Page 1

INSTALLATION

,t_2007 Lennox Industries Inc.

Dallas, Texas, USA

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

®

WARNING

INSTRUCTIONS

CH33 Series Units

EVAPORATOR COILS

505,264M (65484504)

10/07

Supersedes 09/06

CH33 Series Coils ............................. 1

General ...................................... 1

Shipping and Packing List ...................... 1

Releasing Air Charge .......................... 2

Unit Installation ............................... 2

Refrigerant Line Set ........................... 3

Connections .................................. 4

Refrigerant Metering Device .................... 4

Leak Testing, Evacuating and Charging .......... 6

Blower Speed Connection ...................... 6

Condensate Drain Connection .................. 7

Maintenance .................................. 7

_puTeCh ical

n

blications

Litho U.S.A.

WARNING

CAUTION

IMPORTANT

CH33 horizontal evaporator coils are designed for use with

air conditioner or heat pump units. Each coil is equipped

with a compression fitting that provides convenient field

installation of a refrigerant metering device. Either a

refrigerant metering orifice (factory installed in coils and

provided with some Lennox air conditioner units) or a

thermostatic expansion valve (ordered separately) may be

used in air conditioner unit applications. A check

expansion valve (ordered separately) is the only metering

device approved for use in heat pump applications.

Refer to the CH33 Engineering Handbook for proper use of

these coils with Lennox furnaces, air conditioner units,

heat pumps and line sets.

These instructions are intended as a general guide and do

not supersede local or national codes in any way. Consult

authorities who have jurisdiction before installation.

Package 1 of 1 contains the following:

1 -- CH33 evaporator coil

Check the components for shipping damage. If you find

any damage, immediately contact the last carrier.

10/07

[[IHHI[IIIII[HI[[III[IIIH[[II[[III

Page 1

505,264M (65484504)

[III[IHHIIII[IH[IHI[IIH[[IImHI[[III

Page 2

Table 1. Orifice Size Shipped with CH33

Model Number. Orifice Size

CH33-18A-2F 0.053

CH33-19A-2F 0.053

CH33-24/30A-2F 0.062

CH33-25A-2F 0.062

CH33-25B-2F 0.062

CH33-31A-2F 0.071

CH33-31 B-2F 0.071

CH33-36A-2F 0.076

CH33-36B-2F 0.076

CH33-36C-2F 0.076

CH33-42B-2F 0.082

CH33-43B-2F 0.082

CH33-43C-2F 0.082

CH33-44/48-2F 0.082

CH33-48C-2F 0.091

CH33-49C-2F 0.091

CH33-50/60C-2F 0.091

CH33-60D-2F 0.099

CH33-62D-2F 0.099

1, Install the furnace per the installation instructions

provided with the unit.

2, Place a field-provided heat shield, such as a wet rag,

against the piping plate and around the piping stubs,

and sweat in the suction line. The heat shield must be

in place to guard against heat damage to the paint.

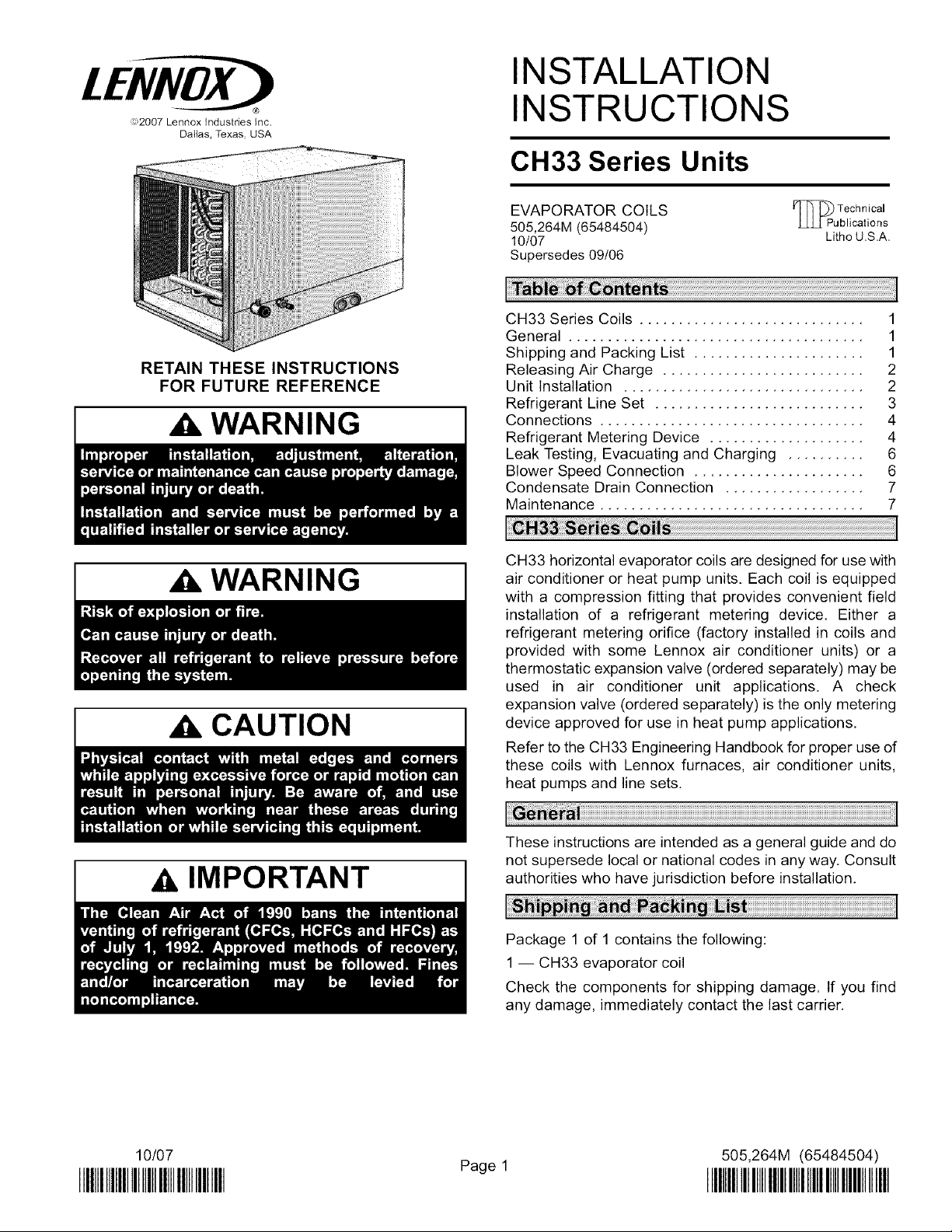

NOTE - In areas of high humidity, the suction line section in

the air stream in the cabinet should be insulated with foam

tape. See figure 1.

FOAM

TAPE

CAUTION

The CH33 coil are shipped with a 15+ 3 psi dry air holding

charge. Ensure that the coil is void of pressure by

performing the following procedure:

a WARNING

1. Remove valve stem cap,

2, Press the liquid line valve stem,

NOTE - If there is no pressure when the valve core is

pressed, check the coil for leaks before continuing with the

installation,

Figure 1. Discharge End of Coil

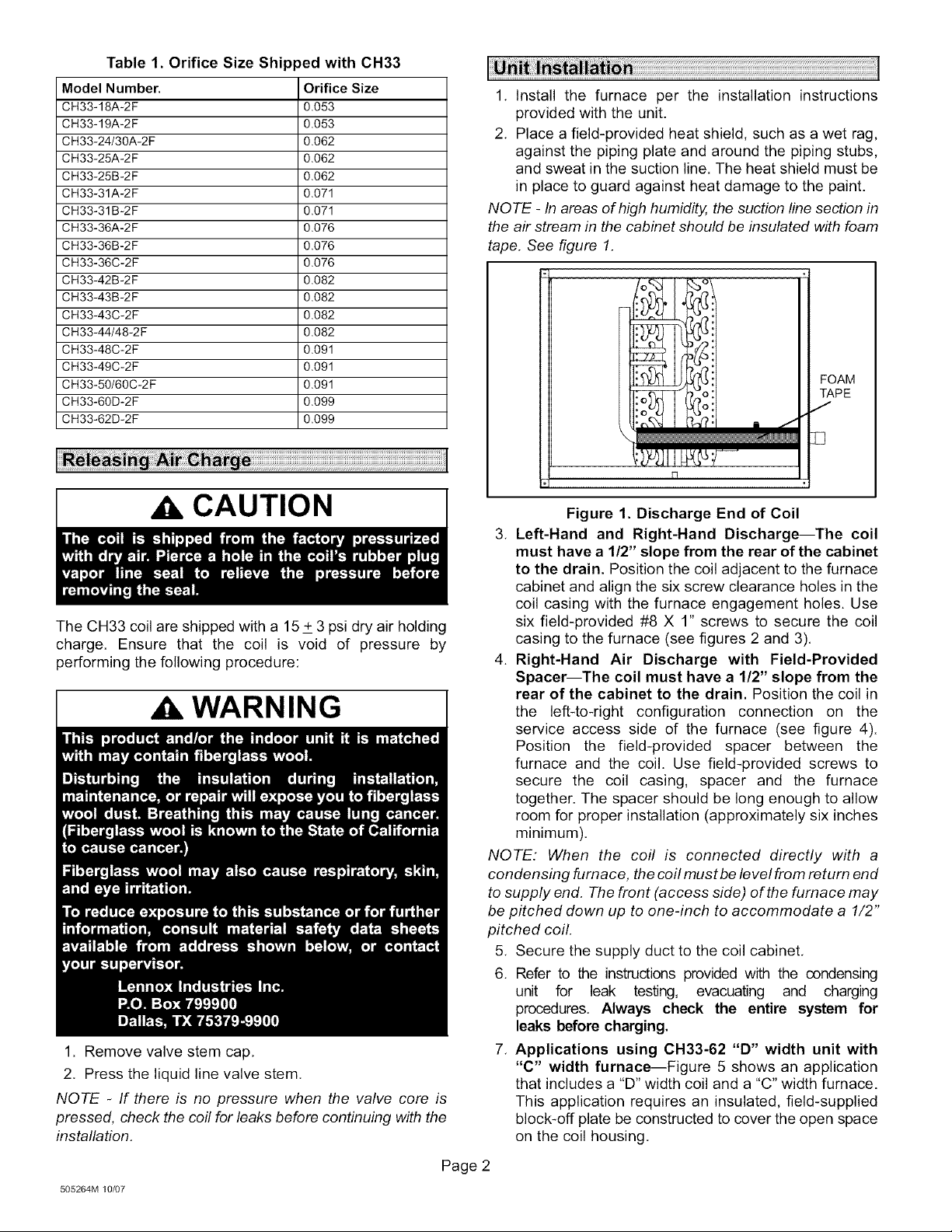

3, Left-Hand and Right-Hand Discharge--The coil

must have a 1/2" slope from the rear of the cabinet

to the drain. Position the coil adjacent to the furnace

cabinet and align the six screw clearance holes in the

coil casing with the furnace engagement holes. Use

six field-provided #8 X 1" screws to secure the coil

casing to the furnace (see figures 2 and 3),

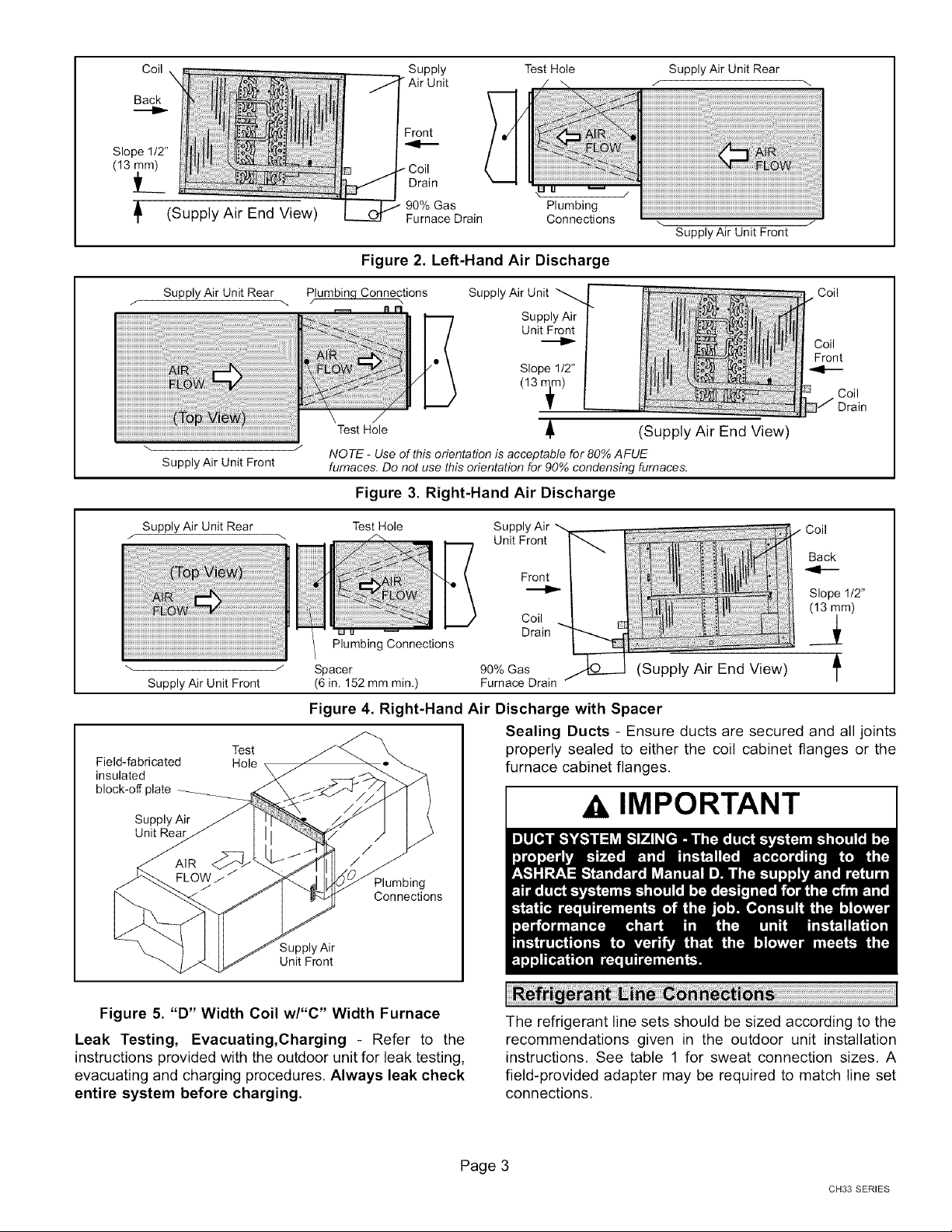

4, Right-Hand Air Discharge with Field-Provided

Spacer--The coil must have a 1/2" slope from the

rear of the cabinet to the drain. Position the coil in

I

the left-to-right configuration connection on the

service access side of the furnace (see figure 4).

Position the field-provided spacer between the

furnace and the coil. Use field-provided screws to

secure the coil casing, spacer and the furnace

together. The spacer should be long enough to allow

room for proper installation (approximately six inches

minimum).

NOTE: When the coil is connected directly with a

condensing furnace, the coil must be level from return end

to supply end. The front (access side) of the furnace may

be pitched down up to one-inch to accommodate a 1/2"

pitched coil.

5, Secure the supply duct to the coil cabinet,

6, Refer to the instructions provided with the condensing

unit for leak testing, evacuating and charging

procedures. Always check the entire system for

leaks before charging.

7, Applications using CH33-62 "D" width unit with

"C" width furnace--Figure 5 shows an application

that includes a "D" width coil and a "C" width furnace.

This application requires an insulated, field-supplied

block-off plate be constructed to cover the open space

on the coil housing,

505264M 10/07

Page 2

Page 3

Coil _ "Air Unit

Back

Slope 112"

(13 mm) Coil

_ Drain

_l (Supply Air End View)

Supply Test Hole Supply Air Unit Rear

Front

90% Gas

Furnace Drain

Figure 2. Left-Hand Air Discharge

Supply Air Unit Rear Plumbinq Connections Supply Air Unit _. [' Coil

Plumbing

Connections

Supply Air b

Unit Front

Slope 1/2"

Supply Air Unit Front

Coil

Front

Supply Air Unit Front

Supply Air Unit Rear

iiiiiiiiiiiiiiii!!!!!!!!!!!!!!!!!_i!iii!i_iil;!i

\ /

Supply Air Unit Front

Field-fabricated

insulated

block-of[ plate

Supply Air

Unit Rear

Test

Hole

II T/i

Test Hole

NOTE - Use of this orientation is acceptable for 80% AFUE

furnaces. Do not use this orientation for 90% condensing furnaces.

Figure 3. Right-Hand Air Discharge

Test Hole

.....

Plumbing Connections

Spacer

(6 in. 152 mm min.)

Figure 4. Right-Hand Air Discharge with Spacer

Sealing Ducts - Ensure ducts are secured and all joints

properly sealed to either the coil cabinet flanges or the

furnace cabinet flanges.

Drain

(Supply Air End View)

IMPORTANT

Plumbing

Connections

SupplyAir

Unit Front

Figure 5. "D" Width Coil wl"C" Width Furnace

Leak Testing, Evacuating,Charging - Refer to the

instructions provided with the outdoor unit for leak testing,

evacuating and charging procedures. Always leak check

entire system before charging.

The refrigerant line sets should be sized according to the

recommendations given in the outdoor unit installation

instructions. See table 1 for sweat connection sizes. A

field-provided adapter may be required to match line set

connections.

Page 3

CH33 SERIES

Page 4

Table . Refrigerant Line Connections

CH33 Model

-18-F

-19-F

-24/30-F

-25-F

-31-F

-36-F

-42-F

-43-F

-44/48-F

-48-F

-49-F

-50/60-F

-60-F

-62-F

Suction (Vapor) Liquid

Line Sweat Size -

314 Inch (19mm)

Line Sweat Size -

3/8 Inch (9.5mm)

Line Sweat Size -

7/8 Inch (22mm)

If replacement parts are necessary, order kit69J46. The kit

includes:

• 10 -- Brass nuts for liquid line assemblies

• 20 -- Teflon rings

• 10 -- Liquid line orifice housings

• 10 -- Liquid line assemblies

LIQUID LINE ORIFICE HOUSINGS (10)

/ TEFLON RINGS (20) _/RETAINER

PISTON

4. Remove the heat shield after brazing and allow the

connections to cool.

CONNECT LIQUID LINE

Use the following procedure to connect the liquid line to the

indoor coil unit:

1. Slide the liquid line compression nut onto the provided

liquid line fitting (the liquid line fitting comes attached

to the front of the delta plate of the uncased coils).

2. Insert the field-supplied liquid line into the liquid line

stub for brazing.

The CH33 coils are shipped with a factory-installed fixed

orifice, CH33 coils are compatible with either HFC-410A

fixed orifice or TXV/CTXV metering devices.

The previously reference TXV/CTXV metering devices will

be referred to in this instruction as TXV,

DETERMINING CORRECT FIXED ORIFICE

A properly sized fixed orifice may be provided with the

outdoor unit. Refer to the outdoor unit instruction to ensure

proper sizing of the refrigerant flow control orifice. An

improperly sized RFC orifice can lead to diminished

capacities and/or efficiencies, as well as potential damage

to the unit, RFCs shipped with the units are identified in

table 1.

I/2TURN

! / BRASS NUTS (I0)

"_ _ _11111_1 L_ _ STRAINER

L,QU,DUNEASSEMBL,ES" O%ER

(INCLUDES STRAINER) (10) LIQUID LINE

Figure 6. 69J46 Kit Components

Use a silver alloy brazing rod (5 or 6 percent silver alloy for

copper-to-copper connections or 45 percent silver alloy for

copper-to-brass or copper-to-steel connections).

BRAZE SUCTION/VAPOR LINE

Use the following procedure to connect the vapor line to

the indoor coil unit:

1. Remove rubber plug.

2. Place a field-provided heat shield, such as a wet rag,

against the piping plate and around the piping stubs,

and sweat in the suction line. The heat shield must be

in place to protect the paint from heat damage.

3. Braze connection.

ASSEMBLY

Figure 7. Tightening Distance

TYPICAL FIXED ORIFICE REMOVAL PROCEDURE

1. On fully cased coils, remove the coil access and

plumbing panels.

2. Remove any shipping clamps holding the liquid line

and distributor assembly.

3. Using two wrenches, disconnect liquid line from

distributor. Take care not to twist or damage distributor

tubes during this process.

4. Remove and discard orifice, valve stem assembly if

present and Teflon ring as illustrated in figure 8.

5. Retain brass nut to be using later with the liquid line

assembly.

505264M 10/07

Page 4

Page 5

VALVE STEM

DISTRIBUTOR TUBES

LIQUID LINE ORIFICE HOUSING

TEFLON RING REMOVE AND DISCARD

VALVE STEM CAP

ORIFICE VALVE STEM ASSEMBLY

(IF PRESENT)

BRASS NUT

/

LIQUID LINE ASSEMBLY

(INCLUDES STRAINER)

(Uncased Coil Shown)

TWO PIECE

PATCH PLATE

dNCASED COIL

)ISTRIBUTOR

TUBES

(Uncased Coil Shown)

LIQUID LINE

ORIFICE STUB END

HOUSING

TXV

RING

SENSING

LINE

Figure 8. Typical Fixed Orifice Removal

TYPICAL FIXED ORIFICE INSTALLATION

PROCEDURE

1. Ensure that the orifice is installed with the nylon seat

pointing toward the liquid line orifice housing,

2. Insert the Teflon ring securely into the liquid line orifice

housing. Lightly lubricate the threads of the liquid line

orifice housing and the expose surface of the Teflon

ring,

3. Connect the liquid line assembly with the brass nut to

the liquid line orifice housing. Finger tighten and use an

appropriately sized wrench to turn an additional 1/2

turn clockwise as illustrated in figure 7, or 20 ftqb,

4. Place the supplied fixed orifice sticker on the indoor

cabinet after installation.

DISTRIBUTOR TUBES

LIQUID LINE ORIFICE HOUSING

\

TEFLON RING

ORIFICE

J BRASS NUT

/

MALE EQUALIZER LINE

FITTING (SEE FIGURE

12 FOR FURTHER

DETAILS)

Sensing bulb insulation is

required if mounted external to

the coil casing. See figure 11 for

bulb positioning.

Figure 10. Typical TXV Installation

LIQUID

LINE

LIQUID LINE ASSEMBLY

(INCLUDES STRAINER)

(Uncased Coil Shown

Figure 9. Typical Fixed Orifice Installation

TYPICAL TXV INSTALLATION PROCEDURE

The TXV unit can be installed internal or external to the

indoor coil. In applications where an uncased coil is being

installed in a field-provided plenum, install the TXV in a

manner that will provide access for field servicing of the

TXV, Refer to figure 10 for reference during installation of

TXV unit,

Figure 11. TXV Sensing Bulb Installation

1. Insert one of the provided Teflon rings into the stubbed

end of the TXV. Lightly lubricate the threads of the

stubbed end of the TXV and the expose surface of the

Teflon ring.

2. Attach the stubbed end of the TXV to the liquid line

orifice housing, Finger tighten and use an appropriately

sized wrench to turn an additional 1/2 turn clockwise

as illustrated in figure 7, or 20 ft-lb,

3. Place the remaining Teflon ring around the other end

of the TXV and lightly lubricate the threads of the that

end of the TXV, and the expose surface of the Teflon

ring,

Page 5

CH33 SERIES

Page 6

4, Attach the liquid line assembly with brass nut to the

TXV. Finger tighten and use an appropriately sized

wrench to turn an additional 1/2 turn clockwise as

illustrated in figure 7, or 20 if-lb.

5, Attach the sensing bulb of the TXV in the proper

orientation as illustrated in figure 11 to the suction line

using the clamp and screws provided in the TXV kit.

6, Connect the equalizer line from the TXV to the

equalizer suction port on the suction line. Finger

tighten the flare nut plus 1/8 turn (7 ft-lbs) as illustrated

in figure 7,

A IMPORTANT

Refer to the outdoor unit instruction for leak testing,

evacuating and charging procedures, Always leak check

entire system before charging,

Proper air volume must be provided over the evaporator

coil. Select a blower motor speed tap that will provide 400 _+

50 CFM per 12,000 Btuh of cooling capacity (wet coil).

A static pressure reading must be taken to see if the

pressure drops are within the proper range. See figure 14

to see for an example to obtain an accurate reading.

Left-HandAir Discharge(TopView)

TEST HOLE 1 Supply Air Unit Rear

FLARE SEAL ,miD,, [ "_'1 r 1

CAP

I

I

]

[_ _ FLARE NUT

OR ._ FLARESEAL

_I (REMOVE)

I

COPPER

BONNET

,R SSE? ,ZER

SUCTION/VAPOR LINE

Figure 12. Copper Flare Seal Bonnet Removal

NOTE - To prevent any possibility of water damage,

properly insulate all parts of the TXV assembly that may

sweat due to temperature differences between the valve

and its surrounding ambient temperatures.

See the CH33 Engineering Handbook for approved TXV

match-ups and application information. Typically, the TXV

kits include the following:

1 -- TXV

2 -- Teflon rings

1 -- 1 1/4" wide copper mounting strap for sensing bulb

2 -- #10 hex head bolts and nuts for securing sensing bulb

AND NUTS (2)

@ TEFLON %/'/

COPPER

MOUNTING

RINGS (2) /%

STRAP (1)

Figure 13. TXV Kit Components

AIR

AIR

RETURN

DUCT

)

TEST

HOLE 2 Supply Air Unit Front

Figure 14. Static Pressure Test

To ensure accuracy, test the air on both sides of the coil

(figure 14 exemplifies the two test hole locations).

CAUTION

Table 2. Air Volume/Static Pressure Drop

Model Cabinet Volume: Drop: in. w.g. (Pa)

CH33 Width in (mm) CFM (L/s) [Dry] [Wet]

-18-F 14-1/2 (394) 600 (285) .14 (35) .17 (42)

-19-F 14-1/2 (394) 800 (380) .15 (37) .17 (42)

-25-F 14-1/2 (394) 800 (380) .15 (37) .19 (47)

-25-F 17-1/2 (444) 800 (380) .09 (22) .11 (27)

-24/30-F 14-1/2 (394) 1000 (470) .22 (55) .30 (80)

-31-F 14-1/2 (394) 1000 (470) .24 (60) .27 (67)

-31-F 17-1/2 (444) 1000 (470) .14 (35) .16 (40)

-36-F 14-1/2 (394) 1200 (565) .27 (67) .30 (75)

-36-F 17-1/2 (444) 1200 (565) .17 (42) .21 (52)

-36-F 21 (533) 1200 (565) .17 (42) .21 (52)

-42-F 17-1/2 (444) 1400 (660) .22 (55) .28 (70)

-43-F 14-1/2 (394) 1400 (660) .26 (65) .31 (77)

-43-F 17-1/2 (444) 1400 (660) .18 (45) .21 (52)

-44/48-F 17-1/2 (444) 1400 (660) .18 (45) .23 (57)

-48-F 21 (533) 1600 (755) .17 (42) .21 (52)

49-F 21 (533) 1600 (755) .25 (62) .29 (72)

-50/60-F 21 (533) 1600 (755) .23 (57) .29 (72)

-60/62-F 24-1/2 (622) 2000 (945) .21 (52) .27 (67)

Across Coil

505264M 10/07

Page 6

Page 7

1, Drilla5/16"(8mm)testholeinthecoilcase1"from

thefurnaceflange(figure14,testhole1).

2. Drilla5/16"(8mm)testholeintotheairsupplyduct

connectedtothecoil.(testhole2infigure14),

3, Connectthezero end of the draft gauge scale to the

furnace end of the coil. Insert the hoses so that 1/4" (6

mm) extends inside the duct or end seal, Seal around

holes with Permagum.

4, Turn on the electrical power to the furnace and set the

thermostat to initiate a cooling demand.

5, Table 2 lists the range of air volumes and equivalent

draft gauge readings for this unit. Observe the draft

gauge reading and if below the required air volume,

increase the blower speed; if above the required air

volume, decrease the blower speed. Refer to the

furnace wiring diagram for blower speed settings.

6. When the required draft gauge readings are obtained,

remove the draft gauge lines and insert snaphole

plugs into the test holes,

IMPORTANT

3. If the auxiliary drain line is to be used, remove the plug

and route the drain line so that water draining from the

outlet will be easily noticed by the homeowner.

4. After removal of drain pan plugs, check the drain port

to see if holes have been drilled. If not drilled, use a

19/32" bit to drill out the primary drain hole; use a 3/8"

drill bit for the secondary drain hole. Remove all drill

shavings.

5. Make sure drain ports and drain pan are free of all

debris.

6. Plug and check any unused drain pan openings for

tightness. Torque plugs to 30 in. lb. to prevent water

leaks or seepage from the drain pan.

XkIMPORTANT

Vent must extend above the height of the coil

drain pan by 2 inches (51 mm). VENT

DRAIN PAN

Trap must be deep enough to offset k k _

maximum static difference (Generally, _v_

2 inches [51ram]).

Drain line should slope a minimum (49P66) _,

1 inch per 10 feet (25 mm per 3 m) TO APPROVED DRAIN

Figure 15. Typical Condensate Drain Connection

CH33 evaporator coils have both main and auxiliary drain

connections, The auxiliary drain removes accumulated

condensate if the main drain becomes plugged,

1, Install a trap in both drain lines per local codes. Ifa vent

tee is required to reduce friction and static pressure,

the trap should be installed between the unit outlet and

the vent tee. See figure 15,

2. Make drain connections at the 3/4" female threaded

pipe using condensate lines of the same size. Pitch the

main drain line down to an open drain or sump,

TRAP

A trained technician or service agency must perform

maintenance and service on equipment. At the beginning

of each heating or cooling season, indoor coils should be

cleaned.

Do not use hydrofluoric acid, alkaline, or similar chemicals

on all coils. These chemicals are not necessary to dissolve

salt, and may damage the fin coating. Acid washes are

used to dissolve oils and greases, which generally are not

present on most installations.

Alkaline washes are useful for dissolving oxides such as

zinc oxide, aluminum oxide, and iron oxide (rust). These

three oxides are more corrosion resistant than base

metals, so dissolving or removing them will cause an

increase in corrosion.

Xk CAUTION

Page 7

CH33 SERIES

Page 8

CLEANING THE COIL:

1, Remove the coil from the cabinet or plenum, and take

the coil to an appropriate place to clean it,

2, Vacuum or brush the coil to remove matted and

surface debris from the fin. Use vacuum attachments

and/or brushes that are non-destructive to fins,

3, If oil deposits are present, spray the coil with ordinary

household liquid detergent, Allow detergent to soften

deposits, Wait 10 minutes,

NOTE - For units in coastal regions, fresh water will

dissolve away any salt deposits. (Wash coils with fresh

water at least every six months.)

4, Spray the coil at a vertical angle of 30 to 45 degrees

with a constant stream of water at moderate pressure.

A pressure washer with a fan nozzle will work best, Do

not spray the coil from a horizontal direction,

5, Direct the spray so that any debris is washed out of the

coil and basepan, For most residential units, hot water

is not necessary,

NOTE - Attempting to back flush from the inside of the coil

will require removing parts from the unit, and it may be very

difficult to flush the whole coil surface. Attempting to blow

water through a coil will slow the water stream and reduce

the flushing action of the outer fin surface.

6, Replace the coil into the cabinet or plenum. Ensure

that you have followed the proper procedure for

routing and securing the refrigerant tubing,

A IMPORTANT

505264M 10/07

Page 8

Loading...

Loading...