Page 1

INSTALLATION AND OPERATION

FREESTANDING

PELLET FIRED

STOVES

RETAIN THESE

INSTRUCTIONS

FOR FUTURE

REFERENCE

These appliances must be properly installed and operated in order to

prevent the possibility of a house fire. Please read this entire owner's

manual before installing and using your pellet stove. Failure to follow

these instructions could result in property damage, bodily injury or even

death. Contact your local building or fire officials to obtain a permit and

information on any installation requirements and inspection requirements in your area.

MANUAL

Freestanding Model

T300P Series

P/N 775025M, Rev. E, 12/03

Page 2

IMPORTANT WARNINGS

CAUTION: Read this manual thoroughly before starting installation. For your safety, follow the installation, operation and maintenance instructions exactly without deviation. Failure to follow these instructions may result

in a possible fire hazard and will void the warranty. If this appliance is not properly installed, a house fire may

result. Contact local building or fire officials about restrictions and installation inspection in your area.

1. DO NOT CONNECT THIS UNIT TO A CHIMNEY

FLUE CONNECTED TO ANOTHER APPLIANCE.

2. Do not connect this appliance to air ducts or any air

distribution system.

3. Do not install a flue damper in the exhaust venting

system of this appliance.

4. Do not use class B venting intended for gas appliances as a chimney or connector pipe on a pelletfired appliance.

5. The minimum clearances must be maintained for all

combustible surfaces and materials including; furniture, carpet, drapes, clothing, wood, papers, etc.

Do not store firewood within this clearance space.

6. INSTALLATION DISCLAIMER - This stoves exhaust

system works with negative combustion chamber

pressure and a slightly positive chimney pressure.

Therefore, it is imperative that the exhaust system

is gas tight and installed correctly. Since Lennox

Hearth Products has no control over the installation of your stove, Lennox Hearth Products grants

no warranty, implied or stated for the installation or

maintenance of your stove, and assumes no responsibility for any consequential damage(s).

7. Burning any kind of fuel consumes oxygen. If outside air is not ducted to the appliance, ensure that

there is an adequate source of fresh air available to

the room where the appliance is installed.

8. This stove is not intended for use in commercial

installations other than where the stove is being

sold without prior approval from Lennox Hearth

Products.

9. The stove will not operate using natural draft, nor

without a power source for the blower and fuel

feeding systems.

10. Never use gasoline, gasoline-type lantern fuel,

kerosene, charcoal lighter fluid, or similar liquids to

start or "freshen up" a fire in this heater. Keep all

such liquids well away from the heater while it is in

use.

11. CONTINUOUS OPERATION: When operated correctly, this appliance cannot be overfired. Continuous operation at a maximum burn can, however,

shorten the life of the electrical components (blowers, motors, and electronic controls), and is not

recommended. Typical approved operation would

include running at the low to mid range setting with

occasional running on the maximum setting during

the coldest periods of the winter. The blower speed

control should be turned to high when operating

the stove on the high heat setting.

12. CAUTION: NEVER PUT FINGERS NEAR AUGER.

Pellet fuel is fed to the UltraGrate by a screw auger. This auger is driven by a high torque motor.

The auger is capable of doing serious harm to fin-

Page 2

gers. Keep pellets in the hopper at all times and

keep fingers away from auger. The auger can start

and stop automatically at any time while the stove

is running.

13. CAUTION: HOT WHILE IN OPERATION. An appliance hot enough to warm your home can severely

burn anyone touching it. Keep children, clothing

and furniture away. Contact may cause skin burns.

Do not let children touch the appliance. Train them

to stay a safe distance from the unit.

14. APPROVED FUEL: This appliance is designed specifically for use only with pelletized wood fuels

only. With its advanced UltraGrate technology,

this appliance is designed and approved for the

burning of wood residue pellets with up to 3% ash

content. This appliance is NOT approved to burn

cardboard, nut hulls, cherry pits, corn, etc. regardless if it is in pellet form. Failure to comply with this

restriction will void all warranties and the safety

listing of the stove. Consult with your authorized

Lennox Hearth Products dealer for more information on approved pellet fuels.

15. FLY ASH BUILD-UP: For all wood pellet fuelburning heaters, the combustion gases will contain

small particles of fly ash. This will vary due to the

ash content of the fuel being burned. Over time, the

fly ash will collect in the exhaust venting system

and restrict the flow of the flue gases. The exhaust

venting system should be inspected regularly and

cleaned as necessary.

16. SOOT FORMATION Incomplete combustion, such

as occurs during startup, shutdown, or incorrect

operation of the room heater will lead to some soot

formation which will collect in the exhaust venting

system. A precautionary inspection on a regular

basis is advisable to determine the necessity of

cleaning. The exhaust venting system should be

inspected regularly and cleaned as necessary.

17. DISPOSING OF ASHES: Any ashes removed from

the pellet stove must be deposited in a metal container with a tight-fitting lid. The closed container of

ashes should be placed on a noncombustible floor

or on the ground, well away from all combustible

materials, outside of the dwelling pending final disposal. If the ashes are disposed of by burial in soil

or otherwise locally dispersed, they should be retained in the closed container until all cinders have

been thoroughly cooled.

18. SAVE THESE INSTRUCTIONS.

19. See the listing label on the stove body (or see

Safety / Listing Label, page 38).

Page 3

TABLE OF CONTENTS

Important Warnings ................................................ 2

Testing / Listing, EPA, Using this Manual................ 3

Planning Your Installation ..................................... 4-6

Manufactured (Mobile) Home Installation ................7

Installation .......................................................... 7-15

Care and Operation .......................................... 16-21

Routine Maintenance........................................ 22-25

Specifications..........................................................26

Definitions ...............................................................27

Wiring Diagram .......................................................28

Troubleshooting ................................................ 29-30

Replacement Parts List / Diagrams .................. 31-34

Optional Accessories ..............................................35

Installation Tips .......................................................36

Simple Operating Instructions.................................37

Safety / Listing Label...............................................38

Ownership Records ................................................39

LISTING / TESTING

Listing: The listing laboratory is ITS (Intertek Testing Services) and the listing mark is Warnock Hersey.

Testing: In accordance with the specifications and procedures listed in UL 1482 & ASTM E1509 for solid fuel room

heater, this appliance has been independently tested to UL,

ULC and CSA standards. UL 1482 states requirements for

installations as a freestanding room heater. The safety listing label is located on an inside hopper surface of the pellet

stove. Please read this safety label carefully. It contains

important information about installation and operation of

this appliance. This appliance is tested and listed for residential installation according to current national and local

building codes as:

• A Freestanding Room Heater

• A Manufactured (Mobile) Home Heater

EPA (Environmental Protection Agency)

Status: EPA Exempt - Pellet appliances that are designed with the combustion air supply exceeding the 35

to 1 (by weight) ratio are exempt from EPA regulations

and are “non-affected facilities.”

PRODUCT IS SUBJECT TO CHANGE WITHOUT NOTICE.

CONGRATULATIONS ON THE PURCHASE OF YOUR

NEW PELLET STOVE MANUFACTURED BY LENNOX

HEARTH PRODUCTS.

When you purchased your new pellet stove, you

joined the ranks of thousands of concerned individuals whose answer to their home heating needs

reflects their concern for aesthetics, efficiency and

our environment. We extend our continued support

to help you achieve the maximum benefit and enjoyment available from your new pellet stove.

It is our goal at Lennox Hearth Products to provide

you, our valued customer, with an appliance that will

ensure you years of trouble free warmth and pleasure.

Thank you for selecting a Lennox Hearth Products

stove as the answer to your home heating needs.

Sincerely,

All of us at Lennox Hearth Products

PACKAGING LIST

The assembled pellet stove models T300P SERIES, are

packaged with an accessory package which contains the

following:

One - Installation and Operation Instructions Manual

One - Warranty

One - Power cord

One - Grate scraper

One - Wall thermostat

One - 20’ roll of 18 gage thermostat wire

One - Trivet, black decorative (for stove top)

One - Damper rod

Four - Levelers, leg, ¼-20x 1”

USING THIS MANUAL

Please read and carefully follow all of the instructions

found in this manual. Please pay special attention to the

safety instructions provided in this manual. The homeowner’s Care and Operation Instructions included here

will assure you have many years of dependable and enjoyable service from your appliance.

Page 3

Page 4

PLANNING YOUR INSTALLATION

QUESTIONS TO ASK LOCAL BUILDING OFFICIAL

A correct installation is critical and imperative for reducing fire hazards and perilous conditions that can arise

when wood pellet burning appliances are improperly

installed. The installer must follow all of the manufacturers’ instructions.

The installation of this appliance must conform to local

codes and applicable state and federal requirements.

Familiarity with these requirements before installation is

essential. Important considerations to discuss with local

building officials include:

1. Applicable codes (i.e. Uniform Mechanical Code,

State or Regional Codes)?

Electrical codes:

In USA, NEC, ANSI / NFPA 70-1987.

In Canada, CSA C22.1

Power Supply Requirements

must be plugged into a standard, 115 volt, 60 Hz

grounded electrical outlet. The approximate

power requirement is 200 watts, and will peak up

to 700 watts for approximately 6 minutes when

the self-igniter is operating (it will turn off 2 minutes after flame detection). The power supply

cord must be routed to avoid contact with any of

the hot or sharp exterior surface areas of the

stove. When installed in a manufactured (mobile)

home appliance must be electrically grounded to

the steel chassis (see page 7, Manufactured

(Mobile) Home Requirements for additional requirements). These requirements must be met

unless otherwise specified by state or local authorities.

WARNING - Electrical Grounding Instructions:

This appliance is equipped with a three-prong

(grounding) plug for your protection against

shock hazard and should be plugged directly

into a properly grounded three-prong receptacle. Do not cut or remove the grounding

prong from this plug.

2. Local amendments?

3. Is a permit required - cost?

You may wish to contact your insurance company

to ask if they require this.

4. Is outside combustion air required?

5. Rooms where the installation is not allowed?

– The power cord

INSTALLATION / MAINTENANCE STANDARDS

National Fire Protection Association – The primary

NFPA standard that refers to installation and maintenance of pellet appliances and venting is NFPA 211:

Chimneys, Fireplaces, Vents, and Solid Fuel appliances, Jan. 2000.

SELECTING A LOCATION

The design of your home and where you place your

stove will determine its value as a source of heat. A

wood stove depends primarily on air circulation (convection) to disperse its heat, and therefore, a central

location is often best. There are other practical considerations, which must be considered before a final selection of locations is made.

♦ Existing Chimneys

♦ Pellet Fuel Storage

♦ Aesthetic Considerations

♦ Roof Design (rafter locations & roof pitch)

♦ Room Traffic

♦ Proximity to Combustibles

♦ Electrical Wiring

The installation of this stove will require some research.

Once your options are determined, consult with your

local building department who will be able to give you

the necessary installation requirements for your area (Is

a building permit required, rooms where installation may

not be allowed, etc.).

WARNING: Check all local building and safety

codes before installation. The installation instructions and appropriate code requirements must be

followed exactly and without compromise. Alterations to the stove are not allowed. Do not connect

the stove to a chimney system serving another

stove, appliance, or any air distribution duct. Failure

to follow these instructions will void the manufacturers warranty.

SMOKE DETECTORS

Since there are always several potential sources of fire

in any home, we recommend installing smoke detectors. If possible, install the smoke detector in a hallway

adjacent to the room (to reduce the possibility of occasional false activation from the heat produced by the

stove). If your local code requires a smoke detector be

installed within the same room, you must follow the requirements of your local code. Check with your local

building department for requirements in your area.

Page 4

Page 5

PLANNING YOUR INSTALLATION

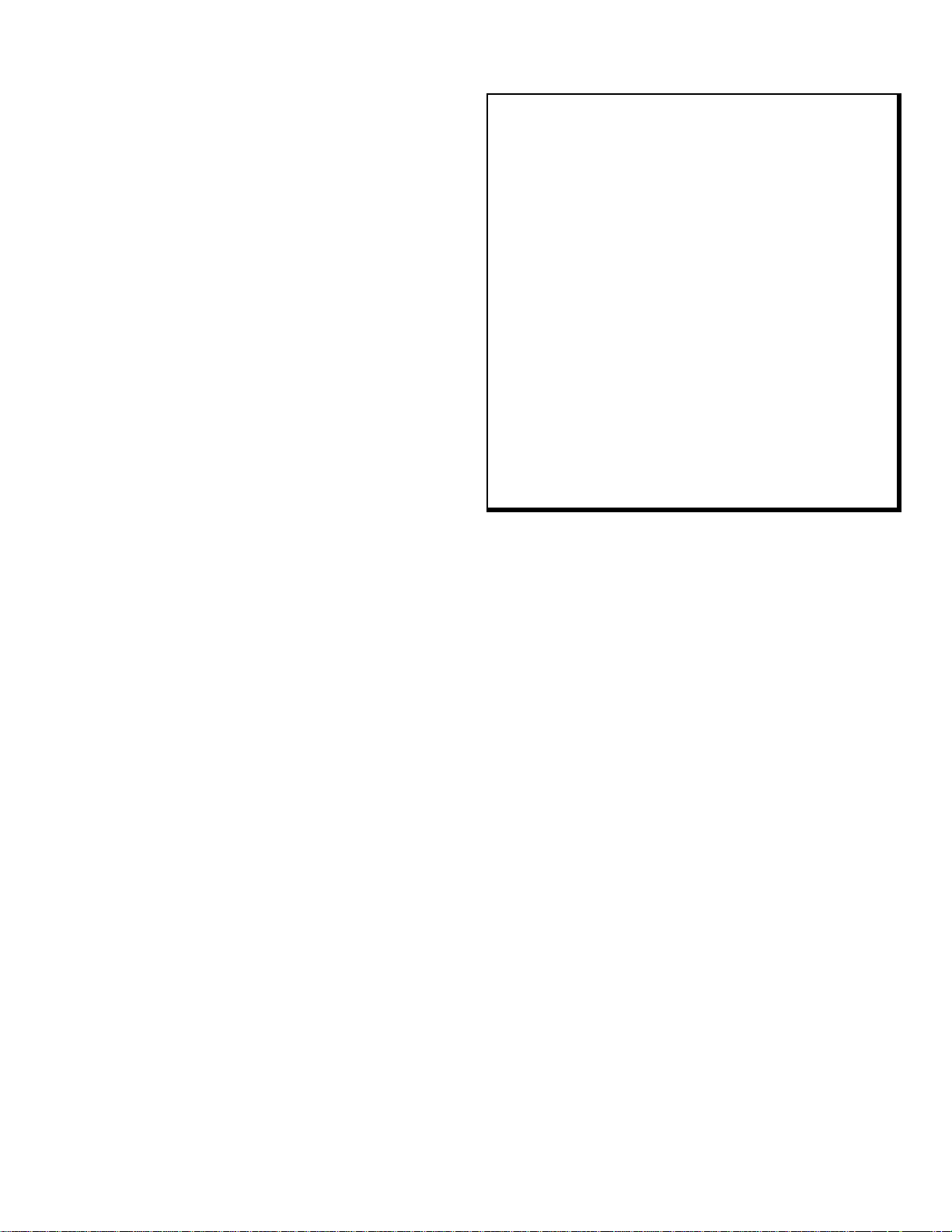

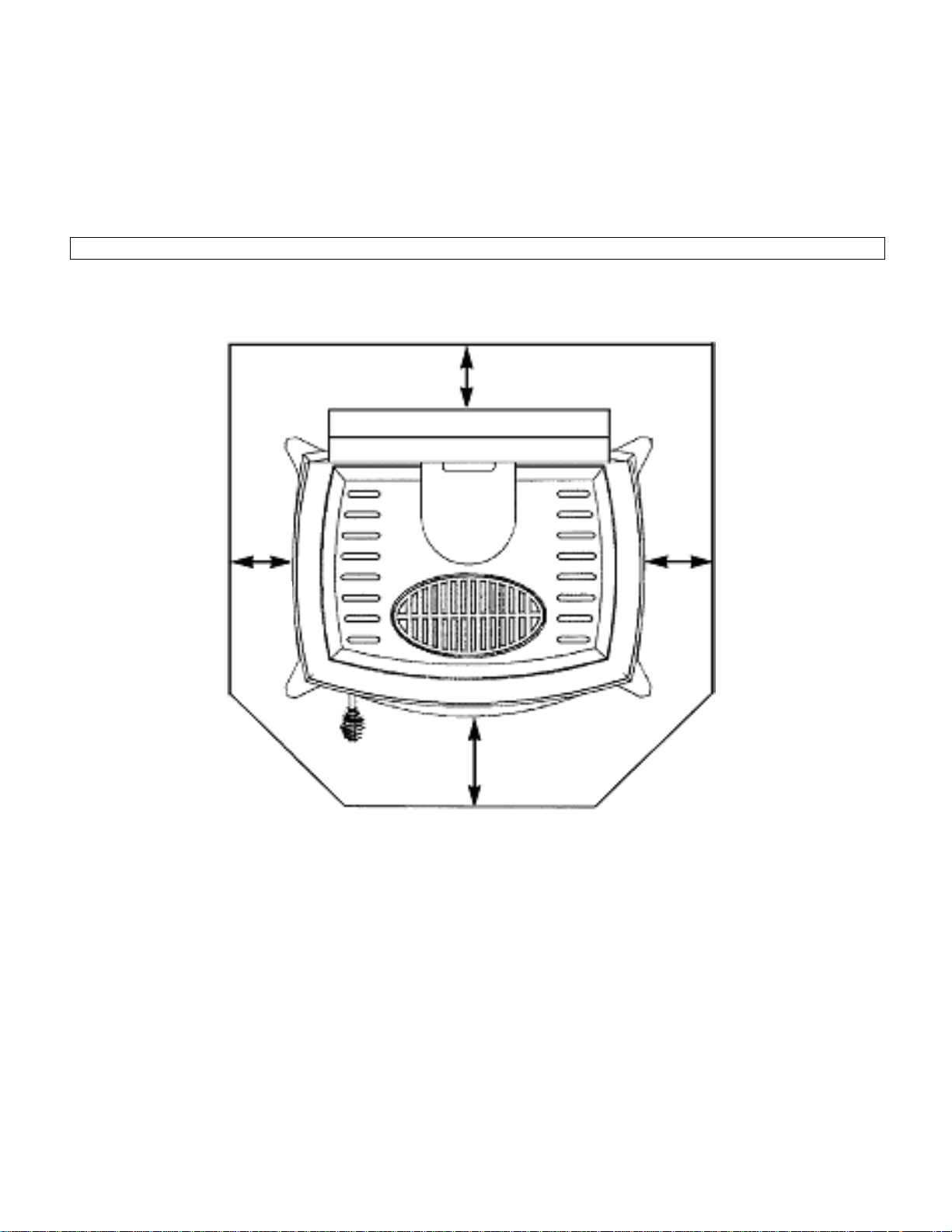

FLOOR PROTECTION

This appliance requires noncombustible floor protection. If the floor protection is to be stone, tile, brick, etc., it must be mortared or grouted to form a continuous non-combustible surface. If a chimney connector extends horizontally over the floor,

the protection must cover the floor under the connector and at least 2" to either side.

A noncombustible floor protector must fully cover the area beneath the appliance and extend 6” to the front, 6” to the

sides, and up to 6" from the back as illustrated below.

*Note: When installed at clearances less than 6”, floor protection is only required to extend to the wall.

T300P SERIES

6"

(153mm}

* Up to 6"/153mm

minimum

6"

6"

(153mm}

(153mm}

Page 5

Page 6

PLANNING YOUR INSTALLATION

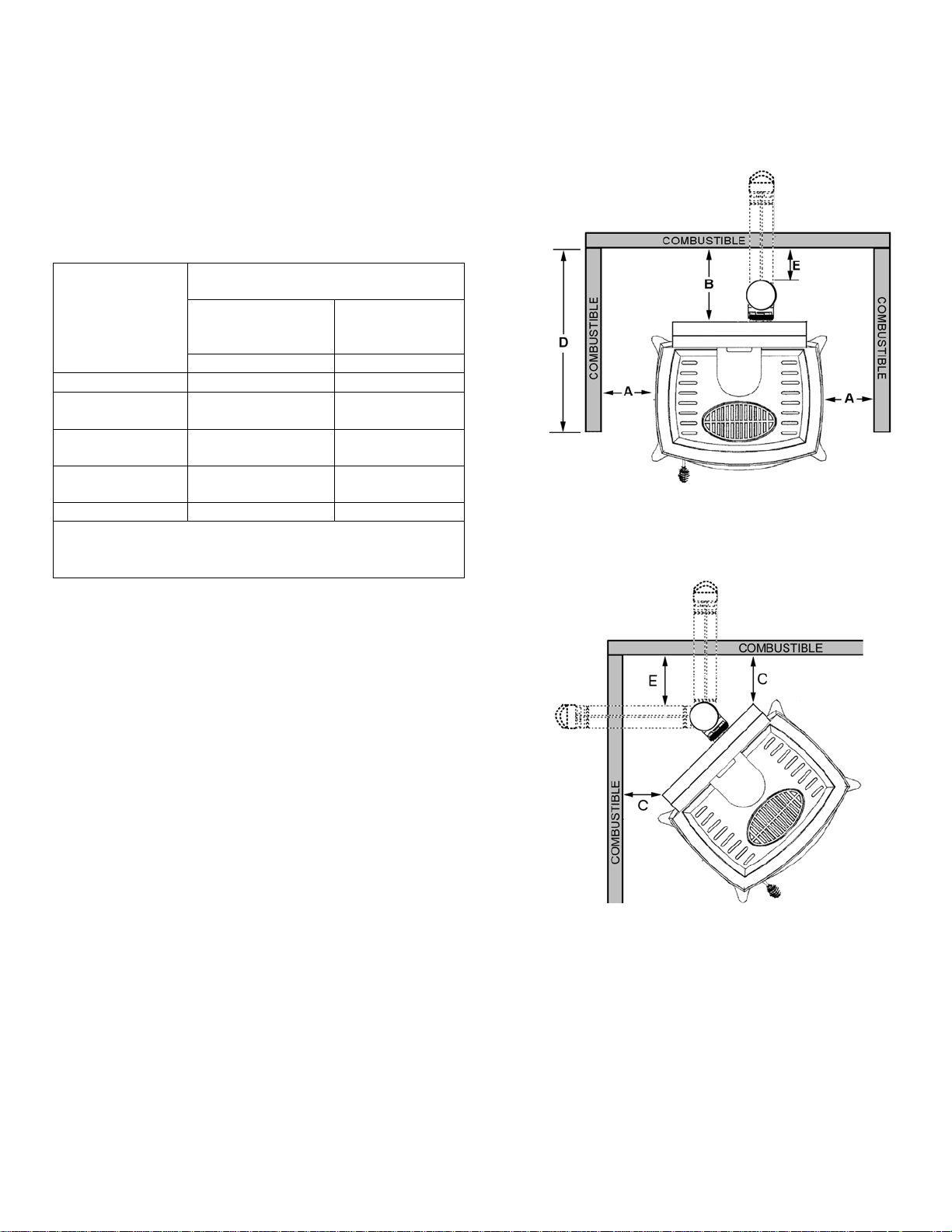

Clearances to combustibles are determined from testing to applicable standards for allowable heat transfer.

The clearances allowed as shown here, do not take into account operation or serviceability requirements.

CLEARANCES

Standard residential or manufactured (mobile) home installation. These appliances require the following minimum

clearances to combustibles:

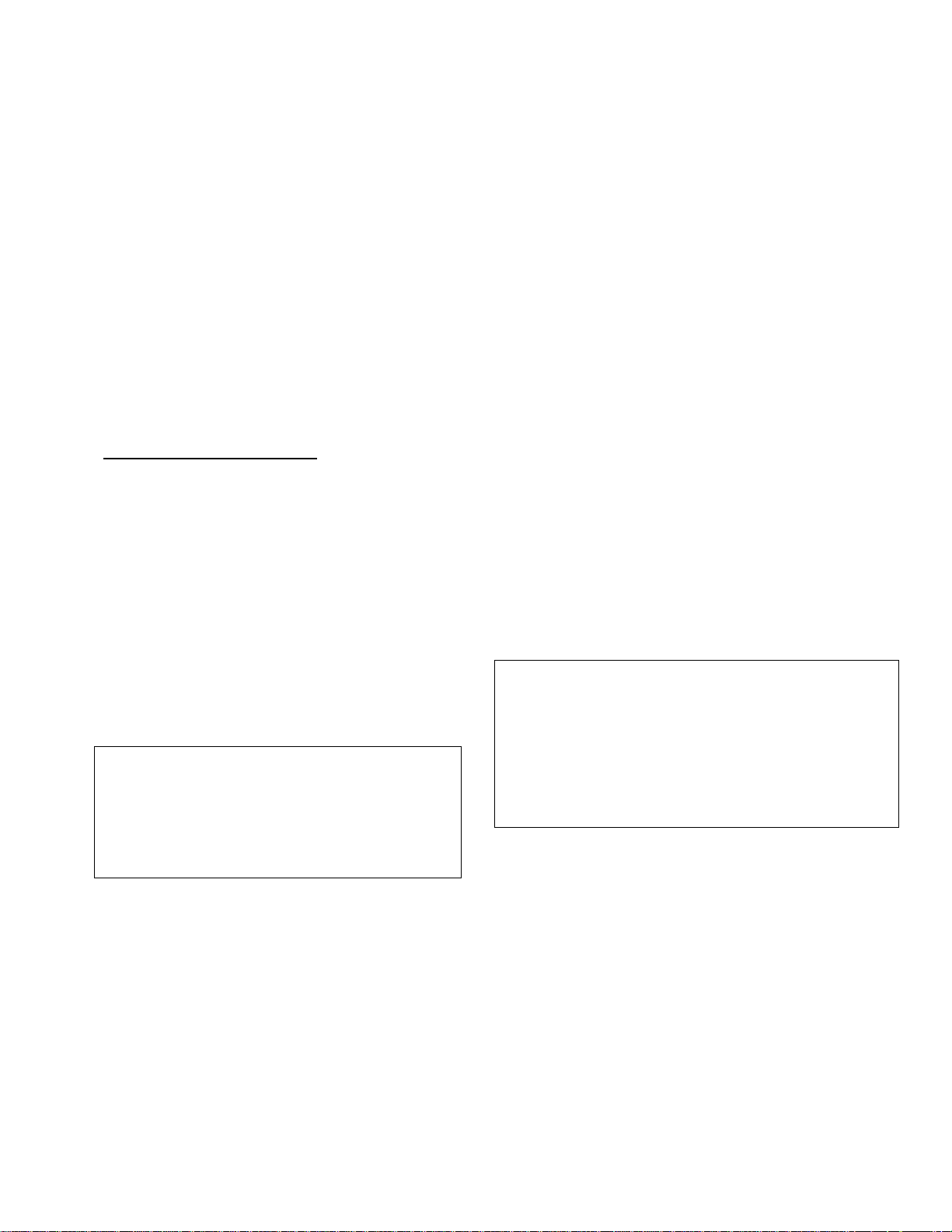

MINIMUM CLEARANCES TO COMBUSTIBLES

Model: T300P

Series

Clearance to

Combustibles

A - Sidewall to unit

B - Backwall to

unit

C - Sidewall to unit

Corner

D - Max. Depth of

Alcove

E - Flue to Wall 3” / 77 mm 3” / 77 mm

♦ Measured to outside projection of cast stove top

• Minimum Alcove Measurements: Height 48” / 1220 mm

Width 41” / 1042 mm

Minimum clearances specified may not allow for ease

of operation and maintenance (please take this into

account when planning the installation). If installed to

the minimum clearances, removal of the appliance may

be necessary for servicing.

Manufactured (Mobile) Home

or Residential Installation

Horizontal Flue –

Directly Through

Wall

inch / millimeter inch / millimeter

♦6” / 153 mm ♦6” / 153 mm

2” / 51 mm 9” / 229 mm

2” / 51 mm 2” / 51 mm

•18” / 458 mm •18” / 458 mm

Interior Vertical

Flue

Rear Wall or Alcove

Corner

Page 6

Page 7

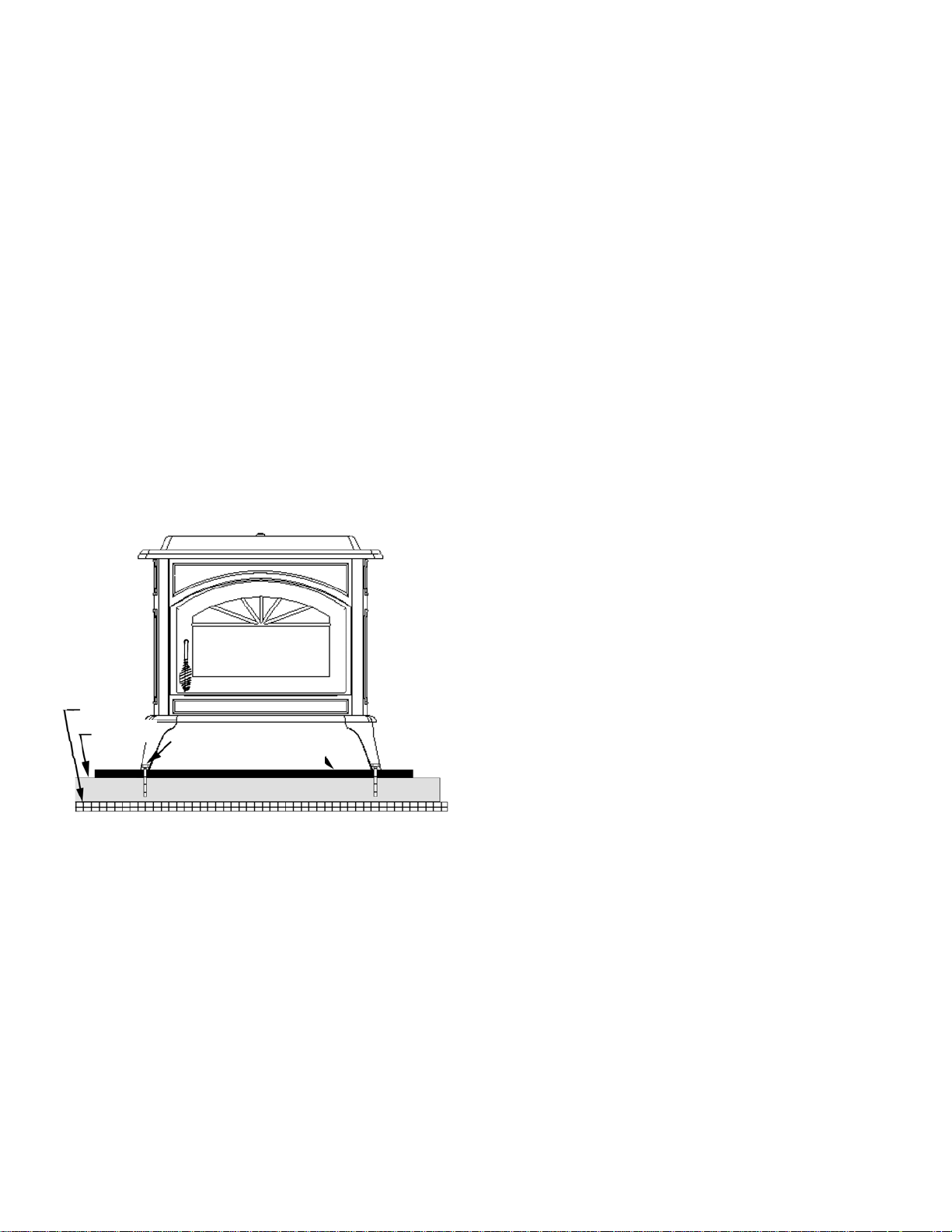

INSTALLATION

MANUFACTURED (MOBILE) HOME INSTALLATION

Model –T300P Series

In addition to the standard installation instructions, the

following instructions may be required by local, state or

federal building codes:

• Stove must be permanently bolted to the floor.

• An outside air inlet must be provided for combustion

and be unrestricted while unit is in use.

• Stove must be permanently electrically grounded to

the steel chassis of the home. The location selected

for ground attachment to the stove must be dedicated

for this purpose.

• See pages 10 through 15 for additional information on

venting requirements.

• Do not install appliance in a sleeping room.

• The structural integrity of the manufactured home

floor, walls, ceiling and roof must be maintained.

NOTE: The grounding of this product, at installation,

must comply with NFPA-70 standards, CSA C22.1 in

Canada, as well as any local codes.

Model - T300P SERIES

Floor

Bolt

MANUFACTURED (MOBILE) HOME EXHAUST VENT

PIPE INSTALLATION GUIDELINES

Use only listed type “PL” pellet vent pipe. Pipe should

extend at least 3 feet above the part of the roof through

which it passes. The top of the pipe should be at least 2

feet above the highest required elevation of any part of

the manufactured (mobile) home within 10 feet of the

pipe.

If the exhaust vent exits the manufactured (mobile)

home at a location other than the roof, and exits at a

point 7 feet or less above the ground level on which the

manufactured (mobile) home is position a guard or

method of enclosing the pipe shall be provided at the

point of exit for a height of up to 7 feet. The openings, if

any, in this guard shall not allow a 3/4” rod to pass

through. A 1/2” rod could pass through but should not

be able to touch the pipe when inserted through the

opening a distance of 4 inches.

Floor

Protector

Page 7

REMOVING APPLIANCE FROM PALLET

1. After removing the packaging from the stove, lift the

hopper lid, and remove all pre-packaged items that

were shipped in the hopper. Next, open the stove

door and remove all pre-packaged items.

2. Remove screws which secure legs to pallet.

INSTALLING LEG LEVELING BOLTS

The four leg leveling bolts (included in accessory package), are provided for leveling the stove if necessary.

To install, thread the bolts into the existing holes in the

bottom of each leg. Turn the leveling bolts to adjust for

correct height.

INSTALLATION CHECK LIST

It is strongly recommended that you have an authorized

Lennox Hearth Products dealer install your stove. If you

install your stove yourself, you should review your installation plan with your authorized Lennox Hearth

Products dealer.

Check list:

Check off each item as you proceed with the installation

process.

Read the ENTIRE stove installation section first.

Determine the appropriate measurements and loca-

tions for your installation.

Follow the general installation directions under

Stove Installation and the installation section appropriate to your stove.

Be sure to pre-fit all items before you install, fasten,

or set up the stove permanently.

Prior to lighting your stove:

Review the safety precaution section.

Review the pellet fuels section.

Review and follow the Operating Instructions.

Plug power cord connector into corresponding con-

nector on the back of appliance (see illustration on

page 9 showing connector locations).

After you have begun operation of your stove:

Review the routine cleaning / maintenance informa-

tion.

Enjoy the warmth from your new Lennox Hearth

Products pellet stove!

Page 8

INSTALLATION

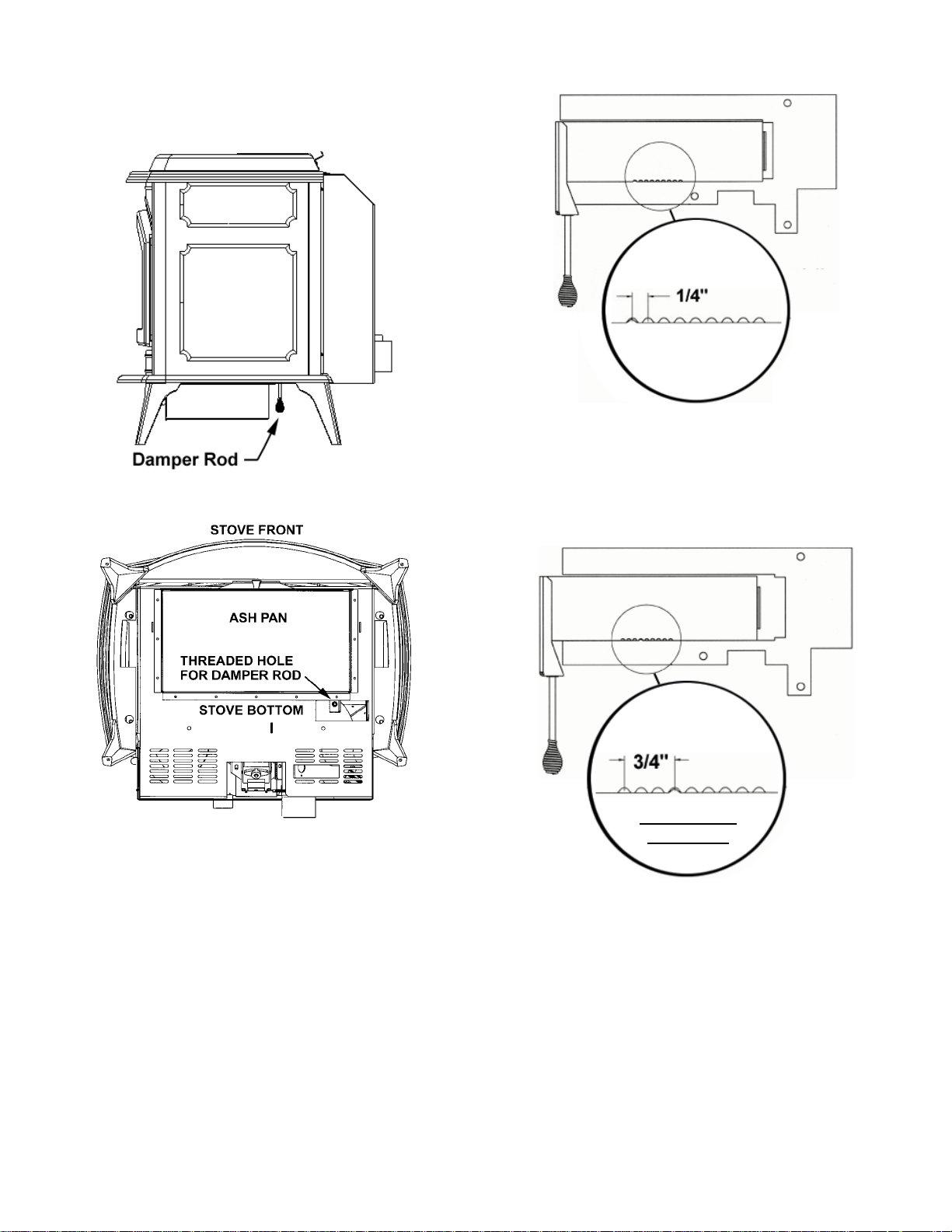

DAMPER ROD INSTALLATION

1. Locate rectangular cutout on bottom stove panel

behind ash pan.

2. Screw damper rod into threaded hole.

DAMPER ADJUSTMENT

The damper rod is located under the bottom plate, on

the right hand side of the stove, just behind the ash

pan. It is very important to preset your damper prior to

burning your pellet stove.

The damper plate contains nine notches spaced in 1/4”

increments that aid in positioning (see Fig. A).

Fig. A

For initial setup, push the damper all the way in (when

facing the front of the stove, “in” is to the left, and “out”

is to the right) and slowly pull back three notches (see

Fig. B).

Pulled Back

3 Notches

Fig. B

This setting should provide an adequate air to fuel ratio

for most installations.

Page 8

Page 9

INSTALLATION

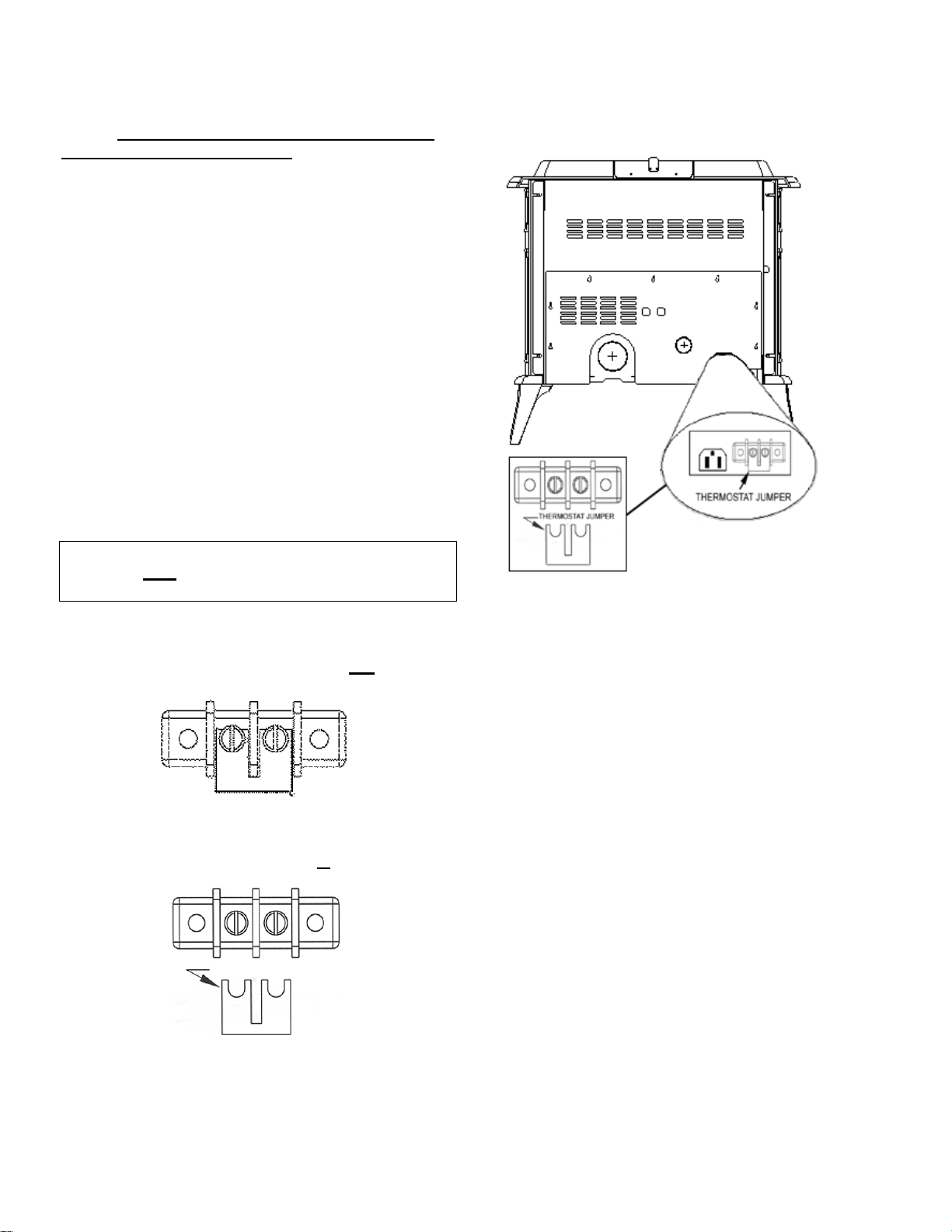

THERMOSTAT INSTALLATION:

NOTE: Always Disconnect Power Before Performing The Thermostat Installation.

A 24-volt wall thermostat and 20 feet of 18-gage thermostat wire is included in your stoves accessory package. It is recommended that the thermostat and thermostat wire be installed by an authorized Lennox

Hearth Products dealer.

Installation Steps:

1. Unplug stove power cord from the wall outlet.

2. Locate the thermostat terminal block (see illustration).

3. Loosen the two terminal screws on the terminal

block and remove the jumper.

4. Connect the two wires from your thermostat to the

terminals (one per terminal). Ensure that the purple

wires from the harness remain connected to the terminal block and tighten the terminal screws. Make

sure the wires are firmly connected to the thermostat.

5. Plug in the stove and you are ready to operate with

your thermostat!

IMPORTANT: IF THE WALL THERMOSTAT PROVIDED IS NOT USED, THE JUMPER IS REQUIRED

FOR THE STOVE TO OPERATE.

Terminal Block for Thermostat

Leave Jumper on, If Thermostat Is Not

Used

Model T300P Series

(viewed from stove back)

Remove Jumper if Thermostat Is

Jumper

To Be Used

Page 9

Page 10

INSTALLATION

VENTING REQUIREMENTS

It is recommended that only an authorized dealer install

your pellet stove. The specified installation requirements

must be followed to ensure conformity with both the

safety listing of the appliance and local building codes. All

clearances, installation instructions and precautions

specified by the vent manufacturer must be followed.

Selecting a Location - Review the appliance clearance

requirements before installing the venting system (see

Clearances, page 6). Position the appliance far enough

away from walls to allow adequate room for servicing.

Choose the appliance location with the least amount of

interference with the house framing, plumbing, wiring,

etc.

Preferred Vent Configuration – For the best performance, we recommend a vent run design which runs vertically and terminates above the roofline. This design will

allow natural draft to improve the flow of flue gases and

will aid in combustion and stove performance.

Type of Pipe – This stove requires type “PL” (pellet vent

pipe, sometimes referred to as “L-Vent pellet vent”),

which conforms to UL standard 641. Connect the pellet

vent pipe or the “tee” to the flue collar using a minimum of

three screws and seal as specified in “Pipe Joint Requirements” on this page. Do not use class B gas chimney

or single wall chimney as a substitute.

Size of Pipe -These pellet appliances are approved for

use with the following vent sizes: 3” (75mm) standard, or

4” (100mm). See page 12 for determining correct size

vent to use. Use a 3” (75mm) to 4” (100mm) adapter

(Cat. No. 14M81) or a 3” (75mm) to 4” (100mm) “tee” in

order to run 4” (100mm) pipe.

Offsets - In every installation, a single or double cleanout “tee” is recommended for every ninety-degree offset

(this tee will help collect ash residue and will allow for

routine cleaning without the need to disconnect sections

of pipe).

Note: Offsets and horizontal runs accumulate fly ash and

soot which reduces the exhaust flow and performance of

the stove.

Total Offsets in venting system should not exceed 270°

total in direction change.

Horizontal Runs - The maximum total horizontal run

must not exceed 10 feet (3.1 meters).

Horizontal run of pipe requires 1/4” / 7 mm rise per foot.

Pipe Clearances / Requirements – See pipe manufacturers instructions for installation of venting components

and clearances. Follow pipe manufacturers installation

precautions for passing pipe through a combustible wall

or ceiling (i.e. use an approved thimble).

Notes:

All pellet vent pipe requires 3” (75mm) clearance from

outside of pipe unless otherwise specified by vent manufacturer.

A support bracket should be installed every 4’ (1.2m) of

pellet vent pipe on the exterior wall of the house unless

otherwise specified by vent manufacturer.

Pipe / Liner Joint Requirements - All pipe joints must

be secured with a minimum of 3 screws. ALL horizontal

joints must be sealed gas tight. Use RTV silicone with a

rating of at least 570° F (969° C), or Interam to provide a

complete seal at the flue collar and on all joints.

Connection to Masonry Chimney through a Wall - Be

sure to verify the construction of a masonry chimney, as it

may have combustible framing.

The use of single wall flex or rigid 24 gage stainless steel

pipe as a liner is approved.

Connection to an Existing Class A Chimney - A chimney adapter can be used to make the connection from 3”

/ 75mm or 4” / 100mm pellet vent pipe to existing UL

chimney system. Verify with the pipe manufacturer that

your pipe brands will interconnect. The use of single wall

flex or rigid pipe (24 gage stainless steel) as a liner is

approved.

Direct-Vent Installations (Horizontal): On all direct-vent

installations (short, horizontal runs with no vertical pipe);

care should be taken when choosing a location for terminating the vent. It is not recommended to directly vent the

exhaust on the prevailing wind side of the house. It is

recommended that when an appliance is vented directly

through a wall, a minimum of 8’ (2.5M) of vertical pipe

should be installed to create some natural draft. This will

reduce the possibility of smoke or odor entering the

dwelling during appliance shutdown or loss of power.

PAGE 10

Page 11

INSTALLATION

A

A

VENT TERMINATION

Do not terminate vent in an enclosed or semi-enclosed

area such as: carports, garage, attic, crawl space, under

a deck, porch, narrow walkway, closely fenced area, or

any location that can build up a concentration of fumes

such as a stairwell, covered breezeway, etc.

Vent surfaces can get hot enough to cause burns if

touched. Adults should supervise children when they are

in the area of a hot stove. Non-combustible shielding or

guards may be required.

Termination Cap: The termination of the outside chimney of the pellet stove shall be located in accordance with

the following:

A. Higher than 3’ (.92M) above any forced air inlet (air

conditioner, etc.) located within 10’ (3M).

B. Not less than 4’ (1.2M) below, 4’ (1.2M) horizontally

from or 1’ (3.1M) above any gravity air inlet (door,

window, etc.) which flue gases could re-enter the

dwelling.

C. Not less than 2’ (.6M) from combustible materials

such as an adjacent buildings, fences, protruding

parts of the structure, roof overhang, plants and

shrubs, etc. and not less than 7’ (2.1M) above grade

when located adjacent to the public sidewalks (access). The final termination of the exhaust system

must be configured so that flue gases do not jeopardize the safety of people passing by, overheat combustible portions of nearby structures or enter the

dwelling.

D. Not less than 3’ (.92M) below an eave (maximum

overhang of 3’ (.92M) or any construction that projects more than 2” (51mm) from the plane of the wall.

E. The distance from the bottom of termination to grade

is 12” (305mm) minimum. This is conditional upon

plants and nature of grade surface: Be careful to

choose a location for the vent termination which does

not expose people or shrubs to high heat from the

exhaust gases. The exhaust gases are not hot

enough to ignite grass, plants and shrubs located in

the vicinity of the termination although they should be

a minimum of 3’ (.92M) away. The grade surface under the termination must not be a lawn.

F. Since sparks may escape from the exhaust pipe of

any stove, use caution when positioning the vent

pipe. Refer to pipe manufacturer’s instructions when

installing and terminating the exhaust. The vent pipe

should be horizontal and never run the pipe in a

downward direction (recommend a ¼” (7mm) rise

per foot horizontal).

Note: It is not recommended to terminate exhaust vent

on the prevailing wind side of the house.

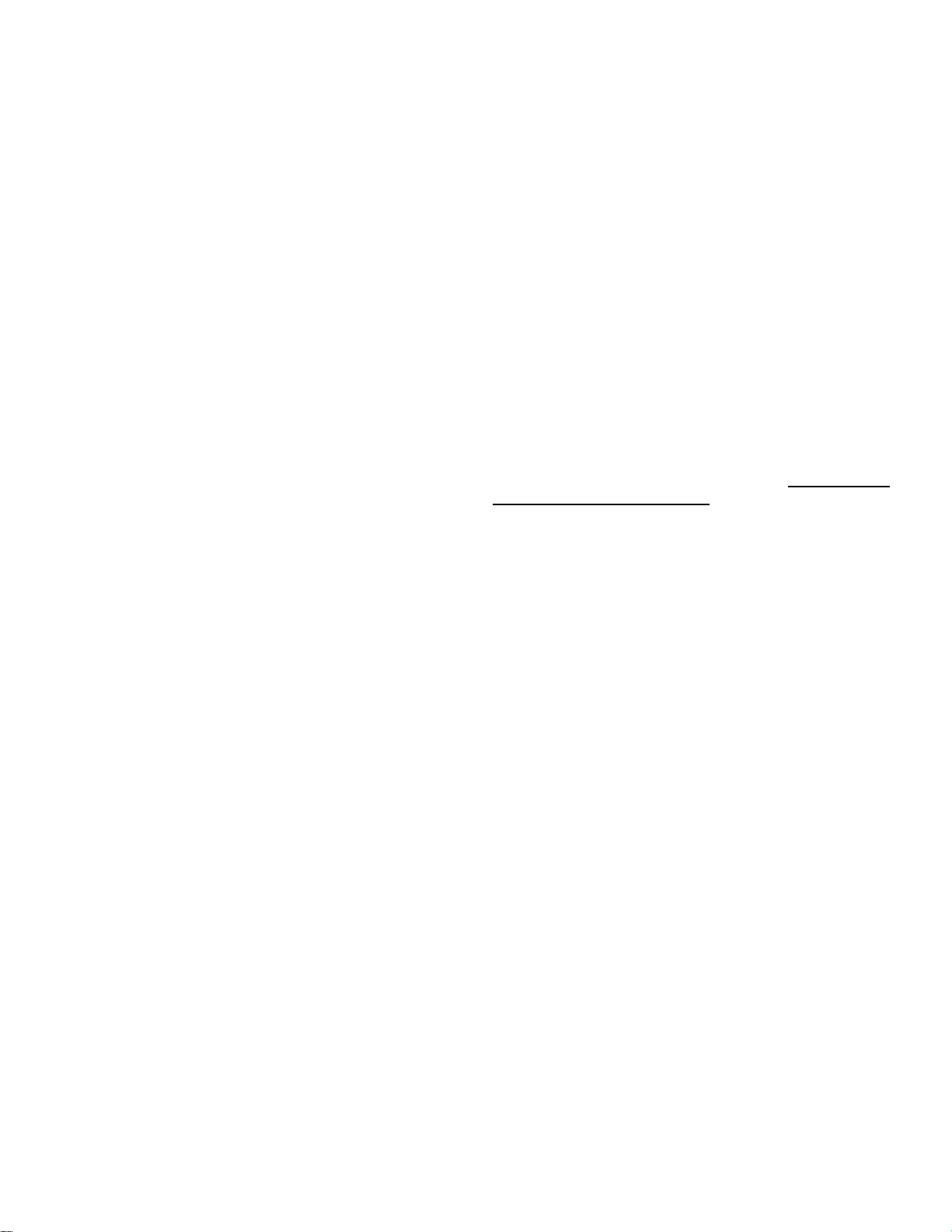

Chimney Height Requirements

The vent termination height required is 12” minimum

above the roof penetration point as illustrated below (Ref.

National Standard, NFPA 7-4.1). Check with your local

building official for additional requirements for your area.

REQUIRES A

LISTED

TERMINATION

✸

CAP

12” MIN

TERMINATION MUST BE

T LEAST 12” (305mm)

BOVE THE HIGHEST

POINT WHERE IT PASSES THROUGH THE ROOF

SURFACE.

Manufactured (Mobile) Home

Chimney Height Requirements

The chimney must extend 3’ (.92M) above the level of

roof penetration and a minimum of 2’ (.61M) higher than

any roof surface within 10’ (3M) (see below). Check with

your local building officials for additional requirements for

your area.

REQUIRES A LISTED

TERMINATION CAP

✸

TOP OF FLUE MUST BE 2’

HIGHER THAN ANY PART OF

ROOF WITHIN 10’ HORIZONTAL

TOP OF FLUE MUST BE 3’

HIGHER THAN HIGHEST POINT

OF ROOF PENETRATION

To pass inspection in nearly any jurisdiction, the chimney

must meet both safety and exhaust flow requirements.

The (3’ by) 2’ by 10’ rule applies to both masonry and

factory built chimneys.

✸

Ref. NFPA 7 – 4.1.2, Vents installed with a listed cap

shall terminate in accordance with the terms of the cap’s

listings.

PAGE 11

Page 12

INSTALLATION

r

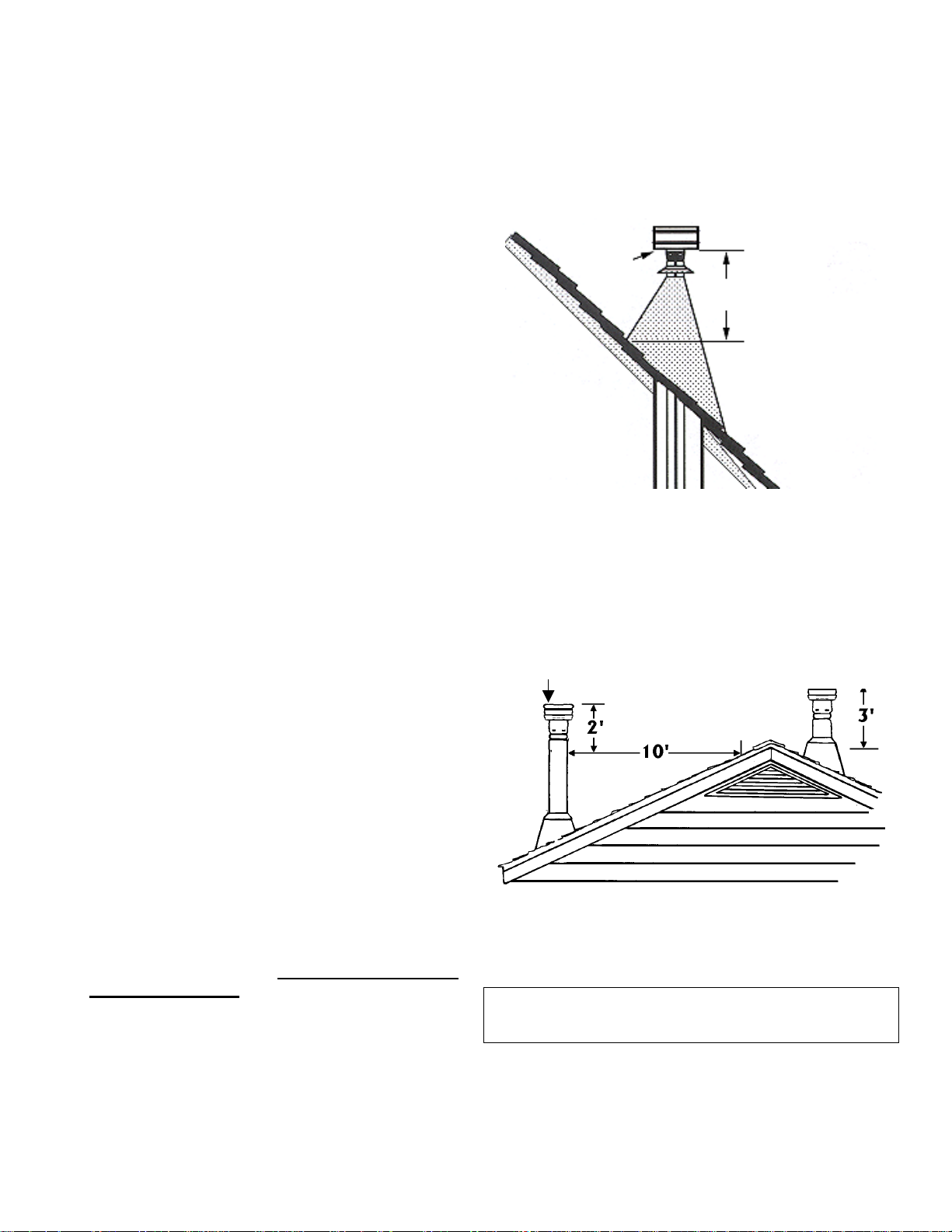

DETERMINING SIZE OF PIPE TO INSTALL

To determine what diameter pipe to use in an installation (3” or 4”), first find the “equivalent pipe length” using the following guidelines, then plot this figure and the altitude on the chart.

Fill out the installation chart, and calculate your total equivalent pipe length. After you have the total equivalent pipe

length, use the Pipe Selection Chart below to determine if your installation requires 3” or 4” exhaust pipe

INSTALLATION CHART

Type of

Pipe

# of Elbows

or Feet of

pipe

Equivalent

Feet

Total

Equivalent

Feet

SAMPLE INSTALLATION CHART

Type of

Pipe

# of Elbows or

Equivalent

Feet

Feet of

pipe

90o Elbows x 5 Ft. (1.5M)

45o Elbows x 3 Ft. (1M)

Horizontal

Pipe

Vertical Pipe x .5 Ft.

x 1 Ft. (.3M)

(.15M)

A- 90 Degree Elbow E- 8’ Vertical Pipe

B- 1’ Horizontal Pipe F- 2’ Horizontal Pipe

C- 45 Degree Elbow G- 90 Degree Tee

D- Standoff Braces

H- Wall Thimble

90o Elbows /

Tee (A & G)

45 o

Elbows (C)

Horizontal

pipe (B & F)

Vertical pipe

(E)

Total = 20

PIPE SELECTION CHART

30

2 x 5 Ft. (1.5M) 10 (3M)

1 x 3 Ft. (1M) 3 (1M)

3 x 1 Ft. (.3M) 3 (1M)

8 x .5 Ft. (.15M) 4 (1.2M)

NOTE: All equivalent pipe styles shown to the right are

standard for all freestanding models.

20

4 “ Diameter Only

3 or 4”

10

Diamete

.

Total

Equivalent Feet

0

0 1 2 3 4 5 6 7 8 9 10

Equivalent Pipe Length (Feet)

Altitude x 1000 Feet

Page 12

Page 13

INSTALLATION

INSTALLING YOUR PELLET STOVE

Standard Horizontal Exhaust Installation (Direct

Vent)

1. Locate the proper position for the listed type “PL”

wall thimble. Avoid cutting wall studs when installing

your pipe. Use a saber saw or keyhole saw to cut

the proper diameter hole through the wall to accommodate the wall thimble. Use extreme caution to

avoid cutting into power lines within the wall of the

home. The hole size will depend on the brand of

pellet vent that you are using. Install the wall thimble

in the hole.

ALL INTERLOCKING PIPE CONNECTIONS WITHIN THE ROOM MUST BE SEALED WITH RTV AND

SECURED WITH A MINIMUM OF 3 FASTENERS

PER CONNECTION.

2. Position the stove approximately 12” (.3M) from the

wall on the floor pad. Push listed type “PL” pipe

through wall thimble. Squeeze a bead of high temperature silicone (RTV) sealer around the end of the

machined portion of the 3” (75mm) pipe connector

on the back of the stove. Firmly push on a section of

listed type “PL” pipe until inner pipe liner pushes into

the bead of RTV sealer

3. Push the stove (with pipe attached) towards wall.

Pipe will go through the wall thimble. Do not position

the back of the stove closer than 1” (25mm) from the

wall.

NOTE: Greater back clearance will improve the serviceability of the stove.

4. Install listed type “PL” 45-degree elbow with rodent

screen or cap (optional) on outside end of pipe. The

rodent screen should be no less than 1/2” (13mm)

mesh and may clog with soot and ash if left unattended during the burn season.

NOTE: The end of the exhaust pipe must extend a

minimum of 12” (.3M) from the outside of the building.

5. If the installation includes a source of outside combustion air; cut a separate hole through the wall for

the fresh air tube. This tube should be 1-5/8” (42mm)

[min.] diameter, steel only. Connect outside air pipe

to air inlet on stove. This tube must be terminated

with a 90 degree elbow or hood.

NOTE: Combustion air may also be drawn from a

vented crawl space under the home. All joints for connector pipe are required to be fastened with at least

three screws. If vented horizontally, joints shall be made

gas-tight in a manner as specified above. Install vent at

clearances specified by the vent manufacturer.

Page 13

Page 14

INSTALLATION

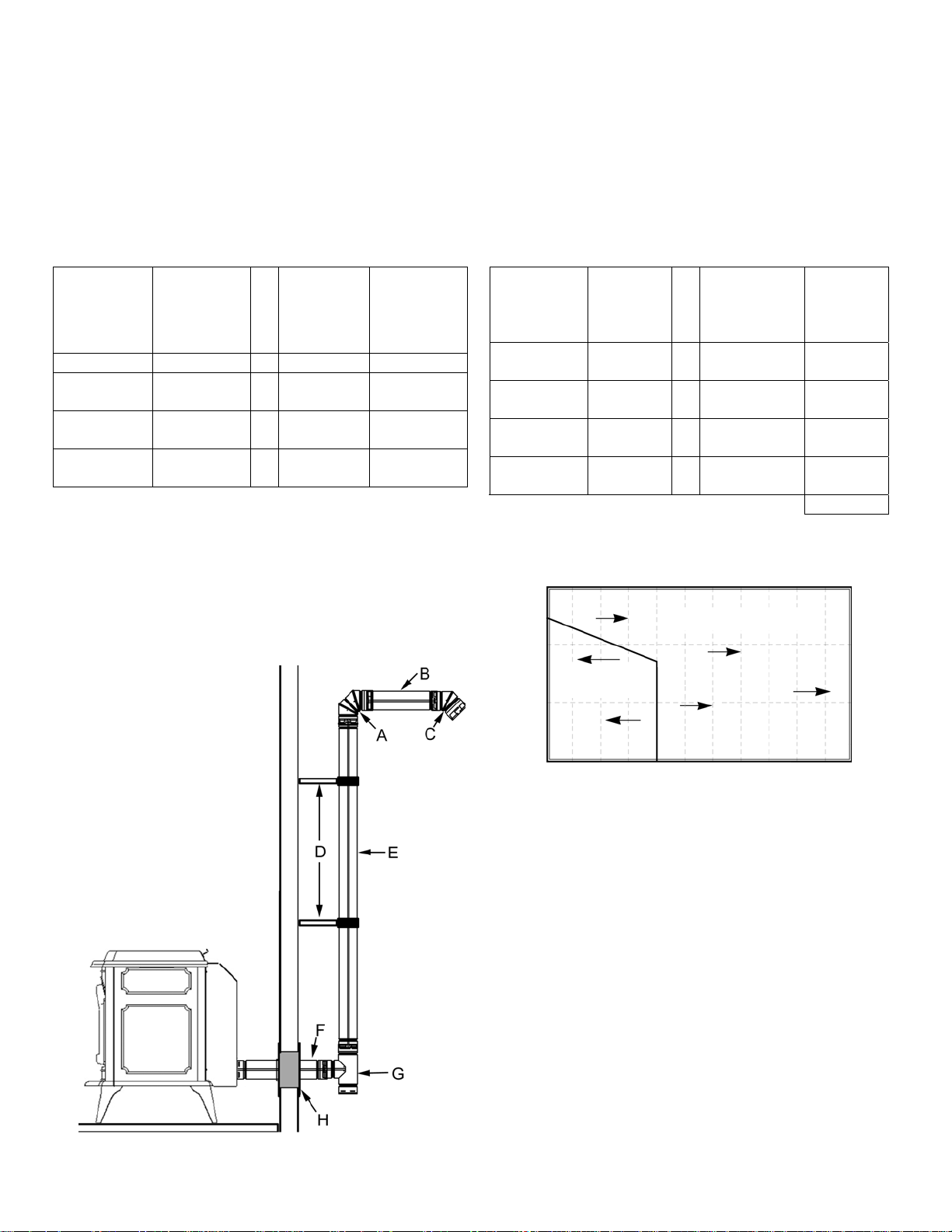

INSTALLATION CONFIGURATIONS – Standard Horizontal Installations

If you vent to the furthest wall, the vent pipe

must maintain a 3”

clearance parallel to the

other wall.

Note: Horizontal run of pipe requires 1/4” / 7 mm rise per foot.

Page 14

Page 15

INSTALLATION

Installation Configurations / Standard Venting Options

This appliance may be connected to an existing flue or

by installing listed type “PL” vent pipe. If a liner is run all

the way to the top of the existing chimney, the existing

flue should be sealed with a steel plate. Start a vertical

run with a Tee at the back of the stove. Other options

are illustrated below. Note: See page 11 for Vent Termination Requirements.

Preferred Installation – Vertical Vent Through the Roof.

This venting configuration allows for the best stove

performance. The vertical pipe promotes natural draft

and with the chimney inside the dwelling, the flue

gases stay warm, thus rising at a consistent rate.

PAGE 15

Page 16

CARE AND OPERATION

CONTROL BOARD OPERATION

Stove On / Off Button – This button will turn your

stove on or off while in Manual or Automatic mode (see

page 19 for details). The green on / off light at the top

of control board will indicate the on / off status.

Heat Output Button – The heat output button has

three selection settings, Low, Medium and High.

Pressing the button will scroll the red indicator lights

from Low to High. The button controls the pellet feed

and combustion airflow simultaneously. The control

board is preset to provide the optimum ratio of fuel and

air at each setting. Settings can be changed at any

time but will only take affect after the start-up cycle is

complete. Each press of the Heat Button will increase

the heat output, and will scroll to the lowest setting after reaching the maximum setting.

Blower – The blower button operates the room air

blower. This will change the flow of hot air into the

room. Three choices are available Low, Medium, and

High. When the Blower Button is pressed the yellow

indicator light will scroll to Low, Medium, or High.

NOTE: When running your stove on high heat output,

the control board will not allow you to select the low

blower speed. This is a safety precaution to protect

against overheating. Blower settings can be changed

at any time, but will only take affect after the start-up

cycle is complete.

Fault Mode – The control system automatically monitors the flame using a photoeye. If the stove runs out of

pellets the control board automatically goes into a

“fault” status. The control board will initiate the shut

down cycle and safely shut down the stove leaving it in

the “fault” mode. The on / off indicator light near the top

of the control board will flash rapidly when in this

mode. After refilling the hopper with pellets, press the

Start Button. If a thermostat is not being used the

stove will go into the start-up cycle. If a thermostat is

being used the stove will go into the start-up cycle if

the thermostat is in the demand mode. If the thermo-

stat is in the stand-by mode when the fault is cleared, the

stove will remain in the stand-by mode until it closes again.

NOTE – If the fuel feed trim or combustion air trim

needs to be adjusted, contact an authorized Lennox

Hearth Products Technician to calibrate internal software. It is recommended that the damper be used to

fine-tune your stove to your particular fuel and installation configuration (see Damper Adjustment on page 8

and Damper Adjustment Guideline on page 20).

POWER LED

(fault when

flashing)

HEAT LED

ON / OFF

START

HEAT SELECT

BUTTON

BLOWER

LED

BLOWER

SELECT

BUTTON

PAGE 16

Page 17

CARE AND OPERATION

A

Note: The control board is equipped with an internal

memory which will recall the last setting and mode

the stove was in prior to loss of power. Because we

individually check each stove prior to packaging, one

of the two scenarios will appear when you first plug in

your stove.

1). The Green LED at the top of the control board will illuminate and the blowers will be running. This is a standard cool down mode and will last no longer than five

minutes. This happens during testing when the stove is

turned off (which initiates cool down mode) and then is

unplugged.

2). The Green LED at the top will illuminate and the red

and yellow LED’s will illuminate on the control board,

indicating that the stove is in the run mode. This happens during testing if the stove is unplugged without

first turning the control board off (the control board remembers its last setting, which was the run mode).

If your stove follows that described in number 2 above,

simply press the ON / OFF button once to turn the stove

off, this will initiate the cool down mode. The stove can be

restarted at any time during the cool down mode by pressing the ON / OFF button once.

Start-up Sequence of Events

1. Fault time delay is initiated (14 minutes 15 seconds).

2. Fuel feed rate of 100% for 1 minute 50 seconds (when

trim left at factory setting of 0) auger trim setting ranges

from 1:26 to 2:14 depending on -4 to +4 respectively.

3. Exhaust blower operation starts (medium range voltage).

4. Room air blower operation starts (medium range voltage).Power LED is activated (steady green).

6. Igniter operation activated (line voltage).

7. Photoeye looks for flame (flame dominance scheme).

8. * If needed second & third fuel dumps are available at

predetermined time deliveries (4 minutes & 6 minutes

after initial).

Flame Detection Sequence of Events - This is what

happens after flame has been detected.

Happens within the Start-up Time Delay sequence.

0 to 1 minute no fuel feed.

Flame settles.

Bed of embers built.

1 minute mark: Fuel Feed rate 20% for 4 minutes

15 seconds (1 second on / 4 seconds off).

2 minute mark: igniter turns OFF / room air blower =

panel setting.

5 minute 15 seconds mark: exhaust blower = panel

setting / LED indicator still active.

Start-up Time delay ends 14 minutes 15 seconds

after pushing the start button!

PHOTOEYE

PN LABEL

LOCATION

POWER

SELECT

MAIN

RNESS

H

FUSE

Page 17

Page 18

CARE AND OPERATION

Combustion Voltage Trim Steps:

1. Push button “twice” for access voltage calibration

mode.

2. Identify the current calibration setting indicated by one

YELLOW LED bar.

3. Push the “HEAT” control button to adjust setting UP.

Each push raises the YELLOW LED bar & increases

voltage 5%.

4. Push the “BLOWER” control button to adjust setting

DOWN. Each push lowers YELLOW LED bar decreasing voltage 5%.

5. Push the calibration button once to lock in selected

results.

Fuel Delivery Rate

The feed rate switch manages the fuel delivery rate by

controlling the amount of time the auger motor will run as

follows:

Feed

Rate

Setting

Low = 1 on / 5.00

Med.= 1 on / 3.30

High = 1 on / 1.60

Auger Motor

ON / OFF

Time (seconds)

off

off

off

* Lb.’s per

hour fuel

delivery

1.5 Lb.’s /

hr.

2.5 Lb.’s /

hr.

3.8 Lb.’s /

hr.

♦ Approxi-

mate

BTU per

hour

fuel de-

livery

13,000

BTU / hr

21,000

BTU / hr

32,000

BTU / hr

* Feed rates are approximations only. Actual feed rate

will vary depending on size, quality and length of fuel

used and variations in line voltage.

♦ Estimated heat input based on fuel value of 8400 BTU

per lb. of fuel.

Burn

Time

(hours)

34

20

14

Your pellet stove can be operated in either manual or

automatic mode. The manual mode is used when operating without a thermostat. The automatic mode is

used when utilizing a wall thermostat. When utilizing

the thermostat capability the burn time can be extended

dramatically depending on thermostat setting. Note: It is

normal for some ash to build up on the inner glass surface at the lower burn settings.

Initial Start-Up / Empty Hopper or Feed Tube:

During an initial start-up, or in the case where the hopper has run out of fuel, it will be necessary to prime the

auger feed system. The control board is set to deliver

fuel for approximately 2 1/2 minutes during start-up,

which, with a fully primed auger tube, will provide the

appropriate amount of fuel for ignition.

When first starting your pellet stove, it will be necessary

to prime the auger tube. To prime the auger tube you

need to first fill the hopper with pellets, and press the

ON button on the control board. Wait approximately 2

1/2 minutes and turn the control OFF and then back ON

again. Wait an additional 2 1/2 minutes (if necessary)

and continue this process until fuel begins to fall into the

UltraGrate. Remember, different brand fuels feed at

different rates.

Once fuel starts to enter the UltraGrate, turn the stove

OFF and then back ON. The auger tube should now be

primed and the stove should deliver enough fuel for

proper ignition. It may be necessary to follow these procedures in the event that the hopper runs completely

out of fuel.

Page 18

Page 19

CARE AND OPERATION

Manual Operation:

Pressing the stove ON / OFF switch initiates the start-up

cycle. The green ON / OFF light, near the top of the control board, will light up to indicate the “on” status. The fan

speeds and pellet feeds are fixed during this time to provide appropriate ignition. The Fast-Fire igniter system will

light the pellets feeding to the UltraGrate, after about 3

minutes. The start-up cycle is in effect for approximately 2

minutes after flame is detected in the UltraGrate. A

photoeye monitors the existence of flame. After the startup cycle your stove will be in the run mode. At this point

the stove will operate in the heat output and blower settings selected. These settings can be selected either during or after the start-up cycle. Pressing the stove ON /

OFF switch during the run mode will initiate the shut down

cycle. The ON / OFF indicator light will turn off. The pellets will stop feeding and the blowers will run at a fixed

speed for approximately 10 minutes. At this point your

stove is safely shut down and can ONLY be re-started by

pressing the stove ON / OFF switch again.

Automatic Operation:

Your stove is capable of running in an automatic mode

with the use of a wall thermostat. NOTE: For the thermostat to control the operation of the stove, the “on” status

must be active on the stove’s on / off switch. The thermostat will establish either a demand mode or a stand-by

mode. The thermostat should be set for the desired room

temperature. If the room temperature drops below the

level on the thermostat the stove will automatically begin

the start-up cycle, as explained above in the Manual Operation section. Once the start-up cycle is completed the

stove will operate in whatever heat and blower setting you

have selected. For best operation under thermostat control, the Medium or High settings recommended. When

the desired room temperature is reached, the stove will

automatically go into the shut down cycle. The pellet feed

will stop and the blowers will continue for a controlled time

allowing safe shut down of your stove. All lights will remain on when the thermostat is open. The heat and

blower settings can be changed at any time, but only take

affect during the run mode. When the temperature in the

room drops to the level set at the thermostat, the stove will

again begin the start-up cycle and resume automatic operation in the demand mode.

NOTE: If the stove on / off switch is pressed while the

thermostat is in the standby mode the stove will not restart

until the thermostat closes.

Lighting Procedure Without Igniter

Your pellet stove can be lit manually without using the

automatic igniter by following the procedure below. If

your stove is set up to run on a thermostat, the thermostat circuit needs to be closed (as if permanently in the

demand mode). The thermostat wires should be removed from the rear of the stove and replaced with the

jumper originally supplied with your stove. If a jumper is

not available the thermostat should be set to the highest

setting. This will keep the stove in the demand mode. If

your automatic ignition system should ever need troubleshooting, repair or replacement, please contact your

authorized Lennox Hearth Products dealer.

1. Press the ON switch on the control board.

2. Wait approximately 2 1/2 minutes while the pellets

prime the grate (the pellets will stop feeding automatically).

3. Place a small amount of an approved (non-volatile)

fire starter on top of the pellets in the grate, (see

your authorized Lennox Hearth Products dealer for

appropriate fire starting products). DO NOT USE

FLAMMABLE LIQUIDS TO START YOUR STOVE!

4. Light the “fire starter” with a match and close the

door.

5. The photoeye will detect that a flame is present and

will begin feeding pellets in approximately 2 minutes.

6. The control board will continue to go through the

normal start-up cycle and the flame should be well

established within 10 minutes from the time the ON

button was initially pressed. Remember – you are

now in manual mode and heat settings should be

selected to the desired room heat level.

Turning Off Your Stove

Press the stove on / off switch to initiate the shut down

cycle. The pellets will stop feeding and the blowers will

continue to run on a timed cycle. The stove will shut

down safely upon completion of the shut down cycle.

Page 19

Page 20

CARE AND OPERATION

DAMPER OPERATION

The damper is a plate that helps control the amount of

airflow supplied for combustion. With the damper pushed

in all the way, the airflow is at its minimum. As the

damper is pulled out, more air is allowed to flow.

It will be necessary to monitor the appearance of the

flame during the first 4-8 bags of pellets. If your flame is

smoky red / orange with evidence of soot at the top of

the flame, you need more combustion air; pull the

damper out one notch and re-evaluate the appearance of

the flame. It may be necessary to continue this process,

moving the damper one notch at a time until proper combustion is attained (the flame should become yellow and

begin to “dance”). If the flame is “short” at the higher

burn rates, or if the pellets are burning up in the grate

before new pellets are fed into the fire, push the damper

in one notch and monitor the flame. Continue the process of moving the damper one notch at a time and evaluating the flame until proper flame appearance is

achieved.

Once the damper has been properly set, it should not

need adjusting unless you are changing the grade of pellet fuel, in which case the damper may need to adjusted.

DAMPER ADJUSTMENT GUIDELINE

Lack of Combustion Air: By opening the damper, this

will increase combustion air delivery. Symptoms of insufficient combustion air include; unburned fuel, lazy smoky

or red / orange flame, excessive ash or soot, excessive

buildup on glass.

Contributing factors:

• High Altitude – Lack of oxygen

• Restrictive Venting (elbows, horizontal runs,

cold external chimneys, etc.).

Note: Excessive amounts of fly ash built-up in the grate,

clinkers in the grate or leakage of air (if the grate is not

properly seated) will starve the fire for air. See Routine

Maintenance, pages 22-25 for information on cleaning

the stove.

• Dirty / Poor Quality Fuel.

Excessive Combustion Air: By closing the damper, this

will reduce combustion air delivery. Symptoms of excessive

air include; fuel burns too quickly (results in smoking or

smoldering pellets), white to yellow flame, etc. If the

damper is open too much, the burning pellets will lift off

the grate and fly up into the air much like popping corn

does.

Contributing factor:

Correct Combustion Air / Proper Burn Characteris-

tics: When the damper is correctly set, the burning pel-

lets should move (wiggle) around slightly and the flame

should be bright yellow.

AUTOMATIC SAFETY FEATURES

Power Outage:

During a power outage, the stove will shut down safely.

The stove will automatically restart when power is resumed. The solid state control board has an internal

memory that will retain heat output and blower speed

settings through voltage interruptions.

A small amount of smoke may leak from the top of

the window glass, the hopper and from the combustion air intake, if the stove is vented horizontally with

no vertical pipe. This will not persist for more than 3 to 5

minutes and will not be safety hazard. It may set off your

smoke alarm.

Note: If the area in which you live is prone to frequent

power outages, it is recommended that a minimum of 8

feet (2 ½ meters) of vertical vent pipe be included in a

freestanding installation to induce a natural draft in the

event of a power failure.

Overheating:

A high temperature disc (thermal switch) will automatically shut down the stove if it overheats. Allow up to 45

minutes cooling time before re-lighting. Keep enough

convection air going through stove to keep it cooling

properly, this will ensure long life of the stove. If the overheating continues, contact your authorized Lennox

Hearth Products dealer for more information.

• Venting system providing excessive draft.

Page 20

Page 21

CARE AND OPERATION

FUEL REQUIREMENTS

Using the UltraGrate burn system, this appliance has

been designed to burn wood residue pellets with up to

3% ash content. Agricultural pellets (i.e…corn, alfalfa

etc.) are not permitted to be burned in the stove. Dirty

fuel will adversely affect the performance of the stove.

Caution: The use of unapproved, dirty, wet and / or high

salt content fuel will void the warranty!

Wood pellets manufactured to the Pellet Fuels Institute

(P.F.I.) certification standard are available in two grades,

standard and premium. The primary difference between

the two is the ash content of the pellets.

The P.F.I., specification for standard grade & premium

grade residential pellet fuel is as follows:

• CHLORIDES (Salt): Less than 300 p.p.m..

• BULK DENSITY: 40 lb. / cu. ft. minimum

• MOISTURE CONTENT: 8% maximum

• ASH CONTENT: < 3% maximum (standard

grade) < 1% maximum (premium grade)

• FINES: 0.5% maximum through a 1/8” screen

Pellet Feed / Pellet Size:

The pellet feed system is designed to handle a wide

range of pellet sizes up to a maximum of 5/16" diameter.

Different pellets may feed at considerably different rates.

You may notice a difference in the burn if you change

pellet fuel sizes. The longer the pellet, the slower it will

feed and vice versa. If the stove will not stay burning at

the minimum fuel feed setting, those particular pellets

may not be feeding fast enough. If this happens, reduce

the amount of combustion air by adjusting the damper.

See page 8 before adjusting the damper.

Long Burn Time:

When operated correctly, this appliance cannot be overfired. Continuous operation at a maximum burn can,

however, shorten the life of the electrical components

(blowers, motors, and electronic controls), and is not recommended. Typical approved operation would include

running at the low to mid range setting with occasional

running on the maximum setting during the coldest periods of the winter. The blower speed control should be

turned to high when operating the stove on the high heat

setting. A lower heat setting is recommended for overnight operation or when the room is vacated for long periods of time.

Note: See Fuel Delivery Rate on page 18 for burn times.

CLINKERING

Silica (or sand) in the fuel, along with other impurities,

can cause clinkering. A clinker is a hard mass of silica

formed in the burning process. Clinkering is a function of

the fuel, (not the stove), but adversely affects the performance of the stove by blocking off the air passages in

the grate. Even P.F.I. approved pellet fuel may tend to

clinker. A clinker can be removed from the UltraGrate

and placed in the ash pan with the use of the grate

scraper / ash pan tool furnished with your stove. See

Routine Maintenance, pages 22-25 for more information

on cleaning.

ASH

The frequency of removal of the ash and maintenance

performed on the stove is directly proportional to the ash

content of the fuel and the operation duration of your pellet stove. Low ash fuel may allow longer intervals between cleaning, however, a stove burning high ash fuel

may need to be cleaned as often as everyday.

PLEASE NOTE: Lennox Hearth Products has no control

over the manufacturing of pellet fuel and will not be held

responsible for poor stove performance or any damage

caused by inferior pellet fuels.

FUEL FEED RATES

Different brands of pellets will feed at varying rates due

to their size and density (length and diameter). This may

require a slight adjustment in the damper control (see

page 8) or the fuel feed trim to compensate (see Note on

page 16).

UltraGrate

Page 21

Page 22

ROUTINE MAINTENANCE

* Inspect your stove or insert at minimum frequency stated until you establish a minimum frequency required for

your installation (frequency will vary depending upon fuel BTU value / ash content, usage, and misc. installation

variables).

ROUTINE CLEANING

Note: Stove will need to be shut off and cooled enough to

handle before routine cleaning is performed.

Always disconnect power before doing any routine cleaning.

The following areas need to be inspected and cleaned

during routine cleaning:

• UltraGrate (burn grate)

• Ash Slide Plate

• Ash Pan

• Heat Exchange Tubes

• Photoeye

• Exhaust Passages and Vent Pipe

• Gaskets

• Window Wash

• Rear Stove Compartment

UltraGrate (BURN GRATE)

The UltraGrate should be inspected periodically to assure that the air holes have not become clogged with ash

or clinkers. The UltraGrate can easily be cleaned with

the grate scraper / ash pan tool, or it can be removed for

cleaning. It is very important to monitor the ash build up

under the UltraGrate, as excessive amounts of ash will

block combustion air from entering the grate, causing

pellets to pile-up in the grate. The ash build-up under the

grate is easily dumped into the ash pan by pulling out the

ash slide weekly as shown below. The grate cleaning

procedure is the same for all models.

UltraGrate

ASH PAN

The ash pan will have to be emptied periodically, depending on amount of fuel consumed. The T300P Series

ash pan is pulled straight out using the black pull knob

located on the front of the ash pan (see following picture).

Ash Pan

* (Recommended Frequency of 2 days – 2 weeks)

ASH SLIDE PLATE

Ash that accumulates around the grate can be “dropped”

into the ash pan without opening the firebox door. Simply

pull open the ash release slide plate as shown in photo

using the grate scraper tool provided. Remove the ash

pan as shown. Note: Make sure to fully close the plates

when finished. Failure to close the ash release slide

plates completely may cause the fuel to burn poorly (due

to reduced airflow through the grate), which may then

cause pellets to “pile up” in the grate.

Ash Slide Plate

* (Recommended Frequency of 1 day – 2 weeks)

*(Recommended Frequency of 1 day – 2 weeks.)

Page 22

Page 23

ROUTINE MAINTENANCE

e

-

r

PHOTOEYE

The photoeye is positioned to view the flame from the top

of the auger feed tube. It is located below the auger

cover and can be accessed from inside the hopper for

annual maintenance or replacement (if necessary).

Photoeye Access Inside Hopper

Using a 11/32"

nut driver remov

the 3 nuts to ac

cess photoeye

and filter.

Photoeye Cove

Plate.

* (Minimum frequency of 6 months to 1 year)

Annual Maintenance Procedure:

Clean Photoeye Lens:

1. To access photoeye, remove cast top by lifting off, then

remove the 3 nuts on the cover plate (see picture

above).

2. Lift off cover plate and turn over (the photoeye is attached to the inside surface of cover). Wipe away

any dust or debris from the photoeye lens (see following picture).

Clean Filter Lens:

1. With the photoeye cover plate removed, look inside

the opening. You will see an amber colored square

glass filter secured in place by a bracket and 2 nuts

(it is on the left when viewed while facing the front of

the stove). Using a 11/32" nut driver, remove the 2

nuts and lift off the bracket. Using your finger slide filter up and out.

2. Wipe away any dust or debris from filter, then reinstall filter, filter bracket and cover plate with photoeye.

IMPORTANT: When reinstalling photoeye and cover,

be careful not to bend bracket or damage wires. Pay

special attention in positioning wires away from photoeye (which could obstruct it from sensing light).

* (Minimum frequency of 4 weeks - 6 months)

EXHAUST PASSAGES AND VENT PIPE

Inspect frequently and clean when necessary. Fly ash

will accumulate at all bends in the exhaust system.

Note: Large amounts of fly ash build-up will create a lack

of combustion air. Removing the Tee cap on vertical installations will allow an inspection of the ash build-up in

the exhaust Tee and will help you to decide how frequently more extensive cleaning must be performed.

Rain Cap

Clean

Lens

Remove Filter and Wipe Clean

Filter

CAUTION: If the filter is not reinstalled, refractive

light in the room may result in a fault, thus shutting

down of the unit.

Page 23

Clean-Out Tee

Page 24

ROUTINE MAINTENANCE

Clean-Out Tee w/ Cover Removed

Remove cover, then

remove ash

Tube Scraper

Use the hole in the handle of the grate scraper tool to

“grab” onto the rod

* (Minimum Frequency of 1-2 months)

HEAT EXCHANGER TUBES

ONLY CLEAN HEAT EXCHANGER TUBES AFTER

STOVE HAS COOLED DOWN. A rod is located above

the heat exchange baffle (inside of firebox) is used for

cleaning the tubes. After opening the firebox door, use

the hole in the handle of the grate scraper tool to “grab”

onto the rod (see pictures on this page). Using the grate

scraper tool, pull the rod up and out towards the opening

of the firebox. Continue pulling until the tube scraper

reaches the top of the firebox.

It may be easier to clean the tubes by first removing the

heat exchanger baffle. Loosen the two screws holding

the baffle in place (do not fully remove). The baffle contains keyhole slots allowing the screws to remain in place

while removing the baffle. The scraper can now be

pulled in a more horizontal manner, which allows the

scraper to move more freely.

Pull the rod up and out towards the opening of the firebox

* (Recommended Frequency of 2 days – 2 weeks)

Page 24

Page 25

ROUTINE MAINTENANCE

DOOR ROPE GASKET

The condition of the rope gasket around the door and

windows should be checked periodically and replaced or

repaired if necessary. A one-inch strip of paper may be

used to perform a test of the integrity of the door seal.

Close the door on the paper in several different locations

and pull. It is normal to feel only a slight amount of friction. The door gasket does not need to be “tight” in all

areas, since a small amount of leakage is not hazardous

or detrimental to the performance of your stove.

Door Rope Gasket

(check seal at points indicated)

WINDOW WASH

Periodically insert a small piece of cardboard (a business card) between the window trim and the window.

Slide the card back & forth a few times to clear any dust

or fibers from the window wash gap. Open the door and

repeat from the other side of the glass.

Window Wash

* (Recommended Frequency of 1 year)

Checking Door Seal

Important Note: Paper should be no longer than a

dollar bill.

* (Recommended Frequency of 1 year)

* (Recommended Frequency of 1 year)

REAR STOVE COMPARTMENT

The rear stove compartment should be cleaned periodically (a minimum of once a year). DISCONNECT ELECTRICAL CORD PRIOR TO CLEANING STOVE. Any

household dust, pet hair or sawdust should be vacuumed or wiped out of the rear compartment of the

stove, room air blower, and Exhaust Blower (paying

special attention to vacuuming out the intakes of both

blowers). The electrical components should be wiped

clean.

MOTOR LUBRICATION

The blowers are permanently lubricated by the

manufacturer. Do not apply oil to any part of the

blower. Doing so may cause damage.

SMALL AREA PAINT TOUCH-UP (Model T300P only)

Using one small piece of 320 grit sand paper and lightly

sand the blemish so that the edges are “feathered” or

smooth to the touch between the painted and bare surfaces. Do not let the sand paper gum up with paint, as

this will cause scratches on the metal surface. If there

are any scratches, use 600 grit sandpaper instead. Mask

off surfaces you do not want painted. Paint lightly over

the bare surface first as this will act as an undercoat.

Then paint over a larger area in smooth even strokes to

blend.

Page 25

Page 26

SPECIFICATIONS - Model T300P Series

Flue Size 3” / 76mm Rear

Width, Overall 28 3/4” / 730 mm

Depth, Overall 26 1/2” / 660 mm

Height 28 3/4” / 730 mm

Floor to Rear

Flue Center 8 3/4” / 222 mm

Facing Back of Unit,

Outside Edge of Left Leg

To Center of Rear

Flue Outlet 10 1/2” / 267 mm

Floor to Rear

Outside Air Inlet 10” / 254 mm

Facing Back of Unit

Outside Edge of Left Leg

To Center of Air Inlet 17 1/2” / 445 mm

Floor Protection + Front and Sides: 6”/152mm

Requirements Back: Up to 6” / 152mm

Standard Features Fastfire Self Igniter

Wall Thermostat

(wire included)

Hopper Capacity 50 lbs.

Burn time ♦ 14-34 hours

Fuse, Control Board 5 amp, 25 volt, 3AG*

Fuse, Igniter 6 amp, 125 volt*

Heat Input (Max.) ♦ 13,000-32,000 BTU / hr

Overall Efficiency 85%

Emissions ♦ 0.43 gram / hr (varies w/

size and type of fuel)

EPA exempt

Ship Weight 363 lbs.

Room Air Blower 150 CFM; 1.5 amps,

2175 rpm

Auger Motor 1 RPM; .4 amps

Exhaust Blower 95 CFM: 1.0 amps,

2880 rpm

Note: Dimensions shown are approximations only (+/- ¼”)

+ Non-combustible thermal rated floor protection must

be used when installed on carpet (see Floor Protection, page 5). When installed at clearances less

than 6”, the floor protector is only required to extend to the wall.

♦ Fuel delivery and burn times will vary depending

on size and type of fuel used. Estimated heat input based on fuel value of 8400 BTU per lb.

* Fuses are rated as fast blow.

Page 26

8 3/4”

10 1/2”

17 1/2”

BACK VIEW

28 3/4”

SIDE VIEW

26 1/2”

Face of door

opening to

23”

10 “

28 3/4”

Page 27

DEFINITIONS

AIR WASH

To inhibit buildup of soot on the door glass, air is delivered to the glass through an air wash system located in

the doorframe surrounding the glass.

AUGER

It transfers the fuel down the burner tube into the burn

grate.

AUGER MOTOR

Drives the Auger. Motor specifications are: .4 Amp, 1 rpm

(revolutions per minute).

BLOWER, ROOM AIR (CONVECTION)

The blower function is to transfer the heat from the appliance to heat the room air.

BLOWER, EXHAUST (DRAFT INDUCER/COMBUSTION)

It has a radial impeller to deliver more air to the burn

grate. It pulls air into the burn grate by creating a negative pressure. This is done by extracting the exhaust

gases out of the firebox and pushing the exhaust downstream to the flue exit.

DISC, HIGH LIMIT (L250-30F, N / C)

There are 2 of these high limit discs on this model. If a

temperature reaches 250° F., the high limit auto reset will

“trip” and stop the flow of electricity to the auger motor.

The discs will not automatically reset until it has cooled

below 220° F).

Disc for Room Air Blower – This disc is located on

the Room Air Blower jacket and is designed to detect an overfire condition.

Disc for Combustion Air Inlet – This disc is located on the combustion air inlet and is designed to

detect reversed flow. If negative pressure in the

dwelling (i.e. An extremely tight house which may

not supply adequate combustion and ventilation air)

causes the exhaust to pull back from the combustion air inlet, the heat from the exhaust will result in

heat activation of this disc.

HOPPER

The hopper is where the pellets are stored.

HEAT OUTPUT BUTTON

This is the main power button, which controls power to

the feed system auger motor and exhaust blower. It has 3

feed rate settings, which controls the burn rate.

PHOTOEYE

The photoelectric eye that senses the flame, or lack of. It

is designed to signal the control board to discontinue

power to the auger motor if it flame is not sensed in the

UltraGrate.

PRESSURE SWITCH

A safety device used to shut off the feed system (auger

motor) if there is too much back pressure in venting system. Some possible causes are as follows:

♦ The venting system is obstructed.

♦ High altitude or other misc. environmental conditions

affecting exhaust flow.

♦ Improper venting system.

ULTRAGRATE (BURN GRATE)

This is where combustion occurs and may be referred to

as the "burn grate".

Page 27

Page 28

WIRING DIAGRAM

Page 28

Page 29

TROUBLESHOOTING (Qualified Technicians Only)

Unplug Appliance Before Performing Any Troubleshooting or Maintenance

PROBLEM CAUSE(S) SOLUTIONS

1. Fire burns with

a lazy orange

flame. Pellets

build up in the

grate and the

window gets

sooted up.

2. Fire goes out

or stove shuts

down automatically

3. Pellets will not

feed.

There is insufficient combustion air. Remove any clinkers or ash from the bottom of the grate that

might be obstructing the primary air holes.

Change to a better grade of fuel if necessary.

Check that the damper has been opened enough for the

amount of fuel feed.

Check that the heat exchange tubes are not coated with ash.

Clean internal exhaust ducts.

Check gasket seal around the door. Use a thin strip of paper,

1 in. wide. Open the door and close it on the paper strip. A

slight friction should be felt when the paper strip is pulled.

Repeat this process at various locations around the door

gasket. Replace the door gasket if necessary.

Check for blockage in the air inlet tube or exhaust pipe.

Clean as necessary.

Close ash slide plates.

Have your authorized Lennox Hearth Products dealer check

your Exhaust Blower.

The hopper is empty

Pellets are not feeding.

The high limit temperature switch

has tripped.

There is too much combustion air

for the amount of fuel.

Stove has run out of fuel.

The auger motor or circuit board

may be defective. The pressure

switch tap or hose may be blocked.

Back pressure in venting tripping

pressure switch.

Thermostat is in stand-by mode.

Thermostat wires disconnect.

High limit switch may have been

tripped.

Self-aligning bearing in auger motor

may be mis-aligned.

Refill hopper.

See Pellets will not feed (#3) below.

Allow stove to cool for 1 hour and re-light. If the stove has

been operating at a medium to high burn rate and the room

air blower has been turned down low then the fan should be

turned up higher. If this problem persists (particularly at

lower burn rates) then the high limit disc should be replaced

by your authorized Lennox Hearth Products dealer.

Adjust the damper to reduce combustion airflow.

Refill hopper.

Check to be sure that there is no blockage in the pressure

tap or hose. Have your authorized Lennox Hearth Products

dealer diagnose the problem and clean or replace any necessary parts.

If new installation check for excessive 90˚ bends, long horizontal runs or excessive vertical run of 3” pipe. Possibly

change to 4” pipe. If older installation check for excessive

ash accumulation in pipe or other obstructions. Clean out

pipe.

Check to see if thermostat is set to low or if sun is shining

directly on thermostat.

Re-install wires.

Allow stove to cool. Increase room air blower setting.

Gently tap the auger motor.

Page 29

Page 30

TROUBLESHOOTING (Qualified Technicians Only)

Unplug Appliance Before Performing Any Troubleshooting or Maintenance

PROBLEM CAUSE(S) SOLUTIONS

4. Blowers will

not operate

when the start

switch is depressed.

5. There is soot

or fly ash in the

house.

6. Stove acts as if

a fire is present

when there is

not a fire in the

grate.

7. Stove will not

light.

8. Fault Photoeye not detecting flame.

There is no power to the stove.

There is no power to the control

board.

The window is being cleaned when

the stove is operating.

There is leakage at the joints between the exhaust blower, connection or exhaust pipe connections.

This will be evidenced by dust on

the impeller of the room air blower,

and in the heat exchanger area.

The vacuum cleaner is leaking.

Excessive sun light may be shining

directly into firebox from window.

The igniter element may have

failed.

There are not enough pellets in the

UltraGrate.

Stove has run out of fuel.

A disk has tripped / pressure

switch.

Check that the stove is plugged in to the wall outlet.

Check to see if your circuit breaker has tripped.

Check the wire connections on the high limit disc and

Control board.

Turn down the room air blower or turn off stove before

cleaning to prevent dispersion of ash and soot into the

room.

Seal up any leaks in the exhaust system with room temperature vulcanizing silicone sealer (RTV).

DO NOT use a standard household vacuum or “shop vac”

as the filters will leak the fine particles of ash. Clean the

stove with an approved ash vacuum ONLY.

Block excessive sunlight. Call your authorized Lennox

Hearth Products dealer if problem persists.

Check igniter element fuse in rear stove compartment.

Call your authorized Lennox Hearth Products dealer. See

alternate manual lighting procedure

Prime the feed system (see page 18, Initial Start

Up/Empty Hopper or Feed Tube).

Clean photoeye lens (see Clean Photoeye Lens on page

23.)

Check connection at control board following yellow wires

to all connectors.

Refill hopper.

Blower intake, exhaust passages and / or venting system

needs cleaning (follow routine and annual maintenance

procedures).

If this does not correct the problem contact your local authorized Lennox Hearth Products dealer.

Page 30

Page 31