Page 1

ENGINEERING DATA

FOR VARIABLE AIR VOLUME HEATING/COOLING SYSTEMS

Harmony

four separate heating/cooling zones utilizing a single indoor unit (G21V/GSR21V or

CB21/CBH21) and single outdoor unit (HS14 or HP21 two-speed). A single speed outdoor unit may be used for up to two zone applications. Two-speed outdoor unit may

be used for two, three or four zone applications. The system consists of the Harmony

control center, discharge air sensor, Harmony control panel, master thermostat and

duct mounted zone dampers with a thermostat in each zone. The zone dampers are

automatically controlled to supply air flow only to zones with a thermostat demand.

At the same time, the variable speed motor (VSM) in the G21V/GSR21V furnace or

CB21/CBH21 blower coil unit automatically adjusts the air volume to the zones as required. Because of the VSM motors’ ability to vary system air volume as required, no

bypass damper is required. Individual air volumes for heating or cooling are available

to each zone. Dampers are available in either round or rectangular configuration. Each

zone is sized for the heating/cooling load. Damper operation and blower air volume

is controlled by the control center. The Harmony system saves energy by allowing

temperature setback in unoccupied areas while maintaining comfort in occupied

areas. System also results in lower equipment costs by eliminating the need for two

separate heating/cooling systems. The Harmony Zone Control System may be used

in conjunction with the FM21 Heat Pump Control System and may also be used in

Smarthouse applications.

Control Center

operate the system. Control center cabinet is constructed of heavy gauge steel with a

enamel paint finish and removeable latching cover. Solid-state circuit board features:

low voltage output terminals for controlling up to four zones and indoor and outdoor

unit connections. Also has low voltage input terminals for up to four zone thermostats,

control panel, zone damper transformer, pressure switch and discharge air sensor.

Board also has jumper selectors for “Zone Air Volume Selection” (25-95%), “Heating

Air Reduction” (0%, 20% or 40%), “Continuous Air Reduction” (0%, 50% or 75%) and

“Discharge Air Temperature” (+ or – 5F heat or cool). LED’s on circuit board indicate

“Heating” (Red), “Cooling” (Green) for each zone and “Reversing Valve” (Amber).

Additional LED’s (Red) on board indicate “Zone Damper Operation”, “Indoor Unit Operation”, “Blower Operation” and “Outdoor Unit Operation”. Four diagnostic LED’s are

furnished as an aid in servicing system. Board stores last two diagnostic codes for easy

servicing. Built-in time delay function prevents short cycling of system. Holes for

mounting are furnished and electrical inlets are provided in top, bottom and rear of panel. Dimensions: 13-1/4” x 10” x 1-3/4”. Power requirements: 24VAC. Control center is

powered by indoor unit transformer. Shipping weight: 6 lbs.

Control Panel

Off” control mode selection, “Cool”, “Auto” or “Heat” mode selection and “Auto“ or

“On” fan control for continuous or intermittent blower operation. LED indicators show

selected features at a glance. Panel is constructed of high impact Cycolac. Dimensions:

3-1/2” x 4-3/4” x 1-5/16”.

Discharge Air Sensor Probe

contains three sensors that monitor air temperature in the supply air stream. Sensors

send a temperature average to the control center to control blower motor speed.

System Equipment Data

pump) for system equipment selection. For G21V/GSR21V series furnace data, see

section Heating Units — Gas. For HS14 series two-speed or other single speed condensing units data, see Cooling Units — Condensing Units section. For add-on evaporator coil unit data, see section, Cooling Units — Coils-Blower Coil Units. For HP21 series two-speed or other single speed heat pump outdoor units data, see Heat Pumps

— Matched Remote Systems section. For CB21/CBH21 blower-coil unit data, see section, Cooling Units — Coils-Blower Coil Units. For EMD14-65 or EMD14M-65 Economizer dampers, see Accessories section.

Sequence of Operation

— a “Central” control mode and a “Zone” control mode.

In the “central” mode, heating or cooling selection and temperature demand are con-

trolled by the zone 1 (master) thermostat, all dampers remain open at mechanically

preset openings and blower is controlled by the central control board (total zone air

volume), delivering air to all zones.

In the “zone” mode, heating or cooling selection is controlled by the control panel (or by

the individual zone thermostats if system is set for auto-changeover), temperature demand is controlled by the individual zone thermostats, zone dampers route air to appropriate zones and blower air volume is adjusted according to central control jumper

setting and number of zones operating.

Individual air volume for each zone is preset at the control center and may be adjusted

from 25% to 95% actual air volume. During heating mode, Heating Air Reduction jumpers

allow a lower heating air volume to be selected (0%, 20% or 40% reduction of cooling air

volume). During continuous (“On”) blower operation, Continuous Air Reduction jumpers allow 0%, 50% or 75% air volume reduction. All dampers remain open if there is

no demand from thermostats.

NOTE — Specifications, Ratings and Dimensions subject to change without notice. 1993 Lennox Industries Inc.

II

Zone Control System

— Control center (16J95) contains all necessary relays and controls to

— Touch sensitive panel (16J96) features: “Zone”, “Central” or “System

— See flow charts on page 4 (gas heat) and page 5 (heat

— Two modes of operation are available at the control panel

— Harmony II system is designed to provide up to

— Probe (16J98) is required for field installation. Probe

HARMONY

II

ZONE CONTROL SYSTEM

ZONE SYSTEM

CONTROL

(cover in place)

POSITION

ONLY

CENTER

ACCESSORIES

HARMONY

Bulletin #480182

February 1993

Supersedes

February 1992

ZONE SYSTEM

CONTROL

CENTER

(cover removed)

POSITION

ONLY

POSITION

ONLY

ZONE SYSTEM

CONTROL

PANEL

II

Page 2

OPTIONAL EQUIPMENT (Must Be Ordered Extra)

RECTANGULAR

ZONE DAMPER

ROUND

ZONE DAMPER

Master (Zone 1) Thermostat (Optional)

mable thermostat for zone 1 master thermostat. See flowcharts on pages 4 and 5 for

recommended thermostats. Also see Thermostats bulletin in Accessories section.

Zone Thermostats (Optional)

zone thermostats. Also see Thermostats bulletin in Accessories section.

Round Zone Damper (Optional) — Round damper is constructed of heavy gauge galvanized steel. Damper shell is furnished with one straight end and one crimped end

for ease of duct connection. Damper blade rotates smoothly in nylon bearings. Adjustable blade stop is furnished on damper blade for system balancing. Damper features

factory installed, heavy duty, synchronous motor with spring return open. Heavy duty

steel gearing provides long motor life. Damper springs open in case of power failure.

See damper specifications table for sizes, air resistance and shipping weights. Power

requirements: 24 VAC.

— See flowcharts on pages 4 and 5 for recommended

Rectangular Zone Damper (Optional)

gauge aluminum and stainless steel. Damper is a slip-in, opposed blade type with duct

mounting plate on one end for ease of duct connection. Damper rotates smoothly in

nylon bearings. A rubber blade stop is furnished for installation on damper blade if

system balancing is required. Damper features factory installed, heavy duty, synchronous motor with spring return open. Heavy duty steel gearing provides long motor life.

Damper springs open in case of power failure. See damper specifications table for

sizes, air resistance and shipping weights. Power requirements: 24 VAC.

Pressure Switch (Required for Heat Pump Operation)

quired for proper system operation in heat pump applications.

Transformer (Optional)

flowcharts on pages 4 and 5.

— Transformer is required for operation of zone dampers. See

— Lennox recommends the use of a program-

— Rectangular damper is constructed of heavy

— Pressure Switch (21J18) is re-

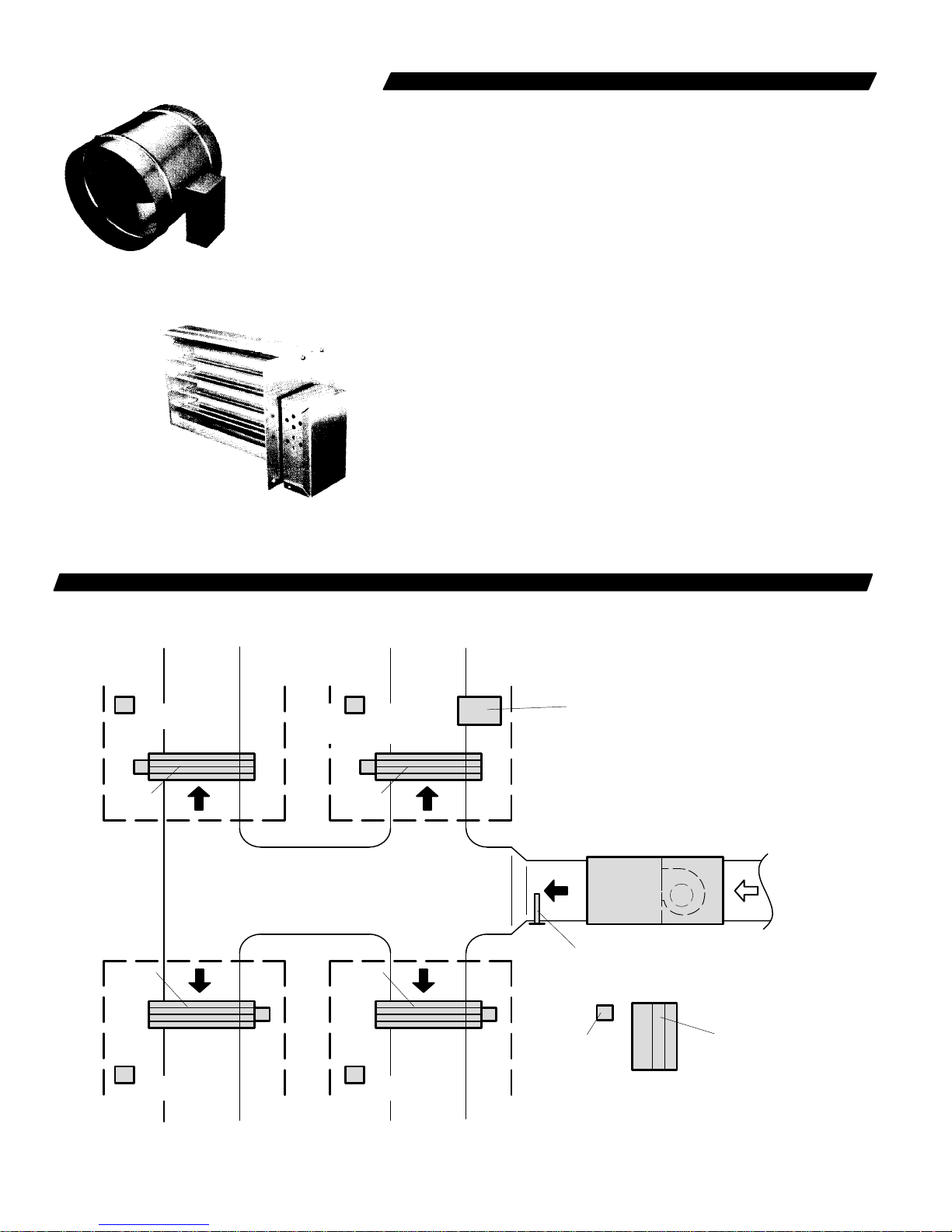

TYPICAL SYSTEM LAYOUT

ZONE 2 ZONE 1

ZONE 2

THERMOSTAT

ZONE

DAMPER

ZONE

DAMPER

ZONE 1

THERMOSTAT

(Master Thermostat)

ZONE

DAMPER

ZONE

DAMPER

SUPPLY

AIR

HARMONY

CONTROL

PANEL

HEATING/

COOLING

UNIT

DISCHARGE

AIR SENSOR

RETURN

AIR

ZONE 3

THERMOSTAT

ZONE 3 ZONE 4

ZONE 4

THERMOSTAT

—2—

ZONE

DAMPER

TRANSFORMER

HARMONY

CONTROL

CENTER

Page 3

DAMPER SPECIFICATIONS

ROUND ZONE DAMPERS

Catalog

No.

77G99 6 100 .04 2

78G00 8 150 .03 4

78G01 10 200 .02 6

78G02 12 350 .03 8

78G03 14 400 .02 10

Dimensions

Dia. (in.)

Air

Volume

(cfm)

50 .01

110 .05

100 .02

210 .05

100 .01

325 .05

200 .02

460 .05

200 .01

640 .06

Total

Resistance

(In. wg.)

Shipping

FIELD WIRING

Weight

(lbs.)

RECTANGULAR ZONE DAMPERS

Catalog

No.

78G04 10 X 8 200 .02 4

78G05 12 X 8 240 .02 3

78G06 14 X 8 350 .03 3

78G07 16 X 8 395 .03 4

78G08 18 X 8 375 .02 4

78G09 20 X 8 415 .02 4

Dimensions

W x H (in.)

Air

Volume

(cfm)

100 .01

325 .05

120 .01

395 .05

200 .02

460 .05

225 .02

520 .05

185 .01

600 .06

210 .01

665 .06

Total

Resistance

(In. wg.)

Shipping

Weight

(lbs.)

ZONE 1 ZONE 2

THERMOSTAT

(MASTER)

ZONE

SYSTEM

CONTROL

PANEL

ZONE

DAMPER

POWER

TRANSFORMER

ZONE DAMPER

A

D

B

B

*ZONE 3 *ZONE 4

THERMOSTAT

(Optional)

A

B

ZONE

DAMPER

A — Three wire low voltage (gas heat systems) — 18 ga. minimum

Five wire low voltage (heat pump systems) — 18 ga. minimum

B — Two wire low voltage — 18 ga. minimum

C — Seven wire low voltage — 18 ga. minimum

D — Six wire low voltage — 18 ga. minimum

E — Two wire low voltage (single speed condensing unit) 18 ga. minimum

Three wire low voltage (two speed condensing unit) 18 ga. minimum

Four wire low voltage (single speed heat pump outdoor unit) 18 ga. minimum

Five wire low voltage (two speed heat pump outdoor unit) 18 ga. minimum

F — Two wire low voltage (discharge air sensor) 18 ga. minimum

G — Two wire low voltage — pressure switch (heat pump only) — 18 ga. minimum

F

COIL

G

G21V /

GSR21V

FURNACE

OR

CB/CBH21

BLOWER

COIL UNIT

ZONE

SYSTEM

CONTROL

CENTER

C

E

B

* NOTE — Zone 3 and Zone 4 Not Available

With Single Speed Outdoor Unit.

— Field Wiring Not Furnished —

—3—

A

THERMOSTAT

(Optional)

ZONE

DAMPER

B

CONDENSING

UNIT

OR

HEAT PUMP

OUTDOOR

UNIT

A

THERMOSTAT

(Optional)

ZONE

DAMPER

Page 4

CONTROL SYSTEM COMPONENT SELECTION (Gas Heat/Condensing Unit Systems)

—4—

STOP

START

UP-FLO

HORIZONTAL OR

DOWN-FLO

TWO ZONES

TWO, THREE

OR FOUR

ZONES

SINGLE SPEED

CONDENSING

UNIT

HS19

HS22

HS23

TWO-SPEED

CONDENSING

UNIT

HS14

UP-FLO

FURNACE

G21V SERIES

HORIZONTAL OR

DOWN-FLO

FURNACE

GSR21V SERIES

GAS

HEAT/

CONDENSING

UNIT

ROUND

ZONE DAMPERS

(See Below)

RECTANGULAR

ZONE DAMPERS

(See Below)

NONO

DAMPER

TRANSFORMER

up to 5 Dampers

(87344) 45VA

ECONOMIZER

DAMPERS

EMD14-65 or

EMD14M-65

ECONOMIZER

DAMPERS

WIRING HARNESS

120 volts (14H57)

ELECTRONIC AIR

CLEANER

EAC12-14

(69H71)

EAC12-20

(69H72)

ZONE

THERMOSTAT

(One Required

For Each

Additional

Zone)

(See Below)

ZONE 1

MASTER

THERMOSTAT

(See Below)

CONTROL

PANEL

(16J96)

CONTROL

CENTER

(16J95)

DISCHARGE AIR

SENSOR PROBE

(16J98)

RECOMMENDED MASTER THERMOSTATS

(For a complete selection of alternate thermostats, see

Thermostats Bulletin in Accessories section.)

Catalog

Description No.

*1 Htg.-1 Clg. 5-1-1 Day Programmable 27H31. . . . . . . . . . . .

1 Htg.-1 Clg. 5-2 Day Programmable 18H10. . . . . . . . . . . . . . . .

1 Htg.-1 Clg. 7 Day Programmable 18H11. . . . . . . . . . . . . . . . .

*Recommended master thermostat.

RECOMMENDED ZONE THERMOSTATS

(For a complete selection of alternate thermostats, see

Thermostats Bulletin in Accessories section.)

Catalog

Description No.

*1 Htg.-1 Clg. Electro-Mech. w/ subbase (Off-Auto) 86H23. .

**1 Htg.-1 Clg. 5-2 Day Programmable 18H10. . . . . . . . . . . . .

1 Htg.-1 Clg. Electro-Mech. w/ subbase 12F99. . . . . . . . . . . . . . .

Subbase for 12F99 (Off-Auto) 13F18. . . . . . . . . . . . . . . . .

1 Htg.-1 Clg. Electro-Mech. w/ subbase 38234. . . . . . . . . . . . .

1 Htg.-1 Clg. Electro-Mech. w/ subbase 17G17. . . . . . . . . . . . .

1 Htg.-1 Clg. Electro-Mech. w/ subbase 17G18. . . . . . . . . . . . .

1 Htg.-1 Clg. Electro-Mech. w/ subbase 78H22. . . . . . . . . . . . .

1 Htg.-1 Clg. Electro-Mech. 12F99. . . . . . . . . . . . . . . . . . . . . . . .

Subbase for 12F99 13F17. . . . . . . . . . . . . . . . . . . . . . . . . . .

*Recommended electro-mechanical zone thermostat.

**Recommended programmable zone thermostat.

ZONE DAMPERS

ROUND DAMPERS

Catalog

Description No.

6” dia. 77G99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8” dia. 78G00. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10” dia. 78G01. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12” dia. 78G02. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14” dia. 78G03. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECTANGULAR DAMPERS

Catalog

Description No.

10” x 8” 78G04. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12” x 8” 78G05. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14” x 8” 78G06. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16” x 8” 78G07. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18” x 8” 78G08. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20” x 8” 78G09. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

CONTROL SYSTEM COMPONENT SELECTION (Heat Pump Systems)

—5 —

STOP

START

UP-FLO OR

DOWN-FLO

HORIZONTAL

TWO ZONES

TWO, THREE

OR FOUR

ZONES

SINGLE SPEED

OUTDOOR UNIT

HP19

HP22

HP23

UP-FLO OR

DOWN-FLO

BLOWER COIL

CB21 SERIES

HORIZONTAL

BLOWER COIL

CBH21 SERIES

HEAT PUMP

SYSTEM

PRESSURE

SWITCH

(21J18)

ROUND

ZONE DAMPERS

(See Below)

RECTANGULAR

ZONE DAMPERS

(See Below)

NONO

DAMPER

TRANSFORMER

up to 5 Dampers

(87344) 45VA

ECONOMIZER

DAMPERS

EMD14-65 or

EMD14M-65

ECONOMIZER

DAMPERS

WIRING HARNESS

120 volts (14H57)

ELECTRONIC AIR

CLEANER

EAC12-14

(69H71)

EAC12-20

(69H72)

ZONE

THERMOSTAT

(One Required

For Each

Additional

Zone)

(See Below)

ZONE 1

MASTER

THERMOSTAT

(See Below)

CONTROL

PANEL

(16J96)

CONTROL

CENTER

(16J95)

DISCHARGE AIR

SENSOR

(16J98)

TWO-SPEED

OUTDOOR UNIT

HP21

RECOMMENDED THERMOSTATS

(For a complete selection of alternate thermostats,

see Thermostats Bulletin in Accessories section.)

Catalog

Description No.

*2 Htg.-1 Clg. 7 Day Programmable 91H72. . . . . . . . . . . . . . . .

3 Htg.-2 Clg. 7 Day Programmable 18H13. . . . . . . . . . . . . . . . .

2 Htg.-2 Clg. Digital Setpoint 43H98. . . . . . . . . . . . . . . . . . . . . . .

2 Htg.-1 Clg. 5-1-1 Day Programmable 27H30. . . . . . . . . . . . . .

**2 Htg.-1 Clg. Electro-Mechanical w/ Subbase 51H40. . . . . .

*Recommended programmable master thermostat or zone thermostat.

**Recommended electro-mechanical zone thermostat.

ZONE DAMPERS

ROUND DAMPERS

Catalog

Description No.

6” dia. 77G99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8” dia. 78G00. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10” dia. 78G01. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12” dia. 78G02. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14” dia. 78G03. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECTANGULAR DAMPERS

Catalog

Description No.

10” x 8” 78G04. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12” x 8” 78G05. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14” x 8” 78G06. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16” x 8” 78G07. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18” x 8” 78G08. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20” x 8” 78G09. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading...

Loading...