Page 1

EDB2130IB/GB

k

00381616

L

Antriebstechni

Operating Instructions

PROFIBUS-FMS/DP

Bus interface module

Type 2130IB

Page 2

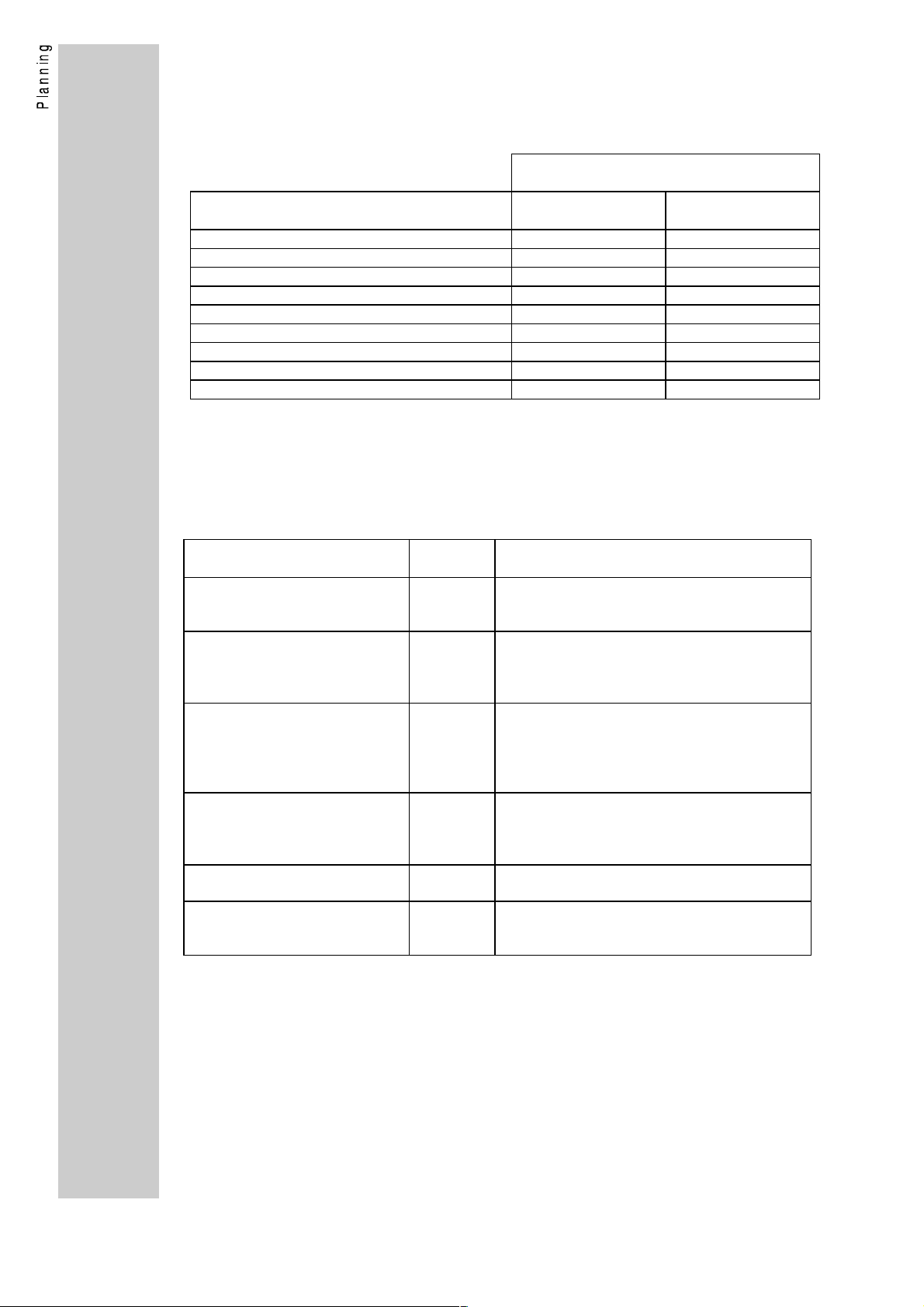

These operating instructions are valid for the interface modules as of nameplate designation:

2130 IB 0x. 0x. V001 PROFIBUS-FMS/DPwith RS485

2130 IB 0x. 0x. V002 PROFIBUS-FMS/DP with

optical fibre cable

together with the controller series as of

Controller type

Design

Hardware version + index

Software version + index

4900 E

3x. 5x.

8600 E 5x. 6x. Frequency inverter

9200 E 4x.

2211 PP. 0B. 1x. Position control

2212 WP. 0B. 1x. Winding calculator

4x.

5x.

4x.

5x.

5x.

DC controller

Servo controller

Variant

Explanation

Important:

These operating instructions are only valid together with the

operating instructions of the suitable controllers or automation

modules!

corresponds to the German edition of 15 February, 1995

revised

Edition of: 10.04.1995

Date of print: 24.04.1995

Page 3

How to use these operating

instructions...

To locate information on specific topics, simply refer to the table of

contents at the beginning and to the index at the end of the operating

instructions.

These operating instructions use a series of different symbols to

provide quick reference and to highlight important items.

This symbol refers to items of information intended to facilitate

operation.

Notes which should be observed to avoid possible damage to or

destruction of equipment.

Notes which should be observed to avoid health risks to the operating

personnel.

L

1

Page 4

Safety information

The equipment described is intended for use in industrial drive

systems.

This equipment can endanger life through rotating machinery and

high voltages, therefore it is essential that guards for both electrical

and mechanical parts are not removed.

The following points should be observed for the safety of the

personnel:

• Only qualified personnel familiar with the equipment are

permitted to install, operate, and maintain the devices

• System documentation must be available and observed at all

times.

• The system must be installed in accordance with local

regulations.

A qualified person is someone who is familiar with all safety notes

and established safety practices, with the installation, operation and

maintenance of this equipment and the hazards involved. It is

recommended that anyone who operates or maintains the electrical

or mechanical equipment should have a basic knowledge of First

Aid. As a minimum, they should know where the First Aid equipment

is kept and the identity of the official First Aiders.

These safety notes do not represent a complete list of the steps

necessary to ensure safe operation of the equipment. If you require

further information, please contact your nearest Lenze

representative.

The information in these operating instructions applies only to the

hardware and software versions that are indicated on the cover

page.

The specifications, processes, and circuitry described in these

operating instructions are for guidance only and must be adapted to

your own specific applications.

Lenze does not guarantee the suitability of the processes and circuitry

described in these operating instructions.

The specifications in these operating instructions describe the

features of the products, without guarantee.

Lenze personnel have carefully checked these operating

instructions and the equipment it describes, but cannot be held

responsible for its accuracy.

2

L

Page 5

Contents

Planning

1. General information about PROFIBUS 7

1.1. Structure of the PROFIBUS system 9

1.1.1. Explanations about PROFIBUS-DP 10

1.1.2. Explanations about PROFIBUS-FMS / mixed operation 11

1.2.3. Selection of the PROFIBUS operating mode 12

1.2.4. Compatibility with Siemens SINEC-L2 12

2. Technical data 13

2.1. General data 13

2.2. Protocol specific data 13

2.2.1. PROFIBUS-DP 13

2.2.2. PROFIBUS-FMS 13

2.3. Dimensions of the 2130IB board 14

2.4. Scope of supply 15

2.5. Manufacturer's Declaration 16

2.5.1. Application as directed of the 2130IB module 16

3. Installation 17

3.1. Installation 17

3.2. Wiring 17

3.2.1. 2130IB.V001 (RS485) 17

3.2.2. 2130IB.V002 (OFC) 19

3.2.3. Additional procedure for FMS / mixed operation 20

L

3

Page 6

Programming

1. Commissioning 22

1.1. Code numbers / Index 22

1.2. How to install the PROFIBUS software 22

1.3. Commissioning sequence 23

1.3.1. Base setting of the drive system 24

1.3.2. PROFIBUS bus parameters 27

1.3.3. PROFIBUS drive control 28

2. 2130IB code table 32

3. PROFIBUS operating mode 34

3.1. PROFIBUS-DP operating mode 35

3.1.1. Simatic-S5 37

3.1.1.1. COM-ET200 settings 37

3.1.1.2. Example program 37

3.1.2. Diagnosis data 38

3.1.3. DP process data 40

3.1.4. DP user data 41

3.1.5. DP parameter setting channel 42

3.1.6. DP command Sync/Unsync 45

3.1.7. DP command Clear_Data 45

3.2. Operating mode PROFIBUS mixed operation (FMS/DP) 46

3.2.1. FMS process data 47

3.2.1.1. Access to process data 47

3.2.2. Communication services 48

3.2.2.1. Entries in the communication reference list 48

3.2.2.2. Initiate 49

3.2.2.3. Abort 49

3.2.2.4. Status 49

3.2.2.5. Get-OV 49

3.2.2.6. Identify 50

3.2.2.7. Read / Write 51

4

L

Page 7

4. DRIVECOM parameters 52

4.1. DRIVECOM code table 52

4.2. Controller states 54

4.2.1. Status diagram of standard control 54

4.2.2. Status diagram DRIVECOM control 56

4.2.3. Control word (6040

4.2.4. Status word (6041

4.3. Ramps for quick stop / disable ramp function generator /

QSP 64

4.3.1. Ramp-min function 64

4.3.2. Speed quick stop (604A

4.3.3. Quick stop time (6051

4.4. Malfunction / Monitoring 66

4.4.1. Malfunction code (603F

4.5. Process data configuration 67

4.5.1. Process input data description (6000

4.5.2. Process output data description (6001

4.5.3. Process output data enable (6002

4.6. Process data 70

4.6.1. Process input data (6010

4.6.2. Process output data (6011

4.7. Speed/Velocity channel 71

4.7.1. Pole number (604D

4.7.2. Face value factor (604B

4.7.3. Speed reference value (604E

4.7.4. Nominal speed (6042

4.7.5. Speed reference variable (6043

4.7.6. Actual speed (6044

4.7.7. Nominal percentage (6052

4.7.8. Percentage reference variable (6053

4.7.9. Actual percentage (6054

4.7.10. Speed-min-max-amount (6046

4.7.11. Ramps 75

4.7.11.1. Ramp-min function 75

4.7.11.2. Speed acceleration (6048

4.7.11.3. Speed deceleration (6049

4.7.11.4. Ramp function time (604F

4.7.11.5. Slow down time (6050

)58

hex

)62

hex

)64

hex

)65

hex

)66

hex

)69

hex

)69

hex

)70

hex

)70

hex

)71

hex

)71

hex

hex

)72

hex

)72

hex

)73

hex

hex

)72

hex

)73

hex

)73

hex

)74

hex

)75

hex

)76

hex

)76

hex

)76

)73

hex

)74

5. Lenze parameters 77

5.1. Lenze code addressing 77

5.2. Lenze data types 77

5.3. AIF process data base controller 78

5.4. Lenze automation module 79

5.4.1. Automation control word (58C5

5.4.2. Automation status word (58C4

5.4.3. AIF process data automation module 84

6. Glossary 85

Index 88

)79

hex

)82

hex

L

5

Page 8

6

L

Page 9

Planning

1. General information about PROFIBUS

The 2130IB interface module is used for serial connection of Lenze

controllers with the standardized serial communication system

PROFIBUS (Process Field Bus). PROFIBUS is suitable for parameter

setting and control of controllers via a host.

The following PROFIBUS variants are supported (see figure below):

• PROFIBUS-FMS (DIN 19245 part 1 and part 2)

• PROFIBUS-DP (DIN19245 part 1 and part 3)

In a PROFIBUS system, hosts, PC or PLC are called master, and

controllers are slaves.

The different PROFIBUS operating modes

PROFIBUS operat. modes

DP operat.

Both PROFIBUS variants have an identical wiring. Their

communication profile, however, is different.

Data are transmitted via RS485 bus (2130IB.V001) or optical fibre

cables (2130IB.V002).

For the complex tasks in power transmission it has become a

necessity for the component suppliers to agree about the most

important device functions and parameters. Therefore, more than 30

international drive manufacturers have come together to form the

DRIVECOM User Group e.V.

Lenze and the other members have brought these functions together

in a so-called profile (DRIVECOM profile power transmission 21) on

the basis of the PROFIBUS standard (part 2). This profile is

implemented on the 2130IB bus interface module 2130IB.

The DRIVECOM profile definition is a useful supplement of

standardardized communication for the user and describes in general

terms the data contents and the controller behaviour.

FMS operat.

Mixed operation

(DP operation

and FMS operation)

7

Page 10

The 2130IB bus interface module has the following features:

• Slave interface module for the communication system PROFIBUS

with the communication profiles

PROFIBUS-FMS and PROFIBUS-DP

• Bus connection according to the RS485 standard (2130IB.V001) or

optical fibre cables according to Siemens SINEC-L2FO

(2130IB.V002).

• Baud rate from 93.75 kBaud to 1.5 MBaud

• Additional module for the Lenze series 4900, 8600 and 9200.

• Can be combined with the automation modules 2211PP, 2212W P

• Standardised parameters and controller functions according to the

DRIVECOM profile 21

• Parameter setting channel as option for PROFIBUS-DP

• Access to all Lenze parameters

• LECOM-A/B interface at the device remains active

• Intelligent module with 16-bit microprocessor

8

L

Page 11

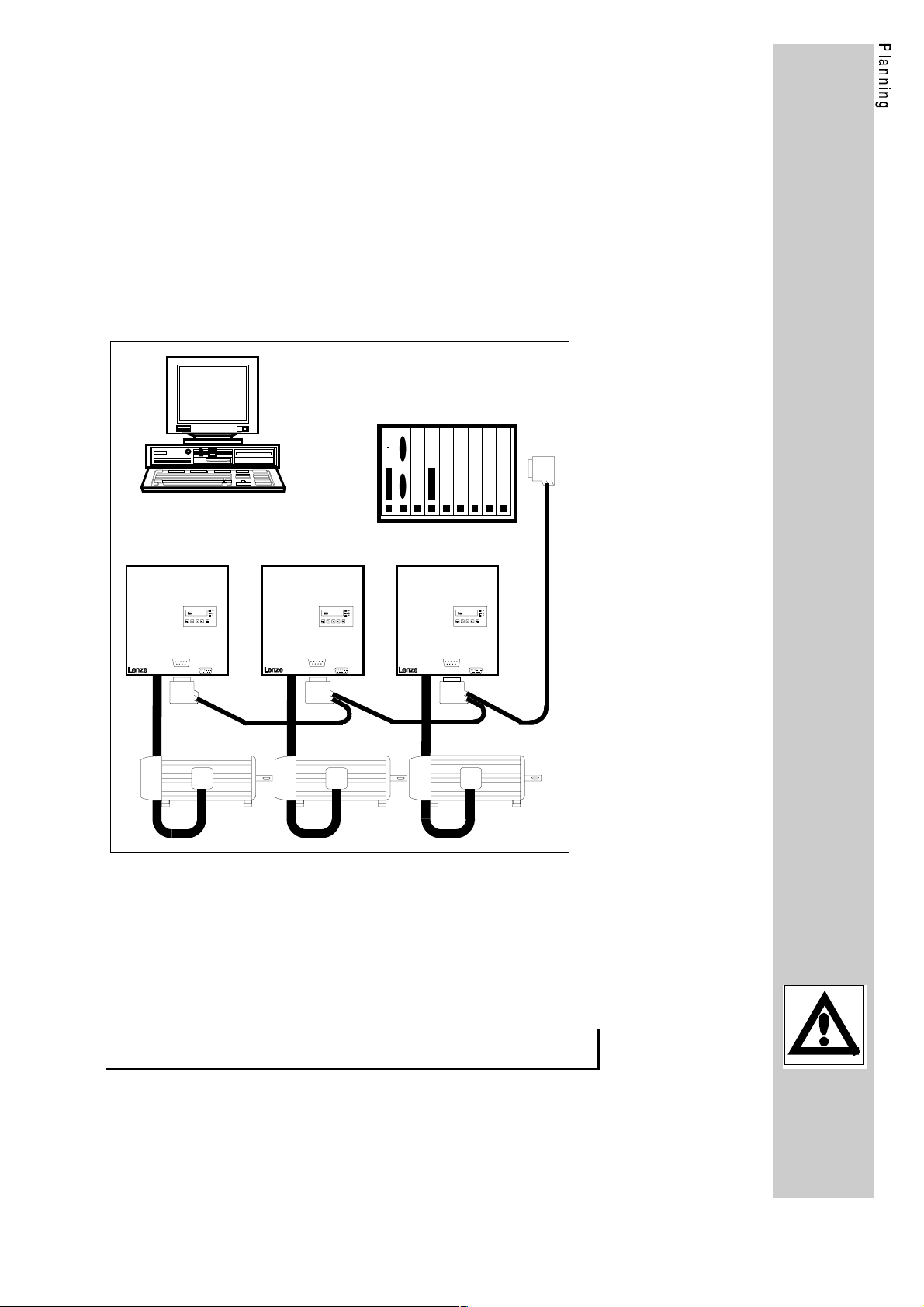

1.1. Structure of the PROFIBUS system

The PROFIBUS network according to DIN 19245 part 1, consists of an

RS485 connection.

As standard, you can connect a maximum of 32 participants (including

hosts) to the RS 485 bus. Using repeaters this structure can be

extended to a maximum of 127 participants in the whole bus system.

The repeaters can also be used to achieve line or tree topologies. The

maximum extension of the bus system depends on the baud rate and

the number of repeaters.

For more information, please consult the documentation of the control

manufacturer.

PROFIBUS using RS485 connection (without repeaters)

Host (Master)

Controller 1 Controller 2 Controller 3

8600

4900

9200

8600

4900

9200

PROFIBUS

LECOM-AB

Motor 1 Motor 3

PROFIBUS

Motor 2

LECOM-AB

8600

4900

9200

PROFIBUS

LECOM-AB

Apart from the RS485 connection you can also use an optical fibre

cabling. Here, the Siemens system SINEC-L2FO is used mainly,

where point-to-point and star connections (using active star

connectors) are possible.

Note:

The module variant 2130IB.V002 has a connection for OFC plastic

fibres for distances from 5 m to 25 m.

9

Page 12

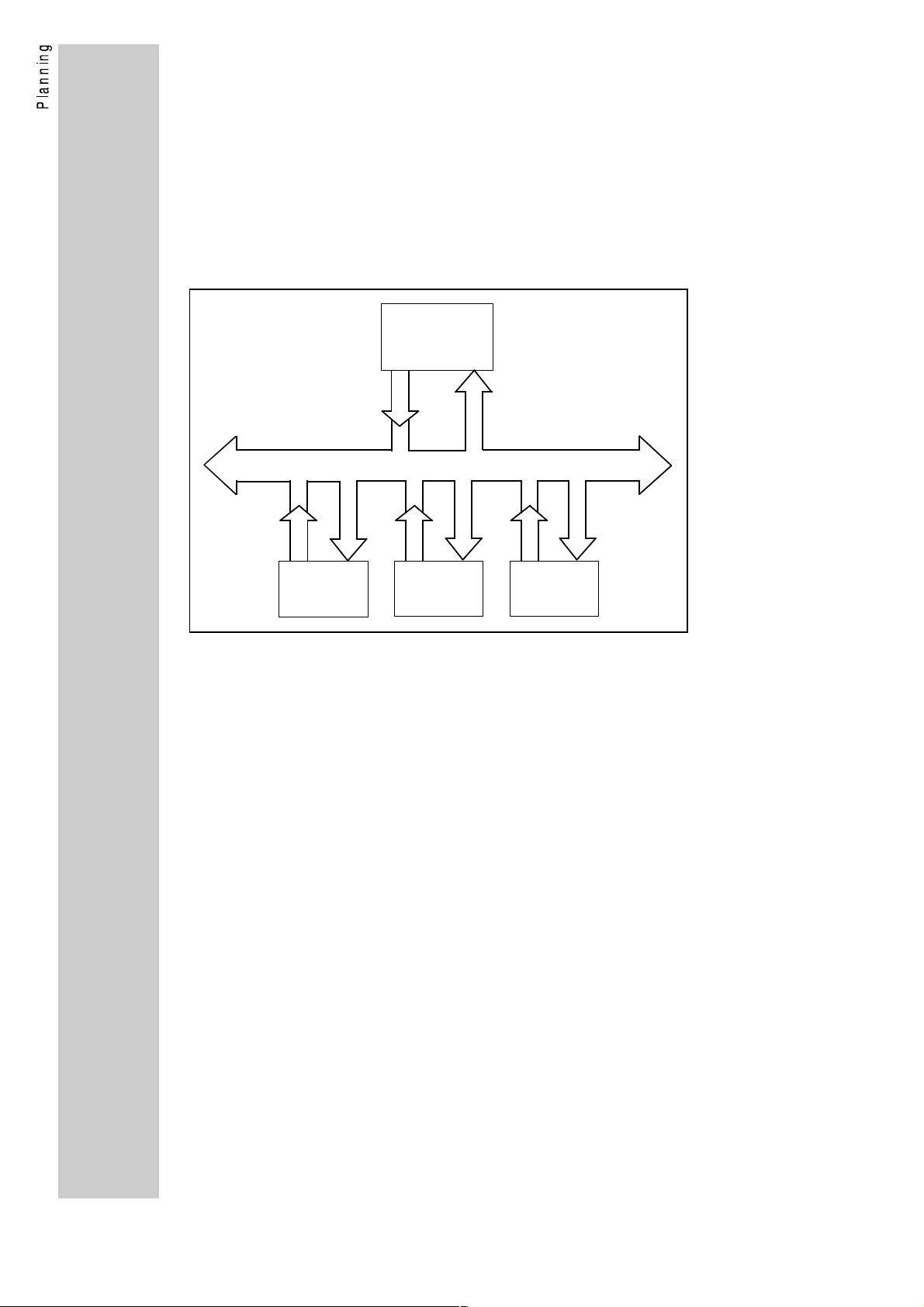

1.1.1. Explanations about PROFIBUS-DP

PROFIBUS-DP is the variant for sensors/actors, when a higher

process response is required. PROFIBUS-DP connects the central

automation devices, like for example programmable logic controllers,

via a fast serial connection using decentral input and output devices,

sensors and actors such as controllers.

The main task of the PROFIBUS-DP system is the fast cyclic data

exchange between the central automation device (master) and the

peripherial devices (slaves); see figure "standard structure".

Standard structure

Master

DP

SlaveSlave

The explanation of the PROFIBUS-DP functions of the Lenze

controller can be obtained from the paragraph "Operating mode

PROFIBUS-DP" (page 35).

Slave

10

L

Page 13

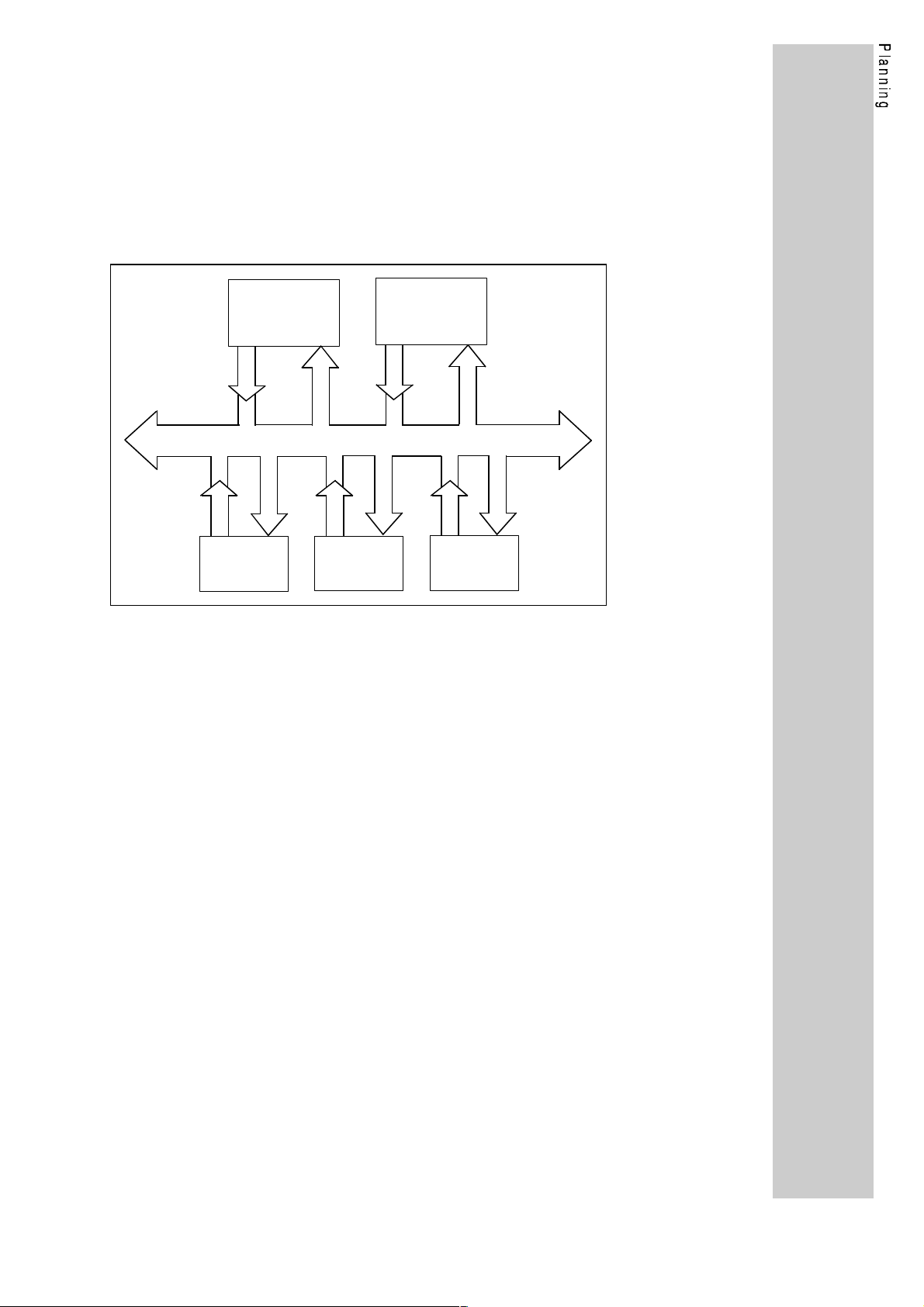

1.1.2. Explanations about PROFIBUS-FMS / mixed operation

PROFIBUS-FMS is the standard PROFIBUS according to part 1 and

part 2 of DIN19245. This operating mode supports the communication

on a bus with several masters (e.g. connected PLC systems) and with

a number of slaves (e.g. controllers). In addition, a mixed bus access

procedure is possible, where several PROFIBUS masters (e.g. PLC

systems) with the same priority can have access to PROFIBUS slaves

(e.g. controllers); see figure "extended structure".

Extended structure

Master

Master

DP, FMS or mixed operation

Slave

PROFIBUS-FMS is based on the description of objects. Devices are

written in as virtual field devices (VFD = virtual field device); with one

device having several VFDs. Parameters or variants are displayed as

objects, which can be read out or written in using the services "Read"

or "Write", when an index (index + subindex) is specified. The FMS

device supplies an object description of every variable or data type

which contains the most important information about the

communication.

Slave

Slave

In a mixed PROFIBUS system, you can operate PROFIBUS-DP

devices and PROFIBUS-FMS devices on the same bus.

In a mixed system, however, only participants with the same

communication profile (FMS or DP) are able to communicate with

each other.

Lenze controllers have both communication profiles. In the operating

mode "mixed operation" PROFIBUS-FMS and PROFIBUS-DP are

active at the same time. This means that in a mixed system the Lenze

controller can be called up by PROFIBUS-FMS masters and

PROFIBUS-DP masters.

A disadvantage of the mixed operation compared with the pure

PROFIBUS-DP operation is the lower protocol efficiency. There are no

disadvantages compared with the pure PROFIBUS-FMS operation.

Therefore, a special operating mode for PROFIBUS-FMS for the

controller is not necessary.

The description of the PROFIBUS-FMS functions of the Lenze

controller can be obtained from the chapter "operating modeOperating

mode PROFIBUS mixed operation (FMS/DP)" (page 46).

11

Page 14

1.2.3. Selection of the PROFIBUS operating mode

Select the desired PROFIBUS operating mode using the following

table.

PROFIBUS operating mode for the

controllers (parameter L-C1900)

Criteria DP operation

(factory setting)

PROFIBUS-DP master available yes yes (DP)

PROFIBUS-FMS master available no yes (FMS)

Several control masters necessary no yes (FMS)

Control of the controller yes yes (FMS/DP)

Parameter setting of the controller yes yes (FMS/DP)

DRIVECOM profile 21 yes yes (FMS/DP)

Baud rate up to 1.5MBaud yes yes (FMS/DP)

Automatic baud rate recognition yes no

Data transmission time / cycle time small medium

Mixed operation

1.2.4. Compatibility with Siemens SINEC-L2

Siemens designates the PROFIBUS communication as SINEC-L2 .

There are a number of variants; their compatibilty with the module

2130IB is listed in the following.

Siemens SINEC-L2 variant Comp. w.

2130IB

SINEC-L2-FMS Yes FMS = "Fieldbus Message Specification"

SINEC-L2-DP (standard) Yes DP = Decentral peripherial units

SINEC-L2-DP (Siemens) No DP = Decentral peripherial units.

SINEC-L2-STF or

SINEC L2-TF

SINEC-L2-Layer2 No Siemens-specific communication of a direct

SINEC-L2-FO Yes Optical fibre cable connection using plastic

No STF = "Siemens Technologische Funktio-

Explanations

Implementation acc. to PROFIBUS standard

DIN 19245 part1 and part 2

Implementation acc. to PROFIBUS standard

DIN 19245 part1 and part 3

(COM ET 200 as of version V4.0)

Older Siemens-specific DP implementations

which are not compatible with the DP

standard

(COM-ET200 up to version V3.x).

onen" (Siemens technological functions).

Siemens-specific

Layer7 implementation

Layer2 access

OFC / HP duplex

Lenze module variant 2130IB.V002.

12

L

Page 15

2. Technical data

2.1. General data

Communication media RS485 (2130IB.V001)

OFC (SINEC-L2FO) (2130IB.V002)

Communication profile PROFIBUS-FMS (DIN 19245 p1+p2)

PROFIBUS-DP (DIN 19245 p1+p3)

PROFIBUS participant Slave

Drive profile DRIVECOM 21

Baud rate [kBit/s] 93.75, 187.5, 500, 1500

Permissible pollution Degree of pollution 2 according to

VDE 110 part 2

Permissible humidity 80% relative humidity no condensation

Surge strength to the bus system 250V AC (2130IB.V001)

infinite (2130IB.V002)

Ambient temperature

2.2. Protocol specific data

2.2.1. PROFIBUS-DP

Max. number of controllers 31 (without repeater)

Supported services Data_Exchange, RD_inp, RD_outp,

Functions available as options Sync, Clear_Data

Maximum PDU length 32 Byte

User data length 12 Byte with DP parameter setting channel

Lenze PNO identification number 0082

Controller master data file for

DIN E 19245 part3

Simatic-S5 COM-ET200/IM 308-B

DP parameter setting data 10100000

Configuration data

with DP parameter setting channel

0...45°C

122 (with repeater)

Slave_Diag, Set_Prm, Chk_Cfg, Get_Cfg,

Global_Control, Set_Slave_add

4 Byte w/o DP parameter setting channel

hex

L_AR0082.GSD

LE0082TD.200

bin

B7

93

hex

hex

(183

(147

dez

dez

),A3

)

hex

(163

dez

),

without DP parameter setting channel

A3

hex

(163

dez

),93

hex

(147

dez

)

2.2.2. PROFIBUS-FMS

Max. number of controllers 31 (without repeater)

126 (with repeater)

Supported services Initiate, Abort, Identify, Status, Get-OV-long,

Read, Write

Maximum PDU length 150 Byte

Communication relations Reference 1: Default Management

Reference 2: MSAC

13

Page 16

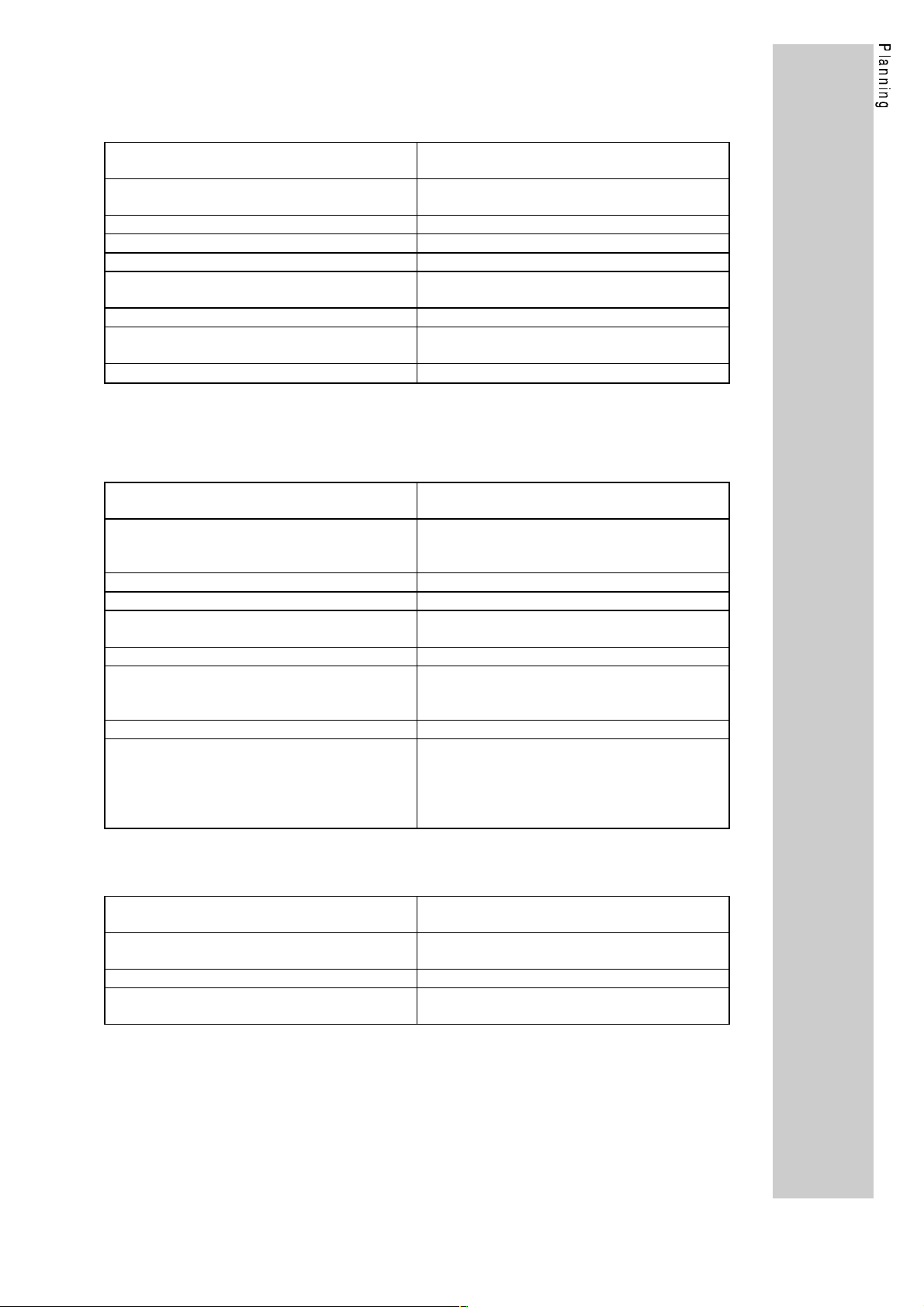

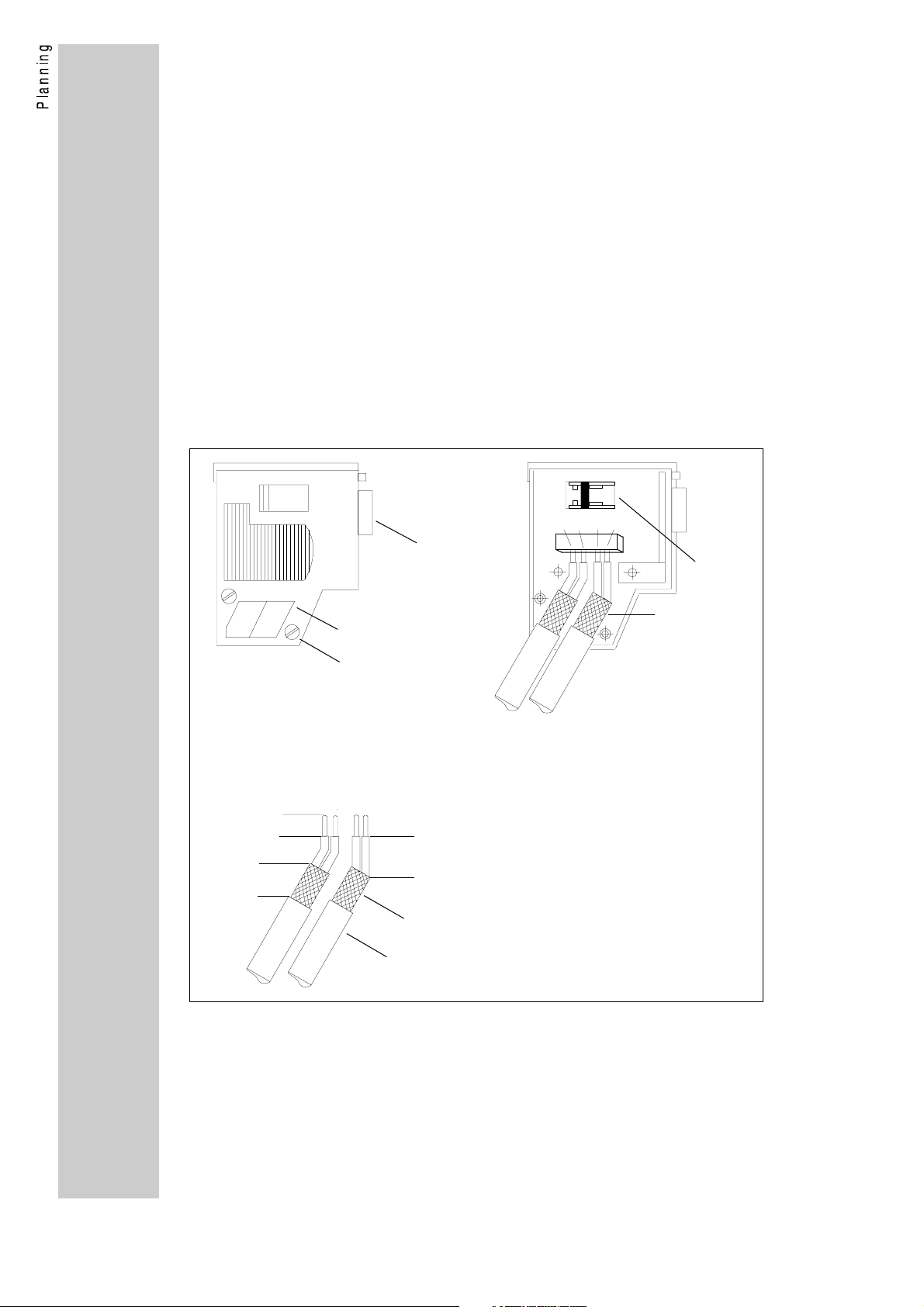

2.3. Dimensions of the 2130IB board

Connections of 2130IB

X12 X13

View of 2130IB with front plate

Explanations:

X4 Automation interface

34-pole plug connector for the

connection with the control board of

the controller

X12 RS485 bus connection

9-pole SubD socket

(only 2130IB.V001)

X13-W30 OFC receiver

(only 2130IB.V002)

X13-W31 OFC transmitter

(only 2130IB.V002)

V1 V2

V1 (LED green) supply 2130

OFF: Module has no supply voltage.

The controller is switched off or the

connection to the controller is

interrupted (X4).

ON: Module has supply voltage.

V2 (LED yellow) Communication

2130

OFF: No supply or 2130 and controller is

not initialized.

ON: Module 2130 and base device are

initialized but there is no

PROFIBUS communication.

FAST FLASHING: (4 times per sec.)

PROFIBUS-DP communication

with user data

SLOW FLASHING: (once per sec.)

PROFIBUS-FMS communication

is established

14

L

Page 17

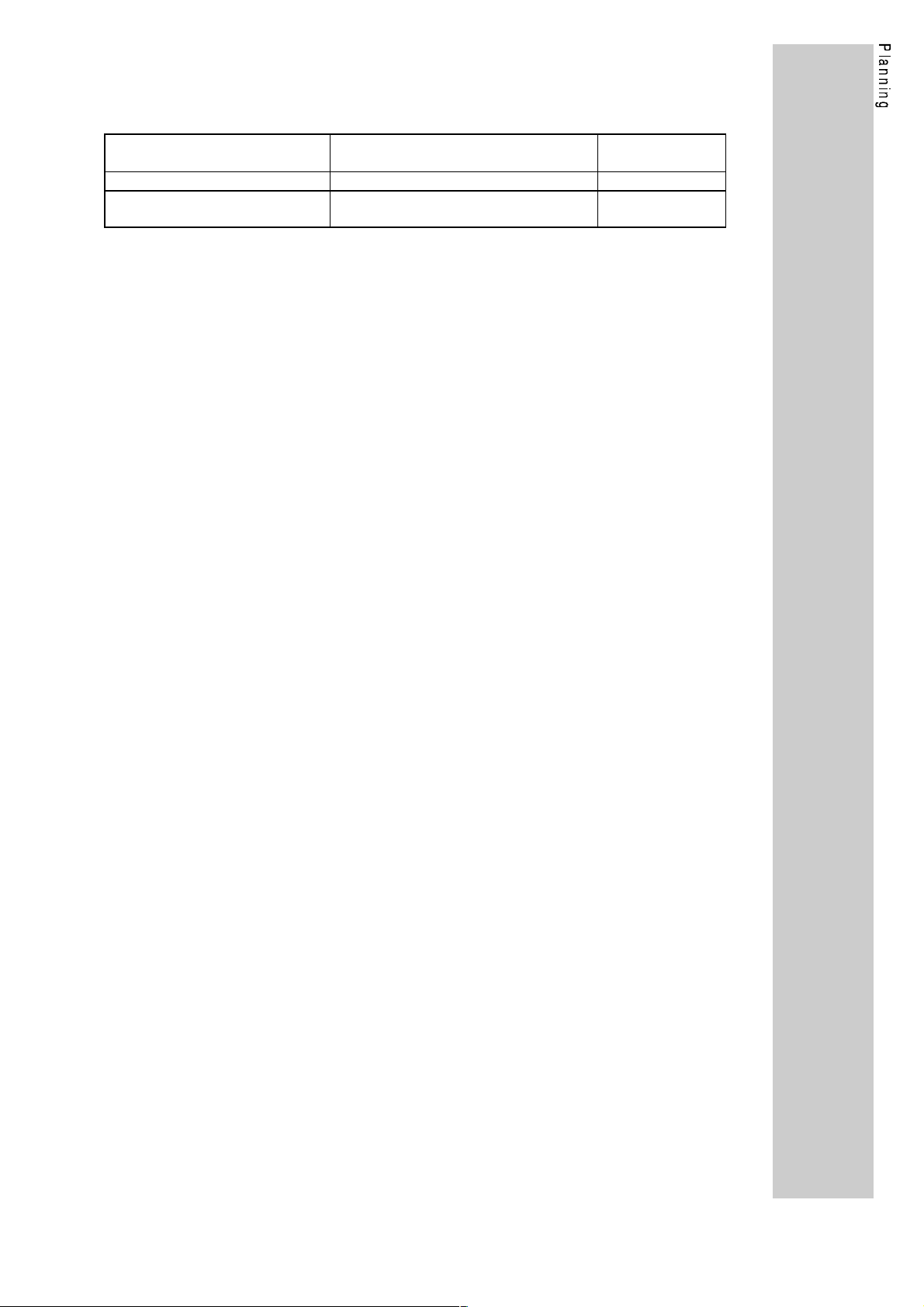

2.4. Scope of supply

Variants of the 2130IB bus interface module:

Variant Communication medium Service no.

2130IB.V001 RS485 33.2130IB.V001

2130IB.V002 Optical fibre cable Siemens SINEC-

L2FO (plastic OFC/HP duplex)

The scope of supply of the 2130IB module includes the following

components:

• 2130IB board

• Diskette 3 1/2", DOS format 1.44 MByte including:

− INSTALL.EXE Installation program for the following

software

− L_AR0082.GSD Controller master data file according to

DIN E 19245 part 3 (PROFIBUS-DP)

− LE0082TD.200 Controller master data file for

Simatic-S5 COM-ET200/ IM-308B

(SINEC-L2-DP)

− 2130@@ST.S5D Example program for Simatic-S5

− LEMOC2 PC program for parameter setting of the

drive as of version V2.2

• 2130IB operating instructions

on request

The controllers can be supplied as a complete system.

15

Page 18

2.5. Manufacturer's Declaration

We hereby certify that the electronic controllers listed in these

Operating Instructions are control components for variable speed

motors intended to be assembled into machines or to form a machine

together with other components. According to the "Council directive ...

relating to machinery" 89/392/EWG, the controllers cannot be called

machines.

These Operating Instructions give advice and recommendations for

the installation and use of the electronic equipment.

As long as the conformity with the protection and safety guidelines

required by the "Council directive ... relating to machinery"

89/392/EWG and its amendment 91/368/EWG is not proved,

commissioning of the machine is prohibited.

The measures required for typically configured controllers to comply

with the EMC limit values are indicated in these Operating Instructions.

The electromagnetic compatibility of the machines depends on the

method and accuracy of the installation. The user is responsible for

the compliance of the machine with the "Council directive ... relating to

electromagnetic compatibility" 89/336/EWG and its amendment

92/31/EWG.

Considered standards and regulations:

• Electronic equipment for use in electrical power installations and

their assembly into electrical power installations:

DIN VDE 0160, 5.88

• Standards for the erection of power installations: DIN VDE 0100

• Degrees of protection: EN 60529, 10.91

• Base material for printed circuits:

DIN IEC 249 part 1, 10.86; DIN IEC 249 part 2-15, 12.89

• Printed circuits, printed boards:

DIN IEC 326 part 1, 10.90; EN 60097, 9.93

• Creepage distances and clearances:

DIN VDE 0110 part 1-2, 1.89; DIN VDE 0110 part 20, 8.90

• Electrostatic discharge (ESD):

prEN 50082-2, 8.92, IEC 801-2, 9.87 (VDE 0843, part 2)

• Electrical fast transient interference (Burst):

prEN 50082-2, 8.92, IEC 801-4, 9.87 (VDE 0843, part 4)

• Surge immunity requirements: IEC 801-5, 10.93

• Radio interference suppression of electrical equipment and

plants: EN 50081-2, 3.94; EN 55011 (VDE 0875, part 11, 7.92)

• Radio interference suppression of radio frequency equipment

for industrial purposes: VDE 0871, 6.78

16

2.5.1. Application as directed of the 2130IB module

The 2130IB module is an additional module for Lenze controllers of

the 4900, 8600, 9200 series. These controllers are industrial

equipment for use in industrial high power plants. They are designed

for use in machinery to control variable speed drives.

Further notes about the use can be obtained from the operating

instructions of the corresponding controller.

L

Page 19

3. Installation

3.1. Installation

You can integrate the 2130IB bus interface module into the controllers

of the 4900, 8600, 9200 series.

It is also possible to use it together with the Lenze automation module

for positioning (2211PP) and winding applications (2211WP).

If you purchase the bus interface module separately, you will need an

installation kit.

Name Service no. Explanation

Installation kit 86004900/2130IB

Installation kit 9200/2130IB 33.9200_N.V008 Installation kit for the 9200 series

Assembly instructions are included in the installation kits.

Further installation kits for the controllers of the 9200 series can be

obtained on request.

33.4900_N.V013 Installation kit for the 8600 and 4900

series

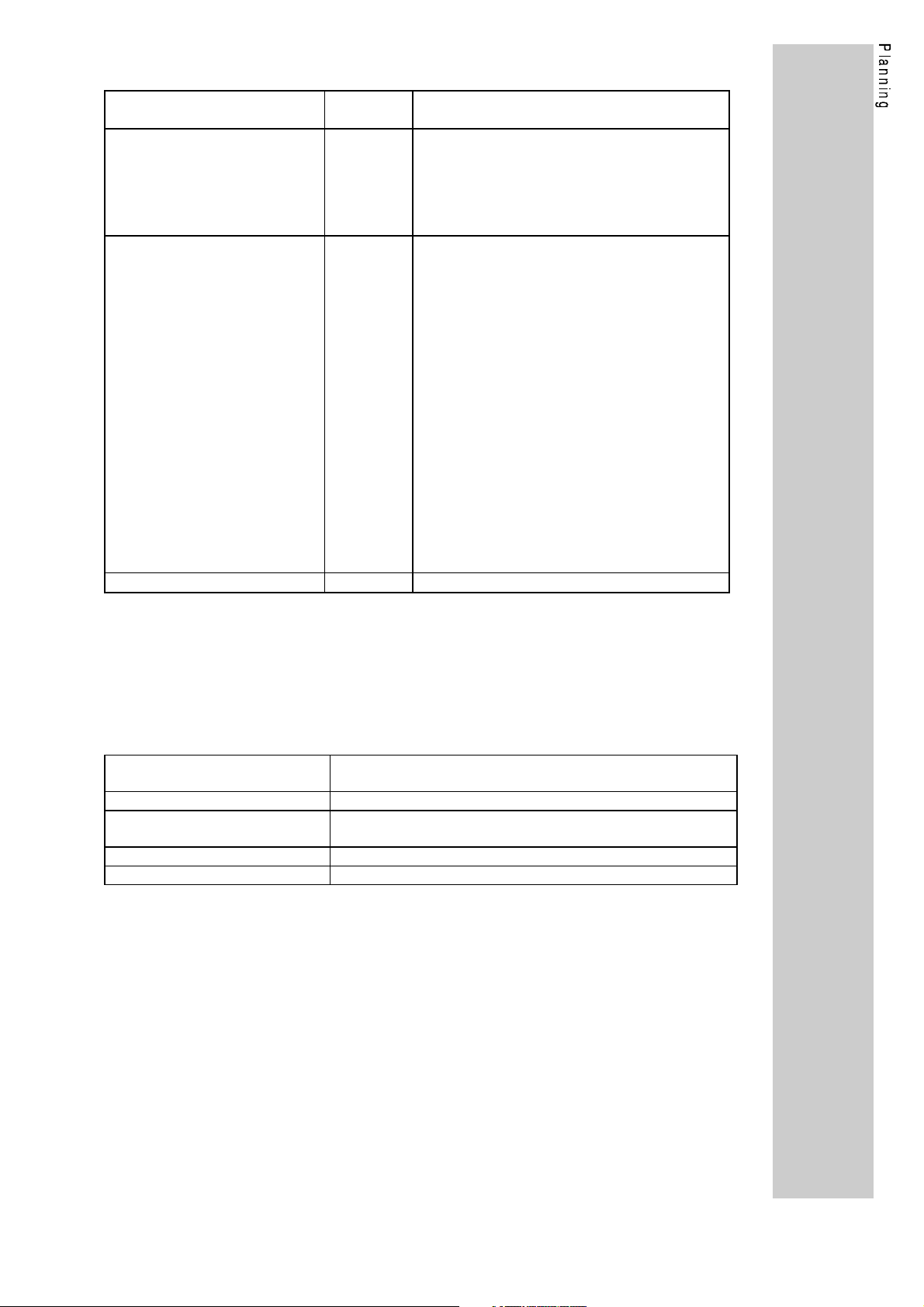

3.2. Wiring

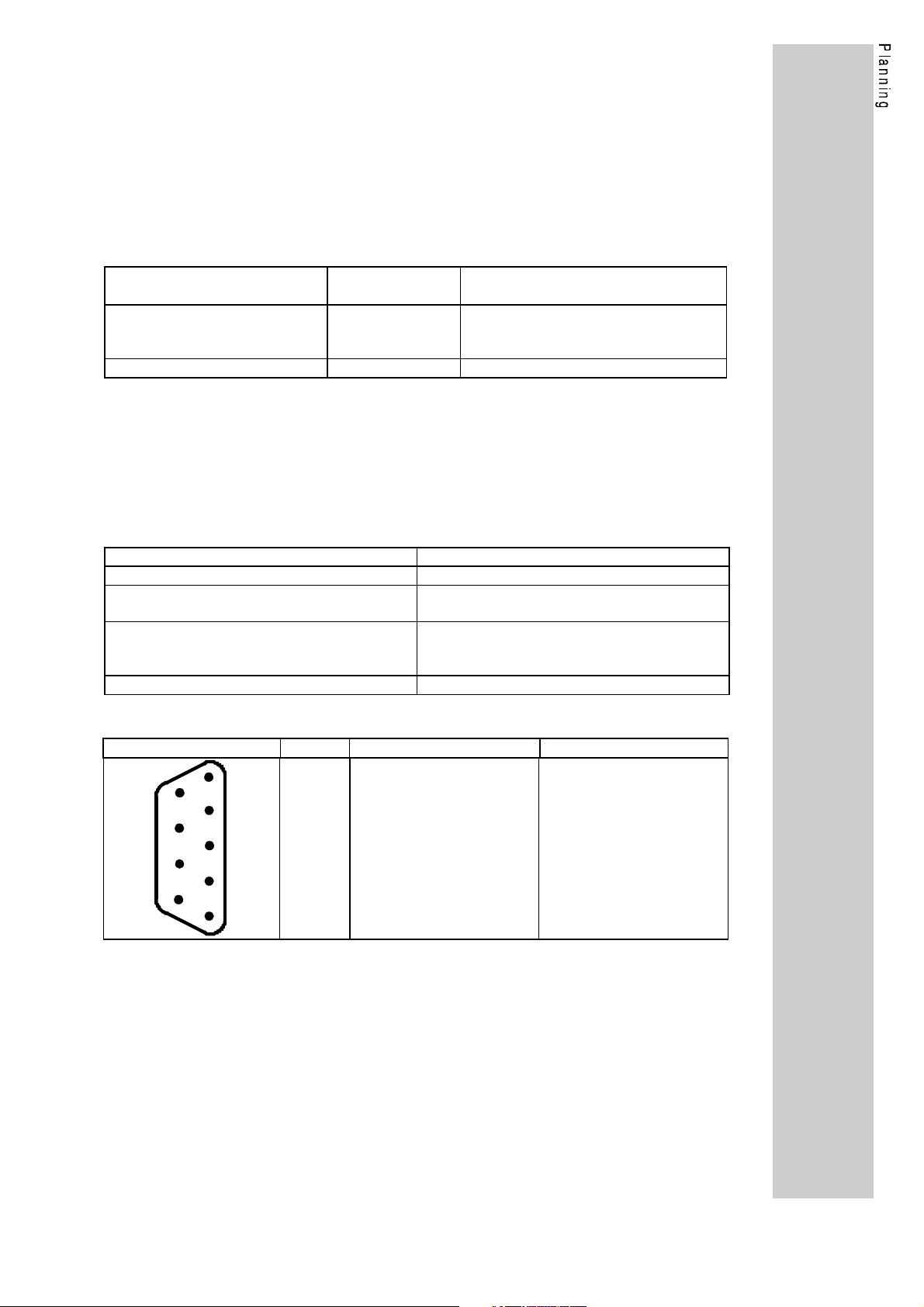

3.2.1. 2130IB.V001 (RS485)

Communication media RS485 (2-wire)

Network topology Line

Number of controllers 31 without repeater. With repeater

max.126.

Maximum cable length 1200 m (depending on the desired baud

rate and cable type. See following cable

specification)

Maximum baud rate 1500 kBaud

X12 Socket 9-pole SubD (RS485)

View Pin no. Signal name Name

1

5

9

4

8

3

7

2

6

1

2

3

4

5

6

7

8

9

PE

−

RxD / TxD-P

RTS

M5V2

P5V2

−

RxD / TxD-N

−

Protective earth

−

Data line B

Request To Send

Data reference potential

Supply plus

−

Data line A

−

17

Page 20

How to wire the module

• Only use cables according to the following cable specification.

• Observe the following illustrations concerning the bus connector.

• Make the connection to the controllers using the bus connector.

The bus system is not interrupted if you disconnect the plug from

the controller.

• Connect a terminating resistor at the physical bus ends . This

resistor is integrated in the bus connection plug. You can activate it

by using a switch.

• If the 2130IB bus interface module is not supplied with power any

more, the bus system continues to operate. The connected

controller, however, cannot be called by the host.

• If you want to disconnect individual bus participants, make sure that

the terminating resistors at the physical cable ends remain active.

• Further notes and wiring instructions can be obtained from the

documentation of the control manufacturer.

Connection of the bus cable in the bus connector

V

V

1

A

ON

B

B

A

4

approx. 6 mm

approx. 11 mm

V

V

2

3

approx. 11 mm

V

V

bus cable

cable screen

1 = 9-pole SubD connector

2 = Guides for the bus cable

3 = Housing screw

4 = Terminating resistor (not connected))

5 = Cable screen; must lay bare

on the metal guide

V

5

18

L

Page 21

Accessories for the wiring of the RS485 connection

Name Part no. Explanation

Bus connector

Service designation:

Bus connector PROFIBUS

RS485

Cable:

Service designation:

Sinec-L2 bus cable 2-core

Cable resistance

Capacitance per unit length

Loop resistance

Wire diameter

Wire cross-section

Wires

Length

363 695 Bus connector for 9-pole SubD socket with

plug terminals to connect the bus cable. Bus

terminal resistor can be added.

Service designation:

Siemens 6ES5 762-1AA12

363 677

(sold by

the meter)

135 - 165 Ω/km (f = 3 - 20 MHz)

≤ 30 nF/km

<110 Ω/km

>0.64mm

>0.34qmm

double twisted, insulated and screened

1200m at 93.75 kBaud

1000m at 187.50 kBaud

400m at 500.00 kBaud

200m at 1500.00 kBaud

Service designation: Siemens SINEC L2 bus

cable (sold by the meter) 6XV1 830-0AH10

• These service designations and technical data of component

manufacturers other than Lenze may not be the latest

information. Therefore they are to be understood as guidelines

only. Precise data can be obtained from the documentation of

these manufacturers.

3.2.2. 2130IB.V002 (OFC)

Communication media Optical fibre cable (plastic)

HP duplex plug connection

Network topology Point-to-point (star network when using star couplers)

Number of controllers 1 (per star coupler 15-1, number of star couplers in a

cascade depends on the baud rate)

Minimum cable length 5m

Maximum cable length 25m

OFC wiring

• A star coupler is not necessary for the wiring to a drive

controller (point-to-point connection).

• If you want to connect several controllers, you must use star

couplers.

Accessories for wiring using optical fibre cables are available from the

Siemens SINEC-L2FO products.

19

Page 22

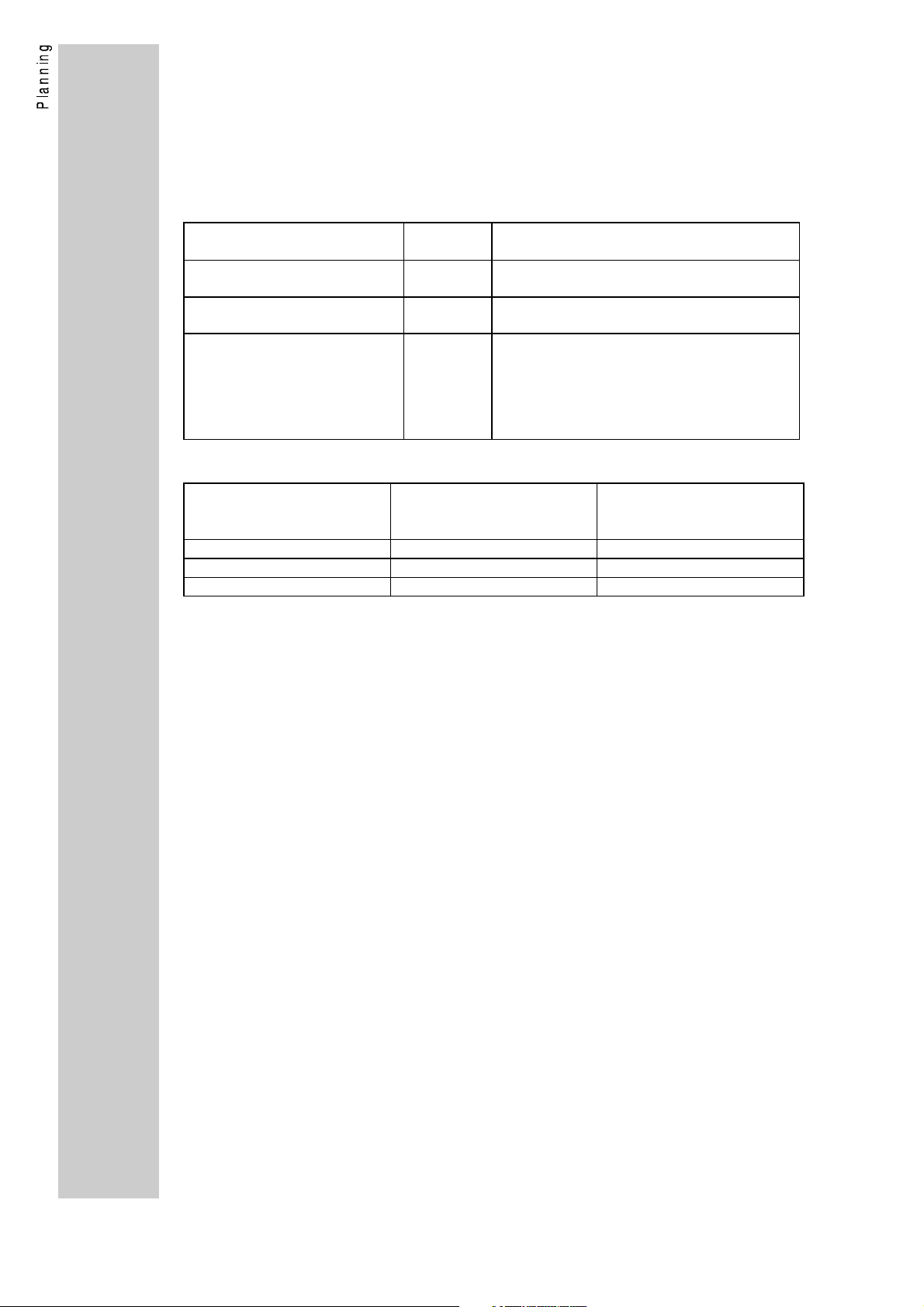

3.2.3. Additional procedure for FMS / mixed operation

When using the FMS / mixed operation, some parameters must be set

for the controller and the field bus module, which is only possible by

means of the LECOM1 interface.

For the parameter setting of the controllers using the LEMOC2

program, connect the PC (RS232) and the controller (LECOM1; X6) by

means of a PC system cable.

Name Part no. Explanation

PC system cable 5 m 338 094 System cable 5m between PC (9-pole

socket) and controller

PC system cable 10 m 338 095 System cable 10m between PC (9-pole

socket) and controller

Cable type

Cable resistance

Capacitance per unit length

Length

Wiring of the system cable

Controller

9-pole SubD socket

Pin no.

2 (RxD) 3 (TxD) 2 (TxD)

3 (TxD) 2 (RxD) 3 (RxD)

5 (GND) 5 (GND) 7 (GND)

−

PC or similar

9-pole socket

Pin no.

LIYCY 4 x 0.25mm

screened

< 100 Ω/km

< 140nF/km

≤ 15m

PC or similar

25-pole socket

Pin no.

Only use metallized SubD housings. Connect the screen to the

housings at both ends.

20

L

Page 23

Programming

The programming section using the 2130IB bus interface module is

divided into the following chapters:

• Commissioning

• Code table 2130IB

• PROFIBUS operating modes

• DRIVECOM parameters

• Lenze parameters

• Glossary

Commissioning

This chapter contains important information about the initial

connection of the 2130IB together with a controller base device and

an automation module.

In addition, you will obtain information about the installation of the

LEMOC2 PC program, which is necessary for the parameter

setting of the 2130IB.

Code table 2130IB

In the code table 2130IB those parameters are listed which are

used for the setting of the module and the bus system. You can set

these parameters by means of LECOM-A/B or the LEMOC2 PC

program or PROFIBUS.

PROFIBUS operating modes

This chapter contains information about the selection of the operating

modes PROFIBUS-DP or PROFIBUS mixed operation DP/FMS.

For these operating modes, the required settings of the master and the

controller are described. For PROFIBUS-DP, an example program for

the SIMATIC-S5 is briefly explained.

DRIVECOM parameters

This chapter describes the DRIVECOM profile parameters which

are implemented on the module. These are, among others, the

DRIVECOM states and the status and control word as well as the

configuration of the process data and the monitoring functions for

communication.

Lenze parameters

This chapter describes the access to Lenze parameters in the base

controller or in the automation module.

In addition, the control of the device together with an automation

module is explained.

Glossary

In this chapter, all the important technical terms and abbreviations (e.g.

AIF, PDU, subindex) are explained, which you will find in these operating

instructions.

21

Page 24

1. Commissioning

1.1. Code numbers / Index

The parameters of the controller are addressed by means of numbers.

These numbers are called "index" according to the PROFIBUS system.

Lenze designates them as code numbers .

All Lenze code numbers begin with 0. They are in an index range from

22576 (5830

numbers by the preceeding letters "L-C" (e.g.: L-C000 for Lenze code

number 000).

The conversion for the address method between code number and index

is given on page 67.

) to 24575 (5FFF

hex

1.2. How to install the PROFIBUS software

The attached "Lenze PROFIBUS diskette" contains

important data and programs about parameter setting

and control of the controller using PROFIBUS.

The diskette (3 ½", DOS format, 1.44 MByte) contains

the following files:

Diskette 3 1/2", DOS format 1.44 MByte including:

INSTALL.EXE Installation program for the following

software

L_AR0082.GSD Controller master data file according to

DIN E 19245 part 3 (PROFIBUS-DP)

LE0082TD.200 Controller master data file for

Simatic-S5 COM-ET200/ IM-308B

(SINEC-L2-DP)

2130@@ST.S5D Example program for Simatic-S5

LEMOC2 PC program for parameter setting of the

drive as of version V2.2

). You can recognize Lenze code

hex

To install the software, insert the diskette into the disk

drive. Enter:

a:\install or b:\install

Further information about the installation is provided by

the "install program".

22

L

Page 25

1.3. Commissioning sequence

The initial commissioning of the 2130IB bus interface module together

with a controller and possibly an automation module is divided into the

following phases:

Base setting of the controller

In this phase the controller receives information about additional modules

and the source of the control information.

This setting is possible using the keypad at the controller of the LEMOC2

PC program.

PROFIBUS bus parameters

It is not necessary to set PROFIBUS bus parameters for the operation

with PROFIBUS-DP. With the factory setting, the 2130IB module is set

automatically to the baud rate of the master.

In addition, you can enter the PROFIBUS address via PROFIBUS.

Modified bus parameters are automatically saved permanently.

For PROFIBUS-FMS or PROFIBUS mixed operation, a local setting of

the baud rate and the address is necessary. These parameters can be

set using the LEMOC PC program, which is included on the attached

diskette. For this, make a LECOM-A/B connection for commissioning.

PROFIBUS drive control

The drive system is controlled via PROFIBUS. Control information is

transmitted to the controller, and the controller returns feedback

information to the master.

23

Page 26

1.3.1. Base setting of the drive system

For the base setting, the keypad on the controller or LEMOC2 can be

used.

Setting using the keypad on the controller

1. Inhibit controller (press STP key).

2. Set parameter code set (L-C000) to -2-. Now you have access to

the extended parameter set using the keypad.

Confirm the setting using SH + PRG.

3. Set parameter operating mode (L-C001) to -0- or -1-. Now a

parameter setting is possible via the keypad.

Confirm the setting using SH + PRG.

4. Enter automation module code (L-C370).

For this, set parameter L-C370 to -1- .

With this setting, the controller recognizes the interface module.

Confirm the setting using SH + PRG.

Only required for automation module:

4a.

Set parameter code set (L-C1000) of the automation module to -2-.

Now you have access to the extended parameter set using the

keypad. Confirm the setting using SH + PRG.

Only required for automation module:

4b.

Enter field bus module code (L-C1120).

For this, set parameter L-C1120 to -3-.

With this setting, the controller recognizes the interface module.

Confirm the setting using SH + PRG.

Note:

After the setting, the operation changes automatically to the code number

which was set last in the base controller (e.g. L-C370), since the

operation re-initializes. This, however, does not influence the parameters

which are already set.

5. Set the operating mode (L-C001).

This setting determines the write access to the drive parameters.

The following combination is effective:

L-C001 Source of parameter

setting

0 Keypad Terminal

1 Keypad Keypad

2 LECOM 1 (LECOM-A/B) Terminal

3 LECOM 1 (LECOM-A/B) LECOM 1 (LECOM-A/B)

4 LECOM 2 (PROFIBUS) Terminal

5 LECOM 2 (PROFIBUS) LECOM 2 (PROFIBUS)

6 Keypad LECOM 2 (PROFIBUS)

7 LECOM 1 (LECOM-A/B) LECOM 2 (PROFIBUS)

For normal operation using PROFIBUS, select 5.

Confirm the setting using SH + PRG.

The read access of LECOM1 (LECOM-A/B) or LECOM2

(PROFIBUS) is possible in any operating mode.

Source of control (e.g.

set-values)

24

L

Page 27

6. To save the setting of L-C001 and L-C370 permanently, set

parameter L-C003 "Save parameter set" to 1 (parameter set 1).

Confirm the setting using SH + PRG.

Only required for automation module:

6a.

To save the setting of the parameter change in the automation

module permanently, save the parameter set (L-C1003 = 1).

Confirm the setting using SH + PRG.

7. Enable the controller (press SH + STP keys). It may be necessary to

undo other controller inhibit sources (terminal 28, TRIP, L-C40).

Note:

If you activate the function "Load factory setting" at the controller, the

settings described under 1 to 7 are deleted.

25

Page 28

Setting using the LEMOC2 PC program

1. Change to your LEMOC2 directory (...\LM2\BIN) and

start LEMOC2 by entering LM2.

2. Load the file "2130_xxx.PDB" (x = serial number)

in the menu "file / controller description".

3. Load a parameter which contains the corresponding factory setting

in the menu "file / load parameter set".

The following parameter sets are available:

2130_FMS.VAR Parameter set for PROFIBUS-FMS or

mixed operation

2130_DP.VAR Parameter set for PROFIBUS-DP

4. Connect your PC to the controller and switch LEMOC2 on-line.

For this, use the option "setting / general settings".

5. Inhibit controller (press STP key or F9 key or use controller inhibit

terminal 28).

6. The 2130IB module can now be activated in the menu

"main menu / drive system"

Set parameter L-C370 (C0370-000) to -1- and transmit the

value to the controller.

Only required for automation module:

6a.

Set parameter L-C1120 (C1120-000) to -3- and

transmit the value to the controller.

Note:

When L-C370 or L-C1120 are modified, the internal interfaces between

the modules are re-initialized. This may result in a delay or refusal of

other services for the time of initialization (max. 30 s). If this is the case,

repeat the service.

7. Set the operating mode with parameter L-C001

(C0001-000), according to the keypad setting, item 5, and transmit

the value to the controller.

8. Save the setting in the controller by setting parameter L-C003 to

-1- and by transmitting the value to the controller.

Only required for automation module:

8a.

Save the setting in the controller by setting parameter L-C1003 to

-1- and transmitting the value to the controller.

9. Enable the controller (press SH + STP keys or F8 key, depending

on item 5). It may be necessary to undo other controller inhibit

sources (terminal 28, TRIP, L-C40).

10. Further information about LEMOC2 and possible error messages

can be obtained from the LEMOC2 help function

(key 1 or "help" menu).

Note:

If you activate the function "Load factory setting" at the controller, the

settings described under 1 to 7 are deleted.

26

L

Page 29

Important notes

Without automation module

• For the 4900 or 8600 series, the freely assignable inputs (Lenze codes

L-C112 and L-C113) must not be assigned to the following functions

with a control using PROFIBUS (L-C001=LECOM2).

− Trip reset

− Ramp generator stop

− Ramp generator input = 0

The reason is that these function are in the DRIVECOM control word

(Index=6040

twice.

) and therefore functions may be inhibited or activated

hex

(L-C112 = 1..n; L-C113 = 3)

(L-C112 = 1..n; L-C113 = 9)

(L-C112 = 1..n; L-C113 = 10)

n = maximum number of

freely assignable inputs

• For configuration (L-C005) using digital frequency input, the speed set-

value is not accepted by the bus system.

With automation module

• When using an automation module, the DRIVECOM profile

parameters are not completely available. Only the DRIVECOM profile

parameters 6000

to 6011

hex

are supported (page 52).

hex

1.3.2. PROFIBUS bus parameters

The PROFIBUS parameters do not have to be changed for the operating

mode PROFIBUS-DP. For PROFIBUS-FMS or PROFIBUS mixed

operation, you can set important parameters like address or baud rate in

the LEMOC2 menu "main menu / PROFIBUS". You can transmit the

parameters to the controller individually or as a whole set (F5 key).

Detailed explanations about the PROFIBUS setting can be obtained from

the chapter "operating mode PROFIBUS mixed operation (FMS/DP) on

page 46 or "operating mode PROFIBUS-DP" on page 35.

27

Page 30

1.3.3. PROFIBUS drive control

Without automation module

1. The controller accepts control and parameter setting data from

PROFIBUS. The controller is controlled by DRIVECOM process

data.

Here you have to distinguish whether the control system (e.g. PLC)

controls to PROFIBUS-DP (page 40) or PROFIBUS-FMS (page 47)

controls the controller.

2. Enable controller

Enable the drive using the DRIVECOM control word and

display the controller states using the DRIVECOM status word

(page 56).

For standard enabling of the controller, proceed as follows:

1. Change to the state "READY TO SWITCH ON

bin

(007E

bin

(007F

bin

POW1 = 0000 0000 0111 1110

2. Wait until state "READY TO SWITCH ON" is reached

PIW1 = xxxx xxxx x01x 0001

3. Change to state "OPERATION ENABLED"

POW1 = 0000 0000 0111 1111

4. Speed set-value (2nd process word; POW2 )

is provided.

PIW = Process input word

POW = Process output word

hex

hex

)

)

28

L

Page 31

Without automation module

1. The controller accepts control and parameter setting data from

PROFIBUS. The controller is controlled by DRIVECOM process

data.

Here you have to distinguish whether the control system (e.g. PLC)

controls to PROFIBUS-DP (page 40) or PROFIBUS-FMS (page 47)

controls the controller. Please note that the operating mode

PROFIBUS-DP is provided as factory setting.

2. Enable controller

Switch on the controller using the automation control word

(page 79) and display the controller states (page 56) using the

automation status word (page 82).

3. For standard enabling of the controller, proceed as follows:

1. Change to state "READY TO SWITCH ON"

POW1 = 0000 0000 0000 1110

(000E

bin

hex

)

2. Wait until state "READY TO SWITCH ON" is reached

PIW1 = xxxx xxxx x01x 0001

bin

3. Change to state "OPERATION ENABLED"

POW1 = 0000 0000 0000 1111

(000F

bin

hex

)

4. Enter other control information in the second process

word (POW2 ).

PIW = Process input word

POW = Process output word

29

Page 32

Communication principle for the access to the controller data

Bus

Controller

PROFIBUS-DP = User data

PROFIBUS-FMS = Read or Write services

Parameter setting channel

from the master

DP = 8 byte

FMS = Read;Write services

Parametrierkanal

to the master

DP = 8 byte

FMS = Read;Write services

Address = Index + Subindex

DRIVECOM-Parameter

PI data description

Index = 6000hex

Process input data

Index = 6010hex

Process output data

Index = 6011hex

Control word

Index = 6040hex

Status word

Index = 6041hex

Nominal speed

Index = 6042hex

Process data

from the master

DP = 4 byte

FMS = not available

Prozeßdatenkanal

to the master

DP = 4 byte

FMS = not available

Process input data

Byte 1

Byte 2

Byte 3

Byte 4

PIW 1

PIW 2

DRIVECOM

Status word (*)

Actual speed (*)

Process output data

Byte 1

POW 1

Byte 2

Byte 3

POW 2

Byte 4

(*) = Assignment with factory setting

PEW = Process input word

PAW = Process output word

DRIVECOM

control word (*)

Nominal speed

value (*)

30

Actual percentage

Index = 6054hex

Lenze parameters

Code set (C0000)

Index = 5FFFhex

Operating mode (C0001)

Index = 5FFEhex

DP parameter sett. channel (C1905)

Index = 588Ehex

L

Page 33

The diagram explains the PROFIBUS access to controller data. Here you

have to distinguish between access to process data and parameter data.

Process data

Process data are data memories where several individual parameters

are combined to form a new parameter: the process data. These

process data are exchanged as fast as possible and cyclically between

the controller and the master. Typical process data are set-value and

control information as well as actual value and status information.

Process data can be divided into process output data (PO data) and

process input data (PI data) and they have a fixed length of 4 byte,

viewed from the master. A summary of parameters is described in the

chapter "process data configuration".

For PROFIBUS-DP, the process data in the user data phase are

permanently exchanged between master and controller. The exact

assignment of the DP user data phase can be obtained from the

chapter "DP user data".

For PROFIBUS-FMS, process data are accessed via parameter

setting using the PROFIBUS services Read or Write. The process

time is considerably longer than for PROFIBUS-DP.The process data

can be accessed under the following index:

Index = 6010hex process input data

Index = 6011hex process output data

Parameter data

Parameters are all DRIVECOM and Lenze controller parameters. A

read and write access is possible for all these parameters. The

parameter is addressed by its index and subindex. The process time in

the controller is considerably longer than the process data access.

For PROFIBUS-DP, the parameters are accessed using the DP

parameter setting channel, which is transmitted cyclically in the user

data. Here, it uses the first 8 byte. The parameter setting channel can

be deactivated using code L-C1905, the DP user data being reduced

by 8 byte.

For PROFIBUS-FMS, the access is possible using the PROFIBUS

services Read or Write.

From the diagram you can see that a parameter which is defined as a

process data value, can be accessed in several ways. The

DRIVECOM parameter, for example, can be directly accessed by its

index 6040hex. It can also be accessed as process output value

(POW1) in the parameter "process output data (index 6011hex). For

PROFIBUS-DP, a direct access using DP user data is also possible.

To avoid write access conflicts, parameters which are process data

must only be changed directly using the user data for PROFIBUS-DP.

For PROFIBUS-FMS, the write access must always be via the

parameter "process output data".

31

Page 34

2. 2130IB code table

In the following, parameters of the 2130IB module are listed which you

can set via the LECOM1 interface (LECOM-A/B).

The parameters listed in the code table are automatically and

permanently saved.

Explanations:

Code: Lenze code number of the parameter. Preceeding

zeros may be omitted.

Name: Name of the parameter

Parameter: Content or meaning of the parameter values.

Parameters printed in bold show the factory setting.

Code

L-C

1810 Software

1900 PROFIBUS

Name Parameter

(Factory setting is printed in bold)

33S2130I_xy000

identification

operating

mode

Software identification of the 2130IB module

x = Software main version

y = Software subversion

-0- DP operation. Only PROFIBUS-DP

-1- Mixed operation. PROFIBUS-FMS and

PROFIBUS-DP services are possible at the

same time

The operating mode defines the masters which are

able to communicate with the controller. In operating

mode 0 only pure DP masters can be used, and in

operating mode 1 the controller can communicate with

DP or FMS masters.

Your

settings

−

Data transmission in operating mode 0 is much more

efficient than in operating mode 1.

When changing the operating mode, codes L-C1903

and L-C1904 are also loaded with the corresponding

factory settings.

1901 Station

address

1902 Baud rate -2- 93.75 kBaud

1903 Baud rate

recognition

126 1 to 126

Number for precise addressing of the drive in the

PROFIBUS network. This number must only be

assigned once in the bus system.

-3- 187.5 kBaud

-4- 500.0 kBaud

-6- 1500.0 kBaud

In the bus system, all participants must have the same

baud rate. In the operating mode DP operation

(L-C1900 = 0) and automatic baud rate recognition

(L-C1903 = 1), this code number has no meaning.

-0- inactive (L-C1900 = 0)

-1- active (L-C1900 = 1)

Automatic baud rate recognition is only possible in DP

operation; i.e. the drive is set automatically to the baud

rate of the master.

32

L

Page 35

Code

Name Parameter

L-C

1904 min T

SDR

1905 DP parameter

setting

channel

(Factory setting is printed in bold)

11 to 255 Bit-times

11 (L-C1900 = 0)

125 (L-C1900 = 1;L-C1902 = 2)

250 (L-C1900 = 1;L-C1902 = 3)

255 (L-C1900 = 1;L-C1902 = 4)

255 (L-C1900 = 1;L-C1902 = 6)

Minimum reaction time of the controller on a telegram

of the master (protocol acknowledgement). The

setting is in bit-times and therefore depends on the

selected baud rate.

Setting is only possible in the PROFIBUS operating

mode mixed operation (L-C1900 = 1).

-0- inactive

-1- active

DRIVECOM parameter setting channel for DP

operation; i.e. DRIVECOM and Lenze parameters can

also be accessed during the user-data phase.

Your

settings

33

Page 36

3. PROFIBUS operating mode

The PROFIBUS operating mode determines the participants for the

bus system. We distinguish between two operating modes:

• pure PROFIBUS-DP operation

• mixed operation of PROFIBUS-DP and PROFIBUS-FMS

In the following, criteria for the selection of the suitable operating

mode are listed.

Criteria Code

numbers

PROFIBUS-DP master

exists

PROFIBUS-FMS master

exists

Station address can be set L-C1901 yes

Station address can be set

via bus

Baud rate up to 1.5MBaud L-C1902 yes

Automatic baud rate

setting

DP parameter setting

channel

Data transmission time /

cycle time

The PROFIBUS operating mode is selected under L-C1900.

L-C1900 PROFIBUS

operating

mode

−

−

−

L-C1903 no possible

L-C1905 possible

−

-0- DP operating mode. Only pure PROFIBUS-DP

-1- Mixed operation. PROFIBUS-FMS and PROFIBUS-

Mixed operation

(FS = factory setting)

possible necessary

possible no

FS = 126

no yes

FS = 500 kBaud

FS = active

medium low

DP services are possible at the same time

DP operation

(FS = factory setting)

yes

FS = 126

yes

FS = 500 kBaud

FS = active

possible

FS = active

The selection of the operating mode causes other bus parameters

to be set automatically to the default values of this operating mode

so that, especially for the DP operating mode, further setttings are

not required.

34

L

Page 37

3.1. PROFIBUS-DP operating mode

In the following only the settings for pure PROFIBUS-DP operation are

explained.

Settings for the master

Most of the controller manufacturers demand a controller description

file (controller master data file). Therefore, the following files are saved

in the DOS format on the attached diskette:

File name Meaning

L_AR0082.GSD Controller master data file according to

DIN E 19245 part 3

LE0082TD.200 Controller master data file (type file) for

Simatic-S5 COM-ET200/IM308-B

The master must be set as follows:

Function Setting

(depending on the type of master)

Baud rate 500 kBaud (factory setting)

Value as controller parameter

L-C1902 (page 32).

Communication profile

(Bus profile)

Slave station address

(Station number)

DP configuration data (configuration)

PROFIBUS-DP DIN E 19245 part 3

(DP standard)

Value in controller parameter

L-C1901 = 0 (page 32).

126 (factory setting)

Value as controller parameter

L-C1901 (page 32).

with DP parameter setting channel

(L-C1905=1)

B7

93

hex

hex

(183

(147

dez

dez

),A3

)

hex

(163

dez

),

(factory setting)

A3

hex

(163

dez

),93

hex

(147

dez

)

without DP parameter setting channel

(L-C1905=0)

Lenze PNO identification number 0082

DP parameter setting data 10100000

hex

bin

DP user data length 12 byte (with DP parameter setting

channel)

4 byte (without DP parameter

setting channel)

Setting as controller parameter

L-C1905 (page 32).

35

Page 38

Controller settings

Code Name Parameter

L-C1900 PROFIBUS

operating

mode

You can set the controller from the master via the bus.

The controller has an automatic baud rate recognition

(see L-C1903). If you want to set the controller locally, proceed just

like in the operating mode mixed operation. More detailed

information can be obtained from the chapter "2130IB code table"

(page 32).

-0- DP operation. Only pure PROFIBUS-DP

-1- Mixed operation. PROFIBUS-FMS and PROFIBUSDP services are possible at the same time

36

L

Page 39

3.1.1. Simatic-S5

Lenze controllers comply with the standard of PROFIBUS-DP

participants. For communication with Simatic-S5, the following hardware

and software components are necessary:

• S5 interface module IM308-B as from version 5.

• Programming software COM ET200 as from version 4.0

3.1.1.1. COM-ET200 settings

In the following, specific settings for Lenze controllers are listed when

using the COM-ET 200 program package.

Menu: ET200 system parameters

Bus profile: DP standard

Menu: Configuration

Station type: Lenze 2130 Vxx

For this setting, copy the file LE0082TD.200 from

the diskette to the COM-ET200 directory.

Configuration: User data with DP parameter setting channel

(controller parameter L-C1905 = 1; factory

setting)

0. = 183; 1. = 163; 2. = 147

User data without DP parameter setting channel

0. = 163; 1. = 147

3.1.1.2. Example program

For easier commissioning, an example program in STEP5 is

provided on the attached diskette (file: 2130@@ST.S5D). The

following function modules (FB) are included:

FB182: Process data communication. Simplified control of

the controller. The standard functions of the Lenze

controller are mapped to the DRIVECOM profile.

FB183 Parameter data communication. Support of the DP

parameter setting channel. All DRIVECOM and

Lenze parameters can be read and written.

37

Page 40

3.1.2. Diagnosis data

The controller supplies the following diagnosis data:

Station status_1

(1 byte)

Diagnosis data of the controller part 1

Bit no. Meaning

----------------------------------------------------------------------------------0 Controller available?

0 = controller available

1 = controller not available.

Caution! The other bit information is not

defined.

1 Controller communication status

0 = controller is ready to communicate

1 = controller is not ready to communicate

2 Comparison of configuration data between master and

controller

0 = configuration data identical

1 = configuration data not identical

3 Controller diagnosis

0 = no fault information

1 = fault (TRIP)

4 Invalid service request from the master

0 = no invalid service request

1 = invalid service request

5 Invalid response from the controller

0 = no invalid response

1 = invalid response

6 Status DP parameter setting

(DP service DDLM_Set_Prm)

0 = no fault

1 = fault

7 Information about the source of parameter setting.

0 = parameter setting by the momentary master

1 = parameter setting by another master

38

L

Page 41

Station status_2

(1 byte)

Diagnosis data of the controller part 2

Bit no. Meaning

----------------------------------------------------------------------------------0 Controller requests new parameter setting.

0 = no request

1 = request for new parameter setting, e.g. since the

DRIVECOM parameter setting channel was changed.

1 User data status

0 = Controller is able to supply user data

1 = Controller is not able supply user data, because

e.g. initializing between communication module and

controller is not yet finished.

2 fixed on 1

3 Communication monitoring in the controller

0 = inactive

1 = active

4 not used

5 Controller input data 'frozen' (Sync)

0 = input data not frozen

1 = input data frozen

6 reserved

7 Information, if the controller parameter set is inactive

and the controller was removed from the cyclic user

data transfer

0 = parameter setting active

1 = parameter setting inactive

Station status_3

(1 byte)

Master_Add

(1 byte)

Ident_Number

( 2 byte)

Ext_Diag_Data_1

(1 byte)

Ext_Diag_Data_2

(2 byte)

Diagnosis data of the controller part 3

Bit no. Meaning

----------------------------------------------------------------------------------0 - 6 reserved

7 Overflow of diagnosis information

0 = no overflow

1 = overflow

1 to 126

PROFIBUS station address of the DP master which has set the

controller parameters. If the parameters are not yet set, the

value 255 is returned.

0082

hex

Fixed identification number for Lenze controllers

Bit no. Meaning

----------------------------------------------------------------------------------0 - 5 fixed value 3

6 - 7 fixed value 0

Controller-related diagnosis information. Fault code according to

DRIVECOM profile parameter 603F

hex

.

39

Page 42

3.1.3. DP process data

Process data are data memories where several individual parameters

are combined to form a new parameter, the process data. These

process data are exchanged as fast as possible and cyclically between

the controller and the master.

Process data can be divided into process output data (PO data) and

process input data (PI data), viewed from the master, that means PO

data are input data for the controller. The controller receives control

information from the master and supplies feedback information to the

master. Process data have a fixed length of 4 byte. A summary of

parameters is described in the chapter "process data configuration"

(page 67).

Factory setting of process input data:

Byte no.

(x) = with DP parameter

setting channel

1 (9) Wort1/High-Byte

Bit 8 - 15

2 (10) Word1/Low-Byte

Bit 0 - 7

3 (11) Word2/High-Byte

Bit 8 - 15

4 (12) Word2/Low-Byte

Bit 0 - 7

Automation

module

no

yes

no

yes

Meaning Index

PIW1

DRIVECOM status word

Automation status word

PIW 2

DRIVECOM actual speed

Automation FDO1

6041

58C4

6044

5A98

hex

hex

hex

hex

Factory setting of process output data:

Byte no.

(x) = with DP parameter

setting channel

1 (9) Word1/High-Byte

Automation

module

Meaning Index

POW1

Bit 8 - 15

2 (10) Word1/Low-Byte

Bit 0 - 7

3 (11) Word2/High-Byte

no

yes

DRIVECOM control word

Automation control word

PIW 2

Bit 8 - 15

4 (12) Word2/Low-Byte

Bit 0 - 7

no

yes

DRIVECOM nominal speed

Automation FDI1

Important note

• If a parameter is set to the process output data, such as for example

DRIVECOM control word in the above table, the parameter (e.g. index

6040

) may not be written directly.

hex

6040

58C5

6042

5A9B

hex

hex

hex

hex

40

L

Page 43

3.1.4. DP user data

With PROFIBUS, process data are exchanged cyclically between

master and controller in the user-data phase. In addition to the

process data you can activate a DP parameter setting channel

which will use the first 8 byte of the user data. The data structure is

the same for input and output data, see following tables.

Data structure of user data

Byte

no.

10 PIW1/POW 1 (Low-Byte) Process data

11 PIW2/POW2 (High-Byte)

12 PIW2/POW2 (Low-Byte)

with parameter setting

channel

1Service

2 Subindex Parameter setting

3 Index (High-Byte) channel

4 Index (Low Byte)

5 Data/Error-Byte 1

6 Data/Error-Byte 2

7 Data/Error-Byte 3

8 Data/Error-Byte 4

9 PIW1/POW 1 (High-Byte)

Byte

no.

without parameter setting

channel

1 PIW1/POW 1 (High-Byte)

2 PIW1/POW 1 (Low-Byte) Process data

3 PIW2/POW2 (High-Byte)

4 PIW2/POW2 (Low-Byte)

41

Page 44

3.1.5. DP parameter setting channel

For the DP parameter setting channel, parameter setting and diagnosis

is possible in the user data operation. This enables the access to all

DRIVECOM and Lenze specific parameters.

If the DP parameter setting channel is active

(module parameter L-C1905 = 1), this channel uses the first 8 byte of the

input and output process data. The DP parameter setting channel has

the same structure for both directions of transmission.

Service

(1 byte)

Service and response control for the parameter setting channel

Bit no. Meaning

----------------------------------------------------------------------------------0 - 2 Service. Service to the controller. The bits are only set

by the master. The controller copies this informationi

into its response telegram.

0 = no service

1 = Read service (read data from the controller)

2 = Write service (write data to the controller)

3 reserved

4 - 5 Data length. Data length in the field Data/Error.

0 = 1 byte

1 = 2 byte

2 = 3 byte

3 = 4 byte

6 Handshake. Code that a new service must be

processed. This bit is changed with every new service.

The controller copies the bit into its response telegram.

7 Status. Status information from the controller to the

master with the service confirmation. Using this bit, the

master is informed whether the service was processed

without errors.

0 = Service processed without errors.

1 = Service not processed. An error has occurred. The

data in the field Data/Error are recognized as fault

indication.

Subindex

(1 byte)

Index

(2 byte)

Additional address to an index. If a parameter consists of

several values (e.g. L-C38 = JOG selection; L-C39 = JOG), the

subindex can be used to directly address a value.

Example: subindex 3 addresses JOG 3

Address of a parameter. For DRIVECOM parameters see

chapter "DRIVECOM" (page 52) and Lenze parameter see

chapter "Lenze parameters" (page 77).

The data are filed in the Motorola format:

Byte 3 High Byte

Byte 4 Low-Byte

42

L

Page 45

Data/Error

(4 byte)

Error messages in the Error field (Data/Error):

Parameter value or fault information in case of an invalid

access. The status of bit service/status determines the meaning

of the data field.

Data

Parameter value which has 1 - 4 bytes, depending on the data

format. Strings or data blocks cannot be transmitted. The data

filed in the Motorola format; i.e. first the High byte/word, then the

low byte/word.

Byte 5 high byte 1 ù high word ù

Byte 6 low byte 1 ûú

Byte 7 high byte 2 ù low word ú

Byte 8 low byte 2 ûû

Error

Error code. For description see the following table.

Byte 5 Error-Class

Byte 6 Error-Code

Byte 7 ù Additional-Code (high byte)

Byte 8 û Additional-Code (low byte)

ú double word

ErrorClass

Error-

Code

6 3 0 0 No access

6 5 1 0 Non-permissible service parameter

6 5 1 1 Invalid subindex

6 5 1 2 Data too long

6 5 1 3 Data too short

6 6 0 0 Object is no parameter

6 7 0 0 Object does not exist

6 8 0 0 Data types are not identical

8 0 0 0 Service cannot be executed

8 0 2 0 Service can currently not be executed

8 0 2 1 Cannot be executed because of local control

8 0 2 2 Cannot be executed because of controller status

8 0 3 0 Out of value range or parameter can only be

8 0 3 1 Parameter value too high

8 0 3 2 Parameter value too small

8 0 3 3 Out of range subparameter

8 0 3 4 Value of subparameter too high

8 0 3 5 Value of subparameter too small

8 0 3 6 max. value smaller than min. value

8

8 0 4 2 Process data length exceeded

8 0 4 3 Collision with other values in general

Additional-Code

[

]

hex

0 4 1 Communication object cannot be mapped to

Meaning

changed when controller is inhibited

process data

43

Page 46

The parameter communication with the controller has the following

sequence:

Read service

1. Determine user-data range of the controller; i.e. the location of the

DP user data in the host.

2. Enter address of the desired parameter in the field "index and

subindex" (DP output data)

3. Service/service = Read service and the bit "service/handshake"

must be exchanged (DP output data).

4. Check if the bit "service/handshake" of the DP input data and

DP output data is identical. If this is the case, the reply has been

received. It is useful to implement a time monitoring.

5. Check if the bit "service/status" is set. If this is not the case, the field

"data/error" contains the desired parameter value. If the bit

"service/status" is set, the read service has not been carried out

correctly, and the field "data/error" contains error information.

Write service

1. Determine user-data range of the controller; i.e. the location of the

DP user data in the host.

2. Enter address of the desired parameter in the field "index and

subindex" (DP output data)

3. Enter parameter value in the field "data/error".

4. Service/service = Read service and the bit "service/handshake"

must be exchanged (DP output data).

5. Check if the bit "service/handshake" of the DP input data and

DP output data is identical. If this is the case, the reply has been

received. It is useful to implement a time monitoring.

6. Check if the bit "service/status" is set. If this is the case, the service

has not been carried out correctly, and the field "data/error" contains

error information. Otherwise, the service has been carried out

correctly.

44

L

Page 47

3.1.6. DP command Sync/Unsync

The Sync command is used to 'freeze' the controller process input data.

This means that the controller works with those process data which it has

used during receipt of the Sync command. The controller receives new

data from the master, but it does not use them. Therefore, the master

can load process data in the controller and activate them simultaneously

using a Sync command to one or several drives.

A Sync command can be sent several times. The Unsync command

cancels the Sync command.

Caution! This function also causes the DP parameter setting

channel to be inactive.

3.1.7. DP command Clear_Data

The Clear_Data command is used to the set controller process input data

to 0.

Caution! This function also makes the DP parameter setting

channel inactive.

45

Page 48

3.2. Operating mode PROFIBUS mixed operation (FMS/DP)

In the operating mode mixed operation, the controller can be called up by

an FMS master or by a DP master. In the following, only these settings

for PROFIBUS-FMS are explained, since the operation using

PROFIBUS-DP is explained on page 35. Notes about restrictions of DP

functions in the operating mode mixed operation are given on page 34.

Settings of the master

Function Setting

Communication relation

(Connecting mode)

Slave-LSAP

(Foreign LSAP)

Slave-Password

(Password)

Slave station address

(Foreign L2 address)

Maximum PDU length

(Max. PDU length)

Baud rate 500 kBaud (factory setting)

Settings of the controller

Function Setting

Station address

L-C1901

Baud rate

L-C1902

MSAC

acyclic master-slave connection

2

0

no password function

126 (factory setting)

Value must be the same as the controller

setting in L-C1901 (page 32).

150

Value must be the same as the controller

setting in L-C1902 (page 32).

126 1 bis 126

Number for precise addressing of the drive

in the PROFIBUS network. This number

can only be assigned once per bus system

(page 32).

-2- 93.75 kBaud

-3- 187.50 kBaud

-4- 500.00 kBaud

-6- 1500.00 kBaud

Baud rate. In the bus system, all

participants must have the same baud rate

(page 32).

46

L

Page 49

3.2.1. FMS process data

Process data are data memories where several individual parameters

are combined to form a new parameter, the process data. These

process data are exchanged as fast as possible and cyclically between

the controller and the master. Process data can be divided into

process output data (PO data) and process input data (PI data),

viewed from the master, that means PO data are input data for the

controller. The controller receives control information from the master

and supplies feedback information to the master. Process data have a

fixed length of 4 byte. A summary of parameters is described in the

chapter "process data configuration" (page 67).

Factory setting of process input data:

Byte no. Auto-

mation

module

1 Word1/High-Byte

Bit 8 - 15

2 Word1/Low-Byte

Bit 0 - 7

No

Yes

3 Word2/High-Byte

Bit 8 - 15

4 Word2/Low-Byte

Bit 0 - 7

No

Yes

Meaning Index

PIW1

DRIVECOM status word

Automation status word

PIW 2

DRIVECOM actual speed

Automation FDO1

6041

58C4

6044

5A98

hex

hex

hex

hex

Factory setting of process output data:

Byte no. Auto-

Meaning Index

mation

module

1 Word1/High-Byte

POW1

Bit 8 - 15

2 Word1/Low-Byte

Bit 0 - 7

3 Word2/High-Byte

No

Yes

DRIVECOM control word

Automation control word

PIW 2

Bit 8 - 15

4 Word2/Low-Byte

Bit 0 - 7

No

Yes

DRIVECOM nominal speed value

Automation FDI1

Important note

•

If a parameter is set to the process output data, such as for example

DRIVECOM control word in the above table, the parameter (e.g. index

6040

) may not be written directly.

hex

3.2.1.1. Access to process data

You can reach the process data via the PROFIBUS services "Read" or

"Write" with the following index:

6040

58C5

6042

5A9B

hex

hex

hex

hex

Index = 6010

Index = 6011

Process input data

hex

Process output data

hex

Further information can be obtained from the chapter "process

data" (page 70).

47

Page 50

3.2.2. Communication services

The following FMS communication services are supported by Lenze

controllers:

• Initiate Make connection from master to controller.

• Abort Abort connection

• Status Read status of the controller

• Get-OV Read object dictionary

• Identify Identification of the controller

• Read Reading of parameters

• Write Writing of parameters

All transmission parameters can be obtained from the host descriptions.

The next chapter contains a list of parameter contents which are returned

by the Lenze controllers.

3.2.2.1. Entries in the communication reference list

You must enter the communication reference list entries yourself.

The following entries in a communication reference list can be set up for

the 2130IB:

Communication reference 1 2

Connection type Master-Slave acyclic Master-Slave acyclic

Connection attribute Defined Defined

Remote LSAP 1 2

R/S Address 0 0

Max-PDU Sending-High-Prio 0 0

Max-PDU Sending-Low-Prio 16 150

Max-PDU Receiving-High-Prio 0 0

Max-PDU Receiving-Low-Prio 16 150

Supported Services Request 00 00 00

Supported Services Response 00 10 00

Max. SCC 1 1

Max. RCC 0 0

Max. SAC 0 0

Max. RAC 0 0

CCI 0 0

hex

hex

80 30 00

00 00 00

hex

hex

48

L

Page 51

3.2.2.2. Initiate

The initiate service is used for the logic initiation between two

participants. The controller returns the following parameters:

Value Meaning

Profile-Number:

When using the automation

module:

Password:

Access Groups:

Access Protection Supported:

Version OV

21

hex

0 No profile

0 The password function of PROFIBUS

0 No access groups

TRUE Access protection is supported

Value: 0

DRIVECOM profile of version 1

is not supported

3.2.2.3. Abort

The abort service is used to abort a logic communication.

3.2.2.4. Status

This service supplies status information about the controller.

The following parameters are returned by the controller:

Status Value Meaning

Logical

Status

Physical

Status

Local

Detail

0 ready to communicate

(L-C001 = 5)

1 limited number of services

(L-C001 <> 5)