Lennox G24MCE2-45, G24MCE3-60, G24MCE3-75, G24MCE4-75, G24MCE4-100 Installation Instructions Manual

...Page 1

INSTALLATION

2000 Lennox Industries Inc.

Dallas, Texas

PRODUCT LITERATURE

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

INSTRUCTIONS

G24MCE Series

GAS-FIRED FURNACE

Direct Spark Ignition

503,956M

05/2000

Supersedes 11/99

Table of Contents

G24MCE Unit Dimensions 2. . . . . . . . . . . . . . . . . . . .

G24MCE GasĆFired Furnace 3. . . . . . . . . . . . . . . . . .

Shipping and Packing List 3. . . . . . . . . . . . . . . . . . . . .

Requirements 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Combustion, Dilution & Ventilation Air 4. . . . . . . . . .

Setting Equipment 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Duct System 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Venting 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vertical Flue Using Metal Flue Pipe 9. . . . . . . . . . .

Vertical Flue Using Lined Masonry Chimney 11. .

Horizontal Flue Using Metal Flue Pipe 12. . . . . . .

Gas Piping 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Start-up 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Adjustments 19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data Table 22. . . . . . . . . . . . . . . . . . . . . . . .

Ignition Control Board Diagnostic Codes 23. . . . . . .

Troubleshooting 24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair Parts List 27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

G24MCE Parts Arrangement 27. . . . . . . . . . . . . . . . .

G24MCE Start-up & Performance Check List 28. . .

Litho USA

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

Do not store or use petrol or other

flammable vapours and liquids in the

vicinity of this or any other appliance.

Installation and service must be perĆ

formed by a qualified installer, serĆ

vice agency or the gas supplier.

WARNING

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Extinguish any open flames.

Do not touch any electrical switch; do not

use any telephone in your building.

Immediately call your gas supplier from a

neighbor's telephone. Follow the gas supĆ

plier's instructions.

If you cannot reach your gas supplier, call

the local fire brigade.

Page 1

Page 2

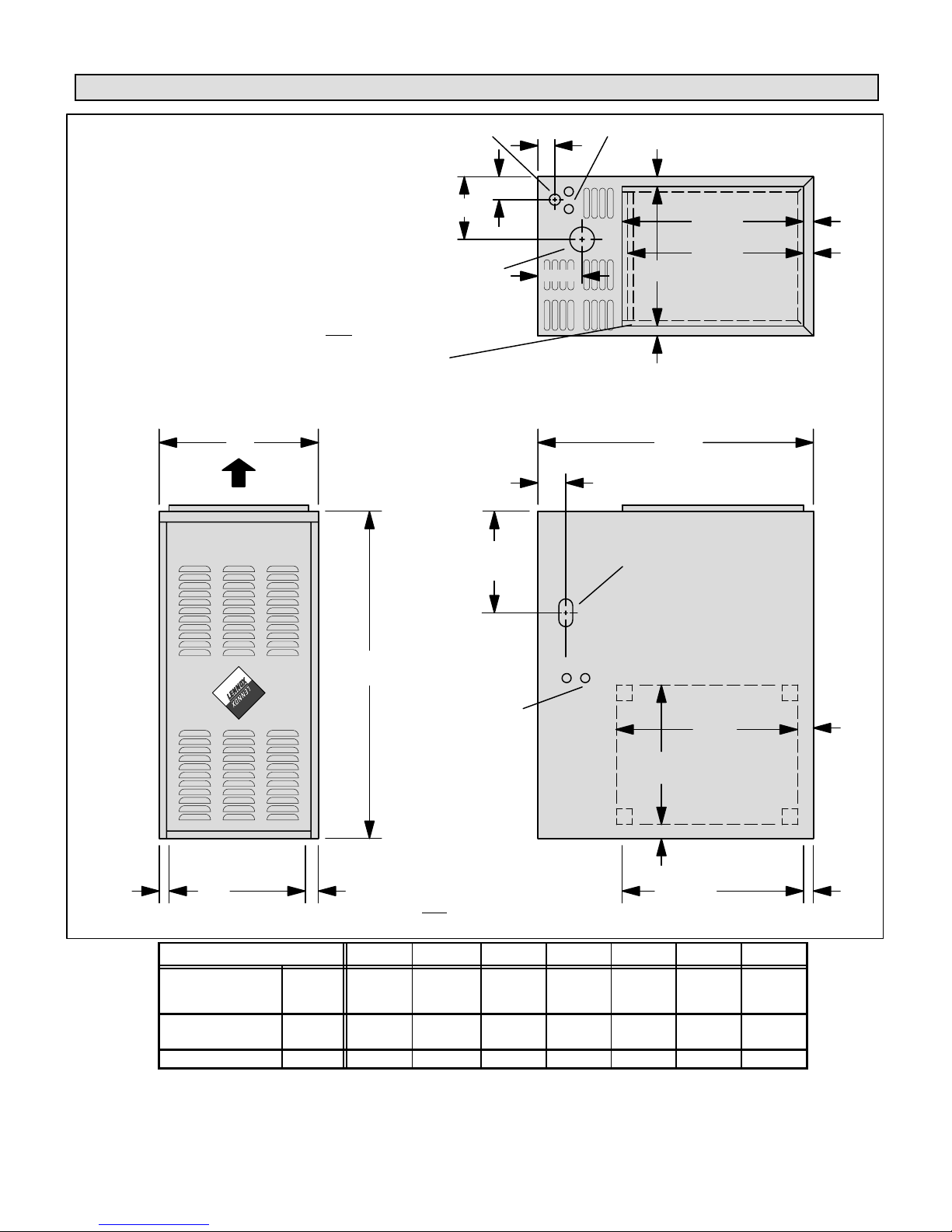

G24MCE Unit Dimensions - millimeters

G24MCE4/5Ć100

GAS PIPING

INLET

G24MCE Series

D

Unit shown in upflow position. Rotate 180° for

downflow applications and 90° clockwise or

counterclockwise for horizontal applications.

*NOTE - The supply air opening is equipped with a 19 mm scored

flange that may be bent 90_ for plenum connection.

The dimensions shown were taken after

The double scored flange at the front of the supply air

opening may be bent for a total opening dimension

(front to rear) of either 495 mm or 483 mm.

the flange was bent.

A

AIR FLOW

FLUE

OUTLET

F Left Side

G Right Side

ELECTRICAL INLETS

(Top & Bottom)

25

E

105

*C

25

*495

*483

SUPPLY

AIR

OPENING

25

25

TOP VIEW

752

51

GAS PIPING

INLET

(Both Sides)

B

ELECTRICAL

INLETS

(Both Sides)

381

**NOTEĊ The return air opening is

equipped with a 19 mm scored flange

Return Air

**C

Opening

FRONT VIEW

Model No. A B C D E F G

G24MCE2Ć45

G24MCE3Ć60/75

G24MCE4Ć75

G24MCE4/5Ć100

G24MCE4/5Ć120

G24MCE4/5Ć140 mm 591 991 540 248 108 329 180

mm 432 921 381 171 62 293 165

mm 521 991 470 213 108 331 203

that may be bent 90_ for plenum conĆ

2525 25

nection. The dimensions shown were

taken after

the flange was bent.

SIDE VIEW

495

RETURN AIR

KNOCKOUT

(Either Side)

19

495

Return Air

Opening

25

Page 2

Page 3

G24MCE GasĆFired Furnace

The G24MCE multi-position gas furnace is shipped ready

for installation in the upflow position. The unit can easily

be converted for installation in either downflow or horizonĆ

tal applications. The furnace is shipped with a bottom seal

panel in place for side return air in upflow applications.

Shipping and Packing List

Package 1 of 1 contains:

1 - Assembled unit

1 - Flue adapter (requires fieldĆinstallation)

1 - Upflow/horizontal filter rack

1 - Filter

The following additional items may be ordered separately,

if required:

1 - Additive base (downflow applications)

1 - Thermostat

1 - Hanging bracket kit

1 - External filter rack kit (downflow applications)

1 - LP Changeover kit

Check equipment for shipping damage. If you find any

damage, immediately contact the last carrier.

Requirements

Lennox G24MCE units carry CE marking and are certified

for installation in the following countries using the gas

categories shown:

II

: GB, IE, ES, PT and CH

2H3P

I

: DK and IT

2H

II

: NL

2L3P

II

: FR

2Er3P

I

and I

2ELL

*I

2E+(S)

* Units for installation in Belgium are set and sealed for use with

G20 reference gas and must not

Units must be adjusted or converted in accordance with

specific instructions provided by Lennox Industries prior

to installation or use in the other countries listed.

These appliances must only be installed, adjusted, conĆ

verted or serviced by properly qualified personnel. Failure

to comply with this requirements may result in a dangerĆ

ous situation.

The installation must comply with all relevant local and

national gas, electrical, building and fire regulations.

Proper ventilation is essential for safe operation and must

be provided as detailed in these instructions.

The flue system must be properly designed to comply with

any relevant regulations and the requirements set out in

these instructions.

Installation clearances must be provided around the apĆ

pliance and access provided for servicing requirements.

See figures 5, 7 and 9.

:DE

3P

:BE

be adjusted by installer.

Before installation, check that the local distribution condiĆ

tions, nature of gas and pressure and adjustment of the

appliance are compatible.

NOTE-For installation on combustible floors, appliance shall

not be installed directly on carpeting, tile, or combustible maĆ

terial such as wood flooring. Protection via a non-combusĆ

tible material must be provided.

The G24MCE unit must not be installed in a residential

or commercial garage.

Unit must be adjusted to obtain a temperature rise within the

range specified on appliance rating plate.

G24MCE unit must be installed so that electrical compoĆ

nents are protected from water.

When furnace is used in conjunction with cooling units, it

shall be installed on the upstream side of cooling units to

avoid condensation in the heating compartment.

When installed, furnace must be electrically earthed in

accordance with national regulations.

Electrical supply must be properly fused and should be

provided with means of isolating the unit from the supply.

When the furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside of the space

containing the furnace, return air shall be handled by a

duct(s) sealed to the furnace casing and terminating outĆ

side of the space containing the furnace.

NOTE Ċ G24MCE series units must not be used as a

construction furnace" at any time during any phase of

construction. Very low return air temperatures, harmful

vapors and misplacement of the filters will damage the

unit and its efficiency.

The Lennox G24MCE furnace may be installed in alĆ

coves, cupboards, attics, basements, and utility rooms in

any of its approved installation positions.

The G24MCE unit must not be installed in a residential

or commercial garage.

The air furnace must not be installed in a room conĆ

taining a bath or shower. In addition, it is recomĆ

mended that the furnace should not be fitted in a bedĆ

room.

A compartment used to enclose the air furnace must be

designed and constructed specifically for this purpose.

An existing cupboard or compartment may be used proĆ

vided that it is modified for the purpose.

WARNING

The Fan door must be securely in place when the

fan and burners are operating. Gas fumes, which

could contain carbon monoxide, can be drawn into

living space resulting in personal injury or death.

General

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

having jurisdiction before installation.

Page 3

Page 4

In addition to the requirements outlined previously, the folĆ

lowing general recommendations should be considered

when installing the Lennox G24MCE furnace.

The furnace should be placed as close to the center of the

air distribution system as possible. The furnace should

also be located close to the chimney or vent termination

point.

Do not install the furnace where draughts might blow diĆ

rectly into it. This could cause improper combustion and

unsafe operation.

Do not block furnace combustion air openings with clothĆ

ing, boxes, doors, etc. Combustion air is needed for propĆ

er combustion and safe unit operation.

When the furnace is installed in an attic or other insulated

space, keep insulation away from the furnace.

WARNING

Product contains glass fibre.

Surface tears due to rough handling during shipĆ

ping or installation should be repaired straight

away to avoid respiratory, skin and eye irritation.

Combustion, Dilution & Ventilation Air

In the past, there was no problem in bringing in sufficient outĆ

door air for combustion. Infiltration provided all the air that

was needed. In today's homes, tight construction practices

make it necessary to bring in air from outside for combustion.

Take into account that exhaust fans, appliance vents, chimĆ

neys, and fireplaces force additional air that could be used

for combustion out of the house. Unless outside air is brought

into the house for combustion, negative pressure (outside

pressure is greater than inside pressure) will build to the point

that a downdraft can occur in the furnace vent pipe or chimĆ

ney. As a result, combustion gases enter the living space

creating a potentially dangerous situation.

In the absence of local codes concerning air for combustion

and ventilation, this section outlines guidelines and recomĆ

mends procedures for installing G24MCE Furnaces in a

manner that ensures efficient and safe operation. Special

consideration must be given to combustion air needs as

well as requirements for exhaust vents and gas piping.

CAUTION

Do not install furnace in a corrosive or contaminated

atmosphere. Meet all combustion and ventilation air

requirements, as well as all local codes.

CAUTION

Insufficient combustion air can cause headaches,

nausea, dizziness or asphyxiation.

Combustion Air Requirements

All gasĆfired appliances require air for the combustion

process. If sufficient combustion air is not available, the

furnace or other appliance will operate inefficiently and

unsafely. Enough air must be provided to meet the needs

of all fuelĆburning appliances and appliances such as exĆ

haust fans which force air out of the house. When fireĆ

places, exhaust fans, or clothes dryers are used at the

same time as the furnace, much more air is required to enĆ

sure proper combustion and to prevent a downdraft. InĆ

sufficient air causes incomplete combustion which can reĆ

sult in carbon monoxide.

In addition to providing combustion air, fresh outdoor air

dilutes contaminants in the indoor air. These contamiĆ

nants may include bleaches, adhesives, detergents, solĆ

vents and other contaminants which can corrode furnace

components.

The requirements for providing air for combustion and

ventilation depend largely on whether the furnace is

installed in an unconfined or a confined space.

Unconfined Space

An unconfined space is an area such as a basement or

large equipment room with a volume greater than 4.85m

per 1 kW (50 ft3 per 1000 Btuh) of the combined input ratĆ

ing of all appliances installed in that space. This space

also includes adjacent rooms which are not separated by

a door. Though an area may appear to be unconfined, it

might be necessary to bring in outdoor air for combustion

if the structure does not provide enough air by infiltration.

If the furnace is located in a building of tight construction

with weather stripping and sealing around the windows

and doors, follow the procedures in the air from outside

section.

Confined Space

A confined space is an area with volume less than 4.85m

per 1 kW (50 ft3 per 1000 Btuh of the combined input rating

of all appliances installed in that space. This definition inĆ

cludes furnace cupboards or small equipment rooms.

When the furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space containĆ

ing the furnace, the return air must be handled by ducts

which are sealed to the furnace casing and which terminate

outside the space containing the furnace. This is especially

important when the furnace is mounted on a platform in a

confined space such as a cupboard or small equipment

room. Even a small leak around the base of the unit at the

platform or at the return air duct connection can cause a poĆ

tentially dangerous negative pressure condition. Air for comĆ

bustion and ventilation can be brought into the confined

space either from inside the building or from outside.

3

3

Page 4

Page 5

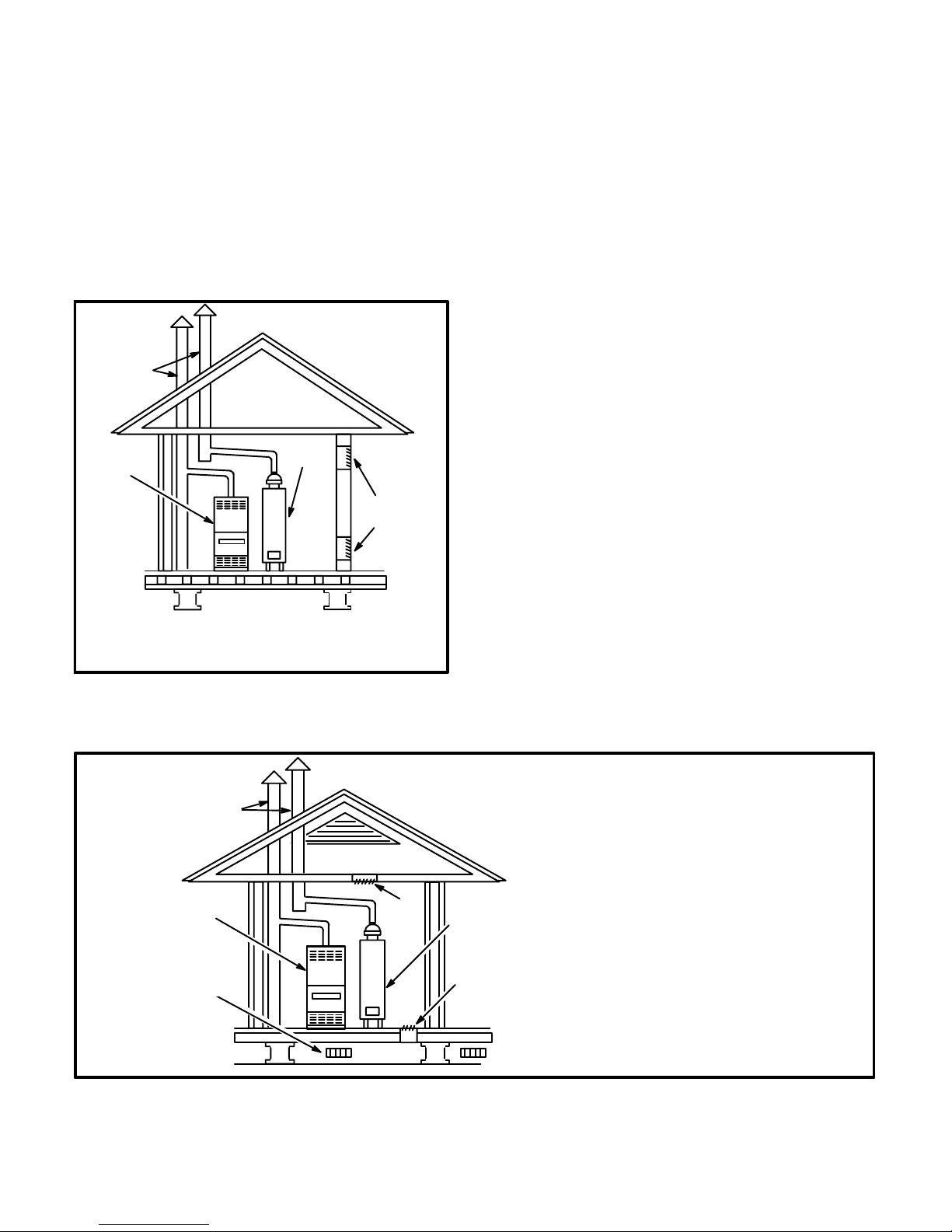

Air from Inside

If the confined space that houses the furnace adjoins a

space categorized as unconfined, air can be brought in by

providing two permanent openings between the two

spaces. Each opening must have a minimum free area of

2

22cm

per 1 kW (1 square inch per 1000 Btuh) of total input

rating of all gas-fired equipment in the confined space. Each

opening must be at least 646cm

2 (

100 square inches). One

opening shall be within 305mm (12 inches) of the top of the

enclosure and one opening within 305mm (12 inches) of the

bottom. See figure 1.

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM INSIDE

CHIMNEY

OR GAS

VENT

G24MCE

FURNACE

WATER

FURĆ

NACE

OPENINGS

(To Adjacent

Room)

Air from Outside

If air from outside is brought in for combustion and ventilation,

the confined space must have two permanent openings.

One opening shall be within 305mm (12 inches) of the top

of the enclosure and one within 305mm (12 inches) of the

bottom. These openings must communicate directly or by

ducts with the outdoors or spaces (underfloor or attic) that

freely communicate with the outdoors or indirectly through

vertical ducts. Each opening shall have a minimum free area

of 5.5cm

2

per 1 kW (1 square inch per 4000 Btuh) of total

input rating of all equipment in the enclosure. See figures 2

and 3. When communicating with the outdoors through horiĆ

zontal ducts, each opening shall have a minimum free area

of 3cm

2

per 1 kW (1 square inch per 2000 Btuh) of total inĆ

put rating of all equipment in the enclosure. See figure 4.

When ducts are used, they shall be of the same cross-secĆ

tional area as the free area of the openings to which they

connect. The minimum dimension of rectangular air ducts

shall be no less than 75mm (3 inches). In calculating free

area, the blocking effect of louvers, grilles, or screens must

be considered. If the design and free area of protective covĆ

ering is not known for calculating the size opening required,

it may be assumed that wood louvers will have 20 to 25 perĆ

cent free area and metal louvers and grilles will have 60 to

75 percent free area. Louvers and grilles must be fixed in

the open position or interlocked with the equipment so that

they are opened automatically during equipment operation.

NOTE-Each opening shall have a free are a of at least 22cm

per 1 kW (1 square inch per 1,000 Btuh) of the total input rating

of all equipment in the enclosure, but not less than 646cm

(100 square inches).

FIGURE 1

CHIMNEY

OR GAS

VENT

VENTILATION LOUVERS

(Each end of attic)

G24MCE

FURNACE

VENTILATION

LOUVERS

(For unheated underfloor

space)

OUTLET

AIR

2

2

EQUIPMENT IN CONFINED SPACE

(Inlet Air from Underfloor Space and Outlet Air to Ventilated Attic)

WATER

FURĆ

NACE

INLET

AIR

NOTE-The inlet and outlet air openings shall each have a free

area of at least 5.5cm

of the total input rating of all equipment in the enclosure.

ALL AIR FROM OUTSIDE

2

per 1 kW (1 square inch per 4000 Btuh)

FIGURE 2

Page 5

Page 6

EQUIPMENT IN CONFINED SPACE

CHIMNEY

OR GAS

VENT

G24MCE

FURNACE

NOTE-The inlet and outlet air openings shall each have a free area

of at least 5.5cm

input rating of all equipment in the enclosure.

2

per 1 kW (1 square inch per 4000 Btuh) of the total

ALL AIR FROM OUTSIDE

(All Air Through Ventilated Attic)

VENTILATION LOUVERS

(Each end of attic)

OUTLET

AIR

FURNACE

FIGURE 3

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

CHIMNEY

OR GAS

VENT

WATER

FURNACE

OUTLET AIR

G24MCE

FURNACE

INLET AIR

INLET AIR

[Ends 305mm

(12") above botĆ

tom]

WATER

NOTE - 1/3 and 1/2 hp fan motors are equipped with eiĆ

ther four flexible mounting legs or three flexible legs and

one rigid leg. The rigid leg is equipped with a shipping bolt

and a flat white plastic washer (rather than the rubber

mounting grommet used with a flexible mounting leg).

This shipping bolt and flat washer must be removed beĆ

fore the furnace is put into operation. Once the shipping

bolt and washer are removed, the rigid leg will not touch

the fan housing.

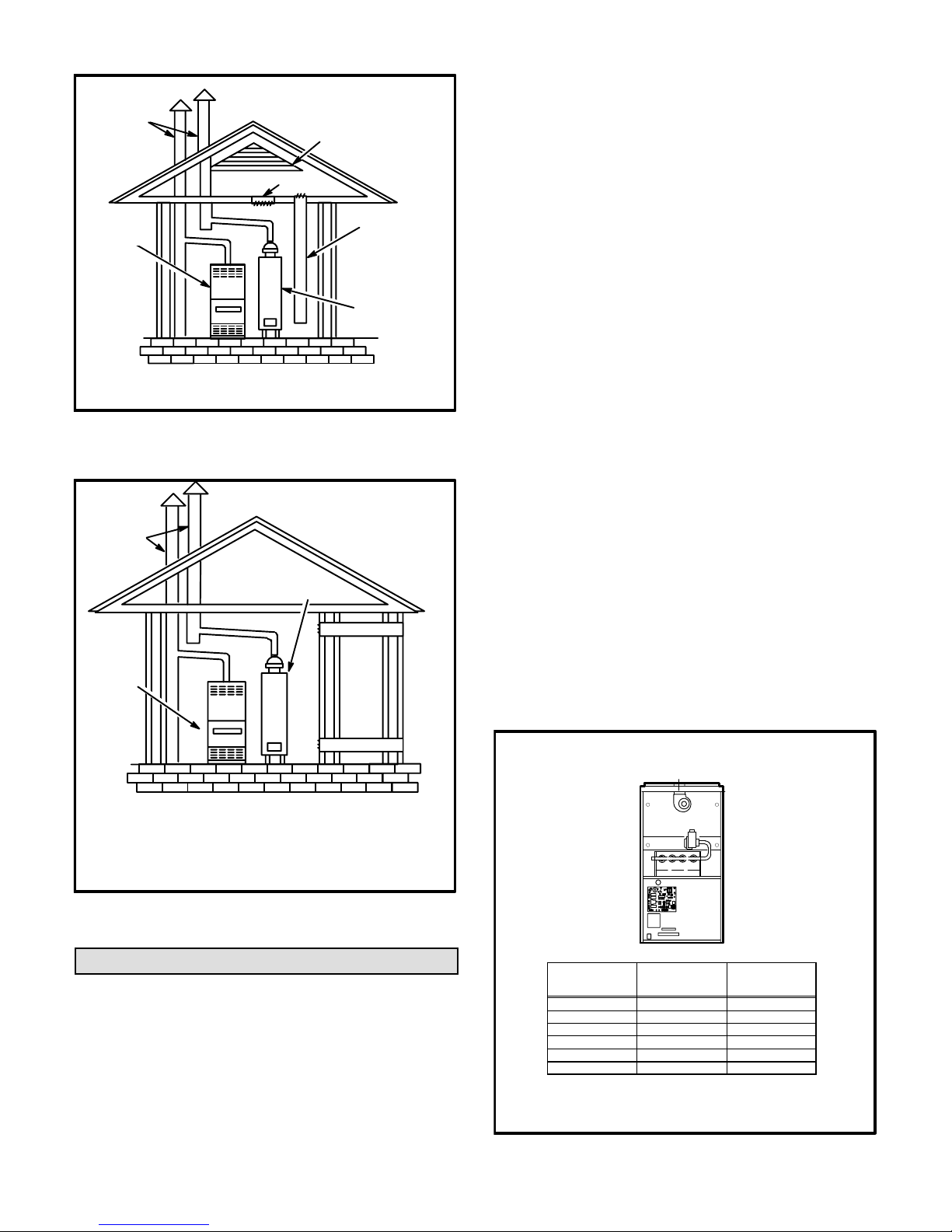

UPFLOW APPLICATIONS

The Lennox G24MCE furnace is shipped in a standard

upflow position. Level the furnace using shims or leveling

bolts. Knockouts are provided in unit base to install fieldprovided leveling bolts. Allow for clearances to combusĆ

tible materials as indicated on the unit rating plate. MiniĆ

mum clearances for cupboard or alcove installations are

shown in figure 5.

In upflow applications, return air can be brought in

through the bottom or either side of the furnace. If a furĆ

nace with bottom return air is installed on a platform,

make an airtight seal between the bottom of the furnace

and the platform to ensure proper and safe operation.

Knockouts are provided on both sides of the furnace cabiĆ

net for installations with side return air. When side return

air is used, seal the bottom of the furnace using the panel

provided.

An upflow filter rack is provided. The adjustable rack can

be installed beneath the furnace (flush with cabinet

edges) for bottom return air applications or on the side of

the furnace for side return air.

NOTE - A sheet metal filter puller is provided along with

filter kit. In bottom return air applications, filter puller must

be installed between frame and filter to hold filter in place.

UPFLOW APPLICATION

INSTALLATION CLEARANCES

TOP

NOTE-Each air duct opening shall have a free area of at least 3cm2 per 1 kW

(1 square inch per 2000 Btuh) of the total input rating of all equipment in the

enclosure. If the equipment room is located against an outside wall and the

air openings communicate directly with the outdoors, each opening shall

have a free area of at least 5.5cm

the total input rating of all other equipment in the enclosure.

2

per 1 kW (1 square inch per 4000 Btuh) of

FIGURE 4

Setting Equipment

The Lennox G24MCE multi-position gas furnace can be

installed as shipped in upflow position or in horizontal

position with right-hand or left-hand discharge. The furĆ

nace can easily be converted for downflow applications.

Select unit location that will allow for required clearances

listed on the unit rating plate. Also consider gas supply

connections, electrical supply, vent connection and

installation and service clearances [610mm (24 in.)] at

unit front.

Page 6

LEFT

SIDE

BOTTOM

VENT

CONNECTOR

TYPE

TOP

*FRONT 51mm (2 in.)

BACK

SIDES

FLUE 25mm (1 in.)

BOTTOM **NC

*Front clearance in alcove installation must be a miniĆ

mum of 610mm (24 in.) for service access.

**On combustible floor with non-combustible protecĆ

tion. NC - Non-Combustible

SINGLE WALL

25mm (1 in.)

51mm (2 in.)

25mm (1 in.)

25mm (1 in.)

152mm (6 in.)

**NC

RIGHT

SIDE

TWIN WALL

25mm (1 in.)

25mm (1 in.)

25mm (1 in.)

FIGURE 5

Page 7

REMOVE

TOP CAP

REMOVE

FOUR

SCREWS

DISCONNECT

IGNITOR & SENSOR

LEADS

REMOVE

BOTTOM

SINGLE-WALLED VENT

PIPE FROM COMBUSTION

AIR FAN FLUE ADAPTER TO

FURNACE FLUE OUTLET

(Furnished by installer)

DISCONNECT

WIRE HARNESS AT

CONTROL BOARD

CONNECTOR

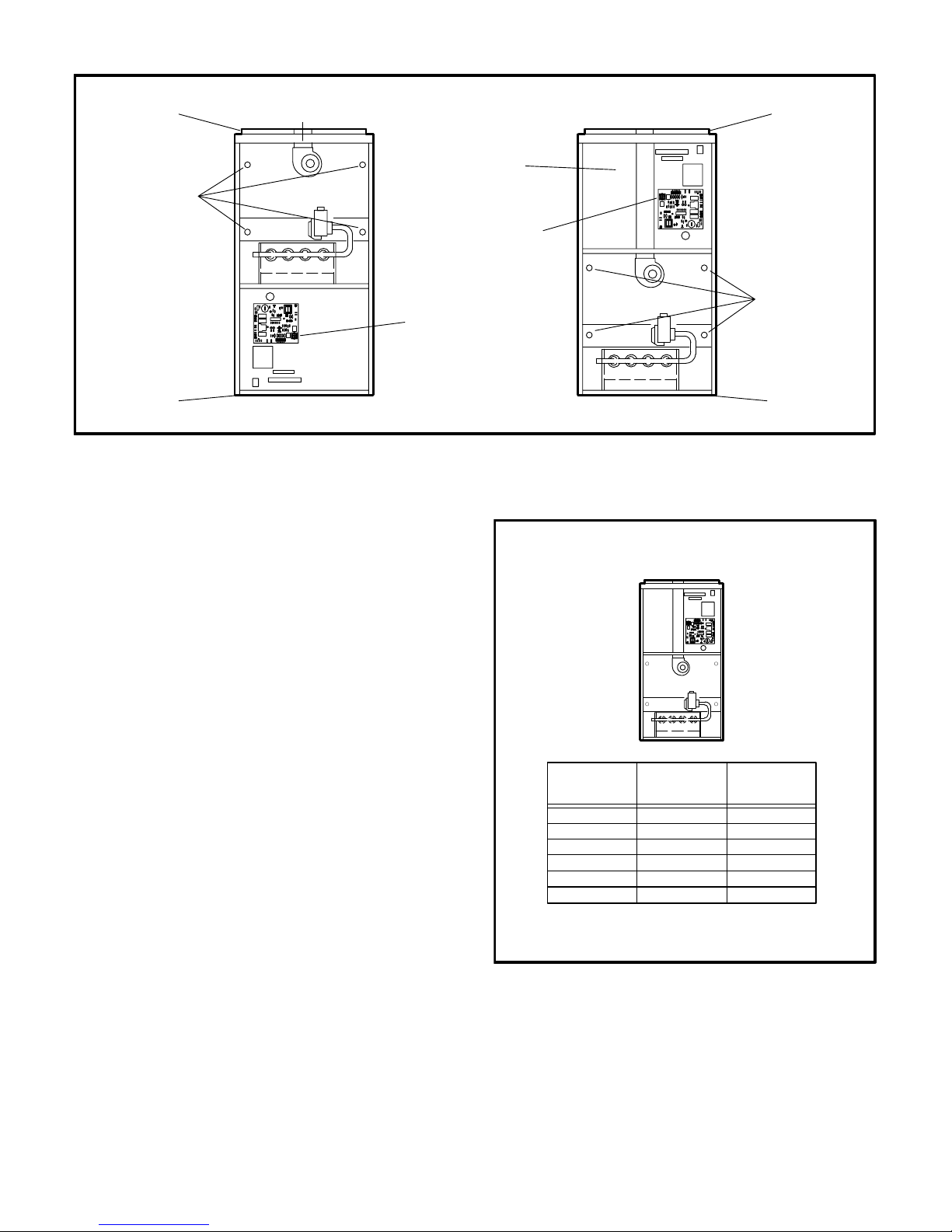

UPFLOW CONFIGURATION DOWNFLOW CONFIGURATION

FIGURE 6

DOWNFLOW APPLICATIONS

The Lennox G24MCE furnace is shipped in the upflow

configuration and must be converted for downflow instalĆ

lation. Refer to figure 6 and the following steps to convert

the unit for downflow installation:

1 - Place unit on its back and remove access panel.

2 - Disconnect wire harness in control area.

3 - Disconnect ignition lead and sensor wire located in

burner box. Use pliers to remove strain relief plugs

from holes on side of burner box.

4 - Remove four no. 10 screws securing cabinet bottom

to unit and remove bottom.

5 - Remove four no. 10 screws securing cabinet top cap to

cabinet. Remove top cap and replace with bottom.

6 - Remove four screws holding heat exchanger assemĆ

bly in place. Slide heat exchanger out through top of

cabinet.

UNIT CONVERSION FOR DOWNFLOW APPLICATION

7 - Rotate heat exchanger 180

o

and slide back into cabiĆ

net through top. Resecure using four screws.

8 - Install cabinet bottom using four no. 10 screws.

9 - Position strain relief grommets on ignition and flame

sensor wires. Insert wires and grommets through

holes on side of burner box. Reconnect wires to igniĆ

tor and flame sensor.

10- Reconnect wire harness plug.

11- Replace unit access panel.

In downflow applications, the unit can be installed in three difĆ

ferent ways: on non-combustible flooring, on combustible

floor using an additive base, or on a reverse-flow cooling cabĆ

inet. Do not drag unit across floor.

Allow clearances to combustible materials as outlined on

unit rating plate. Minimum clearances for cupboard or alĆ

cove installations are outlined in figure 7.

REINSTALL

TOP CAP ON

UNIT BOTTOM

RECONNECT WIRE

HARNESS AT

CONTROL BOARD

CONNECTOR

ROTATE HEAT

EXCHANGER

& REINSTALL

RECONNECT

IGNITOR & SENSOR

LEADS

REINSTALL

BOTTOM

ON UNIT

A separate downflow filter kit is available for use in downĆ

flow applications. Filter rack provided with unit is for use in

horizontal or upflow applications only.

DOWNFLOW APPLICATION

INSTALLATION CLEARANCES

TOP

LEFT

SIDE

BOTTOM

VENT

CONNECTOR

TYPE

TOP 25mm (1 in.)

*FRONT 51mm (2 in.)

BACK

SIDES

FLUE 152mm (6 in.) 25mm (1 in.)

BOTTOM NC** NC**

NC - Non-combustible floor

*Front clearance in alcove installation must be a min. of 610mm

(24 in.) for service access.

**With additive base on combustible floor.

SINGLE WALL TWIN WALL

25mm (1 in.)

51mm (2 in.)

RIGHT

SIDE

25mm (1 in.)25mm (1 in.)

25mm (1 in.)25mm (1 in.)

FIGURE 7

A-Installation on Non-Combustible Flooring

1 - Cut floor opening keeping in mind the clearances

listed on the unit rating plate. Also, keep in mind gas

supply and electrical supply, vent connections and

sufficient installation and service clearances. See

table 1 for correct floor opening size.

TOP

Page 7

Page 8

TABLE 1

NONCOMBUSTIBLE FLOOR OPENING

UNIT

G24MCE-45/60/75 502 388

G24MCE-100/120 502 47719-3/4 18-3/4

G24MCE-140 502 54619-3/4 21-1/2

NOTE-Floor opening dimensions listed are 6mm (1/4") larger

than unit openings.

Front to Rear Side to Side

inmm inmm

19-3/4 15-1/4

2 - Flange warm air plenum and lower into opening.

3 - Set unit over plenum.

4 - Check to see that an adequate seal is made.

B-Installation on Combustible Flooring

1 - When unit is installed on a combustible floor, an addiĆ

tive base (ordered separately) must be installed beĆ

tween the furnace and the floor. See table 2 for openĆ

ing size to cut in the floor.

TABLE 2

ADDITIVE BASE FLOOR OPENING

UNIT

G24MCE-45/60/75 556 440

G24MCE-100/120

G24MCE-140

NOTE-Floor opening dimensions listed are 1/4" (6mm) larger

than additive base openings.

G24MCE UNIT

Front to Rear Side to Side

in mm in mm

21-7/8 17-5/16

556 52821-7/8 20-3/4

556 59721-7/8 23-1/2

SUPPLY AIR

PLENUM

3 - Check glass fibre strips on additive base to make

sure they are properly glued and positioned.

4 - Lower supply air plenum into additive base until pleĆ

num flanges seal against glass fibre strips.

5 - Set unit on additive base so unit flanges drop into pleĆ

num. Refer to figure 8.

NOTE-Be careful not to damage glass fibre strips.

Check for tight seal.

C-Installation on Cooling Cabinet

1 - Refer to reverse flow coil installation instructions for

correctly sized opening in floor and installation of

cabinet.

2 - When cooling cabinet is in place, install furnace so

flanges drop inside cabinet opening.

3 - Seal cabinet and check for air leakage.

HORIZONTAL APPLICATIONS

The Lennox G24MCE furnace can be installed in horizonĆ

tal applications in either upflow or downflow configuration

(See figure 6). It is preferable to install the unit in the stanĆ

dard upflow configuration, if possible, because the vent

pipe will not interfere with service access for fan. The unit

cannot be installed on its back.

Filter rack is provided. Adjustable rack can be installed

flush with cabinet edges.

Allow for clearances to combustible materials as indicated

on the unit rating plate. Minimum clearances for cupboard

or alcove installations are shown in figure 9.

HORIZONTAL APPLICATION

INSTALLATION CLEARANCES

TOP

LEFT

SIDE

RIGHT

SIDE

ADDITIVE

BASE

1. Cut correct size floor opening

2. Set additive base into opening.

3. Set supply air plenum into additive base.

4. Set unit.

FIGURE 8

2 - After opening is cut, set the additive base into

opening.

PROPERLY

SIZED FLOOR

OPENING

Page 8

BOTTOM

VENT

CONNECTOR

TYPE

TOP 25mm (1 in.) 25mm (1 in.)

*FRONT 51mm (2 in.) 51mm (2 in.)

BACK

SIDES

FLUE 152mm (6 in.)

BOTTOM **NC **NC

*Front clearance in alcove installation must be a miniĆ

mum of 610mm (24 in.) for service access.

**On combustible floor with non-combustible protection.

NC - Non-Combustibles

SINGLE WALL TWIN WALL

25mm (1 in.) 25mm (1 in.)

51mm (2 in.) 51mm (2 in.)

25mm (1 in.)

FIGURE 9

Page 9

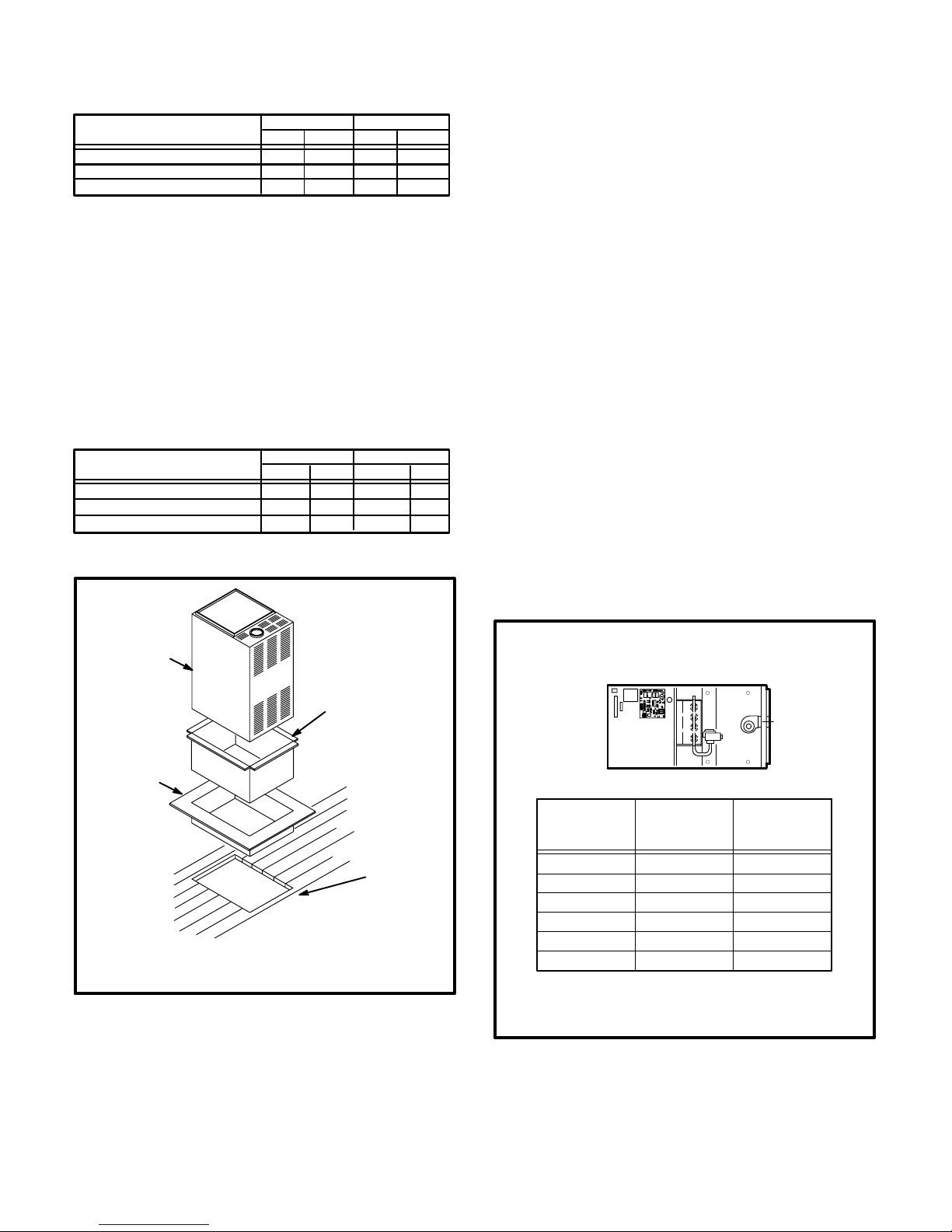

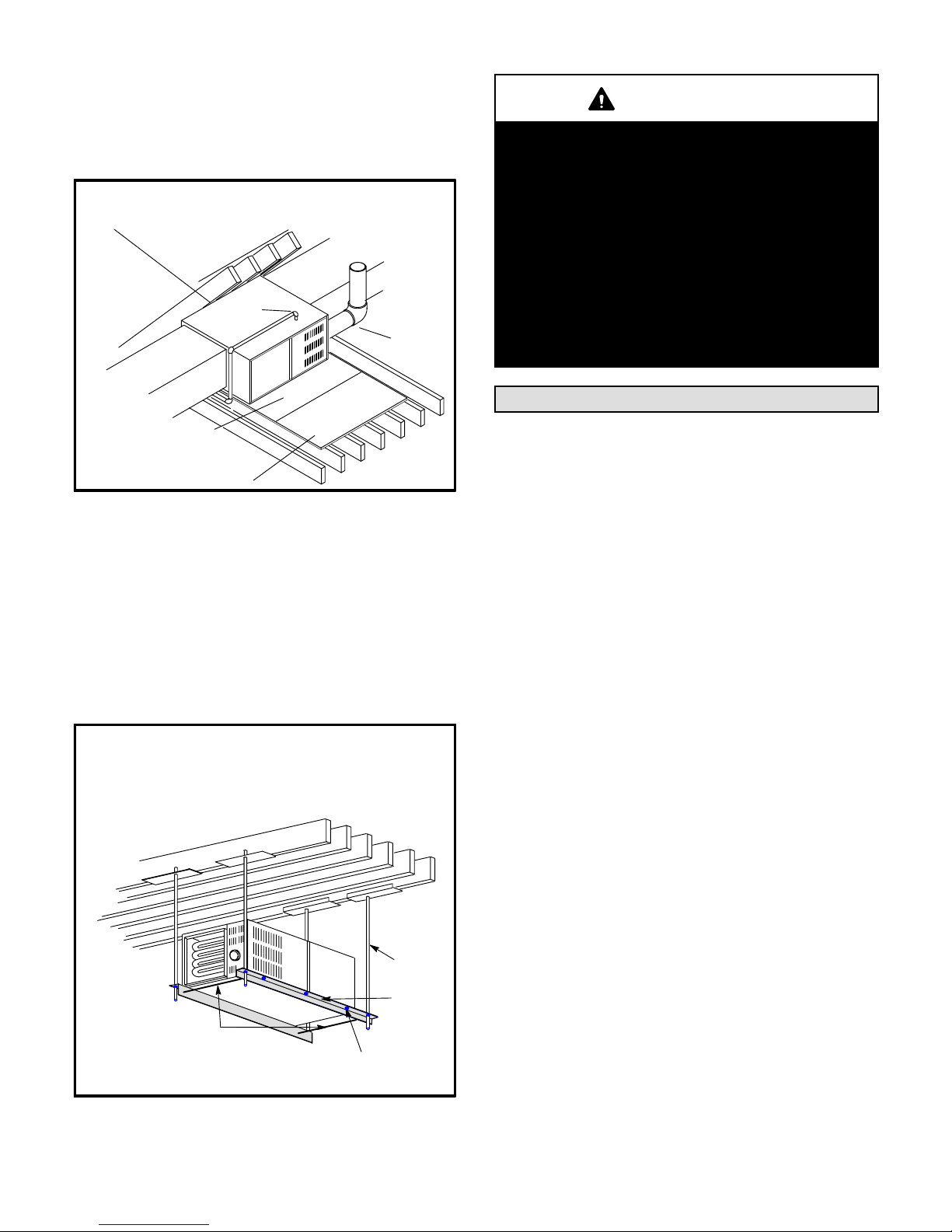

Furnaces may be installed in either an attic or a crawlspace.

See figure 10 for furnace installations on a platform.

NOTE - When the furnace is installed on a platform in a

crawlspace, it must be elevated enough to avoid water

damage and to allow the air conditioning coil to drain.

Horizontal Application

NOTE - Line contact is permiss ible. See the unit rating plate for clearan ces

Unit Installed on Platform

GAS

ENTRY

VENT

PIPE

WARNING

Improper installation of unit can result in personal

injury or death. Flue gases must never be allowed

to enter the return air system or the living space.

Sheet metal screws and sealing tape should be

used to seal ducting to the furnace. In platform

installations, return air must always be ducted to

the unit. A unit must never be installed so that it

draws return air from the furnace chamber, attic or

underfloor space. The furnace platform must be

level with no sagging, cracks or gaps.

Furnaces must always be isolated from other heatĆ

ing appliances to prevent fire, explosion, and carĆ

bon monoxide poisoning. Personal injury and/or

property damage could result..

Duct System

NON-COMBUSTIBLE

UNIT PLATFORM

NON-COMBUSTIBLE

WORKING PLATFORM

FIGURE 10

Anyone of the following methods may be used to suspend

the furnace from roof rafters or floor joists:

1 - Using Lennox hanging bracket kit catalog number

46J66 -

Install as indicated in the installation instructions

provided with the hanging bracket kit.

2 - Using angle iron with at least 1/4 in. diameter rods -

Install as shown in figure 11.

Note - Rods must not interfere with plenum or exĆ

haust piping; cooling coils and supply and return

air plenums must be supported separately.

Horizontal Application

Unit Suspended in Attic or Crawlspace

Using Angle Iron and Rods

Level unit - side to side and end to end.

Leave sufficient clearance between rod and unit to

remove access panels.

1/4 in. ROD

ANGLE

SUPPORT TIES -

INSTALL TO PREVENT

SPREADING

Secure the angle iron to the unit with sheetmetal screws:

maximum screw length - 3/4 in. and minimum screw size - # 10.

IRON

Use industryĆapproved standards to size and install the

supply and return air duct system. This will result in a quiet

and lowĆstatic system that has uniform air distribution.

SUPPLY AIR PLENUM

Furnaces installed without a cooling coil require the installaĆ

tion of a removable access panel in the supply air duct. The

access panel should be large enough to permit inspection

(either by smoke or reflected light) of the heat exchanger for

leaks after installation . The furnace access panel must alĆ

ways be in place when the furnace is operating and it must

not allow leaks into the supply air duct system.

RETURN AIR PLENUM

Return air must not be drawn from a room where

this furnace, or any other gas appliance (ie., a water

heater), is installed. When return air is drawn from a

room, a negative pressure is created in the room. If a

ga s appliance is oper ati ng in a ro om with negative presĆ

sure, the flue products can be pulled back down the vent

pipe and into the room. This reverse flow of the flue gas

may result in incomplete combustion and the formation

of carbon monoxide gas. This toxic gas might then be

distributed throughout the house by the furnace duct

system.

In upflow applications, return air can be brought in

through the bottom or either side of the furnace. If a furĆ

nace with bottom return air is installed on a platform,

make an airtight seal between the bottom of the furnace

and the platform to ensure proper and safe operation.

Use fiberglass sealing strips between the plenum and the

furnace cabinet to ensure a tight seal. If a filter is installed,

size the return air duct to fit the filter frame.

FIGURE 11

Page 9

Page 10

In downflow applications, use the following steps when

installing return air plenum:

1 - Flange bottom edge of plenum with a hemmed edge.

See figure 12.

2 - In all cases, secure the plenum to the top flanges of

the furnace using sheet metal screws. See figure 12.

PLENUM

SECURE

HEMMED EDGE

Venting

The G24MCE unit is not certified for common venting.

A flue adapter is supplied with the furnace. It must be fieldĆ

installed between the induced draught fan flue outlet and

the flue connector using one or two corrosion-resistant

sheet metal screws. Modification of or failure to install

the adapter will cause unsafe unit operation and will

void unit certification. The flue adapter does not require

insulation.

CABINET SIDE PANEL

FIGURE 12

3 - In cupboard installations, it may be necessary to

install sheet metal screws from the inside. If this is the

case, make plenum with a removable front to install

screws as shown in figure 13.

SECURE

FROM

INSIDE

CABINET SIDE PANEL

PLENUM

HEMMED EDGE

FIGURE 13

VERTICAL FLUE USING METAL FLUE PIPE

Note: See the regulations that are in force in the

country of installation for flue connector sizing.

FLUE CAP

STORM COLLAR

FLASHING

STRAIGHT PIPE

FIRST 152mm (6")

FLUE

ADAPTER

MIN. LENGTH - AS SHORT AS PRACTICAL

MAXIMUM LENGTH - SEE NOTE AT SIDE

(Double-walled, single-walled pipe)

CONNECTOR

VERTICAL FLUE USING METAL FLUE PIPE

The flue system should be of the same nominal diameter

as the adapter supplied with the unit and should be fitted

inside the adapter either directly or using a connector deĆ

signed for the flue system used. Where it is not possible to

use the same nominal diameter, a larger size may be

used with an appropriate conversion piece to suit the unit

adapter. A flue system of smaller nominal diameter than

the unit adapter must not be used.

NOTE - Use these instructions as a guide. They do not suĆ

persede local codes.

Size and install the G24MCE vertical flue per local codes

and regulations and these instructions.

See figure 14 for typical application of a vertical flue using

twin wall metal flue pipe.

3.05M (10 FT.)

MINIMUM

.61M (2 FT.)

1.5M (5 FT.)

POINT

MINIMUM

MINIMUM

FLUE

1M (3 FT.)

MINIMUM

DOUBLE

WALL

FLUE PIPE

HIGHEST FLUE

CONNECTOR

FIGURE 14

Page 10

Page 11

Recommendations and Requirements

When sizing and installing a vertical flue using metal flue

connectors and either metal flue pipe or a lined masonry

chimney, the following recommendations and requireĆ

ments should be considered in addition to those outlined

above:

1 - Accessories attached to the flue to reduce heat loss

and improve efficiency have not been tested for use

with this furnace.

2 - When the G24MCE furnace is replacing an existing

furnace, inspect the existing flue system for obstrucĆ

tions, corrosion and proper sizing.

3 - Make runs of single-walled or twin-walled metal pipe

used as flue connector easily accessible, so that it

can be inspected annually and cleaned and replaced

if necessary.

4 - See the regulations that are in force in the counĆ

try of installation for flue connector sizing.

5 - When the vent connector must be located in or pass

through a crawl space or other areas which may be

cold, that portion of the vent connector shall be a

listed twinĆwall flue pipe or a pipe of a material having

equivalent insulation qualities.

6 - Secure all joints with at least two corrosion-resistant

screws. Check all accessible joints for gas tightness

after installation.

WARNING

Failure to properly seal flue system could allow carĆ

bon monoxide leakage resulting in injury or death.

7 - Make flue connector horizontal runs as short as posĆ

sible with a minimum number of elbows. One 90° elĆ

bow is equivalent to 1.5m (5 ft.) of straight pipe. One

45° elbow is equivalent to .75m (2.5 ft.) of straight

pipe.

8 - Horizontal runs of flue connector must rise at least

20mm per meter (1/4 in. per ft.) away from the furĆ

nace.

9 - Horizontal run length must not represent more than 75

percent of the vertical rise of the flue system.

10 - Support horizontal runs of flue connector with straps or

hangers, so that there are no dips or sags.

11 - Support the flue connector at 1m (3 ft.) intervals and

at all elbows.

12 - If single wall flue is used, fasten the flue adapter to the

flue outlet of the furnace and the flue connector to the

flue adapter using one or two corrosion-resistant

sheet metal screws. If twin walled flue pipe is used,

fasten according to manufacturer's instructions

13 - Install first flue connector elbow a minimum of 6 in.

(152mm) from furnace flue outlet.

14 - Terminal location must not be within 600 mm (2 ft.) of

an openable window, air vent, or other ventilation

opening. Flue terminal must be located in accorĆ

dance with any national regulations applicable. A

flue guard must be fitted if required by the regulaĆ

tions.

15 - Fit a split flue socket immediately above the furnace

to facilitate servicing and maintenance.

16 - Flue pipes and fittings should be constructed of aluĆ

minium or stainless steel.

VERTICAL FLUE USING MASONRY CHIMNEY

The following additional requirements apply when a lined

masonry chimney is used to vent a G24MCE furnace:

See figure 15 for exterior chimney application.

Masonry chimneys that once served fireplaces cannot be

used for venting purposes unless the fireplace opening is

permanently sealed.

Tile-lined chimneys must be composed of a non-porous,

acid-resistant material. The internal diameter of the chimĆ

ney liner must not be less than the diameter of the furnace

flue adapter.

The G24MCE gas furnace must not be connected to a

chimney that is servicing a separate appliance which burns

solid fuel.

IMPORTANT

SINGLE appliance venting of a fanĆassisted furnace

into a tileĆlined masonry chimney (interior or outĆ

side wall) is PROHIBITED. The chimney must first

be lined with either twinĆwalled flue or an insulated

single wall flexible vent lining system, sized in acĆ

cordance with the the regulations in force in the

country of installation.

Page 11

Page 12

VENTING USING METAL-LINED

EXTERIOR MASONRY CHIMNEY

Note: See the regulations that are in force in the

country of installation for flue connector sizing.

MIN. LENGTH - AS SHORT AS PRACTICAL

MAXIMUM LENGTH - SEE NOTE AT SIDE

1.5m (5 FT.)

MINIMUM

EXTERIOR CHIMNEY WITH TWIN-WALLED LINER OR

INSULATED (FLEXIBLE) SINGLE-WALLED LINER.

SEALED

HIGHEST FLUE

CONNECTOR POINT

PERMANENTLY SEALED

FIREPLACE OPENING

FIGURE 15

Do not install a manual damper, barometric draught reguĆ

lator, or flue restrictor between the furnace and the chimĆ

ney. Remove any such existing devices.

If twin-wall flue is used inside a chimney, no other apĆ

pliance can be vented into the chimney. Outer wall of twinwall flue pipe must not be exposed to flue products.

If a flexible single-walled liner is used in a masonry chimĆ

ney, the liner must be insulated. Insulation for the flexible

vent pipe must be an encapsulated fiberglass sleeve recĆ

ommended by the flexible vent pipe manufacturer. See

figure 15.

If twin-wall flue or an insulated flexible vent pipe cannot be

used as liners, the chimney must be rebuilt to accommoĆ

date one of these methods or some alternate approved

method must be found to vent the appliance.

The space between the liner and the chimney wall

should NOT be insulated with puffed mica or any othĆ

er loose granular insulating material.

When inspection reveals that an existing chimney is not

safe for the intended purpose, it shall be rebuilt to conform

to nationally recognized standards. The chimney pasĆ

sageway must be checked periodically to ensure that it is

clear and free of obstructions.

HORIZONTAL FLUE USING METAL FLUE PIPE

These instructions should be used as a guide and do not

supersede local codes in any way. Size and install the

G24MCE horizontal flue according to the national and loĆ

cal codes and regulations which are in effect in the counĆ

try of installation.

The following are specific requirements for installation of

the G24MCE furnace:

1 - Install first flue connector elbow a minimum of

152mm (6 in.) from the furnace flue outlet.

2 - If the flue is sloped upward as it is routed away from

the furnace, the furnace must be protected from the

condensate produced in the flue.

3 - The flue system must be sealed (all joints must be

sealed), as positive pressure can occur in the flue.

4 - A 152mm (6 in.) clearance must be maintained to all

combustibles when single-walled flue pipe is used. A

25mm (1 in.) clearance to all combustibles must be

maintained when twin-walled flue pipe is used.

5 - If single-walled flue is used, fasten the flue adapter

to the flue outlet of the furnace and the flue connector

to the flue adapter using one or two corrosion-resisĆ

tant sheet metal screws. If twin-walled flue pipe is

used, fasten to the adapter according to manufacturĆ

er's instructions.

6 - Support flue as required by the regulations in force.

7 - See table 3 for flue diameter, equivalent lengths and

termination allowed.

8 - The tee termination shown in figures 16 and 17 is the

only acceptable termination.

MODEL SIZE

45

60/75/100/120/140

*One 905 elbow equals 1.5 m (5 ft.) of straight pipe. One 455 elbow equals 0.75 m (2.5 ft.) of straight pipe.

UNIT ORIENTATION

HORIZONTAL

UPFLOW / DOWNFLOW

HORIZONTAL 102 (4) 3 (10) 9.2 (30)

UPFLOW / DOWNFLOW 102 (4) 3 (10) 13.7 (45)

TABLE 3

HORIZONTAL FLUE PIPE SIZING

MINIMUM FLUE PIPE

DIAMETER mm (in.)

102 (4) 3 (10) 9.2 (30) 1

MINIMUM FLUE

EQUIVALENT

LENGTH* m (ft.)

Page 12

MAXIMUM FLUE

EQUIVALENT

LENGTH* m (ft.)

TERMINATION

TEE

1

Page 13

9 - The flue termination must be located in accordance

with any national regulations applicable. The termiĆ

nal must be designed such that it will not allow entry

of a 16mm (.6 in.) ball when applied with a 5N force.

A terminal guard must be applied where required by

national regulations.

HORIZONTAL TERMINATION DETAIL

WALL THIMBLE

(inside wall)

OUTER

OVERLAPPING

SHIELD

FLUE PIPE

INNER

SHIELD

INSIDE

WALL

WALL THIMBLE

(outside wall)

SHIELD

COUPLING

203mm

(8 in.) MIN.

PROTECTIVE SCREEN

INNER

(Both ends)

FIGURE 16

HORIZONTAL TERMINATION DETAIL

HIGH WINTER SNOW LEVELS

WALL THIMBLE

FOR COMBUSTIBLE

MATERIALS CLEARANCES

306mm (12 in.) MIN.

ABOVE NORMALLY

EXPECTED SNOW

ACCUMULATION

SEAL

2 - Meters - A gas meter is connected to the service pipe

by the gas supply authorities. An existing meter

should be checked by the gas supply authorities to

ensure that the meter is adequate to deal with the

rate of gas supply required.

3 - Pipework from the meter to the air furnace must be

of adequate size. Do not use pipes of a smaller size

than the inlet gas connection on the furnace. The

complete installation must be tested for soundness

as described in the codes in force.

4 - This unit is shipped standard for left or right side

installation of gas piping (or top entry in horizontal

applications). Connect the gas supply to the piping

assembly.

5 - When connecting gas supply, factors such as

length of run, number of fittings and furnace rating

must be considered to avoid excessive pressure

dr op. Table 4 and 5 list recom mended pipe sizes for

typical applications.

6 - The gas piping must not run in or through air ducts,

clothes chutes, chimneys or gas vents, dumb waiters

or elevator shafts.

7 - In some localities, it may be necessary to take preĆ

cautions against condensation in gas pipes. Where

condensation in pipes is considered likely to occur,

or if such precautions are required by national reguĆ

lations, the following steps should be taken to preĆ

vent condensation from entering the unit.

The piping should be sloped 1/4 inch per 15 feet upward

toward the meter from the furnace. The piping must be

supported at proper intervals (every 8 to 10 feet) using

suitable hangers or straps. A drip leg should be installed

in vertical pipe runs to the unit.

8 - A manual main shut-off valve and union (furnished

by installer) should be installed external to the unit.

Union must be of the ground joint type. See figure 18.

GROUND

LEVEL

FIGURE 17

Gas Piping

GAS SUPPLY

1 - Service pipes - The gas supply authorities should be

consulted at the installation planning stage in order to

establish the availability of an adequate supply of gas.

IMPORTANT

Compounds used on threaded joints of gas piping

must be resistant to the actions of liquified petroĆ

leum gases.

NOTE - Install an 1/8" RC plugged tap in the field piping upĆ

stream of the gas supply connection to the unit. Tap must

be accessible for test gauge connection. See figure 18.

NOTE - In case emergency shutoff is required, shut off main

manual gas valve and disconnect electrical power to unit.

These devices should be properly labeled by the installer.

Page 13

Page 14

TABLE 4 - GAS PIPE CAPACITY (FT3/HR)

Nominal

Iron Pipe Size

inches

1/4 .364 43 29 24 20 18 16 15 14 13 12

3/8 .493 95 65 52 45 40 36 33 31 29 27

1/2 .622 175 120 97 82 73 66 61 57 53 50

3/4 .824 360 250 200 170 151 138 125 118 110 103

1 1.049 680 465 375 320 285 260 240 220 205 195

1-1/4 1.380 1,400 950 770 660 580 530 490 460 430 400

1-1/2 1.610 2,100 460 1,180 990 900 810 750 690 650 620

2 2.067 3,950 2,750 2,200 1,900 1,680 1,520 1,400 1,300 1,220 1,150

2-1/2 2.469 6,300 4,350 3,520 3,000 2,650 2,400 2,250 2,050 1,950 1,850

3 3.068 11,000 7,700 6,250 5,300 4,750 4,300 3,900 3,700 3,450 3,250

4 4.026 23,000 15,800 12,800 10,900 9,700 8,800 8,100 7,500 7,200 6,700

Internal

Diameter

inches

10 20 30 40 50 60 70 80 90 100

NOTE-Capacity given in cubic feet of gas per hour and based on 0.60 specific gravity gas.

Length of Pipe - feet

TABLE 5 - GAS PIPE CAPACITY (M3/HR)

Nominal

Iron Pipe Size

inches

1/2 .622

3/4 .824

1 1.049

1-1/4 1.380

1-1/2 1.610

2 2.067

2-1/2 2.469

3 3.068

4 4.026

Internal

Diameter

inches

3 6 9 12 15 18 21 24 27 30

4.29 3.40 2.74 2.32 2.06 1.87 1.72 1.61 1.50 1.41

10.20 7.08 5.66 4.81 4.27 3.91 3.54 3.34 3.11 2.91

19.27 13.17 10.62 9.06 8.07 7.36 6.80 6.23 5.80 5.52

39.67 26.92 21.82 18.70 16.43 15.02 13.88 13.03 12.18 11.33

59.51 41.37 33.43 28.05 25.50 22.95 21.25 19.55

111.93 79.93 62.34 53.84 47.60 43.07 39.67 36.84 34.57 32.58

178.53 123.27 99.75 85.01 75.09 68.01 63.76 58.09 55.26 52.62

311.72 218.20 117.11 150.19 134.60 121.85 110.52 104.85 97.76 92.10

651.78 447.74 308.89 274.88 249.37 249.37 229.54 212.53 204.03 189.86

NOTE-Capacity given in cubic metres of gas per hour and based on 0.60 specific gravity gas.

Length of Pipe - metres

18.42

17.56

LEFT SIDE PIPING (STANDARD)

MANUAL

MAIN SHUT-OFF VALVE

(With 1/8" RC

Plugged Tap Shown)

GROUND

JOINT

UNION

DRIP LEG

(optional)

AUTOMATIC

GAS VALVE

AND INSTALLED

FIGURE 18

SOUNDNESS CHECK

After gas piping is completed, carefully check all piping

connections (factory- and field-installed) for gas leaks.

Use a leak detecting solution or other preferred means.

NOTE - In case emergency shutdown is required, shut

down main manual gas valve and disconnect electrical

power to unit. These devices should be properly labeled

by the installer.

MAIN SHUT-OFF

RIGHT SIDE PIPING

(ALTERNATE)

FIELD

PROVIDED

AUTOMATIC

GAS VALVE

CAUTION

Some soaps used for leak detection are corrosive

to certain metals. Carefully rinse piping thoroughly

after leak test has been completed. Do not use

matches, candles, flame or other sources of igniĆ

tion to check for gas leaks.

The furnace must be isolated from the gas supply system

by closing its individual manual shut-off valve during any

pressure testing of the gas supply system at pressures

equal to or less than 20 in. w.c. (50 mBAR).

MANUAL

VALV E

(With 1/8" RC

Plugged Tap

Shown)

GROUND

JOINT

UNION

DRIP LEG

(optional)

Page 14

Page 15

IMPORTANT

At pressures greater than 20 in. w.c. (50 mBAR), gas

valve must be disconnected and isolated. See figĆ

ure 19. Gas valves can be damaged if subjected to

more than 20 in. w.c. (50 mBAR).

MANUAL MAIN

SHUT-OFF VALVE

WILL NOT HOLD

NORMAL TEST

PRESSURE

CAP

ISOLATE

GAS VALVE

furĆ

nace

FIGURE 19

Electrical

CAUTION

Electrostatic discharge can affect electronic comĆ

ponents. Take precautions during furnace installaĆ

tion and service to protect the furnace's electronic

controls. Precautions will help to avoid control exĆ

posure to electrostatic discharge by putting the

furnace, the control and the technician at the same

electrostatic potential. Neutralize electrostatic

charge by touching hand and all tools on an unĆ

painted unit surface, such as the gas valve or blowĆ

er deck, before performing any service procedure.

These units operate on 240 volt, single phase, 50 hertz

electrical power. Refer to figure 20 for field wiring and figĆ

ure 22 for schematic wiring diagram and troubleshooting.

1 - Select circuit protection and wire size according to

requirements listed on unit rating plate.

2 - Knockouts are provided on both sides of the furnace

cabinet to facilitate wiring.

3 - Install room thermostat according to instructions proĆ

vided with thermostat.

4 - Install a separate disconnect switch (protected by eiĆ

ther fuse or circuit breaker) near the unit so power

can be turned off for servicing.

5 - Before connecting thermostat or power wiring, check

to make sure wires will be long enough to facilitate

servicing at a later date. Remove blower access panĆ

el and swing panel to check wire length for access.

6 - Complete wiring connections to equipment using wirĆ

ing diagrams provided with unit and in field wiring diaĆ

grams shown in figures 20. Use 18 gauge wire or largĆ

er for thermostat connections.

7 - Electrically earth unit according to national regulaĆ

tions.

8 - Three 240 volt accessory terminals are provided on

the control board. Two are energized with the indoor

blower and one is energized with the combustion air

blower. Any accessory rated up to one amp can be

connected to the accessory terminals with the neutral

leg of the circuit being connected to the 240 volt neuĆ

tral wires.

9 - This unit is equipped with an integrated control board

that controls blower operation, fan off timings and igniĆ

tion. The board includes a terminal strip for thermostat

connections and two diagnostic LEDs. See figure 21

for control board configuration. Diagnostic codes are

given in a chart at the back of this manual.

The red diagnostic button can be used to view the

last failure code.

10- Refer to blower speed chart on wiring diagrams for

factoryĆset cooling, heating and continuous fan

speeds.

Systems using a cooling thermostat subbase may

operate the blower continuously (factory set at low

speed) through the thermostat FAN ON" switch.

Systems which do not include a cooling subbase reĆ

quire a toggle switch which must be wired between

terminals R" and G" on the thermostat connection

terminal strip.

The blower motor will operate at the designated

speed during cooling or heating demand; however,

when demand is satisfied, blower speed will revert to

selected continuous speed.

TYPICAL G24MCE FIELD WIRING DIAGRAM

HEAT ONLY

THERMOSTAT

HEAT/COOL

THERMOSTAT

W

TO COMPRESSOR

CONTACTOR

RW

RGY

HIGHLIMIT

PRESSURE

SWITCH

CONTROL

BOARD

R

G

W

Y

C

TRANSFORMER

CAPILLARY

TUBE LIMIT

GAS

VALV E

BLACK

WHITE

DOOR

INTERLOCK

FUSED OR

CIRCUIT

BREAKER

ISOLATOR

(Furnished by

installer)

240V, 1PH, 50HZ

L1 N

FIGURE 20

Page 15

Page 16

HEATING SPEED

TAP TERMINAL

EGC-3ACE INTEGRATED CONTROL BOARD

CONTINUOUS FAN

TERMINAL

COOLING SPEED

TAP TERMINAL

ACCESSORY

TERMINALS

HEATING

ACCESSORY

TERMINAL

TERMINALS

L1

NEUTRAL

L2

DIAGNOSTIC

LEDS

BLOWER TIME

ADJUSTMENT

JUMPER

GND

DIAGNOSTIC CODE

ERASE JUMPER

(Remove power to control

and short pins for 10 secĆ

onds to erase previous

code.)

RED DIAGNOSTIC BUTTON

(Depress button and hold for

display of last failure code.)

THERMOSTAT

TERMINAL STRIP

FIGURE 21

Page 16

Page 17

G24MCE SCHEMATIC WIRING DIAGRAM

(240V, 1PH, 50HZ)

03/99

FIGURE 22

Page 17

Page 18

Unit Start-Up

FOR YOUR SAFETY READ BEFORE OPERATING

5 - Wait five (5) minutes to clear out any gas. If you then

smell gas, STOP! Immediately call your gas supplier

from a neighbor's phone. Follow the gas supplier's

instructions. If you do not smell gas go to next step.

WARNING

Do not use this furnace if any part has been underĆ

water. Immediately call a qualified service techniĆ

cian to inspect the furnace and to replace any part

of the control system and any gas control which

has been under water.

WARNING

If overheating occurs or if gas supply fails to shut

off, shut off the manual gas valve to the appliance

before shutting off electrical supply.

CAUTION

Before attempting to perform any service or mainteĆ

nance, turn the electrical power to unit OFF at isolaĆ

tor switch.

BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

Use only your hand to turn the main manual gas cock. Never

use tools. If the knob will not turn by hand, do not try to repair

it, call a qualified service technician. Force or attempted reĆ

pair may result in a fire or explosion.

PLACING FURNACE INTO OPERATION

G24MCE units are equipped with an automatic direct

spark ignition system. Do not

burners on these Furnaces. Each time the thermostat

calls for heat, the burners will automatically light.

attempt to manually light

WARNING

If you do not follow these instructions exactly, a fire

or explosion may result causing property damage,

personal injury or death.

GAS VALVE OPERATION (Figure 23)

1 - STOP! Read the safety information at the beginning

of this section.

2 - Set the thermostat to the lowest setting.

3 - Turn off all electrical power to the unit.

4 - This furnace is equipped with an ignition device

which automatically lights the burners. Do not try to

light the burners by hand.

S.I.T. GAS VALVE

MANIFOLD

PRESSURE

OUTLET

MANIFOLD

PRESSURE

ADJUSTMENT

SCREW

FIGURE 23

6- Turn on all electrical power to the unit.

7- Set the thermostat to desired setting.

8- If the appliance will not operate, follow the instrucĆ

tions Turning Off Gas To Unit" and call your service

technician or gas supplier.

NOTE-When unit is initially started, steps 1 through 7

may need to be repeated to purge air from gas line.

TURNING OFF GAS TO UNIT

1 - Set the thermostat to lowest setting.

2 - Turn off all electrical power to the unit if service is to

be performed.

Heating Sequence of Operation

1 - When thermostat calls for heat, combustion air blowĆ

er starts after a 5 second delay.

2 - Combustion air pressure switch proves blower opĆ

eration, then allows power to ignition control. Switch

is factory set and requires no adjustment.

3 - After 15-second prepurge, spark ignitor energizes

and gas valve solenoid valves open.

4 - Spark ignites gas, ignition sensor proves the flame

and combustion process continues.

5 - If flame is not detected after first ignition trial, igniĆ

tion control will repeat steps 3 and 4 four more

times before locking out. To reĆestablish ignition

attempts after lockout, proceed as follows:

a - Turn OFF the power to the furnace.

b - Move the thermostat control from the HEAT" to

the OFF" position.

c - Turn ON the power to the furnace.

d - Move the thermostat control from the OFF" to

HEAT" position.

Page 18

Page 19

Unit Adjustments

HIGH LIMIT AND CAPILLARY TUBE LIMIT

The high limit and manuallyĆreset capillary tube limit are

both located on the heating compartment vestibule panel.

Both limits are factory set and do not require field adjustĆ

ment.

When there is inadequate supply air (a high supply air

temperature), the high limit shuts off the gas supply to

the burners, turns the combustion air blower OFF, and

keeps the air circulating blower ON until the limit resets

itself. While the limit is open, the control board displays

DIAG.1 - FLASHING; DIAG.2 Ć ON. If the limit trips 5

times in succession, a 60 minute Watchguard" occurs.

After 60 minutes, the control board automatically resets

itself. (The control board can also be reset by switching

the thermostat from HEAT to OFF and then back to

HEAT again.)

When there is inadequate supply air (a high supply air

temperature), the manuallyĆreset capillary tube limit

shuts off the gas supply to the burners and turns both the

combustion air blower and the air circulating blower OFF.

(The air circulating blower turns off only after its preset

delayĆoff time expires). While the limit is open, the control

board then displays DIAG.1 - ON; DIAG.2 Ć FLASHING.

To reset the limit, allow the furnace to cool, and then push

the switch on the limit's face inward.

If either limit trips, check for clogged filters or blocked supĆ

ply/return air grilles.

COMBUSTION AIR PRESSURE SWITCH

The combustion air pressure switch is located on the

heating compartment vestibule panel. This switch checks

for proper combustion air fan operation before allowing

ignition trial. The switch is factoryĆset and requires no field

adjustment.

FAN CONTROL

The fan control is part of the control board located on the

heating compartment vestibule panel. The preset fan on

delay time of 45 seconds is not adjustable. The fan off

delay time is factory adjusted at 120 seconds and can be

adjusted by moving the jumper on the integrated control

board. See figure 24 for settings.

TIMING

JUMPER

120

90 60

FAN-OFF TIME ADJUSTMENT

To adjust fan-off timings:

Remove jumper and select one of the

other pin combinations to achieve the

180

desired time.

TIMING PINS

(seconds)

FIGURE 24

GAS FLOW

To check for proper gas flow to combustion chamber, deterĆ

mine heat (kW) input from the unit rating plate. Divide this

input rating (MJ/hr) by the calorific value per unit volume

(MJ/m3) of the gas being used. Result is the volume of gas

required per hour. Determine the flow of gas through gas

meter for two minutes and multiply by 30 to get the hourly

flow of gas.

GAS PRESSURE

1 - Check the gas line pressure with unit firing at maximum

rate. See technical data table on page 22 for minimum

and maximum allowable pressure.

2 - After line pressure has been checked and adĆ

justed, check manifold pressure. Manifold pressurĆ

es are given in technical data table on page 22. See

figure 23 for gas pressure adjustment screw location.

TEMPERATURE RISE

Check the temperature rise and, if necessary, adjust fan

speed to maintain the temperature rise within range

shown on the unit rating plate.

If outdoor air is added to the recirculating room air, the

mixed air temperature at the heat exchanger should not

be lower than 15.5°C for extended periods of time.

THERMOSTAT HEAT ANTICIPATION

Set thermostat heat anticipation to:

0.80 amps S.I.T. gas valve

ELECTRICAL

1 - Check all wiring for loose connections.

2 - Check for correct voltage at the furnace (furnace opĆ

erating).

3 - Check amp-draw on fan motor.

Motor Nameplate__________Actual__________

FAN SPEEDS

Note - CFM readings are taken external to unit with a dry

evaporator coil and without accessories.

1 - Turn off electrical power to furnace.

2 - Remove unit access panel.

3 - Disconnect existing speed tap at control board

speed terminal.

NOTE - TERMINATION OF ANY UNUSED MOTOR

LEADS MUST BE INSULATED.

4 - Refer to fan speed selection chart on unit wiring diaĆ

gram for desired heating or cooling speed.

5 - Connect selected speed tap at control board speed

terminal.

6 - Resecure blower access panel.

7 - Turn on electrical power to furnace.

FLUE AND CHIMNEY

1 - Check flue pipe, chimney and all connections for

tightness and to make sure there is no blockage.

2 - Check unit for proper draught.

3 - Is pressure switch closed? Obstructed flue will cause

unit to shut off at pressure switch. Check flue and

outlet for blockages.

Page 19

Page 20

BURNER FLAME ADJUSTMENT

The G24MCE burner flame is not adjustable; however,

the flame should be inspected at the beginning of each

heating season. If necessary, clean the burners. The

burner flame should be blue when burning natural gas,

and blue/yellow when burning propane gas. See figure

25.

BURNER FLAME

FLAME APPEARS BLUE IF

BURNING NAT. GAS; BLUE/

YELLOW FOR PROPANE.

BURNER

FLAME

EXCHANGER

VEST

PANEL

HEAT

TUBE

FIGURE 25

FAILURE TO OPERATE

If unit fails to operate check the following:

1 - Is the thermostat calling for heat?

2 - Is the main isolator switch closed?

3 - Is there a blown fuse or tripped circuit breaker?

4 - Is the filter dirty or clogged? Dirty or clogged filters

will cause the limit control to shut the unit off.

5 - Is gas turned on at the meter?

6 - Is manual main gas cock open?

7 - Is unit ignition system in lock out? If unit locks out

again, call the service technician to inspect unit for

blockages.

At the beginning of each heating season, service items A

through E as described below:

A - ELECTRICAL

1 - Check all wiring for loose connections.

2 - Check for correct voltage at the furnace (furnace opĆ

erating).

3 - Check amp-draw on the fan motor.

Motor Nameplate__________Actual__________

B - FANS

Check and clean fan wheels for debris and clean if necĆ

essary. The fan motors are prelubricated for extended

bearing life. No further lubrication is needed.

C - FILTERS

All G24MCE filters are installed external to the unit. Filters

should be inspected monthly .Clean or replace the filters

when necessary to ensure proper furnace operation. See

table 6 for filter sizes. Replacement filters for

G24MCE-45/60/75 units must have a minimum velocity

rating of 2 m/s (400 FPM). Replacement filters for

G24MCE-100/120/140 units require a minimum velocity

rating of 3 m/s (625 FPM).

TABLE 6

MODEL NO.

G24MCE-45/60/75

G24MCE-100/120/140

FILTER SIZE -

millimeters (inches)

406X508X25

(16 X 20 X 1)

508X508X25

(20 X 20 X 1)

Service

WARNING

Disconnect power before servicing unit.

CAUTION

Label all wires prior to disconnection when servicĆ

ing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

WARNING

The fan door must be securely in place when the fan

and burners are operating. Gas fumes, which could

contain carbon monoxide, can be drawn into living

space resulting in personal injury or death.

D - FLUE AND CHIMNEY

Check the flue pipe, chimney and all connections for tightĆ

ness and to make sure there is no blockage.

Page 20

Page 21

E - BURNERS

Inspect the burners and burner flame at the beginning of

each heating season. If necessary, clean the burners as

indicated below:

1 - Turn off the electrical and gas supply to the furnace.

2 - Remove the burner box top.

3 - Remove the burner retaining bracket.

4 - Remove the burners.

5 - Clean the inside of each burner with a bottle brush as

shown in figure 26.

Cleaning Burners

BURNER

BOTTLE

BRUSH

FIGURE 26

6 - Replace the burners and the burner retaining brackĆ

et. Make sure the burners are properly seated in the

slots of the tray. The burner and manifold orifice must

be aligned.

7 - Check the electrode gap using appropriately sized

twist drills or feeler gauges. The gap should be beĆ

tween 2.79 and 3.56 mm (0.110 and 0.140 inches).

8 - Reinstall the burner box top.

9 - Restore electrical power and gas supply to the furĆ

nace. Follow lighting instructions on the front of the

unit. Check the appearance of the burner flame, burnĆ

er pressure, gas flow, and temperature rise. If necesĆ

sary, make adjustments. See the other unit adjustĆ

ments section.

HEAT EXCHANGER

Periodically inspect the heat exchanger tubes and flue box

for corrosion. If necessary, clean as indicated below:

1 - Turn off the electrical and gas supply to furnace.

2 - Disconnect wiring to combustion air blower.

3 - Remove the screws securing the flue box to the furĆ

nace. Clean the flue box with a wire brush (brassĆbristle

brush recommended), and rags or a shop vacuum

cleaner.

4 - Disconnect the gas supply piping and the ignitor and

sensor wires. Remove the burner assembly from the

furnace.

5 - Since the heat exchanger tubes are crimped in severĆ

al locations, a thorough cleaning of the entire length of

each tube is not possible. However, remove any soot

deposits which are accessible with a wire brush (brassĆ

bristle brush recommended), and rags or a shop vacuĆ

um cleaner.

6 - Reinstall the flue box using a new gasket.

7 - Reconnect combustion air blower wiring.

8 - Reinstall the burner box, ignitor and sensor wires

and the gas supply piping.

9 - Carefully check all piping connections (factory and field)

for gas leaks. Use a leak detecting solution or other preĆ

ferred means.

IMPORTANT

CAUTION

Some soaps used for leak detection are corrosive

to certain metals. Carefully rinse piping thoroughly

after leak test has been completed. Do not use

matches, candles, flame or other sources of igniĆ

tion to check for gas leaks.

Some soaps used for leak detection are corrosive to

certain metals. Carefully rinse piping thoroughly afĆ

ter leak test has been completed. Do not use

matches, candles, flame or other sources of ignition

to check for gas leaks.

10 Restore electrical power and gas supply. Follow

lighting instructions on front of unit. Check burner

flame and adjust if necessary.

Page 21

Page 22

Technical Data Table

NO. DESCRIPTION UNITS -45 -60 3-75 4-75 -100 -120 -140

*1 INPUT RATING kW 13.2 17.6 22 22 29.9 35.2 41.1

*2 OUTPUT RATING kW 10.5 14 17.6 17.6 23.9 28.1 32.8

3 NUMBER OF INJECTORS 3 4 5 5 5 6 7

4 GAS CONNECTION SIZE

5 FLUE ADAPTER SIZE

6 WEIGHT

7 FAN MOTOR HP

8 FAN MOTOR FLA AMPS 1.6 2.6 2.6 3.42 3.42 3.42 3.42

9

10

11

12

13

14 INJECTOR SIZE

15

16

**17

**18 CALORIFIC VALUE G25 GAS

**19 GAS RATE G20 GAS UK

**20 GAS RATE G25 GAS

COMBUSTION AIR

MOTOR HP

COMBUSTION AIR

MOTOR FLA

FAN WHEEL SIZE:

DIA. X WIDTH

FAN WHEEL SIZE:

DIA. X WIDTH

FAN SUPPLY PRESSURE -

MAX

BURNER PRESSURE

G20 GAS UK

BURNER PRESSURE

G25 GAS

CALORIFIC VALUE

G20 GAS UK

mm

(INCHES)

mm

(INCHES)

KG

(LBS)

WATTS

(HP)

WATTS

(HP)

AMPS 0.6 0.6 0.6 0.6 0.6 0.6 0.6

mm 229X178 254X178 254X203 279X203 305X229 305X229 305X229

INCHES 9X7 10X7 10X8 11X8 12X9 12X9 12X9

mBAR

(WC")

#MORSE

(mm)

mBAR

(WC")

mBAR

(WC")

MJ/cubic

meters

MJ/cubic

meters

cubic

meters/h

cubic

meters/h

13

(1/2)

102

(4)

59

(130)

186

(1/4)

22

(0.03)

1.24

(0.5)

48

(1.93)

8.5

(3.4)

12.75

(5.1)

37.78 37.78 37.78 37.78 37.78 37.78 37.78

32.49 32.49 32.49 32.49 32.49 32.49 32.49

1.26 1.68 2.09 2.09 2.85 3.35 3.91

1.46 1.95 2.44 2.44 3.31 3.9 4.55

13

(1/2)

102

(4)

61

(135)

249

(1/3)

22

(0.03)

1.24

(0.5)

48

(1.93)

8.5

(3.4)

12.75

(5.1)

13

(1/2)

102

(4)

64

(140)

249

(1/3)

22

(0.03)

1.24

(0.5)

48

(1.93)

8.5

(3.4)

12.75

(5.1)

13

(1/2)

102

(4)

64

(140)

373

(1/2)

22

(0.03

1.24

(0.5)

48

(1.93)

8.5

(3.4)

12.75

(5.1)

13

(1/2)

102

(4)

79

(175)

373

(1/2)

22

(0.03

1.24

(0.5)

44

(2.18)

8.5

(3.4)

12.75

(5.1)

13

(1/2)

102

(4)

79

(175)

373

(1/2)

22

(0.03)

1.24

(0.5)

44

(2.18)

8.5

(3.4)

12.75

(5.1)

13

(1/2)

102

(4)

86

(190)

373

(1/2)

22

(0.03)

1.24

(0.5)

44

(2.18)

8.5

(3.4)

12.75

(5.1)

NOTE: FOR OPERATION WITH THIRD FAMILY GAS, USE ONLY MANUFACTURER SUPPLIED CONVERSION KITS:

21 INJECTOR SIZE

22 BURNER PRESSURE G31

23 CALORIFIC VALUE G31 MJ/kg 50.37 50.37 50.37 50.37 50.37 50.37 50.37

24 GAS RATE G31 kg/h 0.94 1.26 1.57 1.57 2.14 2.52 2.93

* DERATE 4% PER 305m (1000FT) FOR ALTITUDES GREATER THAN 610m (2000FT); e.g. AT ALTITUDE 1220M (4000FT) DERATE 16%

** DRY GAS AT 15 deg C AND 1013.25 mBAR

*** NO EQUIVALENT # MORSE

#MORSE

(mm)

mBAR

(WC")

56

(1.18)

23.5

(9.4)

56

(1.18)

23.5

(9.4)

Page 22

56

(1.18)

23.5

(9.4)

56

(1.18)

23.5

(9.4)

***

(1.384)

22.0

(8.8)

***

(1.384)

22.0

(8.8)

***

(1.384)

22.0

(8.8)

Page 23

Ignition Control Board Diagnostic Codes

EGC-3ACE INTEGRATED CONTROL BOARD

DSI BOARD

DIAGNOSTIC PATTERNS

DIAG 1

DIAG 2

Flashing

Together

Flashing

Together

DIAGNOSTICS LEDS

L1

MODE

INDICATION

Normal Operation

RED DIAGNOSTIC BUTTON

(Depress button and hold for

display of last failure code.)

DIAGNOSTIC CODE

ERASE JUMPER

(Remove power to control

and short pins for 10 seconds

to erase previous code.)

GND

STATUS

Slow flashing LED signifies normal

operation. Fast flashing LED indiĆ

cates a heating demand.

DIAG 1

Flashing

Limit

Switch Open

DIAG 2

DIAG 1

DIAG 2

DIAG 1

On

Off

Flashing

Flashing

Alternately

Pressure

Switch Open

Failed Ignition

DIAG 2

DIAG 1

Flashing

Alternately

Flashing

Flame Failure

DIAG 2

DIAG 1

DIAG 2

DIAG 1

Off

On

Flashing

Continuously on

Flame Rollout/

Capillary Tube

Limit Switch Open

Control Board

Failure

DIAG 2

*Hard Lockout Mode Reset Sequence : 1 - Turn off the power to the furnace; 2 - Move thermostat control from HEAT" to OFF" position; 3 - Turn on the power

to the furnace; 4 - Move thermostat control from OFF" to HEAT" position.

Continuously on

This LED pattern indicates that either the primary or

secondary limit switch has opened. Both switches

auto-reset. System may be in Watchguard mode.

This LED pattern indicates that the pressure