Lennox G20RQ3XE-75, G20RQ3E-75, G20RQ4E-75, G20RQ4XE-75, G20RQ5E-100 Installation Instructions Manual

...Page 1

INSTALLATION

PRODUCT LITERATURE

1997 Lennox Industries Inc.

Dallas, Texas

INSTRUCTIONS

G20R SERIES UNITS

GAS UNITS

503,560M

2/97

Supersedes 11/96

TABLE OF CONTENTS

UNIT DIMENSIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARTS ARRANGEMENT 3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

REQUIREMENTS 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMBUSTION, DILUTION AND VENTILATION AIR 5. . . .

INSTALLATION–Setting Equipment 7. . . . . . . . . . . . . . . . . . .

RETURN AIR OPENING GUIDELINES 8. . . . . . . . . . . . . . . .

DUCT SYSTEM 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VENTING 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GAS PIPING 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT START–UP 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HIGH ALTITUDE INFORMATION 15. . . . . . . . . . . . . . . . . . . .

GAS PRESSURE ADJUSTMENT 15. . . . . . . . . . . . . . . . . . . .

OTHER UNIT ADJUSTMENTS 15. . . . . . . . . . . . . . . . . . . . . .

SERVICE 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPAIR PARTS 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

START–UP AND PERFORMANCE CHECK LIST 19. . . . . .

BCC TROUBLESHOOTING 20. . . . . . . . . . . . . . . . . . . . . . . .

Litho U.S.A.

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

WARNING

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Extinguish any open flames.

Do not touch any electrical switch; do not

use any phone in your building.

Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

If you cannot reach your gas supplier, call

the fire department.

Page 1

Page 2

G20R UNIT DIMENSIONS–INCHES (MM)

1Ć1/16

(27)

B

1Ć1/16

17Ć3/4

(451)

RETURN

AIR

OPENING

(27)

26Ć1/8

(664)

FLUE OUTLET

(center side to side)

N O T E Ċ Supply air opening is equipped with a 5/8 in. (16 mm) flange on

E

sides and rear of furnace and may be bent 90 for plenum connecĆ

tion or to help in alignment with cooling coil.

ă*Dimensions before flanges are bent (as shipped).

**Dimensions after flanges are bent.

Dimension after flange (furnished) is field installed on unit.

A

WHISPER HEAT

Model No.

CONTROL VOLTAGE

(Left Side)

LINE VOLTAGE

(Both Sides)

CONTROL VOLTAGE

(Right Side)

GAS PIPING INLET

(Both Sides)

2Ć5/8

(67)

ă8 (203) Right Side

53

(1346)

AIR FLOW

11 (279) Left Side

*19Ć5/8 (498)

**20Ć1/4 (541)

Supply Air

Opening

26Ć1/8

(664)

3Ć3/8

(86)

2Ć3/8

(60)

D

C

Supply Air

Opening

A B *C **C *D **D E

inch mm inch mm inch mm inch mm inch mm inch mm inch mm

G20RQ2/3(X)EĆ50

G20RQ3(X)EĆ75

16Ć1/4 413 14Ć1/8 359 10Ć3/4 273 12 305 1Ć1/2 38 2Ć1/8 54 3Ć1/8 79

G20RQ4(X)EĆ75 21Ć1/4 540 19Ć1/8 486 15Ć3/4 400 17 432 1Ć1/2 38 2Ć1/8 54 3Ć1/8 79

G20RQ3/4(X)EĆ100 21Ć1/4 540 19Ć1/8 486 15Ć3/4 400 17 432 1Ć1/2 38 2Ć1/8 54 3Ć1/4 83

G20RQ5(X)EĆ100

G20RQ3(X(EĆ125

26Ć1/4 667 24Ć1/8 613 18Ć3/4 475 20 508 2Ć1/2 64 3Ć1/8 79 3Ć5/16 84

G20RQ4/5(X)EĆ125

G20RQ4/5EĆ150 31Ć1/4 794 29Ć1/8 740 22 559 24Ć1/4 616 2Ć7/8 73 3Ć1/2 89 3Ć1/2 89

Page 2

Page 3

G20R PARTS ARRANGEMENT

PARTS IDENTIFICATION

(G20R Unit Shown)

LOWER

ACCESS

PANEL

PILOT/ELECTRODE

ASSEMBLY

FLUE TRANSITION

UPPER ACCESS

PANEL

DRAFT

HOOD

MANIFOLD

GAS VALVE

GAS

FILTER ACCESS

PRIMARY

LIMIT

CONTROL

ROLL-OUT

SWITCH

DOOR

DOOR

INTERLOCK

SWITCH

BCC

CONTROL

BLOCKED VENT

SHUT-OFF

SWITCH

BURNER BOX

BURNERS

.

.

EXCHANGER

IGNITION

CONTROL

CABINET

REMOVABLE STRIP

HEAT

ROLL-OUT

SWITCH

REMOVABLE

BURNER BOX TOP

BURNER BOX

DAMPER ASSEMBLY

SWITCH COVER

FIGURE 1

DAMPER BOX PARTS ARRANGEMENT

(G20R Units Shown)

DAMPER

SWITCH

SPRING

DAMPER

PATC H

PLATE

BURNER

BOX

DAMPER

PATCH PLATE

FIGURE 2

DAMPER

MOTOR/GEAR

Page 3

Page 4

REQUIREMENTS

In the US, installation of Lennox gas central furnaces

must conform with local building codes or, in the abĆ

sence of local codes, with the current National Fuel Gas

Code (ANSI-Z223.1). The National Fuel Gas Code is

available from:

American National Standards Institute, Inc.

1430 Broadway

New York, NY 10018

All G20R units are A.G.A. (American Gas Association)

and C.G.A (Canadian Gas Association) certified.

NOTE-G20RXE series units (units equipped with flame

rods) are certified for use with natural gas only.

Air supply for combustion and ventilation must conĆ

form to the methods outlined in the current National

Fuel Gas Code.

WARNING

Product contains fiberglass wool.

Disturbing the insulation in this product during

installation, maintenance, or repair will expose you

to fiberglass wool. Breathing this may cause lung

cancer. (Fiberglass wool is known to the State of

California to cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact

your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379-9900

The furnace is certified for installation clearances to

combustible material as listed on the appliance rating

plate and in table 1:

TABLE 1

Clearances Location Inches (mm)

Service access

To combustible

materials

From draft hood relief

opening

NOTE-Service access clearance must be maintained.

* If tight installation, front service clearance may be 24" (610mm).

** Clearance is 1" (25mm) for type B1 vent.

Accessibility and service clearances must take preceĆ

dence over fire protection clearances.

Vent installations shall be in accordance with the curĆ

rent GAMA/A.G.A. venting tables manual (502,567M),

or applicable provisions of local building codes. Vent

connectors serving appliances vented by natural draft

shall not be connected into any portion of mechanical

draft systems operating under positive pressure.

Front

Top, side and rear

Flue

Front

36 in. (914mm)*

1 in. (25mm)

6 in. (152mm)**

6 in. (152mm)

NOTE-For installation on combustible floors, appliance

shall not be installed directly on carpeting, tile, or other

combustible material other than wood flooring.

For installation in a residential garage, unit must be

installed so that burner(s) and ignition source are loĆ

cated no less than 18 in. (457 mm) above floor. Furnace

must be located or protected to avoid physical damage

by vehicles.

Unit must be adjusted to obtain a temperature rise

within the range specified on appliance rating plate.

The draft hood shall be installed in the same atmospheric

pressure zone as the combustion air inlet to the furnace.

G20R unit must be installed so that electrical compoĆ

nents are protected from water.

When furnace is used in conjunction with cooling

units, it shall be installed in parallel with, or on the upĆ

stream side of, cooling units to avoid condensation in

the heating element. With a parallel flow arrangement,

damper (or other means to control the flow of air) shall

be adequate to prevent chilled air from entering the

furnace and, if manually operated, must be equipped

with means to prevent operation of either unit, unless

damper is in the full heat" or cool" position.

When installed, furnace must be electrically grounded

in accordance with local codes or, in the absence of loĆ

cal codes, with the current National Electric Code,

ANSI/NFPA No. 70. The National Electric Code (ANSI/

NFPA No. 70) is available from:

National Fire Protection Association

470 Atlantic Avenue

Boston, MA 02210

Field wiring connection with unit must meet or exceed

specifications of type T wire and withstand a 63F

(17C) temperature rise. When furnace is installed so

that supply ducts carry air circulated by furnace to

areas outside space containing furnace, return air shall

be handled by a duct(s) sealed to the furnace casing

and terminating outside space containing furnace.

This furnace is certified for installation clearances to

combustible material as listed on appliance rating plate

and in table 1. Accessibility and service clearances must

take precedence over fire protection clearances.

n Canada, installation of C.G.A. certified units must conĆ

form with current Standard CAN/CGA-B149.1 Installation

Code for Natural Gas Burning Appliances and Equipment"

and CAN/CGA-B149.2 In s t a l l a t i o n C o d e f o r P r o p a n e G a s

Burning Appliances and Equipment," local plumbing or

waste water codes and other applicable local codes. AuĆ

thorities having jurisdiction should be consulted before

installation. Adequate clearance shall be made around air

Page 4

Page 5

openings into the vestibule area. Provisions shall be made

for proper operation and for combustion air and ventilaĆ

tion air supply according to the current CAN/CGA-B149

standards.

All electrical wiring and grounding for the unit must be

in accordance with the current regulations of the CanaĆ

dian Electrical Code Part I (C.S.A. Standard C22.1) and/

or local codes.

NOTE Ċ G20R series units must

not be used as a construction

heater" at any time during any

phase of construction. Very low return air temperaĆ

tures, harmful vapors and misplacement of the filters

will damage the unit and its efficiency.

GENERAL

These instructions are intended as a general guide

and do not supersede local codes in any way. AuthoriĆ

ties having jurisdiction should be consulted before

installation.

A-Shipping and Packing List

1-Rubber grommet (for electrical make-up)

1-Base bottom angle

2-Sheet metal screws

B-Shipping Damage

Check unit for shipping damage. Receiving party

should contact last carrier immediately if any shipping

damage is found.

COMBUSTION, DILUTION & VENTILATION AIR

Until recently, there was no problem in bringing in suffiĆ

cient amounts of outdoor air for combustion -- infiltration

provided all the air that was needed and then some. In

today's homes built with energy conservation in mind,

tight construction practices make it necessary to bring in

air from outside for combustion. Consideration must also

be given to the use of exhaust fans, appliance vents, chimĆ

neys and fireplaces because they force additional air that

could be used for combustion out of the house. Unless

outside air is brought into the home for combustion, negĆ

ative pressure (pressure outside is greater than inside

pressure) will build to the point that a down draft can ocĆ

cur in the furnace vent pipe or chimney. Combustion

gases enter the living space creating a potentially dangerĆ

ous situation.

In the absence of local codes concerning air for combusĆ

tion and ventilation, this section outlines guidelines and

recommends procedures for installing G20R furnaces in

a manner that ensures efficient and safe operation. SpeĆ

cial consideration must be given to combustion air needs

as well as requirements for exhaust vents and gas pipĆ

ing. A portion of this information has been reprinted with

permission from the National Fuel Gas Code (ANSIZ223.1). This reprinted material is not the complete and

official position of the ANSI on the referenced subject,

which is represented only by the standard in its entirety.

In Canada, refer to the standard CAN/CGA-B149.1 and

-B149.2 installation codes.

Combustion Air Requirements

CAUTION

Insufficient combustion air can cause headaches,

nausea, dizziness or asphyxiation. Excessive exĆ

posure to contaminated combustion air will result

in safety and performance related problems. Avoid

exposure to the following substances in the comĆ

bustion air supply:

Permanent wave solutions;

Chlorinated waxes and cleaners;

Chlorine base swimming pool chemicals;

Water softening chemicals;

De-icing salts or chemicals;

Carbon tetrachloride;

Halogen type refrigerants;

Cleaning solvents (such as perchloroethylene);

Printing inks, paint removers, varnishes, etc.;

Hydrochloric acid;

Cements and glues;

Antistatic fabric softeners for clothes dryers; and

Masonry acid washing materials.

All gas-fired appliances require air to be used for the

combustion process. If sufficient amounts of combusĆ

tion air are not available, the furnace or other appliance

will operate in an inefficient and unsafe manner.

Enough air must be provided to meet the needs of all

fuel-burning appliances, as well as appliances such as

exhaust fans which force air out of the home. When fireĆ

places, exhaust fans, or clothes dryers are used at the

same time as the furnace, much more air is required to

ensure proper combustion and to prevent a down-draft

situation. Insufficient amounts of air also cause incomĆ

plete combustion which can result in carbon monoxide.

The requirements for providing air for combustion and

ventilation depend largely on whether the furnace is

installed in an unconfined or confined space.

Unconfined Space

An unconfined space is an area such as a basement or

large equipment room with a volume greater than 50

cubic feet per 1,000 Btu per hour of the combined input

rating of all appliances installed in that space. This

space also includes adjacent rooms which are not sepĆ

arated by a door. Though an area may appear to be unĆ

confined, it might be necessary to bring in outdoor air

for combustion if the structure does not provide

enough air by infiltration. If the furnace is located in a

Page 5

Page 6

building of tight construction with weather stripping

and caulking around the windows and doors, follow

the procedures outlined for using air from the outside

for combustion and ventilation.

Confined Space

A confined space is an area with volume less than 50 cuĆ

bic feet per 1,000 Btu per hour of the combined input ratĆ

ing of all appliances installed in that space. This definiĆ

tion includes furnace closets or small equipment rooms.

When the furnace is installed so that supply ducts carry

air circulated by the furnace to areas outside the space

containing the furnace, the return air must be handled

by ducts which are sealed to the furnace casing and

which terminate outside the space containing the furĆ

nace. This is especially important when the furnace is

mounted on a platform in a confined space such as a

closet or small equipment room. Even a small leak

around the base of the unit at the platform or at the reĆ

turn air duct connection can cause a potentially danĆ

gerous negative pressure condition. Air for combusĆ

tion and ventilation can be brought into the confined

space either from inside the building or from outside.

Air from Inside

If the confined space housing the furnace adjoins space

categorized as unconfined, air can be brought in by proĆ

viding two permanent openings between the two

spaces. Each opening must have a minimum free area of

1 square inch per 1,000 Btu per hour of total input rating

of all gas-fired equipment in the confined space. Each

opening must be at least 100 square inches. One opening

shall be within 12 inches of the top of the enclosure and

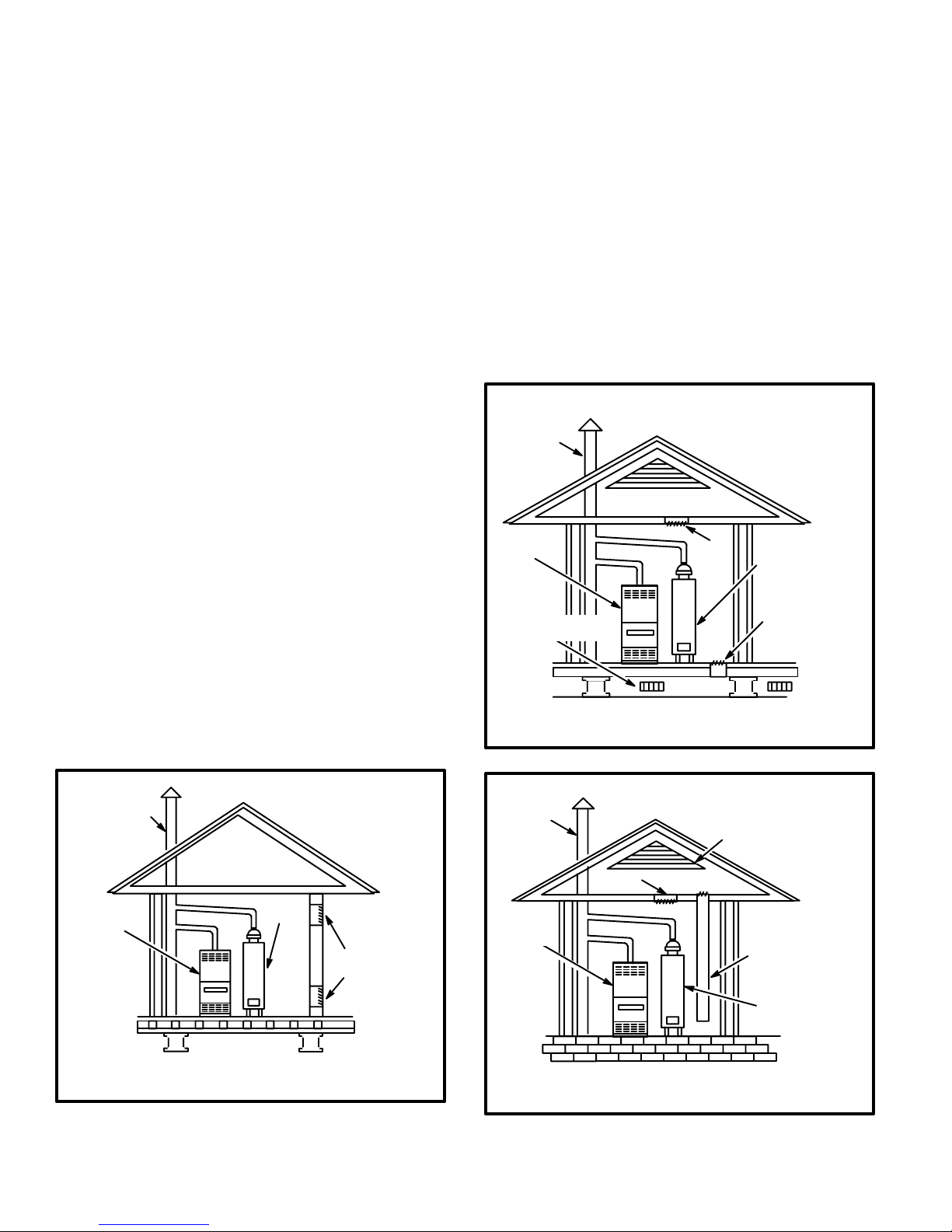

one opening within 12 inches of the bottom. See figure 3.

EQUIPMENT IN CONFINED SPACE

CHIMĆ

NEY OR

GAS

VENT

ALL AIR FROM INSIDE

Air from Outside

If air from outside is brought in for combustion and venĆ

tilation, the confined space must have two permanent

openings. One opening shall be within 12 inches of the

top of the enclosure and one within 12 inches of the botĆ

tom. These openings must communicate directly or by

ducts with the outdoors or spaces (crawl or attic) that freeĆ

ly communicate with the outdoors or indirectly through

vertical ducts. Each opening shall have a minimum free

area of 1 square inch per 4,000 Btu per hour of total input

rating of all equipment in the enclosure. See figures 4 and

5. When communicating with the outdoors through horiĆ

zontal ducts, each opening shall have a minimum free

area of 1 square inch per 2,000 Btu per total input rating of

all equipment in the enclosure. See figure 6.

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

CHIMNEY

OR GAS

VENT

G20R

FURNACE

VENTILATION

LOUVERS

(For unheated crawl space)

NOTE-The inlet and outlet air openings shall each have a

free area of at least one square inch per 4,000 Btu per hour

of the total input rating of all equipment in the enclosure.

(Inlet Air from Crawl Space and Outlet

VENTILATION LOUVERS

(Each end of attic)

Air to Ventilated Attic)

OUTLET

AIR

WATER

HEATER

INLET

AIR

FIGURE 4

EQUIPMENT IN CONFINED SPACE

CHIMNEY

OR GAS

VENT

ALL AIR FROM OUTSIDE

(All Air Through Ventilated Attic)

VENTILATION LOUVERS

(Each end of attic)

G20R

FURNACE

NOTE-Each opening shall have a free area of at least one

square inch per 1,000 Btu per hour of the total input rating of all

equipment in the enclosure, but not less than 100 square inches.

WATER

HEATER

FIGURE 3

OPENINGS

(To Adjacent

Room)

Page 6

OUTLET

AIR

G20R

FURNACE

NOTE-The inlet and outlet air openings shall each have a free area of

at least one square inch per 4,000 Btu per hour of the total input rating

of all equipment in the enclosure.

INLET AIR

(Ends 12" above

bottom)

WATER

HEATER

FIGURE 5

Page 7

When ducts are used, they shall be of the same crosssectional area as the free area of the openings to which

they connect. The minimum dimension of rectangular

air ducts shall be no less than 3 inches. In calculating

free area, the blocking effect of louvers, grilles, or

screens must be considered. If the design and free area

of protective covering is not known for calculating the

size opening required, it may be assumed that wood

louvers will have 20 to 25 percent free area and metal

louvers and grilles will have 60 to 75 percent free area.

Louvers and grilles must be fixed in the open position

or interlocked with the equipment so that they are

opened automatically during equipment operation.

EQUIPMENT IN CONFINED SPACE

ALL AIR FROM OUTSIDE

CHIMNEY

OR GAS

VENT

WATER

HEATER

OUTLET AIR

G20R

FURNACE

INLET AIR

NOTE-Each air duct opening shall have a free area of at least one

square inch per 2,000 Btu per hour of the total input rating of all equipĆ

ment in the enclosure. If the equipment room is located against an outĆ

side wall and the air openings communicate directly with the outdoors,

each opening shall have a free area of at least one square inch per

4,000 Btu per hour of the total input rating of all other equipment in the

enclosure.

FIGURE 6

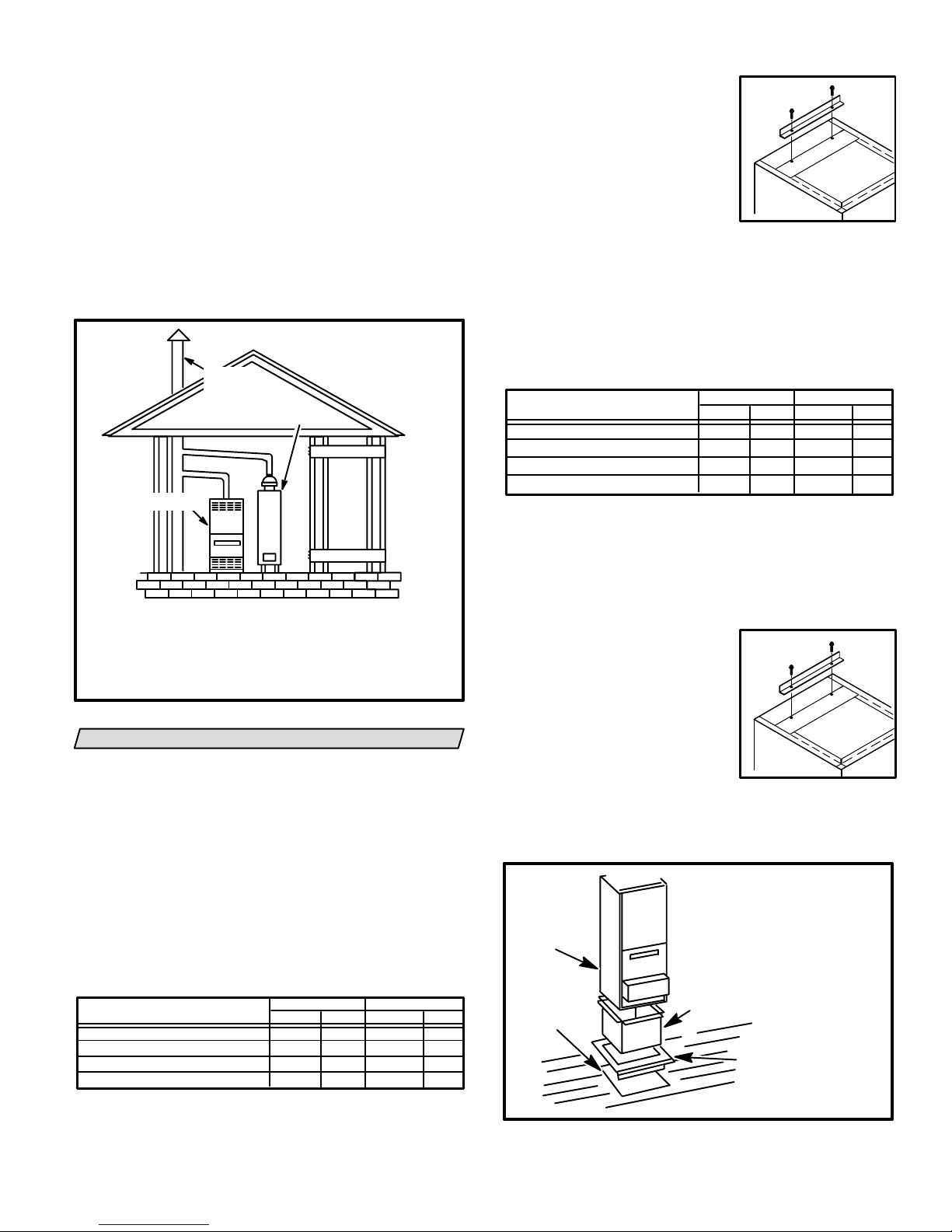

INSTALLATION–Setting Equipment

The G20R series units can be installed in three different

ways: on non-combustible flooring, on combustible

floor using an additive base, or on a reverse-flow coolĆ

ing cabinet. Do not drag unit across floor.

A-Installation on Non-Combustible Flooring

1- Cut floor opening keeping in mind the clearances

listed on the unit rating plate. Also, keep in mind gas

supply and electrical supply, vent connections and

sufficient installation and service clearances. See

table 2 for correct floor opening size.

TABLE 2

NONCOMBUSTIBLE FLOOR

UNIT

Q2/3-50, Q3-75

Q4-75, Q3/4-100

Q5-100, Q3-125, Q4/5-125

Q4/5-150

NOTE-Floor opening dimensions listed are 1/4" (6mm) larger

than unit openings.

Front to Rear Side to Side

in mm in mm

20-1/2

20-1/2

20-1/2

20-1/2

520

520

520

520

12-1/4

17-1/4

22-1/4

27-1/4

311

438

565

692

2- Flange warm air plenum and lower into opening.

3- Use duckbill pliers to bend

unit flanges out from openĆ

INSTALLING

BASE ANGLE

ing. Install provided base

bottom angle (shipped in

vestibule panel) to outside of

base into provided holes.

See illustration at right. SeĆ

cure with screws provided.

4- Set unit over plenum.

5- Check to see that an adequate seal is made.

B-Installation on Combustible Flooring

1- When unit is installed on a combustible floor, an addiĆ

tive base (ordered separately) must be installed beĆ

tween the furnace and the floor. See table 3 for openĆ

ing size to cut in the floor.

TABLE 3

ADDITIVE BASE FLOOR OPENING

UNIT

Q2/3-50, Q3-75

Q4-75, Q3/4-100

Q5-100, Q3-125, Q4/5-125

Q4/5-150

NOTE-Floor opening dimensions listed are 1/4" (6mm) larger

than unit openings.

Front to Rear Side to Side

in mm in mm

22-7/8 581

22-7/8

22-7/8

22-7/8

581

581

581

14-5/8

19-5/8

24-5/8

29-5/8

371

498

625

752

2- After opening is cut, set the additive base into opening.

3- Check fiberglass strips on additive base to make sure

they are properly glued and positioned.

4- Lower supply air plenum into additive base until pleĆ

num flanges seal against fiberglass strips.

5- Use duckbill pliers to bend

unit flanges out from openĆ

INSTALLING

BASE ANGLE

ing. Install provided base

bottom angle (shipped in

vestibule panel) to outside of

base into provided holes.

See illustration at right. SeĆ

cure with screws provided.

6- Set unit on additive base so unit flanges drop into pleĆ

num. Refer to figure 7.

NOTE-Be careful not to damage fiberglass strips.

Check for tight seal.

1. Cut correct size floor opening

2. Set additive base into opening.

G20R UNIT

PROPERLY

SIZED

FLOOR

OPENING

3. Set supply air plenum into

additive base.

4. Set unit.

SUPPLY AIR

PLENUM

ADDITIVE

BASE

FIGURE 7

Page 7

Page 8

C-Installation on Cooling Cabinet

1- Refer to reverse-flow coil installation instructions for corĆ

rectly sized opening in floor and installation of cabinet.

2- Use duckbill pliers to bend

unit flanges out from openĆ

INSTALLING

BASE ANGLE

ing. Install provided base

bottom angle (shipped in

vestibule panel) to outside of

base into provided holes.

See illustration at right. SeĆ

cure with screws provided.

3- With cooling cabinet in place, install furnace so

flanges drop inside cabinet opening. Secure furnace

to cabinet.

4- Seal cabinet and check for air leakage.

RETURN AIR OPENING GUIDELINES

Take the following steps when installing return air

plenum:

1- Bottom edge of plenum should be flanged with a

hemmed edge. See figure 8.

2- Fiberglass sealing strips should be used between pleĆ

num and the unit cabinet to ensure a tight seal.

3- In all cases, the plenum should be secured to the top

flanges of the furnace using sheet metal screws. See

figure 8.

PLENUM

FIBERGLASS

SEALING STRIP

CABINET SIDE PANEL

SECURE

HEMMED EDGE

FIGURE 8

WARNING

Do not put sheet metal screws into top of furnace.

Sheet metal screws must be installed into flange of

furnace. Note warning stickers on unit. MisplaceĆ

ment of screws may prevent normal maintenance

of filters.

4- In closet installations, it may be necessary to install

sheet metal screws from the inside. If this is the case,

make plenum with a removable front to install screws

as shown in figure 9.

SECURE FROM

INSIDE

FIBERGLASS

SEALING STRIP

CABINET SIDE PANEL

FIGURE 9

PLENUM

HEMMED EDGE

WARNING

Improper installation of unit can result in personal

injury or death. Combustion and flue products must

never be allowed to enter the return air system or air

in the living space. Use sheet metal screws and joint

tape to seal return air system to furnace.

The furnace should be sealed airtight to the return

air plenum. A door must never be used as a portion

of the return air duct system. Allow absolutely no

sagging, cracks, gaps, etc.

For no reason should return and supply air duct

systems ever be connected to or from other heatĆ

ing devices such as a fireplace or stove, etc. Fire,

explosion, carbon monoxide poisoning, personal

injury and/or property damage could result.

WARNING

Blower door must be securely in place when blowĆ

er and burners are operating. Gas fumes, which

could contain carbon monoxide, can be drawn into

living space resulting in personal injury or death.

DUCT SYSTEM

Size and install the supply and return air duct system usĆ

ing industry-approved standards that result in a quiet

and low-static system with uniform air distribution.

Installation of units not equipped with a cooling coil reĆ

quire a removable access panel in the supply air duct.

The access panel should be large enough to permit inĆ

spection of heat exchanger for leaks after installation.

Lennox recommends using the SENSITTM HT kit for

heat exchanger inspections. The access panel must not

allow leaks in the supply air duct system.

VENTING

G20R furnaces must be vented in compliance with all

local codes, the current GAMA/A.G.A. venting tables

manual (502,567M) in the U.S.A. and the current stanĆ

dards of CAN/CGA-B149.1 and -B149.2 in Canada and

these instructions.

The G20R series units have been classified as Category

I type furnaces when vertically vented in accordance

with the latest edition of ANSI Z21.47 Central Furnace

Standard in the U.S.A. and the current standard of

CAN/CGA-B149.1 and B149.2 of the National Gas and

Propane Installation Code in Canada.

General Venting Recommendations & Requirements

For Using Masonry Chimney

Any masonry chimney used for venting a G20R gas furĆ

nace must be lined, and must be sized and installed per

all applicable local building codes or, in the absence of

local codes, the current National Fuel Gas Code (ANSIZ223.1) in the U.S.A. and the current standards of CAN/

Page 8

Page 9

CGA-B149.1 and -B149.2 in Canada. The effective area

of the chimney serving a single appliance must be no

less than the effective area of the draft hood outlet. The

chimney must extend vertically at least 5 feet above the

flue collar.

The G20R gas furnace must not be connected to a

chimney servicing a separate appliance designed to

burn solid fuel.

Masonry chimneys serving fireplaces cannot be used

for venting purposes unless the fireplace opening is

permanently sealed. See figure 10.

When inspection reveals that an existing chimney is

not safe for the intended purpose, it shall be rebuilt to

conform to nationally recognized standards, lined or

relined with suitable materials or replaced with a gas

vent or chimney suitable for venting G20R series units.

The chimney passageway must be checked periodicalĆ

ly to ensure that it is clear and free of obstructions.

on any exhaust fans, such as range hoods and bathĆ

room exhausts, so they will operate at maximum

speed. Do not operate a summer exhaust fan. Close

fireplace dampers.

4- Follow the lighting instructions. Place the appliance

being inspected in operation. Adjust thermostat so

appliance will operate continuously.

5- Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the flame of a

match or candle, or smoke from a cigarette, cigar or pipe.

6- After it has been determined that each appliance reĆ

maining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and

any other gas-burning appliance to their previous

condition of use.

7- If improper venting is observed during any of the above

tests, the common venting system must be corrected.

VERTICAL VENT

USING LINED

MASONRY CHIMNEY

H

G20R

FURNACE

L

PERMANENTLY

SEALED FIREĆ

PLACE OPENING

FIGURE 10

Removal of Unit from Common Venting System

In the event that an existing furnace is removed from a

venting system commonly run with separate gas apĆ

pliances, the venting system is likely to be too large to

properly vent the remaining attached appliances. The

following test should be conducted while each apĆ

pliance in operation and the other appliances not in opĆ

eration remain connected to the common venting sysĆ

tem. If the venting system has been installed

improperly, the system must be corrected as outlined

in the previous section.

1- Seal any unused openings in the common venting

system.

2- Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other deficiencies

which could cause an unsafe condition.

3- Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on clothes dryers and any appliances

not connected to the common venting system. Turn

Horizontal Venting

This furnace is design certified by the American Gas

Association for horizontal venting through an outside

wall only with the use of a Field Controls Company

Model #SWG-5L side wall venting kit available from

Lennox Dealer Service Center. No other Field brand

venting kit or any other manufacturer's venting kit is acĆ

ceptable. Horizontal venting of this furnace without the

use of the above stated kit is prohibited. See figure 11

for field wiring of side wall horizontal venting kit.

When horizontally vented, minimum clearance for terĆ

mination from electric meters, gas meters, regulators

and relief equipment is 4 ft. (1.2m).

At vent termination, care must be taken to maintain proĆ

tective coatings over building materials (prolonged exĆ

posure to exhaust condensate can destroy protective

coatings). It is recommended that the exhaust outlet not

be located within 6 ft. (1.8m) of a condensing unit beĆ

cause the condensate can damage the painted coating.

SIDE WALL VENTING KIT WIRING

CK-40 CONTROL BOX

C

PPC-5

(OPTIONAL)

PRESSURE

SWITCH

NO

L1

120VAC

L2

3

1

L1 MN

75

A

B

RELAY

T1 T2 T3

M

THERMOSTAT CONNECTIONS

TERMINAL IN FURNACE

JUNCTION BOX

WR Y G

SWG

POWER

VENTER

MOTOR

FACTORY INSTALLED WIRING

FIELD INSTALLED WIRING

T

G

R

W

Y

24 VAC

THERMOSTAT

FIGURE 11

Page 9

Page 10

GAS PIPING

Nominal

Internal

Gas Supply

1- This unit is shipped standard for left side installation of

gas piping. Simply connect gas supply to piping asĆ

sembly.

2- A piping hole is also fabricated in the right side of the

unit for alternate piping arrangements.

3- When connecting gas supply, factors such as length

of run, number of fittings and furnace rating must be

considered to avoid excessive pressure drop. Table 4

lists recommended pipe sizes for typical applications.

4- Gas piping must not run in or through air ducts,

clothes chutes, chimneys or gas vents, dumb waiters

or elevator shafts.

5- Piping should be sloped 1/4 inch per 15 feet upward toĆ

ward the meter from the furnace. The piping must be

supported at proper intervals (every 8 to 10 feet) using

suitable hangers or straps. A drip leg should be installed

in vertical pipe runs to the unit.

6- In some localities, codes may require installation of a

manual main shut-off valve and union (furnished by

installer) external to the unit. Union must be of the

ground joint type.

unit. Tap must be accessible for test gauge connection.

See figure 12.

NOTE-In case emergency shutoff is required, shut off

main manual gas valve and disconnect main power to

unit. These devices should be properly labeled by the inĆ

staller.

MANUAL

MAIN SHUT-OFF VALVE

(With 1/8" NPT

Plugged Tap Shown)

GROUND

JOINT

UNION

FIELD

PROVIDED

AND INSTALLED

(with manual shut-off valve)

DRIP LEG

AUTOMATIC

GAS VALVE

LEFT SIDE PIPING

(STANDARD)

AUTOMATIC GAS VALVE

(with manual shut-off valve)

RIGHT SIDE PIPING

(ALTERNATE)

MANUAL

MAIN SHUT-OFF VALVE

(With 1/8" NPT

Plugged Tap

Shown)

IMPORTANT

Compounds used on threaded joints of gas piping

must be resistant to the actions of liquified pertoĆ

leum gases.

NOTE-Installer must provide a

1/8" N.P.T. plugged tap in the

field piping upstream of the gas supply connection to the

24

(.68)

52

(1.47)

97

(2.75)

200

(5.66)

375

(10.62)

770

(21.80)

1180

(33.41)

2200

(62.30)

3520

(99.67)

TABLE 4

Nominal Internal

Iron Pipe Size

-Inches(mm)

1/4

(6.35)

3/8

(9.53)

1/2

(12.7)

3/4

(19.05)

1

(25.4)

1-1/4

(31.75)

1-1/2

(38.1)

2

(50.8)

2-1/2

(63.5)

Diameter

-Inches(mm)

.364

(9.246)

.493

(12.522)

.622

(17.799)

.824

(20.930)

1.049

(26.645)

1.380

(35.052)

1.610

(40.894)

2.067

(52.502)

2.469

(67.713)

GAS PIPE CAPACITY - FT3/HR (kL/HR)

10

(3.048)20(6.096)30(9.144)40(12.192)50(15.240)60(18.288)70(21.336)80(24.384)90(27.432)

43

(1.13)

95

(2.69)

175

(4.96)

360

(10.19)

680

(19.25)

1400

(39.64)

2100

(59.46)

3950

(111.85)

6300

(178.39)

29

(.82)

65

(1.84)

120

(3.40)

250

(7.08)

465

(13.17)

950

(26.90)

460

(41.34)

2750

(77.87)

4350

(123.17)

Length of Pipe-Feet(m)

20

(.57)

45

(1.27)

82

(2.32)

170

(4.81)

320

(9.06)

660

(18.69)

990

(28.03)

1900

(53.80)

3000

(84.95

18

(.51)

40

(1.13)

73

(2.07)

151

(4.28)

285

(8.07)

580

(16.42)

900

(25.48)

1680

(47.57)

2650

(75.04)

16

(.45)

36

(1.02)

66

(1.87)

138

(3.91)

260

(7.36)

530

(15.01)

810

(22.94)

1520

(43.04)

2400

(67.96)

FIGURE 12

15

(.42)

33

(.73)

61

(1.73)

125

(3.54)

240

(6.80)

490

(13.87)

750

(21.24)

1400

(39.64)

2250

(63.71)

(13.03)

(19.54)

(36.81)

(58.05)

14

(.40)

31

(.88)

57

(1.61)

118

(3.34)

220

(6.23)

460

690

1300

2050

GROUND

JOINT

UNION

DRIP LEG

13

(.37)

29

(.82)

53

(1.50)

110

(3.11)

205

(5.80)

430

(12.18)

650

(18.41)

1220

(34.55)

1950

(55.22)

100

(30.480)

12

(.34)

27

(.76)

50

(1.42)

103

(2.92)

195

(5.52)

400

(11.33)

620

(17.56)

1150

(32.56)

1850

(52.38)

Page 10

Page 11

3

(76.2)

4

(101.6)

3.068

(77.927)

4.026

(102.260)

11000

(311.48)

23000

(651.27)

7700

(218.03)

15800

(447.39)

6250

(176.98)

12800

(362.44)

5300

(150.07)

10900

(308.64)

4750

(134.50)

9700

(274.67)

4300

(121.76)

8800

(249.18)

3900

(110.43)

8100

(229.36)

3700

(104.77)

7500

(212.37)

NOTE-Capacity given in cubic feet of gas per hour (kilo liters of gas per hour) and based on 0.60 specific gravity gas.

3450

(97.69)

7200

(203.88)

3250

(92.03)

6700

(189.72)

Page 11

Page 12

Leak Check

After gas piping is completed, carefully check all piping

connections (factory and field) for gas leaks. Use a leak

detecting solution or other preferred means.

CAUTION

Some soaps used for leak detection are corrosive

to certain metals. Carefully rinse piping thoroughly

after leak test has been completed. Do not use

matches, candles, flame or other sources of igniĆ

tion to check for gas leaks.

NOTE-In case emergency shutdown is required, shut

down main manual gas valve and disconnect main

power to unit. These devices should be properly laĆ

beled by the installer.

IMPORTANT

When testing pressure of gas lines, gas valve must

be disconnected and isolated. See figure 13. Gas

valves can be damaged if subjected to more than

1/2 psig (3.48 kPa).

MANUAL MAIN

SHUT-OFF VALVE

WILL NOT HOLD

NORMAL TEST

PRESSURE

CAP

FIGURE 13

The furnace must be isolated from the gas supply sysĆ

tem by closing its individual manual shut-off valve durĆ

ing any pressure testing of the gas supply system at

pressures equal to or less than 1/2 psig (3.48 kPa).

G20RXE Series Units

IMPORTANT-G20RXE series units (units equipped with

flame rods) are approved for use with natural gas only.

ISOLATE

GAS VALVE

FURNACE

ELECTRICAL

Refer to figure 14 for thermostat wiring, figure 15 for

BCC location, figure 16 for pointĆtoĆpoint field wiring,

and figure 17 for schematic wiring diagram and troubleĆ

shooting.

1- Select fuse and wire size according to motor amps.

2- Snaphole plugs are provided on both sides of cabinet

to facilitate wiring.

3- Install room thermostat according to instructions proĆ

vided with thermostat.

4- Install a separate fused disconnect switch near the

unit so power can be turned off for servicing.

5- Route thermostat wire as shown in figure 14. Keep

wire away from draft hood and flue pipe. Do not route

wire across draft hood.

6- Complete wiring connections to equipment using wiring

diagrams provided with unit and in figures 15, 16 and 17.

Use 18 gauge wire or larger for thermostat connections.

7- Electrically ground unit in accordance with local codes

or, in the absence of local codes, in accordance with the

current National Electric Code (ANSI/NFPA No. 70) and

in Canada with the current Canadian Electric Code part

1 (CSA standard C22.1).

8- A 120 volt accessory terminal (ACC) is provided on

the BCC blower control center. Any accessory rated

up to 1 amp can be connected to this terminal and the

neutral leg of the accessory can be attached to any

free 120 volt neutral terminal on the BCC blower conĆ

trol center. The accessory terminal is energized whenĆ

ever the blower is in operation. See figure 15 . A trouĆ

bleshooting flowchart for the BCC blower control is

located at the end of this manual.

9- The continuous fan (CF) 120 volt terminal is used with

an optional continuous low fan kit that is available

from Lennox. The kit allows the furnace blower to run

continuously on low speed.

10- Check the thermostat selector jumper on the BCC

board. The jumper is factoryĆpositioned for use

with a mechanical thermostat. This jumper must

be repositioned if an electronic thermostat will be

used in the application.

Page 12

Page 13

THERMOSTAT WIRE ROUTING

ROUTE WIRE AWAY FROM

DRAFT HOOD

BCC

G20R BLOWER CONTROL CENTER

ACCESSORY

TERMINAL

HEATING

SPEED TAP

TERMINAL

BLOWER TIME

ADJUSTMENT

JUMPER

GAS VALVE

Left side thermostat wire entry.

Right side thermostat wire entry.

FIGURE 14

IGNITION

CONTROL

DUMMY

TERMINALS

CONTINUOUS

FAN

TERMINAL

COOLING

SPEED TAP

TERMINAL

NEUTRAL

TERMINALS

THERMOSTAT JUMPER

(Electronic or Mechanical)

TYPICAL G20R FIELD WIRING DIAGRAM

DAMPER

DOOR

SWITCH

FLAME

ROLLOUT

SWITCH

BLOCKED

VENT

SHUTOFF

SWITCH

PRIMARY

LIMIT

IGNITION

CONTROL

FIGURE 15

FUSED DISCONNECT SWITCH

(FURNISHED BY INSTALLER)

THERMOSTAT

CONNECTIONS

L1 N

THERMOSTAT

YRWG

TO COMPRESSOR

CONTACTOR

GAS

VALVE

BCC CONTROL

FIGURE 16

SECONDARY

LIMIT

TRANSFORMER

MAKE-UP

BOX

BLACK

WHITE

GWYTR

DOOR

INTERLOCK

SWITCH

FIELD INSTALLED LOW VOLTAGE

FIELD INSTALLED LINE VOLTAGE

GROUND

Page 13

Page 14

TYPICAL G20R WIRING DIAGRAM

FIGURE 17

Page 14

Page 15

UNIT START–UP

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING

Do not use this furnace if any part has been underĆ

water. Immediately call a qualified service techniĆ

cian to inspect the furnace and to replace any part

of the control system and any gas control which

has been under water.

WARNING

If overheating occurs or if gas supply fails to shut

off, shut off the manual gas valve to the appliance

before shutting off electrical supply.

CAUTION

Before attempting to perform any service or mainĆ

tenance, turn the electrical power to unit OFF at

disconnect switch.

BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the floor because some

gas is heavier than air and will settle on the floor.

Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or turn

by hand, do not try to repair it, call a qualified service techĆ

nician. Force or attempted repair may result in a fire or exĆ

plosion.

To place G20R furnace into operation:

G20R units are equipped with an intermittent pilot igniĆ

tion system. Do not attempt to manually light pilots on

these furnaces. Each time thermostat calls for heat, the

pilot will automatically light. The pilot goes out when

there is no demand for heat.

WARNING

THERMOSTATS

FIGURE 18

4- This appliance is equipped with an ignition device

which automatically lights the pilot. Do not try to light

the pilot by hand.

5- Remove lower access panel.

6- On Honeywell VR8204 gas valves, turn knob on gas

valve clockwise to OFF. Units with Robertshaw

7200 gas valve, depress lever and move to OFF posiĆ

tion. Do not force. See figures 19 and 20.

7- Wait fifteen (15) minutes to clear out any gas. If you then

smell gas, STOP! Immediately call your gas supplier from

a neighbor's phone. Follow the gas supplier's instrucĆ

tions. If you do not smell gas go to next step.

HONEYWELL VR8204 SERIES GAS VALVE

ON

OFF

GAS VALVE SHOWN IN OFF POSITION

FIGURE 19

ROBERTSHAW 7200 GAS VALVE

GAS VALVE

SELECTOR

ARM

IN OFF

POSITION

If you do not follow these instructions exactly, a fire

or explosion may result causing property damage,

personal injury or loss of life.

Gas Valve Operation (Figures 19 & 20)

1- STOP! Read the safety information at the beginning of

this section.

2- Set thermostat to lowest setting. See figure 18.

3- Turn off all electrical power to appliance.

FIGURE 20

8- On Honeywell VR8204 gas valves, turn knob on gas

valve counterclockwise to ON. Units with RobertĆ

shaw 7200 gas valve, depress lever and move to ON

position. Do not force.

9- Replace lower access panel.

10-Turn on all electrical power to unit.

Page 15

Page 16

11-Set thermostat to desired setting.

NOTE-When unit is initially started, steps 1 through 11

may need to be repeated to purge air from pilot line.

12- If the appliance still will not operate, follow the instrucĆ

tions To Turn Off Gas To Unit" and call your service

technician or gas supplier.

To Turn Off Gas To Unit

1- Set thermostat to lowest setting.

2- Turn off all electrical power to unit if service is to be perĆ

formed.

3- Remove lower access panel.

4- On Honeywell VR8204 gas valves, turn knob on gas

valve clockwise to OFF. Units with Robertshaw 7200

gas valve, depress lever and move to OFF position. Do

not force.

5- Replace lower access panel.

Correct manifold pressure for natural gas is 3.5"

w.c. (.87kPa). No adjustment is needed in high altiĆ

tude applications. See figures 22 and 21 for gas

pressure adjustment screw location.

HONEYWELL GAS VALVE

REGULATOR ADJUSTMENT SCREW LOCATION

PRESSURE REGULATOR

ADJUSTING SCREW

(White)

CAP SCREW

(Black)

INLET

PRESSURE

TAP

GAS INLET

HIGH ALTITUDE INFORMATION

G20R series units are certified for installations from 0 to

4000 feet (0 to 1219m) above sea level without modificaĆ

tion. For installations from 4000 feet to 7500 feet (1219m

to 2286m) above sea level, a high altitude kit (44H56)

must be installed. The kit contains special flue baffles

used to replace factory-installed baffles. No derate is reĆ

quired.

GAS PRESSURE ADJUSTMENT

Gas Flow

To check for proper gas flow to combustion chamber, deĆ

termine Btu input from appliance rating plate. Divide this

input rating by the Btu per cubic foot of available gas. ReĆ

sult is the required number of cubic ft. per hour. DeterĆ

mine the flow of gas through gas meter for two minutes

and multiply by 30 to get the hourly flow of gas to burner.

Gas Pressure

1- Check gas line pressure with unit firing at maximum

rate. A minimum of 4.5" w.c. (1.12kPa) for natural

gas or 10.5" w.c. (2.61kPa) for LP/propane gas

should be maintained.

2- After line pressure has been checked and adjusted,

check manifold pressure. Correct manifold presĆ

sure for LP/propane gas is 9.5" w.c. (2.36kPa) No adĆ

justment is needed in high altitude applications.

A natural gas to LP/propane gas changeover kit is

required to convert unit. Refer to the installation

instructions supplied with changeover kit for conĆ

version procedure.

FIGURE 21

ROBERTSHAW 7200 GAS VALVE

REGULATOR ADJUSTMENT SCREW LOCATION

REGULATOR

COVER SCREW

INLET

PRESSURE

TAP

ADJUSTING

SCREW

FIGURE 22

OTHER UNIT ADJUSTMENTS

Limit Control

Limit Control-Factory set at 90 seconds: No adjustment

necessary. If nuisance tripping of limit control occurs, fan

may need to run longer. See Fan Control section below.

Fan Control

The fan on time of 45 seconds is not adjustable. Fan off

time (time that the blower operates after the heat deĆ

mand has been satisfied) can be adjusted by moving

the jumper on the BCC blower control center. The unit

is shipped with a factory fan off setting of 90 seconds.

Fan off time will affect comfort and is adjustable to satĆ

isfy individual applications. See figure 23.

Page 16

Page 17

FAN OFF TIME ADJUSTMENT

270

150 210

90

90 SECOND FAN

OFF TIME

270

150 210

90

210 SECOND FAN

OFF TIME

NO JUMPER

JUMPER

JUMPER

150 210

JUMPER

270 SECOND FAN

270

330 SECOND FAN

90

270

150

150 SECOND FAN

OFF TIME

270

150 210

90

OFF TIME

OFF TIME

210

90

JUMPER

FIGURE 23

Temperature Rise

Check temperature rise and, if necessary, adjust blowĆ

er speed to maintain temperature rise within range

shown on unit rating plate.

Thermostat Selector Jumper

Check the thermostat selector jumper on the BCC

board. The jumper is factoryĆpositioned for use with a

mechanical thermostat. This jumper must be reposiĆ

tioned if an electronic thermostat will be used in the apĆ

plication.

Thermostat Adjustment

Thermostat anticipator setting (if adjustable) should be

set according to amps listed on wiring diagram on unit.

Electrical

1- Check all wiring for loose connections.

2- Check for correct voltage at unit (unit operating).

3- Check amp-draw on blower motor.

Motor Nameplate__________Actual__________

Flue and Chimney

1- Check flue pipe, chimney and all connections for

tightness and to make sure there is no blockage.

2- Check unit for proper draft.

Blower Speeds

Blower speed tap selection is accomplished by changing

the taps at the harness connector at the blower motor.

Disconnect harness connector from motor to expose

speed selectors. See figure 24 and unit wiring diagram.

1- Turn off electrical power to furnace.

2- Remove filter access panel.

3- Lift left side filter over left support angle. For easy hanĆ

dling, hold filter at center bottom.

4- Rotate filter sideways and pull it through the blower

access panel opening.

5- Grasp blower motor harness connector located on

back on motor. Depress lock tab and pull connector

from motor.

6- Pull harness connector and wires through blower acĆ

cess panel opening.

7- Select desired taps for heating and cooling. (White =

common, Red = heating, Black = cooling)

8- Depress harness connector tab to release wire termiĆ

nal. Select connector location for new speed (refer to

unit wiring diagram). Insert wire terminal until it is seĆ

curely in place. See figure 24.

9- Replace harness connector to motor until it is securely

in place.

BLOWER SPEED TAP SELECTION

HARNESS

CONNECTOR

DEPRESS TAB TO RELEASE

WIRE TERMINAL. SELECT CONĆ

NECTOR LOCATION FOR NEW

SPEED (REFER TO UNIT WIRING

DIAGRAM). INSERT WIRE UNTIL

IT IS SECURELY IN PLACE.

FIGURE 24

Failure to Operate

If unit fails to operate check the following:

1- Is thermostat calling for heat?

2- Is main disconnect switch closed?

3- Is there a blown fuse?

4- Is filter dirty or plugged? Dirty or plugged filters will

cause unit to go off on limit control.

5- Is gas turned on at meter?

6- Is manual main shut-off valve open?

7- Is internal manual shut-off valve open?

After items 1 through 7 have been checked and unit still

will not start, manually reset vent safety shut-off switch

located at the right side of draft hood. If unit operation reĆ

sumes and then cuts out again, inspect furnace vent sysĆ

tem for proper sizing and installation. Also, check for

vent blockage and for proper draft. If unit still does not

start, reset roll-out switch on burner box. See figure 27. If

unit starts and cuts out, check heat section for blockage.

Pilot and Burner Flame

CAUTION

Check pilot flame and burner flame periodically to

ensure proper operation.

1- Pilot Flame -- Pilot flame must surround the end of

flame sensor for proper operation of pilot safety cirĆ

cuit. See figure 25.

Page 17

Page 18

2- Burner Flame -- Start burner and allow to operate for

a few minutes to establish normal burning conditions.

Check burner flame by observation. Flame should be

predominantly blue in color, strong in appearance

and should rise directly from the burner ports in the

heat exchanger. Check to see that flame is burning

from all continuous ribbon ports and that flame does

not impinge on the sides of the heat exchanger. Refer

to figure 26.

FLAME SHOULD

ENGULF UPPER

1/3 OF FLAME SENSOR

BURNER

PILOT FLAME

(Side View)

FLAME SENSOR

TABLE 5

MODEL NO. FILTER SIZE

Q2/3-50, Q3-75

Q4-75, Q3/4-100

Q5-100, Q3-125, Q4/5-125

Q4/5-150 20 X 16 X 1

-150 UNITS

MAKE SURE FILTER IS PLACED

INTO THIS CHANNEL

ROTATE FILTER

TO REMOVE

20 X 10 X 1

20 X 12 X 1

20 X 14 X 1

-150 UNITS

RIGHT

FILTER

LEFT FILTER

TAB

PILOT GAS

LINE

ELECTRODE

FIGURE 25

BURNER FLAME

NOTE-VIEW BURNER FLAME THROUGH

DAMPER OPENING (Not Shown)

FIGURE 26

SERVICE

WARNING

Disconnect power before servicing unit.

CAUTION

Label all wires prior to disconnection when servicĆ

ing controls. Wiring errors can cause improper

and dangerous operation. Verify proper operation

after servicing.

At the beginning of each heating season, the system

should be checked as follows:

Blower

Check and clean blower wheel for any debris. Blower

motor is prelubricated for extended bearing life. No

further lubrication is needed.

Filters

G20R series units are equipped with two permanent inĆ

ternal filters which should be inspected monthly and

cleaned when necessary to assure proper furnace opĆ

eration. See table 5 for filter sizes. Use the following

procedure and figure 27 to clean filter.

RIGHT FILTER

LEFT

SUPPORT

ANGLE

SUPPORT ANGLE

(ON THREE SIDES)

BLOWER

FIGURE 27

1- Turn off electric power to furnace.

2- Remove upper access panel.

3- Remove blower access panel.

4- Lift left side filter over left support angle. For easy hanĆ

dling, hold filter at center bottom.

5- Rotate filter sideways and pull it through the blower

access panel opening.

6- Pull the second filter out the same way as the first.

7- Wash filters with warm water and mild detergent.

When dry, filters should be sprayed with filter handiĆ

coater before replacing. Filter Handicoater is RP prodĆ

ucts coating no. 418 and is available as Lennox part

no. P-8-5069.

8- Right filter should be under tab of right filter support angle.

9-Left filter must rest against top edge of right filter.

Flue and Chimney

Check flue pipe, chimney and all connections for tightĆ

ness and to make sure there is no blockage.

Cleaning Heat Exchanger and Burners

NOTE-Use papers or protective covering in front of furĆ

nace while cleaning furnace.

To clean heat exchanger:

1- Turn off both electrical and gas power supplies to furĆ

nace. Refer to figures 1 and 2 during disassembly and

reassembly procedures.

2- Remove burner and upper access panel, flue pipe

and draft hood.

Page 18

Page 19

3- Disconnect supply gas piping.

4- Remove screws holding burner box damper in place

and remove burner box damper assembly and dampĆ

er prove switch cover.

5- Remove screws securing removable burner box top.

6- Remove screws holding gas manifold in place and

pull burners from heat exchanger.

7- Remove baffles inside top opening of heat exchanger by

twisting tabs too align with slots in baffles.

8- Insert a 2 ft. (600 mm) steel rod that has a 20 in. (508

mm) length of chain attached to one end into top

opening of heat exchanger. See figure 28.

CLEANING HEAT EXCHANGER

Connect chain to rod and drop chain

down through top of heat exchanger.

Connect at bottom to another rod.

Move rods up and down, back and

forth to clean heat exchanger.

CLEANING PORTS

FIGURE 30

CLEANING INSIDE

FIGURE 31

FIGURE 28

9- Shake rod to drop chain through the clamshell into

burner cavity in bottom of heat exchanger.

10- Attach bottom of chain to another 2 ft. (600 mm) rod.

11-Push and pull the rods back and forth and up and

down with a vigorous motion. The chain will dislodge

the soot and scale deposits inside the heat exchangĆ

er. Repeat for each clamshell.

12- With a shop vacuum or rags, clean out soot and scale

deposits from bottom of heat exchanger.

To clean burners:

NOTE-FOR UNITS WITH FLAME RODS, remove two

springs and withdraw rods from back of burner. Clean

flame rods with wire brush. Continue with items 13

through 15 below and reinstall flame rods and springs.

13-Clean top of burner ports with a wire brush. See figĆ

ure 29.

14- Clean burner ports by inserting a cleaning tool (made

from a piece of sheet metal cut to fit the burner ports) and

work in and out of each port. See figure 30.

15-Clean inside of each burner with a bottle cleaning

brush. See figure 31.

CLEANING TOP

16-Replace burners making sure to fully engage in rear

receiving slot in heat exchanger. Resecure gas manĆ

ifold and supply piping.

17-Reinstall baffles inside top opening of heat exchanger

twisting tabs to secure baffles.

18-Resecure damper assembly, damper prove switch

cover and burner box top. Carefully open damper by

hand to ensure that the damper spring closes damper

correctly and that the damper prove switch is enĆ

gaged when damper is open.

CAUTION

Use extreme care when opening damper door to

prevent permanent damage to the damper motor.

19- Before replacing draft hood, flue pipe and access panels,

inspect draft hood gasket. Replace gasket if necessary.

20-Carefully check all piping connections (factory and

field) for gas leaks. Use a leak detecting solution or

other preferred means.

CAUTION

Some soaps used for leak detection are corrosive

to certain metals. Carefully rinse piping thoroughly

after leak test has been completed. Do not use

matches, candles, flame or other sources of igniĆ

tion to check for gas leaks.

FIGURE 29

21-Turn on gas and electrical supply.

Page 19

Page 20

REPAIR PARTS LIST

The following repair parts are available through indeĆ

pendent Lennox dealers. When ordering parts, include

the complete furnace model number listed on the

A.G.A. or C.G.A. rating plate Ċ Example: G20RQ4/5-150.

CABINET PARTS

Upper access panel

Lower access panel

Top strip

Control box cover

ELECTRICAL PARTS

Transformer

Blower Control Center (BCC)

Door Interlock Switch

BLOWER PARTS

Blower wheel

Motor

Motor mounting frame

Blower housing cut-off plate

Motor capacitor

HEATING PARTS

Heat exchanger

Draft hood

Main burners

Main burner orifices

Pilot burner

Gas manifold

Gas valve

Flame sensor

Ignition control

Ignition cable

Igniter

Vent pipe extension Pilot Mounting bracket

Pilot orifice

Main burner with pilot mount

Flue baffles

Pilot/electrode assembly

Primary limit control

Flame roll-out switch

Blocked vent shut-off switch

Damper motor

Damper switch

Couplings

Damper spring

Grommets

G20RE START–UP AND PERFORMANCE CHECK LIST

START-UP AND PERFORMANCE CHECK LIST

Job Name

Job Location

Installer

Unit Model No.

HEATING SECTION

Electrical Connections Tight?

Supply Voltage

Blower Motor H.P.

Blower Motor Lubrication O.K.?

Gas Piping Connections Tight & Leak-Tested?

Fuel Type: Natural Gas? LP/Propane Gas?

Furnace Btu Input

Line Pressure

Regulator Pressure

Blower Motor Amps

w.c. Ċ Nat.: w.c. Ċ LP/Propane

Job No.

City

City

Serial No.

Air Shutters Properly Adjusted (If Installed)?

Fan Control Setting (45 Seconds Fixed On)

Filter Clean & Secure?

Calibrated? Heat Anticipator Properly Set? Level?

Flue Connections Tight?

Date

State

State

Service

Technician

Proper Draft?

Temperature RiseFan Control Off Setting

Vent Clear?

THERMOSTAT

Page 20

Page 21

START

BCC

TROUBLESHOOTING

FLOWCHART

REPLACE

BCC

NO

(REMOVE R & G JUMPER)

NO

IS

120VAC ACROSS

N & ACC?

YES

JUMPER ACROSS

R &W

IS

DAMPER MOTOR

ON?

YES

YES

YES

DOES UNIT

OPERATE?

NO

CHECK FUSE.

REPLACE IF NEEDED.

IS

24VAC ACROSS

R & C?

YES

JUMPER ACROSS

SCREWS R & G

IS

BLOWER

RUNNING ON HIGH

SPEED?

IS

UNIT LIT?

YES

NO

NO

CHECK:

1-UNIT POWER

2-INTERLOCK SWITCH

3-TRANSFORMER

4-LIMIT SWITCH

NO

IS

120VAC ACROSS

N & A?

YES

CHECK BLOWER

WIRING AND

BLOWER

CHECK:

1-DAMPER MOTOR

2-IGNITION CONTROL

3-GAS VALVE

4-IGNITOR

5-LIMIT SWITCHES

6-PROVE SWITCH

NO

REPLACE

BCC

NO

REPLACE

BCC

END OF TEST

IS

120VAC ACROSS

N & CAB?

NO

REPLACE

BCC

YES

YES

IS

120VAC ACROSS

N & ACC?

YES

REMOVE

R & W

JUMPER

AFTER

THE SELECTED

TIME, DOES THE

BLOWER TURN

OFF?

CHECK

DAMPER MOTOR

WIRING AND

DAMPER MOTOR

YES

NO

IS BLOWER

RUNNING ON LOW

SPEED, 45 SEC.

AFTER FURNACE LIGHTS?

REPLACE

BCC

FIGURE 32

NO

IS

120VAC ACROSS

N & H?

NO

IS

24VAC ACROSS

C & V?

NO

CHECK

WIRING

YES

CHECK BLOWER

WIRING AND

BLOWER

YES

REPLACE

BCC

Page 21

Loading...

Loading...