LEGRAND Wattstopper LMDM-101 Quick Start Manual

Wattstopper

Blue load

rn ON to last level

Rocker Panel

LMDM-101

LMSW-105

Dimmer

(low voltage, Class 2)

Daylighting

Sensor

®

Digital Lighting Management Low Voltage Dimming Wall Switch (v3)

Gestion numérique de l’éclairage Interrupteur mural basse tension à gradation (v3)

No: 23493 – 10/18 rev. 2

Regulador de pared de bajo voltaje DLM (v3)

Quick Start Guide • Guide de démarrage rapide • Guía de inicio rápido

Catalog Number • Numéro de Catalogue • Número de Catálogo: LMDM-101

Country of Origin: Made in China • Pays d’origine: Fabriqué en Chine • País de origen: Hecho en China

Models ending in -U are BAA and TAA compliant (Product produced in the U.S.)

This unit is pre-set for Plug n’ Go™ operation,

adjustment is optional.

For full operational details, adjustment and more

features of the product, see the DLM System Installation

Guide provided with Wattstopper room controllers, and

also available at www.legrand.us/wattstopper.

Installation shall be in accordance with all applicable

regulations, local and NEC codes. Wire connections

shall be rated suitable for the wire size (lead and building

wiring) employed.

For Class 2 DLM devices and device wiring: To be

connected to a Class 2 power source only. Do not

reclassify and install as Class 1, or Power and Lighting

Wiring.

Do not apply cleaning solvent directly onto unit. Apply

cleaning solvent onto a cloth, then wipe the unit to clean it..

MOUNTING THE SWITCH

WARNING: Do not install to cover a junction box having Class 1, 3 or

Power and Lighting Circuits.

SPECIFICATIONS

Voltage ...................................................................................24VDC

Current Consumption ..................................................................5mA

Power Supply ...................................... Wattstopper Room Controller

Connection to the DLM Local Network ......................... 2 RJ-45 ports

DLM Local Network characteristics when using LMRC-11x/2xx room

controllers:

Low voltage power provided over Cat 5e cable (LMRJ);

max current 800mA. Supports up to 64 load addresses,

48 communicating devices including up to 4 LMRC-10x

series and/or LMPL-101 controllers.

Free topology up to 1,000’ max.

Environment ...................................................... For Indoor Use Only

Operating Temperature ......................32° to 131°F (0° to 55°C)

Storage Temperature ........................23° to 176°F (-5° to 80°C)

Relative Humidity ............................5 to 95% (non condensing)

Patent Pending

BUTTONS AND INDICATORS

status LED

LEDs

show

light

level

setting

When all loads bound to the dimmer are OFF, the Blue load

status LED is dim. A single light level LED is lit to show the last

light level.

When any load bound to the dimmer is ON the load status

LED is bright. The number of illuminated light level LEDs

indicates the highest light level on any of those loads.

Tap when load OFF: Tu

Tap when load ON: Go to full bright

Press & Hold: Ramp Up

Configuration Button

(behind switch plate)

Tap: Fade to OFF

Press & Hold: Ramp Down

Red LED

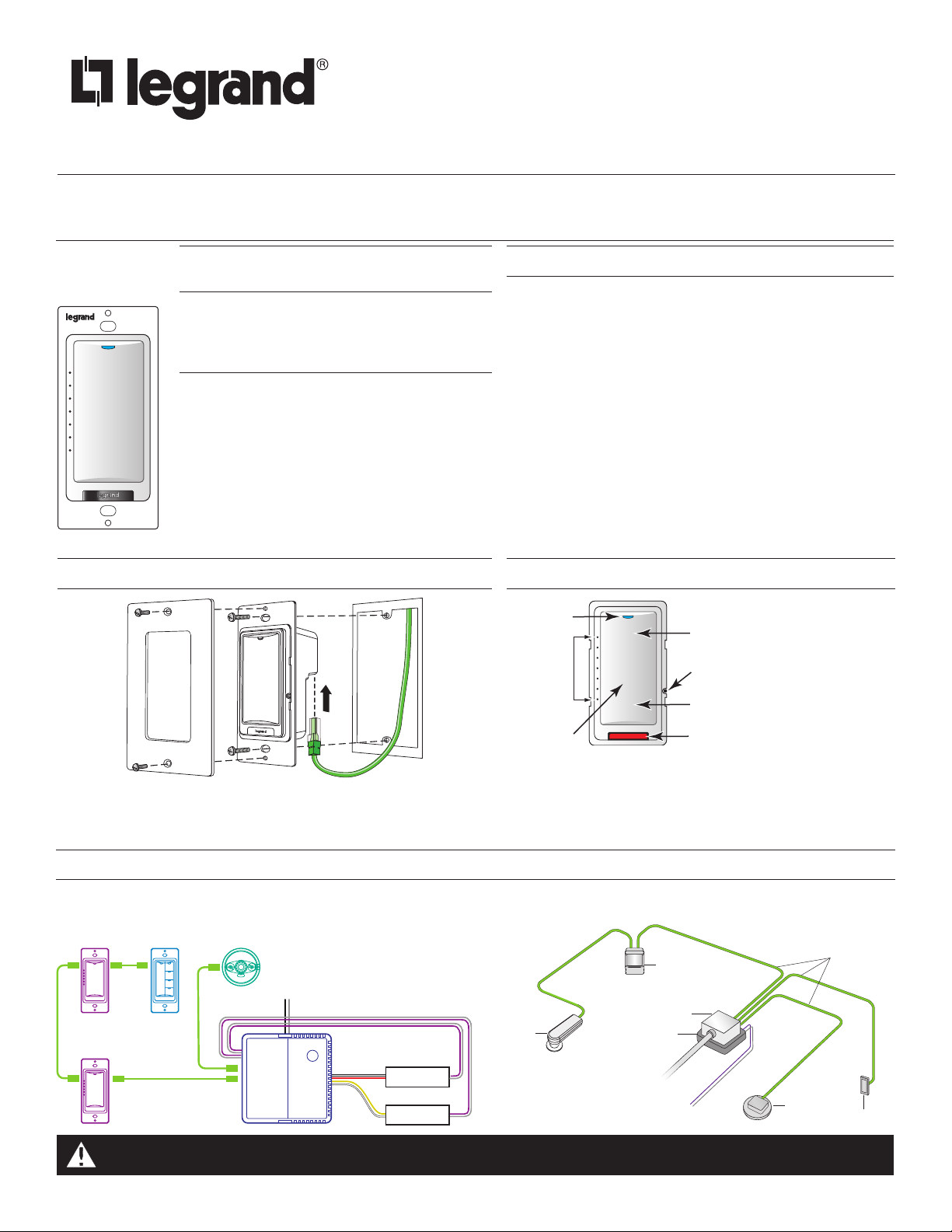

CONNECTIVITY

The illustrations here show examples of free-topology wiring. The LMDM communicate to all other Digital Lighting Management devices

connected to the low voltage DLM Local Network, regardless of their position on the DLM Local Network.

Dimming Switch

LMDM-101

Dimming Switch

CAUTION: TO CONNECT A COMPUTER TO THE DLM LOCAL NETWORK USE THE LMCI-100. NEVER CONNECT THE DLM

Scene Switch

LMRJ Cables

Occupancy Sensor

Line Voltage

LMRC-212

Dimming

Room

Controller

J-Box

Class 2 0-10 Volt Control Wiring

Line Voltage

0-10 Volt

Ballast

0-10 Volt

Ballast

Corner Mount

Occupancy

Sensor

J Box

LMRC-21x

Room

Controller

To

Load

To 0-10V

Dimming Ballast

LOCAL NETWORK TO AN ETHERNET PORT – IT MAY DAMAGE COMPUTERS AND OTHER CONNECTED EQUIPMENT.

DLM Local Network

LMRJ cables

Ceiling Mount

Occupancy

Sensor

Switch/

PLUG N’ GO OPERATION (PNG)

Switch

Line Voltage

All loads are automatically bound to the

LMDM-101.

The rocker paddle on the LMDM-101

controls all loads on the DLM Local

Network. Tap the top of the rocker to

turn ON all loads to the last light level.

Tap the bottom to turn OFF all loads.

Dimmable loads dim (ramp down or up)

in response to a press and hold of the

appropriate portion of the rocker paddle.

Switched loads turn OFF when ramped

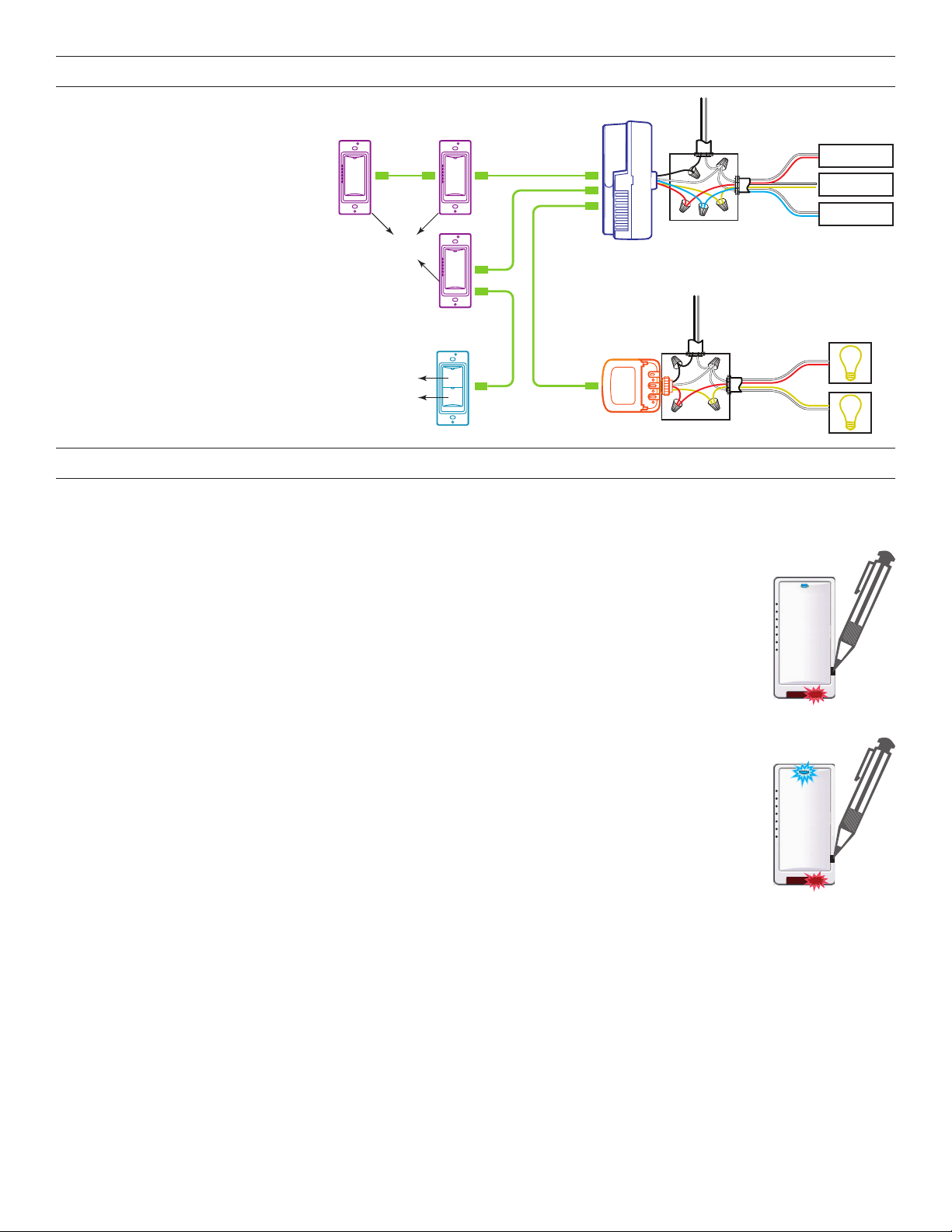

LMDM-101 LMDM-101

Loads:

1,2,3,4,5

LMRC-213

Line

Voltage

Loads

0-10 Volt

1

2

3

Ballast

0-10 Volt

Ballast

0-10 Volt

Ballast

A

B

C

down below 50% and turn ON when

ramped up above 50%.

To change the loads controlled by the

LMDM-101 see UNIT ADJUSTMENT.

Loads:

2,3,4,5

LMDM-101

LMRC-102

1

Line Voltage

J-Box

Loads

4

A

B

5

UNIT ADJUSTMENT - PUSH N’ LEARN (PNL)

Load Binding Procedure

A configuration button allows access to our patented Push n’ Learn™ technology to change the binding relationship between switch

buttons and loads.

Step 1 Enter Push n’ Learn

1. Using a pointed tool, press and hold the configuration button for 3 seconds, until the Red LED on the switch

begins to blink.

2. When you release the switch’s configuration button, the red LED on other communicating DLM Local

Network devices begins to blink.

3. The DLM Local Network is now in PnL mode. The Red LEDs continue to blink until you exit PnL mode.

4. All loads in the room turn OFF after entering PnL. After one second, one load turns ON. This is Load #1,

which is bound to switch button #1 as part of the Plug n’ Go factory default setting. The Blue LED will be ON

for all devices that are bound to this load.

Step 2 Load selection

1. To step through the loads connected to the DLM Local Network, press and quickly release the configuration

button. The first press turns OFF load 1 and turns ON load 2. The next press turns OFF load 2 and turns

ON load 3, and so forth. As each load turns ON note which devices (switch buttons, sensors, etc.) are

showing the blue LED. These devices are currently bound to the load that is ON.

2. To unbind a switch button or rocker paddle from a load, press the switch button or tap the rocker paddle

while its blue LED is ON. The blue LED turns OFF to indicate the device no longer controls the load that is

currently ON.

3. Pressing the switch button or rocker paddle again while the load is ON rebinds the load to the device and

the blue LED illuminates.

Step 3 Exit Push n’ Learn

1. Press and hold the configuration button until the red LED turns off, approximately 3 seconds.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)This device may not cause

harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the interference at his own expense.

2

Loads do not operate as expected.

DEL bleue

indiquant

le statut de

la charge

Allume l'appareil au dernier niveau

Les DE

indiquent

le réglage

du niveau

d'éclairage

Panneau de

culbuteur

TROUBLESHOOTING

Rocker paddle LED

doesn’t light

1. Check to see that the the switch is connected to the DLM Local Network.

2. Check for 24VDC input to the switch: Plug in a different DLM device at the switch location. If the

device does not power up, 24VDC is not present.

• Check the high voltage connections to the room controller.

• If high voltage connections are good and high voltage is present, recheck DLM Local Network

connections between the switch and the room controller.

The wrong lights are

controlled

Rocker paddle doesn’t

actuate

LED turns ON and OFF

but load doesn’t switch

1. Configure the rocker paddle to control the desired lights using the Push n’ Learn adjustment

procedure.

1. Make sure the switch frame and button are assembled properly.

2. Make sure that the wall plate is not pinching the frame.

1. Make sure device is not in PnL.

2. Check load connections to room controller.

INSTRUCTIONS EN FRANÇAIS

Cet appareil est préréglé pour un fonctionnement Plug n’ Go™ et

son réglage est optionnel.

Pour connaître tous les détails opérationnels, les réglages et les fonctions

supplémentaires du produit, consulter le guide d'installation du système DLM

fourni avec les Wattstopper contrôleurs de pièce et aussi disponible au

www.legrand.us/wattstopper.

L'installation doit être effectuée conformément à tous les règlements ainsi

qu'aux codes locaux et de la NEC en vigueur. Les raccordements de fils

doivent être classés comme pouvant convenir au calibre du fil (fil de sortie et de

bâtiment) utilisé.

Pour les dispositifs DLM de classe 2 et le câblage du dispositif : Doit être

connecté à une source d'alimentation de classe 2 seulement. Ne pas reclasser

et installer en tant que classe 1 ou en tant que fil d'alimentation ou d'éclairage.

Ne pas appliquer de solvant de nettoyage directement sur l'appareil. Appliquer le

solvant de nettoyage sur un chiffon et frotter l'appareil pour le nettoyer.

SPÉCIFICATIONS

Tension .................................................................................. 24 VCC

Consommation de courant ..........................................................5mA

Alimentation électrique .................... Wattstopper contrôleur de pièce

Connexion au réseau local DLM .................................. 2 ports RJ-45

Caractéristiques du réseau local DLM pendant l'utilisation des

contrôleurs LMRC-11x/2xx:

La basse tension est générée par le câble Cat 5e (LMRJ);

courant maximal 800mA. Supporte jusqu'à 64 adresses de

charge, 48 dispositifs de communication incluant jusqu'à 4

séries LMRC-10x et contrôleurs LMPL-101. Topologie libre

allant jusqu'à 305 m (1 000 pi) max.

Environnement .................................Pour usage intérieur seulement

Température de fonctionnement ........ 0 ° à 55°C (32 ° à 131°F)

Température d'entreposage ............-5 ° à 80 °C (23 ° à 176 °F)

Humidité relative ..............................5 à 95 % (non condensée)

Brevet en instance

MONTAGE DE L'INTERRUPTEUR

MISE EN GARDE: Ne pas installer avec une boîte de

jonction dotée de circuits de classe 1, 3, d'alimentation

ou d'éclairage.

BOUTONS ET INDICATEURS

Appuyer quand la charge est éteinte:

L

Lorsque toutes les charges liées au gradateur sont éteintes, la DEL bleue

indiquant le statut de la charge est faible. Une DEL de niveau d'éclairage

unique s'allume pour indiquer le denier niveau d'éclairage.

Lorsque toute charge liée au gradateur est allumée, la DEL indiquant le

statut de la charge est vive. Le nombre de DEL de niveau d'éclairage

allumée indique le niveau d'éclairage le plus élevé pour chacune de ces

charges.

3

Appuyer lorsque la charge est allumée: Atteint le niveau le plus fort

Presser et tenir : Augmentation

Bouton de configuration

(derrière la plaque de commutation)

Appuyer : Diminue jusqu'à l'extinction

Appuyer et tenir : Diminution

DEL rouge

Loading...

Loading...