Page 1

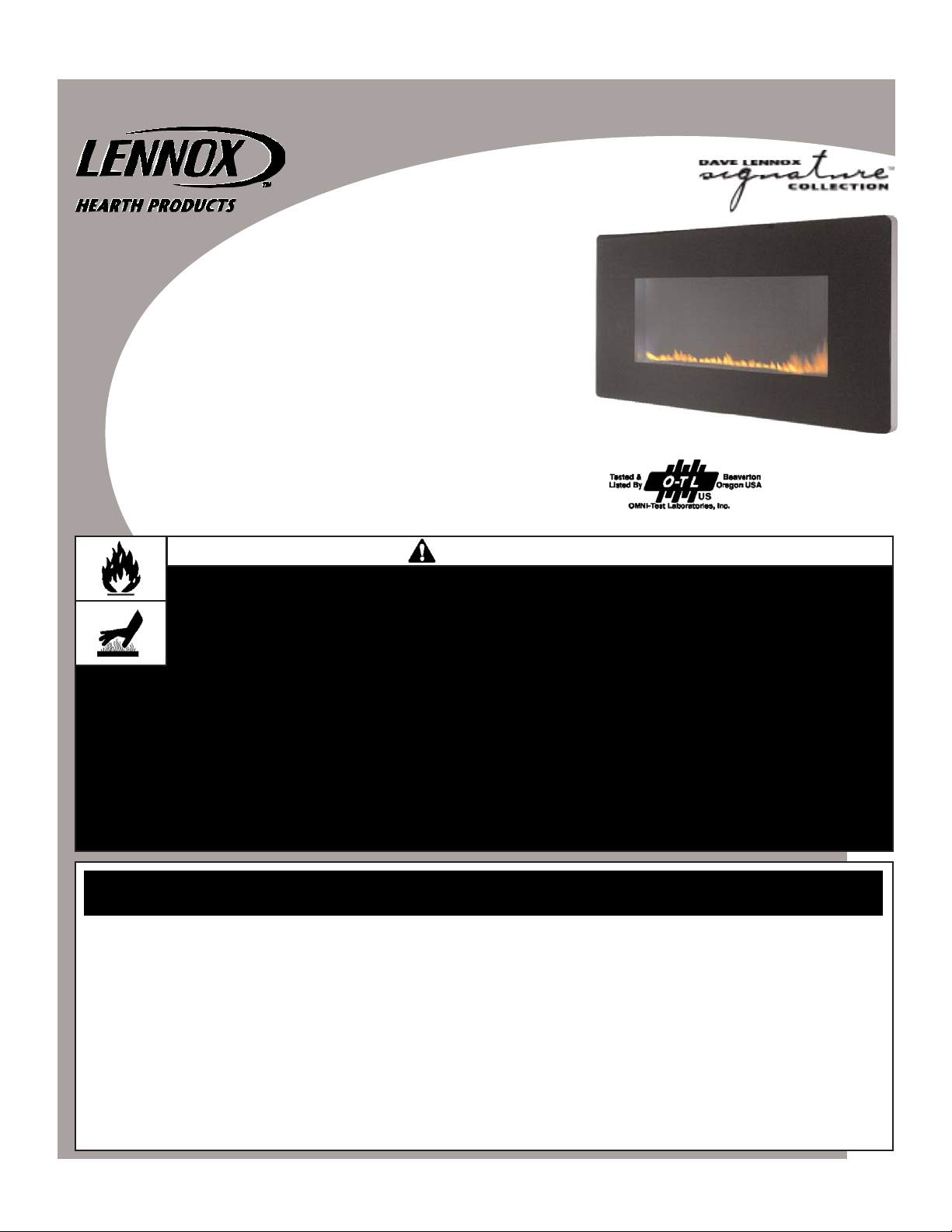

INSTALLATION AND OPERATION INSTRUCTIONS

Catalytic Vent - Free Wall-Mounted

Fireplace

Model: Scandium-NG

P/N 850,055M Rev. NC, 04/2007

Installer: Leave This Manual With The Appliance.

Consumer: Retain This Manual For Future Reference.

In the Commonwealth of Massachusetts:

• Installation must be performed by a licensed plumber or gas fitter

• See Table of Contents for location of additional Commonwealth of

Massachusetts requirements

(Para Instrucciones en español, ver la página 15)

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• DO NOT light any appliance.

• DO NOT touch any electrical switches.

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow your gas supplier's instructions.

• If your gas supplier cannot be reached, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

• Hot! Do not touch! This appliance will be hot during operation and will retain heat for a while after shutting

off the appliance. Severe burns may result.

• Carefully supervise children in the same room as appliance.

• Due to high temperatures, the appliance should be located out of traffic and away from furniture or draperies.

Do not place clothing or other materials on or near this appliance.

• Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this

manual. For assistance or additional information consult a qualified installer, service agency or the gas supplier.

• Do not build a wood fire. Do not burn wood or other material in these appliances.

• This is an unvented gas-fired heater. It uses air (oxygen) from the room in which it is installed. Provisions for adequate

combustion and ventilation air must be provided. Refer to Combustion and Ventilation Air Section.

• This appliance may be installed in an aftermarket, permanently located, manufactured (mobile) home, where not prohibited

by local codes.

• The appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible for use

with other gases.

Scandium

WARNINGS

TM

WARNING: If the information in this manual is not followed exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

317-S-05-5

Report No. :

Page 2

2

This appliance is a high efficiency, unvented, flame effect gas heater. It

provides radiant and convected warmth both efficiently and safely

utilizing the latest type catalytic convertor burner technology. The

appliance does not require a flue system of any type as the catalytic

converter cleans the flue products to provide a complete combustion

system, which is intrinsically safe.

These heaters are fitted with a specially designed pilot utilizing an

oxygen depletion sensor (ODS) which responds to the amount of

oxygen available in the room and shuts the heater off before the oxygen

level drops below 18%. The pilot can be relit only when fresh air is

available. Refer to the Combustion and Ventilation Air section.

The appliance is designed to fit various types of situations as listed in

the Installation Requirements.

This appliance is factory set for operation on the gas type, and at the

pressure stated on the appliance rating plate.

On first light up of a new appliance, initial curing of high temperature

paint and burning off of lubricants may occur for the first few hours of

operation. During this period some smoke may be emitted from outlet

grille, this should be no cause for concern. Accordingly, the room

should be well ventilated with all windows and doors open during this

period.

Read all these instructions before commencing installation. All

instructions must be handed to the user for safekeeping.

QUANTITY DESCRIPTION

1 Firebox and burner assembly

1 Installation and operating instructions

1 Glass facia panel assembly

1 Fitting template

1 Screw and wall plug pack

1 Rubber grommet

Section Contents Page No.

1.0 General Information 2

2.0 Packaging List 2

3.0 Appliance Data 2

4.0 Important Safety Information 2

5.0 Codes 4

6.0 Combustion and Ventilation Air 4

7.0 Site Requirements 4

8.0 Preparing the Appliance 5

9.0 Mounting the Appliance 5

10.0 Checking the Burner 6

11.0 Connecting a Gas Line 6

12.0 Checking the Gas Connections 7

13.0 Gas Pressure Check 7

14.0 Spark Gap 7

15.0 Assembly of the Glass Facia 7

16.0 Fitting the Glass Facia 8

17.0 Fitting the side panels 8

18.0 Briefing the customer 9

19.0 Servicing 9

20.0 Servicing the Burner 9

21.0 Pilot Assembly 10

22.0 Catalysts 10

23.0 Testing for Firebox Leakage 10

24.0 Cleaning 10

25.0 Lighting Instructions 11

26.0 To Turn off gas to Appliance 11

27.0 Troubleshooting Guide 12

28.0 Replacement Parts 12

29.0 Positioning of field assembled parts 13

1.0 GENERAL INFORMATION

2.0 PACKAGING LIST

4.0 IMPORTANT SAFETY INFORMATION

TABLE OF CONTENTS

3.0 APPLIANCE DATA

Gas Type Natural Gas

Gas inlet pressure Maximum 10.5” w.c.

Minimum 6” w.c.

Regulator Pressure Setting 5” w.c.

Max Energy Input

11,950 BTU/hr

Min Energy Input

6,820 BTU/hr

Pilot Energy Input 560 BTU/hour

Burner (Manifold) Pressure High 2.4” w.c.

Low 0.8” w.c.

Main burner flow restrictor 2.0mm (0.079”)

Oxypilot SIT/Bray 9082

Gas Inlet Connection 3/8” NPT at regulator

Ignition Piezo spark

Spark Gap 1/8” - 3/16”

Please see Data Plate affixed to appliance for current data.

This appliance is for use only with the gas type, and at the pressure

stated on the appliance Data Plate.

THE FOLLOWING BOXED INFORMATION APPLIES TO

REQUIREMENTS FOR THE COMMONWEALTH OF MASSACHUSETTS.

Note: The following requirements reference various Massachusetts and

national codes not contained in this document.

Unvented Room Heaters shall be installed in accordance with 527 CMR

30.00 and 248 CMR 3.00 through 7.00:

(a) Permits and Inspections: In addition to complying with 248 CMR 3.05

the following requirements must be satisfied:

1. A permit shall be obtained from the head of the fire department and the

local or state gas inspector having jurisdiction for the installation of all

unvented propane or natural gas-fired space/room heaters.

2. The permits shall be conditioned upon final inspection and approval of

installation by the head of the fire department and the local or state gas

inspector having jurisdiction.

3. A copy of the manufacturer’s installation/operating literature shall be

submitted with each permit application.

4. Before operation, the Head of the Fire Department and the local or state

gas inspector shall inspect the installation for compliance with 527 CMR

(Board of Fire Prevention Regulations) and 248 CMR (Board of State

Examiners of Plumbers and Gas Fitters).

READ AND UNDERSTAND THESE INSTRUCTIONS

COMPLETELY BEFORE INSTALLING OR OPERATING

YOUR UNVENTED ROOM HEATER.

IMPORTANT

Page 3

• Children and adults should be alerted to the hazard of high surface

temperature and should stay away to avoid burns or clothing ignition.

• Young children should be carefully supervised when they are in the

same room with the heater.

• Do not place clothing or other flammable material on or near the

heater.

• Any safety screen or guard removed for servicing the heater must be

replaced prior to operating the heater.

• Installation and repair should be done by a qualified service person.

The heater should be inspected before use and at least annually by a

professional service person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding material, etc. It is

important that control compartments, burners and circulating air

passageways of the heater be kept clean.

• Allow the heater to cool before servicing. Always shut off the gas to

the heater while performing service work.

• The installation must conform with local codes or, in the absence of

local codes with the National Fuel Gas Code, ANSI Z223.1.

• The heater and its individual shut-off valve must be disconnected

from the gas supply piping system while performing any tests of the

gas supply piping system at pressures in excess of 1/2 psig.

• The heater must be isolated from the gas supply piping system by

closing its individual manual shut-off valve during any pressure

testing of the gas supply piping system at test pressures equal to or

less than 1/2 psig.

• Keep heater area clear and free from combustible materials, gasoline

and other flammable vapors and liquids.

• Do not use this heater if any part has been under water. Immediately

call a qualified service technician to inspect the room heater and to

replace any part of the control system and any gas control which has

been under water.

• Input ratings are shown in BTU per hour and are for elevations up to

4,500 feet. If these appliances are installed at elevations above 4,500

feet, nuisance pilot outages may occur. Do not install this heater at an

elevation above 4,500 feet if the gas supply has not been derated for

that elevation. Consult your local gas supplier.

• Ensure that the heater is clean when operating. Excessive dust

accumulation on the burner will increase the amount of carbon

monoxide formation and could lead to carbon monoxide poisoning

and/or death.

• Vent-free gas fireplaces are designed for use as a supplemental

heaters. They are not intended for continuous use as a primary

source.

3

4.0 IMPORTANT SAFETY INFORMATION (continued)

5. A final inspection by the state or local gas inspector of the unvented

space/room heater shall not be performed until proof is provided that the

head of the fire department having jurisdiction has granted a permit.

(b) Unvented natural gas-fired space/room heaters shall conform to ANSI

Z21.11.2, be equipped with an oxygen depletion safety (ODS) shutoff

system and be Product-approved in accordance with 248 CMR.

(c) Unvented natural gas-fired space/room heaters shall be installed in

accordance with their listings and the manufacturer’s instructions. Proper

clearances to combustibles shall be maintained. In no case shall the

clearances be such as to interfere with combustion air and accessibility.

(d) Installations shall be of a permanent type, with a permanently piped

fuel supply in accordance with 248 CMR. LPG appliances shall be subject

to the storage requirements in accordance with 527 CMR 6.00. Portable

unvented or natural gas-fired space/room heaters shall be prohibited.

(e) Unvented natural gas-fired space/room heaters shall be prohibited in

bedrooms and bathrooms.

(f) Space/room heaters shall be properly sized for the room or space of

installation, but shall not exceed a maximum of 40,000 BTU input per room

or space.

(g) In occupancies with an unvented natural gas-fired space/room heater,

no less than one listed carbon monoxide detector that is installed in

accordance with the manufacturers instructions shall be installed and

maintained near the space where the heater is located.

1.Any building wherein the heater is to be installed shall, as a precondition

to such installation, have working smoke detectors installed and

maintained in accordance with the requirements of 780 CMR (State Board

of Building Regulations and Standards) in effect at the time of construction

or;

2. If no requirement was in effect at the time of construction the smoke

detector shall be compliant and installed as provided for in M.G.L. c. 148,

§ 26E.

(h) In rooms and buildings served by an unvented natural gas-fired

space/room heater, a primary source of heat, which is operable, shall be

permanently installed and maintained in the building in accordance with

105 CMR (Department of Public Health).

(i) Sellers of unvented natural gas-fired space/room heaters shall provide

to each purchaser a copy of 527 CMR 30.00 upon sale of the unit.

• Installation and repair must be done by a plumber or gas fitter licensed

in the Commonwealth of Massachusetts.

• The flexible gas line connector used shall not exceed 36 inches (92

centimeters) in length.

•The individual manual shut-off must be a T-handle type valve.

FAILURE TO KEEPTHE PRIMARY AIR OPENING(S) OF THE

BURNER(S) CLEAN MAY RESULT IN SOOTING AND

PROPERTY DAMAGE.

WARNING

THE FOLLOWING BOXED INFORMATION APPLIES TO

REQUIREMENTS FOR THE COMMONWEALTH OF MASSACHUSETTS.

New York : This appliance is approved for installation in the U.S. state

of New York, but not New York City.

FAILURE TO COMPLY WITH THE INSTALLATION AND

OPERATING INSTRUCTIONS PROVIDED IN THIS

DOCUMENT WILL RESULT IN AN IMPROPERLY INSTALLED

AND OPERATING APPLIANCE, VOIDING ITS WARRANTY.

ANY CHANGE TO THIS APPLIANCE AND/OR ITS

OPERATING CONTROLS IS DANGEROUS. IMPROPER

INSTALLATION OR USE OF THIS APPLIANCE CAN CAUSE

SERIOUS INJURY OR DEATH FROM FIRE, BURNS,

EXPLOSION OR CARBON MONOXIDE POISONING.

WARNING

CHECK GAS TYPE : THE GAS SUPPLY MUST BE THE SAME

AS STATED ON THE APPLIANCE’S RATING PLATE. IF THE

GAS SUPPLY IS DIFFERENT DO NOT INSTALL THE

APPLIANCE. CONTACT YOUR DEALER FOR THE CORRECT

MODEL.

WARNING

Page 4

Example:

Vent-free heater #1 9,000 BTU/Hr

Vent-free heater #2 23,000 BTU/Hr

Gas appliance #1 35,000 BTU/Hr

(water heater)

Total = 67,000 BTU/Hr

* Do not include direct-vent gas appliances. Direct-vent is sealed

combustion and draws combustion air from the outdoors.

The space in the previous example is a confined space because the actual

BTU/Hr used is more than the maximum BTU/Hr the space can support.

You must provide additional fresh air. Your options are:

a. Rework equations adding the space of adjoining room(s). If the extra

volume provides an unconfined space, then remove door or add ventilation

grills between rooms. Refer to National Fuel Gas Code, ANSI Z223.1,

Section 5.3.

b.

Vent room directly to the outdoors. Refer to National Fuel Gas Code,

ANSI Z223.1, Section 5.3.

c. Install a lower BTU/Hr heater, to make the area an unconfined space.

If the actual BTU/Hr used is less than the maximum BTU/Hr the space can

support, then the space is an unconfined space. You will need no additional

fresh air ventilation for an unconfined space.

This appliance is designed to be wall-hung. Do not recess any part of

the appliance into the wall. This appliance may be installed in any

room in a home except bedrooms or bathrooms - or areas where large

amounts of steam are likely to be generated.

It should be noted that heaters create warm air currents. These

currents move heat to wall surfaces next to the heater. Installing

the heater next to vinyl or cloth wall coverings or operating the

heater where impurities in the air (such as tobacco smoke or

candle smoke) exist, may discolour walls.

Installation in living rooms is common, however other rooms such as

kitchens, dining rooms and hallways are permitted, providing a suitable

natural gas supply is available, and rooms sizing and ventilation

requirements are strictly adhered to (see section 4).

The appliance is designed to be versatile, and as such will operate correctly

when exposed to normal gentle drafts experienced within the home. It is not

recommended, however that the appliance be installed in areas where it is

likely to be exposed to persistent strong drafts, that may be generated by

outside doors or windows, air vents etc. It is recommended that the

appliance should not be installed within 20” of any air vent.

4

5.0 CODES

Adhere to all local codes or in their absence the latest edition of The

National Fuel Gas Code ANSI Z223.1 or NFPA54 which can be obtained

from The American National Standards Institute, Inc. (1430 Broadway, New

York, NY, 10018) or National Fire Protection Association, Inc. (Batterymarch

Park, Quincy, MA, 02269).

Seller of unvented natural gas fired supplemental room heaters in the

commonwealth of Massachusettes shall provide to each purchaser a copy

of 527 CMR 30 upon sale of the unit. Please refer to section 4.0 on page 2

of this manual.

This Lennox Hearth Products unvented gas room heater is certified by

OMNI-Test Laboratories, Inc to ANSI Z21.11.2-2007 standard.

This heater shall not be installed in a confined space or unusually tight

construction unless provisions are provided for adequate combustion and

ventilation air.

The National Fuel Gas Code, ANSI Z223.1/NFPA 54 defines a confined

space as a space whose volume is less than 50 ft 3per 1,000 BTU/Hr (4.8

m3per kW) of the aggregate input rating of all appliances installed in that

space and an unconfined space as a space whose volume is not less than

50 ft 3per 1,000 BTU/Hr (4.8 m3per kW) of the aggregate input rating of all

appliances installed in that space.

Rooms communicating directly with the space in which the appliances are

installed, through openings not furnished with doors, are considered a part

of the unconfined space.

Unusually tight construction is defined as construction where:

a. wall and ceilings exposed to the outside atmosphere have a continuous

water vapor retarder with a rating of one perm or less with openings

gasketed or sealed, and

b. weather stripping has been added on operable windows and doors, and

c. caulking or sealants are applied to areas such as joints around window

and door frames, between sole plates and floors, between wallceiling joints,

between wall panels, at penetrations for plumbing, electrical, and gas lines,

and at other openings.

Use the following equations to determine if you have a confined or

unconfined space.

Determine the volume of space — ft 3.

Length x Width x Height = _____ ft

3

(Include adjoining rooms with doorless passageways or ventilation

grills between rooms.)

Example: 24' (L) x 16' (W) x 8' (H) = 3072 ft

3

Divide the volume of space by 50 ft 3to determine the maximum

BTU/Hr the space can support.

______ (volume of space – ft 3)/ 50 ft 3=

(Maximum BTU/Hr the space can support)

Example: 3072 ft 3 / 50 ft 3 = 61.44

or 61,440 BTU/Hr the space can support.

Add the BTU/Hr of all the fuel burning appliances in the space.

Vent-Free heater _______ BTU/Hr

Gas appliance #1* _______ BTU/Hr

Gas appliance #2 + _______ BTU/Hr

Gas appliance #3 + _______ BTU/Hr

Total = _______ BTU/Hr

1.

2.

3.

6.0 COMBUSTION AND VENTILATION AIR

4.

Compare the maximum BTU/Hr the space can support with the

actual amount of BTU/Hr used.

_______ BTU/Hr (max. the space can support)

_______ BTU/Hr (actual amount of BTU/Hr used)

Example:

61,440 BTU/Hr (max. the space can support)

67,000 BTU/Hr (actual amount of BTU/Hr used)

7.0 SITE REQUIREMENTS

IF THE AREA IN WHICH THE HEATER MAY BE OPERATED IS

SMALLER THAN THAT DEFINED AS AN UNCONFINED

SPACE OR IF THE BUILDING IS OFUNUSUALLY TIGHT

CONSTRUCTION, PROVIDE ADEQUATE COMBUSTION AND

VENTILATION AIR BY ONE OF THE METHODS DESCRIBED

IN THE NATIONALFUEL GAS CODE, ANSI Z223.1/NFPA 54,

SECTION 5.3 OR APPLICABLE LOCAL CODES.

WARNING

Page 5

Clearances to non-combustibles

Non-combustible surfaces are defined as brick, metal, marble, concrete

etc. and also a number of man-made materials impervious to flame. If in

doubt refer to the material manufacturer for further information before

proceeding with installation.

Clearances to the sides of the appliance are 4”. Clearance to the front of

the appliance is 20”.

The back of the appliance may be installed directly onto a non-combustible

wall, providing the area behind the appliance is flat and does not interfere

with the various vent holes in the back panel of the appliance.

The appliance may be installed with or without a non-combustible hearth. If

a hearth is fitted, the size and design may be as desired.

A non-combustible shelf of any depth may be positioned above the

appliance provided it is no closer than 16” from the top of the appliance

glass panel and the wall above the appliance is non combustible.

Clearances to combustible materials

Combustible materials are defined as wood, fabrics, or other materials

likely to combust if exposed to flame. Generally, any material, which is likely

to discolour, melt or misshape when exposed to moderate heat, should be

considered as a combustible material or surface.

Clearance to the sides of the appliance are 4” but curtains, drapes and

other fabrics are not permitted within a distance of 20” of the appliance

sides. No such materials are permitted directly above the appliance

regardless of distance.

The minimum clearance to the ceiling above the appliance is 32” measured

from the top of the appliance glass panel.

Combustible materials should not be positioned directly in front of the

appliance within a distance of 40”.

Under no circumstances should any electrical equipment e.g. plasma

screen TV sets etc. be positioned on the wall above the appliance. The

appliance is designed to be wall mounted alone and not in conjunction with

any type of combustible fire surround.

No combustible shelves should be positioned on the wall above the

appliance.

It should be established that any mirrors or picture frames etc. to be

positioned on the wall above the appliance are able to withstand prolonged

exposure to moderate heat and moisture before proceeding with their

installation.

The back of the appliance may be installed directly onto a combustible wall,

providing it is flat and does not interfere with the various vent holes in the

back panel of the appliance. The wall must be structurally sound and

constructed from a material capable of withstanding moderate heat.

Finished plaster, conventional wall paper and dry-lined plasterboard are

examples of suitable materials. Materials such as flock, blown vinyl and

embossed paper which are sensitive to even small amounts of heat should

be avoided as scorching and or discoloration may occur over time.

If the appliance is to be mounted on a dry-lined wall or a timber framed

construction wall then the integrity and ability of the wall to carry the weight

of the appliance must be confirmed. It is important in these circumstances

that any vapor control barrier is not damaged, and that any structural

members of the house frame are not damaged.

The appliance may be positioned as close to a solid floor (i.e. stone,

wooden laminate etc.) as the particular design of fire frame permits,

however it is not permitted to install the appliance within 4” of carpet, rugs

or fabric materials of any kind. This dimension is measured vertically to the

bottom of the appliance frame

.

Gas connection :

The heater gas inlet connection is 3/8” NPT at the

regulator, located below the burner, in the center of the heater.

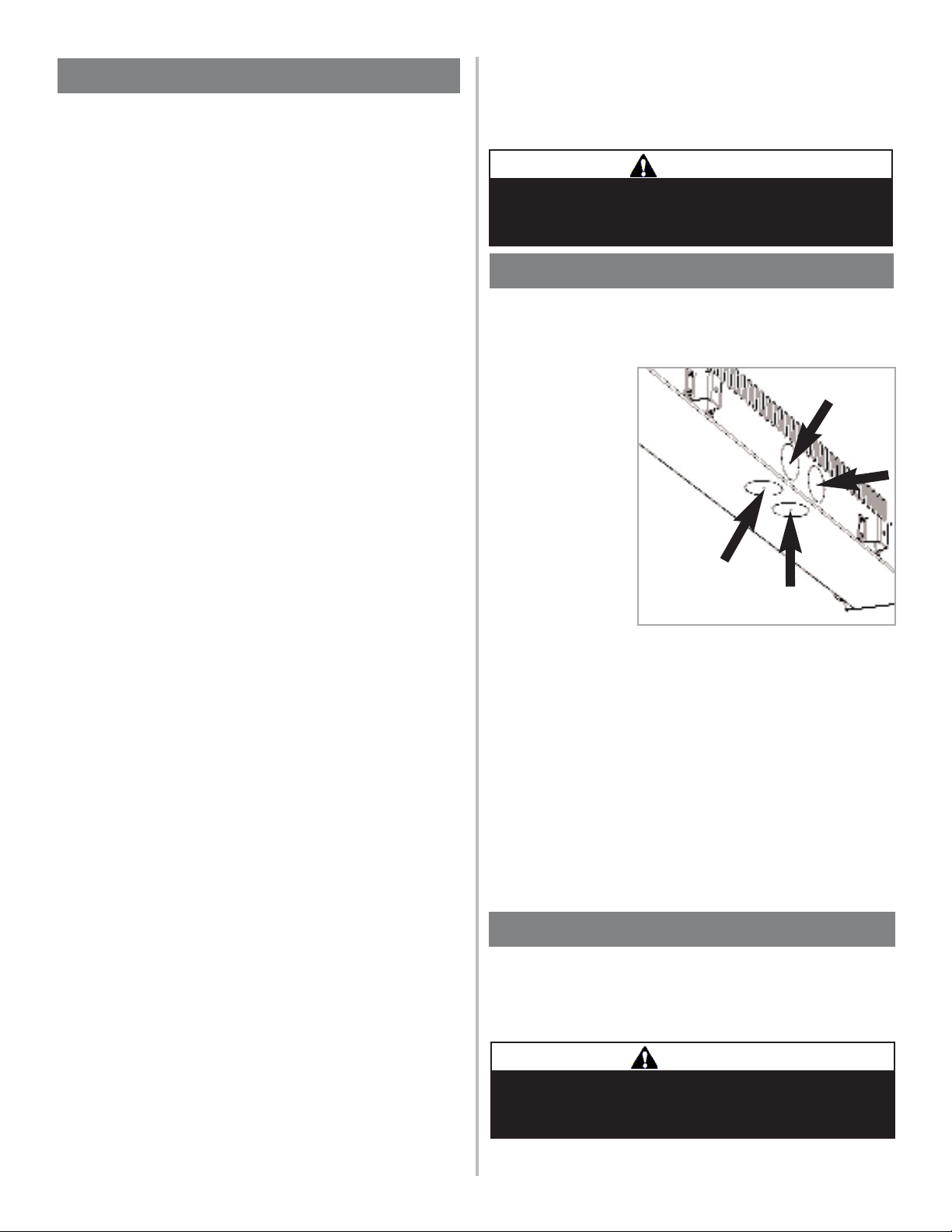

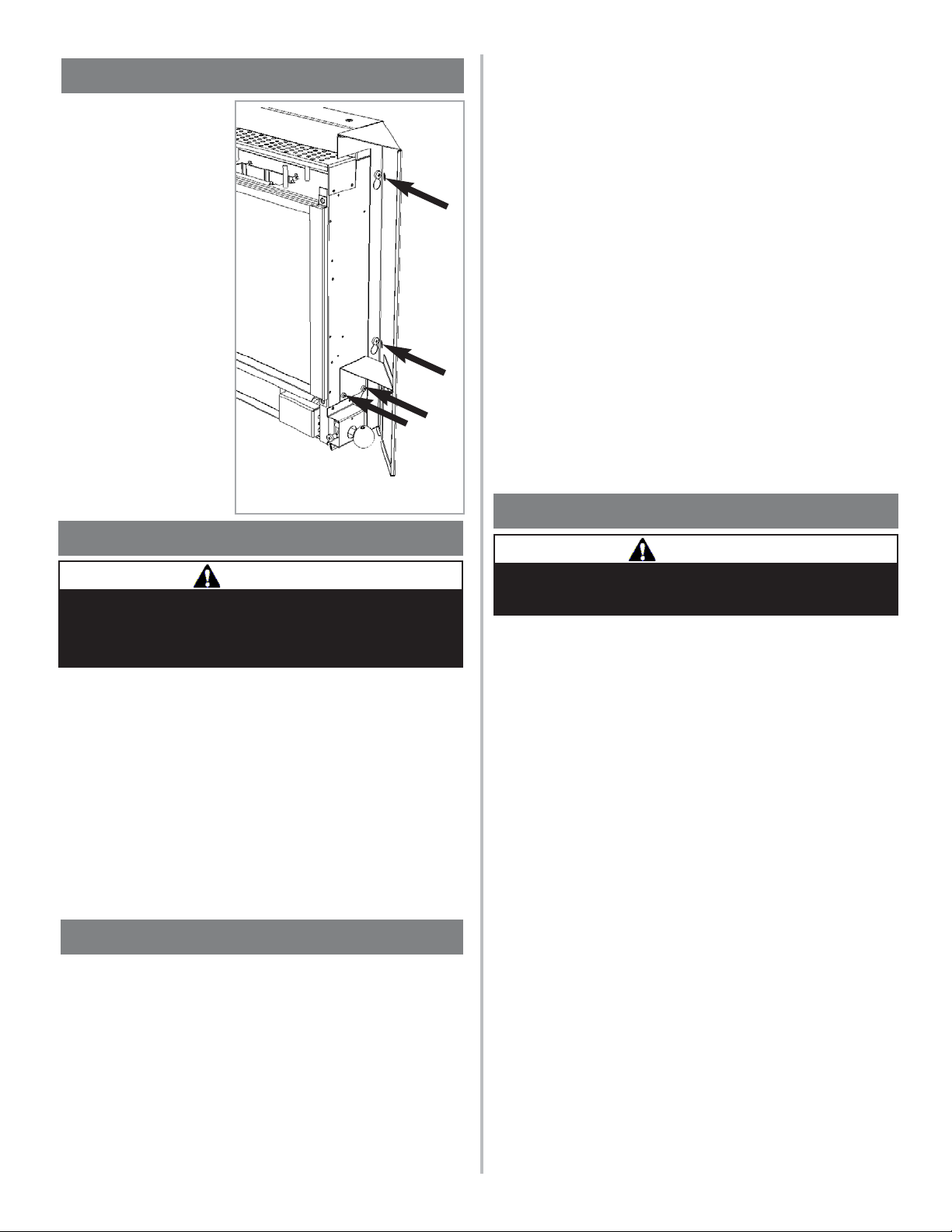

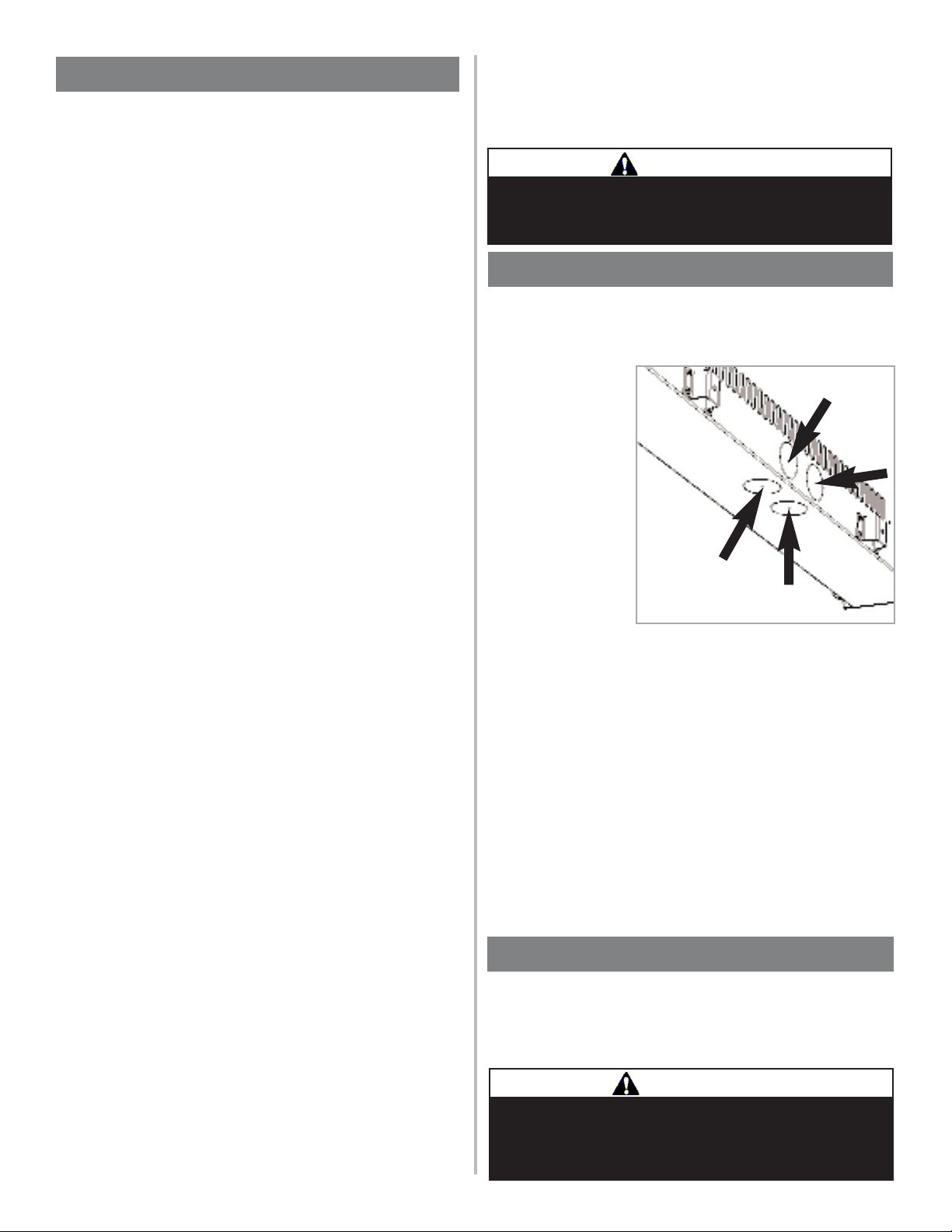

There are four possible

entry points for the gas

supply pipework to enter

the appliance firebox.

These entry points are

‘knock out’ type holes

(shown in figure 1).

Non-concealed gas

connections may be

made using the entry

points on the base of the

firebox. A concealed

gas connection may be

made using the knock

out hole in the centre

back of the firebox.

Select the most

appropriate entry point and knock out the relevant hole.

If a concealed gas connection is to be made, the supply pipe should always

be sleeved through walls and floors using the shortest possible route.

For concealed supply pipe routing, pipes must (where possible) be vertical

and providing there is sufficient wall thickness available, they should be

placed in pipe chases. Horizontal pipe runs should be avoided where

possible. Prior to chasing a solid wall, an inspection should be made to note

the proximity of any cables/sockets outlets which may already be buried.

Pipes must be secured using suitable clips and protected against corrosion.

Ideally factory finished protected pipework and fittings should be used.

Joints should be kept to a minimum and compression fittings must not be

used. The pipework installation must be tested for soundness before any

protection is applied and/or the pipework and fittings are buried.

After having selected the final mounting position of the appliance, taking

into account the site requirements as specified in section 7 of these

instructions, the integrity of the wall, and the feasibility of the proposed

supply pipe routing, the firebox of appliance may be secured to the wall.

5

7.0 SITE REQUIREMENTS (continued)

8.0 PREPARING THE APPLIANCE

9.0 MOUNTING THE APPLIANCE

Figure 1

DO NOT USE A BLOWER INSERT, HEAT EXCHANGER

INSERT OR OTHER ACCESSORY NOT APPROVED FOR

USE WITH THIS HEATER.

WARNING

DO NOT ALLOW ANY FANS TO BLOW DIRECTLY INTO

THE FIREPLACE. AVOID ANY DRAFTS THAT ALTER

BURNER FLAME PATTERNS.

WARNING

Page 6

There are no imitation fuel bed components to install. The appliance

features a ribbon burner which is designed to produce a continuous

band of flame over its length. The burner should be visually inspected

to ensure it is free from any foreign matter. If it is necessary to clean or

dust off the burner then the glass door should be removed by removal

of the four retaining screws. Re-fit the glass door after cleaning or

inspection, ensuring a good seal.

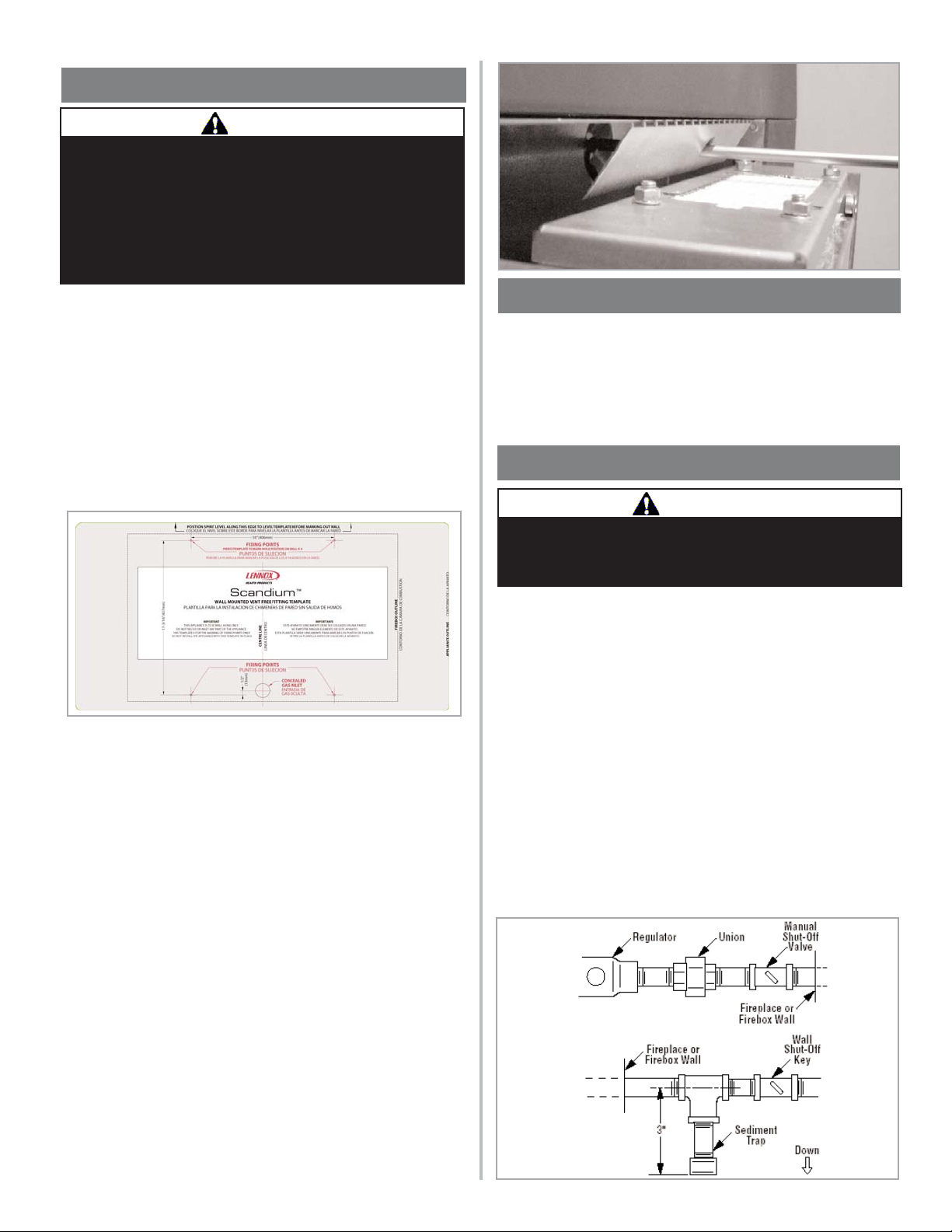

A qualified gas appliance installer must connect the gas room heater to

the gas supply. Consult all local codes. The installer must provide an

ANSI approved manual shut off valve, flex connector and 3/8" NPT

fitting.

Route gas line using techniques and materials prescribed by local

and/or national codes. Only use pipe of 1/2"or greater size to allow full

gas volume to the gas fireplace. Undue pressure loss will occur if the

pipe is too small. An ANSI approved manual shut-off valve and union

must be installed upstream of the heater within the fireplace cavity

when rigid pipe is used. Ensure that a sediment trap is installed

upstream of the heater (figure 4) within the structure’s piping system to

prevent moisture and contaminants from passing through the pipe to

the heater controls and burner. Failure to do so could prevent the heater

from operating reliably. The heater gas inlet connection is 3/8” NPT at

the regulator, located below the burner, in the right hand side of the

heater. When tightening up the joint to the regulator hold the regulator

securely with a wrench to prevent the regulator from moving.

6

To ensure customer safety, be sure to design the installation so that the

strength of both the wall and any wall fixings used are sufficient. Lennox

Hearth Products assumes absolutely no responsibility for injuries and

damages that may occur due to improper installation or handling.

The appliance should not be installed until all dry wall sanding and wall

painting has been completed.

Incorrect installation can cause the appliance to fall from the wall and

cause injury. Do not block the ventilation holes of the appliance. The

wall onto which the appliance is installed must be flat. Install only on a

vertical surface. Avoid sloped surfaces. Installation onto anything other

than a vertical wall may result in fire, damage or injury.

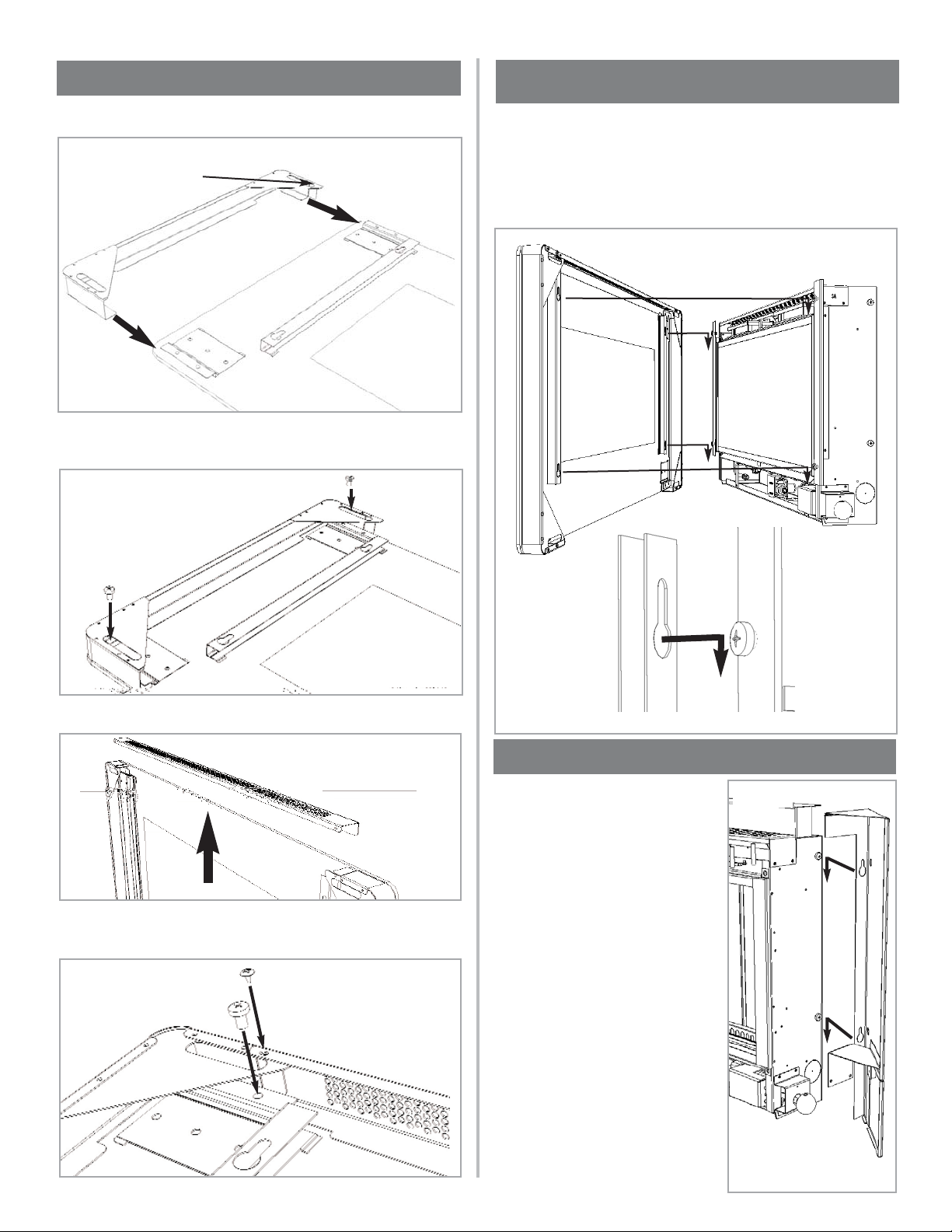

A full size fitting template is supplied to assist with wall mounting.

Mark the positions shown as “Fixing Points” on the wall. If the appliance

is to be mounted on the inner leaf of a conventional cavity wall, or a

solid wall, drill four holes using a 1/4” masonry bit. Insert the fiber wall

plugs provided.

If the appliance is to be mounted on a dry lined wall or a timber framed

construction wall then special cavity screw fixings will be required which

are not supplied with this product. These should be constructed from

metal and not plastic.

If a concealed gas connection is to be made ensure the gas supply pipe

is in it’s final position and can enter the appliance in the correct position

when the appliance is hung on the wall.

Insert the wall mounting screws into the top wall plugs, taking care to

leave the screws protruding approximately 3/8” from the wall. Now hang

the appliance onto these screws through the two keyhole shaped holes

in the back panel of the appliance.

Insert the lower mounting screws into the lower wall plugs through the

corresponding depressed holes in the lower part of the back panel. Do

not tighten fully.

Before tightening the wall mounting screws fully, at this stage it is

recommended to check the horizontal alignment of the appliance with a

spirit level, as small adjustments can still be made if necessary. When

this has been checked, tighten all four fixing screws fully.

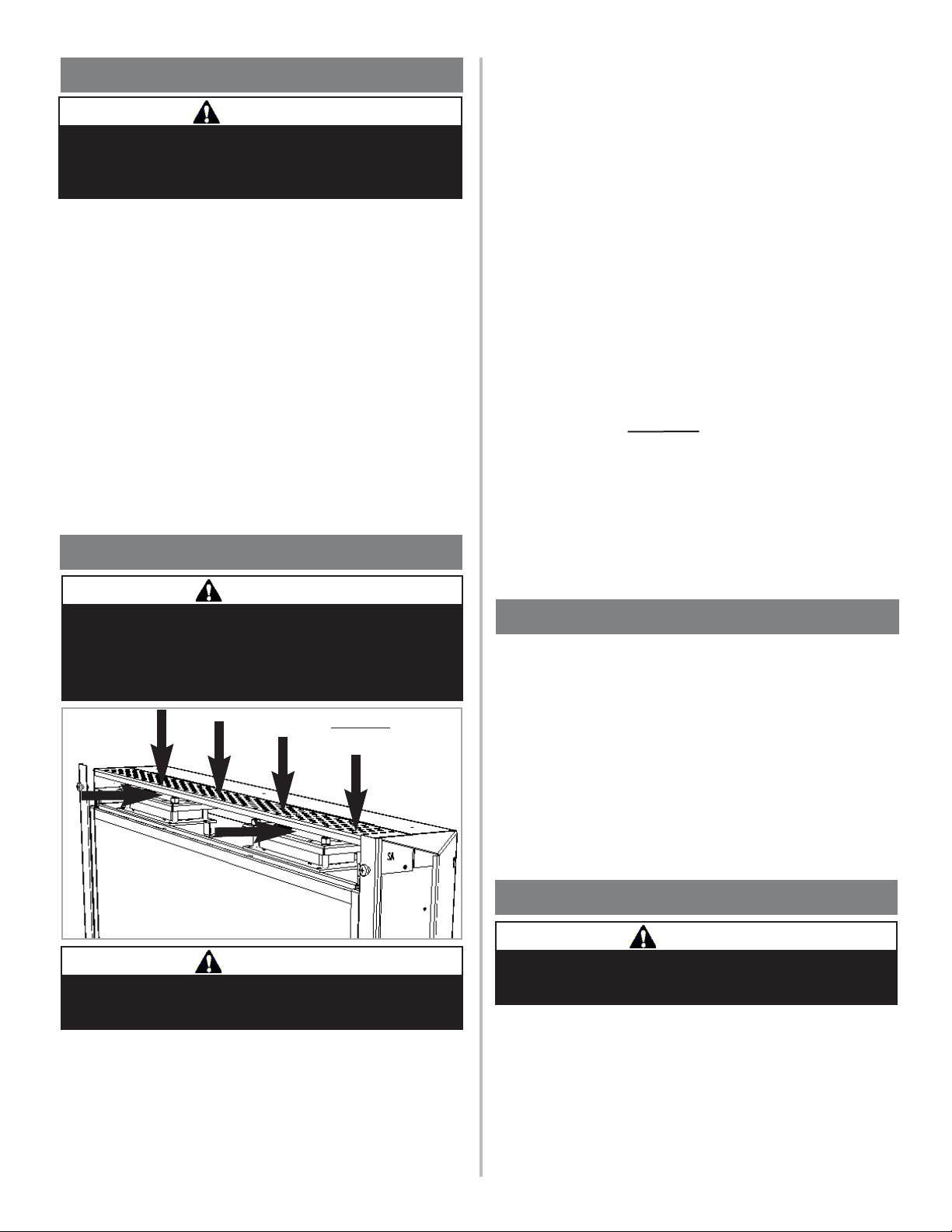

To access the upper fixing screws insert a screwdriver through the

holes in the deflector plates above the catalyst as shown in figure 3.

Figure 2

Figure 3

11.0 CONNECTING A GAS LINE

9.0 MOUNTING THE APPLIANCE (continued)

Figure 4

10.0 CHECKING THE BURNER

THE WALL WHERE THE APPLIANCE IS TO BE

INSTALLED MUST BE CAPABLE OF LONG-TERM

SUPPORT OF THE TOTAL LOAD OF THE APPLIANCE.

MEASURES SHOULD ALSO BE TAKEN TO ENSURE

SUFFICIENT STRENGTH TO WITHSTAND THE FORCE OF

EARTHQUAKES, VIBRATION AND OTHER EXTERNAL

FORCES.

WARNING

HOLD HEATER REGULATOR WITH A WRENCH TO

PREVENT MOVEMENT WHEN CONNECTING TO INLET

PIPING.

IMPORTANT

Page 7

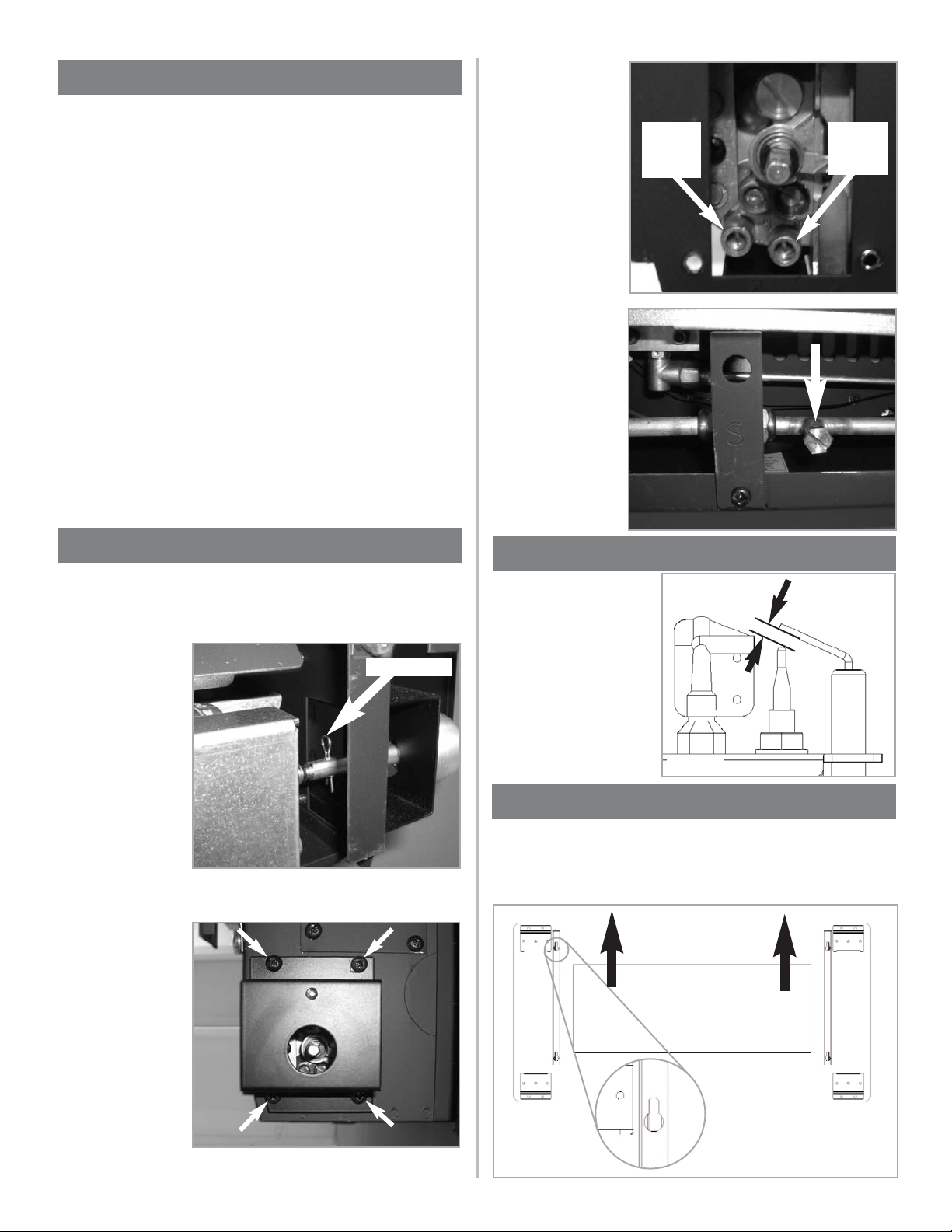

The pressure test

points are located as

shown in figure 7. An

alternative burner

(mainfold test point

is located below the

left hand side of the

burner as shown in

figure 8.

The pressure

regulator on manual

models is preset and

locked to avoid

tampering. If the

pressure is not as

specified in the

Appliance Data section on page 2,

replace the regulator

with P/N H6063.

Replace the test

point screws after

pressure

measurement

ensuring no gas

leaks. All instructions

must be handed to

the user for

safekeeping.

The gap between the

spark electrode and the

pilot should be 1/8” to

3/16” to produce a good

spark. There should be no

need to adjust this. If

under any circumstances

the piezo electric spark

fails, the pilot cannot be lit

manually.

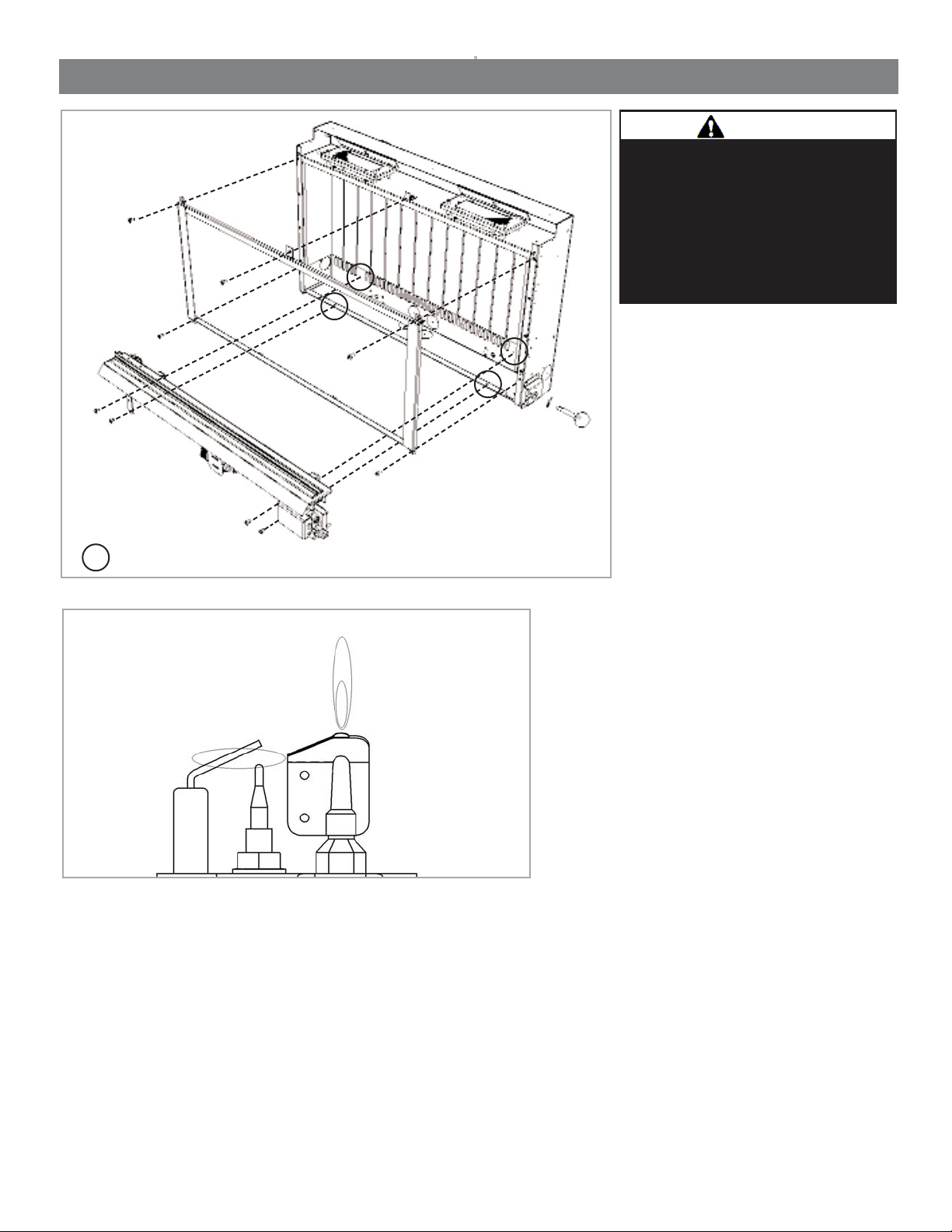

1. Remove the glass panel from all packaging and lay face down on a

soft surface. Identify the top and bottom of the glass facia by

observing the orientation of the keyhole shaped slots in the facia

fixing brackets as shown in figure 10.

7

Turn on gas supply and test for gas leaks using a gas leak test solution

(also referred to as bubble leak solution).

NOTE: using a soapy water solution (50% dish soap, 50% water) is an

effective leak test solution, but it is not recommended, because the

soap residue that is left on the pipes/fittings can result in corrosion over

time.

A. Light the appliance (refer to the lighting instructions label in the control compartment or on page 11).

B. Brush all joints and connections with the gas leak test solution to

check for leaks. If bubbles are formed, or gas odor is detected, turn the

gas control knob (off/pilot/on) to the “OFF” position. Either tighten or

refasten the leaking connection, then retest as described above.

C. When the gas lines are tested and leak free, be sure to rinse off the

leak testing solution.

D. Observe the individual tongues of flame on the burner. Make sure all

ports are open and producing flame evenly across the burner. If any

ports are blocked, or partially blocked, clean out the ports.

The pressure should be checked with the gas heater burning and the

control set to high flame.

The pressure test

points are located

on the gas valve.To

access the valve

and the test points,

firstly remove the

control knob spindle

from the valve

spindle by removing

the retaining clip

shown in figure 5.

Withdraw the control

knob and spindle

from the heater,

remove the gas

valve cover plate by

removing the four

retaining screws

indicated in figure 6.

12.0 CHECKING THE GAS CONNECTIONS

13.0 GAS PRESSURE CHECK

Figure 5

Retaining clip

Figure 6

Burner

(Manifold)

pressure

Regulator

pressure

setting

Figure 7

Figure 8

14.0 SPARK GAP

Figure 9

Spark gap

TOP

Figure 10

15.0 ASSEMBLY OF THE GLASS FACIA

Page 8

8

2. Slide on the side pieces ensuring that the grille fixing holes (shown)

are aligned towards the top of the glass facia (as shown in figure 11).

3.Ensure the sides are neatly aligned with the glass and secure the

sides using two M6 screws for each side as shown in figure 12. Do

not overtighten the screws.

4. Position the grille within the two side pieces ensuring a neat fit.

5. Secure the grille in position using two M6 screws and two no. 8 self

tapping screws as shown in figure 14.

The glass facia panel is supported by four M6 screws which protrude

from the front of the outer casing. Insert the M6 retaining screws and

ensure they are unscrewed approximately 1/8” so the keyhole shaped

holes may engage, and the facia can be hooked on. Ensuring that the

corresponding keyhole shaped holes engage the screwheads fully.

Refer to figure 15.

Remove the two side panel

assemblies from the protective

packaging and fit onto the sides of the

firebox as shown. Insert the M6

retaining screws in the sides of the

firebox and ensure they are

unscrewed approximately 1/8” so the

keyhole shaped holes may engage,

and the sides can be hooked on.

16.0 FITTING THE GLASSFACIA

15.0 ASSEMBLY OF THE GLASS FACIA - (continued)

Grille fixing holes

Figure 11

Figure 12

TOP

Figure 13

Figure 14

Figure 15

17.0 FITTING THE SIDE PANELS

Note : Front frame/facia not shown

for clarity.

Figure 16

Page 9

9

Insert a screwdriver

through the holes in the

right hand side panel to

access the two M6 fixing

screws (designated ‘a’ in

figure 17) and tighten fully.

Next insert two no.8 self

tapping screws (designated

‘b’ in figure 17) through the

side panel support bracket,

and the corresponding

holes in the side of the

firebox. Tighten fully.

Repeat for the left hand

side panel, which is

secured by tightening the

M6 ‘a’ screws only.

The right-hand side panel

has a hinged flap to allow

access to the control knob.

After commissioning the appliance, the customer should be instructed

on the safe use of the appliance and the need for regular servicing.

Frequency of service depends on usage, but MUST be carried out at

least once annually.

Advise that cleaning of the fireplace may be achieved when the

fireplace is cold using a damp cloth and mild detergent on most

surfaces.

Advise that the fireplace will emit an odor for a time after initial

commissioning and that extra ventilation may be needed during this

time. A periodic visual check of the pilot flame and the burner flame

should be carried out. (Refer to figure 22).

A suggested procedure for servicing is detailed as follows;

Turn off the fireplace at the the gas supply. Ensure that the fireplace is

fully cold before attempting service.

1. Lay out the dustsheet and tools.

2. Remove the front glass facia as described in section 16.0,

only in reverse.

3. Remove the glass door assembly (5 screws) and clean

carefully. Remove the valve cover plate (4 screws).

4. Inspect the burner and the catalysts and clean if necessary

with a soft brush.

5. Disconnect the gas supply.

6. Undo the four screws retaining the burner support brackets to

the base and rear of the firebox.

7. Remove the burner unit, strip off the burner pipes and clean

thoroughly.

8. Clean the in-line restrictor, pilot assembly and the burner

tube. Do not attempt to remove the pilot injector as this can

cause damage.

9. Re-assemble components.

10. Turn on the gas supply and leak test. Check pilot and

burner for good ignition.

11. Refit the valve cover and retaining screws.

12. Refit the glass door assembly.

13. Refit the facia Refitting as described in section 15.0.

14. Check the purpose provided ventilation is unobstructed.

15. Light the fire and test setting pressures.

16. Check safe operation of the appliance.

For specific servicing instructions, see relevant sections.

First, remove the front Glass facia as described in Section 16.0 only in

reverse, remove the valve cover (4 screws) and disconnect the gas

connection inside appliance. The gas connections to the gas valve can

now be released. Undo the four screws retaining the burner brackets to

the base and rear of the firebox. The burner may now be removed.

Remove the pilot and main burner pipes and blow through to dislodge

any debris. Now remove the in line restrictor and blow through to make

sure it is entirely clear.

Unclip the pilot lint gauze and clean with a soft brush. Clean the exterior

of the pilot assembly with a soft brush and blow through the flame ports

on the pilot head. Check the aeration holes are free from lint or dirt. The

pilot assembly can be removed if required by disconnecting the

electrode HT lead, gas pipe, thermocouple lead and unscrewing the

mounting screws and lifting away. The pilot assembly is a nonserviceable item and should not be taken apart. Aeration holes must be

absolutely clear internally for proper operation. NEVER MODIFY OR

BEND THE THERMOCOUPLE TO MAKE THE PILOT STAY ALIGHT.

Modifications are dangerous and can have serious unseen effects on

safety. If the pilot will not stay lit there is a problem with dirt, the gas

supply to it, or the thermocouple needs replacement.

The gas valve is a non-serviceable item. If this needs replacement,

remove the cover plate then the securing screw holding the valve

bracket in place, remove all pipe unions, and the complete valve.

Replacement must be original manufacturers parts.

Re-assemble in the reverse of removal. Ensure setting pressures are

as stated in Section 3; Appliance Data.

17.0 FITTING THE SIDE PANELS (continued)

19.0 SERVICING

20.0 SERVICING THE BURNER

‘a’

‘a’

‘b’

‘b’

Figure 17

18.0 BRIEFING THE CUSTOMER

DO NOT ADD LOGS OR ORNAMENTS SUCH AS PINE

CONES, VERMICULITE OR ROCK WOOL. USING

THESE ADDED ITEMS CAN CAUSE SOOTING.

WARNING

ANY CHANGE TO THIS HEATER OR ITS CONTROLS

CAN BE DANGEROUS.

WARNING

Page 10

Remove the glass facia, glass panel and burner unit (as per servicing

section), lint arrestor and pilot unit by using a screwdriver to remove the

retaining screws. Clean the pilot assembly with a soft brush and blow

through. Check the aeration holes are free of any dirt or lint. Clean

thoroughly internally, the connection can be removed from the base of

the pilot unit using two spanners to make cleaning easier. Do not

damage or try to dismantle the pilot injector. The unit is factory set and

the only check necessary is to ensure the spark gap is correct. See

specifications for gas setting.

NEVER MODIFY OR BEND THE THERMOCOUPLE TO MAKE THE

PILOT STAY ALIGHT. If the pilot will not stay lit there is a problem with

dirt, the gas supply, or the thermocouple needs replacement.

Modifications are dangerous and can have a serious unseen effect on

safety and therefore MUST not be done. Replacements must be original manufacturers parts. Re-assemble in the reverse of removal.

Ensure setting pressures are as stated in Section 3; Appliance Data.

It is recommended that the catalysts are inspected for signs of damage

and dirt during routine servicing procedures. The expected life of the

catalysts is in excess of 11,000 hours (10 years of normal use). After

this time the catalyst should be replaced. If there are any deposits of dirt

or soot on the catalysts they should be cleaned with a soft brush and a

vacuum cleaner. If removed for cleaning ensure the seals are in good

condition before replacing the catalyst. New seals will usually be

required.

The performance of the catalyst may be checked using a combustion

gas analyzer as follows. Important: The temperature of the gases

emitted by the catalytic converters is in excess of 700 oF. Measuring gas

of this temperature may damage some types of gas analyzers. If in

doubt consult the equipment manufacturer.

Turn on the fireplace as per the operating instructions, and run at

maximum setting for 15 minutes. Position gas sample probe directly

over a catalyst via the outlet grille, on top of the appliance. Record the

carbon dioxide (CO2) concentration and then the carbon monoxide

(CO) concentration as displayed by the analyzer - also noting the units

in which the values are expressed. Most analyzers display carbon

dioxide (CO2) concentrations in percentage (%) terms and carbon

monoxide concentration in parts per million (ppm) terms.

In order to calculate the combustion ratio for the appliance (CO/CO2) it

is first necessary to express both gas concentrations in terms of percentage. To convert from parts per million (ppm) to a percentage (%)

divide the ppm figure by 10,000. Examples : 35ppm = 0.0035%, 15ppm

= 0.0015%, 5ppm = 0.0005%.

Now divide the concentration of carbon monoxide (CO) expressed in

percent by the concentration of carbon dioxide (CO2) to obtain the

appliance combustion ratio.

The combustion ratio of the gasses emitted by the catalytic convertor

should not exceed 0.0015. If replacing, firstly, remove the glass facia as

described in section 15.0. The catalysts are located on the top of the

internal firebox and can be removed be unscrewing the retaining nuts

securing the clamping plate. Remove the catalysts and seals and

discard. Refit a new catalysts and seals in reverse order, ensure the

catalysts and door have good seals.

Appliances that are several years old or have been extensively dismantled should be checked for soundness. It is important that all the products of combustion pass through the catalytic converters at the top of

the firebox before leaving the appliance.

The firebox is heated by lighting for a few minutes to provide a flow

through the firebox. The burner is then shut off and a smoke pellet or

match introduced at the base of the fire underneath the burner tray.

Large quantities of smoke will emerge from the top of the appliance, but

none should emerge from the joints or gasket faces, especially around

the door. It is important to note that the appliance can never be expected to be 100% smoke tight and small quantities of smoke may be seen

in corners of joints and gasket faces etc without affecting safety when

the fire is in operation.

GLASS PANEL -This can be cleaned with a suitable glass cleaner. The

following solutions are approved for use to clean glass.

• Non-ammonia based household cleaner

• 50% -50% mix of white vinegar and water

• Gas fireplace/stove glass cleaner

Test on a small area first.

PAINTED AREAS - These can be cleaned using a dry cloth.

FINISHED METAL AREAS - These can either be cleaned using a

proprietary metal cleaner or baby oil. Test on a small hidden part before

cleaning. Always clean in the direction of the grain.

10

22.0 CATALYSTS

CO (%)

CO2 (%) = ratio

23.0 TESTING FOR FIREBOX LEAKAGE

24.0 CLEANING

21.0 PILOT ASSEMBLY

NO ADJUSTMENTS ARE TO BE MADE TO THE ODS

PILOT SYSTEM. TAMPERING WITH THIS SYSTEM

CAN BE EXTREMELY HAZARDOUS.

WARNING

DONOT BLOCK THE CATALYSTS OR THE

APPLIANCE OUTLET GRILLE. BLOCKAGE MAY

CAUSE HIGH CARBON MONOXIDE LEVELS AND/OR

BREAKAGE OF THE GLASS FACIAPANEL.

WARNING

DO NOT OPERATE THE APPLIANCE WITH THE

CATALYST UNITS REMOVED.

WARNING

Figure 18

DO

NOT BLOCK

THESE AREAS

TURN OFF THE UNVENTED GAS ROOM HEATER

AND ALLOW TO COOLBEFORE CLEANING.

WARNING

Page 11

11

FOR YOUR SAFETY READ BEFORE LIGHTING

A. This heater has a pilot which must be lit by hand. When

lighting the pilot, follow these instructions exactly.

B. BEFORE OPERATING smell all around the heater area for gas.

Be sure to smell next to the floor because some gas is

heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by hand, do

not try to repair it, call a qualified service technician. Forced or

attempted repair may result in a fire or explosion.

D. Do not use this heater if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

25.0 LIGHTING INSTRUCTIONS

1. Stop! Read the safety information above.

2. Make sure manual shut-off valve is fully open.

3. Open the access panel.

4. Depress control knob in and turn clockwise to the

“OFF” position ( Figure 19 ).

5. Wait 5 minutes to clear out any gas. Then smell for gas, including near

the floor. If you smell gas, STOP! Follow the safety instructions in “What

to do if you smell gas” under section ‘B’ above. If you do not smell gas,

go to next step.

6. The pilot is located on the left side behind the burner (Figure 20).

7. Depress control knob in and turn counterclockwise

to the “SPARK” position ( Figure 19 ) and hold there for a few seconds.

Note: If you are running the heater for the first time or after an extended

period of non use it will be necessary to press the control knob all the

way in for 30 seconds to allow air to bleed out of the gas piping.

8. Continue turning counterclockwise through the spark

click to the PILOT light position, ensuring the pilot has lit. If not, turn the

knob fully clockwise, and repeat.

9. Hold the control knob in for a further 10 seconds to prevent the flame

failure detector from shutting off the gas while the probe is warming up.

10. Release the control knob while turning counterclockwise

to the preferred setting. Close the control access panel.

• If the knob does not pop out when released, stop and immediately call

your service technician or gas supplier.

• If the pilot will not stay lit after several tries, depress and turn the gas

control knob clockwise to “OFF”and wait 30 seconds.

Depress and turn knob counterclockwise to “SPARK” and

ignite the heater again. If your pilot does not relight depress and turn

control knob clockwise to “OFF” and call your service

technician or gas supplier.

11. Wait 30 seconds before readjusting the heater when the control knob

has been turned down to a lower setting.

26.0 TO TURN OFF GAS TO APPLIANCE

2. Depress and turn control knob clockwise to the “OFF”

position (Figure 19). Close the control access panel.

1. Open the control access panel.

Figure 20: Pilot unit. This is located behind

the burner, on the left-hand side of the

appliance.

Figure 20

The control knob is located on the lower right

hand side of the outer case. It is of a

spherical design and is marked as shown in

figure 19

Page 12

12

Fire sparks but pilot does not light No gas to Pilot, check the gas line connections.

Air not fully purged, repurge supply or wait longer.

Spark grounding to metal work, reset gap correctly.

Blocked pilot, clean out internally.

Pilot lights but then goes out Severe restriction in gas supply: clear obstruction.

Faulty thermocouple, replace pilot unit.

Blocked pilot, clean out.

Blocked lint gauze, clean.

Hold control knob in for longer.

Check control knob does not foul data plate.

If the pilot will not stay lit there is a problem with dirt, the gas supply, or the thermocouple needs

replacement. Modifications are dangerous and can have a serious unseen effect on safety.

NEVER MODIFY OR BEND THE THERMOCOUPLE TO MAKE THE PILOT STAY LIT.

Fire does not spark at pilot HT lead detached, refit.

Check the spark gap (see section 14.0).

Faulty piezo unit, replace.

Debris shorting out electrode, clean.

Spark shorting to metalwork under tray, realign HT lead.

Fire runs for a time and then cuts off Loose or faulty thermocouple, rectify.

Blocked pilot, clean out.

Dirt or lint in pilot aeration hole or on the lint gauze, clean thoroughly.

If the pilot will not stay lit there is a problem with dirt, the gas supply, or the thermocouple needs

replacement. Modifications are dangerous and can have a serious unseen effect on safety.

NEVER MODIFY OR BEND THE THERMOCOUPLE TO MAKE THE PILOT STAY LIT.

Pilot flame shrinks when fire is on high Poor gas flow to fire, check pressure with fire on high.

If pressure is low, remove any restriction in pipework or valve.

Check all pipework is adequately sized.

Check meter pressure is adequate.

If the pilot will not stay lit there is a problem with dirt, the gas supply, or the thermocouple needs

replacement. Modifications are dangerous and can have a serious unseen effect on safety.

NEVER MODIFY OR BEND THE THERMOCOUPLE TO MAKE THE PILOT STAY LIT.

Fire smells when first lit or in use Newness smell from brand new appliance.

Leakage occurring. Carry out leakage test and rectify any problems.

Combustible materials used in incorrect positions.

Unit may require a service to remove dust from catalysts.

27.0 TROUBLESHOOTING GUIDE

28.0 REPLACEMENT PARTS

Description Catalog No.

Glass door assembly H6055

Gas valve H6059

Catalyst H6060

Pilot assembly H6061

Burner assembly H6056

Catalyst seal kit H6062

Inlet pressure regulator H6063

Decorative glass facia H6068

When ordering spare parts, always give the following information:

1. The model number of the heater.

2. The serial number of the heater.

3. The part number.

4. The description of the part.

5. The quantity required.

6. The installation date of the heater.

If you encounter any problems, require spare parts, or have any

questions concerning the installation of the heater please contact your

distributor. For the name of your nearest distributor contact:

LENNOX HEARTH PRODUCTS

1110 West Taft Avenue

Orange, CA 92865

Phone: 1-800-9-Lennox

visit us at www.Lennox.com

Page 13

13

Figure 22

Figure 21: Removal and refitting of glass

door assembly and burner assembly.

Figure 22 : Visual check

for correct pilot flame.

29.0 POSITIONING OF FIELD REMOVABLE PARTS

Figure 21

4 off burner installation positions

FAILURE TO POSITION THE PARTS

IN ACCORDANCE WITH THESE

DIAGRAMS OR FAILURE TO USE

ONLY PARTS SPECIFICALLY

APPROVED WITH THIS HEATER

MAY RESULT IN PROPERTY

DAMAGE OR PERSONAL INJURY.

WARNING

Page 14

1110 West Taft Avenue • Orange, CA 92865

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

Lennox reserves the right to make changes at any time, without notice, in design,

materials, specifications, prices and also to discontinue colors, styles and products.

Consult your local dealer or distributor for fireplace code information.

LENNOX HEARTH PRODUCTS

P/N 850,054M REV. NC 04/2007

Lennox Hearth Products Gas Fireplaces, Stoves and Inserts

20 Year Limited Warranty

THE WARRANTY

Lennox Hearth Products ("LHP") warrants your gas fireplace, appliance, stove or insert ("Product") to be free from defects in materials and workmanship at the time of manufacture. After

installation, if any of the components manufactured by LHP in the Product are found to be defective in materials or workmanship during the twenty year warranty period and while the

Product remains at the site of the original installation, LHP will, at its option, replace or repair the defective components. LHP will also pay for reasonable labor costs incurred in replacing

or repairing such components for a period of one year from the date of installation. THERE ARE EXCLUSIONS AND LIMITATIONS to this Limited Warranty as described herein.

EXCLUSIONS AND LIMITATIONS

This Limited Warranty applies only if the Product is installed in the United States or Canada and only if operated and maintained in accordance with the printed instructions accompanying

the Product and in compliance with all applicable installation and building codes and good trade practices. If repair or replacement is not commercially practical, LHP will, at its option,

refund the purchase price of the LHP Product.

The firebox and enclosure are warranted for twenty (20) years from the date of installation as follows: First year - parts at no charge and reasonable labor charges. Second through fifth

year - parts only at no charge. Sixth through twentieth year - parts only at 50% of the then current list price. Vent components, brass components, paint, optional accessories and optional

glass doors are excluded from this Limited Warranty. A separate limited warranty is available from LHP for optional glass doors manufactured by LHP. The following components are

NOT warranted for 20 years but are warranted as follows:

Controls - repair or replacement for one year from the date of installation.

Burner - repair or replacement for one year from the date of installation.

Glass Components - repair or replacement for one year from the date of installation. Ceramic glass is warranted against thermal breakage only for a period of

two years from date of installation.

Gaskets - repair or replacement for one year from the date of installation.

Logs - repair or replacement for one year from the date of installation.

Catalyst - two years parts and labor, 3-5th year, parts only from the date of installation.

We will not be responsible for: (a) damages caused by accident, riot, fire, flood or acts of God; (b) damages caused by abuse, negligence, misuse, or unauthorized alteration or repair

of the Product affecting its stability or performance (The Product must be subject to normal use. The Product is designed to burn either natural or propane gas only. Burning conventional

fuels such as wood, coal or any other solid fuel will cause damage to the Product, will produce excessive temperatures and will result in a fire hazard); (c) damages caused by failing to

provide proper maintenance and service in accordance with the instructions provided with the Product; (d) damages, repairs or inefficiency resulting from faulty installation or application

of the Product.

Page 15

INSTRUCCIONES DE INSTALACIÓN Y OPERACIÓN

Chimenea catalítica de pared

sin salida de humos

Modelo : Scandium-NG

P/N 850,055M Rev. NC, 04/2007

Instalador: Deje este manual junto al aparato.

Consumidor: Guarde este manual para su consulta en el futuro.

En el Estado de Massachusetts:

• La instalación debe ser realizada por un plomero o

gasista matriculado o con licencia.

• Consulte este manual, donde encontrará

otros requisitos del Estado de Massachusetts.

PARA SU SEGURIDAD

No guarde ni utilice gasolina u otros vapores o líquidos inflamables cerca de este o de otros aparatos.

QUÉ HACER SI USTED NOTA OLOR A GAS:

• NO ENCIENDA ningún aparato eléctrico.

• NO TOQUE ningún interruptor eléctrico.

• No utilice ningún teléfono de su edificio.

• Llame inmediatamente a su compañía de gas desde el teléfono de un vecino. Siga las instrucciones de la

compañía de gas.

• Si no puede contactar con su compañía de gas, llame a los bomberos.

La instalación y el mantenimiento deben ser realizados por un instalador o empresa de mantenimiento autorizado,

o por la compañía de gas.

• ¡Caliente! ¡No tocar! Este aparato alcanza altas temperaturas durante su uso y las conserva durante un tiempo

después de apagarlo. Pueden producirse quemaduras graves.

• Supervise con atención a los niños que estén en la misma habitación que el aparato.

• Debido a las altas temperaturas generadas, el aparato debe ubicarse en un lugar con poco tránsito, alejado de

muebles y cortinas. No coloque ropa ni otros materiales sobre o cerca de este aparato.

• La instalación, el ajuste, la modificación, la revisión o el mantenimiento inadecuados pueden causar daños

materiales o lesiones personales. Consulte este manual. Si necesita ayuda o información adicional, consulte a un instalador

calificado, a una empresa de mantenimiento o a la compañía de gas.

• No haga un fuego de leña. No queme madera ni otros materiales en este aparato.

• Éste es un calentador de gas sin salida de humos. Consume aire (oxígeno) de la habitación en la que está instalado. Es necesario

proporcionar un suministro adecuado de aire de combustión y ventilación. Consulte la sección Aire de combustión y ventilación.

• Este aparato puede ser instalado en una casa prefabricada (móvil) con ubicación permanente una vez adquirida, siempre que no

lo prohíba la normativa local.

• El aparato debe utilizarse únicamente con el tipo de gas indicado en la placa de características. Este aparato no es convertible

para el uso con otros gases.

Scandium

ADVERTENCIAS

TM

ADVERTENCIA: Si no se siguen exactamente las indicaciones de este manual, puede producirse un incendio o una explosión

y provocar daños materiales, lesiones personales o pérdida de la vida.

317-S-05-5

Informe N°:

Page 16

16

Este aparato es un calentador de gas de alta eficacia, sin salida de humos,

con efecto de llama. Proporciona calor por radiación y por convección de

manera eficiente y segura, utilizando las últimas tecnologías de combustión

con conversión catalítica. El aparato no necesita ningún sistema de

evacuación de humos, puesto que el convertidor catalítico limpia los

residuos, proporcionando un completo sistema de combustión, que es

intrínsecamente seguro.

Estos calentadores incorporan un piloto de diseño especial que utiliza un

sensor de agotamiento de oxígeno (ODS) que detecta la cantidad de

oxígeno que queda en la habitación y apaga el calentador antes de que el

nivel de oxígeno caiga por debajo del 18%. El piloto sólo puede ser

encendido de nuevo cuando haya suficiente aire fresco. Consulte la sección

Aire de combustión y ventilación.

El diseño del aparato permite su instalación en diferentes situaciones, según

se indica en los Requisitos de instalación.

Este aparato viene ajustado de fábrica para el tipo de gas y la presión

indicados en la placa de características del aparato.

Al encender por primera vez un aparato nuevo, se produce el curado inicial

de la pintura para altas temperaturas y se queman los lubricantes durante

las primeras horas de funcionamiento. Durante este periodo es posible que

se emita cierta cantidad de humo por la rejilla de salida; esto es normal y no

debe ser causa de preocupación. Por ello, la habitación debe ventilarse

bien, dejando abiertas todas las puertas y ventanas durante este periodo.

Lea todas estas instrucciones antes de comenzar la instalación. Todas las

instrucciones deben ser entregadas al usuario para su conservación.

Recomendamos que nuestros

productos de gas sean

instalados y mantenidos por

profesionales autorizados en

los EE.UU. por el National

Fireplace Institute® (NFI) como

Especialistas de Gas del NFI.

CANTIDAD DESCRIPCIÓN

1 Conjunto de cámara de combustión y quemador

1 Instrucciones de instalación y operación

1 Conjunto de panel decorativo de vidrio

1 Plantilla de instalación

1 Paquete de tornillos y tacos de pared

1 Pasamuros de goma

Sección Contenido Página Nº

1.0 Información general 16

2.0 Lista de embalaje 16

3.0 Especificaciones del aparato 16

4.0 Información de seguridad importante 16

5.0 Normativa 18

6.0 Aire de combustión y ventilación 18

7.0 Requisitos del lugar de ubicación 18

8.0 Preparación del aparato 19

9.0 Montaje del aparato 19

10.0 Comprobación del quemador 20

11.0 Conexión de un conducto de gas 20

12.0 Comprobación de las conexiones de gas 21

13.0 Comprobación de la presión del gas 21

14.0 Espacio entre electrodos 21

15.0 Armado del panel decorativo de vidrio 21

16.0 Montaje del panel decorativo de vidrio 22

17.0 Colocación de los paneles laterales 22

18.0 Información al cliente 23

19.0 Mantenimiento 23

20.0 Mantenimiento del quemador 23

21.0 Montaje del piloto 24

22.0 Catalizadores 24

23.0 Comprobación de fugas de la cámara de combustión 24

24.0 Limpieza 24

25.0 Instrucciones de encendido 25

26.0 Cómo cerrar el paso de gas al aparato 25

27.0 Guía de solución de problemas 26

28.0 Repuestos 26

29.0 Ubicación de piezas ensambladas in situ 27

1.0 INFORMACIÓN GENERAL

2.0 LISTA DE EMBALAJE

4.0 INFORMACIÓN DE SEGURIDAD IMPORTANTE

CONTENIDO

3.0 ESPECIFICACIONES DEL APARATO

Tipo de gas Gas natural

Presión de entrada de gas Máxima 10,5” cda

Mínima 6” cda

Ajuste de presión del regulador 5” cda

Consumo máximo de energía

11.950 BTU/h

Consumo mínimo de energía

6.820 BTU/h

Consumo de energía del piloto 560 BTU/hora

Presión del quemador (colector) Alta 2,4” cda

Baja 0,8” cda

Restricción de caudal del quemador principal 2 mm (0,079”)

Piloto con sensor de oxígeno SIT/Bray 9082

Conexión de entrada de gas 3/8” NPT en el regulador

Encendido Piezoeléctrico, por chispa

Espacio entre electrodos 1/8” - 3/16”

Consulte en la placa de características fijada al aparato las especificaciones

actuales.

Este aparato debe utilizarse únicamente con el tipo de gas y a la presión

indicados en la placa de características del aparato.

EN EL SIGUIENTE RECUADRO SE INDICAN LOS REQUISITOS

ESPECÍFICOS DEL ESTADO DE MASSACHUSETTS.

Nota: Los siguientes requisitos se refieren a diversos códigos del Estado de

Massachusetts y de EE.UU. no contenidos en este documento.

Los calentadores sin salida de humos deberán instalarse según lo establecido

en 527 CMR 30 y 248 CMR de 3 a 7:

(a) Permisos e inspecciones: Deben satisfacerse los siguientes requisitos,

además de los establecidos en 248 CMR 3.05:

1. Deberá obtenerse un permiso del jefe de bomberos y del inspector de gas

local o estatal competentes en la instalación de calentadores de gas natural o

propano sin salida de humos.

2. El otorgamiento del permiso quedará supeditado a la inspección y aprobación

finales de la instalación por el jefe de bomberos y el inspector de gas local o

estatal competentes.

3. Deberá presentarse una copia de los manuales de instalación y operación del

fabricante con cada solicitud de permiso.

4. Antes de poner en funcionamiento el aparato, el jefe de bomberos y el

inspector de gas local o estatal deberán inspeccionar la instalación para

determinar su cumplimiento con lo establecido en 527 CMR (Board of Fire

Prevention Regulations [Junta de reglamentación para la prevención de

incendios]) y 248 CMR (Board of State Examiners of Plumbers and Gas Fitters

[Junta de evaluación estatal de plomeros y gasistas]).

LEA Y COMPRENDA COMPLETAMENTE ESTAS

INSTRUCCIONES ANTES DE INSTALAR O PONER EN

FUNCIONAMIENTO SU CALENTADOR SIN SALIDA DE HUMOS.

IMPORTANTE

Page 17

• Es necesario advertir a niños y adultos del peligro de la alta temperatura de

la superficie, y éstos deben mantenerse alejados para evitar quemaduras o

que se les prenda fuego la ropa.

• Es necesario supervisar cuidadosamente a los niños pequeños cuando estén

en la misma habitación que el calentador.

• No coloque ropa ni otros materiales inflamables sobre o cerca del calentador.

• Debe volver a colocarse cualquier rejilla o protector de seguridad que se haya

retirado para efectuar tareas de mantenimiento en el calentador antes de

ponerlo en funcionamiento.

• La instalación y las reparaciones deben ser realizadas por un profesional de

mantenimiento calificado. El calentador debe ser inspeccionado antes del uso,

y al menos una vez por año, por un profesional de mantenimiento calificado.

Puede ser necesario limpiar más a menudo debido a pelusas provenientes de

moquetas y alfombras, ropa de cama, etc. Es importante mantener limpios los

compartimentos de control, los quemadores y los pasos de aire del calentador.

• Deje que se enfríe el calentador antes de realizar tareas de mantenimiento.

Cierre siempre el paso de gas al calentador al realizar trabajos de

mantenimiento.

• La instalación debe realizarse de acuerdo con la normativa local, o en su

ausencia, con el National Fuel Gas Code (Código Nacional del Gas), ANSI

Z223.1.

• El calentador y su llave de paso individual deben ser desconectados del

sistema de tuberías de suministro de gas durante la realización de pruebas del

sistema de tuberías de suministro de gas a una presión superior a 1/2 psig.

• El calentador debe ser aislado del sistema de tuberías de suministro de gas

cerrando su llave de paso manual individual durante cualquier prueba de

presión del sistema de tuberías de suministro de gas a una presión de prueba

igual a o menor de 1/2 psig.

• Mantenga la zona del calentador despejada y libre de materiales

combustibles, gasolina y otros vapores y líquidos inflamables.

• No utilice este calentador si cualquier parte del mismo ha estado sumergida

en agua. Llame inmediatamente a un técnico de mantenimiento calificado para

que inspeccione el calentador y cambie cualquier pieza del sistema de control

y cualquier control de gas que haya estado sumergido en agua.

• Las cifras de consumo se indican en BTU por hora, y son para altitudes de

hasta 4.500 pies. Si estos aparatos se instalan a altitudes superiores a los

4.500 pies, es posible que a veces se apague el piloto y ocasione molestias.

No instale este calentador a altitudes de más de 4.500 pies si el suministro de

gas no ha sido ajustado para dicha elevación. Consulte a su compañía de gas

local.

• Asegúrese de que el calentador está limpio durante el funcionamiento. Una

acumulación excesiva de polvo en el quemador aumentará la cantidad de

monóxido de carbono formada, y podría ser causa de envenenamiento por

monóxido de carbono y/o la muerte.

• Las chimeneas de gas sin salida de humos están diseñadas para usarse

como calentadores complementarios. No están concebidas para usarse de

manera continua como principal fuente de calefacción.

17

4.0 INFORMACIÓN DE SEGURIDAD IMPORTANTE (cont.)

5. El inspector de gas estatal o local no realizará la inspección final del

calentador sin salida de humos hasta que se demuestre que el jefe de

bomberos competente ha otorgado su permiso.

(b) Los calentadores de gas natural sin salida de humos deben cumplir con la

norma ANSI Z21.11.2, estar equipados con un sistema de apagado de

seguridad por agotamiento de oxígeno (ODS) y contar con la aprobación

establecida en 248 CMR.

(c) Los calentadores de gas natural sin salida de humos deben instalarse según

sus especificaciones y las instrucciones del fabricante. Debe mantenerse el

espacio libre adecuado hasta los materiales combustibles. En ningún caso las

características del espacio libre obstaculizarán el aire de combustión ni la

accesibilidad.

(d) Las instalaciones deberán ser de tipo permanente y contar con un

suministro de combustible de tubería permanente según las disposiciones de

248 CMR. Los aparatos de gas LP deberán cumplir con los requisitos de

almacenamiento establecidos en 527 CMR 6. Están prohibidos los calentadores

portátiles de gas natural o sin salida de humos.

(e) Está prohibido el uso de calentadores de gas natural sin salida de humos en

dormitorios y baños.

(f) Debe determinarse correctamente el tamaño del calentador para la

habitación o el espacio de instalación y en ningún caso deberá superar una

entrada de 40.000 BTU, como máximo, por habitación o espacio.

(g) En las viviendas con un calentador de gas natural sin salida de humos,

deberá instalarse y mantenerse, como mínimo, un detector de monóxido de

carbono aprobado cerca del espacio donde está ubicado el calentador. Dicho

detector se instalará según las instrucciones del fabricante.

1. Como condición previa, en todo edificio en el que se vaya a instalar el

calentador deberá haber detectores de humo en buen estado de operación,

cuya instalación y mantenimiento deberán cumplir con los requisitos de 780

CMR (State Board of Building Regulations and Standards [Junta estatal de

reglamentos y normas de la construcción]) vigentes en el momento de la

construcción, o bien

2. Si, en el momento de la construcción, no se encontraba vigente ningún

requisito, el detector de humo deberá cumplir con las disposiciones de M.G.L.

c. 148, § 26E e instalarse según ellas.

(h) En las habitaciones y los edificios en los que se utilice un calentador de gas

natural sin salida de humos, deberá instalarse y mantenerse de forma

permanente una fuente principal de calor operativa en el edificio según las

disposiciones de 105 CMR (Departamento de Salud Pública).

(i) El vendedor de un calentador de gas natural sin salida de humos debe

proporcionar a cada comprador una copia de 527 CMR 30 en el momento de la

venta de la unidad.

• La instalación y las reparaciones deben ser realizadas por un plomero o

gasista matriculado o con licencia en el Estado de Massachusetts.

• El conector flexible de la tubería de gas no deberá superar los 92 centímetros

(36 pulgadas) de largo.

•Cada llave de paso manual debe ser de un tipo con manija en T.

EL NO MANTENER LIMPIA(S) LA(S) ABERTURA(S)

PRINCIPAL(ES) DE VENTILACIÓN DEL/DE LOS QUEMADOR(ES)

PUEDE PRODUCIR HOLLÍN Y DAÑOS MATERIALES.

ADVERTENCIA

EN EL SIGUIENTE RECUADRO SE INDICAN LOS REQUISITOS

ESPECÍFICOS DEL ESTADO DE MASSACHUSETTS.

Nueva York: Este aparato está homologado para su instalación en el

Estado de Nueva York, EE.UU., pero no en la Ciudad de Nueva York.

EL INCUMPLIMIENTO DE LAS INSTRUCCIONES DE INSTALACIÓN Y

SEGURIDAD PROPORCIONADAS EN ESTE DOCUMENTO DARÁ

LUGAR A UN APARATO MAL INSTALADO DE FUNCIONAMIENTO

INCORRECTO, ANULANDO SU GARANTÍA. CUALQUIER

MODIFICACIÓN DE ESTE APARATO Y/O SUS CONTROLES DE

OPERACIÓN ES PELIGROSO. LA INSTALACIÓN O EL USO

INCORRECTOS DE ESTE APARATO PUEDEN CAUSAR GRAVES

LESIONES O LA MUERTE POR INCENDIO, QUEMADURAS, EXPLOSIÓN

O ENVENENAMIENTO POR MONÓXIDO DE CARBONO.

ADVERTENCIA

VERIFIQUE EL TIPO DE GAS: EL SUMINISTRO DE GAS DEBE

COINCIDIR CON EL INDICADO EN LA PLACA DE

CARACTERÍSTICAS DEL APARATO. SI ES DIFERENTE, NO

INSTALE ELAPARATO. SOLICITE EL MODELO CORRECTO ASU

DISTRIBUIDOR.

ADVERTENCIA

Page 18

Ejemplo:

Calentador sin salida de humos N° 1 9.000 BTU/h

Calentador sin salida de humos N° 2 23,000 BTU/h

Aparato de gas Nº 1 35.000 BTU/h

(calentador de agua)

Total = 67.000 BTU/h

* No incluya aparatos de gas con salida de humos directa. La salida de humos

directa tiene combustión sellada y aspira el aire de combustión desde fuera.

El espacio del ejemplo anterior es un espacio confinado porque las BTU/h reales

consumidas son más del máximo de BTU/h que el espacio puede soportar.

Usted debe proporcionar aire fresco adicional. Sus opciones son:

a. Vuelva a calcular las ecuaciones sumando el espacio de una o más

habitaciones colindantes. Si con el volumen adicional se obtiene un espacio no

confinado, elimine una puerta o añada rejillas de ventilación entre las

habitaciones. Consulte el National Fuel Gas Code, ANSI Z223,1, Sección 5.3.

b.

Proporcione ventilación directa de la habitación con el exterior. Consulte el

National Fuel Gas Code, ANSI Z223,1, Sección 5.3.

c. Instale un calentador de menos BTU/H para convertir el área en un espacio

no confinado.

Si el consumo real de BTU/h es menor que el máximo de BTU/h que puede

soportar el espacio, entonces el espacio es un espacio no confinado. Usted no

necesita ventilación adicional alguna para un espacio no confinado.

Este aparato está diseñado para ser colgado en una pared. No empotre

ninguna parte del aparato en la pared. Este aparato puede instalarse en

cualquier habitación de la casa, salvo en dormitorios y baños o en zonas

en las que es probable que se generen grandes cantidades de vapor.

Debe tenerse en cuenta que estos calentadores generan corrientes de

aire caliente. Estas corrientes mueven el calor a las superficies de las

paredes al lado del calentador. Si se instala el calentador al lado de

revestimientos vinílicos o textiles para paredes, o si se utiliza el

calentador en un lugar en el que existen impurezas en el aire (como

humo de cigarrillo o de velas), puede alterarse el color de las paredes.

Es habitual instalarlo en una sala de estar; no obstante, se permite la instalación

en otras habitaciones tales como cocinas, comedores y pasillos, siempre que

esté disponible un suministro de gas natural, y que la habitación cumpla

estrictamente los requisitos de tamaño y ventilación (ver Sección 4).

El aparato está diseñado para ser versátil, y como tal, funcionará correctamente

en presencia de las corrientes de aire suaves que normalmente se producen

dentro de una casa. No obstante, no se recomienda que se instale el aparato en

zonas en las que probablemente quede expuesto a corrientes fuertes continuas

generadas por puertas o ventanas al exterior, huecos de ventilación, etc. Se