Page 1

Leica EM TXP

Target Surfacing System

Page 2

2

Leica EM TXP – Target Surfacing

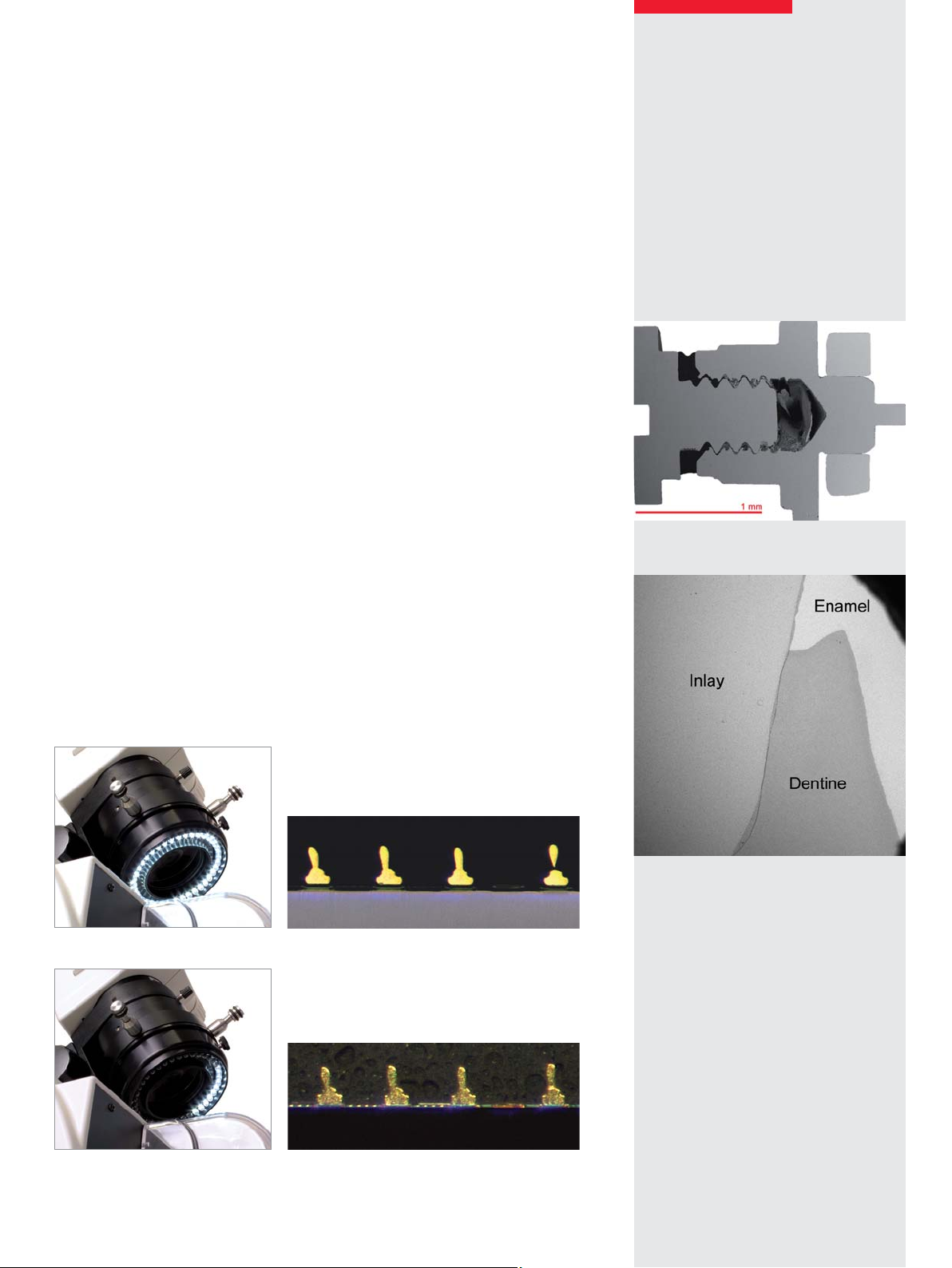

90° rotation view

Processing observation

Front face observation

The Leica EM TXP is a unique target preparation device especially

developed for cutting and polishing samples prior to examina tion by

SEM, TEM and LM techniques. It excels with challenging speci mens where pinpointing and preparing barely visible targets

becomes easy. Before the Leica EM TXP, sawing, milling, grinding

and polishing exactly to the target was often a very time-consuming

and difficult procedure as points of interest were easily missed and

specimens often difficult to handle due to their small size. With the

Leica EM TXP such samples can easily be prepared. Furthermore,

due to its versatility, the EM TXP is a very efficient tool for sample

pre-preparation prior to ion beam milling and ultramicrotomy.

Leica Design by W. Hölbl

Page 3

3

System

Stereomicroscopic target observation during the working process

With the specimen pivot arm the sample can be observed during

preparation at an angle between 0° and 60°, directly onto the front

face, or 90° to the front face for distance determination with an

eyepiece graticule. The Leica EM TXP features brilliant ring LED

top light and optimized backlight illumination for excellent viewing.

I Accurate location and preparation of microtargets

I

In-situ

observation with a stereomicroscope

I Multifunctional machine processing

I Automatic process control

I to produce a mirror-like surface quality

I Brightness control and segment selection

I of LED-ring illumination

Integrated Viewing System

Cross section of watch assembly

(processed without embedding)

Viewing with quarter ring illumination

Cross section of a tooth

(processed without embedding)

Viewing with full ring illumination

Page 4

4

Once the sample is clamped into the specimen holder and inserted in the pivot arm, the specimen can be:

– milled

– sawn

– drilled

– ground

– and polished

without removing the sample from the Leica EM TXP and simply

changing the tools while observing the process directly through

the stereomicroscope. The tool and sample are enclosed within a

protective chamber with a transparent cover for safety. This prevents access to moving parts and avoids particulate matter

escaping. During milling a low-noise extraction and filtration unit

with a Hepa filter (optional) provides a safe, dust-free environment.

Process Possibilities

Diamond and tungsten carbide millers

Diamond disc cutter

Lapping inserts 15, 9, 6, 3, 1, 0.5 µm

Page 5

5

Let the Leica EM TXP do the job

The Leica EM TXP automatic process control mechanism saves

you from time-consuming routine sample preparation:

– with the automatic E-W guiding mechanism

– with the force-regulated feed control

– with the distance or time countdown function

– with force-controlled auto-advance for core-drilling

and level sensor for the integrated lubricant cooling system

Integrated Automatic Process Control

– Pivot arm lever

– Hand wheel for manual feed in steps of

0.5, 1, 10 and 100 µm

– Control panel for manual operation and setting

of all parameters for automatic preparation

E-W guiding mechanism

(manual or automatic)

Peristaltic

cooling system

SM LED gold wire bond

PCB cross section with soldered pin

Page 6

6

Observation via stereo microscope of the Leica EM TXPSawing

After the sample is fixed onto the stub a 3 mm disc is cut out using the

core-drill in conjunction with the force-regulated auto-advance.

The first side is then finished using the grinding and polishing foils.

The surface of the stub is milled with the tungsten carbide miller

so it is parallel to the grinding and the polishing plane for processing

the second side of the sample.

Target preparation on surfaced sample for incident light LM and SEM

All processing steps are carried out consecutively on the Leica EM TXP without removing the sample for pinpointing the area of

interest via another microscope or for making any adjustments. Preparing specimens observed during operation with the integrated stereomicroscope avoids the time consuming interruption of locating the target with a stand alone microscope and then

re-aligning the sample in the polishing instrument.

Sample thinning for transmitted light LM or prior to ion thinning for TEM

Specimen thinning with the Leica EM TXP offers the advantage of observing the complete process during treatment and distance

monitoring at each process step without the need to remove the sample for checking in another instrument.

The Leica EM TXP is a unique target surfacing system developed for cutting and polishing samples. Alignment of sample details

can be rapidly performed using the alignment accessory. Thus, the EM TXP is the instrument of choice for pre-preparation of the

sample prior to ion beam slope cutting with e.g. the Leica EM TIC020.

Sample holder attached on the alignment accessory.

The micro-targets can be aligned during the process

while observing with the stereo microscope.

Within a few minutes all sample details are aligned. LM-image of gold

wire bondings processed with the cut-off wheel and ground with 6 µm

diamond foil during alignment. The surface finish is good enough for

subsequent finishing with the ion beam slope cutter, EM TIC020.

Page 7

7

The area of interest via the stereomicroscope of the Leica EM TXP

The prepared first side is fixed onto the surface of the stub.

The second side is then cut, ground and polished. The thickness of

the sample can be determined with the advance counter display.

In such a manner, even hard and brittle materials can be thinned to be

subsequently prepared for TEM investigation e.g. for ion thinning with

the Leica EM RES101.

Grinding/polishing

The Leica EM TIC020 features three ion guns in one assembly

enabling > 4 mm cutting width and > 1 mm cutting depth.

Gold-wire bondings of IC-package during processing with the

Leica EM TIC020. The dark area above the gold wires has already been

polished by the ion beam.

Page 8

8

Gold-wire bonding of IC-package prepared

with the Leica EM TXP (LM image).

Leica EM RES101 for ion beam processing

of TEM and SEM samples.

Same gold wire bonding subsequently processed for

half an hour with the Leica EM RES101 (SEM image).

High surface quality within a few hours. The user interaction time of the complete process is around

20 minutes using the Leica EM TXP prior to EM TIC020.

Page 9

View the Details

Page 10

“With the user, for the user”

Leica Microsystems

Order no.: English 16214002

•

IX/10

•

Copyright © by Leica Mikrosysteme GmbH, Vienna, Austria, 2010

LEICA and the Leica Logo are registered trademarks of Leica Microsystems IR GmbH.

The statement by Ernst Leitz in 1907, “with the user, for the user,” describes the fruitful collaboration

with end users and driving force of innovation at Leica Microsystems. We have developed five

brand values to live up to this tradition: Pioneering, High-end Quality, Team Spirit, Dedication to

Science, and Continuous Improvement. For us, living up to these values means: Living up to Life.

Active worldwide

Australia: North Ryde Tel. +61 2 8870 3500 Fax +61 2 9878 1055

Austria: Vienna Tel. +43 1 486 80 50 0 Fax +43 1 486 80 50 30

Belgium: Groot Bijgaarden Tel. +32 2 790 98 50 Fax +32 2 790 98 68

Canada: Richmond Hill/Ontario Tel. +1 905 762 2000 Fax +1 905 762 8937

Denmark: Ballerup Tel. +45 4454 0101 Fax +45 4454 0111

France: Nanterre Cedex Tel. +33 811 000 664 Fax +33 1 56 05 23 23

Germany: Wetzlar Tel. +49 64 41 29 40 00 Fax +49 64 41 29 41 55

Italy: Milan Tel. +39 02 574 861 Fax +39 02 574 03392

Japan: Tokyo Tel. +81 3 5421 2800 Fax +81 3 5421 2896

Korea: Seoul Tel. +82 2 514 65 43 Fax +82 2 514 65 48

Netherlands: Rijswijk Tel. +31 70 4132 100 Fax +31 70 4132 109

People’s Rep. of China: Hong Kong Tel. +852 2564 6699 Fax +852 2564 4163

Portugal: Lisbon Tel. +351 21 388 9112 Fax +351 21 385 4668

Singapore Tel. +65 6779 7823 Fax +65 6773 0628

Spain: Barcelona Tel. +34 93 494 95 30 Fax +34 93 494 95 32

Sweden: Kista Tel. +46 8 625 45 45 Fax +46 8 625 45 10

Switzerland: Heerbrugg Tel. +41 71 726 34 34 Fax +41 71 726 34 44

United Kingdom: Milton Keynes Tel. +44 1908 246 246 Fax +44 1908 609 992

USA: Bannockburn/lllinois Tel. +1 847 405 0123 Fax +1 847 405 0164

and representatives in more than 100 countries

Leica Microsystems operates globally in four divisions,

where we rank with the market leaders.

•

Life Science Division

The Leica Microsystems Life Science Division supports the

imaging needs of the scientific community with advanced

innovation and technical expertise for the visualization,

measurement, and analysis of microstructures. Our strong

focus on understanding scientific applications puts Leica

Microsystems’ customers at the leading edge of science.

•

Industry Division

The Leica Microsystems Industry Division’s focus is to

support customers’ pursuit of the highest quality end result.

Leica Microsystems provide the best and most innovative

imaging systems to see, measure, and analyze the microstructures in routine and research industrial applications,

materials science, quality control, forensic science investigation, and educational applications.

•

Biosystems Division

The Leica Microsystems Biosystems Division brings histopathology labs and researchers the highest-quality,

most comprehensive product range. From patient to pathologist, the range includes the ideal product for each

histology step and high-productivity workflow solutions

for the entire lab. With complete histology systems featuring innovative automation and Novocastra™ reagents,

Leica Microsystems creates better patient care through

rapid turnaround, diagnostic confidence, and close customer collaboration.

•

Medical Division

The Leica Microsystems Medical Division’s focus is to

partner with and support surgeons and their care of patients with the highest-quality, most innovative surgical

microscope technology today and into the future.

www.leica-microsystems.com

Loading...

Loading...