Page 1

PRODUCT LITERATURE

1999 Lennox Industries Inc.

Dallas, Texas

503,208M

9/99

Supersedes 9/98

G24MCE

SERIES

GAS-FIRED

FURNACE

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

Do not store or use petrol or other

flammable vapours and liquids in the

vicinity of this or any other appliance.

Installation and service must be perĆ

formed by a qualified installer, serĆ

vice agency or the gas supplier.

Litho USA

WARNING

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Extinguish any open flames.

Do not touch any electrical switch; do not

use any telephone in your building.

Immediately call your gas supplier from a

neighbor's telephone. Follow the gas supĆ

plier's instructions.

If you cannot reach your gas supplier, call

the local fire brigade.

Page 1

Page 2

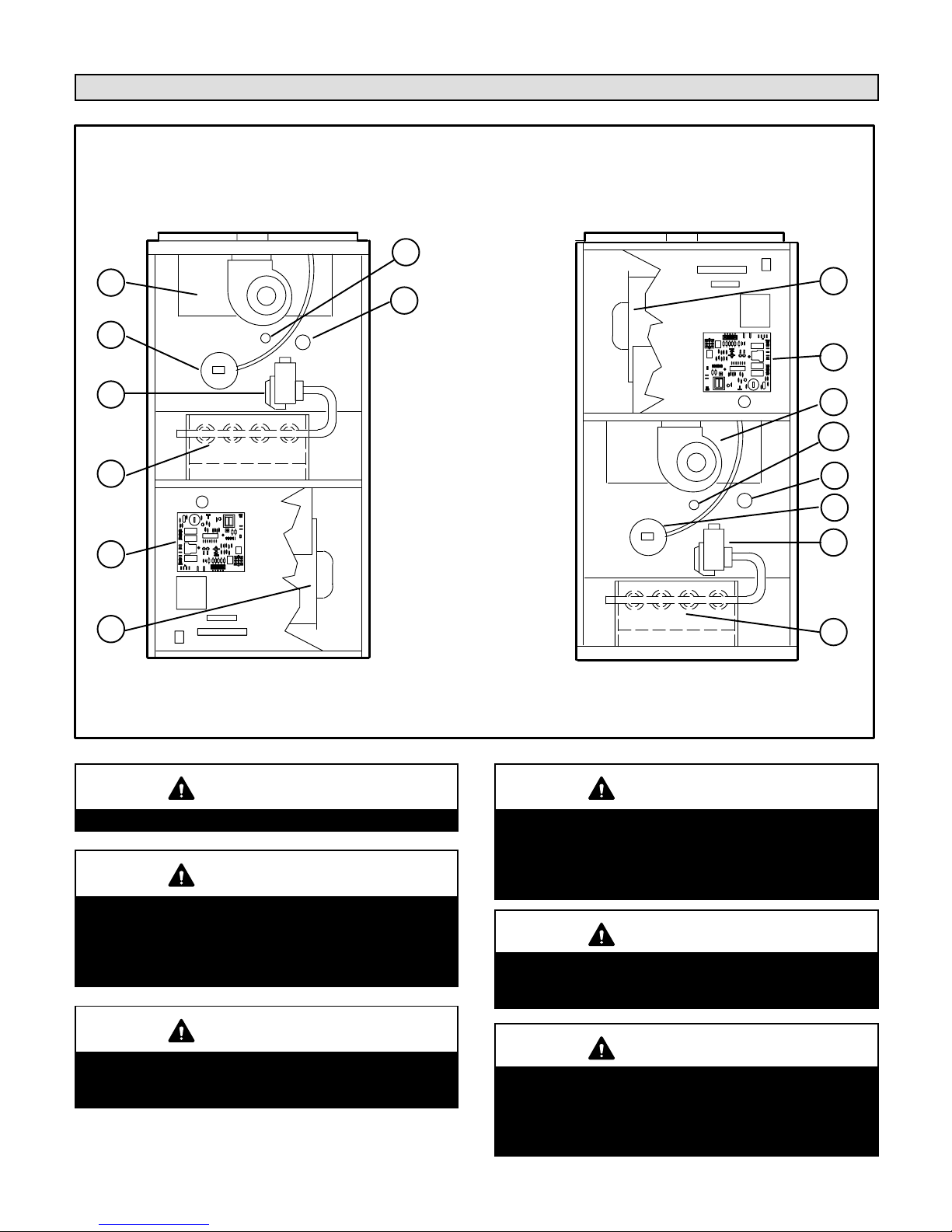

G24MCE Parts Identification

7

1

4

2

3

5

6

8

UPFLOW POSITION DOWNFLOW POSITION

1 - COMBUSTION AIR FAN

2 - PRESSURE SWITCH

3 - GAS VALVE

4 - CAPILLARY TUBE LIMIT

5 - BURNERS

6 - CONTROL BOARD

7 - HIGH LIMIT

8 - MAIN FAN

8

6

1

7

4

2

3

5

WARNING

This appliance must be earthed.

WARNING

This product contains glass fibre insulation.If inĆ

sulation is disturbed during installation, mainteĆ

nance or repair, persons may be exposed to irritaĆ

tion to the skin, eyes and lungs. Tears in the insulaĆ

tion should be repaired straight away.

WARNING

If overheating occurs or if gas supply fails to shut

off, shut off the manual gas valve to the appliance

before shutting off electrical supply.

WARNING

Do not use this furnace if any part has been underĆ

water. Immediately call a qualified service techniĆ

cian to inspect the furnace and to replace any part

of the control system and any gas control which

has been under water.

CAUTION

Before attempting to perform any service or mainteĆ

nance, turn the electrical power to unit OFF at isolaĆ

tor switch.

IMPORTANT

Any additions, changes, or conversions required in

order for the appliance to satisfactorily meet the apĆ

plication needs must be made by a Lennox service

technician using factory specified and approved

parts.

Page 2

Page 3

Important Directions

1 - Keep the furnace area clear and free of combustible

material, petrol, and other flammable vapours and liqĆ

uids. If installed in an insulated area, furnace must be

kept free of insulating material. Insulating material may

be combustible. Inspect furnace venting system to

make sure it is in place, physically sound, and without

holes, corrosion, or blockage. Inspect furnace return

air duct connection to ensure duct is sealed to the furĆ

nace and terminates outside the space containing the

furnace. Inspect the physical support of the furnace to

guarantee that it is sound without sagging, cracks or

gaps around base and it maintains seal between base

and support.

2 - DO NOT obstruct air flow to unit. Unit must receive an

unobstructed flow of combustion and ventilating air.

3 - DO NOT store chlorine or fluorine products near unit or

introduce these products into the combustion air.

These products can cause furnace corrosion.

4- DO NOT draw return air from a room where this

furnace, or any other gas appliance (ie., a water

heater), is installed. When return air is drawn from a

room, a negative pressure is created in the room. If a

gas appliance is operating in a room with negative

pressure, the flue products can be pulled back down

the vent pipe and into the room. This reverse flow of

the flue gas may result in incomplete combustion and

the formation of carbon monoxide gas. This toxic gas

might then be distributed throughout the house by

the furnace duct system.

Your furnace is a gas appliance. It is critical that the gas

supplied to the unit be completely burned to avoid the proĆ

duction of carbon monoxide gas. Complete combustion

of the gas requires, but is not limited to, correct gas presĆ

sure and gas flow rate, adequate combustion, air, and

proper venting.

WARNING

Carbon monoxide gas is invisible, odorless, and

toxic.

Exposure to this gas can cause personal injury and

even death to all occupants, including pets. Any item

th a t is power e d by or gi v e s off he at from a combustion

process (including lawn mowers, automobiles, and

fireplaces) has the potential to produce carbon monĆ

oxide gas. Because of this, Lennox recommends the

use of a carbon monoxide detector in your home,

even if you do not own gas appliances. Reliable deĆ

tectors are available at reasonable retail prices. ConĆ

tact your independent Lennox dealer for more details

about this investment in your safety.

Your furnace is designed to meet standards set by nationĆ

al agencies, and to operate safely when properly installed

and maintained. However, the unit's performance can be

greatly impacted by the individual installation and the opĆ

erating environment. It is your responsibility to ensure

that this appliance is maintained. Proper maintenance is

critical for your safety and the satisfactory operation of the

product. Lennox strongly recommends annual inĆ

spection and maintenance of this appliance. Contact

your independent Lennox dealer for an inspection by a

qualified service technician.

Page 3

Page 4

Lighting Information and Operation

WARNING

If you do not follow these instructions exactly, a fire

or explosion may result causing property damage,

personal injury or loss of life.

BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

Filters

G24MCE series units are equipped with external filters

which should be inspected monthly and replaced when

necessary to assure proper furnace operation. See

table 1 for filter sizes. Replacement filters used with

G24MCE-4 0 / 60/75 uni t s must have a min i m um velocĆ

ity rat i n g of 2 m/s (400 FPM ) . Re p lac e ment fil t ers used

with G24MCE-100/120/140 units require a minimum

velocity rating of 3.2 m/s (625 FPM). Figures 2 and 3

show possible filter locations when the units are

installed in the upflow position.

Placing Furnace Into Operation

G24MCE units are equipped with an electronic ignition sysĆ

tem. Do not

attempt to manually light burners on these furĆ

naces. Each time the thermostat calls for heat, the burner

will automatically light.

THERMOSTATS

FIGURE 1

Gas Valve Operation

1 - STOP! Read the safety information at the beginning

of this section.

2 - Set the thermostat to lowest setting. See figure 1.

3 - Turn off all electrical power to the unit.

4 - This furnace Is equipped with an ignition device

which automatically lights the burner. Do not try to

light the burner by hand.

5 - Wait five (5) minutes to clear out any gas. If you then

smell gas, STOP! Immediately call your gas supplier

from a neighbor's phone. Follow the gas supplier's

instructions. If you do not smell gas go to next step.

6- Turn on all electrical power to the unit.

7- Set the thermostat to desired setting.

NOTE-When unit is first started, steps 1 through 7 may

need to be repeated to purge air from gas line.

8- If the appliance still will not operate, follow the

instructions Turning Off Gas To Unit" and call your

service technician or gas supplier.

Turning Off Gas To Unit

1 - Set the thermostat to the lowest setting.

2 - Turn off all electrical power to the unit if service is to

be performed.

MODEL NO.

G24MCE-45/60/75

G24MCE-100/120/140

UPFLOW FURNACE

BOTTOM RETURN AIR

TABLE 1

FILTER SIZE -

millimeters (inches)

406X508X25

(16 X 20 X 1)

508X508X25

(20 X 20 X 1)

FIGURE 2

Page 4

Page 5

UPFLOW FURNACE

SIDE RETURN AIR

BURNER FLAME

FIGURE 3

Fan

Check and clean fan wheel for any debris. Fan motor is

prelubricated for extended bearing life. No further lubricaĆ

tion is needed.

WARNING

FLAME APPEARS BLUE IF

BURNING NAT. GAS; BLUE/

YELLOW FOR PROPANE.

BURNER

FLAME

EXCHANGER

VEST

PANEL

HEAT

TUBE

FIGURE 4

Venting System Inspection

Annually (before heating season) inspect furnace venting

system, vent cap, heat exchanger and burners for corroĆ

sion, deterioration, or deposits of debris. Remove any obĆ

structions.

Contact your Lennox dealer for a periodic unit inspection

by a qualified gas service engineer.

Capillary Tube Limit Switch

Your Lennox furnace is equipped with a manuallyĆreset

capillary tube limit switch which shuts off the gas supply to

the furnace in the event of inadequate supply air (high air

temperature). It is located on the vestibule panel near the

gas valve. To reset this control, push the switch on the

face of the control sideways. If this switch opens again,

consult a qualified gas service engineer.

Fan door must be securely in place when fan and

burners are operating. Gas fumes, which could

contain carbon monoxide, can be drawn into living

space resulting in personal injury or death.

Burner Flame

The G24MCE burner flame is not adjustable; however,

the flame should be inspected at the beginning of each

heating season and burners should be cleaned, if necesĆ

sary. Burner flame should be blue when burning natural

gas, blue/yellow when burning propane gas.

Control Board Lockouts

Several types of control board lockout modes exist on this

furnace. When in one of these modes, the control board

will not allow the furnace to start. The two modes that can

be manually reset are: a Watchguard lockout mode," and

a Hard lockout mode."

To reset the Watchguard mode," manually switch the therĆ

mostat from HEAT to OFF and then back to HEAT again.

(Note - This lockout mode will also automatically reset after

a 60 minute lockout period.)

The Hard lockout mode" can be reset by turning the elecĆ

trical power OFF and then back ON again.

If either of these two lockouts reoccur, or if the original lockĆ

out cannot be reset, call a qualified gas service engineer.

Page 5

Page 6

Service Reminder

Call your Lennox service technician if unit is inoperative.

Before calling, always check the following to be sure serĆ

vice is required.

1 - Check that electrical isolator switches are ON.

2 - Check room thermostat for proper setting.

3 - Replace any blown fuses or reset circuit breakers.

4 - Air filter should not be clogged limiting air flow.

5 - Is gas turned on at meter?

6 - Is manual gas cock open?

To keep your Lennox gas heating system in peak

operating condition year after year, contact your

independent Lennox dealer about a planned service

program.

Safety Precautions

If you discover any of the following, shut down your

unit, and contact an independent Lennox dealer for

an inspection by a qualified technician.

S If you repeatedly hear any new or unfamiliar sounds

while your unit is operating, there may be a problem.

For example, poorly performing burners can produce

unfamiliar noises.

S If you smell any unusual odors, your unit may be operĆ

ating improperly. For example, units can give off unfaĆ

miliar odors if components are required to operate in

abnormal conditions.

S Look for visible signs of a malfunctioning unit. ExamĆ

ples include unusual amounts of condensate on winĆ

dows inside your house, visibly burnt components or

unusual dirt or rust accumulations on the vent pipe or

in the unit.

S If you experience headache, nausea, fatigue, or dizziĆ

ness, the cause could be exposure to carbon monoxĆ

ide gas. This is often misdiagnosed as the flu because

symptoms are similar. If you suffer from flu-like sympĆ

toms that are exaggerated at home, but seem to subĆ

side while you are away from the house, exposure to

carbon monoxide could be the cause.

Your vigilance may pay off in early detection of a problem

before either personal injury or property damage occurs.

Do not hesitate to contact a qualified service technician as

an investment in your well being.

Planned Service

You should expect a service technician to check the folĆ

lowing items during an annual inspection. Power to the

unit must be shut off for the service technician's safety.

Fresh air grilles and louvers (on the unit and in the room

where the furnace is installed) - Must be open and unobĆ

structed to provide combustion air.

Burners- Must be inspected for rust, dirt, or signs of waĆ

ter.

Vent pipe - Must be inspected for signs of water, damĆ

aged or sagging pipe, or disconnected joints.

Unit appearance - Must be inspected for rust, dirt, signs

of water, burnt or damaged wires, or components.

Fan access door - Must be properly in place and provide

a seal between the return air and the room where the furĆ

nace is installed.

Return air duct - Must be properly attached and provide

an air seal to unit.

Operating performance - Unit must be observed during

operation to monitor proper performance of the unit and

the vent system.

Combustion gases - Flue products must be analyzed

and compared to the unit specifications.

Problems detected during the inspection may make it

necessary to temporarily shut down the furnace until the

items can be repaired or replaced.

Pay attention to your furnace. Situations can arise beĆ

tween annual furnace inspections that may result in unĆ

safe operation. For instance, items innocently stored next

to the furnace may obstruct the combustion air supply.

This could cause incomplete combustion and the producĆ

tion of carbon monoxide gas.

Page 6

Loading...

Loading...