Page 1

B-VENT GAS

FIREPLACE

HEATER INSERTS

RETAIN THIS MANUAL FOR

FUTURE REFERENCE

Suitable for installation

into masonry or factory

built fi replaces

Report No. 116-F-15-5

HOMEOWNER'S CARE AND

OPERATION INSTRUCTIONS

Lennox Elite® Series Models: EBVI25 & EBVI30

P/N 775,155M Rev. D,12/2005

WARNINGS

• Hot! Do not touch! The glass and surfaces of this appliance

will be hot during operation and will retain heat for a while

after shutting off the appliance. Severe burns may result.

• Carefully supervise children in the same room as appliance.

• If small children are present in the home, it is recommended

that this appliance be fi tted with a screen door or screen panel

kit. See Page 12 for ordering information.

WARNING: IF THE INFORMATION IN THIS MANUAL

IS NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE,

PERSONAL INJURY OR LOSS OF LIFE.

FOR YOUR SAFETY

Do not store or use gasoline or other fl ammable

vapors or liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS:

• DO NOT light any appliance.

• DO NOT touch any electrical switches.

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow your gas supplier's

instructions.

• If your gas supplier cannot be reached, call

the fi re department.

Installation and service must be performed by a qualifi ed installer, service agency or the gas supplier.

AVERTISSEMENT: ASSUREZ-VOUS DE BIEN SUIVRE

LES INSTRUCTIONS DONNÉ DANS CETTE NOTICE

POUR RÉDUIRE AU MINIMUM LE RISQUE D’INCENDIE

OU POUR ÉVITER TOUT DOMMAGE MATÉRIEL, TOUTE

BLESSURE OU LA MORT.

POUR VOTRE SÉCURITÉ: Ne pas entreposer ni utiliser

d’essence ni d’autre vapeurs ou liquides infl ammables dans

le voisinage de cet appareil ou de tout autre appareil.

POUR VOTRE SÉCURITÉ: Que faire si vous sentez une

odeur de gaz:

• Ne pas tenter d’allumer d’appareil.

• Ne touchez à aucun interrupteur. Ne pas vous servir

des téléphones se trouvant dans le batiment où vous

vous trouvez.

• Evacuez la piéce, le bâtiment ou la zone.

• Appelez immédiatement votre fournisseur de gaz

depuis un voisin. Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de gaz,

appelez le service dos incendies.

L’installation et service doit être exécuté par un qualifi é

installeur, agence de service ou le fournisseur de gaz.

Page 2

CONGRATULATIONS ON THE PURCHASE OF YOUR NEW GAS APPLIANCE MANUFACTURED BY LENNOX HEARTH PRODUCTS.

When you purchased your new gas-fi red heater, you joined the ranks of thousands of

individuals whose answer to their home heating needs refl ects their concern for effi ciency

and our environment. We extend our continued support to help you achieve the maximum

benefi t and enjoyment available from your new gas-fi red heater. It is our goal at Lennox

Hearth Products to provide you, our valued customer, with an appliance that will ensure

years of trouble-free warmth and pleasure.

Thank you for selecting a Lennox Hearth Products gas-fi red heater as the answer to

your home heating needs.

Sincerely,

All of us at Lennox Hearth Products

WARNING

These fireplace Inserts are

vented heaters. Do not burn

wood or other material in these

appliances.

GENERAL INFORMATION

Installation, repair and annual service inspection should be performed by a qualifi ed

service technician.

TABLE OF CONTENTS

Introduction ......................................Page 2

General Information ..........................Page 2

Burn-In Period ..................................Page 3

Lighting Millivolt Appliances .............Page 3

Gas Controls .....................................Page 3

Control Compartment Access ...........Page 4

Operation & Care of Your Appliance ..Page 4

Maintenance Procedures ...................Page 4

Maintenance Schedule ......................Page 6

Front Glass Door Assembly,

Removal and Installation .................Page 7

Burner Adjustments ..........................Page 7

Flame Appearance and Sooting .........Page 7

Log Placement Instructions ..............Page 8

Millivolt Appliance Checkout .............Page 11

Blower Operation ..............................Page 11

Fireplace Requirements .....................Page 11

Wiring Diagrams ...............................Page 11

Warranty Information ........................Page 12

Accessory Components ....................Page 12

Lighting Instructions – Millivolt ........Page 15

Replacement Parts List .....................Page 17

Troubleshooting Guide ......................Page 19

INTRODUCTION

The Insert model covered in this manual is

a B-Vent gas heater designed for residential

application for installation into an existing

masonry or factory built solid-fuel fi replace

using 4" diameter, UL1777 listed aluminum

liner for the exhaust. The vent must be routed

through the existing fi replace fl ue system to the

vent termination.

This millavolt appliance is designed to operate

on either natural or propane gas. A millivolt

gas control valve with piezo ignition system

provides safe, effi cient operation. External

electrical power is required to operate the air

circulation blower.

2

This appliance complies with National

Safety Standards and is tested and listed

by OMNI-Test Laboratories Inc.; Beaverton,

Oregon (Report No. 116-F-15-5) to ANSI

Z21.88-2002 (in Canada, CSA-2.33-2002),

and CAN/CGA-2.17-M91 in both USA and

Canada, as vented gas heaters.

Installation must conform to local codes. In

the absence of local codes, installation must

comply with the current National Fuel Gas

Code, ANSI Z223.1. (In Canada, the current

CAN-1 B149 installation code.) Electrical

wiring must comply with the National Electrical Code ANSI/ NFPA 70 - latest edition.

In Canada, the current CSA C22-1 Canadian

Electrical Code - latest edition.

WARNING

Do not attempt to alter or modify

the construction of the appliance

or its components. Any modifi cation or alteration may void

the warranty, certifi cation and

listings of this unit.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause injury

or property damage. Refer to

this manual. For assistance or

additional information consult

a qualifi ed installer, service

agency or the gas supplier.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

It is imperative that the control compart-

ment, burners and circulating air passage

ways of the appliance be kept clean.

S'assurer que le brùleur et le compartiment

des commandes sont propres. Voir les

instructions d'installation et d'utilisation

qui accompagnent l'appareil.

Provide adequate clearances around air openings

and adequate accessibility clearance for service

and proper operation.

Never obstruct the front openings of the

appliance.

Due to high temperatures of this appliance

adequate clearances need to be maintained from

furniture and draperies and other combustibles.

Locate furniture and window coverings accordingly.

The recommended clearance zone from

the front of the appliance to combustibles is 36

inches (914 mm)

as outlined in the Installation Manual.

These fi replaces are designed as supplemen-

tal heaters. Therefore, it is advisable to have

an alternate heat source when installed in a

dwelling.

Input of millivolt model is variable. The rates

are shown in the following table:

MAnnually-Modulated Gas Valves

Model No. Input Rate

EBVI25 17,000 to

EBVI30 21,500 to

Table 1

. Maintain all other clearances

Millivolt Models with

Nat. Gas Propane

(BTU/HR)

25,000

30,000

Input Rate

(BTU/HR)

19,500 to

25,000

22,000 to

28,000

Page 3

Table 2 shows the main burner gas orifi ce

size for the elevations indicated.

Model

No.

EBVI25 #41

EBVI30 #37

Orifi ce Size Elevation

Nat.

Gas

(.096")

(.104")

Prop.

Gas

#53

(.0595")

1/16"

(.0625")

(meters)

0-4500

(0-1372)

0-4500

(0-1372)

Feet

Table 2

Tables 3 and 4 show the gas pressure

requirements for all models:

Inlet Gas Supply Pressure (all models)

Fuel # Minimum Maximum

Natural Gas 4.5" WC

(1.12 kPa)

Propane 11.0" WC

(2.73 kPa)

10.5" WC

(2.61 kPa)

13.0" WC

(3.23 kPa)

Table 3

Manifold Gas Supply Pressure (all models)

Fuel # Low High

Natural

Gas

Propane (Lo) 6.3" WC

(Lo) 1.6" WC

(.40 kPa)

(1.57 kPa)

(Hi) 3.5" WC

(.87 kPa)

(Hi) 10.0" WC

(2.49 kPa)

Table 4

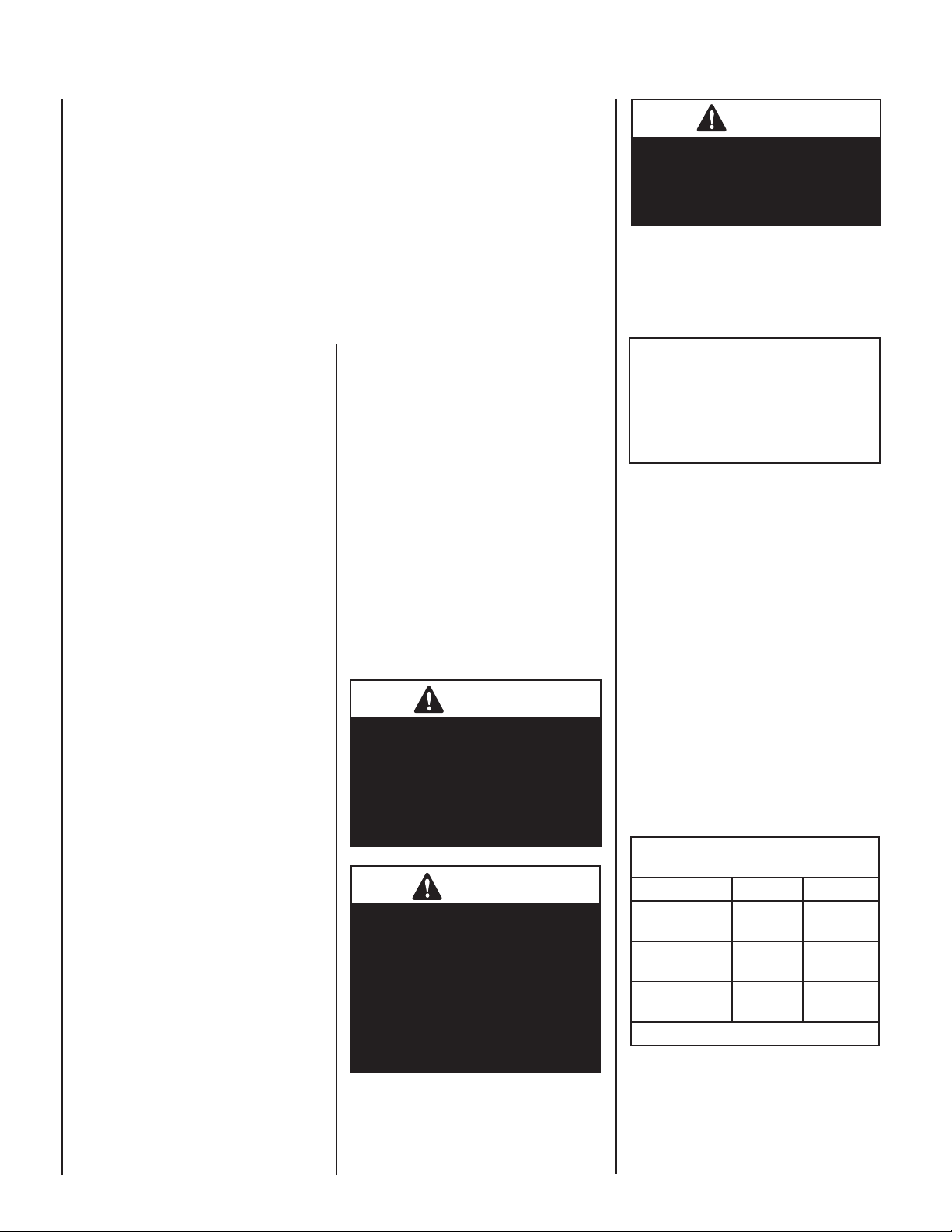

Test gauge connections are provided on the

front of the millivolt gas control valve (identifi ed IN for the inlet and OUT for the manifold

side). See Figures 1 & 2.

This appliance must be isolated from the gas

supply piping system (by closing its individual

manual shut-off valve) during any pressure

testing of the gas supply piping system at

test pressures equal to or less than 1/2

psig (3.5 kPa).

This appliance and its individual shut-off

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system at pressures greater

than 1/2 psig (3.5 kPa).

This appliance must not be connected to a

chimney or fl ue serving a separate solid-fuel

appliance.

WARNING

Carbon monoxide poisoning:

Early signs of carbon monoxide

poisoning are similar to the fl u

with headaches, dizziness and/or

nausea. If you have these signs,

obtain fresh air immediately. Turn

off the gas supply to the appliance

and have it serviced by a qualifi ed professional, as it may not

be operating correctly.

WARNING

Failure to comply with the installation and operating instructions

provided in this document will

result in an improperly installed

and operating appliance, voiding

its warranty. Any change to this

appliance and/or its operating

controls is dangerous. Improper

installation or use of this appliance can cause serious injury or

death from fi re, burns, explosion

or carbon monoxide poisoning.

BURN-IN PERIOD

During the fi rst few burns of these appliances

there will be some odor due to the curing of the

high temperature paint and burning off of lubricants used in the manufacturing process.

Depending on your use, the burn-in period may

take a few hours or a few days. Do not turn on

blower during Burn-In period.

IMPORTANT

Keep your house well ventilated

during the curing process. The

odor and haze emitted by the

curing process can be quite

noticeable and may set off a

smoke detector.

LIGHTING MILLIVOLT APPLIANCES

To light millivolt appliances refer to the detailed

lighting instructions found on Page 15 (English) and Page 16 (French). Millivolt appliance

lighting instructions may also be found on the

pull-out lighting instruction labels located in the

control compartment (below glass door).

GAS CONTROLS

These millivolt appliances are fi tted with a burner

Off/On Switch, located on the side surround

panel as shown in Figure 4 on Page 4. Once the

pilot is lit, and valve knob is in the ON position,

the Off/On switch will control the appliance

Off/On operation. To operate, toggle the switch

between its ON and OFF positions.

Variable Flame Height Adjustment

These millivolt appliances are equipped with

variable gas control valves. Flame height may

be adjusted through a range between fi xed low

and high settings by rotating the HI/LO knob on

the valve (see Figures 1 & 2) while the appliance

is in operation.

Model EBVI30

Honeywell Millivolt Gas Valve Controls

PIEZO

CONVERTIBLE

P

I

L

O

O

F

T

F

INLET

PRESSURE

TAP

IGNITER

HI/LO REGUL ATOR

(adjusts fl ame height

and heat output)

O

N

I

L

O

H

OUTLET

PRESSURE

TAP

PILOT

ADJUSTMENT

SCREW

TP/TH

TP

TH

WIRING

TERMINALS

GAS CONTROL

KNOB

Figure 1

MODEL EBVI25

SIT Millivolt Gas Valve Controls

GAS CONTROL

KNOB

T

O

L

I

O

W

L

H

I

CONVERTIBLE

HI/LO REGUL ATOR

(adjusts fl ame height

and heat output)

P

TPTH TP TH

F

INLET

PRESSURE

TAP

Figure 2

IN

PIEZO

IGNITER

N

O

T

O

L

I

P

OUT

it

O

F

OUTLET

PRESSURE

TAP

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

3

Page 4

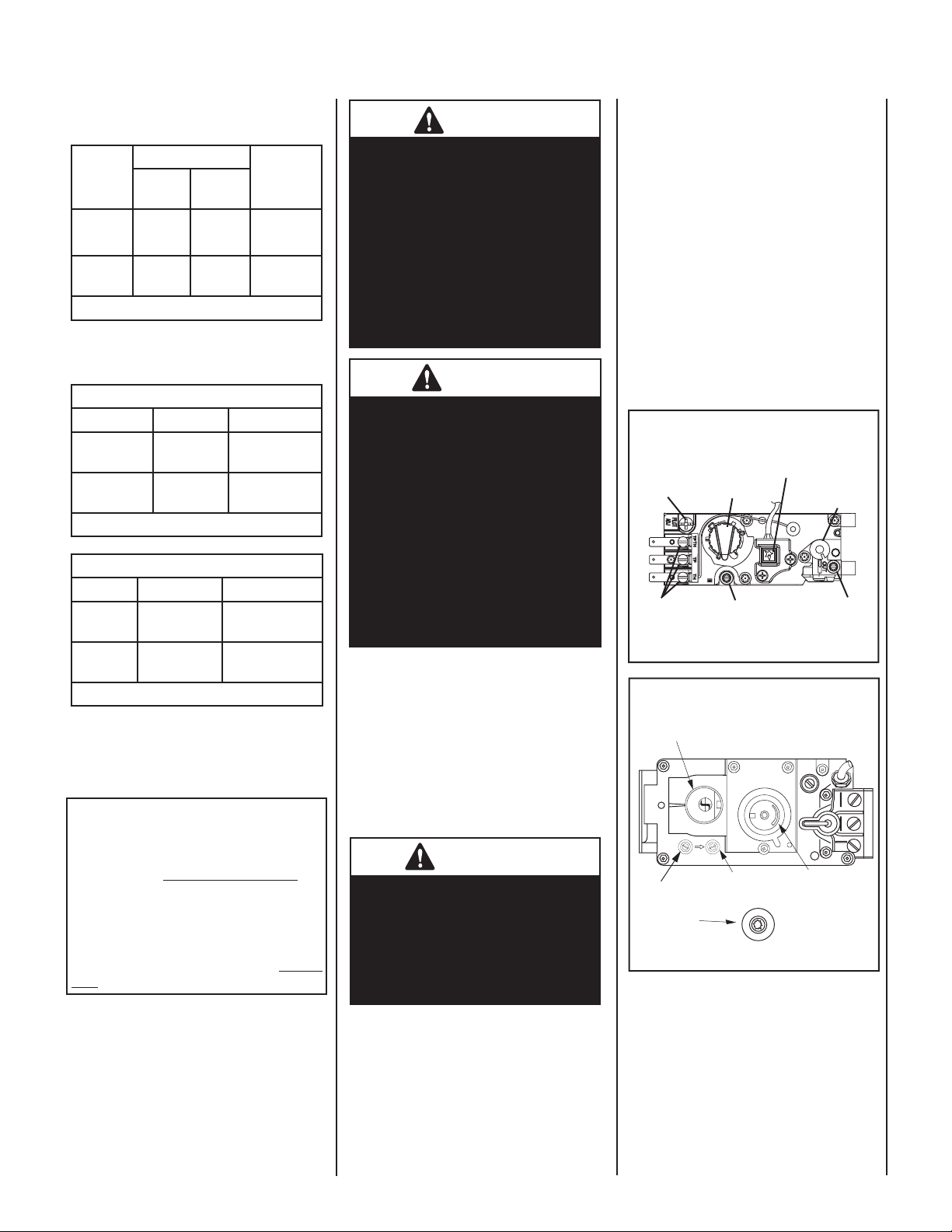

CONTROL COMPARTMENT ACCESS

Pull down hinged door to access control

compartment

Pull down hinged door to access control compartment

Figure 3

Burner Off/on Switch and Rheostat Location

Burner Off/On

Switch

Rheostat

(blower

speed

control)

Figure 4

OPERATION AND CARE OF YOUR

APPLIANCE

Appliance operation may be controlled

through a remotely located optional wall

thermostat or remote control.

In lieu of remote control or remote wall thermostat operation, the appliance must be operated

directly through the off/on switch located on the

side surround panel (see Figure 4).

4

(see Figure 3).

Control Compartment Access

Side View of Insert

Pull down lower

louver (hinged)

If optional surround is installed

Units with Beveled Surround

Left Front

surround

Panel

Units with Flat Surround

Rheostat

(blower

speed

control)

Burner Off/on

Switch

Left Front

surround

Panel

If your millivolt appliance is equipped with an

optional wall thermostat kit or remote control

kit and the pilot is lit (and valve is in the On

position), the appliance main burner may be

turned on and off with the wall thermostat

or remote control.

Always keep the appliance area clear and

free from combustible materials, gasoline

and other fl ammable liquids.

Remember, millivolt appliances have a

continuous burning pilot fl ame. Exercise

caution when using products with combustible vapors.

WARNING

Do not place clothing or other

fl ammable materials on or near

this appliance.

AVERTISSEMENT

Surveiller les enfants. Garder les

vêtements, les meubles, l'essence

ou autres liquides à vapeur infl ammables loin de l'appareil.

WARNING

Children and adults should be

alerted to the hazards of high

surface temperatures. Use caution around the appliance to

avoid burns or clothing ignition.

Young children should be carefully

supervised when they are in the

same room as the appliance.

Do not attempt to touch the front

enclosure glass with your hands

while the fi replace is in use.

Note: An Optional Screen Panel for

the glass is available (see Page

12 for ordering information).

WARNING

Do not use these appliances if

any part has been under water.

Immediately call a qualifi ed,

professional service technician

to inspect the appliances and to

replace any parts of the control

system and any gas controls

which have been under water.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

AVERTISSEMENT

Ne pas se servir de cet appareil

s'il a été plongé dans l'eau,

complètement ou en partie.

Appeler un technicien qualifi é

pour inspecter l'appareil et remplacer toute partie du système de

contrôle et toute commande qui

ont été plongés dans l'leau.

MAINTENANCE

The appliance and venting system should be

thoroughly inspected before initial use and at

least annually by a qualifi ed service technician.

However, more frequent periodic inspections

and cleanings should be performed by the

homeowner. Homeowner must contact a qualifi ed service technician at once if any abnormal

condition is observed.

Refer to the maintenance schedule on Page

6 for maintenance tasks, procedures, recommended frequency and by whom they should

be performed. Always verify proper operation

of the appliance after servicing.

Always turn off the gas and unplug the power

cord to the appliance before cleaning. Before

re-lighting, refer to the lighting instructions in

this manual. Instructions are also found on

pull-out panels located below the glass door

in the control compartment.

Keep lower control compartment clean by

vacuuming or brushing at least twice a year.

More frequent cleaning may be required due to

excessive lint from carpeting, bedding materials,

etc. It is important that control compartments,

burners and circulating air passageways of the

appliance be kept clean.

WARNING

Turn off gas and electrical power

before servicing the appliance.

CAUTION

Wear gloves and safety glasses

for protection while doing

required maintenance

.

IMPORTANT

Always verify proper operation

after servicing.

Check Burner Flame Appearance

Visually check the fl ame of the burner periodically making sure the fl ames are steady and not

lifting or fl oating (see Figure 13 on Page 7).

Page 5

Glass Cleaning

Note: Clean glass after fi rst two weeks of

operation (after Burn-In period is over).

The viewing glass should be cleaned periodically to remove any build-ups caused from the

following:

• During start-up, it is normal for condensation to form on the inside of the glass (this

condensation and fog will usually disappear

in a few minutes). This can cause lint, dust

and other airborne particles to cling to the

glass surface.

• Initial curing of the high temperature paint

and burning off of lubricants used in the

manufacturing process may result in a fi lm

on the glass.

• A white coating may form on the glass as a

result of impurities and minerals in the fuel.

It is recommended that the glass be cleaned

two or three times during each heating season,

depending on the circumstances present.

Use one of the following to clean glass:

• Non-ammonia based household cleaner

• 50%-50% mix of white vinegar & water

• gas stove glass cleaner

IMPORTANT

Do not use abrasive cleaners

on glass. Never clean the glass

when it is hot.

WARNING

Do not attempt to touch the front

enclosure glass with your hands

while the fi replace is in use.

Servicing Blower

To access the blower assembly for maintenance, adjustment or replacement, see the

following procedure:

1. Unplug 120-volt A.C. power supply to

insert.

Model EBVI25

Remove 10 Screws (use phillips screwdriver)

Access Panel

w/ Gasket

Figure 5

Model EBVI30

Remove 12 Screws (use phillips screwdriver)

Access Panel

w/ Gasket

Figure 6

6. (Model EBVI25) Remove the two hex

head bolts shown in Figure 7.

(Model EBVI30) Remove the two

screws shown in Figure 8, then lift

out air duct channel.

Model EBVI25

Remove 2 Bolts

Blower

Figure 7

7. Disconnect wires from the blower.

8. Lift blower up and pull it out from back

opening of fi rebox (see Figure 9).

9. To reinstall blower, reverse Steps 1

through 8.

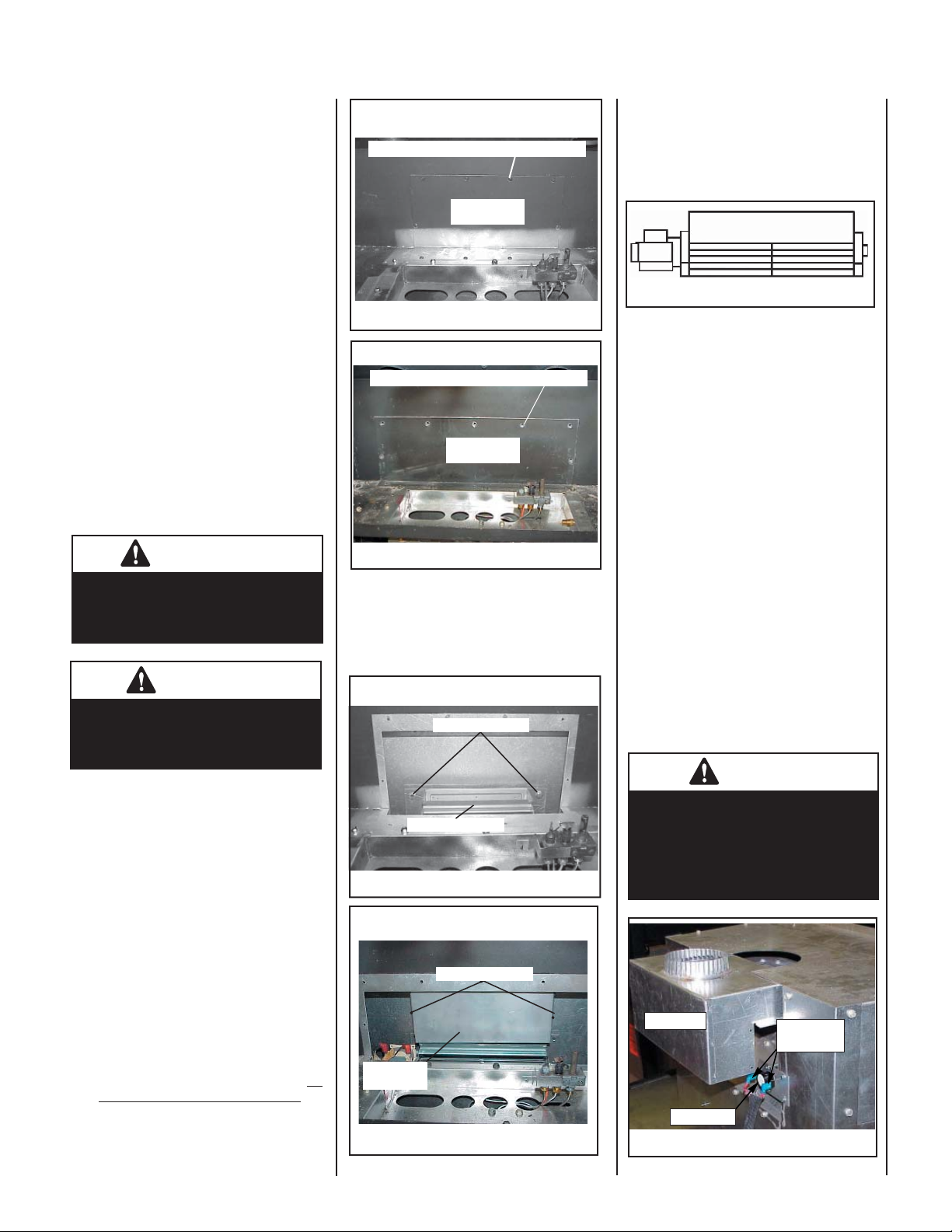

Blower Assembly

Figure 9

Small Area Paint Touch-up

The fi nish of the insert body and surround

(optional) is a high-quality powdercoat. Only

use factory supplied powdercoat paint kit for

touch-ups (cat. no. 90L74).

Do not attempt to repaint the insert until the

fi nish is completely cured (see Burn-In Period

on Page 3). If the surface later becomes stained

or marred, it may be lightly sanded and touched

up with spray paint.

Paint is available at your local authorized Lennox

Hearth Products dealer. Never attempt to paint

a hot insert.

Inspect Wiring

Inspect and clean all wire connections. Ensure

that there is no melting or damage. Inspection

should include:

• Terminals at the valve

• Off/On switch

• Wall thermostat, remote control, or control

kit (optional parts)

• Spill switch

Refer to wiring diagrams on Pages 11 & 12.

CAUTION

Label all wires prior to disconnection when servicing controls. Wiring errors can cause

improper and dangerous appliance operation.

2. Shut off gas supply to insert.

3. Remove Glass Door (see Procedure

For Removing Standard Glass Door

Assembly on Page 7).

4. Remove log set, burner and grate.

5. Remove blower access panel and

gasket (see Figure 5 for model EBVI25

and Figure 6 for model EBVI30). Be

careful not to damage the gasket.

Model EBVI30

Remove 2 Screws

Lift Out Air

Duct Channel

Figure 8

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Draft Hood

Spill Switch

Figure 10

Check

Connections

5

Page 6

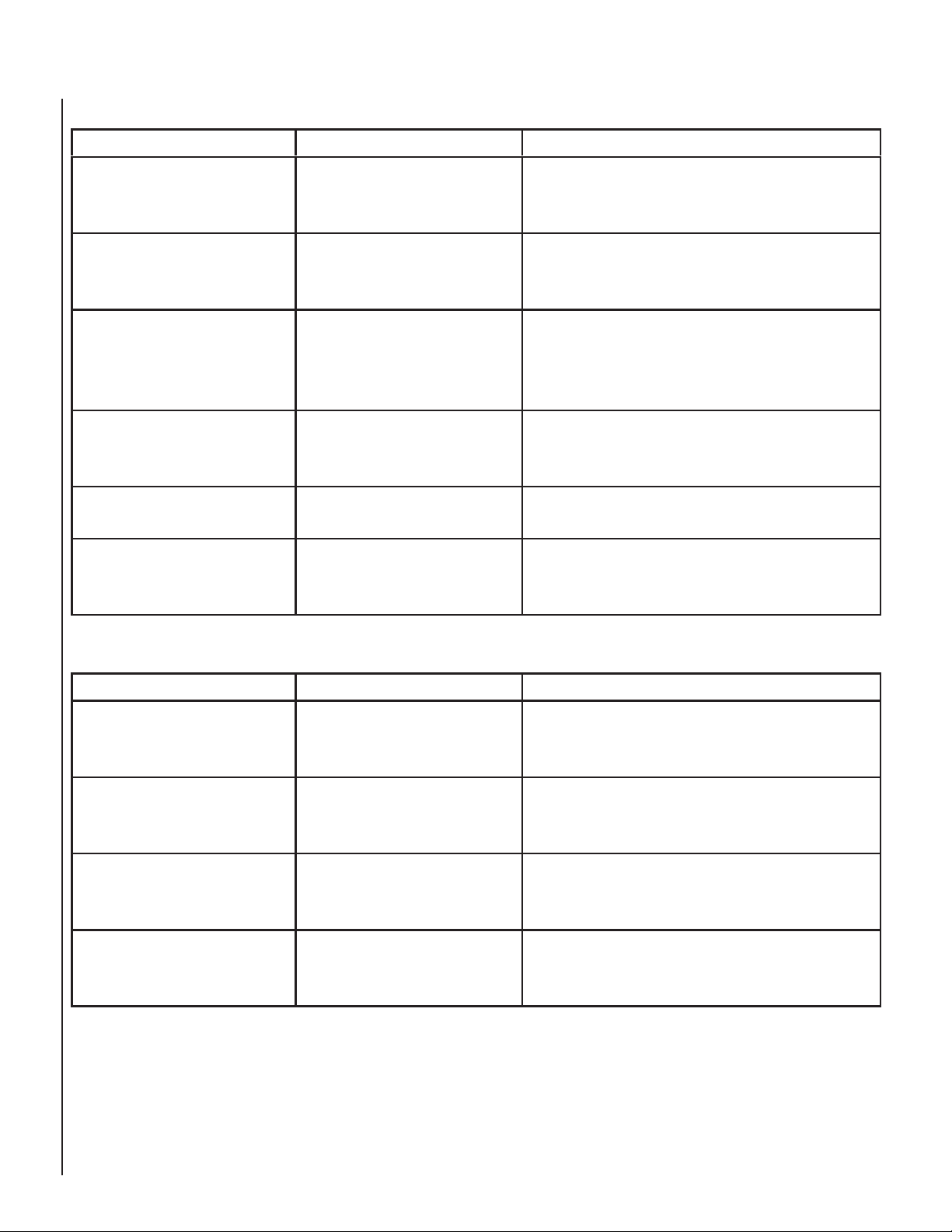

MAINTENANCE

Annually (Before the onset of the Burning Season)

Maintenance Task Accomplishing Person Procedure

Inspecting/Cleaning Burner, Logs

and Controls

Qualifi ed Service Technician Inspect valve and ensure it is properly operating. Check piping

for leaks. Vacuum the control compartment, fi replace logs and

burner area.

Check Flame Patterns and Flame

Height

Qualifi ed Service Technician

Refer to Figure 13 on Page 7 and verify the fl ame pattern

and height displayed by the appliance conforms to the picture.

Flames must not impinge on the logs.

Inspecting/Cleaning Pilot and Burner Qualifi ed Service Technician

Refer to Figure 13 on Page 7 and Figure 25 on Page 11.

Remove any surface build-up on pilot and burner assembly.

Wipe the pilot nozzles, ignitor/fl ame rod and hood. Ensure the

pilot fl ame engulfs the fl ame sensor as shown.

Checking Vent System Qualifi ed Service Technician Inspect the vent system at the top and at the base (within the

fi rebox) for signs of blockage or obstruction. Look for any signs

of dislocation of the vent components.

Appliance Checkout Qualifi ed Service Technician Perform the appropriate appliance checkout procedure detailed

in this manual.

Replacing Rockwool Ember Materials Homeowner/Qualifi ed Services Techni-

cian

Remove old ember materials and vacuum the rockwool placement area. Place new rockwool as described on Page 10 (see

Figure 23).

Periodically (After the Burning Season)

Maintenance Task Accomplishing Person Procedure

Cleaning Firebox Interior Homeowner Carefully remove logs, rockwool and and vermiculite. Vacuum out

interior of the fi rebox. Clean fi rebox walls and log grate. Replace

logs, Rockwool and vermiculite as detailed in this manual.

Check Flame Patterns and Flame

Height

Homeowner

Refer to Figure 13 on Page 7 and verify the fl ame pattern and

height displayed by the appliance conforms to the picture. Flames

must not impinge on the logs.

Checking Vent System Homeowner Inspect the vent system at the top and at the base (within the

fi rebox) for signs of blockage or obstruction. Look for any signs

of dislocation of the vent components.

Cleaning Front Door Window Homeowner Clean as necessary following the directions provided in this

manual. DO NOT TOUCH OR ATTEMPT TO CLEAN GLASS WHILE

HOT.

6

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 7

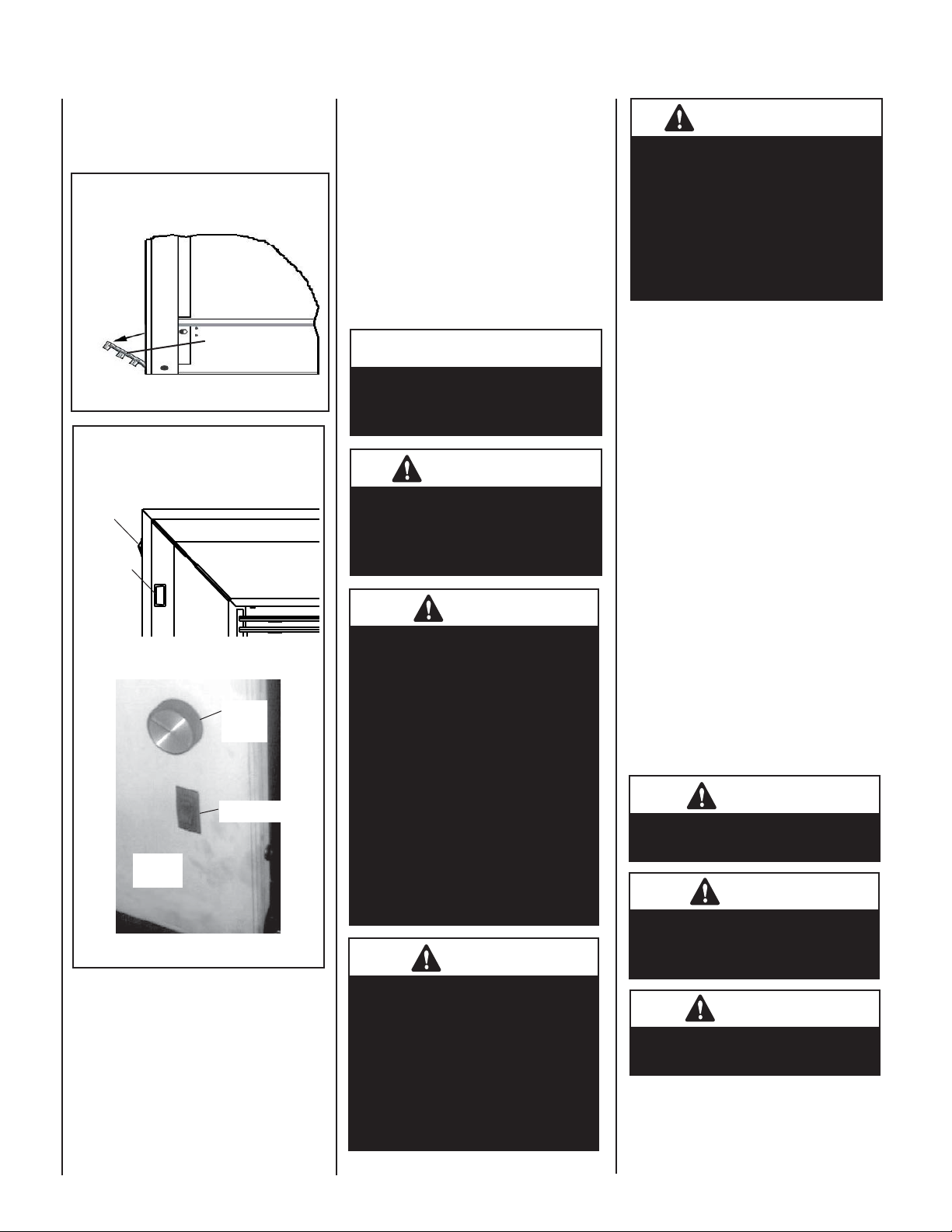

PROCEDURE FOR REMOVING STANDARD

GLASS DOOR ASSEMBLY

WARNING

Handle glass door with extreme care! The glass

door assembly is susceptible to damage. Do not

scratch while handling or while reinstalling.

WARNING

BURNER ADJUSTMENT

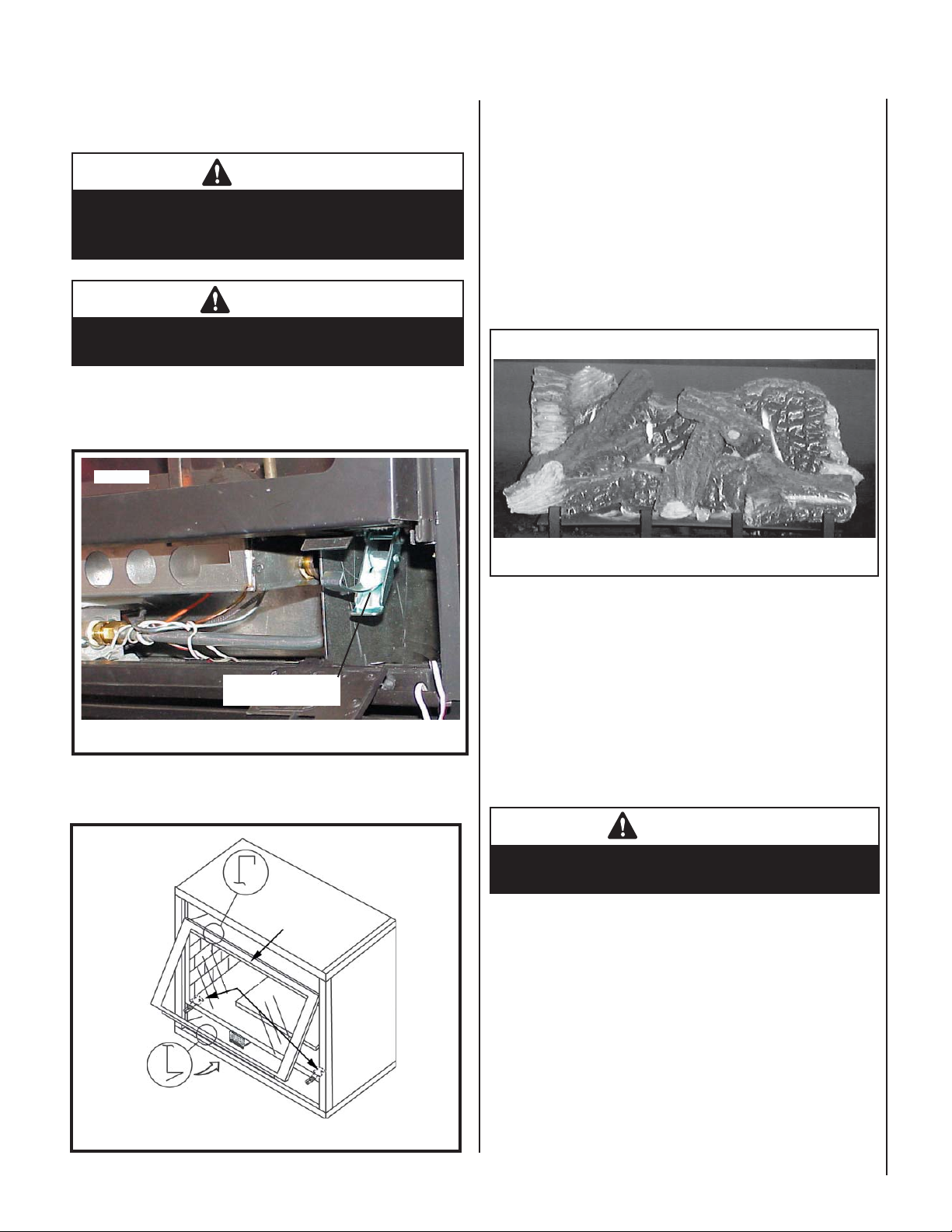

Flame Appearance and Sooting

Proper fl ame appearance is a fl ame which is blue at the base and becomes

yellow/orange in the top of the fl ame. When the insert is fi rst lit, the

entire fl ame may be blue and will graduallay turn yellow/orange during

the fi rst 6-8 minutes of operation. If after 6-8 minutes the fl ame stays

blue, or if the fl ame is orange with evidence of sooting (black tip), the

air shutter may require adjustment.

An appliance operated with an air shutter opening that is too large will

exhibit fl ames that are blue and transparent. These weak, blue and

transparent fl ames are termed anemic. If the air shutter opening is too

small, sooting may develop.

Never operate unit without the front glass door panel

in place and secure.

Remove the front door assembly from insert as follows:

1) Open the two latches below the glass door as shown in Figures

11 & 12.

Glass Door

Release latch on

each side (below door)

Figure 11

2) Swing the bottom of the door outward (see Figure 12) and lift it

off of fi rebox top. Set door aside in a safe place.

Burner Flame Appearance

Figure 13

EBVI25 Shown

Sooting is indicated by black puffs developing at the tips of very long

orange fl ames. Sooting results in black deposits forming on the logs,

appliance inside surfaces and on exterior surfaces adjacent to the

vent termination. Sooting is caused by incomplete combustion in the

fl ames and lack of combustion air entering the air shutter opening. To

achieve a warm yellow to orange fl ame that does not soot, the shutter

opening must be adjusted between these two extremes.

No smoke or soot should be present. Reposition the logs if fl ames

impinge on any of them. If the logs are properly positioned and

sooting conditions exist, the air shutter opening on the main burner

tube should be adjusted.

Figure 12

Firebox Floor

Bottom Vee-fl ange

Door Frame

Latches

Top

Flange

Door

Frame

Glass Door

Ensure that the front glass panel is in place and

sealed during adjustment.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

IMPORTANT

7

Page 8

Burner Adjustment Procedure

WARNING

Air shutter adjustment should

only be performed by a qualifi ed

professional service technician.

CAUTION

The adjustment rod and nearby

appliance surfaces are hot. Exercise caution to avoid injury while

adjusting fl ame appearance.

If the burner fl ame appearance differs greatly

from what is shown in Figure 13 (see Burner

Flame Appearance), some adjustment from

the factory setting for the air shutter gap may

be necessary (to compensate for variables

in the installation and fuel such as, BTU

value/composition, gas pressure, specifi c

gravity of gas, altitude, etc.).

See Table 5 on Page 8 for Burner Air Shutter

Adjustment Guidelines.

Initially, always position the air shutter to the

factory setting as shown in Figure 14 (adjustment rod is located in the lower control area).

This can be done by moving the adjustment

rod up or down accordingly. Allow the burner

to operate for at least 15 minutes. Observe

the fl ame continuously. If it appears weak

or sooty as previously described, adjust the

air shutter to a more open position until the

proper fl ame appearance is achieved.

CAUTION

Carbon will be produced if the air shutter is closed too much. Any

damage due to carboning resulting from improperly setting the air

shutter is not covered under the warranty.

The following chart is provided to aid you in achieving the correct air shutter adjustment

for your installation.

Air Shutter Adjustment Guidelines

Amount of

Primary Air

If air shutter is

closed too far

If air shutter is open

too far

Table 5

LOGS, VERMICULITE AND EMBERS

Installation Instructions

Flame Color Air Shutter

Adjustment

Flame will be orange Air shutter gap should

be increased

Flame will be blue Air shutter gap should

be decreased

WARNING

If logs are not installed according to the directions shown here, fl ame

impingement and improper combustion could occur and result in soot

and/or excessive production of carbon monoxide (CO) - a colorless,

odorless, toxic gas.

Carefully install the seven-piece log set into the fi rebox as shown in these instructions. All

logs should fi t onto corresponding pins and/or log stoppers. This will ensure a proper fl ame

and safe combustion.

Burner Air Shutter Adjustment

Adjusting Set Screw

Burner Tube

Air Shutter

Adjustment Rod Down

(full open position)

MAIN BURNER FACTORY AIR

SHUTTER OPENING SETTING

Model Gas Type Air Shutter Gap

EBVI30 Natural Gas 5/16" (7.94mm)

Propane 1/2" (12.7mm)

EBVI25 Natural Gas 1/16" (1.59mm)

Propane 1/2" (12.7mm)

Figure 14

8

Adjustment Rod Up

(1/8" Open Position)

Note: Place some vermiculite around burner before installing logs (see Figure 24). The entire

bag of vermiculite will NOT be used.

Rear Log

Top Left Log

Front Center Log

Top Right Log

Center Log

Front Left Log

Figure 15

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Front Right Log

Page 9

1. Place the rear log onto the two corresponding locating pins at the

back of the fi rebox as shown in Figure 16.

4. Place the Front Left Log onto the two corresponding locating pins

as shown in Figure 19.

Figure 16

Rear Log

2. Place the Front Right Log onto the two corresponding locating pins

as shown in Figure 17.

Figure 17

Front Right Log

3. Place the Center Log onto the two corresponding locating pins as

shown in Figure 18.

Figure 19

Front Left Log

5. Install the Top Left Log onto the corresponding locating pin and

indentation on Center Log as shown in Figure 20.

Figure 20

Top Left Log

6. Install the Front Center Log over the Front Right Log. The front

of log will rest on the burner and the back of log will rest on rear

log as shown in Figure 21.

Figure 18

Center Log

Figure 21

7. Install the Top Right Log into the corresponding indentations on

Front Center Log and front right twig as shown in Figure 22.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Front Center Log

9

Page 10

Figure 23

Embers

9. Place some vermiculite around the logs as shown in Figure 24

(the entire bag of vermiculite will NOT be used).

Figure 22

Top Right Log

8. Place the glowing embers on the burner as shown in Figure 23.

One package of ember material has been included with this log set

You will not need to use the entire bag.

IMPORTANT: The quantity and placement of the ember material can

affect insert performance therefore it is very important that it be placed

as shown in Figure

a. Unpackage and divide the fi ne ember material (mineral wool) into

dime-sized fl uffy pieces.

b. Distribute the pieces over the top of the front burner ports, fi lling the

area in front of the forward logs.

23.

Figure 24

Vermiculite

10

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 11

MILLIVOLT APPLIANCE CHECKOUT

Light the pilot by following the instructions on

Page 15 or 16 of this manual.

The pilot fl ame should be steady, not lifting

or fl oating. Flame should be blue in color with

traces of orange at the outer edge. The top 3/8"

(10 mm) at the pilot generator (thermopile)

and the top 1/8" minimum (tip) of the quick

drop out thermocouple should be engulfed

in the pilot fl ame. The fl ame should project 1"

(25 mm) beyond the hood at all three ports

(Figure 25).

Replace logs if removed for pilot inspection.

Proper Pilot Flame Appearance

Thermocouple

1/8" Min.

(3 mm)

Pilot

Nozzels

Igniter Rod

Hood

3/8" Min.

(9 mm)

Thermopile

Figure 25

FIREPLACE REQUIREMENTS

IMPORTANT: When installing this appliance

into a factory built fi replace or heatform, the air

fl ow within and around the fi replace shall not

be altered by the installation of the insert (i.e.

DO NOT BLOCK louvers or cooling air inlet or

outlet ports, circulating air chambers in a steel

fi replace liner or metal heat circulator).

CAUTION: The factory built fi rebox must

accept the insert without modifi cation other

than removing bolted or screwed together

pieces such as smoke shelf/defl ectors, ash lips,

screen or door tracks, log grates, refractory and

damper assemblies. Any fi replace component,

which is removed, must be retained so they

can be reinstalled to restore the fi replace to

its original operating condition. The removal

of any part must not alter the integrity of the

outer shell of the pre-engineered fi replace

cabinet in any way.

If any components are removed from (or altered)

from the existing fi replace, a Warning Label

(see below) must be affi xed inside the fi replace

fi rebox, so that it shall be visible upon removal of

the fi replace insert. Note: RTV high temperature

silicone is an approved adhesive.

Fireplace Warning Label

(Provided in Accessory Package)

Room Air Circulation Blower

IMPORTANT: BLOWER GROUND WIRE

WITH POWER CORD GREEN WIRE

SHOULD BE ATTACHED TO THE GROUND

SCREW. FAILURE TO DO SO WILL

RESULT IN A POTENTIAL SAFETY

HAZARD. THE APPLIANCE MUST BE

ELECTRICALLY GROUNDED IN ACCORDANCE WITH LOCAL CODES OR, IN

THE ABSENCE OF LOCAL CODES, THE

NATIONAL ELECTRICAL CODE, ANSI/

NFPA 70 - LATEST EDITION. (IN CANADA,

THE CURRENT CSA C22-1 CANADIAN

ELECTRICAL CODE - LATEST EDITION.

WARNING: THE POWER CORD MUST BE

PLUGGED DIRECTLY INTO A PROPERLY

GROUNDED THREE-PRONG 120 VOLT,

60 HZ WALL RECEPTACLE. DO NOT CUT

OR REMOVE THE GROUNDING PRONG

FROM THIS PLUG. DO NOT ROUTE

POWER CORD UNDER OR IN FRONT

OF APPLIANCE.

Blower Wiring Diagram

120 V AC

To light the burner, rotate the gas valve control

knob counterclockwise to the “ON” position

then turn “ON” the off/on switch mounted

on the surround assembly (see Figures 1 &

2 on Page 3) or operate the burner with the

optional remote control, wall thermostat or

control switch.

With proper care and maintenance, your appliance will provide many years of enjoyment. If

you should experience any problem, fi rst refer

to the troubleshooting guide in this manual. If

problem persists, contact your Lennox Hearth

Products Dealer.

BLOWER OPERATION

When the insert heats up, the blower will automatically be turned on by the fan disc located

under the fi rebox bottom on the front left side.

It will come on at the speed determined by the

rheostat located on the side surround panel (see

Figure 4 on Page 4). To adjust the blower speed,

dial the rheostat to the desired speed setting.

Rotate the dial down (clockwise), just past the

click (the fi rst ON position) for the highest speed

setting. Turning the knob further clockwise will

provide slower blower speeds.

Note: If the rheostat is not turned “on,” the

blower will not operate.

WARNING

THIS FIREPLACE HAS BEEN ALTERED TO

ACCOMMODATE A FIREPLACE INSERT

AND SHOULD BE INSPECTED BY A QUALI-

FIED PERSON PRIOR TO RE-USE AS A

CONVENTIONAL FIREPLACE.

Figure 26

WIRING DIAGRAMS

Wiring diagrams are provided here for reference purposes only. This information is also

provided on schematics attached directly to the

appliance on a pullout panel located within the

control compartment.

CAUTION

Label all wires prior to disconnection when servicing controls. Wiring errors can cause

improper and dangerous appliance operation.

Figure 27

Black

Fan Disc

RedBlackBlack

Rheostat

Black

Hot (Live)

Green

(Ground)

Blower

Assembly

Power Cord

White

(Neutral)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

11

Page 12

SIT & Honeywell

Millivolt Wiring Diagram

If original wire as supplied must be replaced, it must be

replaced with Type AWM 105°C, 18 gauge wire.

PRODUCT REFERENCE INFORMATION

Your Insert's Model Number __________________________________________

Your Insert's Serial Number ___________________________________________

The Date On Which Your Insert Was Installed _____________________________

Spill

Switch

TP

Thermopile

* Switch

* Off/on Switch, Optional Thermostat or Remote

Control Receiver

TH

TP

TH

Figure 28

If you encounter any problems or have any questions concerning the installation or application

of this system, please contact your distributor.

For the number of your nearest Lennox dealer,

please call 800-9-Lennox.

LENNOX HEARTH PRODUCTS

1110 West Taft Avenue

Orange, CA 92865

Visit us at www.LennoxHearthProducts.com

WARRANTY INFORMATION

Your gas appliance is covered by a limited

twenty-year warranty. You will fi nd a copy

of the warranty accompanying this manual.

Please read the warranty to be familiar with

its coverage.

Retain this manual. File it with your other documents for future reference.

The Type of Gas Your Insert Uses ______________________________________

Your Dealer's Name ________________________________________________

ACCESSORY COMPONENTS

Bay Front Kits

These decorative bay front assemblies fi t over

the standard fl at glass doors.

Cat. No. Model Description

H1502 BFK-25I` Bay Front Kit, Small, EBVI25

H1581 BFK-30BVI Bay Front Kit, Medium, EBVI30

Tall Arch Pane Screen Door Kits

These decorative screen door panels fi t on the

face of the appliance surround (eliminating the

need for the top and bottom louver panels).

Screen Door Kit

These decorative screen door panels fi t over

the standard glass door panels.

REPLACEMENT PARTS

A complete parts list is found at the end of

this manual. Use only parts supplied from the

manufacturer.

All parts should be ordered through your

Lennox Hearth Products Distributor or Dealer.

Parts will be shipped at prevailing prices at

time of order.

When ordering repair parts, always give the

following information:

1. The model and serial number of the appli-

ance (see rating plate in control compartment

of appliance).

2. The part number & description of part (see

Page 17).

3. The quantity required.

4. The installation date of the appliance.

12

CAT# MODEL# DESCRIPTION

H3595 TAPSDK25C 25” Charcoal, EBVI25

H3596 TAPSDK25TI 25” Textured Iron, EBVI25

H3597 TAPSDK25SP 25”Satin Pewter EBVI25

H3840 TAPSDK25PC 25” Pewt/Charc, EBVI25

H3598 TAPSDK30C 30” Charcoal, EBVI30

H3599 TAPSDK30TI 30” Textured Iron, EBVI30

H3600 TAPSDK30SP 30” Satin Pewter, EBVI30

H3841 TAPSDK30PC 30” Pewt/Charc, EBVI30

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Cat. No. Model Description

H0916 TPSDK-30BVI Twin-Pane Screen Door Kit, Md. BVI

H1501 TPSDK-25 Twin-Pane Screen Door Kit, Sm. BVI

Page 13

ACCESSORY COMPONENTS

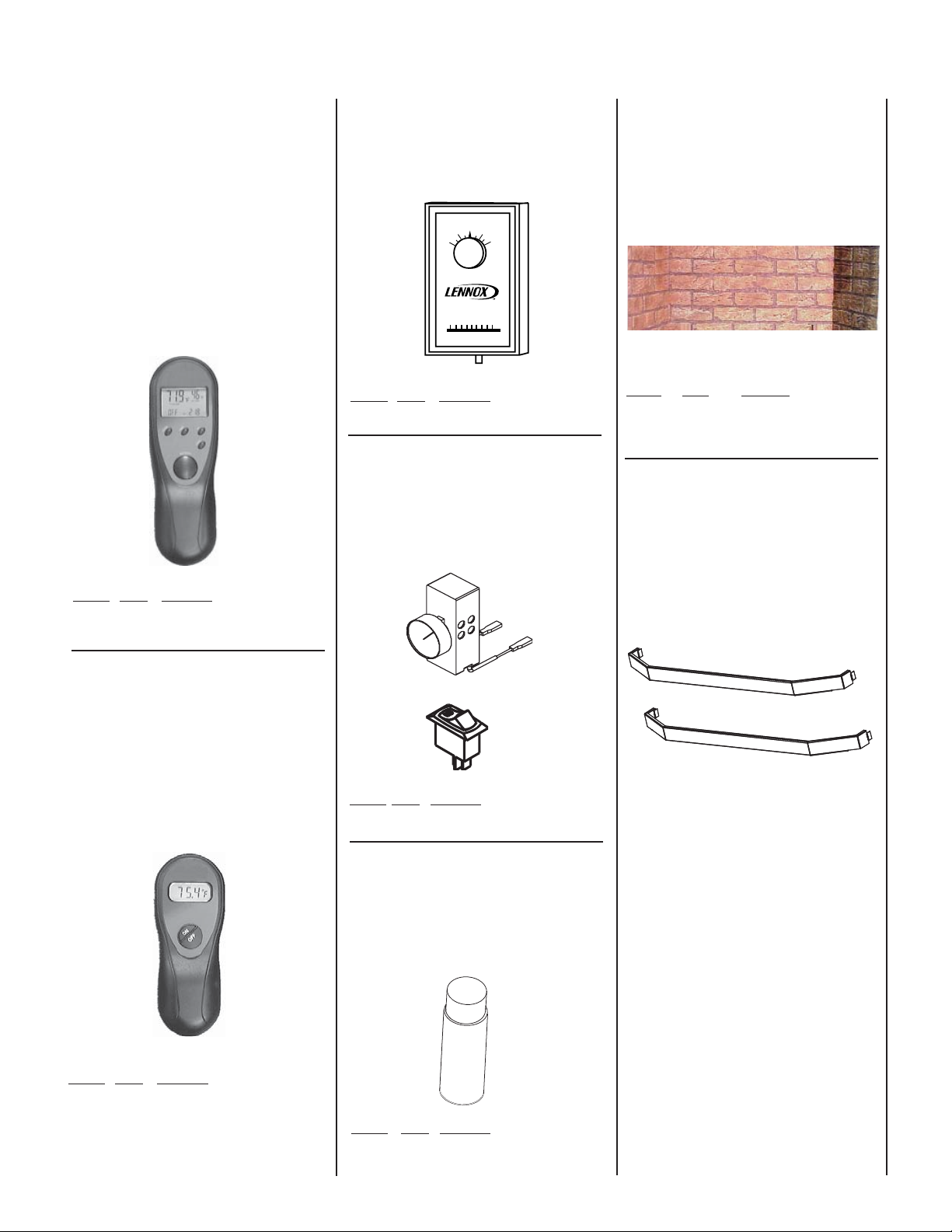

Deluxe Remote Control System

The Model RCL-T (Deluxe) Remote Control

System has all of the features of the standard

system along with an added easy to read LCD

screen which presents access to many enhancements, including battery power level indicator,

timer, mode of operation, thermostatic display

including room temperature in either metric

or English units, fl ame indicator and clock.

Fully programmable, the Model RCL-T allows

for command over nearly all operational and

temperature variables, using the hand held

remote control transmitter.

Wall Thermostat

The wall thermostat kit provides temperature

control for optimum comfort.

Brick Liner Kit

The brickade liner kit includes panels for the rear

and side walls of the fi rebox. The panels have

brick-like features in relief. This kit can be retrofi tted into a previously installed appliance.

Cat. No. Model Description

H0251 RCL-T Remote Control System (Deluxe)

Standard Remote Control System

The Model RCL (Standard) Remote Control

System, features a simple Off/on control

function for the insert. This model includes a

hand-held transmitter, a remote receiver with

wall-mount coverplate and all hardware required

to install the unit. The remote receiver can be

wall or hearth mounted.

Cat. No. Model Description

89L36 WTK Wall Thermostat KiT

Control Kit

If an optional surround kit is not purchased,

this kit is required to provide the off/on switch

and rheostat.

Cat. No. Model Description

H0919 CK-EI Control Kit, Elite Inserts

Touch-Up Powdercoat Paint Kit

Repair of minor scratches and discoloration of

the appliance's charcoal powdercoated surfaces

may be accomplished with the use of this touchup paint kit.

Cat. No. Model Description

H0917 BLK-30BVI Brick Liner Kit, EBVI30

H1577 BLK-25BVI Brick Liner Kit, EBVI25

Decorative Bay Window Trim Kits

These decorative trim accents, install along the

top and bottom front edges of the bay window.

They are available in two different fi nishes to

enhance the beauty of the insert and are sure

to fi t into any decor.

Cat. No. Model Description

H1511 BWTK-25G Bay Window Trim Kit, Gold,

EBVI25

H1512 BWTK-25BS Bay Window Trim Kit, Brushed

Stainless, EBVI25

H0898 BWTK-30G Bay Window Trim Kit, Gold,

EBVI30

H0899 BWTK-30BS Bay Window Trim Kit, Brushed

Stainless, EBVI30

Cat. No. Model Description

H0249 RCL Remote Control System (Standard)

P

T

A

N

I

Cat. No. Model Description

90L74 TPK-C Touch-Up Powdercoat Paint Kit

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

13

Page 14

Decorative Flat Louver Kits

These decorative trim accents, install above and

below the glass door. They are available in three

different fi nishes to enhance the beauty of the

insert and are sure to fi t into any decor.

Beveled Surround Kits

These beveled surround panels install around

the insert body providing an attractive fi nished

look.

Width

Hearth Riser Kits

The hearth riser trim kits are designed to be

used with the optional surround kits (sold

separately). It provides a fi nished look below

the insert face when installed into fi replaces

with a elevated fi rebox.

Cat. No. Model Description

H1505 FLK-25 Flat Louver Kit, Charcoal, EBVI25

H1506 FLK-25G Flat Louver Kit, Gold, EBVI25

H1507 FLK-25BS Flat Louver Kit, Br. Stainless, EBVI25

H0846 FLK-30BVI Flat Louver Kit, Charcoal, EBVI30

H0847 FLK-30BVIG Flat Louver Kit, Gold, EBVI30

H0848 FLK-30BVIBS Flat Louver Kit, Br. Stainless, EBVI30

Decorative Bay Louver Kits

These decorative trim accents, install above

and below the optional Bay Front Assembly.

They are available in three different fi nishes to

enhance the beauty of the insert and are sure

to fi t into any decor.

SKS-25 = 41 1/16" W X 26 1/16" H

SKM-25 = 44 1/8" W X 27 5/8" H

SKS-30 = 40 1/4" W x 27 1/2" H

SKM-30 = 45 3/4" W x 30 1/4" H

SKL-30 = 49 1/4"" W x 30" H

Cat. No. Model Description

H1503 SKS-25 Beveled Surround, Small, EBVI25

H1504 SKM-25 Beveled Surround, Medium, EBVI25

H0881 SKS-30 Beveled Surround, Small, EBVI30

H0882 SKM-30 Beveled Surround, Medium, EBVI30

H0883 SKL-30 Beveled Surround, Large, EBVI30

Sizes

Height

Flat Surround Kits

These fl at surround kits are designed to have

the outside overall dimensions cut down

when custom shaped surround trim panels

are needed.

Insert

Hearth Riser Trim Panel

Panels are available in 1”, 3” & 6” heights

Cat. No. Model Description

EBVI25

H2042 HRKS1-25 Hearth Riser Kit, SM, E25I, 1”

H2043 HRKS3-25 Hearth Riser Kit, SM, E25I, 3”

H2044 HRKS6-25 Hearth Riser Kit, SM, E25I, 6”

H2045 HRKM1-25 Hearth Riser Kit, MED, E25I, 1”

H2046 HRKM3-25 Hearth Riser Kit, MED, E25I, 3”

H2047 HRKM6-25 Hearth Riser Kit, MED, E25I, 6”

EBVI30

H2098 HRKS1-30 Hearth Riser Kit, SM, E30I, 1”

H2099 HRKS3-30 Hearth Riser Kit, SM, E30I, 3”

H2100 HRKS6-30 Hearth Riser Kit, SM, E30I, 6”

H2101 HRKM1-30 Hearth Riser Kit, MED, E30I, 1”

H2102 HRKM3-30 Hearth Riser Kit, MED, E30I, 3”

H2103 HRKM6-30 Hearth Riser Kit, MED, E30I, 6”

H2104 HRKL1-30 Hearth Riser Kit, LG, E30I, 1”

H2105 HRKL3-30 Hearth Riser Kit, LG, E30I, 3”

H2106 HRKL6-30 Hearth Riser Kit, LG, E30I, 6”

Surround

Cat. No. Model Description

H1508 BYLK-25 Bay Louver Kit, Charcoal, EBVI25

H1509 BYLK-25G Bay Louver Kit, Gold, EBVI25

H1510 BYLK-25BS Bay Louver Kit, Brushed

Stainless, EBVI25

H1582 BYLK-30BVI Bay Louver Kit, Charcoal, EBVI30

H1583 BYLK-30BVIG Bay Louver Kit, Gold, EBVI30

H1584 BYLK-30BVIBS Bay Louver Kit, Brushed

Stainless, EBVI30

14

Cat. No Model Description

H3391 EFS-E25I Elite Insert Flat Surround Kit,

EBVI25

H3390 EFS-E30I Elite Insert Flat Surround Kit,

EBVI30

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

SM = used with small surround

MED = used with medium surround

LG = used with large surround

Page 15

it

OUT

IN

LIGHTING INSTRUCTIONS – MILLIVOLT GAS VALVE

FOR YOUR SAFETY, READ BEFORE LIGHTING

WARNING: IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION

MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

A. This appliance has a pilot which must be lighted with a piezo

igniter. When lighting the pilot, follow these instructions

exactly.

B. BEFORE OPERATING, smell all around the appliance area for

gas. Be sure to smell next to the fl oor because some gas is

heavier than air and will settle on the fl oor.

WHAT TO DO IF YOU SMELL GAS

• Extinguish any open fl ame.

• Open windows.

• Do not light any appliance.

• Do not touch any electrical switches.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above on this page.

2. Access the lower control compartment.

3. Turn remote wall switch to “OFF.”

4. Verify main line shut-off valve is open.

5. Push in gas control knob slightly and turn clockwise

to “OFF.”

T

O

L

I

P

TPTH TP TH

TH

TP

TP/TH

- LO/HI +

H

PIEZO

IGNITER

L

O

O

W

L

H

I

- LO/HI +

PIEZO

IGNITER

O

N

I

P

I

L

O

O

F

T

F

SIT Millivolt

Gas Valve

Honeywell Millivolt

Gas Valve

IN

GAS CONTROL

KNOB

TP/TH

TP

TH

T

O

L

I

P

N

O

it

O

F

F

OUT

GAS CONTROL

KNOB

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone.

• If your gas supplier cannot be reached, call the fi re depart-

ment.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by hand,

do not try to repair it, call a qualifi ed service technician. Force

or attempted repair may result in a fi re or an explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualifi ed service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

6. Wait fi ve (5) minutes to clear out any gas. If you then smell gas,

STOP! Follow “B” in the safety information above on this page. If you

do not smell gas, go to the next step.

7. Push in gas control knob slightly and turn counterclockwise

to “PILOT.”

8. Push in control knob all the way and hold in. Immediately light the

pilot by triggering the spark igniter (pushing the button) until pilot

lights. Continue to hold the control knob in for about 1-1/2 minutes

after the pilot is lit. Release knob and it will pop back up. Pilot should

remain lit. If it goes out, repeat steps 5 through 8.

• If knob does not pop up when released, stop

and immediately call your service technician

or gas supplier.

• If pilot will not stay lit after several tries,

turn the control knob to “OFF” and call

your service technician or gas supplier.

Millivolt Pilot

9. Turn gas control knob counterclockwise

to “ON.”

10. Close lower control compartment.

Note: Knob cannot be turned from “PILOT” to “OFF”

unless the knob is pushed in slightly. Do not force.

TO TURN OFF GAS TO APPLIANCE

1. Turn remote wall switch “OFF.” The pilot will remain lit for

normal service.

2. For complete shutdown, turn remote wall switch to “OFF.”

3. Access the lower control compartment.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

4. Depress gas control knob slightly and turn clockwise

to “OFF.” Do not force.

5. Close lower control compartment.

15

Page 16

INSTRUCTIONS D’ALLUMAGE – VANNE GAZ MILLIVOLT

it

OUT

IN

POUR VOTRE SÉCURITÉ, LISEZ CES INSTRUCTIONS AVANT L’ALLUMAGE

AVERTISSEMENT : SI VOUS NE SUIVEZ PAS CES INSTRUCTIONS À LA LETTRE, IL POURRAIT S’EN SUIVRE UN INCENDIE OU

UNE EXPLOSION CAUSANT DES DOMMAGES MATÉRIELS, DES BLESSURES CORPORELLES OU MÊME DES PERTES DE VIE.

A. Cet appareil est muni d’une veilleuse qui doit être allumée avec un

allumeur piézo-électrique. Lorsque vous allumez la veilleuse, suivre

exactement ces instructions.

B. AVANT L’ALLUMAGE: Assurez-vous que vous ne détectez aucune odeur

de gaz autour de l’apareil ainsi que près du sol; certains gaz, étant plus

lourds que l’air, descendent au niveau du sol.

VOICI CE QUE VOUS DEVEZ FAIRE SI VOUS DÉCELEZ UNE ODEUR

DE GAZ:

• Éteignez toute fl amme visible.

• Ouvrez les fenêtres.

• N’allumez aucun appareil.

• Ne touchez à aucun commutateur électrique.

• Ne vous servez d’aucun téléphone dans votre édifi ce.

INSTRUCTIONS D'ALLUMAGE

1. ARRÊTEZ! Lisez les consignes de sécurité au verso de cette plaque.

2. Ouvrez le compartiment de contrôle du bas.

3. Tournez l’interrupteur mural à la position d’arrêt “OFF”.

4. Assurez-vous que la soupape d’arrêt de la canalisation principale est

ouverte.

5. Enfoncez légèrement le bouton de réglage du gaz et tournez-le dans

le sens des aiguilles d’une montre jusqu’à la position

d’arrêt “OFF”.

T

O

L

I

P

O

W

L

H

I

- LO/HI + (COMMANDE

DE TAILLE DE FLAMME)

ALLUMEUR

SIT Vanne

Gaz Millivolt

N

O

T

O

it

L

I

P

O

F

F

OUT

IN

BOUTON DE RÉGLAGE DU GAZ

BOUTON DE RÉGLAGE DU GAZ

Honeywell Vanne

Gaz Millivolt

TP/TH

TP

TH

Remarque: Il est impossible de tourner le bouton de “PILOT” à “OFF” à

moins qu’il ne soit légèrement enfoncé. Ne le forcez pas.

6. Attendez cinq (5) minutes pour l’evacuation du gaz. Si vous décelez

une odeur de gaz, ARRÊTEZ ! Retournez au point “B” des consignes

de sécurité au verso de cette plaque. Si vous ne remarquez aucune

odeur de gaz, passez à l’étape suivante.

7. Enfoncez légèrement le bouton de réglage du gaz et tournez-le en

sens inverse des aiguilles d’une montre jusqu’à la position de veilleuse “PILOT”.

O

N

I

P

I

L

O

O

F

T

F

ALLUMEUR

TH

TP

TP/TH

TPTH TP TH

- LO/HI + (COMMANDE

DE TAILLE DE FLAMME)

L

O

H

• Appelez immédiatement votre compagnie de gaz en utilisant le télé-

phone du voisin.

• S’il vous est impossible de contacter votre compagnie de gaz, appelez

le service des incendies.

C. N’utilisez que votre main pour manipuler le bouton de réglage du gaz.

N’utilisez jamais d’outils. Si le bouton refuse de tourner ou de bouger,

n’essayez pas de le réparer. Communiquez immédiatement avec un

technicien de service qualifi é. Toute tentative pour le forcer ou le

réparer, risquerait de provoquer un incendie ou une explosion.

D. Ne vous servez pas de cet appareil si l’un de ses éléments a été

immergé dans l’eau. Appelez immédiatement un technicien compétent

pour faire inspecter l’appareil et remplacer toute pièce du système de

réglage ou commande du gaz qui a été sous l’eau.

8. Enfoncez le bouton de réglage jusqu’au fond et gardez-le enfoncé.

Allumez immédiatement la veilleuse en déclenchant l’allume-gaz

à étincelle (en poussant le bouton) jusqu’à ce que la veilleuse

s’enfl amme. Continuez de tenir le bouton de réglage enfoncé

pendant environ 90 secondes après l’allumage de la veilleuse.

Relâchez le bouton et il sortira subitement. La veilleuse devrait

rester allumée. Si elle s’éteint, répétez les étapes 5 à 8 inclusivement.

• Si le bouton ne sort pas automatiquement après avoir été relâché,

arrêtez immédiatement et téléphonez à votre technicien de service

ou à votre fournisseur de gaz.

• Si la veilleuse refuse de rester allumée après plusieurs tentatives,

tournez le bouton de réglage jusqu’à sa position d’arrêt “OFF” et

téléphonez à votre technicien de service ou à votre fournisseur de

gaz.

9. Tournez le bouton de réglage du gaz en sens inverse des aiguilles

d’une montre jusqu’à sa position de marche “ON”.

10. Fermez le compartiment de contrôle du bas.

11. Au besoin, rebrancher l’appareil au

courant électrique et remettre

Millivolt Pilot

l’interrupteur du brûleur principal

à la position “ON” ou régler le

0thermostat à la température désirée.

12. Si l’appareil ne fonctionne pas,

suivre les instructions intitulées

“Pour fermer le gaz qui alimente

l’appareil” et appeler un technicien

ou le fournisseur de gaz.

POUR FERMER LE GAZ QUI ALIMENTE L’APPAREIL

1. Tournez l’interrupteur mural à la position d’arrêt “OFF”. La veilleuse

restera allumée jusqu’au retour du service normal.

2. Pour une fermeture complète, tournez l’interrupteur mural à la posi-

tion d’arrêt “OFF”.

16

3. Ouvrez le compartiment de contrôle du bas.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

4. Enfoncez légèrement le bouton de réglage du gaz et tournez-le dans

le sens des aiguilles d’une montre jusqu’à la position

d’arrêt “OFF”. Ne forcez pas le bouton.

5. Fermez le compartiment de contrôle du bas.

Page 17

REPLACEMENT PARTS LIST

Gas Controls

Item # Part/Cat. No. Description Where Used

1 67L7001 Pilot Assembly, NG/LP EBVI25 & EBVI30

2 67L6801 Pilot Tube EBVI25 & EBVI30

3 67L6701 Thermocouple EBVI25 & EBVI30

4 60J79 Thermopile (pilot generator) EBVI25 & EBVI30

5a 111061 Piezo Igniter EBVI25

5b 24M8901 Piezo Igniter EBVI30

6 67L8701 Electrode Cable (piezo igniter wire w/ electrode) EBVI25 & EBVI30

7a H1657 Gas Valve, NG – SIT EBVI25

7b 24M1201 Gas Valve, NG – Honeywell EBVI30

Misc. Gas Components

8 H1161 Burner Assembly NG/LP EBVI25 & EBVI30

H1576 Conversion Kit, NG to LP (GCKNL-E25I) EBVI25

H0920 Conversion Kit, NG to LP (GCKNL-E30I) EBVI30

9 93L32 Connector-Flex Gas EBVI25 & EBVI30

10a 21L79 Orifi ce, Burner, NG (#41) EBVI25

10a 24M1001 Orifi ce, Burner, NG (#37) EBVI30

10b 69L45 Orifi ce, Burner, LP (#53) EBVI25

10b 21L01 Orifi ce, Burner, LP (.0625”) EBVI30

Miscellaneous Parts

12 H1585 Door Kit, Complete EBVI25

12 H0925 Door Kit, Complete EBVI30

13 H0928 Grate Assembly EBVI25 & EBVI30

69L2101 Latch, Door EBVI25 & EBVI30

14a H1138 Switch, Vent Spill Switch EBVI25 & EBVI30

15 27K30 Switch, Off/on EBVI25 & EBVI30

Log Set

16 88L53 FGE Glowing Embers EBVI25 & EBVI30

17 H1095 Log Set, 7 pc. EBVI25 & EBVI30

18 42363 Vermiculite, Bag EBVI25 & EBVI30

Room Air Blower System

19 H1391 Blower Assembly, 7” (H1128) EBVI25

19 H1141 Blower Assembly, 9” EBVI30

20 H1157 Power Cord EBVI25 & EBVI30

21a H1290 Rheostat (knob included) EBVI25 & EBVI30

21b 527 Knob, Rheostat EBVI25 & EBVI30

14b 13M2301 Switch, Temp. Control (TOD) EBVI25 & EBVI30

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

17

Page 18

REPLACEMENT PARTS DIAGRAMS

7a

6

5a

16

7b

5b

15

O

N

I

P

I

L

O

O

F

T

F

10a

L

O

H

9

17

10b

19

18

3

4

12

1

21a

2

18

8

21b

14a

20

13

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

14b

Page 19

TROUBLESHOOTING THE MILLIVOLT GAS CONTROL SYSTEM

Note: Before troubleshooting the gas control system, be sure external gas shut off valve (located at gas supply inlet) is in the

“ON” position. Important: Valve system troubleshooting should only be accomplished by a qualifi ed service technician.

SYMPTOM POSSIBLE CAUSES CORRECTIVE ACTION

1) Spark igniter will not light

pilot after repeated triggering of

igniter button.

WARNING: IF THE PILOT WILL

NOT LIGHT AFTER ONE MINUTE

OF ATTEMPTING, WAIT FOR AT

LEAST FIVE MINUTES FOR GAS

TO CLEAR BEFORE ATTEMPTING AGAIN.

A. Electrode wire (at piezo igniter) not pushed completely

on.

B. Piezo igniter is defective

C. Defective or misaligned electrode at pilot (spark at

electrode)

D. Incorrect lighting procedure • Carefully follow the lighting instructions on Pages 15 &16 or as found in the

E. Gas supply problem

• Check connection

• Replace piezo igniter

• Using a match, light pilot. If pilot lights, turn off pilot and trigger the igniter

button again. If pilot lights, an improper gas mixture caused the bad lighting

and a longer purge period is recommended. If pilot will not light – check gap at

electrode and pilot – It should be between 1/8” and 3/16.” If the gap is out of this

range, adjust the gap or replace the pilot assembly. See Page 11, Figure 25.

insert control compartment.

• Check for multiple gas shut-offs. Check gas supply lines. Check inlet gas

pressure. It should be within the limits as marked on the rating plate.

F. Pilot orifi ce plugged

2) Pilot will not stay lit after

carefully following the lighting

instructions.

3) Pilot fl ame stays lit, but

main burner will not light

(valve pilot/off/on knob is in

ON position, off/on switch, wall

thermostat or remote control is

set to ON).

Read important note below.

IMPORTANT NOTE: If an

optional Remote Switch*

is used for burner operation and if the standard

burner OFF/ON switch is

still installed on appliance, it must be in the

"OFF" position.

4) Frequent pilot/burner outage

problem

5) Main burner stays lit for up

to 10 minutes and then shuts off,

pilot fl ame remains lit.

6) Smell of gas A. Pilot, gas supply system, or pilot & burner adjustment

7) A thin coating of black soot

forms on the window.

Note: See Page 5, Glass Cleaning.

8) A white coating forms on

windows, logs, and/or inside walls

of fi rebox.

*Optional Remote Switch kits: wall switch, wall thermostat or remote control.

A. Thermocouple is not fi rmly connected to control valve

B. Pilot fl ame is not directed to top of thermocouple

C. Thermocouple is defective. The millivolt production

should be a minimum of 14 MV with pilot only.

A. Burner control switch (off/on switch, wall thermostat

or remote control) is in “OFF” position; or thermostat (if

installed) is set to a temperature setting that is too low.

B. Electrical wiring is damaged or poorly connected or

remote switch is defective.

C. One of the following components may be defective:

burner control switch, thermostat, vent spill switch, or

thermopile. Thermopile: Millivolt production should be a

minimum of 325 MV with pilot only.

D. Thermopile may not be generating suffi cient mil-

livolts

E. Plugged burner orifi ce

F. OFF/ON Switch & Remote Switch* are in the "ON"

position resulting in excessive resistance

A. Pilot fl ame may be too low or blowing (high) causing

the pilot/valve safety to drop out.

A. Vent is blocked; fl ue gas is “spilling,” which activates

the spill switch and shuts down the burner.

B. The house is negatively pressurized resulting in spill

switch activation.

screws on valve may be leaking. FOLLOW INSTRUCTIONS

ON THE COVER OF THIS MANUAL

A. Burner primary air inlet is restricted or blocked

B. Flames make contact with logs or other surfaces

C. Improper venting

A. Residues/impurities being burned off or impurities in

the fuel

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

• Clean or replace pilot orifi ce

• Check connection at valve

• Ensure thermocouple is fully inserted into pilot assembly. Clean and/or adjust

pilot for maximum fl ame impingement on thermocouple if necessary.

• Replace thermocouple

• Turn burner off/on switch on and/or refer to instructions provided with optional

thermostat or remote control, if applicable.

• Check wall switch and wires for proper connections. Refer to Millivolt Wiring

Diagram (Page 12, Figure 28). Jump the wire across terminals at the wall switch,

if the burner comes on, replace the defective wall switch. If okay, jumper the

wires across the wall switch wires at the valve. If the burner comes on, wires

are faulty or connections are bad.

• Refer to Millivolt Wiring Diagram (Page 12, Figure 28). Electrically bypass

components one at a time and replace defective item.

• Check thermopile with millivolt meter. Take reading at thermopile terminals

of gas valve. It should read 325 millivolts minimum with optional wall switch

“OFF.” Replace faulty thermopile if reading is below specifi ed minimum.

• Check burner orifi ce for blockage and remove.

• When turning on the burner using a Remote Switch,* ensure that the

standard OFF/ON Switch is in the "OFF" position. If both switches are in

the ON position, it may result in excessive resistance (& millivolt drainage)

and the burner may not come on.

• Clean and/or adjust pilot fl ame for maximum fl ame impingement on thermocouple. See Page 11, Figure 25.

• Examine venting system for blockage. Remove any blockage.

• Open a window to see if the problem is corrected.

• WARNING: NEVER USE AN OPEN FLAME TO CHECK FOR LEAKS.

After the gas company or fi re department has given clearance to re-enter the

dwelling, have a qualifi ed technician test all gas joints from the gas meter to

the gas heater regulator for leaks using a gas leak test solution (also referred

to as bubble leak solution).

• Ensure all openings (fresh air inlets) in the insert are free from dust and debris.

Recheck these areas periodically.

• Ensure ceramic logs are in their correct positions.

• Check for fl ue blockage, disconnected fl ue, improper installation. Make

appropriate corrections.

• Follow cleaning guidelines outlined in the MAINTENANCE section of this

manual.

19

Page 20

LENNOX reserves the right to make changes at any time, without notice, in design, materials,

specifi cations, prices and also to discontinue colors, styles and products.

Consult your local distributor for insert code information.

Printed in U.S.A. © LENNOX HEARTH PRODUCTS 2003

P/N 775,155M Rev. D 12/2005

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

1110 West Taft Avenue • Orange, CA 92865

Loading...

Loading...