Page 1

INSTALLATION

E2006 Lennox Industries Inc.

Dallas, Texas, USA

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE

WARNING

Due to higher operating pressures, CBWMV units

must not be applied to steam boiler systems.

CAUTION

Unit is designed to be used with non−potable boiler

systems only.

CAUTION

Physical contact with metal edges and corners

while applying excessive force or rapid motion can

result in personal injury. Be aware of, and use

caution when working near these areas during

installation or while servicing this equipment.

Introduction

The multi−positional Dave Lennox Signaturet Collection

CBWMV air handler/hot water coil unit is designed to be

used with non-potable boiler systems for warm air heating.

A variety of Lennox air conditioning systems may be applied to the CBWMV unit for optional cooling.

INSTRUCTIONS

CBWMV Series Units

AIR HANDLERS

505,047M

09/06

Supersedes 02/06

Table of Contents

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shipping & Packing List 1. . . . . . . . . . . . . . . . . . . . . . . .

CBWMV Unit Dimensions 2. . . . . . . . . . . . . . . . . . . . . .

General 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CBWMV Unit Parts Arrangement 3. . . . . . . . . . . . . . . .

CBWMV Unit Parts Description 3. . . . . . . . . . . . . . . . . .

CBWMV Unit Optional Accessories 3. . . . . . . . . . . . . .

Requirements 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation − Setting Equipment 4. . . . . . . . . . . . . . . . . .

Duct System 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Return Air Opening Guidelines 6. . . . . . . . . . . . . . . . . .

Filter Assembly & Filters 8. . . . . . . . . . . . . . . . . . . . . . .

Plumbing 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Freezestat Operation 12. . . . . . . . . . . . . . . . . . . . . . . . . .

BDC3 Variable Blower Control Board 12. . . . . . . . . . . . .

Blower Speed Adjustments 12. . . . . . . . . . . . . . . . . . . . .

Initial Air System Purging 16. . . . . . . . . . . . . . . . . . . . . . .

System Adjustments 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Annual Service 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Filters 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Winterizing the CBWMV Unit 17. . . . . . . . . . . . . . . . . . . .

Repair Parts List 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting:

Continuous Fan Sequence of Operation 18. . . . . . . . . .

Cooling Sequence of Operation 19. . . . . . . . . . . . . . . . .

Heating Sequence of Operation 20. . . . . . . . . . . . . . . . .

Shipping & Packing List

1 − CBWMV Air Handler [NOTE − Includes freezestat

mounted to the manifold.]

1 − Bag assembly containing:

1 − Electrical make−up box

1 − Copper fitting

1 − Snap bushing

2 − Water line grommets

3 − Wire nuts

2−7/8" cabinet plugs

Check equipment for shipping damage. If you find any

damage, immediately contact the last carrier.

Litho U.S.A.

09/06 505,047M

Page 1

*2P0906* *P505047M*

Page 2

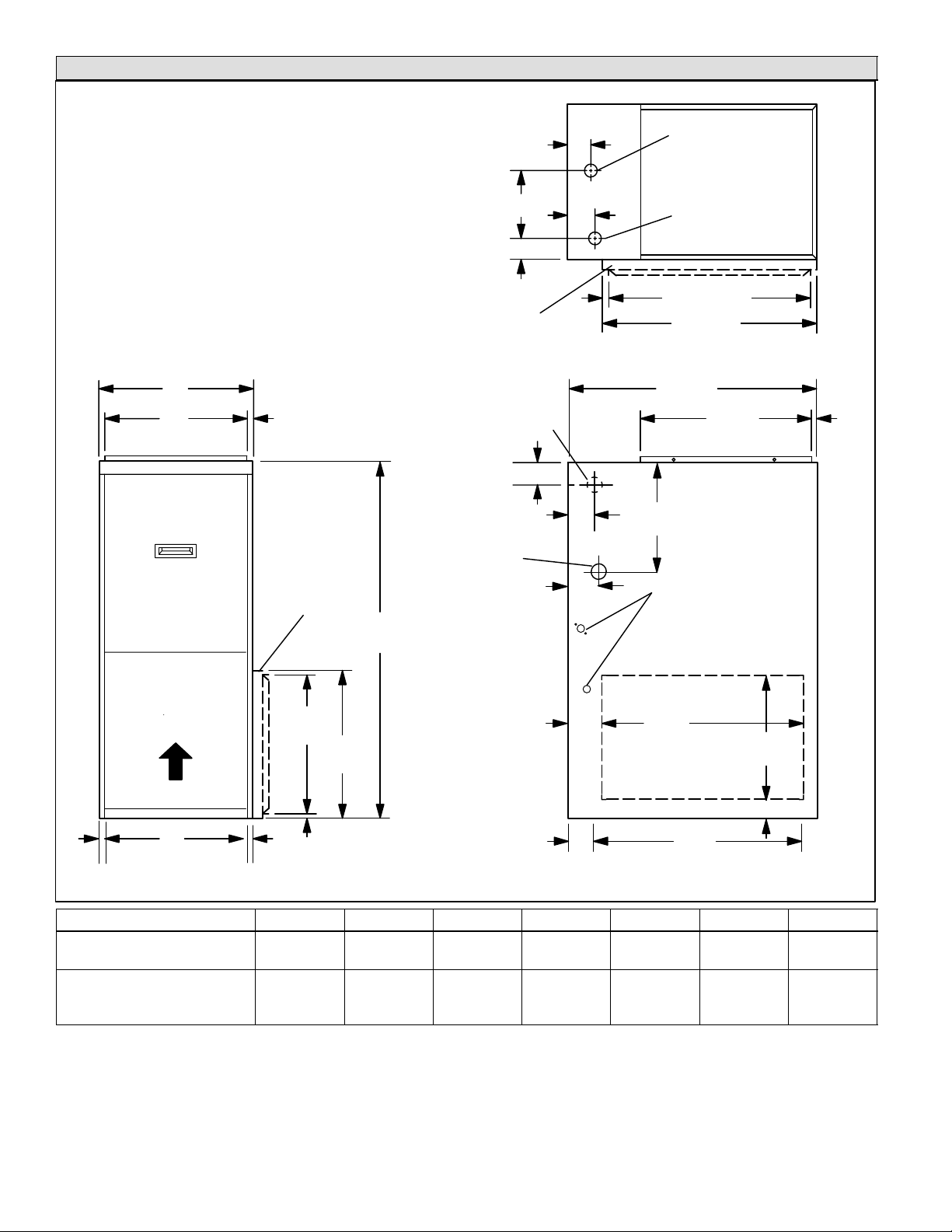

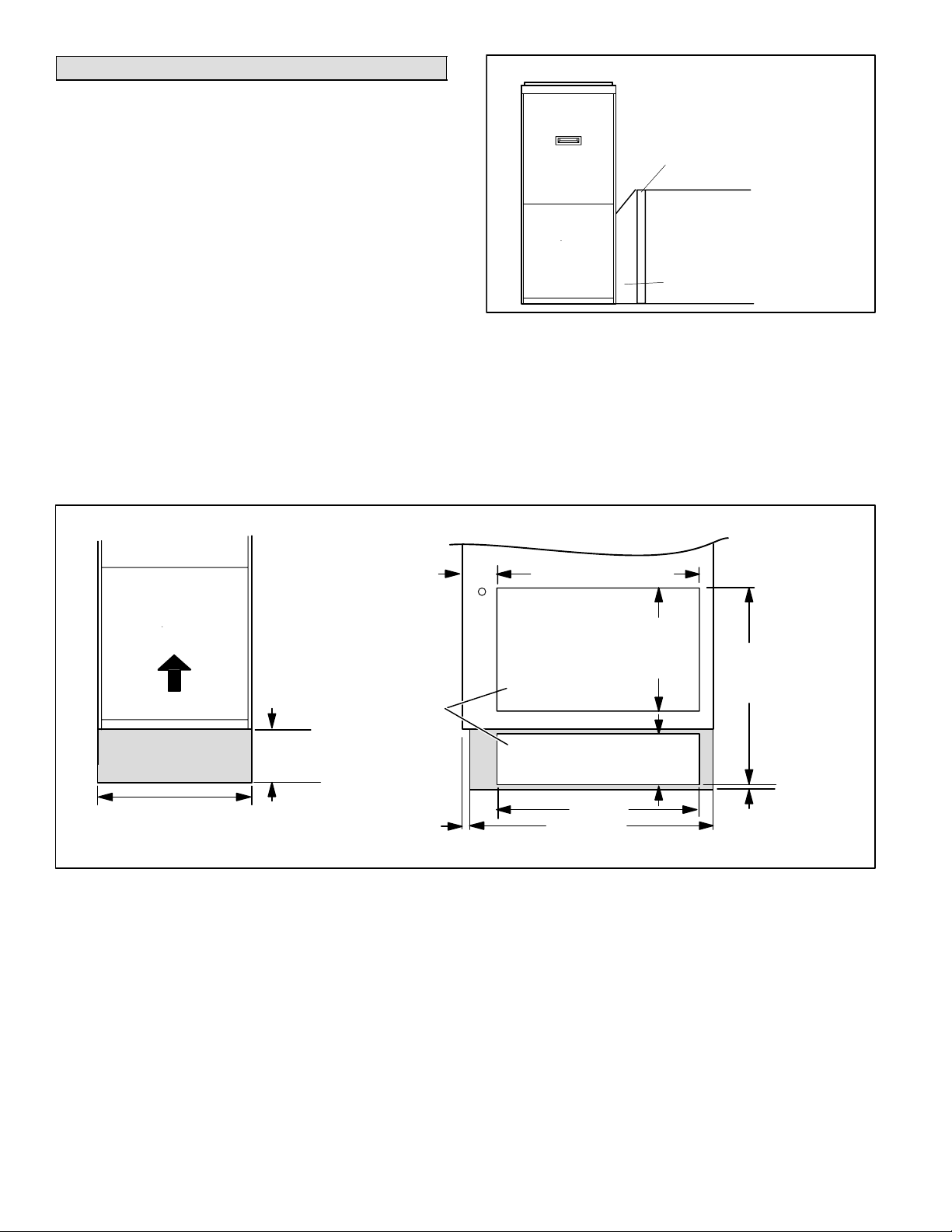

CBWMV Unit Dimensions − inches (mm)

*NOTE − Single side inlet applications result in approximately

4 percent reduction of CFM on B−size units and approximately

5 percent reduction of CFM on C−size units.

OPTIONAL EXTERNAL SIDE RETURN

AIR FILTER KIT (Either Side) − Not for

use with optional Return Air Base.

WATER INLET

G

SUPPLY AIR

OPENING

F

D

E

WATER OUTLET

23-3/4 (603)

25 (635)

TOP VIEW

3/4 (19)

A

B

AIR FLOW

C

*Bottom Return

Air Opening

FRONT VIEW SIDE VIEW

3/4 (19)

9/16

(14)

OPTIONAL

EXTERNAL

SIDE RETURN

AIR FILTER KIT

(Either Side)

14−3/4

(375)

16

(406)

5/8

(16)

40

(1016)

ALTERNATE WATER

INLET (far side)

1−1/4" (32)

1−3/4" (44)

ALTERNATE

WATER OUTLET

2"

(51)

4

(102)

RETURN CUTOUT

4−1/4

*Bottom Return Air Opening

(108)

28−1/2

(724)

19−7/16

(494)

10−1/2"

(267)

ELECTRICAL INLET

(Either Side)

23

(584)

*OPTIONAL

(Either Side)

23−1/2

(597)

9/16

(14)

14

(356)

1−15/16 (49)

CBWMV Model No. A B C D E F G

−24B−040

−36B−070

17−1/2 (445) 16−3/8 (416) 16 (406) 1−1/2 (38) 1−3/4 (44) 8 (203) 2 (51)

−36C−090

−60C−100

21 (533) 19−7/8 (454) 19−1/2 (495) 2 (51) 2−1/2 (64) 9−1/2 (241) 1−1/2 (38)

−60C−120

Page 2

505047 09/06

Page 3

General

CBWMV Unit Parts Description

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

having jurisdiction before installation. Only qualified service technicians or installers may install and service this

unit.

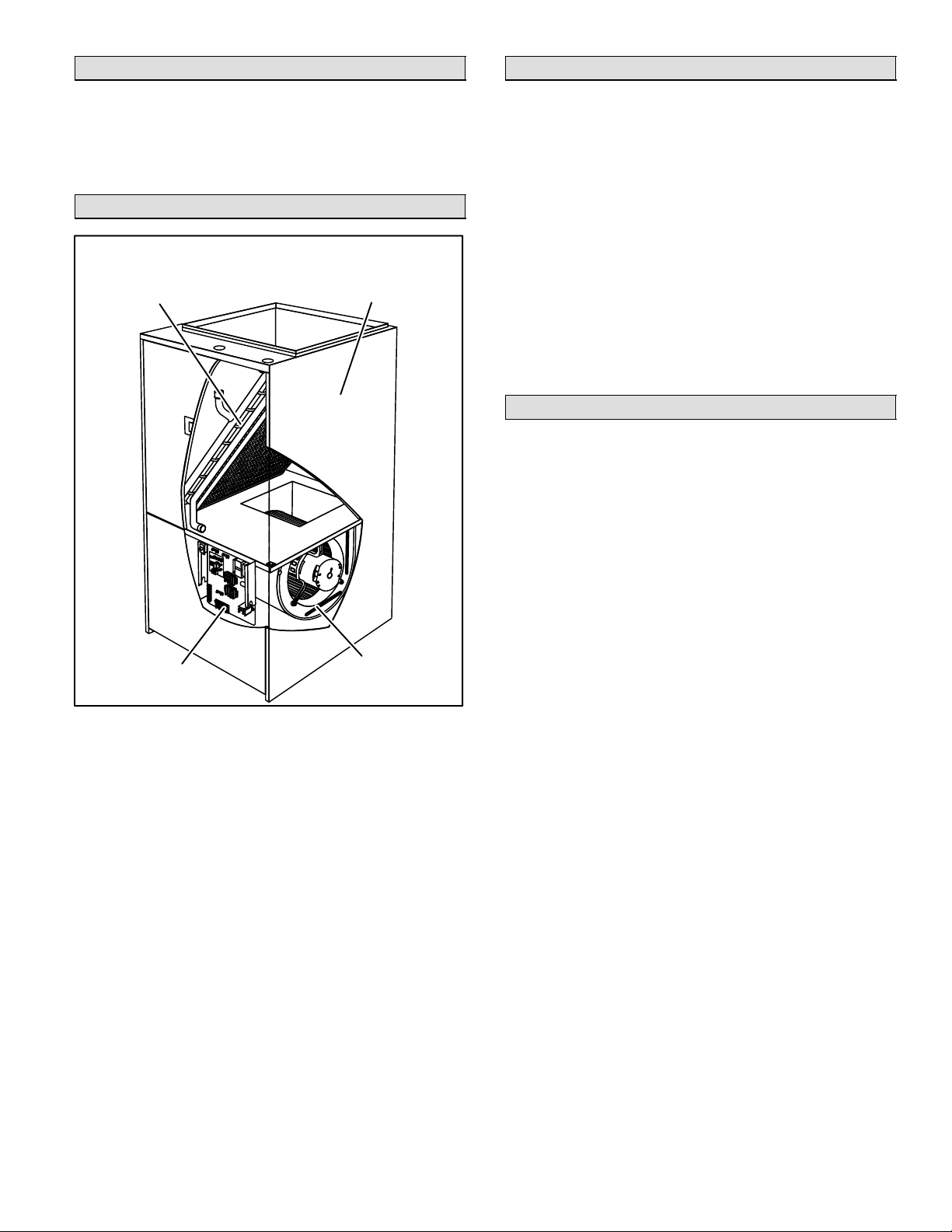

CBWMV Unit Parts Arrangement

CBWMV Unit

HOT WATER

COPPER

TUBE COIL

INSULATED

STEEL

CABINET

Blower

The CBWMV is equipped with a variable speed motor that

provides separate cooling and heating CFM selections

and low continuous fan speeds.

Hot Water Coil

The copper tube coil is equipped with aluminum fins which

provide excellent heat transfer. Manual air bleed ports are

located in the copper tubing to release trapped air in the

water circuit in all unit configurations.

Blower Control

The control provides a fixed blower delay of 45 seconds

ON / 30 seconds OFF on a W call.

Thermostat and accessory connections are made to the

terminal strips in the control box.

CBWMV Unit Optional Accessories

Accessory Circulators (53J76, 99K69)

An accessory circulator should be used in long line applications. Two circulators are available with either 9 gallons per minute (99K69) or 14 gpm (53J76) flow rate. Both

units have 7/8" soldering joints (inlet and outlet) . See piping section for more information.

CBWMV

CONTROL BOX

Figure 1

SUPPLY AIR

BLOWER

Downflow Base (68M03)

A downflow base kit is available for downflow applications

without add−on cooling coils. The base provides clearance

for routing the CBWMV unit’s inlet and outlet water lines.

NOTE − Downflow applications with an add−on cooling coil

require field−fabricated transitions to provide adequate

clearance for servicing/removing the cooling coil without

cutting the water lines.

Page 3

CBWMV SERIES

Page 4

Requirements

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause personal injury, loss

of life, or damage to property.

Installation and service must be performed by a

qualified installer or service agency.

Installation of Lennox CBWMV unit must conform with local building codes. Refer to the electrical section (Page 8)

for US and Canadian electrical regulations.

When paired with a water heating device, refer to local

building codes for special considerations. Refer to water

heating device for agency and service clearances. Clearances to combustibles for the CBWMV unit only is zero

inches on all sides. Table 1 lists recommended service

clearances.

Table 1

CBWMV Unit Service Clearances

Clearances Location Inches (mm)

Recommended

Service Access

NOTE − Service access clearance must be maintained.

Accessibility and service clearances must take precedence over fire protection clearances.

For installation in a residential garage, unit must be located or protected to avoid physical damage by vehicles.

The CBWMV unit must be installed so that its electrical

components are protected from water.

When the CBWMV unit is used with an air conditioner, the

air handler shall be installed on the upstream side of the

cooling evaporator coil to avoid freeze−up of water system

and condensation. With a parallel flow arrangement, a

damper (or other means to control the flow of air) must adequately prevent chilled air from entering the air handler. If

the damper is manually operated, it must be equipped to

prevent operation of either the heating or the cooling unit,

unless it is in the full HEAT or COOL setting.

NOTE − CBWMV series units must not be used in or for the

following applications:

S construction heater − during any phase of construction

S unit heater

S mobile home heater

S potable water applications

Front Access

Panel

30 (762)

Application

The CBWMV unit is designed for use in non−potable water

boiler systems. The water heating device must be adequate to provide enough heat according to the Engineering

Handbook specifications. The water heating device must

provide a minimum of 6 gallons/minute for small units

(CBWMV−040, −070) and 9 gallons/minute for large units

(CBWMV−090, −100, −120).

Installation − Setting Equipment

WARNING

This product contains fiberglass wool.

Disturbing the insulation during installation, maintenance, or repair will expose you to fiberglass wool

dust. Breathing this may cause lung cancer. (Fiberglass wool is known to the State of California to

cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact

your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

The boiler installation must conform to the requirements of

the authority having jurisdiction or, in the absence of such

requirements, to the latest revision of the National Fuel

Gas Code, ANSI Z223. (Available from the American Gas

Association, 8501 E. Pleasant Valley Road, Cleveland,

OH 44134). Reference should also be made to local gas

utility regulations and other codes in effect in the same

area in which the installation is to be made. When installed

in Canada: The latest revision of the CAN1/CSA−B149.1

and/or B149.2 Installation Codes for Gas-Burning Equipment and/or local codes.

Determine the CBWMV unit installation location and position units so that door panels are accessible. Keep in mind

routing of the water and plumbing lines and electrical connections.

The CBWMV unit is multi−positional. No adjustment is necessary to apply unit for upflow or horizontal discharge. A

downflow base is available and provides clearance for

routing the inlet/outlet water lines when the CBWMV unit is

applied without an add−on cooling coil. Downflow applica-

505047 09/06

Page 4

Page 5

tions with add−on cooling coils require field−fabricated transitions that provide at least 6 inches of clearance for the

CBWMV unit’s inlet/outlet water lines. See figure 2 for examples.

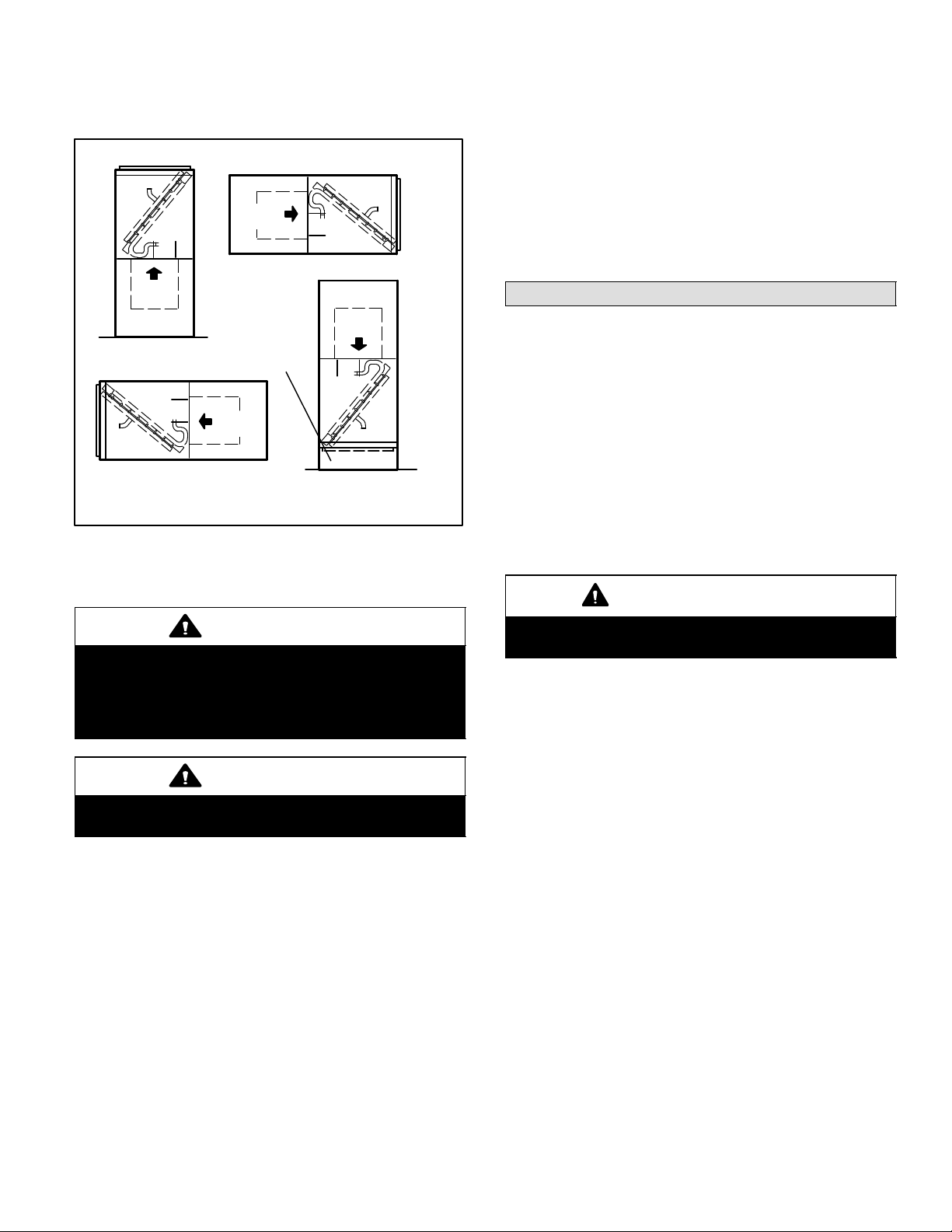

CBWMV Multi−Positional Unit

AIR

FLOW

RIGHT HAND DISCHARGE*

AIR

FLOW

AIR

FLOW

UPFLOW

DOWNFLOW BASE

AIR

FLOW

Either suspend the unit from the roof rafters or floor joists

or mount on a platform. The CBWMV unit must be level

and well supported.

NOTE − 1/2 hp and 1 hp blower motors are equipped with

three flexible legs and one rigid leg. The rigid leg is

equipped with a shipping bolt and a flat white plastic washer (rather than the rubber mounting grommet used with a

flexible mounting leg). The bolt and washer must be re-

moved before the air handler is placed into operation.

After the bolt and washer have been removed, the rigid leg

will not touch the blower housing.

Duct System

Use industry-approved standards (such as those published by Air Conditioning Contractors of America or American Society of Heating, Refrigerating and Air Conditioning

Engineers) to size and install the supply and return air duct

system. This will result in a quiet and low-static system that

has uniform air distribution.

LEFT HAND DISCHARGE*

DOWNFLOW

* CBWMV units must not be installed horizontally on the front or

back of the unit.

Figure 2

Units may be horizontally installed in either attic or crawl

space.

CAUTION

CBWMV series units are shipped with an antifreeze

thermostat to prevent the water coil from freezing.

The freezestat is installed at the factory but must be

field wired (see figures 12 and 13). Do not bypass

this feature when you install or run the unit.

CAUTION

Use a drain pan for installations over finished living

areas.

NOTE − Do not operate the air handler with an external

static pressure that exceeds 0.8 inches w.c. Higher external static pressures may cause erratic operation.

Return Air Plenum

IMPORTANT

Return air must not be drawn from a room where any

fossil fuel appliance (ie., a water heater) is installed.

When return air is drawn from a room, a negative pressure is created in the room. If a fossil fuel appliance is operating in a room with negative pressure, the flue products can be pulled back down the vent pipe and into the

room. This reverse flow of the flue gas may result in incomplete combustion and the formation of carbon monoxide gas. This toxic gas might then be distributed

throughout the house by the air handler duct system.

Page 5

CBWMV SERIES

Page 6

Return Air Opening Guidelines

Side Return Air With Transition And Filter

NOTE − Do not bring in air from the back of the unit. Return

air can be brought in from the sides or bottom only.

Bottom Return

If the air handler is installed on a platform with bottom return, make an airtight seal between the bottom of the air

handler and the platform to ensure that the air handler operates properly and safely. Use aluminum tape or mastic

between the plenum and the air handler cabinet to ensure

a tight seal. The air handler is equipped with a removable

bottom panel to facilitate installation.

Side Return

For side return air applications, cut the air handler cabinet

at the maximum return air dimensions shown on page 2.

See figure 3 for a typical side inlet arrangement with a transition and filter.

NOTE − Single side inlet applications result in approximately a 4 percent reduction of CFM on B−size units and

approximately a 5 percent reduction of CFM on C−size

units:

Optional Return Air Base and Unit Dimensions − Inches (mm)

20" X 25" X 1"

(508MM X 635MM X 25MM)

CLEANABLE FILTER

RETURN AIR

PLENUM

TRANSITION

Figure 3

Return Air Base

For return air with the optional return air base (RAB), see

figure 4 (and refer to installation instructions provided with

Return Air Base kit).

*NOTE − Both unit and return air base openings must be

connected to and entirely covered by a single plenum or

IAQ accessory opening. Optional side return air filter kits

cannot be used with RAB Return Air Base.

4

(102)

*23 (584) Overall (Max.)

AIR FLOW

RETURN

AIR BASE

17 (432) RAB−B (98M60)

21 (533) RAB−C (98M58)

FRONT VIEW

NOTE − IN SIDE RETURN

APPLICATIONS, THE RAB

IS REQUIRED FOR 100%

CFM CAPACITY.

Side Return

Air Openings

(Either Side)

7−1/4

(184)

7/8 (22)

Figure 4

*Unit

Opening

*Base

Opening

27−5/8 (702)

SIDE VIEW

23 (584)

*Minimum

11 (279)

*Maximum

14 (356)

5−5/8

(143)

*Height varies

with plenum or

IAQ accessory

height.

3/4

(19)

505047 09/06

Page 6

Page 7

Removing the Bottom Panel (bottom return or return

air base configurations)Remove the two screws that

secure the bottom cap to the air handler. Pivot the bottom

cap down to release the bottom panel. Once the bottom

panel has been removed, reinstall the bottom cap. See figure 5.

Removing the Bottom Panel

BOTTOM CAP

SCREW

BOTTOM PANEL

through the bottom panel and the bottom flange of the

cabinet.

2. Install one bolt and two nuts into each hole. Screw the

first nut onto a bolt and then insert the bolt into a hole.

A flat washer may be added between the nut and the

bottom of the unit.

3. Screw another nut onto the bolt on the inside of the air

handler base. A flat washer may be added between

the nut and the bottom of the unit.

4. Adjust the outside nut to the appropriate height and

tighten the inside nut to secure the arrangement.

Horizontal Applications

The CBWMV air handler can be installed in horizontal applications. Refer to Engineering Handbook for additional information. Allow for clearances to combustible materials as

indicated on the unit nameplate.

This air handler may be installed in either an attic or a

crawlspace. Either suspend the air handler from roof rafters or floor joists, as shown in figure 7. The unit must be

supported at both ends and beneath the blower deck to

prevent sagging.

Figure 5

Leveling an Upflow UnitWhen the side return air inlets

are used in an upflow application, it may be necessary to

install leveling bolts on the bottom of the air handler. Use

field−supplied corrosion−resistant 5/16 inch machine bolts

(4) and nuts (8). See figure 6.

NOTE − Maximum leveling bolt length is 1−1/2 inches.

Leveling Bolt Installation

AIR HANDLER FRONT

3/8 (10)

1−3/4 (44)

LEVELING BOLT

LOCATIONS

3/8 (10)

3/8 (10)

AIR

HANDLER

BOTTOM

1−3/4 (44)

1−3/4 (44)

inches (mm)

1−3/4 (44)

LEVELING BOLT

LOCATIONS

3/8 (10)

Figure 6

1. Lay the air handler on its back and drill a 5/16 inch diameter hole in each corner of the air handler’s bottom.

See figure 6 for the correct location of the holes. Drill

Unit Suspended in Attic or Crawlspace

1/4 IN.

RODS

DRAIN

ALLOW

SUFFICIENT

CLEARANCE

BETWEEN ROD

AND UNIT TO

REMOVE

ACCESS PANEL.

ANGLE IRON

U−CHANNELS

PAN

Figure 7

NOTE − Heavy−gauge, perforated sheet metal straps

(plumbers’ straps) may be used to suspend the unit from

roof rafters or ceiling joists. When suspending the unit in

this manner, support must be provided for both the ends

and the middle of the air handler to prevent sagging. Straps

must not interfere with plenum or water piping. Securing

screws should be 1/2 inch from the top edge and 1−1/2 inch

from the side edge in all cases. Cooling coils and supply

and return air plenums must be supported separately.

NOTE − When the air handler is installed on a platform in a

crawlspace, it must be elevated enough to avoid water

damage and to allow the optional evaporator coil to drain.

Horizontal and Downflow Applications

Return air can be brought in through the end of an air handler installed in the horizontal or downflow application. The

air handler is equipped with a removable bottom panel to

facilitate installation (see figure 5).

Page 7

CBWMV SERIES

Page 8

Filter Assembly & Filters

Air Handler

This unit is not equipped with a filter or rack. A field−provided high−velocity filter is required for the unit to operate

properly. Table 2 lists recommended filter sizes. A filter

must be in place any time the unit is operating.

Table 2

Recommended Filter Sizes

Air Handler

Cabinet Size

17−1/2" 16 X 25 X 1 (1) 16 X 25 X 1 (1)

21" 16 X 25 X 1 (1) 20 X 25 X 1 (1)

Side Return Bottom Return

Filter Size

Plumbing

Pipe and Fitting Specifications

Refer to local building and plumbing codes for approved

copper pipe and fittings.

Plumbing Procedures

Refer to the installation instructions of the water heating

device to be used with the CBWMV unit. Follow the recommendations outlined in that instruction as well as governing plumbing codes and practices.

Plumbing Checklist

S Flush water lines between the CBWMV unit and the

water heating device before start−up. Normal flushing

procedures should be used to rid the system of contaminants and foreign debris.

S CBWMV units are installed in non-potable systems.

Refer to figure 12 for schematic wiring diagram and troubleshooting.

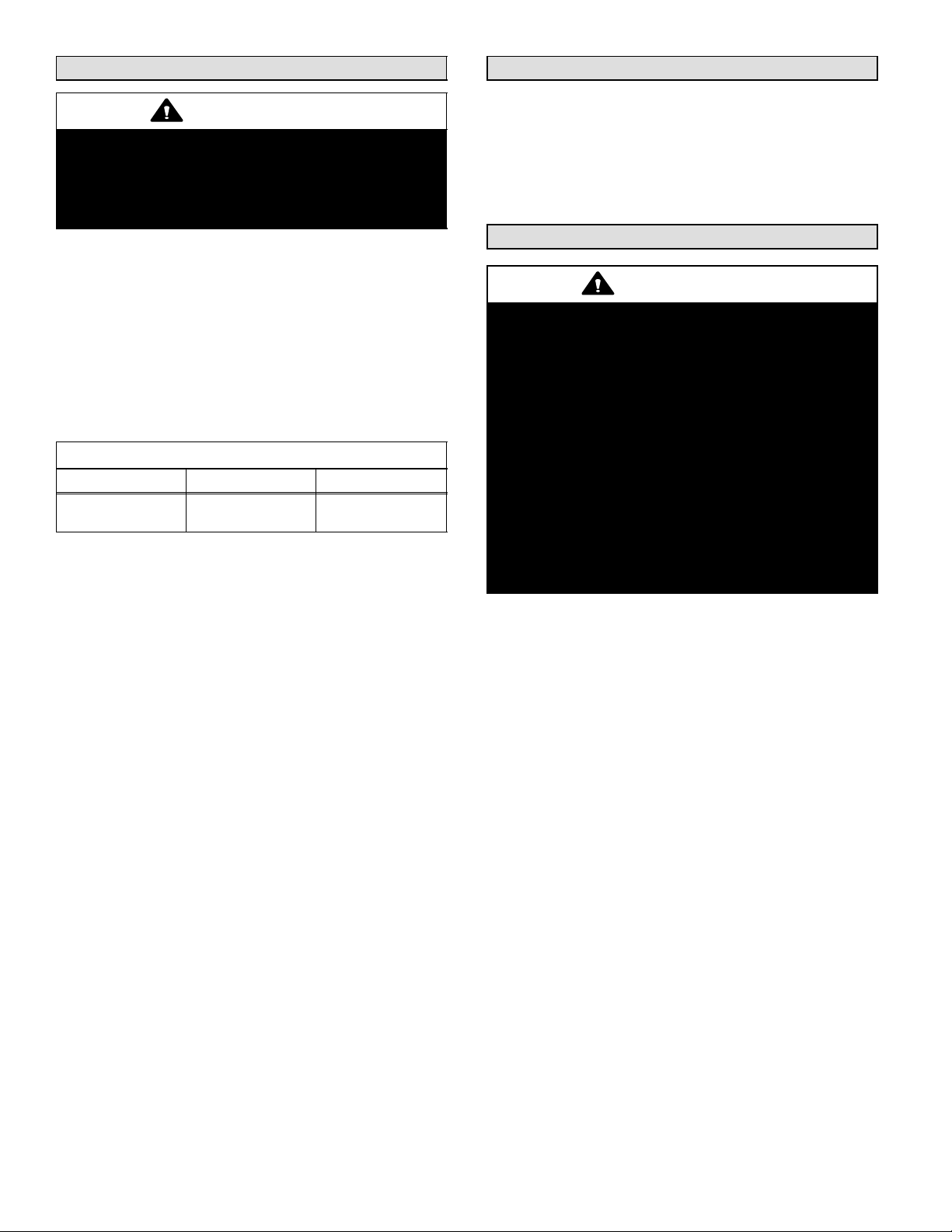

Line Voltage (120V)

Line voltage field supply conductors are terminated at the

CBWMV unit. The unit is shipped with the line voltage connections secured to the lower left coil manifold for left side

make−up box installations. For right side make−up box

installations, remove the wire tie that holds the line voltage

connections and pull excess wires into blower deck/control

box area as shown in figure 8.

Install make−up box (provided for line voltage wiring in the

unit’s bag assembly) as shown in figure 9.

Make−up Box Wiring

WIRES SHOWN AS SHIPPED,

ROUTED FOR LEFT SIDE

MAKE−UP BOX INSTALLATION

FOR RIGHT SIDE MAKE−UP

BOX INSTALLATION

REMOVE WIRE TIE,

PULL EXCESS WIRE INTO

BLOWER DECK / CONTROL

BOX AREA.

Electrical

Wiring and grounding must conform to the current National

Electric Code ANSI/NFPA No. 70, or Canadian Electric

Code Part I, CSA Standard C22.1, and local building

codes. Refer to following wiring diagrams. See unit nameplate for minimum circuit ampacity and maximum overcurrent protection size.

Select the proper supply circuit conductors in accordance with tables 310−16 and 310−17 in the National

Electric Code, ANSI/NFPA No. 70 or tables 1 through 4

in the Canadian Electric Code, Part I, CSA Standard

C22.1.

CAUTION

USE COPPER CONDUCTORS ONLY.

WARNING

Electric shock hazard. Can cause injury or death. Before attempting to perform any service or maintenance, turn

the electrical power to unit OFF at disconnect switch(es). Unit may have

multiple power supplies.

Figure 8

Interior Make−Up Box Installation

MAKE−UP

BOX

LEFT SIDE

Figure 9

MAKE−UP

BOX

RIGHT SIDE

505047 09/06

Page 8

Page 9

Electrostatic Discharge (ESD) - Precautions

And Procedures

National Electric Code (ANSI/NFPA No. 70) for the

USA and current Canadian Electric Code part 1 (CSA

standard C22.1) for Canada. A green ground wire is

provided in the field make−up box.

CAUTION

Electrostatic discharge can affect electronic components. Take precautions during air handler installation and service to protect the air handler’s electronic controls. Precautions will help to avoid control exposure to electrostatic discharge by putting

the air handler, the control and the technician at the

same electrostatic potential. Neu tralize electrostatic

charge by touching hand and all tools on an unpainted unit surface, such as the blower deck, before performing any service procedure.

5. Install the room thermostat according to the instructions provided with the thermostat. See table 3 for field

wiring connections in varying applications. If the air

handler is being matched with a heat pump, refer to the

FuelMaster21® installation instruction.

Removeable Jumpers

Removeable Jumper DS to Y1The factory−installed

wire jumper that connects terminals DS and Y1 on the TB1

terminal strip in the control box must be removed when the

air handler is installed in a system supporting dehumidification using a SignatureStatt thermostat (e.g., Humidi-

Refer to table 3 for field wiring.

1. Refer to the CBWMV unit’s nameplate for minimum

circuit ampacity and maximum overcurrent protection

size.

2. Install a separate disconnect switch (protected by either fuse or circuit breaker) near the air handler so that

power can be turned off for servicing.

3. Complete the wiring connections to the equipment.

Use the provided unit wiring diagram and the field wiring diagrams shown in table 3. Use 18−gauge wire or

larger that is suitable for Class II rating for thermostat

connections.

4. Electrically ground the unit according to local codes or,

in the absence of local codes, according to the current

trol® Enhanced Dehumidification Accessory or Harmony

zone controls).

Removeable Jumper R to OThe factory−installed wire

jumper that connects TB7 (24V) terminal R to TB1 terminal O must be removed when the air handler is installed in

applications which include a heat pump unit and the FuelMaster21® control board. If the jumper is left intact, terminal O will remain energized, eliminating the heat mode in

the heat pump.

Removeable Jumper Y1 to Y2The factory−installed

wire jumper that connects Y1 and Y2 on the TB1 terminal

strip must be removed if two−stage cooling is used. If the

jumper is not removed the outdoor unit will only operate in

second−stage cooling.

Table 3

Field Wiring Application Jumper Settings (See figure 12)

Thermostat (Application) TB1 Y1 to Y2 TB1 DS to Y1 TB1 R to O Wiring Connections

1 Heat / 1 Cool with

SignatureStatt Thermostat

[Single-Stage Heat Pump]

Yes No

(Remove)

No

(Remove)

SignatureStatt CBWMV

TERMINALS

t

OUTDOOR

UNIT

2 Heat / 2 Cool with

SignatureStatt Thermostat

(Remove)

[Two-Stage Heat Pump (Refer

to FM21 Instructions)]

O" terminal used only with heat pumps.

No

No

(Remove)

Page 9

No

(Remove)

SignatureStatt

CBWMV

TERMINALS

JUMPERS

REMOVED

OUTDOOR

UNIT

ALL JUMPERS

REMOVED

CBWMV SERIES

Page 10

Indoor Blower Speeds

1. When the thermostat is set to FAN ON," the indoor

blower will run continuously at approximately 38% of

the second−stage cooling speed when there is no cooling or heating demand.

2. When the CBWMV is in the heating mode, the indoor

blower will run on the heating speed designated by the

position of the HEAT pin.

3. When there is a cooling demand, the indoor blower will

run on the cooling speed designated by the position of

the COOL pin.

Accessory Field Wiring (K212)

Accessory Field Wiring (TB66 & TB67)

Connect wires from accessories (e.g. powered air cleaners, humidifiers) to terminal blocks TB66 and TB67 (see

detail in figure 11).

CBWMV Control Box

TERMINAL BLOCKS

TB2 TB13

(HOT) (NEUTRAL)

TRANSFORMER

T1

Connect field wiring to 3PDT relay K212 (Lennox part

67K66) as shown in figure 10.

Accessory Relay Field Wiring (K212)

1

2

3

4

5

6

7

8

9

AB

24V 125MA 1/4" QUICK CONNECT TERMINALS

RELAY CONTACTS RATING 8 AMPS @ 120V MAX. 24V COIL

ACCESSORY RELAY

Figure 10

DOOR

INTERLOCK

SWITCH

BDC3

VARIABLE

SPEED

CONTROL

ACCESSORY

FIELD

WIRING

TERMINAL

BLOCKS

TERMINAL

BLOCK TB1

TB66

TB67

Figure 11

CB8

CIRCUIT

BREAKER

WIRING

STRAIN

RELIEF

BUSHING

TERMINAL

BLOCK 24V

K212

RELAY

505047 09/06

Page 10

Page 11

Typical CBWMV Wiring Diagram

Figure 12

Page 11

CBWMV SERIES

Page 12

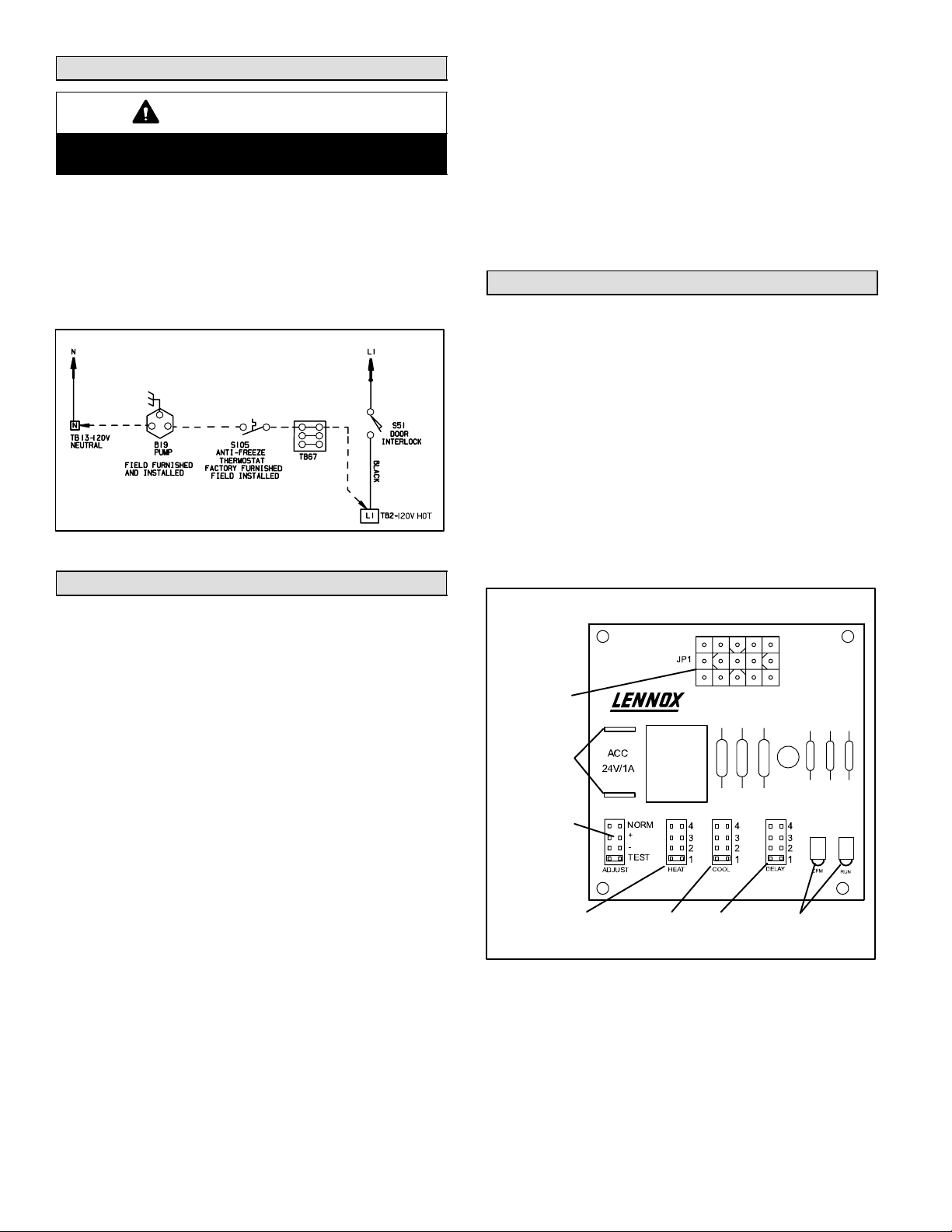

Freezestat Operation

IMPORTANT

Use of the freezestat feature is required in all installations using CBWMV units.

The CBWMV unit is equipped with a field-wired freezestat.

The freezestat protects the CBWMV system from freezing

temperatures when the unit is installed in unconditioned

areas.

The factory-provided freezestat must energize the circulator when water temperatures fall below 45ºF. Freezestat

wiring is shown in figure 13.

Freezestat Field Wiring

Figure 13

BDC3 Variable Blower Control Board

CBWMV units are equipped with a variable speed motor

that is capable of maintaining a specified CFM throughout

the external static range. A particular CFM can be obtained

by positioning jumpers (COOL, HEAT, and ADJUST) on

the BDC3 control board. The COOL and HEAT jumpers

are labeled 1, 2, 3, and 4. Each of the numbers corresponds with an air volume (CFM) setting. The ADJUST

jumper is labeled TEST, −, +, and NORM. The + and − pin

settings are used to add or subtract a percentage of the

CFM selected. The TEST jumper is used to operate the

motor in the test mode. The DELAY jumper controls ramp-

ing profiles.

Figure 14 shows the BDC3 control board. Use tables 5

through 9 to determine the correct air volume for heat and

cool speed taps.

Diagnostic LEDs located on the BDC3 control board are

provided to aid in identifying the unit’s mode of operation.

Certain scenarios will arise depending on the jumper positions. Read through the jumper settings sections before

adjusting blower speed. Refer to figure 14 for identification.

Continuous Low Blower Option

Refer to the blower speed chart located on the CBWMV

unit wiring diagram for factory set cooling, heating and low

(continuous) blower speeds. Systems using a cooling thermostat subbase may operate continuous blower (factoryset to operate at 38% of second-stage cooling speed)

through the FAN−ON switch of the thermostat. For continuous low blower with a system without a cooling subbase, a

fan switching subbase may be used.

Heating or cooling demand will cause blower to go to heat

or cool speed.

Blower Speed Adjustments

Diagnostic LEDs

RUN LED Indicates a demand for blower operation in

either the heating mode or continuous fan−only mode.

RUN LED will not illuminate during a cooling demand.

CFM LED Indicates the CFM at which the unit is operating. The light flashes once for approximately every 100

CFM. For example, if the unit is operating at 1000 CFM,

CFM LED will flash 10 times. If the CFM is 1150, CFM LED

will flash 11 full times plus one fast or half flash.

At times the light may appear to flicker or glow. This takes

place when the control is communicating with the motor

between cycles. This is normal operation.

The appropriate speed according to application and CFM

need is selected by moving jumper pins.

BDC3 Variable Speed Control Board

JP1

15 PIN PLUG

(BOARD TO

MOTOR)

ACCESSORY

RELAY CON-

TACTS

(DRIVES OP-

TIONAL

ACCESSORY

RELAY)

OPERATIONAL

SELECTOR

PINS

(AFFECTS

BOTH

HEATING AND

COOLING

MODES)

HEATING SPEED

SELECTOR PINS

COOLING SPEED

SELECTOR PINS

Figure 14

FAN DELAY

SELECTOR PINS

DIAGNOSTIC

LEDS

505047 09/06

Page 12

Page 13

Bl

Jumper Settings

IMPORTANT

Before changing jumper setting, make sure the motor has completely stopped. Any jumper setting

change will not take place while the motor is running.

Table 4 shows the factory blower speed tap settings for

CBWMV series units. These settings are for nominal tonnage match−ups with the CBWMV. When matched with

other sizes, it is recommended that the CFM be adjusted

approximately to 400 CFM per ton.

Table 4

Factory Blower Speed Tap Settings

CBWMV

ower

Coil

−24B−040 1 2 NORM 4

−36B−070 3 4 NORM 4

−36C−090 3 4 NORM 4

−60C−100 4 4 NORM 4

−60C−120 4 4 NORM 4

Cool Pin Heat Pin Adjust Delay

To change jumper positions, gently pull the jumper off the

pins and place it on the desired set of pins. The following

section outlines the different jumper selections available

and conditions associated with each one. Refer to figure

14.

After the CFM for each application has been determined,

the jumper settings must be adjusted to reflect those given

in tables 5 through 9. From the tables, determine which row

of CFM volumes most closely matches the desired CFM.

Once a specific row has been chosen (+, NORMAL, or −),

CFM volumes from other rows cannot be used. Below are

descriptions of the jumper selections.

ADJUST Pins The ADJUST pins allow the motor to run

at normal speed, approximately 10% higher, or approximately 10% lower than normal speed. Tables 5 through 9

gives three rows (+, NORMAL, and −) with their respective

CFM volumes. Notice that the normal adjustment setting

for heat speed position #3 is 1070 CFM. The + adjustment

setting for that position is 1180 CFM and for the − adjustment setting is 940 CFM. After the adjustment setting has

been determined, chose the remainder speed jumper settings from those offered in the table in that row.

The TEST pin is available to bypass the BDC3 control and

run the motor at approximately 70% to test that the motor is

operational. This is beneficial primarily in troubleshooting.

G must be energized for motor to run.

COOL Pins The COOL jumper is used to determine the

CFM during either 1) cooling or 2) heat pump operation

without a W1 call for electric heat. These jumper selections

are activated for cooling when Y1 and/or Y2 and DS terminals in the CBWMV unit are energized and for heating

when Y1 and/or Y2 is energized.

Speed Tap Selection

Page 13

For applications with the Harmony

®

Zoning System, the

blower CFM volume is determined by the Harmony control

center. The minimum blower speed is predetermined at

400 CFM for −CBWMV−24B−040 and 36B−070 series units

and 600 CFM for CBWMV−36C−090, 60C−100, and

60C−120 series units. This speed is not adjustable.

With the thermostat set for Continuous Fan" and without a

call for heating or cooling, the CBWMV will provide 38% of

the COOL CFM selected.

HEAT Pins

The HEAT jumper is used to determine

CFM heating. These jumper selections are activated only

when W1 is energized. (There is a fixed 45 seconds ON

and 30 seconds OFF delay on a W call.)

DELAY Pins The DELAY jumper is used to set the spe-

cific motor fan operation during cooling mode. Depending

on the application, one of four options may be chosen by

moving the jumper to the appropriate set of pins.

#1 Pins Jumpered

A Motor runs at 100% until demand is satisfied.

A B

OFFOFF

B Once demand is met, motor ramps down to stop.

#2 Pins Jumpered

A Motor runs at 100% until demand is satisfied.

A

OFF

B

C

OFF

B Once demand is met, motor runs at 100% for 45

seconds. Then,

C ramps down to stop.

NOTE − Blower OFF DELAY also applies during heat

pump operation

#3 Pins Jumpered

A Motor runs at 82% for approximately 7−1/2 min-

utes. If demand has not been satisfied after 7−1/2

minutes,

B motor runs at 100% until demand is satisfied.

AB C

OFFOFF

C Once demand is met, motor ramps down to stop.

#4 Pins Jumpered

A Motor runs at 50% for 30 seconds.

B Motor then runs at 82% for approximately 7−1/2

minutes. If demand has not been satisfied after

7−1/2 minutes.

C Motor runs at 100% until demand is satisfied.

D Once demand is met, motor runs at 50% for 30

seconds. Then,

B

A

C D

E

OFFOFF

E ramps down to stop.

CBWMV SERIES

Page 14

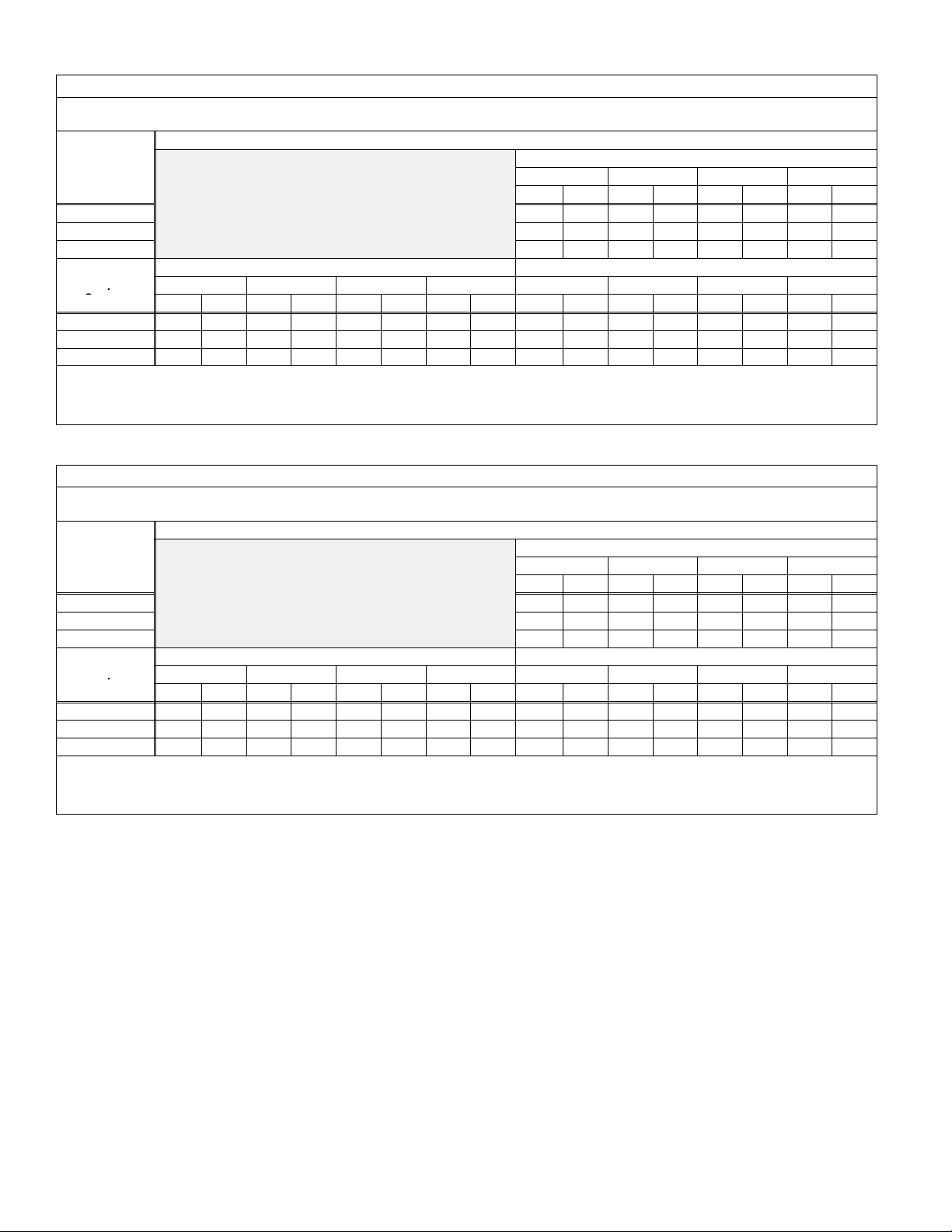

Table 5

J

Setting

Setting

ADJUST

p

J

Setting

ADJUST

p

CBWMV−24B−040 Blower Performance

0 through 0.80 in. w.g. (0 Through 200 Pa) External Static Pressure Range ; Factory Settings: Heating Speed − 2, Cooling

Speed − 1, Speed Adjust − NORM; Applications with single sided inlets will reduce CFM by approximately 4%.

ADJUST"

umper

+ 610 290 770 365 930 440 1010 475

NORM 560 265 700 330 830 390 910 430

510 240 630 295 750 355 810 380

ADJUST"

Jumper

Setting

+ 820 385 990 465 1180 555 1340 630 880 415 1120 530 1340 630 1440 680

NORM 750 355 900 425 1070 505 1230 580 800 375 1000 470 1200 565 1300 615

970 315 810 380 940 445 1080 510 720 340 900 425 1080 510 1170 550

The effect of static pressure and filter resistance is included in air volumes shown.

1st stage COOL is approximately 70% of the same 2nd stage COOL speed position.

Continuous Fan Only speed is approximately 38% of the same 2nd stage COOL speed position.

Lennox Harmony zone control applications − Minimum blower speed is 400 cfm. Max cfm is the same as 2nd stage cool position.

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

HEAT" Speed 2nd Stage COOL" Speed

BDC3 Jumper Speed Positions

1st Stage COOL" Speed

1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s

Table 6

CBWMV−36B−070 Blower Performance

0 through 0.80 in. w.g. (0 Through 200 Pa) External Static Pressure Range ; Factory Settings: Heating Speed − 4, Cooling

Speed − 3, Speed Adjust − NORM; Applications with single sided inlets will reduce CFM by approximately 4%.

ADJUST"

umper

+ 590 280 745 350 895 420 975 460

NORM 545 255 680 320 805 380 890 420

490 230 600 280 725 340 780 370

ADJUST"

Jumper

Setting

+ 790 370 980 465 1140 540 1310 620 850 400 1090 515 1300 620 1430 675

NORM 730 345 870 410 1040 490 1190 560 775 365 990 465 1190 560 1280 605

640 300 770 360 920 435 1070 505 700 330 870 410 1065 500 1150 540

The effect of static pressure and filter resistance is included in air volumes shown.

1st stage COOL is approximately 70% of the same 2nd stage COOL speed position.

Continuous Fan Only speed is approximately 38% of the same 2nd stage COOL speed position.

Lennox Harmony zone control applications − Minimum blower speed is 400 cfm. Max cfm is the same as 2nd stage cool position.

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

HEAT" Speed 2nd Stage COOL" Speed

BDC3 Jumper Speed Positions

1st Stage COOL" Speed

1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s

Page 14

505047 09/06

Page 15

Table 7

J

Setting

Setting

ADJUST

p

J

Setting

ADJUST

p

CBWMV−36C−090 Blower Performance

0 through 0.80 in. w.g. (0 Through 200 Pa) External Static Pressure Range ; Factory Settings: Heating Speed − 4, Cooling

Speed − 3, Speed Adjust − NORM; Applications with single sided inlets will reduce CFM by approximately 5%.

ADJUST"

umper

+ 620 290 770 365 930 440 1010 475

NORM 570 270 700 330 830 390 910 430

520 245 630 295 760 360 810 380

ADJUST"

Jumper

Setting

+ 820 385 1000 470 1180 555 1340 630 890 420 1130 535 1340 630 1450 685

NORM 760 360 900 425 1070 505 1220 575 800 380 1020 480 1220 575 1310 620

675 320 810 380 950 450 1100 520 720 340 900 425 1100 520 1180 555

The effect of static pressure and filter resistance is included in air volumes shown.

1st stage COOL is approximately 70% of the same 2nd stage COOL speed position.

Continuous Fan Only speed is approximately 38% of the same 2nd stage COOL speed position.

Lennox Harmony zone control applications − Minimum blower speed is 400 cfm. Max cfm is the same as 2nd stage cool position.

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

HEAT" Speed 2nd Stage COOL" Speed

BDC3 Jumper Speed Positions

1st Stage COOL" Speed

1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s

Table 8

CBWMV−60C−100 Blower Performance

0 through 0.80 in. w.g. (0 Through 200 Pa) External Static Pressure Range ; Factory Settings: Heating Speed − 4, Cooling

Speed − 3, Speed Adjust − NORM; Applications with single sided inlets will reduce CFM by approximately 5%.

ADJUST"

umper

+ 1110 525 1250 590 1380 650 1530 720

NORM 1000 470 1130 535 1250 590 1380 650

930 440 1040 490 1130 535 1260 595

ADJUST"

Jumper

Setting

+ 1500 710 1700 800 1880 885 2100 990 1540 725 1760 830 1970 930 2200 1040

NORM 1370 645 1540 725 1720 810 1920 905 1400 660 1600 755 1800 850 1980 935

1250 590 1380 650 1540 725 1720 810 1270 600 1420 670 1600 755 1780 840

The effect of static pressure and filter resistance is included in air volumes shown.

1st stage COOL is approximately 70% of the same 2nd stage COOL speed position.

Continuous Fan Only speed is approximately 38% of the same 2nd stage COOL speed position.

Lennox Harmony zone control applications − Minimum blower speed is 600 cfm. Max cfm is the same as 2nd stage cool position.

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

HEAT" Speed 2nd Stage COOL" Speed

BDC3 Jumper Speed Positions

1st Stage COOL" Speed

1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s

Page 15

CBWMV SERIES

Page 16

Table 9

J

Setting

Setting

ADJUST

p

CBWMV−60C−120 Blower Performance

0 through 0.80 in. w.g. (0 Through 200 Pa) External Static Pressure Range ; Factory Settings: Heating Speed − 4, Cooling

Speed − 4, Speed Adjust − NORM; Applications with single sided inlets will reduce CFM by approximately 5%.

ADJUST"

umper

+ 1100 520 1250 590 1400 660 1560 735

NORM 990 465 1130 535 1260 595 1400 660

930 440 1020 480 1130 535 1260 595

ADJUST"

Jumper

Setting

+ 1510 715 1720 810 1900 895 2120 1000 1570 740 1800 850 2000 945 2200 1040

NORM 1380 650 1560 135 1740 820 1920 905 1410 665 1620 765 1820 860 2020 955

1240 585 1380 650 1540 725 1720 810 1260 595 1440 680 1620 765 1810 855

The effect of static pressure and filter resistance is included in air volumes shown.

1st stage COOL is approximately 70% of the same 2nd stage COOL speed position.

Continuous Fan Only speed is approximately 38% of the same 2nd stage COOL speed position.

Lennox Harmony zone control applications − Minimum blower speed is 600 cfm. Max cfm is the same as 2nd stage cool position.

1 2 3 4 1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s cfm L/s

HEAT" Speed 2nd Stage COOL" Speed

BDC3 Jumper Speed Positions

1st Stage COOL" Speed

1 2 3 4

cfm L/s cfm L/s cfm L/s cfm L/s

Initial Air Purging

After all plumbing connections have been made, leak

tested and flushed, the water heating device is ready to be

filled with water and purged of air. Air bleeder valves are

provided as a convenience for installations that are not

equipped with purge manifolds.

1. Make sure electrical power and gas supply to system

are OFF.

2. Remove CBWMV coil section access panel.

3. Remove cap from highest air bleed valve and depress

valve stem until water is released. This may be done with

a refrigerant style hose. See figure 15.

4. Replace cap on valve and access panel.

5. Apply electrical power and gas supply to the system.

6. Follow the System Start−Up section to operate the system. Complete purging of air after unit has gone

through initial start−up.

Air Bleed Valve Location

VALV E

SHOWN

WITH CAP ON

Figure 15

Page 16

505047 09/06

Page 17

System Adjustments

Timed−ON and Timed−OFF Delays

The 45−second timed−ON delay and the 30−second timed−

OFF delay for heating (time that the blower operates after

the heat demand has been satisfied) is not adjustable.

Blower Speeds

Select the blower speed by moving the pins on the variable

speed control board. See figure 14.

Refer to the speed selection chart on unit wiring diagram.

NOTE − To check for proper CFM, take the reading external to the unit. The coil must be dry when you take the

reading.

Annual Service

WARNING

Electric shock hazard. Can cause injury or death. Before attempting to perform any service or maintenance, turn

the electrical power to unit OFF at disconnect switch(es). Unit may have

multiple power supplies.

At the beginning of each heating season, system should be

checked as follows by a qualified service technician:

Electrical

1. Check all wiring for loose connections.

2. Check for correct voltage at CBWMV unit (unit operating).

3. Check to see that blower is operating.

Blower

1. Check and clean blower wheel.

2. Motors are pre−lubricated for extended life; no further

lubrication is required.

Freezestat

Verify that the freezestat functions.

Service Filters

Filters must be cleaned or replaced when dirty to assure

proper unit operation.

Winterizing CBWMV Water Coil

If unit is installed in an unconditioned space, the piping between the CBWMV unit and the water heating device

should be insulated. If power is removed from the unit, water must be drained from the system to prevent freezing.

Repair Parts List

The following repair parts are available. When ordering

parts, include the complete unit model number listed on the

unit rating plate of each piece of equipment.

Cabinet Parts

Blower Access Panel

S

S Coil Access Panel

Hot Water Coil Parts

Coil Replacement Kit

S

Blower Part

Blower Wheel

S

S Blower Motor

S Blower Housing

Electrical Parts

BDC3 Board

S

S Transformer

S Circuit Breaker, 24VAC

S 3PDT Relay

Page 17

CBWMV SERIES

Page 18

WARNING

WARNING TO SERVICE PERSONS! Electric shock hazard. When electrical power to the internal

control box components must be available for troubleshooting, a common practice is to

construct a by−pass" of the door interlock switch. When such a by−pass is in place, a potential

shock hazard is present which can cause injury or death. Make sure any door interlock switch

by−pass has been removed after troubleshooting is complete and BEFORE attempting any repairs to the control box components!

Troubleshooting: Continuous Fan Sequence of Operation

CONDITIONS:

Power On

Normal Operation LED: Steady Flash

Thermostat (S1) Calls for Continuous Fan, G−Only

YES

Blower Operates at the Continuous Fan Speed

Selected by COOL Jumper and ADJUST Jumper

Positions on the BDC3 Control (A52)

YES

RUN Light on BDC3 Control (A52) illuminates to Indicate a Continuous Fan Call

YES

CFM Light on A52 Indicates Blower CFM Selection

with 100CFM / Blink

YES

Thermostat (S1) Continuous Fan Demand Satisfied

YES

Blower Off

NO

Check for 24 Volts Between ’G’ and C at A15 Terminal Strip

NO

Check for 24 Volts Between Pins 3 and 15 on J49

505047 09/06

Page 18

Page 19

WARNING

WARNING TO SERVICE PERSONS! Electric shock hazard. When electrical power to the internal

control box components must be available for troubleshooting, a common practice is to

construct a by−pass" of the door interlock switch. When such a by−pass is in place, a potential

shock hazard is present which can cause injury or death. Make sure any door interlock switch

by−pass has been removed after troubleshooting is complete and BEFORE attempting any repairs to the control box components!

Troubleshooting: Cooling Sequence of Operation

CONDITIONS:

Power On

Normal Operation LED: Steady Flash

Thermostat (S1) Provides 24 Volt Cooling Call to Indoor Blower (B3)

YES

2 Stage Condensing Unit?

YES

Blower (B3) Operates at the 1st Stage Cooling Speed

Determined by COOL, DELAY and ADJUST Jumper

Positions on the BDC3 Control (A52)

CFM Light on A52 Indicates Blower CFM Selection with

100CFM / Blink

YES

Check for 24 Volts Between Y

and C on A15 Terminal Strip

Check for 24 Volts Between

Pins 6 and 3 on J49

First Stage Demand for Cooling Satisfied?

YES

Blower Shuts Off According to the DELAY Jumper

Position on the BDC3 Control (A52)

YES

Demand for Cooling Satisfied

NO

Check for 24 Volts Between Y and C at A15 Terminal Strip

NO

NO

NO

Blower (B3) Operates at the 2nd Stage

Cooling Speed Determined by COOL,

DELAY and ADJUST Jumper Positions on

the BDC3 Control (A52)

YES

CFM Light on A52 Indicates Blower CFM

Selection with 100CFM / Blink

YES

Thermostat (S1) Demand Satisfied

YES

Blower Shuts Off According to the DELAY

Jumper Position on the BDC3 Control

(A52)

YES

Demand for Cooling Satisfied

Thermostat (S1) Calls for

2nd Stage Cooling

YES

Blower Operates at the 2nd

Stage Cooling Speed Determined by COOL, DELAY and

ADJUST Jumper Positions

on the BDC3 Control (A52)

YES

CFM Light on A52 Indicates Blower CFM Selection with 100CFM / Blink

YES

2nd Stage Thermostat

(S1) Demand Satisfied

YES

Blower Returns to 1st

Stage Cooling Speed

NO

NO

Check for 24 Volts Between Pins 14

and 3 on J49

NO

Check for 24 Volts

Between Pins 14 and

3 on J49

Check for 24 Volts Between Y2 on

TB1 and C on A15 Terminal Strip

Page 19

CBWMV SERIES

Page 20

WARNING

WARNING TO SERVICE PERSONS! Electric shock hazard. When electrical power to the internal

control box components must be available for troubleshooting, a common practice is to

construct a by−pass" of the door interlock switch. When such a by−pass is in place, a potential

shock hazard is present which can cause injury or death. Make sure any door interlock switch

by−pass has been removed after troubleshooting is complete and BEFORE attempting any repairs to the control box components!

Troubleshooting: Heating Sequence of Operation

CONDITIONS:

Power On

Normal Operation LED: Steady Flash

Thermostat (S1) Calls for Heat

YES

Fixed blower−ON delay (45−second) complete

Blower Operates at the Heating Speed Selected by

HEAT Jumper and ADJUST Jumper Positions on

the BDC3 Control (A52)

YES

CFM Light on A52 Indicates Blower

Speed Selection with 100CFM / Blink

YES

Thermostat (S1) Demand Satisfied

YES

30 Second Blower Off Delay (Fixed) Complete

YES

Demand for Heat Satisfied

NO

NO

Check for 24 Volts Between

W and C at A52 Terminal Strip

Check for 24 Volts Between Pins 3 and 2 on J49

505047 09/06

Page 20

Loading...

Loading...