Page 1

PRODUCT LITERATURE

Lennox Industries Inc.

Dallas, Texas

INSTALLATION

INSTRUCTIONS

GSB8-E

GAS-FIRED STEAM BOILER

RETAIN THESE INSTRUCTIONS

FOR

FUTURE REFERENCE

These instructions must be

afxed on or adjacent to the

boiler.

GAS-FIRED HOT WATER BOILERS

These Gas-Fired Water Boilers are low

pressure, sectional cast iron boilers Design

Certified by CSA (Canadian Standards

Association) for use with Natural and

Propane Gases. They are constructed

and hydrostatically tested for a maximum

working pressure of 50 psi (pounds per

square inch) in accordance with A.S.M.E.

(American Society of Mechanical Engineers)

Boiler and Pressure Vessel Code Section IV:

Rules for Construction of Heating Boilers.

Improper installation, adjustment,

alteration, service, or maintenance can

cause injury or property damage. Refer

to this manual. For assistance or additional

information consult a qualied installer,

service agency, or the gas supplier.

WARNING

P/N# 14683453, Rev. C [12/2013]

Page 2

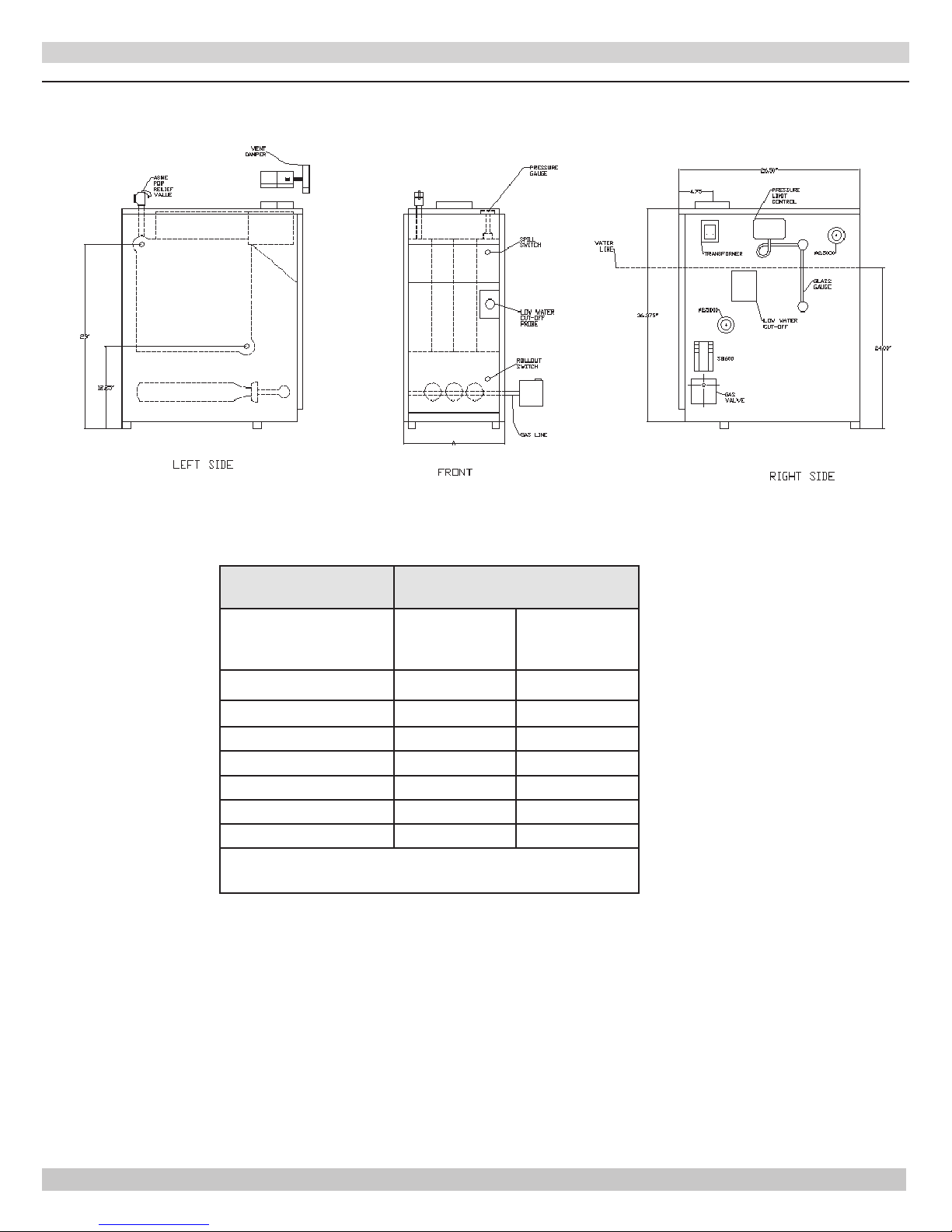

Figure 1 - Dimensions

DIMENSIONS

BOILER MODEL

NUMBER

(1)

Dimensions (Inches)

Intermittent

Ignition w/Vent

Flue Diameter "A" Width

Damper

GSB8-075E 5 11¼

GSB8-112E 6 14½

GSB8-150E 6 17¾

GSB8-187E 7 21

GSB8-225E 7 24¼

GSB8-262E 7 27½

GSB8-299E 7 30¾

Add 5½" to height for Vent Damper

(1)

Add model number sufx 'P' for Propane Gas.

2

Page 3

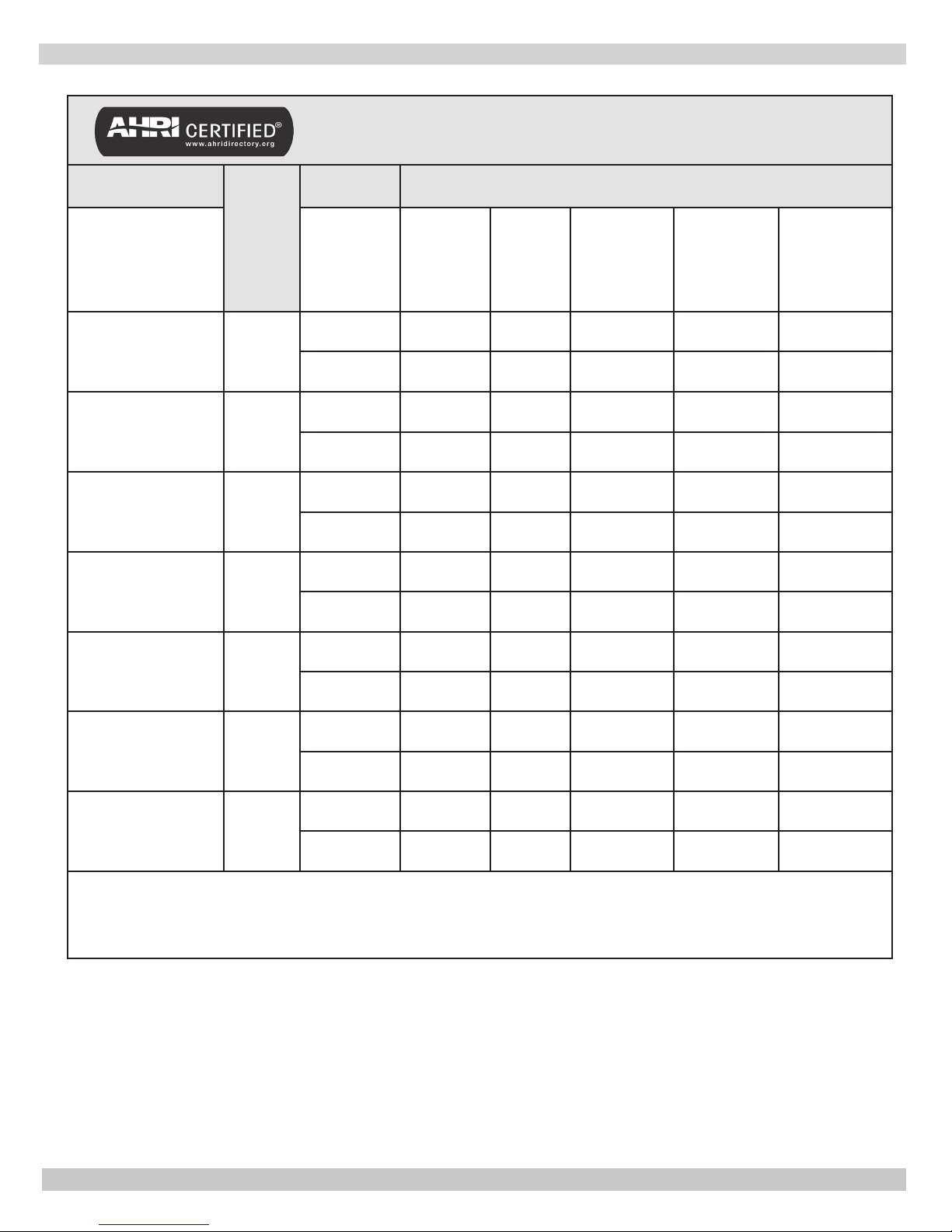

RATINGS AND CAPACITY

Table 1 - Ratings and Capacities

BOILER MODEL

NUMBER

Intermittent

Ignition w/Vent

Damper

(1)

GSB8-075E

(1)

GSB8-112E

(1)

GSB8-150E

(1)

GSB8-187E

No. of

Sec.

3

4

5

6

†Natural Gas

Fuel Type

Input

*MBTUH

Natural Gas 75 62 82.7 47 196

Propane 70 58 82.7 44 183

Natural Gas 112 91 82.0 68 283

Propane 105 85 80.4 64 267

Natural Gas 150 122 82.0 92 383

Propane 140 114 80.6 86 358

Natural Gas 187 153 82.0 115 479

Propane 175 143 80.9 107 446

Heating

Capacity

*MBTUH

AFUE(%)

Net AHRI

Rating *Mbh

Net AHRI

Rating Sq. Ft.

Natural Gas 225 183 82.0 137 571

(1)

GSB8-225E

7

Propane 210 171 81.1 128 533

Natural Gas 262 214 82.0 161 671

(1)

GSB8-262E

8

Propane 245 200 81.3 150 625

Natural Gas 299 245 82.0 184 767

(1)

GSB8-299E

9

Propane 280 229 81.5 172 717

* MBH = 1,000 Btuh. Btuh = British Thermal Unit Per Hour.

† For altitudes above 2,000 ft. reduce input rate 4% for each 1,000 ft. above sea level.

Heating Capacity is based on DOE (Department of Energy) test procedure.

(1)

Add model number sufx 'P' for Propane Gas.

Net AHRI steam Ratings shown are based on a piping and pickup allowance of 1.333.

Base selection of boiler size on "Net AHRI Rating" being equal to or greater than installed radiation in square feet.

Consult manufacturer before selecting a boiler for installations having unusual piping and pickup requirements,such as

intermittent system operation, exhaust piping systems, etc.

3

Page 4

TABLE OF CONTENTS

Dimensions ................................................ 2

Ratings and Capacity .................................. 3

Safety Symbols .......................................... 5

Locating the Boiler ...................................... 6

System Piping ............................................ 7

Installation - System Piping ........................10

Fresh Air for Combustion ............................11

Chimney and Vent Pipe Connection ..............12

Vent Damper Operation ..............................14

Gas Supply Piping ......................................15

Electrical Wiring ........................................16

Operating Instructions ................................17

Operating Your Boiler .................................18

Checking and Adjusting ..............................19

Start-up Cleaning ......................................21

General Maintenance .................................22

Service Hints ............................................23

Wiring Diagrams ........................................24

Wiring diagrams ........................................25

Controls and Accessories ............................26

Introduction

Boiler is designed for use in closed heating systems where

all steam is returned as condensate and make-up water is

minimal. Boiler is not designed for or intended for use in

open systems using 100% make-up water.

Prior to Installation

• Verify correct boiler for type of gas being used

natural or propane. See Rating Plate.

• Verify boiler size and dimensions. See Figure 1 page 2.

• Verify ratings and capacity data for natural gas. See

Table 1 page 3.

Installation Requirements

• Supply boiler with correct gas (natural or propane),

fresh air for combustion, and suitable electrical supply.

• Connect boiler to adequate venting and piping

systems.

• Provide boiler with properly located and adjusted

thermostat.

Installation of boiler in building under construction, use

precaution to insure clean combustion air supply during

construction process. Airborne particulate from construction

materials can clog burner ports and cause incomplete

combustion and sooting.

Complete all steps for safe and proper heating system

operation.

Repair Parts ..............................................27

KEEP THIS MANUAL NEAR BOILER

RETAIN FOR FUTURE REFERENCE

GAS FIRED STEAM BOILERS

Information and specications outlined in this manual in effect at the

time of printing of this manual. Manufacturer reserves the right to

discontinue, change specications or system design at any time without

notice and without incurring any obligation, whatsoever.

4

Page 5

SAFETY SYMBOLS

General

Boiler and venting installation shall be completed by

qualied agency.

WARNING

!

Fire, explosion, asphyxiation and electrical shock

hazard. Improper installation could result in death

or serious injury. Read this manual and understand

all requirements before beginning installation.

Become familiar with symbols identifying potential

hazards.

This is the safety alert symbol. Symbol alerts you to

potential personal injury hazards. Obey all safety messages

following this symbol to avoid possible injury or death.

!

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in death or serious injury.

!

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Installation shall conform to requirements of

authority having jurisdiction or in absence of such

requirements to the National Fuel Gas Code, ANSI

Z223.1/NFPA 54.

Where required by authority having jurisdiction,

installation shall conform to Standard for Controls

and Safety Devices for Automatically Fired Boilers,

ANSI/ASME CSD-1. Controls can be added to make

this boiler CSD-1 compliant. Check with your local

codes for requirements.

Requirements for Commonwealth of Massachusetts:

Boiler installation must conform to Commonwealth of

Massachusetts code 248 CMR which includes but is

not limited to installation by licensed plumber or gas

tter.

WARNING

!

Installing or venting a boiler or any other gas

appliance with improper methods or materials could

result in death or serious injury due to re or to

asphyxiation from poisonous gases such as carbon

monoxide which is odorless and invisible.

!

CAUTION

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE

Used to address practices not related to personal

injury.

WARNING

!

Fire, explosion, asphyxiation hazard. Keep boiler

area clear and free from combustible materials,

gasoline and other ammable vapors and liquids.

Modication, substitution or elimination of factory

equipped, supplied or specied components could

result in death or serious injury.

5

Page 6

LOCATING THE BOILER

Locating the Boiler

1.

Select level location as centralized with piping system,

and as near chimney as possible.

2.

Place crated boiler at selected location. Remove all

crate material. Please recycle responsibly.

!

WARNING

Fire hazard. Do not install boiler on combustible

ooring or carpeting. Failure to follow these

instructions could result in death or serious injury.

3.

Do not install boiler on carpeting. For installation

on non-combustible oors only. For installation on

combustible ooring, special base must be used. See

Repair Parts page 27.

4.

Use metal shims under boiler base legs for nal leveling

if needed.

5.

Install boiler in location that permits satisfactory

combustion of gas, proper venting, and maintenance

of ambient temperature at safe limits under normal

conditions of use. Boiler location should not interfere

with proper circulation of air. Introduce outside air

if normal inltration does not provide necessary

air.“Fresh Air for Combustion” on page 11.

6.

Notify owner to keep air passages free of obstruction.

Ventilating and combustion air must enter boiler room

without restrictions.

7.

Install boiler so automatic gas ignition system

components are protected from water (dripping,

spraying, rain, etc.) during appliance operation and

service.

Table 2 -

Minimum Clearance Dimensions

Top 6"

Rear 6"

Control Side 7"

Opposite Side 6"

Front Alcove

Flue/Vent

Connector

6"

Draft Hood Installation

!

WARNING

Asphyxiation, carbon monoxide hazard. Failure to

follow these instructions could result in improper

combustion and possible leakage of combustion

products into the living space.

Follow directions given in Figure 8. Attach draft diverter,

and blocked vent switch. Mount vent damper. See

"Connecting Vent Damper and Vent Connector" page 12.

See Wiring Diagrams page 25.

6

Page 7

SYSTEM PIPING

!

WARNING

Burn or Scald Hazard. Discharge line shall be installed to relief valve outlet connection to avoid burns,

scalding, or water damage due to discharge of steam and/or hot water during operation.

Discharge line shall:

• Connect to safety valve outlet. Piped down to safe point of disposal. Check local codes for maximum

distance from oor or allowable safe point of discharge.

• Pipe size be of equal to or greater than of safety valve outlet over entire length of discharge line.

• Have no intervening shutoff valve between safety valve and discharge to atmosphere. Do not plug or

place any obstruction in discharge line.

• Terminate freely to atmosphere where any discharge will be clearly visible and at no risk of freezing.

• Allow complete drainage of valve and discharge line.

• Install safety valve with spindle in vertical position.

• Do not install shutoff valve between boiler and safety valve.

• Support safety valve discharge piping.

• Be short and straight as possible.

• Terminate with plain end, not threaded.

• Constructed of material suitable for exposure to temperatures of 375° F (191°C); or greater.

Refer to local codes and appropriate ASME Boiler and Pressure Vessel Code for additional installation

requirements.

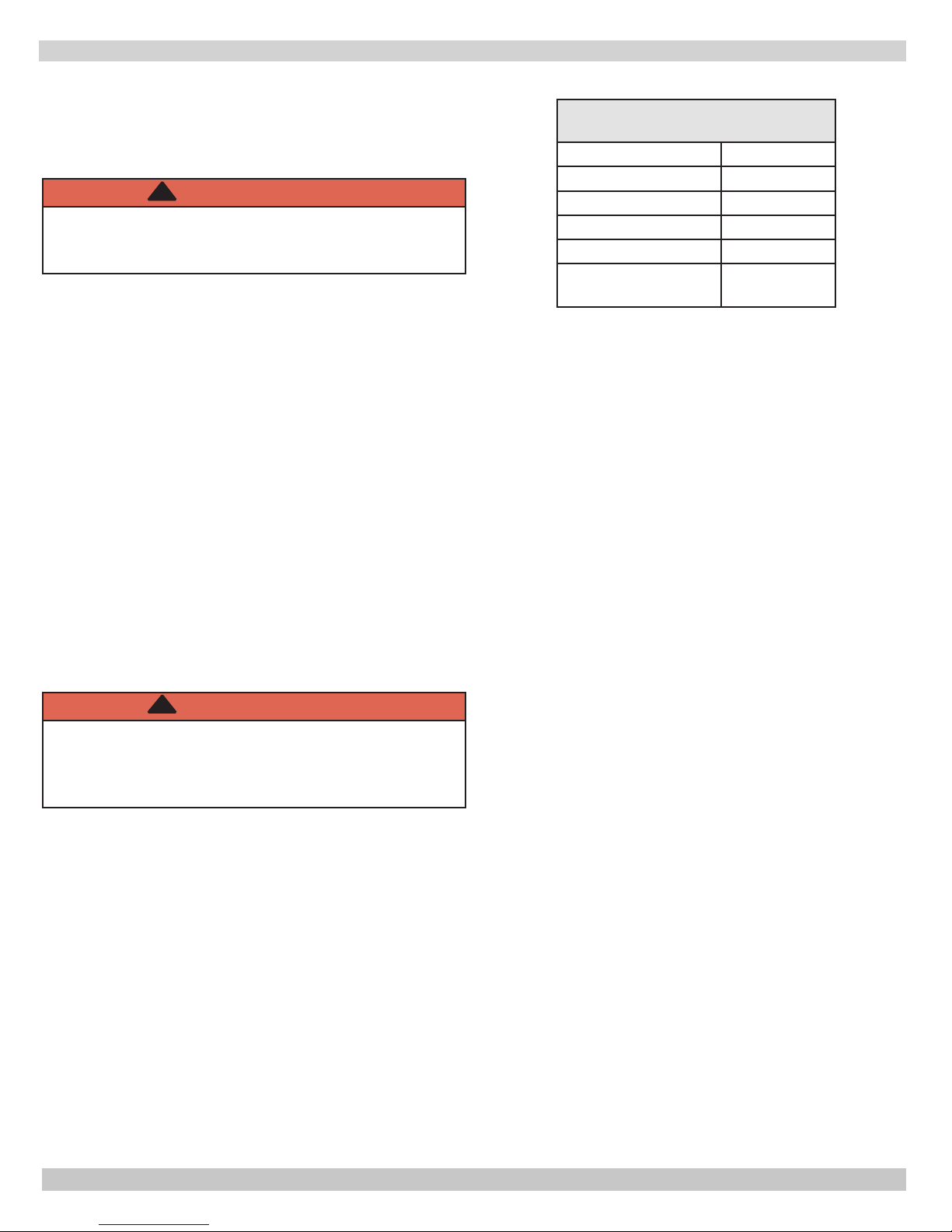

Figure 3 - Safety Valve

Safety Valve

Discharge

Piping

Check local codes

for maximum

distance from

oor or other

allowable safe

point of discharge

6" Above Floor

7

Page 8

SYSTEM PIPING

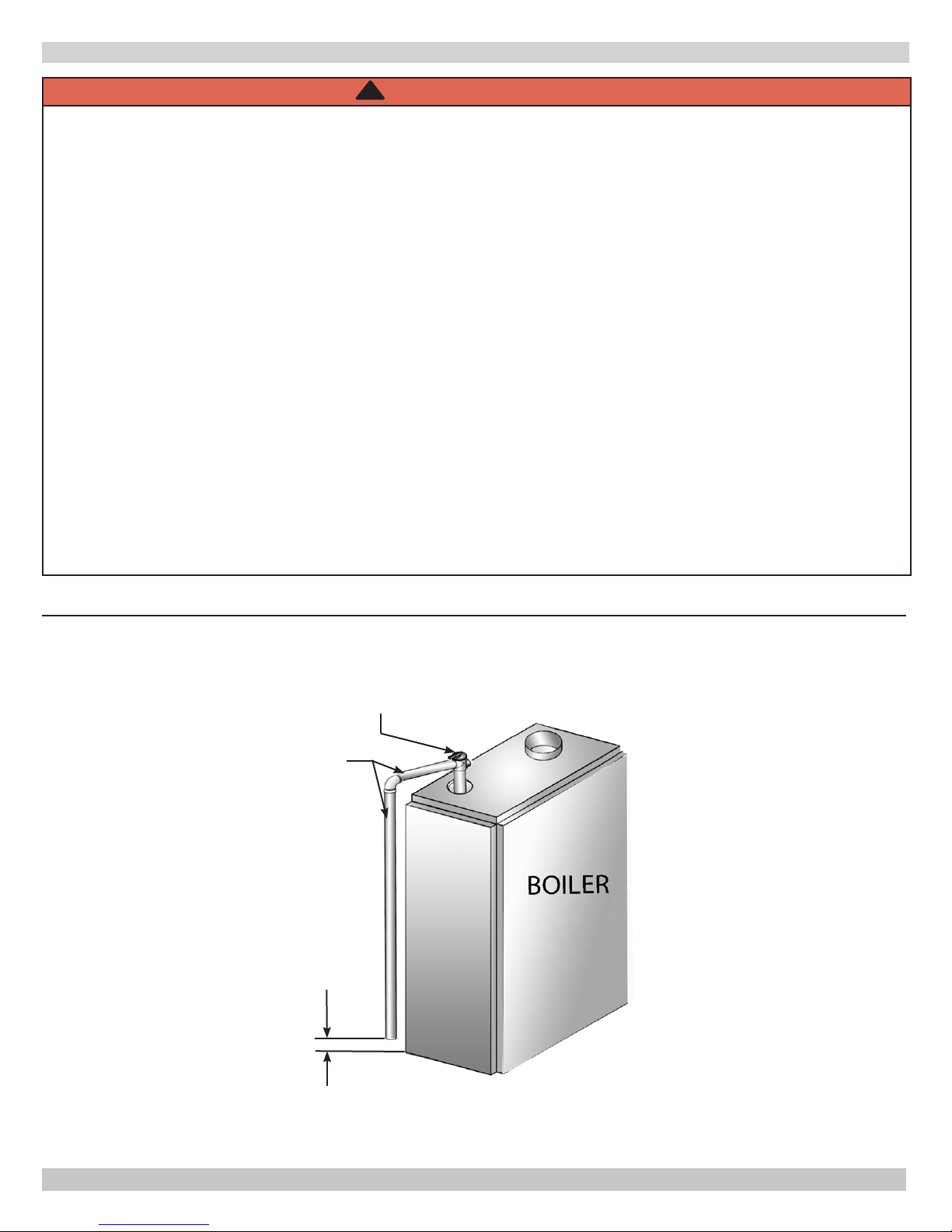

Consider near boiler piping as part of the boiler for proper

water level control and to produce dry steam.

Correct near boiler piping is crucial to proper operation of

boiler and heating system.

Follow these recommendations carefully.

1.

Place boiler in selected location as near chimney as

possible.

2.

Install safety valve. Figure 3 and Warning on Page 7.

• Install union, if used, close to safety valve outlet.

• Install elbows close to safety valve outlet and

downstream of union (if used).

3.

Boiler is equipped with two 2½" supply connections

and two 2½" return connections, one each on both left

and right sides of boiler. Plug unused connections with

furnished 2½" plug (furnished).

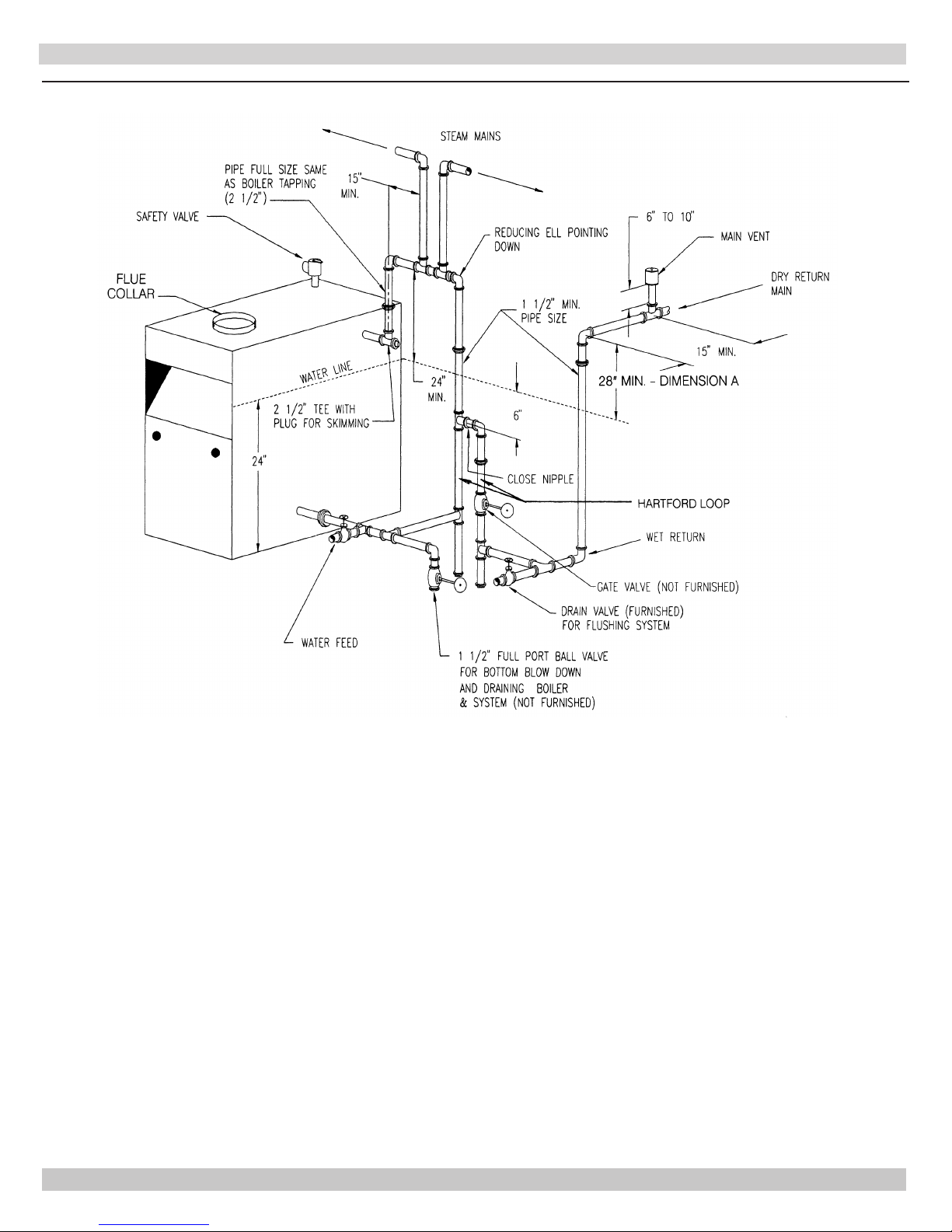

4.

When using both supply tappings to pipe system as

shown in Figure 5, Page 10.

• Fit headers with header offsets, swing joints, or equip

with expansion joints, so thermal expansion and

contraction of header does not damage boiler. Do not

weld headers.

13.

For pumped return systems, follow the condensate

pump or boiler feed pump manufacturer’s instructions

for proper installation and hookup.

14.

In connecting the cold water supply to the water inlet

valve, make sure that a clean water supply is available.

When the water supply is from a well or pump, a sand

strainer should be installed at the pump.

For Use With Cooling Units

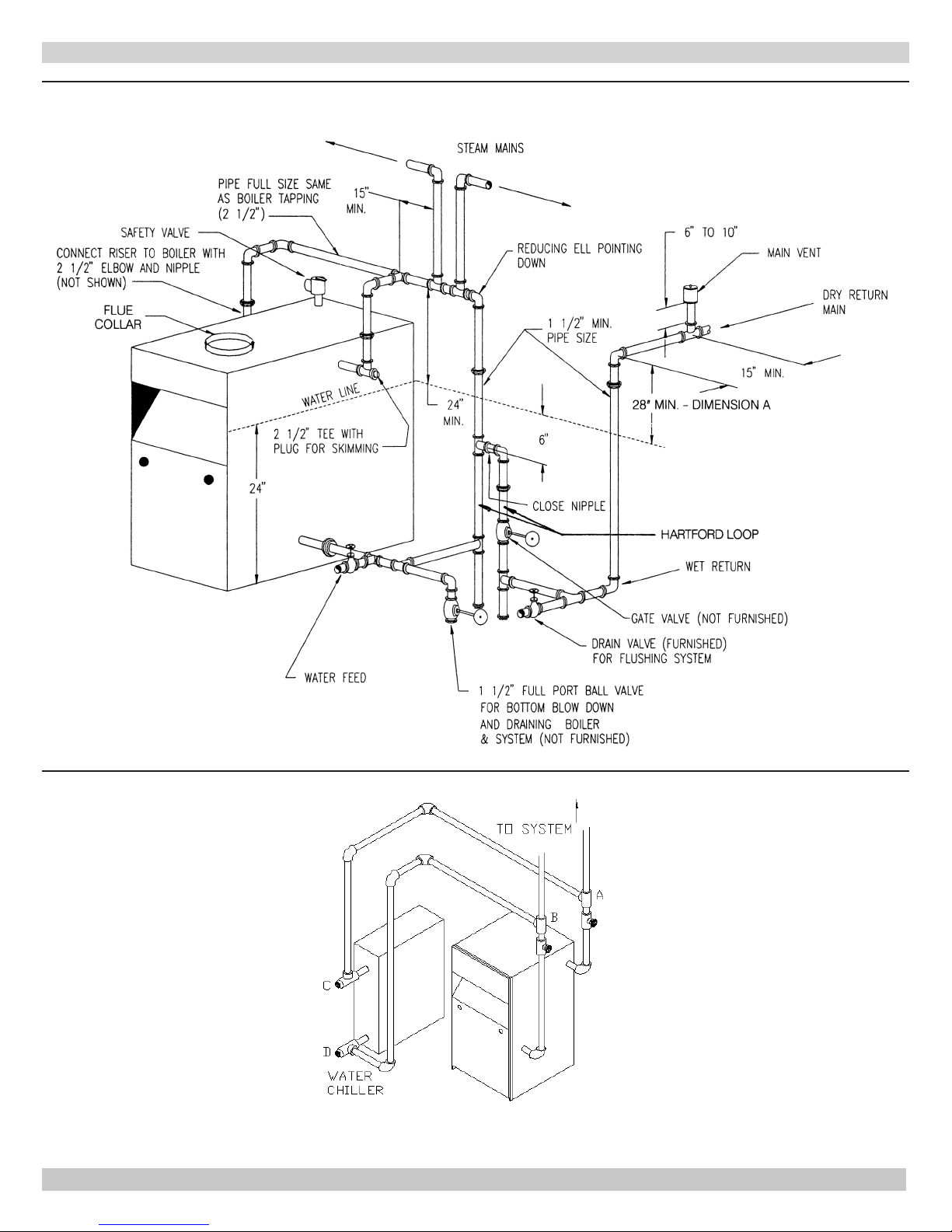

Install boiler, when used in connection with refrigeration

system, so chilled medium is piped in parallel with boiler

with appropriate valves to prevent chilled medium from

entering the boiler. See Figure 6.

• Place system takeoffs from header between equalizer

and riser to header nearest equalizer. System takeoffs

must never be between two risers. If steam main goes

in two directions, place two takeoffs from header, one

for each main.

5.

System takeoffs from the header must never be

bullheaded. If the steam main goes in two directions,

there must be two takeoffs from the header, one for each

main.

6.

All boilers in gravity return systems must be equipped

with a Hartford Loop as shown in Figure 5.

7.

When piping the vertical risers from the boiler to the

header, the bottom of the header must be a minimum

of 24 inches above the water level line on the right side

of the boiler.

8.

Steam riser(s) and header shall be 2½” pipe size.

9.

Equalizer line shall be minimum 1½” pipe size.

10.

The near boiler piping shall include a 2½” tee with a

plug located on the supply line as shown for skimming

(i.e. surface blowdown).

11.

The near boiler piping shall include a 1-1/2 ball valve

in the return piping as shown for bottom blowdown and

draining.

12.

For gravity return systems, the bottom of the lowest

steam carrying pipe, be it a dry return, or the end of the

steam main, must be at least 28” above the normal water

level line on the right side of the boiler. This is known as

“Dimension A.”

8

Page 9

SYSTEM PIPING

Figure 4 - Recommended Near Boiler Piping Using One Supply Tapping

9

Page 10

INSTALLATION - SYSTEM PIPING

Figure 5 - Recommended Near Boiler Piping Using Two Supply Tappings

Figure 6 - Chilled Water Piping

VALVES A & B OPEN FOR HEATING; CLOSE FOR COOLING

VALVES C & D CLOSE FOR HEATING; OPEN FOR COOLING

10

Page 11

FRESH AIR FOR COMBUSTION

!

WARNING

Air openings to combustion area must not be

obstructed. Follow instructions below, to maintain

adequate combustion air

Provide combustion air and ventilation air in accordance

with the section “Air for Combustion and Ventilation,” of the

National Fuel Gas Code, ANSI Z223.1 / NFPA 54, or

applicable provisions of local building codes.

Provide make-up air where exhaust fans, clothes dryers,

and kitchen ventilation equipment interfere with proper

operation.

National Fuel Gas Code recognizes several methods

of obtaining adequate ventilation and combustion air.

Requirements of the authority having jurisdiction may

override these methods.

• Engineered Installations. Must be approved by authority

having jurisdiction.

• Mechanical Air Supply. Provide minimum of 0.35

cfm per Mbh for all appliances located within space.

Additional requirements where exhaust fans installed.

Interlock each appliance to mechanical air supply

system to prevent main burner operation when

mechanical air supply system not operating.

• All Indoor Air. Calculate minimum volume for all

appliances in space. Use a different method if minimum

volume not available.

A. Standard Method. See Table 3 for space with natural

gas boiler only. Use equation for multiple appliances

and/or propane.

Room Volume is greater than 50 cubic feet multiplied

by Total Input [Mbh]

B. Known Air Inltration Rate. See Table 3 for

space with boiler only. Use equation for multiple

appliances. Do not use an air inltration rate air

changes per hour (ACH) greater than 0.60.

Room volume is greater than 21 cubic feet divided by

ACH (air changes per hour) x Total Input [Mbh]

C. Refer to National Fuel Gas Code for opening

requirements between connected indoor spaces.

• All Outdoor Air. Provide permanent opening(s)

communicating directly or by ducts with outdoors.

A. Two Permanent Opening Method. Provide opening

commencing within 12 inches of top and second

opening commencing within 12 inches of bottom of

enclosure.

Direct communication with outdoors or

communicating through vertical ducts. Provide

minimum free area of 1 in² per 4 Mbh of total

input rating of all appliances in enclosure.

Communicating through horizontal ducts.

Provide minimum free area of 1 in² per 2

Mbh of total input rating of all appliances in

enclosure.

B. One Permanent Opening Method. Provide opening

commencing within 12 inches of top of enclosure.

Provide minimum clearance of 1 inch on sides/back

and 6 inches on front of boiler (does not supersede

clearance to combustible materials).

C. Refer to National Fuel Gas Code for additional

requirements for louvers, grilles, screens and air

ducts.

• Combination Indoor and Outdoor Air. Refer to National

Fuel Gas Code for application information.

Table 3 - Minimum Room Volume, Indoor Air Only*

Input Mbh

75 3750 15750 7875 5250 3938 3150 2625

112.5 5625 23625 11813 7875 5906 4725 3938

150 7500 31500 15750 10500 7875 6300 5250

187 9350 39270 19635 13090 9818 7854 6545

225 11250 47250 23625 15750 11813 9450 7875

262.5 13125 55125 27563 18375 13781 11025 9188

299 14950 62790 31395 20930 15698 12558 10465

* Table values based on boiler only. Add volume for any additional appliances.

Standard

Method

0.1 0.2 0.3 0.4 0.5 0.6

Known Air Inltration Rate Method (Air Changes Per Hour)

11

Page 12

CHIMNEY AND VENT PIPE CONNECTION

WARNING

!

Installing or venting a boiler or any other gas

appliance with improper methods or materials could

result in death or serious injury due to re or to

asphyxiation from poisonous gases such as carbon

monoxide which is odorless and invisible.

Boiler and venting installations shall be performed

in accordance with "Venting of Equipment", of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54, or

applicable provisions of the local building codes.

Chimney Inspection

Chimney must be clean, sized correctly, properly

constructed and in good condition.

Installation must conform to requirements of the authority

having jurisdiction or, in absence of such requirements, to

the National Fuel Gas Code, ANSI Z223.1/NFPA 54. See

Figure 7, page 13.

Connecting The Vent Damper And Vent Connector

Refer to Figure 1 for the size and location of the vent (ue

opening). Use a 28 gauge (minimum) galvanized pipe to

connect to the chimney.

Furnished vent damper blade has 1/2 square inch hole

(approximately 3/4” diameter). Boilers equipped with

intermittent ignition, plug hole using plug supplied with

vent damper.

1.

Position furnished vent damper on top of ue outlet

collar. Fasten damper securely to ue outlet collar

with sheet metal screws. Make sure damper blade has

clearance to operate inside of diverter. Do not modify

draft diverter or vent damper

As An Option

Damper may be installed in any horizontal or vertical

position, closer to ue outlet collar preferred. See

Figures 7, 8 and 9.

2.

Install vent damper to service single boiler only for

which it is intended. Damper position indicator shall be

in visible location following installation. Locate damper

so it is accessible for servicing.

3.

Damper must be in open position when appliance main

burners are operating.

4.

Boiler is equipped with factory wired harness that plugs

into vent damper. Connect thermostat to black wires

marked 24 volt thermostat on boiler.

5.

Vent pipe must be same size as ue outlet collar.

6.

Slope pipe up from boiler to chimney not less than 1/4”

per foot.

7.

Run pipe as directly as possible with as few elbows as

possible.

8.

Do not connect to replace ue.

9.

End of vent pipe must be ush with inside face of

chimney ue. Use sealed-in thimble for chimney

connection.

10.

Horizontal run should not be longer than 3/4 the

chimney height (HT) Figure 7, page 13.

Vent Pipe

• Fasten sections of vent pipe with 3 sheet metal screws

at each joint to make piping rigid.

• Support horizontal portions of vent system to prevent

sagging.

• Use stovepipe wires or metal strapping every 5’ to

support pipe from above.

• Vent pipe through crawl space, use double wall vent

pipe.

• Vent pipe passing through combustible wall or partition,

use ventilated metal thimble. Thimble should be 4"

larger in diameter than vent pipe.

NOTICE

Minimum Vent Pipe Clearance - Wood and other

combustible materials must not be closer than 6” from

any surface of single wall metal vent pipe. Listed Type

B vent pipe or other listed venting systems shall be

installed in accordance with their listing.

Removing Existing Boiler From Common Venting

System

When an existing boiler is removed from a common

venting system, the common venting system is likely to be

too large for proper venting of the appliances remaining

connected to it.

At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining

connected to the common venting system placed in

operation, while the other appliances remaining connected

to the common venting system are not in operation.

1.

Seal any unused openings in the common venting

system.

2.

Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deciencies

which could cause an unsafe condition.

3.

Insofar as is practical, close all building doors and

windows and all doors between the space in which the

appliances remaining connected to the common venting

system are located and other spaces of the building.

Turn on clothes dryers and any appliance not connected

to the common venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts, so

they will operate at maximum speed. Do not operate a

summer exhaust fan. Close replace dampers.

12

Page 13

CHIMNEY AND VENT PIPE CONNECTION

3 FT (914mm)

MIN.

2 FT (610mm)

MIN.

4.

Place in operation the appliance being inspected. Follow

the lighting instructions. Adjust thermostat so appliance

will operate continuously.

5.

Test for spillage at the draft hood relief opening after

5 minutes of main burner operation. Use the ame of

a match or candle, or smoke from a cigarette, cigar or

pipe.

6.

After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, replace dampers and

any other gas-burning appliance to their previous

conditions of use.

7.

Any improper operation of the common venting system

should be corrected so the installation conforms with

the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

When re-sizing any portion of the common venting

system, the common venting system should be resized

to approach the minimum size as determined using the

appropriate tables in Chapter 13 of the National Fuel

Gas Code, ANSI Z223.1/NFPA 54.

Figure 7 - Typical Masonry Chimney Requirements

Vent connectors serving appliances vented by natural draft shall

not be connected into any portion of mechanical draft systems

operating under positive pressure.

13

Page 14

VENT DAMPER OPERATION

!

WARNING

Asphyxiation or burn hazard. Improper installation

and operation of vent damper could result in serious

injury or death due to re or to asphyxiation from

poisonous gases such as carbon monoxide which is

odorless and invisible.

Vent Damper Installation - Follow all cautions and

notes.

• Install vent damper to service only single appliance for

which it is intended.

• Do not install vent damper with 6" (15mm) of

combustible material.

• Do not install vent damper on vent pipe curve.

• Do not run wires near high temperature surfaces. Use

standoff brackets if necessary.

• Install vent damper with actuator to sides of vent only.

Do not mount above or below vent.

Check vent damper and all ue product carrying

areas of boiler annually for deterioration from

corrosion or other sources. If you see corrosion or

other deterioration, contact your service agent for

repairs.

Check vent damper operation as follows:

1.

When boiler is off, check vent damper positions

indicator points to closed position. See Figure 10.

2.

Turn thermostat or controller up to call for heat and

check vent damper indicator points to open position

See Figure 10.

3.

Turn thermostat or controller down again and check

damper position indicator returns to closed position.

4.

Return thermostat to desired position.

Inspect vent damper at least once a year by

trained service technician.

Figure 8 - Horizontal Installation

Horizontal Installation

NO

YES YES

NO

Install vent damper

with actuator to sides

of vent only. Do not

vent.

Actuator may

be installer in

any position.

To Boiler

Chimney

To Boiler

Flow

Vent Damper

To

Flow

To

Chimney

mount above or below

Vent Damper

Figure 9 - Alternate Vent Damper Installation

Caution: Do not

install Vent Damper

within 6" (152mm)

of combustible

material

Install Damper Here

Do Not

Install

Here

Chimney

Manual Operation of Vent Damper

• Place vent damper in open position to permit burner

operation by using “HOLD DAMPER OPEN” switch,

located on damper controller.

• Thermostat controls burner ring as before, while

damper remains open.

• DO NOT turn damper open manually, motor damage

will result.

• Set switch to “AUTOMATIC OPERATION” to close vent

damper during burner off cycle.

• For further information, and for vent damper

troubleshooting guide, refer to manual packaged with

vent damper.

Boiler

Figure 10 - Vent Damper Position Indicator

Flue Gas

Flow

Damper Closed

CLOSED

OPEN

ROTATION

Flue Gas Flow

Damper Open

OPEN

CLOSED

Showing Open and Closed Positions

14

ROTATION

Page 15

GAS SUPPLY PIPING

3” Minimum

Sediment

Trap

Manifold

Floor Line

Automatic

Gas Valve

Ground

Joint

Union

!

CAUTION

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the re

department.

General

• Use piping materials and joining methods acceptable

to authority having jurisdiction. In absence of such

requirements National Fuel gas Code, ANSI Z223.1/

NFPA 54.

• Size and install gas piping system to provide sufcient

gas supply to meet maximum input at not less than

minimum supply pressure.

See Tables 4a and 4b.

Table - 4a Gas Pipe Sizes - Natural Gas

Length

of Pipe

- Ft.

Pipe Capacity - BTU Per Hour Input

Includes Fittings

1/2" 3/4" 1" 1 -1/4"

20 92,000 190,000 350,000 625,000

40 63,000 130,000 245,000 445,000

60 50,000 105,000 195,000 365,000

Table - 4b Gas Pipe Sizes - Propane Gas

Length

of Pipe

- Ft.

Pipe Capacity - BTU Per Hour Input

Includes Fittings

5/8" 3/4" 1/2" 3/4"

20 131,000 216,000 189,000 393,000

40 90,000 145,000 129,000 267,000

60 72,000 121,000 103,000 217,000

Propane Installation

WARNING

Fire, explosion, asphyxiation hazard. Verify boiler

is equipped with propane gas orices and gas valve

is congured for propane. Failure to follow these

instructions may result in serious injury or death.

•

Connections by licensed propane dealer only.

•

Use two stage regulator provided by propane

supplier.

•

Have propane supplier check piping.

!

DANGER

Fire Hazard. Do not use matches, candles, open

ames, or other methods providing ignition source.

Failure to comply will result in death or serious

injury.

Leak Check Gas Piping

Pressure test boiler and gas connection before placing

boiler in operation. Avoid excessive pressure that could

damage pressure regulators, valves, or meters.

•

Pressure test at 1/2 psig (3.5 kPa) or less. Isolate

boiler from gas supply system by closing manual gas

shutoff valve.

•

Locate leakage using gas detector, noncorrosive

detection uid, or other leak detection method

acceptable to authority having jurisdiction. Do not

use matches, candles, open ames, or other methods

providing ignition source.

•

Correct leaks immediately and retest.

Figure 11 - Gas Piping At Boiler

* Outside diameter

Length of pipe or tubing should be measured from the gas meter

or propane second stage regulator.

• Support piping with hooks straps, bands, brackets,

hangers, or building structure components to prevent or

dampen excessive vibrations and prevent strain on gas

connection. Gas valve will not support piping weight.

• Use thread (joint) compound (pipe dope) suitable for

natural and liqueed petroleum gas.

• Install eld sourced manual main shutoff valve, ground

joint union, and sediment trap upstream of gas valve.

See Figure 11.

15

Page 16

ELECTRICAL WIRING

!

WARNING

Electronic Thermostats

Electrical shock hazard. Turn OFF electrical power

supply at service panel before making electrical

connections. Failure to do so could result in death

or serious injury.

NOTICE

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

Electric Power Supply

Electrically bond boiler to ground in accordance with

requirements of authority having jurisdiction. Refer to

National Electrical Code, ANSI/NFPA 70.

Line Voltage Connections

A. Provide individual 120V, 15 amp circuit

(recommended) with fused disconnect or service

switch as required by authority having jurisdiction.

B. Locate a shut-off switch at the boiler.

C. Connect 115V electrical supply to primary leads on

24 volt transformer. Securely fasten with wire nuts.

D. Set heat anticipator at 0.6 amps for boilers

equipped with intermittent ignition. Connect 24

volt thermostat leads to two wires tagged “24 volt

thermostat” on boiler.

E. Boilers with 67D-1 oat type low water cut-off, two

wires are black. One wire is located on secondary

of 24 volt transformer, second wire is located on

pressure limit control.

F. Boilers with PS-802 probe type low water cut-

off, one wire is green and is located on terminal

B of PS-802, second wire is black and located on

pressure limit control.

VENT DAMPER

Boiler is equipped with factory wired 4 pin molex harness,

that plugs into 4 pin molex receptacle inside vent damper

control.

Vent damper must be connected for boiler to operate.

Figure 12a - Isolation Relay Wiring For Steam Boilers

With Float Type Low Water Cut Off And Use of

Electronic Thermostat

Figure 12b - Isolation Relay Wiring For Steam

Boilers With Probe Type Low Water Cut Off And Use

of Electronic Thermostat

A. Some electronic thermostats may lose their

memory or shut down. With probe type low water

cutoff, this may occur each time low water cutoff

detects low water condition. If this is the case, an

isolation relay is required for thermostat circuit. A

24 volt single pole single throw (SPST) normally

open (N.O.) relay is required, such as Honeywell

R8222A or equivalent. Wire as shown in Figure 12a

or Figure 12b.

B. Some electronic thermostats are not acceptable

for use with steam systems, check manufacturer

suggested use.

Thermostat Installation

1.

Install thermostat on inside wall per manufacturer's

instructions.

2.

NEVER install thermostat on outside wall.

3.

Do not install thermostat where it will be affected by

drafts, hot or cold pipes, sunlight, lighting xtures,

televisions, replace, or chimney.

4.

Check thermostat operation by raising and lowering

thermostat setting as required to start and stop

burners.

5.

Instructions for nal adjustment of thermostat see

manufacturer's instructions.

16

Page 17

OPERATING INSTRUCTIONS

For Your Safety Read Before Operating

!

WARNING

If you do not follow these instructions

exactly, a re or explosion may result

causing property damage, personal injury

or loss of life.

• This appliance is equipped with an ignition device

which automatically lights burner. Do NOT try to

light this burner by hand.

• Before operating smell all around appliance area

for gas. Be sure to smell next to oor because

some gas is heavier than air and will settle to the

oor.

• Use only your hand to turn the gas shutoff

valve. Never use tools. If valve will not turn

by hand, do not try to repair it, call a qualied

service technician. Force or attempted repair may

result in re or explosion.

• Do not use this appliance if any part has

been under water. Immediately call a qualied

service technician to inspect appliance and to

replace any part of control system and any gas

control which has been under water.

!

CAUTION

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the re

department.

1.

STOP! Read the safety information on this page.

2.

Set the thermostat to lowest setting.

3.

Turn off all electric power to the appliance.

4.

This appliance is equipped with an ignition device which

automatically lights the pilot. Do not try to light the

pilot by hand.

Figure 13 - Gas Valve

5.

Remove lower front panel.

6.

Rotate the gas control knob clockwise to“OFF”.

7.

Wait ve (5) minutes to clear out any gas. Then smell

for gas, including near the oor. If you smell gas,

STOP! Follow “B” in the safety information on this page

If you don’t smell gas, go to next step.

8.

Rotate the gas control knob counterclockwise

to “ON.”

9.

Replace lower front panel.

10.

Turn on all electric power to the appliance.

11.

Set thermostat to desired setting.

12.

If the appliance will not operate, follow the instructions

“To Turn Off Gas To Appliance” and call your service

technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

1.

Set the thermostat to lowest setting.

2.

Turn off all electric power to the appliance if service is

to be performed.

3.

Push in gas control knob slightly and turn clockwise

to “OFF” Do not force.

17

Page 18

OPERATING YOUR BOILER

!

WARNING

Burn Hazard. Never run water into a hot empty

boiler. Failure to follow these instructions could

result in death or serious injury.

Filling System With Water

Steam heating systems boiler is partially lled with water.

Fill boiler to correct level for proper system operation.

Correct water level is about halfway up glass water level

gauge as marked on boiler jacket.

1.

Close boiler drain valve.

2.

Open valves at top and bottom of glass water level

gauge.

3.

Open ll valve. Allow water to run into boiler.

4.

Allow boiler to ll until water runs out gauge drain

valve. Then close gauge drain valve.

5.

Continue to ll boiler until water reaches indicated

water line about halfway up glass gauge.

Water Level

• Normal water level is 24" above the oor as shown on

left side of boiler.

Thermostat

A. Set thermostat to desired room temperature.

B. Set thermostat to lower setting if heat is not

required

C. System is self-checking. If failure of any component

system will not operate or will go into safety

lockout.

D. On call for heat, each component must function

properly to permit operation.

E. Turn thermostat to lowest setting for one minute

and back to normal setting to reset on safety

lockout.

• Determine water level when boiler is off and cold, when

all water in the system is inside the boiler and return

piping below water line, and everything above water

line is air, no steam.

• When boiler is making steam, water level drops two to

three inches below normal water line.

18

Page 19

CHECKING AND ADJUSTING

Adjust Pilot Burner

Pilot ame should surround 3/8” to 1/2” of pilot sensor. See

Figure 15.

To adjust Flame.

1.

Remove screw cover over pilot adjusting screw. See

Figure 13.

2.

Insert small screwdriver and adjust ame as needed.

Turn screw counterclockwise to increase ame, clock-

wise to decrease.

3.

Replace screw cover over pilot adjusting screw.

Figure 14 - Igniter

Main Burners

• Main burners do not require primary air adjustment and

are not equipped with primary air shutters.

• Main burner ames form sharp blue inner cones in

softer blue outer mantel, with no yellow. Remain still

when observing main burner ames.

• Check main burner orices, burner throat and ame

ports for dust and lint obstruction if ame appearance

is not correct.

• Remove rollout shield if necessary to observe main

burner ames.

• Replace rollout shield after observation.

Figure 15 - Main Burner

Gas Valve Safety Shutdown Test

1.

Test ignition system safety shutoff device after placing

boiler in operation.

2.

Boilers equipped with intermittent ignition, with

main burners ring, disconnect ignition cable from

intermittent pilot control box. Gas valve will shut off

main burners.

3.

TURN OFF ELECTRIC POWER to boiler before

reconnecting ignition cable, to prevent electric shock.

19

Page 20

CHECKING AND ADJUSTING

Adjust Steam Pressure Control

• Steam pressure limit control (pressuretrol) shuts

off gas to main burners when steam pressure in

boiler reaches cut-off setpoint (i.e. sum of cut-in and

differential setpoints).

• Burners rere when steam pressure drops to cut-in

setpoint.

• System pressure requirements are based on size and

condition of pipes, and load.

• Cut-in setting of pressuretrol should never be less than

twice system pressure drop for good system operation.

A. In typical single family residence with clean one-

pipe heating system and cast iron radiation, cut-in

is usually set at minimum setting, i.e. 1/2 psi.

• Steam radiation is sized based on square feet of

equivalent direct radiation (EDR). This is based on

steam pressure in the radiator of just less than 2 psi.

• Set differential adjustment at 1 psi, i.e. steam pressure

required in radiators. Results in cut-off setpoint of 1½

psi.

• Larger systems or other types of systems such as two

pipe systems, or systems with convectors or fan coil

units, pressuretrol settings need to be determined on

system-by-system basis.

• Cut-in setpoint is determined by system pressure drop

to furthest radiator or terminal unit. Double system

pressure drop as safety factor, resulting in the rule

cut-in setting should never be less than twice system

pressure drop.

• Differential setpoint is steam pressure required at

terminal heating units.

Boiler Equipped With Optional WF-2U-24 Water

Feeder

E. Continue thermostat call for heat after low water

cut off recognizes low water condition.

F. One minute time delay, water feeder starts feeding

water to boiler.

G. Feeder feeds for one minute, and then goes into

another one minute waiting period.

H. Cycle of alternately waiting and feeding will repeat

until :

• For Model 67D-1 oat type low water cutoffs - as

the water level raises the oat above the burner

cut off switch level, the burners should ignite. The

water feeder remains powered until the water

level raises the oat to the water feeder switch

level, satisfying the water feeder.

• For probe type low water cutoffs - the water level

will rise until water in the boiler makes contact

with the probe, satisfying the water feeder, and

igniting the burners.

I. In either case, one and two inches of water should

be visible in glass gauge when both water feeder is

satised, and burners are allowed to ignite.

• Time delays in feed cycles are designed to prevent

boiler from ooding due to slow return lines.

• To check pressure limit, run boiler until pressure

reaches system demand. Turn pressure screw and drop

pressure setting until boiler shuts down. This shows the

pressure limit is operating properly.

• Refer to control manufacturer’s instructions for more

information.

Boiler will now operate in correct pressure range. It

maintains enough steam pressure to send steam out to

furthest radiator, and not go over optimum steam pressure

required at the radiators.

Checking Controls

Low Water Cut-Off

A. Turn off power to boiler or turn thermostat down to

lowest setting.

B. Drain water to below visible bottom of water gauge

glass. Turn power on and turn thermostat to call for

heat.

C. Gas valve opens for approximately 10 seconds

(time delay on probe type LWCO), gas valve will

close and red indicator illuminates on LWCO.

D. When water is restored, it waits 30 seconds before

reactivating burner circuit.

20

Check Thermostat Operation

Thermostat set above temperature indicated on

thermometer, boiler should ignite.

Verify thermostat turns boiler off when room temperature

reaches selected setting and starts boiler operating when

room temperature falls few degrees.

Set thermostat for desired temperature. Conditions in your

home and location of thermostat will govern this setting.

Page 21

START-UP CLEANING

!

WARNING

Following service procedures must be performed

by qualied service agent. Boiler owner shall not

attempt these steps. Failure to do so could result in

8.

death or serious injury.

It is very important to clean a new steam boiler after it has

been installed and put into continuous operation.

This must be done to remove any accumulation of oil,

grease, sludge, etc., that may have be present in system.

These substances may cause boiler water to foam and

surge, producing an unsteady water line, throwing

water into steam header, and possibly preventing steam

generation.

Follow skimming and blow-down steps in order to remove

contaminants.

Skimming and Blow-down

!

WARNING

Burn Scald Hazard. Water temperatures in excess

of 125°F. Failure to follow these instructions could

result in death or serious injury.

New boilers must be skimmed at time of installation to

remove threading oil and other impurities that oat on

surface of water.

1.

Remove cap from skimmer female adapter tee and pipe

to oor drain or bucket. See Figures 4 and 5 page 9.

Raise water level to skimmer tapping.

2.

Fire burners to maintain water temperature of 180200°F.

3.

Feed water to boiler to maintain water level. Adjust

water feed rate to maintain continuous ow of 1 gallon

per minute. Do not allow boiler to steam.

4.

Continue skimming until water runs clear. This may

take several hours.

5.

Drain boiler completely to remove any foreign material.

6.

Fill boiler to water line.

• Fire burners, allow normal steam pressure to build up.

Clean water with no additives is essential to proper

operation of your boiler and heating system. Boiler

cleaners and chemical cleaning, if used and not

rinsed properly, may be harmful to the system

If cleaning is necessary, repeat skimming and blow-down

procedure above. A long skim will be all you need to clean

the boiler.

In more troublesome cases it may be desirable to ush the

system while, in very extreme cases, it may be necessary

to chemically clean and ush heating system.

Consult boiler manufacturer before introducing any

chemicals into boiler.

Check water level frequently. Be sure top and bottom

valves on gauge are always open so actual water level is

shown at all times.

• Maintain at least 180°F for 15 minutes to remove

dissolved gasses from fresh water.

• Shut off burners.

Allow system to operate for one week to give majority

of system dirt a chance to work its way back to boiler.

• Check water in gauge glass. Gauge glass should be

dry above water line.

• Water line should not bounce more than one inch

when boiler is steaming.

• If you see water droplets carrying over from top of

gauge glass, or excessive bouncing of water line,

boiler needs further cleaning.

• Take water sample and boil it on stove to see if it

foams. If it does, this indicates boiler needs to be

cleaned.

NOTICE

.

• Run connection from boiler drain valve to safe

discharge point outside.

• Shut off gas burners, open drain valve, allow all of

water in boiler to drain out.

• Close drain valve.

• Allow boiler to cool, slowly rell boiler to water line.

• Repeat this step as many times as necessary until

blow-down water is clear.

7.

Following nal blow-down, allow boiler to cool.

• Add fresh water slowly up to normal water line.

• Start burners.

21

Page 22

GENERAL MAINTENANCE

Low Water Cut-Off

Low Water Cut-Off interrupts electrical current to burner

when water line in boiler drops to low level.

Check Low Water Cut-Off monthly to verify it is providing

proper protection. See “Checking and Adjusting” on page

21.

Remove Low Water Cut-Off probes beginning of each

heating season for inspection and cleaning. More cleaning

may be required on boilers requiring frequent additions of

make up water.

Boiler Flue Passages and Burners

Beginning of heating season visually check pilot and main

burner ames. See page 19.

Recommend you have ue passages, burner adjustment,

and operation of controls checked once each year by

trained Service Technician.

Before start of each season or whenever system has been

shut down for some time, check system, boiler and vent

pipe for leaks.

Boiler Water Treatment Other Than Cleaners

In steam systems where system is tight, free from leaks,

and all steam is returned to boiler as condensate, amount

of make up water is small. Water treatment is generally not

required.

In steam systems with less than 90% of steam being

returned as condensate, or with very hard or corrosive

make up water, treatment may be desirable. Follow

recommendations of your local boiler water treatment

specialist.

Foaming, Priming, or Surging

These terms are used to describe a uctuating water line

when water leaves boiler with steam. It is caused by any

combination of following:

1. Threading oil and organic matter in boiler water. Follow

2.

3.

Vent Pipe

Check vent piping at lease once a season. Verify vent pipe

connections to chimney are secure and no obstructions

are present. If vent piping shows sign of leaking, replace it

immediately.

4.

Safety Valve

See Manufacturer's Instructions.

instructions under “Start-up Cleaning.”

Faulty quick vents that do not release air until sizeable

pressure is built up - if old style, replace - if dirty, clean

until you can easily blow through valve.

Adjustment of steam limit control to wide differential

increases difculty if quick vents are old style, slow-

releasing type or dirty. Always set steam limit control

differential as low as possible.

Soap and chemicals in boiler water cause extreme

surging. Boiler cleaners and chemical cleaning additives

are not recommended. If used and not rinsed properly,

may be harmful to the system.

Cleaning Boiler Flue Passages and Burners

1. Remove burners, pilot, vent pipe, top and front jacket

panels. Remove hold-down nuts and bolts from ue

collector.

2. Use putty knife to cut through silicone. Lift ue collector

off boiler sections. Remove old silicone material.

3. Clean passageways between sections with ue brush.

Remove dirt from bottom of boiler and from between

sections by vacuuming.

4. Verify all ame ports in burners are open and clear.

Shake or blow out loose dirt in burners.

5. Apply generous bead of 400°F RTV silicone to four

mounting surface anges of ue collector. Mount ue

collector on heat exchanger. Tighten nuts and bolts.

6. Seal front edge and four corners of ue collector to

heat exchanger with silicone sealant.

7. Use ashlight to verify there are no gaps in silicone

seal.

8. Install draft diverter, vent damper, vent pipe, and

jacket top and front cover.

9. Reassemble all parts.

10. Check tightness of pilot connections and condition of

burner ames after reassembly. See Figures 14 and 15.

22

Page 23

SERVICE HINTS

You may avoid inconvenience and service calls by checking these points before you call for service.

!

CAUTION

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the re

department.

IF YOUR SYSTEM IS NOT HEATING OR NOT GIVING ENOUGH HEAT . . .

Possible Cause What to do

Thermostat is not set correctly

Burner is not operating properly

No electric power to boiler

Controls out of adjustment

Radiators not heating

Poor electrical contact

Reset thermostat above room temperature.

Inspect ame. If yellow, burner is not getting enough air. If blue and noisy and

seems to lift off burner, burner is getting too much air. Contact service technician.

Verify electric power supply circuit is “ON”. Contact your service technician to

verify over current protection.

Reset according to instructions.

Inspect steam air vents for proper operation. Contact service technician to inspect for faulty

steam traps.

Contact your service technician to inspect all control terminals and wire joints.

Rollout switch blown

Chimney ue is blocked

Vent damper not operating

Have your service technician check heat exchanger for blockage.

Spill switch contacts open, requiring manual reset of spill switch. Have your service

technician check and correct chimney problem.

Consult troubleshooting guide, packaged with vent damper.

IF BURNER IS NOISY . . .

Gas input amount is incorrect Contact your service technician.

IF WALLS OR WINDOWS SWEAT . . .

Not enough ventilation Contact your service technician

Chimney ue is blocked Contact service technician to inspect and correct, if necessary.

IF RADIATORS ARE NOISY . . .

Air in system refer to "Radiators Not Heating" above

SAFETY VALVE LEAKING . . .

Dirt on seat

HAVE YOUR SERVICE TECHNICIAN CHECK ANY PROBLEM YOU ARE UNABLE TO CORRECT.

Contact service technician.

23

Page 24

WIRING DIAGRAMS

Figure 13 - Wiring Diagrams For Boilers With PS-802 Probe Type Low Water Cut-Off

Shown PS802

Terminals

PS802 To CG400

Cross Reference

PS802 CG400

N 2

H 1

C P1

E P2

W A

If any of the original wire as supplied with this appliance must be replaced, it must be replaced

with type 105°C Thermoplastic wire or its equivalent.

24

Page 25

WIRING DIAGRAMS

Figure 17 - Wiring Diagrams For Boilers With 67D-1 Float Type Low Water Cut-Off

If any of the original wire as supplied with this appliance must be replaced, it must be replaced

with type 105°C Thermoplastic wire or its equivalent.

25

Page 26

CONTROLS AND ACCESSORIES

SAFETY VALVE

Safety valve is designed to open automatically if boiler steam

pressure exceeds pressure rating of valve (15 psig). Should

it fail to open under this condition, shut down your boiler. If

valve discharge occurs, or valve fails to open as described

above, contact a qualied service technician to replace safety

valve and inspect heating system to determine cause, as this

may indicate equipment malfunction.

STEAM PRESSURE GAUGE

Boiler is equipped with pressure gauge installed. Gauge

enables monitoring of the pressure in the system. If safety

devices fail to shut off your boiler at proper settings, notify

your serviceman immediately.

WATER LEVEL GAUGE

Boiler water level can be seen through glass tube in water

level gauge at side of boiler. Correct cold boiler water level

is stamped on side jacket panel. Check water level regularly

for proper level.

Located on right side of boiler jacket panel, there are three

holes for glass water level gauge. Top hole is common for

both types of low water cut off, and is used for upper gauge

glass tting. Middle hole, 9” down from top hole, is used for

bottom gauge glass tting for the Model 67D-1 and 47-2

oat type low water cut off. Lowest hole, 121/4” down from

top hole, is used for bottom gauge glass tting for Model

PS-802 probe type low water cut off. Cover unused with

sheet metal knockout.

STEAM PRESSURE CONTROL

Steam pressure limit control (pressuretrol) shuts off gas to

main burners when steam pressure in boiler reaches cutoff setpoint (i.e. sum of cut-in and differential setpoints).

Burners rere when steam pressure drops to cut-in

setpoint. System pressure requirements are based on size

and condition of pipes, and load.

WATER FEEDER (Optional)

Model WF-2U-24 water feeder maybe used with either

of the low water cutoffs listed. Water feeder maintains

safe minimum water level. Keeps boiler running by

compensating for minor evaporative steam leaks, and

prevents freeze-ups if homeowners are away and return

line leaks.

McDonnell and Miller Model 101 water feeders may be

used, however water feed rates are too high and need to

be regulated or throttled and wiring will have to be revised.

Consult boiler manufacturer before using these or any

other non-standard types of controls.

Automatic water feeder is safety device, not convenience

item. It is not designed to maintain “normal” water line.

Water feeder does not take place of responsible person

monitoring and maintaining normal water line. Steam

boilers require attention.

VENT DAMPER

Automatic, motorized stack damper developed to increase

efciency of heating systems by reducing standby losses

from boiler and conditioned air space. Damper closes

chimney vent when burner is off and fully opens it when

combustion is required.

ROLLOUT SWITCH

(FLAME ROLLOUT SAFETY SHUTOFF)

Rollout switch is temperature-sensitive fuse link device.

Located on boiler base just outside re box. In event of heat

exchanger ueway blockage causing ame to roll out of

re box, fuse will blow, shutting down ow of gas to main

burners. Fuse does not change in appearance when blown.

If rollout switch blows, replace with exact replacement.

Check heat exchanger ueways for blockage when

restoring system to operating condition. Do not operate

system without rollout switch.

LOW WATER CUT-OFF

Model 67D-1

Float operated switch which shuts down gas burner if water

falls below visible bottom of gauge glass.

Probe Type Models

Electronic probe type LWCO. Probe is located inside boiler.

LWCO will shut down burners if water loses contact with

probe for 10 seconds.

Refer to manufacturer’s instructions (enclosed) for more

information.

SPILL SWITCH

(BLOCKED VENT SAFETY SHUTOFF)

Spill switch is manual reset disc thermostat with xed

setpoint (280° F), and normally closed contacts. It is located

at relief opening of draft diverter. In event of chimney or

venting system blockage causing products of combustion

to spill out of relief opening, spill switch disc heats up and

spill switch contacts open, shutting down ow of gas to main

burners by removing power to gas valve.

In event spill switch contacts open, reset button on back of

switch will pop up. Manually reset spill switch after switch has

cooled off, push reset button down. Check venting system

and chimney for blockage when restoring system to operating

condition. DO NOT operate boiler without spill switch.

26

Page 27

REPAIR PARTS

27

Page 28

REPAIR PARTS

28

Page 29

REPAIR PARTS

29

Page 30

REPAIR PARTS

Safety Relief Valve

14

11

½NPT X 4" Nipple PF-033.02

30

Page 31

Date Service Performed Company Name & Tech Initials Company Address & Phone #

31

Page 32

PRODUCT LITERATURE

Lennox Industries Inc.

Dallas, Texas

Loading...

Loading...