Page 1

HEARTH PRODUCTS

KITS AND ACCESSORIES

DIRECT VENT

750,207M

REV. A 07/2007

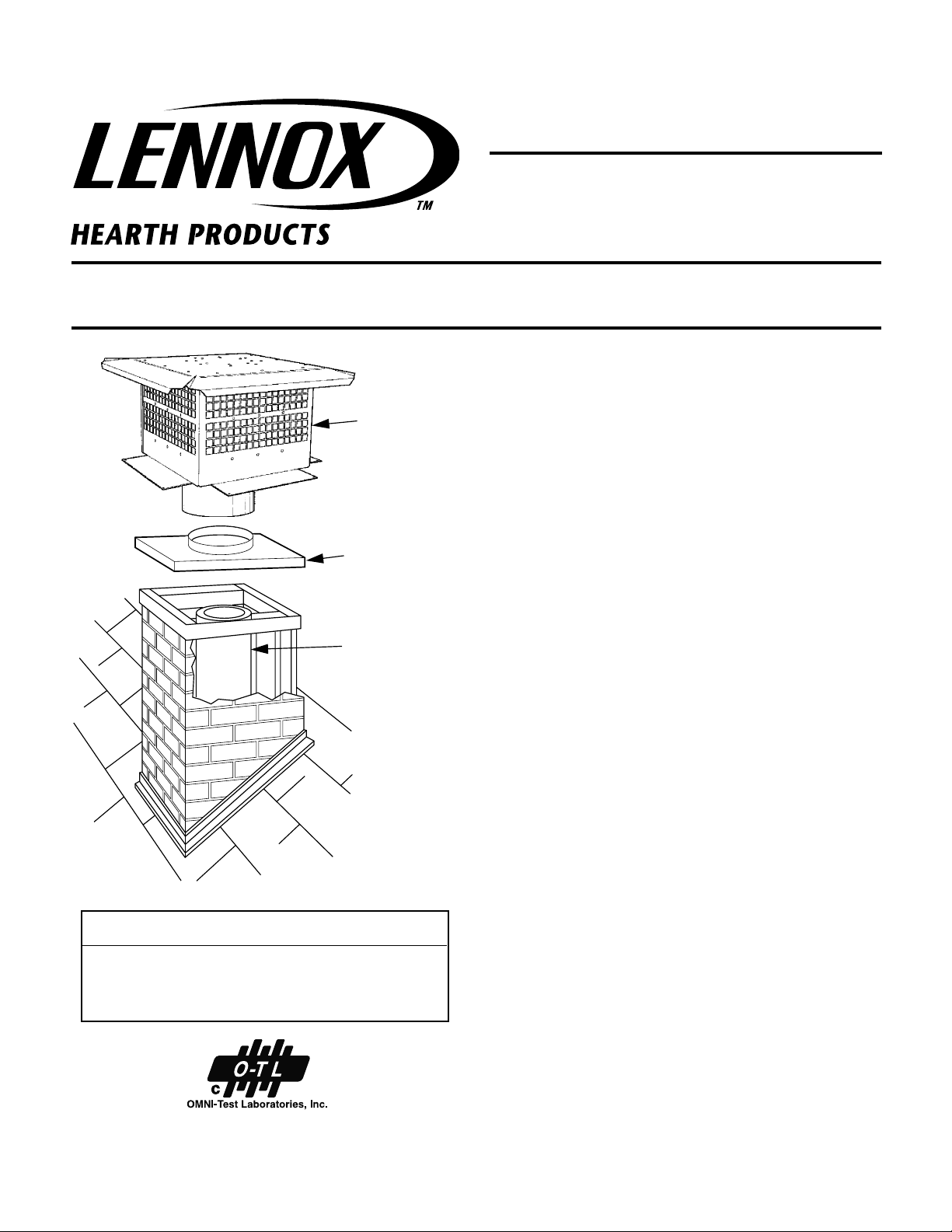

CHASE TOP SQUARE

VERTICAL TERMINATIONS

INST ALLATION INSTRUCTIONS FOR BLACK - SV4.5CTS-B (CAT. NO. H4716) & SV8CTS-B (CA T. NO. H6179)

AND TERRA COTT A - SV4.5CTS-TC (CAT. NO. H4717) & SV8CTS-TC (CAT. NO. H6180) TERMINATIONS

GENERAL INFORMATION

The SV4.5CTS and SV8CTS series terminations are designed to be

SV4.5CTS

Or SV8CTS

Termination

Chase Flashing

(Field Fabricated)

Pipe

Section

installed on top of locally fabricated chimney enclosure, referred to

herein as a chase. The terminations are designed to be used with tested

and listed Direct Vent pipe systems and manufactured appliances listed

for use with this product. The SV4.5CTS and SV8CTS terminations are

additionally designed and painted to be suitable for use by itself without

surround, providing a beautiful top to a standard chase.

WARNINGS

This termination is intended to be installed in accordance with the

installation guidelines of the pipe system and appliance it is joined to.

Failure to install this product within those guidelines as well as these

installation instructions can result in damage of property, bodily injury,

or death. The installation must conform with local codes or, with the

national fuel gas code, or ANSI Z223.1.

It is highly recommended that this product be installed by a qualified

technician. It is highly recommended that the technician be NFI certified

for gas appliance installations.

KIT CONTENTS

1 - Termination

1 - Bag with fifteen (15) stainless steel screws

1 - Instruction Sheet

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

APPROVALS AND LISTINGS

The SV4.5CTS and SV8CTS series terminations are tested as a integral

component of the Direct Vent pipe system and may be used with any

manufactured fireplace listed for use with these components. These

terminations are listed for this application by Omni-Test Laboratories.

FOR YOUR SAFETY

When working on ladders, roofs, scaffolding, or any high surface, take

precautions to protect against accidents. Properly secure ladders, wear

safety harnesses and verify all operations are done to OSHA standards.

Also be aware of and avoid any and all electrical wires in or near your

working area.

When working with and around sheet metal, be aware of material edges.

Always wear gloves, safety glass and any other needed protective gear

when working with sheet metal.

Take appropriate precautions when operating power equipment.

1

Page 2

CHASE CONSTRUCTION

INSTALLATION STEPS

The chase is a hollow vertical enclosure framed as a part of the building

and covered with a suitable exterior veneer. Always consult local building

codes for approved chase construction techniques.

The chase flashing, fabricated locally, is used to anchor the termination

to the chase. The flashing should be constructed to overlap the chase to

seal out the elements.

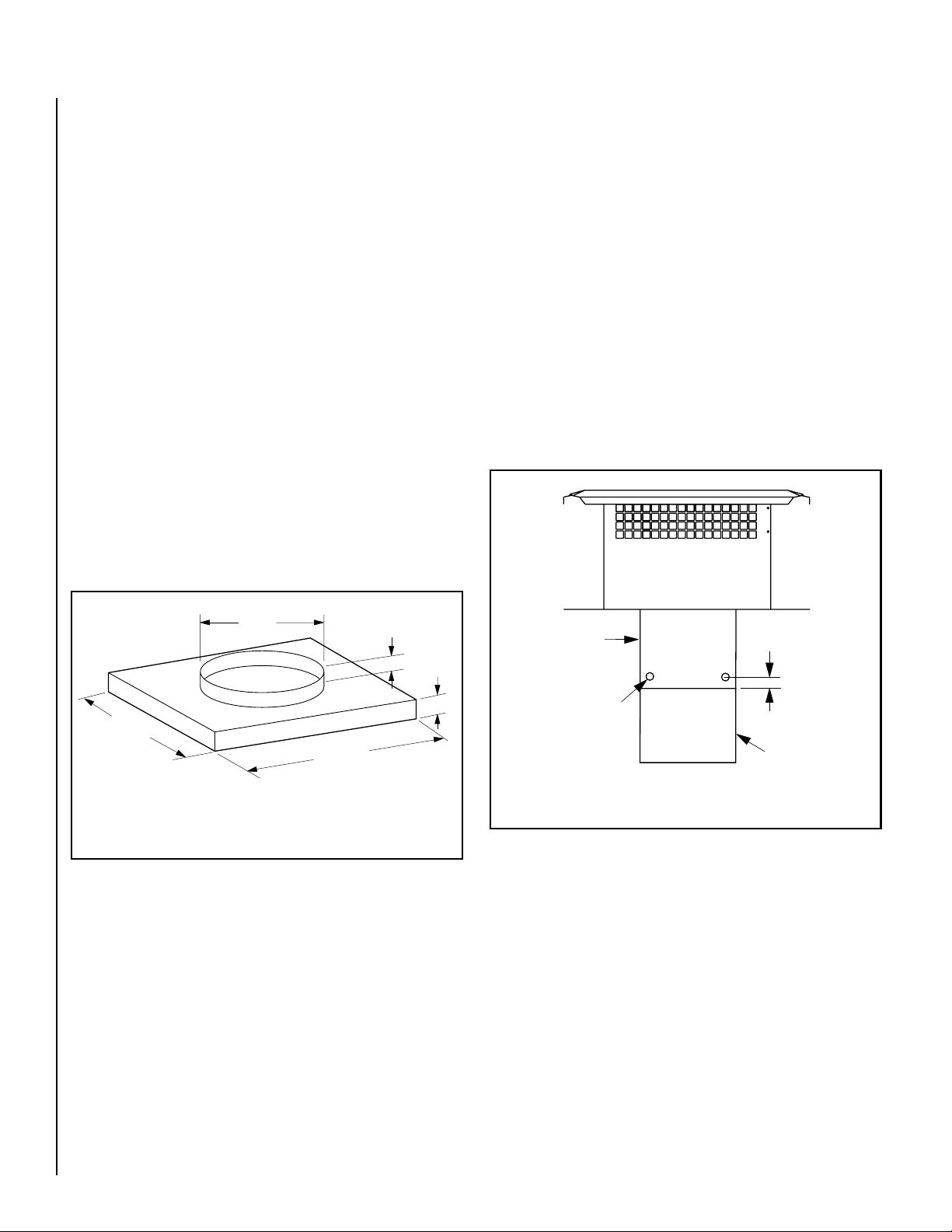

CHASE DIMENSIONS

The chase must be large enough to accommodate the vent system and its

required clearances to combustibles. The base of the Direct Vent Chase

Top Vertical Termination is nineteen and five eights inches (19 5/8" ) for

the SV4.5CTS and twenty three inches (23") for the SV8CTS. The chase

and its chase flashing must exceed those dimensions by one (1) inch on

all sides. This means the minimum chase dimensions must be a

minimum of twenty one and five eights inches (21 5/8" ) for the SV4.5CTS

and twenty five (25") for the SV8CTS.

TO INSTALL THE TERMINATION

The installation of this termination also requires additional components.

• Chase Flashing - The flashing should be a minimum 0.018" thick G90

galvanized steel or equivalent per ASTM 525. The chase flashing must

have, integrated into it, a vertical collar (

see Figure 1

).

Step 1. Install the gas appliance in accordance with its installation

instructions.

Step 2. Determine the chimney height vent configuration and number of

strait direct vent pipe sections required to bring the top of the last pipe

section flush with the chase top. Two inches (2") maximum above to

three inches (3") maximum below are the acceptable limits. Please see

the Installation Instructions accessories list for pipe information. Install

the direct vent pipe system.

If the top of the last pipe section exceeds the 3" maximum from the chase

top (up to 5" maximum), please use an adjustable length slip section

SV4.5LA (Cat. No. 77L75) or SV8LA (Cat. No. H2255) to engage the

termination with the pipe. See Step 3 for details.

Step 3. Install the sweaged side of the adjustable pipe section all the way

inside the termination. Secure it with three sheet metal screws (not

provided) one inch (1") above the termination outer collar bottom, in

three equally spaced places around the termination (

see Figure 2

).

(550 mm)

3/4" (38 mm) Min. to

2" (51 mm) Max.

2"

(51 mm)

**21-5/8" Min.

(550 mm)

*For SV8CTS - 12” (305 mm) I.D.

**For SV8CTS - 25” (635 mm)

*9"

(229 mm) I.D.

**21-5/8" Min.

Figure 1 Chase Flashing

Too short of a collar or no collar at all will allow water to seep into the

chase around the outside of the pipe system, and too tall of a collar will

interfere with the proper attachment of the termination.

The collared opening must be large enough to allow for the direct vent pipe

system to be installed and the termination outer collar to move freely. The

collared opening can be no larger than nine (9) inched in diameter.

• Strap Support - The SV4.5SU strap support is to be used for keeping

the vent pipe system in the center of the chase (

• Silicone Caulk - This is to be used for the final sealing of the

installation. The collar must be properly sealed to the chase flashing

with appropriate caulk. Hi-Temp sealant P/N 10K81 is recommended.

Failure to properly seal the collared opening will result in leakage into

the chase.

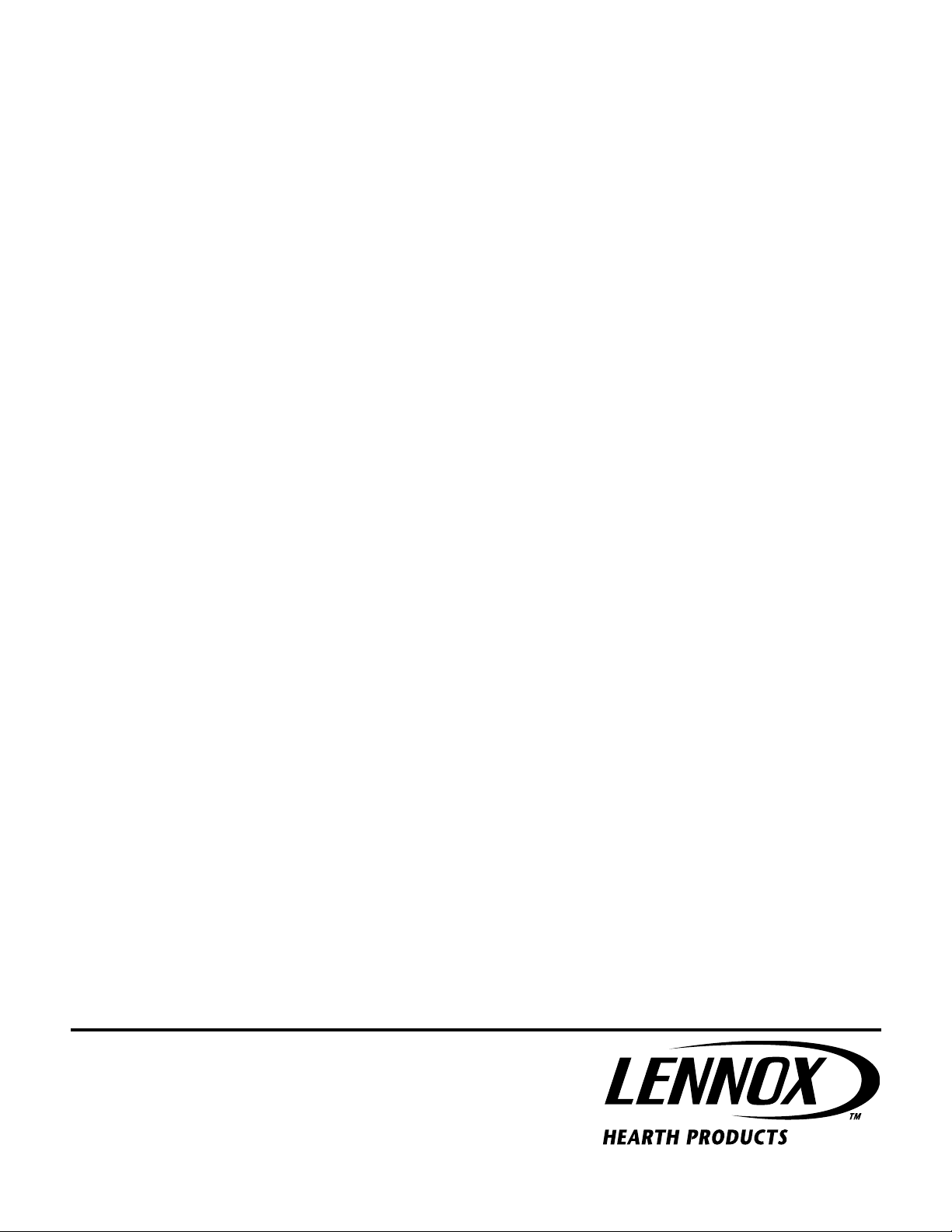

refer to Figure 3

).

Outer Collar

Sheet Metal Screw

# 8-32

(Three Places)

1"

Adjustable

Slip Section

(Sweaged

Side At Top)

Figure 2

Step 4. Install the SV4.5 pipe strap support (Cat. No. 96K93) or SV8SU

pipe strap support (Cat. No. H2262) to keep the vent system from

moving (

of one foot (1') to a maximum of 2 feet (2') below the chase top.

Step 5. Install the chase flashing on the top of the chase. Secure the

flashing to the top of the chase, using 8d nails.

Step 6. Connect the termination with the top pipe section. Slide the

termination inside pipe and lower it onto the chase flashing.

Step 7. Rotate the termination as needed to square it to the chase

flashing for proper aesthetic appearance.

see Figure 3

). The strap support should be placed a minimum

2

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 3

Step 8. Once the termination is positioned, secure it to the chase

flashing using the stainless steel screws provided, through the prepunched attachment holes in the attachment tabs of the termination.

Be careful not to over tighten the screws so as to strip out the chase

flashing. In the event of a strip, a larger screw can be used so long

as it is stainless steel. DO NOT use common sheet metal screws, as

they will corrode over time and the termination will no longer be

secure at that point.

Step 9. Once the termination is permanently attached, seal all of the

screw tops with silicone. In order to properly apply the silicone, the

surface of the termination and screws must be clean and dry. Not sealing

the screws tops will result in water leakage into the chase.

VERTICAL VENT TERMINATION CLEARANCES

These instructions should be used as a guideline and do not supersede local codes in any way. Install SV4.5 vent according to the current

National Fuel Gas Code, ANSI-Z223.1 - latest edition, in the USA or CAN/

CGA-B149.1 and B149.2 - latest editions in Canada.

Terminate single vent caps relative to building components according to

Figure 4

.

Horizontal Overhang

Chase

Flashing

Chase

Pipe

Section

Strap

Support

2"

(Min.)

2 feet

(Max.)

1 foot

(Min.)

2"

(Max.)

3"

(Max.)

Figure 3

MAINTENANCE

As part of an annual inspection, the termination should be checked for

any foreign debris, animal or insect nests, or material of any kind which

may have become lodged in it. The exterior of the termination should be

visually inspected for damage of any kind.

In the event of damage to the termination, it should be replaced with a

new termination. All screw attachments should be checked to insure

they have not loosened over time and they should also be checked for

the water tightness of their silicon seal. The termination must be

removed to clean the chimney. Following cleaning, reinstall the termination and inspect as detailed in this document.

Vertical

Wall

2 FT MIN.

2 FT

MIN.

Lowest

Vent

Termination

Discharge

Opening

H*

X

12

Roof Pitch is X/12

*H = MINIMUM HEIGHT FROM ROOF TO

LOWEST DISCHARGE OPENING OF VENT

The vent/air intake termination clearances above the high side of

an angled roof is as shown in the following chart:

Termination Heights For Vents Above Flat Or

Slopped Roofs Ref. NFPA 54 / ANSI Z223.1, 7.6

hctiPfooR

H

)teef(

H

)sretem(

21/6ottalF0.13.0

21/7ot21/6revO52.183.0

21/8ot21/7revO5.164.0

21/9ot21/8revO0.216.0

21/01ot21/9revO5.267.0

21/11ot21/01revO52.399.0

21/21ot21/11revO0.422.1

21/41ot21/21revO0.525.1

21/61ot21/41revO0.638.1

21/81ot21/61revO0.731.2

21/02ot21/81revO5.792.2

21/12ot21/02revO0.844.2

Figure 4

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

3

Page 4

The manufacturer reserves the right to make changes at any time, without notice, in design,

materials, specifications, prices and also to discontinue colors, styles and products.

Consult your local distributor for fireplace code information.

Printed in U.S.A. © 2006 by Lennox Hearth Products

P/N 750,207M REV. A 07/2007

4

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

1110 West Taft Avenue • Orange, CA 92865

Loading...

Loading...