Page 1

E N G I N E E R I N G D A TA

I N D O O R A I R Q U A L I T Y

HCSTEAM

Healthy Climate

Residential Whole-Home Steam Humidier

Bulletin No. 210605

June 2011

®

MODEL NUMBER IDENTIFICATION

HCSTEAM - 16

®

HCSTEAM = Healthy Climate

Steam Humidier

FEATURES

WARRANTY

All covered components - limited ve-year warranty

in residential applications, one year in non-residential

applications.

Refer to the Lennox Equipment Limited Warranty

certicate included with the unit for additional details.

APPROVALS

All models are ETL/Intertek listed.

APPLICATIONS

The HCSteam humidier is designed to directly add

desired humidity levels to a duct distribution system for

improved comfort.

The humidier produces non-pressurized steam which

is then used to humidify the air.

Water quality can affect the operation of this unit, the

humidier water supply should be untreated potable

water, not softened or demineralized.

Unit Type

Nominal Capacity

16 = 15 US Gallons per day

35 = 35 US Gallons per day

The water converted into steam is automatically

replaced through an electric ll valve. Periodically,

based on the water quality, the unit will also drain and

add some water to dilute the build−up of minerals in the

Steam Generator Cylinder.

The humidier has been designed for installation on

a wall. Since it is an atmospheric steam humidier, it

should be placed close to the point where the steam

will be used to minimize the steam hose length and the

amount of condensate.

Included with the humidier:

• Steam nozzle

• Steam hose (10 ft.)

• Steam nozzle condensate drain hose (10 ft.)

• Water ll hose (6 ft.)

• Air proving pressure switch (required)

Page 2

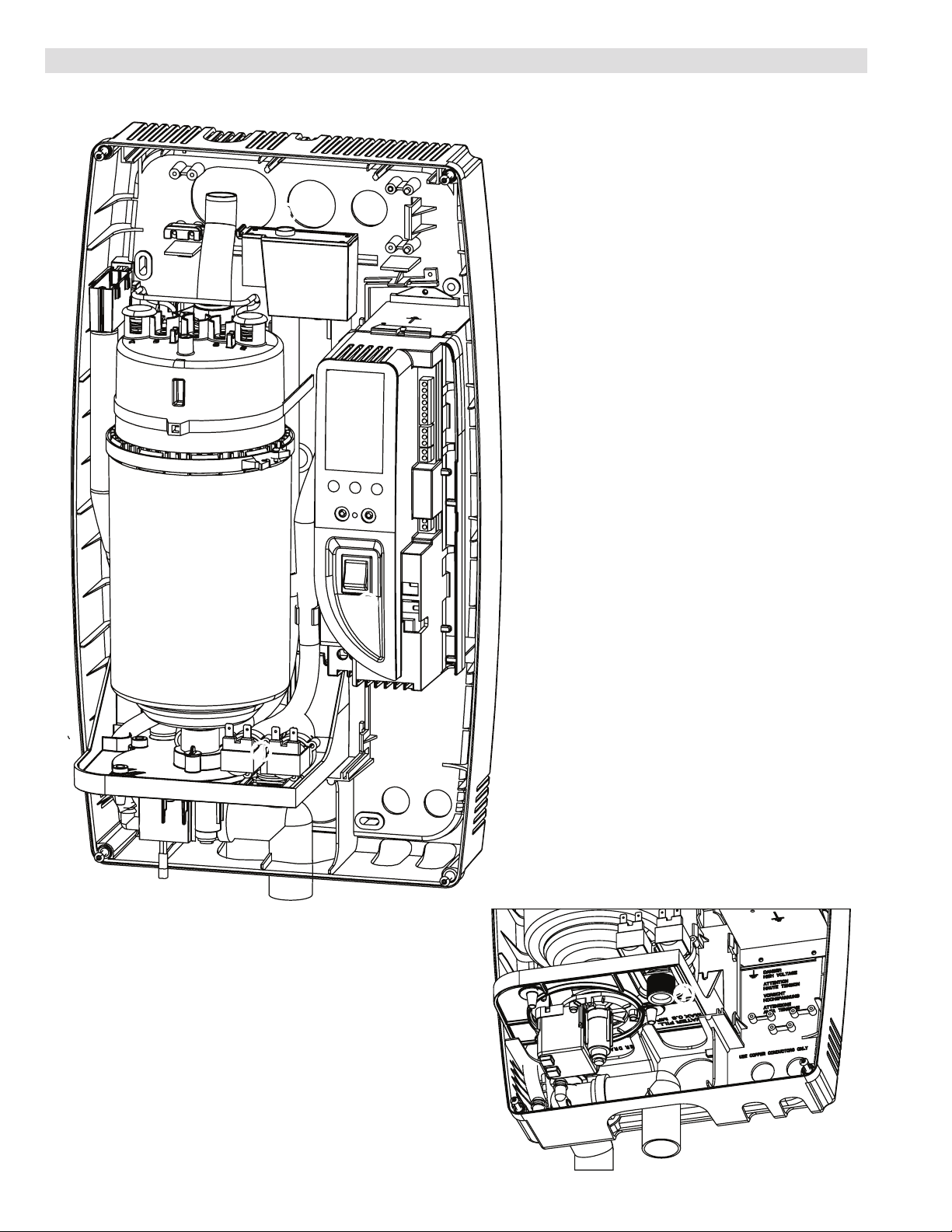

FEATURES

I

J

C

Steam Generator Cylinder

AB

Humidifier Controller

C

Power Button

D

Fill and Tempering Valves

E

Drain Pump

F

F

B

E

D

Water Drain

G

Water Inlet and Filter Screen

H

Steam Hose Connection

I

Condensate Drain Connection

J

H

HCSteam - Steam Humidier / Page 2

G

Page 3

FEATURES

INSTALLATION CONSIDERATIONS

This product must be installed by qualified HVAC and electrical contractors and in compliance with local, state,

and federal governing codes.

Humidifier is mounted on a wall and should be located close to the ductwork to minimize the length of the

steam hose for maximum performance.

The steam hose length between the humidifier and the ductwork varies depending on the type of installation.

See Installation Instructions.

Steam nozzle must be mounted in a supply duct. Nozzle must be installed downstream in a straight section of

duct with 3 ft. of straight metal ductwork free of elbows or obstructions.

The preferred installation for the steam hose and nozzle is higher than the humidifier for proper condensate

drainage.

Provisions to an open drain for periodic water draining from steam cylinder must be provided.

Air proving switch is required for proper operation and must be mounted close to the humidifier and ductwork

to ensure that the blower is operating prior to humidifier operation. Pressure tap must be installed in supply

duct. A second tap may be used in the return air duct for differential pressure applications.

Water for humidification should have the following characteristics:

• Water pressure between 20 and 110 psi

• Water temperature between 33 and 104°F

• Flow rate 0.21 GMP (minimum)

• Water hardness less than 400 ppm3 of calcium carbonate (CaCO3)

• Water conductivity from 125 to 1250 microsiemens per centimeter (μS/cm) for HCSteam-16

• 1 Water conductivity from 350 to 1250 microsiemens per centimeter (μS/cm) for HCSteam-35

• Absence of organic compounds

DO NOT use with softened water.

Refer to the Installation Instructions for detailed information.

Required Items

1/2 inch water line.

25 Amp dedicated electrical circuit.

1-1/4 inch drain tube extension (plumbed from the humidifier to an open drain, water drain receiver or a

condensate pump capable of holding one gallon of 140º F water then plumbed into a 3/4 inch drain line).

1

For HCSteam-35 model with low conductivity water conditions (125-350 μS/cm range) order optional Steam Generator Cylinder. See Optional Accessories.

Page 4

CYLINDER

STEAM

FEATURES

OUTLET

8

ELECTRODE

CYLINDER

STRAINER

7

STEAM

5

12

11

DRAIN

PUMP

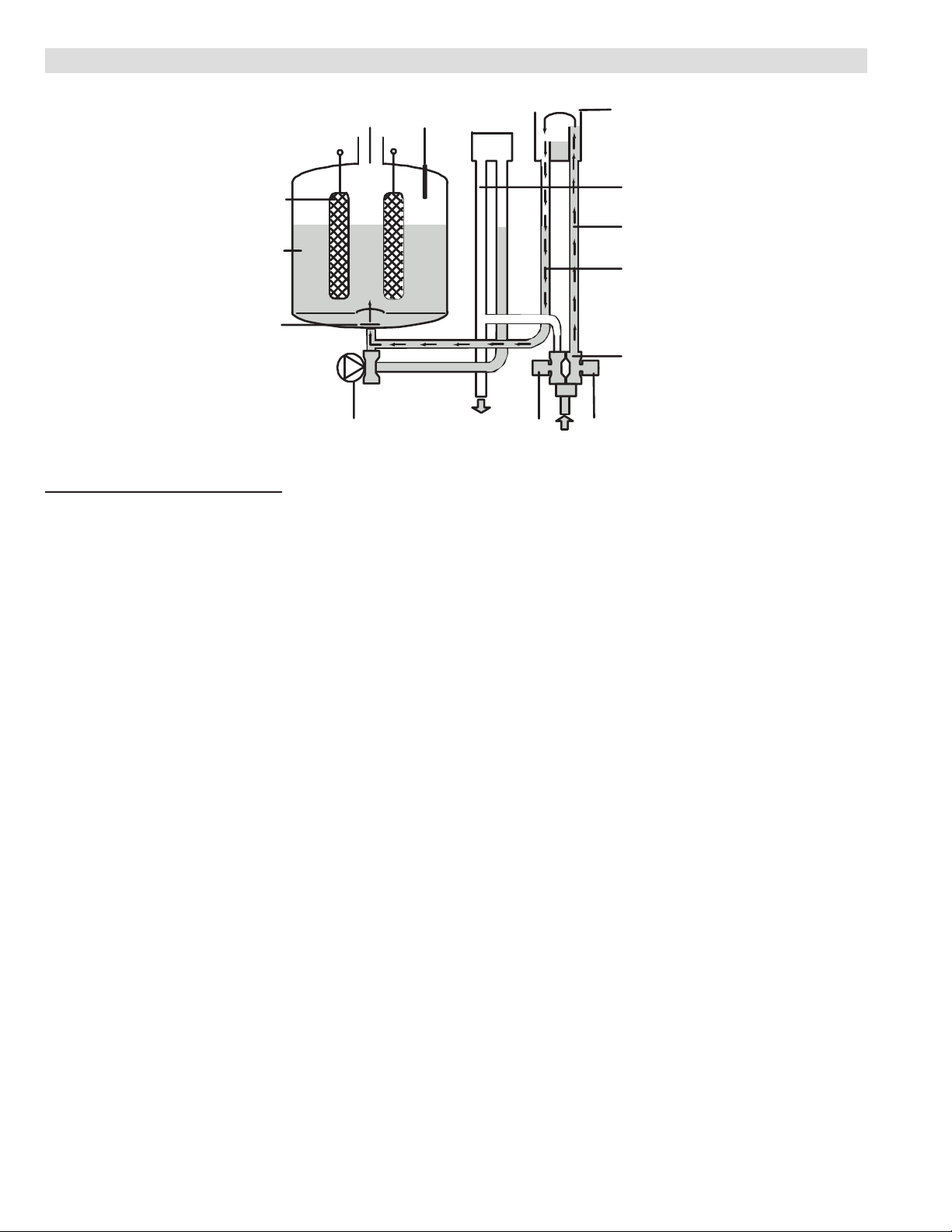

SEQUENCE OF OPERATION

The HCSteam steam humidier is an electrode

humidier. It produces steam for humidication by

passing electric current through metal electrodes (7)

immersed in water inside a plastic steam cylinder (5).

There are no heating elements.

Steam output is directly proportional to the conductivity

of the water, and the amount of electrode immersed in

the water.

On a call for humidity, the humidier controller will

open the water ll valve (1) and allow water to enter

the cylinder. A ow restrictor (4) prevents the unit from

lling too quickly or with too much pressure. Water

ows up the ll tube (2) and into the ll cup (3). Water

then ows over the dam in the ll cup (3), which creates

a 1-inch air gap to prevent backow of contaminated

water into the feed lines, it then ows through the ll

tube (6) and into the bottom of the steam cylinder (5).

Any backow or overow of water travels through the

overow hose (13) to the drain.

As the water lls the cylinder, it will reach the

electrodes (7) and current will begin to ow. As

the water continues to ll the cylinder, the current

will increase. This is monitored by an amperage

transformer connected to one of the power wires and

located on the electronic controller. When the desired

current is reached, the ll valve closes (1) and the

water will begin to warm and produce steam. If the

water reaches the cylinder full probe (9) or if current

rises too much, the drain pump (11) will be activated to

drain away excess water, reducing the water level in

the cylinder and reducing the current ow to acceptable

levels. Note that, any time the drain pump is activated,

the tempering valve (10) will be opened for tempering

the hot drained water down to 140ºF in accordance

with local and national standards.

FULL PROBE

9

HL

TEMPERING

Periodically, based on the incoming water conductivity,

the unit will run the drain pump (11) to drain and add

some water to reduce the mineral concentration. A lter

screen (12) in the cylinder helps to prevent mineral

debris from blocking the drain pump (11).

In case the humidier remains powered, but idle for

more than 48 hours (without producing steam), the

cylinder will automatically be emptied to eliminate

stagnant water inside.

If there is no water in the cylinder, there will be no

current ow and no steam production. The electrodes

do not burn out, but they will eventually become coated

with mineral deposits and the cylinder will require

replacement.

NOTE - Field installed air proving switch (furnished and

required) allows humidier to operate only when indoor

blower is operating.

VALVE

DT

10

3

FILL CUP

13

OVERFLOW

HOSE

2

FILL TUBE

6

FILL TUBE

4

FLOW

RESTRICTOR

1

FILL VALVE

HCSteam - Steam Humidier / Page 4

Page 5

FEATURES

HUMIDIFIER CONTROLLER

Microprocessor Humidity Controller automatically

manages all the functions of the unit, and includes a

self-diagnostic system with easy-to-read indicators

(numeric and icons). A comprehensive information

display shows the operation of the system at a glance.

1. Display is % of nominal

capacity

2. Maintenance or adjustment

3. Display is amperage

(default)

4. Steam is being produced

5. Cylinder filling

6. Foaming

7. Water presence inside

the cylinder

8. Cylinder draining

9. LED icons indicate: left:

operation (green);

middle: power (yellow);

right: alarms (red)

operation power alarm

10. Drain button for manual

draining of cylinder and

confirming parameter

values

11. ON/OFF button ("I" depressed is the ON posi-

OFF)

12. Reset button to reset

alarms and access parameters

13. Level of output: 33%,

66%, 100%

14. Fan relay is activated.

14

13

Controller Features

Controller features a eld programmable reduction in

maximum unit capacity (in 5% increments), allowing the

unit to adapt to the size of the area being humidied.

Includes an ON/OFF switch and a proportional input

function, a remote enabling input function for required

air proving switch (furnished), alarm relay contacts

for eld supplied alarm, ow sensor input and 24V

power supply output (for optional Healthy Climate

®

humidistat).

Ambient humidity control is managed by an external

humidistat (not furnished).

Steam production can be programmed for a specic

output capacity of 20% to 100% (in 5% increments).

Factory default settings:

HCSteam-16 - 100%, HCSteam-35 - 70%.

The optional Healthy Climate® Digital Automatic

Humidistat includes an on/off setting and a fully

proportional mode for steam output.

Water level is controlled by two valves (ll and

tempering) and the drain pump.

Automatic monitoring and ushing of the steam

generating cylinder is based on conductivity of the

electrode current draw.

Humidier automatically controls the amount of mineral

salts in the water by activating the ll valve and

drain pump. This reduces the amount of current ow

between the electrodes in the cylinder and eliminates

current leakage through the drain.

1

2

3

4

5

6

7

8

9

1012

Drain button allows manual drain/rell cycle for

maintenance.

Automatic monitoring and periodic drainage to handle

unacceptable water conditions.

Programmable to allow for a modulating hi-limit

humidity sensor or outdoor temperature sensor for

automatic trimming of the output to avoid condensation.

Hour counter keeps a record of operating hours and

has programmable maintenance alarm schedules.

Digital LCD Display

1. Instant current (default) / Steam production % /

Hour counter (hold Reset button to scroll values)

2. Active alarm

11

3. Electric current draw in amps

4. Steam production in progress

5. Cylinder lling in progress

6. Foam detected in cylinder

7. Water in cylinder

8. Cylinder drain in progress

Alarm and Pre-Alarm Functions

Controller panel has a green LED (operation), a

yellow LED (power) and a red alarm LED

LCD Display will show an error code related to the

following:

• Internal memory error

• Control board conguration not valid

• High current alarm

• Low production, low supply water conductivity or

excessive foam/lime scale in the Steam Generator

Cylinder

• Steam Generator Cylinder almost exhausted,

already used for 2000 hrs

• Fill alarm, unable or slow ll (current does not

increase within time-out)

• Drain alarm, unable to drain (current does not

decrease within time-out)

• Steam Generator Cylinder exhausted (critical

performance detected)

• Foam detected

• Steam Generator Cylinder lifetime expired (2000

hours)

• High controller temperature (above 176°F)

HCSteam - Steam Humidier / Page 5

Page 6

FEATURES

STEAM HEATING SYSTEM

Heating Electrodes

Designed for long life.

Immersion type.

Constructed of expanded low carbon steel, zinc-plated

and dynamically formed for precise current control.

Wiring to electrodes is secured by lock washer and nut.

Steam Generator Cylinder

Plastic cylinder is UL listed.

Single cylinder full electrode operates as an

independent circuit from the main power electrodes.

Full cylinder sensor detects foaming of the water and

end of cylinder life.

Power Drain Pump

Drain pump is used for ushing the system and for

maintaining proper water and current levels.

Pump drains water if there is excess water in the

steam generator cylinder and during steam generation

process to provide proper water level and minerals mix.

If the current generated in the water reaches excess

levels the humidier controller activates the drain pump

to drain a quantity of water to restore the current to

acceptable levels.

Tempering valve reduces the water temperature to

140°F before draining.

Drain connection can be from the bottom (vertical) or

rear (horizontal) of unit.

Anti-Foaming System

Automatic detection and correction of water foaming.

Steam Hose

Embedded steel spiral.

FDA approved (220°F, tested for 5000 hr).

Water Fill Hose

3/4 in. NPT female garden hose connection at each

end 90° angle on one end.

Air Proving Switch (Required)

Allows humidier to operate only when indoor blower is

operating.

Cabinet

Rugged, corrosion resistant molded plastic.

Removable front cover (4 Phillips head screws) for

easy access for servicing and maintenance.

OPTIONAL ACCESSORIES

icomfort Touch® Communicating Thermostat

(part of the icomfort™ Residential Communicating

Control System)

The icomfort Touch® Communicating Thermostat

recognizes and connects

to all icomfort™-enabled

products to automatically

congure and control the

system (based on userspecied settings) for the

highest level of comfort,

and performance. Also

recognizes model and serial

number information for icomfort™-enabled products to

simplify installation.

Large full color touchscreen - no hidden buttons or

doors.

A simple easy-to-use menu-driven touchscreen

allows complete system conguration. Scheduled

maintenance alerts, system warnings and

troubleshooting are also displayed in simple English on

thermostat screen.

Conventional products (not icomfort™-enabled) can

easily be added and controlled by the icomfort Touch®

Communicating Thermostat. NOTE - HCSteam

humidiers are not icomfort™-enabled.

(NOTE - An icomfort™-enabled indoor unit (furnace

or air handler) is required for proper operation with a

conventional outdoor unit.)

A tabbed interface lists all programming options on the

screen.

icomfort™-enabled Equipment (Indoor and Outdoor Units only)

Installer setup screens allow quick and simple system

conguration without a manual, Installer can also run

tests on complete system or individual components for

easy maintenance and troubleshooting.

Serial communications bus (RSBus), with less wiring

than a conventional heating/cooling system, allows

system communication. Uses 4-wire, 18-gauge

standard thermostat wiring.

See the icomfort Touch® Communicating Thermostat

Engineering Handbook bulletin in the Controls section

for more information.

HCSteam - Steam Humidier / Page 6

Page 7

FEATURES

INDOOR RH 26%

WED AN 21 12:35AM

MODE

ON

AUTO

HOME SCHEDULE OPTIONS

SETAT

SETAT

HEAT

COOL

SCHED

OPTIONAL ACCESSORIES (CONTINUED)

ComfortSense® 7000 Touchscreen Thermostat

Electronic 7-day, universal, multi-stage, programmable,

touchscreen thermostat.

4 Heat/2 Cool.

Auto-changeover.

Controls humidity during

cooling mode.

Offers enhanced

capabilities including

humidication /

dehumidication / dewpoint measurement and control,

Humiditrol® control, and equipment maintenance

reminders.

Easy-to-use, menu-driven thermostat with a back-lit,

LCD touchscreen.

Remote outdoor temperature sensor (optional)

allows the thermostat to display outdoor temperature.

Required in dual-fuel and Humiditrol® applications.

See the ComfortSense® 7000 Engineering Handbook

bulletin in the Controls section for more information.

Healthy Climate® Digital Automatic Humidistat

Basic humidity control (on/off or proportional) and

temperature display.

Control Buttons:

• Power button

• °F/°C display

• Set button for changing

humidity setpoints.

• SLEEP button for

changing day/night modes.

• PRG button for programming timed settings and

setting the clock.

• Up/Down buttons to change humidity setpoint and

time.

Built-in humidity sensor.

Outdoor temperature sensor furnished.

24VAC powered directly by the humidier.

LCD with alphanumeric characters and icon graphics

for Humidity and Temperature (indoor/outdoor),

Humidity Mode, Sleep Mode, Auto Mode, Lock Mode,

Program Timer On.

Large LCD display shows humidity (or temperature)

setpoint while the small display shows temperature (or

time) setpoint.

Built-in clock (with backup) for automatic humidity

control. Two time settings per day.

Error code display.

Lock mode indicates a parameter has been set.

Dimension (H x W x D): 3-3/8 x 5-1/2 x 1-3/8 in.

Healthy Climate® Water Conductivity Test Kit

A conductivity meter is recommended for testing the

water.

Measures total

dissolved solids

(TDS) and

temperature.

Automatic

Temperature Compensation (ATC).

Water-resistant housing

Measurement Range: 0-5000 ppm

Digital Calibration (Push button)

Auto-off function, data-hold function and low-battery

indicator.

Display: large and easy-to-read LCD screen includes

simultaneous temperature reading.

Factory-calibrated with a 342 ppm NaCl solution. The

meter can be recalibrated with digital calibration using

the Push buttons, rather than a screwdriver.

Includes cap and CR2032 battery.

Steam Generator Cylinder For Low Conductivity

Water (HCSteam-35 Model Only)

Normal water conductivity range is 350-1250 μS/cm.

For low conductivity water conditions (125-350 μS/cm

range) order optional Steam Generator Cylinder.

MAINTENANCE SUPPLIES

Replacement Steam Cylinders

Steam cylinders are available for annual

replacement (no more than 2500 operating hours).

HCSteam - Steam Humidier / Page 7

Page 8

SPECIFICATIONS

Model No. HCSteam-16 HCSteam-35

Performance Duct Steam Injection US gallons per day 15 35

lbs. per hour 5.5 12

Steam pressure 3.81 in. wg 3.81 in. wg

Input Water Type Potable water Potable water

Conductivity Range 125-1250 μS/cm

Ambient

Conditions

Storage

Conditions

Operating Temperature 34°F to 104°F 34°F to 104°F

Operating Humidity 10 to 60% RH 10 to 60% RH

Temperature Storage 14°F to 158°F 14°F to 158°F

Humidity Storage 5 to 95% RH 5 to 95% RH

Connections Water ll connection 3/4 in. NPT 3/4 in. NPT

Drain connection 1.25 in. OD 1.25 in. OD

Steam Hose 1-1/4 OD, 7/8 in. ID 1-1/4 OD, 7/8 in. ID

Drain Water Temperature < 140°F < 140°F

Drain Pump Flow 2.16 US GPM 2.16 US GPM

Weight Data lbs.

Shipping 22 22

Empty 18 18

Installed with water 26 26

1

350-1250 μS/cm

ELECTRICAL DATA

Voltage 115/120V-1ph 220/240V-1ph

Amps 16.40 16.95

Maximum overcurrent protection 25 25

Power relays (amps) (2) 20 (2) 20

Ground connection Wire Nut Wire Nut

Electrode power cables 10 AWG 10 AWG

OPTIONAL ACCESSORIES

icomfort Touch® Communicating Thermostat 49W95 49W95

2

Remote Outdoor Temperature Sensor

X2658 X2658

(for dual fuel, Humiditrol® and outdoor temperature display)

3

Discharge Temperature Sensor 88K38 88K38

ComfortSense

4

Remote Outdoor Temperature Sensor

®

7000 Thermostat Y2081 Y2081

X2658 X2658

(for dual fuel and Humiditrol)

Healthy Climate

Healthy Climate

1

Steam Generator Cylinder for Low Conductivity Water (below 350 μS/cm) - - - Y3484

®

Digital Automatic Humidistat Y3760 Y3760

®

Water Conductivity Test Kit Y3480 Y3480

MAINTENANCE SUPPLIES

Replacement Steam Generator Cylinders Y3481 Y3482

For HCSteam-35 (low conductivity water models) - - - Y3484

1

For low water conductivity conditions (125-350 μS/cm range) order optional Steam Generator Cylinder for Low Conductivity Water (Y3484).

2

Remote Outdoor Sensor may be used with an icomfort®-enabled outdoor unit for a secondary (alternate) sensor reading. Sensor may also be used with a conventional

outdoor unit.

3

Optional for service diagnostics.

4

Remote Outdoor Temperature Sensor for ComfortSense 7000 Thermostat must be connected directly to the thermostat.

HCSteam - Steam Humidier / Page 8

Page 9

HUMIDIFICATION LOAD REQUIRED - GALLONS PER DAY

(Reference: AHRI Guideline F-2008)

Type of

Construction

8000 10,000 12,000 16,000 20,000 24,000 32,000 40,000

Volume of Building ft

Tight 4.3 5.3 6.4 8.5 10.6 12.7 17.0 21.2

Average 8.6 10.6 12.8 17.0 21.3 25.4 34.0 42.6

Loose 12.7 15.9 19.1 25.5 31.8 38.1 51.0 63.6

Legend: HCSteam-16

HCSteam-35

Exceeds capacity of one HCSteam unit

NOTES - Tight = 1/2 air change per hour.

Average = 1 air change per hour.

Loose = 1-1/2 air changes per hour.

3

(approximate)

HCSteam - Steam Humidier / Page 9

Page 10

DIMENSIONS - INCHES (MM)

17-5/8

(448)

13-7/16

5

(128)

MOUNTING

HOLES

(341)

10-1/8

(257)

C L

5

(128)

8

(204)

1-5/8

(40)

7/8

2-3/8

(24)

(60)

STEAM

2-1/8

STEAM

2-3/4

(70)

(54)

2-1/2

(65)

C L

CONDENSATE

3/8

(9)

1-7/8

2-3/4

(48)

(70)

1-1/8 dia. (30)

1-5/8 dia. (40)

CONDENSATE

(600)

23-5/8

2 dia. (51) 7/8 dia. (23)

2-3/8"

(60)

DRAIN

2

(51)

1-1/2

(38)

2-3/8

(60)

3-7/8

(98)

5/8 (16)

3-5/8

(92)

DRAIN

4

(102)

INSTALLATION CLEARANCES - INCHES

Top 6 in.

3-7/8

(98)

ELECTRICAL

FILL

3-1/4

(82)

3-1/8

(78)

FILL

1-3/8

(35)

1-1/2

2-1/8

(37)

(53)

ELECTRICAL

1-3/8

(36)

2-1/2

(62)

Bottom 6 in.

Left Side 6 in.

Right Side 6 in.

Front 24 in.

Page 11

Page 12

REVISIONS

Sections Description of Change

Maintenance Supplies New Section - Added replacement steam cylinders.

Visit us at www.lennox.com

For the latest technical information, www.lennoxdavenet.com

Contact us at 1-800-4-LENNOX

NOTE - Due to Lennox’ ongoing commitment to quality, Specications, Ratings and Dimensions subject to change without notice and without incurring liability.

Improper installation, adjustment, alteration, service or maintenance can cause property damage or personal injury.

Installation and service must be performed by a qualied installer and servicing agency. ©2011 Lennox Industries, Inc.

Loading...

Loading...