Page 1

PRODUCT LITERATURE

¤

1992 Lennox Industries Inc.

Dallas, Texas

502,754M

9/98

Supersedes 4/95

£

*

6(5,(6

*$6 )851$&(

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury, or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinityofthisorany other appliance.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

Litho U.S.A.

:$51,1*

- Do not try to light any appliance.

- Extinguish any open flames.

- Do not touch any electrical switch; do not

use any phone in your building.

- Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

- If you cannot reach your gas supplier, call

the fire department.

3DJH

Page 2

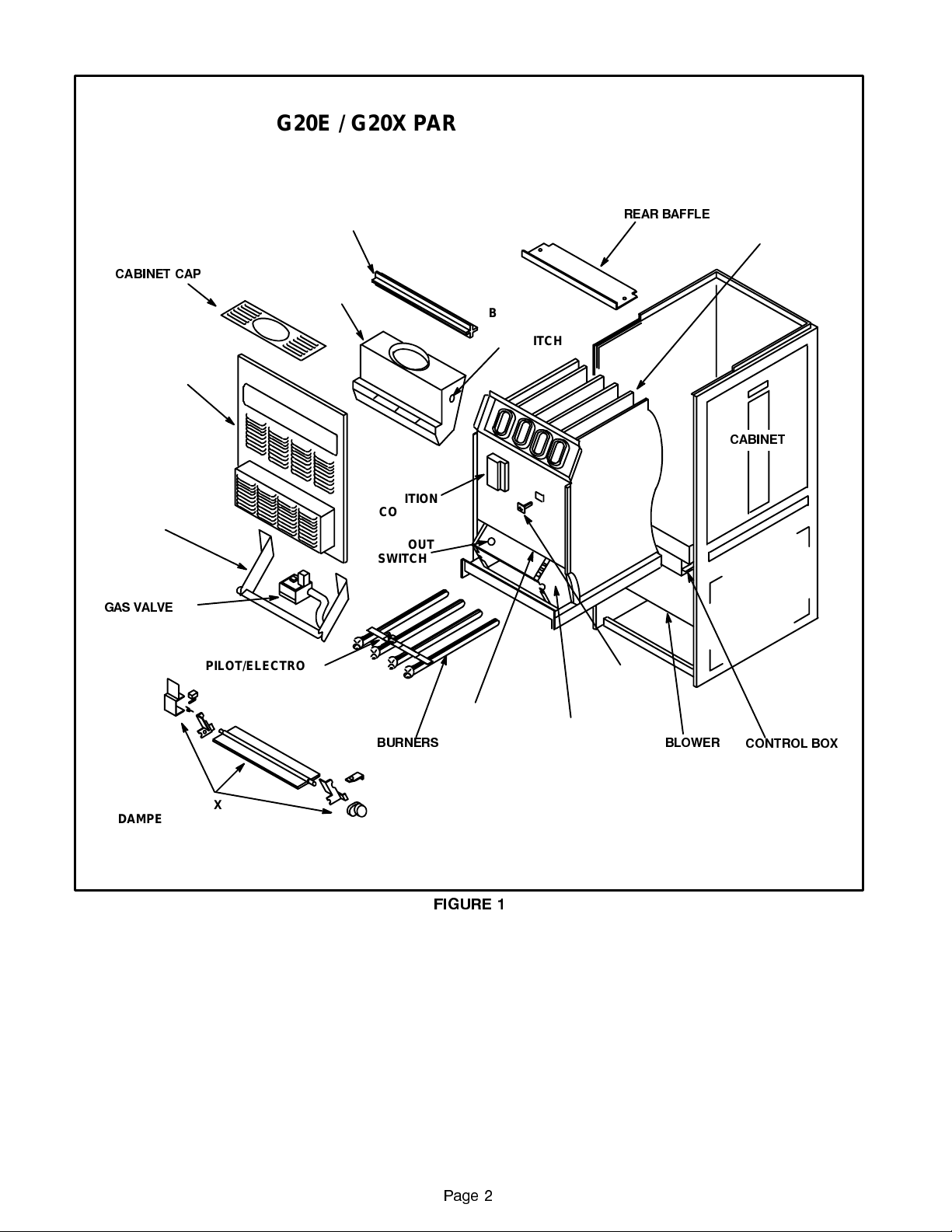

G20E / G20X PARTS IDENTIFICATION

&$%,1(7 &$3

UPPER ACCESS

PANEL

GAS

MANIFOLD

*$6 9$/9(

TOP STRIP

DRAFT

HOOD

IGNITION

CONTROL

ROLL-OUT

SWITCH

BLOCKED VENT

SHUT-OFF

SWITCH

5($5 %$))/(

HEAT

EXCHANGER

&$%,1(7

PILOT/ELECTRODE

ASSEMBLY

BURNER BOX

DAMPER ASSEMBLY

%851(56

REMOVABLE

BURNER

BOX TOP

),*85(

CONTROL

BURNER

BOX

LIMIT

%/2:(5

&21752/ %2;

3DJH

Page 3

WARNING

Product contains fiberglass wool.

Disturbing the insulation in this product during

installation, maintenance, or repair will expose you

to fiberglass wool. Breathing this may cause lung

cancer. (Fiberglass wool is known to the State of

California to cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

Toreduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact

your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379-9900

WARNING

Do not use this furnace if any part has been under

water. Immediately call a qualified service technician to inspect the furnace and to replace any part

of the control system and any gas control which

has been under water.

WARNING

If overheating occurs or if gas supply fails to shut

off, shut off the manual gas valve to the appliance

before shutting off electrical supply.

IMPORTANT

Any additions, changes, or conversions required

in order for the appliance to satisfactory meet the

application needs must be made by a Lennox service technician using factory specified and approved parts.

CAUTION

Before attempting to perform any service or maintenance, turn the electrical power to unit OFF at

disconnect switch.

holes, corrosion, or blockage. Inspect furnace return

air duct connection to ensure duct is sealed to the furnace and terminates outside the space containing the

furnace. Inspect the physical support of the furnace to

guarantee that it is sound without sagging, cracks or

gaps around base and it maintains seal between base

and support.

DO NOT

2-

unobstructed flow of combustion and ventilating air.

DO NOT

3-

introduce these products into the combustion air.

These products can cause furnace corrosion.

DO NOT draw return air from a room where this

4-

furnace, or any other gas appliance (ie., a water

heater), is installed.

aroom,anegativepressureiscreatedintheroom.If

a gas appliance is operating in a room with negative

pressure, the flue products can be pulled back down

the vent pipe and into the room. This reverse flow of

the flue gas may result in incomplete combustion

andtheformation ofcarbon monoxidegas.This toxic

gas might then be distributed throughout the house

by the furnace duct system.

Yourfurnace is agas appliance.

suppliedto theunit becompletely burned to avoidtheproduction of carbon monoxide gas. Complete combustion

of the gas requires, but is not limited to, correct gas pressure and gas flow rate, adequate combustion, air, and

proper venting.

obstruct air flow to unit. Unit must receive an

store chlorine or fluorine products near unit or

When return air is drawn from

Itis criticalthat the gas

WARNING

Carbon monoxide gas is invisible, odorless, and

toxic.

Exposure to this gas can cause personal injury and

even death to all oc cupant s, including pets. Any item

that is powered by or gives off heat from a combustion

process(includinglawnm owers ,automobiles,andfireplaces) has the potential to produce carbon monox ide

gas. Because of this,

of acarbon monoxidedetectorin your home,even

ifyo u do not own gas applian ces.

are available at reasonable retail prices . Contac t your

independent Lennox dealer for more details about this

investment in your safety.

Lennox recommends the use

Reliabledetector s

IMPORTANT DIRECTIONS

1- Keep the furnace area clear and free of combustible

material, gasoline, and other flammable vapors and liquids. If installed in an insulated area, furnace must be

kept free of insulating material. Insulating material may

be combu sti b l e. Inspect furnace venting system to

make sure it is in place, physically sound, and without

Yourfurnace isdesignedto meet standards set bynationalagencies,andto operate safely whenproperlyinstalled

and maintained. However,the unit’s performance can be

greatly impacted by the individual installation and the operating environment. It is your responsibility to ensure

that this appliance is maintained. Proper maintenance is

criticalfor your safety andthe satisfactory operationof the

3DJH

Page 4

product. Lennox strongly recommends annual inspection and maintenance of this appliance. Contact

your independent Lennox dealer for an inspection by a

qualified service technician.

+21(<:(// 95 6(5,(6 *$6 9$/9(

LIGHTING INFORMATION AND OPERATION

WARNING

Ifyou do not follow these instructions exactly,afire

or explosion may result causing property damage,

personal injury or death.

BEFORE OPERATING smell all around the appliance

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

Useonly your hand to push inor turn the gas control knob

or lever.Never use tools. If the knob or lever will not push

inorturnby hand,do nottry to repairit,calla qualifiedservice technician. Force or attempted repair may result in a

fire or explosion.

To place G20E or G20X furnace into operation:

G20E or G20X units are equipped with an intermittent pilotignitionsystem. Do not

on these furnaces. Each time thermostat calls for heat,

the pilot will automatically light. The pilot does not burn

when there is no call for heaton units with electronic ignitions.

Gas Valve Operation (Figures 3 and 4)

1- STOP! Read the safety information at the beginning

of this section.

2- Set thermostat to lowest setting. See figure 2.

THERMOSTATS

3- Turn off all electrical power to appliance.

4- This appliance is equipped with an ignition device

whichautomatically lights the pilot. Donot try to light

the pilot by hand.

5- Remove control access panel.

HoneywellVR8204 Gas Valve

6-

gas valve clockwise

Robertshaw 7200Gas Valve

move to OFF position. Do not force. See figure 4.

attempt to manually light pilots

FIGURE 2

-Turn the knobonthe

to OFF. See figure 3.

-Depress theleverand

ON

OFF

GAS VALVE SHOWN IN OFF POSITION

FIGURE 3

52%(576+$: *$6 9$/9(

GAS VALVE

SELECTOR

ARM

IN OFF

POSITION

),*85(

7- Waitfive (5) minutes toclear out any gas. If youthen

smell gas, STOP! Immediately callyour gassupplier

from a neighbor’s phone. Follow the gas supplier’s

instructions. If you do not smell gas go to next step.

Honeywell VR8204 Gas Valves

8-

the gas valve counterclockwise

Robertshaw 7200Gas Valve

- Turn the knob on

to ON.

-Depress theleverand

move to ON position. Do not force.

9- Replace control access panel.

10- Turn on all electrical power to unit.

11- Set thermostat to desired setting.

NOTE-When unit is initially started, steps 1 through 11

may need to be repeated to purge air from pilot line.

12- If the furnace still will not operate, follow the instruc-

tions “ToTurn Off Gas ToUnit” and call your service

technician or gas supplier.

To Turn Off Gas To Unit

1- Set thermostat to lowest setting.

2- Turn off all electrical power to unit if service is to be

performed.

3- Remove control access panel.

Honeywell VR8204 Gas Valves

4-

gas valve clockwise

Robertshaw 7200 Gas Valve-De

- Turn the knob on the

to OFF.

press the lever and

move to OFF position. Do not force.

5- Replace control access panel.

3DJH

Page 5

Filters

g

g

g

g

g

g

g

g

g

g

g

g

G20E and G20X series units are equipped with reusable

filters which should be inspected monthly and cleaned

whennecessary to assure proper furnace operation.See

table 1 for filter sizes. Use the following procedure to

clean filter.

1- Turn off electric power to furnace.

2- Remove blower access panel. Wait for blower to stop.

3- Remove filter by sliding up and out of filter brackets.

4- Wash filter with water and a mild detergent. For in-

creased efficiency, filter media should be sprayed

withfilter Handicoater when dry.Filter Handicoateris

RP products no. 418and is available as Lennox part

no. P-8-5069.

NOTE-If filter media must be replaced, order Lennox

part no.P-9-7831 for 20”x 25” filter,P-8-7822 for 16”

x 25” filter, 97H0601 for 18” x 25” filter, 97H0701 for

25” x25” filter, and 97H0801 for 24” x 30” filter.

5- Reinstall filter. Slide filter into top bracket and drop

into lower bracket.

NOTE-Do not replace reusable foam filters with

throw-away filters.

6- Replace blower access panel.

7$%/(

02'(/ 12

Q2-50, Q3-50, Q2-75,

Q3-75,

Q4-75, Q3/4-100 16X25X1 18X25X1

Q5/6-100, Q3/4-125,

Q5/6-125

4

6,'( 5(7851 %27720 5(7851

16 X 25 X 1

20 X 25 X 1

20 X 25 X 1

),/7(5 6,=(

16 X 25 X 1

; ;

; ;

Blower

Checkandclean blower wheel foranydebris. Blower motoris prelubricated forextended bearin

life.No further lu-

brication is needed.

Pilot and Burner Flame

PILOT FLAME

BURNER

PILOT GAS

LINE

(Side View)

FLAME SENSOR

ELECTRODE

(G20E & G20X)

FIGURE 7

Burner Flame

2-

a few minutes to establish normal burnin

--Start burner and allow to operate for

condi-

tions. Check burner flame by observation. Flame

should be predominantly blue in color, stron

in appearance and should rise directly from the burner

ports in the heat exchan

is burnin

from all continuous ribbon ports and that

flame does not impin

chan

er. See figure 8.

BURNER FLAME

NOTE-VIEW BURNER FLAME

THROUGH OBSERVATION PORT ON

BURNER BOX OR DAMPER OPENING

(Not Shown)

er.Check to see that flame

e on the sides of the heat ex-

FIGURE 8

VENTING SYSTEM INSPECTION

Annually (before heatingseason)inspectfurnaceventin

system, draft hood, vent cap, heat exchanger, burners

and pilot for corrosion, deterioration, or deposits of debris. Remove any obstructions.

Contact your Lennox dealer for a periodic unit inspection

by a qualified service technician.

CAUTION

Check pilot flame and burner flame periodically to

ensure proper operation.

Pilot Flame

1-

flame sensor for proper operation of pilot safety circuit. See fi

-- Pilot flame must surround the end of

ure 7.

BLOCKED VENT SHUT-OFF SYSTEM

Your Lennox furnace is equipped with a blocked vent

shut-off switch and a flame roll-out switch. The blocked

ventshut-offswitch shuts offthe

in the event of flue or vent blocka

switch shuts off the

as supply to the furnace if there is a

assupply tothe furnace

e. The flame roll-out

3DJH

Page 6

blockage of the heat exchanger.If the furnace fails to operate due to the functioning of either of these switches,

DONOT attempt to placethe furnaceinto operation.Contact a qualified service person.

SERVICE REMINDER

Call your Lennox service technician if unit is inoperative.

Before calling, always check the following to be sure service is required.

ness, the cause could be exposure to carbon monoxidegas. This is often misdiagnosed as the flu because

symptoms are similar. If you suffer from flu-like symptoms that are exaggerated at home, but seem to subside while you are away from the house, exposure to

carbon monoxide could be the cause.

Yourvigilance may pay off in early detection of a problem

before either personal injury or property damage occurs.

Do not hesitate to contact a qualified service technician

as an investment in your well being.

1- Check to see that electrical disconnect switches are

ON.

2- Check room thermostat for proper setting.

3- Replace any blown fuses or reset circuit breakers.

4- Gas valve should be ON.

5- Air filter should not be plugged limiting air flow.

6- Is gas turned on at meter?

7- Is manual main shut-off valve open?

6$)(7< 35(&$87,216

Tokeep yourLennox gas heating system in peak operating condition year after year, contact your independent

Lennox dealer about a planned service program.

If you discover any of the following, shut down your

unit, and contact an independent Lennox dealer for

an inspection by a qualified technician.

-

If you repeatedly hear any new or unfamiliar sounds

while your unit is operating, there may be a problem.

For example, poorly performing burners can produce

unfamiliar noises.

-

If you smell any unusual odors, your unit may beoperating improperly.For example, units can give offunfamiliar odors if components are required to operate in

abnormal conditions.

-

Look for visible signs of a malfunctioning unit. Examples include unusual amounts of condensate on windows inside your house, visibly burnt components or

unusual dirt or rust accumulations on the vent pipe or

in the unit.

-

If you experience headache, nausea, fatigue, or dizzi-

3/$11(' 6(59,&(

You should expect a service technician to check the following items during an annual inspection. Power to the

unit must be shut off for the service technician’s safety.

Fresh air grilles and louvers (on the unit and in the

room where the furnace is installed) - Must be open and

unobstructed to provide combustion air.

Burners- Must be inspected for rust, dirt, or signs of water.

Vent pipe - Must be inspected for signs of water, dam-

aged or sagging pipe, or disconnected joints.

Unit appearance - Must beinspected for rust, dirt, signs

of water, burnt or damaged wires, or components.

Blower access door -Must beproperlyinplace and providea seal between the return air andthe room where the

furnace is installed.

Return air duct - Must be properly attached and provide

an air seal to unit.

Operating performance - Unit must be observed during

operation to monitor proper performance of the unit and

the vent system.

Combustion gases - Flue products must be analyzed

and compared to the unit specifications.

Problems detected during the inspection may make it

necessary to temporarily shut down the furnace until the

items can be repaired or replaced.

Pay attention to your furnace. Situations can arise between annual furnace inspections that may result in unsafeoperation. For instance, itemsinnocently storednext

to the furnace may obstruct the combustion air supply.

This couldcauseincomplete combustion and theproduction of carbon monoxide gas.

3DJH

Loading...

Loading...