Lennox CBX32MV-018/024, CBX32MV-024/030, CBX32MV-060, CBX32MV-068, CBX32MV-036 User Manual

...Page 1

Corp. 1005-L2

Service Literature

Revised April 7, 2015

CBX32MV (HFC-410A) SERIES UNITS (iComfort®-enabled)

NOTICE

A thermostat is not included and must be ordered

separately.

®

A Lennox iComfort

communicating applications.

In non-communicating applications, the Lennox

ComfortSense

as other non-communicating thermostats.

In all cases, setup is critical to ensure proper system

operation.

Field wiring for both communicating and noncommunicating applications is illustrated in diagrams,

which begin on page 24.

®

thermostat must be used in

7000 thermostat may be used, as well

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause personal injury, loss of life, or

damage to property.

Installation and service must be performed by a licensed

professional installer (or equivalent) or a service agency.

CAUTION

As with any mechanical equipment, contact with sharp

sheet metal edges can result in personal injury. Take care

while handling this equipment and use protective cloth

ing.

CBX32MV

TABLE OF CONTENTS

Specifications 2.................................

Model Identification 3............................

Blower Data 3..................................

Electric Heat Data 9.............................

Upflow/Downflow Unit Dimensions 13..............

Horizontal LH/RH Unit Dimensions 14..............

Installation Clearances 15.........................

General 15......................................

Installation Requirements 15......................

Brazing Connections 19...........................

Condensate Drain Requirements 22................

Inspecting and Replacing Filters 23.................

Sealing the Unit 23...............................

Field Control Wiring 24...........................

Air Handler Control Button, Display and Jumpers 31..

Configuring Unit 36...............................

Error Code Recall Mode 43........................

Indoor Blower Test 44............................

Checkout Procedures 44..........................

Operation 45....................................

Maintenance 45..................................

Cabinet Insulation 45.............................

Sequence of Operations 47.......................

Unit Components 60..............................

Electric Heat (ECB40) 66.........................

This indoor unit is designed for installation with optional

field-installed electric heat and a matched remote outdoor

unit that is charged with HFC-410A refrigerant. These units,

designed for indoor installation in multiple positions, are

completely assembled for upflow and horizontal right-hand

discharge before being shipped from the factory.

All CBX32MV air handlers are equipped with a

factory-installed, internally mounted check expansion

valve (CTXV), which is suitable for use in HFC-410A

applications.

This air handler is compatible with the ComfortSense® 7000

non-communicating thermostat and non- communicating

outdoor units. In addition, newer model units have the

enhanced capability of communicating with iComfort

thermostats and compatible outdoor units using the Lennox

RSBus protocols.

NOTE - For downflow or horizontal left-hand air discharge,

certain field modifications are required.

This document provides information only on the

CBX32MV-XXX-230-6-06 and later which features the new

iComfort-enabled hardware. Refer to Corp. 0206-L3 for

earlier model service related information.

®

Page 1

2015 Lennox Industries Inc.

Page 2

Specifications

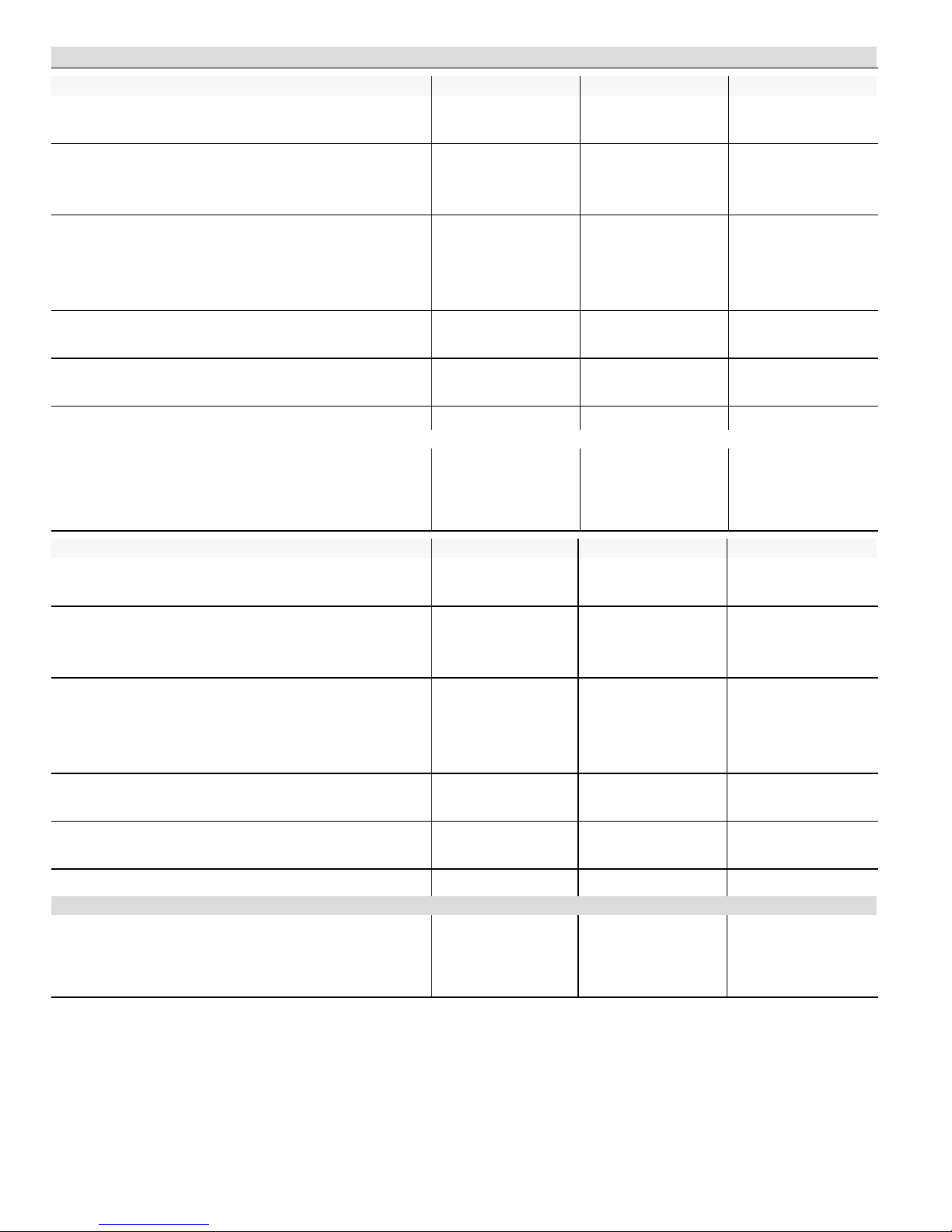

General Data Model Number CBX32MV‐018/024 CBX32MV‐024/030 CBX32MV‐036

Nominal cooling capacity - tons (kW) 1.5 - 2 (5.3 - 7) 2 - 2.5 (7 - 8.8) 3 (10.6)

Refrigerant R-410A R-410A R-410A

Connections

in. (mm)

Indoor Coil

Blower Data

Wheel nominal diameter x width - in. (mm) 10 x 7 (279 x 178) 10 x 8 (279 x 203) 10 x 8 (279 x 203)

Filters

Shipping Data - 1 Package lbs. (kg) 126 (57) 152 (69) 183 (83)

ELECTRICAL DATA

Voltage - phase - 60hz 208/230V-1ph

Maximum overcurrent protection (unit only)

Suction (vapor) line - sweat 5/8 (15.8) 3/4 (19) 3/4 (19)

Liquid line - sweat 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Condensate drain (fpt) (2) 3/4 (19) (2) 3/4 (19) (2) 3/4 (19)

Net face area - ft.2 (m2) 3.56 (0.33) 4.44 (0.41) 5.0 (0.46)

Tube outside diameter - in. (mm) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Number of rows 3 3 3

Fins per inch (fins per m) 12 (472) 12 (472) 12 (472)

Motor output - hp (W) 1/2 (373) 1/2 (373) 1/2 (373)

1

Number and size - in. (1) 15 x 20 x 1 (1) 20 x 20 x 1 (1) 20 x 20 x 1

mm 381 x 508 x 25 508 x 508 x 25 508 x 508 x 25

208/230V-1ph 208/230V-1ph

2

15 15 15

Minimum circuit ampacity (unit only) 5 5 5

General Data Model Number CBX32MV‐048 CBX32MV‐060 CBX32MV‐068

Nominal cooling capacity - tons (kW) 4 (14.1) 5 (17.6) 5+ (17.6+)

Refrigerant HFC-410A HFC-410A HFC-410A

Connections

in. (mm)

Suction (vapor) line - sweat 7/8 (22.2) 1‐1/8 (28) 1‐1/8 (28)

Liquid line - sweat 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Condensate drain (fpt) (2) 3/4 (19) (2) 3/4 (19) (2) 3/4 (19)

Indoor Coil

Net face area - ft.2 (m2) 7.22 (0.67) 7.22 (0.67) 7.77 (0.72)

Tube outside diameter - in. (mm) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Number of rows 3 3 3

Fins per inch (fins per m) 12 (472) 12 (472) 12 (472)

Blower Data

Wheel nominal diameter x width - in. (mm) 12 x 9 (305 x 229) 12 x 9 (305 x 229) 15 x 9 (381 x 229)

Motor output - hp (W) 1 (746) 1 (746) 1 (746)

Filters

1

Number and size - in. (1) 20 x 24 x 1 (1) 20 x 24 x 1 (1) 20 x 25 x 1

mm 508 x 610 x 25 508 x 610 x 25 508 x 635 x 25

Shipping Data - 1 Package - lbs. (kg) 212 (96) 212 (96) 244 (111)

ELECTRICAL DATA

Voltage - phase - 60hz 208/230V-1ph

Maximum overcurrent protection (unit only)

2

20 20 20

208/230V-1ph 208/230V-1ph

Minimum circuit ampacity (unit only) 11 11 11

CBX32MV

Page 2

Page 3

Optional Accessories

For up-to-date information, see any of the following publications:

Lennox CBX32MV Product Specification bulletin (EHB)

Lennox Commercial Price Book

Model Identification

Unit Type

X

MV

−

−

230CB 32 036

−−

05

6

Minor Revision Number

CB = Air Handler

Refrigerant Type

X = R-410A

Series

Configuration

MV = Multi-Position, Variable

speed blower motor

Refrigerant Metering Device

2 = Fixed Orifice

3 = TXV - Bleedport (indoor unit)

4 = TXV - Non-bleedport (indoor unit)

5 = TXV - Non-bleedport (outdoor unit)

6 = TXV - R-410A Non-bleedport (indoor

unit)

Voltage

230 = 208/230V-60hz-1ph

Nominal Cooling Capacity

018/024 = 1.5 to 2 tons (5.3 to 7 kW)

024/030 = 2 to 2.5 tons (7 to 8.8 kW)

036 = 3 tons (10.6 kW)

048 = 4 tons (14.1 kW)

060 = 5 tons (17.6 kW)

068 = 5+ tons (17.6+ kW)

Blower Data

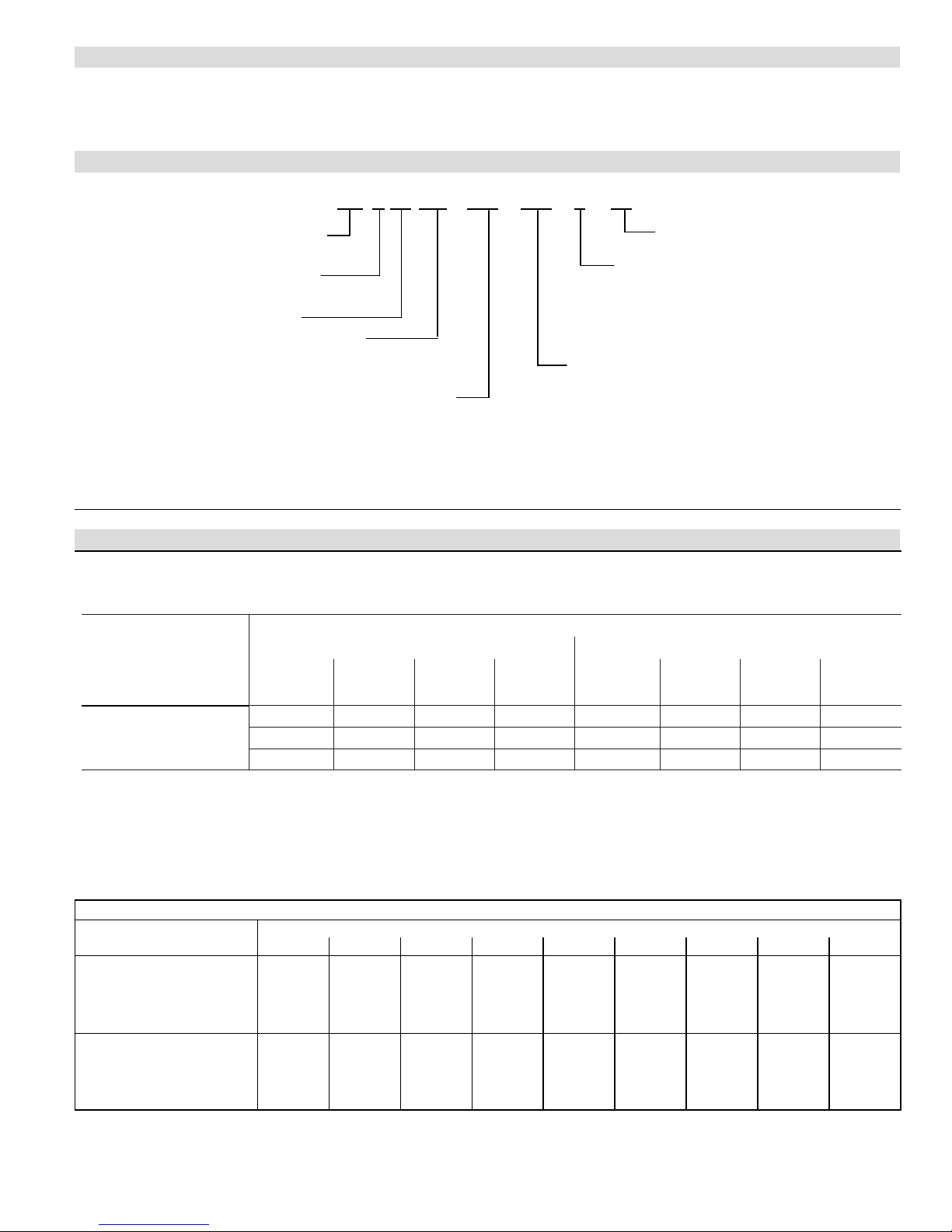

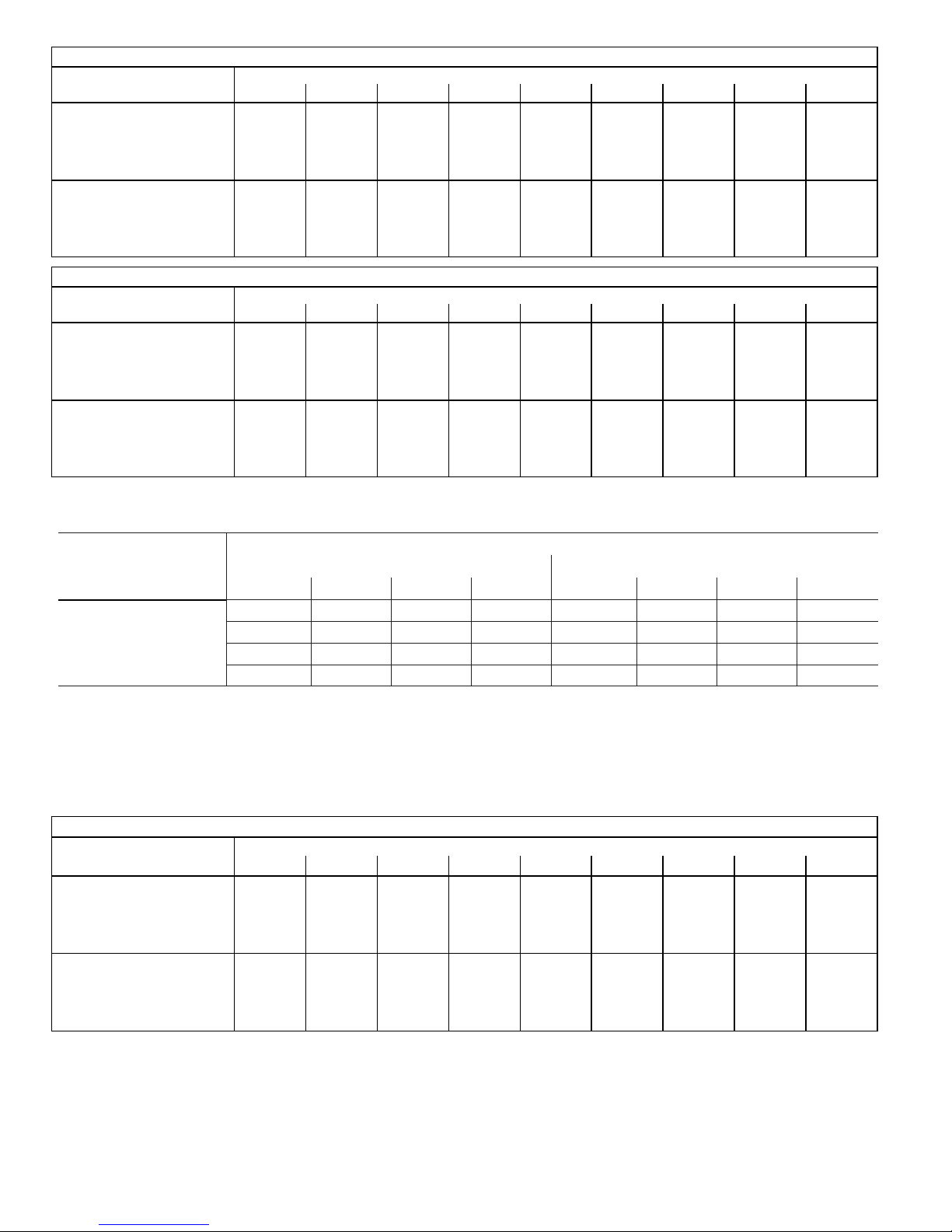

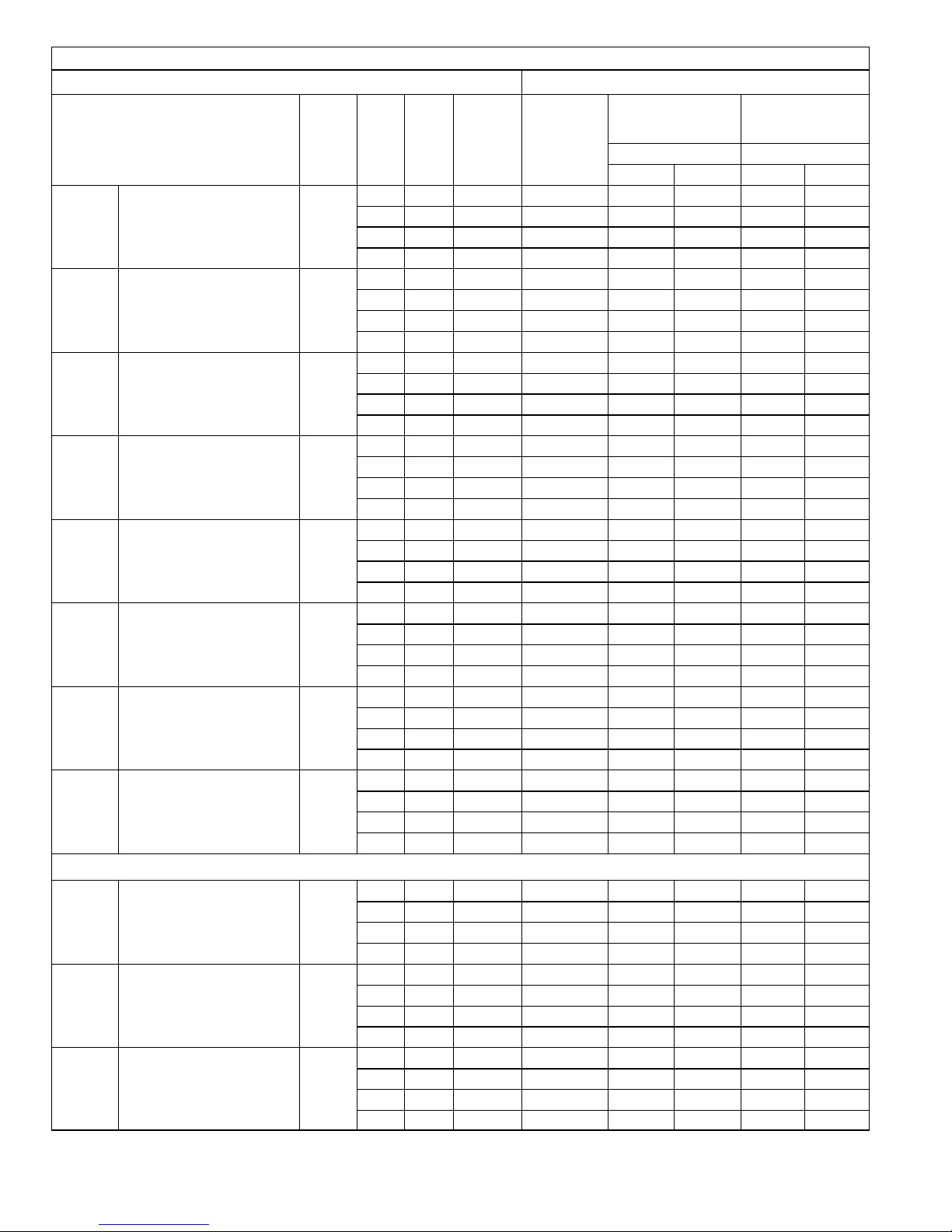

CBX32MV018/024 BLOWER PERFORMANCE

0 through 0.80 in. w.g. External Static Pressure Range

Jumper Speed Positions

“AJUST”

Jumper Setting

NORM

NOTES:

1

cfm

+

-

715 855 1000 1130 465 690 900 1050

670

580 700 800 930 385 560 735 850

“HEAT” Speed “COOL” Speed

2

cfm

770 900 1035 425 620 825 950

3

cfm

4

cfm

1

cfm

2

cfm

3

cfm

cfm

The effect of static pressure, filter and electric heater resistance is included in the air volumes listed.

First stage cooling air volume is 70% of COOL speed settings. Continuous fan speed is approximately 28%, 38%, 70% and 100% (Jumper

selectable) of the same secondstage COOL speed selected, minimum 250 cfm.

Lennox Harmony III™ Zone Control applications - minimum blower speed of 250 cfm.

4

CBX32MV‐018/024 BLOWER MOTOR WATTS AT + (Plus) SETTING (Adjust Jumper at + Setting)

Jumper Speed Positions

Tap 1 100 113 126 142 154 172 190 206 230

HEAT Speed

COOL Speed

Tap 2 155 176 197 221 237 260 278 295 310

Tap 3 237 260 289 305 314 337 356 373 390

Tap 4 338 361 379 409 433 457 447 426 406

Tap 1 36 47 61 71 81 95 106 11 8 135

Tap 2 89 103 118 129 143 163 177 197 207

Tap 3 183 198 229 248 266 290 307 327 343

Tap 4 266 294 315 330 349 373 390 411 401

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

Page 3

CBX32MV

Page 4

CBX32MV‐018/024 BLOWER MOTOR WATTS AT NORM SETTING

Jumper Speed Positions

Tap 1 77 96 106 123 130 150 165 178 201

HEAT Speed

COOL Speed

Tap 2 118 136 154 177 189 212 224 247 265

Tap 3 183 198 224 248 264 284 307 321 343

Tap 4 264 284 300 326 343 367 385 406 390

Tap 1 30 41 55 62 76 86 94 106 114

Tap 2 71 83 101 113 125 138 156 166 185

Tap 3 137 158 176 199 219 238 254 273 296

Tap 4 211 225 249 272 295 318 331 342 367

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

(Adjust Jumper at NORM Setting)

CBX32MV‐018/024 BLOWER MOTOR WATTS AT - (Minus) SETTING (Adjust Jumper at - Setting)

Jumper Speed Positions

Tap 1 59 73 89 106 113 130 142 156 173

HEAT Speed

COOL Speed

Tap 2 95 106 118 136 152 171 183 200 215

Tap 3 132 148 171 186 211 225 248 266 284

Tap 4 195 217 242 259 283 302 314 336 349

Tap 1 27 35 47 59 71 77 88 92 106

Tap 2 57 65 83 94 110 119 134 148 166

Tap 3 110 124 141 157 176 188 213 231 242

Tap 4 148 170 195 207 230 248 272 282 306

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

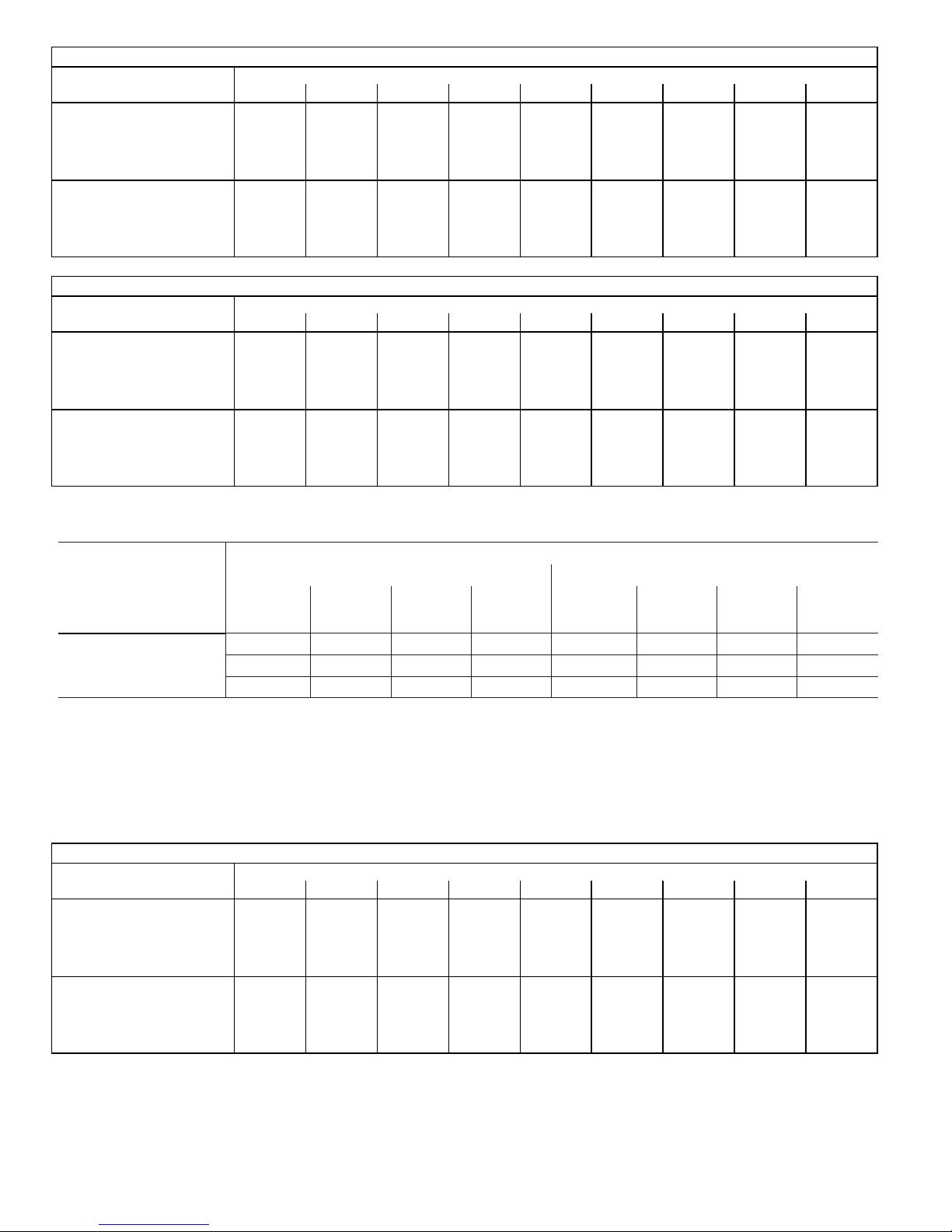

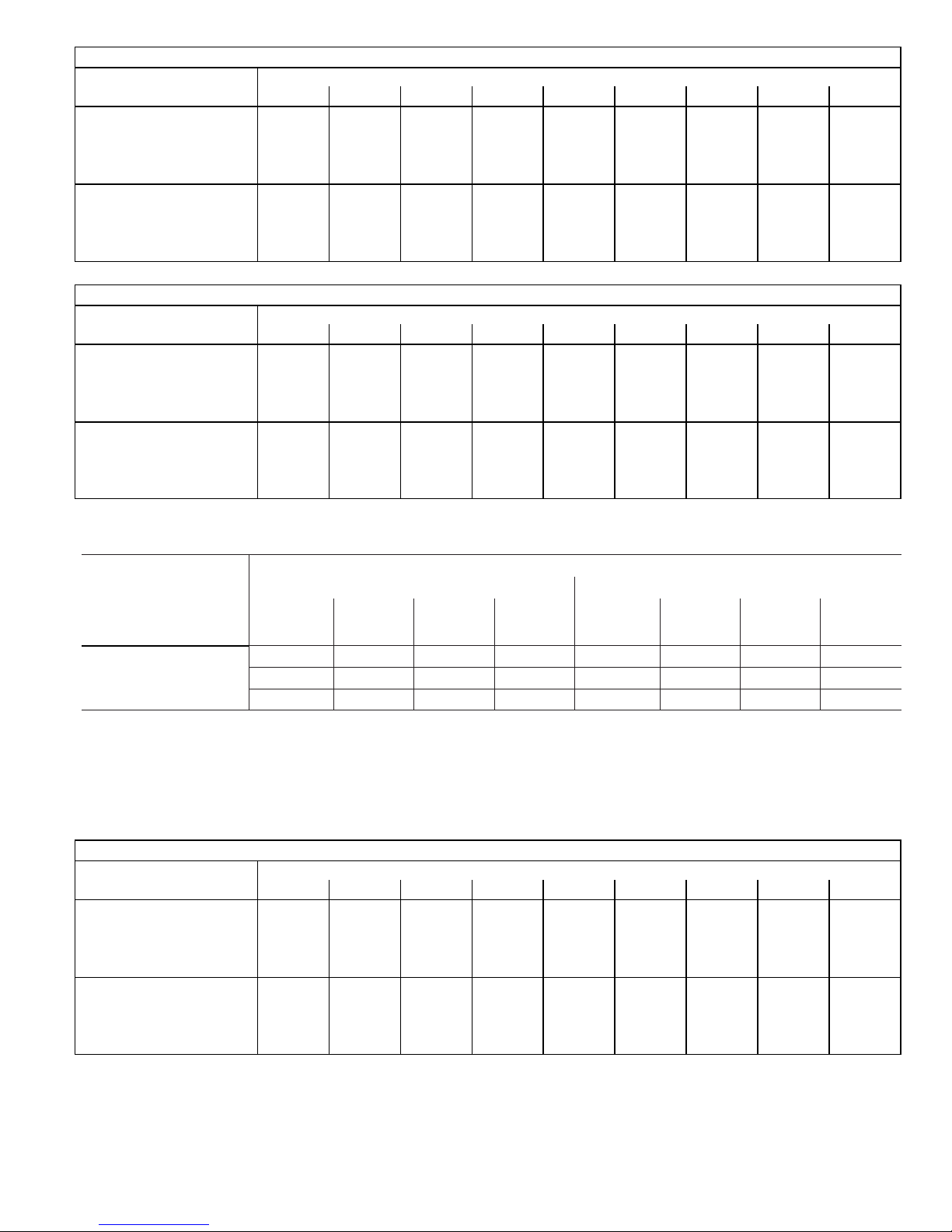

CBX32MV024/030 BLOWER PERFORMANCE

0 through 0.80 in. w.g. External Static Pressure Range

Jumper Speed Positions

“AJUST”

Jumper Setting

NORM

NOTES:

1

cfm

+

-

800 935 1070 1210 660 880 1100 1320

725

655 765 880 990 540 720 900 1080

“HEAT” Speed “COOL” Speed

2

cfm

850 975 1100 600 800 1000 1200

3

cfm

4

cfm

1

cfm

2

cfm

3

cfm

cfm

The effect of static pressure, filter and electric heater resistance is included in the air volumes listed.

First stage cooling air volume is 70% of COOL speed settings. Continuous fan speed is approximately 28%, 38%, 70% and 100% (Jumper

selectable) of the same secondstage COOL speed selected, minimum 250 cfm.

Lennox Harmony III™ Zone Control applications - minimum blower speed of 250 cfm.

CBX32MV‐024/030 BLOWER MOTOR WATTS AT + (Plus) SETTING (Adjust Jumper at + Setting)

Jumper Speed Positions

Tap 1 65 90 120 145 185 210 240 250 275

HEAT Speed

COOL Speed

Tap 2 95 125 150 185 230 265 310 345 365

Tap 3 140 190 225 250 290 320 350 405 450

Tap 4 215 250 285 315 350 390 440 480 505

Tap 1 45 60 90 120 140 155 165 185 200

Tap 2 80 110 135 165 205 250 285 315 335

Tap 3 150 195 225 260 295 320 370 425 465

Tap 4 265 315 350 400 440 485 525 555 605

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

4

CBX32MV

Page 4

Page 5

CBX32MV‐024/030 BLOWER MOTOR WATTS AT NORM SETTING

Jumper Speed Positions

Tap 1 50 75 100 135 155 180 195 215 230

HEAT Speed

COOL Speed

Tap 2 80 105 130 155 200 245 265 295 310

Tap 3 110 150 175 200 235 275 320 350 390

Tap 4 155 205 230 270 290 325 360 405 460

Tap 1 40 55 80 105 120 130 150 165 180

Tap 2 65 90 120 145 190 210 240 260 285

Tap 3 105 145 175 220 250 285 335 370 405

Tap 4 200 245 275 300 335 385 420 470 515

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

(Adjust Jumper at NORM Setting)

CBX32MV‐024/030 BLOWER MOTOR WATTS AT - (Minus) SETTING (Adjust Jumper at - Setting)

Jumper Speed Positions

Tap 1 45 65 90 110 130 150 165 190 195

HEAT Speed

COOL Speed

Tap 2 60 85 110 145 175 200 215 235 240

Tap 3 85 105 130 165 210 245 280 305 330

Tap 4 115 145 175 205 230 280 325 370 390

Tap 1 30 50 70 90 100 115 125 140 165

Tap 2 55 75 100 135 155 185 190 210 225

Tap 3 85 115 135 175 210 255 295 320 345

Tap 4 145 175 215 245 280 325 355 410 450

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

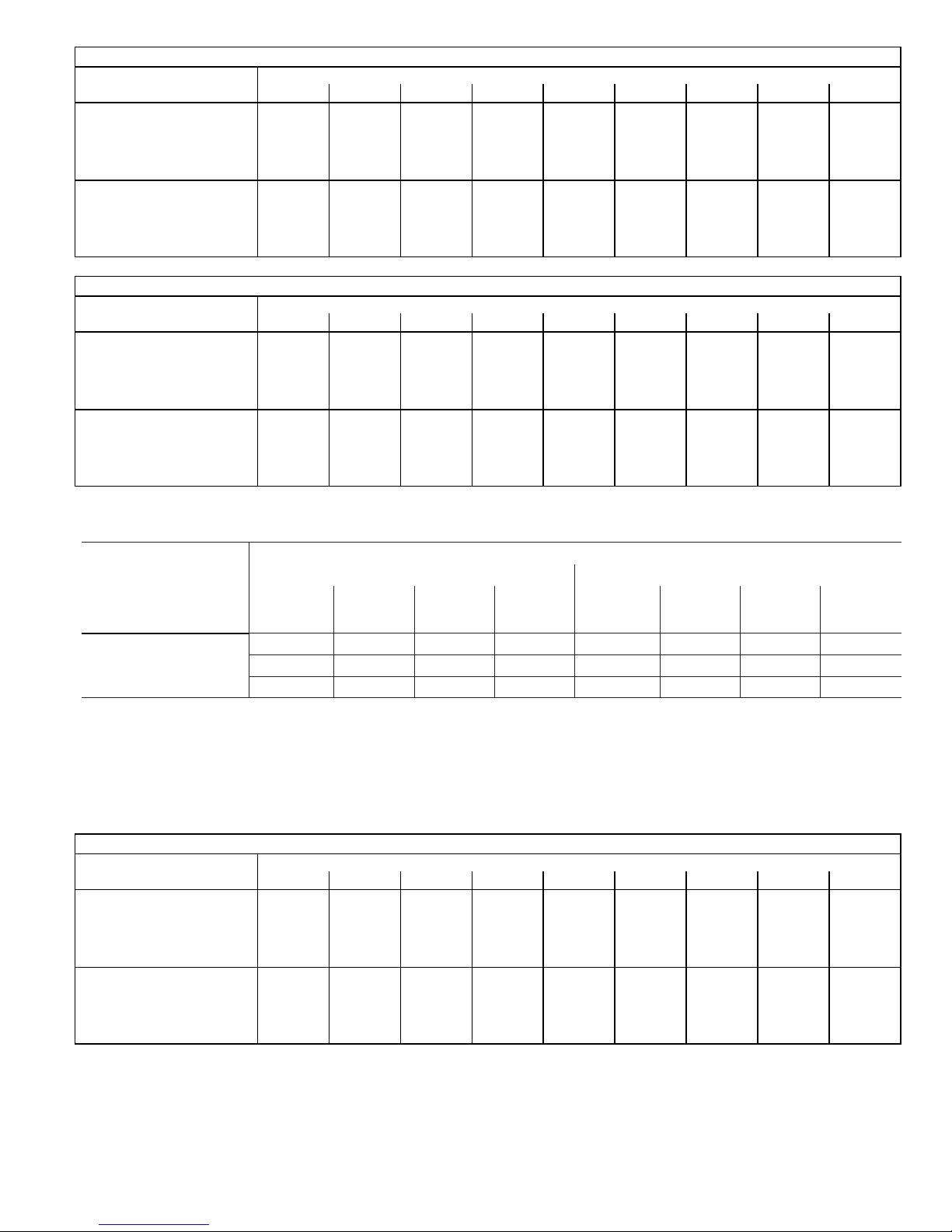

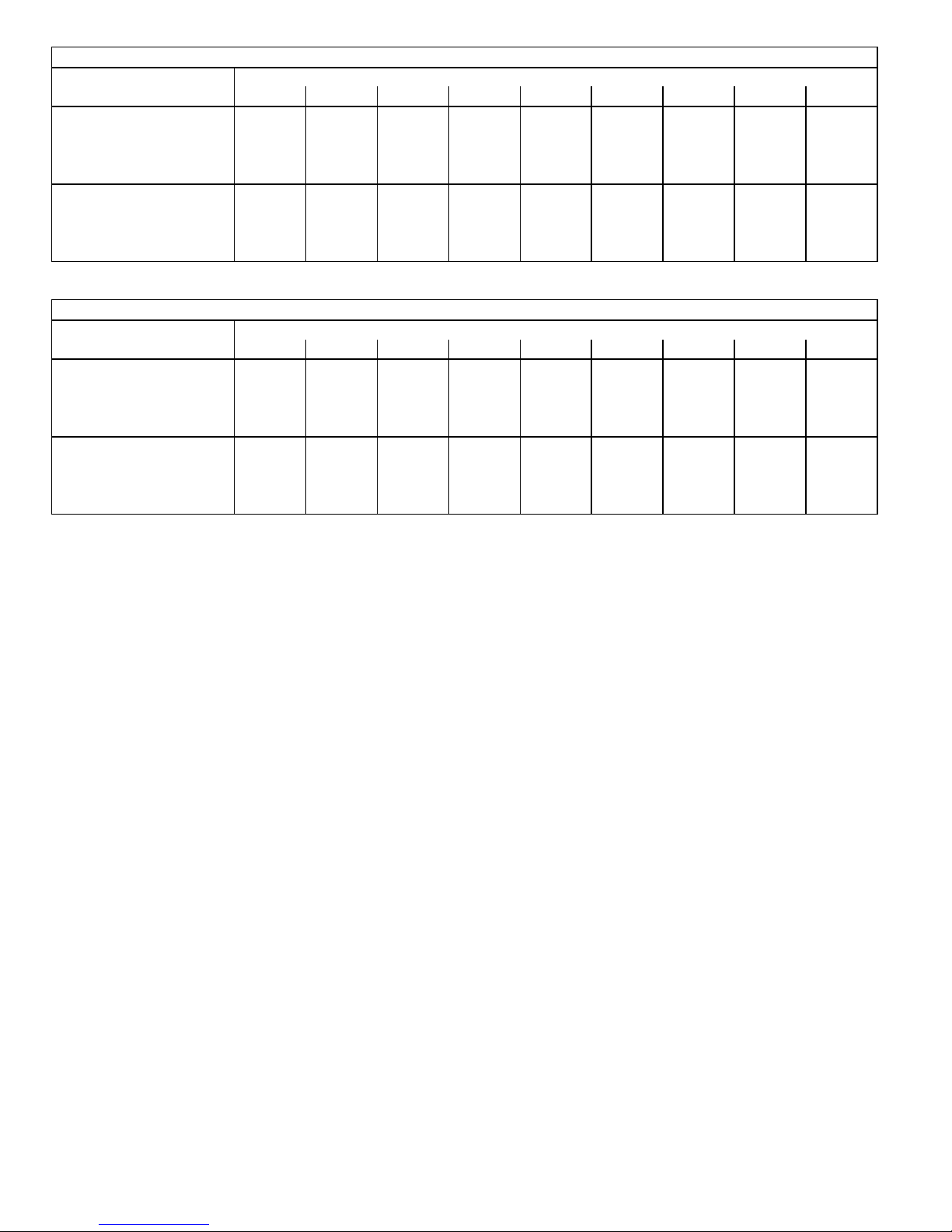

CBX32MV036 BLOWER PERFORMANCE

0 through 0.80 in. w.g. External Static Pressure Range

Jumper Speed Positions

“AJUST”

Jumper Setting

NORM

NOTES:

1

cfm

+

-

1230 1335 1445 1545 900 1225 1380 1545

1120

1010 1185 1200 1265 730 1000 1135 1265

“HEAT” Speed “COOL” Speed

2

cfm

1215 1315 1400 810 1125 1275 1400

3

cfm

4

cfm

1

cfm

2

cfm

3

cfm

cfm

The effect of static pressure, filter and electric heater resistance is included in the air volumes listed.

First stage cooling air volume is 70% of COOL speed settings. Continuous fan speed is approximately 28%, 38%, 70% and 100% (Jumper

selectable) of the same secondstage COOL speed selected, minimum 250 cfm.

Lennox Harmony III™ Zone Control applications - minimum blower speed of 250 cfm.

CBX32MV‐036 BLOWER MOTOR WATTS AT + (Plus) SETTING (Adjust Jumper at + Setting)

Jumper Speed Positions

Tap 1 220 235 265 290 310 335 360 385 465

HEAT Speed

COOL Speed

Tap 2 285 305 330 355 380 405 430 450 475

Tap 3 345 365 405 430 455 485 515 545 570

Tap 4 470 495 515 530 545 560 575 595 610

Tap 1 145 165 200 225 250 275 300 325 350

Tap 2 225 245 265 290 320 350 370 395 410

Tap 3 305 325 350 390 420 445 475 505 535

Tap 4 470 495 515 530 545 560 575 595 610

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

4

Page 5

CBX32MV

Page 6

CBX32MV‐036 BLOWER MOTOR WATTS AT NORM SETTING

Jumper Speed Positions

Tap 1 155 185 215 240 265 285 300 335 355

HEAT Speed

COOL Speed

Tap 2 225 245 270 295 325 345 370 390 415

Tap 3 275 290 315 340 375 400 420 445 465

Tap 4 320 345 375 405 435 460 485 515 540

Tap 1 120 140 160 190 210 230 255 275 300

Tap 2 160 190 220 240 265 290 320 340 365

Tap 3 255 270 295 320 345 375 400 420 445

Tap 4 320 345 375 405 435 460 485 515 540

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

(Adjust Jumper at NORM Setting)

CBX32MV‐036 BLOWER MOTOR WATTS AT - (Minus) SETTING (Adjust Jumper at - Setting)

Jumper Speed Positions

Tap 1 120 135 165 185 205 225 245 265 300

HEAT Speed

COOL Speed

Tap 2 140 165 195 215 245 270 300 315 335

Tap 3 185 210 240 265 285 310 330 360 385

Tap 4 245 255 290 310 335 355 380 405 430

Tap 1 90 110 135 155 180 195 210 230 250

Tap 2 120 140 160 185 215 235 255 275 295

Tap 3 160 190 225 240 275 295 320 350 380

Tap 4 245 255 290 310 335 355 380 405 430

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

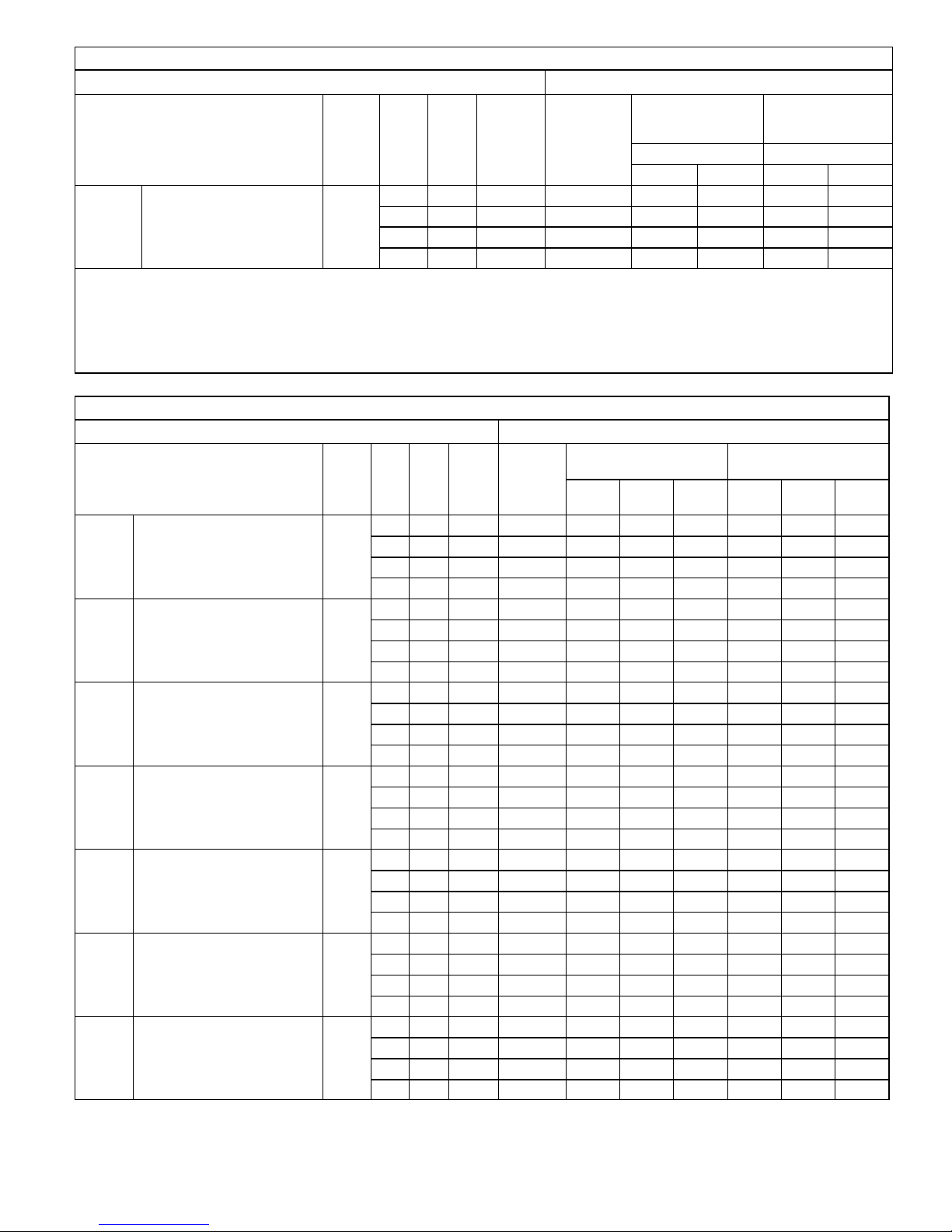

CBX32MV048 and CBX32MV060 BLOWER PERFORMANCE

0 through 0.80 in. w.g. External Static Pressure Range

Jumper Speed Positions

“AJUST”

Jumper Setting

NORM

NOTES:

1 2 3 4 1 2 3 4

+

-

cfm cfm cfm cfm cfm cfm cfm cfm

1850

1705

1560 1625 1720 1770 1205 1375 1555 1725

“HEAT” Speed “COOL” Speed

1960 2090 2150 1625 1820 2055 2145

1800 1900 2005 1425 1625 1805 2005

The effect of static pressure, filter and electric heater resistance is included in the air volumes listed.

First stage cooling air volume is 70% of COOL speed settings. Continuous fan speed is approximately 28%, 38%, 70% and 100% (Jumper

selectable) of the same secondstage COOL speed selected, minimum 450 cfm.

Lennox Harmony III™ Zone Control applications - minimum blower speed of 450 cfm.

CBX32MV‐048 AND CBX32MV‐060 BLOWER MOTOR WATTS AT + (Plus) SETTING (Adjust Jumper at + Setting)

Jumper Speed Positions

Tap 1 455 505 540 585 630 665 710 745 780

HEAT Speed

COOL Speed

Tap 2 555 595 645 675 730 780 820 865 895

Tap 3 680 720 770 820 865 900 945 985 1030

Tap 4 730 780 825 870 920 970 1020 1055 1110

Tap 1 300 335 370 360 435 465 500 535 575

Tap 2 425 475 500 545 585 635 670 710 745

Tap 3 625 660 705 755 810 850 885 940 970

Tap 4 700 750 800 845 895 940 990 1030 1080

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

CBX32MV

Page 6

Page 7

CBX32MV‐048 AND CBX32MV‐060 BLOWER MOTOR WATTS AT NORM SETTING

Jumper Speed Positions

Tap 1 360 385 425 465 495 525 565 600 635

HEAT Speed

COOL Speed

Tap 2 400 440 485 520 555 595 640 670 705

Tap 3 480 520 560 605 640 685 765 785 805

Tap 4 580 625 665 710 760 800 835 875 925

Tap 1 215 235 275 295 330 360 400 430 465

Tap 2 310 335 375 405 440 465 500 530 565

Tap 3 415 445 490 535 565 605 650 675 715

Tap 4 580 610 655 695 740 785 830 870 910

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

(Adjust Jumper at NORM Setting)

CBX32MV‐048 AND CBX32MV‐060 BLOWER MOTOR WATTS AT - (Minus) SETTING (Adjust Jumper at - Setting)

Jumper Speed Positions

Tap 1 265 305 340 370 410 440 460 505 540

HEAT Speed

COOL Speed

Tap 2 320 350 395 420 450 475 515 545 580

Tap 3 375 410 435 470 515 545 575 610 645

Tap 4 400 435 480 525 555 595 640 670 700

Tap 1 140 170 195 215 250 275 300 335 360

Tap 2 200 230 260 285 315 355 385 415 450

Tap 3 280 315 340 380 415 445 465 505 540

Tap 4 375 420 440 475 515 550 575 610 645

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

CBX32MV068 BLOWER PERFORMANCE

0 through 0.80 in. w.g. External Static Pressure Range

Jumper Speed Positions

“AJUST”

Jumper Setting

NORM

NOTES:

1

cfm

+

-

1875 1975 2090 2150 1640 1840 2075 2150

1760

1550 1650 1725 1800 1250 1390 1560 1720

“HEAT” Speed “COOL” Speed

2

cfm

1825 1920 2030 1465 1625 1800 2000

3

cfm

4

cfm

1

cfm

2

cfm

3

cfm

cfm

The effect of static pressure, filter and electric heater resistance is included in the air volumes listed.

First stage cooling air volume is 70% of COOL speed settings. Continuous fan speed is approximately 28%, 38%, 70% and 100% (Jumper

selectable) of the same secondstage COOL speed selected, minimum 450 cfm.

Lennox Harmony III™ Zone Control applications - minimum blower speed of 450 cfm.

CBX32MV‐068 BLOWER MOTOR WATTS AT + (Plus) SETTING (Adjust Jumper at + Setting)

Jumper Speed Positions

Tap 1 365 410 455 495 545 610 660 725 790

HEAT Speed

COOL Speed

Tap 2 430 485 540 590 640 690 765 835 865

Tap 3 540 585 635 695 750 800 815 840 865

Tap 4 665 710 755 770 790 810 830 845 870

Tap 1 255 290 320 365 415 455 505 550 590

Tap 2 355 390 425 475 515 580 630 695 750

Tap 3 505 565 610 70 715 790 815 845 865

Tap 4 725 745 755 770 790 810 830 850 870

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

4

Page 7

CBX32MV

Page 8

CBX32MV‐068 BLOWER MOTOR WATTS AT NORM SETTING (Adjust Jumper at NORM Setting)

Jumper Speed Positions

Tap 1 310 345 385 425 465 510 560 610 665

HEAT Speed

COOL Speed

Tap 2 345 385 420 460 500 620 615 680 735

Tap 3 385 430 480 525 580 640 695 750 815

Tap 4 475 525 560 615 660 720 785 845 810

Tap 1 180 205 240 285 325 365 405 435 480

Tap 2 250 285 320 355 410 455 505 535 585

Tap 3 345 375 415 460 505 560 610 670 735

Tap 4 445 510 560 595 665 725 790 845 865

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

CBX32MV‐068 BLOWER MOTOR WATTS AT - (Minus) SETTING (Adjust Jumper at - Setting)

Jumper Speed Positions

Tap 1 215 245 285 325 375 415 460 495 540

HEAT Speed

COOL Speed

Tap 2 255 295 325 370 410 460 510 545 580

Tap 3 295 330 375 395 445 495 555 600 660

Tap 4 335 370 400 445 505 550 600 660 705

Tap 1 125 150 170 210 245 270 300 340 370

Tap 2 160 185 225 255 300 335 365 415 450

Tap 3 225 245 280 320 370 420 460 510 545

Tap 4 290 325 355 400 445 490 545 595 650

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures - in. wg. (Pa)

CBX32MV

Page 8

Page 9

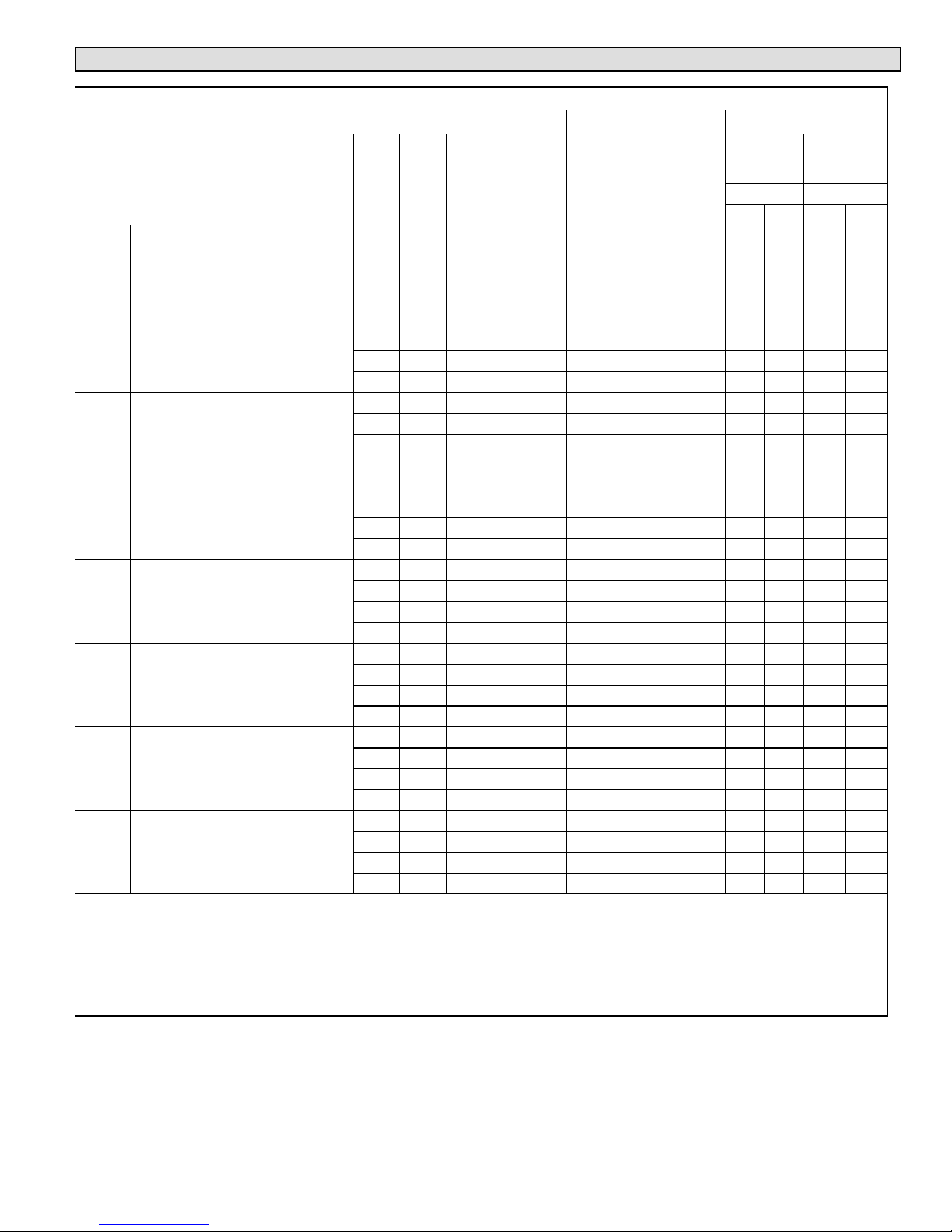

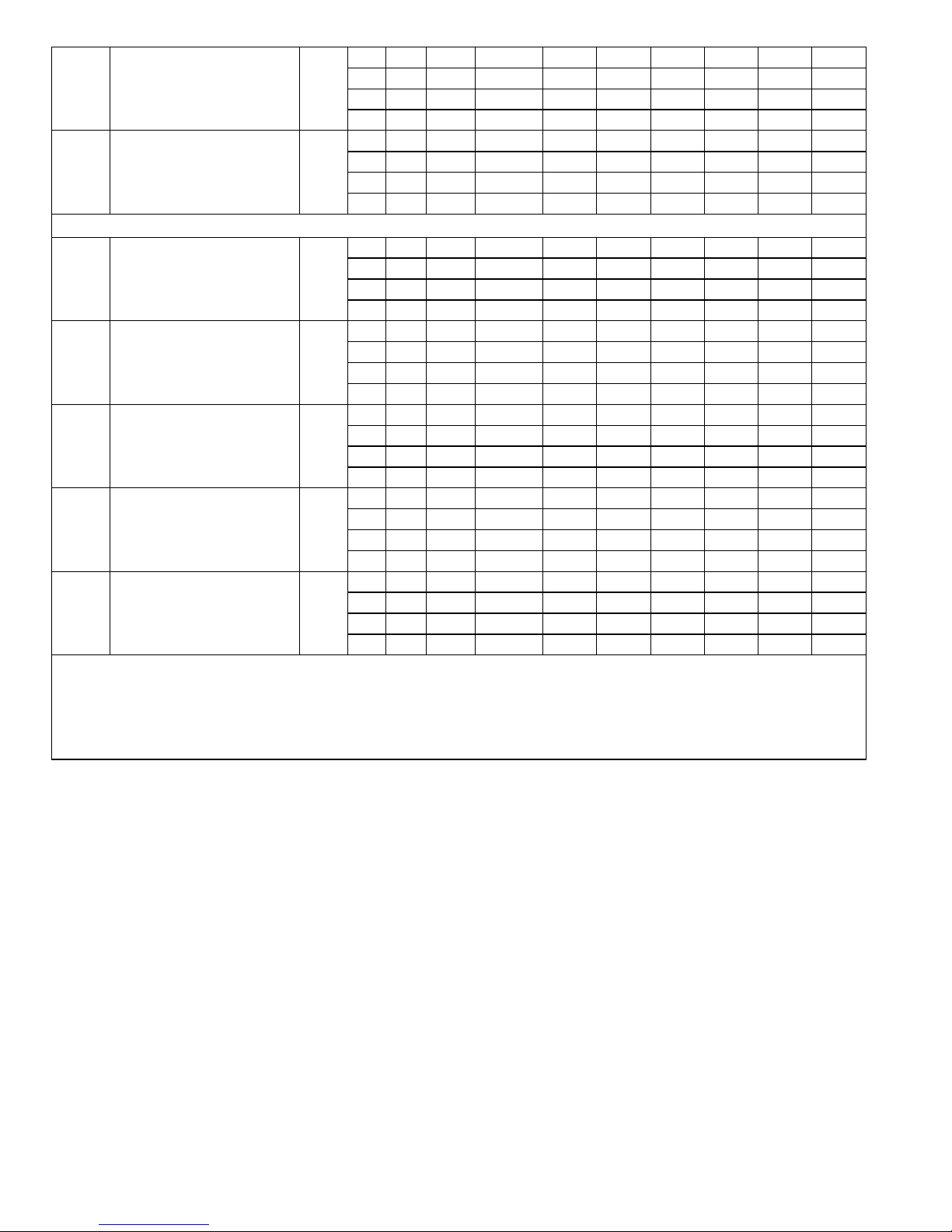

Electric Heat Data

ELECTRIC HEAT DATA - CBX32MV-018/024 AND CBX32MV-024/030

SINGLE PHASE ELECTRIC HEAT

2

1

Btuh

Input

2.5 kW

4 lbs.

Model Number

ECB40-2.5 (34W86)

Terminal Block

No. of

Stages

1

Volts

InputkWInput

208 1.9 6,400 4.0 16 20 - - - - - - - - - - - -

220 2.1 7,200 4.0 17 20 - - - - - - - - - - - -

230 2.3 7,800 4.0 18 20 - - - - - - - - - - - -

240 2.5 8,500 4.0 18 20 - - - - - - - - - - - -

4 kW

4 lbs.

ECB40-4 (55W89)

Terminal Block

ECB40-4CB (55W90)

30A Circuit breaker

1

208 3.0 10,250 4.0 23 25 23 - - - 25 - - -

220 3.4 11,450 4.0 24 25 24 - - - 25 - - -

230 3.7 12,550 4.0 25 25 25 - - - 25 - - -

240 4.0 13,650 4.0 26 30 26 - - - 30 - - -

5 kW

4 lbs.

ECB40-5 (34W87)

Terminal Block

ECB40-5CB (34W90)

35A Circuit breaker

1

208 3.8 12,800 4.0 28 30 28 - - - 30 - - -

220 4.2 14,300 4.0 29 30 29 - - - 30 - - -

230 4.6 15,700 4.0 30 30 30 - - - 30 - - -

240 5.0 17,100 4.0 31 35 31 - - - 35 - - -

6 kW

4 lbs.

ECB40-6 (34W88)

Terminal Block

ECB40-6CB (34W91)

40A Circuit breaker

1

208 4.5 15,400 4.0 32 35 32 - - - 35 - - -

220 5.0 17,100 4.0 33 35 33 - - - 35 - - -

230 5.5 18,800 4.0 35 35 35 - - - 35 - - -

240 6.0 20,500 4.0 36 40 36 - - - 40 - - -

8 kW

5 lbs.

ECB40-8 (34W89)

Terminal Block

ECB40-8CB (34W92)

50A Circuit breaker

1

208 6.0 20,500 4.0 41 45 41 - - - 45 - - -

220 6.7 22,900 4.0 43 45 43 - - - 45 - - -

230 7.3 25,100 4.0 45 45 45 - - - 45 - - -

240 8.0 27,300 4.0 47 50 47 - - - 50 - - -

9 kW

5 lbs.

ECB40-9CB (34W93)

60A Circuit breaker

2

208 6.8 23,100 4.0 - - - - - - 46 - - - 50 - - -

220 7.6 25,800 4.0 - - - - - - 48 - - - 50 - - -

230 8.3 28,200 4.0 - - - - - - 50 - - - 50 - - -

240 9.0 30,700 4.0 - - - - - - 52 - - - 60 - - -

12.5

kW

10 lbs.

ECB40-12.5CB (34W94)

(1) 30A & (1) 45A Circuit

breaker

2

208 9.4 32,000 4.0 - - - - - - 24 38 25 40

220 10.5 35,800 4.0 - - - - - - 25 40 25 40

230 11.5 39,200 4.0 - - - - - - 26 42 30 45

240 12.5 42,600 4.0 - - - - - - 27 44 30 45

15 kW

12 lbs.

ECB40-15CB (34W95)

(1) 35A & (1) 60A Circuit

breaker

2

208 11.3 38,400 4.0 - - - - - - 28 45 30 45

220 12.6 43,000 4.0 - - - - - - 29 48 30 50

230 13.8 47,000 4.0 - - - - - - 30 50 30 50

240 15.0 51,200 4.0 - - - - - - 31 52 35 60

NOTE − Circuit 1 Minimum Circuit Ampacity includes the Blower Motor Full Load Amps.

1

Electric heater capacity only − does not include additional blower motor heat capacity.

2

Amps shown are for blower motor only.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements. Use wires suitable for at least

167F.

4

Bold text indicates that the circuit breaker on “CB” circuit breaker models must be replaced with size noted. See Table on page 6.

5

HACR type circuit breaker or fuse.

Blower

Motor

Full Load

Amps

CBX32MV-018/024 CBX32MV-024/030

3

Minimum

Circuit

Ampacity

5

Maximum

Overcurrent

Protection

3

Minimum

Circuit

Ampacity

Circuit Circuit

5

Overcurrent

1 2 1 2

Maximum

Protection

Page 9

CBX32MV

Page 10

ELECTRIC HEAT DATA - CBX32MV-036

SINGLE PHASE ELECTRIC HEAT

No. of

Stages

1

1

1

1

2

2

2

2

4 kW

4 lbs.

5 kW

4 lbs.

6 kW

4 lbs.

8 kW

5 lbs.

9 kW

5 lbs.

12.5 kW

10 lbs.

15 kW

12 lbs.

20 kW

19 lbs.

Model Number

ECB40−4 (55W89)

Terminal Block

ECB40−4CB (55W90)

35A Circuit breaker

ECB40−5 (34W87)

Terminal Block

ECB40−5CB (34W90)

35A Circuit breaker

ECB40−6 (34W88)

Terminal Block

ECB40−6CB (34W91)

40A Circuit breaker

ECB40−8 (34W89)

Terminal Block

ECB40−8CB (34W92)

50A Circuit breaker

ECB40−9CB (34W93)

60A Circuit breaker

ECB40−12.5CB (34W94)

(1) 30A & (1) 45A Circuit

breaker

ECB40−15CB (34W95)

(1) 35A & (1) 60A Circuit

breaker

ECB40−20CB (34W96)

(2) 60A Circuit breaker

THREE PHASE ELECTRIC HEAT

8 kW

5 lbs.

10 kW

6 lbs.

15 kW

12 lbs.

ECB40−8 (34W98)

Terminal Block

ECB40−10 (34W99)

Terminal Block

ECB40−15CB (35W00)

50A Circuit breaker

1

1

1

CBX32MV-036

5

Maximum

Overcurrent

Protection

Volts

InputkWInput

1

Btuh In

put

2

Blower Mo

tor Full Load

Amps

3

Minimum Circuit

Ampacity

Circuit Circuit

1 2 1 2

208 3.0 10,250 4.0 23 - - - 25 - - -

220 3.4 11,450 4.0 24 - - - 25 - - -

230 3.7 12,550 4.0 25 - - - 25 - - -

240 4.0 13,650 4.0 26 - - - 30 - - -

208 3.8 12,800 4.0 28 - - - 30 - - -

220 4.2 14,300 4.0 29 - - - 30 - - -

230 4.6 15,700 4.0 30 - - - 30 - - -

240 5.0 17,100 4.0 31 - - - 35 - - -

208 4.5 15,400 4.0 32 - - - 35 - - -

220 5.0 17,100 4.0 33 - - - 35 - - -

230 5.5 18,800 4.0 35 - - - 35 - - -

240 6.0 20,500 4.0 36 - - - 40 - - -

208 6.0 20,500 4.0 41 - - - 45 - - -

220 6.7 22,900 4.0 43 - - - 45 - - -

230 7.3 25,100 4.0 45 - - - 45 - - -

240 8.0 27,300 4.0 47 - - - 50 - - -

208 6.8 23,100 4.0 46 - - - 50 - - -

220 7.6 25,800 4.0 48 - - - 50 - - -

230 8.3 28,200 4.0 50 - - - 50 - - -

240 9.0 30,700 4.0 52 - - - 60 - - -

208 9.4 32,000 4.0 24 38 25 40

220 10.5 35,800 4.0 25 40 25 40

230 11.5 39,200 4.0 26 42 30 45

240 12.5 42,600 4.0 27 44 30 45

208 11.3 38,400 4.0 28 45 30 45

220 12.6 43,000 4.0 29 48 30 50

230 13.8 47,000 4.0 30 50 30 50

240 15.0 51,200 4.0 31 52 35 60

208 15.0 51,200 4.0 46 50 50 50

220 16.8 57,300 4.0 48 53 50 60

230 18.4 62,700 4.0 50 55 50 60

240 20.0 68,200 4.0 52 57 60 60

208 6.0 20,500 4.0 26 - - - 30 - - -

220 6.7 22,900 4.0 27 - - - 30 - - -

230 7.3 25,100 4.0 28 - - - 30 - - -

240 8.0 27,300 4.0 28 - - - 30 - - -

208 7.5 25,600 4.0 31 - - - 35 - - -

220 8.4 28,700 4.0 33 - - - 35 - - -

230 9.2 31,400 4.0 34 - - - 35 - - -

240 10.0 34,100 4.0 35 - - - 35 - - -

208 11.3 38,400 4.0 44 - - - 45 - - -

220 12.6 43,000 4.0 46 - - - 50 - - -

230 13.5 47,000 4.0 48 - - - 50 - - -

240 15.0 51,200 4.0 50 - - - 50 - - -

CBX32MV

Page 10

Page 11

ELECTRIC HEAT DATA - CBX32MV-036 (Continued)

THREE PHASE ELECTRIC HEAT

2

Blower Mo

tor Full Load

Amps

put

1

Btuh In

put

20 kW

19 lbs.

Model Number

ECB40−20CB (35W01)

(2) 35A Circuit breaker

No. of

Stages

2

Volts

kW In

Input

208 15.0 51,200 4.0 31 26 35 30

220 16.8 57,300 4.0 33 28 35 30

230 18.4 62,700 4.0 34 29 35 30

240 20.0 68,200 4.0 35 30 35 35

NOTE - Circuit 1 Minimum Circuit Ampacity includes the Blower Motor Full Load Amps.

1

Electric heater capacity only − does not include additional blower motor heat capacity.

2

Amps shown are for blower motor only.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements. Use wires suitable for at least

167F.

4

Bold text indicates that the circuit breaker on “CB” circuit breaker models must be replaced with size noted. See Table on page 6.

5

HACR type circuit breaker or fuse.

CBX32MV-036

5

3

Minimum Circuit

Ampacity

Maximum

Overcurrent

Protection

Circuit Circuit

1 2 1 2

ELECTRIC HEAT DATA - CBX32MV-048, CBX32MV-060, AND CBX32MV-068

SINGLE PHASE ELECTRIC HEAT

Model Number

4 kW

4 lbs.

5 kW

4 lbs.

6 kW

4 lbs.

8 kW

5 lbs.

9 kW

5 lbs.

12.5 kW

10 lbs.

15 kW

12 lbs.

ECB40-4 (55W89)

Terminal Block

ECB40-4CB (55W90)

35A Circuit breaker

ECB40-5 (34W87)

Terminal Block

ECB40-5CB (34W90)

35A Circuit breaker

ECB40-6 (34W88)

Terminal Block

ECB40-6CB (34W91)

40A Circuit breaker

ECB40-8 (34W89)

Terminal Block

ECB40-8CB (34W92)

50A Circuit breaker

ECB40-9CB (34W93)

60A Circuit breaker

ECB40-12.5CB (34W94)

(1) 30A & (1) 45A Circuit

breaker

ECB40-15CB (34W95)

(1) 35A & (1) 60A Circuit

breaker

No. of

Stage

s

1

1

1

1

2

2

2

Volts

InputkWInput

1

Btuh

Input

208 3.0 10,250 7.4 27 - - - - - - 30 - - - - - -

220 3.4 11,450 7.4 28 - - - - - - 30 - - - - - -

230 3.7 12,550 7.4 29 - - - - - - 30 - - - - - -

240 4.0 13,650 7.4 30 - - - - - - 30 - - - - - -

208 3.8 12,800 7.4 32 - - - - - - 35 - - - - - -

220 4.2 14,300 7.4 33 - - - - - - 35 - - - - - -

230 4.6 15,700 7.4 34 - - - - - - 35 - - - - - -

240 5.0 17,100 7.4 35 - - - - - - 35 - - - - - -

208 4.5 15,400 7.4 36 - - - - - - 40 - - - - - -

220 5.0 17,100 7.4 38 - - - - - - 40 - - - - - -

230 5.5 18,800 7.4 39 - - - - - - 40 - - - - - -

240 6.0 20,500 7.4 41 - - - - - - 45 - - - - - -

208 6.0 20,500 7.4 45 - - - - - - 45 - - - - - -

220 6.7 22,900 7.4 47 - - - - - - 50 - - - - - -

230 7.3 25,100 7.4 49 - - - - - - 50 - - - - - -

240 8.0 27,300 7.4 51 - - - - - - 60 - - - - - -

208 6.8 23,100 7.4 50 - - - - - - 50 - - - - - -

220 7.6 25,800 7.4 52 - - - - - - 60 - - - - - -

230 8.3 28,200 7.4 54 - - - - - - 60 - - - - - -

240 9.0 30,700 7.4 56 - - - - - - 60 - - - - - -

208 9.4 32,000 7.4 28 38 - - - 30 40 - - -

220 10.5 35,800 7.4 29 40 - - - 30 40 - - -

230 11.5 39,200 7.4 30 42 - - - 30 45 - - -

240 12.5 42,600 7.4 31 44 - - - 35 45 - - -

208 11.3 38,400 7.4 32 45 - - - 35 45 - - -

220 12.6 43,000 7.4 33 48 - - - 35 50 - - -

230 13.5 47,000 7.4 34 50 - - - 35 50 - - -

240 15.0 51,200 7.4 35 52 - - - 35 60 - - -

CBX32MV-048, CBX32MV-060, AND CBX32MV-068

2

Blower

Motor Full

Load

Amps

3

Minimum Circuit Ampacity

Circuit1Circuit2Circuit3Circuit1Circuit2Circuit

5

Maximum Overcurrent

Protection

3

Page 11

CBX32MV

Page 12

20 kW

19 lbs.

ECB40-20CB (34W96)

(2) 60A Circuit breaker

2

208 15.0 51,200 7.4 50 50 - - - 50 50 - - -

220 16.8 57,300 7.4 52 53 - - - 60 60 - - -

230 18.4 62,700 7.4 54 55 - - - 60 60 - - -

240 20.0 68,200 7.4 56 57 - - - 60 60 - - -

25 kW

19 lbs.

ECB40-25CB (34W97)

(1) 60A & (2) 45A Circuit

breaker

3

208 18.8 64,100 7.4 47 38 38 50 40 40

220 21.0 71,700 7.4 49 40 40 50 40 40

230 23.0 78,300 7.4 51 42 42 60 45 45

240 25.0 85,300 7.4 53 44 44 60 45 45

THREE PHASE ELECTRIC HEAT

8 kW

5 lbs.

10 kW

6 lbs.

15 kW

12 lbs.

20 kW

19 lbs.

25 kW

19 lbs.

NOTE - Circuit 1 Minimum Circuit Ampacity includes the Blower Motor Full Load Amps.

1

Electric heater capacity only − does not include additional blower motor heat capacity.

2

Amps shown are for blower motor only.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements. Use wires suitable for at least

167F.

4

Bold text indicates that the circuit breaker on “CB” circuit breaker models must be replaced with size noted. See Table on page 6.

5

HACR type circuit breaker or fuse.

ECB40-8 (34W98)

Terminal block

ECB40-10 (34W99)

Terminal block

ECB40-15CB (35W00)

50A Circuit breaker

ECB40-20CB (35W01)

(2) 35A Circuit breaker

ECB40-25CB (35W02)

(1) 50A & (1) 40A Circuit

breaker

1

208 6.0 20,500 7.4 30 - - - - - - 35 - - - - - -

220 6.7 22,900 7.4 31 - - - - - - 35 - - - - - -

230 7.3 25,100 7.4 32 - - - - - - 35 - - - - - -

240 8.0 27,300 7.4 33 - - - - - - 35 - - - - - -

1

208 7.5 25,600 7.4 35 - - - - - - 40 - - - - - -

220 8.4 28,700 7.4 37 - - - - - - 40 - - - - - -

230 9.2 31,400 7.4 38 - - - - - - 40 - - - - - -

240 10.0 34,100 7.4 39 - - - - - - 40 - - - - - -

1

208 11.3 38,400 7.4 48 - - - - - - 50 - - - - - -

220 12.6 43,000 7.4 51 - - - - - - 60 - - - - - -

230 13.5 47,000 7.4 52 - - - - - - 60 - - - - - -

240 15.0 51,200 7.4 54 - - - - - - 60 - - - - - -

2

208 15.0 51,200 7.4 35 26 - - - 40 30 - - -

220 16.8 57,300 7.4 37 28 - - - 40 30 - - -

230 18.4 62,700 7.4 38 29 - - - 40 30 - - -

240 20.0 68,200 7.4 39 30 - - - 40 35 - - -

2

208 18.8 64,100 7.4 42 33 - - - 45 35 - - -

220 21.0 71,700 7.4 44 34 - - - 45 35 - - -

230 23.0 78,300 7.4 45 36 - - - 50 40 - - -

240 25.0 85,300 7.4 47 38 - - - 50 40 - - -

CBX32MV

Page 12

Page 13

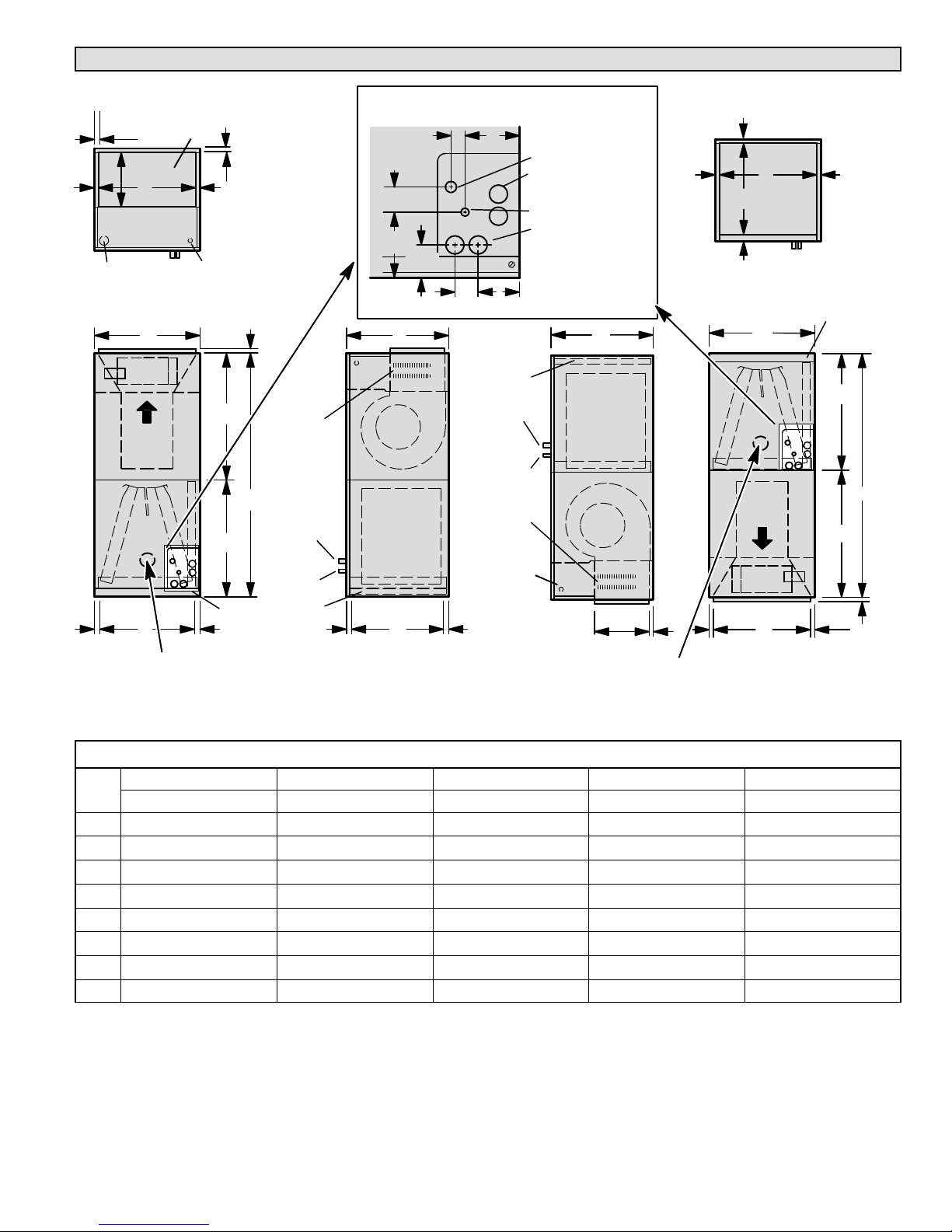

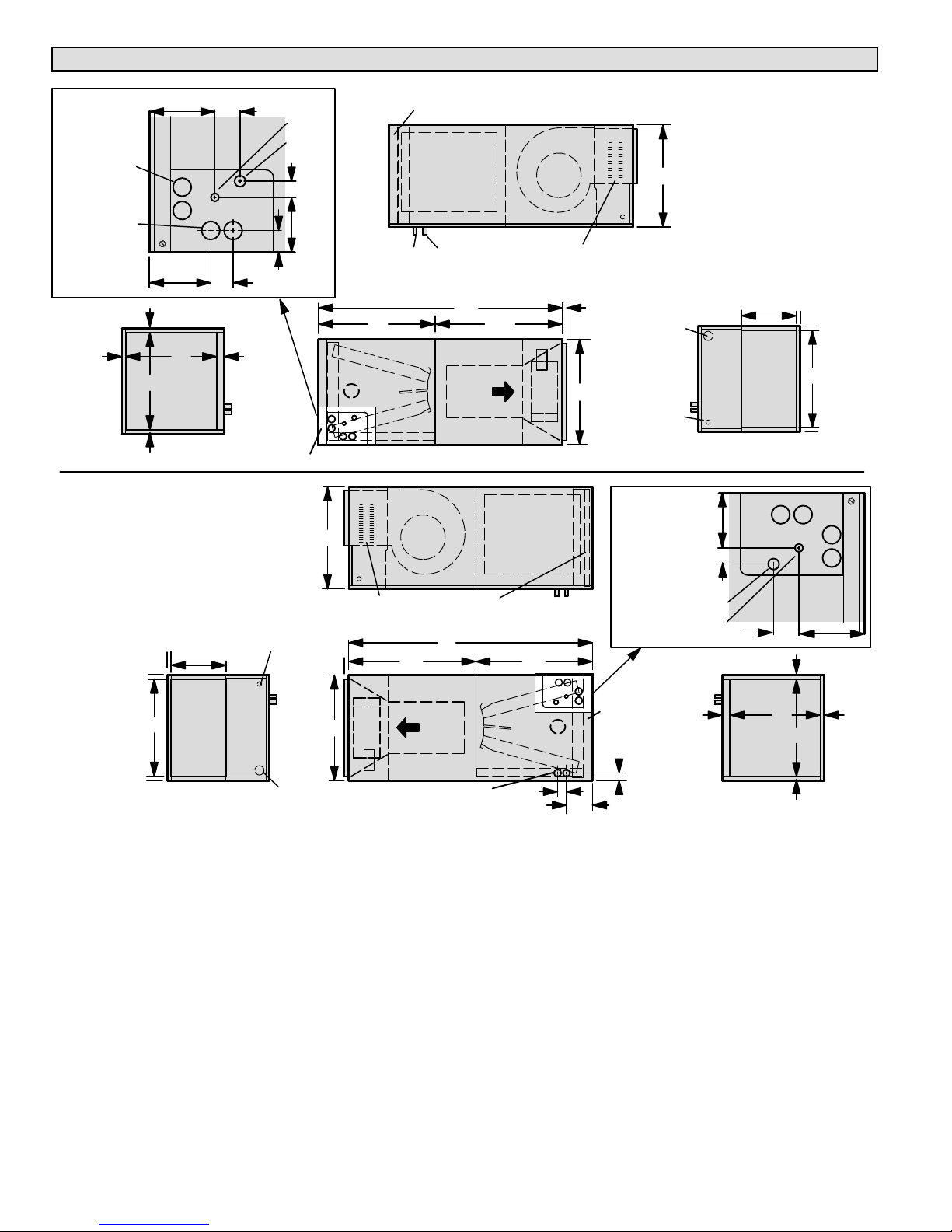

CBX32MV Upflow and Downflow Unit Dimensions — Inches (millimeters)

3/4 (19)

SUPPLY AIR

OPENING

D

11‐1/16 (281)

LINE VOLTAGE

INLETS (TOP

AND LEFT SIDE)

TOP VIEW

3/4 (19)

LOW VOLTAGE

INLETS (TOP AND

RIGHT SIDE)

5/8 (16)

BC

AIR

FLOW

G

OPTIONAL

ELECTRIC HEAT

(FIELD-INSTALLED)

A

SUCTION

H

RETURN AIR

5/8 (16) 1 (25)

KNOCKOUT FOR OPTIONAL HEALTHY

F

®

CLIMATE

GERMICIDAL UVC LIGHT.

FRONT VIEW

FILTER ACCESS

5/8 (16)

UPFLOW POSITION

LINE

LIQUID

LINE

FILTER

(FOR UPFLOW AND DOWNFLOW POSITIONS)

1‐1/8 (29)

2

(51)

5‐3/8

(137)

BLOWER

COIL

RETURN AIR

SIDE VIEW

PIPING PLATE DETAIL

2‐3/4

(70)

E

5/8 (16)

1‐3/4 (44)

FILTER

SUCTION

LINE

LIQUID

LINE

OPTIONAL

ELECTRIC HEAT

(FIELD-INSTALLED)

LOW VOLTAGE

(RIGHT SIDE)

LINE VOLTAGE

(LEFT SIDE)

4‐3/8 (111)

SUCTION LINE

CONDENSATE DRAINS

(2) (HORIZONTAL)

LIQUID LINE

CONDENSATE DRAINS

(2) (UPFLOW AND

DOWNFLOW)

3‐1/2 (89)

11‐1/16 (281)

5/8 (16)

C

COIL

BLOWER

SUPPLY

AIR

5/8 (16)

KNOCKOUT FOR OPTIONAL HEALTHY

®

CLIMATE

SIDE VIEW

DOWNFLOW POSITION

5/8 (16)

GERMICIDAL UVC LIGHT.

5/8 (16)

F

RETURN

E

OPENING

1 (25)

TOP VIEW

B

AIR FLOW

SUPPLY AIR

D

FRONT VIEW

5/8 (16)

AIR

FILTER ACCESS

H

A

G

5/8 (16)

CBX32MV Model Dimensions (Upflow, Downflow, Left- and Right-Hand Horizontal applications)

Dim.

A

B

C

D

E

F

G

H

-018/024 -024/030 -036 -048 and -060 -068

in. (mm) in. (mm) in. (mm) in. (mm) in. (mm)

45-1/4 (1149) 49-1/4 (1251) 51 (1295) 58‐1/2 (1486) 65 (1651)

16-1/4 (413) 21-1/4 (540) 21‐1/4 (540) 21‐1/4 (540) 21-1/4 (540)

20-5/8 (524) 20-5/8 (524) 22‐5/8 (575) 24‐5/8 (625) 26-5/8 (676)

14-3/4 (375) 19-3/4 (502) 19‐3/4 (502) 19‐3/4 (502) 19-3/4 (502)

19 (483) 19 (483) 21 (533) 23 (584) 25 (635)

15 (381) 20 (508) 20 (508) 20 (508) 20 (508)

24-5/8 (625) 24-5/8 (625) 26‐3/8 (670) 27‐7/8 (708) 32-3/8 (822)

20-5/8 (524) 24-5/8 (625) 24‐5/8 (625) 30‐5/8 (778) 32-5/8 (829)

Page 13

CBX32MV

Page 14

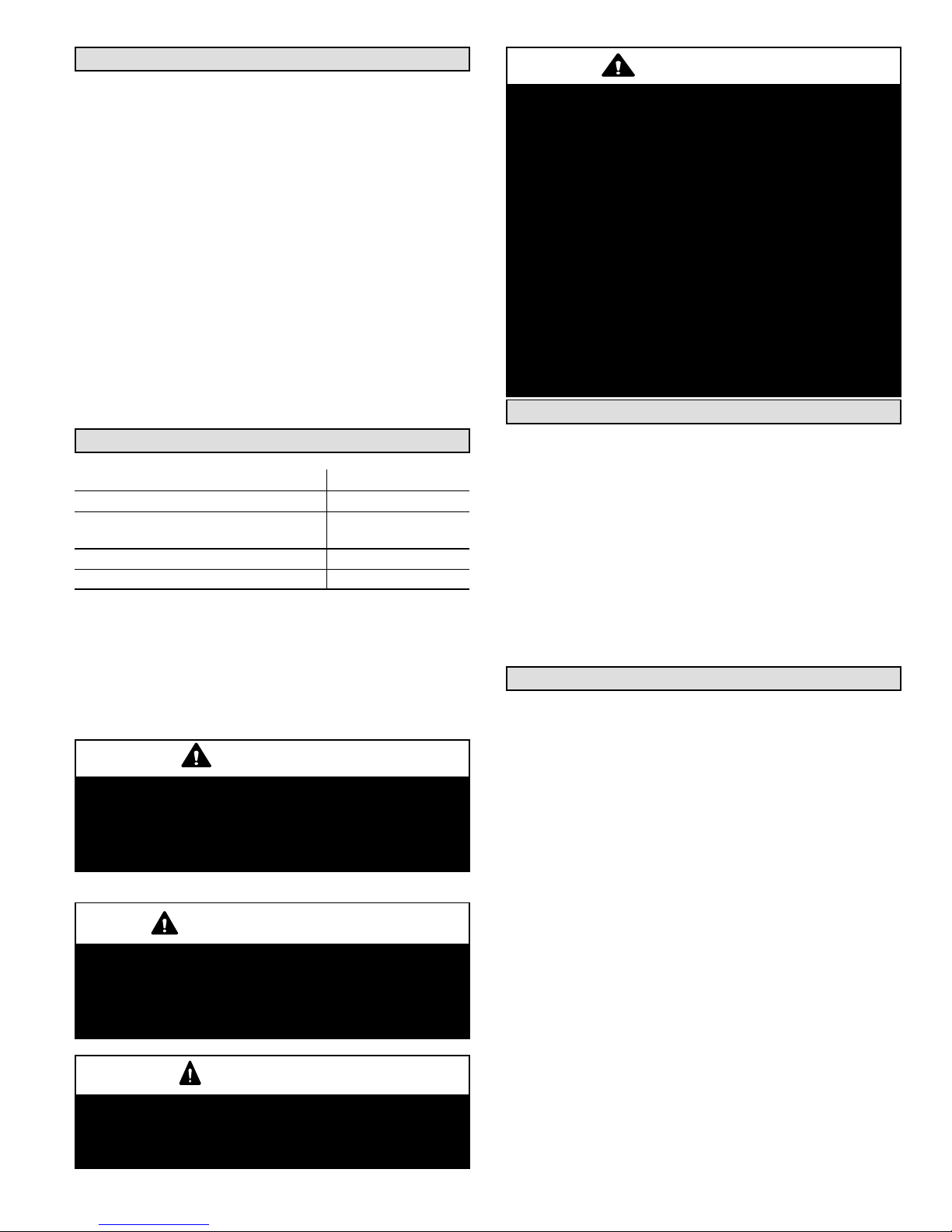

CBX32MV Horizontal Left- and Right-Hand Unit Dimensions — Inches (mm)

5‐3/8

(137)

CONDENSATE

DRAINS (2)

(UPFLOW AND

DOWNFLOW)

CONDENSATE

DRAINS (2)

(HORIZONTAL)

PIPING PLATE

DETAIL

5/8 (16)

5/8 (16)

5/8 (16)

5‐3/4

(46)

E

RETURN AIR

OPENING

F

END VIEW

Horizontal Position

(Left‐Hand Air

Discharge)

1‐3/4

(44)

(51)

2

LIQUID

1‐1/2

(38)

1 (25)

FILTER ACCESS

LINE

SUCTION

LINE

1‐1/8

(29)

4‐3/8

(111)

FILTER

Horizontal Position

(Right‐Hand Air

Discharge)

COIL

LIQUID

SUCTION

LINE

LINE

TOP VIEW

A

H

AIR

FLOW

FRONT VIEW

C

BLOWER

BLOWER

OPTIONAL ELECTRIC

HEAT (FIELD-INSTALLED)

G

COIL

5/8 (16)

B

C

LINE VOLTAGE

INLETS (TOP

AND RIGHT

SIDE)

LOW VOLTAGE

INLETS

(BOTTOM AND

RIGHT SIDE)

FOR DIMENSIONS “A”

THROUGH “H”, SEE CHART ON

4‐3/8

(111)

1‐1/8

(29)

PAGE 13.

11‐1/16

(281)

SUPPLY

AIR

OPENING

END VIEW

3/4 (19)

3/4 (19)

D

3/4 (19)

3/4 (19)

3/4 (19)

3/4 (19)

11‐1/16

(281)

SUPPLY

D

OPENING

LINE VOLTAGE INLETS

(BOTTOM AND LEFT SIDE)

END VIEW

INLETS (TOP AND

AIR

LOW VOLTAGE

LEFT SIDE)

OPTIONAL ELECTRIC

HEAT (FIELD INSTALLED)

5/8 (16)

B

CONDENSATE DRAINS (2)

(HORIZONTAL)

G

TOP VIEW

A

AIR

FLOW

FRONT VIEW

FILTER

SUCTION

LINE

H

1‐3/4

(44)

LIQUID

LINE

5‐3/4

(146)

SUCTION LINE

PIPING PLATE

DETAIL

FILTER ACCESS

1‐1/2 (38)

LIQUID

LINE

1 (25)

(51)

E

RETURN

AIR OPENING

END VIEW

2

5‐3/8

(137)

5/8 (16)

5/8 (16)

F

5/8 (16)

CBX32MV

Page 14

Page 15

General

This indoor unit is designed for installation with optional

field-installed electric heat and a matched remote outdoor

unit that is charged with HFC-410A refrigerant. These units,

designed for indoor installation in multiple positions, are

completely assembled for upflow and horizontal right-hand

discharge before being shipped from the factory.

All CBX32MV air handlers are equipped with a

factory-installed, internally mounted check expansion

valve (CTXV), which is suitable for use in HFC-410A

applications.

NOTE - For downflow or horizontal left-hand air discharge,

certain field modifications are required.

These instructions are intended as a general guide and do

not supersede local or national codes in any way. Consult

authorities having jurisdiction before installation. Check

equipment for shipping damage; if found, immediately

report damage to the last carrier.

Installation Clearances

Cabinet 0 inch (0 mm)

To Plenum 1 inch (25 mm)

To Outlet Duct within 3 feet (914

mm)

Floor See Note #1

Service / Maintenance See Note #2

1

Units installed on combustible floors in the down-flow position with

electric heat require optional down-flow additive base.

2 Front Service Access - 24 inches (610mm) minimum.

NOTE - If cabinet depth is more than 24 inches (610 mm), allow a

minimum of the cabinet depth plus 2 inches (51 mm).

1 inch (25 mm)

WARNING

The State of California has determined that this product

may contain or produce a chemical or chemicals, in very

low doses, which may cause serious illness or death. It

may also cause cancer, birth defects, or reproductive

harm.

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting of

refrigerant (CFCs, HCFCs and HFCs) as of July 1, 1992.

Approved methods of recovery, recycling or reclaiming

must be followed. Fines and/or incarceration may be

levied for noncompliance.

WARNING

During blower operation, the ECM motor emits energy

that may interfere with pacemaker operation.

Interference is reduced by both the sheet metal cabinet

and distance.

WARNING

Improper installation of the air handler can result in

personal injury or death.

Do not allow external combustion products or other

contaminants to enter the return air system or to be mixed

with air that will be supplied to the living space. Use sheet

metal screws and joint tape or duct mastic to seal return

air system to air handler. In platform installations, the air

handler should be sealed airtight to the return air plenum.

A door must never be used as a portion of the return air

duct system. The base must provide a stable support and

an airtight seal to the air handler. Allow absolutely no

sagging, cracks, gaps. etc.

For no reason should return and supply air duct systems

ever be connected to or from other heating devices such

as a fireplace or stove. etc. Fire, explosion, carbon

monoxide poisoning, personal injury and/or property

damage could result.

Requirements

In addition to conforming to manufacturer's installation

instructions and local municipal building codes, installation

of Lennox air handler units (with or without optional electric

heat), MUST conform with the following National Fire

Protection Association (NFPA) standards:

NFPA No. 90A — Standard for Installation of Air

Conditioning and Ventilation Systems

NFPA No. 90B — Standard for Installation of Residence

Type Warm Air Heating and Air Conditioning Systems

This unit is approved for installation clearance to

combustible material as stated on the unit rating plate.

Accessibility and service clearances must take precedence

over combustible material clearances.

Installation Requirements

CBX32MV units are factory-configured for upflow and

horizontal right-hand discharge installation. For downflow or

horizontal left-hand discharge, certain field modifications are

required.

DISASSEMBLE AND REASSEMBLE AIR HANDLER

UNIT

This unit consists of two sections which are shipped

assembled from the factory. If necessary, the unit may be

disassembled to facilitate setting the unit. Follow the steps

below:

To disassemble:

1. Remove access panels.

2. Remove both blower and coil assemblies. This will

lighten the cabinet for lifting.

3. Remove one screw from the left and right posts inside

the unit. Remove one screw from each side on the back

of the unit. Unit sections will now separate.

To reassemble:

1. Align cabinet sections together.

2. Reinstall screws.

3. Replace blower and coil assemblies.

4. Replace access panel.

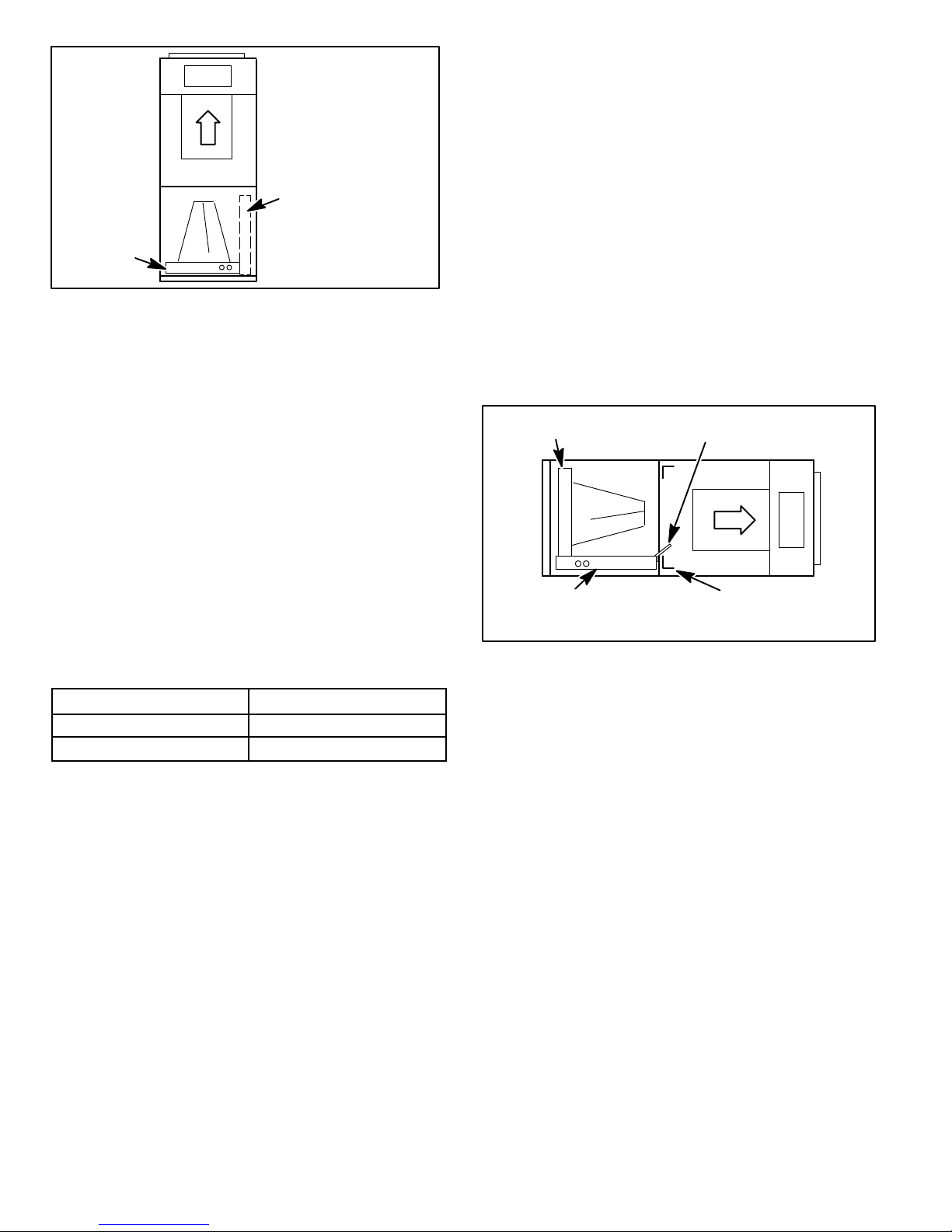

UPFLOW APPLICATION

Use the following procedures to configure the unit for

upflow operations:

Page 15

CBX32MV

Page 16

HORIZONTAL DRAIN

PAN (MUST BE

REMOVED)

UPFLOW/

DOWNFLOW

DRAIN PAN

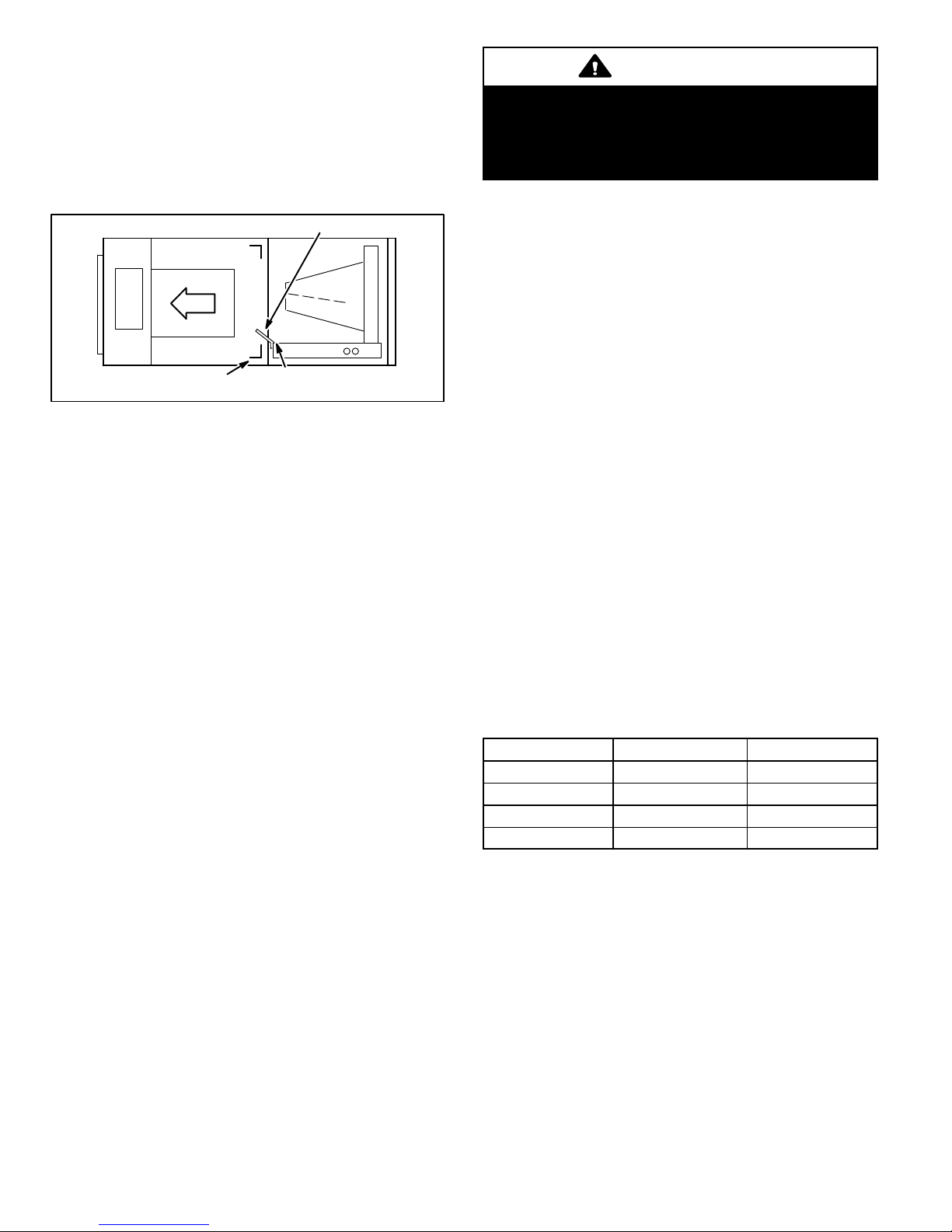

Figure 1. Upflow Configuration

NOTE - (-068 model Only) Remove access panels and the

horizontal drip shield along with the corrugated padding

between the blower and coil assembly before operation.

Discard drip shields from the foam pads on top of the unit.

Shields are used for downflow applications only.

1. The horizontal drain pan must be removed when the

coil blower is installed in the upflow position. Removing

horizontal drain pain will allow proper airflow and

increase efficiency.

2. After removing horizontal drain pan, place the unit in

desired location. Set unit so that it is level. Connect

return and supply air plenums as required using sheet

metal screws as illustrated in Figure 1.

3. Install units that have no return air plenum on a stand

that is at least 14” from the floor to allow for proper air

return. Lennox offers an optional upflow unit stand as

listed in Table 1.

Table 1. Optional Unit Side Stand (Upflow Only)

Models

-018/024 45K31

-024/030, -036, -048 and -060

Kit Numbers

45K32

HORIZONTAL RIGHT-HAND DISCHARGE APPLICATION

NOTE - When air handler is located above a finished space,

the secondary drain pan must have a larger footprint than

the air handler. In addition, a 3/4” (19.1MM) overflow drain

line must be:

Connected to secondary drain pan

or

Connected to the overflow drain outlet of the air handler

drain pan.

Use the following procedures to configure the unit for

horizontal right-hand discharge operations:

NOTE - For horizontal applications, a secondary drain pan

is recommended. Refer to local codes.

NOTE - (-068 Model Only) Before operating the unit,

remove access panels and the horizontal drip shield and

the corrugated padding between the blower and coil

assembly. Discard the corrugated padding and the

downflow drip shields from the foam pads on top of the unit.

NOTE - (-068 Model Only) Install the horizontal shield on

the front edge of the horizontal drain pan as illustrated in

Figure 2.

4. No further adjustment is necessary. Set unit so that it is

sloped 1/4 inch (6.35mm) towards the drain pan end of

the unit.

UP-LOAD / DOWNFLOW

DRAIN PAN

HORIZONTAL DRAIN

PAN

NO ADJUSTMENT IS NECESSARY

Figure 2. Right-Hand Discharge Configuration

5. If the unit is suspended, the entire length of the cabinet

must be supported. If you use a chain or strap, use a

piece of angle iron or sheet metal attached to the unit

(either above or below) to support the length of the

cabinet. Use securing screws no longer than 1/2 inch

(12.7mm) to avoid damaging the coil or filter as

illustrated in Figure 4. Use sheet metal screws to

connect the return and supply air plenums as required.

HORIZONTAL RIGHT-HAND DISCHARGE APPLICATION

IN HIGH HUMIDITY AREAS

For horizontal applications in high humidity areas remove

the downflow rail closest to the drain pan.

HORIZONTAL DRIP SHIELD (-068

MODELS)

DOWNFLOW RAIL

CBX32MV

Page 16

Page 17

CABINET

SUPPORT

DRAIN PAN

REINSTALLED

HERE

TOP CAP ROTATED TO

CORRECT POSITION

90º

BEND

TOP CAP

SCREWS

3/16” PLASTIC

PLUG (REAR COIL

END SEAL)

HORIZONTAL DRIP

SHIELD SCREW

(FRONT COIL END

SEAL)

DRAIN PAN

SHIPPING

LOCATION

INSTALL DRAIN PAN

BETWEEN TAB AND

EXTERIOR INNER WALL.

DETAIL C

REINSTALLED HERE REMOVED FROM HERE

———— DRAIN PLUGS ————

FRONT VIEW

COIL SHOWN IN UPFLOW POSITION FOR EASY

CONVERSION (LEFT-HAND AIR DISCHARGE)

DETAIL A

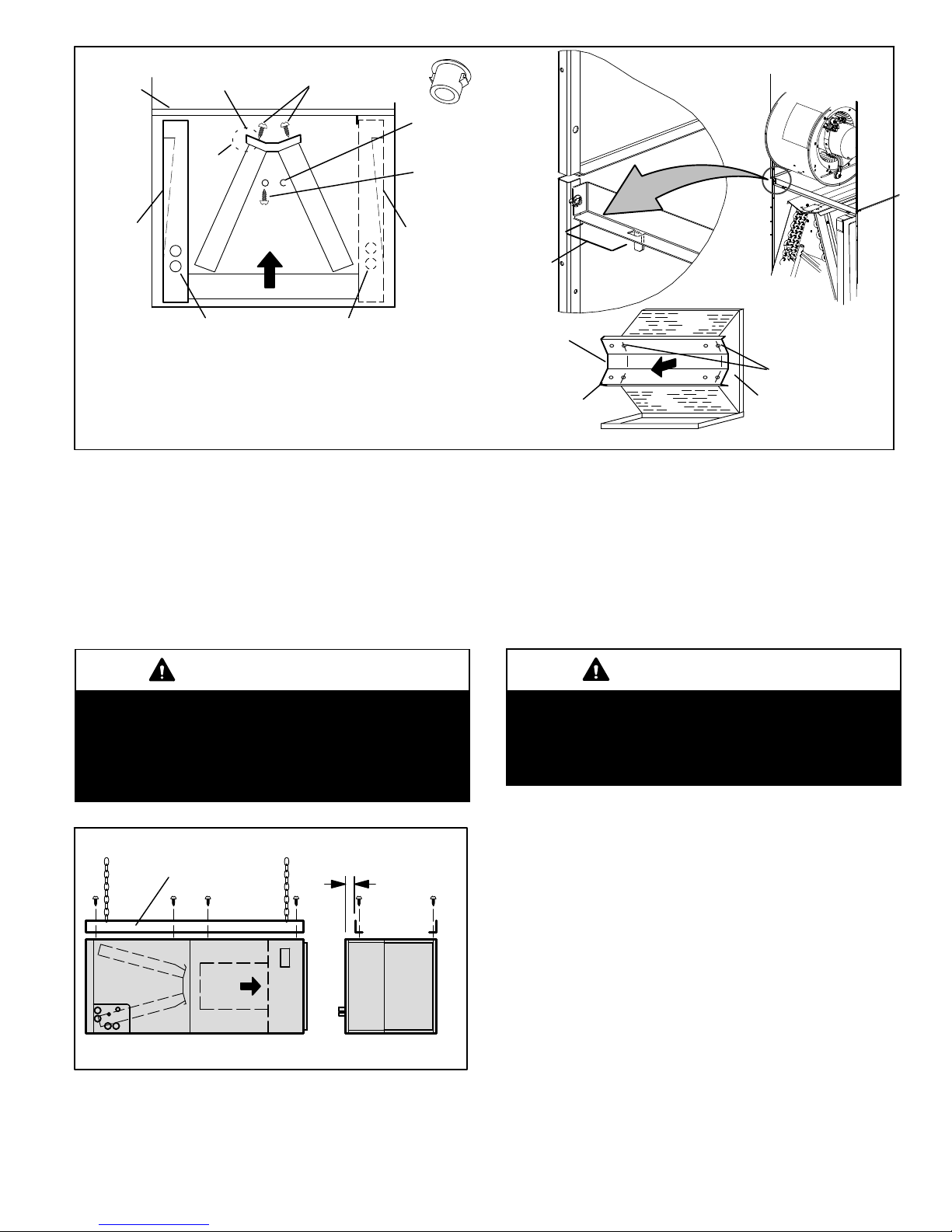

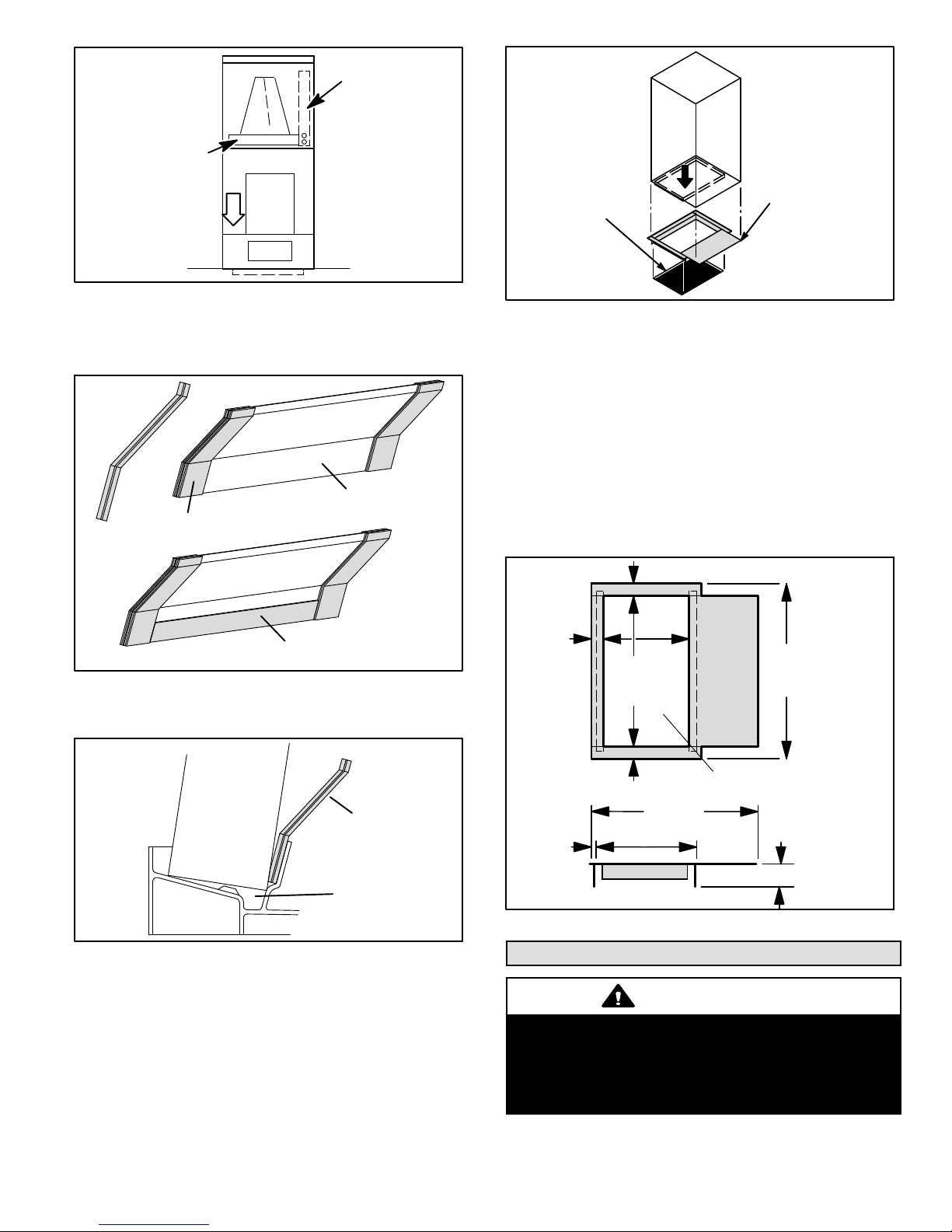

Figure 3. Field Modification for Left-Hand Discharge

To remove rail:

1. Remove the screws from the rail at the back of unit and

at the cabinet support rail.

2. Remove the downflow rail then replace screws.

3. Seal around the exiting drain pipe, liquid line, and

suction line to prevent humid air from infiltrating into the

unit.

IMPORTANT

When removing the coil, there is possible danger of

equipment damage and personal injury. Be careful when

removing the coil assembly from a unit installed in rightor left-hand applications. The coil may tip into the drain

pan once it is clear of the cabinet. Support the coil when

removing it.

1/2 IN. SCREWS MAXIMUM

ANGLE IRON OR

SHEET METAL

FRONT VIEW END VIEW

Figure 4. Suspending Horizontal Unit

HORIZONTAL LEFT-HAND DISCHARGE APPLICATION

Use the following procedures to configure the unit for

horizontal left-hand discharge operations:

ELECTRICAL INLET

CLEARANCE 4 IN. (102 MM)

TOP CAP

DETAIL B

90º

BEND

ALIGN HOLES WITH

HOLES IN COIL END

PLATE.

BACK COIL

END SEAL

NOTE - For horizontal applications, a secondary drain pan

is recommended. Refer to local codes.

NOTE - (-068 Model Only) Remove access panels and

horizontal drip shield from the corrugated padding between

the blower and coil assembly. Discard the corrugated

padding and the downflow drip shields from the foam pads

on top of the unit. (The shields are used for downflow

applications only.)

IMPORTANT

After removal of drain pan plug(s), check drain hole(s) to

verify that drain opening is fully open and free of any

debris. Also check to make sure that no debris has fallen

into the drain pan during installation that may plug up the

drain opening.

1. Pull the coil assembly from unit. Pull off the horizontal

drain pan.

2. Remove the drain plugs from back drain holes on

horizontal drain pan and reinstall them on front holes.

3. Rotate drain pan 180º front‐to‐back and install it on the

opposite side of the coil.

4. Remove screws from top cap as illustrated in Figure 3,

Detail A.

5. Remove horizontal drip shield screw located in the left

center of the back coil end seal as illustrated in Figure

3, Detail A.

6. Rotate horizontal drip shield 180º front to back.

7. Remove plastic plug from hole located on the left center

of front coil end seal and reinstall plug in back hole on

rear coil end seal.

8. Reinstall horizontal drip shield screw in front coil end

seal. Drip shield should drain downward into horizontal

drain pan inside coil.

Page 17

CBX32MV

Page 18

9. Rotate top cap 180º front‐to‐back and align with

unused screw holes. Holes must align with front and

back coil end plates. The top cap has a 45º bend on one

side and a 90º bend on the other. The 90º bend must be

on the same side as the horizontal drain pan as

illustrated in Figure 3, Detail B.

NOTE - Be very careful when you reinstall the screws into

coil end plate engaging holes. Misaligned screws may

damage the coil.

HORIZONTAL DRIP SHIELD (-068 MODEL)

DOWNFLOW RAIL

FRONT EDGE OF HORIZONTAL

DRAIN PAN

Figure 5. Left-Hand Discharge Configuration

10. From the upload position, flip cabinet 90º to the left and

set into place. Replace coil assembly. Replace coil

assembly. Install drain pan between exterior inner wall

and tab as illustrated in Figure 3, Detail C.

11. (-068 Model Only) Install the horizontal shield on the

front edge of the horizontal drain pan as shown in figure 5.

NOTE - For horizontal applications in high humidity areas,

remove the downflow rail closest to the drain pan. To

remove rail, remove screw from rail at back of unit and at

cabinet support rail. Remove downflow rail then replace

screws. Also, seal around the exiting drain pipe, liquid and

suction lines to prevent infiltration of humid air.

12. Knock out drain seal plate from access door. Secure

plate to cabinet front flange with screw provided.

13. Flip access door and replace it on the unit.

14. Set unit so that it is sloped 1/4 inch (6.35mm) toward

the drain pan end of the unit. Connect return and supply

air plenums as required using sheet metal screws.

15. If suspending the unit, it must be supported along the

entire length of the cabinet. If using chain or strap, use a

piece of angle iron or sheet metal attached to the unit

(either above or below) so that the full length of the

cabinet is supported. Use securing screws no longer

than 1/2 inch (12.7mm) to avoid damage to coil or filter

as illustrated in Figure 4 on page 17. Connect return

and supply air plenums as required using sheet metal

screws.

DOWNFLOW APPLICATION

Use the following procedures to configure the unit for

downflow operations:

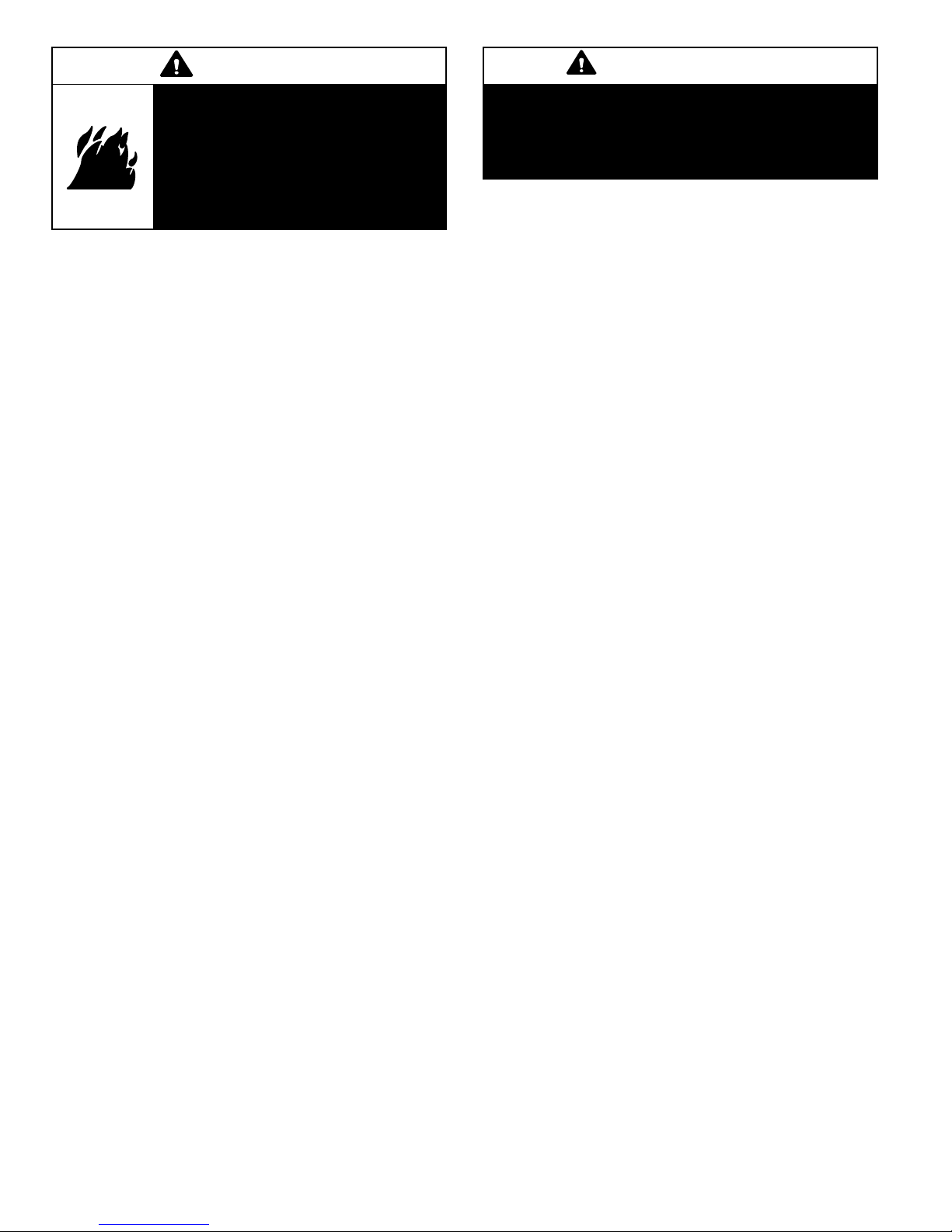

CAUTION

If electric heat section with circuit breakers

(ECB29/ECB31) is applied to downflow CBX32MV

unit, the circuit breakers must be rotated 180° to the

UP position. See ECB29/ECB31 installation

instructions for more details.

Table 2 outlines the sizes of the various drip shields.

NOTE — (-068 Model Only) Remove access panels and

horizontal drip shield from the corrugated padding between

the blower and coil assembly.

NOTE — Discard the corrugated padding and the downflow

drip shields from the foam pads on top of the unit. (The

shields are used for downflow applications only.)

1. Remove the coil assembly from the unit.

2. For best efficiency and air flow, remove the horizontal

drain pan from the units in downflow positions as

illustrated in figure 6 on page 19.

3. Rotate cabinet 180º from the upright position. See

figure 6. You may need to first remove the blower

assembly to lighten the cabinet for lifting.

4. Foam tape that is provided creates a seal between the

drip shield and the coil so that water does not leak into

the air stream. The foam tape pieces are precut. Apply

the tape to the drip shields as illustrated in figure 7 and

specified as follows:

Apply two pieces of foam tape provided down both

ends of each shield. The tape should measure

4-3/4” X 2” (120 X 25 mm). Ensure that the tape

covers both sides of the shield equally.

Apply the longer piece of 1‐inch wide foam tape

between the end pieces of tape.

5. From the underside of the coil, install the downflow drip

shield firmly in place as illustrated in figure 8.

Table 2. Downflow Drip Shields (Tape Required)

Units

-018/024 Not Required Not Required

-024/030 15-7/8” 4-11/16”

-036 17-7/8” 4-11/16”

-048, -060, and -068 19-7/8” 4-11/16”

Length Width

CBX32MV

Page 18

Page 19

SIDE

VIEW

HORIZONTAL DRAIN PAN

UP-LOAD /

DOWNFLOW

DRAIN PAN

Figure 6. Downflow Discharge Position

DRIP SHIELD

2” WIDE FOAM TAPE

(REMOVE FROM UNIT)

AIR

HANDER

UNIT

COMBUSTIBLE FLOOR

PROPERLY SIZED

FLOOR OPENING

ADDITIVE BASE

Figure 9. Combustible Flooring Additive Base

8. For downflow installation on combustible flooring, an

additive base must be used as illustrated in figure 9 on

page 19.

9. Cut an opening appropriately sized for combustible

base. Base dimensions are illustrated in figure 10.

After opening has been cut, set the additive base into

opening. Connect outlet air plenum to the additive

base. Set the unit on the additive base so flanges of

the unit drop into the base opening and seal against

the insulation strips. The unit is now locked in place.

Install return air plenum and secure with sheet metal

screws.

1‐5/8 (41)

TOP VIEW

1” WIDE FOAM TAPE (LONGER PIECE)

Figure 7. Applying Foam Tape to Drip Shield

COIL

DRIP SHIELD

DRIP PAN

Figure 8. Downflow Drip Shields

6. Replace the coil assembly and blower if you have

removed it. Replace the coil access panel.

7. Set the unit so that it is level. Using sheet metal screws,

connect the return and supply air plenums as required.

NOTE - For downflow application, metal or class I supply

and return air plenums must be used.

11‐3/8

1‐5/8 (41)

1‐5/8 (41)

5/8 (16)

(289)

-018/-024 15

(381)

-024/-030 AND

UP 20 (508)

SUPPLY AIR OPENING

24 (610) -068 ONLY

22‐1/8 (562) OTHER MODELS

13‐3/8 (340)

OPENING

SIDE VIEW

-018/-024 08-1/4 (464)

-024/-030 and up 23-1/4 (591)

INCHES (MM)

2 (51)

Figure 10. Downflow Combustible Base Dimensions

Brazing Connections

WARNING

Polyol ester (POE) oils used with HFC-410A refrigerant

absorb moisture very quickly. It is very important that

the refrigerant system be kept closed as much as

possible. DO NOT remove line set caps or service valve

stub caps until you are ready to make connections.

Page 19

CBX32MV

Page 20

WARNING

Danger of fire. Bleeding the refrigerant

charge from only the high side may result

in the low side shell and suction tubing

being pressurized. Application of a

brazing torch while pressurized may

result in ignition of the refrigerant and oil

mixture - check the high and low

pressures before unbrazing.

IMPORTANT

To prevent the build up of high levels of nitrogen when

purging, be sure it is done in a well ventilated area. Purge

low pressure nitrogen (1 to 2 psig) through the refrigerant

piping during brazing. This will help to prevent oxidation

and the introduction of moisture into a system.

CBX32MV

Page 20

Page 21

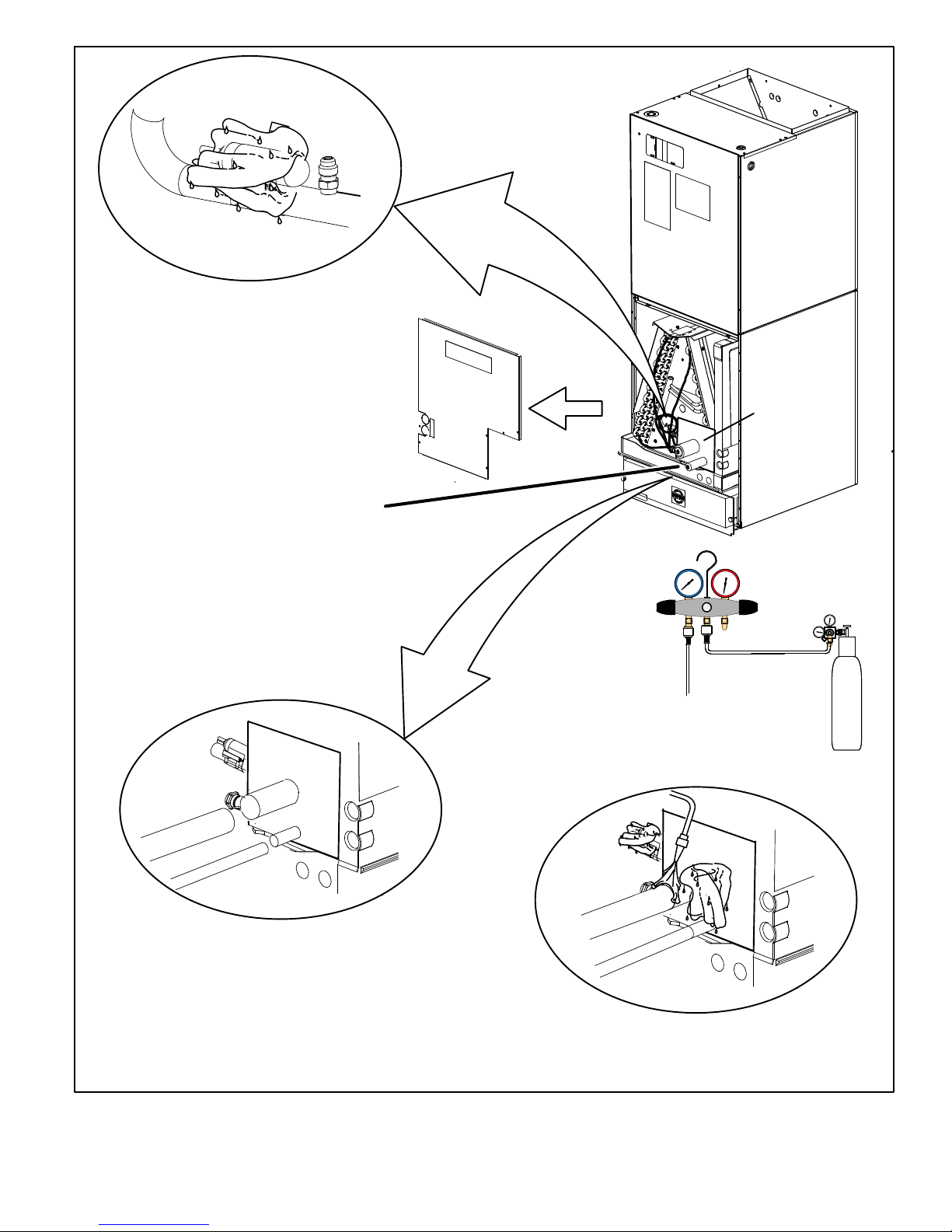

PLEASE READ IMPORTANT ISSUES CONCERNING BRAZING

OPERATIONS ON PAGE 10 BEFORE PROCEEDING.

USE A WET RAG TO PROTECT CTXV

C

SENSING BULB WHEN BRAZING

SUCTION LINE CONNECTIONS.

NOTE — REFER TO OUTDOOR UNIT INSTALLATION INSTRUCTIONS

FOR REFRIGERANT PIPING SIZE REQUIREMENTS.

NOTE - Use silver alloy brazing rods with five or six

percent minimum silver alloy for copper-to-copper

brazing, 45 percent alloy for copper-to-brass and

copper-to-steel brazing.

REMOVE ACCESS PANEL

A

REMOVE RUBBER PLUG FROM BOTH LIQUID

B

AND SUCTION LINES

NOTE — CBX32MV SERIES UNITS USE NITROGEN OR DRY

AIR AS A HOLDING CHARGE. IF THERE IS NO PRESSURE

WHEN THE RUBBER PLUGS ARE REMOVED, CHECK THE

COIL FOR LEAKS BEFORE INSTALLING.

EITHER REMOVE OR PUSH PIPE WRAPPING BACK

D

THROUGH HOLE IN PIPING PLATE BEFORE LINE

SET CONNECTION AND BRAZING.

LOW

PIPING

PLATE

HIGH

CONNECT PIPES

E

NOTE — REFRIGERANT LINE SETS

SHOULD BE ROUTED TO ALLOW

FILTER ACCESSIBILITY.

REPEAT PREVIOUS PROCEDURE FOR LIQUID

I

LINE.

FLOW REGULATED NITROGEN (AT 1 TO 2 PSIG)

THROUGH THE REFRIGERATION GAUGE SET INTO THE

VALVE STEM PORT CONNECTION ON THE OUTDOOR

UNIT LIQUID LINE SERVICE VALVE AND OUT OF THE

VALVE STEM PORT CONNECTION ON THE SUCTION

SERVICE VALVE.

PLACE A WET RAG AGAINST PIPING

G

PLATE AND AROUND THE SUCTION

LINE CONNECTION. A

BRAZE CONNECTION. ALLOW PIPE TO

H

COOL BEFORE REMOVING WET RAG

FROM CTXV SENSING BULB AND PIPING

PANEL AREA.

CONNECT GAUGES AND

F

START NITROGEN FLOW

NITROGEN

REFER TO INSTRUCTIONS PROVIDED WITH OUTDOOR UNIT FOR

LEAK TESTING, EVACUATING AND CHARGING PROCEDURES

Figure 11. Brazing Connections

Page 21

CBX32MV

Page 22

WARNING

When using a high pressure gas such as

dry nitrogen to pressurize a refrigeration

or air conditioning system, use a regulator

that can control the pressure down to 1 or

2 psig (6.9 to 13.8 kPa).

Condensate Drain Requirements

IMPORTANT

After removal of drain pan plug(s), check drain hole(s) to

verify that drain opening is fully open and free of any

debris. Also check to make sure that no debris has fallen

into the drain pan during installation that may plug up the

drain opening.

CAUTION

Brazing alloys and flux contain materials which are

hazardous to your health.

Avoid breathing vapors or fumes from brazing operations.

Perform operations only in well ventilated areas.

Wear gloves and protective goggles or face shield to

protect against burns.

Wash hands with soap and water after handling brazing

alloys and flux.

Table 3. CBX32MV Refrigerant Connections and Line

Set Requirements

Models

-018/024

-024/030

and -036

-048

-060

-068

NOTE — Some applications may require a field provided 7/8” to

1-1/8” adapter

Liquid

Line

3/8”

(10mm)

3/8”

(10mm)

3/8”

(10mm)

3/8”

(10mm)

3/8”

(10mm)

NOTE - When installing refrigerant lines longer than 50

feet, see the Lennox Refrigerant Piping Design and

Fabrication Guidelines, CORP. 9351-L9, or contact Lennox

Technical Support Product Applications for assistance.

Vapor /

Suction

Line

5/8”

(16mm)

3/4”

(19mm)

7/8”

(22mm)

7/8”

(22mm)

1-1/8”

(29mm)

L15 Line Set

L15 line set sizes are

dependent on unit matchups.

See CBX32MV Product

Specification bulletin to

determine correct line set

sizes.

Field-fabricated

MAIN DRAIN

Connect the main drain and route downward to drain line or

sump. Do not connect drain to a closed waste system. See

Figure 13 for typical drain trap configuration.

OVERFLOW DRAIN

It is recommended that the overflow drain is connected to a

overflow drain line for all units. If overflow drain is not

connected, it must be plugged with provided cap.

For downflow orientation, the overflow drain MUST be

connected and routed to a overflow drain line. See Figure

13 for main and overflow drain locations based on coil

orientation.

LEFT-HAND AIR

DISCHARGE

OVERFLOW

DRAIN ON LEFT

UPFLOW OR

DOWNFLOW

RIGHT-HAND AIR

DISCHARGE

MAIN DRAIN ON

RIGHT

Figure 12. Main and Overflow Drain Locations based

on Coil Orientation

BEST PRACTICES

The following best practices are recommended to ensure

better condensate removal:

Main and overflow drain lines should NOT be smaller

than both drain connections at drain pan.

Overflow drain line should run to an area where

homeowner will notice drainage.

It is recommended that the overflow drain line be

vented and a trap installed. Refer to local codes.

CBX32MV

Page 22

Page 23

ABOVE

FINISHED

SPACE?

OVERFLOW DRAIN LINE

ALWAYS RUN AN OVERFLOW DRAIN LINE. IF NOT POSSIBLE TO

ROUTE OVERFLOW DRAIN LINE, INSTALL LOW VOLTAGE

OVERFLOW SWITCH KIT. WIRE KIT TO SHUT DOWN

COMPRESSOR PER INSTRUCTIONS.

LENNOX #

X3169

COMPACT OVERFLOW SWITCH WITH 3/4” FEMALE SLIP INLET

NO

AND MALE ADAPTER, TWO PART DESIGN FOR USE WHERE

OBSTRUCTIONS PREVENT DIRECT THREADING

CLEAN OUT

PRESS IN

(DO NOT GLUE)

VENT MUST EXTEND

ABOVE HEIGHT OF

COIL DRAIN PAN BY

TWO INCHES (51MM)

VENT

MAIN

MAIN

DRAIN

CUT TO

REQUIRED

LENGTH

PROVIDED

PIPE NIPPLE

SIDE VIEW

2

FOR NEGATIVE PRESSURE COILS (BLOWER

AFTER COIL) TRAPS ARE REQUIRED ON ALL

DRAIN LINES CONNECTED TO COIL.

AIR HANDLER DRAIN PAN

OVERFLOW

DRAIN

YES

NOTE — WHEN A AIR HANDLER IS LOCATED

ABOVE A FINISHED SPACE THE SECONDARY

DRAIN PAN MUST HAVE A LARGER FOOTPRINT

THAN THE AIR HANDLER.

DRAIN

SECONDARY

DRAIN PAN

WHEN A COIL IS LOCATED ABOVE A FINISHED SPACE, A

3/4” (19.1MM) SECONDARY DRAIN LINE MUST BE:

CONNECTED TO SECONDARY DRAIN PAN

OR

CONNECTED TO THE OVERFLOW DRAIN OUTLET OF

THE AIR HANDLER DRAIN PAN.

TRAPS MUST BE DEEP ENOUGH TO OFFSET MAXIMUM STATIC DIFFERENCES —

GENERALLY, TWO INCHES (51MM).

1

LENNOX P-TRAP 49P66 REQUIRES A LARGER INSTALLATION SPACE THAN THE J-TRAP 91P90.

2

PIPE NIPPLE PROVIDED IN BAG ASSEMBLY - SCH 80, 3/4” I. D. X 5” - 34K7401 (1): CUT THE PIPE IN HALF AND USE IT TO ROUTE THE MAIN DRAIN.

1” X 3/4” X 3/4”

REDUCING

TEE WITH

PLUG

1

LENNOX

P-TRAP

49P66, J-TRAP #

91P90 OR ANY

PVC SCH 40 P- OR

J-TRAP 3/4”

Figure 13. Typical Main and Overflow Drain Installations

Inspecting and Replacing Filters

IMPORTANT

Filter access door must be in place during unit operation.

Excessive warm air entering the unit from unconditioned

space may result in water blow-off problems.

Unit Model No. Filter Size Inches (mm)

-018/024 15 X 20 x 1(381 x 508 x 25)

-024/030 20 x 20 x 1(508 x 508 x 25)

-036 20 x 20 x 1(508 x 508 x 25)

-048 and -060 20 x 24 x 1(508 x 610 x 25)

-068 20 x 25 x 1(508 x 635 x 25)

Table 4. Filter Dimensions

2”

(51MM)

TRAP DEPTH

TO APPROVED

DRAIN

DRAIN LINE SHOULD

SLOPE A MINIMUM OF

ONE INCH PER 10

FEET (25MM PER 3

METERS)

Filters may be duct-mounted or installed in the cabinet. A

filter is installed at the factory. Note that filter access door

fits over access panel. Air will leak if the access panel is

placed over the filter door.

Filters should be inspected monthly and must be cleaned or

replaced when dirty to assure proper furnace operation.

To replace filter:

1. Loosen the thumbscrews holding the filter panel in

place.

2. Slide the filter out of the guides on either side of cabinet.

3. Insert new filter.

4. Replace panel.

See Table 4 for replacement filter sizes.

Sealing the Unit

WARNING

There must be an airtight seal between the bottom of the

air handler and the return air plenum. Use fiberglass

sealing strips, caulking, or equivalent sealing method

between the plenum and the air handler cabinet to ensure

a tight seal. Return air must not be drawn from a room

where this air handler or any gas-fueled appliance (i.e.,

water heater), or carbon monoxide-producing device

(i.e., wood fireplace) is installed.

Seal the unit so that warm air is not allowed into the cabinet.

Warm air introduces moisture, which results in water

blow-off problems. This is especially important when the

unit is installed in an unconditioned area.

Page 23

CBX32MV

Page 24

Make sure the liquid line and suction line entry points are

sealed with either the provided flexible elastomeric thermal

insulation, or field provided material (e.g. Armaflex,

Permagum or equivalent). Any of the previously mentioned

materials may be used to seal around the main and

auxiliary drains, and around open areas of electrical inlets.

Field Control Wiring

WARNING

Electric Shock Hazard.

Can cause injury or death.

Foil‐faced insulation has conductive characteristics simi

lar to metal. Be sure there are no electrical connections

within a ½” of the insulation. If the foil‐faced insulation

comes in contact with electrical voltage, the foil could pro

vide a path for current to pass through to the outer metal

cabinet. While the current produced may not be enough

to trip existing electrical safety devices (e.g. fuses or cir

cuit breakers), the current can be enough to cause an

electric shock hazard that could cause personal injury or

death.

Wiring must conform to the current National Electric Code

ANSI/NFPA No. 70, or Canadian Electric Code Part I, CSA

Standard C22.1, and local building codes. Refer to

following wiring diagrams. See unit nameplate for minimum

circuit ampacity and maximum over-current protection

size.

Select the proper supply circuit conductors in

accordance with Tables 310-16 and 310-17 in the

National Electric Code, ANSI/NFPA No. 70 or Tables 1

through 4 in the Canadian Electric Code, Part I, CSA

Standard C22.1.

Separate openings have been provided for 24V low voltage

and line voltage. Refer to the dimension illustration for

specific location.

CAUTION

USE COPPER CONDUCTORS ONLY.

Wiring connections

1. Install line voltage power supply to unit from a

properly-wired circuit breaker.

2. Ground unit at unit disconnect switch or to an earth

ground.

NOTE - Connect conduit to the unit using a proper conduit

fitting. Units are approved for use only with copper

conductors. A complete unit wiring diagram is located on

the back side of the unit's access panel.

3. Install low voltage wiring from outdoor to indoor unit

and from thermostat to indoor unit.

NOTE - For proper voltages, select control wiring gauge per

the charts on page 28.

WARNING

Run 24V Class II wiring only through specified low voltage

opening. Run line voltage wiring only through specified

high voltage opening. Do not combine voltage in one

opening.

CBX32MV

Page 24

Page 25

Air Handler or Furnace Control

DS

Heat Pump or Air Conditioner Control

W

L

Y2

Y1

O

DS

C

i−

i+

R

O

L

H

DH

R

C

Y1

Y2

G

W3

W2

W1

iComfortt

THERMOSTAT

C

i−

i+

R

OUTDOOR UNIT

C

i−

i+

R

C

THERMOSTAT

i−

i+

R

Outdoor sensor for outdoor

temperature display

OUTDOOR AIR SENSOR

(Optional).

Figure 14. Control (Field) Wiring — Communicating System (iComfortt thermostat)

Page 25

CBX32MV

Page 26

AIR

CONDITIONER

UNIT

(TWO-STAGE)

BROWN

YELLOW

BLUE

BLACK

RED

CBX32MV

R

2

W3

W2

W1

O

3

Y1

Y2

G

DS

C

COMFORTSENSE

7000

R

H

1

W2

W1

O

L

Y1

Y2

G

D

B

C

AIR HANDLER CONTROL COMES FROM FACTORY WITH A

METAL JUMPERS BETWEEN W1 TO W2 AND W2 TO W3. SEE

FIGURE 20 FOR HEAT SECTION CONFIGURATION.

1

CONNECTED ON UNIT WITH LSOM. RESISTOR KIT (CAT #

47W97) IS REQUIRED WHEN CONNECTING THE

2

COMFORTSENSE 7000 (CATALOG# Y0349) WITH THE LSOM 2.

RESISTOR KIT NOT REQUIRED WHEN USING COMFORTSENSE

7000 CATALOG# Y2081).

3

L CONNECTION WIRED ON UNITS WITH LSOM.

IMPORTANT — USE CARE WHEN CUTTING LINKS TO

PREVENT DAMAGE TO CONTROL. SEE FIGURE 19,

CBX32MV JUMP AND LINK GUIDE FOR FURTHER

DETAILS.

CUT ON-BOARD LINK Y1-Y2 FOR TWO-STAGE AC

DO NOT CUT ON-BOARD LINK R -O.

CUT ON-BOARD LINK R-DS WHEN DEHUMIDIFICATION TERMINAL IS USED.

Figure 15. Control (Field Wiring) — Cooling Application (Non-Communicating)

AIR HANDLER

CONTROL

Y1-Y2

2-STAGE

COMPR

R-O

HEAT

PUMP

R-DS

DEHUM

OR

HARMONY

CUT FOR OPTION

HEAT PUMP

UNIT

(TWO-STAGE)

R

W1

L

Y1

Y2

OUT

BL

CC

CBX32MV

RR

W3

W2

W1 W1

OO

2

Y1

G

DS

3

Y2

Figure 16. Control (Field Wiring) — Heat Pump (Non-Communicating)

COMFORTSENSE

7000

H

W2

O

L

Y1

Y2Y2

G

D

T

B

T

C

1

O. D.

SENSOR

(X2658)

X2658 OUTDOOR SENSOR IS REQUIRED FOR OUTDOOR

1

TEMPERATURE DISPLAY, DEW POINT CONTROL, HEAT

PUMP AND DUAL FUEL BALANCE POINTS.

CONNECTED ON UNIT WITH LSOM. RESISTOR KIT (CAT

2

# 47W97) IS REQUIRED WHEN CONNECTING THE

COMFORTSENSE 7000 (CATALOG# Y0349) WITH THE

LSOM 2. RESISTOR KIT NOT REQUIRED WHEN USING

COMFORTSENSE 7000 CATALOG# Y2081).

FIELD PROVIDED JUMPER BETWEEN Y2 OUT BL ON

3

HEAT PUMP TO Y2 ON CX32MV.

IMPORTANT — USE CARE WHEN CUTTING LINKS TO

PREVENT DAMAGE TO CONTROL. SEE FIGURE 19,

CBX32MV JUMP AND LINK GUIDE FOR FURTHER

DETAILS.

CUT ON-BOARD LINK Y1-Y2 FOR TWO-STAGE HP

CUT ON-BOARD LINK R -O.

CUT ON-BOARD LINK R-DS WHEN DEHUMIDIFICATION TERMINAL IS USED.

Y1-Y2

2-STAGE

COMPR

R-O

HEAT

PUMP

R-DS

DEHUM

OR

HARMONY

CUT FOR OPTION

CBX32MV

Page 26

Page 27

OUTDOOR

SENSOR

(X2658)

RED

RED

FAN

RELAY

PUR

BLK

D

BLK

PUR

EDA UNIT

YEL

BLU

BLK

BRN

CBX32MV

OUTDOOR UNIT

NOTES -

NOT REQUIRED FOR APPLICATIONS WITHOUT LSOM

/1\

NOT REQUIRED WITH SINGLE‐SPEED OUTDOOR FAN

/2\

NOT REQUIRED FOR SINGLE STAGE

/3\

AIR HANDLER CONTROL COMES FROM FACTORY WITH A METAL

4

JUMPERS BETWEEN W1 TO W2 AND W2 TO W3. SEE FIGURE 20

FOR HEAT SECTION CONFIGURATION.

.

4

T

T

CONNECTED ON UNIT WITH LSOM.

RESISTOR KIT (CAT # 47W97) IS

REQUIRED WHEN CONNECTING THE

COMFORTSENSE 7000 (CATALOG#

Y0349) WITH THE LSOM 2. RESISTOR

KIT NOT REQUIRED WHEN USING

COMFORTSENSE 7000 CATALOG#

Y2081).

COMFORTSENSE

7000 THERMOSTAT

CUT ON-BOARD LINK R-DS WHEN DEHUMIDIFICATION

IMPORTANT — USE CARE WHEN CUTTING LINKS TO

PREVENT DAMAGE TO CONTROL. SEE FIGURE 19,

CBX32MV JUMP AND LINK GUIDE FOR FURTHER

DETAILS.

CUT ON-BOARD LINK Y1-Y2 FOR TWO-

DO NOT CUT ON-BOARD LINK R -O.

STAGE A/C

TERMINAL IS USED.

Y1-Y2

2-STAGE

COMPR

R-O

HEAT

PUMP

R-DS

DEHUM

OR

HARMONY

CUT FOR OPTION

Figure 17. Control (Field Wiring) — Cooling Application (Humiditrol

Relay Wiring) Non-Communicating

OUTDOOR UNIT

FAN RELAY (NOT REQUIRED

WITH SINGLE−SPEED

OUTDOOR FAN)

RED

PURPLE

BLACK

YELLOW

BLUE