Page 1

G23(X)

GasPipingSizeI.P.S.

GasPipingSizeI.P.S.

Blowerwheelnomina

l

Blowerwheelnomina

l

Nominalcoolin

g

Nominalcoolin

g

Corp. 9814-L8

Service Literature

G23(X) SERIES UNITS

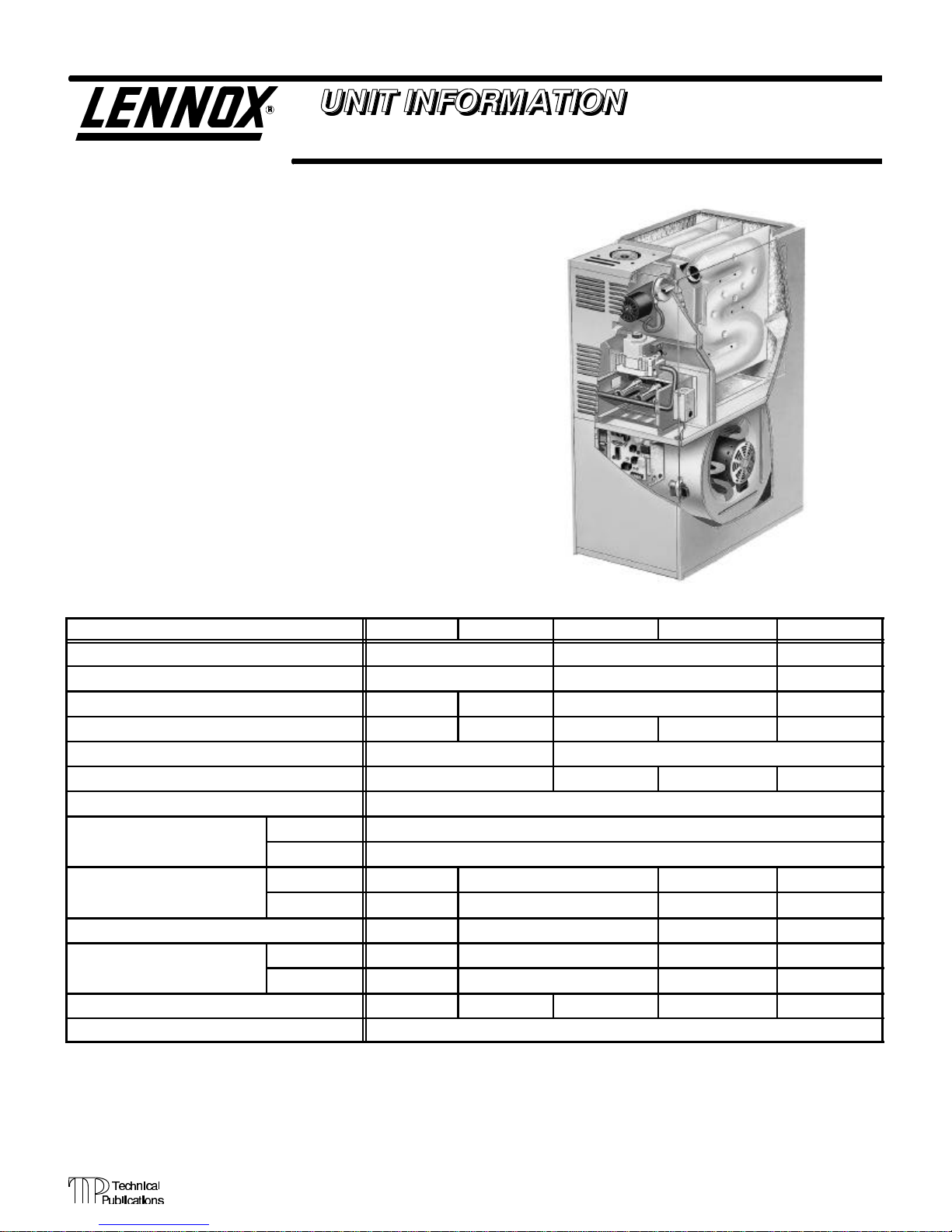

G23(X) series units are mid-efficiency upflow gas furnaces manufactured with Duralokt aluminized steel

clamshell type heat exchangers. G23(X) units are available in heating capacities of 50,000 to 150,000 Btuh and

cooling applications up to 6 tons. Refer to Engineering

Handbook for proper sizing.

Unitsare factory equipped for use with natural gas. A kit is

availablefor conversionto LPG operation.G23(X)-1, -2, -3

and-4modelunitsuse electronic(intermittentpilot)ignition.

G23(X)-5 and -6 model units feature the Lennox SureLightT silicon nitride ignition system. All units meet the

CaliforniaNitrogenOxides(NOx) Standardsand California

Seasonal Efficiency requirements with the installation of

flamebaffles.Allunitsusea redundantgasvalveto assure

safety shut-off as required by A.G.A. or C.G.A.

Informationcontainedin this manual is intendedforuse by

qualified service technicians only. All specifications are

subject to change. Procedures outlined in this manual are

presented as a recommendation only and do not supersede or replace local or state codes. In the absence of local or state codes, the guidelines and procedures outlined

in this manual (except where noted) are recommended

only.

Model No. G23Q2(X)-50 G23Q3(X)-50 G23Q2/3(X)-75 G23Q4/5(X)-75 G23Q3(X)-100

Input Btuh(kW) 50,000 (14.7) 75,000 (22.0) 100,000 (29.3)

Output Btuh (kW) 40,000 (11.7) 61,000(17.8) 80,000 (23.4)

lA.F.U.E. 80.7% 80.8% 80.4% 80.1%

California Seasonal Efficiency 75.5% 75.6% 76.9% 74.2% 76.6%

Flue size connection diameter— in. (mm) round 3 (76) 4 (102)

Temperature riserange — _F (_C) 30-60 (17-33) 35-65 (19-36) 20-50 (11-28) 45-75 (25-42)

High static certified by A.G.A. — in wg.(Pa) .50 (125)

in. 1/2

Natural or LPG/propane

diameter x width

Blower motor output — hp (W) 1/5 (149) 1/3 (249) 3/4 (560) 1/3 (249)

that canbe added

Shipping weight — lbs. (kg) 1 package 135 (61) 140 (64) 146 (66) 186 (84) 159 (72)

Electrical characteristics 120 volts — 60 hertz — 1 phase (all models) (less than12 amps)

lAnnual Fuel Utilization Efficiency based on U.S. DOE test procedures and FTC labeling regulations. Isolated combustion system rating for non-weatherized furnaces.

}Cleanable polyurethane frame type filter.

mm 12.7

in. 10 x 7 10 x 8 11-1/2 x 9 10 x 8

mm 254 x 178 254 x 203 292 x 229 254 x 203

Tons 1 to 2 1 to 3 3-1/2 to 5 1 to 3

kW 3.5 to 7.0 3.5 to 10.6 12.3 to 17.6 3.5 to 10.6

Revised 08-2001

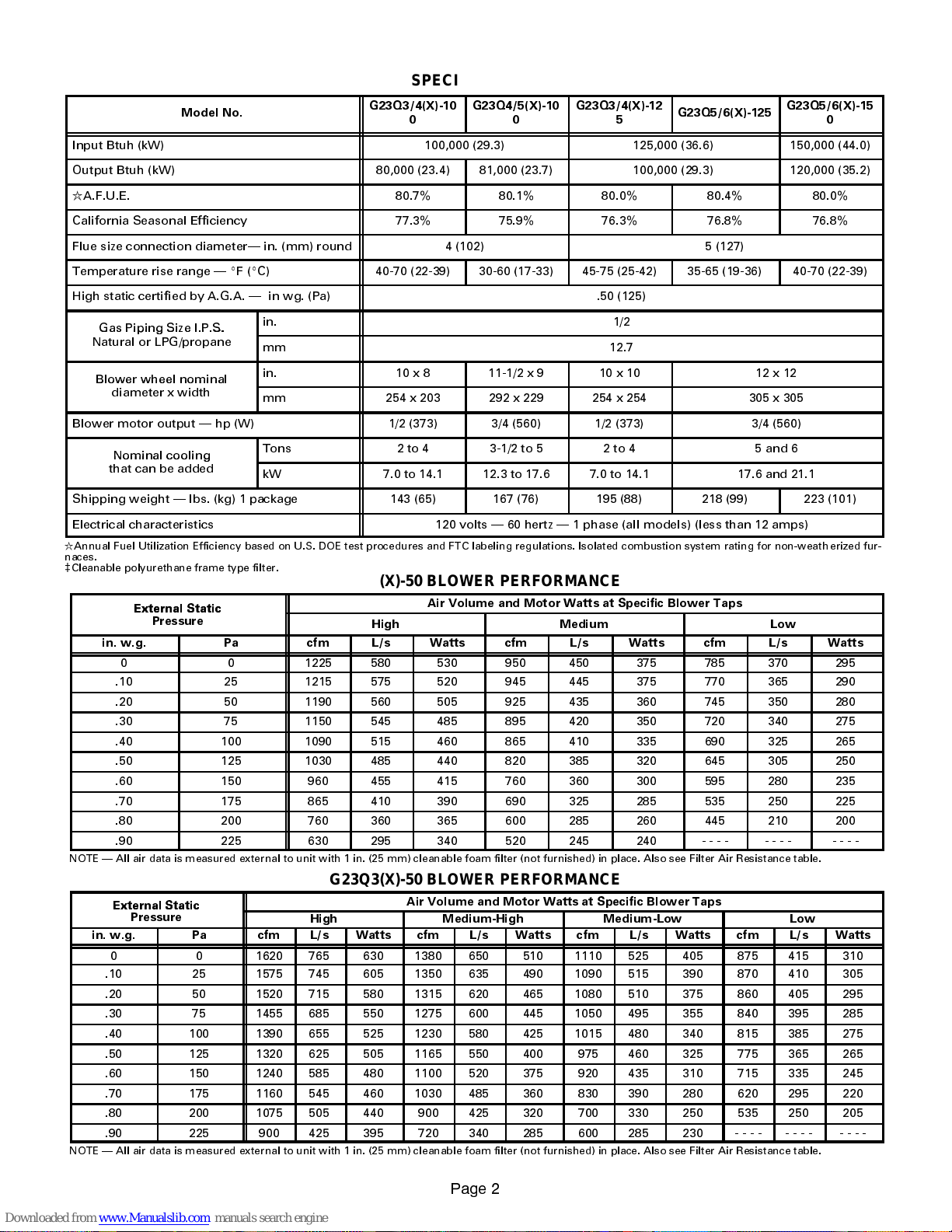

SPECIFICATIONS

Page 1

ã 1998 Lennox Industries Inc.

Page 2

SPECIFICATIONS

Gas Piping Size I.P.S

Blower wheel nominal

Nominal cooling

External Static

External Static

Model No.

Input Btuh (kW) 100,000 (29.3) 125,000 (36.6) 150,000 (44.0)

Output Btuh (kW) 80,000 (23.4) 81,000 (23.7) 100,000 (29.3) 120,000 (35.2)

R

A.F.U.E. 80.7% 80.1% 80.0% 80.4% 80.0%

California Seasonal Efficiency 77.3% 75.9% 76.3% 76.8% 76.8%

Flue size connection diameter in. (mm) round 4 (102) 5 (127)

Temperature rise range EF(EC) 40-70 (22-39) 30-60 (17-33) 45-75 (25-42) 35-65 (19-36) 40-70 (22-39)

High static certified by A.G.A. in wg. (Pa) .50 (125)

Gas Piping Size I.P.S.

Natural or LPG/propane

Blower wheel nominal

diameter x width

Blower motor output hp (W) 1/2 (373) 3/4 (560) 1/2 (373) 3/4 (560)

Nominal cooling

that can be added

Shipping weight lbs. (kg) 1 package 143 (65) 167 (76) 195 (88) 218 (99) 223 (101)

Electrical characteristics 120 volts 60 hertz 1 phase (all models) (less than 12 amps)

R

Annual Fuel Utilization Efficiency based on U.S. DOE test procedures and FTC labeling regulations. Isolated combustion system rating for non-weath erized fur-

naces.

c

Cleanable polyurethane frame type filter.

in. 1/2

.

mm 12.7

in. 10x8 11-1/2 x 9 10x10 12x12

mm 254 x 203 292 x 229 254 x 254 305 x 305

Tons 2to4 3-1/2 to 5 2to4 5 and 6

kW 7.0 to 14.1 12.3 to 17.6 7.0 to 14.1 17.6 and 21.1

G23Q3/4(X)-100G23Q4/5(X)-100G23Q3/4(X)-12

5

G23Q5/6(X)-125

G23Q5/6(X)-15

0

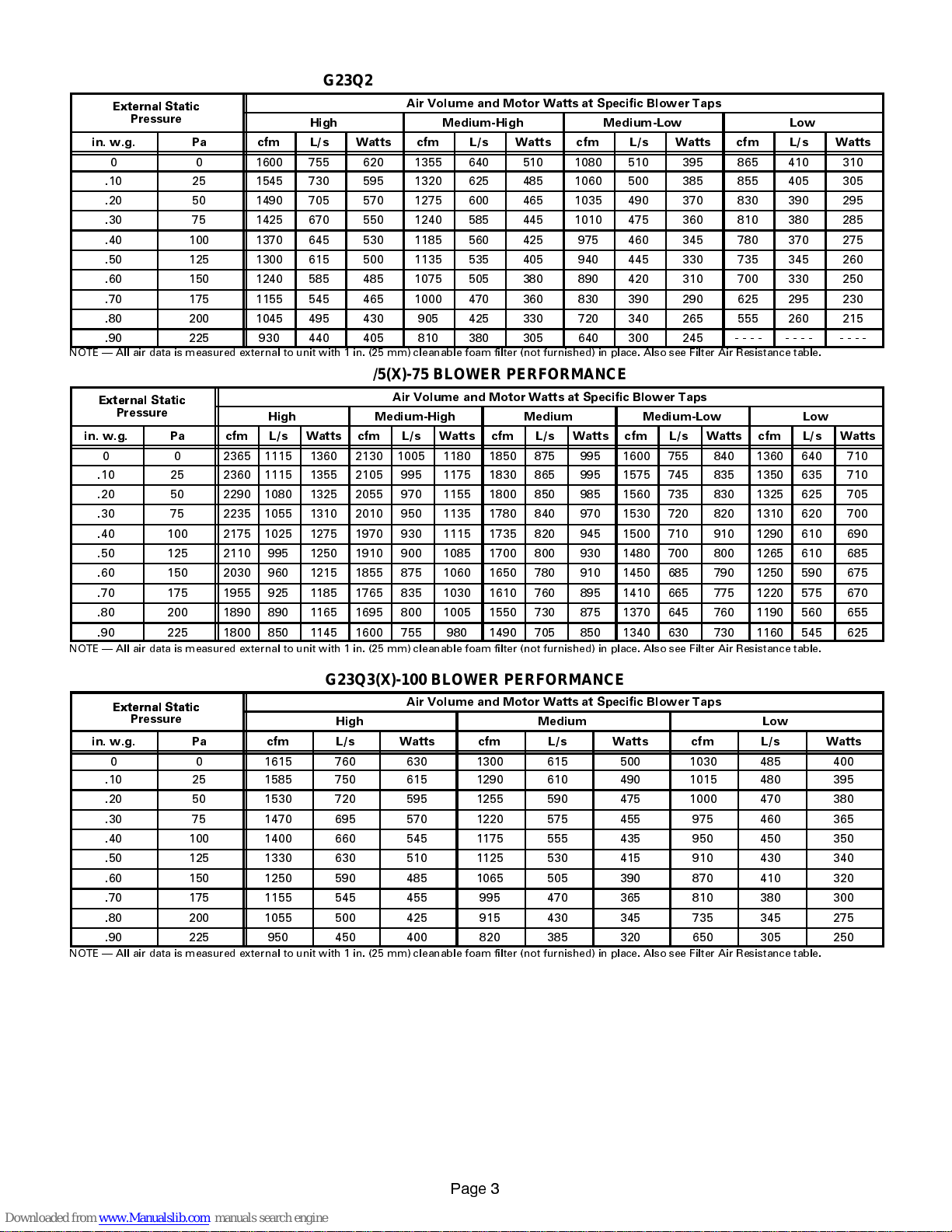

G23Q2(X)-50 BLOWER PERFORMANCE

Air Volume and Motor Watts at Specific Blower Taps

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 1225 580 530 950 450 375 785 370 295

.10 25 1215 575 520 945 445 375 770 365 290

.20 50 1190 560 505 925 435 360 745 350 280

.30 75 1150 545 485 895 420 350 720 340 275

.40 100 1090 515 460 865 410 335 690 325 265

.50 125 1030 485 440 820 385 320 645 305 250

.60 150 960 455 415 760 360 300 595 280 235

.70 175 865 410 390 690 325 285 535 250 225

.80 200 760 360 365 600 285 260 445 210 200

.90 225 630 295 340 520 245 240 ---- ---- ----

NOTE All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High Medium Low

G23Q3(X)-50 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 1620 765 630 1380 650 510 1110 525 405 875 415 310

.10 25 1575 745 605 1350 635 490 1090 515 390 870 410 305

.20 50 1520 715 580 1315 620 465 1080 510 375 860 405 295

.30 75 1455 685 550 1275 600 445 1050 495 355 840 395 285

.40 100 1390 655 525 1230 580 425 1015 480 340 815 385 275

.50 125 1320 625 505 1165 550 400 975 460 325 775 365 265

.60 150 1240 585 480 1100 520 375 920 435 310 715 335 245

.70 175 1160 545 460 1030 485 360 830 390 280 620 295 220

.80 200 1075 505 440 900 425 320 700 330 250 535 250 205

.90 225 900 425 395 720 340 285 600 285 230 ---- ---- ----

NOTE All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High Medium-High Medium-Low Low

Air Volume and Motor Watts at Specific Blower Taps

3DJH

Page 3

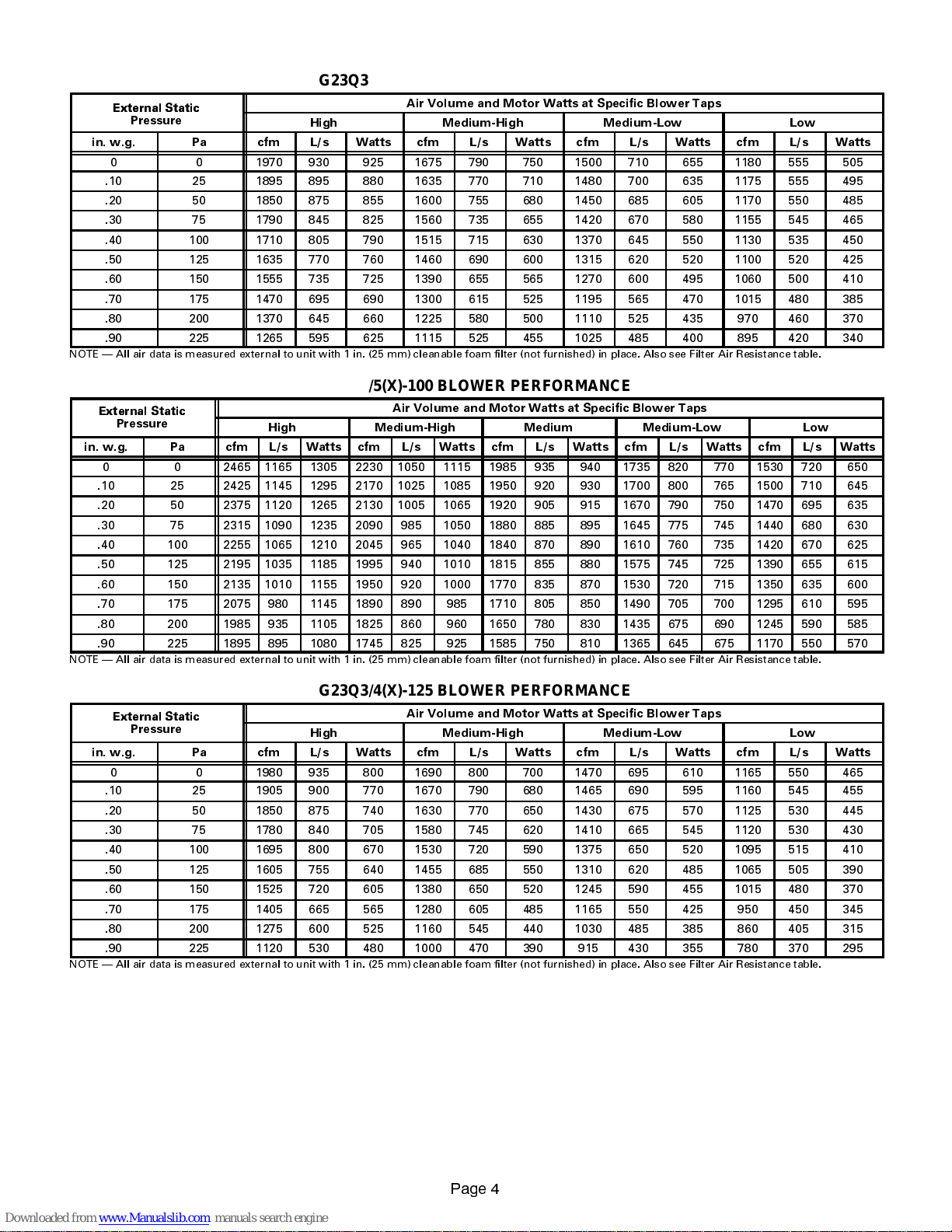

G23Q2/3(X)-75 BLOWER PERFORMANCE

External Static

External Static

External Static

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 1600 755 620 1355 640 510 1080 510 395 865 410 310

.10 25 1545 730 595 1320 625 485 1060 500 385 855 405 305

.20 50 1490 705 570 1275 600 465 1035 490 370 830 390 295

.30 75 1425 670 550 1240 585 445 1010 475 360 810 380 285

.40 100 1370 645 530 1185 560 425 975 460 345 780 370 275

.50 125 1300 615 500 1135 535 405 940 445 330 735 345 260

.60 150 1240 585 485 1075 505 380 890 420 310 700 330 250

.70 175 1155 545 465 1000 470 360 830 390 290 625 295 230

.80 200 1045 495 430 905 425 330 720 340 265 555 260 215

.90 225 930 440 405 810 380 305 640 300 245 ---- ---- ----

NOTE All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High Medium-High Medium-Low Low

Air Volume and Motor Watts at Specific Blower Taps

G23Q4/5(X)-75 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 2365 1115 1360 2130 1005 1180 1850 875 995 1600 755 840 1360 640 710

.10 25 2360 1115 1355 2105 995 1175 1830 865 995 1575 745 835 1350 635 710

.20 50 2290 1080 1325 2055 970 1155 1800 850 985 1560 735 830 1325 625 705

.30 75 2235 1055 1310 2010 950 1135 1780 840 970 1530 720 820 1310 620 700

.40 100 2175 1025 1275 1970 930 1115 1735 820 945 1500 710 910 1290 610 690

.50 125 2110 995 1250 1910 900 1085 1700 800 930 1480 700 800 1265 610 685

.60 150 2030 960 1215 1855 875 1060 1650 780 910 1450 685 790 1250 590 675

.70 175 1955 925 1185 1765 835 1030 1610 760 895 1410 665 775 1220 575 670

.80 200 1890 890 1165 1695 800 1005 1550 730 875 1370 645 760 1190 560 655

.90 225 1800 850 1145 1600 755 980 1490 705 850 1340 630 730 1160 545 625

NOTE All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High Medium-High Medium Medium-Low Low

Air Volume and Motor Watts at Specific Blower Taps

G23Q3(X)-100 BLOWER PERFORMANCE

Air Volume and Motor Watts at Specific Blower Taps

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 1615 760 630 1300 615 500 1030 485 400

.10 25 1585 750 615 1290 610 490 1015 480 395

.20 50 1530 720 595 1255 590 475 1000 470 380

.30 75 1470 695 570 1220 575 455 975 460 365

.40 100 1400 660 545 1175 555 435 950 450 350

.50 125 1330 630 510 1125 530 415 910 430 340

.60 150 1250 590 485 1065 505 390 870 410 320

.70 175 1155 545 455 995 470 365 810 380 300

.80 200 1055 500 425 915 430 345 735 345 275

.90 225 950 450 400 820 385 320 650 305 250

NOTE All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High Medium Low

3DJH

Page 4

G23Q3/4(X)-100 BLOWER PERFORMANCE

External Static

External Static

External Static

Air Volume and Motor Watts at Specific Blower Taps

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 1970 930 925 1675 790 750 1500 710 655 1180 555 505

.10 25 1895 895 880 1635 770 710 1480 700 635 1175 555 495

.20 50 1850 875 855 1600 755 680 1450 685 605 1170 550 485

.30 75 1790 845 825 1560 735 655 1420 670 580 1155 545 465

.40 100 1710 805 790 1515 715 630 1370 645 550 1130 535 450

.50 125 1635 770 760 1460 690 600 1315 620 520 1100 520 425

.60 150 1555 735 725 1390 655 565 1270 600 495 1060 500 410

.70 175 1470 695 690 1300 615 525 1195 565 470 1015 480 385

.80 200 1370 645 660 1225 580 500 1110 525 435 970 460 370

.90 225 1265 595 625 1115 525 455 1025 485 400 895 420 340

NOTE All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High Medium-High Medium-Low Low

G23Q4/5(X)-100 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 2465 1165 1305 2230 1050 1115 1985 935 940 1735 820 770 1530 720 650

.10 25 2425 1145 1295 2170 1025 1085 1950 920 930 1700 800 765 1500 710 645

.20 50 2375 1120 1265 2130 1005 1065 1920 905 915 1670 790 750 1470 695 635

.30 75 2315 1090 1235 2090 985 1050 1880 885 895 1645 775 745 1440 680 630

.40 100 2255 1065 1210 2045 965 1040 1840 870 890 1610 760 735 1420 670 625

.50 125 2195 1035 1185 1995 940 1010 1815 855 880 1575 745 725 1390 655 615

.60 150 2135 1010 1155 1950 920 1000 1770 835 870 1530 720 715 1350 635 600

.70 175 2075 980 1145 1890 890 985 1710 805 850 1490 705 700 1295 610 595

.80 200 1985 935 1105 1825 860 960 1650 780 830 1435 675 690 1245 590 585

.90 225 1895 895 1080 1745 825 925 1585 750 810 1365 645 675 1170 550 570

NOTE All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High Medium-High Medium Medium-Low Low

Air Volume and Motor Watts at Specific Blower Taps

G23Q3/4(X)-125 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 1980 935 800 1690 800 700 1470 695 610 1165 550 465

.10 25 1905 900 770 1670 790 680 1465 690 595 1160 545 455

.20 50 1850 875 740 1630 770 650 1430 675 570 1125 530 445

.30 75 1780 840 705 1580 745 620 1410 665 545 1120 530 430

.40 100 1695 800 670 1530 720 590 1375 650 520 1095 515 410

.50 125 1605 755 640 1455 685 550 1310 620 485 1065 505 390

.60 150 1525 720 605 1380 650 520 1245 590 455 1015 480 370

.70 175 1405 665 565 1280 605 485 1165 550 425 950 450 345

.80 200 1275 600 525 1160 545 440 1030 485 385 860 405 315

.90 225 1120 530 480 1000 470 390 915 430 355 780 370 295

NOTE All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High Medium-High Medium-Low Low

Air Volume and Motor Watts at Specific Blower Taps

3DJH

Page 5

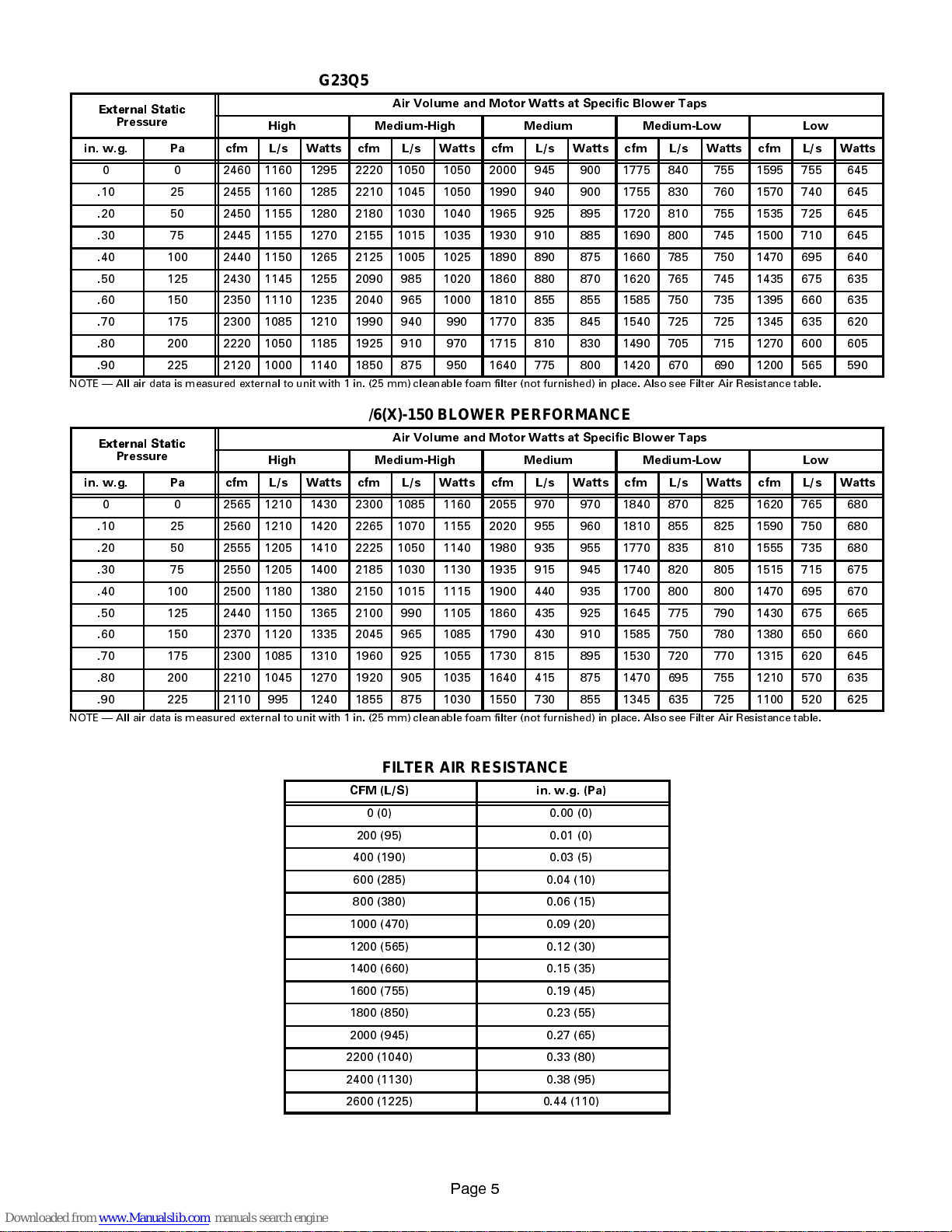

G23Q5/6(X)-125 BLOWER PERFORMANCE

External Static

External Static

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 2460 1160 1295 2220 1050 1050 2000 945 900 1775 840 755 1595 755 645

.10 25 2455 1160 1285 2210 1045 1050 1990 940 900 1755 830 760 1570 740 645

.20 50 2450 1155 1280 2180 1030 1040 1965 925 895 1720 810 755 1535 725 645

.30 75 2445 1155 1270 2155 1015 1035 1930 910 885 1690 800 745 1500 710 645

.40 100 2440 1150 1265 2125 1005 1025 1890 890 875 1660 785 750 1470 695 640

.50 125 2430 1145 1255 2090 985 1020 1860 880 870 1620 765 745 1435 675 635

.60 150 2350 1110 1235 2040 965 1000 1810 855 855 1585 750 735 1395 660 635

.70 175 2300 1085 1210 1990 940 990 1770 835 845 1540 725 725 1345 635 620

.80 200 2220 1050 1185 1925 910 970 1715 810 830 1490 705 715 1270 600 605

.90 225 2120 1000 1140 1850 875 950 1640 775 800 1420 670 690 1200 565 590

NOTE All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High Medium-High Medium Medium-Low Low

Air Volume and Motor Watts at Specific Blower Taps

G23Q5/6(X)-150 BLOWER PERFORMANCE

External Static

Pressure

in. w.g. Pa cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts cfm L/s Watts

0 0 2565 1210 1430 2300 1085 1160 2055 970 970 1840 870 825 1620 765 680

.10 25 2560 1210 1420 2265 1070 1155 2020 955 960 1810 855 825 1590 750 680

.20 50 2555 1205 1410 2225 1050 1140 1980 935 955 1770 835 810 1555 735 680

.30 75 2550 1205 1400 2185 1030 1130 1935 915 945 1740 820 805 1515 715 675

.40 100 2500 1180 1380 2150 1015 1115 1900 440 935 1700 800 800 1470 695 670

.50 125 2440 1150 1365 2100 990 1105 1860 435 925 1645 775 790 1430 675 665

.60 150 2370 1120 1335 2045 965 1085 1790 430 910 1585 750 780 1380 650 660

.70 175 2300 1085 1310 1960 925 1055 1730 815 895 1530 720 770 1315 620 645

.80 200 2210 1045 1270 1920 905 1035 1640 415 875 1470 695 755 1210 570 635

.90 225 2110 995 1240 1855 875 1030 1550 730 855 1345 635 725 1100 520 625

NOTE All air data is measured external to unit with 1 in. (25 mm) cleanable foam filter (not furnished) in place. Also see Filter Air Resistance table.

High Medium-High Medium Medium-Low Low

Air Volume and Motor Watts at Specific Blower Taps

FILTER AIR RESISTANCE

CFM (L/S) in. w.g. (Pa)

0 (0) 0.00 (0)

200 (95) 0.01 (0)

400 (190) 0.03 (5)

600 (285) 0.04 (10)

800 (380) 0.06 (15)

1000 (470) 0.09 (20)

1200 (565) 0.12 (30)

1400 (660) 0.15 (35)

1600 (755) 0.19 (45)

1800 (850) 0.23 (55)

2000 (945) 0.27 (65)

2200 (1040) 0.33 (80)

2400 (1130) 0.38 (95)

2600 (1225) 0.44 (110)

3DJH

Page 6

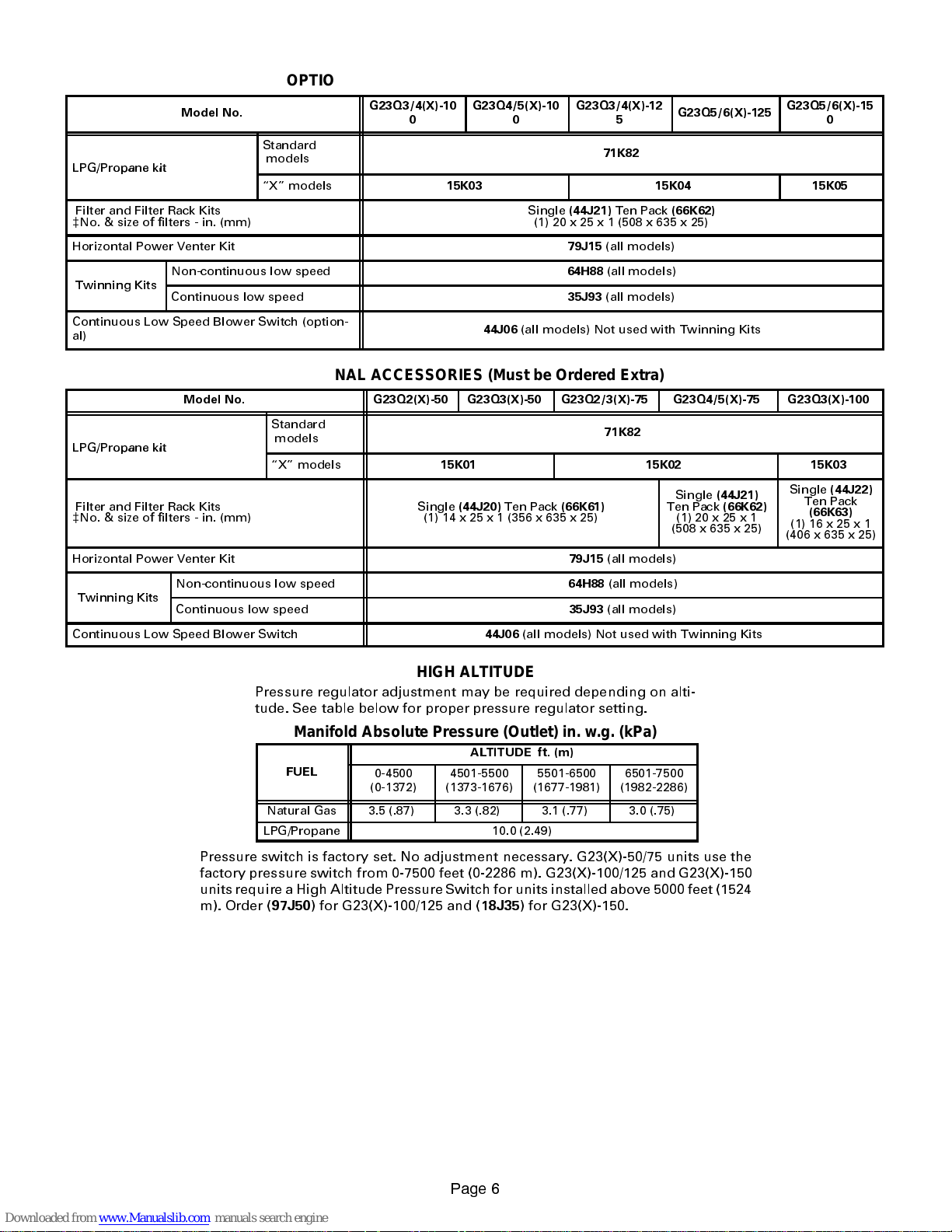

OPTIONAL ACCESSORIES (Must be Ordered Extra)

LPG/Propane kit

LPG/Propane kit

Model No.

Standard

LPG/Propane kit

Filter and Filter Rack Kits

c

No. & size of filters - in. (mm)

Horizontal Power Venter Kit

Twinning Kits

Continuous Low Speed Blower Switch (option-

al)

Non-continuous low speed

Continuous low speed

models

X models

OPTIONAL ACCESSORIES (Must be Ordered Extra)

Model No. G23Q2(X)-50 G23Q3(X)-50 G23Q2/3(X)-75 G23Q4/5(X)-75 G23Q3(X)-100

Standard

LPG/Propane kit

Filter and Filter Rack Kits

c

No. & size of filters - in. (mm)

Horizontal Power Venter Kit

Twinning Kits

Continuous Low Speed Blower Switch

Non-continuous low speed

Continuous low speed

models

X models

G23Q3/4(X)-100G23Q4/5(X)-100G23Q3/4(X)-12

15K03 15K04 15K05

Single

(44J21)

(1) 20 x 25 x 1 (508 x 635 x 25)

79J15

64H88

35J93

44J06

(all models) Not used with Twinning Kits

15K01 15K02 15K03

Single

(44J20)

(1) 14 x 25 x 1 (356 x 635 x 25)

Ten Pack

44J06

(66K61)

79J15

64H88

35J93

(all models) Not used with Twinning Kits

5

71K82

Ten Pack

(all models)

(all models)

(all models)

71K82

(all models)

(all models)

(all models)

G23Q5/6(X)-125

(66K62)

Single

Ten Pack

(44J21)

(66K62)

(1) 20 x 25 x 1

(508 x 635 x 25)

G23Q5/6(X)-15

0

Single

(44J22)

Ten Pack

(66K63)

(1)16x25x1

(406 x 635 x 25)

HIGH ALTITUDE

Pressure regulator adjustment may be required depending on alti-

tude. See table below for proper pressure regulator setting.

Manifold Absolute Pressure (Outlet) in. w.g. (kPa)

ALTITUDE ft. (m)

FUEL

Natural Gas 3.5 (.87) 3.3 (.82) 3.1 (.77) 3.0 (.75)

LPG/Propane 10.0 (2.49)

Pressure switch is factory set. No adjustment necessary. G23(X)-50/75 units use the

factory pressure switch from 0-7500 feet (0-2286 m). G23(X)-100/125 and G23(X)-150

units require a High Altitude Pressure Switch for units installed above 5000 feet (1524

m). Order (

97J50

) for G23(X)-100/125 and (

0-4500

(0-1372)

4501-5500

(1373-1676)

18J35

5501-6500

(1677-1981)

) for G23(X)-150.

6501-7500

(1982-2286)

3DJH

Page 7

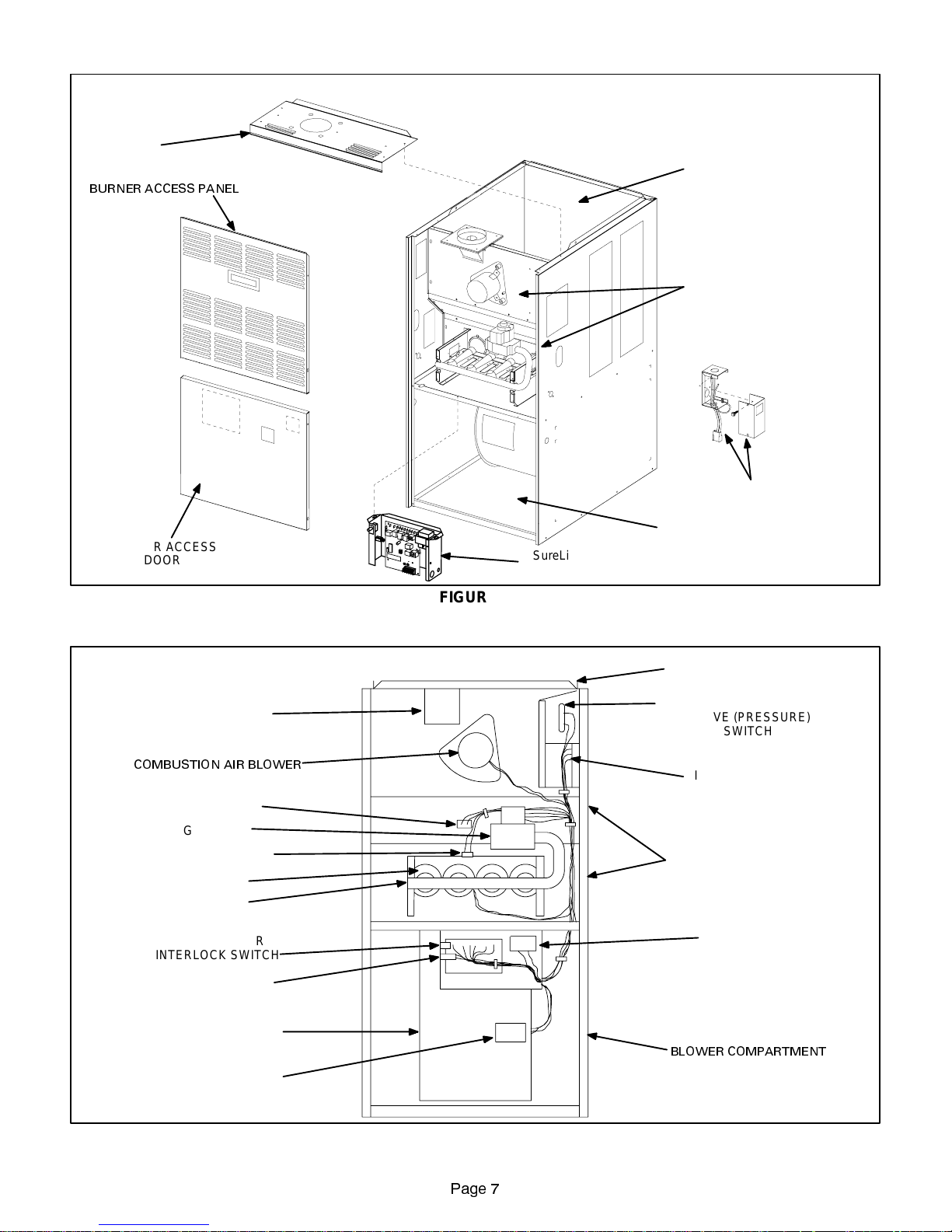

TOP PANEL

BURNER ACCESS PANEL

BLOWER ACCESS

DOOR

G23(X) ORIENTATION

SUPPLY AIR OPENING

HEATING COMPARTMENT

MAKE-UP BOX ASSEMBLY

BLOWER COMPARTMENT

SureLight Control

(-5 and -6 models only)

FLUE TRANSITION

COMBUSTION AIR BLOWER

PRIMARY LIMIT

GAS VALVE

ROLLOUT SWITCH

BURNERS

MANIFOLD

BLOWER DOOR

INTERLOCK SWITCH

CIRCUIT BREAKER

SUPPLY AIR BLOWER

FIGURE 1

G23(X) GENERAL PARTS ORIENTATION

SUPPLY AIR DUCT FLANGE

COMBUSTION AIR BLOWER

PROVE (PRESSURE)

SWITCH

IGNITION CONTROL

(-1 through -4 models only)

HEATING COMPARTMENT

CONTROL BOX

BLOWER COMPARTMENT

BLOWER CAPACITOR

FIGURE 2

3DJH

Page 8

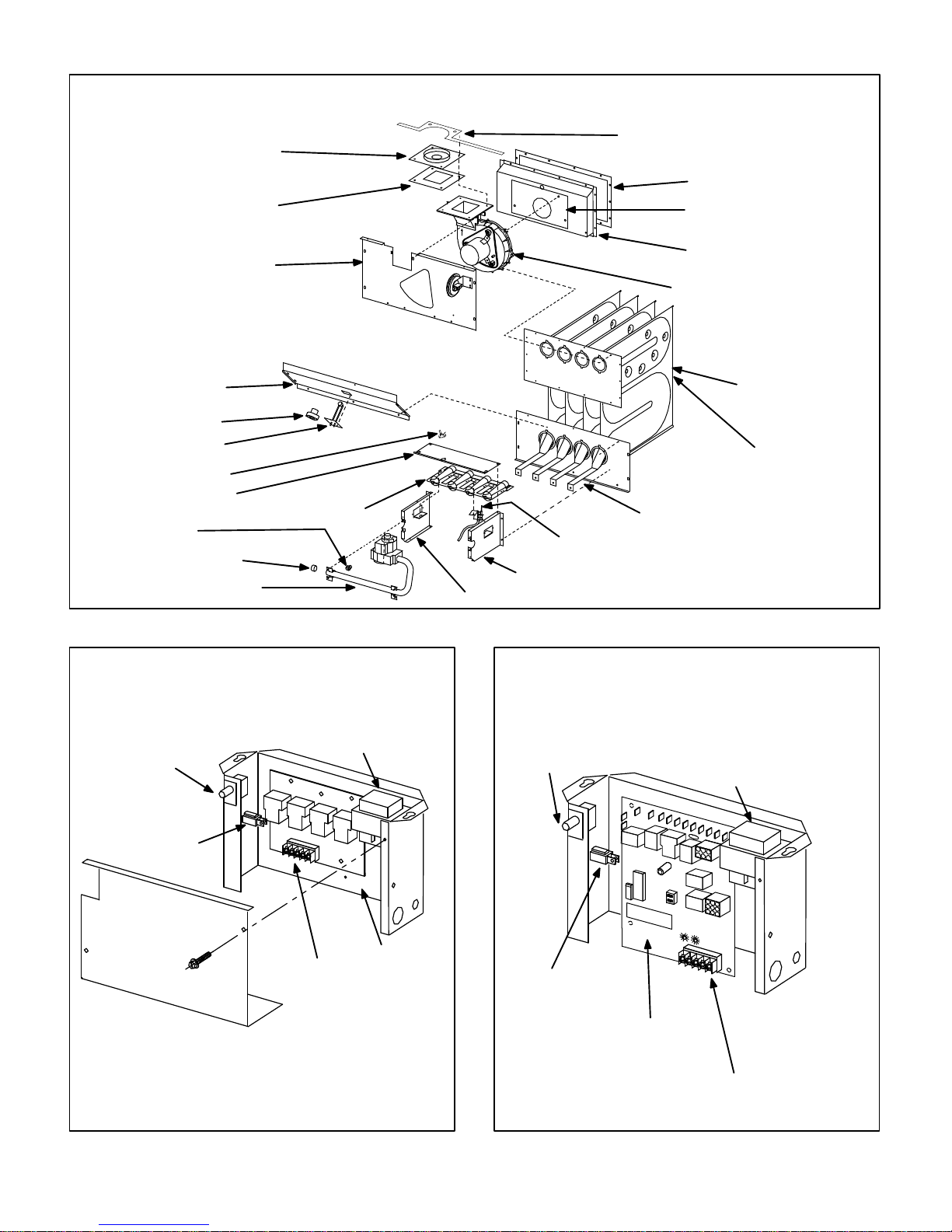

(FLUE TRANSITION ASSEMBLY)

FIGURE4

FIGURE5

ORIFICE PLATE

FLUE OUTLET

GLASS FIBER GASKET

UPPER VEST

PANEL

G23(X) HEAT EXCHANGE ASSEMBLY

-5 and -6 G23X Models

TOP CAP

GLASS FIBER

GASKET

FLUE BOX

GLASS FIBER GASKET

COMBUSTION BLOWER

GLASS FIBER GASKET

FLUE COLLECTOR

BOX

COMBUSTION AIR BLOWER

MID VEST PANEL

PRIMARY LIMIT

PRIMARY LIMIT

ALTERNATE STYLE

ROLLOUT SWITCH

ROLLOUT BRACKET

ORIFICE

MANIFOLD END PLUG

MANIFOLD AND GAS VALVE

CONTROL BOX

(-1 through -4 G23X models)

DOOR INTERLOCK

SWITCH

BURNER ASSEMBLY

TRANSFORMER

HEATEXCHANGER

(Heat Train

Assembly)

CLAMSHELL

(Each Segment)

FLAME BAFFLES (NOx UNITS ONLY)

FLAME SENSE ASSEMBLY

RIGHT MANIFOLD BRACKET

LEFT MANIFOLD BRACKET

FIGURE 3

CONTROL BOX

(-5 and -6 G23X models))

DOOR INTERLOCK

SWITCH

TRANSFORMER

CIRCUIT BREAKER

LOW VOLTAGE STRIP

BCC CONTROL

CIRCUIT BREAKER

SURELIGHT CONTROL

LOW VOLTAGE STRIP

Page 8

Page 9

I-UNIT COMPONENTS (Figures 1 and 2)

G23(X)unitcomponentsareshowninfigures1and2.The

gasvalve,ignitioncontrolandburnerscanbeaccessedby

removing the burner access panel. The blower, blower

control and SureLight control can be accessed by removing the blower access door.

G23(X) units are factory equipped with bottom and side return

air panels in place. The panels are designed to be field removed as required for bottom air return or side air return.

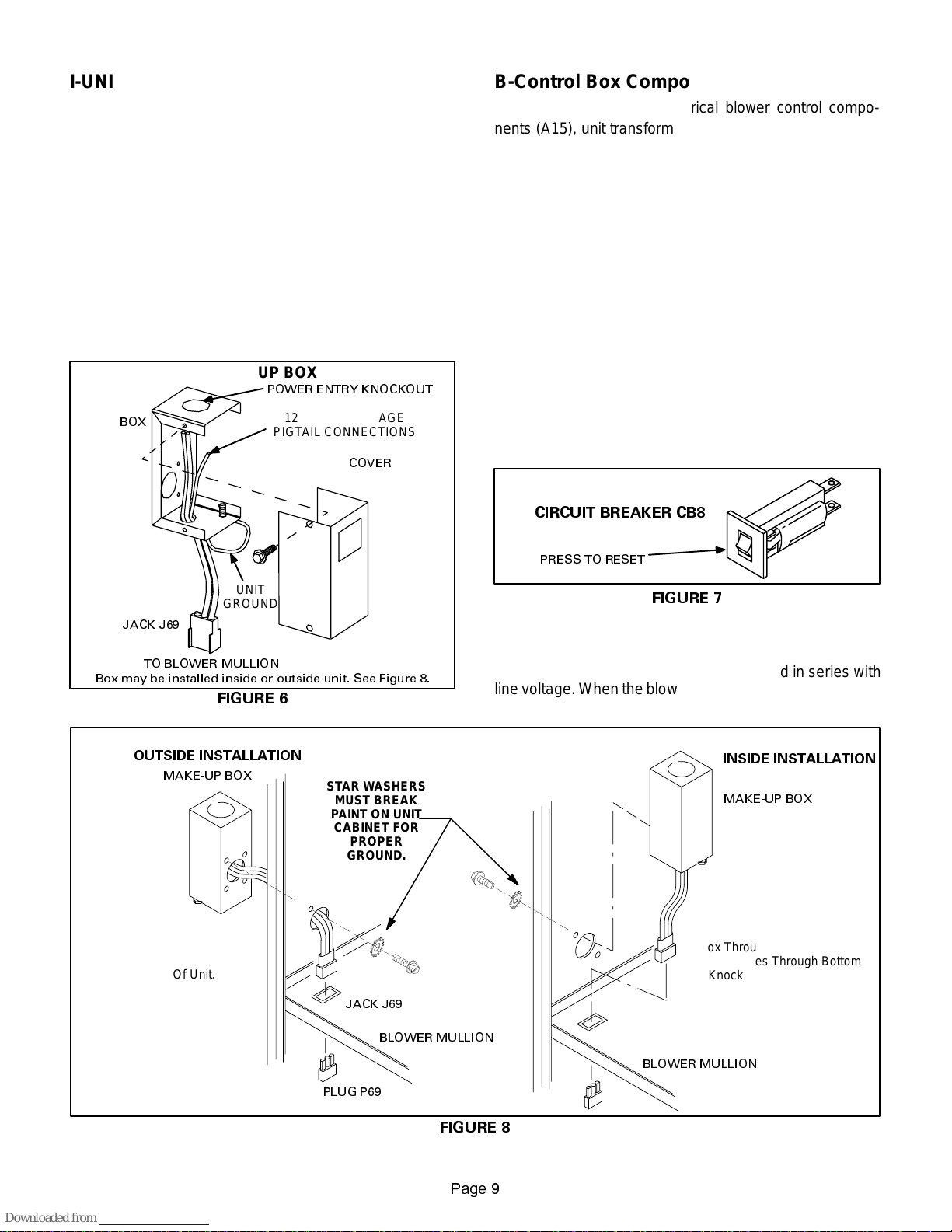

A-Make-Up Box (Figure 6)

Thelinevoltagemake-upboxisshowninfigure6.Thebox

may be installed inside or outside the unit and may be

installed on the unit left or right side (figure 8).

MAKE-UP BOX

POWER ENTRY KNOCKOUT

BOX

120V LINE VOLTAGE

PIGTAIL CONNECTIONS

COVER

B-Control Box Components (Figures 4 & 5)

SureLight control (A3), Electrical blower control components (A15), unit transformer (T1) and 24V circuit breaker

(CB8)are located in the controlbox. In addition, a door interlockswitch(S51)islocatedin thecontrolbox.Jackplugs

allow the control box to be easily removed for blower service.

1. Control Transformer (T1)

Atransformer locatedinthe controlbox provides powerto

thelow voltage 24volt section of the unit.Transformers on

all models are rated 40VA with a 120V primary and a 24V

secondary.

2. Circuit Breaker (CB8)

A24Vcircuit br eaker isalso locate d in the c ontrol box .

The switch provides ove rcurr ent protec tion to the

transformer ( T1). Thebreaker is rated3A at 32V.Ifthe

currente xcee dsthis limitthebreakerwill tr ipand allunit

operation will shut down. T he brea ker can bemanually

reset by pres sing the button on the face. See figure 7.

CIRCUIT BREAKER CB8

UNIT

GROUND

JACK J69

Box may be installed inside or outside unit. See Figure 8.

TO BLOWER MULLION

FIGURE 6

MAKE-UP BOX INSTALLATION

OUTSIDE INSTALLATION

MAKE-UP BOX

Line Voltage Enters Through

Knockout In Make-Up Box. J69

Passes Through Side Knockout

Into Side Of Unit.

Box may be installed inside or outside cabinet and may

be installed on left side or right side of cabinet

STARWASHERS

MUST BREAK

PAINT ON UNIT

CABINET FOR

PROPER

GROUND.

UNIT

CABINET

JACK J69

PRESS TO RESET

FIGURE 7

3.Door Interlock Switch (S51)

A door interlock switch rated 14A at 125VACislocated on

the blower access door.The switch is wired in series with

linevoltage. When the blower dooris removed theunitwill

shut down.

INSIDE INSTALLATION

MAKE-UP BOX

Line Voltage Enters Make-Up

Box Through Side Of Unit and

J69 Passes Through Bottom

Knockout in Make-Up Box.

BLOWER MULLION

BLOWER MULLION

PLUG P69

FIGURE 8

3DJH

Page 10

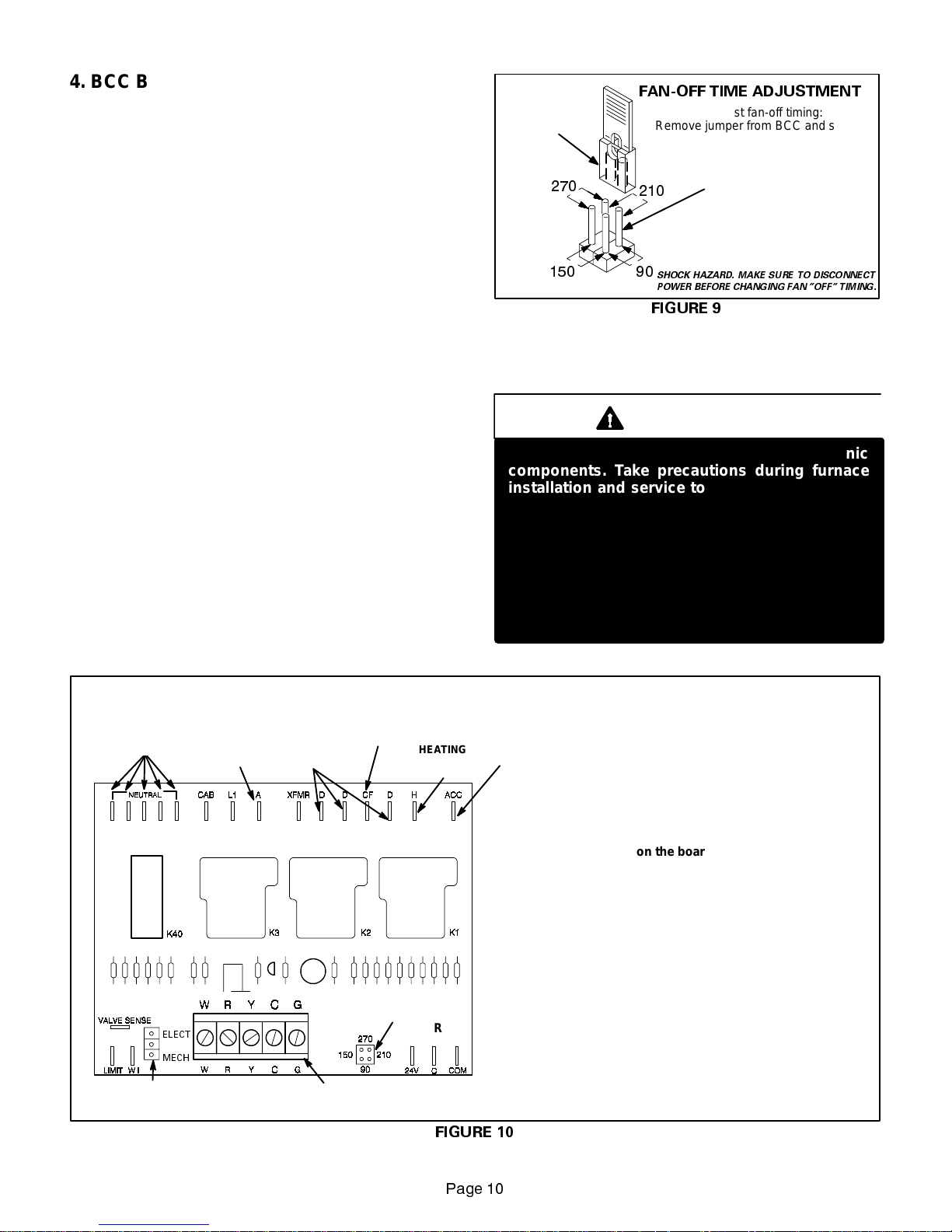

4. BCC Blower Control (A15)

-1 Through -4 Models

G23(X)-1, -2, -3 and -4 model units utilize the BCC blower

controlmanufacturedby Heatcraft. Seefigure10.TheBCC

is a printed circuit board which controls the supply air blower and monitors primary limit and gas valve operation. The

BCC is equipped with a jumper for electronic (isolation

relay) or electro-mechanical thermostat selection.The controlhasanon-adjustable,factorypresetfan“on”timing.Fan

“off”timing is adjustable. The board is divided into two sections, 120 and 24VAC. Line voltage comes into the board

on the 120VACside. See table 1 for terminal designations.

Fan Timings

Fan“off”timing (time that thebloweroperates after theheat

demand has been satisfied) is determined by the arrangement of a jumper across pins on the BCC blower control

board.Seefigure9.To adjust fan“off”timing,gentlydisconnect jumper and reposition across pins corresponding with

newtiming.Fan “on” time is factoryset at 45 seconds andis

not adjustable.

NOTE—If fan “off” time is set too low, residual heat in

heat exchanger may cause primary limit S10 to trip resulting in frequent cycling of blower. If this occurs, adjust blower to longer time setting.

Figure 9 shows the various fan “off” timings and how jumper

should be positioned. Unit is shipped with a factory fan “off”

setting of 90 seconds. Fan “off” time will affect comfort and

efficiency and is adjustable to satisfy individual applications.

Thefan “off” timing is initiated aftera heating demand butnot

after a blower or cooling demand (that is, when indoor thermostat switch is changed from ON to AUTO and heating/

cooling demand is not present, the blower stops immediately).

FAN-OFF TIME ADJUSTMENT

TIMING

JUMPER

To adjust fan-off timing:

Remove jumper from BCC and select

one of the other pin combinations to

achieve the desired time.

TIMING PINS

(seconds)

Leave jumper off for

330 second fan-off timing.

SHOCK HAZARD. MAKE SURE TO DISCONNECT

POWER BEFORE CHANGING FAN OFF TIMING.

FIGURE 9

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during furnace

installation and service to protect the furnace’s

electroniccontrols.Precautions will helptoavoid

control exposure to electrostatic discharge by

putting the furnace, the control and the technician at the same electrostatic potential. Neutralize electrostatic charge by touching hand and all

tools on an unpainted unit surface, such as the

gas valve or blower deck, before performing any

service procedure.

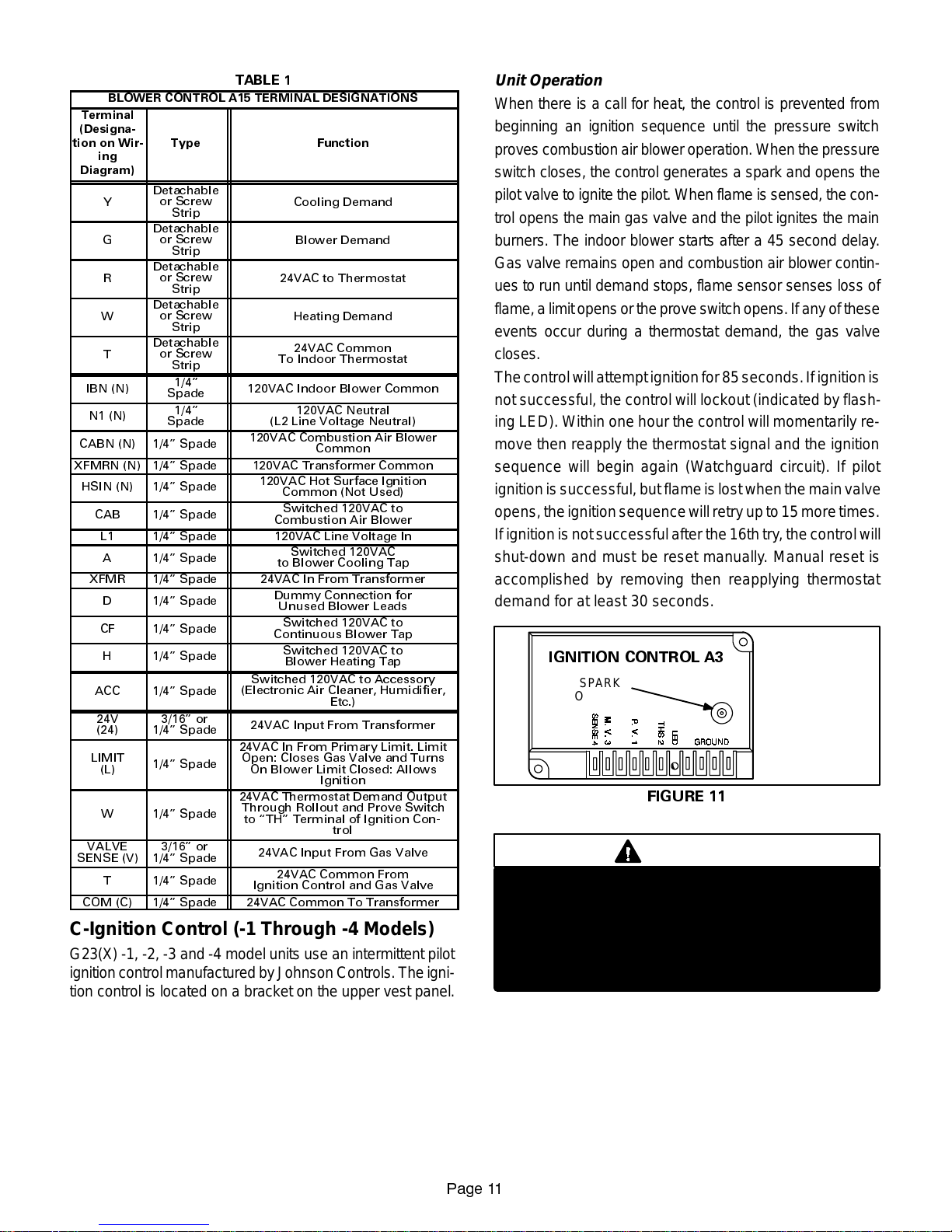

NEUTRAL

TERMINALS

ELECT

MECH

THERMOSTATJUMPER

(Electronic or Mechanical)

G23(X)-1, -2 ,-3 and -4 MODELS

BLOWER CONTROL - BCC

COOLING

SPEED TAP

TERMINAL

(DETACHABLE ON EARLY BOARDS ONLY))

TERMINALS

THERMOSTATTERMINAL STRIP

CONTINUOUS FAN

DUMMY

TERMINAL

BLOWER TIME

ADJUSTMENT

JUMPER

(A15)

HEATING

SPEED TAP

TERMINAL

FIGURE 10

ACCESSORY

TERMINAL

Heat Anticipator Settings

Beginning with the BCC3-2 series, a 3 pin jumper

has been installed on the board next to the removable 24V terminal strip to account for both programmable and electromechanical thermostat usage in

the field. For electromechanical thermostat, position

the jumper over the middle and bottom pin labeled

”MECH.” Set the heat anticipator setting to 0.65

amps for Honeywell valves or 0.50 amps for White

Rodgers valves. For programmable (electronic) thermostats, position the jumper over the middle and

top pin labeled ”ELECT.” Set the heat anticipator

setting to 0.1 amps.

3DJH

Page 11

TABLE 1

BLOWER CONTROL A15 TERMINAL DESIGNATIONS

Terminal

(Designa-

tion on Wir-

ing

Diagram)

Y

G

R

W

T

IBN (N)

N1 (N)

CABN (N) 1/4 Spade

XFMRN (N) 1/4 Spade 120VAC Transformer Common

HSIN (N) 1/4 Spade

CAB 1/4 Spade

L1 1/4 Spade 120VAC Line Voltage In

A 1/4 Spade

XFMR 1/4 Spade 24VAC In From Transformer

D 1/4 Spade

CF 1/4 Spade

H 1/4 Spade

ACC 1/4 Spade

24V

(24)

LIMIT

(L)

W 1/4 Spade

VALVE

SENSE (V)

T 1/4 Spade

COM (C) 1/4 Spade 24VAC Common To Transformer

Type Function

Detachable

or Screw

Strip

Detachable

or Screw

Strip

Detachable

or Screw

Strip

Detachable

or Screw

Strip

Detachable

or Screw

Strip

1/4

Spade

1/4

Spade

3/16 or

1/4 Spade

1/4 Spade

3/16 or

1/4 Spade

120VAC Indoor Blower Common

(Electronic Air Cleaner, Humidifier,

24VAC In From Primary Limit. Limit

Open: Closes Gas Valve and Turns

24VAC Thermostat Demand Output

Through Rollout and Prove Switch

to TH Terminal of Ignition Con-

Cooling Demand

Blower Demand

24VAC to Thermostat

Heating Demand

24VAC Common

To Indoor Thermostat

120VAC Neutral

(L2 Line Voltage Neutral)

120VAC Combustion Air Blower

120VAC Hot Surface Ignition

Switched 120VAC to Accessory

24VAC Input From Transformer

On Blower Limit Closed: Allows

24VAC Input From Gas Valve

Ignition Control and Gas Valve

Common

Common (Not Used)

Switched 120VAC to

Combustion Air Blower

Switched 120VAC

to Blower Cooling Tap

Dummy Connection for

Unused Blower Leads

Switched 120VAC to

Continuous Blower Tap

Switched 120VAC to

Blower Heating Tap

24VAC Common From

Etc.)

Ignition

trol

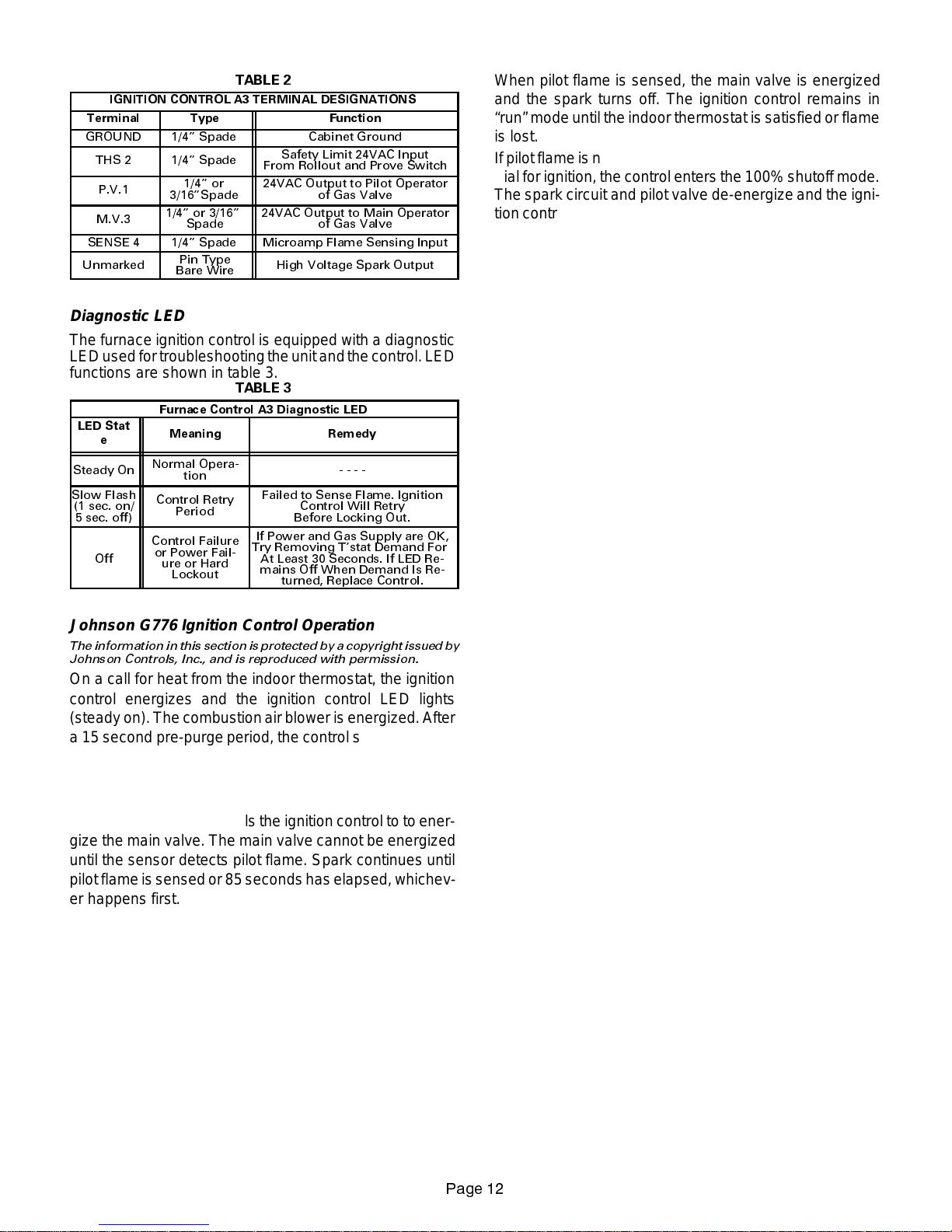

C-Ignition Control (-1 Through -4 Models)

G23(X) -1, -2, -3 and -4 model units use an intermittent pilot

ignitioncontrol manufacturedby Johnson Controls. The ignition control is located on a bracket on the upper vest panel.

Unit Operation

When there is a call for heat, the control is prevented from

beginning an ignition sequence until the pressure switch

proves combustion air blower operation. When the pressure

switch closes, the control generates a spark and opens the

pilot valve to ignite the pilot. When flame is sensed, the control opens the main gas valve and the pilot ignites the main

burners. The indoor blower starts after a 45 second delay.

Gas valve remains open and combustion air blower continues to run until demand stops, flame sensor senses loss of

flame,alimit opens ortheprove switchopens. If anyofthese

events occur during a thermostat demand, the gas valve

closes.

Thecontrolwillattempt ignitionfor85seconds.Ifignitionis

not successful, the control will lockout (indicated by flashing LED). Within one hour the control will momentarily remove then reapply the thermostat signal and the ignition

sequence will begin again (Watchguard circuit). If pilot

ignitionissuccessful, but flameislost whenthemainvalve

opens,theignitionsequencewill retry up to 15moretimes.

Ifignitionisnotsuccessfulafterthe16thtry,thecontrolwill

shut-down and must be reset manually. Manual reset is

accomplished by removing then reapplying thermostat

demand for at least 30 seconds.

IGNITION CONTROL A3

SPARK

OUTPUT

SEE TABLE 2

FOR TERMINAL

DESIGNATIONS

FIGURE 11

DANGER

Shock hazard.

Spark related components contain high voltage.

Disconnect power before servicing. Control is

not field repairable. If control is inoperable, simply replace entire control.

Can cause injury or death. Unsafe operation will

result if repair is attempted.

3DJH

Page 12

TABLE 2

IGNITION CONTROL A3 TERMINAL DESIGNATIONS

Terminal Type Function

GROUND 1/4 Spade Cabinet Ground

THS 2 1/4 Spade

P.V.1

M.V.3

SENSE 4 1/4 Spade Microamp Flame Sensing Input

Unmarked

1/4 or

3/16Spade

1/4 or 3/16

Spade

Pin Type

Bare Wire

Safety Limit 24VAC Input

From Rollout and Prove Switch

24VAC Output to Pilot Operator

24VAC Output to Main Operator

of Gas Valve

of Gas Valve

High Voltage Spark Output

Diagnostic LED

The furnace ignition control is equipped with a diagnostic

LEDusedfortroubleshootingtheunitandthe control.LED

functions are shown in table 3.

TABLE 3

Furnace Control A3 Diagnostic LED

LED Stat

e

Steady On

Slow Flash

(1 sec. on/

5 sec. off)

Off

Meaning Remedy

Normal Opera-

tion

Control Retry

Period

Control Failure

or Power Fail-

ure or Hard

Lockout

Failed to Sense Flame. Ignition

Control Will Retry

Before Locking Out.

If Power and Gas Supply are OK,

Try Removing Tstat Demand For

At Least 30 Seconds. If LED Re-

mains Off When Demand Is Re-

turned, Replace Control.

----

Johnson G776 Ignition Control Operation

The information inthis section is protected by a copyright issued by

Johnson Controls, Inc., and is reproduced with permission.

On a call for heat from the indoor thermostat, the ignition

control energizes and the ignition control LED lights

(steady on). The combustionair blower is energized.After

a 15 second pre-purge period, the control simultaneously

opens the pilot valve and sends spark to the pilot electrode.

If the pilot ignites within 85 seconds, the flame sensor detects pilot flame and signals the ignition control to to energize the main valve. The main valve cannot be energized

until the sensor detects pilot flame. Spark continues until

pilotflameissensed or 85 secondshas elapsed, whichever happens first.

When pilot flame is sensed, the main valve is energized

and the spark turns off. The ignition control remains in

“run” mode until the indoor thermostat is satisfied or flame

is lost.

Ifpilotflame is not sensedbefore the end of the85second

trialfor ignition, thecontrol enters the 100% shutoffmode.

The spark circuit and pilot valve de-energize and the ignitioncontrol automatically begins the60 minute retry delay

period. During the 60 minute delay the diagnostic LED

continually flashes on for one second and off for five seconds. After the delay period, another trial for ignition sequence starts, beginning with pre-purge.

Ifpilotflamegoesoutwhiletheindoorthermostat is calling

forheat, both main and pilotvalves de-energizewithin 0.8

seconds and remain de-energized for five seconds. After

this delay, the spark and pilot valve energize until flame is

sensedorthe85secondtrialforignitionperiod ends.Ifthis

“flameout” cycle repeats 16 times (pilot flame is established and then lost), the control locks out and the LED

goes off. A new trial for ignition sequence begins after the

thermostat contacts are opened for 30 seconds and then

closed.

If flame is detected when the thermostat calls for heat, it

must extinguish within30 seconds for normaloperation. If

flameisstillpresentafter30seconds,thecontrolgoesinto

lockout and the LED goes off.

D-Combustion Air Blower (B6)

All G23(X) units use a combustion air blower to move air

through the burners and heat exchanger during heating operation. The blower uses a shaded pole 120VAC motor.

Shaded pole motors do not use run capacitors. The motor

operates during all heating operation and is controlled by

blower control A15. The blower operates continuously while

there is a call for heat. The ignition control is prevented from

proceeding through the ignition sequence until combustion

air blower operation is sensed by the prove switch.

The pressure switch connected to the upper vest panel is

used to prove combustion air blower operation. The switch

monitors air pressure in the blower housing. During normal

operation, the pressure in the housing is negative. If the

pressure drops (becomes more positive), the pressure

switch opens. When the pressure switch opens, the ignition

control (A3) immediately closes the gas valve to prevent

burner operation.

3DJH

Page 13

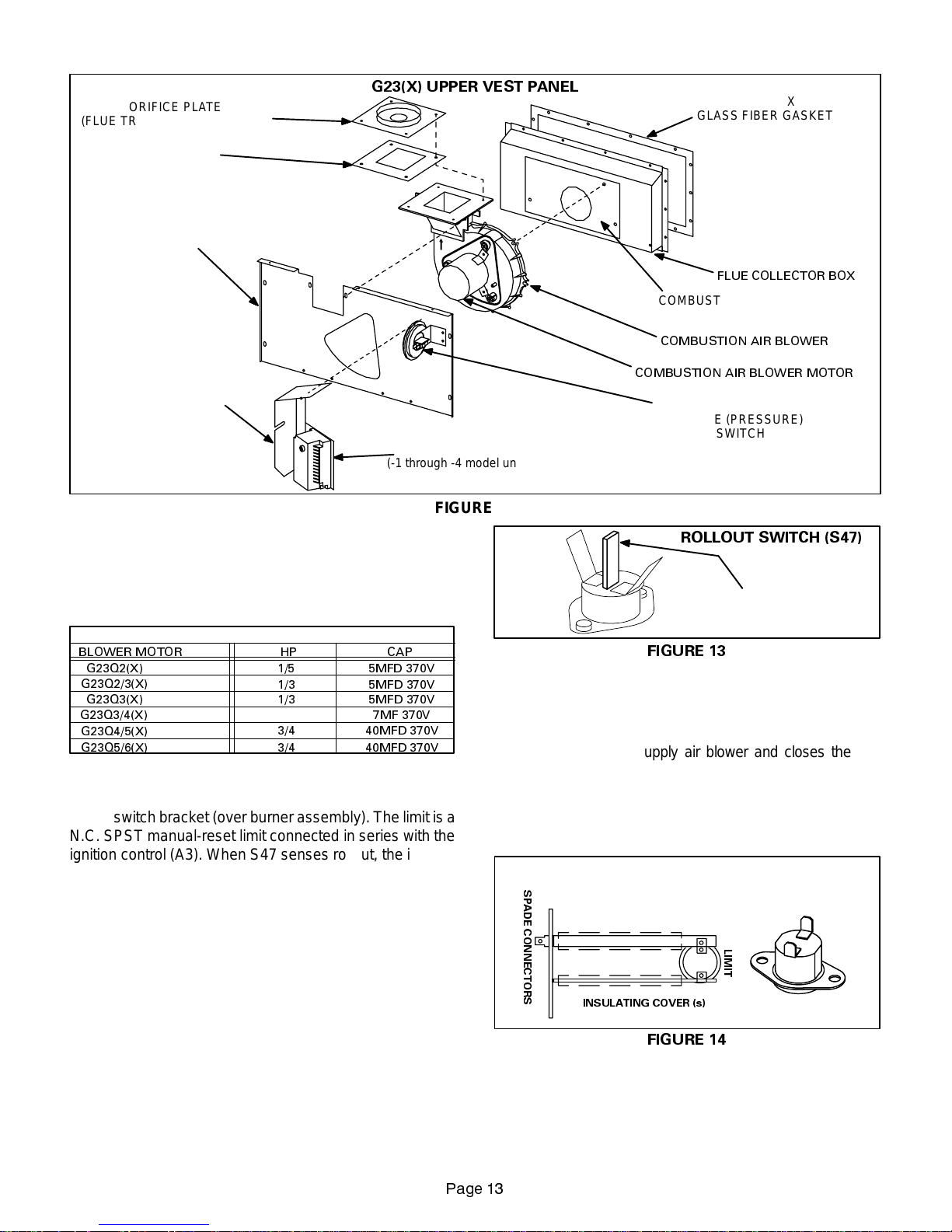

G23(X) UPPER VEST PANEL

(FLUE TRANSITION ASSEMBLY)

ORIFICE PLATE

FLUE OUT-

LET

GLASS FIBER

GASKET

UPPER VEST

PANEL

IGNITION CONTROL

BRACKET

IGNITION CONTROL

(-1 through -4 model units)

FIGURE 12

E-Blower Motors and Capacitors

All G23(X) units use direct drive blower motors. All motors

used are 120V permanent split capacitor motors to ensure

maximum efficiency. See table 4 for ratings.

TABLE 4

G23(X) BLOWER RATINGS 120V 1PH

BLOWER MOTOR HP

G23Q2(X) 1/5 5MFD 370V

G23Q2/3(X)

G23Q3(X)

G23Q3/4(X)

G23Q4/5(X)

G23Q5/6(X)

1/3

1/3

1/2

3/4 40MFD 370V

3/4 40MFD 370V

CAP

5MFD 370V

5MFD 370V

7MF 370V

F-Flame Rollout Switch (S47)

Flame rollout switch is a high temperature limit located on

rollout switch bracket (over burner assembly). The limit is a

N.C. SPST manual-reset limit connected in series with the

ignition control (A3). When S47 senses rollout, the ignition

controlimmediately stops ignitionandcloses the gas valve.

If unit is running andflame rollout is detected, the gasvalve

will close and ignition control will be disabled. Rollout can

be caused by a reverse draft, blocked flue or lack of combustion air. The switch is factory set and cannot be adjusted. The switch may have different setpoints for each

unitmodel number.However,thesetpoint will beprinted on

the side of the limit. The switch can be manually reset. To

manually reset a tripped switch, push the reset button located on the control (see figure 13).

FLUE BOX

GLASS FIBER GASKET

FLUE COLLECTOR BOX

COMBUSTION AIR BLOWER

GLASS FIBER GASKET

COMBUSTION AIR BLOWER

COMBUSTION AIR BLOWER MOTOR

COMBUSTION AIR BLOWER

PROVE (PRESSURE)

NOTE-ALL components located behind up-

per vest panel including combustion air blow-

er are exposed to supply air stream.

SWITCH

ROLLOUT SWITCH (S47)

MANUAL

RESET BUTTON

FIGURE 13

G-Primary Limit Control (S10)

Primary limit (S10) on G23(X) units is located in the middle of

the vestibule panel. When excess heat is sensed in the heat

exchanger ,the limit will open. If the limit is tripped, the furnace

control energizes the supply air blower and closes the gas

valve. The limit automatically resets when temperature retur ns to nor mal .The switch is factory set and cannot be adjusted. The switch may have different setpoints for each

unitmodel number.However,thesetpoint will be printed on

the side of the limit.

SPADE CONNECTORS

G23(X) SERIES UNITS AND ALTERNATE STYLE

LIMIT CONTROL (S10) FOR

Units may be equipped with

either style limit.

LIMIT

INSULATING COVER (s)

FIGURE 14

3DJH

Page 14

Units may be equipped with either flush style or extended

(masted) limit (figure14). Masted limits may be installed

with limit facing blower or away from blower. This orientationcannotbechanged.Whenremovinglimitfromunit,pay

careful attentionto its orientation and make sure limit is reinstalled facing same direction.

H-Pilot, Spark Electrode, Flame Sensor

and Burners (-1 Through -4 Models)

Figure 17 shows the arrangement of pilot, flame sensor,

spark electrode and burners. The ignition control uses direct spark to ignite the pilot. The pilot ignites the burners

and the burners cross-light. The flame sensor uses flame

rectification to sense ignition. The ignition control requires

that pilot flame must be sensed before the main gas valve

is allowed to open. Typically, a 2 to 4 second delay occurs

between the pilot ignition and the main valve opening.

Figure16showsthe gap between tip of the electrodesand

the burner surface. It is important that the gap be maintained for consistent ignition of pilot flame.

A flame retention ring in the end of each burner is used to

maintain correct flame length and shape and to keep the

flamefrom lifting offthe burner head. In addition, the burner entrance to each clamshell (Figure 3) is fitted with a

flamebaffle or corbel toenhance the combustion process.

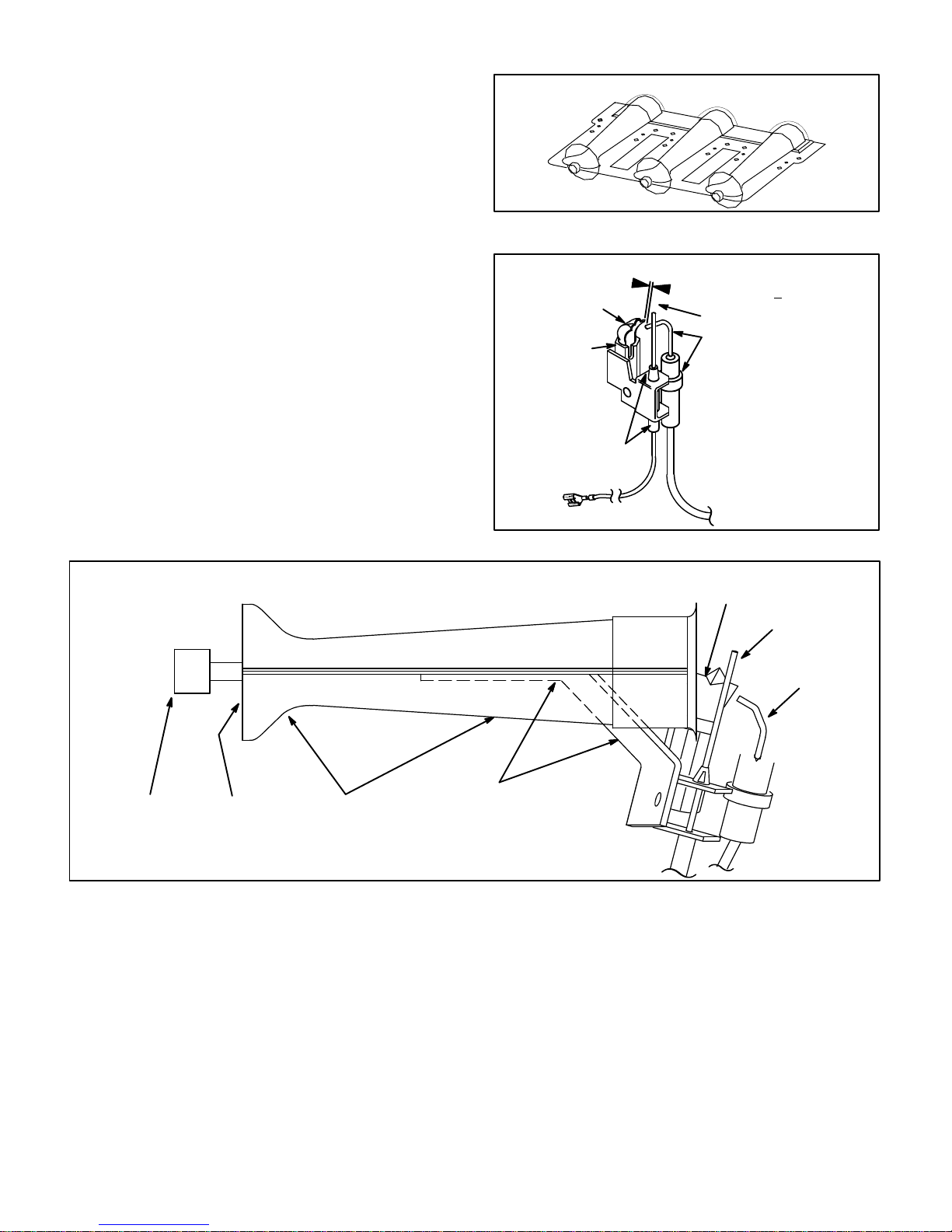

G23(X)-1, -2, -3 AND -4 MODELS BURNER PILOT/ELECTRODE

ORIENTATION

view looking at side of burners

TYPICAL BURNER ASSEMBLY

FIGURE 15

PILOT, SPARK ELECTRODE AND FLAME SENSOR

PILOT HOOD

PILOT

FLAME SENSOR

SENSE WIRE

1/8 (.125) Inch + ”1/32 (.031)

GAP

SPARKELECTRODE

SPARKWIRE

FIGURE 16

PILOT HOOD

FLAME SENSOR

ORIFICE

RETAINER

PRIMARY

AIR INLET

BURNER

SPARK

ELECTRODE

PILOT MOUNTING

BRACKET

FIGURE 17

Page 14

Page 15

127( 7KH *; IXUQDFH FRQWDLQ

V HOHFWURQLF FRP

SRQHQWV WKDW DUH SRODULW\ VHQVLWLYH 0DNH VXUH WKDW WKH

IXUQDFH LV ZLUHG FRUUHFWO\ DQG LV SURSHUO\ JURXQGHG

DANGER

Shock hazard.

Disconnect power before servicing. Control is not

field repairable. If control is inoperable, simply

replace entire control.

Can cause injury or death. Unsafe operation will

result if repair is attempted.

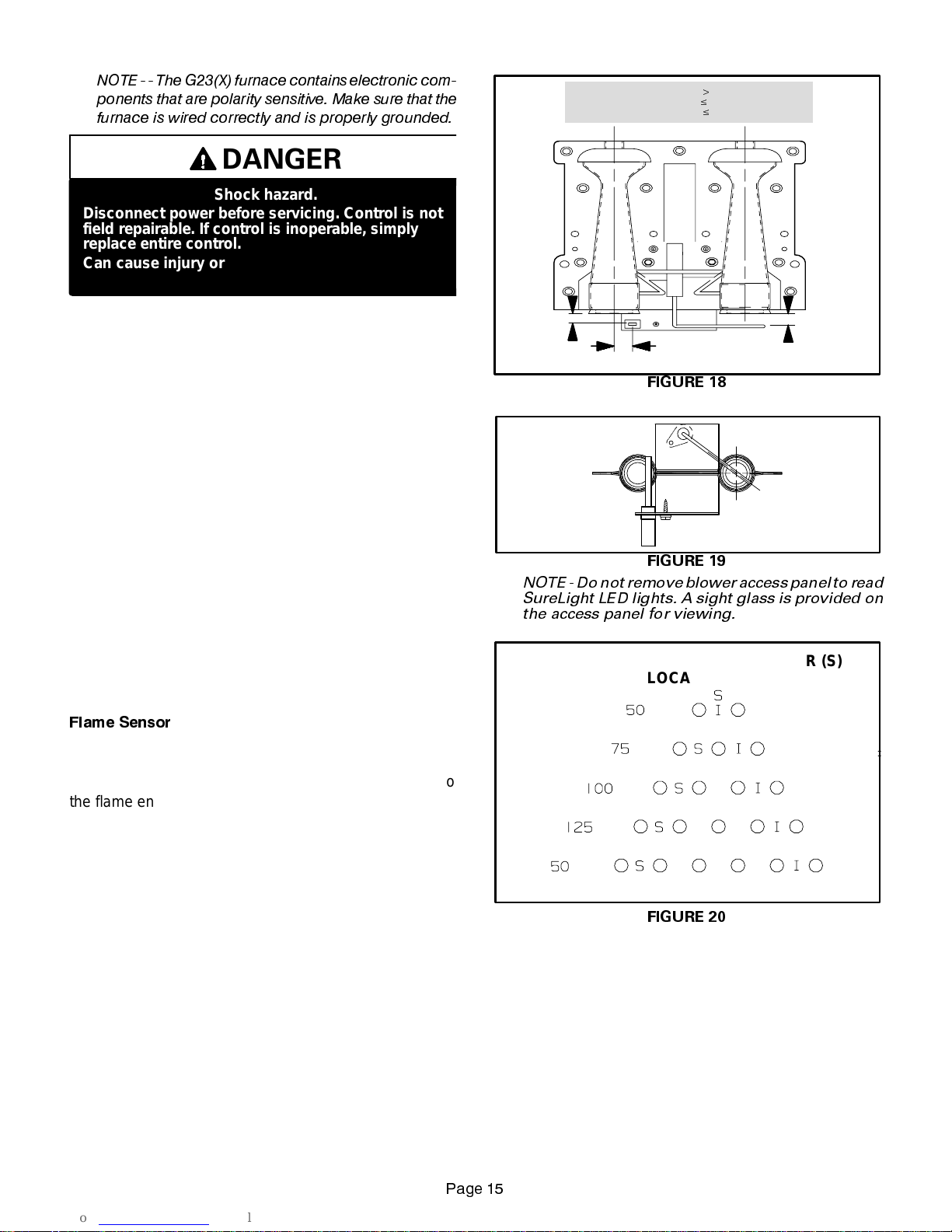

I- SureLight Ignition System A3

(-5 and -6 models)

All G23(X)-5 and -6 model units are equipped with the

Lennox SureLight ignition system. The system consists

of ignition control board (figure 21 with control terminal

designationsintable5)and ignitor(figures 18,19and20.

The board and ignitor work in combination to ensure furnace ignition and ignitor durability. The SureLight integrated board controls all major furnace operations. The

board also features two LED lights for troubleshooting

and two accessory terminals rated at (4) four amps. See

table6 for troubleshooting diagnostic codes. Table7and

8 show jack plug terminal designations. Units equipped

withtheSureLightboardcanbeusedwitheitherelectronic or electro-mechanical thermostats without modification. The SureLight ignitor is made of durable silic on-nitride. Ignitor longevity isalso enhanced by voltage ramping by the control board. The board finds the lowest ignitor temperature which will succes s fully light the burner,

thus increasing the life of t he ignitor.

NORMAL FLAME SIGNAL0.7 MICROAMPS

1/4”

IGNITOR

LOW FLAME SIGNAL

MINIMUM FLAME SIGNAL$0.15 MICROAMPS

19/64”

$

0.7 MICROAMPS

SENSOR

3/8”

FIGURE 18

SENSOR

IGNITOR

FIGURE 19

NOTE -Donotremove blower access panel to read

SureLight LED lights. A sight glass is provided on

the access panel for viewing.

SURELIGHT IGNITOR (I) AND SENSOR (S)

LOCATION

)ODPH 6HQVRU

Aflamesensorislocatedontheleftside of the burner support. See figures 18,19and 20. The sensoris mounted on

a bracket in the burner support and the tip protrudes into

the flame envelope of the left-most burner. The sensor is

fastened to burner supports and can be removed for service without removing any part of the burners. During operation, flame is sensed by current passed through the

flameandsensingelectrode.TheSureLightcontrolallows

the gas valve to remain open as long as flame signal is

sensed.

FIGURE 20

3DJH

Page 16

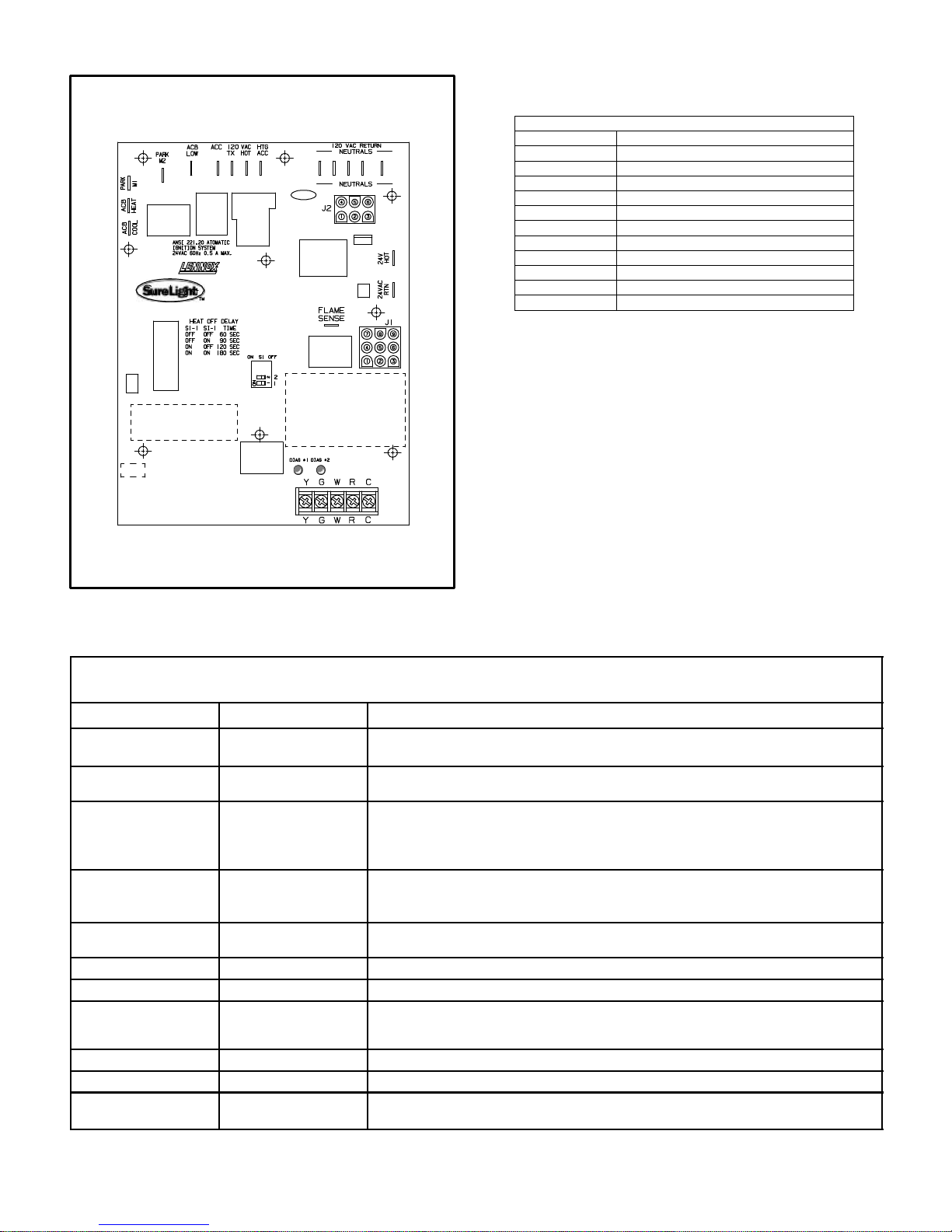

SURELIGHT CONTROL BOARD

TABLE 5

SURELIGHT CONTROL TERMINAL DESIGNATIONS

ACB COOL

ACB HEAT

PARK

ACB LOW

ACC

TX

HOT

HTG ACC

NEUTRALS

24VACHOT

24VACRTN

FLAME SENSE

Blower - Cooling Speed (Line Volt)

Blower - Heating Speed (Line Volt)

Alternate Blower Speeds (Dead)

Continuous Low Speed Blower

Accessory Terminal (Line Volt)

120VACHot to Transformer

120VACHot Input

Heat Only Accessory (Line Volt)

120VACNeutrals

24VACHot from Transformer

24VACReturn from Transformer

Flame Sense Terminal

FIGURE 21

TABLE 6

DIAGNOSTIC CODES

MAKE SURE TO ID LED’S CORRECTLY: REFER TO INSTALLATION INSTRUCTIONS FOR CONTROL BOARD LAYOUT.

LED #1 LED #2 DESCRIPTION

SIMULTANEOUS

SLOW FLASH

SIMULTANEOUS FAST

FLASH

SLOW FLASH ON

OFF SLOW FLASH

ALTERNATING SLOW

FLASH

SLOW FLASH OFF

ON SLOW FLASH

ON

ON

OFF

FAST FLASH SLOW FLASH

SLOW FLASH FAST FLASH

ALTERNATING FAST

FLASH

SIMULTANEOUS

SLOW FLASH

SIMULTANEOUS FAST

ALTERNATING SLOW

ALTERNATING FAST

FLASH

FLASH

ON

OFF

ON

FLASH

Also signaled during cooling and continues fan.

Normal operation - signaled when heating demand initiated at thermostat.

Primary or Secondary limit open. Units with board 63K8901 or 24L85: Limit must

close within 5 trials for ignition or board goes into one hour limit Watchguard.

Units with board 56L83 or 97L48: Limit must close within 3 minutes or board

Pressure switch open or has opened 5 times during a single call for heat; OR:

Blocked inlet/exhaust vent; OR: Condensate line blocked; OR: Pressure switch

closed prior to activation of combustion air blower.

Flame sensed without gas valve energized.

Rollout switch open. OR: 9 pin connector improperly attached.

Circuit board failure or control wired incorrectly.

Main power polarity reversed. Switch line and neutral.

Low flame signal. Measures below .7 microAmps. Replace flame sense rod.

Improper main ground or line voltage below 75 volts; OR: Broken ignitor; OR:

Power - Normal operation

goes into one hour limit Watchguard.

Watchguard - burners fail to ignite.

Open ignitor circuit.

NOTE - Slowflash equals1 Hz (oneflash persecond). Fast flashequals 3Hz (threeflashes per second).Drop out flamesense current< 0.15microAmps

Page 16

Page 17

TABLE 7

SureLight BOARD J156 (J2) TERMINAL

PIN # FUNCTION

1 Ignitor

2

3

4

5

6

DESIGNATIONS

Not Used

Ignitor Neutral

Combustion Air Blower Line Voltage

Not Used

Combustion Air Blower Neutral

TABLE 8

SureLight BOARD J58 (J1) TERMINAL

PIN # FUNCTION

1 Primary Limit In

2

3

4

5

6

7

8

9

DESIGNATIONS

Gas Valve Common

Roll Out Switch Out

Gas Valve 24V

Pressure Switch In

Pressure Switch and Primary Limit Out

Not Used

Roll Out Switch In

Ground

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during furnace

installation and service to protect the furnace’s

electronic controls. Precautions will help to

avoid control exposure to electrostatic discharge by putting the furnace, the control and

the technician at the same electrostatic potential. Neutralize electrostatic charge by touching

hand and all tools on an unpainted unit surface,

such as thegas valve or blower deck, before performing any service procedure.

a-Electronic Ignition

On a call for heat the SureLight control monitors the combustionair blower pressureswitch. The control will notbegin the heating cycle if the pressure switch is closed (bypassed). Once the pressure switch is determined to be

open, the combustion air blower is energized. When the

differential in the pressure switch is great enough, the

pressure switch closes and a 15-second pre-purge begins. If the pressure switch is not proven within 2-1/2 minutes, the control goes into Watchguard-Pressure Switch

mode for a 5-minute re-set period.

After the 15-second pre-purge period, the SureLight ignitor warms up for 20 seconds after which the gas valve

opens for a 4-second trial for ignition. G23X units

equipped with board 24L85, 56L83 or 63K89: the ignitor

stays energized for the first second of the 4-second trial.

Units equipped with board 97L48: ignitor stays energized

duringthetrialuntilflameissensed.If ignition is not proved

during the 4-second period, the control will try four more

times with an inter purge and warm-up time between trials

of 35 seconds. After a total of five trials for ignition (including the initial trial), the control goes into WatchguardFlame Failure mode. After a 60-minute reset period, the

control will begin the ignition sequence again.

The SureLight control board has an added feature that

prolongs the life of the ignitor. After a successful ignition,

theSureLightcontrolutilizeslesspowertoenergize the ignitoron successive callsfor heat. Thecontrol continues to

rampdown the voltage tothe ignitor until itfinds the lowest

amount of power that will provide a successful ignition. It

finds this by ramping down until the ignitor will not light,

then steps up the amount of power by three times. This

amount of power is used for 255 cycles. On the 256th call

for heat, the control will again ramp down until the lowest

power is determined and the cycle begins again.

b-Fan Time Control

The fan on time of 45 seconds is not adjustable. Fan off

time (time that the blower operates after the heat demand

has been satisfied) can be adjusted by flipping the dip

switches located on the SureLight integrated control. The

unit is shipped with a factory fan off setting of 90 seconds.

Fan off time will affect comfort and is adjustable to satisfy

individual applications. See figure 22.

FAN-OFF TIME ADJUSTMENT

60sec. 90sec. 120sec. 180sec.

To adjust fan-off timing, flip dip switch to desired setting.

FIGURE 22

Page 17

Page 18

J-Gas Valve

TheG23(X) usesa gas valvemanufacturedbyHoneywell

or White Rodgers. See figure 23. The valve is internally

redundant to assure safety shut-off. If the gas valve must

be replaced, the same type valve must be used.

24VAC terminals and gas control knob are located on top of

the valve. All terminals on the gas valve are connected to

wires from the ignition control. 24V applied to the “PV” terminals opens the pilot (-1 through -4 models)and 24V appliedto

the “MV” terminals opens the valve on G23X. Inlet and outlet

pressure taps are located on the valve. A regulator adjustment screw (figure 24) is located on the valve.

An LPG changeover kit is available from Lennox. The kit includes main and pilot burner orifices, burner corbel plate (Nox

only), and regulator conversion kit.

K-Combustion Air Blower Prove

(Pressure) Switch (S64)

G23(X) series units are equipped with a combustion air

(pressure) switch located on the vestibule panel. The switch

is connected tothe combustion airblower housing by means

of a flexible silicon hose. It monitors air pressure in the combustion air blower housing. The other side of the pressure

switch is open to atmosphere.

The switch is a single-pole single-throw pressure switch

electrically connected in series with the ignition control. The

purpose of the switch is to prevent burner operation if the

combustion air blower is not operating.

On start-up, the switch senses that the combustion air blower is operating. It closes a circuit to the ignition control when

pressure inside the combustion air blower increases above

the setpoint. The setpoint is measured in negative inches

water gauge. The pressure sensed by the switch is relative

to atmospheric pressure. If the flue becomes obstructed during operation, the switch senses a loss of negative pressure

(drops below setpoint) and opens the circuit to the ignition

control .

The switch setpoint varies with unit model number. Look

for the setpoint printed on the side of the switch.

The switch is factory set and is not field adjustable. It is a

safety shut-down control in the furnace and must not be

bypassed for any reason.

HONEYWELL VR8204 SERIES GASVALVE

INLET

GAS VALVE SHOWN IN OFF POSITION

21

2))

WHITE RODGERS

36E GAS VA

LVE

INLET

GAS VALVE

SHOWN

IN OFF

POSITION

FIGURE 23

WHITE RODGERS 36E GAS VALVE

REGULATOR ADJUSTMENT SCREW LOCATION

REGULATOR

COVER

SCREW

$'-867,1*

6&5(:

:KLWH

635,1*

HONEYWELL VR8204 GAS VALVE

REGULATOR ADJUSTMENT SCREW LOCATION

&$3 6&5(:

%ODFN

$'-867,1* 6&5(:

:KLWH

35(6685(

5(*8/$725

635,1*

5HG

,1/(7

35(6685(

7$3

*$6 ,1/(7

FIGURE 24

3DJH

Page 19

II-PLACEMENT AND INSTALLATION

Make sure unit is installed in accordance with installation

instructions and applicable codes.

A-Fresh Air Requirements

Until recently, there was no problem in bringing in sufficient

amounts of outdoor air for combustion -- infiltration provided

all the air that was needed and then some. In today’s homes

built with energy conservation in mind, tight construction practices make it necessary to bring in air from outside for combustion. Consideration must also be given to the use of exhaust fans, appliance vents, chimneys and fireplaces because they draw additionalair that could be used for combustion out of the house. Unless outside air is brought into the

home for combustion, negative pressure (pressure outside is

greater than inside pressure) will build to the pointthat a down

draft can occur in the furnace vent pipe or chimney . Combustion gases can enter the living space creating a potentially

dangerous situation.

Theimportanceofthe previous paragraphcannotbeoverstated. Users may inadvertently block fresh air intakes after installation.

In the absence of local codes concerning air for combustion

and ventilation, the following section outlines guidelines and

recommends procedures for operating G23(X) furnaces in a

manner that ensures efficient and safe operation. Special

consideration must be given to combustion air needs as well

as requirements for exhaust vents and gas piping. A portion

of this information has been reprinted with permission from

the National Fuel Gas Code (ANSI-Z223.1). This reprinted

material is not the complete and official position of the ANSI

on the referenced subject, which is represented only by the

standard in its entirety .

In Canada, refer to the standard CAN/CGA-B149.1 and B149.2 installation codes.

Combustion Air Requirements

&$87,21

Insufficient combustion air can cause headaches,

nausea, dizziness or asphyxiation. Excessive exposure to contaminated combustion air will result

in safety and performance related problems.

Avoidexposuretothe following substances in the

combustion air supply:

Permanent wave solutions;

Chlorinated waxes and cleaners;

Chlorine base swimming pool chemicals;

Water softening chemicals;

De-icing salts or chemicals;

Carbon tetrachloride;

Halogen type refrigerants;

Cleaning solvents (such as perchloroethylene);

Printing inks, paint removers, varnishes, etc.;

Hydrochloric acid;

Cements and glues;

Antistatic fabric softeners for clothes dryers; and

Masonry acid washing materials.

All gas-fired appliances require air to be used for the combustion process. If sufficient amounts of combustion air are

not available, the furnace or other appliance will operate in

an inefficient and unsafe manner . Enough air must be provided to meet the needs of all fuel-burning appliances, as

well as appliances such as exhaust fans which force air out

of the home. When fireplaces, exhaust fans, or clothes dryers are used at the same time as the furnace,much more air

is required to ensure proper combustion and to prevent a

down-draft situation. Insufficient amounts of air also cause

incomplete combustion which can result in carbon monoxide. The requirements for providing air for combustion and

ventilationdepend largely onwhether the furnace is installed

in an unconfined or confined space.

Unconfined Space

An unconfined space is an area such as a basement or

largeequipmentroomwithavolumegreaterthan 50cubic

feetper 1,000 Btu per hour of thecombined input rating of

all appliances installed in that space. This space also includesadjacent rooms which are not separated by adoor.

Though an area may appear to be unconfined, it might be

necessary to bring in outdoor air for combustion if the

structure does not provide enough air by infiltration. If the

furnace is located in a building of tight construction with

weather stripping and caulking around the windows and

doors,followthe procedures outlined for using air fromthe

outside for combustion and ventilation.

Confined Space

A confined space is an area with volume less than 50 cubic

feetper 1,000 Btu per hour of the combined input rating of all

appliances installed in that space. This definition includes

furnace closets or small equipment rooms.

3DJH

Page 20

Whenthefurnace is installed sothatsupplyducts carryair

circulated by the furnace to areas outside the space containingthefurnace,thereturnairmustbehandledbyducts

which are sealed to the furnace casing and which terminate outside the space containing the furnace. This is especially important when the furnace is mounted on a platform in a confined space such as a closet or small equipment room. Even a small leak around the base of the unit

at the platform or at the return air duct connection can

cause a potentially dangerous negative pressure condition.Airforcombustion and ventilation can be brought into

the confined space either from inside the building or from

outside.

Air from Inside

If the confined space housing the furnace adjoins space

categorizedasunconfined,air canbebroughtinbyprovid-

Air from Outside

Ifair from outsideis brought in forcombustion and ventilation,theconfined space shallbeprovidedwithtwo permanent openings. One opening shall be within 12 inches of

the top of the enclosure and one within 12 inches of the

bottom. These openings must communicate directly or by

ductswiththeoutdoorsorspaces(crawlor attic) thatfreely

communicate with the outdoors or indirectly through verticalducts.Eachopeningshallhaveaminimumfreeareaof

1square inch per 4,000Btu per hour of totalinput rating of

all equipment in the enclosure (See figures 26 and 27).

When communicating with the outdoors through horizontalducts, each opening shall have a minimumfree areaof

1 square inch per 2,000 Btu per total input rating of all

equipment in the enclosure (See figure 28).

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

(Inlet Air from Crawl Space and

CHIMNEY

OR GAS

VENT

Outlet Air to Ventilated Attic)

VENTILATION LOUVERS

(Each end of attic)

ing two permanent openings between the two spaces.

Eachopening must have aminimum free areaof 1 square

inch per 1,000 Btu per hour of the total input rating of all

gas-fired equipment in the confined space. Each opening

must be at least 100 square inches. One opening shall be

within12 inchesof the top of the enclosure and one opening within 12 inches of the bottom (See figure 25).

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM INSIDE

CHIMNEY OR

GAS VENT

WATER

G23(X)

FURNACE

HEATER

OPENINGS

(To Adjacent

Room)

G23

FURNACE

VENTILATION

LOUVERS

(For unheated

crawl space)

OUTLET

AIR

WATER

HEATER

INLET

AIR

NOTE-The inlet and outlet air openings shall each have a free

area of at least one square inch per 4,000 Btu per hour of the

total input rating of all equipment in the enclosure.

FIGURE 26

EQUIPMENT IN CONFINED SPACE

CHIMNEY

OR GAS

VENT

G23(X)

FURNACE

ALL AIR FROM OUTSIDE

(All Air Through Ventilated Attic)

VENTILATION LOUVERS

(Each end of attic)

OUTLET

AIR

INLET AIR

(Ends 12 above

bottom)

NOTE-Each openingshall have a free areaof at least one square

inch per 1,000 Btu per hour of the total input rating of all equip-

ment in the enclosure, but not less than 100 square inches.

FIGURE 25

3DJH

WATER

HEATER

NOTE-The inlet and outlet air openings shall each have a free

area of at least one square inch per 4,000 Btu per hour of the

total input rating of all equipment in the enclosure.

FIGURE 27

Page 21

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

CHIMNEY

OR GAS

VENT

WATER

HEATER

OUTLET AIR

G23(X)

FURNACE

INLET AIR

NOTE-Each air duct opening shall have a free area of at least

one square inch per 2,000 Btu per hour of the total input rating

of all equipment in the enclosure. If the equipment room is lo-

cated against an outside wall and the air openings communi-

cate directly with the outdoors, each opening shall have a free

area of at least one square inch per 4,000 Btu per hour of the

total input rating of all other equipment in the enclosure.

FIGURE 28

When ducts are used, they shall be of the same cross-sectional area as the free area of the openings to which they

connect. The minimum dimension of rectangular air ducts

shall be no less than 3 inches. In calculating free area, the

blocking effect of louvers, grilles, or screens must be considered. If thedesign and freearea of protective covering is

not known for calculating the size opening required, it may

be assumed that wood louvers will have 20 to 25 percent

free area and metal louvers and grilles will have 60 to 75

percent free area. Louvers and grilles must be fixed in the

openpositionorinterlocked with the equipmentsothatthey

are opened automatically during equipment operation.

B-Flue Venting Requirements

G23(X)seriesfurnacesmustbeventedincompliancewith

all local codes, the venting tables provided in this manual

and these instructions.

The G23(X) series units have been classified as fan assisted Category I type furnaces when vertically vented in

accordance with the latest edition of ANSI Z21.47 Central

Furnace Standard. The definition of a fan assisted Category I type furnace is an appliance equipped with an integral

mechanical means to either draw or force products of combustion through the combustion chamber and/or heat exchanger.

The vent sizing tables in this manual have been extracted

fromtheNationalFuelGasCode(NFPA54/ANSI Z223.1)

and are provided for convenience to serve as a guideline

for proper vent installation. Proper application, termination,constructionandlocationofvents must conform to local codes having jurisdiction. In the absence of local

codes, the NFGC serves as the defining document.

Referto the tables and the venting information contained in

these instructions for proper sizing and installation of the

venting system.

The G23(X) series units have the following flue collar

sizes: -50 unit, 3” diameter; -75 and -100 units, 4” diameter; and -125 & -150 units, 5” diameter. Use this informationinconjunctionwiththe providedventingtablestoproperlysizetheventorventconnectorthatattaches to thefurnace flue collar.

Venting Using a Masonry Chimney

The following additional requirements apply when a lined

masonry chimney is beingused to vent a G23(X) furnace:

A Category I appliance must never be connected to a

chimney that is servicing a solid fuel appliance. If a fireplace chimney flue is used to vent this appliance, the fireplace opening must be permanently sealed.

3DJH

Page 22

COMMON VENTING USING TILE-LINED INTERIOR MASONRY

CHIMNEY AND COMBINED VENT CONNECTOR

MINI. LENGTH = AS SHORT

AS PRACTICAL.

OTHER

APPLIANCE

G23

FIGURE 29

A chimney with one or more sides exposed to the outside

of the structure is considered to be an exterior chimney.A

TypeBorlistedchimneyliningsystempassingthroughan

unused masonry chimney flue is not considered to be exposed to the outdoors.

Masonry chimneys used to vent Category I central furnaces must be either tile-lined or lined with a listed metal

lining system or dedicated gas vent. Unlined masonry

chimneys are prohibited.

A fan assisted furnace may be commonly vented into an

existing lined internal masonry chimney provided:

1 - The chimney is currently serving at least one draft-

hood equipped appliance.

2 - The vent connectors and chimneyare sized in accor-

dance with the provided venting tables.

SINGLE

APPLIANCE VENTING OF A FAN ASSISTED

FURNACE INTO A TILE-LINED MASONRY CHIMNEY

(INTERIOR OR OUTSIDE WALL) IS

PROHIBITED

.THE

CHIMNEY MUST FIRST BE LINED WITH EITHER TYPE

“B” VENT OR AN INSULATEDSINGLE WALL FLEXIBLE

VENTLININGSYSTEM,SIZEDIN ACCORDANCE WITH

THE PROVIDED VENTING TABLES.

See figures 29 and 30 for common venting.

A Type “B” vent or masonry chimney liner shall terminate

above the roof surface with a listed cap or a listed roof assembly in accordance with the terms of their respective

listings and the vent manufacturer’s instructions.

Donotinstallamanualdamper,barometricdraftregulator,

or flue restrictor between the furnace and the chimney.

INTERIOR

TILE-LINED MASONRY

CHIMNEY

NOTE - CHIMNEY MUST BE

PROPERLY SIZED PER THE PRO-

VIDED VENTING TABLES OR LINED

WITH LISTED METAL LINING SYSTEM.

VENT

CONNECTOR

(Double-walled,

single-walled, or

insulated single-

walled pipe)

PERMANENTLY SEALED

FIREPLACE OPENING

If type “B” double-wall vent is used inside a chimney, no

otherappliancecanbeventedintothechimney. Outer wall

oftype “B” vent pipe mustnot be exposed toflueproducts.

Insulation for the flexible vent pipe must be an encapsulated fiberglass sleeve recommended by the flexible vent

pipe manufacturer. See figure 30.

The space between liner and chimney wall should

NOT be insulated with puffed mica or any other loose

granular insulating material.

COMMON VENTING USING

METAL-LINED MASONRY CHIMNEY

SEALED

MIN. LENGTH -- AS

5FT.

(1.5m)

MINIMUM

4 IN. MIN.

(102mm)

SHORT AS PRACTICAL

PERMANENTLY

SEALED FIREPLACE

CHIMNEY WITH

FLEXIBLE VENT

OPENING

EXTERIOR

“B” VENT OR

INSULATED

FIGURE 30

PIPE.

3DJH

Page 23

If“B”ventoraninsulatedflexiblevent pipe cannot be used

as liners, the chimney must be rebuilt to accommodate

oneofthesemethodsorsomealternateapprovedmethod

must be found to vent the appliance.

When inspection reveals that an existing chimney is not

safefor the intended purpose, itshall be rebuilt toconform

to nationally recognized standards, lined or relined with

suitable materials or replaced with a gas vent or chimney

suitableforventingG23(X)series units. The chimney passageway must be checked periodically to ensure that it is

clear and free of obstructions.

General Venting Requirements

All G23(X) furnaces must be vented in accordance with

the methods outlined in these instructions.

1 - Vent diameter recommendations and maximum runs

allowed are found in the provided venting tables.

2 - In no case should the vent or vent connector diameter

be less than the diameter specified in the provided

venting tables.

3-

For single appliance vents:

If the vertical vent or tilelinedchimney has a larger diameter or flow area than

theventconnector,usethe

determinethe

minimum vent capacity

verticalventdiameter

andthe vent

to

connector diameter to determine the maximum

ventcapacity. Theflowareaoftheverticalvent,how-

ever, shall not exceed 7 times the flow area of the

listedappliancecategorizedventarea,drafthoodoutlet area or flue collar area unless designed in accordance with approved engineering methods.

4-

For multiple appliance vents:

The flow area of the

largestsectionofverticalventorchimneyshallnotexceed 7 times the smallest listed appliance categorized vent area, flue collar area or drafthood outlet

area unless designed in accordance with approved

engineering methods.

5 - The entire length of single wall metal vent connector

shall be readily accessible for inspection, cleaning,

and replacement.

6 - Single appliance venting configurations with zero lat-

eral lengths, see tables 9 and 10, are assumed to

have no elbowsin the vent system.For all other vent

configurations, the vent system is assumed to have

two 90Eelbows. For each additional 90Eelbow or

equivalent (for example two 45Eelbows equal one

90Eelbow) beyond two, the maximum capacity listed

in the venting table should be reduced by 10 percent

(0.90 x maximum listed capacity).

7 - The common venting tables 11, 12, 13, and 14 were

generated using a maximum horizontal vent connector length of 1-1/2 feet (18 inches) for each inch of

connector diameter as follows:

CONNECTOR

DIAMETER

(INCHES)

3 4-1/2

4 6

5 7-1/2

6 9

7 10-1/2

MAXIMUM HORIZONTAL

CONNECTOR LENGTH

(FEET)

8 - If the common vertical vent is offset, the maximum

common vent capacity listed in the common venting

tables should be reduced by 20%, the equivalent of

two 90Eelbows (0.80 x maximum common vent capacity).Thehorizontallength oftheoffsetshallnotexceed 1-1/2 feet for each inch of common vent diameter.

9 - The vent pipe should be as short as possible with

the leas t number of elbows and angles to do the

job. The vent connector should be routed to the vent

utilizing the shortest possible route.

10- A vent connector shall be supported without any dips

or sags and shall slope a minimum of 1/4” per linear

foot of connector, back towards the appliance.

11- Vent connectors shall be firmly attached to furnace

flue collars by sheet metal screws or other approved

means,exceptventconnectorsoflistedType“B”vent

material which shall be assembled in accordance

with the manufacturer’s instructions. Joints between

sections of single wall connector piping shall be fastened by sheet metal screws or other approved

means.

12- When the vent connector used for Category I ap-

pliances must be located in or pass through a crawl

space or other areas which may be cold, that portion

of the vent connector shall be listed double-wall Type

B vent material or material having equivalent insulation qualities.

13- All venting pipe passing through floors, walls, and

ceilings must be installed with the listed clearance to

combustible materials and be fire stopped according

to local codes. In absence of local codes, refer to

NFGC (Z223.1).

14- No portion of the venting system can extend into, or

pass through any circulation air duct or plenum.

15- Vent connectors serving Category I appliances shall

not be connected to any portion of mechanical draft

systems operation under positive pressure such as

Category III or IV venting systems.

16- If vent connectors are combined prior to entering the

common vent, the maximum common vent capacity

listed in the common venting tables must be reduced

by 10%, the equivalent of one 90Eelbow (0.90 x maximum common vent capacity).

17- Common vent diameter must always be at least as

large as the largest vent connector diameter.

3DJH

Page 24

18- In no case, shall the vent connector be upsized more

(feet)

(feet)

5

than two consecutive table size diameters over the

size of the drafthood outlet or flue collar outlet.

19- A manual damper, barometric draft regulator or flue

restrictor must not be installed between furnace and

any chimney.

20- When connecting this appliance to an existing dedi-

cated or common venting system, the venting system,

must be inspected for signs of corrosion, and general

condition. The sizing of the vent system must be reviewed and conform to these instructions and the provided venting tables. If the existing system is in conflict

with these requirements, the venting system must be

resized.

TABLE 9

CAPACITY OF TYPE B DOUBLE-WALL VENTS WITH TYPE B DOUBLE-WALL CONNECTORS

SERVING A SINGLE CATEGORY I APPLIANCE

Vent and Connector Diameter - D (inches)

Height

H

(feet)

6

8

10

15

20

30

NOTE: Singleappliance venting configurations with zerolateral lengths areassumed to haveno elbows inthe ventsystem. For allother vent configura-

tions,the ventsystem is assumedto havetwo 90

beyond two, the maximum capacity listed in the venting table should be reduced by 10 percent (0.90 x maximum listed capacity).

Lateral

L

(feet)

0 0 78 0 152 0 251 0 375

2 13 51 18 97 27 157 32 232

4 21 49 30 94 39 153 50 227

6 25 46 36 91 47 149 59 223

0 0 84 0 165 0 276 0 415

2 12 57 16 109 25 178 28 263

5 23 53 32 103 42 171 53 255

8 28 49 39 98 51 164 64 247

0 0 88 0 175 0 295 0 447

2 12 61 17 118 23 194 26 289

5 23 57 32 113 41 187 52 280

10 30 51 41 104 54 176 67 267

0 0 94 0 191 0 327 0 502

2 11 69 15 136 20 226 22 339

5 22 65 30 130 39 219 49 330

10 29 59 40 121 51 206 64 315

15 35 53 48 112 61 195 76 301

0 0 97 0 202 0 349 0 540

2 10 75 14 149 18 250 20 377

5 21 71 29 143 38 242 47 367

10 28 64 38 133 50 229 62 351

15 34 58 46 124 59 217 73 337

20 48 52 55 116 69 206 84 322

0 0 100 0 213 0 374 0 587

2 9 81 13 166 14 283 18 432

5 21 77 28 160 36 275 45 421

10 27 70 37 150 48 262 59 405

15 33 64 44 141 57 249 70 389

20 56 58 53 132 66 237 80 374

30 NR NR 73 113 88 214 104 346

3 Inch 4 Inch 5 Inch 6 Inch

Appliance Input Rating in Thousands of Btu Per Hour

MIN MAX MIN MAX MIN MAX MIN MAX

elbows.For eachadditional 90Eelbowor equivalent(for example two45Eelbowsequal one90Eelbow)

E

3DJH

Page 25

TABLE 10

(feet)

(feet)

5

30

CAPACITY OF TYPE B DOUBLE-WALL VENTS WITH SINGLE-WALL METAL CONNECTORS

SERVING A SINGLE CATEGORY I APPLIANCE

Vent and Connector Diameter - D (inches)

Height

H

(feet)

6

8

10

15

20

30

NOTE: Singleappliance venting configurations with zerolateral lengths areassumed to haveno elbows inthe ventsystem. For allother vent configura-

tions,the ventsystem is assumedto havetwo 90

beyond two, the maximum capacity listed in the venting table should be reduced by 10 percent (0.90 x maximum listed capacity).

Lateral

L

(feet)

0 38 77 59 151 85 249 126 373

2 39 51 60 96 85 156 123 231

4 NR NR 74 92 102 152 146 225

6 NR NR 83 89 114 147 163 220

0 37 83 58 164 83 273 123 412

2 39 56 59 108 83 176 121 261

5 NR NR 77 102 107 168 151 252

8 NR NR 90 95 122 161 175 243

0 37 87 57 174 82 293 120 444

2 39 61 59 117 82 193 119 287

5 52 56 76 111 105 185 148 277

10 NR NR 97 100 132 171 188 261

0 36 93 56 190 80 325 116 499

2 38 69 57 136 80 225 115 337

5 51 63 75 128 102 216 144 326

10 NR NR 95 116 128 201 182 308

15 NR NR NR NR 158 186 220 290

0 35 96 54 200 78 346 114 537

2 37 74 56 148 78 248 113 375

5 50 68 73 140 100 239 141 363

10 NR NR 93 129 125 223 177 344

15 NR NR NR NR 155 208 216 325

20 NR NR NR NR 186 192 254 306

0 34 99 53 211 76 372 110 584

2 37 80 55 164 76 281 109 429

5 49 74 72 157 98 271 136 417

10 NR NR 91 144 122 255 171 397

15 NR NR 115 131 151 239 208 377

20 NR NR NR NR 181 223 246 357

30 NR NR NR NR NR NR NR NR

3 Inch 4 Inch 5 Inch 6 Inch

Appliance Input Rating in Thousands of Btu Per Hour

MIN MAX MIN MAX MIN MAX MIN MAX

elbows.For eachadditional 90Eelbowor equivalent(for example two45Eelbowsequal one90Eelbow)

E

3DJH

Page 26

TABLE 11

Vent

C

Height

Rise

6

0

5

30

V

g

Height

CAPACITY OF TYPE B DOUBLE-WALL VENTS WITH TYPE B DOUBLE-WALL CONNECTORS

SERVING TWO OR MORE CATEGORY I APPLIANCES

VENT CONNECTOR CAPACITY

Height

H

(feet) (feet)

6

8

10

15

20

30

onnector

Rise

3 Inch 4 Inch 5 Inch 6 Inch