doesnot accept any services.

l

Always send the direction of rotation with a low setpoint before the new setpoint:

If the setpoint and the direction of rotation are changed at the same time via the DRIVECO Mspeed setpoint, the speed can change to the

wrong direction or rotation for a short time. This is because first the setpoint is sent as unipolar value to the controller and then the

information about the direction of rotation is sent.

l

For first switch on, the automatic DC-injection brake must be activated in both parameter sets:

– C0106 = 0

– C2106 = 0

l

If the automatic DC-injection brake (DCB) is activated (DCB holding time LC106 <> 0) , the drive will automatically change from the status

“OPERA TIO NENABLED“ to the status “SWI TCHEDON“ when reaching the speed 0 and after the DCB holding time. If the setpoint is > 0, the

drive automatically changes to the status “OPER ATION ENABLED“.

l

Digital and analog input and output signals can be freely configured (see Operating Instructions for 8200 vector; codesC0410, C0412, C0417

and C0421)

l

The change of the code L-C0001 to xxx3 starts the preconfiguration of the process data words in the controller

l

Set the signal configu r ationL-C0005 = xxx3 instead of the operating mode L-C0001.

l

The change of the code L-C0005 to xxx3 starts the preconfiguration of the process data words in the controller

l

Set the parameter L-C0142 = 0 (autostart lock), to avoid a short time start of the drive during the initialization phase.

5-4

BA2131EN

Page 24

6 Parameter setting

Show/Hide Bookmarks

The parameter setting of the 2131 module is subdivided into:

l

Controller parameters, which can also be set with the 8201BB or 9371BB keypad.

l

2131 parameters, which can only be accessed via the 2131 fieldbus module.

Only the controller parameters are permanently saved in the corresponding controller.

Inthe following, you will onlyfind parameterswhichareimportant for theserial communication.For

further information on parameter setting of the controllers see the Manual 93XX or the Operating

Inst ructions of t he corresponding controller.

The PROFIBUS-DP transmits two different types of data between the host and the controllers.

l

Parameter, e.g. op eration parameters, diagnostic information, m ot or data.

In general, the transmission of parameters is not as time-critical as the transmission of the

second group of process data, but there is a larger data volume.

l

Process data, e.g. setpoints and actual value, which must be exchanged within a minimum

of t ime.

The data volume is small (e.g. 2 words with DRIVECOM or Lenze), which are to transmitted

cyclically.

For these two different tasks the transmitted data is divided into two logical communication

channels:

l

Parameter channel for the transfer of parameters

l

Process-data channel for fast transfer of process data. Process data are cyclically

transferred. Thus, the latest input and output data are constantly exchanged between the

host and the controllers.

Parameter setting

6.1 Parameters

Thesystem distinguishestwo parameter types: the Lenzeparameters which are implemented into

the Lenzecontrollers, and theDRIVECO Mparameters. Thischapter givesa shortdescriptionofthe

two parameter types and their relation to each other.

6.1.1 Lenze parameters

In general, the Lenze parameters of the Lenze controllers are addressed via the Lenze codes. For

detailed information about the Lenze parameters and their value ranges, see the Operating

Inst ructions of t he corresponding controllers.

Lenze codes

Inthese OperatingInstructions Lenzecodes are identified withL-Cxxxx, to ensurethat theyarenot

mixed up with the DRIVECOM index (e. g. L-C0001 for the Lenze code C0001).

Lenze code addressing

The access to Lenze parameters is possible. However, the addressing of the parameters (code

numbers)is shifted and calculated as follows:

Index = 24575 - LENZE_CODENR

Index

The index for Lenze code numbers is between 20576 (5060hex)and 24575 (5FFFhex).

Example:

The Lenze parameter L-C0001 (operating mode) can be accessed via the PROFIBUS-DP under

index 24574 ( = 24575 - 1).

hex

= 5FFF

- LENZE_CODENR

hex

hex

BA2131EN

6-1

Page 25

Parameter setting

Show/Hide Bookmarks

Lenze data types

The possible Lenze parameters and their value ranges can be obtained from the corresponding

Operating Instructions for the controller.

The data of the Lenze parameters are mainly represented in a fixed-point format of the data type

Integer32 with four decimal digits. This means, that the parameter value listed in the Operating

Instructions must be multiplied with 1000.

Example:

Operating Instructions L-C0039 (JOG)= 150.4 Hz

results in 150.4 x 10000 = 1504000

82Xxparameter sets

The 82XX controller is equipped with 2 parameter sets, which can be directly addressed via the

PROFIBUS. They are addressed by means of a code-digit offset:

l

Offset 0 addresses parameter set 1 with the Lenze codes L-C0000 to L-C1999

l

Offset 2000 addresses parameter set 2 with the Lenze codes L-C2000 to L-C3999

If a parameter is only available once (see 82XX Operating Instructions), use the code offset 0.

Example for L-C0011 (maximum field frequency):

L-C0011 in parameter set 1: Lenze code = 11

L-C0011 in parameter set 2: Lenze code = 2011

Changes of the parameters are automatically saved in the controller (see Operating Instructions

82XX). Exceptions are theprocess data,e.g. control words or setpoints.

(0016F300

dec

hex

)

Parameter sets for 8200 vector

The8200 vectorcontroller is equipped with4 parametersets, which can bedirectly addressed via

the PROFIBUS. They are addressed by means of a code-digit offset:

l

Offset 0 addresses parameter set 1 with the Lenze codes L-C0000 to L-C1999

l

Offset 2000 addresses parameter set 2 with the Lenze codes L-C2000 to L-C3999

l

Offset 4000 addresses parameter set 3 with the Lenze codes L-C3000 to L-C4999

l

Offset 6000 addresses parameter set 4 with the Lenze codes L-C6000 to L-C7999

If a parameter is only available once (see Operating Instructions 8200 vector), use the codeoffset

0.

Example for L-C0011 (maximum field frequency):

L-C0011 in parameter set 1: Lenze code = 11

L-C0011 in parameter set 2: Lenze code = 2011

L-C0011 in parameter set 3: Lenze code = 4011

L-C0011 in parameter set 4: Lenze code = 6011

Changes of the parameters are automatically saved in the controller (see Operating Instructions

8200 vector). Exceptions are the process data, e.g. control words or setpoints.

Parameter sets for 93XX

The 93XX controllers are equipped with 4 parameter sets for non-volatile storage. Another

parameter set is in the user memory of the controller. This is the current parameter set. Only the

current parameter set can be directly addressed via PROFIBUS. For the codes, see Operating

Instructions or Manual for 93XX . Changes of the current parameter set will be lost after switching

off the controller. Code C0003 is for saving the current parameter set. After switching on the

controller , parameter set 1 is automatically loaded into the current parameter set.

6.1.2 DRIVECOM pa ra meters

In the following, the controller parameters, which are standardized according to the DRIVECOM

profile20,arenamedDRIV ECOM parameters.Each DRIVECOM parameteris addressed by means

of the index.

6-2

BA2131EN

Page 26

Parameter setting

Show/Hide Bookmarks

6.1.3 Operating mode C0001

82XX / 8200 vector controllers

CodeC0001 (Operatingmode)determines thesource( terminal, keypad, PROFIBUS)which writes

the frequency setpoint (C0046)and the control word (C0135).

C0001 = 0 1 2 3

Read andwriteparameter yes yes yes yes

P arameter C0046 no yes no yes

Process data no no no yes

Independently of the selected operating mode (C0001), the controller can be inhibited under the

code C0040 via the PROFIBUS.

Please note that the operating mode C0001is available in both parameter sets.Thus, C0001 must

be set identically in both parameter sets.

PROFIBUScontrol (C0001= 3)is subject to theoperatingmodeinparameterset1. Terminalcontrol

(C0001 <> 3) is subject to the operating mode in parameter set 1.

93XX controllers

The93X Xcontroller does not provide an operating mode which can bechanged by only one code.

The93XXcontroller i operated via the“control codes“. By means ofthe control codesit is possible

to select the signal source valid for an input. Thesignal sourcecan be a terminal, an internalsignal

or a signal of a bus system.

For further information refer to the 93XX Manual.

6.1.4 Bus address/station address

To address the controllers in the PROFIBUS system, each participant gets an address. Each

participant must have a different address. This address is called station address.

The address can be set in two different ways:

l

Address setting via the keypad or PC program:

– Set the address under code C0009 in the controller.

– The valid address range is the unit address 3 ¤ 99.

l

Setting of the unit address through a master (only master class 2):

– With this method only one PROFIBUS participant must be connected. This can be achieved

by a special switch-on sequence.

– The Lenze setting of C0009 is 1. This means that the station address is addressed with 126.

If C0009 is set to 2, the station addresses 100 ¤ 125 can be selected.

BA2131EN

6-3

Page 27

Parameter setting

Show/Hide Bookmarks

Thefollowingtableshowstheassignmentoftheaddresses:

PROFIBUS-DP station address Mapping to code C0009 LECOM unit address

1-2 No (master addresses)

3-99 Yes (3-99)

100-125 Yes (C0009=2)

126 (Lenze setting ) Yes (C0009=1 )

6.1.5 Baud rate

Baud-ratesettingsarenot required.The2131 fieldbusmoduleisautomatically adjusted tothebaud

rate of the master.

6.1.6 Master settings

Themasterneedsaunit-descriptionfile(unitmaster-data file)foroperationwithPROFIBUS-DP.The

diskette provides the following files:

File name Meaning

L_AR00AA.GSD Unit master-data file to DIN 19245 T3

LE00A ATD.200 Contro ller master data file (type file) for Simatic-S5 COM-ET200 V4.X (IM308B )

LE00AAAX.200 Controller master data file (type data) forSimatic-S5 COM-ET 200V5.X(IM308C)

You also have to set:

Function Setting (depends on the master t ype)

Baud rate The 2131 module is equipped with an automatic baud-rate detection

Communication profile PROFIBUS-DPDINE 19245 T3

Slave-station address 126(Lenze setting)

DP-configuration data (configuration) see chapter 6.2

PNO-identification number 00AA

DPuser-datalength see chapter 6.2

Value the same as in controller parameterC0009 (see chapter 6.1.4 “Bus

address/station address“).

6.2 PROFIBUS-DP configuration

ThePROFIBUS-DPuser datalength is determined duringtheDPinitializationphase(configuration).

You can select from 4 fixed lengths.

The user data lengths for input data and output data must be the same.

For simplification we use the following abbreviations:

l

PIW:

Process input word (process data from the controller to the master)

l

POW:

Process output word (process data from the master to the controller)

hex

The 4 selectable user data lengths are:

l

2 words process data; label 71

PIW/POW 1 PIW/POW 2

Byte 1 Byte 2 Byte 3 Byte 4

6-4

(113)

hex

BA2131EN

Page 28

Parameter setting

Show/Hide Bookmarks

l

3 words process data; label 72

PIW/POW 1 PIW/POW 2 PIW/POW 3

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

l

DP parameter-setting channel1)+ 2 words process data;

label 73

DP parameter-setting channel PIW/POW 1 PIW/POW 2

Byte 1 Byte 8 Byte 9 Byte 10 Byte 11 Byte12

1) see chapter 6.3

l

DP parameter-setting channel1)+ 3 words process data;

label 73

DP parameter-setting channel PIW/POW 1 PIW/POW 2 PIW/POW 3

Byte 1 Byte 8 Byte 9 Byte 10 Byte 11 Byte 12 Byte 13 Byte 14

1) see chapter 6.3

hex71hex

hex72hex

(115, 113)

(115, 114)

hex

(114)

6.3 PROFIBUS-DP parameter-setting channel

ThePROF I BUSDPparameter-settingchanneloffersaparameter settinganddiagnosticspossibility

for controllers. It is therefore possible to access all Lenze parameters (codes).

If theDPparameter-setting channelisactive, it assignsthe first 8 bytes of theand input and output

data. The DP parameter-setting channel has the same structure for both transmission directions.

6.3.1 Structure of the DP parameter-setting channel

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Service Subindex Index

High byte

Byte 1: Service

Job and response control for the DP parameter-channel.

Bit no. Meaning

0-2 Service

Job for the controller. The bits are set only by the master.

l

0=nojob

l

1 = read job (read data from the controller)

l

2 = write job ( write data to the controller )

3 Reserved

4-5 Data length

Length of the data in the field data/error.

l

0=1byte

l

1=2byte

l

2=3byte

l

3=4byte

6 Handshake

Indicates a new job. The master changes this bit for every new job. The controller copies the bit to its response message.

7 Status

Status information from the controller to the master when sending acknowledgement. This bit informs the master whether the job

was carried out without faults.

l

0 = Job completed with fault.

l

1 = Job not completed. A fault occured. The data in the field Data/Error are interpreted as error message.

Index

Low byte

Data 4

(Erro r4)

Data 3

(Erro r3)

Data 2

(Error 2)

Data 1

(Error 1)

BA2131EN

6-5

Page 29

Parameter setting

g

Show/Hide Bookmarks

Byte 2: Subindex

l

The series 82XX do not have codes with subindex, the value is always 0.

l

With the series 93XX it is necessary for many codes to address them additionally via a

subindex.

Example: Code C0039 subindex 3 adresses JOG 3

Byte 3 and 4: Index

The parameters or the Lenze codes are selected with these two bytes according to the formula:

Index = 24575 - Lenze code number

Example:

The parameter C0012 (acceleration time) is to be addressed:

24575 - 12 = 24563 = 5FF3

The entries for this example would be:

l

Byte3:IndexHighByte=5F

l

Byte 4: IndexLow Byte = F3

hex

hex

hex

Byte5-8:data1-4;error1-4

Parameter value or fault information indicated with invalid access. The status ofthe bit Job/Status

determines the meaning of the data field.

Data

Parameter value, which assigns 1 to 4 bytes depending on the data format. Strings or data blocks

cannot be transferred.

The most common data format in Lenze controllers is a fixed-point format with 4 decimal places.

Pleasenote, that theseparametersmust bemultiplied by10,000,e.g. thevalue10willbedisplayed

as value 100,000.

Thedataisfiled accordingto theMotorolaformat, i.e. first highbyte/high word, secondlow byte/low

word.

Byte 5 High byte 1

Byte 6 Low byte 1

Byte 7 High byte 2

Byte 8 Low byte 2

High word D ouble word

Low word

Error

Fault detection (for description see the following table).

l

Byte 5: Error c lass

l

Byte 6: Error c ode

l

Byte 7: Additional code (high byte)

l

Byte8: Additionalcode(low byte)

6-6

BA2131EN

Page 30

Fault messages in the error field (Data/Error)

Show/Hide Bookmarks

Parameter setting

Error class Error

code

0 0 00 No fault

6 3 00 No access permission

6 5 10 Inadmissible job parameter

6 5 11 Invalid subindex

6 5 12 D ata toolong

6 7 00 The object does not exist

6 8 00 D ata types are notidentical

8 0 21 Cannot be executed because of local control

8 0 22 Cannot be executed because of unit status

8 0 30 Leave value range

8 0 40 Collision with other values

8 0 20 Service cannot be executed currently

Additional

code [hex]

Meaning

6.3.2 Parameter communication w ith the controller

Read job

1. Determine the user dataof thecontroller: i. e. determinethelocationof theDPuserdatain

thehost.

2. Enter the address of the desired parameter in the field ”Index and subindex“ (DPoutput

data).

3. Job/service = Read job and the bit “job/handshake“ must be changed (DP output data).

4. Check, whether the bit “job/handshake“ is the same for the DP input data and the DP output

data. If the bit “job/handshake“ is the same, the response has been received. You should

implement a time monitoring.

5. Check, whether the bit “job/status“ is set. If the bit “job/status“ is not set, the field

“data/error“ contains the required parameter value. If the bit “job/status“ is set, the reading

job is not executed properly and the field “data/error“ contains an error information.

Write job

1. Determine the user-data range of the controller, i. e. determine the location of the DP

user-data in the host system.

2. Enter the address of the desired parameter in the field “Index and subindex“ (DPoutput

data).

3. Entertheparameter valueinto thefield Data/Error.

4. Job/Service = Write job and the bit job/handshake must be changed (DP output data).

5. Check, whether the bit “job/handshake“ is the same for the DP input data and the DP output

data. If the bit “job/handshake“ is the same, the response has been received. You should

implement a time monitoring.

6. Check, whether the bit “job/status“ is set. If the bit “job/status“ is not set, the job has not

been executed properly and the field “data/error“ contains an error information. Otherwise,

the job has been executed without any faults.

BA2131EN

6-7

Page 31

Parameter setting

Show/Hide Bookmarks

6.3.3 Example 1: Write parameter

Task

The acceleration time C0012 of the controller is to be changed to 20 s.

Job (byte 1/service)

Bit 0-2 = 2 Write job (xxxx x010)

Bit 3 = 0 Reserved (xxxx 0010)

Bit 4-5 = 3 Data length 4 byte (xx11 0010)

Bit 6 = X Handshake changes frequently (xX 110010)

Bit 7 = 0 Only relevant with response (0x110010)

SUBINDEX (byte 2)

Subindex = 0, as there is not subindex under code C0012.

INDEX (byte 3 + 4)

Index calculation:

Index = 24575 - code number

Index = 24575 - 12 = 24563 = 5FF3hex

DATA(byte5-8)

Calculation of the value for the acceleration time

20 s x 10.000 = 200.000 = 00 03 0D 40hex

Response to drive

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Service Subindex Index

High byte

0x11 0010 0 5F F3 00 03 0D 40

Index

Low byte

Data 4 Data 3 Data 2 Data 1

Response of the c ontroller w hen no fault occurs

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Service Subindex Index

High byte

0x11 0000 0 5F F3 00 00 00 00

Index

Low byte

Data 4 Data 3 Data 2 Data 1

6-8

BA2131EN

Page 32

6.3.4 Example 2: Write parameter

Show/Hide Bookmarks

Task

The heatsink temperature (value = 43 C) C0061 is to be read by the controller.

Job (byte 1/service)

Bit 0-2 = 2 Write job (xxxx x001)

Bit 3 = 0 Reserved (xxxx 0001)

Bit 4-5 = 3 Data length 4 byte (xx11 0001)

Bit 6 = X Handshake changes frequently (xx110001)

Bit 7 = 0 Only relevant with response (0x110001)

SUBINDEX (byte 2)

Subindex = 0, as there is not subindex under code C0061.

INDEX (byte 3 + 4)

Parameter setting

Index calculation:

Index = 24575 - code number

Index = 24575 - 61 = 24514 = 5FC2

Response to drive

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Service Subindex Index

0x11 0001 0 5F C2 00 00 00 00

Response of the c ontroller w hen no fault occurs

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Service Subindex Index

0x11 0000 0 5F C2 00 06 8F B0

Index of the read request = 5FC2

Data1todata4=43C x 10000 = 430000 = 00 06 8F B0

6.4 Process data

High byte

High byte

hex

hex

Index

Low byte

Index

Low byte

Data 4 Data 3 Data 2 Data 1

Data 4 Data 3 Data 2 Data 1

BA2131EN

Process data are data memories in which several parameters for a new parameter - the process

data - are summarized for fast transmission.Thehost has direct access to theprocessdata. In the

PLC, for instance, the data are directly assigned to the I/O area. These process data are cyclically

exchanged between the controller and the master. They are subdivided into

l

Process output data (PO data)

l

Process input data (P Idata)

Herethedataflowstartsfrom themaster,i.e.the POdataofthe masterarePIdataforthecontroller.

The controller getsthecontrolinformation fromthemaster andreturnsstatus information.

6-9

Page 33

Parameter setting

Show/Hide Bookmarks

6.4.1 Process-data assignments for 82XX

Structure of the PO- data response (data to drive)

Byte 1 Byte 2 Byte 3 Byte 4

DRI V ECOMcontrol word

High byte

DRIV ECOM control word: see chapter 6.5.3 or chapter 6.5.2.

Setpoint: frequency setpoint

Here thefrequency setpoint is preselected as process data word. The standardization differs from

C0046. It is indicated with a sign:

Structure of the PI data response (data from drive)

Byte 1 Byte 2 Byte 3 Byte 4

DRIVECOM status word

High byte

DRI V ECOMcontrol word

Low byte

á

24000 =á480 Hz.

DRIVECOM status word

Low byte

Setpoint

High byte

Actual value

High byte

Setpoint

Low byte

Actual value

Low byte

DRIV ECOM status word: see chapter 6.5.4 or chapter 6.5.2.

Actual value: act. frequency value

The actual frequency value is indicated with a sign:

6.4.2 Process-data assignment for 8200 vector

Structure of the PO data response

Digital and analog input and output signals can be freely configured (see Operating Instructions for

8200 vector; codes C0410, C0412, C0417 and C0421)

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

DRIVECOM

Control word

High byte

Structure of the PI- data response

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

DRIVECOM

Status word

High byte

DRIVECOM

Control word

Low byte

DRIVECOM

Status word

Low byte

AIF-IN .W1

High byte

AIF-OU T.W 1

High byte

AIF-IN .W1

Low byte

AIF-OU T.W 1

Low byte

á

24000 =á480 Hz.

AIF-IN .W2

High byte

AIF-OU T.W 2

High byte

AIF-IN .W2

Low byte

AIF-OU T.W 2

Low byte

6-10

BA2131EN

Page 34

6.4.3 Process-data assignment for 93XX

Show/Hide Bookmarks

Unlike the82XXcontroller,the process-data assignment ofthe 93XXcontroller canbe changed via

reconfiguration of the function blocks AIF-IN and AIF-OUT.

Structure of the PO data response

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

DRIVECOM

Control word

High byte

AIF-IN.W1 to AIF-IN.W2 depend on the signal configuration selected under L-C0005 and are then

sensibly preassigned.

Signal configuration (L-C0005) AIF-IN.W1 AIF-IN.W2

Speed control

1003

1013

1113

Torque control

4003

4013

4113

DF master

5003

5013

5113

DF-slave bus

6003

6013

6113

DF-slave cascade

7003

7013

7113

Not equal to xxx3 (except own

configurations)

DRIVECOM

Control word

Low byte

AIF-IN .W1

High byte

NSET-N

Speed setpoint

MCTRL-MADD

Torque setpoint

NSET-N

Speed setpoint

DFSET-A-TRIM

Phase trimming

DFSET-V P-DIV

DF factor

Not assigned Not assigned

Parameter setting

AIF-IN .W1

Low byte

AIF-IN .W2

High byte

Not assigned

Not assigned

Not assigned

DFSET-N-TRIM

Speed trimming

DFSET-A-TRIM

Phase trimming

AIF-IN .W2

Low byte

For detailed description of the 93XX signal configuration see the Operating Instructions for 93XX

(only the main configurations: 1000, 4000, 5000, etc.) or the Manual 93XX.

In the controller other signals can be assigned to AIF-IN.W1 to AIF-IN.W2. For this, the

function-block configuration - described in the Manual 93XX - is used. The function block AIF-IN

determines the input data of the controller as data interface for the 2131IB fieldbus module.

For more detailed information about the function block AIF-IN, see the Manual 93XX.

BA2131EN

6-11

Page 35

Parameter setting

X

Show/Hide Bookmarks

A IF -IN *

)

AIF-C TRL.B3

16 Bit

C 0136/3

16 Bit

16 Bit

16 Bit

C 0855/1

16 binary

signals

C 0855/2

16 binary

signals

16 Bit

Low W ord

16 Bit

H igh W ord

AIF-C TRL.B8

AIF-C TRL.B9

AIF-C TRL.B10

AIF-C TRL.B11

C 0856/1

16 Bit

Low W ord

16 Bit

C 1197

H igh W ord

C 0856/2

C 0856/3

C 0857

AIF-IN

AIF-C TRL.B3

AIF-C TRL.B8

AIF-C TRL.B9

AIF-C TRL.B10

AIF-C TRL.B11

Bit 0

16 Bit

C ontrol w ord

Bit 15

B y te 3 ,4

1

B y te 5 ,6

B y te 7 ,8

16 Bit

16 Bit

16 Bit

C 0855/1

16 binary

signals

C 0855/2

16 binary

signals

16 Bit

Low W ord

16 B it

High W ord

C 0856/1

C 0856/2

C 0856/3

C 0857

DCTRL

QSP

DISABLE

CINH

TRIP -SE T

TRIP -R ESET

AIF-CTRL.B0

AIF-CTRL.B1

AIF-CTRL.B2

AIF-CTRL.B4

AIF-CTRL.B5

AIF-CTRL.B6

AIF-CTRL.B7

AIF-CTRL.B12

AIF-CTRL.B13

AIF-CTRL.B14

AIF-CTRL.B15

A IF - IN .W 1

A IF - IN .W 2

AIF-IN.W 3

AIF-IN.B0

AIF-IN.B2

. . .. . .

A IF - IN .B 1 4

A IF - IN .B 1 5

AIF-IN.B16

AIF-IN.B17

A IF - IN .B 3 0

A IF - IN .B 3 1

A IF - IN .D 1

Bit 0

S teuerw ort

Bit 15

B y te 3 ,4B y te 5 ,6

X1

B y te 7 ,8

DCTRL

QSP

DISABLE

CINH

TRIP -S ET

TRIP -R ESE T

AIF-C TRL.B0

AIF-C TRL.B1

AIF-C TRL.B2

AIF-C TRL.B4

AIF-C TRL.B5

AIF-C TRL.B6

AIF-C TRL.B7

AIF-CTRL.B12

AIF-CTRL.B13

AIF-CTRL.B14

AIF-CTRL.B15

A IF - IN .W 1

A IF - IN .D 2

A IF - IN .W 2

A IF - IN .W 3

AIF-IN.B0

AIF-IN.B2

. . .. . .

A IF - IN .B 1 4

A IF - IN .B 1 5

AIF-IN.B16

AIF-IN.B17

A IF - IN .B 3 0

A IF - IN .B 3 1

AIF-IN.D1

2111IBU003

Fig. 6-1 Function block AIF-IN and AIF-IN

(AIF-IN*)is available for the 9300 technology variants servo inverter, positioning controller and cam profiler as of software

version2.0)

DRIVECOM control word:

The assignment of t he DRIVECOM control word differsfrom the AIFcontrol word

For further information see chapter 6.5.2 or chapter 6.5.3.

Structure of the PI- data response

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

DRIVECOM

Status word

High byte

For more detailed information about the function block AIF-OUT, see the Manual 93XX.

6-12

DRIVECOM

Status word

Low byte

*)

AIF-OU T.W 1

High byte

BA2131EN

AIF-OU T.W 1

Low byte

AIF-OU T.W 2

High byte

AIF-OU T.W 2

Low byte

Page 36

C 0156/1

Show/Hide Bookmarks

C 0156/6

C 0156/7

C 0850/1

C 0850/2

C 0850/3

C 0116/1

C 0116/16

C 0116/17

C 0116/32

C 0851

STAT

STAT.B0

DCTRL-IMP

...

STAT.B14

STAT.B15

C 0858/1

C 0858/2

C 0858/3

FDO -0

...

FDO -15

FDO -16

...

FDO -31

AIF-O UT.D 1

C 0859

FDO

16 Bit

AIF-O UT.W 1

AIF-O UT.W 2

AIF-O UT.W 3

16 Bit

Low W ord

16 Bit

H igh W ord

16 Bit

Low W ord

16 Bit

H igh W ord

C 0852

0

1

2

C 0853

0

1

2

AIF-O UT

Bit 0

Bit 15

Bit 0

Bit 15

Bit 0

Bit 31

Parameter setting

)

AIF-O UT *

STAT

STAT.B0

C 0156/1

DCTRL-IMP

...

STAT.B14

C 0156/6

STAT.B15

Status w ord

B y te 3 ,4

X1

B y te 5 ,6

B y te 7 ,8

C 0156/7

C 1195

C 0850/1

C 0850/2

C 0850/3

C 0116/1

C 0116/16

C 0116/17

C 0116/32

C 0851

AIF-O UT.D 2

C 1196

AIF-O UT.W 1

C 0858/1

C 0858/2

C 0858/3

FDO -0

...

FDO -15

FDO -16

...

FDO -31

AIF-O UT.D 1

C 0859

FDO

16 Bit

16 Bit

Low W ord

16 Bit

H igh W ord

AIF-O UT.W 2

AIF-O UT.W 3

16 Bit

Low W ord

16 Bit

H igh W ord

16 Bit

Low W ord

16 Bit

H igh W ord

C 0854

0

3

C 0852

0

1

2

3

C 0853

0

1

2

Bit 0

Bit 15

Bit 0

Bit 15

Bit 0

Bit 31

Status w ord

B y te 3 ,4

X1

B y te 5 ,6

B y te 7 ,8

2111IBU002

Fig. 6-2 Function block AIF-OUT and AIF-OUT*)(AIF-OUT*)is available for the 9300 technology variants servo inverter, positioning

controller and cam profiler as of software version 2.0)

DRIVECOM status word:

The assignment of the DRIVECOM status word differs from the AIF status word!

For further information see chapter 6.5.2 or chapter 6.5.3.

6.5 Controller status

6.5.1 Standard unit control

For standard control you enter the control information via the corresponding control inputs

(terminal):

With82XXcontrollers,the corresponding control inputisselectedviathe LenzeparameterL-C0001

(operating mode).

Information about the current unit status (Fig. 6-3, see below) (rectangles) are available in the

DRIVECOM parameter “status word“. Commandsin the DRIVECOM parameter“controlword“ are

switched off andcannotchangethecontrollerstatus.Thecommandsto changethecontrollerstatus

are entered via the corresponding control inputs. These commands are marked by arrows in the

following diagram.

BA2131EN

6-13

Page 37

Parameter setting

Show/Hide Bookmarks

Switch on unit

NOT READY TO SWITCH ON

Status word xxxx xxxx x0xx 0000

automatically when

initializing is completed

READY TO SWITCH ON

Status word xxxx xxxx x01x 0001

automatically

SWITCHED ON

Status word xxxx xxxx x01x 0011

Ctrl.enable** Ctrl.inhibit**

OPERATION ENABLED

Status word xxxx xxxx x01x 0111

QSP**

TRIP (fault)

Fault

Status word xxxx xxxx x0xx 1000

TRIP reset**

Note:

The terms marked with ** are

commands

Fig. 6-3 Status diagram for standard unit control

Status

NOT READY TO SWITCHONThe controller is being initialized and is not yet ready to operate.

READYTOSWITCHON The controller is inhibited and waits for the power stage to be charged. It then automatically switches to the status “SWITCHED ON“.

SWI TCHEDON The controller is inhibited and waits for controller enable.

OPER A TI ONENABLED The controller is enabled. In this status, a pulse inhibit can be set automatically.

FAUL T The controller is in the status “FAULT“ (TR IP ) .

Meaning

It then automaticallyswitchesto the statusREADYTOSWITCHON.

6.5.2 DRIVECOM unit control

With PROFIBUScontrol (for 82XX:Lenze parameter L-C0001=3; for 93XX:always)and whenusing

the 2131 fieldbus module, Lenze controllers have a controller status as standardized in the

DRIV ECOM profile 20.

Information about the current unit status (Fig. 6-4, see below) (rectangles) are available in the

DRIVECOM parameter “status word“. Commands in theDRIVECOM p arametercontrol word can

change the controller status. These commands are marked by arrows in the following diagram.

6-14

BA2131EN

Page 38

Parameter setting

Show/Hide Bookmarks

NOTREADY TO SWITCHON

Status word xxxx xxxxx0xx 0000

automatically when in-

itializing is completed

Status word xxxx xxxxx0xx 0000

9

Inhibit voltage

xxxx xxxx xxxxxx0x

READY TO SWITCH ON

Status word xxxx xxxxx01x 0001

8

Standstill

xxxx xxxx xxxx

x110

Status word xxxx xxxxx01x 0011

Example:

Status information by means of “status word“

Bit 15 ... bit 0 (binary display)

Switch on unit

SWITCH ONINHIBIT

10

2

Standstill

xxxx xxxx

xxxx x110

3

Switchon

xxxx xxxx

xxxx x111

SWITCHED ON

Inhibit voltage

xxxx xxxx xxxxxx0x

Quick stop

xxxx xxxx xxxxx01x

6

Standstill

xxxx xxxx xxxxx110

13

Fault

was

recognized

MALFUNCTION REACTIONACTIVE

Status word xxxx xxxxx0xx 1111

automatically when

fault reactionis over

Fault

Status word xxxx xxxxx0xx 1000

14

Reset fault

xxxx xxxx 0xxx xxxx

xxxx xxxx 1xxx xxxx

12

Inhibit voltage

xxxx xxxx xxxxxx01

or

quickstop completed

7

45

Operation enable

xxxx xxxx xxxx1111 and

act. speed value <> 0*

OPERATION ENABLED

Status word xxxx xxxxx01x 0111

Inhibit RFGismappedtoquick

stop

Operation inhibit

xxxx xxxx xxxx0111 or act.

speed value = 0*

QUICK STOP ACTIVE

Status word xxxx xxxxx01x 0111

11

Quick stop

xxxx xxxx xxxxx01x

*onlyeffectivefor821X,8200 vectorwhenthe

automatic DC-injection brakeisactive(L-C0106,

Note:

L-C2106 <> 0)

Fig. 6-4 Status diagram DRIVECOM unit control

Status

Meaning

NOT READY TO SWITCHONThe controller is being initialized and is not yet ready to operate. It automatically switches to the status READYTO SWITCH ON.