Lennox FCM 100, FCM 170, FCM 120, FCM 150, FCM 200 Installation, Operating And Maintenance

...Page 1

Providing indoor climate comfort

FLEXY & FLEXY WSHP

Installation, operating

and maintenance

FLEXYII-WSHP-IOM-0909-E

Page 2

Page 3

CONTENTS

FLEXYII_WSHP-IOM-0909-E Page 1

INSTALLATION

OPERATION

MAINTENANCE MANUAL

Ref. FLEXYII_WSHP-IOM-0909-E

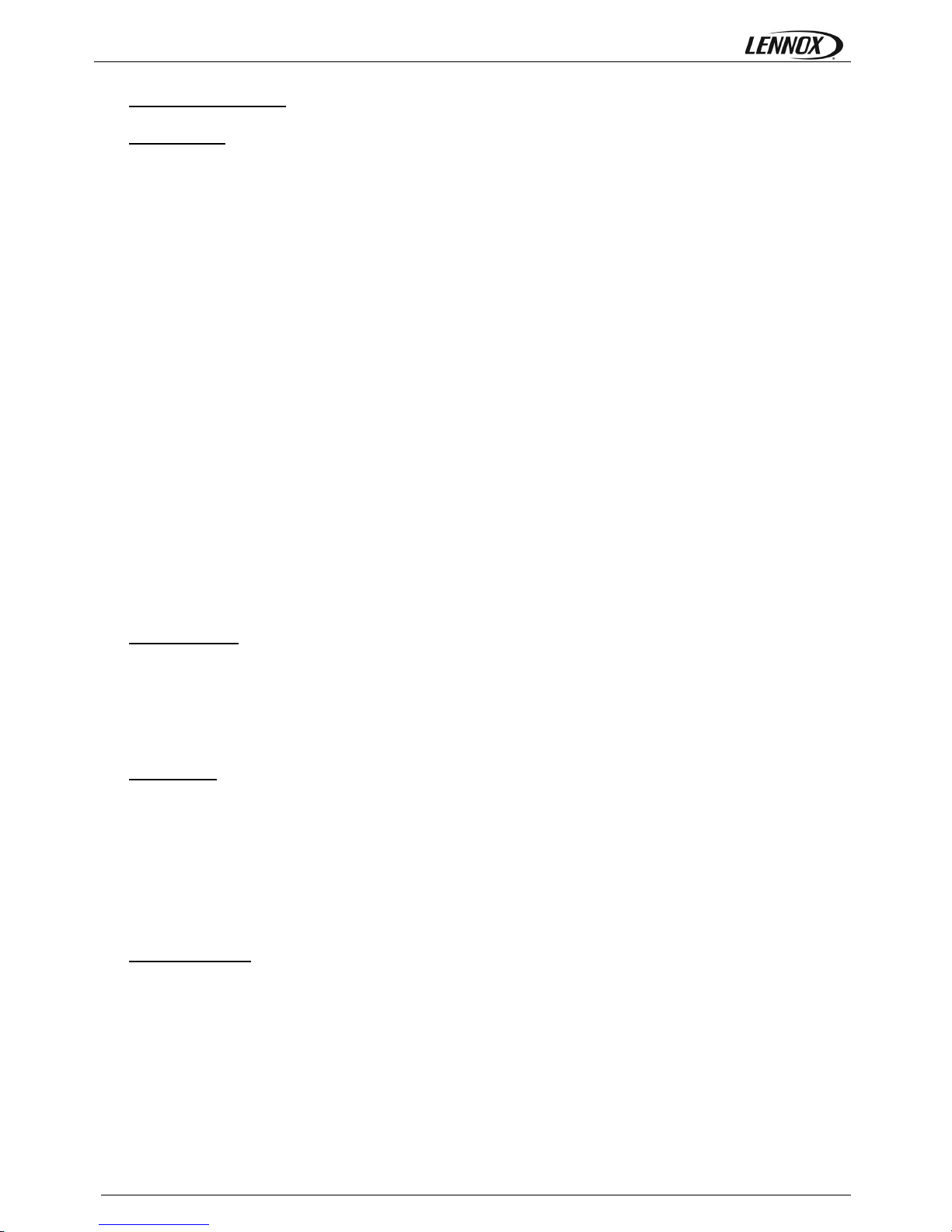

The present manual applies to the following ROOFTOP versions:

FCM 85 - FCM 100 - FCM 120 - FCM 150 - FCM 170 - FCM 200 - FCM 230

FHM 85 - FHM 100 - FHM 120 - FHM 150 - FHM 170 - FHM 200 - FHM 230

FDM 85 - FDM 100 - FDM 120 - FDM 150 - FDM 170 - FDM 200 - FDM 230

FGM 85 - FGM 100 - FGM 120 - FGM 150 - FGM 170 - FGM 200 - FGM 230

FWH 85 - FWH 100 - FWH 120 – FWH150 – FWH170

FWM 85 - FWM 100 - FWM 120 – FWM150 – FWM170

FXK 25 - FXK 30 - FXK 35 - FXK 40 - FXK 55 - FXK 70 - FXK 85 - FXK 100 - FXK 110 - FXK 150 - FXK 170

NOTES FOR UNIT FITTED WITH GAS BURNER:

All the technical and technological information contained in this manual, including any drawing and technical descriptions

provided by us, remain the property of Lennox and must not be used (except in operation of this product), reproduced, issued

to or made available to third parts without the prior written agreement of Lennox.

The technical informations and specifications contained in this manual are for reference only. The manufacturer reserves the right to modify

these without warning and without obligation to modify equipment already sold.

THE UNIT MUST BE INSTALLED IN ACCORDANCE WITH LOCAL SAFETY

CODES AND REGULATIONS AND CAN ONLY BE USED IN WELL

VENTILATED AREA.

PLEASE READ CAREFULLY THE MANUFACTURER'S INSTRUCTIONS

BEFORE STARTING THIS UNIT.

THIS MANUAL IS ONLY VALID FOR UNITS DISPLAYING THE FOLLOWING

CODES: GB IR GR DA NO FI IS

In case these symbols are not displayed on the unit, please refer to the technical

documentation which will eventually detail any modifications required to the

installation of the unit in a particular countr

y

.

Switchgear must be installed on each unit in accordance with the Machine

Directive and the standard NF EN 60204.

Page 4

CONTENTS

FLEXYII_WSHP-IOM-0909-E Page 2

COMMISSIONING SHEET....................................................................................................................................6

INSTALLATION

Transport - Handling.......................................................................................................................................10

Dimensions and weights.................................................................................................................................12

Lifting the units ...............................................................................................................................................14

Preliminary checks .........................................................................................................................................15

Minimum clearance around the unit................................................................................................................16

Duct connections ............................................................................................................................................17

Water connection (water source heat pump)..................................................................................................18

Water loop configuration (water source heat pump) ......................................................................................20

Installation on roof mounting frame ...............................................................................................................22

Curbing and flashing ......................................................................................................................................23

Non-adjustable non-assembled roof curb installation .....................................................................................24

Non-adjustable roof curb - Installation instructions.........................................................................................25

Adjustable roof curb .......................................................................................................................................26

Non-adjustable Non-assembled roof curb .....................................................................................................27

Multidirectional roof curb ...............................................................................................................................28

Return roof curb .............................................................................................................................................29

Return horizontal roof curb .............................................................................................................................30

Transition roof curb.........................................................................................................................................31

Energy Recovery............................................................................................................................................32

Economiser and extraction .............................................................................................................................44

COMMISSIONING

Before connecting the power..........................................................................................................................45

CLIMATIC.......................................................................................................................................................46

Powering the unit............................................................................................................................................46

Run test ..........................................................................................................................................................47

VENTILATION

Belt tension......................................................................................................................................................48

Mounting and adjusting pulleys.......................................................................................................................49

Airflow balancing............................................................................................................... ..............................50

Filters...............................................................................................................................................................58

Air sock control...............................................................................................................................................59

UV Light..........................................................................................................................................................60

HEATING OPTIONS

Hot water coils ...............................................................................................................................................61

Electric heater.................................................................................................................................................63

Gas burners....................................................................................................................................................64

Modulating gas burners ..................................................................................................................................75

Page 5

CONTENTS

FLEXYII_WSHP-IOM-0909-E Page 3

ELECTRICAL DATA: WIRING DIAGRAMS

Diagram reference legend ..............................................................................................................................84

Main current diagram TRI/400V/50Hz + T……………………………………………………...............................85

CLIMATIC 50 controller………………………………………………………………………….. ............................87

CLIMATIC 50 input…………………………………………………………………………………….......................88

CLIMATIC 50 output…………………………………………………………………………………. .......................89

DAD smoke detector……………………………………………………………………………… ...........................90

General customer connection (TCB) ..............................................................................................................91

General customer connection with Advanced Control Pack (ADC) ................................................................92

Gas burner 60 kW and hot water coil .............................................................................................................93

Gas burner 120 kW ........................................................................................................................................94

Gas burner 180/240 kW..................................................................................................................................95

Electric heater.................................................................................................................................................96

General customer connection diagram...........................................................................................................97

Electrical data control variables ......................................................................................................................98

REFRIGERATION CIRCUIT

R410A ............................................................................................................................................................99

Advanced scroll temperature protection (ASTP).............................................................................................100

Principle sketches...........................................................................................................................................101

HOT WATER COIL DIAGRAM .............................................................................................................................107

MAINTENANCE DIAGNOSTIC

.............................................................................................................................108

MAINTENANCE PLAN

.........................................................................................................................................112

WARRANTY

..........................................................................................................................................................115

CERTIFICATES

....................................................................................................................................................116

Page 6

IMPORTANT NOTICE – Safety instructions

FLEXYII_WSHP-IOM-0909-E Page 4

All FLEXY II Units are compliant with the PED directive 97-23/CE

The following note must be followed carefully

All work on the unit must be carried out by a qualified and authorised employee.

Non-compliance with the following instructions may result in injury or serious accidents.

Work on the unit:

• The unit shall be isolated from the electrical supply by disconnection and locking using the main isolating switch.

• Workers shall wear the appropriate personal protective equipment (helmet, gloves, glasses, etc.).

Work on the electrical system:

• Work on electric components shall be performed with the power off by employees having valid electrical qualification and

authorisation.

Work on the refrigerating circuit(s):

• Monitoring of the pressures, draining and filling of the system under pressure shall be carried out using connections provided

for this purpose and suitable equipment.

• To prevent the risk of explosion due to spraying of coolant and oil, the relevant circuit shall be drained and at zero

pressure before any disassembly or unbrazing of the refrigerating parts takes place.

• There is a residual risk of pressure build-up by degassing the oil or by heating the exchangers after the circuit has been

drained. Zero pressure shall be maintained by venting the drain connection to the atmosphere on the low pressure side.

• The brazing shall be carried out by a qualified brazier. The brazing shall comply with standard NF EN1044 (minimum 30%

silver).

Replacing components:

• In order to maintain CE marking compliance, replacement of components shall be carried out using spare parts, or using

parts approved by Lennox.

• Only the coolant shown on the manufacturer’s nameplate shall be used, to the exclusion of all other products (mix of

coolants, hydrocarbons, etc.).

CAUTION:

In the event of fire, refrigerating circuits can cause an explosion and spray coolant gas and oil.

TRANSPORT – HANDLING:

- Never lift the unit without forklift protections

- Remove the forklift protection before installation

- An approach ramp must be installed if the unit’s installation requirements tell that it's necessary to reach the main switch.

This recommendation is valid for installations in general and in particular for return and curbs. It’s also valid to reach other parts

of the unit: filters, refrigerant circuit, etc…

- It’s advised to fix curbs and roofcurbs to the unit

- Whatever the supply configuration is, respect a minimal duct’s length of 2m before any elbow or any duct’s section change.

COMMISSIONING:

- It must only be carried out by trained refrigeration engineers.

- Don’t forget to open the insulation valve on the liquid line before starting the unit

FILTERS:

- Do the filters fire classification’s choice according to local regulations.

FANSTART:

- Any adjustment has to be done power stopped.

GAS:

- Any work on gas module must be carried out by qualified personnel

- A unit with gas module must be installed in accordance with local safety codes and regulations and can only be used in

planed installation conditions for outdoor.

- Before commissioning this type of unit, it’s mandatory to ensure that the gas distribution system is compatible with the

adjustment and settings of the unit.

Page 7

IMPORTANT NOTICE – Safety instructions

FLEXYII_WSHP-IOM-0909-E Page 5

UV LIGHT :

- The UV lamp emits shortwave UV-C ultraviolet radiation which is harmful to skin and eyes

- It can cause serious skin burns and eye inflammation within ONE SECOND of exposure

- Do not enter the machine while UV are switched on

- Make sure the UV light circuit breaker is OFF when opening the return air section door and the supply air section doors

- The following logo will appear to inform about the UV-C radiation risk

Page 8

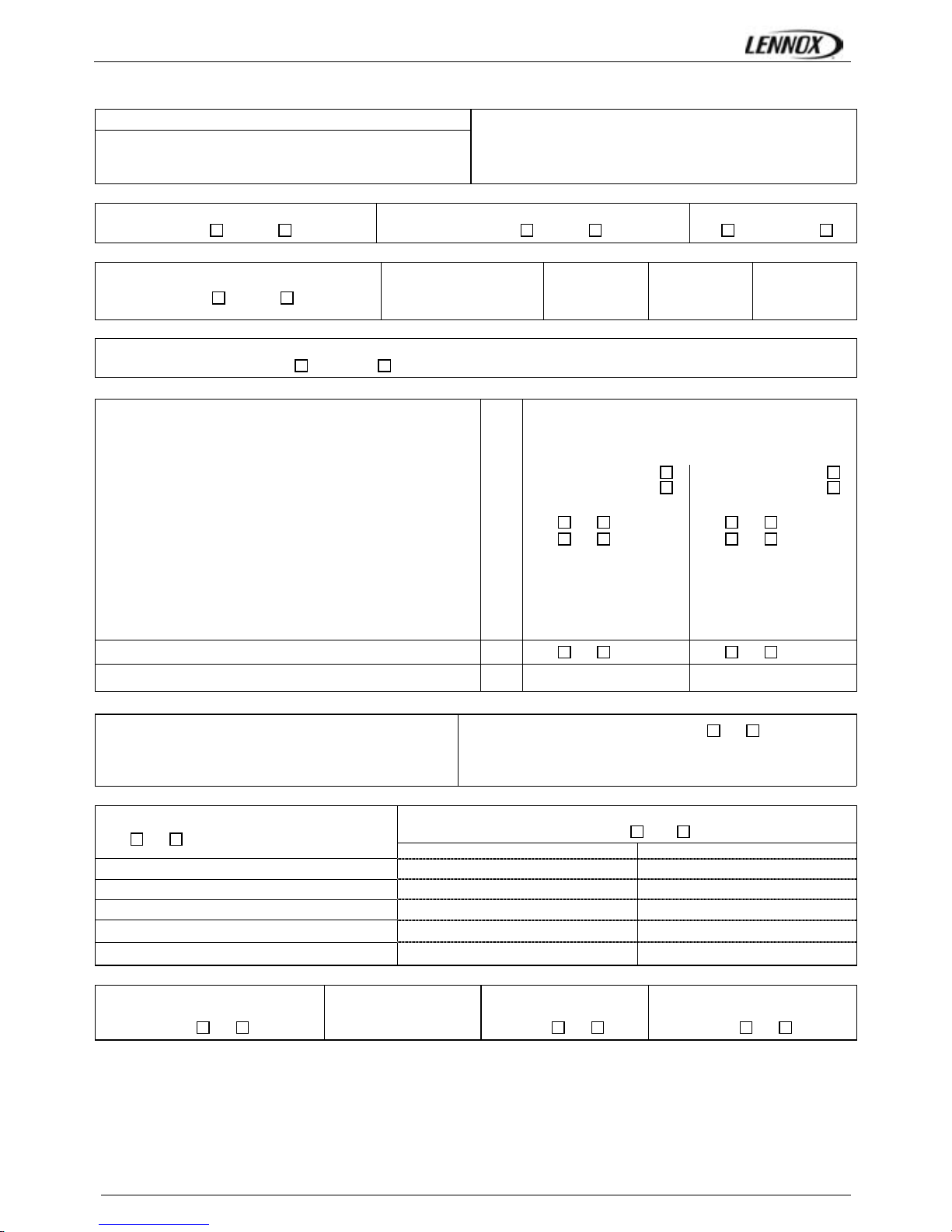

COMMISSIONNING REPORT

FLEXYII_WSHP-IOM-0909-E Page 6

Site details

Site

Unit Ref

Installer

………………………………………

……………………………………....

………………………………………

Controller

Model

Serial No

Refrigerant

………………………………….

……………….…………………

…………………………………

…………………………………

(1) ROOF INSTALLATION

Sufficient Access OK

Yes

No

Condensate drain fitted

Yes No

Roofcurb

OK Not OK

(2) CONNECTIONS CHECK

Phase check

Yes

No

Voltage between Phases

1 / 2

……………….

2 / 3

……………….

1 / 3

……………….

(3)CLIMATIC CONFIGURATION CHECK

CLIMATIC 50 Configured according to the Options and Specifications:

Yes

No

(4) SUPPLY BLOWER SECTION

Type :

Power displayed on plate:

Voltage displayed on plate:

Current displayed on plate:

KW

V

A

N°1

……………………

……………………

……………………

N°2

……………………

……………………

……………………

Fan Type : Forward

Backward

Forward

Backward

Displayed Belt Length : mm …………………… ……………………

Tension Checked: Yes No Yes No

Alignment Checked : Yes No Yes No

Motor Pulley Diameter: DM mm …………………… ……………………

Fan Pulley Diameter: DP mm …………………… ……………………

Fan Speed = Motor rpm x DM / DP

Averaged Measured Amps :

rpm

A

……………………

……………………

……………………

……………………

Shaft Mechanical Power (Refer to airflow balancing) W …………………… ……………………

Operating point checked : Yes No Yes No

Estimated Airflow

m3/h

…………………… ……………………

(5) AIRFLOW PRESS. SENSOR CHECK

Measured pressure drop…………………………… mbar

Set Points Adjusted: Yes

No

If Yes enter new values:

3410: ………… 3411: ………… 3412: …………

(6) EXTERNAL SENSOR CHECKS

Check and record temp. in menu 2110

Yes

Non

Check electrical connections :

Yes

No

100% Fresh Air 100% return Air

Supply Temperature ………………………..°C ………………………..°C

Return Temperature ………………………..°C ………………………..°C

Outdoor Temperature ………………………..°C ………………………..°C

Inlet Water Temp. (for Water Condensing) ………………………..°C ………………………..°C

Outlet Water Temp. (for Water Condensing) ………………………..°C ………………………..°C

(7) MIXING AIR DAMPERS CHECKS

Dampers open & close freely

OK

% Minimum FA: Power exhaust checked Enthalpy sensor(s) checked

Yes No ……………..% Yes No Yes No

Page 9

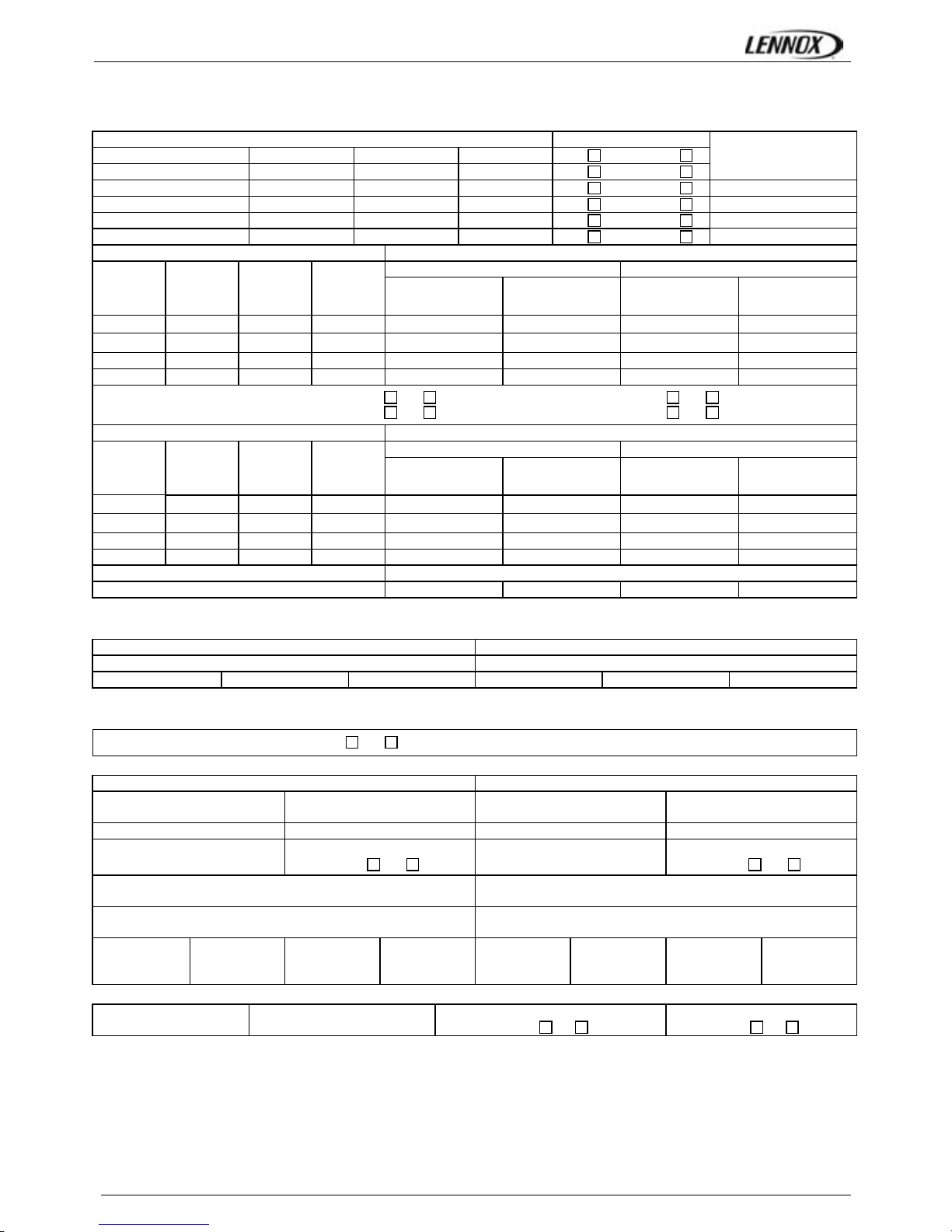

COMMISSIONNING REPORT

FLEXYII_WSHP-IOM-0909-E Page 7

(8) REFRIGERATION SECTION

Outdoor Fan Motor Current: Check Rotation

Motor 1 / Moteur 1 L1 ……..A L2 ……..A L3 ……A Yes No

Motor 2 / Moteur 2 L1 ……..A L2 ……..A L3 ……A Yes No

Compressor Voltage

Motor 3 / Moteur 3 L1 ……..A L2 ……..A L3 ……A Yes No Comp1: …….. V

Motor 4 / Moteur 4 L1 ……..A L2 ……..A L3 ……A Yes No Comp2: …….. V

Motor 5 / Moteur 5 L1 ……..A L2 ……..A L3 ……A Yes No Comp3: …….. V

Motor 6 / Moteur 6 L1 ……..A L2 ……..A L3 ……A Yes No Comp4: …….. V

Compressor Amps COOLING Pressures & Temperatures

Temperatures Pressures

Phase 1 Phase 2 Phase 3

Suction

Discharge

LP/ BP

HP / HP

Comp 1 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Comp 2 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Comp 3 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Comp 4 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Check Reversing valves :

Valve1: Yes

No

Valve2: Yes

No

Valve3: Yes

No

Valve4: Yes

No

Compressor Amps HEATING Pressures & Temperatures

Temperatures Pressures

Phase 1 Phase 2 Phase 3

Suction

Discharge

LP/ BP

HP / HP

Comp 1 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Comp 2 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Comp 3 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

Comp 4 …..… A …..… A …..… A ……… °C ……… °C ……… Bar ……… Bar

HP cut out ……Bar LP cut out ………..…... Bar

Refrigerant charge C1 : ………..kg C2 : ………..kg C3 : ………..kg C4 : ………..kg

(8)ELECTRIC HEATER SECTION

Type : …………………………………………………. Serial No.:………………………..

AMPS 1st stage (Baltic) AMPS 2nd stage (Baltic)

1 ………………. 2 ………………. 3 ………………. 1 ………………. 2 ………………. 3 ……………….

(9) HOT WATER COIL SECTION

Check Three Way Valve Movement : Yes No

(10) GAS HEATING SECTION

Gas Burner N°1 Gas Burner N°2

Size :

……………………….

Valve type :

…………………….

Size :

……………………….

Valve type :

…………………….

Pipe size:

Gas type : G…….

Pipe size

Gas type : G…….

Line pressure :

………………………

Drop test

Yes No

line pressure :

………………………

Drop test

Yes No

Check manifold pressure:

High fire …….…Low fire ………..

Check manifold pressure:

High fire …….…... Low fire ………..

Pressure cut out airflow press switch :

……………………mbar /Pa

Pressure cut out airflow press switch :

……………………mbar /Pa

Motor amps :

……….A

Flue temp.

……… °C

CO2 %:

………%

CO ppm:

………%

Motor Amps:

……….A

Flue temp.

………. °C

CO2 %:

………%

CO ppm:

………%

(11) REMOTE CONTROL BMS CHECK

Type :

…………………………..

Sensor type

………………………………..

KP07 KP/17 checked:

Yes No

Interconnect wiring checked:

Yes No

Page 10

COMMISSIONNING REPORT

FLEXYII_WSHP-IOM-0909-E Page 8

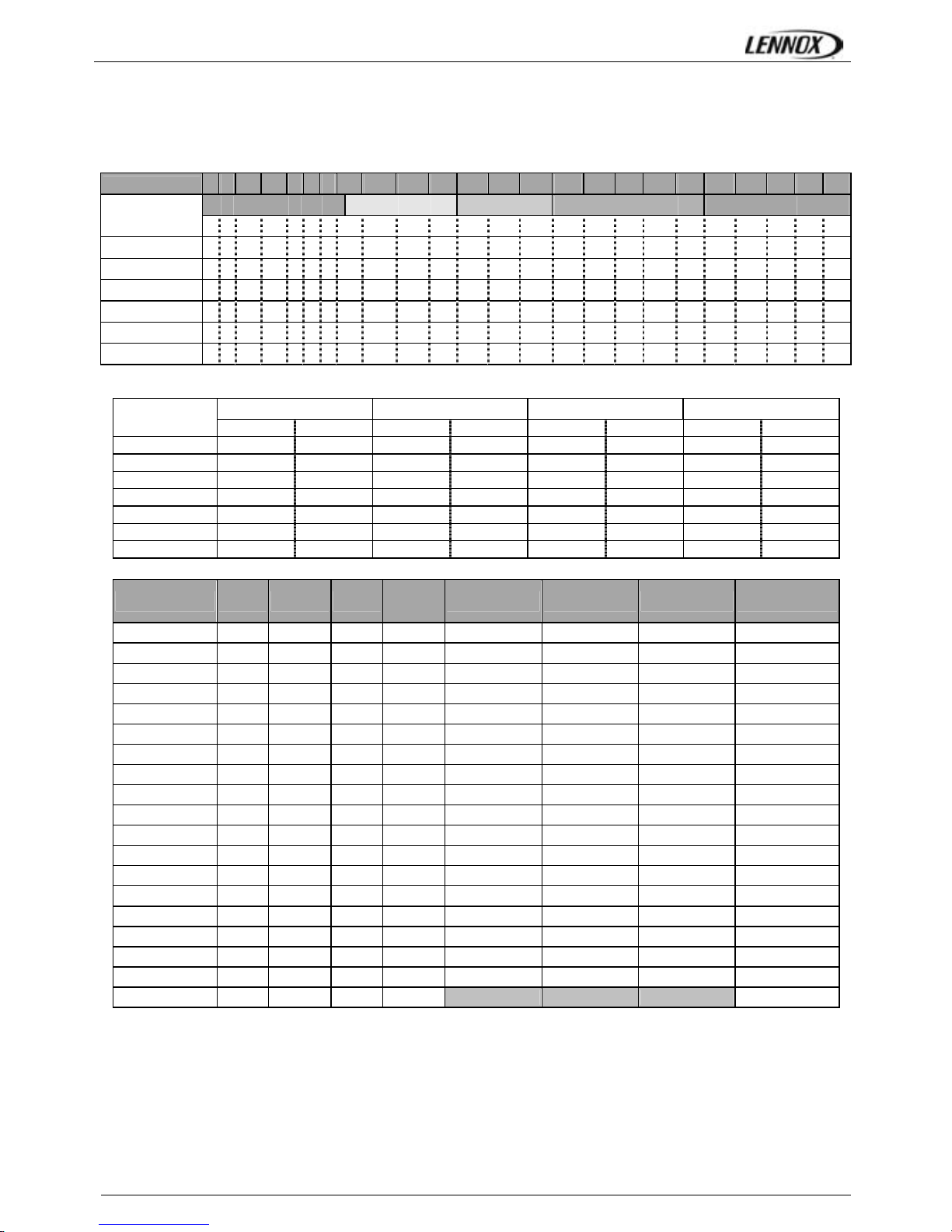

It is recommended that you fill the two tables below before transferring the zone settings to the Climatic 50 controller.

Refer to control section page 55 / Se référer à la section régulation page 55

Time Zones / Zones Horaires

Hour

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

Example

UNO

7h15

ZA

11h00

ZB

14h00

ZC

19h00

UNO

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

Variables to adjust for each time zone / Consignes à renseigner pour chaque zone horaire

Start z.A Start z.B Start z.C Start UNO

hour (3211) min (3212) hour (3213) min (3214) hour (3215) min (3216) hour (3217) min (3218)

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

Description Unit Menu Min

Max

Zone A Zone B Zone C UNOC

Sp Room °C 3311 8 35

Mini.Air % 3312 0 100

Sp Dyna °C 3321 0 99.9

Sp Cool °C 3322 8 35

Sp Heat °C 3323 8 35

Swap Heater On/Off 3324 ~ ~

Activation On/Off 3331 ~ ~

Swap Heater On/Off 3332 ~ ~

Sp.Dehu % 3341 0 100

Sp.Humi % 3342 0 100

Fan On/Off On/Off 3351 ~ ~

Fan Dead On/Off 3352 ~ ~

F.Air On/Off 3353 ~ ~

CO2 On/Off 3354 ~ ~

Comp.Cool. On/Off 3355 ~ ~

Comp.Heat. On/Off 3356 ~ ~

AuxHeat On/Off 3357 ~ ~

Humidif. On/Off 3358 ~ ~

Low Noise On/Off 3359 ~ ~ N/A N/A N/A

Page 11

COMMISSIONNING REPORT

FLEXYII_WSHP-IOM-0909-E Page 9

COMMENTS:

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

............. ………….……………………………………………………………………………………………………………………………...

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

.......................................................................................................................................................................................................

Page 12

TRANSPORT – HANDLING – WARNING

FLEXYII_WSHP-IOM-0909-E Page 10

DELIVERY CHECKS

On receipt of a new equipment please check the following

points. It is the customer’s responsibility to ensure that the

products are in good working order:

- The exterior has not been damaged in any way.

- The lifting and handling equipment are suitable for the

equipment and comply with the specifications of the

handling instructions enclosed here-in.

- Accessories ordered for on site installation have been

delivered and are in good working order.

- The equipment supplied corresponds to the order and

matches the delivery note.

If the product is damaged, exact details must be confirmed

in writing by registered post to the shipping company within

48 hours of delivery (working days). A copy of the letter

must be addressed to Lennox and the supplier or

distributor for information purposes. Failure to comply will

invalidate any claim against the shipping company.

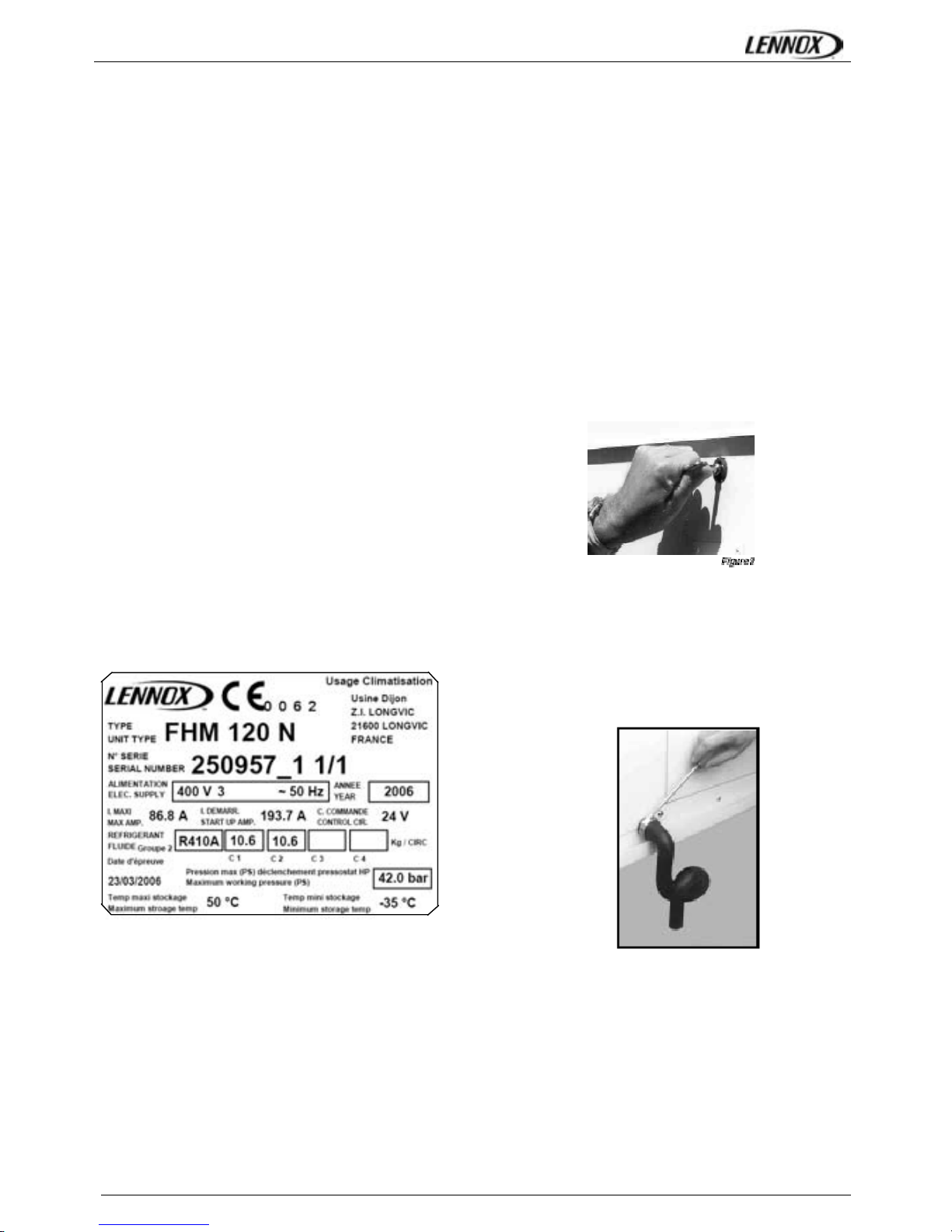

RATING PLATE

The rating plate provides a complete reference for the

model and ensures that the unit corresponds to the model

ordered. It states the electrical power consumption of the

unit on start-up, its rated power and its supply voltage. The

supply voltage must not deviate beyond +10/-15 %. The

start-up power is the maximum value likely to be achieved

for the specified operational voltage. The customer must

have a suitable electrical supply. It is therefore important to

check whether the supply voltage stated on the unit's rating

plate is compatible with that of the mains electrical supply.

The rating plate also states the year of manufacture as well

as the type of refrigerant used and the required charge for

each compressor circuit.

Fig. 1

STORAGE

When units are delivered on site they are not always

required immediately and are sometimes put into storage.

In the event of medium to long-term storage, we

recommend the following procedures:

- Ensure that there is no water in the hydraulic systems.

- Keep the heat exchanger covers in position (AQUILUX cover).

- Keep protective plastic film in position.

- Ensure the electrical panels are closed.

- Keep all items and options supplied in a dry and clean

place for future assembly before using the equipment.

MAINTENANCE KEY

On delivery we recommend that you keep the key which is

attached to an eyebolt in a safe and accessible place. This

allows you to open the panels for maintenance and

installation work.

The locks are ¼ turn + then tighter (figure 2).

CONDENSATE DRAINS

The condensate drains are not assembled when delivered

and are stored

in the electrical panel with their clamping collars.

To assemble them, insert them on the condensate tray outlets

and use a screwdriver to tighten the collars (Figure 3).

Fig. 3

Page 13

TRANSPORT – HANDLING

FLEXYII_WSHP-IOM-0909-E Page 11

Handling slings to guide the

unit towards the roofcurb

Vacuum lifting beam to

position the unit

COMPLIAN

T

NON-COMPLIAN

T

Page 14

TRANSPORT – HANDLING

FLEXYII_WSHP-IOM-0909-E Page 12

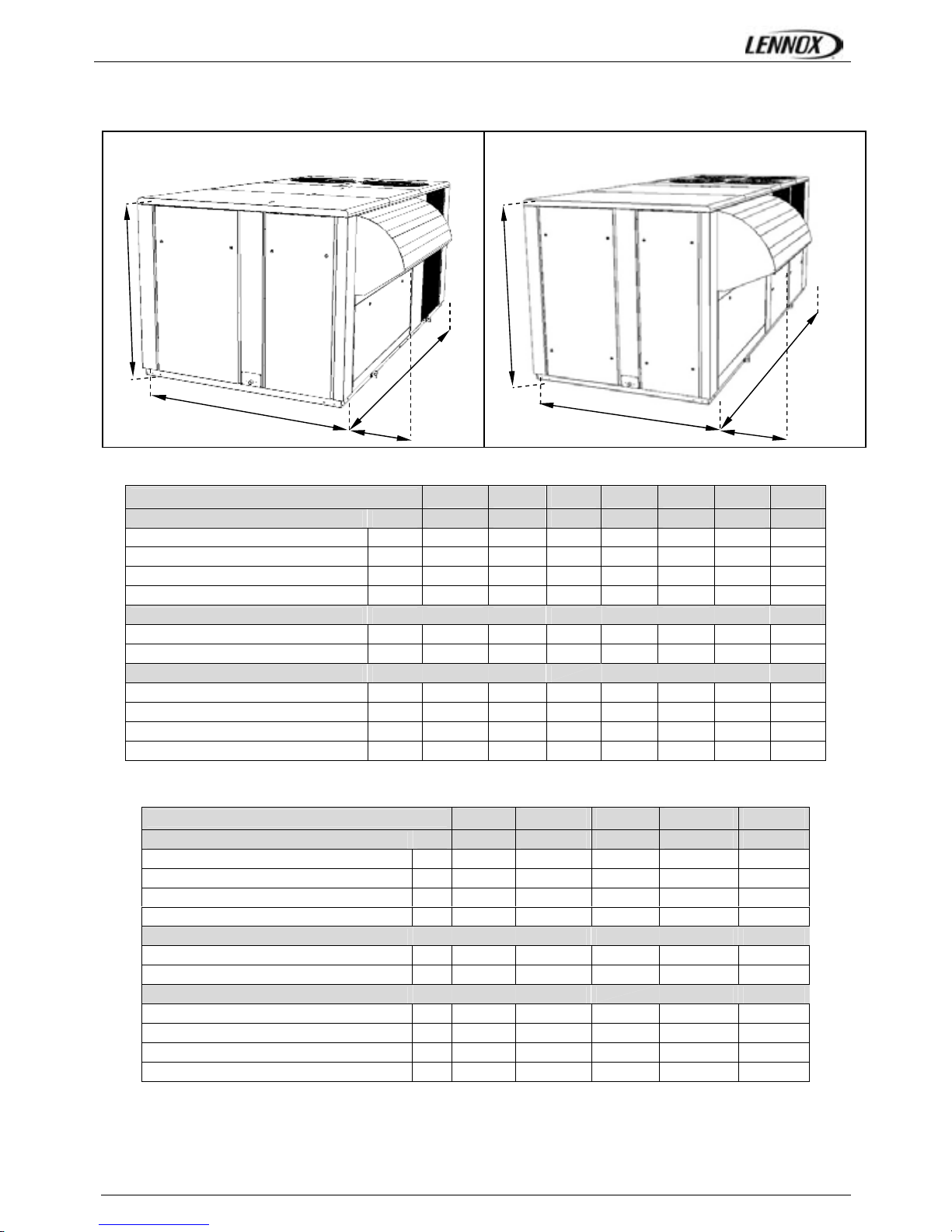

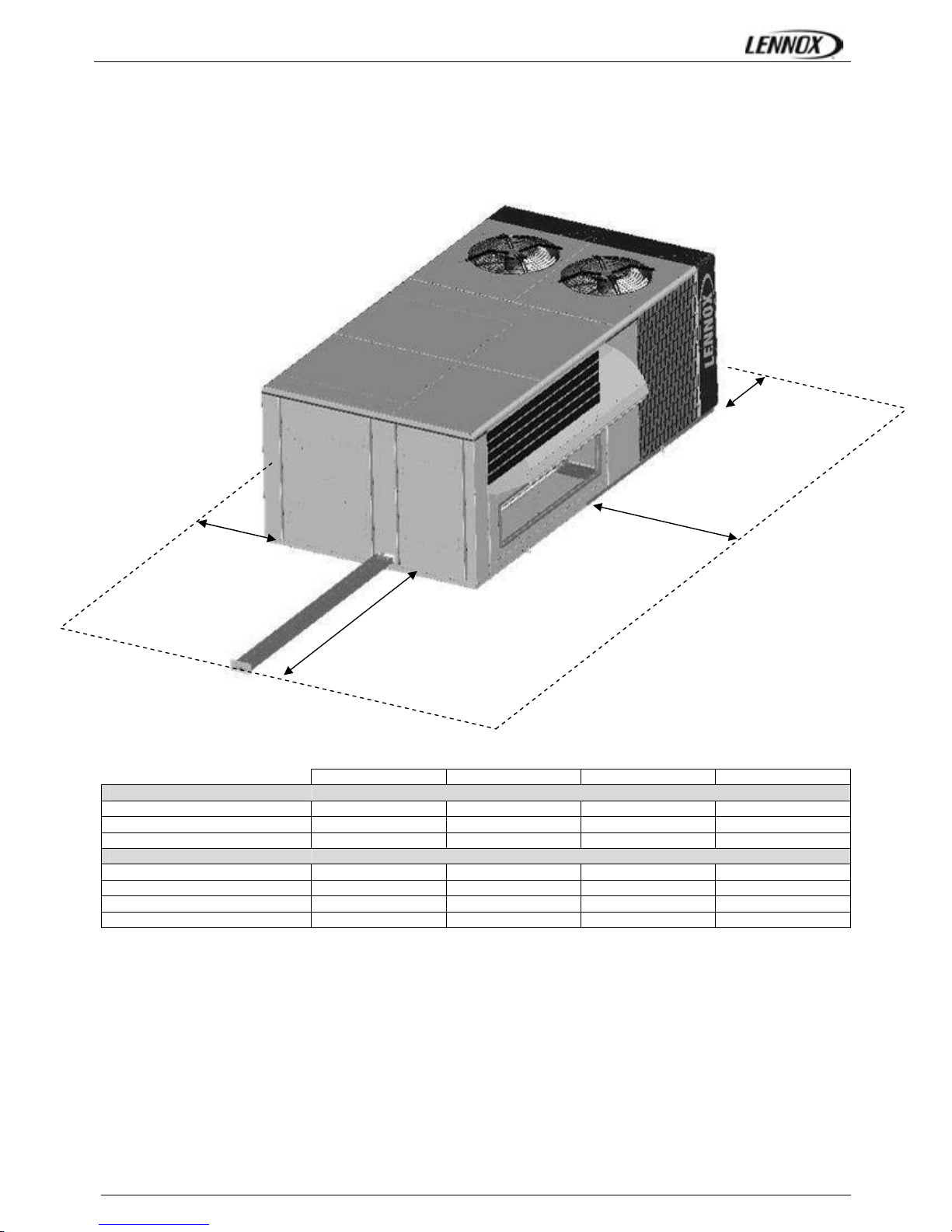

DIMENSIONS AND WEIGHTS

FLEXY2 FCM/FHM/FGM/FDM

85 100 120 150 170 200 230

View (F, G, H box)

F BOX F BOX F BOX G BOX G BOX H BOX H BOX

A

mm 2200 2200 2200 2200 2200 2200 2200

B

mm 3350 3350 3350 4380 4380 5533 5533

C

mm 1510 1510 1510 1834 1834 2134 2134

D

mm 360 360 360 450 450 615 615

Weight of standard units FCM

Without economiser kg 934 1009 1085 1367 1430 1650 1950

With economiser kg 990 1065 1141 1442 1505 1752 2052

Weight gas unit FGM

Standard heat Without economiser kg 1041 1116 1192 1608 1671 1914 2214

Standard heat With economiser kg 1097 1172 1248 1683 1746 2016 2316

High heat without economiser kg 1111 1186 1262 1631 1694 1954 2254

High heat With economiser kg 1167 1242 1318 1706 1769 2056 2356

WSHP FWH/FWM

85 100 120 150 170

View (F & G box)

F BOX F BOX F BOX G BOX G BOX

A

mm 2200 2200 2200 2200 2200

B

mm 3350 3350 3350 4380 4380

C

mm 1510 1510 1510 1834 1834

D

mm 360 360 360 450 450

Weight of standard units FWH

Without economizer kg 797 883 969 1250 1313

With economizer kg 853 939 1026 1325 1388

Weight gas unit FWM

Standard heat Without economiser kg 904 990 1076 1491 1554

Standard heat With economiser kg 960 1046 1133 1566 1629

High heat without economiser kg 974 1060 1146 1514 1577

High heat With economiser kg 1030 1116 1203 1589 1652

F & G BOX H BOX

A

D

B

C

D

A

B

C

Page 15

TRANSPORT – HANDLING

FLEXYII_WSHP-IOM-0909-E Page 13

DIMENSIONS AND WEIGHTS

LENGTH HEIGHT WIDTH HOOD WEIGHT

Side Fan Standard

mm mm mm

mm mm kg

FXK025 4070 1635 1055 490 600 950

FXK030 4070 1635 1055 490 600 980

FXK035 4750 2255 1290 490 600 1400

FXK040 4750 2255 1290 490 600 1450

FXK055 4750 2255 1290 490 600 1600

FXK070 5050 2255 1725 890 600 1800

FXK085 5050 2255 1725 890 600 1900

FXK100 5050 2255 1725 890 600 2000

FXK110 5650 2255 2000 860 - 2620

FXK140 5650 2255 2000 860 - 2620

FXK170 5650 2255 2000 860 - 2650

Page 16

TRANSPORT – HANDLING

FLEXYII_WSHP-IOM-0909-E Page 14

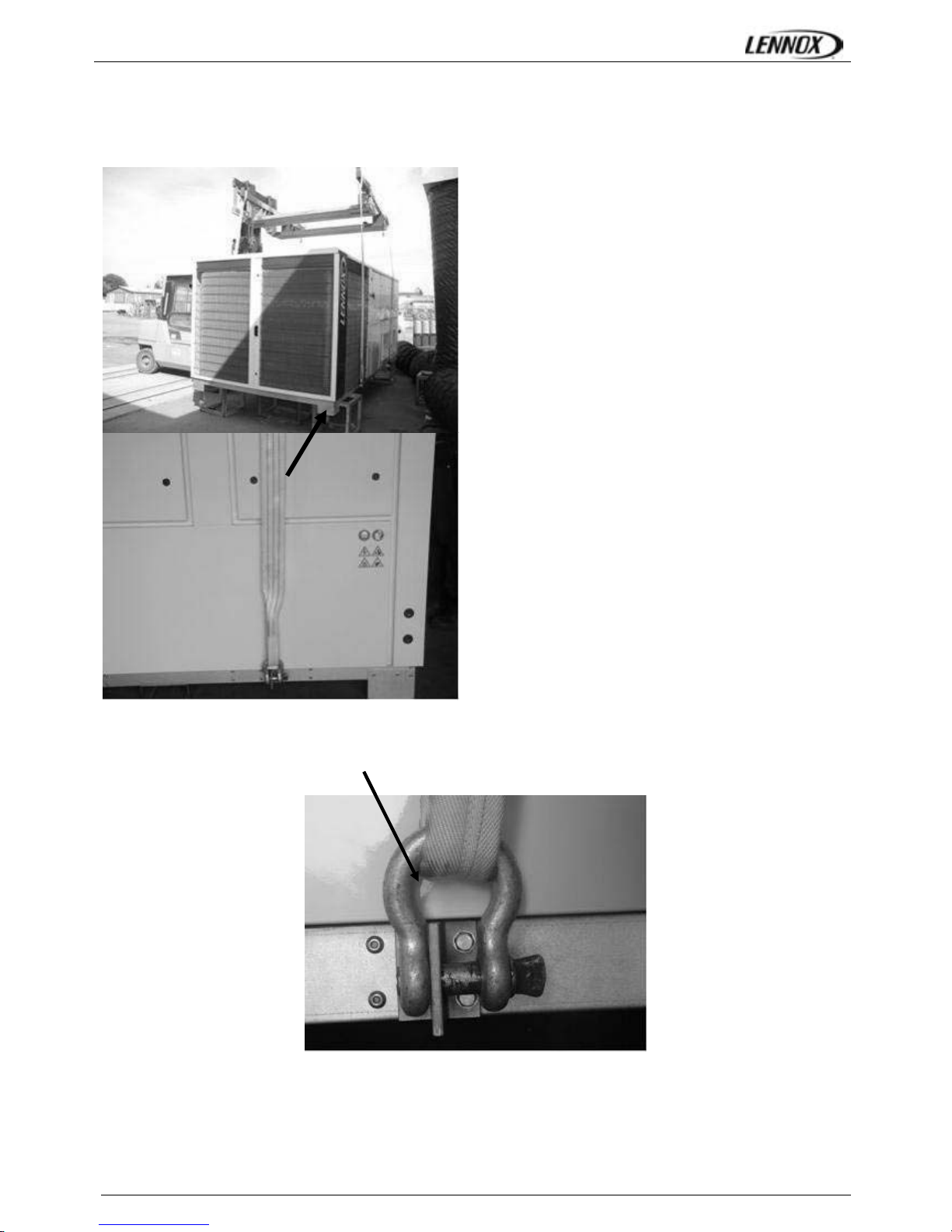

LIFTING THE UNIT

As shown on the picture below, a lifting frame is necessary.

After lifting, withdraw angle’s feet and lifting lugs.

Page 17

INSTALLATION

FLEXYII_WSHP-IOM-0909-E Page 15

FORKLIFT PROTECTIONS

NEVER LIFT THE UNIT WITHOUT FORKLIFT PROTECTIONS

REMOVE THE FORKLIFT PROTECTIONS

BEFORE INSTALLATION

PRELIMINARY CHECKS

Before installing the equipment, the following points MUST

be checked:

- Have the forklift protections been removed?

- Is there sufficient space for the equipment?

- Is the surface on which the equipment is to be

installed sufficiently solid to withstand its weight? A

detailed study of the frame must be made beforehand.

- Do the supply and return ductwork openings

excessively weaken the structure?

- Are there any obstructing items which could hinder the

operation of the equipment?

- Does the electrical power available correspond to the

equipment's electrical specifications?

- Is drainage provided for the condensate?

- Is there sufficient access for maintenance?

- Installation of the equipment could require different

lifting methods which may vary with each installation

(helicopter or crane). Have these been evaluated?

- Ensure that the unit is installed in accordance with the

installation instructions and local applicable codes.

- Check to ensure that the refrigerant lines do not rub

against the cabinet or against other refrigerant lines.

In general, make sure no obstacles (walls, trees or roof

ledges) are obstructing the duct connections or hindering

assembly and maintenance access.

INSTALLATION REQUIREMENTS

The surface on which the equipment is to be installed must

be clean and free of any obstacles which could hinder the

flow of air to the condensers:

-Avoid uneven surfaces

-Avoid installing two units side by side or close to each

other as this may restrict the airflow to the condensers.

Before installing a packaged Rooftop unit it is important to

understand:

- The direction of prevailing winds

-The direction and position of air flows.

-The external dimensions of the unit and the

dimensions of the supply and return air connections.

-The arrangement of the doors and the space required

to open them to access the various components.

CONNECTIONS

-Ensure that all the pipe-work crossing walls or roofs

are secured, sealed and insulated.

-To avoid condensation problems, make sure that all

pipes are insulated according to the temperatures of

fluids and type of rooms.

NOTE: The AQUILUX protection sheets fitted to the finned

surfaces must be removed prior to start up.

Page 18

INSTALLATION

FLEXYII_WSHP-IOM-0909-E Page 16

MINIMUM CLEARANCE AROUND THE UNIT

Figure 4 shows the required clearances and service access around the unit.

NOTE: Ensure the fresh air inlet does not face prevailing wind direction.

A B C D

FCM/FHM/FGM/FDM/FWH/FWM

F BOX

2200

(1)

2000 2000 2000

G BOX

2700

(1)

2000 2000 2000

H BOX

2700

(1)

2000 2000 2000

FX

25 & 30

* 1100 * 1700

35Æ55

* 1300 * 2300

70Æ100

* 1700 * 2300

110Æ170

* 2000 * 2300

(1) Add 1 meter if the units are equipped with gas burner

A

B

C

D

Page 19

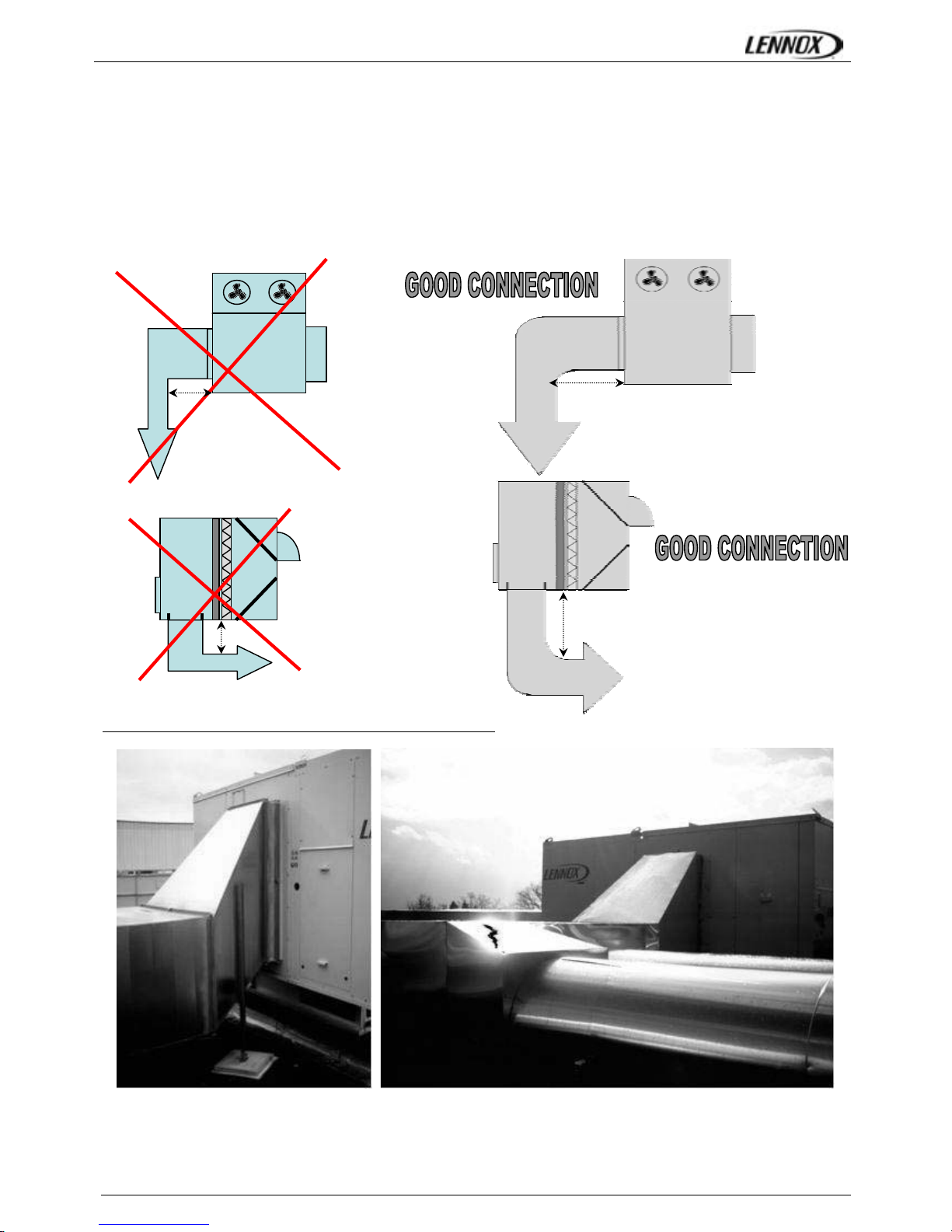

DUCT CONNECTIONS

FLEXYII_WSHP-IOM-0909-E Page 17

RECOMMENDATIONS FOR DUCTS CONNECTIONS

Some rules must be complied with for the connections between ducts and unit done on site.

Whatever the supply configuration is, respect a minimal duct’s length (D) of 2m before any elbow or any duct’s diameter

change.

These recommendations are imperative in the case of 2 independent turbines (sizes from 150kW to 230kW and all units

equipped with gas module)

Horizontal supply

Vertical supply

Here are obvious bad examples of ducts connections noted on site:

D ≥ 2m

D ≥ 2m

D ≤ 2m

D ≤ 2m

Page 20

WATER CONNECTIONS

FLEXYII_WSHP-IOM-0909-E Page 18

WATER SOURCE HEAT PUMP ONLY

Water connections

The water circulating pump will be preferably installed upstream so that the evaporator/condenser will be subjected to positive

pressure. Inlet and Outlet water connections are indicated on the certified drawing sent with the unit or shown in the sales

brochure.

The water pipes connected to the unit must not transmit any radial or axial force or any vibration to the heat exchangers.

It is important to follow non exhaustive recommendations hereunder:

• Comply with the water inlet and outlet connections shown on the unit.

• Install manual or automatic air purge valves at all high points in the circuit.

• Install a safety valve as well as an expansion tank to maintain the circuit pressure.

• Install thermometers in both the inlet and outlet water connections.

• Install drain connections at all low points to allow the whole circuit to be drained.

• Install stop valves, close to the inlet and outlet water connections.

• Use flexible connections to reduce vibrations transmission.

• After testing for leaks, insulate all pipe work, to reduce thermal leaks and to prevent condensation.

• If the external water pipes are in an area, where the ambient temperature is likely to fall below 0°C, insulate the piping and

add an electric heater.

• Ensure full earthling continuity

A drainage plug is located at the base of the evaporator. A drainage pipe may be connected to this to enable drainage of

evaporator water for service operations or for seasonal shut down.

Connections at the inlet and outlet are Victaulic type.

Water analysis

The water must be analysed; the water circuit installed must include all items necessary for water treatment: filters, additives,

intermediate exchangers, bleed valves, vents, isolating valves etc... depending on the results of the water analysis.

We do not advise operation of the units with open loops which can cause troubles with oxygenation, or

operation with untreated ground water.

Use of untreated or improperly treated water can cause deposits of scale, algae and sludge or cause corrosion and erosion. It is

advisable to call in a qualified water treatment specialist to determine what kind of treatment will be necessary. The

manufacturer cannot accept liability for damage caused by the use of untreated or improperly treated water, salt water or brine.

Here are our non exhaustive recommendations given as an indication:

• No NH4+ ammonium ions in the water, they are very detrimental for copper. <10mg/l

• Cl- Chloride ions are detrimental for copper with a risk of perforations by corrosion by puncture. < 10 mg/l.

• SO42- sulphate ions can cause perforating corrosion.< 30 mg/l.

• No fluoride ions (<0.1 mg/l).

• No Fe2+ and Fe3+ ions with dissolved oxygen. Dissolved iron < 5 mg/l with dissolved oxygen < 5 mg/l. Over

those values, it means a corrosion of steel which may generate a corrosion of copper parts under deposite of Fe – this is

mainly the case with shell and tube heat exchangers.

• Dissolved silicon: silicon is an acid element of water and can also lead to corrosion risks. Content < 1mg/l.

• Water hardness: TH >2.8 K. Values between 10 and 25 can be recommended. This will facilitate scale deposit that can limit

corrosion of copper. TH values that are too high can cause piping blockage over time.

• TAC< 100.

• Dissolved oxygen: Any sudden change in water oxygenation conditions must be avoided. It is as detrimental to

deoxygenate the water by mixing it with inert gas as it is to over-oxygenate it by mixing it with pure oxygen. The disturbance

of the oxygenation conditions encourages destabilisation of copper hydroxides and enlargement of particles.

• Specific resistance – electric conductivity: the higher the specific resistance, the slower the corrosion tendency. Values

above 3000 Ohm/cm are desirable. A neutral environment favours maximum specific resistance values.

For electric conductivity values in the order of 200-6000 S/cm can be recommended.

• pH: pH neutral at 20°C (7 < pH < 8)

Page 21

WATER CONNECTIONS

FLEXYII_WSHP-IOM-0909-E Page 19

Antifreeze protection

Use glycol/water solution

ADDITION OF GLYCOL IS THE ONLY EFFICIENT WAY TO PROTECT AGAINST FREEZING

The glycol/water solution must be sufficiently concentrated to ensure proper protection and prevent formation of

ice at the lowest outdoor air temperatures expected on an installation. Take precautions when using non

passivated MEG antifreeze solutions (Mono Ethylene Glycol or MPG Mono Propylene Glycol). Corrosion can

occur with these antifreeze solutions with oxygen.

Drain the installation

To enable drainage of the circuit, make sure that drain cocks are installed at all the low points of the circuit.

To drain the circuit, the drain cocks must be opened and an air inlet ensured.

Note : air bleeders are not designed to admit air.

EVAPORATOR FREEZING DUE TO COLD WEATHER CONDITIONS IS NOT COVERED BY LENNOX

WARRANTY.

Minimum water content

The minimum volume of the rooftop water circuit must be determined. If necessary, install a buffer tank. Proper operation of

regulating and safety devices can only be ensured if the volume of water is sufficient.

The theoretical volume of the water loop for a proper air conditioning operation can be calculated using the formulas hereafter:

WATER COOLED FLEXYII RANGE

Vt Æ Minimum water content of the installation

Q Æ Water capacity in kW

N Æ Number of control steps available in the unit

Dt Æ Maximum acceptable temperature rise (Dt = 6°c for an air conditioning application)

Vmini = 86 x Q / (N x Dt)

Unit Size

Number of

stages

Mini Water

Volume (L)

FWH/FWM 085

FWH/FWM 100

FWH/FWM 120

FWH/FWM 150

FWH/FWM 170

2

2

2

3

4

631

781

867

702

627

Page 22

WATER CONDENSING

FLEXYII_WSHP-IOM-0909-E Page 20

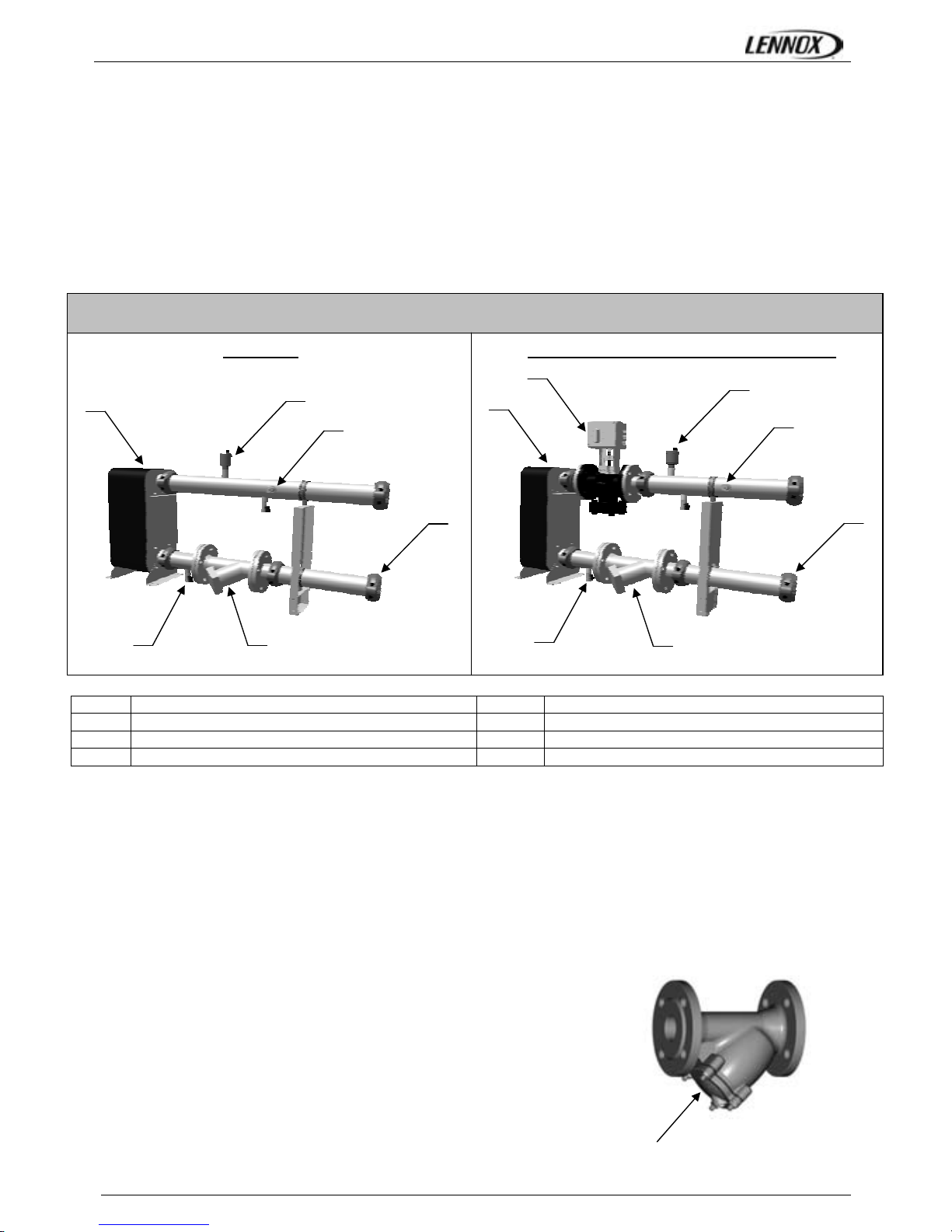

WATER LOOP CONFIGURATION (FOR WATER SOURCE HEAT PUMP)

Figures below show the 2 water configurations.

Figure 1 indicates all components used as standard :

• the electronic water flow switch,

• the water filter,

• the pressure taps and drain valves,

• the automatic airvent,

The second figure shows rooftop water loop with Low Water Loop Temperature option.

LOW WATER LOOP TEMPERATURE (OPTION)

In order to operate with low water inlet temperature in cooling mode (ie: ground source water loops) it is necessary to control

the water flow rate in the heat exchanger to maintain a minimum condensing pressure in the refrigeration circuit.

In cooling mode the climatic 50 will control the water flow rate in the condenser by monitoring the condensing pressure and by

closing the water flow valve accordingly by a 0-10 Volts signal.

This option offers a second opportunity: give the possibility to close the rooftop water loop when compressors are stopped.

WATER FILTER REPLACEMENT (ONLY FOR WAT ER SOURCE HEAT PUMP)

It is important that units are serviced regularly by a qualified technician, at least

once every year or every 1000 hours of operation.

CAUTION: The water circuit may be pressurised. Observe the usual

precautions when depressurising the circuit before opening it. Failure to

observe these rules could lead to accidents and cause injury to service

personal.

1

All Victaulic Connections

5

Pressure Taps and drain Valve

2

Inlet Water Filter

6

Stainless steel Exchanger

3

Automatic Air Vent

7

ElectroValve (HP control option)

4

Electronic Flow Switch

2

1

3

4

5

6

1

2

3

4

5

6

7

Low Water Loop Temperature Option

Hydraulic Data

Standard

Access for cartridge cleaning

Figure 1 Figure 2

Page 23

WATER CONDENSING

FLEXYII_WSHP-IOM-0909-E Page 21

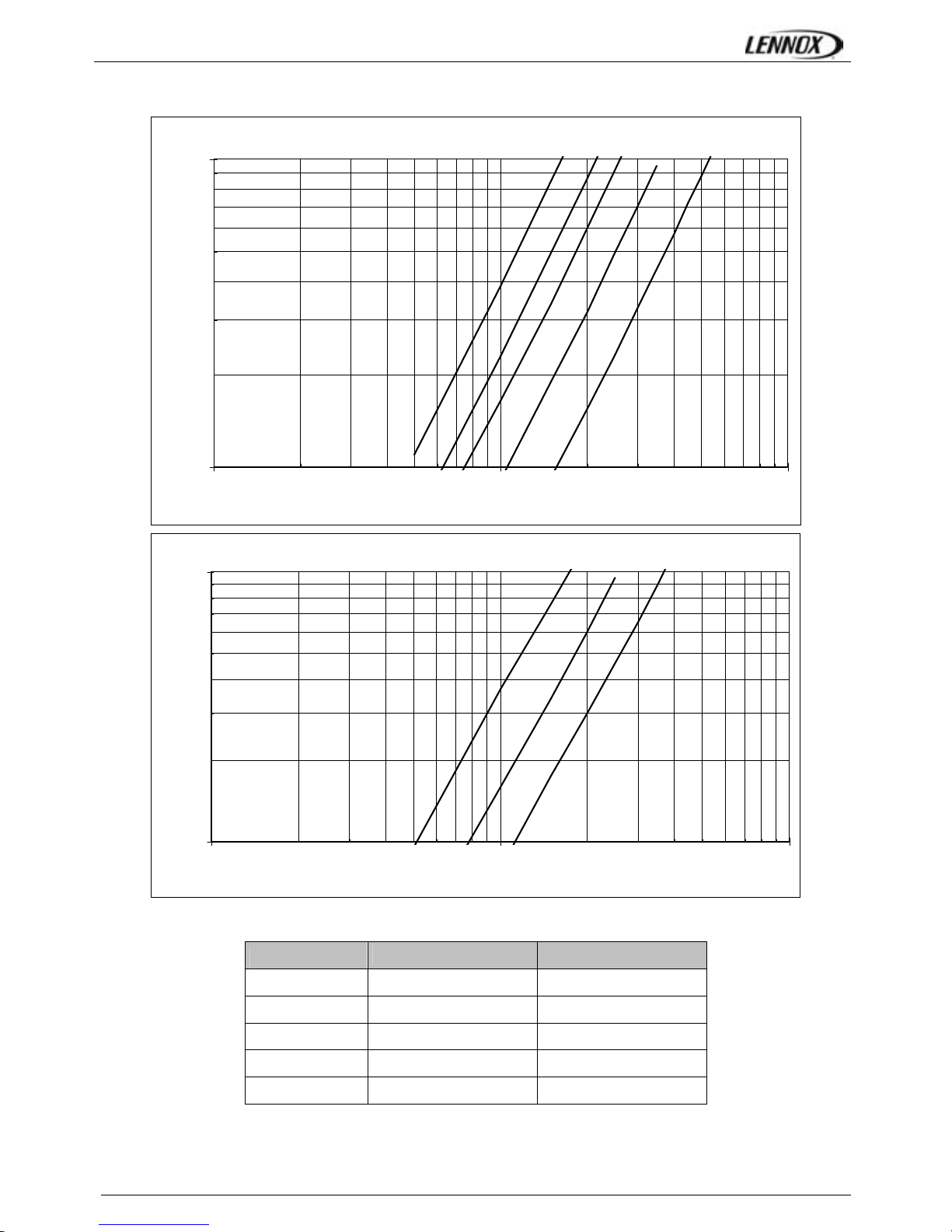

Pressure Loss - Heat plate Exchanger

A

B

CD

E

10

100

1 10 100

Water flow (m3/h)

Pressure Loss (kPa)

Pressure Loss - WATER FILTER

A

B

C

1.0

10.0

1 10 100

Water flow (m3/h)

Pressure Loss (kPa)

FWH/FWM

Exchanger Curve Filter Curve

85 C B

100 D B

120 D B

150 E C

170 E C

Page 24

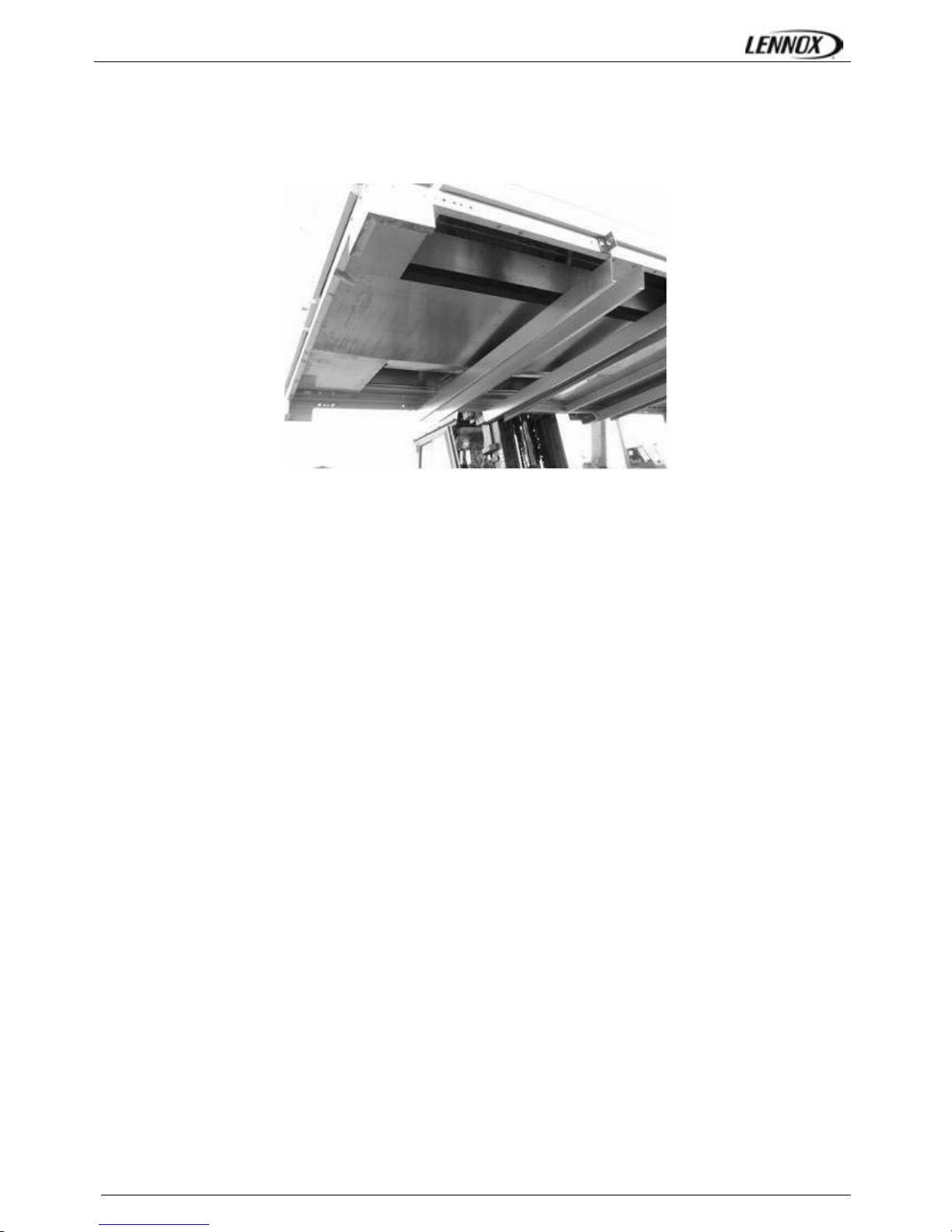

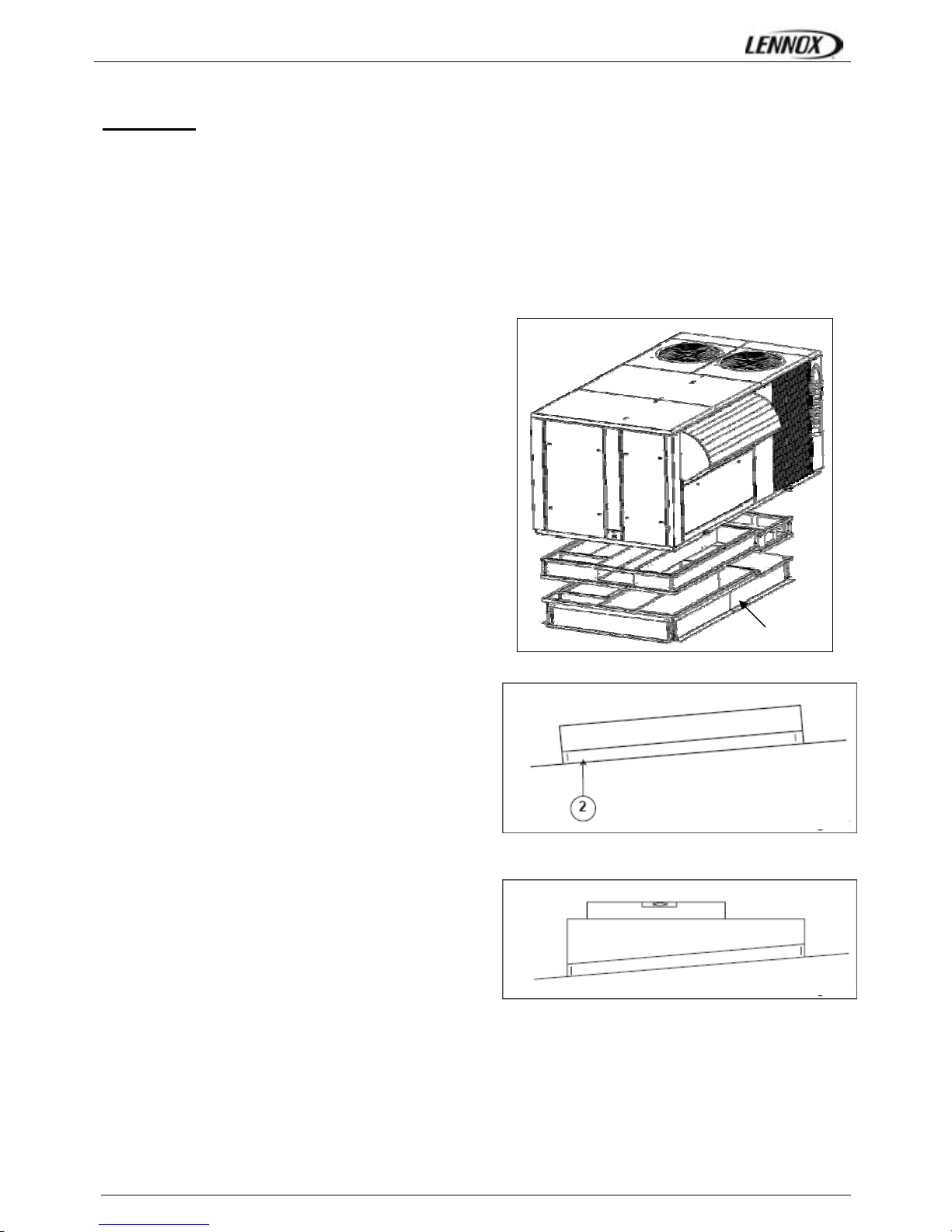

INSTALLATION ON A ROOFMOUNTING FRAME

FLEXYII_WSHP-IOM-0909-E Page 22

CAUTION:

- An approach ramp must be installed if the unit’s installation requirements tell that it's

necessary to reach the main switch. This recommendation is valid for installations in

general and in particular for return and curbs. It’s also valid to reach other parts of the

unit: filters, refrigerant circuit, etc…

- It’s advised to fix curbs and roofcurbs to the unit.

As levels are adjustable, observe the following

recommendations when installing the equipment

Above all, ensure that all the adjustable returns are facing

outward (“1” figure 4). They are usually turned inside-out

for transport.

Place the roof mounting frame on the trimmer beam by first

lining up the inlet and the outlet opening. (“2”- figure 5)

After levelling the frame, secure the adjustable returns on

the trimmer.

It is important to centre the unit on the roof frame

c

Fig. 4

Fig. 5

Fig. 6

Page 25

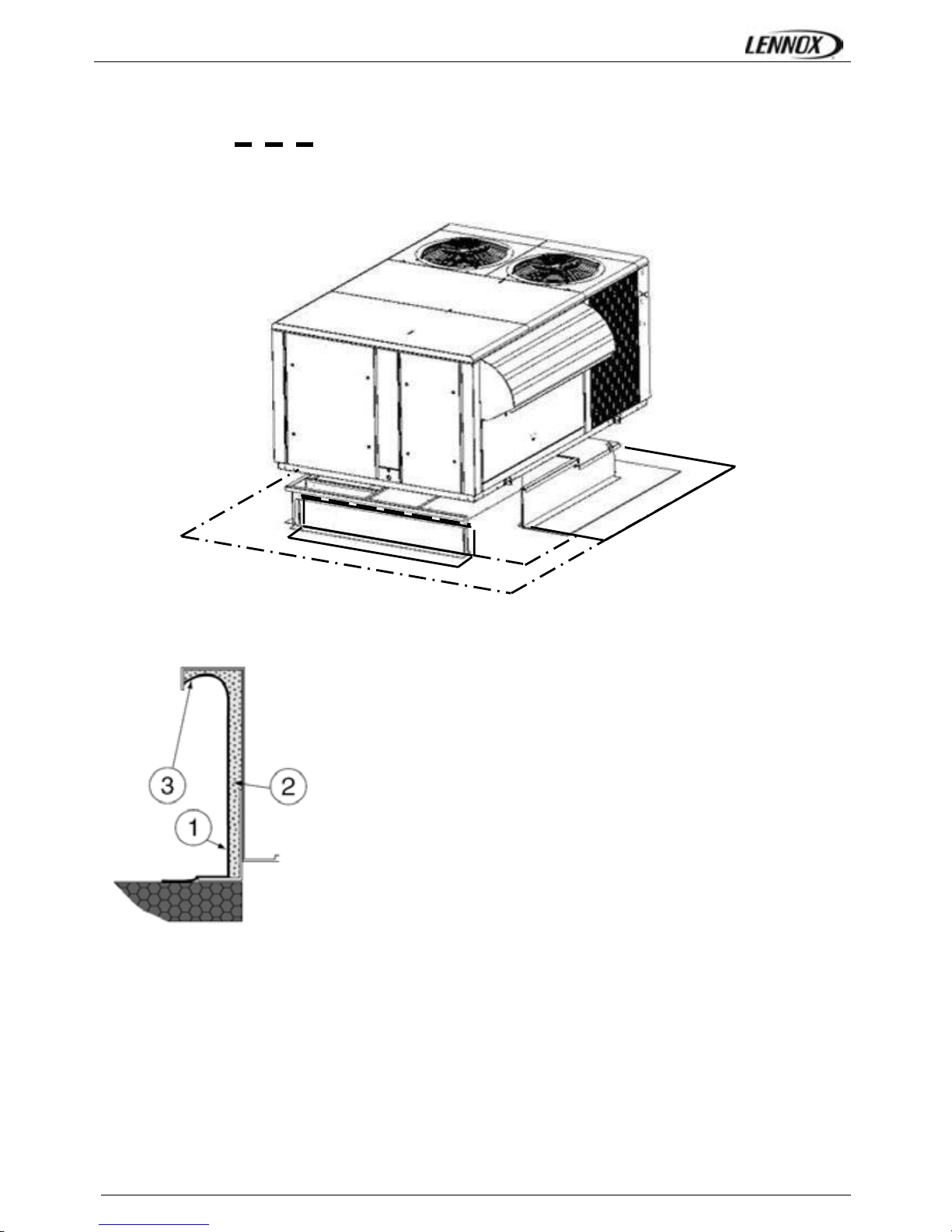

INSTALLATION ON A ROOFMOUNTING FRAME

FLEXYII_WSHP-IOM-0909-E Page 23

When the frame is correctly positioned, it is essential to secure the assembly with a disconnected stitched welded seam (20 to

30mm every 200mm

) along the outside or by using an alternative method

CURBING AND FLASHING

Outside of frame must be insulated with rigid type insulation;

We recommend a minimum of 20 mm thick insulation (2 - figure 7).

Check that the insulation is continuous, counter flash and seal around the frame

as shown in (1-figure 7).

CAUTION: To be effective, the upstream must end below the drop edge (3 - figure

7).

Where pipes and electrical conduits extend through the roof, flashing must

conform to local codes of practice

Before installing the equipment, make sure that seals are not damaged and check that the unit is secured to the mounting

frame. Once in position, the bottom of the equipment must be horizontal.

The installer must comply with local authority standards and specifications.

Fig. 7

Page 26

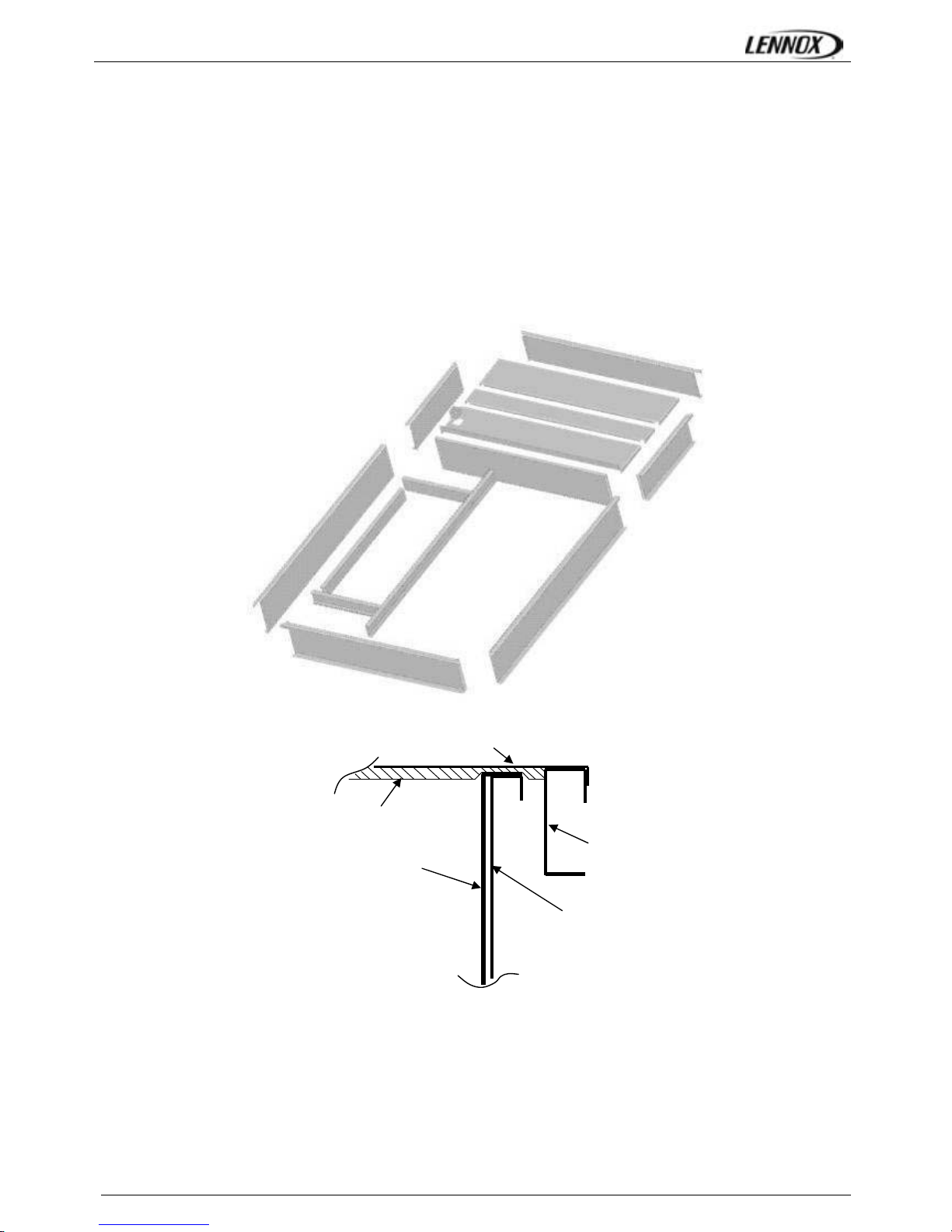

INSTALLATION ON A ROOF MOUNTING FRAME

FLEXYII_WSHP-IOM-0909-E Page 24

NON ADJUSTABLE NON ASSEMBLIED ROOFCURB INSTALLATION

FRAME PARTS IDENTIFICATION

Figure 8 shows the different parts used in the assembly of this roof mounting frame.

INSTALLATION

The roof mounting frame provides support when the units are installed in down-flow configurations.

The non adjustable, non assembled roof mounting frame can be installed directly on decks having adequate structural strength

or on roof supports under deck.

NOTE: frame assembly must be installed flat, leveled within 5mm per linear meter in any direction

UNIT FLOOR

UNIT FLOOR

A

IR DUCT

UNIT Support rail

ROOFCURB

Fig. 8

Page 27

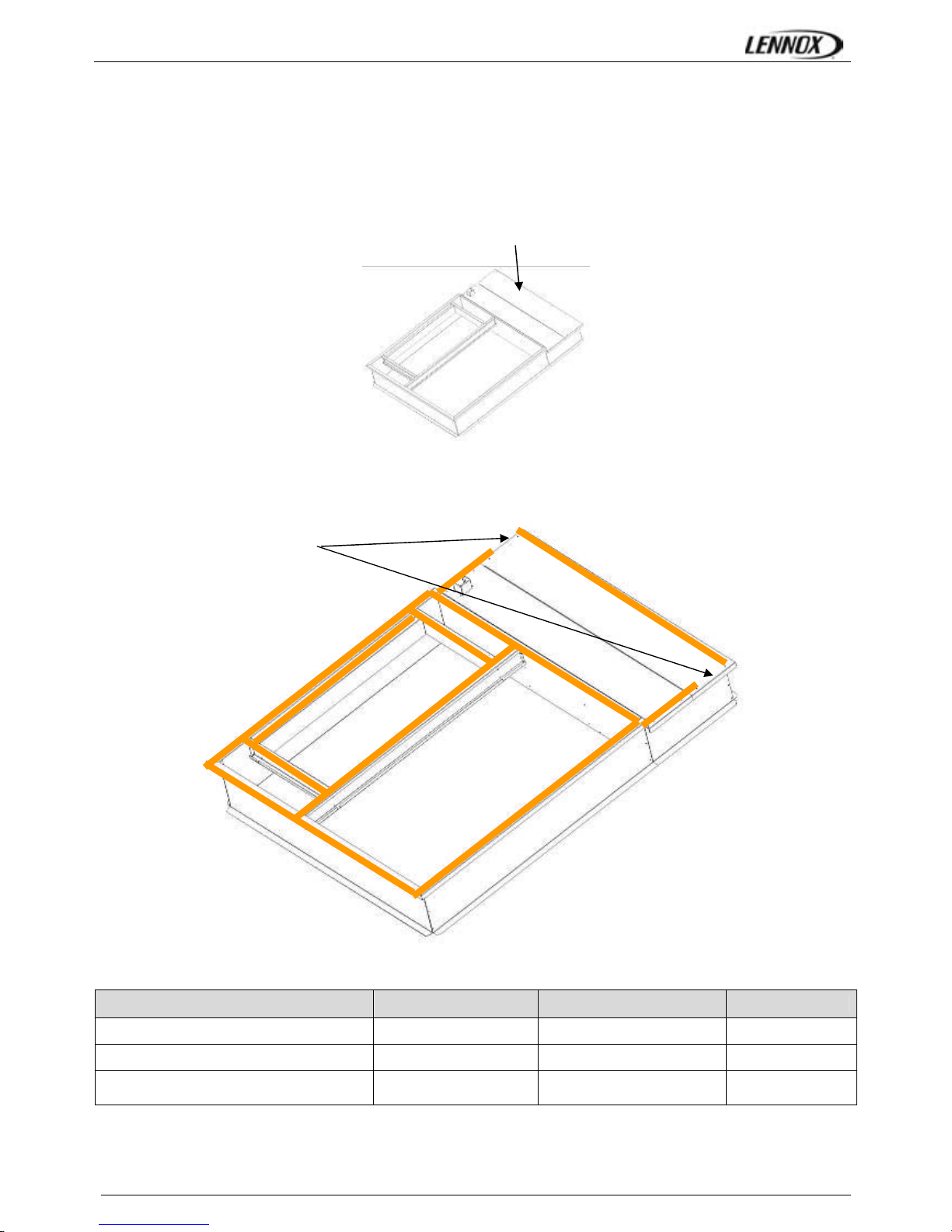

NON ADJUSTABLE ROOFCURB – Installation instructions

FLEXYII_WSHP-IOM-0909-E Page 25

This roof curb will arrive as a packaged on a pallet and need to be built together.

The part will be connected by special corrosion free nails. It is not possible to connect with standard nail equipment because

there is a lot of power needed. Therefore, you need a pneumatic or electric device.

All parts must be sealed with polyurethan sealant during assembly.

Foam Insulation Installing

• Stick large foam pieces underneath the flat top

Foam Gasket Installing

• Stick gasket all around the curb flange’s top

Spare parts

Fbox Gbox Hbox

GASKET 5840071R Grey foam M1 17 m / 0.85 m² 19 m / 0.95 m² 21 m /1.1 m²

INSULATION 5840071R 760 x 1960 - 1.39 m² 920 x 1960 - 1.79m² tbd

Rivets 5820542X 4.8 x 8 mm 100 130 160

Let it free on 200 mm

long to enable water

drainage

Page 28

ADJUSTABLE ROOFCURB

FLEXYII_WSHP-IOM-0909-E Page 26

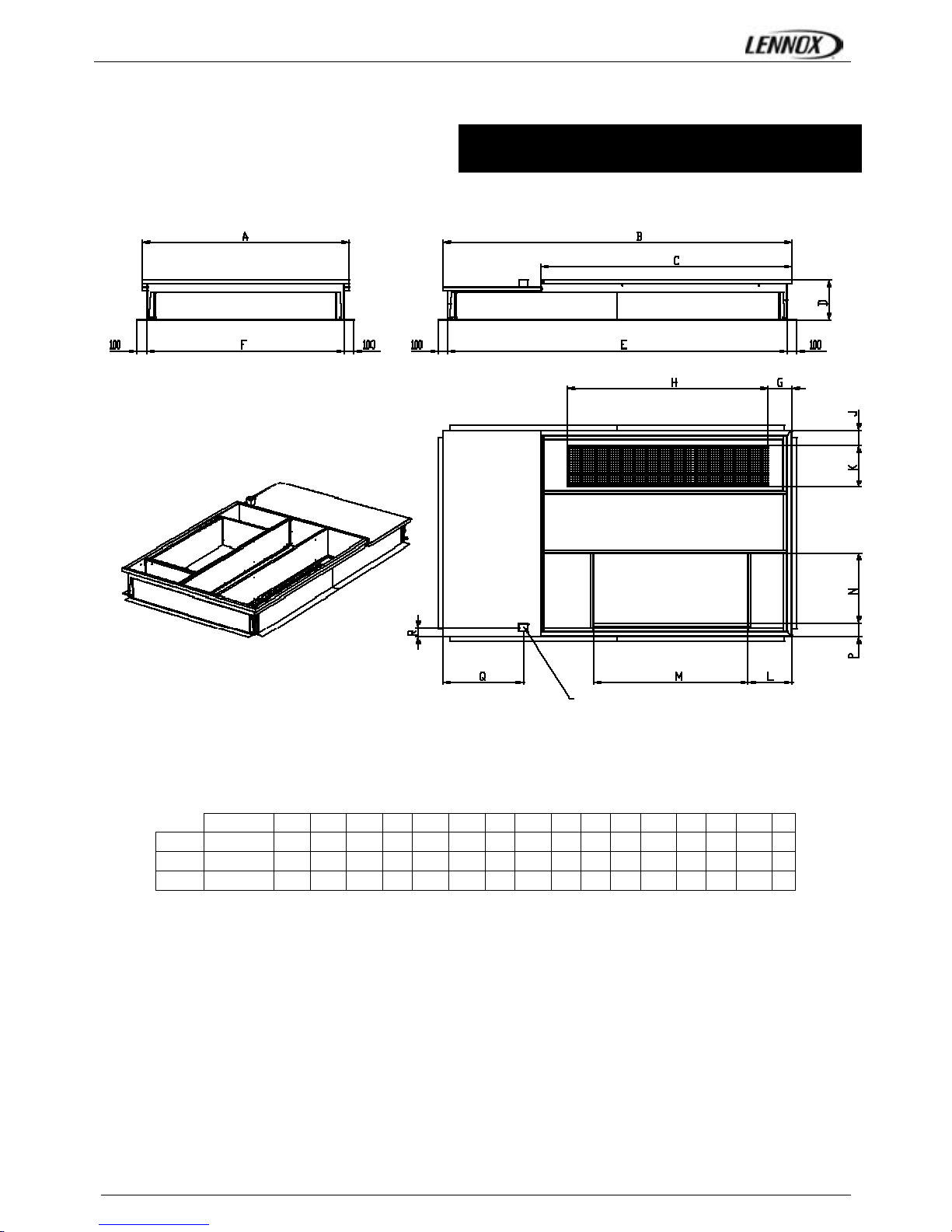

SIZE A B C D E F G H J K L M N P Q R

F-BOX 85-100-120 2056 2770 2005 400 2672 1959 130 1747 145 420 336 1432 700 140 620 95

G-BOX 150-170 2056 3466 2493 400 3367 1959 234 1997 145 420 430 1540 700 140 800 95

H-BOX 200-230 2056 4100 2493 400 4003 1959 234 1997 145 420 430 1830 800 80 1133 95

All units

RETURN AIR

SUPPLY AIR

MAIN POWER ENTRY

Page 29

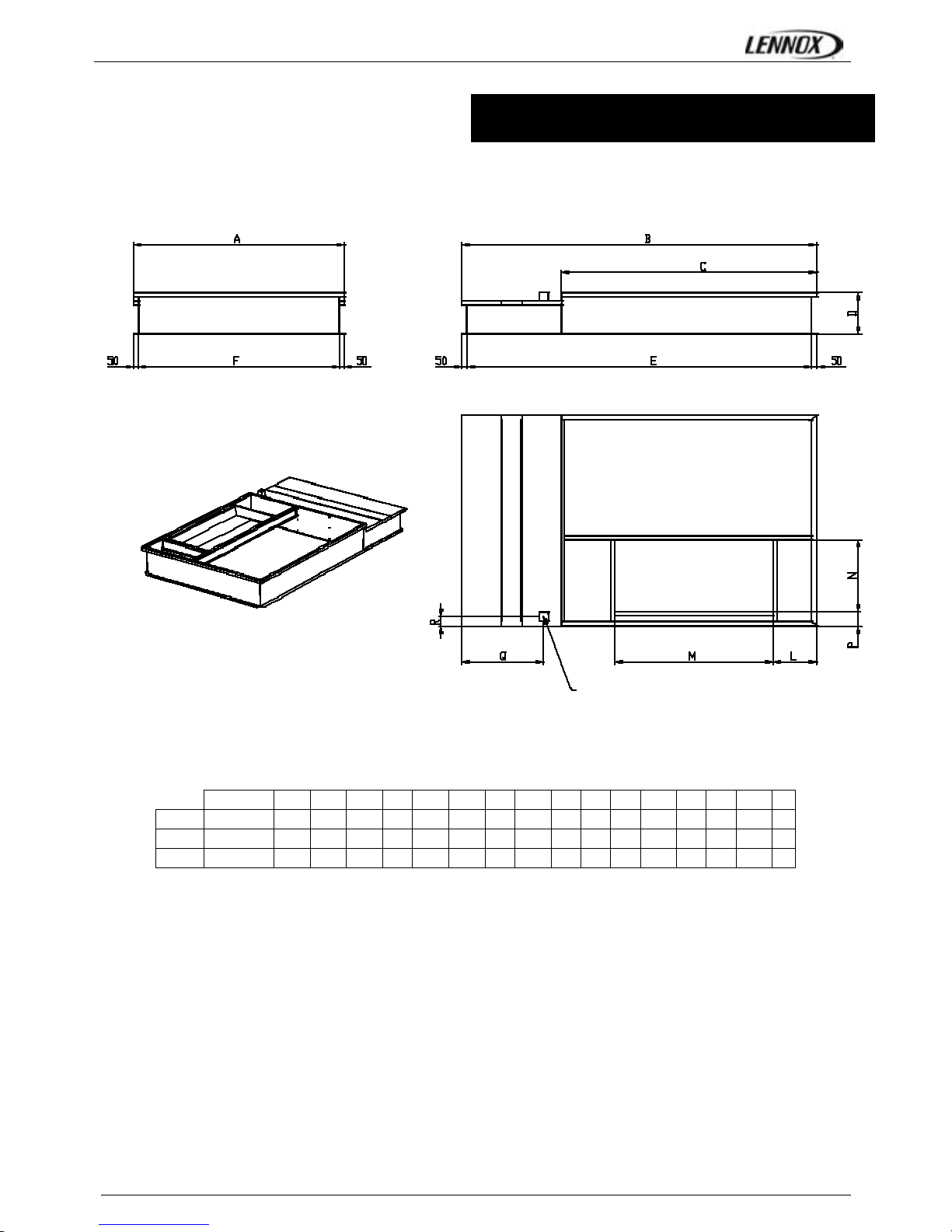

NON ADJUSTABLE NON ASSEMBLED ROOFCURB

FLEXYII_WSHP-IOM-0909-E Page 27

SIZE A B C D E F G H J K L M N P Q R

F-BOX 85-100-120 2056 2770 2005 400 2672 1959 130 1747 145 420 336 1432 700 140 620 95

G-BOX 150-170 2056 3466 2493 400 3367 1959 234 1997 145 420 430 1540 700 140 800 95

H-BOX 200-230 2056 4100 2493 400 4003 1959 234 1997 145 420 430 1830 800 80 1133 95

SUPPLY AIR

MAIN POWER ENTRY

All units

Page 30

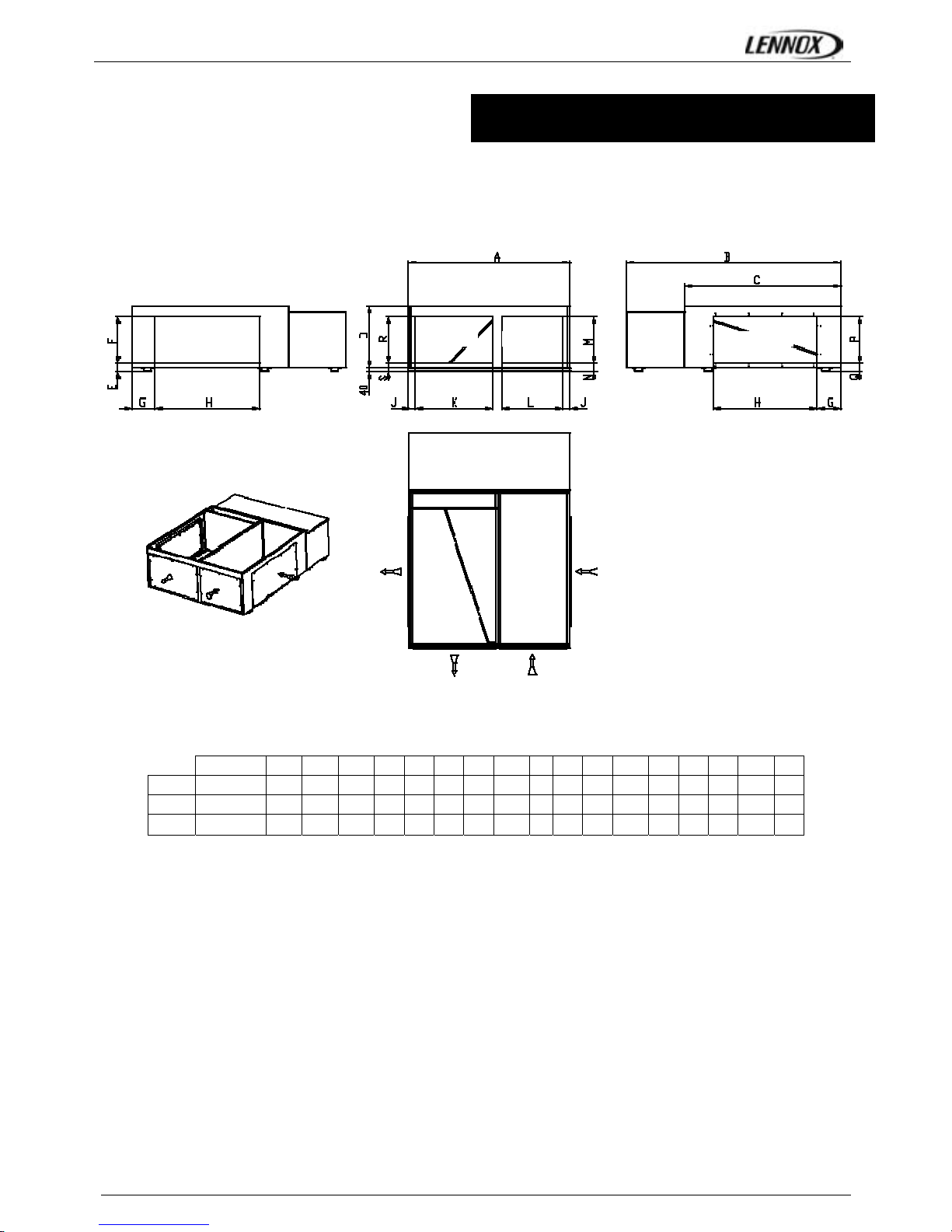

MULTIDIRECTIONAL ROOFCURB

FLEXYII_WSHP-IOM-0909-E Page 28

SIZE A B C D E F G H J K L M N P Q R S

F-BOX 85-100-120 2056 2745 2005 800 100 600 300 1335 88 980 780 600 100 600 100 600 100

G-BOX 150-170 2056 3441 2493 800 100 600 300 1540 88 980 780 900 100 600 100 900 100

H-BOX 200-230 2056 4063 2493 800 100 600 300 1830 88 980 780 1000 100 600 100 1000 100

SUPPLY AIR RETURN AIR

RETURN AIR

SUPPLY AIR

All units

Page 31

RETURN ROOFCURB

FLEXYII_WSHP-IOM-0909-E Page 29

SIZE A B C D E F G H J K L M N P Q R

F-BOX 85-100-120 2156 2740 2005 1030 2056 2005 1650 180 310 840 140 700 1440 326 593 95

G-BOX 150-170 2156 3437 2494 1030 2056 2494 1650 410 310 840 140 700 1540 434 770 95

H-BOX 200-230 2156 4073 2494 1030 2056 3294 2550 100 310 840 80 800 1830 434 1113 95

CAUTION: An approach ramp must be installed if the

machine installation requirements tell that it's necessary

to reach the main switch. This recommendation is valid

for installations in general and in particular for return

and curbs. It’s also valid to reach other parts of the unit:

filters, refrigerant circuit, etc…

SUPPLY AIR

EXHAUST AIR

All units

RETURN AIR

MAIN POWER ENTRY

Page 32

RETURN HORIZONTAL ROOFCURB

FLEXYII_WSHP-IOM-0909-E Page 30

SIZE A B C D E F G H J K L M N P

F-BOX 85-100-120 2056 2755 2005 1220 1180 100 400 100 1335 200 1605 200 100 700

G-BOX 150-170 2056 3465 2493 1220 1180 100 400 100 1540 200 2000 200 100 700

H-BOX 200-230 2056 4095 2493 1305 1205 200 400 150 1830 150 2293 100 260 700

CAUTION: An approach ramp must be installed if the

machine installation requirements tell that it's necessary to

reach the main switch. This recommendation is valid for

installations in general and in particular for return and

curbs. It’s also valid to reach other parts of the unit: filters,

refrigerant circuit, etc…

EXHAUST AIR

All units

RETURN AIR

SUPPLY AIR MAIN POWER ENTRY

Page 33

TRANSITION CURB

FLEXYII_WSHP-IOM-0909-E Page 31

SIZE A B C D E F G H J K L M N

F-BOX 85-100-120 2056 2008 2072 366 2783 1880 70 85 530 700 145 1432 342

G-BOX 150-170 2056 2496 2072 366 3480 2377 70 85 530 700 145 1540 440

H-BOX 200-230 2056 2493 2072 366 4106 2377 70 85 530 800 85 1830 440

SUPPLY AIR

MAIN POWER ENTRY

RETURN AIR

All units

Page 34

ENERGY RECOVERY

FLEXYII_WSHP-IOM-0909-E Page 32

SIZE A B C D E F

F-BOX 85-100-120 2279 2212 1447 360 1911 938

G-BOX 150-170 2539 2473 1544 457 2211 938

H-BOX 200-230 2789 2723 1703 616 2461 938

All units

A

C

B

E

F

D

Page 35

ENERGY RECOVERY INSTALLATION

FLEXYII_WSHP-IOM-0909-E Page 33

1) The unit being already erected on the roofcurb, remove the lifting lug shown on [A], and the doors of the Recovery

module

[B].

2) Fit the support part of the Recovery Module on interior level of the rooftop ,

3) Fix the Recovery Module at the roof of the rooftop

and corner structures by using self-driling screws.

4) Apply Mastic on side junctions and on higher junction.

Pictures taken during assembling test of Recovery Module (H Size)

Fig. 25

zoom

1

2

3

zoom

zoom

1

2

3

Page 36

ENERGY RECOVERY INSTALLATION

FLEXYII_WSHP-IOM-0909-E Page 34

STEP 1: Rooftop configuration

This picture shows how the rooftop configuration has to be before recovery module assembling

No Hood

No panel

The lifting lug and the corner sheet metal

have to be removed.

The head guard on the left corner of the

rooftop has to be flattened.

Page 37

ENERGY RECOVERY INSTALLATION

FLEXYII_WSHP-IOM-0909-E Page 35

STEP 2: Lifting

For Recovery module lift, use lifting lugs localised at the top of each corner structures

Page 38

ENERGY RECOVERY INSTALLATION

FLEXYII_WSHP-IOM-0909-E Page 36

During installation phase, fit the support part on the interior level of the rooftop

STEP 3: Fitting

SUPPORT PART

INTERIOR LEVEL

Page 39

ENERGY RECOVERY INSTALLATION

FLEXYII_WSHP-IOM-0909-E Page 37

STEP 4: Check

In the same way, roof of the recovery module and the rooftop has to be at the same level

SAME LEVEL

MODULE ROOFTOP

A good fit can be controled by looking at the junction between the rooftop and the recovery module:

The junction has to be at the same level.

SAME LEVEL

70 mm

Size 150 & 170

For 150 and 170 sizes, a deviation of 70mm

exists between rooftop and recovery module

(see picture on the right).

Page 40

ENERGY RECOVERY INSTALLATION

FLEXYII_WSHP-IOM-0909-E Page 38

STEP 5 : Fixing

And fix the top of the module to the rooftop by using self-driling screws 19mm

Self-drilling screws 19mm D6.3

When the module is well fitted, fix the corner structures to the rooftop by using self-

drilling screws 32mm

Self-drilling screws 32mm D4.8

Page 41

ENERGY RECOVERY INSTALLATION

FLEXYII_WSHP-IOM-0909-E Page 39

Apply mastic on side junctions and higher junction

STEP 6: Masticate

Page 42

ENERGY RECOVERY INSTALLATION

FLEXYII_WSHP-IOM-0909-E Page 40

The Recovery module is sent with a power cable and a T-lan cable

STEP 7: Electrical wiring

Power cable

T-lan cable

These 2 cables have to be inserted through this hole

Page 43

ENERGY RECOVERY INSTALLATION

FLEXYII_WSHP-IOM-0909-E Page 41

Then fix the 2 cables on the grid of the extraction roofcurb and insert them in rooftop electrical panel as shown

Cables from the module, through the

hole, to rooftop electrical panel

Page 44

ENERGY RECOVERY INSTALLATION

FLEXYII_WSHP-IOM-0909-E Page 42

To check the wiring, please refer to Rooftop and Recovery Module electrical diagram.

Then connect the power cable from the module to the rooftop, and the t-lan to the

Climatic50 (or the BE50 if presents in electrical rooftop panel)

Recovery Module Connection

Exctraction Roofcurb Connection

Be careful: Check connections and connect male connections to good

female one.

Roofcurb and recovery module connectors are the same.

Actuator Roofcurb Connection

Page 45

ENERGY RECOVERY INSTALLATION

FLEXYII_WSHP-IOM-0909-E Page 43

STEP 8: Roof curb economiser Adjustment

With Heat Recovery module option the extract air goes through the wheel, that’s why the

economiser of the roofcurb has to be permanently fully closed.

If roofcurb economiser is not fully closed, close it manually

And don’t connect the actuator to the rooftop.

Actuator Roofcurb

not connected

Page 46

ECONOMISER AND EXTRACTION

FLEXYII_WSHP-IOM-0909-E Page 44

ECONOMISER

Free cooling can be provided through the use of fresh air which is more appropriate

than excessive cooling amounts of return air.

The economiser is factory fitted and tested prior to shipment.

It includes two dampers operating from a 24V actuator

RAIN HOOD

It also includes a factory fitted rain hood. Hoods is folded during transportation to limit

risks of damage and must be unfolded on site as shown on fig. 9

EXTRACTION

Installed with economiser assembly, the gravity exhaust dampers relieve the pressure

when outside air is introduced into the system.

When large amount of fresh air is introduced into the system power exhaust fans can be used to equalise the pressures.

The extraction fan runs when return air dampers are being closed and supply air blower is in operation. The extraction fan runs

when outdoor air dampers are at least 50% open (adjustable value). It is overload protected.

NOTE: When horizontal flow configuration is required, the multidirectional roof curb will be installed.

0-25% FRESH AIR MANUAL

It is enough to loosen the mobile grid's screws and to make it slip.

0%: screw into limit stop on the right

25%: screw into limit stop on the left

FRESH AIR

R

ETURN AIR

E

XHAUST AIR

SUPPLY AIR

Fig. 9

FLEXY II PRINCIPLE SKETCH

MULTIDIRECTIONAL ROOFCURB

PRINCIPLE SKETCH

ENERGY RECOVERY MODULE PRINCIPLE SKETCH RETURN ROOFCURB PRINCIPLE SKETCH

Page 47

COMMISSIONING

FLEXYII_WSHP-IOM-0909-E Page 45

THIS WORK MUST ONLY BE CARRIED OUT BY TRAINED REFRIGERATION ENGINEERS

FILL THE COMMISSIONNING SHEET AS YOU GO ALONG

Don’t forget to open the isolation Valves on the liquid line before starting the unit (see sticker below)

ELECTRICAL CONNECTIONS

- Ensure that the power supply between the building and the unit meets local authority standards and that the cable specification

satisfies the start-up and operating conditions.

ENSURE THAT THE POWER SUPPLY INCLUDES 3 PHASES

- Check the following wire connections for tightness: Main switch connections, mains wires linked to the contactors and

circuit breakers and the cables in the 24V control supply circuit.

PRELIMINARY CHECKS

- Ensure that all drive motors are secure.

- Ensure that the adjustable pulley blocks are secure and that the belt is tensioned with the transmission correctly aligned.

Refer to the next section foe details.

- Using the electrical wiring diagram, check the conformity of the electrical safety devices (circuit breaker settings, presence

and rating of fuses).

- Check the temperature probe connections.

ISOLATION VALVES MUST BE

OPENED BEFORE RUNNING

G1 G2

Page 48

COMMISSIONING

FLEXYII_WSHP-IOM-0909-E Page 46

STARTING THE UNIT

At this point the unit circuit breakers should be open

You will need a DS50 maintenance controller or Adalink with

appropriate Interface.

The jumpers are factory set and the configuration switches

are adjusted depending on the option the type of unit.

Connecting the CLIMATIC displays

Close the 24V Control Circuit breakers.

The CLIMATIC 50 starts after 30s

Reset the DAD photo (If fitted)

Check and adjust the control settings.

Refer to the control section in this manual to adjust the

different parameters.

POWERING THE UNIT

- Power up the unit by closing the isolator switch (if fitted). At this point the blower should start unless the climatic does

not energise the contactor. In this particular case the blower

can be forced by bridging the port NO7 and C7 on

connector J14 on the Climatic. Once the fan is running,

check the rotation direction. Refer to the rotation arrow

located on the fan.

- The fans and compressors direction of rotation is checked

during the end of line test. They should therefore all turn in

either the right or wrong direction.

NOTE: A compressor rotating in the wrong direction will fail.

- If the fan turns in the wrong direction (the right direction is

shown on figure n° 11), disconnect the main power supply

to the machine at the building's mains switch, reverse two

phases and repeat the above procedure.

- Close all circuit breakers and power up the unit, remove

the bridge on connector J14 if fitted.

- If now only one of the components rotates in the wrong

direction, disconnect the power supply at the machine's

isolator switch (if fitted) and reverse two of the component’s

phases on the terminal within the electrical panel.

- Check the current drawn against the rated values, in

particular on the supply fan (ref. page 33).

- If the readings on the fan are outside the specified limits,

this usually indicates excessive air flow which will affect the

life expectancy and the thermodynamic performances of the

unit. This will also increase the risks of water ingress into

the unit. Refer to the "Air Flow Balancing" section to correct

the problem.

At this point attach the manometers to the refrigerant circuit

Fig. 11

Page 49

COMMISSIONING

FLEXYII_WSHP-IOM-0909-E Page 47

RUN TEST

Start unit in cooling mode

Thermodynamic readings using manometers and prevailing

environmental conditions

No rated values are given here. These depend on the climatic

conditions both outside and inside the building during

operation. However, an experienced refrigeration engineer

will be able to detect any abnormal machine operation.

Safety test

- Check Air pressure switch (if fitted) "Dirty filter" detection

test: vary the set-point value (menu page 3413 on DS50) in

respect to the air pressure value. Observe the response of

the CLIMATIC™.

- Same procedure for detecting "Missing Filter" (page menu

3412) or "Air Flow Detection" (page menu 3411).

- Check the smoke detection function (if fitted).

- Check the Firestart by pressing the test button (if fitted).

- Disconnect the circuit breakers of the capacitor fans and

check the high pressure cut-out points on different refrigerant

circuits.

Reverse cycle test

This test is designed to check the good operation of the 4way reversing valves on heat pump reversible systems. Start

the reverse cycle by adjusting the cold or hot temperature

threshold data according to the indoor and outdoor conditions

at the time of test (menu 3320).

Page 50

VENTILATION : BELT TENSION

FLEXYII_WSHP-IOM-0909-E Page 48

BELT TENSION

On delivery, the drive belts are new and correctly tensioned.

After the first 50 operating hours check and adjust the

tension. 80% of the total elongation of belts is generally

produced during the first 15 hours of operation.

Before adjusting the tension, make sure that the pulleys are

correctly aligned.

To tension the belt, set the height of motor support plate by

moving the plate adjustment screws.

The recommended deflection is 20 mm per meter from centre

to centre.

Check that according to the diagram below (figure 12), the

following ratio remains the same.

The belts should always be replaced when:

- The disk is set to maximum,

- The belt rubber is worn or the wire is visible.

Replacement belts must have the same rated size as the

ones they are replacing. If a transmission system has several

belts, they must all be from the same

NOTE:

An under-tensioned belt will slip, heat and wear prematurely.

On the other hand, if a belt is over-tensioned, the pressure on

the bearings will cause them to over-heat and wear

prematurely. Incorrect alignment will also cause the belts to

wear prematurely.

Fig. 12

Page 51

VENTILATION : PULLEYS

FLEXYII_WSHP-IOM-0909-E Page 49

MOUNTING AND ADJUSTING PULLEYS

F

AN PULLEY REMOVAL

Remove the 2 screws and put one of them in the extraction

threaded screw.

Screw in fully. The hub and the pulley will separate from each

other.

Remove the hub and the pulley by hand without damaging

the machine.

F

AN PULLEY INSTALLATION

Clean and de-grease the shaft, hub and conical bore of the

pulley. Lubricate the screws and install the hub and pulley.

Position the screws without turning them.

Place the assembly on the shaft and screw in the screws

alternatively and evenly. Using a mallet or a hammer with a

wooden wedge, tap on the face of the hub to keep the

assembly in place. Torque the screws to 30 Nm.

Take the pulley in both hands and shake it vigorously to make

sure everything is in place.

Fill the holes with grease for protection.

NOTE: During installation, the key should never protrude out

of its groove.

After 50 operating hours, check that the screws are still in

place.

M

OTOR PULLEY INSTALLATION & REMOVAL

The pulley is held in position by the key and a screw located

in the groove. After unlocking, removing this screw by pulling

against the shaft spindle (if necessary, use a mallet and tap

uniformly on the hub to remove it).

To assemble, proceed in the reverse order after having

cleaned and de-greased the motor shaft and the pulley bore.

P

ULLEYS ALIGNMENT

After adjusting one or both of the pulleys, check the

transmission alignment using a ruler placed on the inner face

of the two pulleys.

NOTE: The warranty may be affected if any major

modification is made to the transmission without obtaining our

agreement beforehand.

Page 52

VENTILATION : AIRFLOW BALANCING

FLEXYII_WSHP-IOM-0909-E Page 50

The actual resistance of ductwork systems is not always identical to the calculated theoretical values. To rectify this, it may be

necessary to modify the pulley and belt setting. To this effect, the motors are fitted with variable pulleys.

SITE TEST AND MAINTENANCE

Measure the motor absorbed power.

If the absorbed power is greater and the pressure lower than the rated values, the ventilation system has a lower pressure drop

than anticipated. Reduce the flow by reducing the rpm. If the system resistance is significantly lower than design, there is a risk

that the motor will overheat resulting in an emergency cut out.

If the absorbed power is lower and the pressure greater than the rated values, your system has a higher pressure drop than

anticipated. Increase the flow by increasing the rpm. At the same time you will increase the absorbed power which may result in

having to increase the motor size.

To carry out the adjustment and to avoid a time-consuming re-start, stop the machine and if necessary lock the main switch.

First unscrew the 4 Allen screw(s) on the pulley (see figure 13).

Actual diameter (DM) or distance between faces for a given number of

turns from fully closed with SPA belt in (mm)

Pulley

type

Pulley

External

Diameter

Min

Dia /

Min

Dist

Max

Dia /

Max

Dist

Nb of turns

from fully

closed to

fully open

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

95 116 5 114 112 110 108 106 103 101.3 99.2 97.1 95 -

8450 /

D8450

120

20.2 28 5 21 21.8 22.5 23.3 24.1 24.9 25.7 26.4 27.2 28 -

110 131 5 129 127 125 123 121 118 116 114 112 110 -

8550 /

D8550

136

20.6 31.2 5 21.6 22.7 23.8 24.8 25.9 26.9 28 29.1 30.1 31 -

Table_1

The easiest way to determine the fan rotation speed is to

use a Tachometer. If not available the fan rpm can be

estimated using the following two methods.

1

st

Method with the pulley secured in place:

Measure the distance between the two outside faces of the

pulley.

Using table (1) the motor pulley actual diameter can be

estimated.

L

Fig. 13

Page 53

VENTILATION : AIRFLOW BALANCING

FLEXYII_WSHP-IOM-0909-E Page 51

2nd method when adjusting the pulley :

-Close the pulley fully and count the number of turns

from fully closed position. Using table_1 determine the

motor pulley actual diameter.

-Record the fix fan pulley diameter.(DF)

-Determine the fan speed using the following formulae:

FMMOTORFAN

/DDrpmrpm ×=

Where: rpm

MOTOR

:from the motor plate or table_2

D

M

: from table_1

D

F

: from machine

Once the pulleys are adjusted and the belt checked and

tensioned, start the fan motor and record the Amps and

Voltage between the phases:

Using the measured data and table_2

-Theoretical mechanical power at the fan shaft:

P

meca fan

= P

meca Motor

x η

Transmission

P

meca fan

= P

elec

x η

meca motor

x η

Transmission

P

meca fan

= V x I x √3 x cosϕ x η

meca motor

x η

Transmission

This formula can be approximated in this way

P

meca fan

= V x I x 1.73 x 0.85 x 0.76 x 0.9

With the fan “rpm” and the mechanical power at the fan

shaft an operating point and the supplied airflow can be

estimated using the fan curves.

CHECKING AIRFLOW AND ESP

Using the fan curves on page 36 to 40, the airflow, the total

pressure available (P

TOT

) and the corresponding dynamic

pressure (Pd) can now be estimated, for a specific

operating point;

The next step consists in estimating the pressure losses

across the unit.

This can be achieved using the “dirty filter pressure sensor”

and the accessories pressure drop table: table_3

Also the pressure drop due to the duct inlet into the roof-top

unit can be taken as 20 to 30 Pa.

∆P

INT

= ∆P

filter + coil

+ ∆P

Inlet

+ ∆P

Options

Using the results from above, the external static pressure

(ESP) can then be estimated:

ESP = P

TOT

- Pd - ∆P

INT

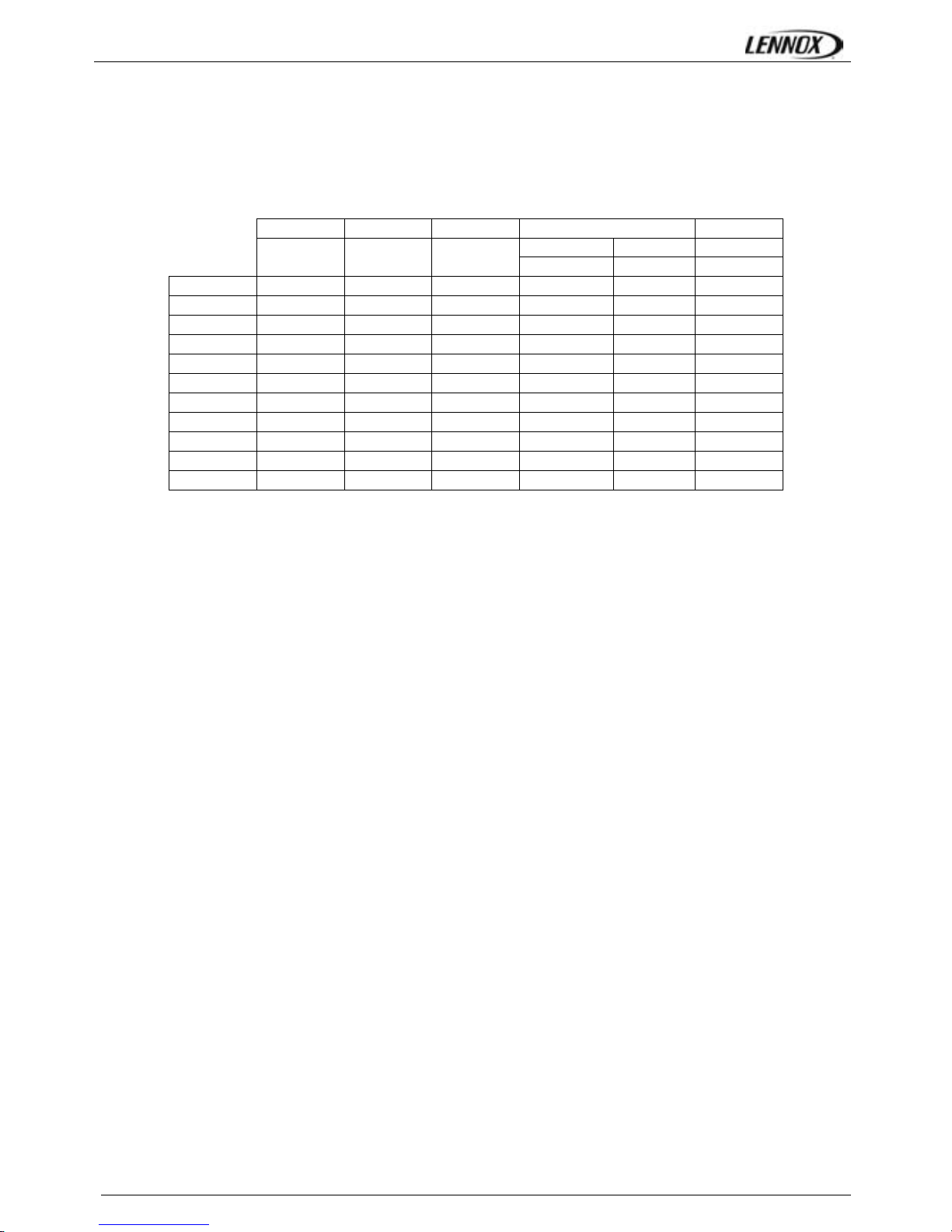

Table_ 2 Motor information

Motor Size Nom. Speed

Cos ϕ η

meca motor

0.75 kW 1400 rpm 0.77 0.70

1.1kW 1429 rpm 0.84 0.77

1.5kW 1428 rpm 0.82 0.79

2.2kW 1436 rpm 0.81 0.81

3.0kW 1437 rpm 0.81 0.83

4kW 1438 rpm 0.83 0.84

5.5kW 1447 rpm 0.85 0.86

7.5kW 1451 rpm 0.82 0.87

9.0kW 1455 rpm 0.82 0.88

11.0kW 1451 rpm 0.85 0.88

Table_3 Accessories pressure drops

Economiser

G4

Filters

F7

Filters

UV

LIGH

T

Hot

Water

coil S

Hot

Water

coil H

Electric

Heater

S

Electric

Heater

M

Electric

Heater

H

Heating

Gaz

fired H

Adjustable

roofcurb

Multidire

ctional

Roofcurb

Heat

Recovery

Modul

Fresh Air

12000 12 1 75 18 9 15 3 5 6 14 17 22 164

15000 19 7 105 30 13 22 6 7 7 23 27 33 204

85

23000 45 28 199 63 26 44 7 9 11 53 63 73 313

14000 17 5 94 26 11 19 6 7 8 20 23 30 191

18500 29 15 143 44 18 31 8 10 11 34 41 51 252

100

23000 45 28 199 63 26 44 11 14 16 53 63 78 313

15000 19 7 105 30 13 22 7 8 9 23 27 35 204

20500 36 21 167 52 21 37 10 12 13 42 50 62 279

120

23000 45 28 199 63 26 44 12 15 17 53 63 78 313

18000 6 1 75 15 6 10 4 5 7 16 30 35 170

150

26000 12 12 130 33 12 19 9 10 13 33 62 72 245

35000 22 29 204 54 19 33 15 18 23 59 112 131 329

21000 8 5 94 21 8 14 8 9 10 21 40 49 198

30000 16 19 161 42 15 25 10 13 15 44 82 95 282

170

35000 22 29 204 54 19 33 17 19 21 59 112 131 329

24000 12 3 88 18 7 11 16 15 14 21 53 67 173

35000 26 18 154 39 13 22 22 21 20 44 112 133 252

200

43000 39 31 211 54 19 31 24 26 29 66 169 195 310

27000 15 7 105 24 8 14 18 18 17 26 67 84 195

39000 32 24 182 46 16 26 24 24 25 55 139 163 281

230

43000 39 31 211 54 19 31 24 26 29 66 169 195 310

Page 54

VENTILATION : AIRFLOW BALANCING

FLEXYII_WSHP-IOM-0909-E Page 52

EXAMPLE

The unit used for this example is a FGM170ND with standard supply and return airflow configuration. It is also fitted with an

economiser and an electric heater type H.

It is fitted with 2 ADH450 L fans which curve is shown on page 36 and 2x 5.5 kW motors..

- Motor rpm: 1447 rpm

- cosϕ = 0.83

- Voltage = 400V

- Current = 9.00A (per fan)

P

mech fan

= V x I x √3 x cosϕ x η

mech motor

x η

Transmission

= 400 x 9.00 x √3 x 0.83 x 0.86 x 0.9 = 4.00kW

The unit is also fitted with 2 transmission kits 3.

- Fixed Fan pulley: 200mm

- Motor adjustable pulley type “8550” opened 4 turns from fully closed or measured distance between pulley end plates is

29.1mm: from table_1 it can be determined that each motor pulley has a diameter of 114.2mm

rpm

FAN

= rpm

MOTOR

x DM / DF = 1447 x 114.2 / 200 = 826 rpm

Using the fan curve, the operating point can

be located.

In order to facilitate the calculation, you

won’t make any mistake by considering

that the external static pressure available is

the one calculated with one fan providing

the half of the nominal flow (here

15000m3/h).

It can be determined that the fan is providing

approximately 15000 m3/h

with a total

pressure P

TOT

= 630 Pa

The pressure losses in the unit are the sum of

all pressure drops across the different parts of

a unit:

- Coil and filter (measured) = 89 Pa

- Inlet into the unit = 50 Pa

- Options = 16 Pa for economiser and 15

Pa for electric heater H

∆P = 89 + 16 + 15 +50 = 170 Pa

The dynamic pressure at 15000m

3

/h is given

at the bottom of the fan curve.