Walkerduct Pro Series

Wiremold/Legrand electrical systems conform to and should

be properly grounded in compliance with requirements of the

current National Electrical Code or codes administered by

local authorities.

All electrical products may present a possible shock or fire

hazard if improperly installed or used. Wiremold/Legrand

electrical products may bear the mark as UL Listed and/or

Classified and should be installed in conformance with

current local and/or the National Electrical Code.

Round Flush Cover Plates

I N S T A L L A T I O N I N S T R U C T I O N S

Installation Instruction No.: 1 002 970R1 – Updated May 2009

Products Covered: PSRC9TC, PSRC9AMDTC, PSRC9AMDRTTC, PSRC9FFTC, & PSRC9FF2TC

CAUTION: Do not operate tile stripper or resurfacing equipment over top of covers. This may result in damage to the finish of the product.

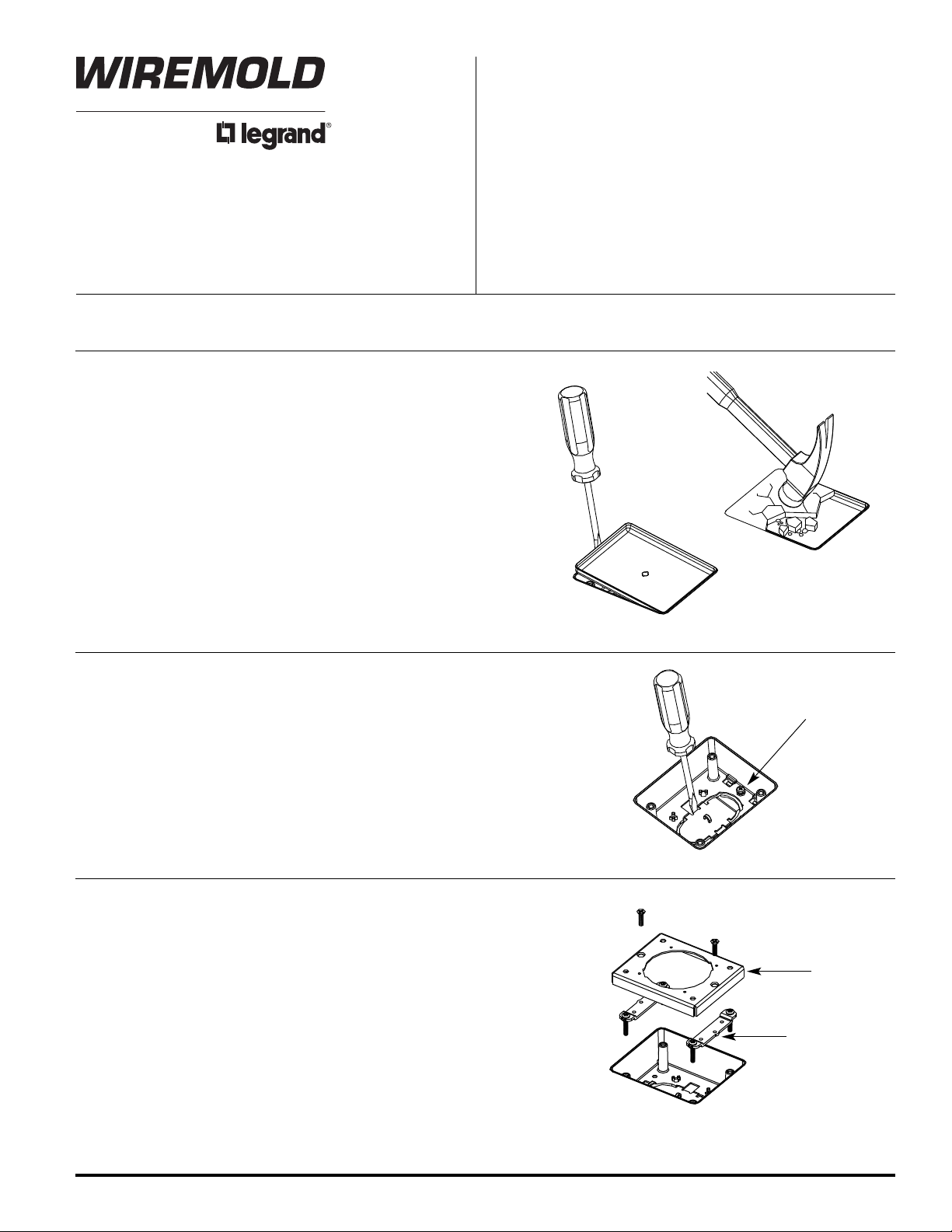

PRESET LOCATION:

1. Determine location of preset cover by measuring (when layout is

known) or by using an electronic preset finder (Cat. No. 480).

Cut and remove carpeting or tile over preset. Carpet may be

saved for later abandoning.

2. Using a hammer, chip out the concrete from the mud cap cover.

3. Strike the edge of the exposed mud cap with a blade type

screwdriver to deflect the cap inward.

4. Insert the screwdriver along the edge of the preset and pry up

removing the cap.

5. Remove any debris that may have fallen into the preset opening.

6. Grout around preset opening if concrete does not break away cleanly.

PRESET PREPARATION:

1. Insert a wire hook into the arched opening to prevent the knockout

from falling into the duct.

2. Push screwdriver toward center of the preset, breaking the tabs to

release the knock-out.

3. De-burr the edges after knock-out removal.

4. Tighten the bonding screw in the base of the preset.

IMPORTANT: Please read all instructions

before beginning.

Bonding Screw

COVER ADAPTER INSTALLATION:

1. Install Link Strap to posts in preset as shown. Heads of screws should be

slightly below concrete pour level.

2. Position Adapter Plate over Link Straps as shown.

3. Adjust Link Strap Screws until the adapter plate is flush with finished floor.

4. Secure Adapter Plate to Link Straps using (2) #10 x 3/4” flat head screws.

NOTE: To maintain proper ground continuity, tighten

screws to minimum 10 inch pounds.

Adapter Plate

Link Strap

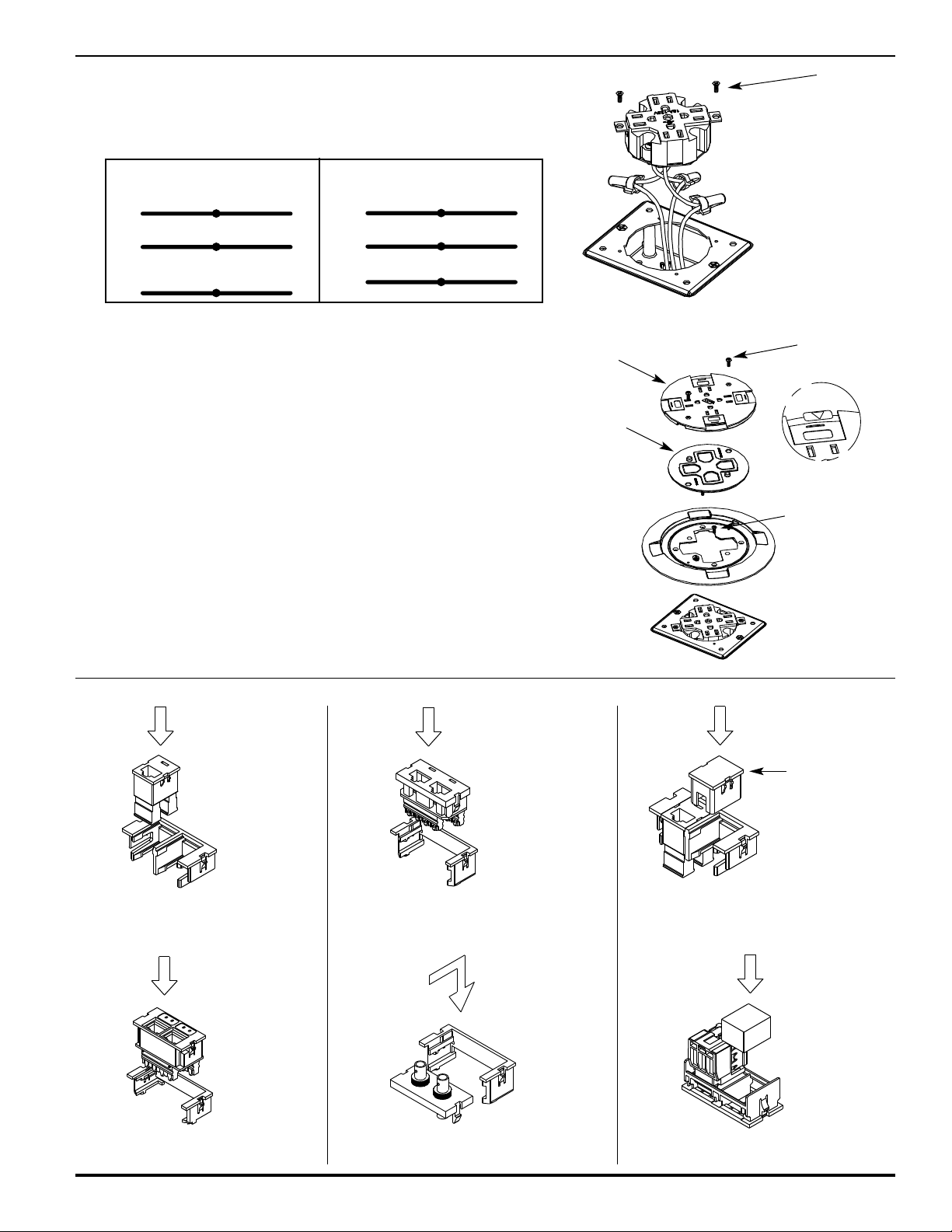

QUAD RECEPTACLE INSTALLATION: (2" [51mm] min. preset depth)

1. Pull conductors through the adapter plate and wire to the receptacle leads.

2. Line up the receptacle strap with the notches in the adapter plate and

secure with (2) #6-32 flat head screws.

ONVENTIONAL WIRING SCHEMATIC ISOLATED GROUND WIRING SCHEMATIC

C

BLACK or HOT BLACK BLACK or HOT BLACK

rom branch circuit from receptacle From branch circuit from receptacle

F

HITE or NEUTRAL WHITE WHITE or NEUTRAL WHITE

W

From branch circuit from receptacle From branch circuit from receptacle

GREEN or GROUND GREEN GREEN or GROUND GREEN

rom branch circuit from receptacle From branch circuit from receptacle

F

ystem Ground

S

#6-32 Flat

Head Screw

CAUTION: Receptacle mounting means not grounded. Grounding

wire connection required. For isolated ground wiring,

connect ground leads to a separate isolated grounding

conductor. See NEC 250-146(d).

QUAD RECEPTACLE COVER:

1. Attach trim flange to cover adapter and receptacle strap using (2)

#6-32 flat head screws.

2. Align gasket over receptacle and press bead into flange.

CAUTION:

Gasket must be in place to provide

scrub water seal.

3. Attach slide cover with (2) #6-32 pan head cover screws.

CAUTION: Do not over tighten cover screws.

4. Apply icon on receptacle slide if wired for isolated ground circuit.

NOTE: Place orange triangle on devices that are wired for

isolated ground. See NEC 250-146 (d).

COMMUNICATION DEVICES:

Point Keystone Tab

Away From Bezel.

Point Keystone Tab

Away From Bezel.

Slide Cover

Gasket

#6-32 Pan

Head Screw

Step 4

#6-32 Flat

Head Screw

TracJack Blank

(supplied)

Ortronics TracJack Bezel and

Communication Jack (TracJack

Modular Inserts sold separately)

Pass & Seymour ACTIVATE

Bezel and Communication Jack

Ortronics Series II Bezel and Communication

Jack (Series II Bezel Included; Series II

Modular Inserts sold separately)

Lower Level Bezel Installation (Typical for Fiber

Installations) (Fiber Jack sold separately)

TracJack

(sold separately)

Communication Jack (sold separately)

Foam Plug

(supplied)

COMMUNICATIONS COVER: (2" [51mm] min. preset depth)

1. Wire and snap appropriate communication jacks into adapters as

shown above.

2. Insert blanking plugs or neoprene foam blocks in unused

communication ports.

3. Insert jacks through underside of trim flange and snap into place.

4. Attach trim flange with jacks to the preset adapter plate using (4)

#6-32 flat head screws.

5. Align gasket over devices and press bead into trim flange channel.

CAUTION: Gasket must be in place to provide scrub water seal.

6. Install slide cover with (2) #6-32 pan head cover screws.

CAUTION: D

o not over tighten cover screws.

PARTITION FEED COVER: (1" [25mm] min. preset depth)

1. Attach conduit flange to the preset adapter plate using (4)

#6-32 pan head screws.

2. Remove screw plugs and install flexible conduit fittings with conduit.

NOTE: Keep screw plugs for future abandonment.

#6-32 Pan

Head Screw

Slide Cover

Gasket

#6-32 Flat

Head Screw

Trim Flange

#6-32 Pan

Head Screw

Conduit

Flange

2" TRADE SIZE PARTITION FEED COVER:

(1" [25mm] min. preset depth)

1. Attach conduit flange to the preset adapter plate using

(4) #6-32 pan head screws.

2. Remove screw plugs and install conduit fittings with conduit.

NOTE: Keep screw plugs for future abandonment.

#6-32 Pan

Head Screw

Conduit

Flange

PRESET INSERT INSTALLATION DETAILS

To Field Installed Presets:

1. Be certain correct preset height is selected.

2. Position preset so that hooks on bottom of preset drop into openings on duct.

3. Push down evenly and slide forward. Knockout tab should snap into opening.

To Remove Mudcap:

1. Strike a 1/4" flat blade screwdriver along the side of the mudcap to deflect the top edge.

2. Use a screwdriver to pry out mudcap.

To Install Alignment Plates:

1. Install plates at first set of presets on each length of duct before securing supports and couplings.

. All presets must be aligned within 1/8" [3.2mm].

2

#2 DUCT SYSTEMS ONLY #4 DUCT SYSTEMS ONLY

S

SYSTEM PRESET CATALOG INCHES

EPTH HEIGHT NUMBER VOLUME

D

2 1/4" [57mm] 7/8" [22.2mm] 419-1 13.7

2 3/4" [70mm] 1 3/8" [34.0mm] 419-11/2 22.6

3 1/4" [83mm] 1 7/8" [47.0mm] 419-2 31.2

3 3/4" [95mm] 2 3/8" [61.0mm] 419-21/2 39.8

4 1/4" [73mm] 2 7/8" [73.0mm] 419-3 48.3

P PRESET CUBIC

Pry Out Here

Galvanized Steel

Screw when Preset

Mudcap

2 1/2" [64mm] 7/8" [22.2mm] 419-1 13.7

3 1/2" [89mm] 1 7/8" [47.0mm] 419-2 31.2

4 1/2" [115mm] 2 7/8" [73.0mm] 419-3 48.3

NOTE: Important!

Tighten Bonding

is activated.

S

SYSTEM PRESET CATALOG INCHES

EPTH HEIGHT NUMBER VOLUME

D

3" [76mm] 1 3/8" [34.0mm] 419-11/2 22.6

4" [102mm] 2 3/8" [61.0mm] 419-21/2 39.8

P PRESET CUBIC

Galvanized Steel

Mudcap

Pry Out Here

1/8" [3.2mm] Concrete over Preset

3.3 Sq. In.

Add 1/4" [6.4mm] to System when

using both #2 and #4 Duct.

Die Cast Preset

(See Chart)

P

1 1/4"

[32mm]

NOTE: Three Duct Systems are Similar.

Alignment Plate

1/8" [3.2mm] Concrete over Preset

S

3.3 Sq. In.

8.5 Sq. In.

1 11/16"

[43mm]

Minimum 1 1/2" [38mm] Concrete

required below duct or solid surface.

Wiremold/Legrand

U.S. and International:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX 860-232-2062 • Outside U.S.: 860-233-6251

Canada:

570 Applewood Crescent • Vaughan, Ontario L45K 4B4

1-800-723-5175 • FAX 905-738-9721

Die Cast Preset

(See Chart)

P

S

1 1/2"

[38mm]

© Copyright 2009 Wiremold/Legrand All Rights Reserved

1 002 970T1 0509

Loading...

Loading...