Page 1

INSTALLATION AND OPERATION MANUAL

TM

US

Portland

Direct-Vent

Gas Fireplace

Retain These Instructions For Future Reference

P/N 775,219M Rev. B, 08/2008

A French manual is available upon request. Order P/N 775,219CF.

Ce manuel d’installation est disponible en francais, simplement

en faire la demande. Numéro de la pièce 775,219CF.

In the Commonwealth of Massachusetts:

• Installation must be performed by a licensed plumber or gas tter

• See Table of Contents for location of additional Commonwealth of

Massachusetts requirements

Report No.050-S-08c-5

WARNINGS

• Hot! Do not touch! The glass and surfaces of this appliance will be hot during operation and will

retain heat for a while after shutting off the appliance. Severe burns may result.

• Carefully supervise children in the same room as appliance. If small children are present in the home, it

is recommended that this appliance be fitted with a screen door. See Page 37 for ordering information.

Ravelle™ 42 (RAVL42)

• These appliances may be installed in an aftermarket permanently located, manufactured (mobile) home (USA

only), where not prohibited by local codes. This appliance is only for use with the type of gas indicated on the

rating plate. This appliance is not convertible for use with other gases unless a certified kit is used.

• Lennox Hearth Products gas-burning appliances are designed for use as a supplemental heater. They are not

intended for continuous use as a primary heat source.

WARNING: If the information in this manual is not

followed exactly, a fire or explosion may result

causing property damage, personal injury or loss

of life.

Do not store or use gasoline or other flammable

vapors or liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not light any appliance.

• Do not touch any electrical switch; do not

Use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow your gas supplier's

instructions.

• If your gas supplier cannot be reached, call

the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

AVERTISSEMENT : S’assurer de bien suivre les instructions données dans ce guide pour minimiser les risques

d’incendie ou d’explosion pouvant entraîner des dommages matériels, des blessures ou la mort.

Ne pas entreposer ni utiliser d’essence ou d’autres produits ou

liquides inflammables à proximité de cet appareil ou de tout

autre appareil de chauffage.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer l’appareil.

• Ne pas toucher aux interrupteurs électriques; ne pas utiliser

un téléphone dans le bâtiment.

• Aller immédiatement chez un voisin pour téléphoner au

fournisseur du gaz et suivre leurs instructions.

• Si le fournisseur de gaz n’est pas disponible, appeler les

pompiers.

L’installation et l’entretien doivent être assurés par un installateur certifié, une société de service spécialisée

ou le fournisseur de gaz.

Page 2

IMPORTANT SAFETY AND WARNING

INFORMATION

FOR YOUR SAFETY do not install or operate your

Ravelle™ 42 gas fireplace without first reading and

understanding this manual. Any installation or operation

of the appliance deviating from that which is stated in

this manual WILL void the warranty and may be hazardous.

INSTALLATION AND REPAIR SHOULD ONLY BE DONE BY

A QUALIFIED SERVICE TECHNICIAN. DO NOT ATTEMPT

TO SERVICE THE APPLIANCE YOURSELF.

The fireplace should be inspected and cleaned before

use and at least annually by a qualified service technician. More frequent cleaning may be required due to

excessive lint from bedding material, carpeting, etc.

It is imperative that control compartments, burners and

circulating air passageways of the room heater be kept

clean.

Adequate clearances around the combustion chamber

and accessibility clearances for servicing and proper

operation must be maintained.

Turn off the gas before servicing this appliance. It is

recommended that a qualified service technician perform an appliance check-up at the beginning of each

heating season.

All installations must conform with all local, state

and national codes. In the absence of local codes, the

installation must conform with National Fuel Gas Code

ANSI Z223.1-latest edition, also known as NFPA 54

(In Canada, the current CAN/CSA B149.1 installation

code). Refer to the National Fuel Gas Code and local

zoning and code authorities for details on installation

requirements. Your Ravelle 42 gas fireplace must be

vented to the outside in accordance with the latest

edition of the National Fuel Gas Code.

This gas fireplace MUST be vented directly to the outside

and MUST NEVER be attached to a chimney serving a

separate solid fuel burning appliance. Each gas appliance MUST USE a separate vent system. Common vent

systems are PROHIBITED.

Mobile home installations must conform with the Mobile

Home Construction and Safety Standard, Title 24 CFR,

Part 3280 (in Canada CAN/CSA Z240 MH), or, when such

a standard is not applicable, the Standard for Mobile

Home Installations, ANSI A225.1 - latest edition.

The appliance, when installed, must be electrically

grounded in accordance with local codes or in the absence of local codes, with the National Electrical Code,

ANSI/NFPA 70 - latest edition. In Canada, the current

CSA C22-1 Canadian Electrical Code - latest edition.

Do not make any make-shift compromises during in-

stallation. Any modification or alteration may result

in damage to the appliance or dwelling and will void

the warranty, certification and listings of this unit.

2

Failure to use manufacturer provided parts, variations

in techniques and construction materials or practices

other than those described in this manual may create

a fire hazard and void the limited warranty.

Your Lennox Hearth Products gas fireplace must be

equipped for the proper fuel type and altitude at which

it will be operated. Any operation outside the parameters outlined in this manual may result in a hazardous

condition and will void the warranty. Please carefully

read the sections pertaining to these subjects and/or

be sure your appliance is properly equipped.

Do not use this fireplace if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

Due to high temperatures, the fireplace should be lo-

cated out of traffic areas and away from furniture and

draperies.

Children and adults should be alerted to the hazards

of high surface temperature and should stay away to

avoid burns or clothing ignition. Young children should

be carefully supervised when they are in the same room

as the Lennox Hearth Products gas fireplace. Clothing

or any other flammable material should not be placed

on or near the fireplace.

Never use solid fuels such as wood, paper, cardboard,

coal, or any flammable liquids, etc., in this appliance.

Any grill, panel, or glass removed for service MUST be

replaced prior to operating the fireplace. Do not operate appliance with the glass front removed, cracked or

broken. Replacement of the glass should be done by a

qualified service technician.

DO NOT USE abrasive cleaner on the glass door as-

sembly. DO NOT ATTEMPT to clean the glass door when

it is hot.

Gold and nickel plated surfaces must be cleaned with

glass cleaner and a clean soft cloth before firing the first

time or fingerprints will remain permanently. NEVER use

brass polish to clean gold or nickel, this will remove

the plating!!!

Lennox Hearth Products, its employees, or any of its

representatives assume no responsibility for any damages caused by an inoperable, inadequate, or unsafe

condition as a result of any improper operation, service

or installation procedures, whether direct or indirect.

INSTALLER: THESE INSTRUCTIONS ARE TO REMAIN

WITH THE HOME OWNER!

Page 3

CONGRATULATIONS ON THE PURCHASE OF YOUR NEW

GAS APPLIANCE MANUFACTURED BY LENNOX HEARTH

PRODUCTS.

When you purchased your new gas fireplace, you joined the ranks of

thousands of individuals whose answer to their home heating needs

reflects their concern for efficiency and our environment. We extend

our continued support to help you achieve the maximum benefit and

enjoyment available from your new gas fireplace. It is our goal at Lennox

Hearth Products to provide you, our valued customer, with an appliance

that will ensure years of trouble-free warmth and pleasure.

Thank you for selecting a Lennox Hearth Products gas fireplace as the

answer to your supplemental home heating needs.

Sincerely, All of us at Lennox Hearth Products

TABLE OF CONTENTS

Cautions and Safety ........................................................ 2

Orifice Size/Altitude Adjustment .......................................... 4

Codes and Approvals ....................................................... 5

New York City, New York (MEA) .......................................... 5

Commonwealth of Massachusetts Requirements ...................... 5

Pre-Installation............................................................ 6-7

Features ............................................................

Venting ..............................................................

Fuel

Packaging List .....................................................

Specifications ......................................................

Preparing your Fireplace for Installation .........................

Clearances to Combustibles .....................................

Installation ............................................................... 8-13

Framing Dimensions .............................................

Fireplace Dimensions ............................................

Raised Installations .............................................

Hearth Extension Considerations ..............................

Facing Installation Considerations ............................

Face Installation .................................................

Vent Installation ....................................................... 14-20

Application ........................................................

Vent Parts List ....................................................

Vent Considerations .............................................

Horizontal Vent Installation .....................................

Vertical Vent Installation ........................................

Flue Restrictors ..................................................

.................................................................. 6

6

6

6

6

7

7

8

9

10

10

11

13

14

15

16

17

17

18

Vertical Vent Termination Clearances ........................

Horizontal Terminations .........................................

Vertical Terminations ............................................

Horizontal Vent Termination Clearances ..................... 20

Brick Panel and Log Set Installation .................................... 21

Electrical Connections .................................................... 22

Gas Line Installation ......................................................23

Gas Pressure Requirements .................................... 23

LP and Natural Gas Supplies ................................... 23

Increasing Efficiency And Hot Air Movement ..........................24

Forced Air Heating Installation ......................................25-28

Operating Instructions ................................................ 29-32

Pre-Lighting Checklist ........................................... 29

Lighting Instructions ............................................. 29

Flame Color and Behavior ......................................

Air Shutter Adjustment ..........................................

Paint Curing .......................................................

Quiet Operation ...................................................

Blower Operation .................................................

Optional Wall Thermostat .......................................

Operating Options ................................................ 32

Millivolt Control System ........................................ 32

Maintenance and Servicing ..........................................33-34

Maintenance Checklist ..........................................

Vent Pipe Maintenance ..........................................

Opening and Removing Door ...................................

Glass/Door Maintenance ........................................

Blower Removal ..................................................

Fuel Conversion ..................................................

Troubleshooting ............................................................ 35

Replacement Parts ........................................................ 36

Accessories ............................................................. 36-37

Fireplace Labels .......................................................38-39

Product Reference Information .......................................... 40

18

19

19

30

31

31

31

31

31

33

33

34

34

34

34

USING THIS MANUAL

Please read and carefully follow all of the instructions found in this

manual. Please pay special attention to the safety instructions provided

in this manual.

PRODUCT IS SUBJECT TO CHANGE WITHOUT NOTICE

3

Page 4

ORIFICE SIZE/ALTITUDE ADJUSTMENT

For altitudes above 2,000 feet (In Canada 4,500 FT/1370 M),the orifice

should be de-rated by 4% for every 1,000 feet to maintain the proper

ratio of gas to air. Improper orifice sizing may result in damage and

unsafe conditions. Changing the orifice should only be done by a quali

fied service technician. Contact your Lennox Hearth Products dealer for

proper orifice sizes.

SMOKE DETECTORS

Since there are always several potential sources of fire in any home, we

recommend installing smoke detectors. If possible, install the smoke

detector in a hallway adjacent to the room (to reduce the possibility of

occasional false activation from the heat produced by the appliance). If

your local code requires a smoke detector be installed within the same

room, you must follow the requirements of your local code. Check with

your local building department for requirements in your area.

THE RAVELLE™ 42 FIREPLACE

• Must conform with all local, state and national installation codes.

In the absence of local codes, the installation must conform with

-

National Fuel Gas Code ANSI Z223.1 - latest edition, also known

as NFPA 54 (In Canada, the current CAN/CSA B149.1 installation

code). Refer to the National Fuel Gas Code and local zoning and

code authorities for details on installation requirements.

• Mobile home installations must conform with the Mobile Home

Construction and Safety Standard, Title 24 CFR, Part 3280 (in Canada

CAN/CSA Z240 MH), or, when such a standard is not applicable,

the Standard for Mobile Home Installations, ANSI A225.1 - latest

edition.

• Must be vented directly to the outside in accordance with the latest

edition of the National Fuel Gas Code and must never be attached

to a chimney serving a separate solid fuel burning appliance.

• Has been certified for use with either natural gas or propane.

• Is not for use with solid fuels.

• Is approved for sitting rooms and/or bedrooms.

4

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 5

CODES AND APPROVALS

COMMONWEALTH OF MASSACHUSETTS REQUIREMENTS

Certification

Gas appliances must be tested and certified by a nationally recognized

testing and certification laboratory to ANSI (American National Standard

Institute) gas appliance safety standards.

This fireplace has been tested and certified by OMNI -Test Laboratories to

ANSI Z21.88/CSA 2.33 Standard for Vented Gas Fireplace Heater and CGA

2.17-M91 and UL 307B Gas Burning Heating Appliances for Manufactured

(Mobile) Homes in both USA and Canada.

It has met all necessary ANSI Standards and is fully certified for installa

tion in any community. If there are any questions or if you need further

substantiation either write to or call your Lennox Hearth Products dealer.

If you have further questions, please contact Lennox Hearth Products.

Check all local building and safety codes before installation. The installation

instructions and appropriate code requirements must be followed exactly

and without compromise. In the absence of local codes the following

standards and codes must be followed.

NEW YORK CITY, NEW YORK (MEA)

(Massachusetts Approval #G3-1104-102)

These fireplaces are approved for installation in the US state of Mas

sachusetts if the following additional requirements are met:

• Install this appliance in accordance with Massachusetts Rules and

Regulations 248 C.M.R. Sec. 5.08 2(a) through 2(e).

• Installation and repair must be done by a plumber or gas fitter licensed

in the Commonwealth of Massachusetts.

• The flexible gas line connector used shall not exceed 36 inches (92

centimeters) in length.

• The individual manual shut-off must be a T-handle type valve.

Massachusetts Horizontal Vent Requirements

In the Commonwealth of Massachusetts, horizontal terminations installed

less than seven (7) feet above the finished grade must comply with the

following additional requirements:

• A hard wired carbon monoxide detector with an alarm and battery

back-up must be installed on the floor level where the gas fireplace

is installed. The carbon monoxide detector must comply with NFPA

720, be ANSI/UL 2034 listed and be ISA certified.

-

(NYC MEA Approval #138-07-E)

Installation of these fireplaces are approved for installation in New York

City in the US state of New York.

• A metal or plastic identification plate must be permanently mounted to

the exterior of the building at a minimum height of eight (8) feet above

grade and be directly in line with the horizontal termination. The sign

must read, in print size no less than one-half (1/2) inch in size, GAS

VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

5

Page 6

PRE-INSTALLATION

Features

Installation Options

Residential

Vented vertical and horizontal

Manufactured (mobile) home

Natural gas (NG) or propane (LP)

Bedrooms

Optional wall-mounted or remote thermostat

Ductable for greater heat distribution

Venting

This fireplace can be vented with Security™ Secure Vent™ pipe*. Coaxial

pipe diameters are 6-5/8” outer and 4” inner. The combustion air for this

fireplace is drawn from outside the house through the outer DV (direct

vent) pipe. Room air is not required for combustion.

When planning your installation, select the correct length of vent pipe

for your particular requirements. Determine the minimum clearance to

combustibles from the rear of the unit to the wall. It is also important

to note the thickness of the wall. Before cutting the vent hole through

the wall make sure that ALL vent and termination clearances (see Pages

18-20) will be met.

Electrical

The standard fan motor requires 120 Volts AC for operation. The fireplace

is not dependent on the fan or an outside electrical supply to operate.

Millivolt Valve

This fireplace is operated with a millivolt valve and therefore burns even

during a power outage.

Fuel

This fireplace comes from the factory equipped to burn natural gas at a

specified elevation. The fireplace can be converted to burn LP gas (liquid

propane) by changing the cassette (valve and pilot assembly) or installing a

conversion kit. Only Lennox Hearth Products conversion kits can be used to

convert from NG to LP or LP to NG. Contact your Lennox Hearth Products

dealer for details.

Specifications

Fireplace weight: 250 lbs

Pipe:Type - direct-vent

Recommended manufacturer*

Security™ Secure Vent™*

Diameter - 6-5/8”x 4” for vertical terminations

Diameter - 8”x 5” for horizontal terminations

Packaging List

The Ravelle™ 42 gas fireplace comes with the following parts:

1 Fireplace Body with Burner Cassette

1 Log Set

1 Bag of Ember Material

1 Installation and Operation Manual

Decorative Faces - One Required

Arch Inset

Classic Inset

Screen

Foundry™

Brick Liners - One Required

Standard Brick

Red Brick

Architectural Stone

Ductability (optional)

Forced Air Duct Kit

Whole Home Comfort

System

* Other approved chimney brand is Simpson Dura-Vent DV-GS.

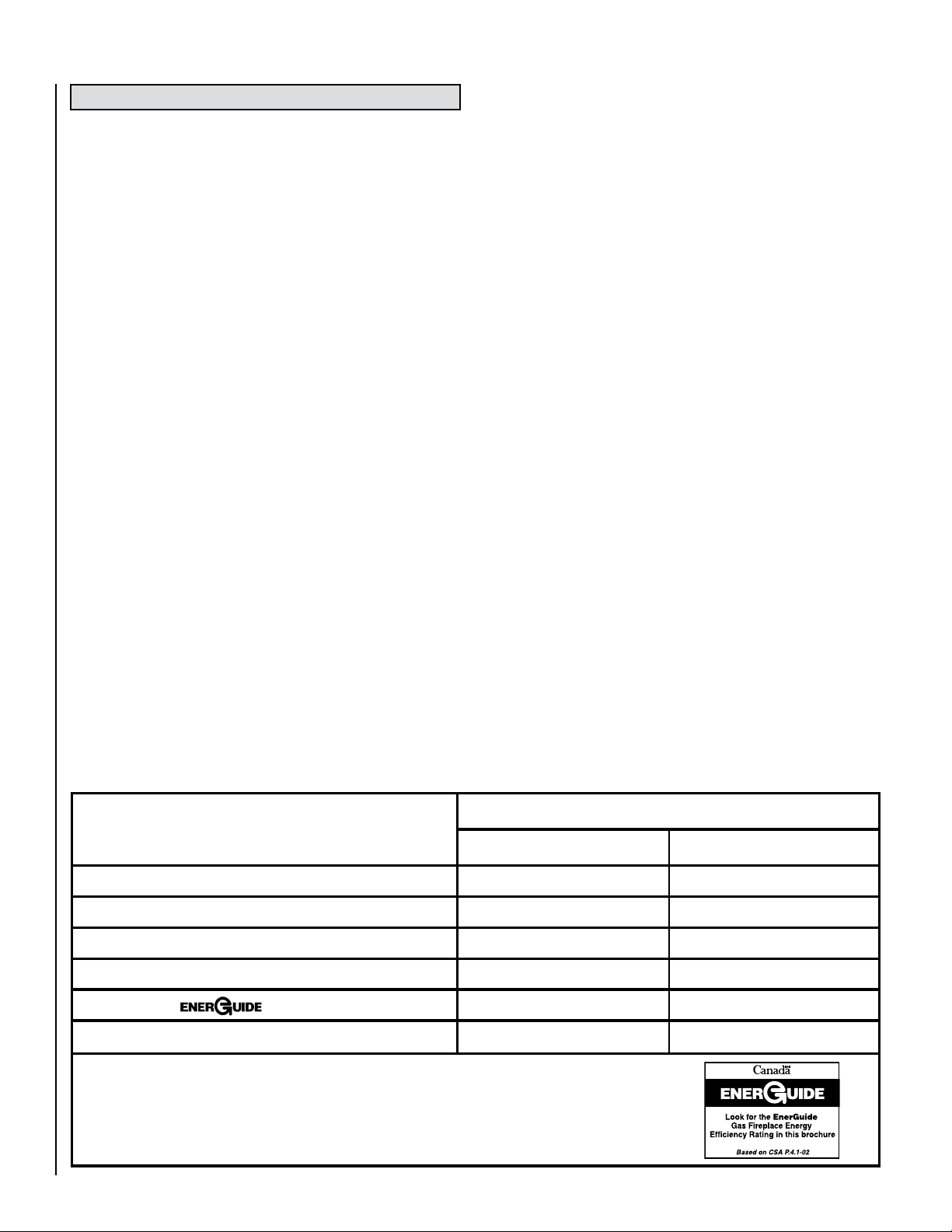

RATINGS

Max/Min Input BTUh 0-2,000 Feet (0-610 M)u

Manifold Pressure (IN. WC)

Min. Inlet Pressure (IN. WC)

Maximum heat output BTUs/hour-steady state

P4 Efficiency

Orifice (DMS) 0-2,000 Feet (0-610 M)u

uUnit factory equipped for 0-2000 FT/0-610 M, In Canada 0-4500 FT/0-1370 M

vThe Steady State Efficiency numbers based on maximum vent configuration.

wTested to CSA P.4.1-02 “Testing Method for Measuring Annual Fireplace Efficiency.

Electrical Rating: 120 VAC, 60 HZ, Less Than 2 Amps

6

w

Model Ravelle 42

NATURAL GAS LP GAS

42,000 / 29,500 36,000 / 25,000

3.5 / 1.7 10 / 5.1

5 11

34,860 29,880

50.43% 53.47%

#30 #49

Page 7

Preparing Your Ravelle™ 42 Fireplace For Installation

*

*

Installations in the shaded

area require five inches

clearance on top of pipe.

Fireplace side view

(drawing not to scale)

Base of Fireplace

Dimensions

Read all instructions before beginning your installation. If instructions

have not been read carefully, your installation could void your warranty

and may create a serious fire, health, or other safety hazard.

The Lennox Hearth Products warranty will be voided if one of the following occurs:

• Installation of any damaged fireplace or vent system compo

nent.

• Unauthorized modification of the direct vent system.

• Installation other than as instructed by Lennox Hearth Products,

Security™, or Simpson Dura-Vent.

• Installation of any fireplace or vent system component not manufactured or approved by Lennox Hearth Products, Security™ or

Simpson Dura-Vent.

When planning the installation for your Ravelle 42 gas fireplace, it’s

necessary to consider the following:

• Where the unit is to be installed

• The vent system configuration to be used

• Gas supply (NG or LP)

• Electrical wiring

• Framing and finishing

• Optional accessories

-

Clearances to Combustibles

Minimum clearances include any projections such as shelves, window

sills, mantels, spacers/standoffs or surfaces to combustible construction

etc. above the appliance. Paint or lacquer used to finish the mantel

must be heat resistant in order to avoid discoloration.

29-3/4”

w

35-1/2”

(902mm)

41”

(1041mm)

u

(756mm)

38-1/4”

(972mm)

47-3/4”

(1213mm)

v

43”

(1092mm)

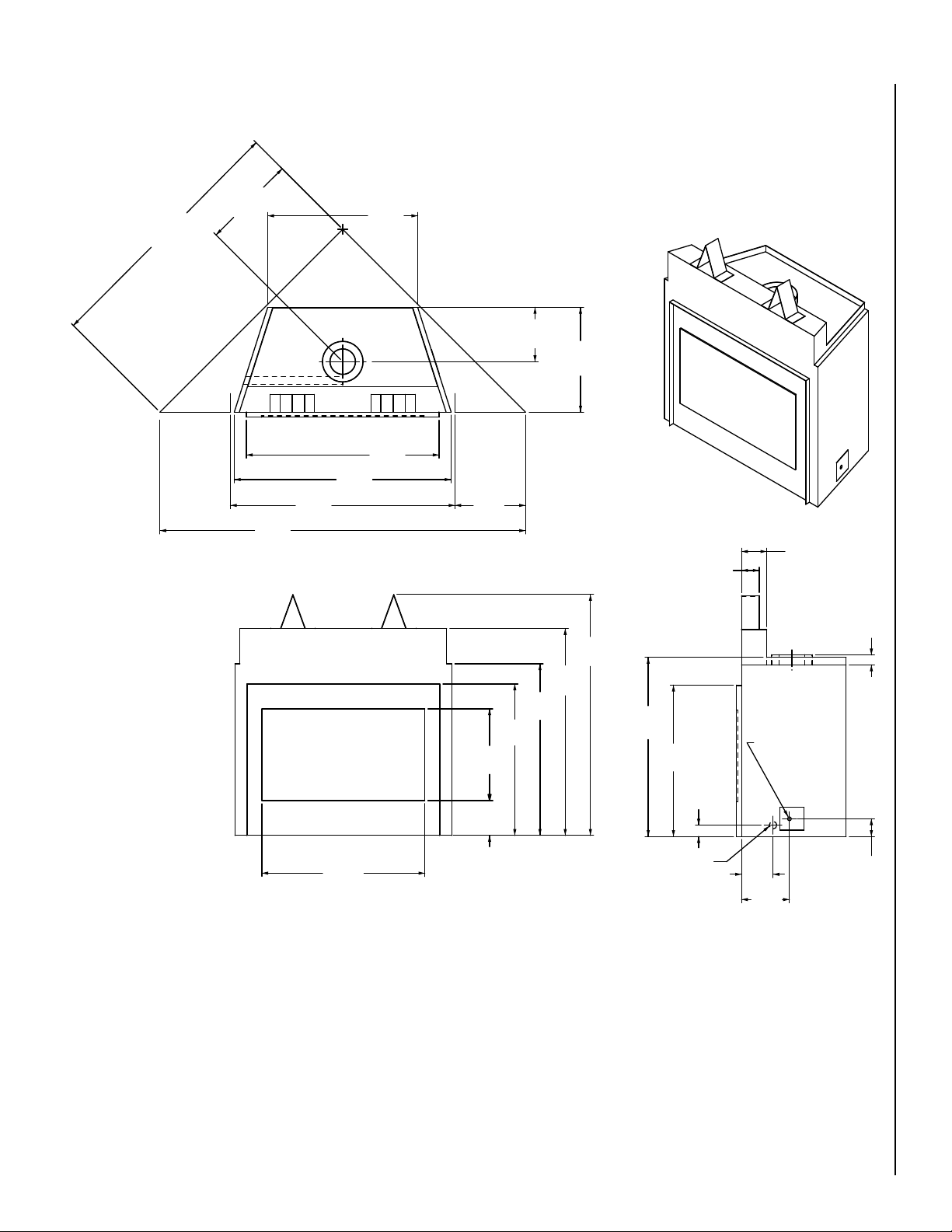

Figure 1

uThe center of the access hole for the gas piping is located at the

left side of the fireplace 6-7/8” back from the front edge and 2-1/8”

up from the base of the unit.

vThe electrical access is located at the right lower rear of the fire-

place.

w These dimensions include the 3/4” stand-offs.

20-3/4”

(527mm)

w

Minimum clearances to combustible materials in inches:

Front corners to enclosure (from stand-offs) 0 (0mm)

Rear corners to enclosure (from stand-offs) 0 (0mm)

Top to header (from stand-offs) 0 (0mm)

Bottom of unit to floor 0 (0mm)

Edge of door glass to side wall and side trim 7-1/2 (191mm)

Back to enclosure (from stand-offs) 0 (0mm)

Mantel: The drawing at the lower right shows the minimum distances

from the base of the fireplace to combustible mantel and facing material.

Combustible materials may be placed above and within the shaded areas.

If your fireplace has an arched face, the combustible mantel facing material may curve with the arch of the face as long as a minimum distance

of 10” is maintained between the top of the face and the combustible

facing material.

Hearth Protection: Hearth protection in front of the Ravelle™ 42 gas

fireplace is not required. However, hearth protection is recommended

and will enhance the appearance of the fireplace.

Pipe Clearances: All installations using a vertical termination cap

must maintain 1” (25mm) clearance between the direct vent pipe and

combustibles. For horizontal terminations, when the top of the horizontal

run of pipe is less than 8 feet (2.4 M) above the base of the fireplace, 1”

(25mm) clearance on the sides and bottom and 5” (127 mm) on the top

of the pipe is required. For those horizontal runs at or above 8 feet, 1”

(25 mm) is required on the sides and bottom and 2” (51 mm) on the top

of the pipe. See Page 19 for allowable pipe configurations.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

(133mm)

Figure 2

Mantel and Facing Material (side view)

12”

(305mm)

(51mm)

5-1/4”

7-1/2”

(191mm)

49-5/8”

(1261mm)

47-5/8”

(1210mm)

41-5/8”

(1057mm)

2”

1-1/4”

(32mm)

7

Page 8

C/L

INSTALLATION

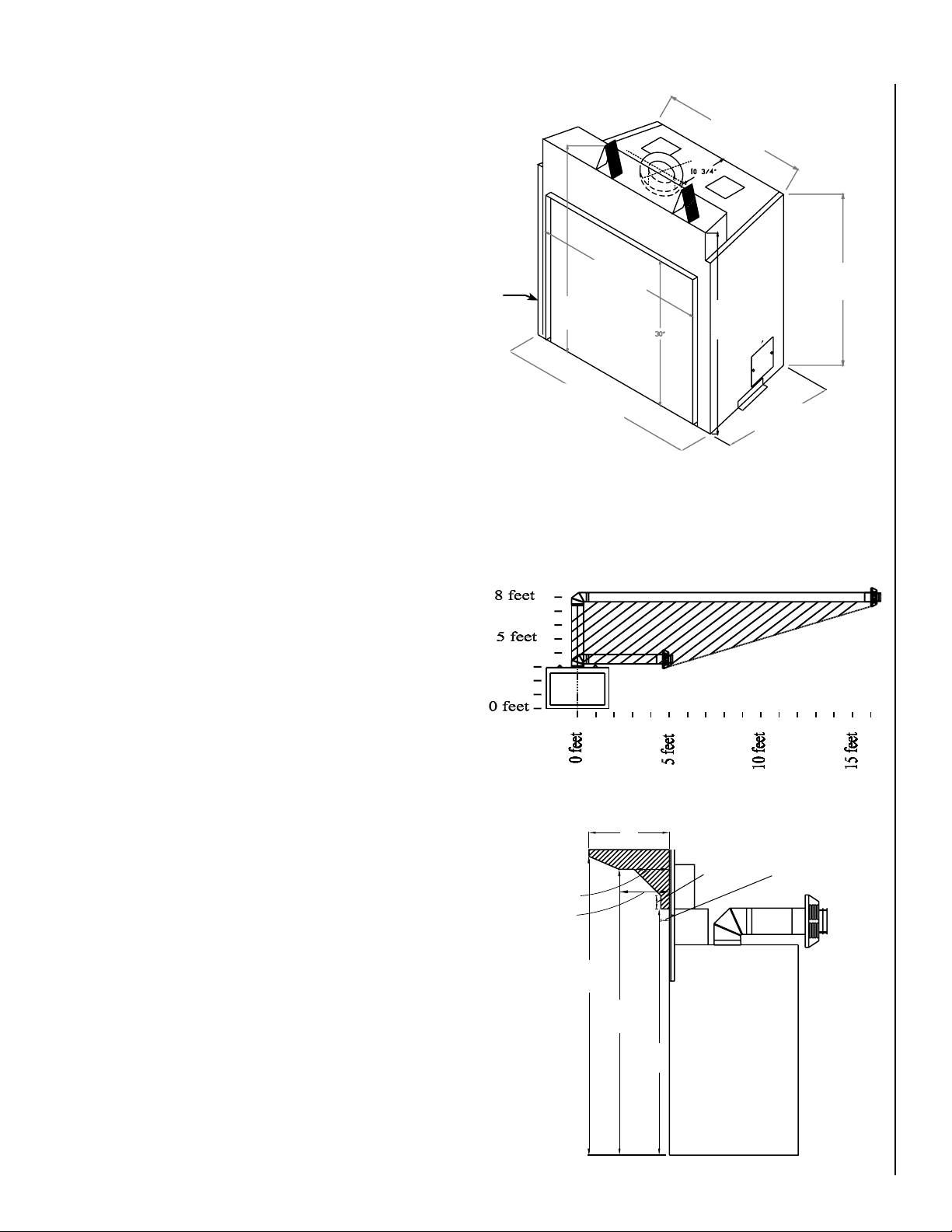

Framing Dimensions

The dimensions given on this page are minimum framing distances necessary to maintain safe clearances between the Ravelle™ 42 gas fireplace

and combustible materials.

uIf the unit is to be vented horizontally with a 90º elbow right off the

top of the fireplace and directly through an exterior wall, then a hole

10-3/4” (273 mm) square with a center line 42-1/4” (1073 mm)

above the base of the fireplace will accommodate the wall thimble

and direct vent pipe.

vThe gas line should be routed to the left side of the unit. The access

hole in the fireplace for the gas line is 6-7/8” (175 mm) back from

the front edge and 2-1/8” (54 mm) up from the base of the unit. If

the gas line enters the unit from the right side the piping will need to

be disconnected to remove the fan.

If a wall-mounted on/off switch or thermostat is to be used, these

wires should be routed to the left front of the unit for access to the

fireplace. The wire should be fed through the gas line hole, along the

gas line, to the valve.

A 6” (152 mm) header may need to be notched to accommodate vertical

vent pipe. If the fireplace is going to be horizontally vented directly out

the back, do not place a stud in line with the wall thimble. If a hearth

extension greater than 1” (25 mm) thick is going to be used, the fireplace and the header must be raised accordingly. See Hearth Extension

Considerations for further details.

Insulation: The exterior walls adjacent to the fireplace should be

insulated like the rest of the house, but insulation should not be placed

around the fireplace or vent pipe.

Corner Installations: The dimensions on this page are minimum and

show the stand-offs on the rear corners of the fireplace up against the

corner walls.

u

48”

(1219mm)

v

wThe electrical power supply wiring should be routed to the right rear

of the unit.

Note: The fireplace may be placed directly on wood or non-combustible

flooring, but not on vinyl floor covering or carpet.

Framing Suggestions: The framing header above the front of the

fireplace should be as narrow front to back as allowable to give maximum

clearance to the direct vent pipe (i.e. don’t use a 6” (152 mm) thick header

when a 4” (102 mm) thick one is allowed).

Figure 3

44-1/2”

(1130mm)

44-1/2”

(1130mm)

21”

(533mm)

w

8

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 9

18-9/16

(471)

14

(356)

44-1/2

(1130)

51-1/4

(1302)

29-3/4

(756)

20-3/4

(527)

47-3/4

(1213)

35-1/2

(902)

2

(51)

34

(864)

41

(1041)

38-1/4

(972)

30

(762)

43

(1092)

30

(762)

3-1/2

(89)

9-1/2

(241)

10-3/4

(273)

72-1/2

(1842)

6-7/8

(175)

18-3/16

(462)

32-5/16

(821)

3-1/2

(89)

5

(127)

6-1/4

(159)

2-1/4

(57)

GAS INLET

ELECTRICAL

INLET

Fireplace Dimensions

Corner Installation

Framing Details

Inches (millimeters)

Figure 4

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

9

Page 10

Base of Fireplace

One Inch Space

Fireplace

Face

Raised

Platform

Nailing

Plate

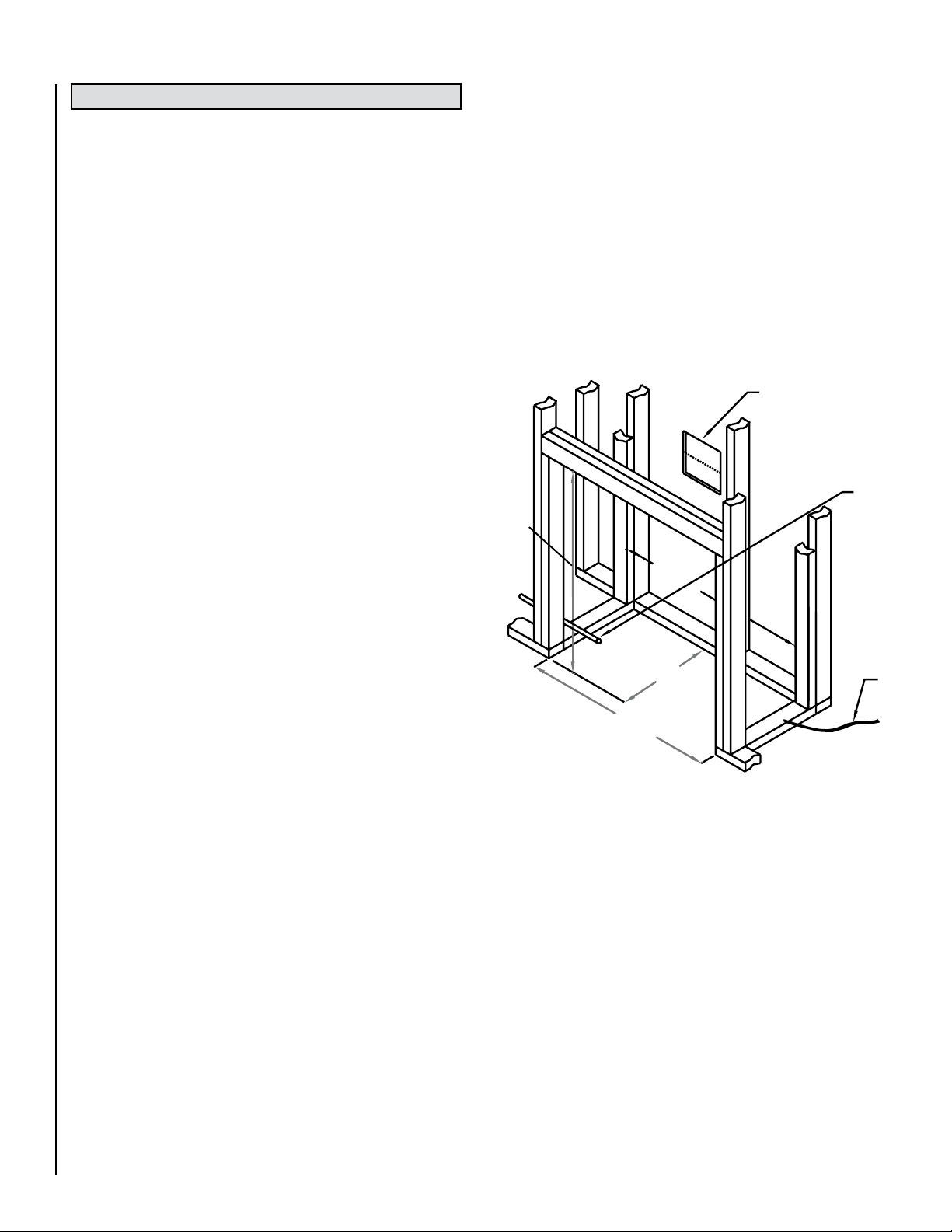

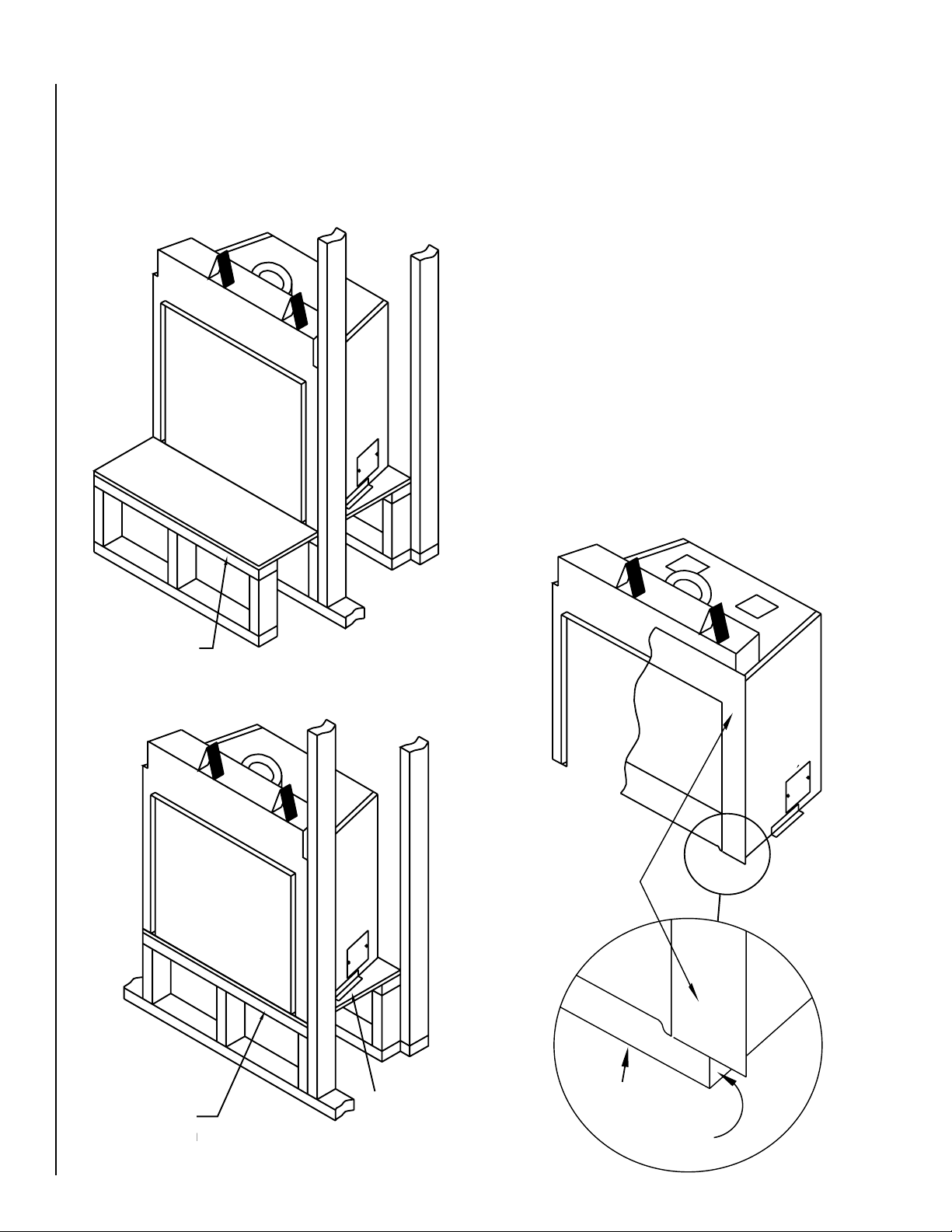

Raised Installations

Raised Platform

for Hearth Extension and Fireplace

Hearth Extension Considerations

The fireplace may be raised by building a platform of sufficient strength to

support the fireplace and pipe. When building a raised hearth extension,

please see the note below regarding height of the fireplace in relation to

the thickness of the hearth extension material.

A hearth extension in front of the fireplace is not required; however, to

enhance the appearance of the Ravelle™ 42 gas fireplace, one is recom

mended. Note: There is a 1” (25 mm) space between the base of the

fireplace and the bottom of the decorative fireplace face. This space

will allow a 7/8” (22 mm) thick hearth extension (including backer board

if desired). Should a hearth extension thicker than 7/8” (22 mm) be

desired, the height of the fireplace must be raised the thickness of that

hearth extension less the 7/8” (22 mm). For example, if a 2-7/8” (73 mm)

thick cultured stone is to be placed on the floor to serve as the hearth

extension, then the fireplace must be raised 2” (51 mm) (possibly using

1/2” (13 mm) plywood over 2 x 4’s laid flat) to accommodate the 2-7/8”

(73 mm) stone. It is important to note that if the fireplace is raised then

it is necessary to raise the height of the header above the stand-offs

an equal amount. If you wish to install your fireplace without a hearth

extension you must remember to set your finished flooring height 1” (25

mm) higher than the bottom base of the fireplace or install the fireplace

1” (25mm) lower than the finished flooring materials for that room. This

will assure that no gap will exist between the room’s flooring and your

new fireplace decorative face after it is installed.

-

Raised Platform

for Hearth Extension

and Fireplace

Figure 5

Figure 6

10

Raised

Platform

Nailing

Plate

Figure 7

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Fireplace

Face

Base of Fireplace

One Inch Space

Page 11

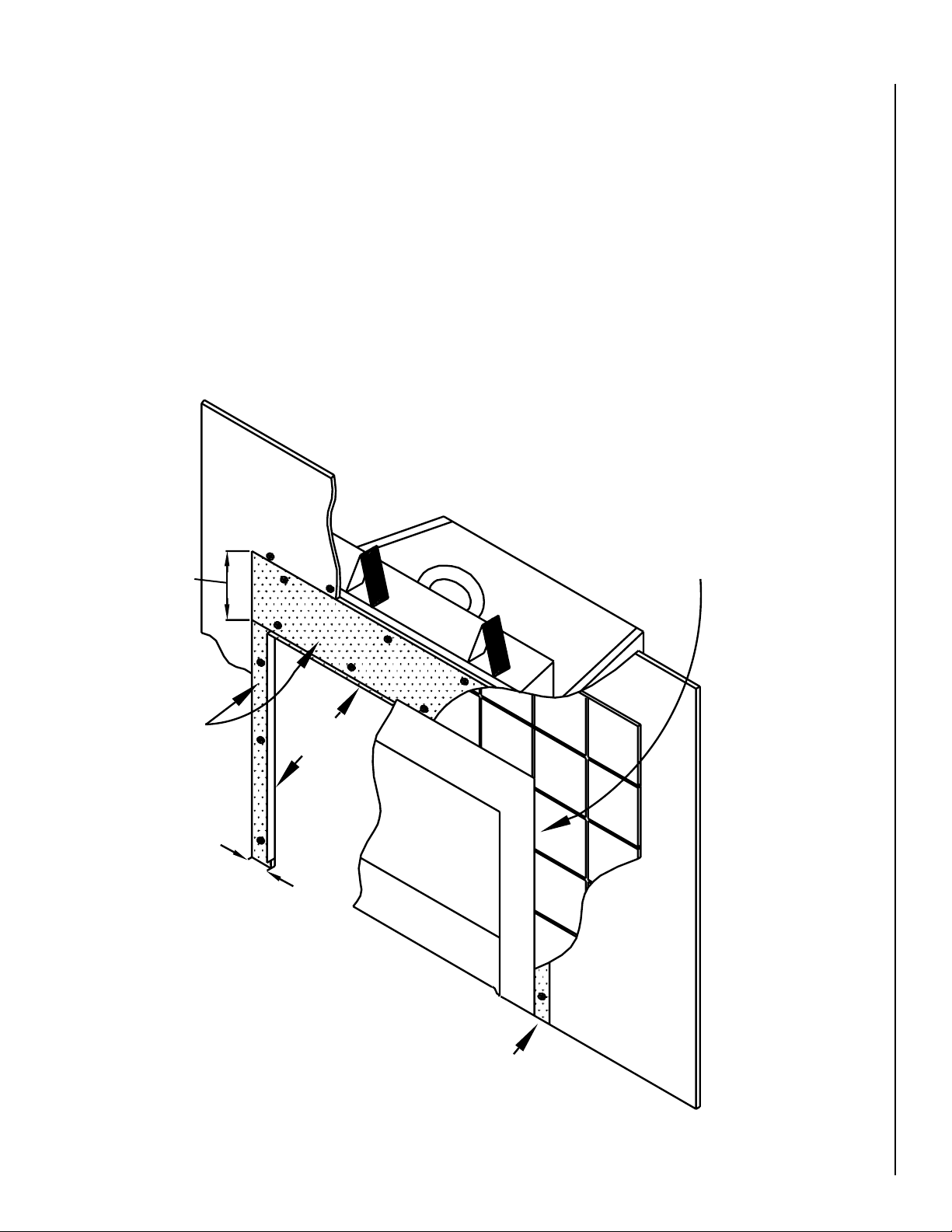

Facing Installation Considerations

Cement Board

3/8” Tile and 1/2” Cement

Board Behind Fireplace Face

Cement Board - a minimum

of five inches wide.

Sheetrock

1” Reveal

5” (127mm)

Minimum

Sheetrock

Non-combustible cement board (such as Wonderboard, Durock, or

Hardybacker) must extend 10” (254 mm) above the 1” (25 mm) top

reveal and a minimum of 3” (76 mm) from each side reveal (see Figure

8). This cement board may be 1/4” (6.3 mm) thick or greater, but would

normally be the thickness of the drywall - for example 1/2” (13 mm).

The cement board may be fastened by drywall screws.

Sheetrock

The screws should be driven through the cement board into the outer

metal skin of the fireplace. The sheetrock (drywall) is then butted up

to the cement board. The sheetrock above the fireplace should also be

fastened to the fireplace by driving screws into the outer metal skin of

the fireplace.

Facing Less Than 1” Thick: If the combined thickness of the facing

material (eg. 3/8” [9.5 mm] thick ceramic tile and 1/2” [13 mm] thick

cement board) is less than 1” (25mm), then the tile can be placed behind

the fireplace face (see below).

10” (254mm)

Minimum

Cement Board

3” (76mm)

Minimum

3/8” (9.5mm) Tile and 1/2” (12.7mm) Cement Board

Behind Fireplace Face

(25mm)

1” Reveal

Sheetrock

Figure 8

Cement Board - Minimum

of 3” (76mm) Wide

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

11

Page 12

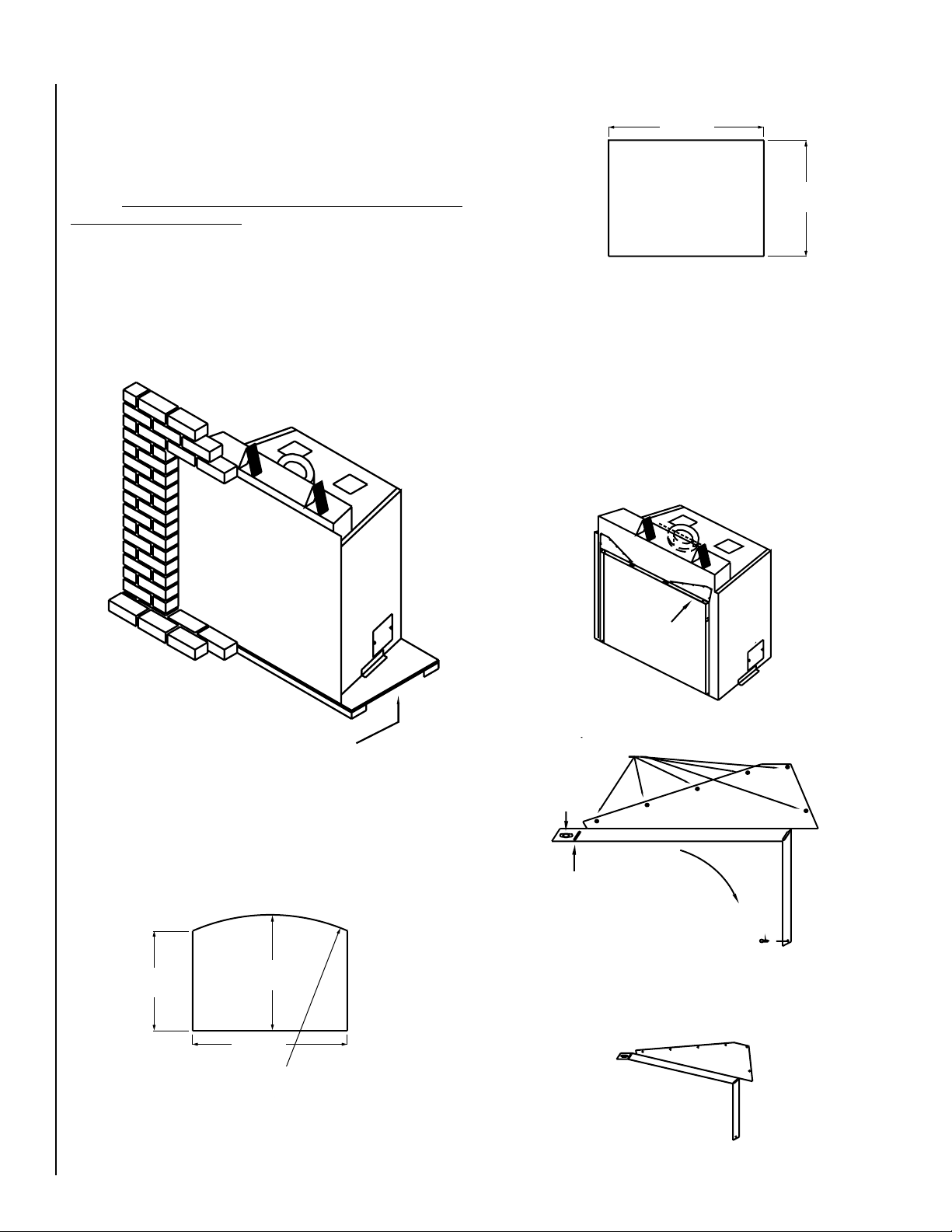

Facing Greater Than 1” (25mm) Thick:

Reveal Corner

Template

A

B

C

Expanded View of Reveal Corner

A

If the combined thickness of the facing material (eg. brick or cultured

stone) and concrete board is greater than 1”, then the facing material

must be placed around the face. A template (Arch #75098, Foundry™

#75035 and Louver #75101) should be used while installing the facing

material. Templates for the various faces may be purchased from your

Lennox Hearth Products dealer or a template may be made of plywood

using the dimensions listed on this page. If you choose to make a

template, 1/8” (3mm) must be added to each side and top dimension to

provide sufficient clearance so the face may be removed for access to

the firebox. Since the bottom of the fireplace face is 1” above the base

of the fireplace, 1” (25mm) must be added to the height of the template

if the template is to rest on the floor or platform on which the fireplace

is placed. It is extremely IMPORTANT that the template be centered left

to right on the glass door of the fireplace.

Traditional Face

41”

(1041mm)

30-5/8”

(778mm)

Figure 12

Adjustment prior to arched face installation:

The corners of the 1” (25mm) reveal around the fireplace opening need

to be adjusted prior to installing an arched face (see drawings below).

Remove screws A and loosen screw B. Rotate the corner downward

bending the metal at pivot point C until the holes from which screws A

were removed line up with the lower set of holes. Reinstall screws A and

tighten screw B. When finished, the corners should look like the corner

below at the far right.

Platform to raise fireplace to accommodate a

hearth extension greater than 1” in thickness.

Figure 9

The fireplace face dimensions are:

26-3/8”

(670mm)

Template

Arch Face

30-5/8”

(778mm)

41”

(1041mm)

51-1/2” R

(1308mm)

Figure 13

Figure 14

Reveal Corner

A

B

C

Expanded View of

Reveal Corner

A

Reveal Corner Adjusted

for Arch Face

Figure 10

12

Figure 15

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 13

Face Installation

A

B

C

D

E

Expanded View

Expanded View

A number of different faces are available for the Ravelle™ 42 gas fireplace, however, all the faces are installed in a similar manner. A total of

four screws (two upper and two lower) attach the face to the fireplace.

To install a face:

1. Locate the two screws found in the hardware bag shipped with the face.

Position the face (with the lower door open) in front of the fireplace.

Install the two screws, A in the diagram below, through the holes in the

lower door hinge bracket and screw them into the captive nut on tab B

located on the fireplace. Do not fully tighten these screws yet.

B

2. Bracket C in the diagram below is installed on the face during the face

assembly (see instructions included with face). The captive screws D

on this bracket should be screwed into captive nuts E on the fireplace.

A phillips head screwdriver inserted through the vent holes in the face

can be used to complete this task. Align the face for plumb and level

and then tighten all four screws.

CAUTION: Any masonry that has been cleaned with an acid

wash must be properly neutralized before installing the fireplace face. The acid wash will tarnish the face. Consult your

masonry installer.

Expanded View

A

E

C

D

Figure 16

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Expanded View

13

Page 14

VENT INSTALLATION

Application:

The Ravelle™ 42 gas fireplace, has been tested and listed as a direct

vent heater system by OMNI-Test Laboratories, Portland, Oregon. and

is recommended for use with Security™ Secure Vent™ pipe.

IMPORTANT:

• Read all instructions carefully before starting the installation.

Failure to follow these instructions may create a fire or other

safety hazard and will void the warranty. Be sure to check for

specific clearances to combustible requirements on Page 7.

Do not extend the venting system vertically or horizontally in

excess of the distance prescribed on Page 19. Consult your

local building codes before beginning the installation.

• Always maintain the proper air spaces (see Page 7) between

the vent pipe and nearby combustibles to prevent a fire hazard.

Do not fill air spaces with insulation. Be sure to check the

vent termination clearance requirements from decks, windows,

soffits, gas regulators, air supply inlets and public walkways,

as specified in these installation instructions on Page 20 and

local building codes.

• This gas appliance and vent system must be vented directly to

the outside of the building and never be attached to a chimney

serving a separate solid fuel or gas-burning appliance. Each

direct vent gas appliance must use its own separate vent system.

Common vent systems are prohibited.

• The Ravelle 42 gas fireplace is recommended for use

with Security Secure Vent pipe. The appliances and vent

manufacturers warranties will be voided and serious fire, health,

or other safety hazards may result from any of the following

actions:

• Installation of any damaged direct vent component.

• Unauthorized modification of the direct vent system.

• Installation of any vent component part not approved or

manufactured by the approved vent manufacturer.

• Installation other than as instructed by Lennox Hearth

Products and vent manufacturers instructions.

Vent Parts List

Direct vent pipe Security™ Secure Vent™* may be used with the Ravelle

42 gas fireplace. Please see the lists below to verify the components avail

able from each direct vent pipe manufacturer. Snorkel terminations are

available for applications which may require vertical rise on the building

exterior. The components listed below come in a galvanized finish. Most

of the components are also available in a painted black finish. Add a “B”

to the end of the part number when ordering if a black part is desired.

Security™ Secure Vent 6-5/8”x 4” Pipe

Part Number Description

SV4L6 6” Pipe Length

SV4L12 12” Pipe Length

SV4L24 24” Pipe Length

SV4L36 36” Pipe Length

SV4L48 48” Pipe Length

SV4LA 6” Pipe, Adjustable

SV4LA12 12” Pipe, Adjustable

SV4FA Flashing, 1/12 to 176/12 Roof Pitch

SV4FB Flashing, 8/12 to 12/12 Roof Pitch

SV4RSM Wall Radiation Shield

SV4E46 45° Elbow

SV4E90 90° Elbow

SV4VS Vinyl Shield Protector

SV4FC Storm Collar

SV4CGV Vertical Termination Cap

SV4BF Firestop

SV4CHC Horizontal Termination Cap

SV4STC36 Snorkel Termination (36”) Cap

SV4STC14 Snorkel Termination (14”) Cap

SV4BM Wall Band

Simpson DuraVent 6-5/8”x 4” GS Pipe

Part Number Description

908 6” Pipe Length

907 9” Pipe Length

906 12” Pipe Length

904 24” Pipe Length

903 36” Pipe Length

902 48” Pipe Length

911 11” to 14-5/8” Pipe, Adjustable

912 12” to 17” Pipe, Adjustable

917 17” to 24” Pipe, Adjustable

942 Wall Thimble

943 Flashing, 0/12 to 6/12 Roof Pitch

943S Flashing, 7/12 to 12/12 Roof Pitch

945 45° Elbow

950 Vinyl Siding Standoff

953 Storm Collar

963 Ceiling Firestop

980 Vertical Termination

981 Snorkel Termination (36”)

982 Snorkel Termination (14”)

984 Horizontal Square Termination (High Wind)

988 Wall Strap

991 Vertical Termination (High Wind)

-

14

Page 15

Vent Parts List - Horizontal

Vent Parts List - Vertical

Direct vent pipe by Security™ or Simpson Dura-Vent may be used

with the Ravelle™ 42 gas fireplace. Please see the lists below to verify

the components available from each direct vent pipe manufacturer. All

horizontally terminated venting of the Ravelle 42 gas fireplace uses 8”

x 5” size vent pipe and all vertically terminated venting uses 6-5/8” x 4”

size vent pipe. The flue collar on the fireplace is 8” x 5” in size. Therefore,

when vertically terminating it is necessary to use a reducer - part number

75247 (available from Lennox Hearth Products) - to make the transition

from the 8” x 5” flue collar to the 6-5/8” x 4” pipe. Snorkel terminations

are available for applications which may require vertical rise on the building

exterior. The components listed below come in a galvanized finish. Most

of the components are also available in a painted black finish. Add a “B”

to the end of the part number when ordering if a black part is desired.

Security™ Secure Vent™ 8”x 5” Pipe

Part Number Description

SV5L6 6” Pipe Length

SV5L12 12” Pipe Length

SV5L24 24” Pipe Length

SV5L36 36” Pipe Length

SV5L48 48” Pipe Length

SV5LA 6” Pipe, Adjustable

SV5LA12 12” Pipe, Adjustable

SV5E45 45º Elbow

SV5E90 90º Elbow

SV5RSM Wall Radiation Shield

SV5VS Vinyl Shield Protector

SV5BF Firestop

SV5CHC-1 Horizontal Termination Cap

SV5STC14 Snorkel Termination (14”) Cap

SV5STC36 Snorkel Termination (36”) Cap

SV5BM Wall Band

Simpson Dura-Vent GS 8”x 5” Pipe

Part Number Description

1208 6” Pipe Length

1207 9” Pipe Length

1206 12” Pipe Length

1204 24” Pipe Length

1203 36” Pipe Length

1202 8” Pipe Length

1211 11” to 14-5/8” Pipe, Adjustable

1217 17” to 24” Pipe, Adjustable

1290 90° Elbow

1247 Wall Thimble

1263 Ceiling Firestop

1288 Wall Strap

1281 Snorkel Termination (36”)

1282 Snorkel Termination (14”)

1284 Horizontal Termination Cap

1285 Horizontal Termination Cap (High Wind)

1250 Vinyl Siding Standoff

Direct vent pipe by Security or Simpson Dura-Vent may be used with

the Ravelle 42 gas fireplace. Please see the lists below to verify the

components available from each direct vent pipe manufacturer. All

horizontally terminated venting of the Ravelle 42 gas fireplace uses 8”

x 5” size vent pipe and all vertically terminated venting uses 6-5/8” x 4”

size vent pipe. The flue collar on the fireplace is 8” x 5” in size. Therefore,

when vertically terminating it is necessary to use a reducer - part number

75247 (available from Lennox Hearth Products) - to make the transition

from the 8” x 5” flue collar to the 6-5/8” x 4” pipe. Snorkel terminations

are available for applications which may require vertical rise on the building

exterior. The components listed below come in a galvanized finish. Most

of the components are also available in a painted black finish. Add a “B”

to the end of the part number when ordering if a black part is desired.

Security Secure Vent 6-5/8”x 4” Pipe

Part Number Description

SV4L6 6” Pipe Length

SV4L12 12” Pipe Length

SV4L24 24” Pipe Length

SV4L36 36” Pipe Length

SV4L48 48” Pipe Length

SV4LA 6” Pipe, Adjustable

SV4LA12 12” Pipe, Adjustable

SV4FA Flashing, 1/12 to 176/12 Roof Pitch

SV4FB Flashing, 8/12 to 12/12 Roof Pitch

SV4RSM Wall Radiation Shield

SV4E46 45° Elbow

SV4E90 90° Elbow

SV4VS Vinyl Shield Protector

SV4FC Storm Collar

SV4CGV Vertical Termination Cap

SV4BF Firestop

SV4BM Wall Band

Part Available from Lennox Hearth Products Only:

75247 8” x 5” to 6-5/8” x 4” Reducer

Simpson Dura-Vent GS 6-5/8” x 4” Pipe

Part Number Description

908 6” Pipe Length

907 9” Pipe Length

906 12” Pipe Length

904 24” Pipe Length

903 36” Pipe Length

902 48” Pipe Length

911 11” to 14-5/8” Pipe, Adjustable

912 12” to 17” Pipe, Adjustable

917 17” to 24” Pipe, Adjustable

942 Wall Thimble

945 45° Elbow

943 Flashing, 0/12 to 6/12 Roof Pitch

943S Flashing, 7/12 to 12/12 Roof Pitch

953 Storm Collar

963 Ceiling Firestop

988 Wall Strap

980 Vertical Termination Cap

991 Vertical Termination Cap (High Wind)

15

Page 16

Vent Considerations

Twist-lock procedure: Four indentations, located on the female ends

of pipes and fittings, are designed to slide straight onto the male ends of

adjacent pipes and fittings by orienting the four pipe indentations so they

match and slide into the four entry slots on the male ends (see Figure

17). Push the pipe sections completely together, then twist-lock one sec-

tion clockwise approximately one-quarter turn until the two sections are

fully locked. The female locking lugs will not be visible from the outside

on the pipe or fittings. They may be located by examining the inside of

the female ends.

Female

Locking

Lugs

Sealant

Supports: Horizontal runs of vent must be supported every three feet.

Wall straps are available for this purpose.

Pipe Sealing: If Security™ Secure Vent™ pipe is used, then sealant is

required at only the first pipe joint attaching the pipe to the flue collar on

the fireplace. If Simpson Dura-Vent GS pipe is used, then the pipe must

be sealed as follows: seal both the inner and outer pipes with a high

temperature silicone sealant rated for at least 600º F (commonly known

as “RTV”). Run a 1/8” (3mm) bead of silicone around the outside of the

male end of the outer sleeve. Run a 1/8” (3mm) bead of silicone about

1/4” (6mm) from the end of the male inner pipe, which is found in the

pipe to be attached above. Twist-lock the pipes or fittings together.

Figure 17

Male

Locking

Lugs

16

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 17

Horizontal Vent Installation

Flashing

Simpson

(Part # 943 or 943S)

Secuirty (Part #SV4FA or SV4FB)

Vertical Termination Cap

Security (Part #SV4CGV)

Simpson (Part # 980)

Pipe

Length

Ceiling Firestop

Simpson (Part # 963)

Security (Part # SV4BF)

Ceiling Minimum

Framing 10” x 10”

(254mm x 254mm)

Storm Collar

Simpson (Part # 953)

Security (Part #SV4FC)

Roof- Maintain 1”

(25mm) Clearance

to Combustibles

Vertical Vent Installation

IMPORTANT NOTES:

1. All Ravelle™ 42 gas fireplaces horizontally terminated vent

installations use 8”x 5” Security™ Secure Vent™ or Simpson

Dura-Vent GS direct-vent pipe.

2. When this pipe passes through a wall, a wall thimble - Security

#SV5RSM or Simpson #1247 is required. The hole in the wall

for the wall thimble should be 10-3/4” x 10-3/4”.

3. Horizontal runs of vent must be supported every three feet. Wall

straps - Security #SV5BM or Simpson #1288 are available for

this purpose.

4. If the vent passes through a ceiling or floor, a firestop - Security

#SV5BF or Simpson #1263 is required.

5. Venting terminals shall not be recessed into a wall or siding.

If installing the termination cap on a wall covered with siding,

a vinyl siding standoff - Security #SV5VS or Simpson #1250

or furring strips must be used to ensure that the termination

cap is not recessed into the siding.

6. The horizontal run of vent must have a 1/4” (6mm) rise for

every 12” (305mm) of run towards the termination.

7. If the wall being penetrated is constructed of non-combustible material, such as masonry block or concrete, an 8-1/2”

(216mm) diameter hole is acceptable and a wall thimble is

not required.

8 The location of the horizontal vent termination on an exterior

wall must meet all local and national building codes and must

not be blocked or obstructed. For allowable external vent terminations locations, see the diagram on Page 20.

9. Allowable clearances from the vent pipe to combustible materials must be maintained. See Page 7 for these clearances.

10.Do not locate the termination cap where it may be blocked by

shrubbery or snow.

IMPORTANT NOTES:

1. All Ravelle 42 gas fireplace vertically terminated vent installations

use 6-5/8” x 4” Security or Simpson Dura-Vent GS direct-vent

pipe.

2. Fireplaces that are vertically terminated require pipe reducer

- Lennox Hearth Products #75247 - installed on the fireplace’s

flue collar before the

direct vent pipe can be installed.

3. If the vent passes through a ceiling or floor, a firestop - Security

#SV4BF or Simpson #963,

4. If the vent passes through the roof, a roof flashing - Security

#SV4FA or SV4FB, Simpson #943 or 943S and storm collar

- Security #SV4FC, Simpson #953 are required.

5. Allowable clearances from the vent pipe to combustible materials must be maintained. See Page 7 for these clearances.

6. A maximum of two 45º elbows may be used. See Page 18 for

allowable offsets.

7. The maximum system height is 30 feet (9.1 M) and the minimum

is 10 feet (3 M).

10-3/4”x 10-3/4”

(273mm x 273mm)

Framed Hole

Elbow

Termination Cap

Wall Thimble

Note:

Verify that you have

at least the minimum clearance to

combustibles at the

roofline.

Figure 19

Figure 18

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

17

Page 18

Flue Restrictors

12

X

Roof Pitch is X/12

2 FT

MIN.

2 FT MIN.

Lowest

Discharge

Opening

H*

*H = MINIMUM HEIGHT FROM ROOF TO

LOWEST DISCHARGE OPENING OF VENT

TERMINATION HEIGHTS FOR VENTS ABOVE

FLAT OR SLOPED ROOFS

Horizontal Overhang

Vertical

Wall

Vent

Termination

Storm Collar

Concentric

Vent Pipe

Flashing

1 inch (25.4 mm) Minimum

Clearance to Combustibles

Restrictors

Interior of Firebox

The flue restrictor settings shown in Figures 22 and 23 are for typical

installations and may need to be adjusted from standard to take into

account other variables in the installation to achieve proper combustion.

See Flue Restrictor Guidelines on this page to assist you in making a

proper flue restrictor adjustment.

The Ravelle™ 42 gas fireplace uses balanced flue technology to ensure

proper combustion. Flue restrictors may need to be installed depending

on the vent configuration of your fireplace. The drawings on Page 19

show all the allowable pipe configurations for the Ravelle 42 gas fireplace.

To properly install the flue restrictor, find your pipe configuration in the

drawings on Page 19 and note which restrictor setting is recommended.

The flue restrictors and four black self-tapping 5/32” allen head screws

can be found in the firebox in a plastic bag. The restrictors should be

placed over the openings at both sides of the ceiling of the firebox. For

each restrictor, two self-tapping 5/32” allen head screws should be in

stalled in either holes 1, 2, 3, or 4 in the restrictor and screwed into the

two holes in the firebox ceiling. (There are four holes at each side of the

firebox ceiling to receive only two screws. Insert the screws into either

two holes). See the drawing to the right for the location of hole numbers

on the restrictor. The numbered holes in which the screws are inserted

in the restrictor should correspond to the restrictor position numbers

found on the drawings for your pipe configuration. Restrictor positions

are based on tests run in a laboratory. The optimum restrictor positions

may need to be adjusted slightly depending on the conditions surround

ing the residential installation. Do not adjust restrictors to a point where

the fireplace is sooting.

Notes: The higher the number of the flue restrictor position, the greater

amount of combustion air will be delivered.

Restrictors

Interior of Firebox

-

Figure 20

Vertical Vent Termination Clearances

The vent / air intake termination clearances above the high side of an

angled roof is as shown in the table below.

Figure 21

Flue Restrictor Adjustment Guidelines

After the flue restrictors have been set to the standard settings as shown

in Figures 22 and 23, the burner flame appearance should be evaluated

to determined if the flue restrictors need to be set to a different position

to adjust for variables in your installation. Light the appliance and allow

it to burn for 20 minutes. See

determine if you have a proper burner flame appearance. If the proper

flame appearance cannot be achieved, the flue restrictor may need to be

set to a different position. See the following guidelines to determine if

you need to readjust the flue restrictors.

Before proceeding, confirm the manifold and inlet gas pressure is correct,

primary air shutter is properly adjusted, venting system connections are

secure and not blocked and if you are at a high elevation, ensure unit has

been properly derated:

Symptoms - Lack of Combustion Air

If the symptoms listed below are present, you may need to adjust the

flue restrictor to a more open position.

• Flame appears yellow

• Floating Flames (lazy, ill defined, quiet, may roll)

• Sooting

• Pilot becomes yellow and appliance shuts down

Symptoms - Excessive Combustion Air

If the symptoms listed below are present, you may need to adjust the

flue restrictor to a more closed position.

• Low Flame

• Pilot pulls and appliance shuts down

• Pilot flame ghosts

18

Flame Color and Behavior on Page 30 to

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Termination Heights For Vents

Above Flat Or Sloped Roofs

Ref. NFPA 54 / ANSI Z223.1

Roof Pitch * Feet * Meters

Flat to 6/12

6/12 to 7/12

7/12 to 8/12

8/12 to 9/12

9/12 to 10/12

10/12 to 11/12

11/12 to 12/12

12/12 to 14/12

14/12 to 16/12

16/12 to 18/12

18/12 to 20/12

20/12 to 21/12

1.0 0.3

1.25 0.38

1.5 0.46

2.0 0.61

2.5 0.76

3.25 0.99

4.0 1.22

5.0 1.52

6.0 1.83

7.0 2.13

7.5 2.29

8.0 2.44

Page 19

Horizontal Terminations

(Use 8” Direct-Vent Pipe)

Vertical Terminations

(Use 6-5/8” Direct-Vent Pipe)

The shaded areas in the diagram below show all allowable combinations

of vent configuration with horizontal terminations. Horizontal sections

of pipe require 1/4” (6.4 mm) of rise for every 12” (305 mm) of run.

A second 90º or 45º elbow (in addition to the first 90º elbow at the top

of the vertical length of pipe) is allowed as long as the overall length of

the horizontal run of pipe does not exceed those shown below. Use the

restrictor positions indicated. If the fireplace is vented with an elbow

directly off the top of the flue collar and three to four feet of horizontal

pipe is used, then no restrictor is to be installed in the fireplace.

Horizontal Terminations

18 Ft.

(5.5M)

15 Ft.

(4.6M)

Restrictor

Position #2

The shaded areas in the diagram below show all allowable combinations

of straight vertical and offset to vertical (maximum four 45º elbows or two

90º elbows) vent configurations with vertical terminations. The termina

tion must fall within the shaded areas on the diagram. Use the restrictor

positions indicated. The maximum offset length at a 45º angle consists

of one three foot and one four foot section of pipe. The maximum height

is 30 feet (9.1 M) and the minimum is 10 feet (3 M).

Vertical Terminations

5 Ft. 2 In. (1.6M)

30 Ft.

(9M)

25 Ft.

(7.6M)

Maximum

-

(1.5M)

0 Ft.

(0M)

10 Ft.

(3M)

5 Ft.

0 Ft.

(0M)

5 Ft.

(1524M)

Restrictor

Position #3

No Restrictor

10 Ft.

(3M)

Restrictor Position #4

15 Ft.

(4.6M)

Figure 22

Snorkel Terminations: For installations requiring a vertical rise on the exterior

of the building, 14-inch (356 mm) and 36-inch (914 mm) tall snorkel terminations -

Security™ #SV5STC14 or SV5STC36 and Simpson #1281 or 1282 are available. Follow

the same installation procedures as used for standard horizontal terminations. If the

snorkel termination must be installed below grade (i.e. basement application), proper

drainage must be provided to prevent water from entering the snorkel termination.

Do not attempt to enclose the snorkel within the wall or any other type of enclosure.

On vinyl siding, furring strips may be used to ensure that the snorkel is not recessed

into the siding. NEVER install the snorkel upside down.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

20 Ft.

(6M)

20 Ft.

(6M)

15 Ft.

(4.6M)

10 Ft.

(3M)

(1524M)

0 Ft.

(0M)

Figure 23

5 Ft.

0 Ft.

(0M)

Restrictor

Position #1

Restrictor

Position #2

5 Ft.

(1524M)

19

Page 20

Exterior Horizontal Vent Termination Clearance Requirements

V

V

V

V

V

F

C

B

B

A

B

H

M

I

X

V

D

V

A

A

A

V

L

B

J

X

E

V

A

G

*18”

18”

B

C

C

C

* See Item D in the Text Below.

Exterior Wall

Horizontal

Termination

Inside Corner

= Air Supply Inlet

Center Line

of Termination

DETAIL D

Ventilated Soffit

Fixed

Closed

Window

= Vent Terminal

Inside

Corner Detail

= 9" in U.S.

= 12" in Canada

Operable

Window

= Area where Terminal is NOT permitted

3 ft.

3 ft.

Minimum Clearances Canadian Installation * US Installation **

A = Clearance above grade, veranda, porch, deck

or balcony.

B = Clearance to window or door that may be

opened.

C = Clearance to permanently closed window 12 inches (305 mm) recommended to prevent window

12 inches (30 cm) * 12 inches (30 cm) **

6 in. (15.2 cm) for appliances < 10,000 BTU/hr (3kW),

12 in. (30 cm) for appliances > 10,000 BTU/hr (3kW) and <

100,000 BTU/hr (30kW), 36 inches (91 cm) for appliances

> 100,000 BTU/hr (30kW)*

condensation

6 in. (15.2 cm) for appliances < 10,000 BTU/hr (3kW),

9 in. (23 cm) for appliances > 10,000 BTU/hr (3kW) and <

50,000 BTU/hr (15kW), 12 inches (30 cm) for appliances

> 50,000 BTU/hr (15kW)*

9 inches (229 mm) recommended to prevent window

condensation

D = Vertical clearance to ventilated soffit located

18 inches (458 mm) 18 inches (458 mm)

above the terminal within a horizontal distance of 18

in. (458 mm) from the center line of the terminal

E = Clearance to unventilated soffit 12 inches (30 cm) 12 inches (30 cm)

F = Clearance to outside corner 5 inches (12.7 cm) 5 inches (12.7 cm)

G = Clearance to inside corner 6 in. (15 cm) 6 in. (15 cm)

H = Clearance to each inside of center line extended

above meter / regulator assembly

3 feet (91 cm) within a height of 15 feet above the meter /

regulator assembly *

3 feet (91 cm) within a height of 15 feet above the meter

/ regulator assembly **

I = Clearance to service regulator vent outlet 3 feet (91 cm) * 3 feet (91 cm) **

J = Clearance to non-mechanical air supply inlet

to building or the combustion air inlet to any other

appliance

K = Clearance to mechanical air supply inlet 6 feet (1.8 meters) * 3 feet (91 cm) above, if within 10 feet (3 m) horizon

L = Clearance above paved sidewalk or paved

driveway located on public property

M = Clearance under veranda, porch, deck or

balcony

6 in. (15.2 cm) for appliances < 10,000 BTU/hr (3kW), 12

in. (30 cm) for appliances > 10,000 BTU/hr (3kW) and <

100,000 BTU/hr (30kW), 36 inches (91 cm) for appliances

> 100,000 BTU/hr (30kW)*

7 feet (2.13 m) ‡ 7 feet (2.13 m) ‡

12 in. (30 cm) * ‡ 12 in. (30 cm) ** ‡

6 in. (15.2 cm) for appliances < 10,000 BTU/hr (3kW), 9

in. (23 cm) for appliances > 10,000 BTU/hr (3kW) and <

50,000 BTU/hr (15kW), 12 inches (30 cm) for appliances

> 50,000 BTU/hr (15kW)*

tally**

* In accordance with the current CSA/CAN-B149.1 National Gas and B149.2 Propane Installation Code - Latest Editions.

** In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Codes - Latest Edition.

‡ A vent shall not terminate directly above a sidewalk or paved driveway which is located between two single family dwellings and serves both dwellings.

*‡ Only permitted if veranda, porch, deck or balcony is fully open on a minimum 2 sides beneath the floor.

Figure 24

20

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

-

Page 21

Brick Panel and Log Set Installation

Brick Panel

The brick panels are extremely fragile so handle them with care.

1. Remove brick panels from box and wrapping.

6. Place Log #6 on tab located on right side of firebox. The other end of

the log is placed on the burner.

7. Volcanic stone may be placed along the front edge of the burner, but

not directly over the burner ports.

2. The long rectangular panel goes in the rear of the firebox - the thin layer

of bricks should be down. The panel rests on three metal tabs protruding

from the rear of the firebox about 3” above the firebox floor.

3. On the side panels, the rounded edge goes to the front. Install the side

panels by sliding them along the side of the firebox into retainers at

the top and bottom.

Figure 25

Log Set

Insert

Tabs

Rockwool

Figure 26

Important!!! Maintain a 1/4” (6.4mm) air

space along the entire length of log.

Log #6

Log Installation Instructions

If logs are not installed according to the log installation instructions,

flame impingement and improper combustion could occur and result

in soot and/or excessive production of carbon monoxide (CO), a colorless, odorless, toxic gas.

The size and position of the log set is critical to achieve a safe, reliable and attractive flame pattern. Any attempt to use a different log

set in the fireplace will void the warranty and will result in incomplete

combustion, sooting and poor flame quality.

1. Remove the six logs from the box and foam packaging. Lay them out

for easy identification during installation.

2. Place rear log on insert tabs (these tabs will penetrate the center of

the log) at the rear of the burner.

3. Place a light (fluffed) layer of embers (rockwool) directly on top of

the port holes in the burner. CAUTION: A 1/4” (6.4mm) air space

between the rockwool and lower base of the rear log needs to be

maintained for combustion air and proper flame aesthetics.

4. Place Log #2 on tab. An air shield is provided for natural gas use only.

For LP conversions, remove the air shield.

5. Place Logs #3, #4 and #5 on tab inserts.

Figure 27

Log #3

Log

#2

Figure 28

Air Shield

Embers

Volcanic Stone

Log Locater

Tab for Log #6

Log

#4

Log #5

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

21

Page 22

Electrical Connections:

* The breaker supplying electricity to the fireplace must be turned off at the

electrical panel before any connections are made at the fireplace.

* The wire supplying the fireplace should be a minimum of 14 gage and

provide 120 Volts at 60 hz.

* The fireplace must be grounded in accordance with local electrical

codes or, in the absence of local codes, with the National Electrical

Code or ANSI/NFPA 70 - latest edition.

* The electrical box is located at the right rear of the fireplace (see Figures

29 and 30

household supply line through the clamp and retighten clamp.

* Connect the supply ground wire to the green screw B.

* Remove the wire nut C from the black wires coming from the fireplace

and join these wires to the black supply wire reusing the wire nut.

Repeat for white wires.

* Reinstall the cover to the fireplace.

* If a wall-mounted burner on/off switch or thermostat is to be used,

the wires running from the switch or thermostat should be routed to

the left side of the fireplace. The wire should be fed through the gas

line supply hole along the gas line to the valve.

). Remove the cover, loosen the wire clamp A and feed the

B

Figure 30

Wall-Mounted Fan Speed Control:

If desired, a wall-mounted fan speed control can be installed. The breaker

supplying electricity to the fireplace must be turned off at the electrical

panel before any connections are made. The loop of wire with the label

attached (E in Figure 29

) may be cut and the wire leads from the wall-

mounted speed control connected to each end of the cut wire.

Optional Heat Ducting System:

Figure 29

Fan Wiring Diagram

From Power Source

To Optional Heat Duct Fan

E

C

Green (Ground)

Black (Hot)

White (Neutral)

Red

White

D

Blower

A

29) are for the optional Forced Air Heating System. See the instructions

provided with the system for installation details.

Snap Switch (Contacts Close When Fireplace is Hot)

Speed Control

Black

Black

The remaining red and white wires with capped ends (wires D in Figure

22

Figure 31

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 23

Gas Line Installation

The Ravelle™ 42 gas fireplace must be connected to the gas line in accordance with local codes and/or the National Fuel Gas Code, ANSI Z223.1

(In Canada, the current CAN/CSA B149.1 installation code). The gas line

should enter the fireplace on the left side (see diagrams on Pages 8 and

9). If the gas line enters the unit from the right side, the line will need to

be disconnected to remove the fan. The fireplace comes with a flex line

attached to the supply side of the gas valve. The fitting on the end of the

flex line can receive a 1/2” female iron pipe coupling, a 3/8” male iron

pipe, or a shut-off valve. There is sufficient room to locate the shut-off

valve under the firebox at the end of this flex line, however, local codes

may require the shut-off to be located on the exterior of the fireplace. After

connecting the gas line, all joints in the line and connections at the valve

should be checked for leaks before final positioning of the unit. Conduct a

gas leakage test of the appliance piping and control system downstream

of the shutoff valve in the supply line to the appliance.

Gas Pressure Requirements

A MAJOR CAUSE OF OPERATING PROBLEMS WITH GAS APPLIANCES IS IMPROPER GAS PRESSURE!

The most important item to check during the initial installation

and the first thing to check when operating problems occur is

gas pressure!

This fireplace will not function properly unless the required

gas pressure is supplied. See the table on this page for gas

pressure requirements.

Two pressure taps are provided on the fireplace’s valve to check gas

pressures. To access the taps remove the two socket head screws to

remove the valve control panel/heat shield. The taps are located below

the on/off/pilot knob (see Figure 32

pressure side. To check inlet pressure (with the fireplace burning) insert

a small flat bladed screwdriver into the tap and turn a half turn counterclockwise. Cover the tap with the line from a manometer and read the

pressure. Close the tap gently but securely after completing the check.

The manifold (outlet) tap is to the right of the inlet tap. To check manifold

pressure (with the fireplace burning at the high burn setting) insert a

small flat bladed screwdriver into the tap and turn a half turn counterclockwise. Cover the tap with the line from the manometer and check

the pressure. Again close the tap gently but securely after completing

the check. Check the taps for gas leaks with a gas leak test solution

(retighten if necessary).

). The left tap is the inlet (supply)

If the pressure is not sufficient, make sure the gas supply line is large

enough, the supply regulator is properly adjusted and the total gas load

for the residence does not exceed the amount supplied.

Note: The appliance and its individual shut-off valve must be disconnected

from the gas supply piping system during any pressure testing of that

system at test pressures in excess of 1/2 psig. The appliance must be

isolated from the gas supply piping system by closing its individual

manual shut-off valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig. Check with your

gas supplier or plumber.

Fuel

Type

Natural

Desired Minimum Maximum On Hi

7" WC 5" WC 10.5" WC 3.5" WC 1.7" WC

Inlet Pressure Manifold Pressure

On Lo

Fire

Fire

Gas

LP Gas 11" WC 11" WC 13" WC 11" WC 5.4” WC

SIT Millivolt Gas Valve

TH

TP

TP/TH

Inlet (Supply)

Pressure Tap

The Manifold

(Outlet) Tap

Figure 32

LP and Natural Gas Supplies

Your Ravelle gas fireplace is equipped from the factory for use with

natural gas only as specified on the Safety / Listing label attached to the

appliance. This appliance can only be operated using propane gas (LP)

if a certified fuel conversion kit provided by Lennox Hearth Products is

installed by a qualified service technician.

Also check the orifice size on the label on the igniter bracket. It must be

the correct size for the fuel and altitude.

Do not run propane tank dry. Running the tank dry may cause a

hazardous condition due to pressure drop in empty tank.

Solid fuel is NOT to be used with this unit.

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

23

Page 24

Increasing Efficiency and Hot Air Movement

A number of different options are available to the homeowner to maximize

the heat output and air movement to different rooms in the house.

Grills: If your Ravelle™ 42 gas fireplace is installed in a cabinet or a chase,

heat can be drawn from these enclosures and circulated into the living

area by cutting one or two openings covered by a register or Grill.

Opening and Grill into

Adjoining Room

Whole Home Comfort System: The Whole Home Comfort System is a

very inexpensive and efficient way to move air into and heat other areas

of the house. In the bottom of the Ravelle™ 42 gas fireplace are four inch

and Six inch (152 mm) diameter knock-out plates. Four inch (102 mm)

or six inch (152 mm) diameter return air ducting may be fastened to the

bottom of the fireplace, run into another room in the house and terminated

with a grill. When the fireplace is burning, with or without the fireplace

fan running, air is drawn from a distant room (lowering the pressure in

that room) through the return air duct into the bottom of the fireplace.

The air then passes through the outer shell and heat exchanger of the

fireplace and into the room in which the fireplace is located. The hot air

in the fireplace room moves through an open doorway or hall into the

low pressure room from which the air was drawn. This system functions

well by convection even without the use of the fireplace fan. Six inch (152

mm) diameter ducting moves more air than four inch diameter ducting.

Ducting in uninsulated areas of a house (for example in the crawl space)

should be wrapped in insulation to ensure maximum heat retention. Check

local building codes - some areas may require firestops when the duct

passes from room to room.

Note: Grill can be in the Wall, Ceiling, or Floor.

Figure 33

Possible Opening and Grill Locations on Cabinet

4” (102mm) or

6” (152mm)Duct

Figure 35

Up to 100 Feet (30.5M)

Maximum Run

Starter Ring

24

Figure 34

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Page 25

Forced Air Heating Installation

System Overview

Fan Box

Duct Adapter (6" round to

10" x 31/4" Rectangular)

Six Inch Duct (20' maximum length)

Switch Box

Fan Speed Control

Wall Stack Duct (10" x 31/4") for use

in areas of restricted clearance (Not

included as part of the kit--- available

at major hardware stores).

Fan Box

Forced Air Kit Components

Two Switch Boxes, Two Covers and Two Speed Control Knobs

Floor Mount

Adapters

Speed Control

Grille

Spacer

Fan Box

Duct Adapter

Six Inch Flex Duct

Starter Ring

Starter Ring Adapter

Cover Plate

Flapper Plate

Flapper

Fireplace Side Adapter

Additional Parts:

Two Angled Mounting Brackets

Two White---Headed Grille Screws

Six Wire Nuts

Sixteen Sheet Metal Screws

One Wire Clamp

Hot air can be drawn off the Ravelle™ 42 gas fireplace and moved into

other rooms of the house with the forced air heating system. This system

can be purchased as an option from your Lennox Hearth Products dealer

(part #75134).

SYSTEM OVERVIEW

Figure 36

FORCED AIR KIT COMPONENTS

Blower Box

Duct Adapter (6” round to

10” x 3-1/4” rectangular)

The system draws heated air from the Ravelle 42 gas fireplace and moves

it with the use of a 150 CFM fan through six inch ducts into other rooms

in the house. The system acts as a forced air furnace. One or two systems

can be used with each Ravelle 42 gas fireplace.

Six Inch Duct (20 ft. maximum length)

Fireplace Side Adapter

Switch Box

Blower Speed Control