Page 1

PRODUCT LITERATURE

¤

1998 Lennox Industries Inc.

503,891M

9/98

Supersedes 503,299M

Dallas, Texas

£

G24E

SERIES

GAS FURNACE

0$.(5·6

This appliance complies

with the requirements of

THE AUSTRALIAN

GAS ASSOCIATION

:$55$17<

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

:$51,1*

Litho U.S.A.

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any otherappliance.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Extinguish any open flames.

Do not touch any electrical switch; do not

use any phone in your building.

Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

If you cannot reach your gas supplier, call

the fire department.

Page 1

Page 2

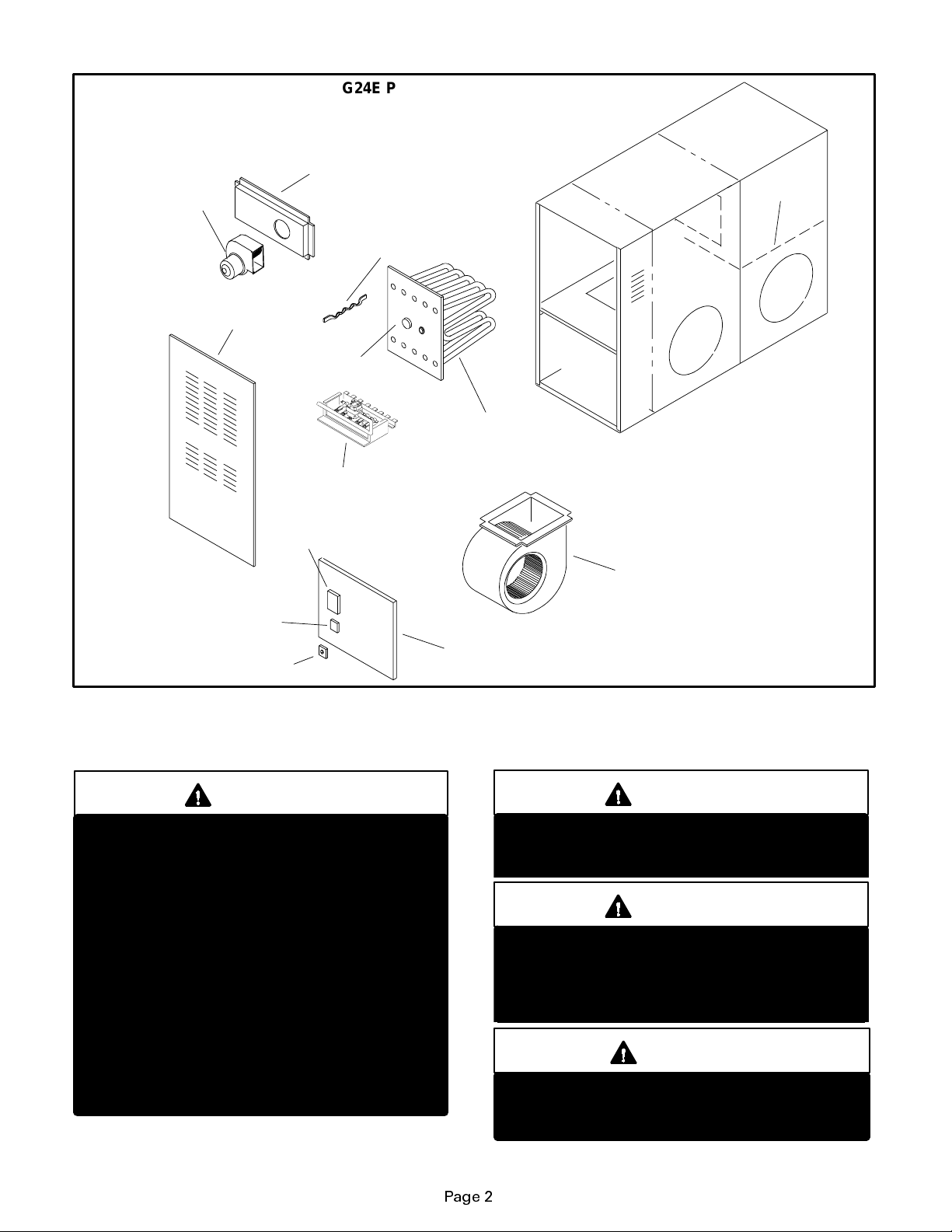

COMBUSTION AIR

BLOWER

FRONT LOUVERED

G24E PARTS IDENTIFICATION

FLUE BOX

COIL DECK

FLUE BAFFLES

(75 only)

PANEL

PRESSURE

SWITCH

HEAT EXCHANGER

ASSEMBLY

BURNER ASSEMBLY

CONTROL BOARD

TRANSFORMER

DOOR INTERLOCK SWITCH

WARNING

Product contains fiberglass wool.

Disturbing the insulation in this product during

installation, maintenance, or repair will expose

you to fiberglass wool. Breathing this may

causelungcancer.(Fiberglasswoolisknownto

the State of California to cause cancer.)

Fiberglass wool may also cause respiratory,

skin, and eye irritation.

To reduce exposure to this substance or for further information, consult material safety data

sheets available from address shown below, or

contact your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379-9900

BLOWER ASSEMBLY

BLOWER ACCESS

PANEL

WARNING

If overheating occurs or if gas supply fails to

shut off, shut offthemanualgasvalvetotheappliance before shutting off electrical supply.

WARNING

Do not use this furnace if any part has been

underwater.Immediatelycall a qualified service

technician to inspect the furnace and to replace

any part of the control system and any gas control which has been under water.

CAUTION

Before attempting to perform any service or

maintenance, turn the electrical power to unit

OFF at disconnect switch.

Page 2

Page 3

IMPORTANT

Any additions, changes, or conversions requiredinorderforthe appliance to satisfactorily

meet the application needs must be made by a

Lennox service technician using factory specified and approved parts.

IMPORTANT DIRECTIONS

1 - Keep the furnace area clear and free of combustible

material,gasoline,andotherflammablevaporsandliquids. If installed in an insulated area, furnace must be

kept free of insulating material. Insulating material may

be combustible. Inspect furnace venting system to

make sure it is in place, physically sound, and without

holes, corrosion, or blockage. Inspect furnace return

air duct connection to ensure duct is sealed to the furnace and terminates outside the space containing the

furnace. Inspect the physical support of the furnace to

guarantee that it is sound without sagging, cracks or

gaps around base and it maintains seal between base

and support.

2 - DO NOT obstruct air flow to unit. Unit must receive an

unobstructed flow of combustion and ventilating air.

3 - DO NOT store chlorine or fluorineproducts near unit or

introduce these products into the combustion air.

These products can cause furnace corrosion.

LIGHTING INFORMATION AND OPERATION

4 - This appliance Is equipped with an ignition device

which automatically lights the burner. Do

light the burner by hand.

5 - Remove control access panel.

6-

White Rodgers 36E Gas Valve -

valve 180qeither way to

OFF

Honeywell VR8205 Gas Valve -

valve clockwise

3.

THERMOSTATS

WHITE RODGERS 36E SERIES GAS VALVE

12

2))

OFF

to

FIGURE 1

Turn knob on gas

. See figure 2.

Turn knob on gas

. Do not force. Seefigure

not

try to

WARNING

If you do not follow these instructions exactly,a

fire or explosion may result causing property

damage, personal injury or loss of life.

BEFORE LIGHTING smell all around the appliance

area forgas.Be sure to smell nextto the floor because

some gas is heavier than air and will settle on the

floor.

Use only your hand to push in or turn the gas control

knob. Never usetools.Ifthe knob will not push in orturn

by hand, do not try to repair it, call a qualified service

technician. Force or attempted repairmayresultina fire

or explosion.

To place G24E furnace into operation:

G24E units are equipped with an electronic ignition sys-

tem. Do not

furnaces. Each time thermostat calls for heat, the burn-

er will automatically light.

Gas Valve Operation (Figures 2 and 3)

STOP

1-

of this section.

2 - Set thermostat to lowest setting. See figure 1.

3 - Turn off all electrical power to appliance.

attempt to manually light burners on these

! Read the safety information at the beginning

GAS VALVE SHOWN IN OFF POSITION

FIGURE 2

HONEYWELL VR8205SERIESGASVALVE

ON

OFF

GAS VALVE SHOWN IN OFF POSITION

FIGURE 3

7 - Wait five (5) minutes to clear out any gas. If you then

smell gas,

from a neighbor’s phone. Follow the gas supplier’s

instructions. If you do not smell gas go to next step.

8-

White Rodgers 36E Gas Valve -

valve 180qeither way toON.

Honeywell VR8205 Gas Valve -

valve counterclockwise

STOP

! Immediately call your gas supplier

Turn knob on gas

Turn knob on gas

toON. Do not force.

Page 3

Page 4

9 - Replace control access panel.

10- Turn on all electrical power to unit.

11- Set thermostat to desired setting.

NOTE-When unit is first started, steps 1 through 1 1 may

needtoberepeatedtopurgeairfromgasline.

12- If the appliance still will not operate, follow the

instructions “To Turn Off Gas To Unit” and call your

service technician or gas supplier.

To Turn Off Gas To Unit

1 - Set thermostat to lowest setting.

2 - Turn off all electrical power to unit if service is to be

performed.

3 - Remove control access panel.

4 - TurnknobonWhite Rodgers gas valve 180qeitherway

toOFF; turn knobon Honeywell valve clockwise

to

OFF. Do not force.

5 - Replace control access panel.

BLOWER

Check and clean blower wheel for any debris. Blower

motor is prelubricated for extended bearing life. No

further lubrication is needed.

WARNING

Blower door must be securely in place when

blower and burners are operating. Gas fumes,

which could contain carbon monoxide, can be

drawn into living space resulting in personal injury or death.

BURNER FLAME

The G24E burner flame is not adjustable; however,

the flame should be inspected at the beginning of

each heating season and burners should be cleaned,

if necessary. Burner flameshould bebluewhenburn-

ing natural gas, blue/yellow when burning propane

gas.

BURNER FLAME

FLAME APPEARS BLUE IF

BURNING NAT.GAS; BLUE/

YELLOW FOR PROP ANE.

BURNER

FLAME

EXCHANGER

VEST

PANEL

HEAT

TUBE

FIGURE 4

VENTING SYSTEM INSPECTION

Annually (before heating season) inspect furnace

venting system, vent cap, heat exchanger and burn-

ers for corrosion, deterioration, or deposits of debris.

Remove any obstructions.

Contact your Lennoxdealerfor a periodic unit inspec-

tion by a qualified service technician.

FLAME ROLLOUT SAFETY SWITCHES

Your Lennox furnace is equipped with two flame roll--

out safety switches which shut off the gas supply to

the furnace in case of heat exchanger blockage. If the

furnace failstooperate dueto the functioning ofthese

safety switches, DO NOT attempt to place the furnace

into operation. Contact a qualified service technician.

SERVICE REMINDER

Call your Lennox service technician if unit is inopera-

tive. Before calling, always check the following to be

sure service is required.

1 - Check that electrical disconnect switches are ON.

2 - Check room thermostat for proper setting.

3 - Replace any blown fuses or reset circuit breakers.

4 - Gas valve should be ON.

5 - Air filter should not be plugged limiting air flow.

6 - Is gas turned on at meter?

7 - Is manual main shut-off valve open?

To keep your Lennox gas heating system in peak op-

erating condition year after year, contact your inde-

pendent Lennox dealer about a planned service pro-

gram.

Page 4

Loading...

Loading...