Page 1

ENGINEERING DATA

COILS – BLOWER COIL UNITS

CB19 AND CBH19 SERIES

UP-FLOW, DOWN-FLOW AND HORIZONTAL

BLOWER COIL UNITS

*12,600 to 65,500 Btuh (3.7 to 19.2 kW) Cooling Capacity

11,500 to 60,000 Btuh (3.4 to 17.6 kW) Heat Pump Heating Capacity

6,400 to 102,400 Btuh (1.9 to 30.0 kW) Optional Electric Heat

*ARI Standard 210/240 Ratings With Matching Outdoor Unit

CB19/

CBH19

Bulletin #210056

January 1995

Supersedes

April 1994

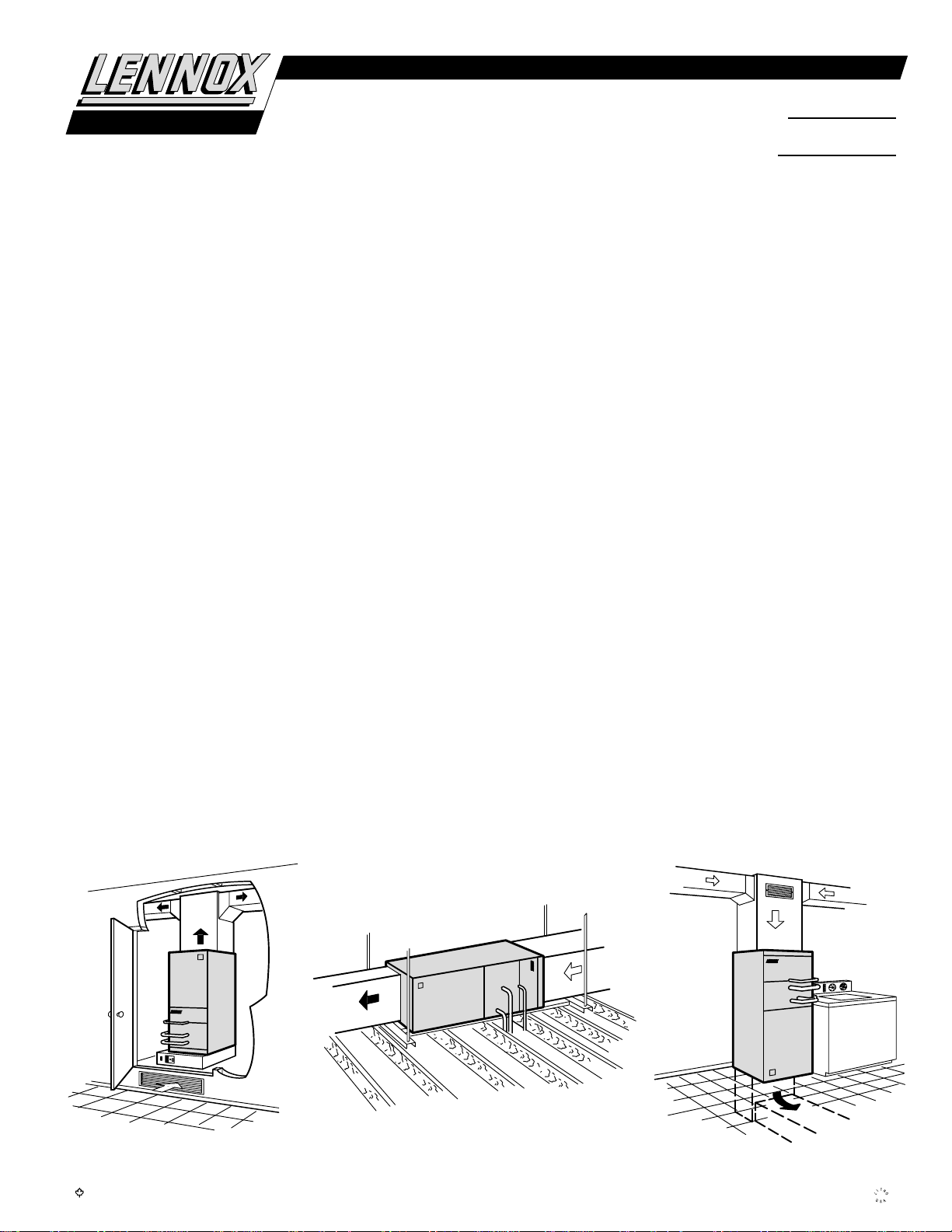

Applications —

signed for multi-position installation in a basement, utility

room, alcove, closet, crawlspace or attic. Units are applicable

to expansion valve systems in cooling applications and

check and expansion valve systems in heat pump applications. Units have factory installed check and expansion valve.

Several models are available in varying sizes with a wide

range of cooling and heating capacities. See Condensing Unit

bulletins in section Cooling Units — Condensing Units for

cooling capacities. See Heat Pump Outdoor Unit Bulletins in

section Heat Pumps — Matched Remote Systems for cooling

and heating capacities. Optional field installed electric heaters

are available in several sizes for additive heating capacity.

CB19 models are applicable to up-flow or down-flow discharge air applications. Units are shipped for up-flow applications and may easily be field converted to the downflow position by turning the unit upside down and

repositioning the coil, drip shields and cabinet access panel.

Filters are not furnished and must be provided by the installer. An optional side return air adapter with filter(s) is available for up-flow applications only. An optional additive

base is available for models with electric heat installed in

the down-flow position on combustible floors.

CBH19 models are designed for horizontal discharge air applications. Units are furnished with left hand air discharge as

standard and may be field changed to right hand discharge by

turning the unit over (end for end) and repositioning the coil.

CBH19-51 and CBH19-65 models are furnished in a two piece

cabinet with blower and optional electric heaters in one section and the indoor coil in the other. Hardware is furnished for

field connection of cabinets. Filters are not furnished and

must be provided by the installer.

The CB19 and CBH19 blower coil units are de-

CB19 MODEL — UP-FLO CB19 MODEL — DOWN-FLO

CBH19 MODEL — HORIZONTAL

Typical Applications

Horizontal Installation

Up-Flow Installation

with optional electronic air cleaner

The maple leaf symbol in this bulletin denotes Canadian only usage where applicable

NOTE — Due to Lennox’ ongoing committment to quality, Specifications, Ratings and Dimensions subject to change without notice and without incurring liability.

Down-Flow Installation

1995 Lennox Industries Inc.

Page 2

FEATURES

Completely Tested —

ing condensing units in the Lennox Research Laboratory environmental test room in accordance with ARI Standard

210/240-89. Optional electric heaters are rated in accordance

with U.S. Department of Energy (DOE) test procedures and

Federal Trade Commission (FTC) labeling regulations. Blower

performance data is according to actual unit tests conducted

in Lennox air test chamber. Blower-coil units and components

within are bonded for grounding to meet safety standards for

servicing required by U.L., C.S.A., CEC and NEC.

Cabinet —

completely insulated with thick fiberglass insulation. The prepainted steel cabinets have a finish of mildly textured enamel

with a primer coat on the unpainted side of all panels. Removable panels provide complete service access. Electrical inlets

are provided in both sides of cabinet. Return air entry is possible in either side or bottom of cabinet on up-flow units.

Drain Pan —

pipe drains extended outside of cabinet for ease of connection. See dimension drawings.

Constructed of heavy gauge galvanized steel and

Deep, corrosion resistant drain pan has dual

Direct Drive Blower —

built direct drive blower. Each blower is statically and dynamically balanced as an assembly before it is installed in the

unit. Multi-speed motor is resiliently mounted. A choice of

blower speeds is available. See blower performance tables.

Change of blower speeds is easily accomplished by a simple

change in wiring.

Refrigerant Line Connections —

lines have sweat connections and extend outside of the cabinet

for ease of connection. See dimension drawings for locations.

Check and Expansion Valve Furnished —

sion valve furnished and factory installed on all models.

Copper Tube/Enhanced Fin Evaporator Coil —

signed twin coils, assembled in a ‘V’ configuration, provides

extra large surface and contact area, excellent heat transfer

and low air resistance for maximum efficiency. Precise circuiting gives uniform refrigerant distribution. Lennox fabricated coil is constructed of precisely spaced ripple-edged aluminum fins fitted to durable seamless copper tubes. Fins are

strengthened to resist bending and are equipped with collars

that grip tubing for maximum contact area. Lanced fins provide maximum exposure of fin surface to air stream. Flared

shoulder tubing joints and silver soldering provide tight, leakproof joints. Long life copper tubing is easy to field service.

Coil is thoroughly factory tested under high pressure to insure leakproof construction.

Transformer and Blower Cooling Relay —

former and blower cooling relay are furnished as standard

equipment and are factory installed in the unit control box.

A terminal strip is also furnished as standard.

Blower coil units are tested with match-

Equipped with a Lennox designed and

Suction (vapor) and liquid

Check and expan-

Lennox de-

A 24 volt trans-

OPTIONAL ACCESSORIES (Must Be Ordered Extra)

Electric Heat (Optional) —

internal to the unit cabinet and are available in several kw sizes,

see Electric Heat table. The helix wound nichrome bare heating elements are exposed directly in the air stream resulting in

instant heat transfer, low element temperatures and long service life. Each heating element is equipped with accurately located limit control with fixed temperature off setting and automatic reset. In addition, elements have supplemental thermal

cutoff safety fuses providing positive protection in case of excessive temperatures. Cutoff fuses are mounted external to

the element face plate for quick and easy replacement. Thermal sequencer relay brings the heating elements on and off line,

in sequence and equal increments, with a time delay between

each element. Sequencer also initiates and terminates blower

operation. Heating control relay(s), is furnished as standard.

Control box and access cover are constructed of heavy gauge

galvanized steel. Heaters are factory assembled with controls

installed and wired and only require plug-in field connection.

Additive electric heaters field install

Circuit Breakers —

(208/240v-1ph) and ECB19-15,-20 and -25 kw (208/240v-3ph)

electric heaters are equipped with circuit breakers to provide

overload and short circuit protection. Breakers are factory

wired and mounted on electric heat unit. Circuit breakers are

current sensitive and temperature actuated to shut off heater if

current draw is excessive. Must be reset manually. Circuit

breakers qualify as the disconnect means at unit in many

areas and eliminate the need for a field provided disconnect.

Consult local electrical code in your area.

ECB19-12.5,-15,-20,-25 and -30 kw

Single-Point Power Source Control Box (Optional) —

Box (21H39) may be used with optional electric heat when

two or three circuits (if required by code) are specified. Field

installs external to the unit cabinet on either side or top. Provides single power service connection to the unit.

Constructed of heavy gauge steel with baked enamel finish,

prepunched mounting holes, electrical inlet knockouts, and

terminal strip. Removeable cover provides easy access.

Box is 7” x 7” x 4” deep (178mm x 178mm x 102mm), shipping

weight is 5 lbs. (2 kg.)

CCB1 EfficiencyPlus Humidity Control (Optional) —

CCB1 Humidity Control (35H00) is an electronic control which

installs next to the room thermostat and allows the selection of

the desired indoor humidity level in the cooling mode. During

the heating season the control is inoperable. The CCB1 controls

the indoor humidity by altering the indoor blower speed

and the compressor speed.

Humidity level desired may be

accomplished by adjusting a

vertical slide to a set point on

a scale of 40% thru 60% with

50% recommended as the initial set point. Five indicator

lights (MIN — MAX) in a bar

graph configuration indicate

the difference in the actual relative humidity and the set point. This indicates the demand

imposed on the system equipment, the more lights on, the

longer the equipment will operate to obtain the desired humidity level. If no lights are on, the humidity is at or below the

set point. Control is not furnished and must be ordered extra.

Requires EBR1 Blower Relay Kit

EBR1 Blower Relay Kit (Optional) —

(75H90) allows CCB1 to be used with CB19/CBH19 blower

coil units.

Down-Flow Additive Base (Optional) —

base is required for models with electric heat installed in the

down-flow position on combustible floors. Base is not furnished

and must be ordered extra for field installation. See Specifications table and dimension drawing.

Air Filters (Not Furnished) —

Specifications tables for sizes. Filter rails are provided in return

air opening of unit. See dimension drawings.

Filters must be ordered extra. See

EBR1 Blower Relay Kit

An optional additive

CB19 Up-Flow Side Return Air Filter Adaptor (Optional) —

Field installs on either side return air opening of up-flow cabinet. Constructed of heavy gauge galvanized steel with a bakedon paint finish. Equipped with flanges for ease of duct connection. Access panel allows easy removal an replacement of

filter(s). One inch thick (25mm) frame type filter is furnished as

standard. Media is washable or vacuum cleanable oil coated

polyurethane. CB19-21 thru 41 adaptor requires one filter.

CB19-51 and CB19-65 model has two. See Specification table

for sizes. CB19-51 and CB19-65 fiberglass insulated adaptor is

shipped knocked down and must be field assembled.

—2—

Control

The

Page 3

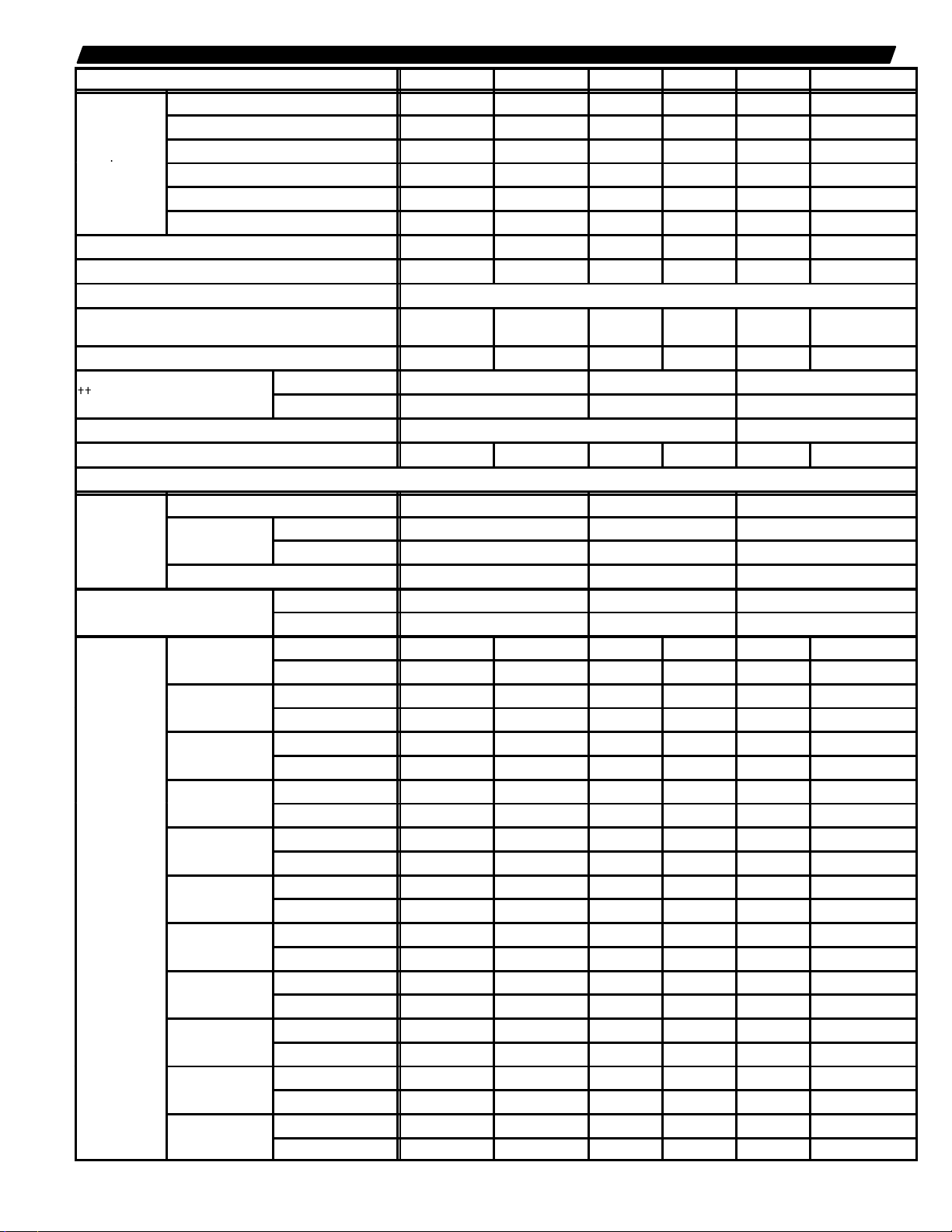

SPECIFICATIONS — CB19 UP-FLOW/DOWN-FLOW

p

{{Number and size of filters

Filter Adaptor

ECB19-2.5

ECB19-5

ECB19-6

ECB19-75

ECB19-8

Heat

ECB19-10

ECB19-12.5

ECB19-15

ECB19-20

ECB19-25

ECB19-30

Evaporator

Coil

Condensate drain connection (pvc) — in. (mm) (2) 3/4 (19) (2) 3/4 (19) (2) 3/4 (19) (2) 3/4 (19) (2) 3/4 (19) (2) 3/4 (19)

Nominal cooling capacity — tons (kW) 1-1/2 (5.3) 2 (7.0) 2-1/2 (8.8) 3 (10.6) 4 (14.1) 5 (17.6)

Refrigerant HCFC-22

Blower wheel nominal diameter x width — in. (mm)

Blower motor output — hp (W) 1/10 (75) 1/5 (149) 1/3 (149) 1/3 (249) 1/3 (249) 1/2 (373)

Electrical characteristics 208/230 volts — 60 hz — 1 ph 208/230/460 volt 60 hz – 1 ph

Shipping weight — lbs. (kg) 1 package 143 (65) 146 (66) 167 (76) 167 (76) 209 (95) 213 (97)

Side Return Air

(Up-Flow Only)

Down-Flow

Combustible Base

Electric

Capacity

{Annual Fuel Utilization Efficiency based on U.S. DOE test procedures and according to FTC labeling regulations

{{Filters are not furnished and must be ordered extra.

*Includes additional blower motor heat capacity.

Model Number CB19-21 CB19-26 CB19-31 CB19-41 CB19-51 CB19-65

Net face area — ft.2 (m2) 4.22 (0.39) 4.22 (0.39) 5.27 (0.49) 5.27 (0.49) 7.0 (0.65) 7.0 (0.65)

Tube outside diameter — in. (mm) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Number of rows 3 3 3 3 3 3

Fins per inch (fins per m) 12 (472) 12 (472) 13 (512) 13 (512) 14 (551) 14 (551)

Suct. (vapor) line conn. – in. (mm) sweat 5/8 (16) 5/8 (16) 3/4 (19) 3/4 (19) 7/8 (22.2) 1-1/8 (28)

Liquid line conn. — in. (mm) sweat 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

9 x 7

(229 x 178)

in. (1) 16 x 20 x 1 (1) 20 x 20 x 1 (1) 20 x 25 x 1

mm (1) 406 x 508 x 25 (1) 508 x 508 x 25 (1) 508 x 635 x 25

b Optional Accessories (Must Be Ordered Extra) b

Catalog number 95G73 95G74 95G75

Number and size

of filters

Shipping weight — lbs. (kg) 4 (2) 5 (2) 24 (11)

in. (1) 16 x 20 x 1 (1) 20 x 20 x 1 (2) 16 x 25 x 1

mm (1) 406 x 508 x 25 (1) 508 x 508 x 25 (2) 406 x 635 x 25

Catalog number 85G52 85G53 85G54

Ship. wt. – lbs. (kg) 8 (4) 8 (4) 8 (4)

*Output — Btuh (kW) 9,000 (2.6) 9,500 (2.8) - - - - - - - - - - - - - - - -

{A.F.U.E.

*Output — Btuh (kW) 18,000 (5.3) 18,000 (5.3) 18,000 (5.3) 18,000 (5.3) 19,000 (5.6) - - - -

{A.F.U.E.

*Output — Btuh (kW) 21,000 (6.2) 22,000 (6.4) 22,000 (6.4) 22,000 (6.4) 23,000 (6.7) - - - -

{A.F.U.E.

*Output — Btuh (kW) 25,000 (7.3) 25,000 (7.3) 25,000 (7.3) 25,000 (7.3) 26,000 (7.6) - - - -

{A.F.U.E.

*Output — Btuh (kW) 28,000 (8.2) 28,000 (8.2) 29,000 (8.5) 29,000 (8.5) 29,000 (8.5) 30,000 (8.8)

{A.F.U.E.

*Output — Btuh (kW) 35,000 (10.3) 35,000 (10.3) 35,000 (10.3) 35,000 (10.3) 36,000 (10.5) 37,000 (10.8)

{A.F.U.E.

*Output — Btuh (kW) - - - - 44,000 (12.9) 44,000 (12.9) 44,000 (12.9) 45,000 (13.2) 46,000 (13.5)

{A.F.U.E.

*Output — Btuh (kW) - - - - 52,000 (15.2) 52,000 (15.2) 53,000 (15.5) 53,000 (15.5) 54,000 (15.8)

{A.F.U.E.

*Output — Btuh (kW) - - - - - - - - - - - - 70,000 (20.5) 70,000 (20.5) 71,000 (20.8)

{A.F.U.E.

*Output — Btuh (kW) - - - - - - - - - - - - - - - - 87,000 (25.5) 88,000 (25.8)

{A.F.U.E.

*Output — Btuh (kW) - - - - - - - - - - - - - - - - - - - - 105,000 (30.8)

{A.F.U.E.

100% 100% - - - - - - - - - - - - - - - -

100% 100% 100% 100% 100% - - - -

100% 100% 100% 100% 100% - - - -

100% 100% 100% 100% 100% - - - -

100% 100% 100% 100% 100% 100%

100% 100% 100% 100% 100% 100%

- - - - 100% 100% 100% 100% 100%

- - - - 100% 100% 100% 100% 100%

- - - - - - - - - - - - 100% 100% 100%

- - - - - - - - - - - - - - - - 100% 100%

- - - - - - - - - - - - - - - - - - - - 100%

9 x 8

(229 x 203)

10 x 7

(254 x 178)

10 x 9

(254 x 229)

11 x 8

(279 x 203)

12 x 9

(317 x 229)

—3—

Page 4

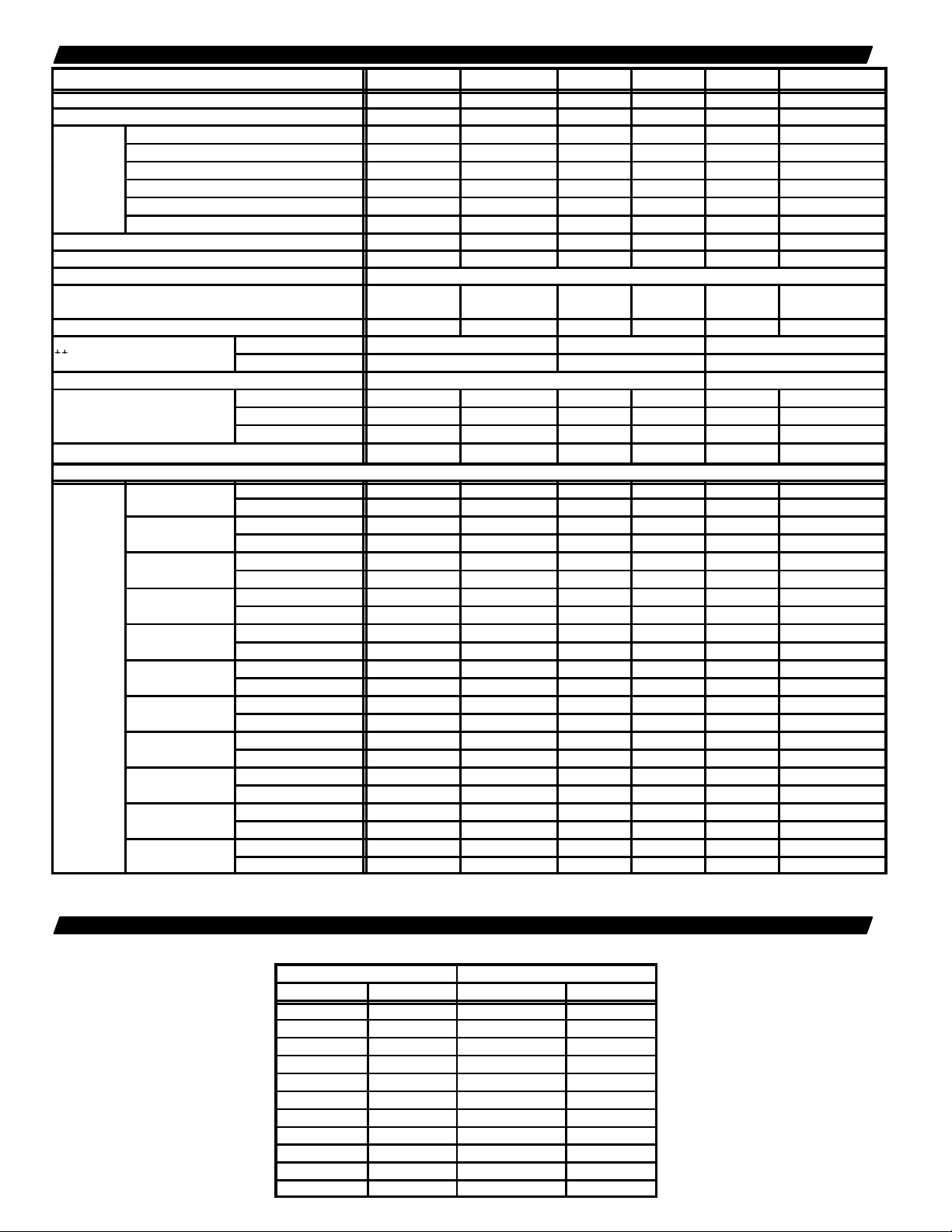

SPECIFICATIONS — CBH19 HORIZONTAL

{{Numb

fil

Shippi

ht

lbs. (kg)

ECB19-5

ECB19-6

ECB19-7

ECB19-8

Heat

y

ECB19-10

Capacity

ECB19-12.5

ECB19-15

ECB19-20

ECB19-25

ECB19-30

Model Number CBH19-21 CBH19-26 CBH19-31 CBH19-41 CBH19-51 CBH19-65

Blower section - - - - - - - - - - - - - - - - B19-51 B19-65

Indoor coil section - - - - - - - - - - - - - - - - CH19-51 CH19-65

Net face area — ft.2 (m2) 4.22 (0.39) 4.22 (0.39) 5.27 (0.49) 5.27 (0.49) 7.22 (0.67) 7.22 (0.67)

Tube outside diameter — in. (mm) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

Evaporator

Coil

Condensate drain connection (mpt) — in. (mm) (2) 3/4 (19) (2) 3/4 (19) (2) 3/4 (19) (2) 3/4 (19) (2) 3/4 (19) (2) 3/4 (19)

Nominal cooling capacity — tons (kW) 1-1/2 (5.3) 2 (7.0) 2-1/2 (8.8) 3 (10.6) 4 (14.1) 5 (17.6)

Refrigerant HCFC-22

Blower wheel nominal diameter x width — in. (mm)

Blower motor output — hp (W) 1/10 (75) 1/5 (149) 1/3 (149) 1/3 (249) 1/3 (249) 1/2 (373)

Electrical characteristics 208/230v — 60 hz — 1 ph 208/230/460v 60 hz – 1 ph

Number of packages in shipment

Electric

Capacit

{Annual Fuel Utilization Efficiency based on U.S. DOE test procedures and according to FTC labeling regulations

{{Filters are not furnished and must be ordered extra.

*Includes additional blower motor heat capacity.

Number of rows 3 3 3 3 3 3

Fins per inch (fins per m) 12 (472) 12 (472) 13 (512) 13 (512) 14 (551) 14 (551)

Suct. (vapor) line conn. — in. (mm) sweat 5/8 (16) 5/8 (16) 3/4 (19) 3/4 (19) 7/8 (22.2) 1-1/8 (28)

Liquid line connection — in. (mm) flare 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5) 3/8 (9.5)

er and size of

ng weig

9 x 7

(229 x 178)

in. (1) 16 x 20 x 1 (1) 20 x 20 x 1 (1) 20 x 25 x 1

ters

mm (1) 406 x 508 x 25 (1) 508 x 508 x 25 (1) 508 x 635 x 25

Complete unit 149 (68) 149 (68) 176 (80) 178 (81) 240 (109) 242 (109)

Blower section - - - - - - - - - - - - - - - - 118 (54) 120 (54)

9 x 8

(229 x 203)

10 x 7

(254 x 178)

10 x 9

(254 x 229)

11 x 8

(279 x 203)

Coil section - - - - - - - - - - - - - - - - 122 (55) 122 (55)

1 1 1 1 2 2

b Optional Accessories (Must Be Ordered Extra) b

ECB19-2.5

*Output — Btuh (kW) 9,000 (2.6) 9,500 (2.8) - - - - - - - - - - - - - - - -

{A.F.U.E. 99.8% 99.8% - - - - - - - - - - - - - - - -

*Output — Btuh (kW) 18,000 (5.3) 18,000 (5.3) 18,000 (5.3) 18,000 (5.3) 19,000 (5.6) - - - -

{A.F.U.E. 99.7% 99.7% 99.9% 100% 100% - - - -

*Output — Btuh (kW) 21,000 (6.2) 22,000 (6.4) 22,000 (6.4) 22,000 (6.4) 23,000 (6.7) - - - -

{A.F.U.E. 99.7% 99.7% 99.9% 100% 100% - - - -

*Output — Btuh (kW) 25,000 (7.3) 25,000 (7.3) 25,000 (7.3) 25,000 (7.3) 26,000 (7.6) - - - -

{A.F.U.E. 99.7% 99.7% 99.9% 100% 100% - - - -

*Output — Btuh (kW) 28,000 (8.2) 28,000 (8.2) 29,000 (8.5) 29,000 (8.5) 29,000 (8.5) 30,000 (8.8)

{A.F.U.E. 99.7% 99.7% 99.8% 100% 100% 100%

*Output — Btuh (kW) 35,000 (10.3) 35,000 (10.3) 35,000 (10.3) 35,000 (10.3) 36,000 (10.5) 37,000 (10.8)

{A.F.U.E. 99.7% 99.7% 99.8% 99.9% 100% 100%

*Output — Btuh (kW) - - - - 44,000 (12.9) 44,000 (12.9) 44,000 (12.9) 45,000 (13.2) 46,000 (13.5)

{A.F.U.E. - - - - 99.5% 99.7% 99.9% 100% 100%

*Output — Btuh (kW) - - - - 52,000 (15.2) 52,000 (15.2) 53,000 (15.5) 53,000 (15.5) 54,000 (15.8)

{A.F.U.E. - - - - 99.5% 99.7% 99.9% 100% 100%

*Output — Btuh (kW) - - - - - - - - - - - - 70,000 (20.5) 70,000 (20.5) 71,000 (20.8)

{A.F.U.E. - - - - - - - - - - - - 99.8% 99.8% 100%

*Output — Btuh (kW) - - - - - - - - - - - - - - - - 87,000 (25.5) 88,000 (25.8)

{A.F.U.E. - - - - - - - - - - - - - - - - 99.8% 99.9%

*Output — Btuh (kW) - - - - - - - - - - - - - - - - - - - - 105,000 (30.8)

{A.F.U.E. - - - - - - - - - - - - - - - - - - - - 99.9%

12 x 9

(317 x 229)

BLOWER DATA

UP-FLOW SIDE RETURN AIR FILTER ADAPTOR RESISTANCE

Air Volume Filter Resistance

cfm L/s in. wg. Pa

400 190 .01 2

600 285 .02 5

800 380 .03 7

1000 470 .05 12

1200 565 .08 20

1400 660 .08 20

1600 755 .08 20

1800 850 .09 22

2000 945 .09 22

2200 1040 .10 25

2400 1135 .10 25

—4—

Page 5

BLOWER DATA

CB19-21 AND CBH19-21 BLOWER PERFORMANCE

External Static

Pressure

in. wg. Pa cfm L/s cfm L/s cfm L/s

0 0 855 405 630 295 530 250

.05 12 830 390 625 295 525 250

.10 25 800 380 620 295 520 245

.15 37 765 360 610 290 515 245

.20 50 730 345 595 280 505 240

.25 62 685 325 570 270 490 230

.30 75 640 300 535 250 465 220

.40 100 525 250 425 200 365 170

NOTE — All air data is measured external to unit.

Electric heaters have no appreciable air resistance.

For optional up-flow air filter resistance see separate table.

CB19-31 AND CBH19-31 BLOWER PERFORMANCE

External Static

Pressure

in. wg. Pa cfm L/s cfm L/s cfm L/s

0 0 1400 660 1270 600 1050 495

.05 12 1370 645 1250 590 1050 495

.10 25 1335 630 1220 575 1050 495

.15 37 1290 610 1190 560 1040 490

.20 50 1240 585 1150 545 1025 485

.25 62 1190 560 1110 525 1000 470

.30 75 1130 535 1060 500 970 460

.40 100 1000 470 945 445 885 420

.50 125 855 405 815 385 765 360

NOTE — All air data is measured external to unit.

Electric heaters have no appreciable air resistance.

For optional up-flow air filter resistance see separate table.

CB19-51 AND CBH19-51 BLOWER PERFORMANCE

External Static

Pressure

in. wg. Pa cfm L/s cfm L/s cfm L/s

0 0 1950 920 1640 775 1380 650

.05 12 1910 900 1620 765 1370 645

.10 25 1870 880 1600 755 1350 635

.15 37 1830 865 1580 745 1330 630

.20 50 1780 840 1550 730 1310 620

.25 62 1730 815 1520 715 1290 610

.30 75 1680 795 1490 705 1260 595

.40 100 1570 740 1400 660 1200 565

.50 125 1410 665 1280 605 1100 520

NOTE — All air data is measured external to unit.

Electric heaters have no appreciable air resistance.

For optional up-flow air filter resistance see separate table.

CB19-65 AND CBH19-65 BLOWER PERFORMANCE

External Static

Pressure

in. wg. Pa cfm L/s cfm L/s cfm L/s

0 0 2415 1140 2205 1040 1830 865

.05 12 2360 1115 2165 1020 1815 855

.10 25 2305 1090 2125 1005 1800 850

.15 37 2245 1060 2085 985 1780 840

.20 50 2185 1030 2040 965 1760 830

.25 62 2130 1005 2000 945 1735 820

.30 75 2070 975 1950 920 1705 805

.40 100 1940 915 1845 870 1630 770

.50 125 1810 855 1725 815 1540 725

.60 150 1665 785 1585 750 1405 665

NOTE — All air data is measured external to unit.

Electric heaters have no appreciable air resistance.

For optional up-flow air filter resistance see separate table.

Air Volume at Various Blower Speeds

High Medium Low

Air Volume at Various Blower Speeds

High Medium Low

WITH 208/230 VOLT MOTOR

Air Volume at Various Blower Speeds

High Medium Low

WITH 208/230 VOLT MOTOR

Air Volume at Various Blower Speeds

High Medium Low

CB19-26 AND CBH19-26 BLOWER PERFORMANCE

External Static

Pressure

in. wg. Pa cfm L/s cfm L/s cfm L/s

0 0 1150 545 1020 480 870 410

.05 12 1105 520 985 465 860 405

.10 25 1065 505 955 450 850 400

.15 37 1020 480 920 435 825 390

.20 50 960 455 875 415 795 375

.25 62 905 425 830 390 755 355

.30 75 845 400 780 370 710 335

.40 100 680 320 625 295 550 260

NOTE — All air data is measured external to unit.

Electric heaters have no appreciable air resistance.

For optional up-flow air filter resistance see separate table.

Air Volume at Various Blower Speeds

High Medium Low

CB19-41 AND CBH19-41 BLOWER PERFORMANCE

External Static

Pressure

in. wg. Pa cfm L/s cfm L/s cfm L/s

0 0 1630 770 1380 650 1130 535

.05 12 1590 750 1370 645 1150 545

.10 25 1550 730 1350 635 1160 545

.15 37 1500 710 1330 630 1160 545

.20 50 1460 685 1310 620 1160 545

.25 62 1400 660 1270 600 1150 545

.30 75 1340 630 1230 580 1130 535

.40 100 1200 565 1130 535 1050 495

.50 125 1010 475 960 455 890 420

NOTE — All air data is measured external to unit.

Electric heaters have no appreciable air resistance.

For optional up-flow air filter resistance see separate table.

Air Volume at Various Blower Speeds

High Medium Low

CB19-51 AND CBH19-51 BLOWER PERFORMANCE

WITH 460 VOLT (1 phase) MOTOR

External Static

Pressure

in. wg. Pa cfm L/s cfm L/s

0 0 2020 955 1630 770

.05 12 1950 920 1610 760

.10 25 1920 905 1600 755

.15 37 1870 880 1570 740

.20 50 1820 860 1540 725

.25 62 1770 835 1500 710

.30 75 1710 805 1460 690

.40 100 1590 750 1350 635

.50 125 1430 675 1250 590

NOTE — All air data is measured external to unit.

Electric heaters have no appreciable air resistance.

For optional up-flow air filter resistance see separate table.

Air Volume at Various Blower Speeds

High Low

CB19-65 AND CBH19-65 BLOWER PERFORMANCE

WITH 460 VOLT (1 phase) MOTOR

External Static

Pressure

in. wg. Pa cfm L/s cfm L/s

0 0 2380 1125 2250 1060

.05 12 2340 1105 2180 1030

.10 25 2290 1080 2140 1010

.15 37 2250 1060 2110 995

.20 50 2190 1035 2065 975

.25 62 2130 1005 2015 950

.30 75 2075 980 1970 930

.40 100 1945 920 1860 880

.50 125 1820 860 1760 830

NOTE — All air data is measured external to unit.

Electric heaters have no appreciable air resistance.

For optional up-flow air filter resistance see separate table.

—5—

Air Volume at Various Blower Speeds

High Low

Page 6

ELECTRIC HEAT DATA — CB19/CBH19-21,-26

Model Number

& Shipping Weight

Steps & Phase

Input

Input

Input

Amps

(68G86)

(g)

ECB19-5

(69G87)

g

ECB19-6

(69G88)

g

ECB19-7

(69G89)

g

ECB19-8

(69G90)

g

ECB19-10

(69G91)

g

ECB19-2.5

(69G86)

g

ECB19-5

(69G87)

g

ECB19-6

(69G88)

g

ECB19-7

(69G89)

g

ECB19-8

(69G90)

g

ECB19-10

(69G91)

g

ECB19-12.5

(69G92)

g

(69G93)

(g)

Blower Coil Unit

Electric Heat Model Number

Number of

Volts

kW

**Btuh

DBlower

Circuit 1 Circuit 2

ECB19-2.5

4 lbs. (2 kg)

4 lbs. (2 kg)

5 lbs. (2 kg)

CB19-21

CBH19-21

5 lbs. (2 kg)

5 lbs. (2 kg)

5 lbs. (2 kg)

4 lbs. (2 kg)

4 lbs. (2 kg)

5 lbs. (2 kg)

5 lbs. (2 kg)

CB19-26

CBH19-26

5 lbs. (2 kg)

5 lbs. (2 kg)

10 lbs. (5 kg)

ECB19-15

10 lbs. (5 kg)

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements. Use wires suitable for at least 167°F (75_C).

**Electric heater capacity only — does not include additional blower motor heat capacity.

DMinimum circuit ampacity for blower motor only.

1 step

1 phase

1 step

1 phase

2 steps

1 phase

2 steps

1 phase

2 steps

1 phase

2 steps

1 phase

1 step

1 phase

1 step

1 phase

2 steps

1 phase

2 steps

1 phase

2 steps

1 phase

2 steps

1 phase

3 steps

1 phase

3 steps

1 phase

208 1.9 6,400 1.0 12.3 - - - 220 2.1 7,200 1.0 12.8 - - - 230 2.3 7,800 1.0 13.4 - - - 240 2.5 8,500 1.0 13.9 - - - -

208 3.8 12,800 1.0 23.5 - - - -

220 4.2 14,300 1.0 24.8 - - - 230 4.6 15,700 1.0 25.9 - - - 240 5.0 17,100 1.0 26.9 - - - -

208 4.5 15,400 1.0 28.0 - - - -

220 5.0 17,100 1.0 29.3 - - - 230 5.5 18,800 1.0 30.9 - - - 240 6.0 20,500 1.0 32.2 - - - -

208 5.3 17,900 1.0 32.5 - - - -

220 5.9 20,100 1.0 34.4 - - - 230 6.4 21,900 1.0 35.8 - - - 240 7.0 23,900 1.0 37.4 - - - -

208 6.0 20,500 1.0 37.0 - - - -

220 6.7 22,900 1.0 39.0 - - - 230 7.3 25,100 1.0 40.8 - - - 240 8.0 27,300 1.0 42.6 - - - -

208 7.5 25,600 1.0 45.9 - - - -

220 8.4 28,700 1.0 48.6 - - - 230 9.2 31,400 1.0 50.8 - - - 240 10.0 34,100 1.0 53.0 - - - -

208 1.9 6,400 2.0 13.2 - - - -

220 2.1 7,200 2.0 13.7 - - - 230 2.3 7,800 2.0 14.3 - - - 240 2.5 8,500 2.0 14.8 - - - -

208 3.8 12,800 2.0 24.4 - - - -

220 4.2 14,300 2.0 25.7 - - - 230 4.6 15,700 2.0 26.8 - - - 240 5.0 17,100 2.0 27.8 - - - -

208 4.5 15,400 2.0 28.9 - - - -

220 5.0 17,200 2.0 30.2 - - - 230 5.5 18,800 2.0 31.8 - - - 240 6.0 20,500 2.0 33.7 - - - -

208 5.3 17,900 2.0 33.4 - - - -

220 5.9 20,100 2.0 35.3 - - - 230 6.4 21,900 2.0 36.7 - - - 240 7.0 23,900 2.0 38.3 - - - -

208 6.0 20,500 2.0 37.9 - - - -

220 6.7 22,900 2.0 39.9 - - - 230 7.3 25,100 2.0 41.7 - - - 240 8.0 27,300 2.0 43.4 - - - -

208 7.5 25,600 2.0 46.8 - - - -

220 8.4 28,700 2.0 49.5 - - - 230 9.2 31,400 2.0 51.7 - - - 240 10.0 34,100 2.0 53.9 - - - -

208 9.4 32,000 2.0 39.4 18.9

220 10.5 35,800 2.0 41.2 19.9

230 11.5 39,200 2.0 43.4 20.8

240 12.5 42,600 2.0 45.2 21.8

208 11.3 38,400 2.0 46.9 22.7

220 12.6 43,000 2.0 49.1 23.9

230 13.5 47,000 2.0 51.7 25.0

240 15.0 51,200 2.0 53.9 26.0

—6—

*Minimum

Circuit Ampacity

Page 7

ELECTRIC HEAT DATA — CB19/CBH19-31,-41

Model Number

& Shipping Weight

Steps & Phase

Input

Input

Input

Amps

(69G87)

(69G88)

p

(69G89)

p

and

(69G90)

p

(69G91)

p

(68G92)

p

(69G93)

p

(69G97)

p

(69G98)

p

(69G99)

p

(70G00)

p

(69G94)

p

Blower Coil Unit

Electric Heat Model Number

Number of

Volts

kW

**Btuh

DBlower

*Minimum

Circuit Ampacity

Circuit 1 Circuit 2

208 3.8 12,800 3.0 25.0 - - - -

ECB19-5

4 lbs. (2 kg)

ECB19-6

5 lbs. (2 kg)

ECB19-7

5 lbs. (2 kg)

CB19-31

CBH19-31

CB19-41

CBH19-41

CB19-41

CBH19-41

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements. Use wires suitable for at least 167°F (75_C).

**Electric heater capacity only — does not include additional blower motor heat capacity.

DMinimum circuit ampacity for blower motor only.

ECB19-8

5 lbs. (2 kg)

ECB19-10

5 lbs. (2 kg)

ECB19-12.5

10 lbs. (5 kg)

ECB19-15

10 lbs. (5 kg)

ECB19-5

6 lbs. (3 kg)

ECB19-7.5

6 lbs. (3 kg)

ECB19-10

6 lbs. (3 kg)

ECB19-15

9 lbs. (4 kg)

ECB19-20

14 lbs. (6 kg)

1 step

1 phase

2 steps

1 phase

2 steps

1 phase

2 steps

1 phase

2 steps

1 phase

3 steps

1 phase

3 steps

1 phase

3 steps

3 phase

3 steps

3 phase

3 steps

3 phase

3 steps

3 phase

3 steps

1 phase

220 4.2 14,300 3.0 26.3 - - - -

230 4.6 15,700 3.0 27.4 - - - -

240 5.0 17,100 3.0 28.4 - - - -

208 4.5 15,400 3.0 29.5 - - - -

220 5.0 17,100 3.0 30.8 - - - -

230 5.5 18,800 3.0 32.4 - - - -

240 6.0 20,500 3.0 33.7 - - - -

208 5.3 17,900 3.0 34.0 - - - -

220 5.9 20,100 3.0 35.9 - - - -

230 6.4 21,900 3.0 37.3 - - - -

240 7.0 23,900 3.0 38.9 - - - -

208 6.0 20,500 3.0 38.5 - - - -

220 6.7 22,900 3.0 40.5 - - - -

230 7.3 25,100 3.0 43.3 - - - -

240 8.0 27,300 3.0 44.0 - - - -

208 7.5 25,600 3.0 47.4 - - - -

220 8.4 28,700 3.0 50.1 - - - -

230 9.2 31,400 3.0 52.3 - - - -

240 10.0 34,100 3.0 54.5 - - - -

208 9.4 32,000 3.0 40.0 18.9

220 10.5 35,800 3.0 42.2 19.9

230 11.5 39,200 3.0 44.0 20.8

240 12.5 42,600 3.0 45.8 21.8

208 11.3 38,400 3.0 47.5 22.7

220 12.6 43,000 3.0 50.1 23.9

230 13.5 47,000 3.0 52.3 25.0

240 15.0 51,200 3.0 54.5 26.0

208 3.8 12,800 3.0 15.4 - - - -

220 4.2 14,300 3.0 16.2 - - - -

230 4.6 15,700 3.0 16.8 - - - -

240 5.0 17,100 3.0 17.4 - - - -

208 5.6 19,200 3.0 21.9 - - - -

220 6.3 21,500 3.0 23.0 - - - -

230 6.9 23,500 3.0 24.0 - - - -

240 7.5 25,600 3.0 24.9 - - - -

208 7.5 25,600 3.0 28.4 - - - -

220 8.4 28,700 3.0 29.9 - - - -

230 9.2 31,400 3.0 31.3 - - - -

240 10.0 34,100 3.0 32.5 - - - -

208 11.3 38,400 3.0 41.5 - - - -

220 12.6 43,000 3.0 43.7 - - - -

230 13.5 47,000 3.0 45.7 - - - -

240 15.0 51,200 3.0 47.5 - - - -

208 15.0 51,200 3.0 47.4 45.0

220 16.8 57,300 3.0 50.1 47.8

230 18.4 62,700 3.0 52.3 49.9

240 20.0 68,200 3.0 54.5 52.2

—7—

Page 8

ELECTRIC HEAT DATA — CB19/CBH19-51

Unit

Model Number

p

(69G87)

g)

1 step

4 lbs. (2 kg)

(69G88)

g)

2 steps

5 lbs. (2 kg)

(69G89)

g)

2 steps

5 lbs. (2 kg)

ECB19 7

3

12 lb

)

3 phase

(69G98)

g)

3 steps

6 lbs. (3 kg)

(69G90)

g)

2 steps

5 lbs. (2 kg)

(69G91)

g)

2 steps

5 lbs. (2 kg)

(69G99)

g)

3 steps

6 lbs. (3 kg)

CB19 51

ECB19 10

3

12 lb

)

3 phase

(68G92)

g)

3 steps

10 lbs. (5 kg)

(69G93)

g)

3 steps

10 lbs. (5 kg)

(70G00)

g)

3 steps

9 lbs. (4 kg)

5

ECB19 15

3

12 lb

)

3 phase

(69G94)

g)

4 steps

14 lbs. (6 kg)

(70G01)

g)

6 steps

19 lbs. (9 kg)

ECB19 20

6

18 lb

)

3 phase

(69G95)

g)

5 steps

18 lbs. (8 kg)

Blower Coil

Model Number

CB19-51

CBH19-51

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements. Use wires suitable for at least 167°F (75_C).

**Electric heater capacity only — does not include additional blower motor heat capacity.

DMinimum circuit ampacity for blower motor only.

Electric Heat

& Shipping Weight

ECB19-5

4 lbs. (2 k

ECB19-6

5 lbs. (2 k

ECB19-7

5 lbs. (2 k

EB1-7

(70G03)

s. (5 kg

ECB19-7.5

6 lbs. (3 k

ECB19-8

5 lbs. (2 k

ECB19-10

5 lbs. (2 k

ECB19-10

6 lbs. (3 k

ECB19-10

(70G04)

s. (5 kg

ECB19-12.5

10 lbs. (5 k

ECB19-15

10 lbs. (5 k

ECB19-15

9 lbs. (4 k

ECB19-1

(70G05)

s. (5 kg

ECB19-20

14 lbs. (6 k

ECB19-20

19 lbs. (9 k

ECB19-20

(70G06)

s. (8 kg

ECB19-25

18 lbs. (8 k

Number of

Steps & Phase Input Input Input

1 ste

1 phase

2 steps

1 phase

2 steps

1 phase

steps

3 steps

3 phase

2 steps

1 phase

2 steps

1 phase

3 steps

3 phase

steps

3 steps

1 phase

3 steps

1 phase

3 steps

3 phase

steps

4 steps

1 phase

6 steps

3 phase

steps

5 steps

1 phase

Volts kW **Btuh

208 3.8 12,800 3.0 25.7 - - - - - - - 220 4.2 14,300 3.0 26.9 - - - - - - - 230 4.6 15,700 3.0 28.0 - - - - - - - 240 5.0 17,100 3.0 29.0 - - - - - - - 208 4.5 15,400 3.0 30.2 - - - - - - - 220 5.0 17,100 3.0 31.4 - - - - - - - 230 5.5 18,800 3.0 33.0 - - - - - - - 240 6.0 20,500 3.0 34.3 - - - - - - - 208 5.3 17,900 3.0 34.7 - - - - - - - 220 5.9 20,100 3.0 36.6 - - - - - - - 230 6.4 21,900 3.0 37.9 - - - - - - - 240 7.0 23,900 3.0 39.5 - - - - - - - 440 5.9 20,100 3.0 11.3 - - - - - - - 460 6.4 21,900 3.0 11.7 - - - - - - - 480 7.0 25,900 3.0 12.2 - - - - - - - 208 5.6 19,200 3.0 22.5 - - - - - - - 220 6.3 21,500 3.0 23.7 - - - - - - - 230 6.9 23,500 3.0 24.7 - - - - - - - 240 7.5 25,600 3.0 25.5 - - - - - - - 208 6.0 20,500 3.0 39.2 - - - - - - - 220 6.7 22,900 3.0 41.1 - - - - - - - 230 7.3 25,100 3.0 42.9 - - - - - - - 240 8.0 27,300 3.0 44.7 - - - - - - - 208 7.5 25,600 3.0 48.0 - - - - - - - 220 8.4 28,700 3.0 50.8 - - - - - - - 230 9.2 31,400 3.0 52.9 - - - - - - - 240 10.0 34,100 3.0 55.2 - - - - - - - 208 7.5 25,600 3.0 29.0 - - - - - - - 220 8.4 28,700 3.0 30.6 - - - - - - - 230 9.2 31,400 3.0 31.9 - - - - - - - 240 10.0 34,100 3.0 33.2 - - - - - - - 440 8.4 28,700 2.0 15.4 - - - - - - - 460 9.2 31,400 2.0 16.1 - - - - - - - 480 10.0 34,100 2.0 16.7 - - - - - - - 208 9.4 32,000 3.0 40.7 18.9 - - - 220 10.5 35,800 3.0 42.8 19.9 - - - 230 11.5 39,200 3.0 44.7 20.8 - - - 240 12.5 42,600 3.0 46.4 21.8 - - - 208 11.3 38,400 3.0 48.2 22.7 - - - 220 12.6 43,000 3.0 50.8 23.9 - - - 230 13.5 47,000 3.0 52.9 25.0 - - - 240 15.0 51,200 3.0 55.2 26.0 - - - 208 11.3 38,400 2.0 42.2 - - - - - - - 220 12.6 43,000 2.0 44.3 - - - - - - - 230 13.5 47,000 2.0 46.3 - - - - - - - 240 15.0 51,200 2.0 48.2 - - - - - - - 440 12.6 43,000 2.0 22.3 - - - - - - - 460 13.8 47,000 2.0 23.3 - - - - - - - 480 15.0 51,200 2.0 24.2 - - - - - - - 208 15.0 51,200 3.0 48.0 45.0 - - - 220 16.8 57,300 3.0 50.8 47.8 - - - 230 18.4 62,700 3.0 52.9 49.9 - - - 240 20.0 68,200 3.0 55.2 52.2 - - - 208 15.0 51,200 2.0 29.0 26.0 - - - 220 16.8 57,300 2.0 30.6 27.6 - - - 230 18.4 62,700 2.0 31.9 28.9 - - - 240 20.0 68,200 2.0 33.2 30.2 - - - 440 16.8 57,300 2.0 29.2 - - - - - - - 460 18.4 62,700 2.0 30.5 - - - - - - - 480 20.0 68,200 2.0 31.7 - - - - - - - 208 18.8 64,100 2.0 48.0 45.0 22.7

220 21.0 71,700 2.0 50.8 47.8 23.9

230 23.0 78,300 2.0 52.9 49.9 25.0

240 25.0 85,300 2.0 55.2 52.2 26.0

DBlower

Amps

*Minimum Circuit Ampacity

Circuit 1 Circuit 2 Circuit 3

—8—

Page 9

ELECTRIC HEAT DATA — CB19/CBH19-65

Unit

Model Number

(69G90)

(g)

ECB19-10

(69G91)

g

ECB19-10

(69G99)

g

3 st

p

6 lb

)

3 phase

ECB19-12.5

(69G92)

g

ECB19-15

(69G93)

g

ECB19-15

(70G00)

g

3 st

p

12 lb

)

3 phase

ECB19-20

(69G94)

g

ECB19-20

(70G01)

g

6 st

p

18 lb

)

3 phase

(69G95)

(g)

(70G02)

(g)

6 st

p

18 lb

)

3 phase

(69G96)

(g)

Model Number

*Refer to National or Canadian Electrical Code manual to determine wire, fuse and disconnect size requirements. Use wires suitable for at least 167°F (75_C).

**Electric heater capacity only — does not include additional blower motor heat capacity.

DMinimum circuit ampacity for blower motor only.

Blower Coil

CB19-65 ECB19-15

CBH19-65 (70G05)

Electric Heat

& Shipping Weight

ECB19-8

5 lbs. (2 kg)

5 lbs. (2 kg)

12 lbs. (5 kg)

ECB19-10

(70G04)

s. (3 kg

10 lbs. (5 kg)

10 lbs. (5 kg)

9 lbs. (4 kg)

s. (5 kg

14 lbs. (6 kg)

19 lbs. (9 kg)

ECB19-20

(70G06)

s. (8 kg

ECB19-25

18 lbs. (8 kg)

ECB19-25

19 lbs. (9 kg)

ECB19-25

(70G07)

s. (8 kg

ECB19-30

19 lbs. (9 kg)

Number of Volts kW **Btuh

Steps & Phase Input Input Input

208 6.0 20,500 6.0 41.7 - - - - - - - -

2 steps

1 phase

2 steps

1 phase

3 steps

3 phase

eps

3

hase

3 steps

1 phase

3 steps

1 phase

3 steps

3 phase

eps

hase

3

4 steps

1 phase

6 steps

3 phase

eps

3

hase

5 steps

1 phase

6 steps

3 phase

eps

3

hase

6 steps

1 phase

220 6.7 22,900 6.0 43.6 - - - - - - - 230 7.3 25,100 6.0 45.4 - - - - - - - 240 8.0 27,300 6.0 47.2 - - - - - - - -

208 7.5 25,600 6.0 50.5 - - - - - - - -

220 8.4 28,700 6.0 53.3 - - - - - - - 230 9.2 31,400 6.0 55.4 - - - - - - - 240 10.0 34,100 6.0 57.7 - - - - - - - -

208 7.5 25,600 6.0 31.5 - - - - - - - -

220 8.4 28,700 6.0 33.1 - - - - - - - 230 9.2 31,400 6.0 34.4 - - - - - - - 240 10.0 34,100 6.0 35.7 - - - - - - - -

440 8.4 28,700 3.0 16.2 - - - - - - - -

460 9.2 31,400 3.0 16.8 - - - - - - - 480 10.0 34,100 3.0 17.4 - - - - - - - -

208 9.4 32,000 6.0 43.2 18.9 - - - -

220 10.5 35,800 6.0 45.3 19.9 - - - 230 11.5 39,200 6.0 47.2 20.8 - - - 240 12.5 42,600 6.0 48.9 21.8 - - - -

208 11.3 38,400 6.0 50.7 22.7 - - - -

220 12.6 43,000 6.0 53.3 23.9 - - - 230 13.5 47,000 6.0 55.4 25.0 - - - 240 15.0 51,200 6.0 57.7 26.0 - - - -

208 11.3 38,400 6.0 44.7 - - - - - - - -

220 12.6 43,000 6.0 46.8 - - - - - - - 230 13.5 47,000 6.0 48.8 - - - - - - - 240 15.0 51,200 6.0 50.7 - - - - - - - -

440 12.6 43,000 3.0 23.0 - - - - - - - -

460 13.8 47,000 3.0 24.0 - - - - - - - 480 15.0 51,200 3.0 24.9 - - - - - - - -

208 15.0 51,200 6.0 50.5 45.0 - - - -

220 16.8 57,300 6.0 53.3 47.8 - - - 230 18.4 62,700 6.0 55.4 49.9 - - - 240 20.0 68,200 6.0 57.7 52.2 - - - -

208 15.0 51,200 6.0 31.5 26.0 - - - -

220 16.8 57,300 6.0 33.1 27.6 - - - 230 18.4 62,700 6.0 34.4 28.9 - - - 240 20.0 68,200 6.0 35.7 30.2 - - - -

440 16.8 57,300 3.0 29.9 - - - - - - - -

460 18.4 62,700 3.0 31.2 - - - - - - - 480 20.0 68,200 3.0 32.4 - - - - - - - -

208 18.8 64,100 6.0 50.5 45.0 22.7

220 21.0 71,700 6.0 53.3 47.8 23.9

230 23.0 78,300 6.0 55.4 49.9 25.0

240 25.0 85,300 6.0 57.7 52.2 26.0

208 18.8 64,100 6.0 38.2 32.7 - - - -

220 21.0 71,700 6.0 39.9 34.4 - - - 230 23.0 78,300 6.0 41.5 36.0 - - - -

240 25.0 85,300 6.0 43.2 37.7 - - - -

440 21.0 71,700 3.0 36.8 - - - - - - - -

460 23.0 78,300 3.0 38.4 - - - - - - - 480 25.0 85,300 3.0 39.9 - - - - - - - -

208 22.5 76,900 6.0 50.5 45.0 45.0

220 25.2 86,000 6.0 53.3 47.8 47.8

230 27.5 94,000 6.0 55.4 49.9 49.9

240 30.0 102,400 6.0 57.7 52.2 52.2

—9—

DBlower

Amps

*Minimum Circuit Ampacity

Circuit 1 Circuit 2 Circuit 3

Page 10

DIMENSIONS — inches (mm)

1-1/16 (27)

CB19 UP-FLOW POSITION

1-1/16

(27)

FILTER

RAILS (2)

(Filter Not

Furnished)

1-1/16

(27)

D

E

SUPPLY

AIR

OPENING

TOP VIEW

ELECTRICAL INLETS

B

AIR FLOW

BLOWER

(Both Sides)

5/8

(16)

A

1-1/2

(38)

3 (76)

G

Return Air

H

M

L

1-1/2

(38)

LIQUID

LINE

SUCTION

K

LINE

J

CONDENSATE

DRAINS (2)

1-1/16

(27)

FRONT VIEW SIDE VIEW

C

BLOWER

N

P

4-1/4 (108)

F

Return Air

OPTIONAL

ELECTRIC HEAT

(Field Installed)

2-1/2 (64)

RETURN AIR

OPENING

(Either Side

or Bottom)

3/4

(19)

Model

No.

CB19-21 & -26 CB19-31 & -41 CB19-51 & -65

inch mm inch mm inch mm

A 48 1219 51 1295 60 1524

B 18-1/4 464 21-1/2 546 23-1/4 591

C 23-1/4 591 23-1/4 591 25-1/4 641

D 18 457 18 457 20 508

E 15-7/8 403 19-1/8 486 20-7/8 530

F 21-7/16 545 21-7/16 545 23-7/16 595

G 15 381 18-1/4 464 20 508

H 9-1/8 232 10-3/4 273 11-5/8 295

J 7-7/16 189 10-5/16 262 11-11/16 297

K 5-1/4 133 5-1/4 133 10 254

L 7-9/16 192 9-3/16 233 10-1/16 256

M 5-5/8 143 5-3/16 132 7-11/16 195

N 18-1/4 464 18-1/4 464 20-1/4 514

P 14-1/4 362 18-1/4 464 25-1/4 641

CB19 DOWN-FLOW POSITION

NOTE — When unit with optional electric heat is installed on a combustible floor,

an additive base is required. Base is optional and must be ordered extra.

When using additive base make opening in floor 2-3/8 inches (60mm)

larger (side to side) and 2-1/2 inches (64mm) larger (front to rear) than

unit supply air opening.

Model

No.

CB19-21 & -26 CB19-31 & -41 CB19-51 & -65

inch mm inch mm inch mm

A 48 1219 51 1295 60 1524

B 18-1/4 464 21-1/2 546 23-1/4 591

C 23-1/4 591 23-1/4 591 25-1/4 641

D 18 457 18 457 20 508

E 15-7/8 403 19-1/8 486 20-7/8 530

F 21-7/16 545 21-7/16 545 23-7/16 595

G 15 381 18-1/4 464 20 508

H 9-1/8 232 10-3/4 273 11-5/8 295

J 8-15/16 227 12-3/4 324 11-7/18 302

K 5-1/4 133 5-1/4 133 10 254

L 7-9/16 192 9-3/16 233 10-1/16 256

M 9-3/16 233 22 559 25-7/8 657

—10—

3/4

(19)

1-1/16

(27)

1-1/2 (38)

1-1/16

(27)

FILTER RAILS (2)

(Filter Not Furnished)

G

RETURN

OPENING

1-1/2 (38)

TOP VIEW

F

AIR

C B

LIQUID

AIR

FLOW

BLOWER

Supply Air

LINE

SUCTION

LINE

CONDENSATE

DRAINS (2)

ELECTRICAL

INLETS

(Both Sides)

OPTIONAL

ELECTRIC HEAT

(Field Installed)

5/8

(16)

A

1-1/16

M

(27)

H

BLOWER

Supply Air

FRONT VIEWSIDE VIEW

(76)

J

K

L

3

ED

1-1/16

(27)

Page 11

DIMENSIONS — inches (mm)

*NOTE—Air flow may be

either direction.

UP-FLOW SIDE RETURN AIR FILTER ADAPTOR (CB19-21,-26,-31 and -41)

*AIR FLOW

AIR FILTER

(Furnished)

3/4

(19)

1-3/16

(30)

3/4

(19)

1

(25)

20

(508)

OPENING

SAME

BOTH SIDES

18

(457)

1

(25)

A

Model

B

1

(25)

Number

CB19-21 & 26

CB19-31 & 41

A

Inch mm

1620406

5081418

B

Inch mm

356

457

*NOTE—Air flow may be

either direction.

OPTIONAL

18

(457)

ELECTRIC HEAT

(Field Installed)

1-1/16

(27)

Supply Air

23-1/4

(591)

3/4

(19)

AIR FILTERS

(Furnished)

*AIR FLOW

FRONT VIEW

SIDE VIEW

1

(25)

UP-FLOW SIDE RETURN AIR FILTER ADAPTOR (CB19-51 and -65)

8-1/8

(206)

FRONT VIEW

3/4

(19)

2-1/2

(64)

25

(635)

OPENING

SAME

BOTH SIDES

20

(508)

SIDE VIEW

24-3/4

(629)

1

(25)

1

(25)

2-1/2

(64)

26-3/4

(679)

CBH19-21,-26,-31 and -41 HORIZONTAL MODELS

3/4 (19)

1-1/2

(38)

21-7/16

(545)

BLOWER

AIR

FLOW

D

RETURN

AIR

OPENING

1-1/2

(38)

ELECTRICAL INLETS

(Both Sides)

5/8

(16)

1-1/16

(27)

C

Supply Air

B

1-1/16

(27)

TOP VIEW

1-5/16 (33)

BLOWER

SUCTION

LINE

2-1/16

CONDENSATE

DRAINS

A

(52)

3(76)

LIQUID

LINE

(76)

2-1/16 (52)

E

3

H

J

1-5/16

(33)

G

FILTER RAILS (2)

(Filter Not Furnished)

F

NOTE — Units are shipped with left hand air

discharge. For right hand air discharge, turn

unit over (end for end) and reposition coil.

1-1/16

(27)

INLET VIEW

SIDE VIEW

Model

Number

CBH19-21,-26 48 1219 18-1/4 464 15-7/8 403 15 381 4-1/2 144 9-1/8 232 13-1/8 333 10-1/16 256 8-15/16 227

CBH19-31,-41 51 1295 21-1/2 546 19-1/8 486 18-1/2 470 4-1/4 108 10-3/4 273 15 381 12 305 13-3/4 337

A B C D E F G H J

in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm

—11—

Page 12

DIMENSIONS — inches (mm)

OPTIONAL

ELECTRIC HEAT

(Field Installed)

ELECTRICAL INLETS

(Both Sides)

30 (762)

1-1/16 (27)

B19-51 and B19-65 BLOWER SECTION

BLOWER

5/8 (16)

33 (838)

30 (762)

15/16 (25)

1-1/16

(27)

1-1/16

(27)

24-3/4 (629)

19-1/2

(495)

1-1/16 (27)

SUPPLY

AIR

OPENING

21-5/8

(549)

AIR

FLOW

BLOWER

1-1/16

(27)

19-3/4

(502)

15/16 (25)

28-5/16

(719)

RETURN

AIR

OPENING

OUTLET VIEW SIDE VIEW INLET VIEW

CH19-51 and CH19-65 COIL SECTION

30 (762)

1-1/16 (27)

26-15/16 (684)

19-1/2

(495)

AIR OUTLET

OPENING

1-1/16 (27)

OUTLET VIEW

2

(51)

21-5/8

(549)

5/8 (16)

AIR

FLOW

SUCTION

LINE

1-1/4

(32)

2-1/8

(54)

10-5/8

(270)

30-1/2 (775)

3(76)

LIQUID

LINE

9

(229)

3

(76)

13-9/16

(344)

2-1/8

(54)

12

(305)

DRAIN PAN

1-1/4

(32)

CONDENSATE

DRAINS

FILTER RAILS (2)

(Filter

Not Furnished)

1-1/16

10-15/16

(278)

(27)

1-1/2 (38)

18-5/8

(473)

1-1/2 (38)

INLET VIEW

30 (762)

28-1/4 (718)

AIR INLET

OPENING

SIDE VIEW

5/8

(16)

11/16

(17)

21-5/8

(549)

5/8 (16)

CBH19-51 and -65 HORIZONTAL MODELS

AIR

BLOWER

FLOW

33 (838)

BLOWER

SECTION

30-1/2 (775)

SECTION

63-1/2 (1613)

SIDE VIEW

NOTE — Units are shipped with left hand air

discharge. For right hand air discharge, turn

unit over (end for end) and reposition coil.

COIL

INSTALLATION CLEARANCES — ALL MODELS

Cabinet 0 inch (0 mm)

Plenum and Outlet duct on blower/coil units 1 inch (25 mm)

Plenum and Warm air duct within 3 feet

(914mm) of cabinet

Floor *Combustible

*When unit is installed in the down-flow position with electric heat on a

combustible floor an optional down-flow base is required.

—12—

1 inch (25 mm)

Loading...

Loading...