Lennox HP13 Series Installation Instructions Manual

INSTALLATION

';_)2007 Lennox industries Jnc,

0( us

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

A CAUTION

A IMPORTANT

®

Dallas, Texas, USA

WARNING

INSTRUCTIONS

HP13 Series Units

HEAT PUMP UNITS _Technical

505,076M LLJJ Publications

06107 LithoU.S.A.

Supersedes 07/06

HP13 Outdoor Unit ............................ 1

Shipping & Packing List ........................ 1

General Information ........................... 3

Unit Dimensions ............................... 2

Setting the Unit ............................... 3

Removing Panels ............................. 5

Electrical ..................................... 6

Refrigerant Piping ............................. 8

Refrigerant Metering Device .................... 10

Manifold Gauge Set ........................... 10

Service Valves ................................ 11

Leak Testing .................................. 11

Evacuation ................................... 12

Start-Up ...................................... 12

Refrigerant Charging ........................... 13

System Operation ............................. 15

Defrost System ............................... 15

Maintenance .................................. 16

Optional Accessories .......................... 16

Homeowner Information ........................ 17

Thermostat Operation .......................... 17

Start-Up and Performance Check List ............ 18

X_ IMPORTANT

06/07

IIIlllllllllllllllllllllllllllllllllllll

Lennox Elite ® Series HP13 outdoor units are approved

and warranted only for installation with specially

matched indoor coils, line sets, and refrigerant control

devices aC designated by Lennox. Refer to Lennox

engineering handbook for check expansion valve

(CTXV) kits which may need to be ordered separately.

1 - Assembled HP13 outdoor unit

Check unit for shipping damage. Consult last carrier

immediately if damage is found.

Page 1

505,076M

IIIllllllllllllllllllllllllllllllHlllllllll

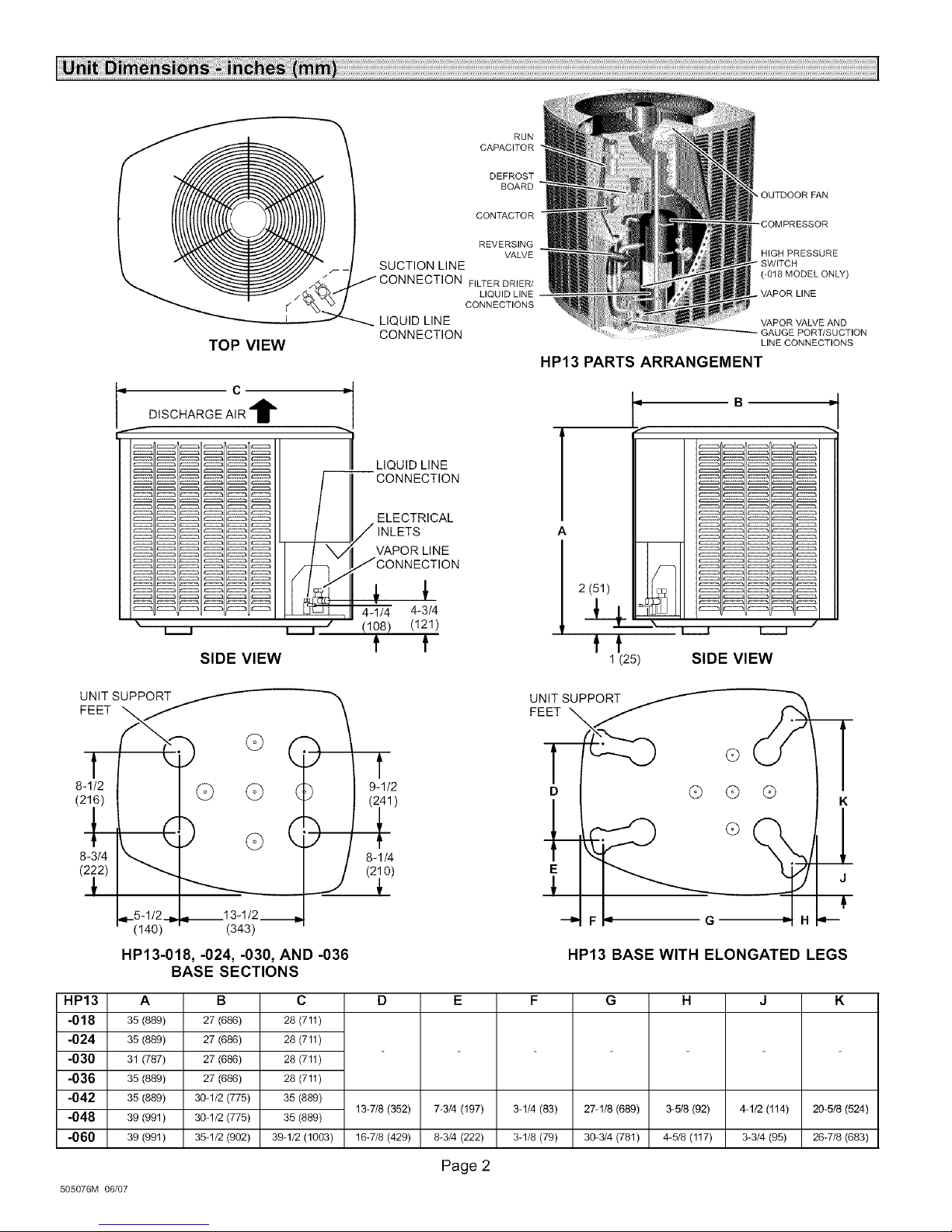

TOP VIEW

4 C

DISCHARGE AIR t

f--

/

'X/

CONTACTOR

SUCTION LINE

CONNECTION FILTER DRIER/

CONNECTIONS

LIQUID LINE

CONNECTION

LIQUID LINE

CONNECTION

ELECTRICAL

/ INLETS

VAPOR LINE

JCONNECTION

RUN

CAPACITOR

DEFROST

BOARD

REVERSING

VALVE

LIQUID LINE

HP13 PARTS ARRANGEMENT

A

,OUTDOOR FAN

-COMPRESSOR

HIGH PRESSURE

SWITCH

(-018 MODEL ONLY)

, VAPOR LINE

VAPOR VALVE AND

- GAUGE PORT/SUCTION

LINE CONNECTIONS

q

UNIT SUPPORT

FEET

8-1/2

(2"

8-3/4

(2

HP13-018, -024, -030, AND -036

HP13 A

-018 35 (889)

-024 35 (889)

-030 31 (787)

-036 35 (889)

-042 35 (889)

-048 39 (991)

-060 39 (991)

SIDE VIEW

(343)

BASE SECTIONS

B

27 (686)

27 (686)

27 (686)

27 (686)

30-1/2 (775)

30-1/2 (775)

35-1/2 (902)

I I

C

28 (711)

28 (711)

28 (711)

28 (711)

35 (889)

35 (889)

39-1/2 (1003)

4-1/4 4-3/4

(108) (121)

f f

9-1/2

41)

8-1/4

(210)

l

D

13-7/8 (352) 7-3/4 (197)

16-7/8 (429) 8-3/4 (222)

E F

2(51) [_-

J

-

UNIT SUPPORT / "_

1 (25)

N

I I i i

SIDE VIEW

FEET\

D (_ @ C)

E

l

HP13 BASE WITH ELONGATED LEGS

G H J K

3-1/4 (83)

3-1/8 (79)

27-1/8 (689)

30-3/4 (781)

3-5/8 (92)

4-5/8 (117)

4-1/2 (114)

3-3/4 (95)

-r

K

_l

J

----I-

20-5/8 (524)

26-7/8 (683)

505076M 06/07

Page 2

WARNING

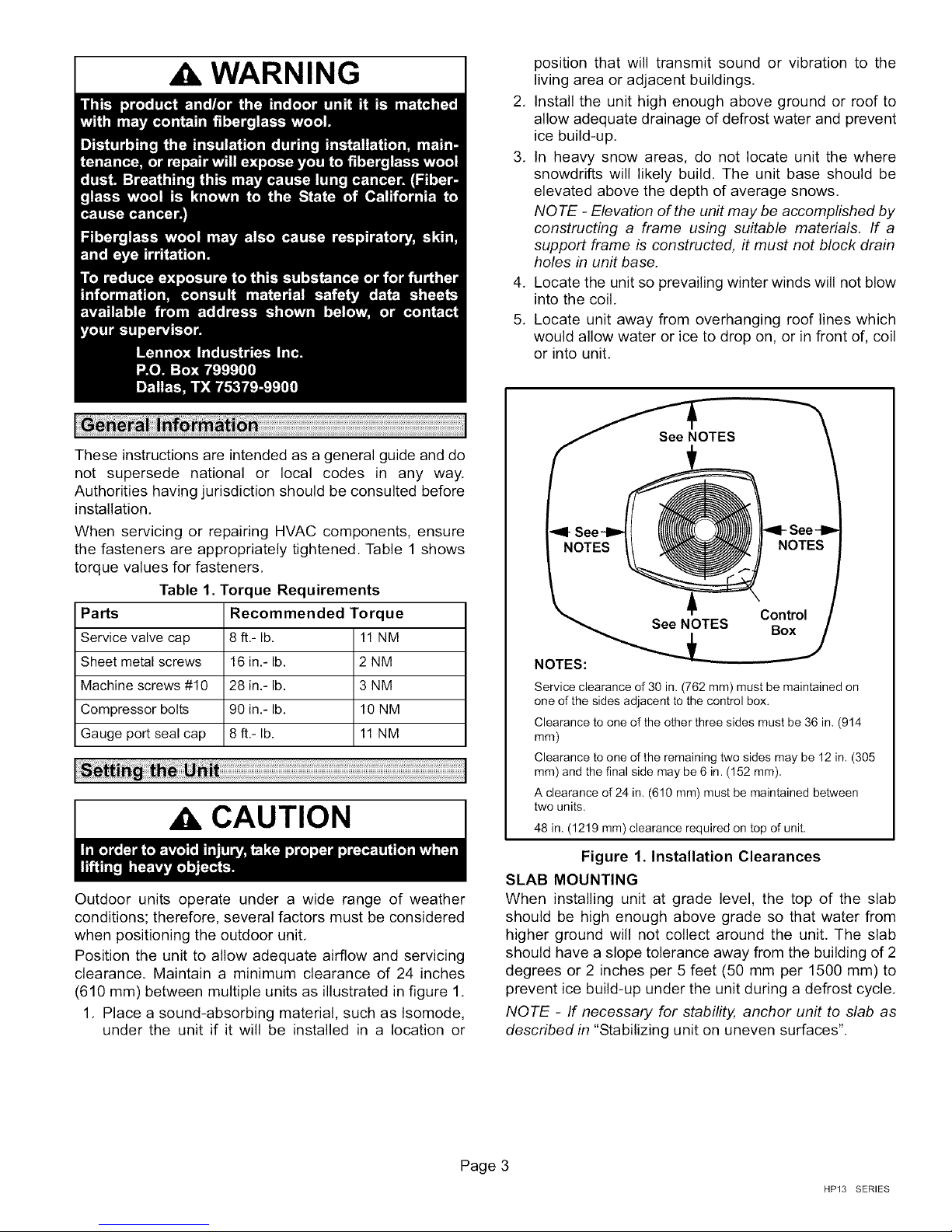

These instructions are intended as a general guide and do

not supersede national or local codes in any way.

Authorities having jurisdiction should be consulted before

installation+

When servicing or repairing HVAC components, ensure

the fasteners are appropriately tightened. Table 1 shows

torque values for fasteners+

Table 1. Torque Requirements

Parts Recommended Torque

Service valve cap 8 ft.- lb. 11 NM

Sheet metal screws 16 in.- lb. 2 NM

Machine screws #10 28 in.- lb. 3 NM

Compressor bolts 90 in.- lb. 10 NM

Gauge port seal cap 8 ft.- lb. 11 NM

CAUTION

position that will transmit sound or vibration to the

living area or adjacent buildings.

2+ Install the unit high enough above ground or roof to

allow adequate drainage of defrost water and prevent

ice build-up.

3+ In heavy snow areas, do not locate unit the where

snowdrifts will likely build. The unit base should be

elevated above the depth of average snows.

NOTE - Elevation of the unit may be accomplished by

constructing a frame using suitable materials. If a

support frame is constructed, it must not block drain

holes in unit base.

4+ Locate the unit so prevailing winter winds will not blow

into the coil.

5. Locate unit away from overhanging roof lines which

would allow water or ice to drop on, or in front of, coil

or into unit.

NOTES:

Service clearanceof30in. (762mm)mustbe maintainedon

oneof the sidesadjacentto the control box+

Clearanceto one of the otherthree sides must be 36 in. (914

mm)

Clearanceto one of the remainingtwo sides may be 12 in+(305

mm) and the final side may be 6 in. (152mm),

A clearanceof24 in, (610mm) must be maintained between

two units.

48 in. (1219mm)clearancerequired on top of unit,

Outdoor units operate under a wide range of weather

conditions; therefore, several factors must be considered

when positioning the outdoor unit+

Position the unit to allow adequate airflow and servicing

clearance. Maintain a minimum clearance of 24 inches

(610 mm) between multiple units as illustrated in figure 1+

1+ Place a sound-absorbing material, such as Isomode,

under the unit if it will be installed in a location or

Figure 1. Installation Clearances

SLAB MOUNTING

When installing unit at grade level, the top of the slab

should be high enough above grade so that water from

higher ground will not collect around the unit. The slab

should have a slope tolerance away from the building of 2

degrees or 2 inches per 5 feet (50 mm per 1500 mm) to

prevent ice build-up under the unit during a defrost cycle+

NOTE - If necessary for stability, anchor unit to slab as

described in "Stabilizing unit on uneven surfaces".

Page 3

HP13 SERIES

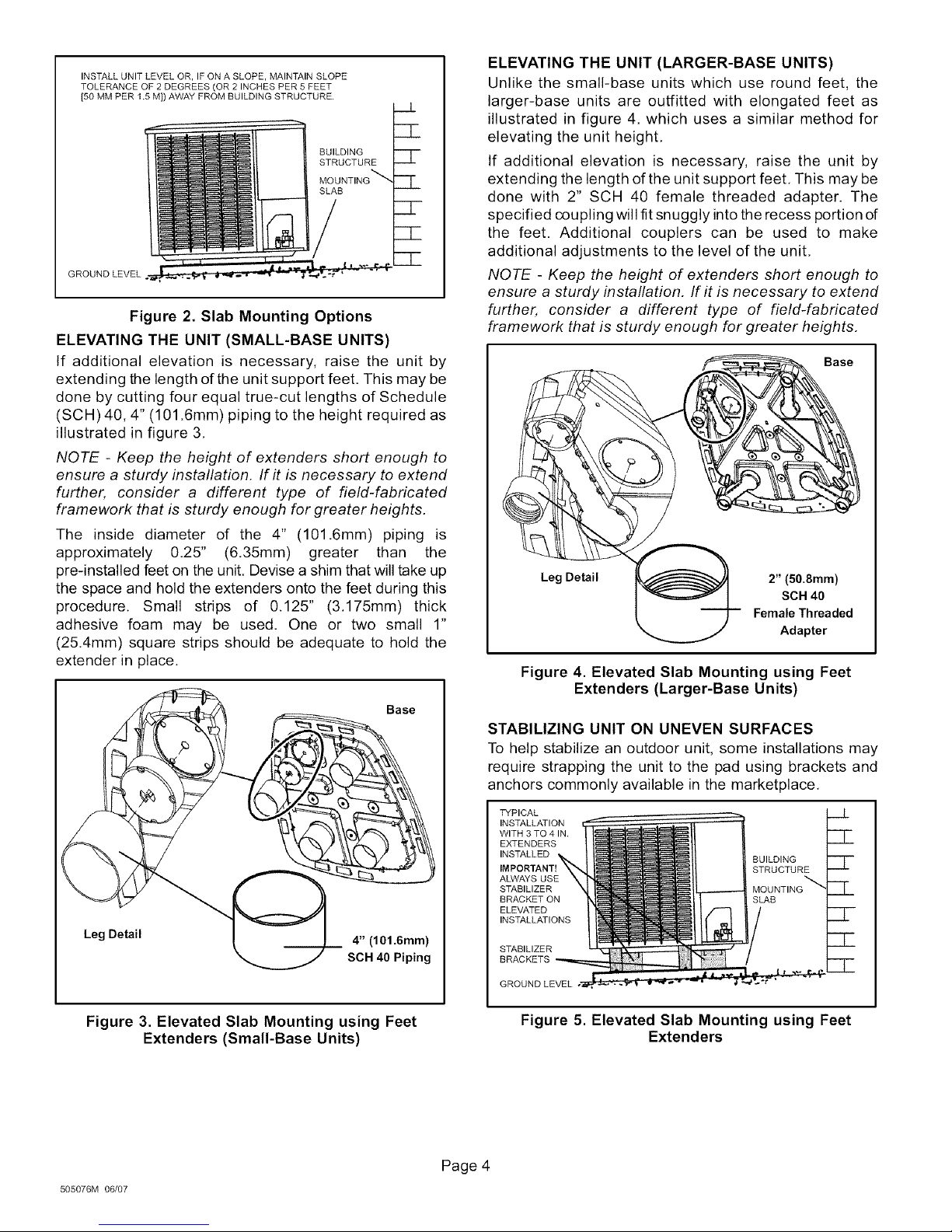

INSTALLUNITLEVELOR,IFONASLOPE,MAINTAINSLOPE

TOLERANCEOF2DEGREES(OR2INCHESPER5FEET

[50MMPER1.5M])AWAYFROMBUILDINGSTRUCTURE.

BUILDING

STRUCTURE

MOUNTING _ i T

SLAB

GROUND LEVEL

__L

Figure 2. Slab Mounting Options

ELEVATING THE UNIT (SMALL-BASE UNITS)

If additional elevation is necessary, raise the unit by

extending the length of the unit support feet. This may be

done by cutting four equal true-cut lengths of Schedule

(SCH) 40, 4" (101.6mm) piping to the height required as

illustrated in figure 3.

NOTE - Keep the height of extenders short enough to

ensure a sturdy installation. If it is necessary to extend

further, consider a different type of field-fabricated

framework that is sturdy enough for greater heights.

The inside diameter of the 4" (101.6mm) piping is

approximately 0.25" (6.35mm) greater than the

pre-installed feet on the unit. Devise a shim that will take up

the space and hold the extenders onto the feet during this

procedure. Small strips of 0.125" (3.175mm) thick

adhesive foam may be used. One or two small 1"

(25.4mm) square strips should be adequate to hold the

extender in place.

Base

Leg Detail

4" (101.6mm)

SCH 40 Piping

ELEVATING THE UNIT (LARGER-BASE UNITS)

Unlike the small-base units which use round feet, the

larger-base units are outfitted with elongated feet as

illustrated in figure 4. which uses a similar method for

elevating the unit height.

If additional elevation is necessary, raise the unit by

extending the length of the unit support feet. This may be

done with 2" SCH 40 female threaded adapter. The

specified coupling will fit snuggly into the recess portion of

the feet. Additional couplers can be used to make

additional adjustments to the level of the unit.

NOTE - Keep the height of extenders short enough to

ensure a sturdy installation. If it is necessary to extend

further, consider a different type of field-fabricated

framework that is sturdy enough for greater heights.

Base

Leg Detail

2" (50.8ram)

SCH 40

Female Threaded

Adapter

Figure 4. Elevated Slab Mounting using Feet

Extenders (Larger-Base Units)

STABILIZING UNIT ON UNEVEN SURFACES

To help stabilize an outdoor unit, some installations may

require strapping the unit to the pad using brackets and

anchors commonly available in the marketplace.

TYPICAL __,,,t

INSTALLATION

WITH 3 TO 4 IN.

EXTENDERS

IMPORTANT! STRUCTURE

INSTALLED _ BUILDING

ALWAYS USE MOUNTING _ i TSTABILIZER

BRACKET ON SLAB

ELEVATED

INSTALLATIONS

STABILIZER

BRACKETS

GROUNDLEVEL

Figure 3. Elevated Slab Mounting using Feet

Extenders (Small-Base Units)

505076M 06/07

Figure 5. Elevated Slab Mounting using Feet

Extenders

Page 4

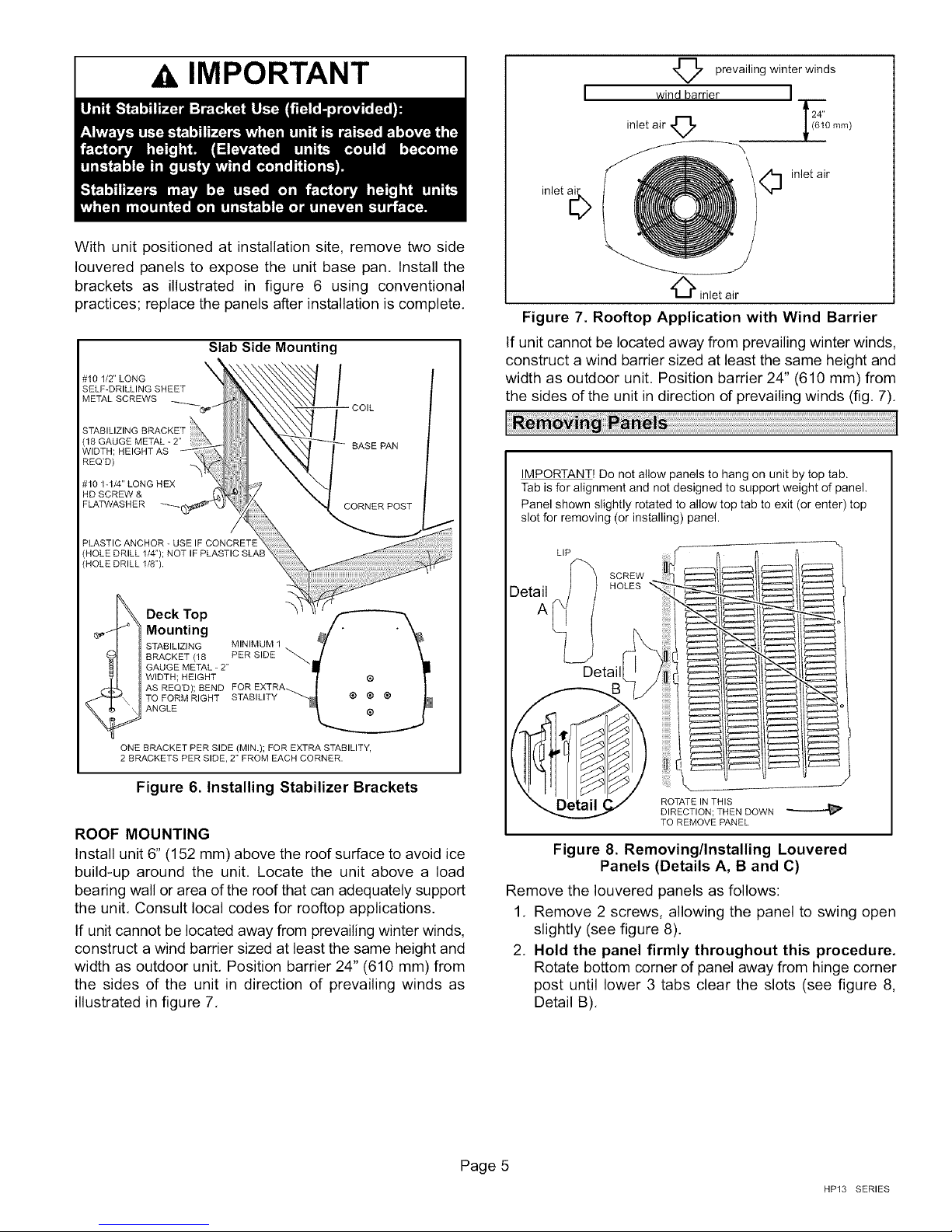

IMPORTANT

With unit positioned at installation site, remove two side

Iouvered panels to expose the unit base pan. Install the

brackets as illustrated in figure 6 using conventional

practices; replace the panels after installation is complete.

Slab Side Mounting

prevailing winter winds

wind barrier ]

24"

inlet air ,_ _641'0 ram)

inlet air

inlet a[_

O inlet air

Figure 7. Rooftop Application with Wind Barrier

If unit cannot be located away from prevailing winter winds,

construct a wind barrier sized at least the same height and

width as outdoor unit. Position barrier 24" (610 mm) from

the sides of the unit in direction of prevailing winds (fig. 7).

IMPORTANT! Do not allow panels to hang on unit by top tab.

Tab is for alignment and not designed to support weight of panel,

Panel shown slightly rotated to allow top tab to exit (or enter) top

slot for removing (or installing) panel.

ONE BRACKET PER SIDE (MIN.); FOR EXTRA STABILITY,

2 BRACKETS PER SIDE, 2" FROM EACH CORNER.

Figure 6. Installing Stabilizer Brackets

ROOF MOUNTING

Install unit 6" (152 mm) above the roof surface to avoid ice

build-up around the unit. Locate the unit above a load

bearing wall or area of the roof that can adequately support

the unit, Consult local codes for rooftop applications.

If unit cannot be located away from prevailing winter winds,

construct a wind barrier sized at least the same height and

width as outdoor unit, Position barrier 24" (610 mm) from

the sides of the unit in direction of prevailing winds as

illustrated in figure 7,

LIP

SCREW

HOLES

Detail

J

ROTATE IN THIS

DIRECTION; THEN DOWN

TO REMOVE PANEL

Figure 8. Removing/Installing Louvered

Panels (Details A, B and C)

Remove the Iouvered panels as follows:

1, Remove 2 screws, allowing the panel to swing open

slightly (see figure 8).

2. Hold the panel firmly throughout this procedure.

Rotate bottom corner of panel away from hinge corner

post until lower 3 tabs clear the slots (see figure 8,

Detail B),

Page 5

HP13 SERIES

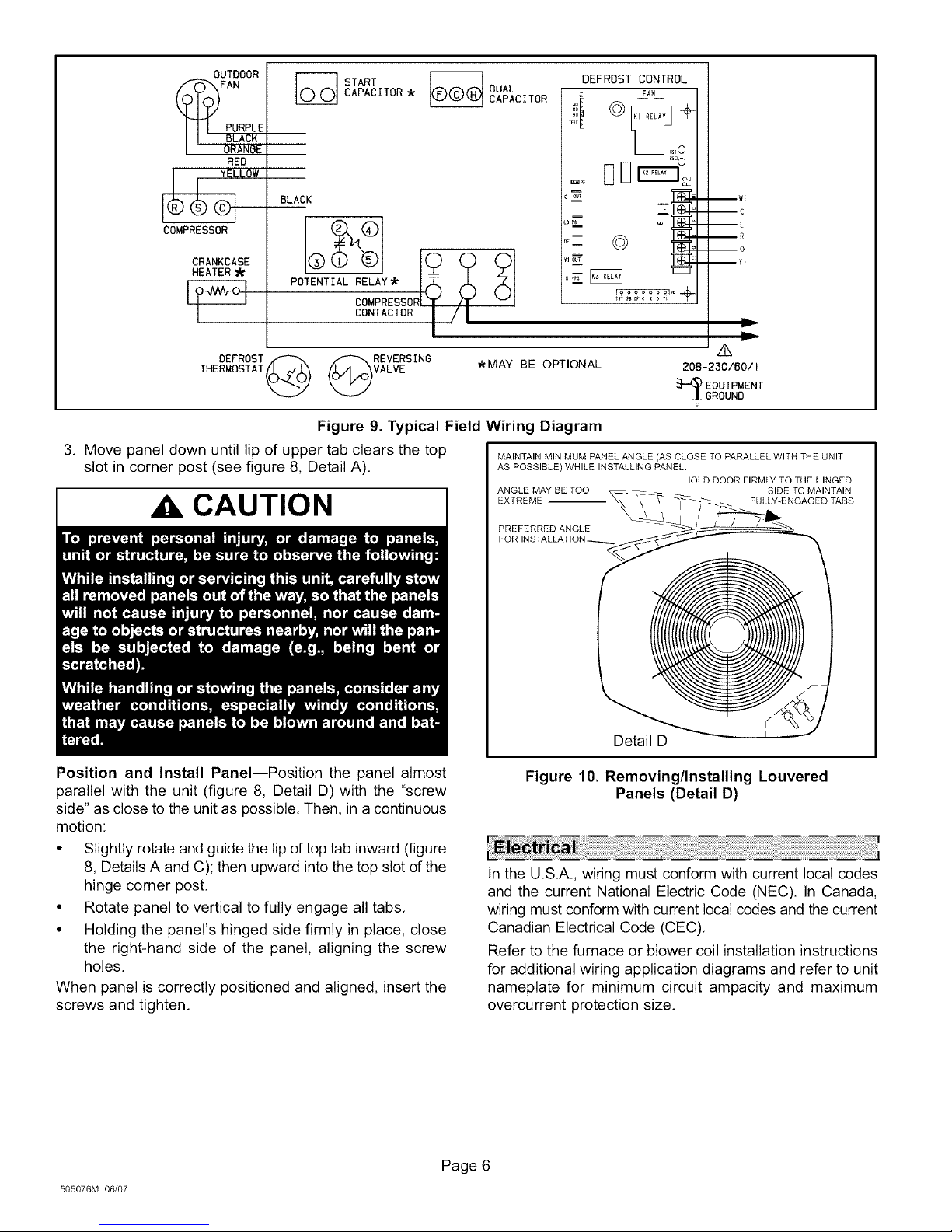

UTDOOR

FAN

PURPLE

BLACK

ORANGE

RED

CAPACITOR

START

DUAL

CAPACITOR

DEFROST CONTROL

,j! o +

BLACK

POTENTIAL _M_SOR (_

o_- ©

Y1ou_

--C

--L

--R

--0

--YI

COMPRESSOR

CRANKCASE

HEATER

LLOW

CONTACTORI / I

DEFROST.ff'"x _'\,REVERSING

THERMOSTAT_ _VALVE

*MAY BE OPTIONAL

Figure 9. Typical Field Wiring Diagram

3. Move panel down until lip of upper tab clears the top MAINTAINMINIMUMPANELANGLE(AS CLOSETOPARALLELWITHTHEUNIT

slot in corner post (see figure 8, Detail A). AS POSSIBLE) WHILEINSTALLINGPANEL.

ANGLE MAY BE TOO SIDE TO MAINTAIN

CAUTION

EXTREME _-_ FULLY-ENGAGED TABS

PREFERRED ANGLE

/k

20B-230/60/I

EQUIPMENT

GROUND

T

HOLD DOOR FIRMLY TO THE HINGED

Position and Install Panel--Position the panel almost

parallel with the unit (figure 8, Detail D) with the "screw

side" as close to the unit as possible, Then, in a continuous

motion:

• Slightly rotate and guide the lipof top tab inward (figure

8, Details A and C); then upward into the top slot of the

hinge corner post,

• Rotate panel to vertical to fully engage all tabs,

• Holding the panel's hinged side firmly in place, close

the right-hand side of the panel, aligning the screw

holes.

When panel is correctly positioned and aligned, insert the

screws and tighten,

505076M 06/07

Detail D

Figure 10. Removing/Installing Louvered

Panels (Detail D)

In the U.S.A., wiring must conform with current local codes

and the current National Electric Code (NEC). In Canada,

wiring must conform with current local codes and the current

Canadian Electrical Code (CEC).

Refer to the furnace or blower coil installation instructions

for additional wiring application diagrams and refer to unit

nameplate for minimum circuit ampacity and maximum

overcurrent protection size.

Page 6

Loading...

Loading...