Page 1

Service Literature

CBX32MV (HFC−410A) SERIES UNITS

TABLE OF CONTENTS

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model Number Identification.. 2. . . . . . . . . . . . . . . . . . .

Specifications / Electrical Data 2. . . . . . . . . . . . . . . . . .

Blower Performance 4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Arrangement 10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

I− Application 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II− Unit Components 11. . . . . . . . . . . . . . . . . . . . . . . . . . .

III− Troubleshooting the Variable Speed Motor 15. . . . .

IV− Optional Electric Heat 17. . . . . . . . . . . . . . . . . . . . . . .

V− Optional Humidity Control 23. . . . . . . . . . . . . . . . . . . .

VI− Configuration Modifications 30. . . . . . . . . . . . . . . . . .

VII− Start Up Operation 34. . . . . . . . . . . . . . . . . . . . . . . . .

VIII− Operating Characteristics 35. . . . . . . . . . . . . . . . . .

XI− Maintenance 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X− Wiring and Operation Sequence 36. . . . . . . . . . . . . .

Corp. 0206−L3

Revised 02−2010

CBX32MV

Introduction

The CBX32MV is a high efficiency residential split system

blower/coil featuring a variable speed motor controlled by an

electronic blower drive control (BDC).

CBX32MV series units are designed to be matched with

Lennox two-speed or single-speed HFC−410A condensing

units and heat pumps. Several models are available in sizes

ranging from 1.5 through 5 tons. All units are equipped with

factory installed check and expansion valve for cooling or heat

pump applications.

Electric heat is available in several voltages and KW sizes,

and can be field installed in the cabinet.

Some CBX32MV applications may include the optional

Lennox ComfortSense

Efficiency Plus Comfort Management Control (CCB1). The

purpose of both controls is to vary indoor blower speed in

response to indoor dehumidification demand. When a

two-speed outdoor unit is used, compressor speed can

also be controlled by the SignatureStat or CCB1 in

response to indoor dehumidification demand.

Information contained in this manual is intended for use by

experienced HVAC service technicians only. All

specifications are subject to change. Procedures outlined

in this manual are presented as a recommendation only

and do not supersede or replace local or state codes.

®

7000, SignatureStatt or

WARNING

Electric shock hazard. Can cause injury

or death. Before attempting to perform

any service or maintenance, turn the

electrical power to unit OFF at disconnect switch(es). Unit may have multiple

power supplies.

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic

components. Take precautions during unit installation and service to protect the unit’s electronic

controls. Precautions will help to avoid control

exposure to electrostatic discharge by putting

the unit, the control and the technician at the

same electrostatic potential. Neutralize electrostatic charge by touching hand and all tools on an

unpainted unit surface before performing any

service procedure.

Page 1

2002 Lennox Industries Inc.

Page 2

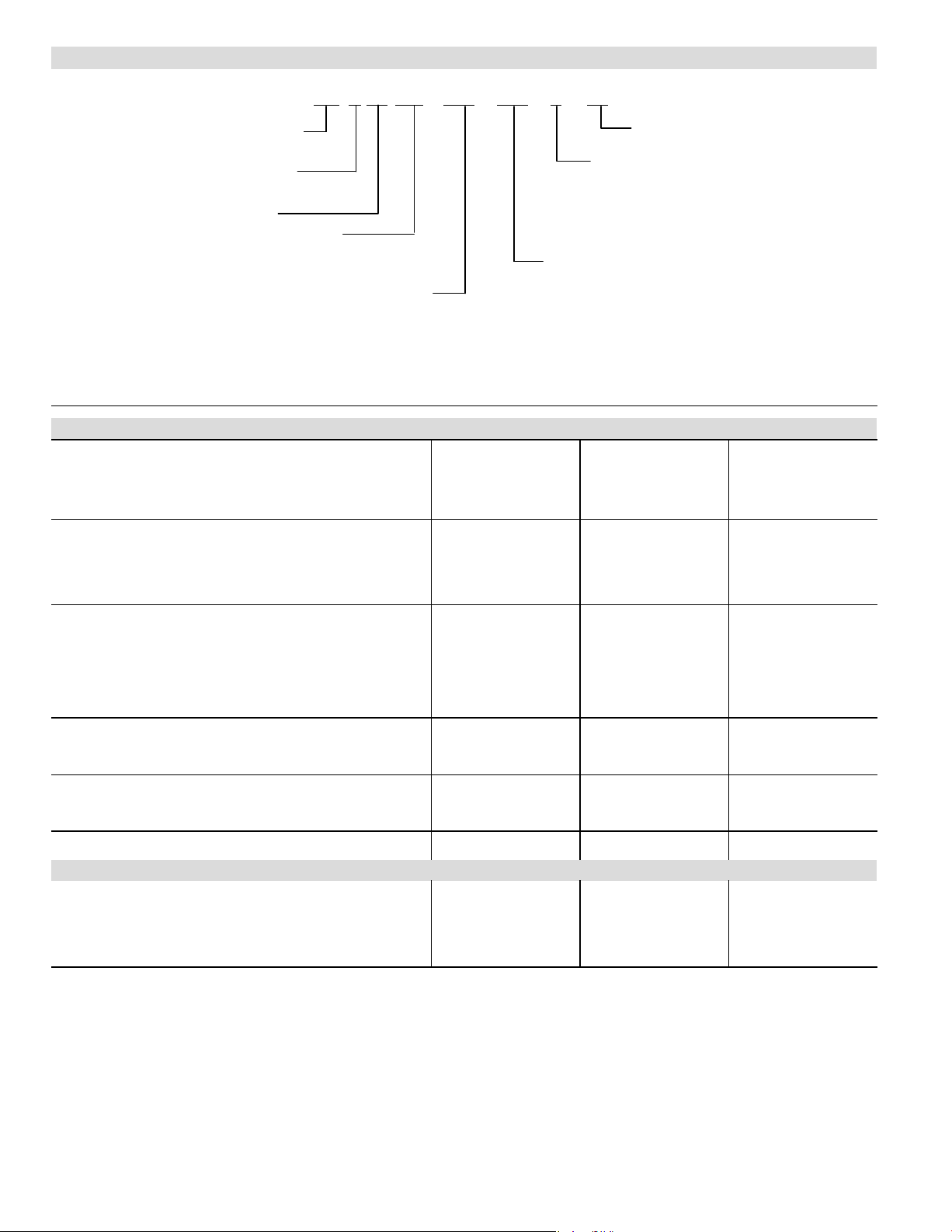

Model Number Identification

Unit Type

CB = Air Handler

Refrigerant Type

X = R−410A

Series

Configuration

MV = Multi−Position, Variable

speed blower motor

Nominal Cooling Capacity

018/024 = 1.5 to 2 tons (5.3 to 7 kW)

024/030 = 2 to 2.5 tons (7 to 8.8 kW)

036 = 3 tons (10.6 kW)

048 = 4 tons (14.1 kW)

060 = 5 tons (17.6 kW)

068 = 5+ tons (17.6+ kW)

X

MV

−

−

230CB 32 036

−−

05

6

Minor Revision Number

Refrigerant Metering Device

2 = Fixed Orifice

3 = TXV − Bleedport (indoor unit)

4 = TXV − Non−bleedport (indoor unit)

5 = TXV − Non−bleedport (outdoor unit)

6 = TXV − R−410A Non−bleedport (indoor unit)

Voltage

230 = 208/230V−60hz−1ph

Specifications

General Data Model Number CBX32MV-018/024 CBX32MV-024/030 CBX32MV-036

Connections

in. (mm)

Nominal cooling capacity − tons (kW)

Refrigerant

Suction (vapor) line − sweat

Liquid line − sweat

1.5 − 2 (5.3 − 7) 2 − 2.5 (7 − 8.8) 3 (10.6)

R−410A R−410A R−410A

5/8 (15.8) 3/4 (19) 3/4 (19)

3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Condensate drain (fpt)

Indoor

Coil

Blower Data

Filters

Shipping Data − 1 Package lbs. (kg) 126 (57) 152 (69) 183 (83)

ELECTRICAL DATA

Voltage − phase − 60hz 208/230V−1ph

2

Maximum overcurrent protection (unit only) 15 15 15

Minimum circuit ampacity (unit only) 5 5 5

Tube outside diameter − in. (mm)

Wheel nominal diameter x width − in. (mm)

Net face area − ft.2 (m2)

Number of rows

Fins per inch (fins per m)

Motor output − hp (W)

1

Number and size − in.

mm

(2) 3/4 (19) (2) 3/4 (19) (2) 3/4 (19)

3.56 (0.33) 4.44 (0.41) 5.0 (0.46)

3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

3 3 3

12 (472) 12 (472) 12 (472)

10 x 7 (279 x 178) 10 x 8 (279 x 203) 10 x 8 (279 x 203)

1/2 (373) 1/2 (373) 1/2 (373)

(1) 15 x 20 x 1 (1) 20 x 20 x 1 (1) 20 x 22 x 1

381 x 508 x 25 508 x 508 x 25 508 x 559 x 25

208/230V−1ph 208/230V−1ph

Page 2

Page 3

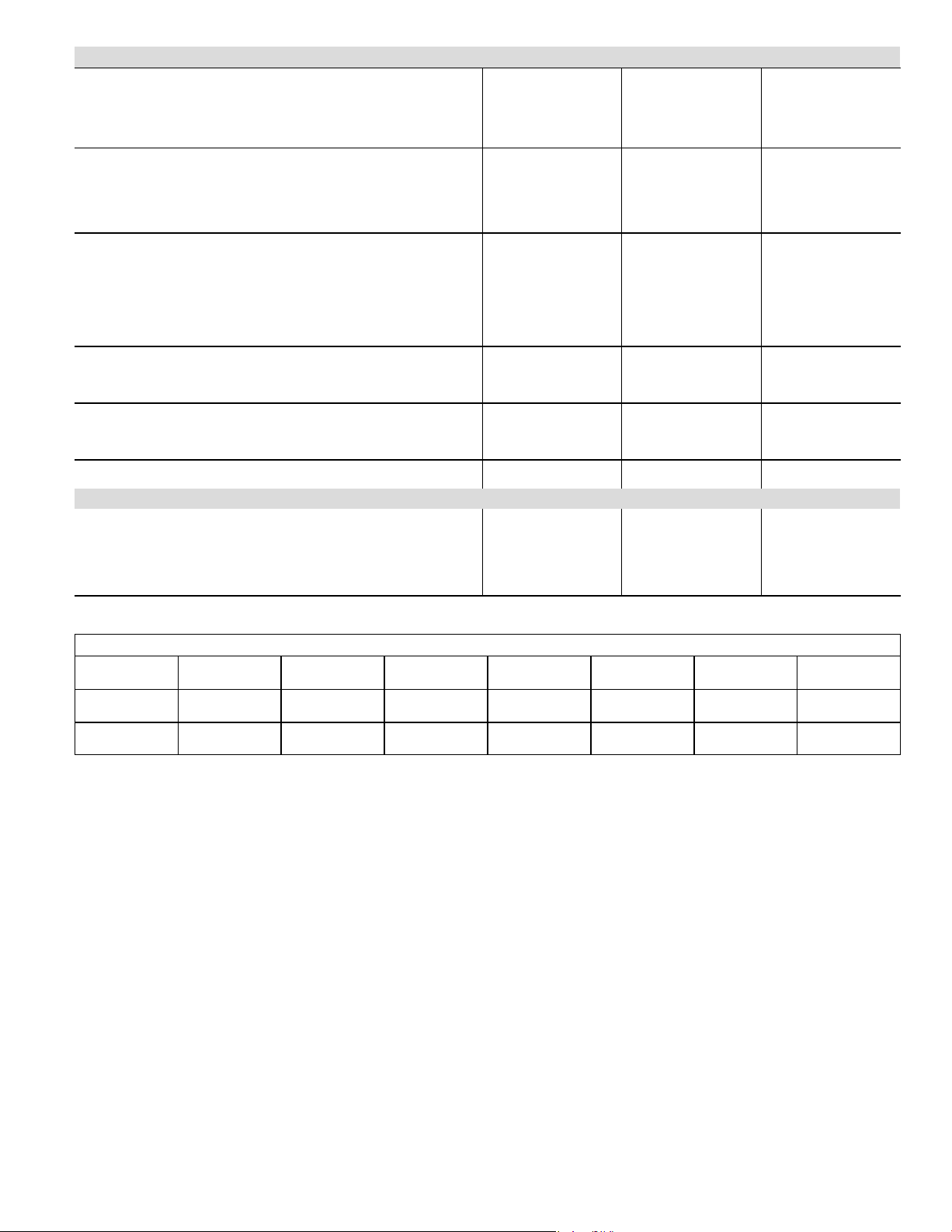

Specifications

General Data Model Number CBX32MV-048 CBX32MV-060 CBX32MV-068

Nominal cooling capacity − tons (kW)

4 (14.1) 5 (17.6) 5+ (17.6+)

Connections

in. (mm)

Indoor

Coil

Blower Data

Filters

Refrigerant

Suction (vapor) line − sweat

Liquid line − sweat

Condensate drain (fpt)

Net face area − ft.2 (m2)

Tube outside diameter − in. (mm)

Number of rows

Fins per inch (fins per m)

Wheel nominal diameter x width − in. (mm)

Motor output − hp (W)

1

Number and size − in.

mm

R−410A R−410A R−410A

7/8 (22.2) 1-1/8 (28) 1-1/8 (28)

3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

(2) 3/4 (19) (2) 3/4 (19) (2) 3/4 (19)

7.22 (0.67) 7.22 (0.67) 7.77 (0.72)

3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

3 3 3

12 (472) 12 (472) 12 (472)

12 x 9 (305 x 229) 12 x 9 (305 x 229) 15 x 9 (381 x 229)

1 (746) 1 (746) 1 (746)

(1) 20 x 24 x 1 (1) 20 x 24 x 1 (1) 20 x 25 x 1

508 x 610 x 25 508 x 610 x 25 508 x 635 x 25

Shipping Data − 1 Package − lbs. (kg) 212 (96) 212 (96) 244 (111)

ELECTRICAL DATA

Voltage − phase − 60hz 208/230V−1ph

2

Maximum overcurrent protection (unit only) 20 20 20

208/230V−1ph 208/230V−1ph

Minimum circuit ampacity (unit only) 11 11 11

Optional CIRCUIT BREAKER KITS − Must Be Ordered Extra

Amperage 25 30 35 40 45 50 60

Single Phase 23M58 23M59 23M60 23M61 23M62 23M63 23M64

Three Phase − − − 23M65 − − − 23M66 23M67 23M68 23M69

Page 3

Page 4

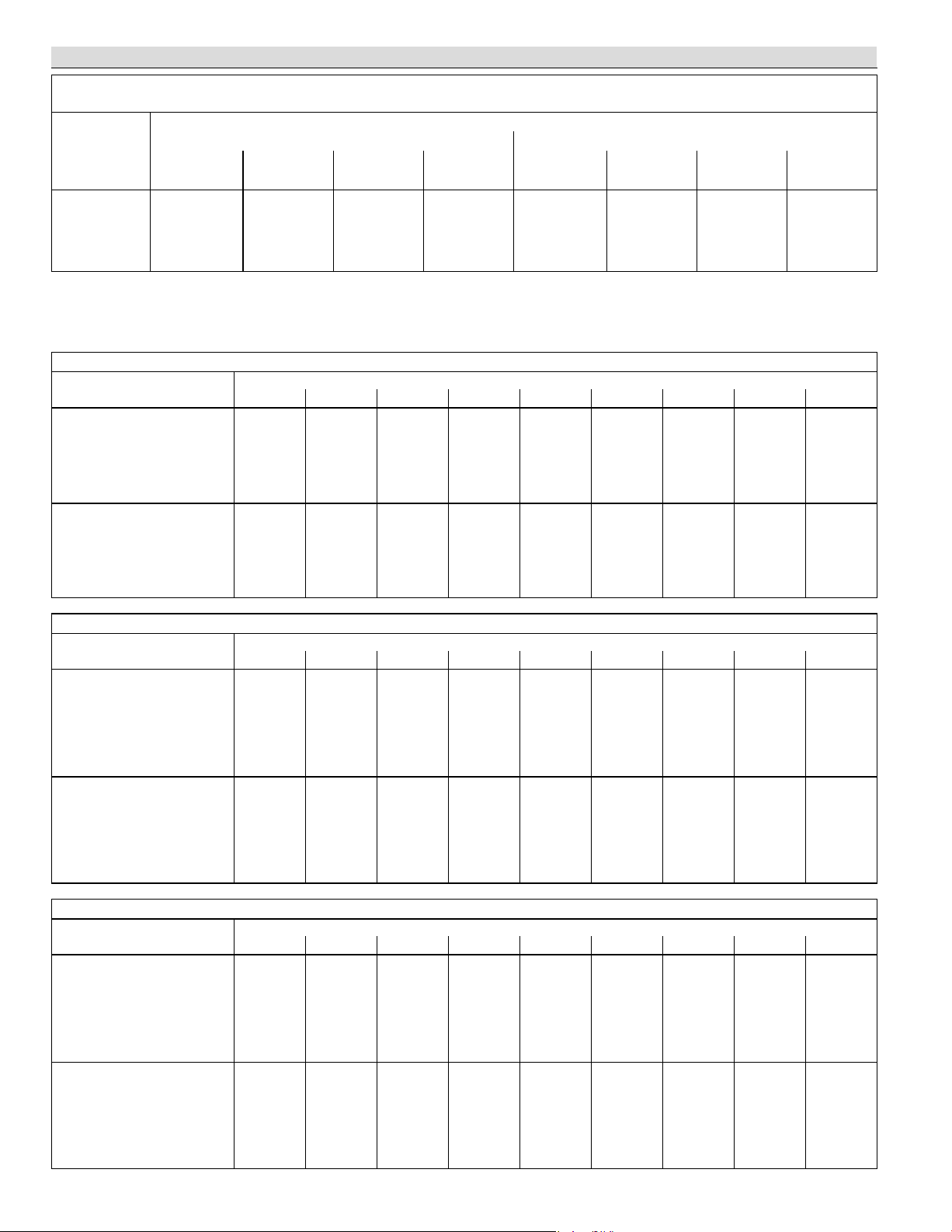

Blower Data

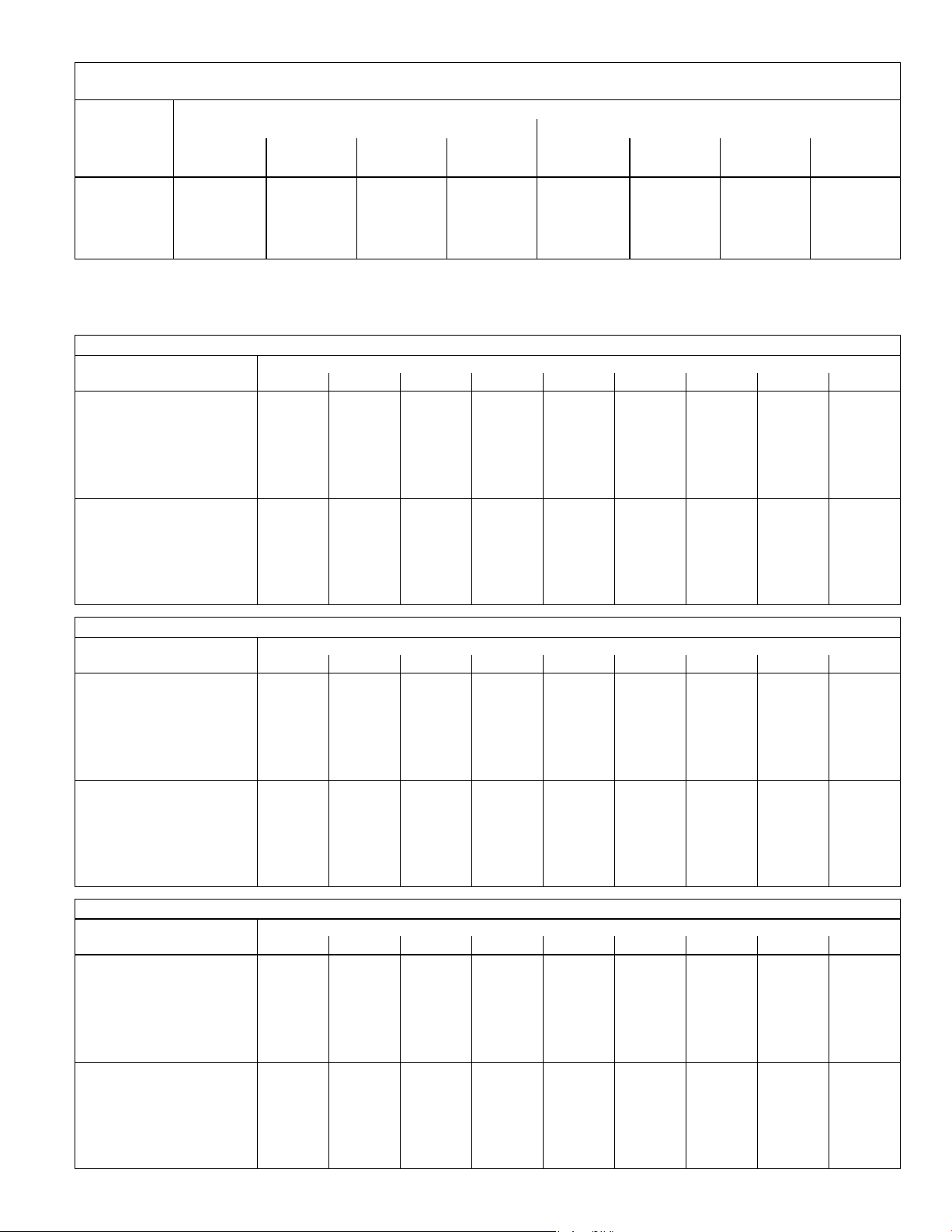

CBX32MV-018/024 BLOWER PERFORMANCE

0 through 0.80 in. w.g. (0 through 200 Pa) External Static Pressure Range

BDC3 Jumper Speed Positions

ADJUST"

Jumper

Setting

+ 715 337 855 405 1000 470 1130 535 465 220 690 325 900 425 1050 495

NORM 670 315 770 365 900 425 1035 490 425 200 620 290 825 390 950 450

− 580 275 700 330 800 375 930 440 385 180 560 265 735 345 850 400

NOTES − The effect of static pressure, filter and electric heater resistance is included in the air volumes listed.

Low speed cooling air volume is 70% of COOL speed setting. Production units September 2005 and later; continuous blower speed for is approximately 38% of

COOL speed setting. Earlier production units continuous blower speed is approximately 50% of COOL speed setting.

Harmony Zone Control applications − Low speed cooling is approximately 250 cfm (118 L/s).

Lennox Harmony IIIt Zone Control applications − Low speed cooling is 300 cfm (145 L/s)

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

CBX32MV-018/024 BLOWER MOTOR WATTS AT +" (Plus) BDC3 SETTING (Adjust" Jumper at +" Setting)

BDC3 Jumper

Speed Positions

HEAT" Speed

COOL" Speed

Tap 1 100 113 126 142 154 172 190 206 230

Tap 2 155 176 197 221 237 260 278 295 310

Tap 3 237 260 289 305 314 337 356 373 390

Tap 4 338 361 379 409 433 457 447 426 406

Tap 1 36 47 61 71 81 95 106 118 135

Tap 2 89 103 11 8 129 143 163 177 197 207

Tap 3 183 198 229 248 266 290 307 327 343

Tap 4 266 294 315 330 349 373 390 411 401

HEAT" Speed COOL" Speed

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

CBX32MV-018/024 BLOWER MOTOR WATTS AT NORM" BDC3 SETTING (Adjust" Jumper at NORM Setting)

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

Speed Positions

HEAT" Speed

COOL" Speed

BDC3 Jumper

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Tap 1 77 96 106 123 130 150 165 178 201

Tap 2 118 136 154 177 189 212 224 247 265

Tap 3 183 198 224 248 264 284 307 321 343

Tap 4 264 284 300 326 343 367 385 406 390

Tap 1 30 41 55 62 76 86 94 106 11 4

Tap 2 71 83 101 11 3 125 138 156 166 185

Tap 3 137 158 176 199 219 238 254 273 296

Tap 4 211 225 249 272 295 318 331 342 367

CBX32MV-018/024 BLOWER MOTOR WATTS AT −" (Minus) BDC3 SETTING (Adjust" Jumper at −" Setting)

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

Speed Positions

HEAT" Speed

BDC3 Jumper

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Tap 1 59 73 89 106 113 130 142 156 173

Tap 2 95 106 11 8 136 152 171 183 200 215

Tap 3 132 148 171 186 211 225 248 266 284

Tap 4 195 217 242 259 283 302 314 336 349

COOL" Speed

Tap 1 27 35 47 59 71 77 88 92 106

Tap 2 57 65 83 94 110 119 134 148 166

Tap 3 110 124 141 157 176 188 213 231 242

Tap 4 148 170 195 207 230 248 272 282 306

Page 4

Page 5

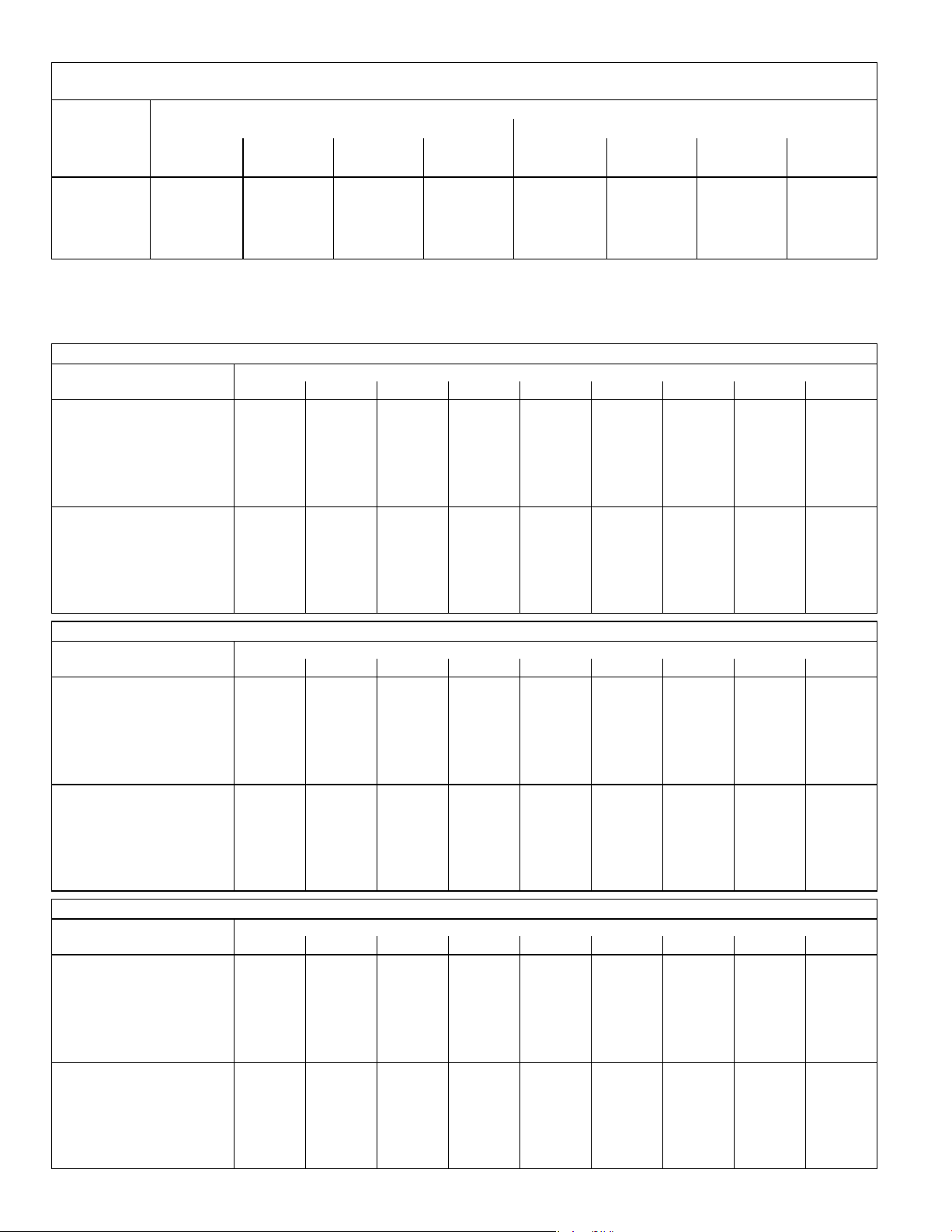

CBX32MV-024/030 BLOWER PERFORMANCE

0 through 0.80 in. w.g. (0 through 200 Pa) External Static Pressure Range

BDC3 Jumper Speed Positions

ADJUST"

Jumper

Setting

+ 800 380 935 440 1070 505 1210 570 660 310 880 415 1100 520 1320 625

NORM 725 340 850 400 975 460 1100 520 600 285 800 380 1000 470 1200 565

− 655 310 765 360 880 415 990 470 540 255 720 340 900 425 1080 510

NOTES − The effect of static pressure, filter and electric heater resistance is included in the air volumes listed.

Low speed cooling air volume is 70% of COOL speed setting. Production units September 2005 and later; continuous blower speed for is approximately 38% of

COOL speed setting. Earlier production units continuous blower speed is approximately 50% of COOL speed setting.

Harmony Zone III Control applications − Low speed cooling is approximately 300 cfm (145 L/s).

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

HEAT" Speed COOL" Speed

CBX32MV-024/030 BLOWER MOTOR WATTS AT +" (Plus) BDC3 SETTING (Adjust" Jumper at +" Setting)

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

Speed Positions

HEAT" Speed

BDC3 Jumper

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Tap 1 65 90 120 145 185 210 240 250 275

Tap 2 95 125 150 185 230 265 310 345 365

Tap 3 140 190 225 250 290 320 350 405 450

Tap 4 215 250 285 315 350 390 440 480 505

COOL" Speed

Tap 1 45 60 90 120 140 155 165 185 200

Tap 2 80 110 135 165 205 250 285 315 335

Tap 3 150 195 225 260 295 320 370 425 465

Tap 4 265 315 350 400 440 485 525 555 605

CBX32MV-024/030 BLOWER MOTOR WATTS AT NORM" BDC3 SETTING (Adjust" Jumper at NORM Setting)

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

Speed Positions

HEAT" Speed

COOL" Speed

BDC3 Jumper

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Tap 1 50 75 100 135 155 180 195 215 230

Tap 2 80 105 130 155 200 245 265 295 310

Tap 3 110 150 175 200 235 275 320 350 390

Tap 4 155 205 230 270 290 325 360 405 460

Tap 1 40 55 80 105 120 130 150 165 180

Tap 2 65 90 120 145 190 210 240 260 285

Tap 3 105 145 175 220 250 285 335 370 405

Tap 4 200 245 275 300 335 385 420 470 515

CBX32MV-024/030 BLOWER MOTOR WATTS AT −" (Minus) BDC3 SETTING (Adjust" Jumper at −" Setting)

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

Speed Positions

HEAT" Speed

BDC3 Jumper

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Tap 1 45 65 90 110 130 150 165 190 195

COOL" Speed

Tap 2 60 85 110 145 175 200 215 235 240

Tap 3 85 105 130 165 210 245 280 305 330

Tap 4 115 145 175 205 230 280 325 370 390

Tap 1 30 50 70 90 100 115 125 140 165

Tap 2 55 75 100 135 155 185 190 210 225

Tap 3 85 115 135 175 210 255 295 320 345

Tap 4 145 175 215 245 280 325 355 410 450

Page 5

Page 6

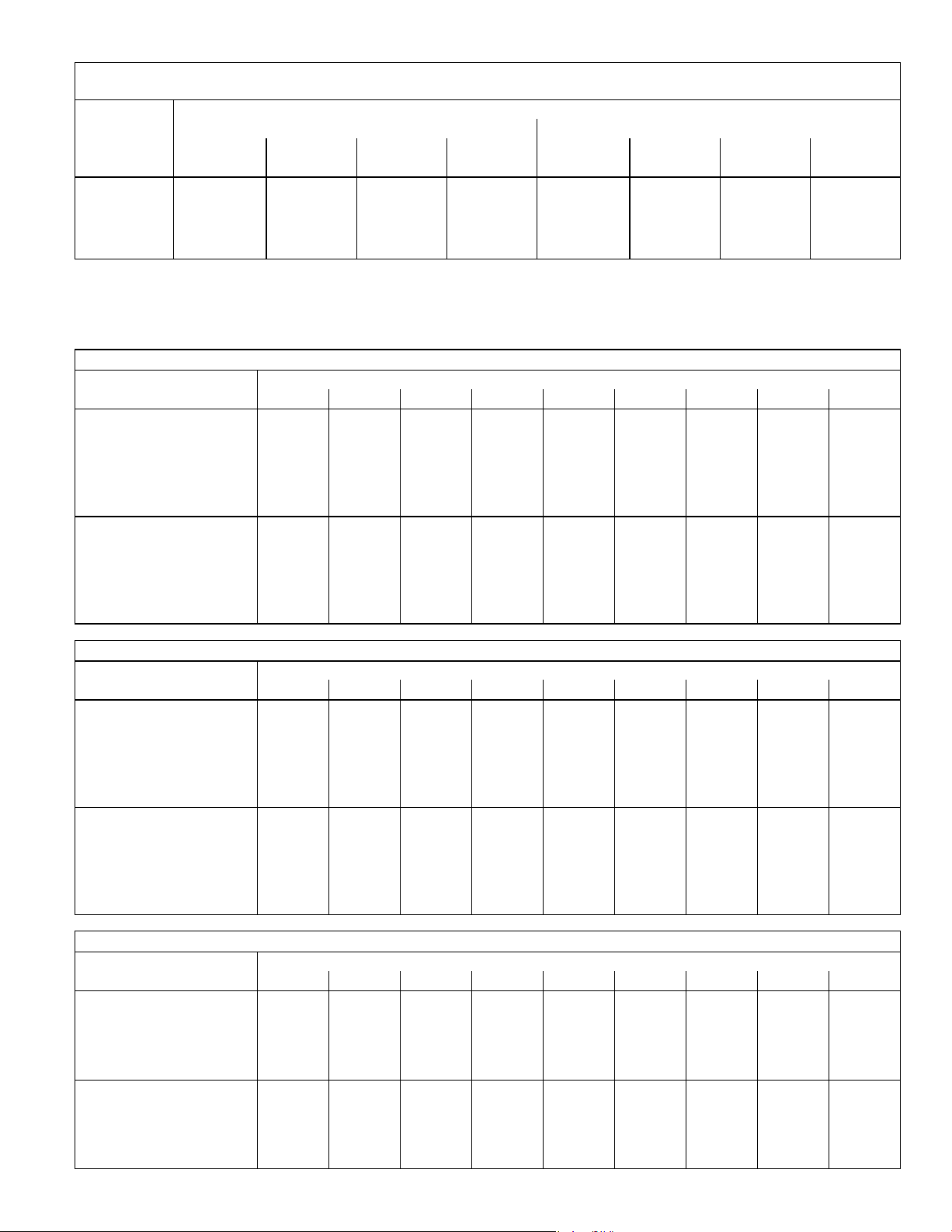

CBX32MV-036 BLOWER PERFORMANCE

0 through 0.80 in. w.g. (0 through 200 Pa) External Static Pressure Range

BDC3 Jumper Speed Positions

ADJUST"

Jumper

Setting

+ 1230 580 1335 630 1445 680 1545 730 1090 515 1225 580 1380 650 1545 730

NORM 1120 530 1215 575 1315 620 1400 660 975 460 1125 530 1275 600 1400 660

− 1010 475 1185 560 1200 565 1265 595 900 425 1000 470 1135 535 1265 595

NOTES − The effect of static pressure, filter and electric heater resistance is included in the air volumes listed.

Low speed cooling air volume is 70% of COOL speed setting (65% COOL speed for production prior to August 2002). Production units September 2005 and later;

continuous blower speed for is approximately 38% of COOL speed setting. Earlier production units continuous blower speed is approximately 50% of COOL

speed setting.

Harmony Zone Control applications − Low speed cooling is approximately 380 cfm (178 L/s).

Lennox Harmony IIIt Zone Control applications − minimum blower speed is 442 cfm (210 L/s).

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

HEAT" Speed COOL" Speed

CBX32MV-036 BLOWER MOTOR WATTS AT +" (Plus) BDC3 SETTING (Adjust" Jumper at +" Setting)

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

Speed Positions

HEAT" Speed

BDC3 Jumper

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Tap 1 220 235 265 290 310 335 360 385 465

Tap 2 285 305 330 355 380 405 430 450 475

Tap 3 345 365 405 430 455 485 515 545 570

Tap 4 470 495 515 530 545 560 575 595 610

COOL" Speed

Tap 1 145 165 200 225 250 275 300 325 350

Tap 2 225 245 265 290 320 350 370 395 410

Tap 3 305 325 350 390 420 445 475 505 535

Tap 4 470 495 515 530 545 560 575 595 610

CBX32MV-036 BLOWER MOTOR WATTS AT NORM" BDC3 SETTING (Adjust" Jumper at NORM Setting)

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

Speed Positions

HEAT" Speed

COOL" Speed

BDC3 Jumper

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Tap 1 155 185 215 240 265 285 300 335 355

Tap 2 225 245 270 295 325 345 370 390 415

Tap 3 275 290 315 340 375 400 420 445 465

Tap 4 320 345 375 405 435 460 485 515 540

Tap 1 120 140 160 190 210 230 255 275 300

Tap 2 160 190 220 240 265 290 320 340 365

Tap 3 255 270 295 320 345 375 400 420 445

Tap 4 320 345 375 405 435 460 485 515 540

CBX32MV-036 BLOWER MOTOR WATTS AT −" (Minus) BDC3 SETTING (Adjust" Jumper at −" Setting)

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

Speed Positions

HEAT" Speed

BDC3 Jumper

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Tap 1 120 135 165 185 205 225 245 265 300

COOL" Speed

Tap 2 140 165 195 215 245 270 300 315 335

Tap 3 185 210 240 265 285 310 330 360 385

Tap 4 245 255 290 310 335 355 380 405 430

Tap 1 90 110 135 155 180 195 210 230 250

Tap 2 120 140 160 185 215 235 255 275 295

Tap 3 160 190 225 240 275 295 320 350 380

Tap 4 245 255 290 310 335 355 380 405 430

Page 6

Page 7

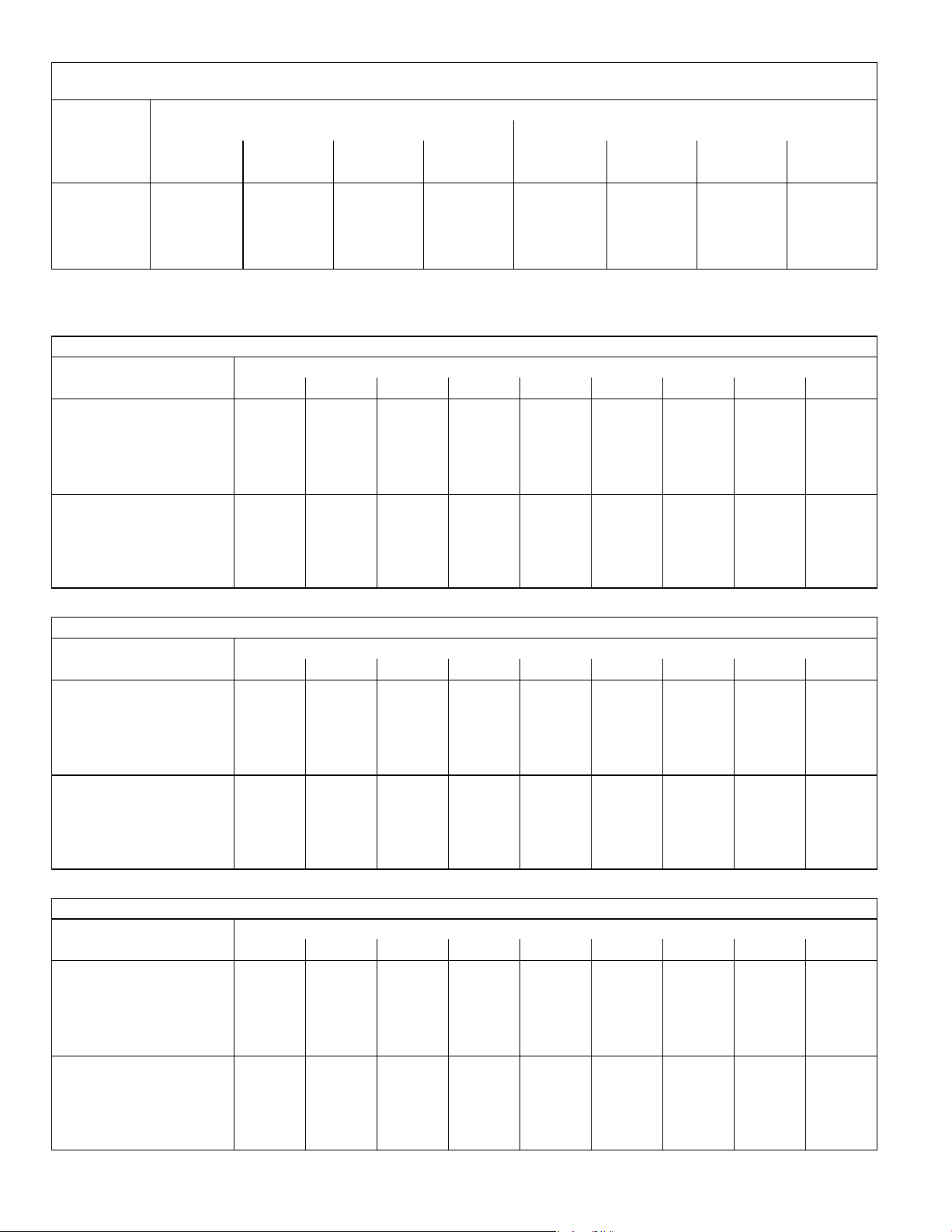

CBX32MV-048 AND CBX32MV-060 BLOWER PERFORMANCE

0 through 0.80 in. w.g. (0 Through 200 Pa) External Static Pressure Range

BDC3 Jumper Speed Positions

ADJUST"

Jumper

Setting

+ 1850 875 1960 925 2090 985 2150 1015 1625 765 1820 860 2055 970 2145 1010

NORM 1705 805 1800 850 1900 895 2005 945 1425 670 1625 765 1805 850 2005 945

− 1560 735 1625 765 1720 810 1770 835 1205 570 1375 650 1555 735 1725 815

NOTES − The effect of static pressure, filter and electric heater resistance is included in the air volumes listed.

Low speed cooling air volume is 70% of COOL speed setting (60% of COOL speed for production prior to August 2002). Production units September 2005 and

later;continuous blower speed for is approximately 38% of COOL speed setting. Earlier production units continuous blower speed is approximately 50% of COOL

speed setting.

Harmony Zone Control applications − Low speed cooling is approximately 400 cfm (190 L/s).

Lennox Harmony IIIt Zone Control applications − minimum blower speed is 442 cfm (210 L/s)

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

HEAT" Speed COOL" Speed

CBX32MV-048 AND CBX32MV-060 BLOWER MOTOR WATTS AT +" (Plus) BDC3 SETTING (Adjust" Jumper at +" Setting)

BDC3 Jumper Speed

HEAT"

Speed

Positions

Tap 1 455 505 540 585 630 665 710 745 780

Tap 2 555 595 645 675 730 780 820 865 895

Tap 3 680 720 770 820 865 900 945 985 1030

Tap 4 730 780 825 870 920 970 1020 1055 1110

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

COOL"

Speed

Tap 1 300 335 370 360 435 465 500 535 575

Tap 2 425 475 500 545 585 635 670 710 745

Tap 3 625 660 705 755 810 850 885 940 970

Tap 4 700 750 800 845 895 940 990 1030 1080

CBX32MV-048 AND CBX32MV-060 BLOWER MOTOR WATTS AT NORM" BDC3 SETTING (Adjust" Jumper at NORM Setting)

BDC3 Jumper Speed

Positions

HEAT"

Speed

COOL"

Speed

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Tap 1 360 385 425 465 495 525 565 600 635

Tap 2 400 440 485 520 555 595 640 670 705

Tap 3 480 520 560 605 640 685 765 785 805

Tap 4 580 625 665 710 760 800 835 875 925

Tap 1 215 235 275 295 330 360 400 430 465

Tap 2 310 335 375 405 440 465 500 530 565

Tap 3 415 445 490 535 565 605 650 675 715

Tap 4 580 610 655 695 740 785 830 870 910

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

CBX32MV-048 AND CBX32MV-060 BLOWER MOTOR WATTS AT −" (Minus) BDC3 SETTING (Adjust" Jumper at −" Setting)

BDC3 Jumper Speed

Positions

HEAT"

Speed

COOL"

Speed

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Tap 1 265 305 340 370 410 440 460 505 540

Tap 2 320 350 395 420 450 475 515 545 580

Tap 3 375 410 435 470 515 545 575 610 645

Tap 4 400 435 480 525 555 595 640 670 700

Tap 1 140 170 195 215 250 275 300 335 360

Tap 2 200 230 260 285 315 355 385 415 450

Tap 3 280 315 340 380 415 445 465 505 540

Tap 4 375 420 440 475 515 550 575 610 645

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

Page 7

Page 8

CBX32MV-068 BLOWER PERFORMANCE

0 through 0.80 in. w.g. (0 Through 200 Pa) External Static Pressure Range

BDC3 Jumper Speed Positions

HEAT" Speed COOL" Speed

ADJUST"

Jumper

Setting

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

+ 1875 885 1975 930 2090 985 2150 1015 1640 775 1840 870 2075 980 2150 1015

NORM 1760 830 1825 860 1920 905 2030 960 1465 690 1625 765 1800 850 2000 945

− 1550 730 1650 780 1725 815 1800 850 1250 590 1390 655 1560 735 1720 810

NOTES − The effect of static pressure, filter and electric heater resistance is included in the air volumes listed.

First stage cooling air volume is 60% of COOL speed setting. Production units September 2005 and later;continuous blower speed for is approximately 38% of

COOL speed setting. Earlier production units continuous blower speed is approximately 50% of COOL speed setting.

Lennox Harmony IIIt Zone Control applications − minimum blower speed is 442 cfm (210 L/s).

CBX32MV-068 BLOWER MOTOR WATTS AT +" (Plus) BDC3 SETTING (Adjust" Jumper at +" Setting)

BDC3 Jumper Speed

Positions

HEAT"

Speed

Tap 1 365 410 455 495 545 610 660 725 790

Tap 2 430 485 540 590 640 690 765 835 865

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

Tap 3 540 585 635 695 750 800 815 840 865

Tap 4 665 710 755 770 790 810 830 845 870

COOL"

Speed

Tap 1 255 290 320 365 415 455 505 550 590

Tap 2 355 390 425 475 515 580 630 695 750

Tap 3 505 565 610 70 715 790 815 845 865

Tap 4 725 745 755 770 790 810 830 850 870

CBX32MV-068 BLOWER MOTOR WATTS AT NORM" BDC3 SETTING (Adjust" Jumper at NORM Setting)

BDC3 Jumper Speed

Positions

HEAT"

Speed

Tap 1 310 345 385 425 465 510 560 610 665

Tap 2 345 385 420 460 500 620 615 680 735

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

Tap 3 385 430 480 525 580 640 695 750 815

Tap 4 475 525 560 615 660 720 785 845 810

COOL"

Speed

Tap 1 180 205 240 285 325 365 405 435 480

Tap 2 250 285 320 355 410 455 505 535 585

Tap 3 345 375 415 460 505 560 610 670 735

Tap 4 445 510 560 595 665 725 790 845 865

CBX32MV-068 BLOWER MOTOR WATTS AT −" (Minus) BDC3 SETTING (Adjust" Jumper at −" Setting)

BDC3 Jumper Speed

Positions

HEAT"

Speed

Tap 1 215 245 285 325 375 415 460 495 540

Tap 2 255 295 325 370 410 460 510 545 580

0 (0) 0.1 (25) 0.2 (50) 0.3 (75) 0.4 (100) 0.5 (125) 0.6 (150) 0.7 (175) 0.8 (200)

Motor Watts @ Various External Static Pressures − in. wg. (Pa)

Tap 3 295 330 375 395 445 495 555 600 660

Tap 4 335 370 400 445 505 550 600 660 705

COOL"

Speed

Tap 1 125 150 170 210 245 270 300 340 370

Tap 2 160 185 225 255 300 335 365 415 450

Tap 3 225 245 280 320 370 420 460 510 545

Tap 4 290 325 355 400 445 490 545 595 650

Page 8

Page 9

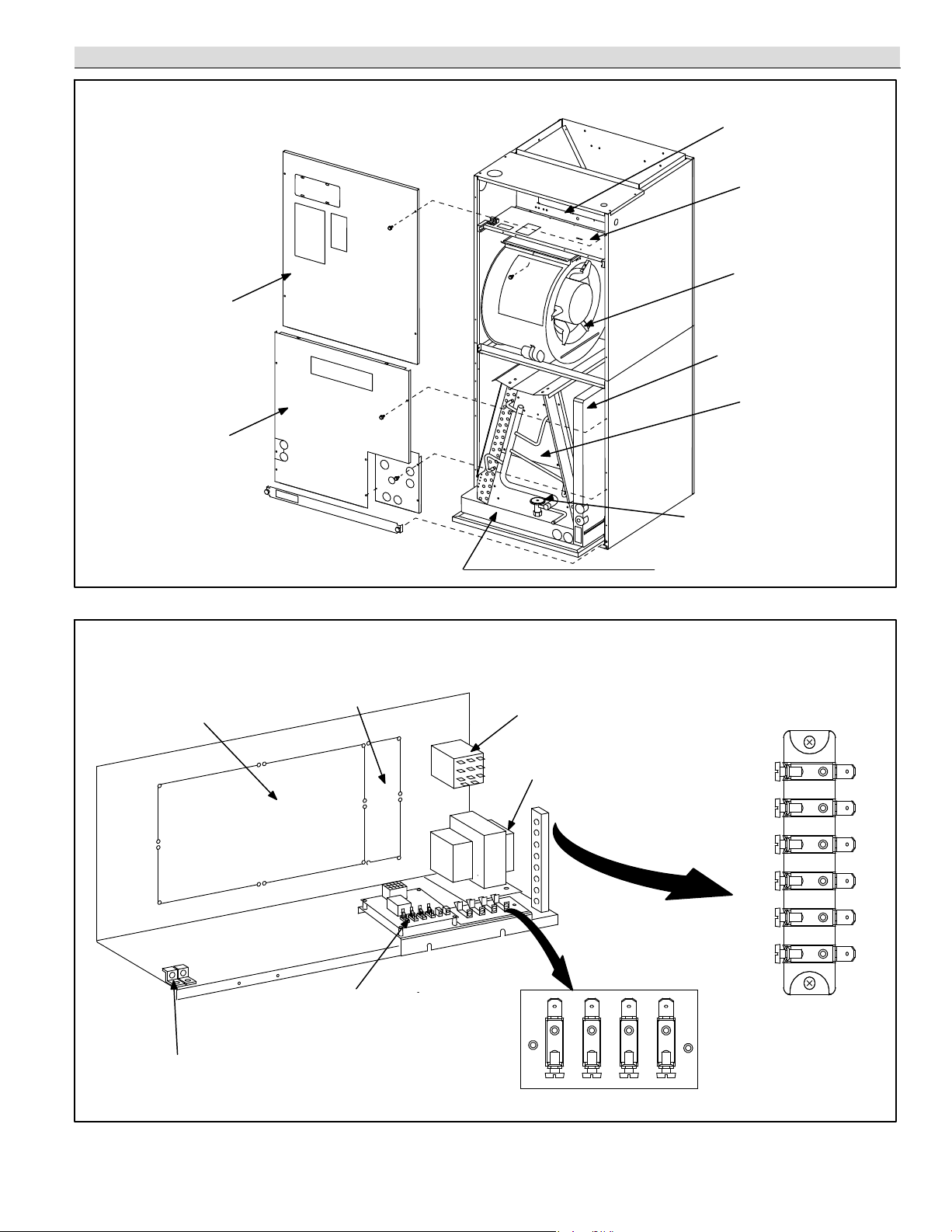

Parts Arrangement

ELECTRIC HEAT

SECTION

CBX32MV

BLOWER ACCESS

PANEL

COIL ACCESS

PANEL

CONTROL BOX

BLOWER

COMPARTMENT

HORIZONTAL

DRAIN PAN

COIL

CHECK AND EXPANSION VALVE

(COMPLETE WITH SCREEN)

UPFLOW/DOWNFLOW

DRAIN PAN

FIGURE 1

SMALL ELECTRIC HEAT

KNOCK OUT FOR

2.5 − 15 kW

GROUNDING

LUGS

CBX32MV CONTROL BOX

LARGE ELECTRIC HEAT

ADDITIONAL KNOCK

OUT FOR

20 − 30 kW

BDC3 BLOWER

CONTROL (A15)

TERMINAL

STRIP

(TB2)

BLOWER

RELAY (K20)

TRANSFORMER

(T1)

TERMINAL

STRIP (TB1)

R

W3

W2

W1

G

C

0Y1Y2DS

FIGURE 2

Page 9

Page 10

I−APPLICATION

CBX32MV blower coils are designed for R410A

applications only. All major blower coil components

must be matched according to Lennox

recomme n d ations fo r the unit to be covered under

warranty. Refer to the Engineering Handbook for approved

system matchups. A misapplied system will cause erratic

operation and can result in early unit failure. The units come

with factory installed check and expansion valve for all

applications. It has been installed internally and is accessible if

required.

II−UNIT COMPONENTS

A−Control Box

The CBX32MV control box is shown in figure 2. Line voltage

and electric heat connections are made in the control box.

Optional electric heat fits through an opening located in the

center of the control box. When electric heat is not used,

knockout plates cover the opening. The electric heat control

arrangement is detailed in the electric heat section of this

manual.

B−Terminal Strips (TB1 and TB2)

All CBX32MV units are equipped with two low voltage

terminal strips (TB1 and TB2) located in the control box.

See figure 2. The strips are used for making up all indoor

thermostat wires.

All CBX32MV units have factory installed jumpers

connecting DS to Y1, R to O and Y1 to Y2. These jumpers

will have to be removed in certain unit application. See table

1.

TABLE 1

Application

Harmony II, CCB1,

SignatureStatt

Remove Jumpers

DS to Y1

Heat Pump R to O

Two−Stage Cooling Y1 to Y2

C−Transformer (T1)

All CBX32MV series units use a single line voltage to

24VAC transformer mounted in the control box. The

transformer supplies power to the control circuits in the

indoor and outdoor unit.

D−Blower Relay (K20)

All units use SPDT relay to energize the blower motor in

response to heating demand. The relay coil is energized

when the 1st stage electric heat relay closes. When K20 is

energized, its N.O. contacts close to energize jack plug

JP46 pin 2 (located on blower drive control A15). When

JP46−2 is energized, the blower drive control immediately

energizes the blower on heating speed. Heating speed will

override cooling speed. K20−2 will energize the

economizer if used ( refer to wiring diagram.)

208 / 240 VOLT TRANSFORMER

PRIMARY

ORANGE

240 VOLTS

RED

208 VOLTS

BLACK

FIGURE 3

E−Circuit Breaker (CB8)−1 units & Fuse (F1)

All transformers used in the CBX32MV−1 series units are

equipped with internal secondary voltage overcurrent

protection. Each transformer uses a manual re−set circuit

breaker (CB8) located on the transformer. The circuit

breaker is connected in series with the blue secondary

voltage wire and is rated at 3.5 Amps. CBX23MV−2 units

and later are equipped with a fuse (F1) rated at 3 amps. F1

is connected in series with the blue secondary voltage wire

and like CB8 provides overcurrent protection.

SECONDARY

BLUE

YELLOW

CB8

F−Plastic Drain Pans

Both upflow/downflow and horizontal drain pans are

provided and installed on the CBX32MV units. The drain

pans are made from fiberglass-filled plastic. The drain hole

is used for right-hand air discharge only, and must be

plugged when the unit is configured for left-hand air

discharge (see page 24 for horizontal left-hand

application). Each pan has a set of connections, one for a

primary drain and one for an auxiliary drain.

G−Coil

All CBX32MV series units have dual slab coils arranged in

an "A" configuration. Each coil has two or three rows of

copper tubes fitted with ripple-edge aluminum fins. A check

and expansion valve complete with screen feeds multiple

parallel circuits through the coils. The coil is designed to

easily slide out of the unit cabinet.

Optional electric heating elements are sequenced so

blower relay K20 operates on a first on/last off basis.

H−Variable Speed Blower Motor (B3)

CBX32MV series units use a single-phase variable-speed

motor. See figure 4. A solid-state controller is attached to

the motor.

Page 10

Page 11

CBX32MV MOTOR BLOWER HOUSING

ARROW MUST

BE UP

MOTOR

BLOWER HOUSING

CBX32MV BLOWER MOTOR

B3

SHAFT

MOTOR

CONTROLLER

J48

J49

CBX32MV BLOWER MOTOR COMPONENTS

STATOR

(WINDINGS)

BEARING

OUTPUT

SHAFT

ROTOR

FIGURE 4

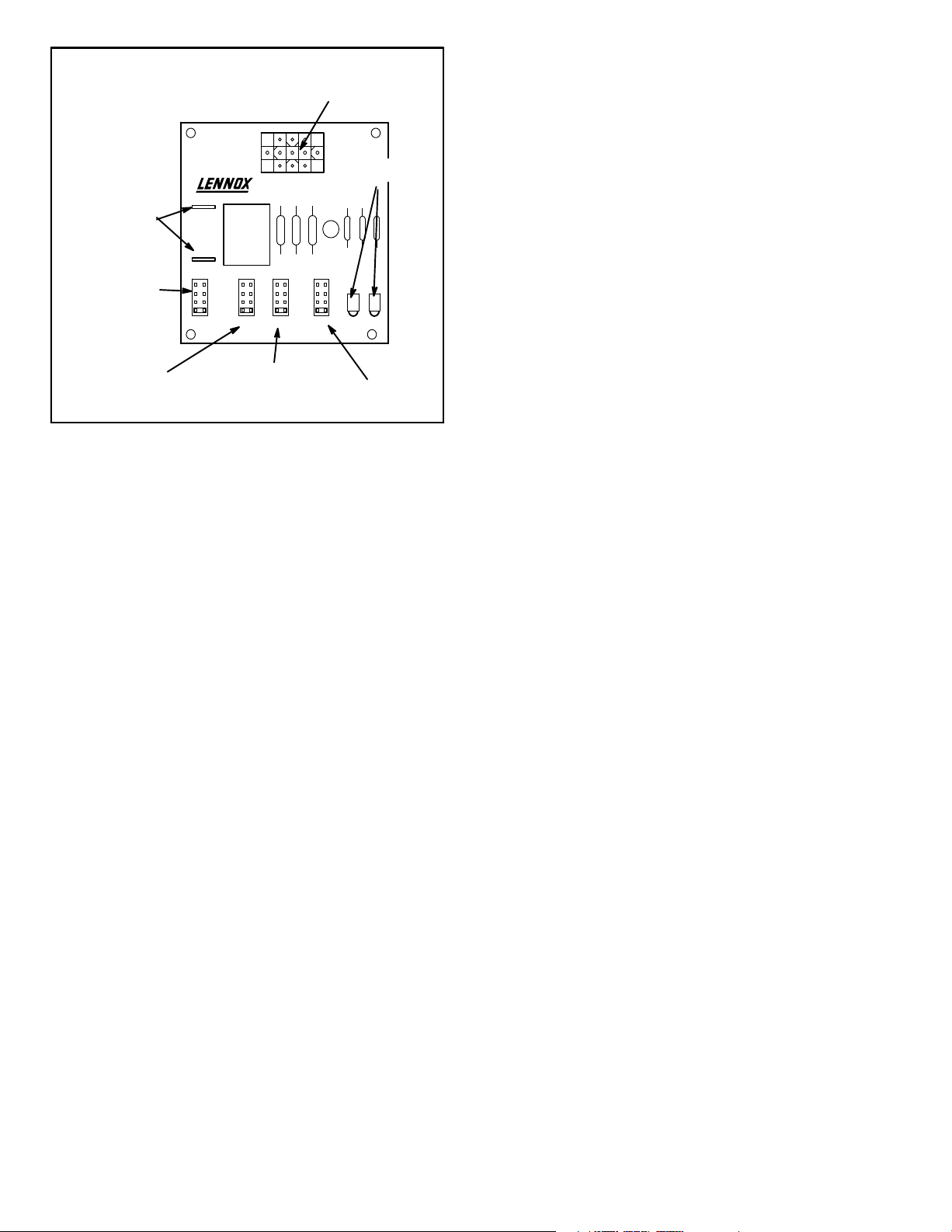

I−BDC3 Blower Control Board (A15)

CFM on the CBX32MV unit is controlled by the BDC3 board

(A15) located in the control box. CFM can be obtained by

positioning jumpers (COOL, HEAT and ADJUST) on the

BDC3 board. The jumpers are labeled 1,2,3, and 4. Each

enables a different air volume. Diagnostic LEDs are

provided as an aid in identifying the unit’s mode of

operation. The LEDs are labeled RUN and CFM. See

figure 5.

BLOWER SPEED ADJUSTMENTS

Diagnostic LEDs

RUN"

RUN indicates there is a demand for the blower motor to

run.

CFM"

CFM LED indicates the CFM the unit is operating according to

the jumper settings. The light flashes once for approximately

every 100 CFM. For example, if the unit is operating at 1000

CFM, CFM LED will flash 10 times. If the CFM is 1150, CFM

LED will flash 11 full times plus one fast or half flash.

At times the light may appear to flicker or glow. This takes

place when the control is communicating with the motor

between cycles. This is normal operation.

The appropriate speed according to application and CFM

need is selected by moving jumper pins.

Jumper Settings

IMPORTANT

Before changing jumper setting, make sure the

motor has completely stopped. Any jumper setting change will not take place while the motor is

running.

Table 2 shows the recommended factory blower speed tap

selections for CBX32MV series units. These settings are

for nominal tonnage match−ups with the CBX32MV. When

matched with other sizes, it is recommended that the CFM

be adjusted to approximately 400 CFM per ton.

FACTORY BLOWER SPEED TAP SELECTION

UNIT

−018/

024

−024/

−030

−036

−048

−060

−068

*Minimum setting for heat.

COOL" HEAT"

Condensing

Unit

COOL

PIN #3

COOL

PIN #3

COOL

PIN #3

COOL

PIN #2

COOL

PIN #3

COOL

PIN #3

To change jumper positions, gently pull the jumper off the pins

and place it on the desired set of pins. The following section

outlines the different jumper selections available and

conditions associated with each one. Refer to figure 5 for

identification.

After the CFM for each application has been determined,

the jumper settings must be adjusted to reflect those given

in the blower data tables at the front of this manual. From

the tables determine which row of CFM volumes most

closely matches the desired CFM. Once a specific row has

been chosen (+, NORMAL, or −), CFM volumes from other

rows cannot be used. Below are the descriptions of each of

the jumper selections.

TABLE 2

SPEED TAP SELECTION

*Condensing Unit

Heat

PIN

#3

PIN

#3

PIN

#3

PIN

#2

PIN

#3

PIN

#3

with Electric Heat

Only

HEAT

PIN #4

HEAT

PIN #4

HEAT

PIN #4

HEAT

PIN #1

HEAT

PIN #1

HEAT

PIN #4

Pump

COOL

COOL

COOL

COOL

COOL

COOL

*Heat Pump

with Electric

Heat

HEAT

PIN #4

HEAT

PIN #4

HEAT

PIN #4

HEAT

PIN #1

HEAT

PIN #1

HEAT

PIN #4

Page 11

Page 12

BDC3 VARIABLE SPEED CONTROL SELECTIONS

JP1 15 PIN PLUG

(BOARD TO MOTOR)

15

15

4

3

2

1

DIAGNOSTIC

4

3

2

1

CFM RUN

DS LEDS

ACCESSORY RELAY

CONTACTS

(DRIVES OPTIONAL

ACCESSORY

RELAY)

OPERATIONAL

SELECTOR PINS

(Affects both heating

and cooling modes)

11

JP1

ACC

24V/1A

NORM

4

+

3

−

2

TEST

ADJUST HEAT COOL DELAY

1

NOTE − For two speed heat pump units blower will operate at

60%, 65% or 70% of COOL CFM. For single speed heat pump

units blower will operate at 100% COOL CFM until

supplemental electric heat is demanded. At that time, the

blower will operate at HEAT speed selected. This arrangement

provides for warmer supply air during heat pump operation

only.

HEAT"

The HEAT jumper is used to determine CFM during a W1

demand for electric heat operation. These jumper

selections are activated when W1 is energized with or

without a Y1 demand for heat pump compressor.

DELAY"

HEATING SPEED

SELECTOR PINS

COOLING SPEED

SELECTOR PINS

FAN DELAY

SELECTOR PINS

FIGURE 5

ADJUST"

The ADJUST pins allow the motor to run at normal speed,

approximately 10% higher, or approximately 10% lower than

normal speed. The blower tables give three rows (+,

NORMAL, and −) with their respective CFM volumes. Notice

that the normal adjustment setting for heat speed position #3

is 1315 CFM. The + adjustment setting for that position is

1445 CFM and for the − adjustment setting is 1185 CFM.

After the adjustment setting has been determined, chose the

remainder speed jumper settings from those offered in the

table in that row.

The TEST pin is available to bypass the BDC3 control and

run the motor at approximately 70% to test that the motor is

operational. This is beneficial primarily in troubleshooting.

G must be energized for motor to run.

COOL"

The COOL jumper is used to determine the CFM during

either 1) cooling or 2) heat pump operation without a call for

electric heat. These jumper selections are activated for

cooling when Y2 and DS terminals in the CBX32MV are

energized and for heating when Y2 is energized.

Applications without the Lennox SignatureStatt or

TM

EfficiencyPlus

CCB1 humidity control will provide 70% of

the COOL CFM during first−stage cooling for two−speed

outdoor units. Units built prior to August 2002, will provide

either 60% (−048, −060 series units) or 65% (−036 series

units) of the COOL CFM during first stage cooling for two

stage outdoor units. 100% of COOL speed is provided for

systems with a single−speed outdoor units.

The DELAY jumper is used to set the specific motor fan

mode of operation during cooling. Depending on the

application, one of four fan options may be chosen by

moving the jumper pins to the appropriate set of pins.

Options 1, 2, 3, or 4 will have an increased dehumidification

effect on the system. Option 1 will have the least effect and

option 4 will have the greatest effect.

Applications with the EfficiencyPlus CCB1 humidity

control create different CFM volumes. For example,

during a first−stage cooling call (two−speed outdoor unit)

with no demand from the CCB1, the air volume is 40% of

the COOL jumper selection. For a normal COOL (Pin #2

setting for CBX32MV−036), the CFM is 1125; the reduced

speed is 450 CFM (1125 x 40% = 450). This arrangement

provides for additional dehumidification during standard

first stage cooling. See tables 10 and 11 for various

scenarios concerning use of the CCB1 humidity control

and the CBX32MV series unit.

Applications with the Lennox SignatureStat but no

demand for de−humidification will operate as follows:

during a first−stage cooling call (two−stage outdoor unit),

the air volume is 70% of the COOL jumper selection. For a

normal COOL (Pin #2 setting for CBX32MV−036), the

CFM is 1125; the reduced speed is 788 CFM (1125 x 70% =

788). This arrangement provides for additional

dehumidification during standard first stage cooling. See

tables 12 and 13 for various scenarios concerning use of

the SignatureStat and the CBX32MV series unit.

For applications with Harmonyr zone control, the blower

CFM volume is determined by the Harmony control center.

This speed is not adjustable. See footnotes in the blower

tables (table of contents).

Page 12

Page 13

CBX32MV units built prior to February 2003

#1 PIN JUMPERED

A−Motor runs at 100% until demand is satisfied.

B− Once demand is met, motor ramps down to off.

A B

OFF

A

100% CFM

COOLING DEMAND

* CB32XMV units date coded prior to 2−2006 will delay 60 seconds

B

100% CFM

(*45 seconds)

C

OFF

100% CFM

COOLING

DEMAND

OFFOFF

#2 PIN JUMPERED

A−Motor runs at 82% for approximately 7−1/2 minutes. If

demand has not been satisfied after 7−1/2 minutes,

B−motor runs at 100% until demand is satisfied.

C− Once demand is met, motor ramps down to off.

C

OFF

OFF

A

7 1/2 MIN

82%CFM

B

100% CFM

COOLING DEMAND

#3 PIN JUMPERED

A−Motor runs at 50% for 1/2 minute. B−Motor then runs at

82% for approximately 7−1/2 minutes. If demand has not

been satisfied after 7−1/2 minutes. C−Motor runs at 100%

until demand is satisfied. D− Once demand is met, motor

ramps down to off.

C D

100% CFM

OFF

OFF

A

1/2 MIN

50% CFM

B

7 1/2 MIN

82% CFM

COOLING DEMAND

#4 PIN JUMPERED

A−Motor runs at 50% for 1/2 minute. B−Motor then runs at

82% for approximately 7−1/2 minutes. If demand has not

been satisfied after 7−1/2 minutes. C−Motor runs at 100%

until demand is satisfied. D− Once demand is met, motor

runs at 50% for 1/2 minute then E− Motor ramps down to off.

C D

100%

CFM

1/2 MIN

50% CFM

E

OFF

OFF

A

1/2 MIN

50% CFM

B

7 1/2 MIN

82% CFM

COOLING DEMAND

CBX32MV units built February 2003 and later

#1 Pins Jumpered

A− Motor runs at 100% until demand is satisfied.

B− Once demand is met, motor ramps down to stop.

A B

100% CFM

COOLING

DEMAND

#2 Pins Jumpered

A− Motor runs at 100% until demand is satisfied.

B− Once demand is met, motor runs at 100% for 45*

seconds.

C− Motor ramps down to stop.

OFFOFF

#3 Pins Jumpered

A− Motor runs at 82% for approximately 7−1/2 minutes. If

demand has not been satisfied after 7−1/2 minutes −

B− Motor runs at 100% until demand is satisfied.

C− Once demand is met, motor ramps down to stop.

C

OFF

OFF

A

7 1/2 MIN

82%CFM

B

100% CFM

COOLING DEMAND

#4 Pins Jumpered

A− Motor runs at 50% for 30 seconds.

B− Motor then runs at 82% for approximately 7−1/2

minutes. If demand has not been satisfied after 7−1/2

minutes,

C− Motor runs at 100% until demand is satisfied.

D− Once demand is met, motor runs at 50% for 30

seconds.

E− Motor ramps down to stop.

C D

100%

CFM

1/2 MIN

50% CFM

E

OFF

OFF

A

1/2 MIN

50% CFM

B

7 1/2 MIN

82% CFM

COOLING DEMAND

III−VARIABLE SPEED MOTOR

TROUBLESHOOTING

DO

• Check motor, controls, wiring and connections

thoroughly before replacing.

• Use proper replacement parts for motor and control

model numbers.

• Keep duct static to a minimum.

• Size equipment properly.

• Check orientation before inserting motor connector.

DON’T

• Automatically assume the motor is bad.

• Locate connectors above 7 and 4 o’clock positions.

• Replace a control or motor number with an

unauthorized replacement.

• Use high pressure drop filters.

• Use restricted returns.

• Oversize systems then compensate with low airflow.

MOISTURE CHECK

• Connectors should point downward.

• Arrange harness with drip loop under motor.

• Check condensate drain plug.

• Check for airflow (too much latent capacity).

• Check for undercharged condition.

• Check for plug leaks in return ducts, cabinet.

Page 13

Page 14

MOTOR CHECK

Kit #70J11 can be used to check the motor. The kit is

available at the Lennox parts center. If not using the kit,

follow the procedure below. These settings and jumper

placements will bypass the BDC3 control board and

confirm correct motor operation.

Symptom Cause/Procedure

Motor rocks slightly

when starting

Motor will not start,

no movement

Motor rocks, but

won’t start

Motor starts, but

varies up and down

or intermittent

Motor "Hunts" or

"Puffs" at high CFM

Stays at low CFM

despite system call

for cool or heat CFM

Stays at high CFM

Blower will not shut

off

Air noise

Noisy Blower or

cabinet

Motor failure has

occurred and

moisture is present

• Disconnect power to the unit.

• Change delay pin setting on the BDC3 board to #1

• Remove wires from terminal strips in control box.

• Install jumpers between "R" and "Y1" and "R

and "G"

• Turn on power to unit. Blower should operate on

60%, 65% or 70% of cool speed.

• When check is complete disconnect power and

replace delay setting to original position.

This is normal start−up for the variable speed

motor

• Check power at motor

• Check low voltage (24vac R to C) at motor

• Check low voltage connection (G, Y, R, C) at

motor.

• Check for unseated pins on motor harness.

• Test with temporary jumper between R−G.

• Check motor for tight shaft.

• Run moisture check.

• Check for loose or compliant motor mount.

• Make sure blower wheel is tight on shaft.

• Check line voltage for variation or "sag."

• Check low voltage connections (G, Y, R, C)

at motor

• Check for unseated pins in motor harness.

• Check "DS" on terminal strip for CFM

command

• Check system controls thermostat.

• Perform moisture check.

If removing panel or filter reduces "Puffing"

reduce restriction or reduce max airflow.

• Check low voltage thermostat wires and

connections.

• Verify fan is not in delay mode.

• Check "R" missing/not connected to motor.

• Perform motor check.

• Check "R" connection at motor.

• Check fan delay, wait until complete.

• Perform motor check.

• Current leakage from controls into G, Y or

W?

• Check for Triac switched thermostat or solid

state relay.

• Check for proper airflow setting.

• Check/replace filter.

• Use low pressure drop filter.

• Check/correct duct restrictions.

• Check for loose blower housing, panels, etc

• If high static causing noise, check for air

whistling through seams in ducts, cabinets or

panels.

• Check cabinet/duct for deformation.

Replace motor and perform moisture check.

*60/65/70% OF COOL SPEED

*Reduced blower speed for production August 2002 and later

is 70% of COOL speed for ALL model units. Reduced blower

speed for production prior to August 2002 is 65% of COOL for

the −036 units and 60% of COOL for −048 and −060 series

units.

COOL SPEED

• Disconnect power to unit.

• Change delay pin setting on the BDC3 board to #1

• Remove wires from terminal strips in control box.

• Install jumpers between "R" and "Y1", "R" and

"Y2","R" and "DS"and "R" and "G".

• Turn on power to unit. Blower should operate on

cool speed.

• When check is complete disconnect power and

replace delay setting to original position.

HEAT SPEED

• Disconnect power to the unit.

• Change delay pin setting on the BDC3 board to #1

• Remove wires from terminal strips in control box.

• Install jumper between "R" and "W1".

• Turn on power to unit. Blower should operate on

heat speed.

• When check is complete disconnect power and

replace delay setting to original position.

Notes on 5 Pin AC Line Connection

• The motor connects directly to the line.

• Pins 1 & 2 are jumpered in the harness for 115V

operation.

• Make sure power is off before inserting power

connector.

• Plug is polarized.

Notes on 16 Pin Control Connection

• Control functions (G, Y1, Y2) may be active at greater

than .5 x control transformer voltage.

• Do not apply 24vac to either "Out" pin (8 or16).

• High voltage on control pins will destroy motor.

• Make sure pins are fully seated in connector and

housing.

• Verify common connection from transformer (C or B)

to C1, C2 (Pin 1 and Pin 3).

• Once common is verified, test motor by applying

24vac (R) to control pins.

(See Figure 6)

(See Figure 6)

Motor Connectors

(Cable Half)

5 Pin Power

connector

16 Pin Control

Connector

Out −

Adjust

Y1

Cool

Delay

Common 2

W/W1

Common 1

AC Line

AC Line

Gnd

Line 1 and 2 will be

connected for 120 Vac

applications only

Out+

G (fan)

Y/Y2

EM ht/W2

24Vac (R)

Heat

DS/Pwn (Speed)

O (Rev Valve)

FIGURE 6

Page 14

Page 15

IV−OPTIONAL ECB29/31 ELECTRIC HEAT

A−Matchups and Ratings

Tables 4, 5 and 6 show all approved CBX32MV to ECB29

matchups and electrical ratings.

B−Electric Heat Components

ECB29 parts arrangement is shown in figures 7 through 10. All

electric heat sections consist of components mounted to the

electric heat vestibule panel and electric heating elements

exposed directly to the air stream. 208/230V electric heat

sections may be equipped with circuit breakers. The circuit

breakers are designated by CB in the model number.

1−Primary(S15) & Secondary(S20) Temperature Limits

Both the primary (S15) and secondary (S20) limits are

located on the electric heat vestibule panel and are

exposed directly to the air stream through an opening in

the panel. The high temperature limits are SPST N.C.

limits with the primary limit being an auto-reset limit and the

secondary limit being a one-time" limit. One-time limits

must be replaced when opened. The limits are factory set

and are not adjustable.

208/230 Volt Electric Heat Sections

Each stage of the 208/230 electric heat is protected

by a primary (S15) and secondary (S20) high

temperature limit. Both S15 and S20 are located in the

same housing. Each stage uses the same style of limits.

Both the primary and secondary limits are wired in series

with a heat element. When either S15 or S20 opens, the

corresponding heat element is de-energized. All

other heating elements remain energized. The primary

high temperature limit opens at 150_F +

2.8_C) on a temperature rise and automatically resets

at 110_F +

fall. The secondary high temperature limit opens at

333_F +

rise. If the secondary limit opens it must be replaced.

2−Electric Heat Sequencer Relays

(K32, K33, K34, K35, and K116) (208/230 volt only)

Relays K32, K33, K34, K35 and K116 are N.O.

sequencer relays with a resistive element for a coil

and a bi-metal disk which actuates the contacts. The

relays are located on the electric heat vestibule panel and

are energized by a 24V heating demand (W1, W2, and

W3) via jack/plug 2 (J2), which is used to connect electric

heat to the blower coil control circuit. When energized, the

internal resistance heats the bi-metal disk causing the

9_F (43.3_C + 5.0_C) on a temperature

10_F (167.2_C + 5.6_C) on a temperature

5_F (65.5_C +

contacts to close. When the relay is de-energized, t h e

disk cools and the contacts open. The relays

energize different stages of heat, as well as the

blower. The blower is always first on and last off.

3−Circuit Breaker (CB1, CB2, and CB3)

(208/230 volt only)

Line voltage connections are made to circuit breakers

CB1, CB2, and CB3 in the electric heat sections with

circuit breakers (designated by CB in the model numbers).

Table 3 shows the amperage rating for each circuit

breaker used. Single-phase electric heat uses two pole

circuit breakers; while three-phase electric heat uses three

pole circuit breakers.

TABLE 3

ECB29 CIRCUIT BREAKERS

UNIT

ECB29-5CB-1 (P) 30 AMP −−− −−−

ECB29-8CB-1 (P) 50 AMP −−− −−−

ECB29-12.5CB-1 (P) 25 AMP 50 AMP −−−

ECB29-15CB-1 (P) 30 AMP 60 AMP −−−

ECB29-25CB-1 (P) 50 AMP 50 AMP 50 AMP

ECB29-30CB-1 (P) 60 AMP 60 AMP 60 AMP

ECB29-15CB-1 (Y) 60 AMP −−− −−−

ECB29-20CB-1 (Y) 40 AMP 35 AMP −−−

ECB29-25CB-1 (Y) 50 AMP 35 AMP −−−

Note: Do not remove patch plate or insulation on units

without circuit breakers!!

4−Terminal Strip (TB2) 208/230 volt only)

For the electric heat sections without circuit breakers or

fuses, line voltage connections are made to terminal strip

TB2. The terminal strip is located in the lower left corner of

the electric heat vestibule panel. Single-phase electric

heat uses two pole terminal strips; while three-phase

electric heat uses three pole terminal strips.

5−Heating Elements (HE1 through HE6)

Heating elements are composed of helix wound bare

nichrome wire exposed directly to the air stream. The

elements are supported by insulators mounted to th e wire

frame. For single phase applications, one element is

used per stage. Each stage is energized

independently by the corresponding relay located

on the electric heat vestibule arranged in a three

phase delta. Once energized, heat transfer is

instantaneous. High temperature protection is

provided by primary and secondary high

temperature limits.

CB1

AMPS

CB2

AMPS

CB3

AMPS

Page 15

Page 16

TABLE 4 − ELECTRIC HEAT DATA

SINGLE PHASE ELECTRIC HEAT

Model Number

2.5 kW

4 lbs.

ECB29-2.5 (28K30)

Terminal Block

1

No. of

Vol ts

Steps

InputkWInput

1

208 1.9 6,400 4.3 17 15 − − − − − − − − − − − − − − −

Btuh

Input

220 2.1 7,200 4.3 17 20 − − − − − − − − − − − − − − −

CBX32MV−018/024 CBX32MV−024/030

3

2

Blower

Motor

Full

Load

Amps

3

Minimum

Circuit

Ampacity

5

Maximum

Overcurrent

Protection

2

Blower

Motor

Full

Load

Amps

Minimum

Circuit

Ampacity

Circuit Circuit

1 21 2

230 2.3 7,800 4.3 18 20 − − − − − − − − − − − − − − −

240 2.5 8,500 4.3 18 20 − − − − − − − − − − − − − − −

5 kW

4 lbs.

ECB29-5 (28K31)

Terminal Block

ECB29-5CB (28K32)

30A Circuit breaker

1

208 3.8 12,800 4.3 28 30 4.3 28 − − − 30 − − −

220 4.2 14,300 4.3 31 35 4.3 31 − − − 35 − − −

230 4.6 15,700 4.3 31 35 4.3 31 − − − 35 − − −

240 5.0 17,100 4.3 31 35 4.3 31 − − − 35 − − −

6 kW

4 lbs.

ECB29-6 (47L22)

Terminal Block

ECB29-6CB (47L23)

35A Circuit breaker

1

208 4.5 15,400 4.3 32 35 4.3 32 − − − 35 − − −

220 5.0 17,100 4.3 37 40 4.3 37 − − − 40 − − −

230 5.5 18,800 4.3 37 40 4.3 37 − − − 40 − − −

240 6.0 20,500 4.3 37 40 4.3 37 − − − 40 − − −

8 kW

5 lbs.

ECB29-8 (28K33)

Terminal Block

ECB29-8CB (28K34)

45A Circuit breaker

2

208 6.0 20,500 4.3 41 45 4.3 41 − − − 45 − − −

220 6.7 22,900 4.3 47 50 4.3 47 − − − 50 − − −

230 7.3 25,100 4.3 47 50 4.3 47 − − − 50 − − −

240 8.0 27,300 4.3 47 50 4.3 47 − − − 50 − − −

9 kW

5 lbs.

ECB29−9CB (10L11)

50A Circuit breaker

ECB29EH-9CB (91K67)

50A Circuit breaker

2

208 6.8 23,100 4.3 46 50 4.3 46 − − − 50 − − −

220 7.6 25,800 4.3 52 60 4.3 52 − − − 60 − − −

230 8.3 28,200 4.3 52 60 4.3 52 − − − 60 − − −

240 9.0 30,700 4.3 52 60 4.3 52 − − − 60 − − −

10 kW

6 lbs.

ECB29−10 (28K35)

Terminal Block

ECB29-10CB (28K36)

60A Circuit breaker

2

208 7.5 25,600 4.3 51 60 − − − − − − − − − − − − − − −

220 8.4 28,700 4.3 53 60 − − − − − − − − − − − − − − −

230 9.2 31,400 4.3 55 60 − − − − − − − − − − − − − − −

240 10.0 34,100 4.3 58 60 − − − − − − − − − − − − − − −

12.5 kW

10 lbs.

ECB29-12.5CB (28K37)

(1) 25A & (1) 50A Circuitbreaker

ECB29EH-12.5CB (91K68)

(1) 25A & (1) 50A Circuitbreaker

3

208 9.4 32,000 − − − − − − − − − 4.3 24 31 25

220 10.5 35,800 − − − − − − − − − 4.3 27 35 30 50

230 11. 5 39,200 − − − − − − − − − 4.3 27 35 30 50

240 12.5 42,600 − − − − − − − − − 4.3 27 35 30 50

15 kW

12 lbs.

(1) 30A & (1) 60A Circuit breaker

(1) 30A & (1) 60A Circuit breaker

ECB29-15CB (28K38)

ECB29EH-15CB (91K69)

3

208 11. 3 38,400 − − − − − − − − − 4.3 28 37 30

220 12.6 43,000 − − − − − − − − − 4.3 31 42 35 60

230 13.8 47,000 − − − − − − − − − 4.3 31 42 35 60

240 15.0 51,200 − − − − − − − − − 4.3 31 42 35 60

NOTE − Circuit 1 Minimum Circuit Ampacity includes the Blower Motor Full Load Amps.

1

Electric heater capacity only does not include additional blower motor heat capacity.

2

Amps shown are for blower motor only.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements. Use wires suitable for at least 167°F (75_C).

4

Bold text indicates that the circuit breaker on CB" circuit breaker models must be replaced with size noted.

5

HACR type circuit breaker or fuse.

5

Maximum

Overcurrent

Protection

4

45

4

50

Page 16

Page 17

TABLE 5 − ELECTRIC HEAT DATA

SINGLE PHASE ELECTRIC HEAT

Model Number

5 kW

4 lbs.

6 kW

4 lbs.

8 kW

5 lbs.

9 kW

5 lbs.

12.5 kW

10 lbs.

15 kW

12 lbs.

20 kW

19 lbs.

(1) 25A & (1) 50A Circuitbreaker

ECB29EH-12.5CB (91K68)

(1) 25A & (1) 50A Circuitbreaker

(1) 30A & (1) 60A Circuit breaker

(1) 30A & (1) 60A Circuit breaker

(1) 50A & (1) 60A Circuit breaker

(1) 50A & (1) 60A Circuit breaker

ECB29-5 (28K31)

Terminal Block

ECB29-5CB (28K32)

30A Circuit breaker

ECB29-6 (47L22)

Terminal Block

ECB29-6CB (47L23)

35A Circuit breaker

ECB29-8 (28K33)

Terminal Block

ECB29-8CB (28K34)

45A Circuit breaker

ECB299CB (10L11)

50A Circuit breaker

ECB29EH-9CB (91K67)

50A Circuit breaker

ECB29-12.5CB (28K37)

ECB29-15CB (28K38)

ECB29EH-15CB (91K69)

ECB29-20CB (11L31)

ECB29EH-20CB (91K70)

CBX32MV−036

3

Minimum

No.

Vol ts

of

InputkWInput

Steps

1

208 3.8 12,800 4.3 28 − − − 30 − − −

1

Input

Btuh

2

Blower

Motor Full

Load Amps

220 4.2 14,300 4.3 31 − − − 35 − − −

230 4.6 15,700 4.3 31 − − − 35 − − −

240 5.0 17,100 4.3 31 − − − 35 − − −

1

208 4.5 15,400 4.3 32 − − − 35 − − −

220 5.0 17,100 4.3 37 − − − 40 − − −

230 5.5 18,800 4.3 37 − − − 40 − − −

240 6.0 20,500 4.3 37 − − − 40 − − −

2

208 6.0 20,500 4.3 41 − − − 45 − − −

220 6.7 22,900 4.3 47 − − − 50 − − −

230 7.3 25,100 4.3 47 − − − 50 − − −

240 8.0 27,300 4.3 47 − − − 50 − − −

2

208 6.8 23,100 4.3 46 − − − 50 − − −

220 7.6 25,800 4.3 52 − − − 60 − − −

230 8.3 28,200 4.3 52 − − − 60 − − −

240 9.0 30,700 4.3 52 − − − 60 − − −

3

208 9.4 32,000 4.3 24 31 25

220 10.5 35,800 4.3 27 35 30 50

230 11 .5 39,200 4.3 27 35 30 50

240 12.5 42,600 4.3 27 35 30 50

3

208 11 .3 38,400 4.3 28 37 30

220 12.6 43,000 4.3 31 42 35 60

230 13.8 47,000 4.3 31 42 35 60

240 15.0 51,200 4.3 31 42 35 60

4

208 15.0 51,200 4.3 47 41 50 60

220 16.8 57,300 4.3 52 46 60 60

230 18.4 62,700 4.3 52 46 60 60

240 20.0 68,200 4.3 52 46 60 60

Circuit

Ampacity

Overcurrent Protection

Circuit Circuit

1 212

5

Maximum

4

45

4

50

THREE PHASE ELECTRIC HEAT

8 kW

5 lbs.

10 kW

6 lbs.

15 kW

12 lbs.

20 kW

19 lbs.

NOTE − Circuit 1 Minimum Circuit Ampacity includes the Blower Motor Full Load Amps.

1

Electric heater capacity only does not include additional blower motor heat capacity.

2

Amps shown are for blower motor only.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements. Use wires suitable for at least 167°F (75_C).

4

Bold text indicates that the circuit breaker on CB" circuit breaker models must be replaced with size noted.

5

HACR type circuit breaker or fuse.

ECB29-8 (28K42)

Terminal Block

ECB29-10 (28K43)

Terminal Block

ECB29-15CB (28K44)

50A Circuit breaker

ECB29-20CB (28K45)

(2) 35A Circuit breaker

3

208 6.0 20,500 4.3 26 − − − 30 − − −

220 6.7 22,900 4.3 29 − − − 30 − − −

230 7.3 25,100 4.3 29 − − − 30 − − −

240 8.0 27,300 4.3 29 − − − 30 − − −

3

208 7.5 25,600 4.3 31 − − − 35 − − −

220 8.4 28,700 4.3 35 − − − 35 − − −

230 9.2 31,400 4.3 35 − − − 35 − − −

240 10.0 34,100 4.3 35 − − − 35 − − −

3

208 11 .3 38,400 4.3 44 − − −

4

45 − − −

220 12.6 43,000 4.3 50 − − − 50 − − −

230 13.5 47,000 4.3 50 − − − 50 − − −

240 15.0 51,200 4.3 50 − − − 50 − − −

6

208 15.0 51,200 4.3 31 21 35

220 16.8 57,300 4.3 35 24 35 35

230 18.4 62,700 4.3 35 24 35 35

240 20.0 68,200 4.3 35 24 35 35

4

30

Page 17

Page 18

TABLE 6 − ELECTRIC HEAT DATA

SINGLE PHASE ELECTRIC HEAT CBX32MV−048, CBX32MV−060 and CBX32MV−068

2

Blower

Motor

Full Load

Amps

5 kW

4 lbs.

Model Number

ECB29-5 (28K31)

ECB29-5CB (28K32)

30A Circuit breaker

Terminal Block

No.

of

Steps

1

1

Volts

InputkWInput

Btuh

Input

208 3.8 12,800 9.1 34 − − − − − − 40 − − − − − −

220 4.2 14,300 9.1 37 − − − − − − 45 − − − − − −

230 4.6 15,700 9.1 37 − − − − − − 45 − − − − − −

240 5.0 17,100 9.1 37 − − − − − − 45 − − − − − −

6 kW

4 lbs.

ECB29-6 (47L22)

Terminal Block

ECB29-6CB (47L23)

35A Circuit breaker

208 4.5 15,400 9.1 36 − − − − − − 45 − − − − − −

1

220 5.0 17,100 9.1 43 − − − − − − 50 − − − − − −

230 5.5 18,800 9.1 43 − − − − − − 50 − − − − − −

240 6.0 20,500 9.1 43 − − − − − − 50 − − − − − −

8 kW

5 lbs.

ECB29-8 (28K33)

Terminal Block

ECB29-8CB (28K34)

45A Circuit breaker

208 6.0 20,500 9.1 47 − − − − − − 50 − − − − − −

2

220 6.7 22,900 9.1 53 − − − − − − 60 − − − − − −

230 7.3 25,100 9.1 53 − − − − − − 60 − − − − − −

240 8.0 27,300 9.1 53 − − − − − − 60 − − − − − −

9 kW

5 lbs.

ECB29-9CB (10L11)

50A Circuit breaker

ECB29EH-9CB (91K67)

50A Circuit breaker

208 6.8 23,100 9.1 52 − − − − − − 60 − − − − − −

2

220 7.6 25,800 9.1 58 − − − − − − 60 − − − − − −

230 8.3 28,200 9.1 58 − − − − − − 60 − − − − − −

240 9.0 30,700 9.1 58 − − − − − − 60 − − − − − −

12.5 kW

10 lbs.

ECB29-12.5CB (28K37)

(1) 25A & (1) 50A Circuit breaker

ECB29EH-12.5CB (91K68)

(1) 25A & (1) 50A Circuit breaker

208 9.4 32,000 9.1 30 31 − − −

3

220 10.5 35,800 9.1 33 35 − − −

230 11.5 39,200 9.1 33 35 − − −

240 12.5 42,600 9.1 33 35 − − −

15 kW

12 lbs.

(1) 30A & (1) 60A Circuit breaker

(1) 30A & (1) 60A Circuit breaker

ECB29-15CB (28K38)

ECB29EH-15CB (91K69)

208 11.3 38,400 9.1 34 37 − − −

3

220 12.6 43,000 9.1 37 42 − − −

230 13.5 47,000 9.1 37 42 − − −

240 15.0 51,200 9.1 37 42 − − −

20 kW

19 lbs.

(1) 50A & (1) 60A Circuit breaker

(1) 50A & (1) 60A Circuit breaker

ECB29-20CB (11L31)

ECB29EH-20CB (91K70)

208 15.0 51,200 9.1 53 41 − − − 60 60 − − −

4

220 16.8 57,300 9.1 58 46 − − − 60 60 − − −

230 18.4 62,700 9.1 58 46 − − − 60 60 − − −

240 20.0 68,200 9.1 58 46 − − − 60 60 − − −

25 kW

19 lbs.

ECB29-25CB (28K40)

(3) 50A Breakers

208 18.8 64,100 9.1 49 31 31 50

6

220 21.0 71,700 9.1 54 35 35 60 50 50

230 23.0 78,300 9.1 54 35 35 60 50 50

240 25.0 85,300 9.1 54 35 35 60 50 50

THREE PHASE ELECTRIC HEAT

8 kW

5 lbs.

10 kW

6 lbs.

15 kW

12 lbs.

20 kW

19 lbs.

25 kW

19 lbs.

NOTE − Circuit 1 Minimum Circuit Ampacity includes the Blower Motor Full Load Amps.

1

Electric heater capacity only does not include additional blower motor heat capacity.

2

Amps shown are for blower motor only.

3

Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements. Use wires suitable for at least 167°F (75_C).

4

Bold text indicates that the circuit breaker on CB" circuit breaker models must be replaced with size noted.

5

HACR type circuit breaker or fuse.

ECB29-8 (28K42)

Terminal block

ECB29-10 (28K43)

Terminal block

ECB29-15CB (28K44)

50A Circuit breaker

ECB29-20CB (28K45)

(2) 35A Circuit breakers

ECB29-25CB (28K46)

(2) 45A Circuit breakers

208 6.0 20,500 9.1 32 − − − − − − 40 − − − − − −

3

220 6.7 22,900 9.1 35 − − − − − − 40 − − − − − −

230 7.3 25,100 9.1 35 − − − − − − 40 − − − − − −

240 8.0 27,300 9.1 35 − − − − − − 40 − − − − − −

208 7.5 25,600 9.1 37 − − − − − − 45 − − − − − −

3

220 8.4 28,700 9.1 41 − − − − − − 50 − − − − − −

230 9.2 31,400 9.1 41 − − − − − − 50 − − − − − −

240 10.0 34,100 9.1 41 − − − − − − 50 − − − − − −

208 11.3 38,400 9.1 50 − − − − − − 60 − − − − − −

3

220 12.6 43,000 9.1 56 − − − − − − 60 − − − − − −

230 13.5 47,000 9.1 56 − − − − − − 60 − − − − − −

240 15.0 51,200 9.1 56 − − − − − − 60 − − − − − −

208 15.0 51,200 9.1 37 21 − − −

6

220 16.8 57,300 9.1 41 24 − − −

230 18.4 62,700 9.1 41 24 − − −

240 20.0 68,200 9.1 41 24 − − −

208 18.8 64,100 9.1 44 27 − − − 50

6

220 21.0 71,700 9.1 49 30 − − −

230 23.0 78,300 9.1 49 30 − − −

240 25.0 85,300 9.1 49 30 − − −

3

Minimum

Circuit Ampacity

5

Maximum

Overcurrent Protection

Circuit1Circuit2Circuit3Circuit1Circuit2Circuit

4

40

4

45 50 − − −

4

45 50 − − −

4

4

40

4

4

45 60 − − −

4

45 60 − − −

4

45

4

50 35 − − −

4

50 35 − − −

4

50 35 − − −

4

60 45 − − −

4

4

60 45 − − −

4

45 − − −

45 50 − − −

4

50 − − −

45 60 − − −

4

45

4

30 − − −

4

40 − − −

60 45 − − −

3

4

45

Page 18

Page 19

ECB29-5, -5CB 208/230 SINGLE−PHASE

ELECTRIC HEAT VESTIBULE PARTS ARRANGEMENT

ELECTRIC HEAT

VESTIBULE PANEL

TERMINAL BLOCK

(TB2)

ELECTRIC HEAT

CIRCUIT BREAKER

(CB1)

SEQUENCER RELAY (K32)

ELECTRIC HEAT

ELEMENT (HE1)

PRIMARY LIMIT (S15)

& SECONDARY LIMIT (S20)

ECB29−8 CIRCUIT

BREAKER (CB1)

FIGURE 7

ECB29-8 AND -8CB 208/230 SINGLE−PHASE

ELECTRIC HEAT VESTIBULE PARTS ARRANGEMENT

ELECTRIC HEAT

VESTIBULE PANEL

ELECTRIC HEAT

ELEMENT (HE1)

PRIMARY LIMIT (S15)

& SECONDARY LIMIT (S20)

TERMINAL BLOCK

(TB2)

ELECTRIC HEAT

SEQUENCER RELAY (K33)

ELECTRIC HEAT

SEQUENCER RELAY (K32)

ELECTRIC HEAT

ELEMENT (HE2)

FIGURE 8

Page 19

Page 20

CIRCUIT BREAKER

(CB1)

ECB29-8,−10 208/230 THREE−PHASE

ECB29-12.5CB, -15CB 208/230 SINGLE & THREE−PHASE

ELECTRIC HEAT VESTIBULE PARTS ARRANGEMENT

ELECTRIC HEAT

ELEMENT (HE3)

ELECTRIC HEAT

SEQUENCER RELAY (K32)

ELECTRIC HEAT

VESTIBULE PANEL

ELECTRIC HEAT

SEQUENCER RELAY (K33)

TERMINAL BLOCK

(TB2)

PRIMARY LIMIT (S15)

& SECONDARY LIMIT (S20)

ELECTRIC HEAT

ELEMENT (HE2)

ELECTRIC HEAT

ELEMENT (HE1)

PRIMARY LIMIT (S15)

& SECONDARY LIMIT (S20)

ELECTRIC HEAT

VESTIBULE PANEL

PRIMARY LIMIT (S15)

& SECONDARY LIMIT (S20)

CIRCUIT BREAKER

CIRCUIT BREAKER

(CB1)

CIRCUIT BREAKER

(CB2)

ECB29−20CB,−25CB 208/230 THREE−PHASE

ELECTRIC HEAT VESTIBULE PARTS ARRANGEMENT

ELECTRIC HEAT

SEQUENCER RELAY (K33)

(CB2)

FIGURE 9

ECB29-25CB, -208/230 SINGLE−PHASE

ELECTRIC HEAT

ELEMENT (HE6)

ELECTRIC HEAT

ELEMENT (HE1 & HE2)

(not shown)

ELECTRIC HEAT

ELEMENT (HE4)

ELECTRIC HEAT

ELEMENT (HE3)

ELECTRIC HEAT

ELEMENT (HE5)

PRIMARY LIMIT (S15)

& SECONDARY LIMIT (S20)

ELECTRIC HEAT

SEQUENCER RELAY (K32)

ELECTRIC HEAT

SEQUENCER RELAY (K116)

CIRCUIT BREAKER

(CB3)

ELECTRIC HEAT

SEQUENCER RELAY (K35)

ELECTRIC HEAT

SEQUENCER RELAY (K34)

FIGURE 10

Page 20

Page 21

V− OPTIONAL HUMIDITY CONTROL (A20)

EfficiencyPlus PARTS IDENTIFICATION

HINGES

SLIDE

(ON CIRCUIT BOARD)

COVER

VERTICAL SLIDE CONTROL

(control setpoint)

NOTE−TO REMOVE COVER, HOLD BASE SECTION

AND GENTLY PULL THE COVER OUT AT THE BOTTOM AND PIVOT IT UP AND AWAY FROM BASE.

BASE SECTION

CONTROL WIRE ENTRY

TERMINAL BLOCK

INDICATING LIGHTS

HUMIDITY SENSOR

FIGURE 11

A−CCB1

Optional Comfort Control Board (CCB1) A20 may be

installed adjacent to the indoor thermostat (figure 11). The

control monitors indoor humidity conditions and creates a

dehumidification demand in response to indoor humidity

just as the thermostat creates a cooling demand in

response to indoor temperature. The CCB1 works in

combination with the indoor thermostat to adjust

compressor speed and indoor blower speed. Although the

control provides a dehumidification demand, only the

thermostat can directly control compressor operation. The

CCB1 cannot call for a compressor cycle by itself.

Principles of Cooling with Drier Air

The humidity comfort range for humans is between 40%

and 60% relative humidity (RH). A vertical slide on the

control allows the humidity setpoint to be adjusted within

that comfort range. 50% RH is the recommended initial

setpoint until personal comfort level is established. The

personal comfort level will vary with humidity as with

temperature. For example, if air at 75°F and 50% RH is

changed to 60% RH, the air will feel" much warmer.

Likewise, if the air is reduced to 40% RH, it will feel" much

cooler.

Even when inactive, the body evaporates a large amount of

moisture away from the skin. This evaporation produces a

cooling effect (during wintertime this phenomenon is called

wind-chill"). Dry air is capable of absorbing more moisture

away from the skin thereby increasing the cooling effect.

When the CCB1 senses that the indoor humidity level is

above the control setpoint, the control places the

CBX32MV and outdoor unit in a dehumidification mode .

To produce drier air, the CBX32MV will slow down the

speed of the air crossing the indoor coil. Because the air is

moving much slower than normal, the indoor coil is allowed

more time to remove moisture from the air (a higher

percentage of the air passing over the coil is cooled to its

dew point removing more moisture). At the same time the

two-speed outdoor unit will switch to high-speed to produce

a colder indoor coil. The colder indoor coil and slower

moving air combine to produce drier supply air.

NOTE−The indoor blower speed is reduced in order to

slow the air speed across the indoor coil. The supply air

exiting the unit may not feel as forceful. This is normal.

Remember that when the unit is in dehumidification

mode, the comfort level is increased because the unit is

producing cooler, drier air.

The exact sequence of operation to produce cooler, drier air

is described in the following section.

Operation

The CCB1 operates only during cooling mode. During

normal cooling operation, when there is no indoor humidity

demand, the unit operates as a straight two-speed cooling

system. First stage thermostat demand energizes the

compressor and indoor blower on low speed. Increased

cooling demand energizes the compressor and indoor

blower on high speed.

The control is equipped with a row of orange LED lights on

its face which indicate the amount of relative humidity

demand present. When one or more LEDs are lit, the

control signals the CBX32MV to begin dehumidification

mode. Tables 10 and 11 shows system response to

thermostat and CCB1 demand.

Calibration Precautions

Extreme care should be taken to avoid exposing the CCB1

to fumes from household chemicals. The humidity sensing

element in the CCB1 is a precise component which can be

damaged or the calibration changed by household

chemicals and cleaning agents. Make sure all household

chemicals are stored in a different room in the building.

Also, use only mild diluted soapy water when cleaning the

CCB1 cover or the area surrounding the CCB1. The

sensing element cannot be field calibrated. The CCB1

contains no field repairable parts and must be replaced

when damaged in this manner.

Agents which can damage the CCB1 include alcohol,

benzene, chlorine and chlorine based solutions, acetone

(nail polish remover), bug sprays and other household

cleaners.

Calibration can also be adversely affected by the

placement of the CCB1 with respect to the indoor

thermostat, exterior doors and windows and supply air

registers. Most thermostats have anticipation resistors

Page 21

Page 22

which give off heat. If the CCB1 is installed directly above

the indoor thermostat, the humidity sensor calibration will

be thrown off. If the CCB1 is installed directly above the

indoor thermostat, it should be relocated to the side of the

thermostat. Refer to CCB1 installation instructions.

Other Conditions Which Adversely Affect

CCB1 Performance

Blower speed selection can adversely affect CCB1

performance. Higher blower speeds should be selected to

provide maximum sensible cooling, while lower blower

speeds should be selected to provide maximum humidity

removal. Refer to CBX32MV and CCB1 installation

instructions.

It is recommended that the indoor blower be left in AUTO

mode at all times. During dehumidification mode, the

indoor coil and drain pan may become saturated with

moisture. If the indoor blower is left in ON mode, much of

that moisture can be re-evaporated into the living space

between thermostat demands. This can create a constant

demand for humidity removal and may cause extended

compressor run times. Refer to table 7 for jumpers per

application. CBX32MV units manufactured January 2002

and later, will have factory installed jumpers. Remove

jumpers not used.

TABLE 7

JUMPERS REQUIRED

DS to Y1 and

Y1 to Y2

DS to Y1 and

Y1 to Y2 and

O to R

DS to Y1 and

O to R

Y1 to Y2 and

O to R

Without CCB1

Humidity

Control

With CCB1 Hu-

midity

Control

Heat Pump

Condensing

Unit

Heat Pump

Condensing

Unit

Single Speed

Two Speed DS to Y1

Single Speed

Two Speed

Single Speed Y1 to Y2

Two Speed None

Single Speed

Two Speed O to R

The CCB1 may become indefinitely latched in the

dehumidification mode when power to the unit is turned off.

This condition can be caused by turning off power while

dehumidification demand is present, then turning on power

when dehumidification demand is satisfied. If the CCB1

becomes stuck in this manner, it can be reset by removing

thermostat demand then moving the CCB1 slide switch all

the way down and back up to its setpoint.

How to unlatch CCB1

1− Force a cooling demand by setting thermostat to COOL

mode and by moving thermostat lever to lowest

position.

2− Move CCB1 slide control down to 40% relative

humidity. CCB1 lights should come on.

3− Now, move CCB1 slide control back up to 60% relative

humidity. The lights should go off.

4− Remove thermostat demand by moving thermostat

lever to cycle unit off.

Applications with the EfficiencyPlus CCB1 humidity control

create different CFM volumes. For example, during a

first−stage cooling call (two−speed outdoor unit) with no

demand from the CCB1, the air volume is 40% of the COOL

jumper selection. For a normal COOL (Pin #2 setting for

CBX32MV−036), the CFM is 1125; the reduced speed is

450 CFM (1125 x 40% = 450). This arrangement provides

for additional dehumidification during first stage cooling.

See tables 10 and 11 for various scenarios concerning use

of the CCB1 humidity control and the CBX32MV series unit.

B−SignatureStatt or ComfortSense® 7000

The reference thermostats can be installed in place of the

indoor thermostat. The thermostat monitors indoor

humidity conditions and creates a dehumidification

demand in response to indoor humidity just as it creates a

cooling demand in response to indoor temperature. The

SignatureStat adjusts compressor speed and indoor

blower speed to maintain humidity at a comfortable level.

Principles of Cooling with Drier Air

The humidity comfort range for humans is between 40%

and 60% relative humidity (RH). 50% RH is the

recommended initial setpoint until personal comfort level is

established. The personal comfort level will vary with

humidity as with temperature. For example, if air at 75°F

and 50% RH is changed to 60% RH, the air will feel" much

warmer. Likewise, if the air is reduced to 40% RH, it will

feel" much cooler.

Even when inactive, the body evaporates a large amount of

moisture away from the skin. This evaporation produces a

cooling effect (during wintertime this phenomenon is called

wind-chill"). Dry air is capable of absorbing more moisture

away from the skin thereby increasing the cooling effect.

When the thermostat senses that the indoor humidity level

is above the control setpoint, the control places the

CBX32MV and outdoor unit in a dehumidification mode.

To produce drier air, the CBX32MV will slow down the