LENCO SVB Owner's Manual

WE MAKE THE BEST BOATS BETTER!

The world leader in

trim tab systems &

hatch lift innovation.

Owner's

Manual

LENCO MARINE

1

The contents of this manual are subject to change without notice and do not constitute a commitment on the part of Lenco Marine,

Inc. Every effort has been made to ensure the accuracy of this document. However due to ongoing product improvement and revision,

Lenco Marine cannot guarantee the accuracy of printed material after date of publication nor can it accept the responsibility for errors

or omissions. Lenco Marine will update and revise this document as needed. Reproduction or duplication of the manual, or any part

thereof is prohibited without the expressed written permission of Lenco Marine, Inc. All rights reserved. © 2013 Lenco Marine, Inc.

Lenco Electric Actuators

Contents

Trim Tabs

Overview ................................. 3

Special Conditions ......................... 4

Safety ................................... 4

Installation Instructions .....................5-8

Switch Operation

Operation................................. 9

Switch Wiring Diagram Standard #124SSR ..... 10

Switch Wiring Diagram Indicator #123SC....... 11

Switch Wiring Diagram Dual Ram Indicator ..... 12

Switch Wiring Diagram Double Rocker......... 13

Switch Mounting Template .................. 22

Bennett Marine RetroFit Kit

Installation Instructions ...................14-15

Wiring Diagram ........................... 16

Hatch Lifts

Installation/Operation ...................... 17

Wiring .................................. 17

Mounting ................................ 18

System Parts ............................. 18

Trim Tab Maintenance Tips........................19

Warranty Policy ................................ 20

Glossary ...................................... 21

Switch Template................................ 22

2

Owner’s Manual

Lenco Trim Tabs:

• Electric

• Fuel efficient

• Oil-free

• Environmentally

friendly

CONGRATULATIONS!

You have just purchased the finest trim tab

system in the world! Welcome to the future.

Lenco trim tabs make the single most important difference

in the way your boat rides and performs. They are optional

on some boats but should be as standard as power trim

and tilt. Lenco trim tabs make your boat ride smoother,

drier, faster and with increased safety whether on a small

skiff or a mega-yacht. Our ball screw design makes

our tabs more reliable and twice as powerful as typical

hydraulic trim tabs. Coupled with any of our trim tab

switches, they also perform with instant response which

makes them more precise and user-friendly.

Our goal is to manufacture products that simply make

boating more enjoyable.

Visit our website: www.lencomarine.com

All Lenco Trim Tab products

are CE certified

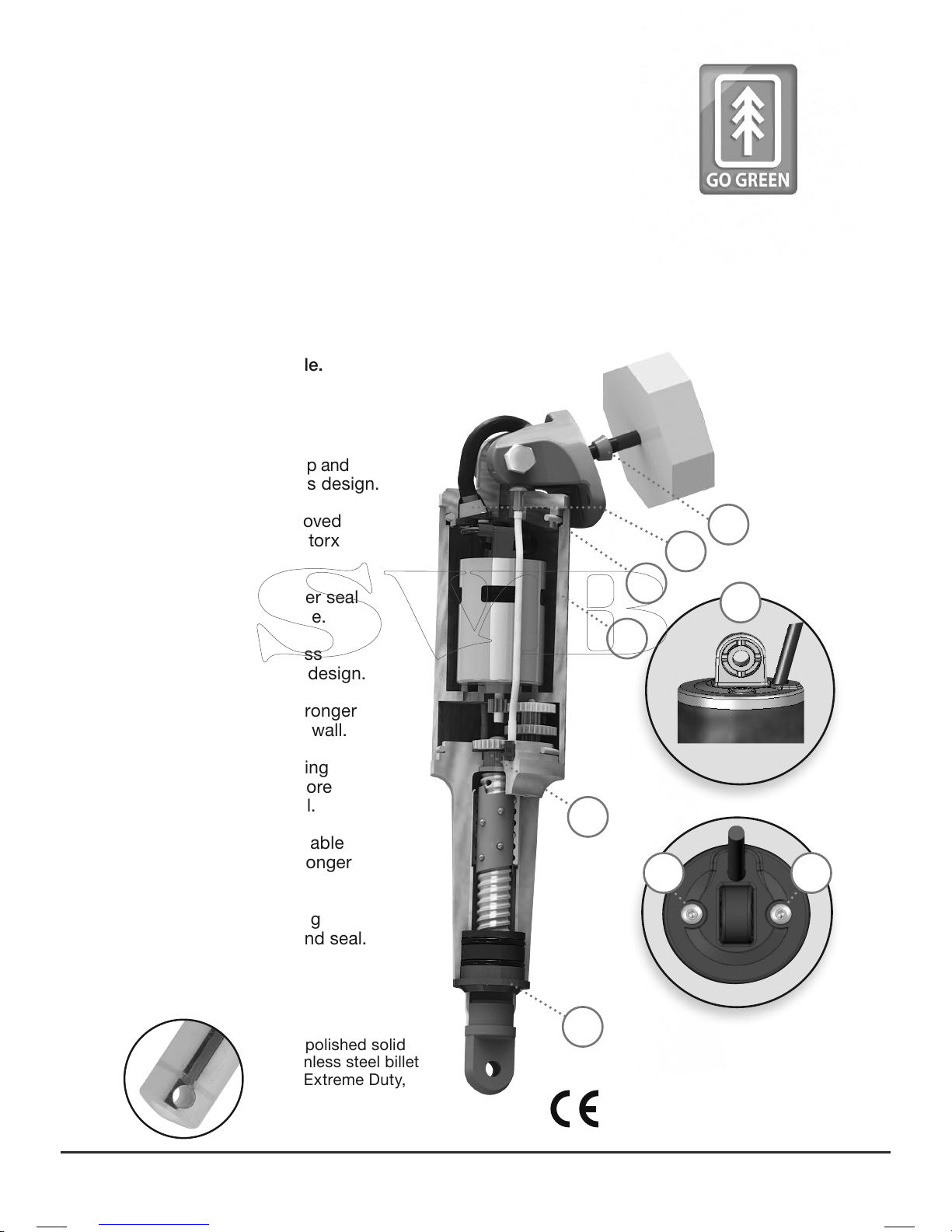

Electro-polished solid

316 stainless steel billet

end for Extreme Duty,

Heavy Duty, and High

Performance applications

1. Stronger top cap and

mounting clevis design.

2.

N

ew and improved

pressure-tight torx

screws.

3. Integrated wiper seal

a

t actuator base.

4.

M

olded-in brass

t

hrust bearing design.

5. Thicker and stronger

motor housing wall.

6. Improved O-Ring

design for a more

consistent seal.

7.

Ov

er-molded cable

providing a stronger

tighter seal.

8.

U

pper mounting

bracket w/ gland seal.

6

7

8

5

4

3

7 8

9

and more durable.

the threaded rod protruding from the actuator cap

providing an improved, pressure-tight seal.

remained from the molding process allowing for a

more consistant seal under extreme loads.

strength by 50% an

d improves symmetry which

strengthens the O-ring seals.

1

3

4

5

7 8

9

and more durable.

the threaded rod protruding from the actuator cap

providing an improved, pressure-tight seal.

remained from the molding process allowing for a

more consistant seal under extreme loads.

strength by 50% an

d improves symmetry which

strengthens the O-ring seals.

support to the gear train and ball screw creating a

smoother, more stable run cycle which decreases

internal wear.

of the actuator provides greater stability during

operation and also serves as a scraper whereby

eliminating particle entry that could potentially

damage internal seals.

o

ver-molded cable feature which eliminates the strain

2 2

LENCO ELECTRIC ACTUATORS

3

LENCO MARINE

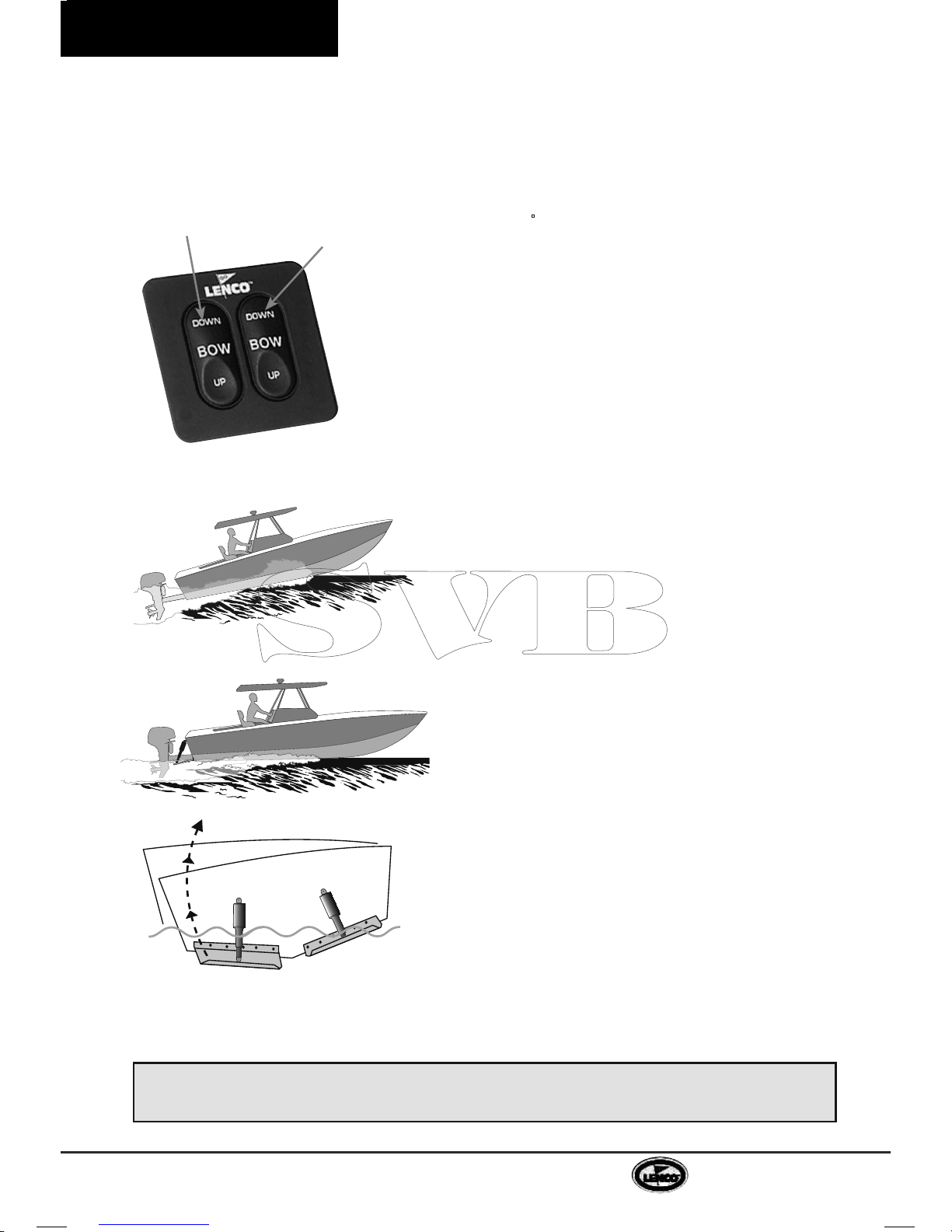

Lowers

Starboard

Bow

Lowers

Port Bow

Lenco Trim Tab kits include two stainless steel

planes, two electromechanical actuators and

all mounting hardware for installation (Kits

with backplates do not include mounting

hardware)

. The trim tabs operate independently

of one another to provide optimal performance

by redirecting water flow at the transom of the

boat. Lenco Trim Tabs have been designed to

improve the overall attitude of a boat. If used

properly, Lenco Trim Tabs improve the ride,

reduce drag, increase speed and improve the

fuel efficiency of your boat.

The operation of Lenco Trim Tabs is basic. The

two stainless steel planes are mounted with the

actuators on the transom of the boat. When the

tabs are lowered, the water flow is redirected

creating an upward force at the stern of the

boat. When the stern rises, the bow will lower.

Since Lenco actuators are electromechanical,

they provide an immediate response at the

touch of the switch. This applies to all of our

trim tab switch kits. All Lenco switches are

based on the position of the bow. The left

side of the switch controls the starboard tab.

The right side of the switch controls the port

tab. The system is set up this way to minimize

the guesswork while underway. To lower the

starboard bow, press the right (starboard)

switch where it reads DOWN. To lower the port

bow, press the left (port) switch where it reads

DOWN.

Since all boats are different in weight, length,

speed and performance, it takes practice to

understand how your boat reacts with trim tabs

installed. Lenco Trim Tabs allow your boat to get

on plane faster and continue planing at lower

speeds. This improves visibility and the overall

safety of your boat. When making adjustments

with the trim tabs, use short momentary taps of

the switch.

To become knowledgeable on how your boat

performs with Lenco Trim Tabs, remember,

practice makes perfect.

The Lenco Tactile Switch is

based on the position of the

bow.

When the tabs are lowered,

the water flow is redirected

creating an upward force at

the stern of the boat.

Without Trim Tabs

With Trim Tabs

Lenco electromechanical actuators provide an instant response.

When making adjustments, use short momentary taps of the switch.

Standard

Switch Kit

#124SSR

Trim Tab Overview

Trim Tab Operation

4

Owner’s Manual

Trim Tab Operation

Head Sea —

(Waves or current running directly against

the course of a boat)

Lower both tabs slightly by pressing

BOW DOWN on both sides. This brings bow down while

maintaining speed. This adjustment allows the hull of the

boat to absorb the impact of the waves, resulting in a

more efcient and smoother ride.

Following Sea —

(Waves or current running with the

course of a boat)

Make sure the tabs are fully retracted

by pressing BOW UP on both sides. This brings both

tabs to a fully retracted position decreasing lift in the

stern, allowing the bow to rise. If tabs are deployed, the

bow may dig.

Windy Chop — To raise the windward side of the boat

press B

OW UP o

n that side. If this is not sufcient, press

B

OW DOWN o

n the leeward side of the boat. Do not over

trim when attempting this. This allows the windward side

of the boat to rise and minimizes spray.

Shallow Water/Hole Shot — Lower both tabs completely

down by pressing B

OW DOWN o

n both sides. This

provides lift in the stern of the boat and keeps the bow

down. As you throttle up and speed increases, raise tabs

by pressing B

OW UP o

n both sides.

Uneven Load

—

If one side of the boat is higher than the

other while running, press B

OW DOWN o

n the switch on

that side. This lowers the tab on the listing side (low side)

to bring the boat level.

Porpoising —

(When the bow of the boat leaps clear out

of the water after striking a wave.)

To stop porpoising,

press BOW DOWN on both sides of the switch. The tabs

need only to be deployed slightly to correct this adverse

situation.

• While the boat is underway, do not move one tab up or down signicantly

as this may cause listing.

• While at higher speeds, do not over trim. This causes the bow to lower

quickly, resulting in a reduction of speed and may cause the boat to veer.

• When running in a following sea the tabs should be fully retracted. This

allows for optimal performance.

• While operating trim tabs, use caution. Improper use of trim tabs may

cause accidents and/or injury.

SAFETY

SPECIAL CONDITIONS

HEA

D SEA

FOLLOWING SEA

WINDY CHOP

SHALLOW WATER

HOLE SHOT

UNEVEN LOAD

PORPOISING

5

LENCO MARINE

Trim Tab System Installation Instructions

Warning: The following instructions contain important safety information and should

be followed carefully. Failure to do so may result in injury and will void warranty.

Please read through the instructions in their entirety prior to beginning installation!

Trim Tab Installation Instructions

• Electric drill

• Tape measure

• 3/16" & 3/8" drill bits (.48 & .95 cm)

• 7/16" (1.11 cm) wrench

• 1/2" or 9/16" wrench socket

• Straight edge

• 4' level

• 2" (5.08 cm) hole saw

• #2 & #3 Phillips screwdrivers

• 3M 5200 adhesive caulking

• Wire crimper / cutter

2"

(or more)

2"

(or more)

3/8"

(.95 cm) up from hull

Edge of hinge must be

2" (5.08 cm) from strake

edge in either direction

1" to 4"

in from chine

TRANSOM

FIG.4

Fig. 1

TOOLS AND MATERIALS LIST

Installation of Trim Tab Blades

1. To begin, determine where the Lenco Trim

Tab Kit will be installed. Note: When laying

out the desired tab location, hold the tab

against the transom with the bottom of

the hinge knuckle 3/8" (.95 cm) up from

the bottom of the transom, approximately

1" to 4" (2.54 to 10.16 cm) in from the

chine, and parallel with the hull.

Note: The reason the hinge knuckle

is mounted 3/8" (.95 cm) from the

bottom of the transom is to allow water

to continue to travel freely along the

bottom of the boat past the transom

edge. Tabs are also mounted in this

manner for protection while on a boat

trailer or when being dry-stored.

When mounting the hinge to

the hull make sure that the inside

corner of the hinge knuckle is no

closer than 2" (5.08 cm) to the left or

right of any strake edge. The hinge

may overlap a strake edge as long as

the corner of the hinge knuckle is no

closer than 2" (5.08 cm) to the left or

right of the strake edge (see Fi g.1).

Transfer (trace) the hinge screw hole

pattern onto the transom for drilling.

Note: All Performance Series tabs

with single-tapered blades should be

mounted with the tapered end facing

toward the center of the boat.

2. Using the 3/16" (.48 cm) drill bit, drill

the previously marked hole locations to

a depth of 1-1/4" (3.18 cm).

Note: When drilling out the screw

hole pattern for the trim tab hinge you

may drill through the transom. Hinge

screws should be installed with 3M 5200

adhesive caulking which will seal the

holes. All supplied screws and fasteners

are stainless steel. Do not use any other

type of alloy.

Mount the trim tab hinge to the transom

using provided #14 x 1-1/4" (3.18 cm)

stainless steel sheet metal screws. We

recommend using 3M 5200 adhesive

caulking to bed the hinge and screws.

DO NOT OVERTIGHTEN.

6

Owner’s Manual

Installation of Upper and Lower

Mounting Brackets & Actuators

1. Loosely attach the upper mounting bracket

(bracket with four holes) to the top of the actuator

using the 5/16-18" X 1-3/4" (4.45 cm) large hex

head bolt and 5/16-18 hex nut provided. Attach

the actuator to the lower mounting bracket using

the 5/16-18" X 1-3/4" (4.45 cm) large hex head

bolt and 5/16-18" hex (.79 cm) nut provided.

Attach the lower mounting bracket to the tab with

the bolts, washers, and nylon lock nuts provided

(Kit# 4 - Part# 10000-001) (see Fig. 4).

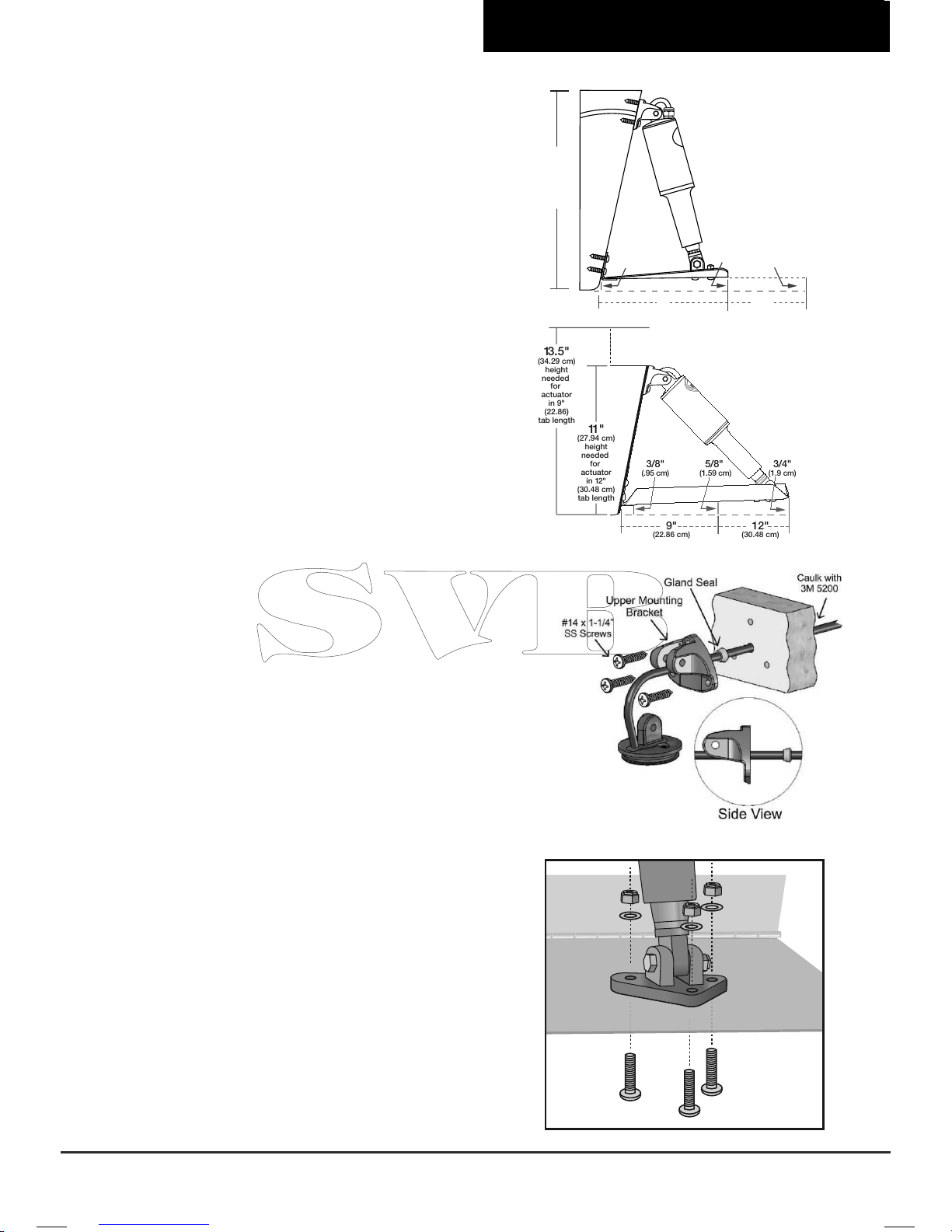

2. In order to properly position the upper mounting

bracket against the transom, you must lift the

trim tab so that the trailing edge is approximately,

5/8" (1.59 cm) for a 9" trim tab and 3/4" (1.9 cm)

for a 12" trim tab, above the straight edge when

held to the hull (see Fig. 2.1 & 2.2). When the trim

tab is at the appropriate level and the actuators

are fully retracted, transfer (trace) the outer shape

of the upper mounting bracket onto the transom.

The upper mounting bracket should be marked

where it lays naturally against the transom to

prevent binding during functioning of trim tabs.

Note: Do not adjust the upper mounting bracket

to the right or left, as this will cause binding.

Allow the bracket to come to rest at its natural

position.

Remove the upper mounting bracket from the

actuator and align to the previously marked

location to mark the upper mounting bracket

screw hole locations and cable hole location.

Using the 3/16" (.48 cm) drill bit, drill the three

previously marked screw hole locations to a

depth of 1-1/4" (3.18 cm).

Warning: With some installations, fuel, water

tanks and/or other systems may prevent the

actuator cable from entering the hull through

the upper mounting bracket. Be sure to check

inside the hull before drilling the 3/8" (.95 cm)

cable hole.

Note: When drilling out the screw hole pattern

for the upper mounting bracket, you may drill

through the transom. The screws should be

installed with 3M 5200 adhesive caulking which

will seal the holes when installed.

All supplied screws and fasteners are stainless

steel. Do not use any other type of alloy.

(Continued on page 7)

Trim Tab Installation Instructions

5/8"

(1.59 cm)

14"

(35.56 cm)

max.

height

needed

for

actuator

3/8" (.95 cm)

9"

(22.86 cm)

3/4" (1.9 cm)

12"

(30.48 cm)

Standard Mount

Fig. 2 .1

Edge Mount

Fig. 2.2

Fig. 3

ANGLE OF THE TAB

5/8"gap

(1.59 cm)

3/8"gap

(.95 cm)

14"

(35.56 cm)

maximum

transom

height

needed

HULL LINE

HULL LINE

9" TAB

(22.86 cm)

3/4"gap

(1.9 cm)

1"gap

(2.54 cm)

12" TAB

(30.48 cm)

16" TAB

(40.64 cm)

2"

(or more)

2"

(or more)

3/8"

(.95 cm) up from hull

Edge of hinge must be

2" (5.08 cm) from strake

edge in either direction

1" to 4"

in from chine

TRANSOM

Bolts enter

from the

underside

of tab

FIG.4

FIG.5

Fig. 4

3/4"

(1.9 cm)

3/8"

(.95 cm)

11"

(27.94 cm)

height

needed

for

actuator

in 12"

(30.48 cm)

tab length

13.5"

(34.29 cm)

height

needed

for

actuator

in 9"

(22.86)

tab length

9"

(22.86 cm)

12"

(30.48 cm)

5/8"

(1.59 cm)

7

LENCO MARINE

If all is clear, use the 3/8" (.95 cm)

drill bit and drill the previously marked

cable hole completely through the

transom. Insert the actuator cable

through the appropriate hole in the

upper mounting bracket until the

mount reaches the actuator. Insert the

actuator cable through the gland seal

until it reaches the rear of the upper

mounting bracket.

Note: For appropriate orientation

of upper mounting bracket and gland

seal, (see Fig 3 on page 6).

If, however, you are prevented from

drilling a hole through the transom at

the bracket location, using the 3/8"

(.95 cm) drill bit, simply drill a 3/8" (.95

cm) hole 4" to 5" (10.16 to 12.7 cm)

above the waterline and insert the

cable. Cover the hole and cable with a

clamshell vent sealed with 3M 5200 for

a waterproof and nished eect.

Insert the actuator cable through the

transom. With the actuator loosely

supported, start the provided #14 x

1-1/4" (3.18 cm) stainless steel sheet

metal screws through the upper

mounting bracket holes and into the

transom. MAKE SURE TO LEAVE

THE SCREWS ONLY PARTIALLY

INSTALLED.

Insert the actuator clevis (mounting

ear) into the upper mounting

bracket and hold the actuator in

the approximate installed position.

Pass the actuator cable through the

transom removing slack on the cable

until it looks like the installation on

F

ig 2.1 on page 6. Finish installing the

previously started #14 x 1-1/4" (3.18

cm) stainless steel sheet metal screws

through the upper mounting bracket

and into the transom. We recommend

using 3M 5200 adhesive caulking to

bed the upper mounting bracket and

screws. DO NOT OVERTIGHTEN.

Attach and secure the actuator to the

upper mounting bracket using the

5/16-18 X 1-3/4" (4.45 cm) large hex

head bolt and 5/16-18 (.79 cm) hex nut

provided.

We recommend using 3M 5200

adhesive caulking to seal the cable

hole on the inside of the transom.

Attach connector ends to the actuator

wire pins as instructed in Actuator

Deutsch Connector Instructions

insert card provided. If using actuator

extension cables, this would be a

good time to run them to the control

box mounting area.

NOTE:

SA

CRI

FICIAL ANODES FOR

YOU

R LENCO SS TRIM T

ABS

Be aware that stray currents in your

marina or in a visiting marina can

cause damage to your trim tab blades

if not protected by sacricial anodes.

• The addition of anodes on each tab

will deter electrolysis.

• Do not paint under the anode or the

anode itself.

• Check Anode condition frequently.

Replace when necessary.

Switch Installation

Installation instructions for Standard

(124SSR), Indicator (123SC), and Dual Ram

Indicator (123DR) Digital Tactile Switches.

1. At the helm, determine where the

tactile key pad will be installed, locate

the template on page 22 and secure

to helm. Cut a circular opening using

a 2" (5.08 cm) hole saw (Hole must

be 2"). Before cutting, make sure the

area inside the helm is clear of wires

and other equipment that could be

damaged. Using the template on

page 22, drill four 3/16" (.48 cm) holes

through the helm.

2. Install the black control box (hardware

not included) within 24" (60.96 cm) of

the key pad hole.

Make sure control

box is mounted on a vertical surface

with wires facing down toward the deck.

Mounting the control box in the incorrect

orientation will void the warranty.

Trim Tab Installation Instructions

Installation Instructions continued from page 6.

Loading...

Loading...