ThinkSystem SR250

Maintenance Manual

Machine Types: 7Y51, 7Y52, 7Y72 and 7Y73

Note

Before using this information and the product it supports, be sure to read and understand the safety

information and the safety instructions, which are available at:

http://thinksystem.lenovofiles.com/help/topic/safety_documentation/pdf_files.html

In addition, be sure that you are familiar with the terms and conditions of the Lenovo warranty for your server,

which can be found at:

http://datacentersupport.lenovo.com/warrantylookup

First Edition (November 2018)

© Copyright Lenovo 2018.

LIMITED AND RESTRICTED RIGHTS NOTICE: If data or software is delivered pursuant to a General Services

Administration (GSA) contract, use, reproduction, or disclosure is subject to restrictions set forth in Contract No. GS-35F-

05925.

Contents

Safety . . . . . . . . . . . . . . . . . . iii

Safety inspection checklist . . . . . . . . . . . iv

Chapter 1. Introduction . . . . . . . . . 1

Specifications . . . . . . . . . . . . . . . . 1

Firmware updates . . . . . . . . . . . . . . . 5

Configuring the LAN over USB interface

manually. . . . . . . . . . . . . . . . . 8

Installing the LAN over USB Windows device

driver . . . . . . . . . . . . . . . . . . 9

Tech Tips . . . . . . . . . . . . . . . . . . 9

Security advisories . . . . . . . . . . . . . 10

Power on the server . . . . . . . . . . . . . 10

Power off the server . . . . . . . . . . . . . 10

Chapter 2. Server components . . . . 11

Front view . . . . . . . . . . . . . . . . . 12

Front operator panel . . . . . . . . . . . 14

Rear view . . . . . . . . . . . . . . . . . 15

System-board switches, jumpers, and buttons. . . 16

System-board LEDs . . . . . . . . . . . 16

System-board connectors . . . . . . . . . 17

System-board jumpers and buttons . . . . . 19

RAID adapters and the NVMe switch card . . . . 20

Backplates and backplanes . . . . . . . . . . 21

PCIe riser assembly . . . . . . . . . . . . . 23

Internal cable routing. . . . . . . . . . . . . 24

Front VGA cable. . . . . . . . . . . . . 24

Fan cable . . . . . . . . . . . . . . . 26

Power supply . . . . . . . . . . . . . . 27

Flash power module . . . . . . . . . . . 29

3.5-inch simple-swap drive model . . . . . . 30

Four 3.5-inch hot-swap drive model . . . . . 32

Eight 2.5-inch hot-swap drive model . . . . . 34

Ten 2.5-inch hot-swap drive model . . . . . 36

Parts list. . . . . . . . . . . . . . . . . . 38

Power cords . . . . . . . . . . . . . . 45

Chapter 3. Hardware replacement

procedures . . . . . . . . . . . . . . . 47

Installation Guidelines . . . . . . . . . . . . 47

System reliability guidelines . . . . . . . . 48

Working inside the server with the power on . . 49

Handling static-sensitive devices . . . . . . 49

Adapter replacement. . . . . . . . . . . . . 49

Remove an adapter . . . . . . . . . . . 49

Install an adapter . . . . . . . . . . . . 50

Air baffle replacement . . . . . . . . . . . . 51

Remove the air baffle . . . . . . . . . . . 51

Install the air baffle . . . . . . . . . . . . 52

Backplane replacement. . . . . . . . . . . . 53

Remove the hot-swap drive backplane . . . . 53

Install the hot-swap drive backplane . . . . . 54

Backplate replacement . . . . . . . . . . . . 56

Remove the backplate . . . . . . . . . . 56

Install the backplate . . . . . . . . . . . 57

CMOS battery replacement . . . . . . . . . . 58

Remove the CMOS battery . . . . . . . . 58

Install the CMOS battery (CR2032) . . . . . 59

DIMM replacement . . . . . . . . . . . . . 61

Remove a DIMM. . . . . . . . . . . . . 61

Install a DIMM . . . . . . . . . . . . . 63

Drive replacement . . . . . . . . . . . . . . 65

Remove a simple-swap drive. . . . . . . . 65

Install a simple-swap drive. . . . . . . . . 66

Remove a hot-swap drive . . . . . . . . . 66

Install a hot-swap drive . . . . . . . . . . 67

Fan replacement . . . . . . . . . . . . . . 68

Remove a fan . . . . . . . . . . . . . . 68

Install a fan. . . . . . . . . . . . . . . 70

Flash power module replacement . . . . . . . . 72

Remove the flash power module . . . . . . 72

Install the flash power module . . . . . . . 74

Front operator panel replacement. . . . . . . . 75

Remove the front operator panel (2.5-inch

HDD model) . . . . . . . . . . . . . . 75

Install the front operator panel (2.5-inch HDD

model) . . . . . . . . . . . . . . . . 77

Remove the front operator panel (3.5-inch

HDD model) . . . . . . . . . . . . . . 79

Install the front operator panel (3.5-inch HDD

model) . . . . . . . . . . . . . . . . 81

Heat sink replacement . . . . . . . . . . . . 83

Remove the heat sink. . . . . . . . . . . 83

Install the heat sink. . . . . . . . . . . . 85

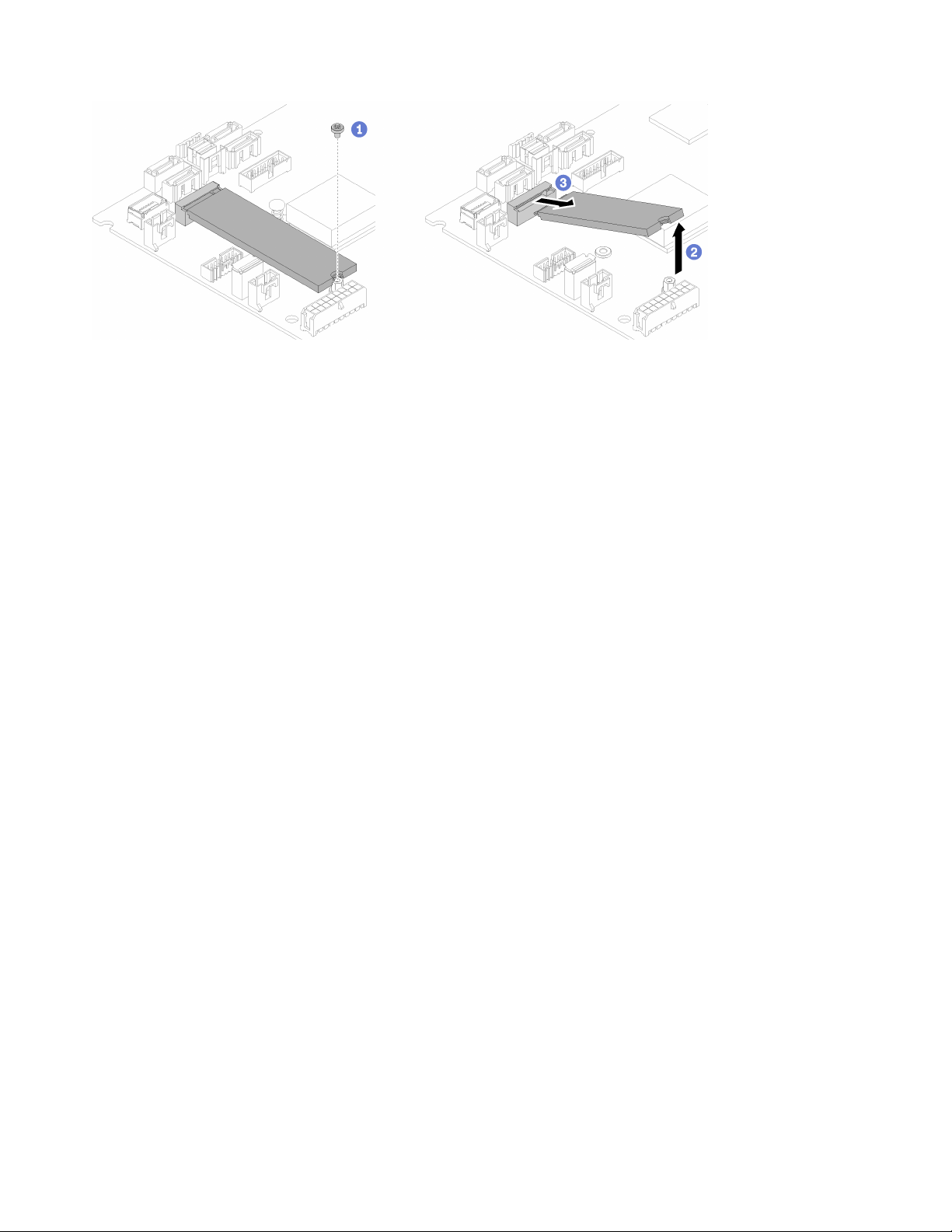

M.2 drive replacement . . . . . . . . . . . . 86

Remove the M.2 drive . . . . . . . . . . 86

Install the M.2 drive . . . . . . . . . . . 88

PCIe riser assembly replacement . . . . . . . . 90

Remove the PCIe riser assembly . . . . . . 90

Install the PCIe riser assembly . . . . . . . 91

Power supply unit replacement. . . . . . . . . 93

Remove the fixed power supply unit . . . . . 93

Install the fixed power supply unit . . . . . . 95

© Copyright Lenovo 2018 i

Remove a hot-swap power supply unit . . . . 97

Install a hot-swap power supply unit . . . . . 99

Power interface board replacement . . . . . . . 101

Remove the power interface board . . . . . 101

Install the power interface board . . . . . . 104

Processor replacement . . . . . . . . . . . . 107

Remove the processor . . . . . . . . . . 107

Install the processor . . . . . . . . . . . 108

Rack latches replacement. . . . . . . . . . . 110

Remove the rack latches . . . . . . . . . 110

Install the rack latches . . . . . . . . . . 112

RAID adapter replacement . . . . . . . . . . 114

Remove the RAID adapter . . . . . . . . . 114

Install the RAID adapter . . . . . . . . . . 115

Security bezel replacement . . . . . . . . . . 117

Remove the security bezel . . . . . . . . . 117

Install the security bezel . . . . . . . . . . 118

System board replacement . . . . . . . . . . 119

Remove the system board . . . . . . . . . 119

Install the system board . . . . . . . . . . 121

Update the Universal Unique Identifier

(UUID). . . . . . . . . . . . . . . . . 124

Update the DMI/SMBIOS data . . . . . . . 125

Enable TPM . . . . . . . . . . . . . . 127

Enable UEFI Secure Boot . . . . . . . . . 131

Top cover replacement . . . . . . . . . . . . 131

Remove the top cover . . . . . . . . . . 132

Install the top cover . . . . . . . . . . . 133

TPM card (for China only) replacement. . . . . . 134

Remove the TPM card (for China only) . . . . 134

Install the TPM card (for China only) . . . . . 135

VGA cable replacement. . . . . . . . . . . . 136

Remove the VGA cable (2.5-inch HDD

model) . . . . . . . . . . . . . . . . 136

Install the VGA cable (2.5-inch HDD

model) . . . . . . . . . . . . . . . . 137

Remove the VGA cable (3.5-inch HDD

model) . . . . . . . . . . . . . . . . 138

Install the VGA cable (3.5-inch HDD

model) . . . . . . . . . . . . . . . . 140

Complete the parts replacement . . . . . . . . 142

Chapter 4. Problem

determination . . . . . . . . . . . . . 143

Event logs . . . . . . . . . . . . . . . . . 143

The front operator panel and error LEDs . . . . . 145

Power supply LEDs . . . . . . . . . . . 146

System-board LEDs . . . . . . . . . . . 147

General problem determination procedures . . . . 148

Resolving suspected power problems . . . . 148

Resolving suspected Ethernet controller

problems . . . . . . . . . . . . . . . 149

Troubleshooting by symptom . . . . . . . . . 149

Power on and power off problems. . . . . . 150

Memory problems . . . . . . . . . . . . 151

Hard disk drive problems . . . . . . . . . 152

Monitor and video problems . . . . . . . . 154

Keyboard, mouse, or USB-device

problems . . . . . . . . . . . . . . . 155

Optional-device problems . . . . . . . . . 156

Serial-device problems . . . . . . . . . . 158

Intermittent problems. . . . . . . . . . . 158

Power problems. . . . . . . . . . . . . 159

Network problems . . . . . . . . . . . . 159

Observable problems. . . . . . . . . . . 160

Software problems. . . . . . . . . . . . 162

Appendix A. Getting help and

technical assistance . . . . . . . . . . 165

Before you call . . . . . . . . . . . . . . . 165

Collecting service data . . . . . . . . . . . . 166

Contacting Support . . . . . . . . . . . . . 167

Appendix B. Notices. . . . . . . . . . 169

Trademarks . . . . . . . . . . . . . . . . 170

Important notes. . . . . . . . . . . . . . . 170

Particulate contamination . . . . . . . . . . . 170

Telecommunication regulatory statement. . . . . 171

Electronic emission notices . . . . . . . . . . 171

Taiwan BSMI RoHS declaration. . . . . . . 172

Taiwan import and export contact information . . . 172

Index . . . . . . . . . . . . . . . . . . 173

ii ThinkSystem SR250 Maintenance Manual

Safety

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

在安装本产品之前,请仔细阅读 Safety Information (安全信息)。

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d'installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

© Copyright Lenovo 2018 iii

Antes de instalar este producto, lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

Safety inspection checklist

Use the information in this section to identify potentially unsafe conditions with your server. As each machine

was designed and built, required safety items were installed to protect users and service technicians from

injury.

Important: Electrical grounding of the server is required for operator safety and correct system function.

Proper grounding of the electrical outlet can be verified by a certified electrician.

S041

CAUTION:

• This equipment must be installed or serviced by trained personnel, as defined by IEC 60950-1 and

IEC 62368-1, the Standard for Safety of audio/video, information and communication technology

equipment.

• Access to the equipment is by the use of a tool, lock and key, or other means of security, and is

controlled by the authority responsible for the location.

Make sure all power cords are disconnected from the system when reading the following step in

this manual: Turn off the server. Disconnect the power cords and all external cables.

Use the following checklist to verify that there are no potentially unsafe conditions:

1. Make sure that the power is off and the power cord is disconnected.

2. Check the power cord.

iv

ThinkSystem SR250 Maintenance Manual

• Make sure that the third-wire ground connector is in good condition. Use a meter to measure thirdwire ground continuity for 0.1 ohm or less between the external ground pin and the frame ground.

• Make sure that the power cord is the correct type.

To view the power cords that are available for the server:

a. Go to:

http://dcsc.lenovo.com/#/

b. In the Customize a Model pane:

1) Click Select Options/Parts for a Model.

2) Enter the machine type and model for your server.

c. Click the Power tab to see all line cords.

• Make sure that the insulation is not frayed or worn.

3. Check for any obvious non-Lenovo alterations. Use good judgment as to the safety of any non-Lenovo

alterations.

4. Check inside the server for any obvious unsafe conditions, such as metal filings, contamination, water or

other liquid, or signs of fire or smoke damage.

5. Check for worn, frayed, or pinched cables.

6. Make sure that the power-supply cover fasteners (screws or rivets) have not been removed or tampered

with.

© Copyright Lenovo 2018 v

vi ThinkSystem SR250 Maintenance Manual

Chapter 1. Introduction

The ThinkSystem SR250 server is a 1U rack server designed for high-volume network transaction

processing. This high-performance, multi-core server is ideally suited for networking environments that

require superior processor performance, input/output (I/O) flexibility, and high manageability.

Figure 1. SR250

The server comes with a limited warranty. For details about the warranty, see:

https://support.lenovo.com/us/en/solutions/ht503310

For details about your specific warranty, see:

http://datacentersupport.lenovo.com/warrantylookup

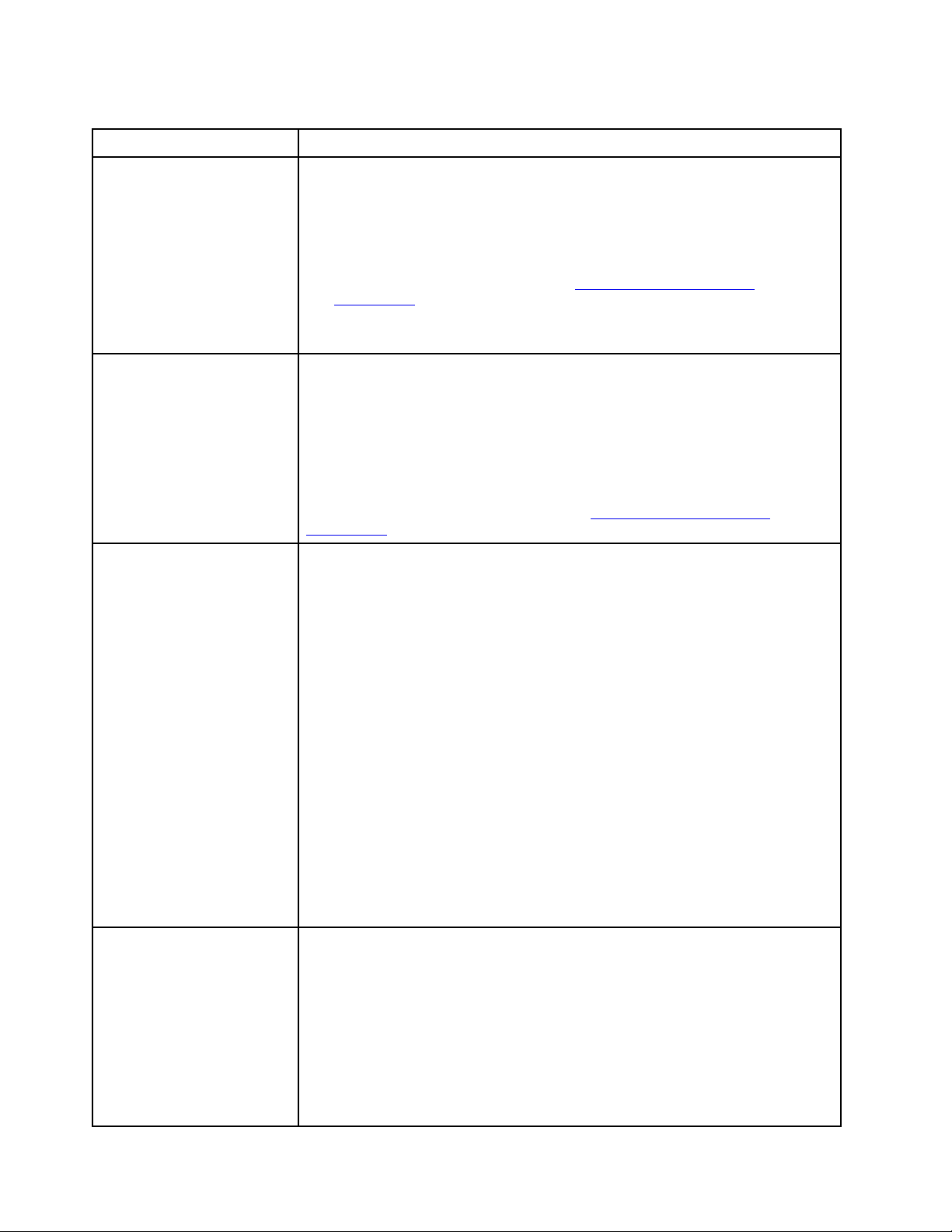

Specifications

The following information is a summary of the features and specifications of the server. Depending on the

model, some features might not be available, or some specifications might not apply.

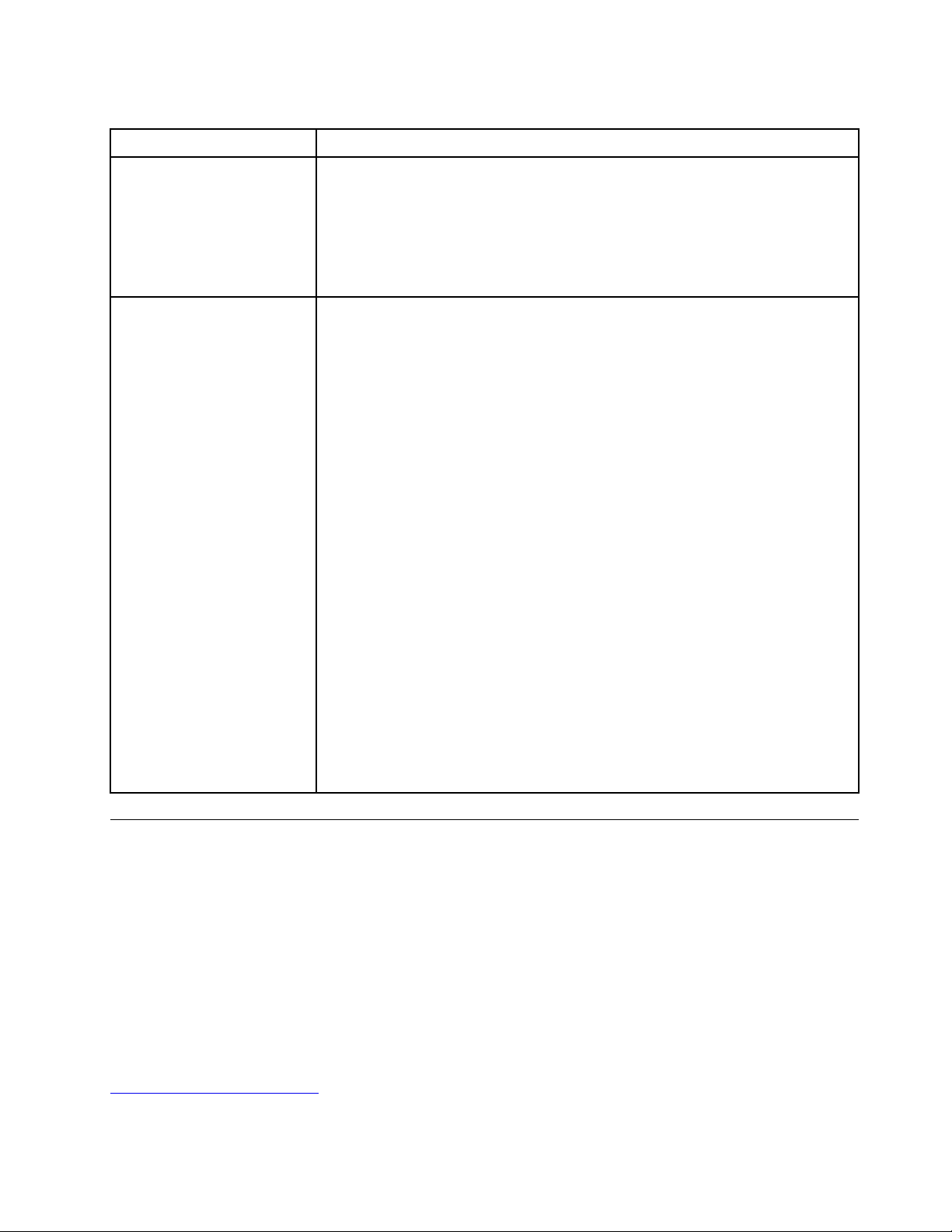

Table 1. Server Specifications

Specification

Size

Weight Maximum: 12.3 kg (27.1 lbs)

Description

1U rack

• Height: 43.0 mm (1.7 inches)

• Width: 434.4 mm (17.1 inches)

– With rack handles: 481.7 mm (18.9 inches)

– Without rack handles: 434.4 mm (17.1 inches)

• Depth: 497.8 mm (19.6 inches)

Note: The depth is measured from the front mounting flange of the rack to the

rear of the server.

© Copyright Lenovo 2018 1

Table 1. Server Specifications (continued)

Specification

Processor (depending on the

model)

Memory

Drive bays (depending on the

model)

Description

One Intel® multi-core processor from Core™, Pentium®, Celeron® or Xeon® E

processor family

Notes:

1. Use the Setup utility to determine the type and speed of the processors in the

node.

2. For a list of supported processors, see

serverproven/

.

http://www.lenovo.com/us/en/

3. If the 95 W processor is used, the server only supports the eight 2.5-inch hotswap drive backplane.

• Slots: 4 DIMM slots

• Minimum: 8 GB (1 x 8GB DIMM)

• Maximum: 64 GB (4 x 16GB DIMM)

• Type:

– PC4-21300, 2666 MT/s, error correcting code (ECC), double-data-rate 4

(DDR4) unbuffered DIMM (UDIMM)

Note: For a list of supported processors, see

serverproven/

.

http://www.lenovo.com/us/en/

• 2.5-inch models:

– Supports up to four simple-swap SAS/SATA drive bays.

– Supports up to eight hot-swap SAS/SATA drive bays.

– Supports up to ten hot-swap SAS/SATA drive bays with two NVMe drive bays.

• 3.5-inch models:

– Supports up to four simple-swap SAS/SATA drive bays.

– Supports up to four hot-swap SAS/SATA drive bays.

Notes:

1. When the eighth SATA drive is installed, the M.2 drive is disabled.

2. When all eight storage drives have been installed, and the system has been set

to software RAID mode in the UEFI settings, regardless if the disks are

configured as an array or as separate disks, drives 6 and 7 cannot be used to

install the Windows operating system.

3. If the M.2 drive has been installed, and the system has been set to software

RAID mode in the UEFI settings, regardless if the disks are configured as an

array or as separate disks, the M.2 drive cannot be used to install the Windows

operating system.

M.2 drive

Supports 2 different physical sizes of M.2 drives:

• 42 mm (2242)

• 80 mm (2280)

Notes:

1. When the eighth SATA drive is installed, the M.2 drive is disabled.

2. If the M.2 drive has been installed, and the system has been set to software

RAID mode in the UEFI settings, regardless if the disks are configured as an

array or as separate disks, the M.2 drive cannot be used to install the Windows

operating system.

2 ThinkSystem SR250 Maintenance Manual

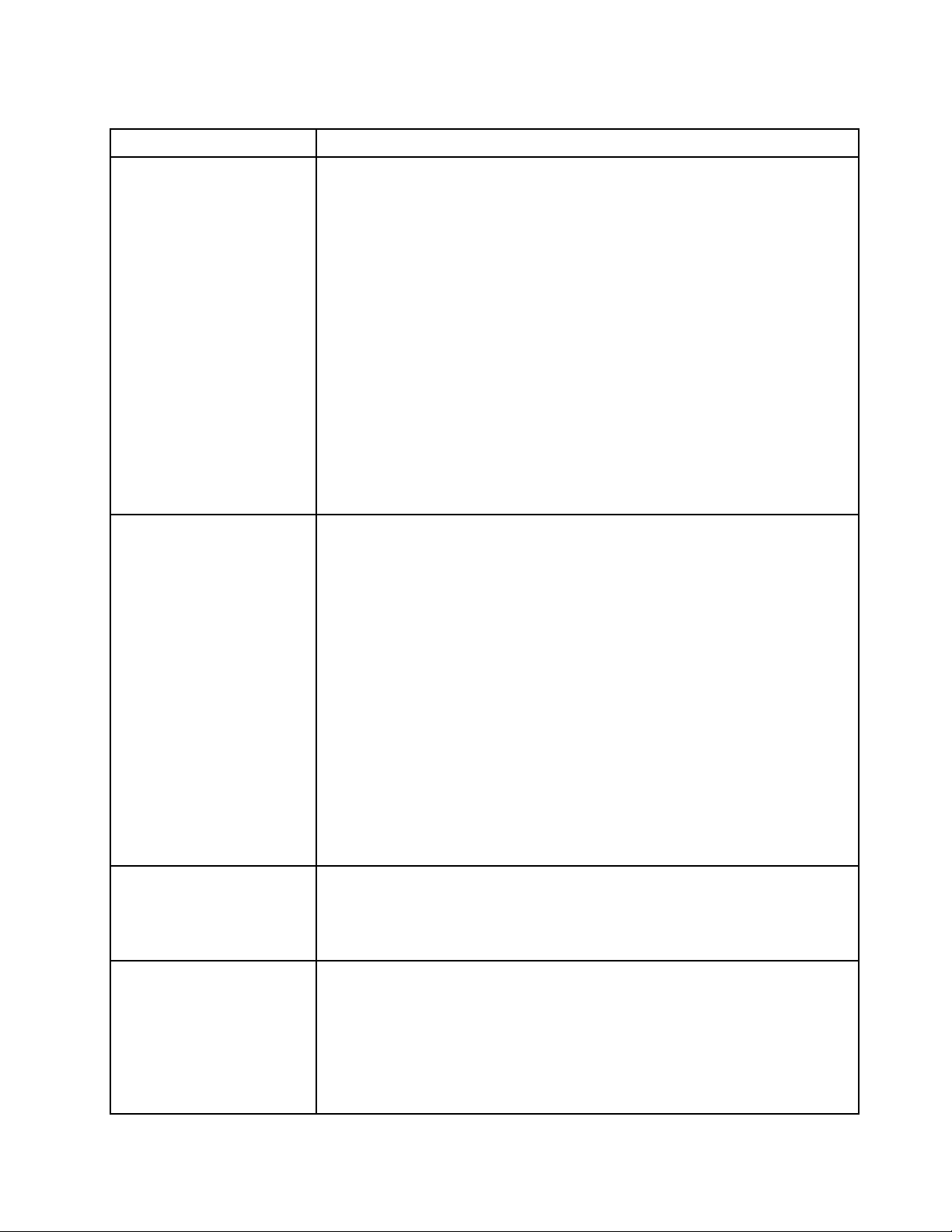

Table 1. Server Specifications (continued)

Specification

PCIe riser cards and

expansion slots

Integrated functions

RAID controllers (depending

on the model)

Description

Up to two expansion slots (depending on the sever configuration):

• Slot 1-2: PCI Express 3.0 for PCIe -card with the following slots available

depending on the card installed:

1. x16 PCIe (full-height, half-length) kit provides:

– Slot 1: Not available

– Slot 2: PCI Express 3.0 x16

2. x8/x8 butterfly card:

– Slot 1: PCI Express 3.0 x8 (x8, x4, x1), low profile

– Slot 2: PCI Express 3.0 x8 (x8, x4, x1), full-height, half-length

• Slot 4 (on-board): PCI Express 3.0 x8 (x4, x1), low-profile

Notes:

1. PCIe slot 1 and slot 2 do not support ARI and SR-IOV.

2. PCIe slot 4 supports ARI and SR-IOV.

3. QLogic QL41262 PCIe 25Gb 2-Port SFP28 Ethernet Adapter does not support

shared storage V3700 V2/XP and V5030 V2 configurations.

• Lenovo XClarity Controller, which provides service processor control and

monitoring functions, video controller, and remote keyboard, video, mouse, and

remote drive capabilities.

• Light-path diagnostics

• Front standard connectors (front of server):

– One USB 2.0 connector

– One USB 3.1 Gen 1 connector

– One front operator panel

– One VGA connector (optional)

• Rear standard connectors (rear of server):

– Two USB 3.1 Gen 2 connectors

– Two Ethernet connectors

– One Lenovo XClarity Controller network connector

– One VGA connector

– One serial connector

Hardware RAID: Additional RAID levels supported when an optional RAID controller

is installed. The hardware RAID controller supports RAID levels 0, 1, 5, and 10.

Video controller (integrated

into Lenovo XClarity

Controller)

Software RAID: A software RAID controller is integrated on the system board. The

software RAID controller supports RAID levels 0, 1, 5, and 10.

Matrox G200

• ASPEED

• SVGA compatible video controller

• Avocent Digital Video Compression

• 16 MB of video memory (not expandable)

Note: Maximum video resolution is 1600 x 1200 at 75 Hz.

Chapter 1. Introduction 3

Table 1. Server Specifications (continued)

Specification

Fans

Power supplies

Acoustical noise emissions

(base configuration)

Description

Four internal system fans (40mm x 28mm)

One fixed power supply: 300-watt ac 80 PLUS Gold

Supports up to two power supplies for redundancy support: 450-watt ac 80 PLUS

Platinum

• Operation:

– Minimum: 5.3 bels

– Typical: 5.4 bels

– Maximum: 5.7 bels

• Idle

– Minimum: 4.9 bels

– Typical: 5.0 bels

– Maximum: 5.4 bels

Notes:

1. These sound power levels are measured in controlled acoustical environments

according to procedures specified by ISO 7779 and are reported in accordance

with ISO 9296.

2. The declared acoustic noise levels are based on specified configurations, which

may change slightly depending on configurations/conditions.

3. The options supported in this server vary in function, power consumption, and

required cooling. Any increase in cooling required by these options will increase

the fan speed and generated sound level. The actual sound pressure levels

measured in your installation depend upon a variety of factors, including: the

number of racks in the installation; the size, materials, and configuration of the

room; the noise levels of other equipment; the room ambient temperature and

barometric pressure; and the location of employees in relation to the equipment.

Heat output Approximate heat output:

• Minimum configuration: 287.46 BTU per hour (84.25 watts)

• Maximum configuration : 783.02 BTU per hour (229.49 watts)

4 ThinkSystem SR250 Maintenance Manual

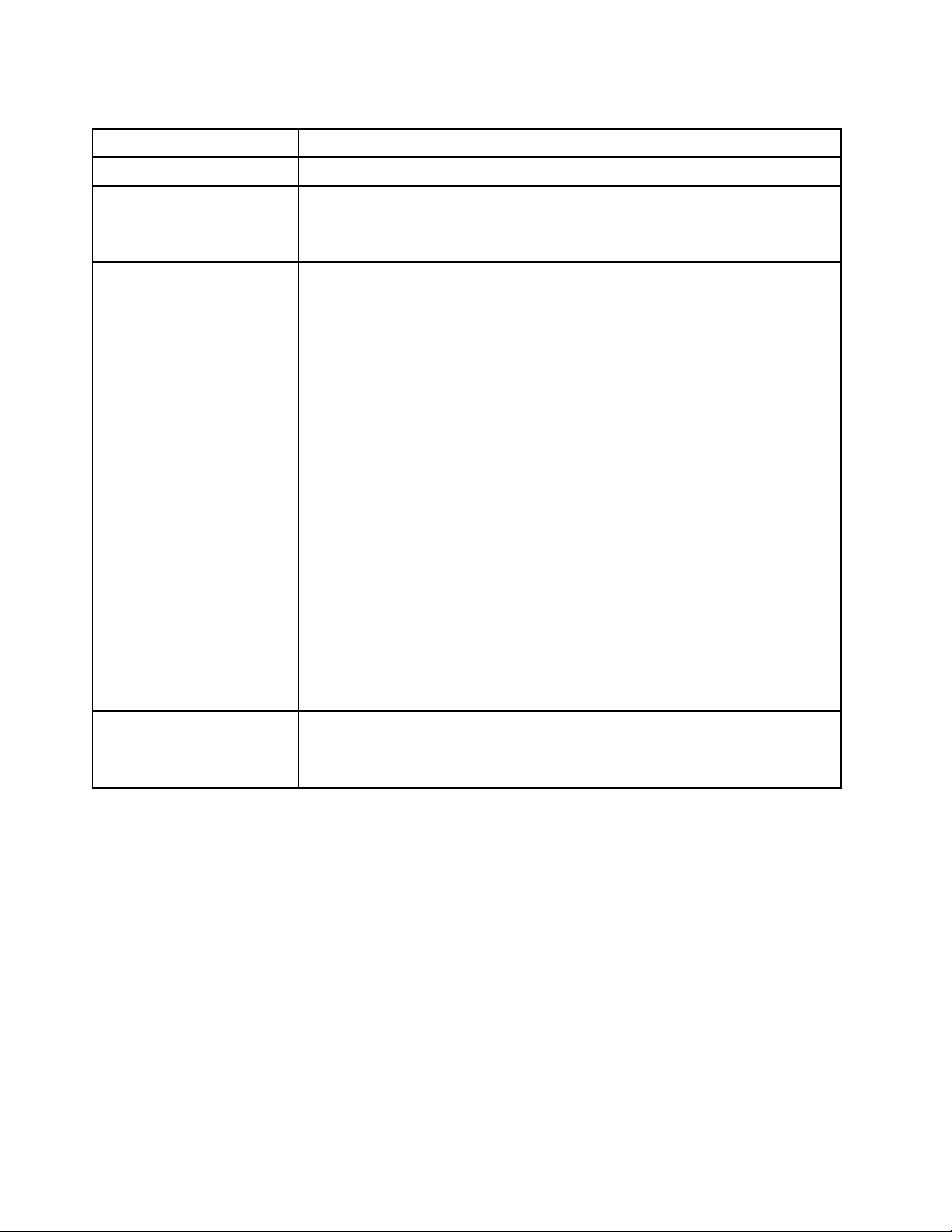

Table 1. Server Specifications (continued)

Specification

Electrical input

Environment

Description

Sine-wave input (50–60 Hz) required

• 300-Watt power supply:

100-127 V ac /200-240 V ac, 4/2A

• 450-Watt power supply:

100-127 V ac /200-240 V ac, 5.8/2.9A

The ThinkSystem SR250 complies with ASHRAE class A2 specifications. System

performance may be impacted when operating temperature is outside ASHRAE A2

specification or fan failed condition.

The ThinkSystem SR250 is supported in the following environment:

• Air temperature:

– Server on:

– (ASHRAE Class A2): 10°C to 35°C (50°F to 95°F); decrease the maximum

ambient temperature by 1°C for every 300 m (984 ft) increase in altitude

above 900 m (2,953 ft).

– Sever off: 5°C to 45°C (41°F to 113°F)

– Shipping/storage: -40 - 60°C (-40 - 140°F)

• Maximum altitude: 3050 m (10 000 ft)

• Relative Humidity (non-condensing):

– Operating:

– ASHRAE Class A2: 8% - 80%, maximum dew point : 21°C (70°F)

– Shipment/storage: 8% to 90%

• ASHRAE A3 is supported for the eight 2.5-inch hot-swap drive configuration with

80W processor only.

• Particulate contamination:

Airborne particulates and reactive gases acting alone or in combination with other

environmental factors such as humidity or temperature might pose a risk to the

solution. For information about the limits for particulates and gases, see

“Particulate contamination” on page 170.

Firmware updates

Several options are available to update the firmware for the server.

You can use the tools listed here to update the most current firmware for your server and the devices that are

installed in the server.

Note: Lenovo typically releases firmware in bundles called UpdateXpress System Packs (UXSPs). To ensure

that all of the firmware updates are compatible, you should update all firmware at the same time. If you are

updating firmware for both the Lenovo XClarity Controller and UEFI, update the firmware for Lenovo XClarity

Controller first.

Best practices related to updating firmware is available at the following location:

http://lenovopress.com/LP0656

Chapter 1. Introduction 5

Important terminology

• In-band update. The installation or update is performed using a tool or application within an operating

system that is executing on the server’s core CPU.

• Out-of-band update. The installation or update is performed by the Lenovo XClarity Controller collecting

the update and then directing the update to the target subsystem or device. Out-of-band updates have no

dependency on an operating system executing on the core CPU. However, most out-of-band operations

do require the server to be in the S0 (Working) power state.

• On-Target update. The installation or update is initiated from an Operating System executing on the

server’s operating system.

• Off-Target update. The installation or update is initiated from a computing device interacting directly with

the server’s Lenovo XClarity Controller.

• UpdateXpress System Packs (UXSPs). UXSPs are bundled updates designed and tested to provide the

interdependent level of functionality, performance, and compatibility. UXSPs are server machine-type

specific and are built (with firmware and device driver updates) to support specific Windows Server, Red

Hat Enterprise Linux (RHEL) and SUSE Linux Enterprise Server (SLES) operating system distributions.

Machine-type-specific firmware-only UXSPs are also available.

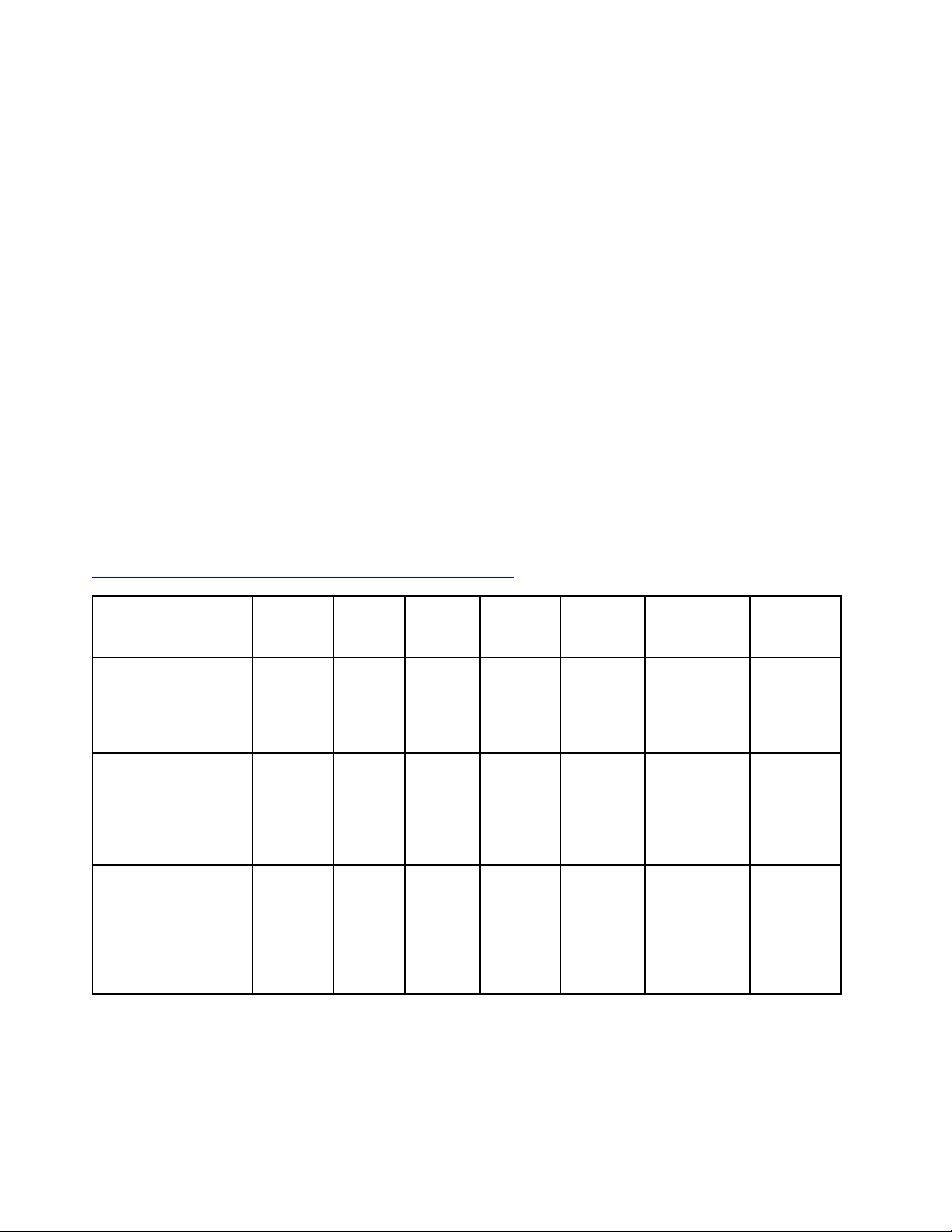

See the following table to determine the best Lenovo tool to use for installing and setting up the firmware:

Note: The server UEFI settings for option ROM must be set to Auto or UEFI to update firmware using

Lenovo XClarity Administrator or Lenovo XClarity Essentials. For more information, see the following Tech

Tip:

https://datacentersupport.lenovo.com/us/en/solutions/ht506118

Tool

Lenovo XClarity

Provisioning

Manager

Limited to core system

firmware only.

Lenovo XClarity

Controller

Supports core system

firmware and most

advanced I/O option

firmware updates

Lenovo XClarity

Essentials OneCLI

Supports all core

system firmware, I/O

firmware, and installed

operating system

driver updates

Out-ofIn-band

update

√ √ √ √

√ √ √ √

band

update

√ √ √ √

Ontarget

update

Offtarget

update

Graphical

user

interface

Commandline interface

Supports

UXSPs

6 ThinkSystem SR250 Maintenance Manual

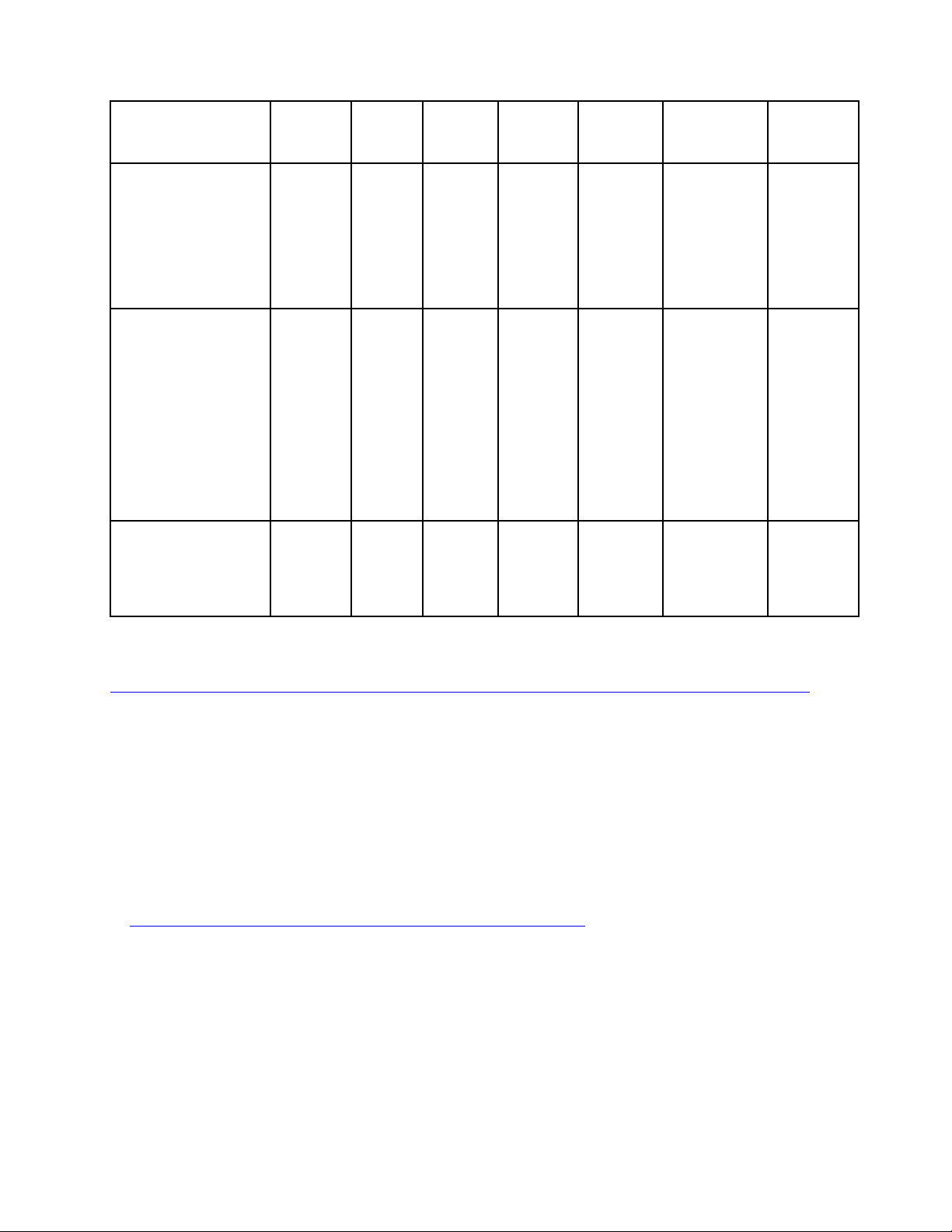

Tool

Lenovo XClarity

Essentials

UpdateXpress

Supports all core

system firmware, I/O

firmware, and installed

operating system

driver updates

Out-ofIn-band

update

√ √ √ √

band

update

Ontarget

update

Offtarget

update

Graphical

user

interface

Commandline interface

Supports

UXSPs

Lenovo XClarity

Essentials Bootable

Media Creator

Supports core system

firmware and I/O

firmware updates. You

can update the

Microsoft Windows

operating system, but

device drivers are not

included on the

bootable image

Lenovo XClarity

Administrator

Supports core system

firmware and I/O

firmware updates

√ √ √ √

√ √ √ √

The latest firmware can be found at the following site:

http://datacentersupport.lenovo.com/us/en/products/servers/system-x/system-x3850-x6/6241/downloads

• Lenovo XClarity Provisioning Manager

From Lenovo XClarity Provisioning Manager, you can update the Lenovo XClarity Controller firmware, the

UEFI firmware, and the Lenovo XClarity Provisioning Manager software.

Note: By default, the Lenovo XClarity Provisioning Manager Graphical User Interface is displayed when

you press F1. If you have changed that default to be the text-based system setup, you can bring up the

Graphical User Interface from the text-based system setup interface.

Additional information about using Lenovo XClarity Provisioning Manager to update firmware is available

at:

http://sysmgt.lenovofiles.com/help/topic/LXPM/platform_update.html

• Lenovo XClarity Controller

If you need to install a specific update, you can use the Lenovo XClarity Controller interface for a specific

server.

Notes:

– To perform an in-band update through Windows or Linux, the operating system driver must be installed

and the Ethernet-over-USB (sometimes called LAN over USB) interface must be enabled.

Additional information about configuring Ethernet over USB is available at:

Chapter 1. Introduction 7

http://sysmgt.lenovofiles.com/help/topic/com.lenovo.systems.management.xcc.doc/NN1ia_c_

configuringUSB.html

– If you update firmware through the Lenovo XClarity Controller, make sure that you have downloaded

and installed the latest device drivers for the operating system that is running on the server.

Specific details about updating firmware using Lenovo XClarity Controller are available at:

http://sysmgt.lenovofiles.com/help/topic/com.lenovo.systems.management.xcc.doc/NN1ia_c_

manageserverfirmware.html

• Lenovo XClarity Essentials OneCLI

Lenovo XClarity Essentials OneCLI is a collection of command line applications that can be used to

manage Lenovo servers.Its update application can be used to update firmware and device drivers for your

servers. The update can be performed within the host operating system of the server (in-band) or remotely

through the BMC of the server (out-of-band).

Specific details about updating firmware using Lenovo XClarity Essentials OneCLI is available at:

http://sysmgt.lenovofiles.com/help/topic/toolsctr_cli_lenovo/onecli_c_update.html

• Lenovo XClarity Essentials UpdateXpress

Lenovo XClarity Essentials UpdateXpress provides most of OneCLI update functions through a graphical

user interface (GUI). It can be used to acquire and deploy UpdateXpress System Pack (UXSP) update

packages and individual updates. UpdateXpress System Packs contain firmware and device driver

updates for Microsoft Windows and for Linux.

You can obtain Lenovo XClarity Essentials UpdateXpress from the following location:

https://datacentersupport.lenovo.com/solutions/lnvo-xpress

• Lenovo XClarity Essentials Bootable Media Creator

You can use Lenovo XClarity Essentials Bootable Media Creator to create bootable media that is suitable

for applying firmware updates, running preboot diagnostics, and deploying Microsoft Windows operating

systems.

You can obtain Lenovo XClarity Essentials BoMC from the following location:

https://datacentersupport.lenovo.com/solutions/lnvo-bomc

• Lenovo XClarity Administrator

If you are managing multiple servers using the Lenovo XClarity Administrator, you can update firmware for

all managed servers through that interface. Firmware management is simplified by assigning firmwarecompliance policies to managed endpoints. When you create and assign a compliance policy to managed

endpoints, Lenovo XClarity Administrator monitors changes to the inventory for those endpoints and flags

any endpoints that are out of compliance.

Specific details about updating firmware using Lenovo XClarity Administrator are available at:

http://sysmgt.lenovofiles.com/help/topic/com.lenovo.lxca.doc/update_fw.html

Configuring the LAN over USB interface manually

To perform a firmware update through the operating system using Lenovo XClarity Essentials OneCLI, the

Lenovo XClarity Controller must be configured to use the LAN over USB interface. The firmware update

package attempts to perform the setup automatically, if needed. If the automatic setup fails or if you prefer to

set up the LAN over USB manually, use one of the following procedures.

Additional information about using the Lenovo XClarity Controller to enable LAN over USB is available at:

8

ThinkSystem SR250 Maintenance Manual

http://sysmgt.lenovofiles.com/help/topic/com.lenovo.systems.management.xcc.doc/NN1ia_c_

configuringUSB.html

Installing the LAN over USB Windows device driver

When you install a Windows operating system, there might be an unknown RNDIS device in the Device

Manager. Lenovo provides a Windows INF file that identifies this device.

Complete the following steps to install ibm_rndis_server_os.inf:

Note: You only have to perform these steps if the compute node is running a Windows operating system

and the ibm_rndis_server_os.inf file has not been previously installed. The file only has to be installed once. It

is required by Windows operating systems to detect and use the LAN over USB functionality.

Step 1. Click Administrative Tools ➙ Computer Management ➙ Device Manager and find the RNDIS

Device. Click Properties ➙ Driver ➙ Reinstall driver. Point the server to the \Windows\inf

directory where it can find the ibm_rndis_server_os.inf file and install the device.

Step 2. Click Administrative Tools ➙ Device Manager. Right-click Network adapters and select Scan

for hardware changes. A small pop-up confirms that the Ethernet device is found and installed.

The New Hardware Wizard starts automatically.

Step 3. When you are prompted Can Windows connect to Windows Update to search for software?, select No,

not this time. Click Next to continue.

Step 4. When you are prompted What do you want the wizard to do?, select Install from a list or specific

location (Advanced). Click Next to continue.

Step 5. When you are prompted Please choose your search and installation options, select Don't search. I

will choose the driver to install. Click Next to continue.

Step 6. When you are prompted Select a hardware type, and then click Next, select Network adapters.

Click Next to continue.

Step 7. When you are prompted with the statement Completing the Found New Hardware Wizard, click Finish.

A new local area connection appears. If the message This connection has limited or no

connectivity is displayed, ignore this message.

Step 8. Return to the Device Manager. Lenovo USB Remote NDIS Network Device appears under

Network Adapters.

Step 9. Use the Lenovo XClarity Controller interface to view or set the IP address for the LAN adapter.

Additional information about using the Lenovo XClarity Controller to configure LAN over USB is

available at:

http://sysmgt.lenovofiles.com/help/topic/com.lenovo.systems.management.xcc.doc/NN1ia_c_

configuringUSB.html

Tech Tips

Lenovo continually updates the support website with the latest tips and techniques that you can use to solve

issues that you might have with your server. These Tech Tips (also called retain tips or service bulletins)

provide procedures to work around issues related to the operation of your server.

To find the Tech Tips available for your server:

1. Go to

2. Click How-tos & Solutions.

http://datacentersupport.lenovo.com and navigate to the support page for your server.

Expand Symptom to choose a category for the type is problem that you are having.

Chapter 1. Introduction 9

Security advisories

Lenovo is committed to developing products and services that adhere to the highest security standards in

order to protect our customers and their data. When potential vulnerabilities are reported, it is the

responsibility of the Lenovo Product Security Incident Response Team (PSIRT) to investigate and provide

information to our customers so they may put mitigation plans in place as we work toward providing

solutions.

The list of current advisories is available at the following site:

https://datacentersupport.lenovo.com/product_security/home

Power on the server

After the server performs a short self-test (power status LED flashes quickly) when connected to input power,

it enters a standby state (power status LED flashes once per second).

The server can be turned on (power LED on) in any of the following ways:

• You can press the power button.

• The server can restart automatically after a power interruption.

• The server can respond to remote power-on requests sent to the Lenovo XClarity Controller.

For information about powering off the server, see “Power off the server” on page 10.

Power off the server

The server remains in a standby state when it is connected to a power source, allowing the Lenovo XClarity

Controller to respond to remote power-on requests. To remove all power from the server (power status LED

off), you must disconnect all power cables.

To place the server in a standby state (power status LED flashes once per second):

Note: The Lenovo XClarity Controller can place the server in a standby state as an automatic response to a

critical system failure.

• Start an orderly shutdown using the operating system (if supported by your operating system).

• Press the power button to start an orderly shutdown (if supported by your operating system).

• Press and hold the power button for more than 4 seconds to force a shutdown.

When in a standby state, the server can respond to remote power-on requests sent to the Lenovo XClarity

Controller. For information about powering on the server, see “Power on the server” on page 10.

10

ThinkSystem SR250 Maintenance Manual

Chapter 2. Server components

Use the information in this section to learn about each of the components associated with your server.

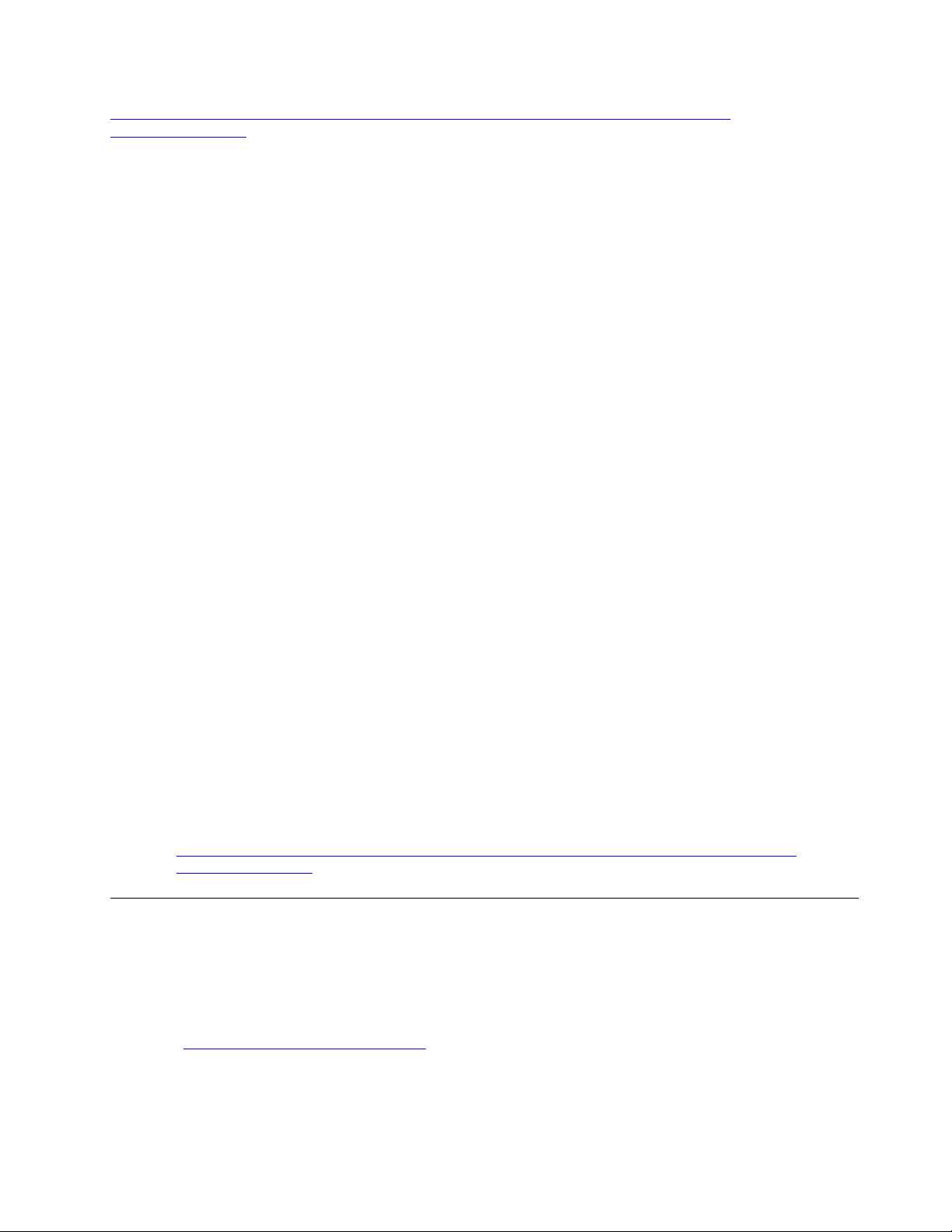

Identifying your server

When you contact Lenovo for help, the machine type, model, and serial number information helps support

technicians to identify your server and provide faster service.

The model number and serial number are on the ID label on the front of the server. The following illustration

shows the location of the ID label containing the machine type, model, and serial number.

Figure 2. Location of the machine type, model, and serial number

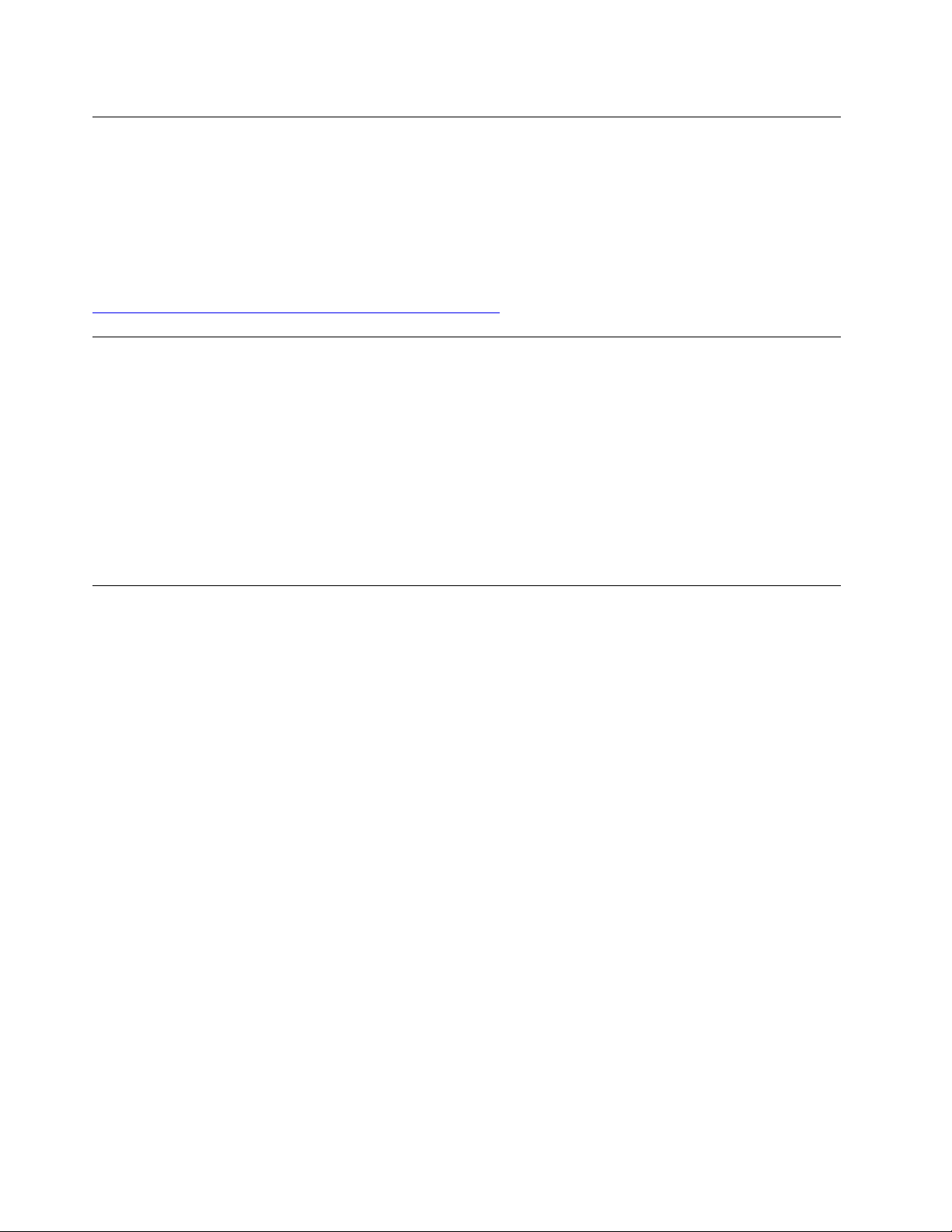

Network access tag

The network access tag can be found on the front of the server. You can pull way the network access tag to

paste your own label for recording some information such as the hostname, the system name and the

inventory bar code. Please keep the network access tag for future reference.

© Copyright Lenovo 2018 11

Figure 3. Network access tag

QR code

In addition, the system Service Card that is located on the top cover of the server, provides a quick reference

(QR) code for mobile access to service information. You can scan the QR code with a mobile device using a

QR code reader application and get quick access to the Service Information web page. The Service

Information web page provides additional information for parts installation and replacement videos, and error

codes for server support.

Figure 4. SR250 QR code

Front view

The front view of the server varies by the model.

12

ThinkSystem SR250 Maintenance Manual

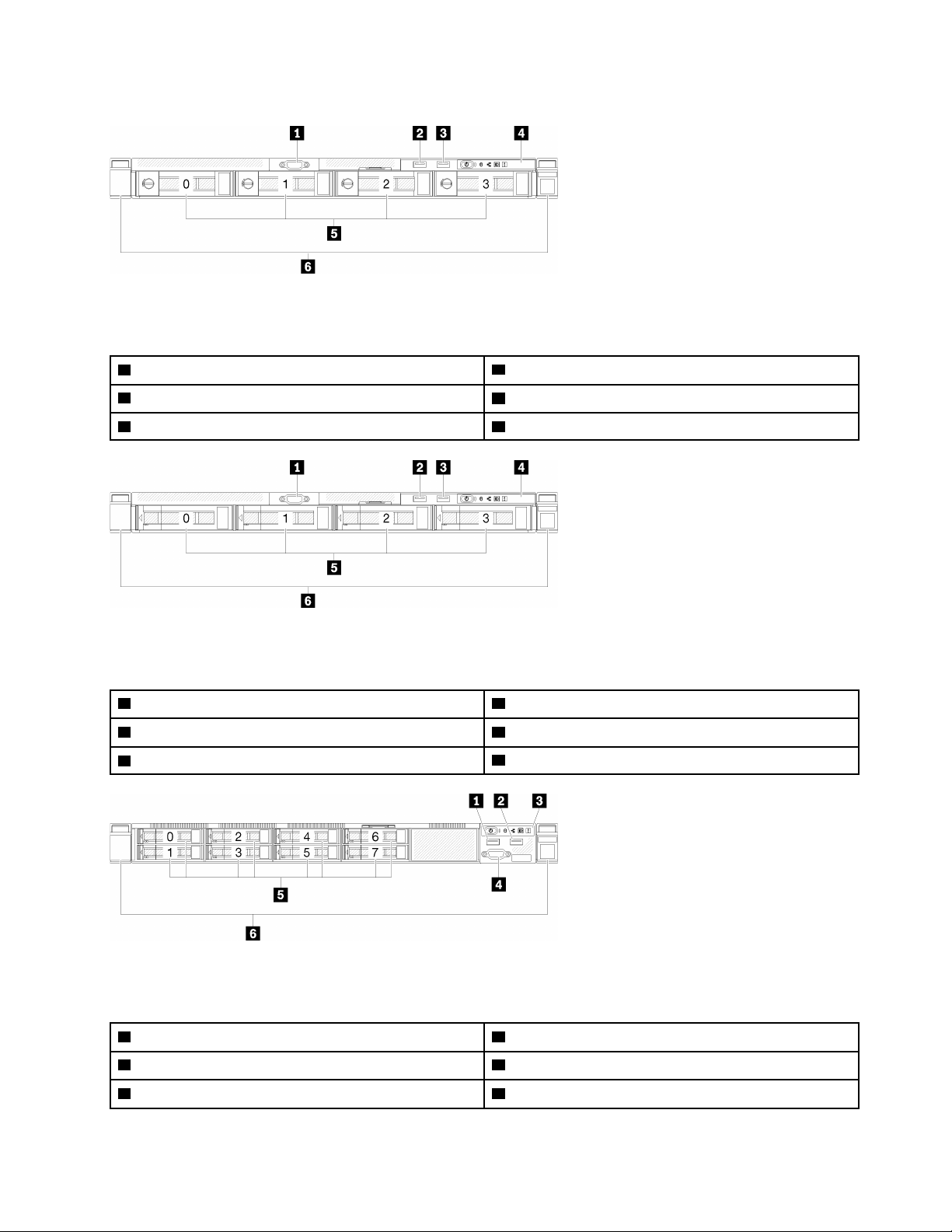

Front view of the server

Figure 5. Four simple-swap drives model front view

Table 2. Components on the four simple-swap drives model front view

1 VGA connector (optional)

2 USB 2.0 connector 5 Four simple-swap drive bays (0-3)

3 USB 3.1 Gen 1 connector

4 Front operator panel

6 Rack release latches

Figure 6. Four hot-swap drives model front view

Table 3. Components on the four hot-swap drives model front view

1 VGA connector (optional)

2 USB 2.0 connector 5 Four hot-swap drive bays (0-3)

3 USB 3.1 Gen 1 connector

4 Front operator panel

6 Rack release latches

Figure 7. Eight 2.5-inch hot-swap drives model front view

Table 4. Components on the eight 2.5-inch hot-swap drives model front view

1 USB 2.0 connector 4 VGA connector (optional)

2 USB 3.1 Gen 1 connector 5 Eight 2.5-inch hot-swap drive bays (0-7)

3 Front operator panel 6 Rack release latches

Chapter 2. Server components 13

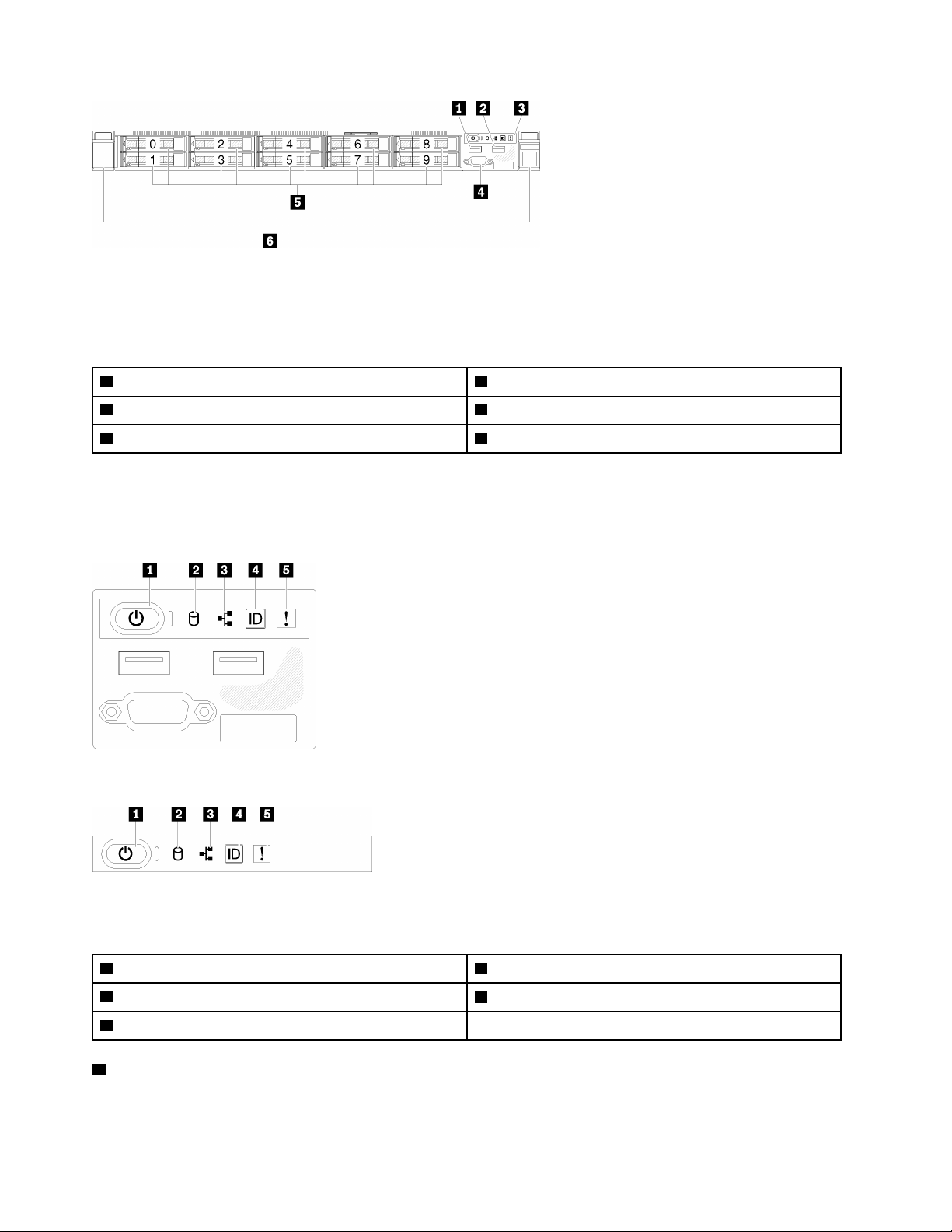

Figure 8. Ten 2.5-inch hot-swap drives model front view

Note: The last two drive bays may not be supported if only the eight-bay backplane is installed.

Table 5. Components on the ten 2.5-inch hot-swap drives model front view

1 USB 2.0 connector 4 VGA connector (optional)

2 USB 3.1 Gen 1 connector 5 Ten 2.5-inch hot-swap drive bays (0-9)

3 Front operator panel 6 Rack release latches

Front operator panel

The front operator information panel of the server provides controls, connectors, and LEDs. The front

operator panel varies by model.

Figure 9. 2.5-inch drive chassis front I/O assembly

Figure 10. 3.5-inch drive chassis front operator panel

Table 6. Front operator panel controls and indicators

1 Power button and power LED (green) 4 System ID button/LED (blue)

2 Drive activity LED (green) 5 System-error LED (yellow)

3 Network activity LED (green)

1 Power button and power LED (green): Press this button to turn the server on and off manually. The

states of the power LED are as follows:

Off: Power is not present or the power supply, or the LED itself has failed.

14

ThinkSystem SR250 Maintenance Manual

Flashing rapidly (4 times per second): The server is turned off and is not ready to be turned on. The

power button is disabled. This will last approximately 5 to 10 seconds.

Flashing slowly (once per second): The server is turned off and is ready to be turned on. You can press

the power button to turn on the server.

On: The server is turned on.

2 Drive activity LED (green): Each hot-swap drive comes with an activity LED. If the LED is lit, it indicates

that the drive is powered, but not actively reading or writing data. If the LED is flashing, the drive is being

accessed.

3 Network activity LED (green): When this LED flickers, it indicates that the server is transmitting to or

receiving signals from the Ethernet LAN.

4 System ID button/LED (blue): Use this blue LED to visually locate the server among other servers. This

LED is also used as a presence detection button. You can use Lenovo XClarity Administrator to light this LED

remotely.

5 System-error LED (yellow): When this yellow LED is lit, it indicates that a system error has occurred.

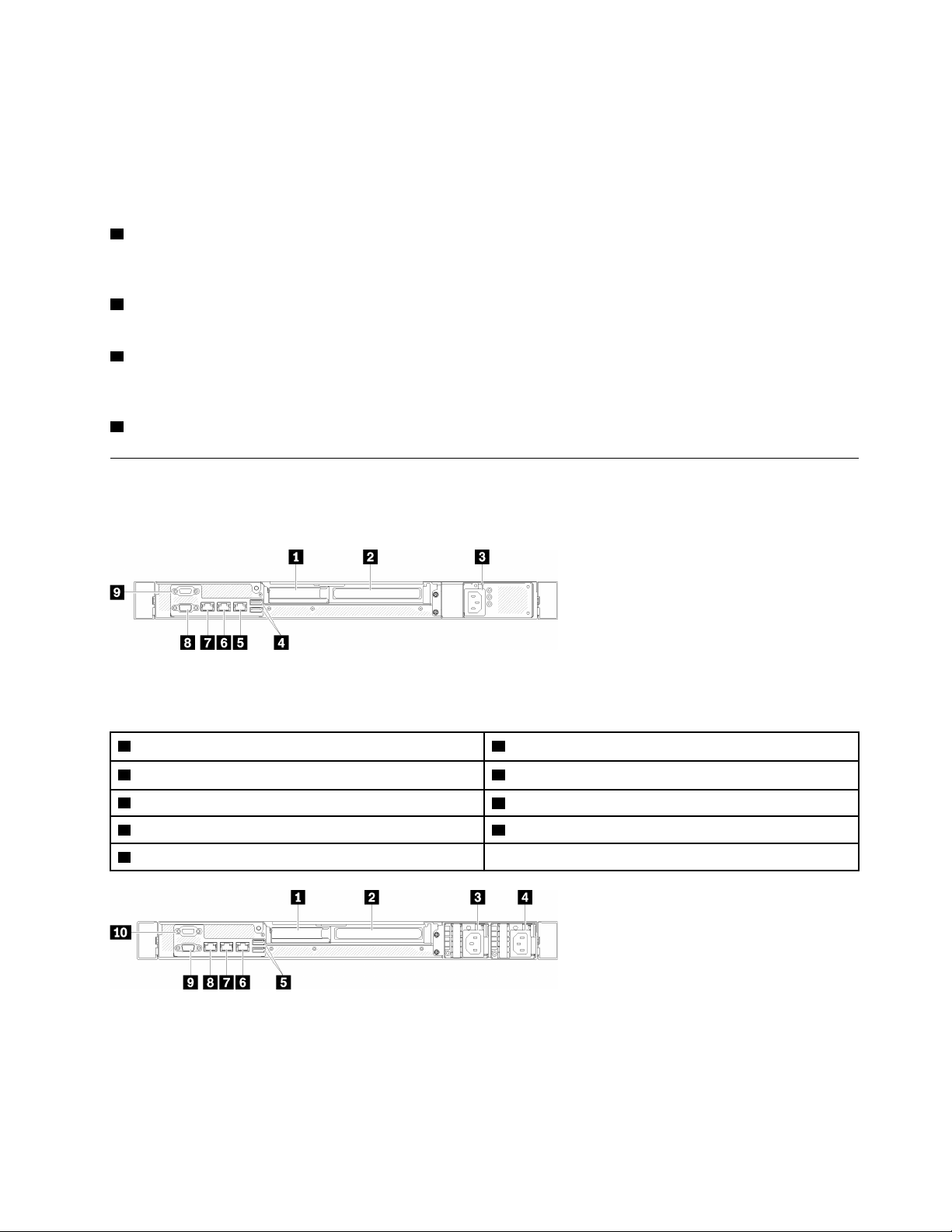

Rear view

The rear of the server provides access to several components, including the power supplies, PCIe adapters,

serial port, and Ethernet port.

Figure 11. Rear view - Non-redundant power supply model

Table 7. Rear view - Non-redundant power supply model

1 PCIe slot 1 6 Ethernet connector 1 (shared with XCC network port)

2 PCIe slot 2 7 Dedicated XClarity Controller (XCC) network connector

3 Power connector

4 USB 3.1 Gen 2 connectors 9 Serial connector

5 Ethernet connector 2

Figure 12. Rear view - Redundant power supply model

8 VGA connector

Chapter 2. Server components 15

Table 8. Rear view - Redundant power supply model

1 PCIe slot 1

2 PCIe slot 2 7 Ethernet connector 1 (shared with XCC network port)

3 Power connector 1

4 Power connector 2

5 USB 3.1 Gen 2 connectors 10 Serial connector

6 Ethernet connector 2

8 Dedicated XClarity Controller (XCC) network connector

9 VGA connector

PCIe slot 1 and 2: Your server has PCIe slots on the system board for you to install appropriate PCIe

adapters. For information about the PCIe slots, see “PCIe riser assembly” on page 23.

Power connector 1 and 2: Connect the power cord to this component.

USB 3.1 Gen 2 connectors: Used to attach a device that requires a USB 3.1 connection, such as a

keyboard, a mouse, or a USB flash drive.

Ethernet connector 1 and 2: Used to attach an Ethernet cable for a LAN. Each Ethernet connector has two

status LEDs to help you identify the Ethernet connectivity and activity. If the LOM adapter is not installed,

Ethernet connector 1 can be set as XClarity Controller Network connector. To set Ethernet connector 1 as

XClarity Controller Network connector, start Setup Utility and select BMC Settings ➙ Network Settings ➙

Network Settings Network Interface Port : Shared. Then, click Shared NIC on and select Onboard Port

1.

Dedicated XClarity Controller (XCC) network connector : Used to attach an Ethernet cable to manage the

system using XClarity Controller.

VGA connector : Used to attach a VGA-compatible video device, such as a VGA monitor.

Serial connector: Connect a 9-pin serial device to this connector. The serial port is shared with the XCC.

The XCC can take control of the shared serial port to redirect serial traffic, using Serial over LAN (SOL).

System-board switches, jumpers, and buttons

The illustrations in this section provide information about the switches, jumpers, and buttons that are

available on the system board.

For more information about the LEDs that are available on the system board, see “System-board LEDs” on

page 16.

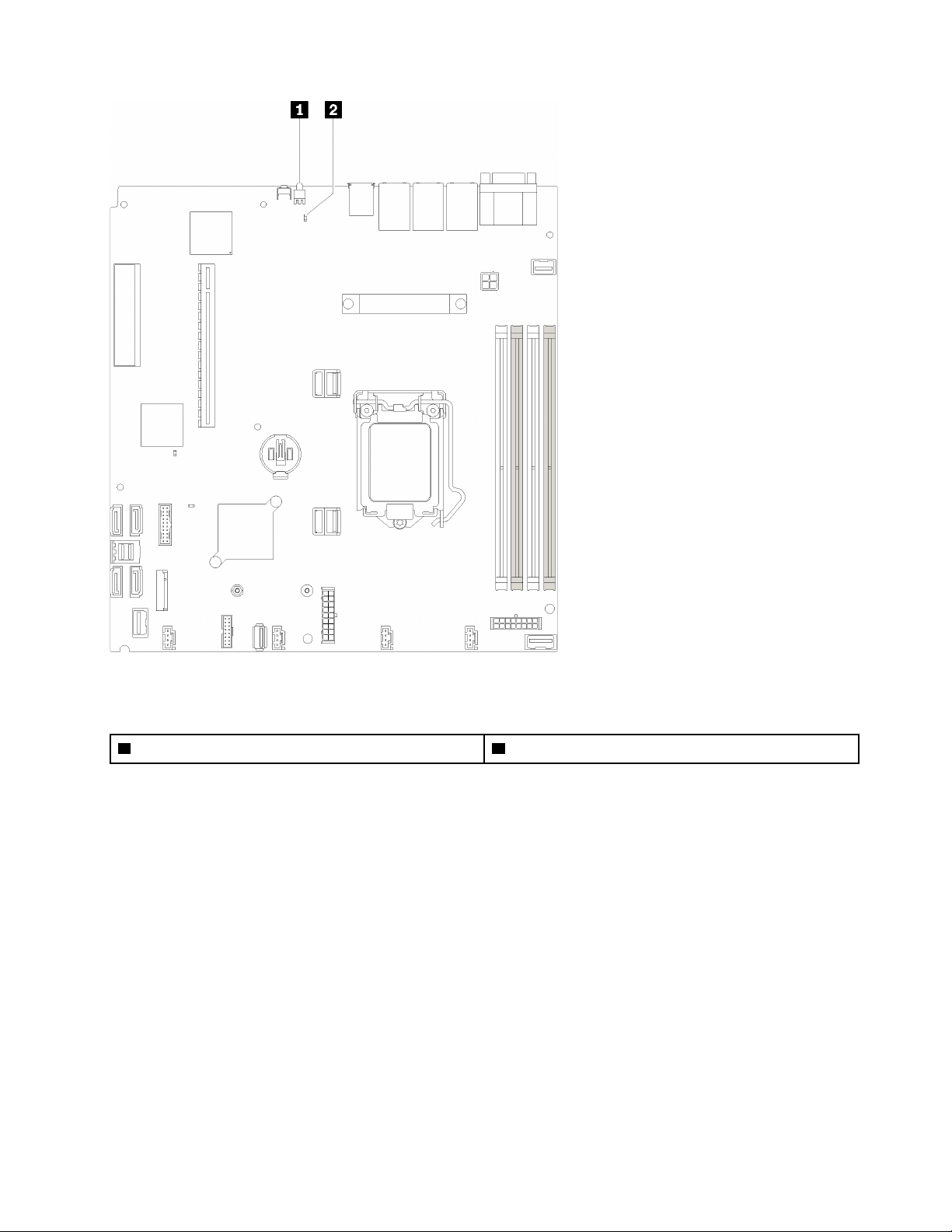

System-board LEDs

The following illustrations show the light-emitting diodes (LEDs) on the system board.

16

ThinkSystem SR250 Maintenance Manual

Figure 13. System-board LEDs

Table 9. System-board LEDs

1 Rear identification LED (blue) 2 System error LED (yellow)

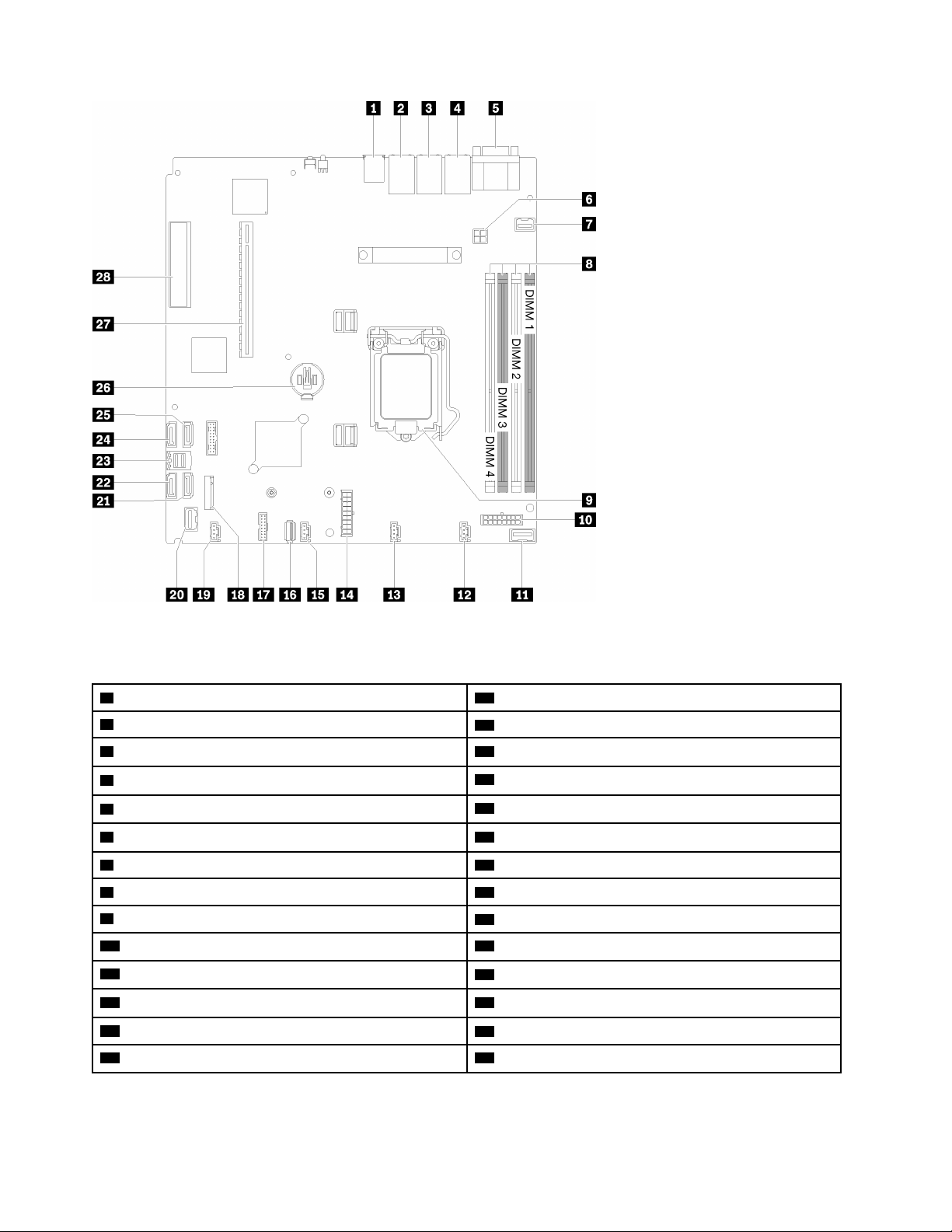

System-board connectors

The following illustrations show the connectors on the system board.

Chapter 2. Server components 17

Figure 14. System-board connectors

Table 10. System-board connectors

1 USB 3.1 Gen 1 connector

2 Lan 2 connector

3 Lan 1 connector (shared with XCC) 17 TPM card/TPM connector

4 Dedicated XClarity Controller (XCC) network connector

5 VGA and serial port connector

6 Processor power connector 20 Front panel connector

7 Front VGA connector 21 SATA connector 6

8 DIMM slot 1-4

9 Processor

10 Backplane power connector

11 PIB signal connector

12 Fan 1 connector

13 Fan 2 connector 27 slot

14 System power connector 28 PCIe3x 8 (4,1) - slot 4

15 Fan 3 connector

16 Internal USB 3.1 Gen 1 connector

18 M.2 backplane connector

19 Fan 4 connector

22 SATA connector 7

23 SATA connector 0-3

24 SATA connector 4

25 SATA connector 5

26 CMOS battery - CR2032

18 ThinkSystem SR250 Maintenance Manual

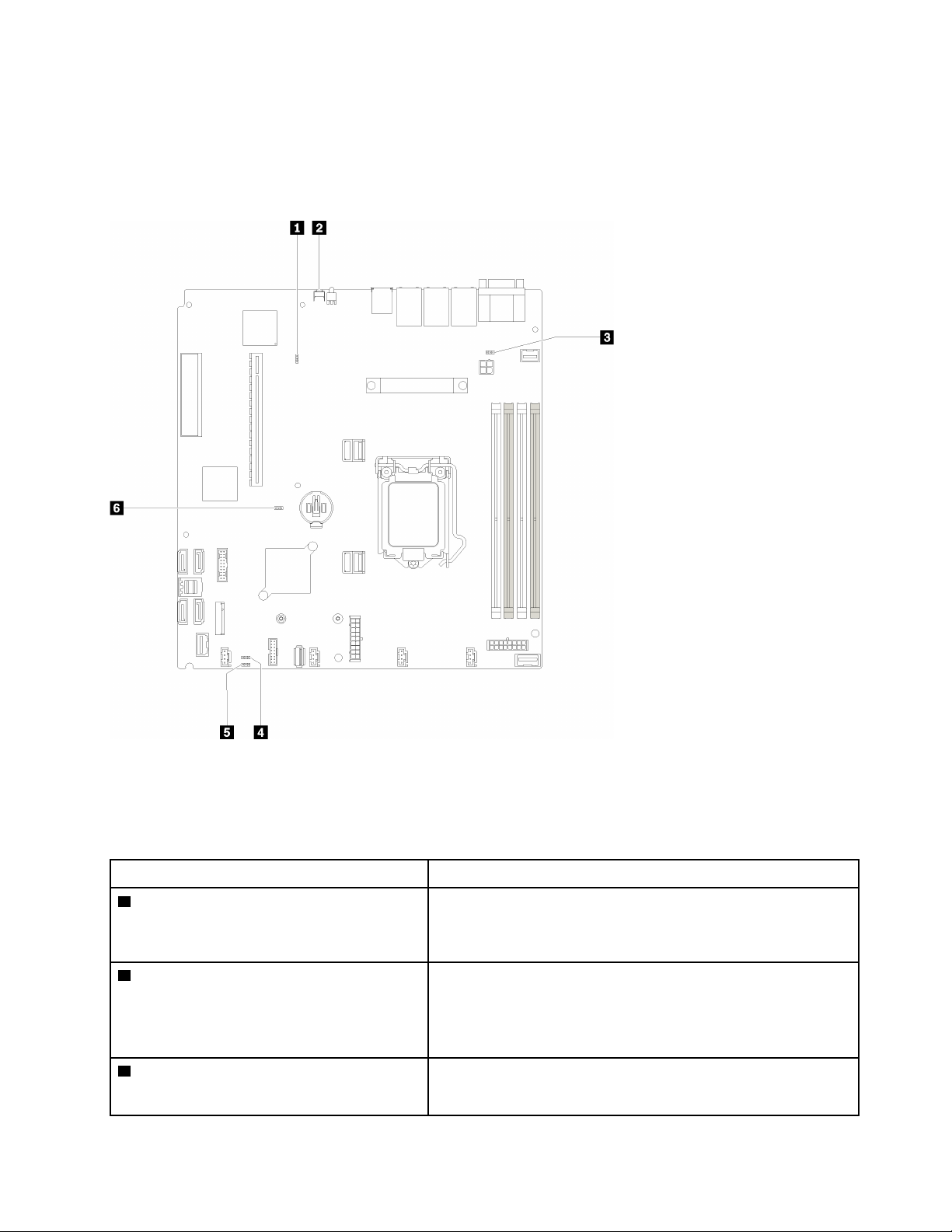

System-board jumpers and buttons

The following illustrations show the location of the jumpers and buttons on the server.

Note: If there is a clear protective sticker on the top of the switch blocks, you must remove and discard it to

access the switches.

Figure 15. System-board jumpers and buttons

The following table describes the jumpers and buttons on the system board.

Table 11. System-board jumpers and buttons

Jumper and button name Jumper setting / Button function

1 Force XCC update jumper

2 Force NMI button This button is on the rear of the server. Press this button to force a

3 NCSI functional header jumper

• Pins 1 and 2: Normal (default).

• Pins 2 and 3: Force the Lenovo XClarity Controller to update to

the latest version.

nonmaskable interrupt to the processor. You might have to use a

pen or the end of a straightened paper clip to press the button.

You can also use it to force a blue-screen memory dump (use this

button only when you are directed to do so by Lenovo Support).

• Pins 1 and 2: Normal (default).

• Pins 2 and 3: Disable

Chapter 2. Server components 19

Table 11. System-board jumpers and buttons (continued)

Jumper and button name Jumper setting / Button function

4 Power permission override jumper

5 Clear CMOS jumper

6 TPM/TPM card physical presence jumper

• Pins 1 and 2: Normal (default).

• Pins 2 and 3: Override the power-on permission.

• Pins 1 and 2: Normal (default).

• Pins 2 and 3: Clear the real-time clock (RTC) registry.

• Pins 1 and 2: Normal (default).

• Pins 2 and 3: TPM/TPM card physical presence is asserted.

Important:

1. Before you change any switch settings or move any jumpers, turn off the server; then, disconnect all

power cords and external cables. Review the information in

safety_documentation/pdf_files.html

, “Installation Guidelines” on page 47, “Handling static-sensitive

http://thinksystem.lenovofiles.com/help/topic/

devices” on page 49, and “Power off the server” on page 10.

2. Any system-board switch or jumper block that is not shown in the illustrations in this document are

reserved.

RAID adapters and the NVMe switch card

Use this information to locate the connectors on the RAID adapters and the NVMe switch card.

20

ThinkSystem SR250 Maintenance Manual

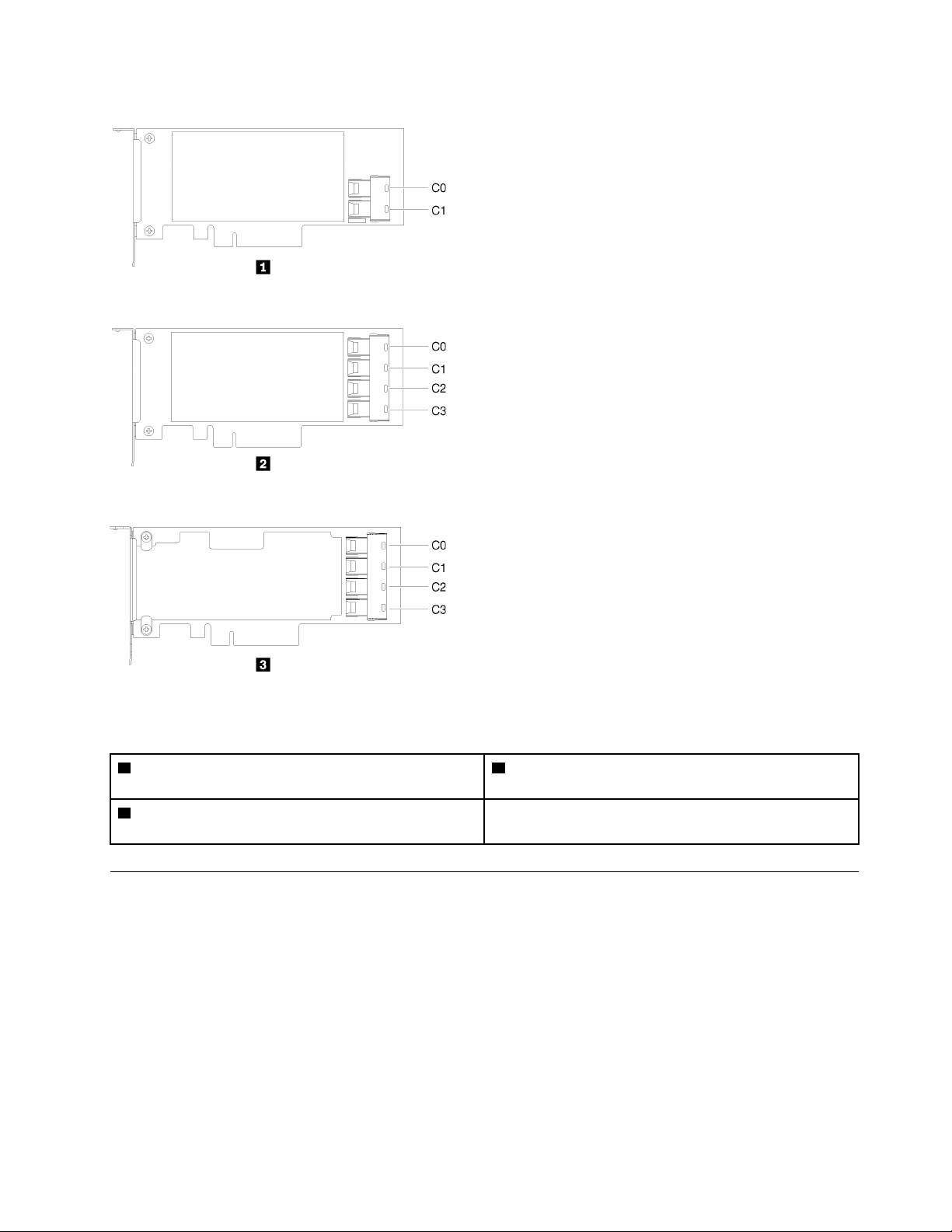

Connectors on RAID adapters and the NVMe switch card

Figure 16. Connectors on RAID adapters and the NVMe switch card

Table 12. Connectors on RAID adapters and the NVMe switch card

1 SATA/SAS RAID adapter (8i) with two SATA/SAS

connectors (C0, C1)

2 SATA/SAS RAID adapter (16i) with four SATA/SAS

connectors (C0, C1, C2, C3)

3 PCIe switch card with four connectors (C0, C1, C2, C3)

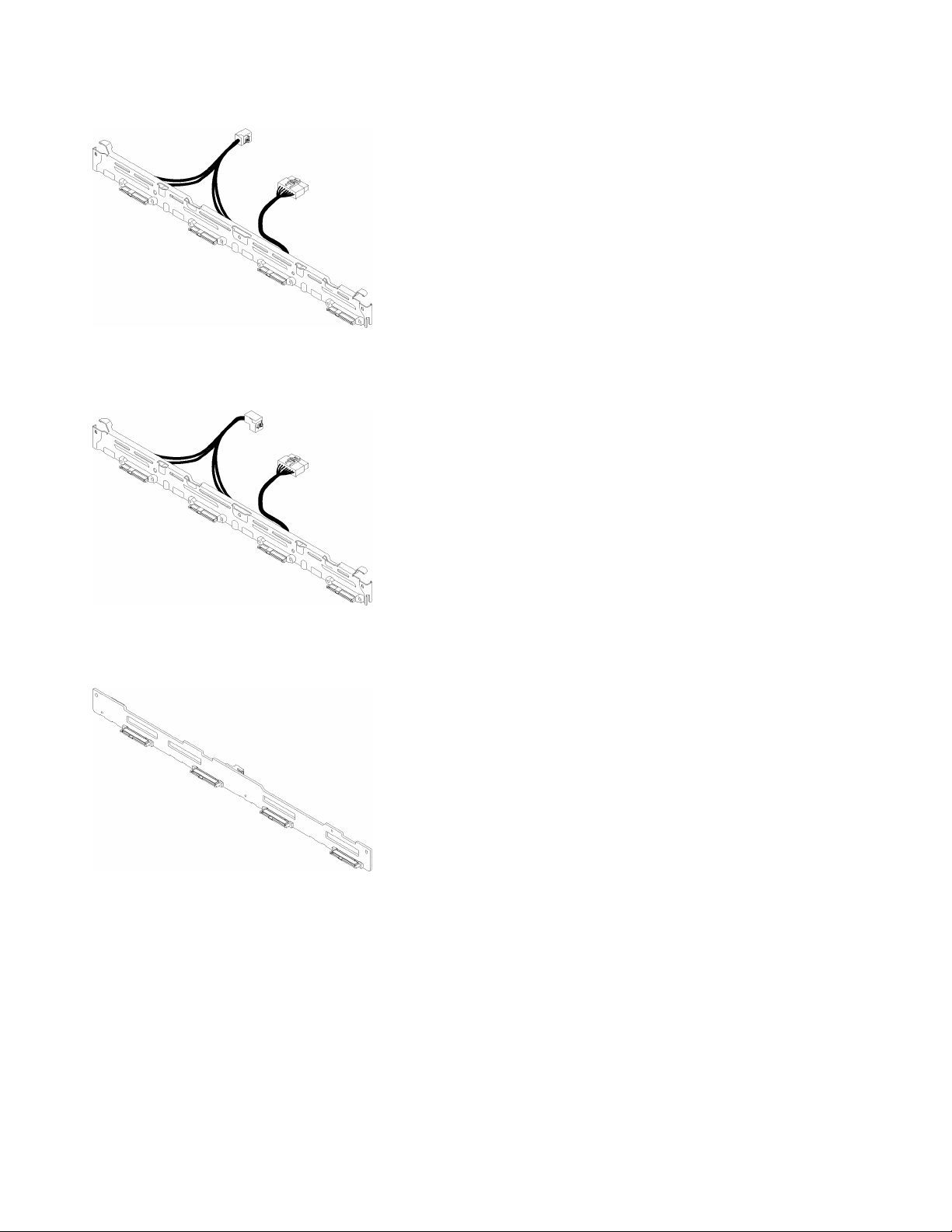

Backplates and backplanes

Use this information to identify the backplate or the backplane you use.

Chapter 2. Server components 21

Backplate, four 3.5-inch simple-swap drives (connects to RAID adapter)

Figure 17. Backplate, four 3.5-inch simple-swap drives (connects to RAID adapter)

Backplate, four 3.5-inch simple-swap drives (connects to onboard connectors)

Figure 18. Backplate, four 3.5-inch simple-swap drives (connects to onboard connectors)

Backplane, four 3.5-inch hot-swap drives

Figure 19. Backplane, four 3.5-inch hot-swap drives

22 ThinkSystem SR250 Maintenance Manual

Backplane, eight 2.5-inch hot-swap drives

Figure 20. Backplane, eight 2.5-inch hot-swap drives

Backplane, ten 2.5-inch hot-swap drives

Figure 21. Backplane, ten 2.5-inch hot-swap drives

Note: If the 95 W processor is used, the server does not support the ten 2.5-inch hot-swap drive backplane.

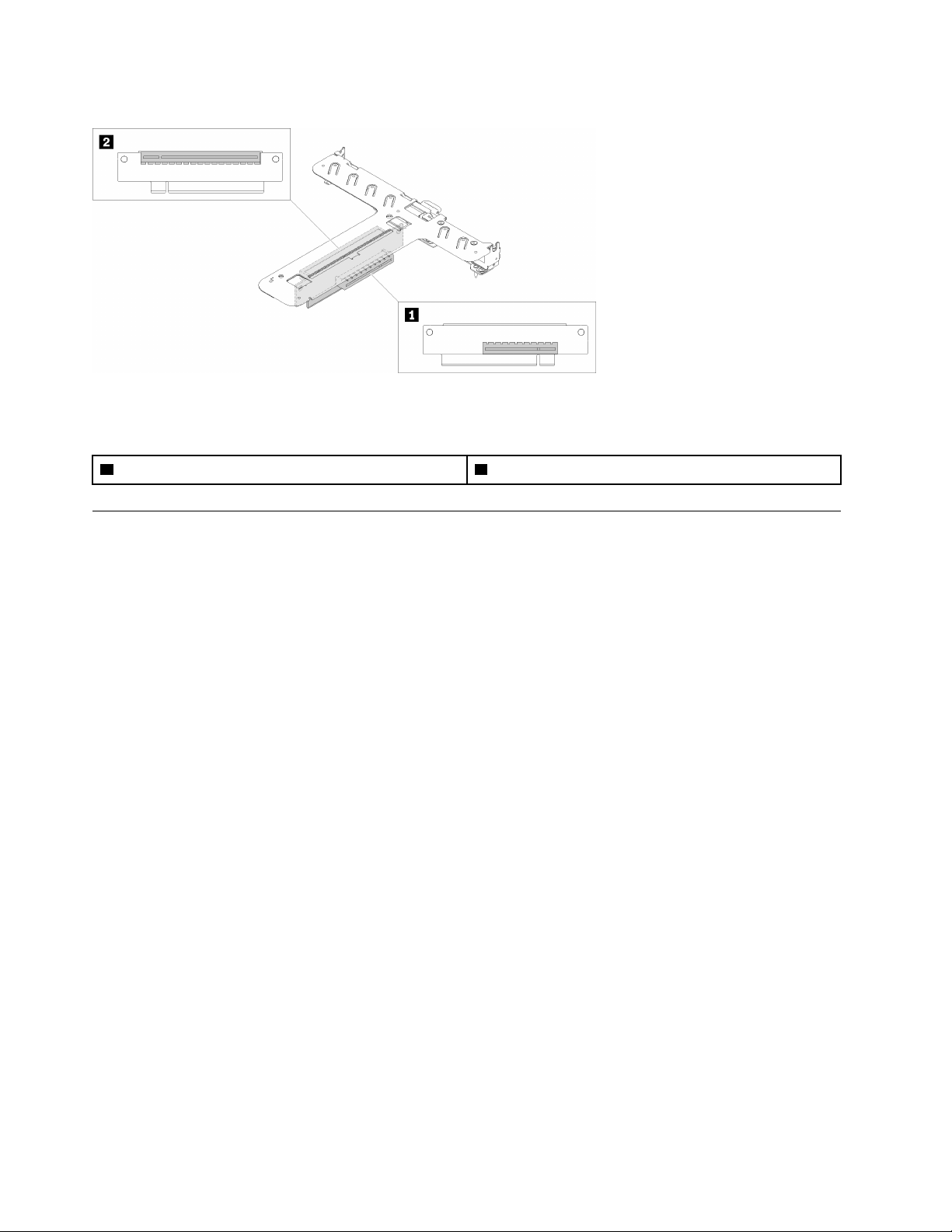

PCIe riser assembly

Use this information to locate the connectors on the PCIe riser assembly.

x16 PCIe riser assembly

Figure 22. x16 PCIe riser assembly

Table 13. x16 PCIe riser assembly

1 Slot 2, PCIe 3 x16, Full height, half-length

Chapter 2. Server components 23

x8/x8 Butterfly riser assembly

Figure 23. x8/x8 Butterfly riser assembly

Table 14. x8/x8 Butterfly riser assembly

1 Slot 1, PCIe 3 x8, low profile 2 Slot 2, PCIe 3 x8, full-height, half-length

Internal cable routing

Some of the components in the server have internal cables and cable connectors.

Note: Disengage all latches, release tabs, or locks on cable connectors when you disconnect cables from

the system board. Failing to release them before removing the cables will damage the cable sockets on the

system board, which are fragile. Any damage to the cable sockets might require replacing the system board.

Some options, such as RAID controllers, might require additional internal cabling. See the documentation

that is provided for the option to determine any additional cabling requirements and instructions.

Front VGA cable

Use the section to understand the internal routing and connectors for the front video graphic adapter (VGA)

cable.

24

ThinkSystem SR250 Maintenance Manual

3.5-inch HDD model

Figure 24. Front VGA cable routing with four drives

Chapter 2. Server components 25

2.5-inch HDD model

Figure 25. Front VGA cable routing with ten drives

Fan cable

Use the section to understand the internal routing and connectors for fan cables.

26

ThinkSystem SR250 Maintenance Manual

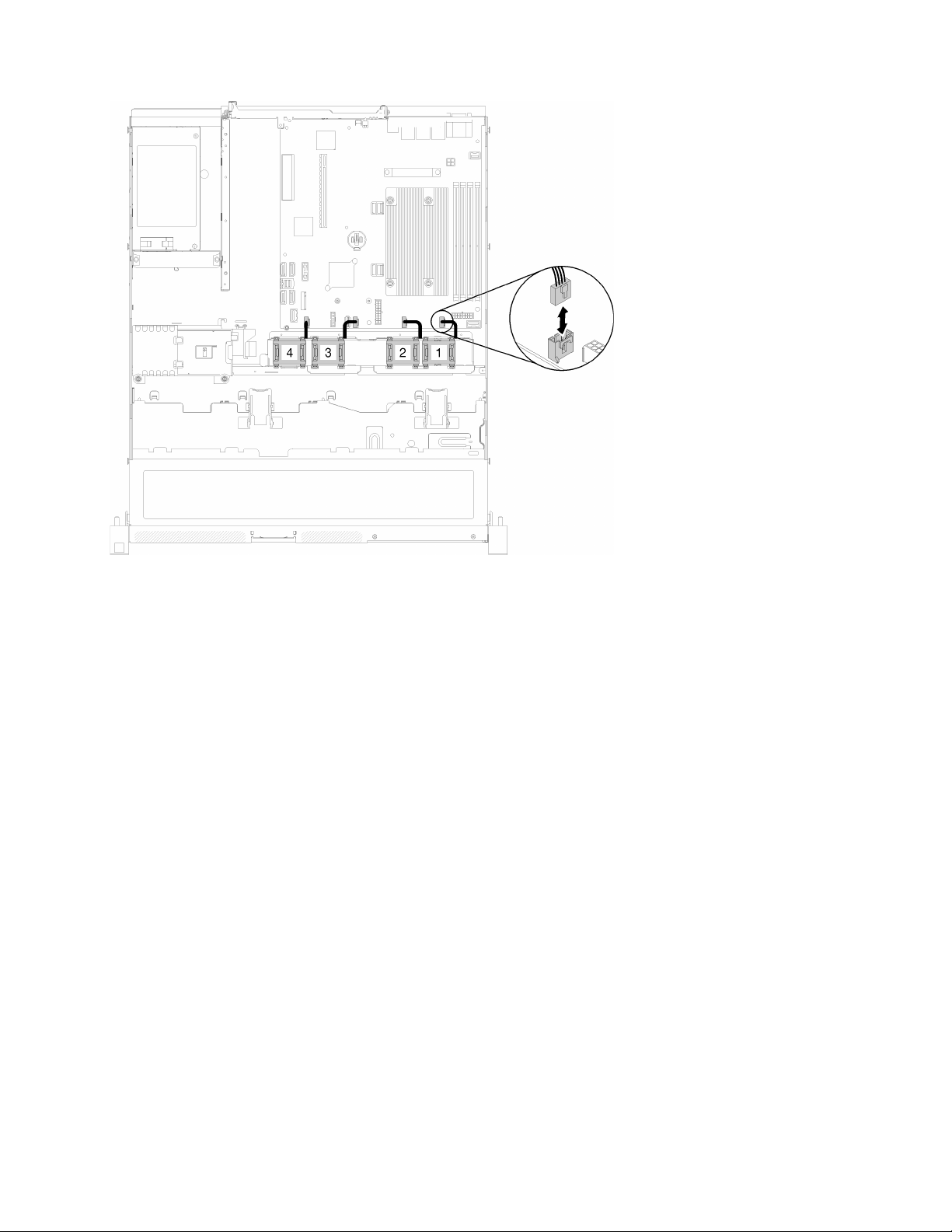

Figure 26. Fan cable routing

Power supply

Use the section to understand the internal routing and connectors for the power supply cables.

Chapter 2. Server components 27

Fixed power supply unit cable routing

Figure 27. Fixed power supply unit cable routing

Table 15. Fixed power supply unit cable routing

1 Processor power connector

2 System-board power connector

28 ThinkSystem SR250 Maintenance Manual

Hot-swap power supply unit cable routing

Figure 28. Hot-swap power supply unit cable routing

Table 16. Hot-swap power supply unit cable routing

1 Processor power connector

2 PIB signal connector

3 System-board power connector

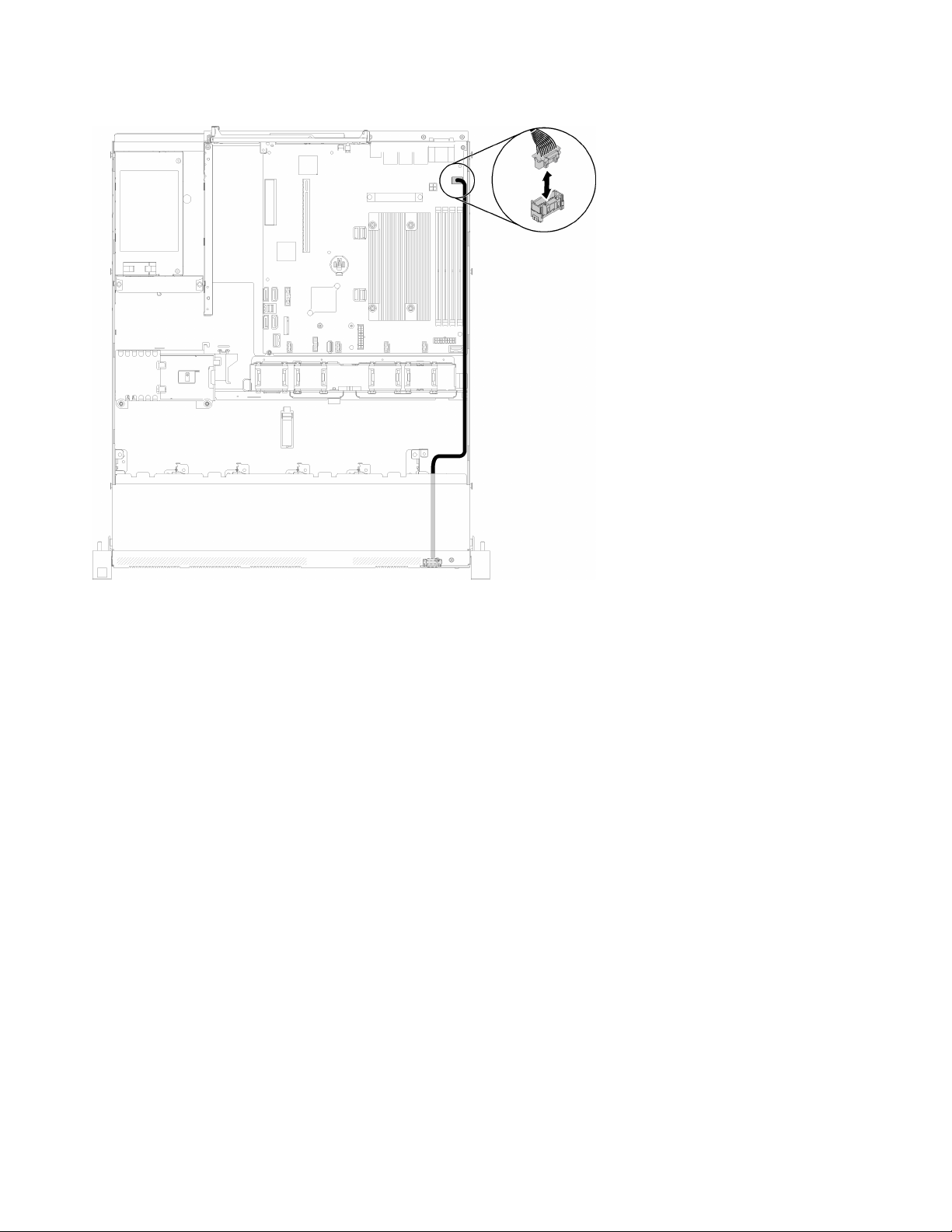

Flash power module

Use the section to understand the internal routing and connectors for the flash power module.

Chapter 2. Server components 29

Figure 29. Flash power module cable routing

Table 17. Flash power module cable routing

1 Flash power module

3.5-inch simple-swap drive model

Use this section to understand how to route cables for the 3.5-inch simple-swap drive models.

3.5-inch simple-swap drive model with software RAID

If you are implementing RAID through software, route the SAS cables and power cables as shown in the

following illustration.

30

ThinkSystem SR250 Maintenance Manual

Figure 30. 3.5-inch simple-swap drive model with software RAID

Table 18. 3.5-inch simple-swap drive model with software RAID

1 Backplane power connector

3.5-inch simple-swap drive model with hardware RAID

If you are implementing RAID through hardware, route the SAS cables and power cables as shown in the

following illustration.

Chapter 2. Server components 31

Table 19. 3.5-inch simple-swap drive model with hardware RAID

1 Backplane Power connector

Figure 31. 3.5-inch simple-swap drive model with hardware RAID

Four 3.5-inch hot-swap drive model

Use this section to understand how to route cables for the four 3.5-inch hot-swap drive model.

Four 3.5-inch hot-swap drive model with software RAID

If you are implementing RAID through software, route the SAS cables and power cables as shown in the

following illustration.

32

ThinkSystem SR250 Maintenance Manual

Figure 32. Four 3.5-inch hot-swap drive model with software RAID

Table 20. Four 3.5-inch hot-swap drive model with software RAID

1 Backplane power connector

Four 3.5-inch hot-swap drive model with hardware RAID

If you are implementing RAID through hardware, route the SAS cables and power cables as shown in the

following illustration.

Chapter 2. Server components 33

Table 21. Four 3.5-inch hot-swap drive model with hardware RAID

1 Backplane power connector

Figure 33. Four 3.5-inch hot-swap drive model with hardware RAID

Eight 2.5-inch hot-swap drive model

Use this section to understand how to route cables for the eight 2.5-inch hot-swap drive model.

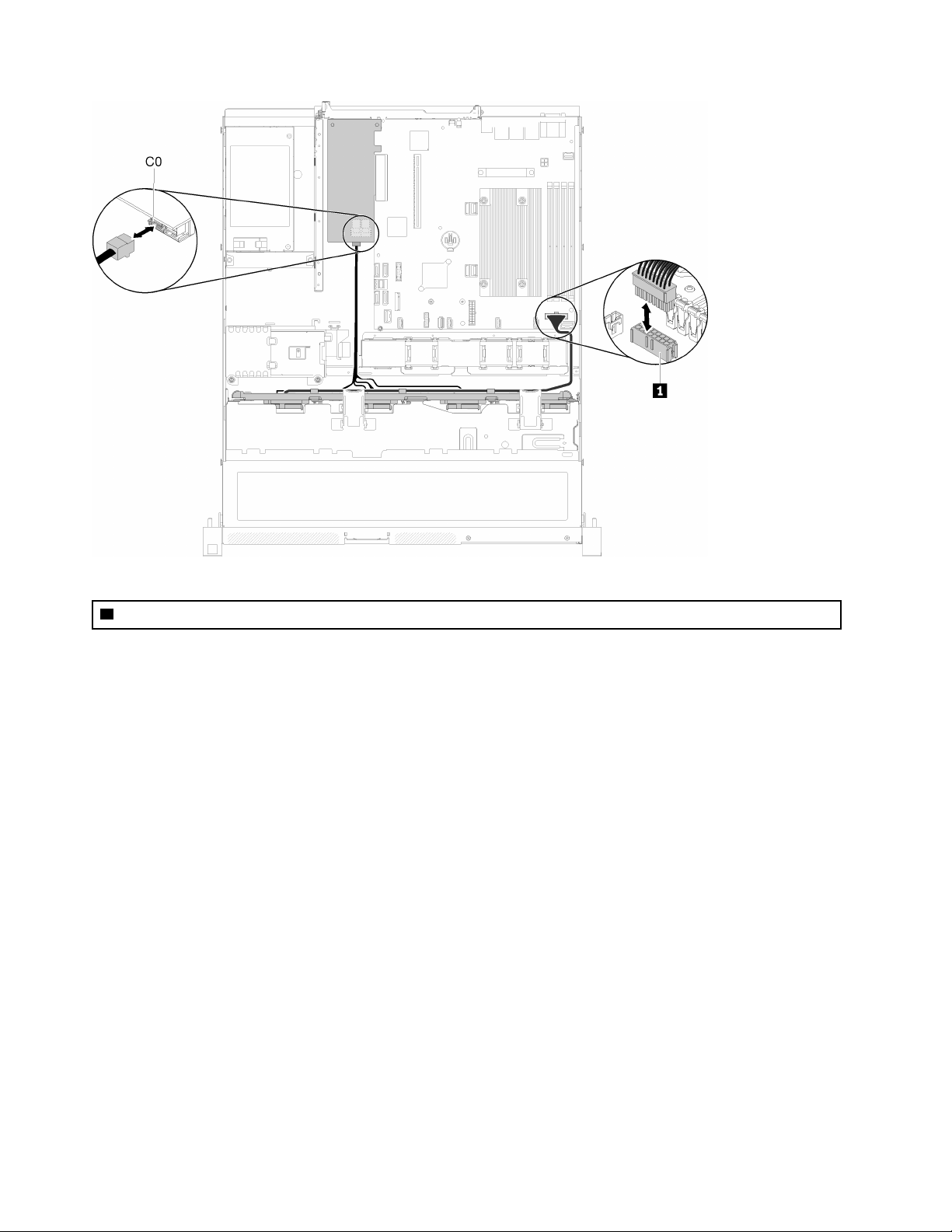

Eight 2.5-inch hot-swap drive model with software RAID

If you are implementing RAID through software, route the SAS cables and power cables as shown in the

following illustration.

34

ThinkSystem SR250 Maintenance Manual

Figure 34. Eight 2.5-inch hot-swap drive model with software RAID

Table 22. Eight 2.5-inch hot-swap drive model with software RAID

1 Backplane power connector

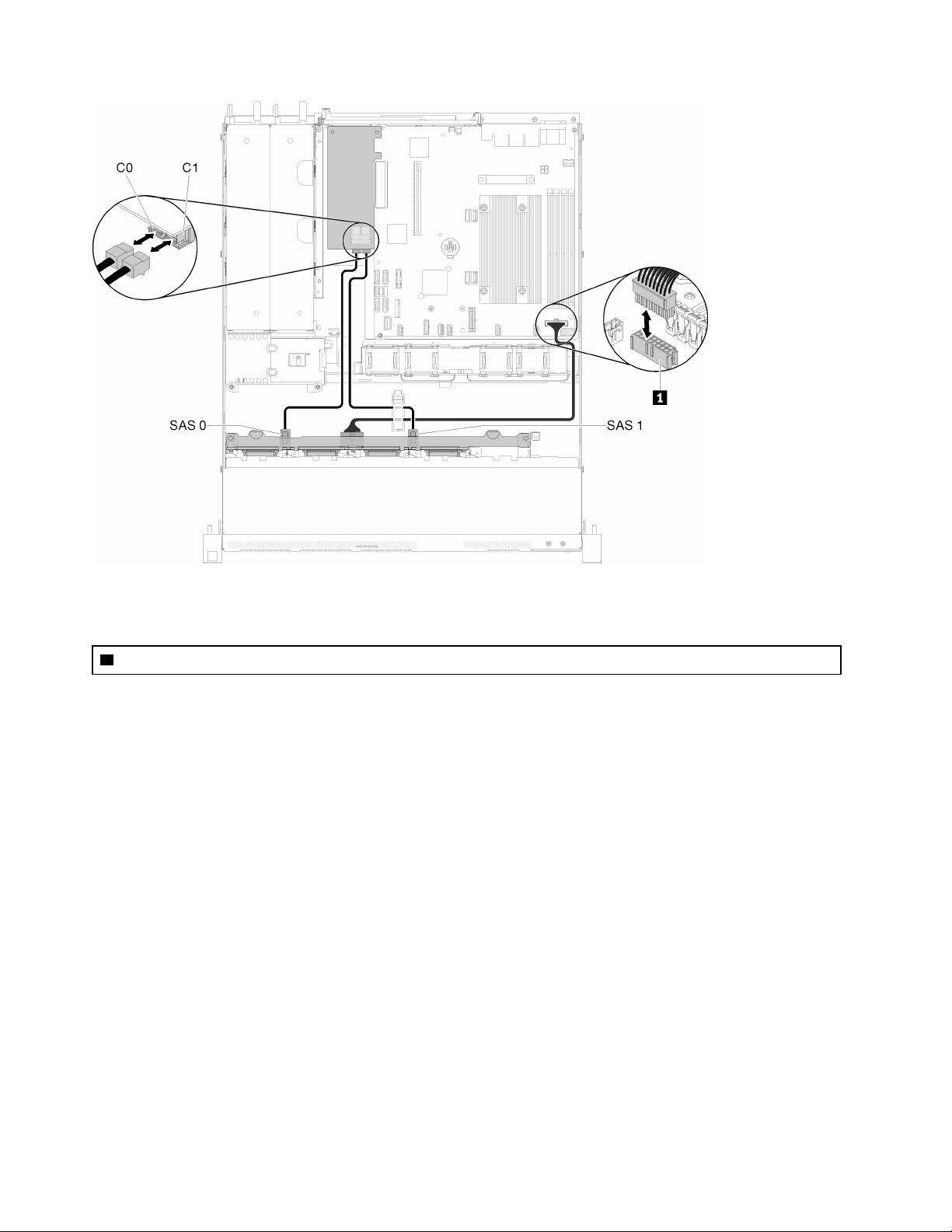

Eight 2.5-inch hot-swap drive model with hardware RAID

If you are implementing RAID through hardware, route the SAS cables and power cables as shown in the

following illustration.

Chapter 2. Server components 35

Figure 35. Eight 2.5-inch hot-swap drive model with hardware RAID

Table 23. Eight 2.5-inch hot-swap drive model with hardware RAID

1 Backplane power connector

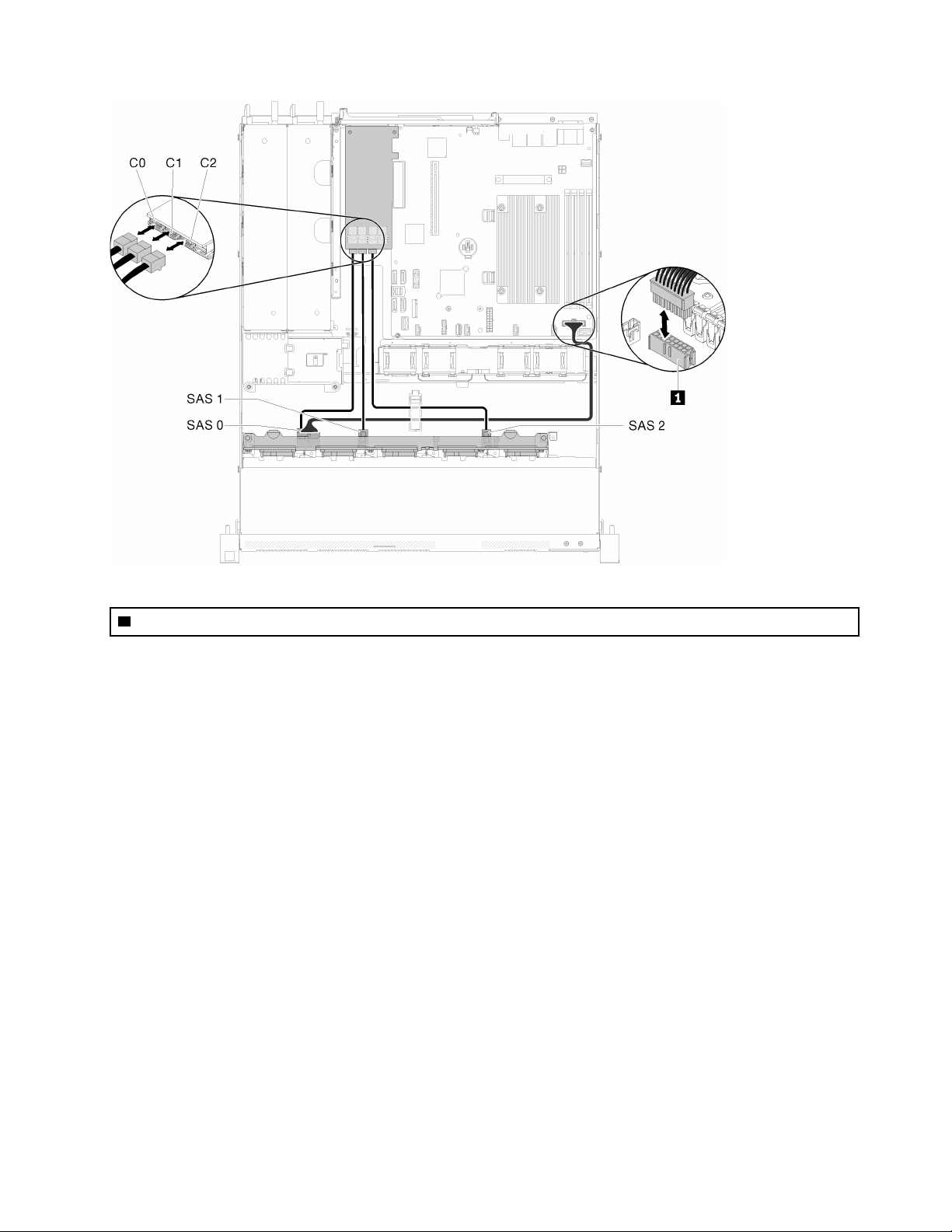

Ten 2.5-inch hot-swap drive model

Use this section to understand how to route cables for the ten 2.5-inch hot-swap drive model.

Ten 2.5-inch hot-swap drive model with hardware RAID

If you are implementing RAID through hardware, route the SAS cables and power cables as shown in the

following illustration.

36

ThinkSystem SR250 Maintenance Manual

Table 24. Ten 2.5-inch hot-swap drive model with hardware RAID

1 Backplane power connector

Figure 36. Ten 2.5-inch hot-swap drive model with hardware RAID

Chapter 2. Server components 37

Ten 2.5-inch hot-swap drive model (two NVMe drives supported)

Figure 37. Ten 2.5-inch hot-swap drive model (two NVMe drives supported)

Table 25. Ten 2.5-inch hot-swap drive model (two NVMe drives supported)

1 Backplane power connector

Parts list

Use the parts list to identify each of the components that are available for your server.

For more information about ordering the parts shown in the Figure 38 “Server components - 2.5-inch drive

model” on page 40:

http://datacentersupport.lenovo.com/us/en/products/servers/thinksystem/sr250/7Y51/parts

Note: Depending on the model, your server might look slightly different from the illustration.

38

ThinkSystem SR250 Maintenance Manual

The parts listed in the following table are identified as one of the following:

• Tier 1 customer replaceable unit (CRU): Replacement of Tier 1 CRUs is your responsibility. If Lenovo

installs a Tier 1 CRU at your request with no service agreement, you will be charged for the installation.

• Tier 2 customer replaceable unit: You may install a Tier 2 CRU yourself or request Lenovo to install it, at

no additional charge, under the type of warranty service that is designated for your server.

• Field replaceable unit (FRU): FRUs must be installed only by trained service technicians.

• Consumable and Structural parts: Purchase and replacement of consumable and structural parts

(components, such as a cover or bezel) is your responsibility. If Lenovo acquires or installs a structural

component at your request, you will be charged for the service.

Chapter 2. Server components 39

2.5-inch drive model

Figure 38. Server components - 2.5-inch drive model

40 ThinkSystem SR250 Maintenance Manual

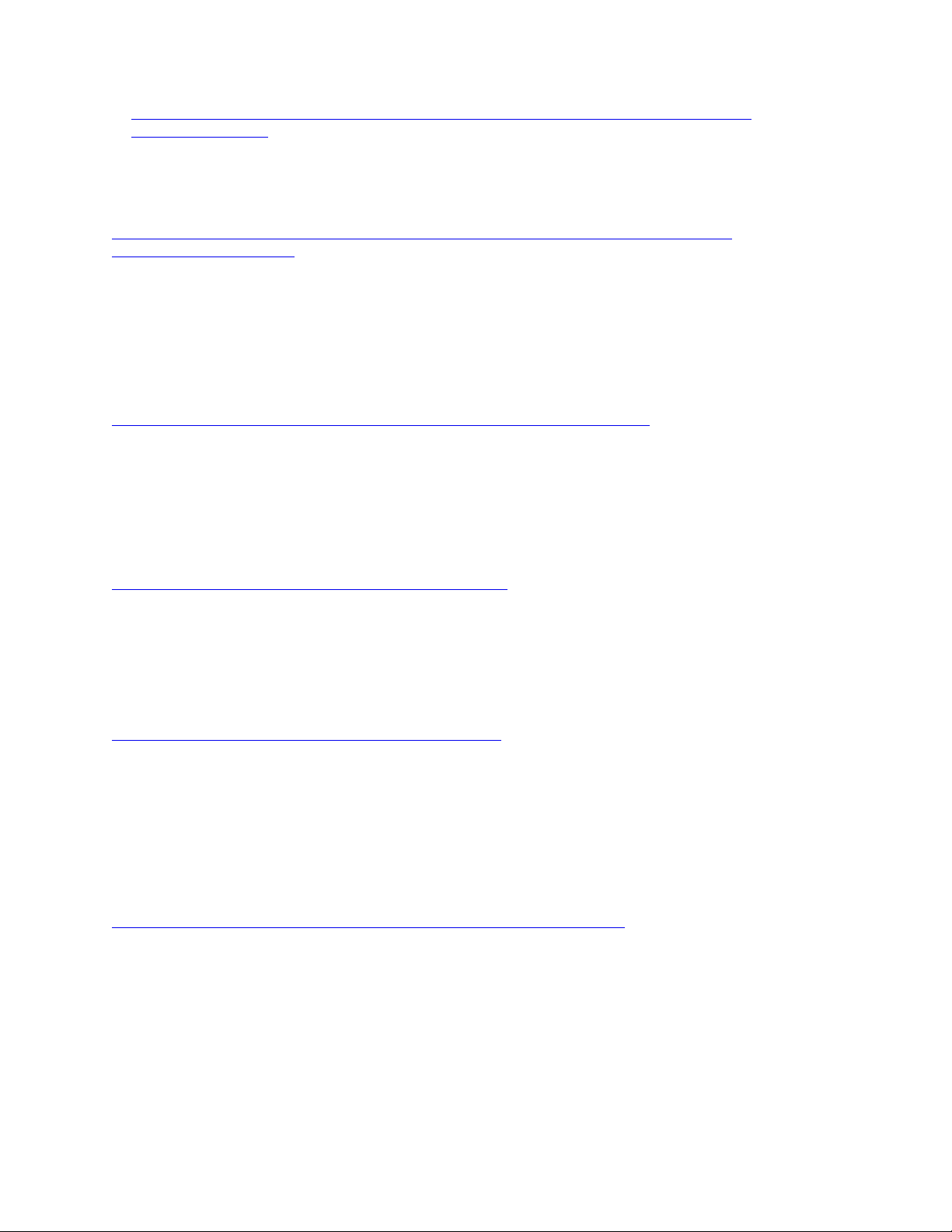

Table 26. Parts listing - 2.5-inch drive model

Index Description

Tier 1 CRU Tier 2 CRU

FRU

Consumable and

Structural

part

For more information about ordering the parts shown in Figure 38 “Server components - 2.5-inch drive model” on

page 40:

http://datacentersupport.lenovo.com/us/en/products/servers/thinksystem/sr250/7Y51/parts

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Top cover

PCIe riser assembly

SATA/SAS RAID adapter (8i)

SATA/SAS RAID adapter (16i)

PCIe switch card

Air baffle

Fan

TPM card

System board

Fixed power supply unit

Redundant power supply unit

Chassis for the redundant power supply

Front I/O assembly

VGA cable

2.5-inch hot-swap drive

Drive filler

Chassis for the fixed power supply

Power interface board

Flash power module

M.2 drives (42 mm and 80mm)

DIMM

Processor

Heat sink

Backplane, eight 2.5-inch hot-swap drives

Backplane, ten 2.5-inch hot-swap drives

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

√

3.5-inch drive model

For more information about ordering the parts shown in Figure 39 “Server components - 3.5-inch drive

model” on page 42:

http://datacentersupport.lenovo.com/us/en/products/servers/thinksystem/sr250/7Y51/parts

Chapter 2. Server components 41

Note: Depending on the model, your server might look slightly different from the illustration.

Figure 39. Server components - 3.5-inch drive model

42 ThinkSystem SR250 Maintenance Manual

Table 27. Parts listing - 3.5-inch drive model

Index Description

Tier 1 CRU Tier 2 CRU

FRU

Consumable and

Structural

part

For more information about ordering the parts shown in Figure 39 “Server components - 3.5-inch drive model” on

page 42:

http://datacentersupport.lenovo.com/us/en/products/servers/thinksystem/sr250/7Y51/parts

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Top cover

PCIe riser assembly

SATA/SAS RAID adapter (8i)

SATA/SAS RAID adapter (16i)

PCIe switch card

Air baffle

Fan

TPM card

System board

Fixed power supply unit

Redundant power supply unit

Chassis for the redundant power supply

Front operator panel

VGA cable

3.5-inch hot-swap drive

3.5-inch simple-swap drive

2.5-inch simple-swap drive with 3.5-inch drive

√

√

√

√

√

√

√

√

√

√

√

√

√

√

tray

√

√

√

18

19

20

21

22

23

24

25

26

27

Chassis for the fixed power supply

Power interface board

Flash power module

M.2 drives (42 mm and 80mm)

DIMM

Processor

Heat sink

Backplane, four 3.5-inch hot-swap drives

Backplate, four 3.5-inch simple-swap drives

(connects to RAID card)

Backplate, four 3.5-inch simple-swap drives

(connects to onboard connectors)

√

√

√

√

√

√

√

√

√

√

Chapter 2. Server components 43

44 ThinkSystem SR250 Maintenance Manual

Power cords

Several power cords are available, depending on the country and region where the server is installed.

To view the power cords that are available for the server:

1. Go to:

http://dcsc.lenovo.com/#/

2. Click Preconfigured Model or Configure to order.

3. Enter the machine type and model for your server to display the configurator page.

4. Click Power ➙ Power Cables to see all line cords.

Notes:

• For your safety, a power cord with a grounded attachment plug is provided to use with this product. To

avoid electrical shock, always use the power cord and plug with a properly grounded outlet.

• Power cords for this product that are used in the United States and Canada are listed by Underwriter's

Laboratories (UL) and certified by the Canadian Standards Association (CSA).

• For units intended to be operated at 115 volts: Use a UL-listed and CSA-certified cord set consisting of a

minimum 18 AWG, Type SVT or SJT, three-conductor cord, a maximum of 15 feet in length and a parallel

blade, grounding-type attachment plug rated 15 amperes, 125 volts.

• For units intended to be operated at 230 volts (U.S. use): Use a UL-listed and CSA-certified cord set

consisting of a minimum 18 AWG, Type SVT or SJT, three-conductor cord, a maximum of 15 feet in length

and a tandem blade, grounding-type attachment plug rated 15 amperes, 250 volts.

• For units intended to be operated at 230 volts (outside the U.S.): Use a cord set with a grounding-type

attachment plug. The cord set should have the appropriate safety approvals for the country in which the

equipment will be installed.

• Power cords for a specific country or region are usually available only in that country or region.

Chapter 2. Server components 45

46 ThinkSystem SR250 Maintenance Manual

Chapter 3. Hardware replacement procedures

This section provides installation and removal procedures for all serviceable system components. Each

component replacement procedure references any tasks that need to be performed to gain access to the

component being replaced.

For more information about ordering parts:

http://datacentersupport.lenovo.com/us/en/products/servers/thinksystem/sr250/7Y51/parts

Note: If you replace a part, such as an adapter, that contains firmware, you might also need to update the

firmware for that part. For more information about updating firmware, see “Firmware updates” on page 5.

Installation Guidelines

Before installing components in your server, read the installation guidelines.

Before installing optional devices, read the following notices carefully:

Attention: Prevent exposure to static electricity, which might lead to system halt and loss of data, by

keeping static-sensitive components in their static-protective packages until installation, and handling these

devices with an electrostatic-discharge wrist strap or other grounding system.

• Read the safety information and guidelines to ensure that you work safely.

– A complete list of safety information for all products is available at:

http://thinksystem.lenovofiles.com/help/topic/safety_documentation/pdf_files.html

– The following guidelines are available as well: “Handling static-sensitive devices” on page 49 and

“Working inside the server with the power on” on page 49.

• Make sure the components you are installing are supported by the server. For a list of supported optional

components for the server, see

• When you install a new server, download and apply the latest firmware. This will help ensure that any

known issues are addressed, and that your server is ready to work with optimal performance. Go to

ThinkSystem SR250 Drivers and Software to download firmware updates for your server.

Important: Some cluster solutions require specific code levels or coordinated code updates. If the

component is part of a cluster solution, verify that the latest level of code is supported for the cluster

solution before you update the code.

• It is good practice to make sure that the server is working correctly before you install an optional

component.

• Keep the working area clean, and place removed components on a flat and smooth surface that does not

shake or tilt.

• Do not attempt to lift an object that might be too heavy for you. If you have to lift a heavy object, read the

following precautions carefully:

– Make sure that you can stand steadily without slipping.

– Distribute the weight of the object equally between your feet.

– Use a slow lifting force. Never move suddenly or twist when you lift a heavy object.

– To avoid straining the muscles in your back, lift by standing or by pushing up with your leg muscles.

http://www.lenovo.com/us/en/serverproven/.

© Copyright Lenovo 2018 47

• Make sure that you have an adequate number of properly grounded electrical outlets for the server,

monitor, and other devices.

• Back up all important data before you make changes related to the disk drives.

• Have a small flat-blade screwdriver, a small Phillips screwdriver, and a T8 torx screwdriver available.

• To view the error LEDs on the system board and internal components, leave the power on.

• You do not have to turn off the server to remove or install hot-swap power supplies, hot-swap fans, or hotplug USB devices. However, you must turn off the server before you perform any steps that involve

removing or installing adapter cables, and you must disconnect the power source from the server before

you perform any steps that involve removing or installing a riser card.

• Blue on a component indicates touch points, where you can grip to remove a component from or install it

in the server, open or close a latch, and so on.

• Orange on a component or an orange label on or near a component indicates that the component can be

hot-swapped if the server and operating system support hot-swap capability, which means that you can

remove or install the component while the server is still running. (Orange can also indicate touch points on

hot-swap components.) See the instructions for removing or installing a specific hot-swap component for

any additional procedures that you might have to perform before you remove or install the component.

• The Red strip on the drives, adjacent to the release latch, indicates that the drive can be hot-swapped if

the server and operating system support hot-swap capability. This means that you can remove or install

the drive while the server is still running.

Note: See the system specific instructions for removing or installing a hot-swap drive for any additional

procedures that you might need to perform before you remove or install the drive.

• After finishing working on the server, make sure you reinstall all safety shields, guards, labels, and ground

wires.

System reliability guidelines

Review the system reliability guidelines to ensure proper system cooling and reliability.

Make sure the following requirements are met:

• When the server comes with redundant power, a power supply must be installed in each power-supply

bay.

• Adequate space around the server must be spared to allow server cooling system to work properly. Leave

approximately 50 mm (2.0 in.) of open space around the front and rear of the server. Do not place any

object in front of the fans.

• For proper cooling and airflow, refit the server cover before you turn the power on. Do not operate the

server for more than 30 minutes with the server cover removed, for it might damage server components.

• Cabling instructions that come with optional components must be followed.

• A failed fan must be replaced within 48 hours since malfunction.

• A removed hot-swap fan must be replaced within 30 seconds after removal.

• A removed hot-swap drive must be replaced within two minutes after removal.

• A removed hot-swap power supply must be replaced within two minutes after removal.

• Every air baffle that comes with the server must be installed when the server starts (some servers might

come with more than one air baffle). Operating the server with a missing air baffle might damage the

processor.

• All processor sockets must contain either a socket cover or a processor with heat sink.

• When more than one processor is installed, fan population rules for each server must be strictly followed.

48

ThinkSystem SR250 Maintenance Manual

Working inside the server with the power on

You might need to keep the power on with the server cover removed to look at system information on the

display panel or to replace hot-swap components. Review these guidelines before doing so.

Attention: The server might stop and loss of data might occur when internal server components are

exposed to static electricity. To avoid this potential problem, always use an electrostatic-discharge wrist

strap or other grounding systems when working inside the server with the power on.

• Avoid loose-fitting clothing, particularly around your forearms. Button or roll up long sleeves before

working inside the server.

• Prevent your necktie, scarf, badge rope, or long hair from dangling into the server.

• Remove jewelry, such as bracelets, necklaces, rings, cuff links, and wrist watches.

• Remove items from your shirt pocket, such as pens and pencils, in case they fall into the server as you

lean over it.

• Avoid dropping any metallic objects, such as paper clips, hairpins, and screws, into the server.

Handling static-sensitive devices

Review these guidelines before you handle static-sensitive devices to reduce the possibility of damage from

electrostatic discharge.

Attention: Prevent exposure to static electricity, which might lead to system halt and loss of data, by

keeping static-sensitive components in their static-protective packages until installation, and handling these

devices with an electrostatic-discharge wrist strap or other grounding system.

• Limit your movement to prevent building up static electricity around you.

• Take additional care when handling devices during cold weather, for heating would reduce indoor

humidity and increase static electricity.

• Always use an electrostatic-discharge wrist strap or other grounding system, particularly when working

inside the server with the power on.

• While the device is still in its static-protective package, touch it to an unpainted metal surface on the

outside of the server for at least two seconds. This drains static electricity from the package and from your

body.

• Remove the device from the package and install it directly into the server without putting it down. If it is

necessary to put the device down, put it back into the static-protective package. Never place the device

on the server or on any metal surface.

• When handling a device, carefully hold it by the edges or the frame.

• Do not touch solder joints, pins, or exposed circuitry.

• Keep the device from others’ reach to prevent possible damages.

Adapter replacement

Use the following information to remove and install the adapter.

Remove an adapter

Use this information to remove an adapter.

Before you remove an adapter, complete the following steps:

Chapter 3. Hardware replacement procedures 49

Attention: Replacing the adapter might impact your RAID configurations. Back up your data before the

replacement to avoid any data loss due to a RAID configuration change.

1. Read the following section(s) to ensure that you work safely.

• “Safety” on page iii

• “Installation Guidelines” on page 47

2. Turn off the server. Disconnect the power cords and all external cables (see “Power off the server” on

page 10).

3. If server is installed in a rack, remove the server from the rack.

4. Remove the top cover (see “Remove the top cover” on page 132).

5. Remove the PCIe riser assembly (see “Remove the PCIe riser assembly” on page 90).

6. Record the cable connections on the adapter; then, disconnect all cables from the adapter.

To remove an adapter, complete the following steps:

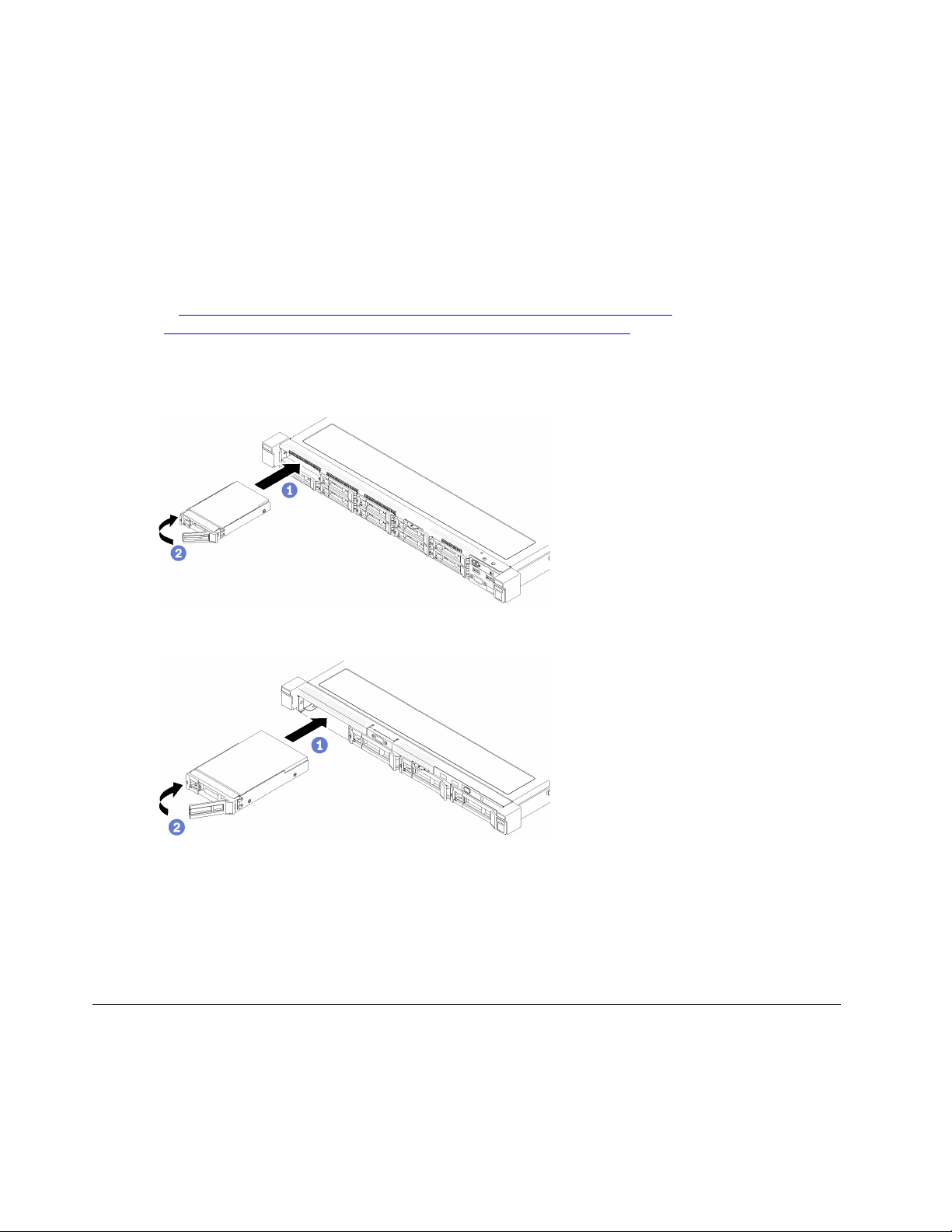

Watch the procedure. A video of the process is available:

• Youtube:

• Youku: http://i.youku.com/i/UMjk0OTEwMDExMg==?spm=a2h1n.8251843.0.0

https://www.youtube.com/channel/UCjqE4XzuvdHpVM9lXt41M8g/playlists

Figure 40. Adapter removal

Step 1. Disengage the adapter by pulling it straight out of the riser cage.

Note: Remove one adapter at a time, do not pull out two adapters at the same time.

If you are instructed to return the defective component, please package the part to prevent any shipping

damage. Reuse the packaging the new part arrived in and follow all packaging instructions.

Install an adapter

Use this information to install an adapter.

Before you install an adapter, complete the following steps:

1. Read the following section(s) to ensure that you work safely.

• “Safety” on page iii

• “Installation Guidelines” on page 47

2. Touch the static-protective package that contains the component to any unpainted metal surface on the

server; then, remove it from the package and place it on a static-protective surface.

50

ThinkSystem SR250 Maintenance Manual

Notes:

1. PCIe slot 1 and slot 2 do not support ARI and SR-IOV.

2. PCIe slot 4 supports ARI and SR-IOV.

3. QLogic QL41262 PCIe 25Gb 2-Port SFP28 Ethernet Adapter does not support shared storage V3700

V2/XP and V5030 V2 configurations.

To install an adapter, complete the following steps:

Watch the procedure. A video of the process is available:

• Youtube:

• Youku: http://i.youku.com/i/UMjk0OTEwMDExMg==?spm=a2h1n.8251843.0.0

https://www.youtube.com/channel/UCjqE4XzuvdHpVM9lXt41M8g/playlists

Figure 41. Adapter installation

Step 1. Remove the fillers on the rear side of the riser cage.

Step 2. Align and insert an adapter into the slot on the riser card. Make sure you install the adapter into the

right slot.

Notes:

• For the detail connectors on the PCIe riser card, see “PCIe riser assembly” on page 23.

• Install one adapter at a time, do not insert two adapters to the riser card at the same time.

After you install an adapter, complete the following steps:

1. Reconnect the cables.

2. Reinstall the PCIe riser assembly (see “Install the PCIe riser assembly” on page 91).

3. Install the top cover onto the server (see “Install the top cover” on page 133).

4. Install the server into the rack if necessary.

5. Reconnect power cords and all external cables.

6. If necessary, configure the RAID array using the Setup utility configuration.

Air baffle replacement

Use the following information to remove and install the air baffle.

Remove the air baffle

Use this information to remove the air baffle.

Chapter 3. Hardware replacement procedures 51

Before you remove the air baffle, complete the following steps:

1. Read the following section(s) to ensure that you work safely.

• “Safety” on page iii

• “Installation Guidelines” on page 47

2. Turn off the server. Disconnect the power cords and all external cables (see “Power off the server” on

page 10).

3. If server is installed in a rack, remove the server from the rack.

4. Remove the top cover (see “Remove the top cover” on page 132).

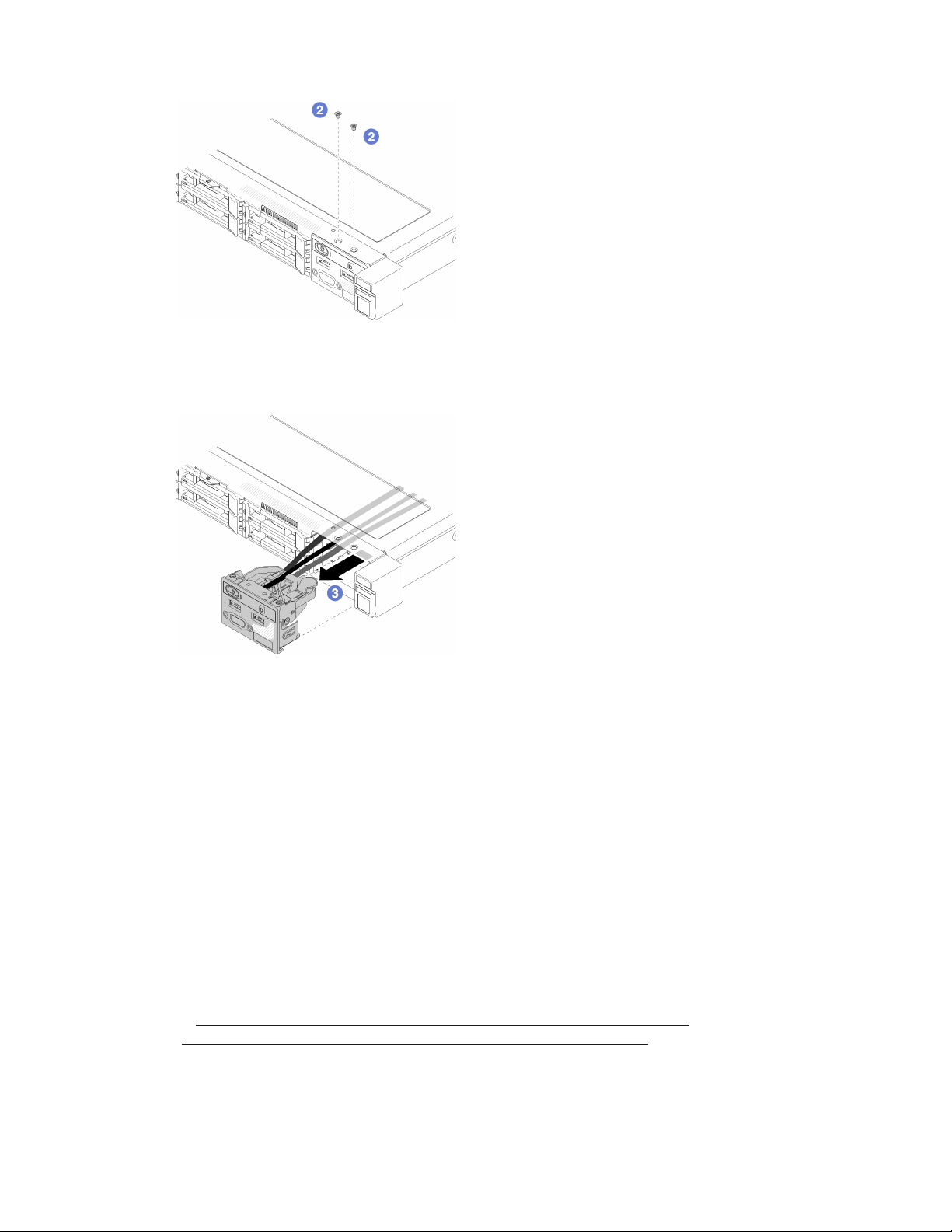

To remove the air baffle, complete the following steps:

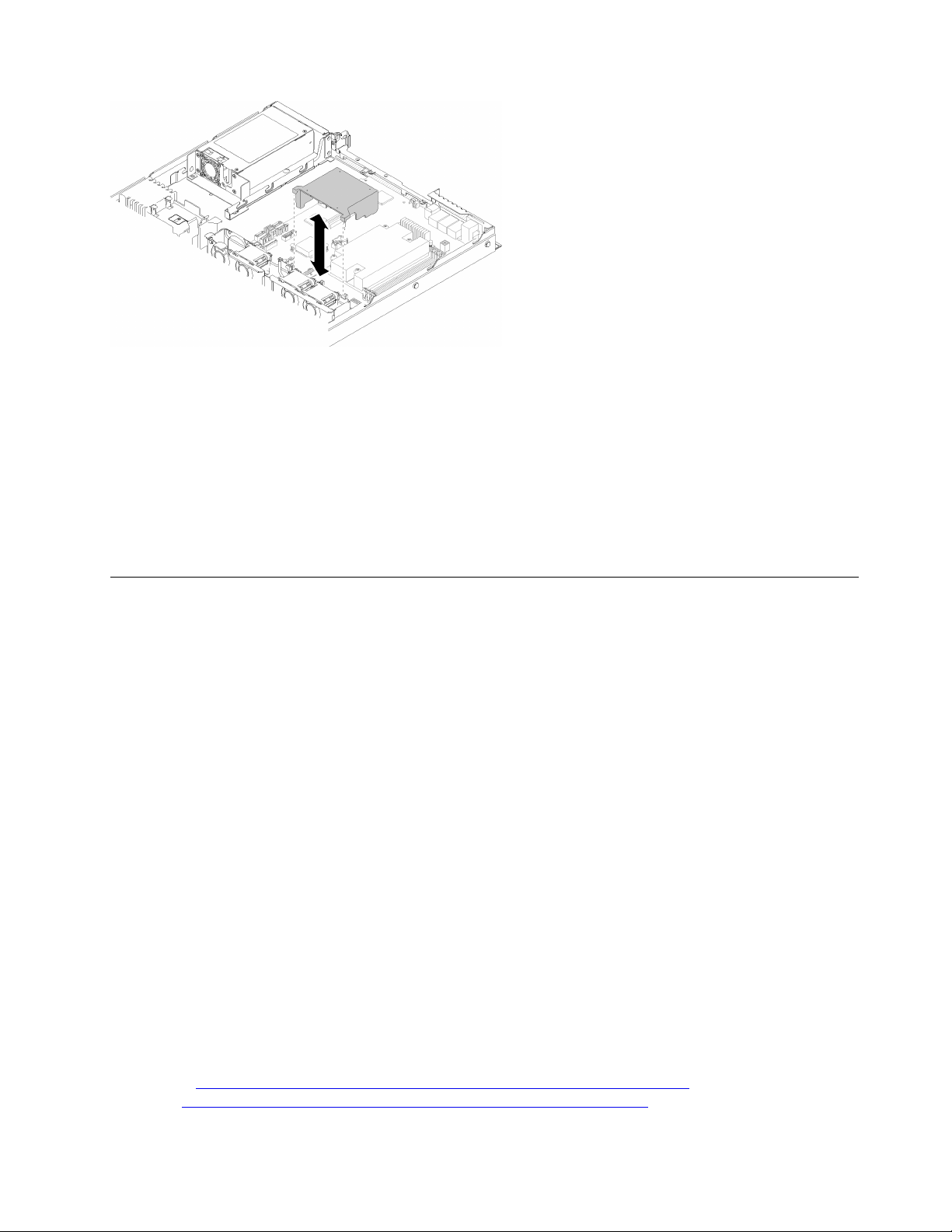

Figure 42. Air baffle removal

Step 1. Lift the air baffle up and set it aside.

Attention: For proper cooling and airflow, reinstall the air baffle before you turn on the server.

Operating the server with the air baffle removed might damage server components.

If you are instructed to return the defective component, please package the part to prevent any shipping

damage. Reuse the packaging the new part arrived in and follow all packaging instructions.

Install the air baffle

Use this information to install the air baffle.

Before you install the air baffle, complete the following steps:

1. Read the following section(s) to ensure that you work safely.

• “Safety” on page iii