Page 1

PRODUCT LITERATURE

¤

1996 Lennox Industries Inc.

Dallas, Texas

503,073M

9/98

Supersedes 6/96

£

GSR21Q & V

SERIES

GAS

FURNACE

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury, or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinityofthis or anyother appliance.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

Litho U.S.A.

:$51,1*

WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance.

- Extinguish any open flames.

- Do not touch any electrical switch; do not

use any phone in your building.

- Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call

the fire department.

3DJH

Page 2

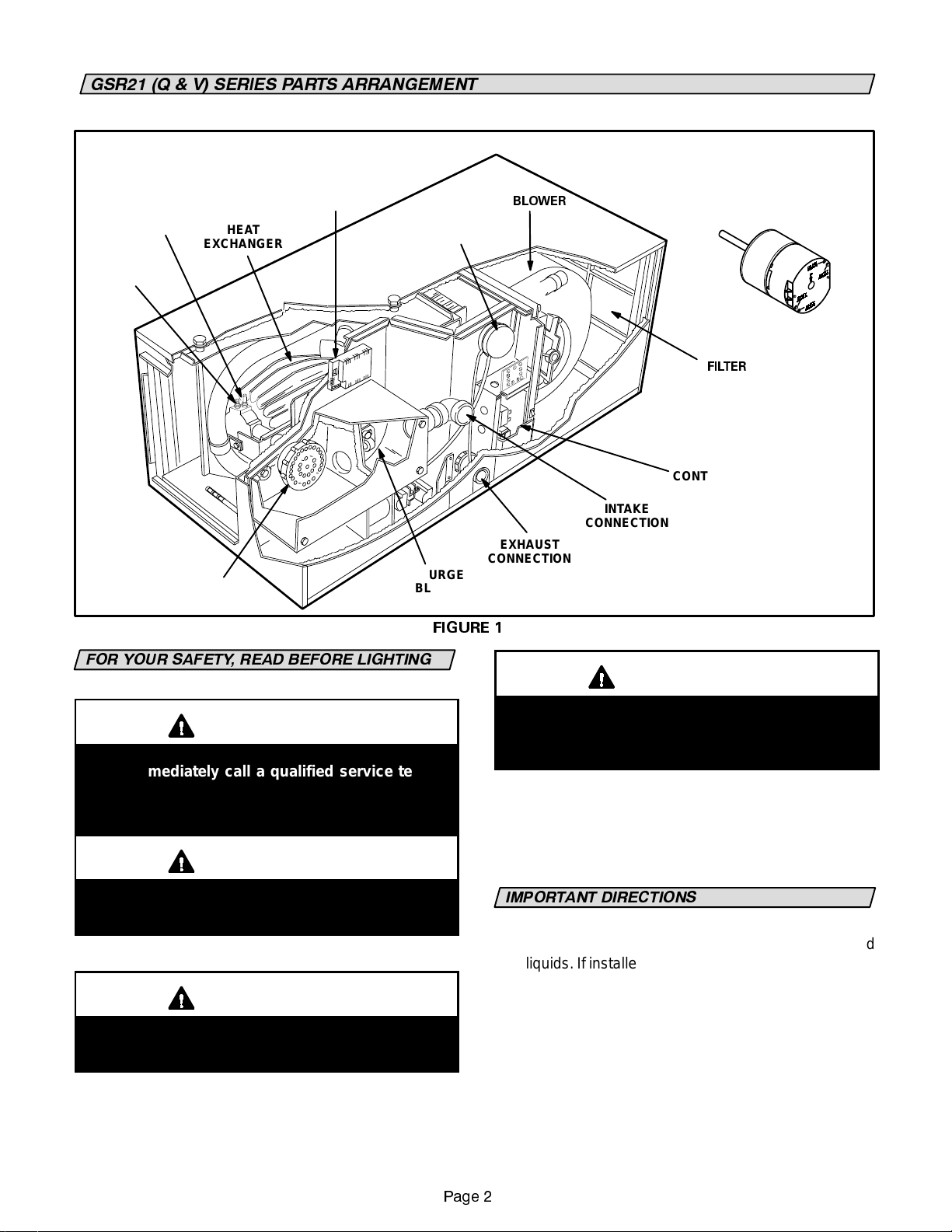

*65 4 9 6(5,(6 3$576 $55$1*(0(17

(Horizontal Application Shown)

ELECTRONIC

IGNITION

SPARK

PLUG

FLAME

SENSOR

FLAPPER

HEAT

EXCHANGER

AIR

VALVE

PRESSURE

SWITCH

PURGE

BLOWER

FIGURE 1

BLOWER

EXHAUST

CONNECTION

VARIABLE SPEED BLOWER MO-

TOR

USED ON GSR21V UNITS ONLY

FILTER

CONTROL

BOX

INTAKE

CONNECTION

)25 <285 6$)(7< 5($' %()25( /,*+7,1*

WARNING

Do not use this furnace if any part has been underwater. Immediately call a qualified service technician to inspect the furnace and to replace any part

of the control system and any gas control which

has been under water.

WARNING

If overheating occurs or if gas supply fails to shut

off, shut off the manual gas valve to the appliance

before shutting off electrical supply.

CAUTION

Beforeattemptingtoperform any serviceormaintenance, turn the electrical power to unit OFF at disconnect switch.

BEFORE LIGHTING smell all around the appliance

area for gas. Be sure to smell next to the floor because some gas is heavier than air and will settle on

the floor.

WARNING

Do not set thermostat below 60ºF(16ºC) in heating

mode. Settingthermostat below 60º (16ºC) reduces

the number of heating cycles. Damage to the unit

may occur that is not covered by the warranty.

Useonlyyourhandtopushinormovethegas control

lever or switch. Never use tools. If the lever or switch

willnotpushinormovebyhand,donottrytorepairit,

callaqualifiedservicetechnician.Forceorattempted

repair may result in a fire or explosion.

,03257$17 ',5(&7,216

1- Keep thefurnace area clear and freeof combustible

material, gasoline, and other flammable vapors and

liquids. If installedin aninsulated area,furnace must

bekeptfreeof insulatingmaterial.Insulatingmaterial

may be combustible.

2- DONOTobst ruc tairf lowtouni t.Unitmustrec eive

an unobs truc ted flow ofcombust ion and v entilating air. D o not obstruct termi nation ends of exhaust and intake pipes.

3- DO NOT store chlorineor fluorineproducts near unit

or introduce these products into the combustion air.

These products can cause furnace corrosion.

3DJH

Page 3

4- DO NOT draw the return air from a room where

another gas appliance (ie., a water heater) is

installed. Even though this furnace draws its com-

bustion air from outside of the structure, other gas

appliances that share a utility room may not. When

return air is drawnfrom a room, a negative pressure

is createdin theroom.If agas applianceis operating

in a room with negative pressure, the flue products

can be pulled back down the vent pipe and into the

room. This reverse flow of the flue gas may result in

incomplete combustion and the formation of carbon

monoxide gas. This toxic gas might then be distributed through the house by the furnace duct system.

Your furnace isagas appliance. Itis criticalthat the gas

suppliedtotheunit be completely burnedtoavoidtheproduction of carbon monoxide gas. Complete combustion

of thegas requires, but is not limited to, correct gas pressure and gas flow rate, adequate combustion, air, and

proper venting.

81,7 23(5$7,21

This appliance does not have a pilot. It is equipped

with an ignition system which automatically lights

the burner. Do not try to light by hand.

A-Gas Valve Operation

WARNING

Ifyou donot followthese instructionsexactly,afire

or explosion may result causing property damage,

personal injury or loss of life.

Gas Valve Operation for Robertshaw and White

Rodgers Valves (Figures 2 and 5)

ROBERTSHAW 7200 GAS VALVE

GAS VALVE

SELECTOR ARM

IN OFF

POSITION

WARNING

Carbon monoxide gas is invisible, odorless, and

toxic.

Exposure to this gas can cause personal injury and even

deathtoall occupants,includingpets. Anyitemthat is powered by or gives off heat from a combustion process (includinglawnmowers, automobiles,andfireplaces)hasthe

potential to produce carbon monoxide gas. Because of

this, Lennox recommendsthe use of a carbon monox-

ide detector in your home, even if you do not own gas

appliances. Reliable detectors are available at reason-

ableretailprices.Contact yourindependentLennoxdealer

for more details about this investment in your safety.

Yourfurnace is designedtomeet standardssetby nationalagencies,and tooperatesafelywhen properlyinstalled

and maintained.However,the unit’s performance can be

greatly impactedby the individual installation and theoperating environment. It is your responsibility to ensure

that this appliance is maintained. Proper maintenance is

criticalforyour safetyandthesatisfactory operationofthe

product. Lennox strongly recommends annual in-

spection and maintenance of this appliance. Contact

your independent Lennox dealer for an inspection by a

qualified service technician.

WHITE RODGERS

36E GAS VALVE

GAS VALVE

SHOWN

IN OFF

POSITION

FIGURE 2

1- Set thermostat to lowest setting. See figure 3.

2- Turn off all electrical power to furnace. See figure 4.

3- This appliance Is equipped with an ignition device

which automatically lights the burner. Do

light the burner by hand.

4- Remove unit access panel.

5- OnRoberts haw7200 gasvalve,depres s leveron

gas control and move to

WhiteRodgers 36Egas valves,move switchto

Do not force.

6- Wait five (5) minutes to clear out any gas. Smell for

gas, including near the floor. If you then smell gas,

STOP! Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instruc-

tions. If you do not smell gas go to next step.

OFF

and release. For

not

try to

OFF

.

3DJH

Page 4

THERMOSTATS

GAS PIPING

DOWNFLOW APPLICATION

MANUAL MAIN

SHUT--OFF VALVE

GROUND JOINT

UNION

GAS VALVE

FIGURE 3

7- On Robertshaw 7200 gas valve, depress lever on

gas control and move to ON and release. For White

Rodgers 36E gas valves, move switch to ON.

8- Replace unit access panel.

9- Turn on all electrical power to unit.

10- Set thermostat to desired setting. See figure 3.

11- If the furnace will not operate, follow the instructions

“ToTurnOffGasToUnit”andcallyour servicetechni-

cian or gas supplier.

B-To Turn Off Gas To Unit

1- Set thermostat to lowest setting. See figure 3.

2- Turn off all electrical power to unit if service is to be

performed. See figure 4.

3- Remove heat section access panel.

4- On Robertshaw 7200 gas valve, depress lever on

gas controland moveto OFFand release. For White

Rodgers 36E gas valves, move switch to OFF.

5- Replace unit access panel.

FOR UNIT TO

OPERATE DISCONNECT

SWITCH MUST

BE IN “ON” POSITION

TYPICAL

FUSE/DISCONNECT

SWITCH BOX MOUNTED

ON FURNACE

FIGURE 4

GAS CONNECTOR*

GAS PIPING

HORIZONTAL APPLICATION

UNIT

REAR PANEL

*Gas connector may be

used for Canadian

installationifacceptable

bylocalauthorityhaving

jurisdiction.

GAS

CONNECTOR*

GROUND

JOINT UNION

GAS VALVE

MANUAL MAIN

SHUT--OFF VALVE

FIGURE 5

6(59,&,1* ),/7(5

Inspect and clean air filters each month. Filters must

be cleaned when dirty to assure proper furnace operation and maintain efficiency.

A-Cleaning Reusable Foam Filter

1- Turn off electrical power to furnace.

2- Remove blower access panel. W a it for blower to stop.

3- Remove filter by sliding up and out of channel.

4- Wash filter with water and a mild detergent. For in-

creased efficiency, filter media should be sprayed

with Filter Handicoater when dry. Filter Handicoater

is RP products No. 418 and is available as Lennox

part No. P-8-5069. If replacement filters is needed,

use Lennox part no. P-8-7831 for 20” x 25” (508 x

635mm) filter.

5- Reinstall filter. Slide filter into top channel and drop

into lower channel.

IMPORTANT-Do not replace foam reusable filters

with throw-away type filters.

6- Replace blower access panel.

3DJH

Page 5

/8%5,&$7,21

Motors are pre-lubricated for extended bearing life;

no further lubrication is required.

6(59,&(

At the beginning of each heating season, the system

should be checked as follows:

1- Examine the termination ends of the intake and ex-

haust lines for obstructions or blockages.

2- Check the intake and exhaust lines for holes, sag-

ging or broken isolation hangers. If a sag is found in

either line, raise the line and support it with an isola-

tion hanger. Replace any damaged isolation hang-

ers.

3- The return air duct connection should be sealed to

the furnace casing and terminate outside thespace

containing the furnace.

4- Check the physical support of the furnace. It should

besoundwithoutsagging,cracks, gaps, etc.,around

thebase soas toprovide asealbetween thesupport

and the base.

5- Check that there is no obvious signs of deterioration

of the furnace.

6- Inspect and clean condensate drain system forfree

flow of condensate.

IMPORTANT-Ifa changeinthesoundlevel oftheunit

is detected or there is evidence of condensate leakage around the unit, contact your Lennox service

technician.

6(59,&( 5(0,1'(5

CallyourLennoxservicetechnicianiftheunitisinoperative. Before calling, always check the following to

be sure service is required:

1- Be sure electrical switches are ON.

2- Check the room thermostat for proper setting.

3- Replace any blown fuses or reset circuit breakers.

4- Make sure gas valve is on.

5- Blower access panel is in place.

6- Air filter must be clean.

6$)(7< 35(&$87,216

If you discover any of the following, shut down your

unit, and contact an independent Lennox dealer for

an inspection by a qualified technician.

-

If you repeatedly hear any new or unfamiliar sounds

while your unit is operating, there may be a problem.

For example, poorly performing burners can produce

unfamiliar noises.

-

If yousmell anyunusual odors,your unit may be operating improperly. For example, units can give offunfamiliar odors if components are required to operate in

abnormal conditions.

-

Look for visible signs of a malfunctioning unit. Examples include unusual amounts of condensate on windows inside your house, visibly burnt components or

unusual dirt or rust accumulations on the vent pipe or

in the unit.

-

If youexperience headache, nausea, fatigue, or dizziness, the cause could be exposure to carbon monoxidegas. This isoften misdiagnosedas theflu because

symptoms are similar. If you suffer from flu-like symptoms that are exaggerated at home, but seem to subside while you are away from the house, exposure to

carbon monoxide could be the cause.

Your vigilance may pay offin early detectionof a problem

before either personal injury or property damage occurs.

Donothesitatetocontactaqualifiedservicetechnicianas

an investment in your well being.

3/$11(' 6(59,&(

Y o ushould expect a service technicianto check the following

items during an annualinspection. Power to the unit must be

shut off for the service technician’s safety.

Fresh air grilles and louvers (on the unit and in the room

where the furnace is installed) - Must be open and unobstructed t o provide combustion air.

Burners- Must beinspectedfor rust,dirt, or signs of water .

V ent pipe - Must be inspected for dirt, signs of water, dam-

aged or sagging unsupported pipe, or disconnected joints.

Unit appearance - Must be inspected for rust, dirt, signs of

water , burnt or damaged wires, or components.

Blower access door - Must be properly in place and provide

a sealbetween thereturn air and the roomwhere thefurnace

is installed.

Return air duct - Must be properly attached and provide an

airtight seal to the unit.

Operating performance -Unit must be observed during operation to monitor proper performance of the unit and the

vent system.

Combustion gases - Flue products must be analyzed and

compared to the unit specifications.

Problems detected during the inspection may make it necessary to temporarily shut down the furnace until the i tems can

be repaired or replaced.

Pay attention to your furnace. Situations can arise between annual furnace inspections that may result in unsafe

operation. For instance, items innocently stored next to the

furnace may obstruct the combustion air supply . This could

cause incomplete combustion and the production of carbon

monoxide gas.

3DJH

Page 6

£

3DJH

Loading...

Loading...