LEGRAND Wattstopper HB300W Installation Instructions Manual

Wattstopper

L7 lens may require pliers

to remove the lens. (Grab

one of the fins to remove.)

Sensor Assembly

High Bay • Line Voltage • Passive Infrared

IP65 Occupancy Sensors for Wet Locations

No: 24161 – 08/17 rev. 2

Installation Instructions • Instructions d’Installation • Instrucciones de Instalación

Catalog Number • Numéro de Catalogue • Número de Catálogo: HB300W

Country of Origin: Made in China • Pays d’origine: Fabriqué en Chine • País de origen: Hecho en China

SPECIFICATIONS

Voltage ...........................................................................................24VDC

Wiring cable ................ 3 or 4-conductor 18AWG stranded, UL Style 2517

Unit Dimensions ............................................... 4.08” diameter, 1.88” thick

Threaded nipple ................................................0.81” diameter, 0.40” long

fits standard 1/2” electrical conduit fitting

Weight ........................................................................ 0.28 lb (130 grams)

Material ......................................................... PC flame retardant material,

............................................................UV resistant, indoor use only,

............................................. minimum plastic wall thickness 2.5mm

HB300W L3W

HB300W L7W

Environment ...................................................................... IP65 Compliant

Operating humidity .................................... 5 to 95% RH, non-condensing

Maximum Dew Point ............................................................. 29°C (85°F)

US Patents: ........................................................5,640,113 and 5,804,991

®

DESCRIPTION AND OPERATION

The HB300W low voltage occupancy sensor is designed for automatic lighting control in high bay wet location applications. The

HB300W sensor contains a passive infrared sensor (PIR) and is modular being made up of two parts, a Sensor Module and a Lens.

Time delay and PIR sensitivity values are set using DIP switches.

INSTALLATION OVERVIEW

1. Review the ADJUSTMENTS section and complete any

necessary DIP switch setting changes.

2. Mount the sensor so the lens is below the edge of the

fixture and away from the lamps. Heat from the lamps

CIRCUIT BREAKER BEFORE INSTALLING THE SENSOR.

could affect the sensor operation.

Make sure that you have the appropriate accessories for the sensor

mounting configuration. (See MOUNTING OPTIONS.)

3. Assemble any necessary mounting accessories and attach them to the

sensor module. Make sure that the flying leads from the sensor module

cable are accessible inside the fixture.

4. Connect the line voltage and load wires to the power pack leads as

shown in the applicable Wiring Diagram for the sensor module.

• Do not allow bare wire to show.

• Make sure all connections are secure.

• Check all gaskets for watertight fit.

5. Connect the low voltage wires from the power pack to the sensor.

6. Check sensor operation. Refer to the TESTING section.

7. Attach the Lens to the HB300W as shown in the sensor assembly

drawing.

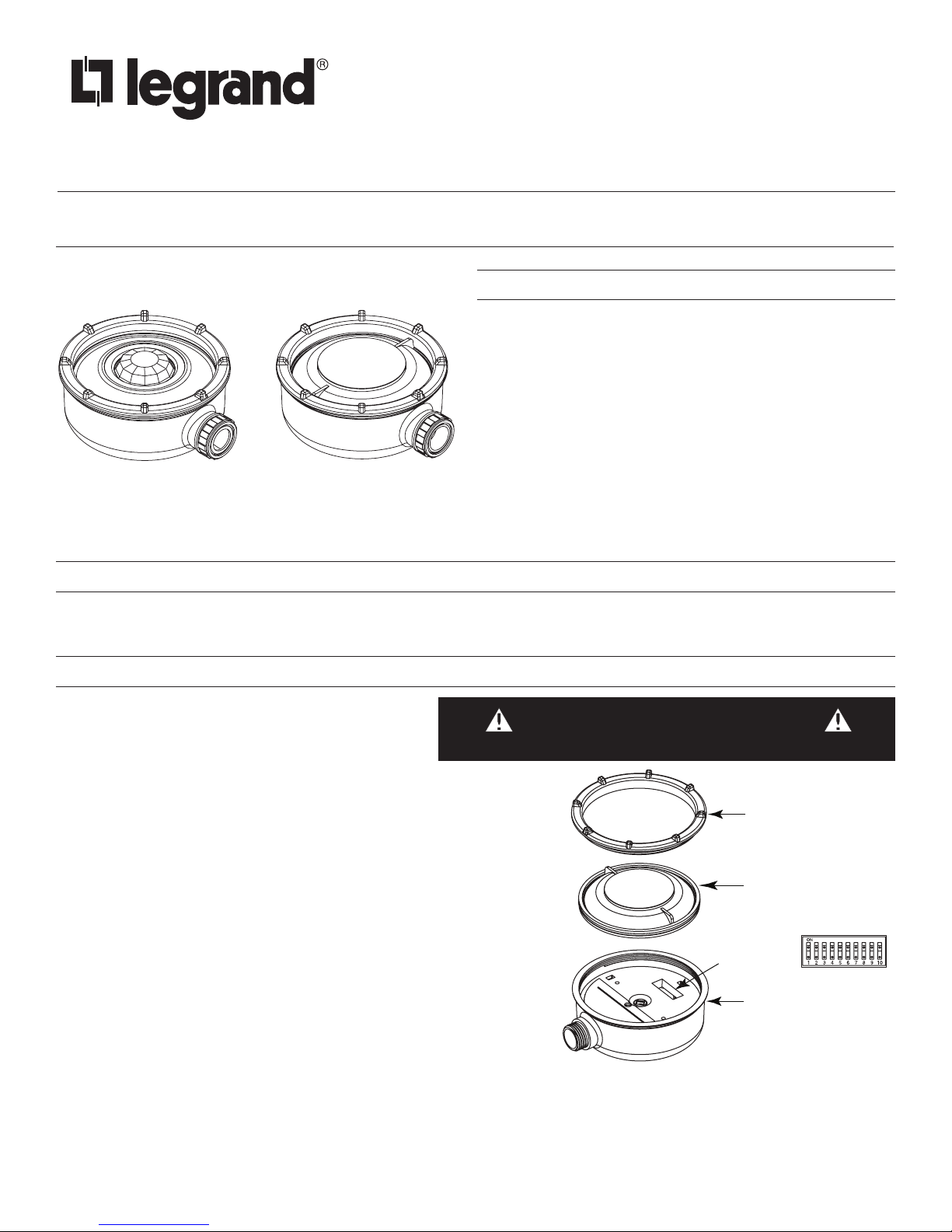

TURN THE POWER OFF AT THE

CAUTION

Tightening ring

HBLxW (lens module)

DIP switches

HB300W (sensor module)

ADJUSTMENTS

Threaded nut

MOUNTING OPTIONS

The sensor is pre-set at the factory to meet the requirements of

most applications. Review this section if your application requires

changing factory pre-sets.

Sensor factory pre-sets are as follows (default settings are bold):

Factory Switch Settings (N/A = not applicable, no effect)

1 2 3 4 5 6 7 8 9 10

ON OFF OFF OFF OFF ON ON OFF N/A N/A

PIR Sensitivity (switches 1&2) .....................Normal

Time Delay (switches 3-7) ....................15 minutes

Override (switch 8) ....Occupancy control enabled

PIR Sensitivity (Switches 1-2)

The factory setting (Normal) is suitable for most applications, but

it may be necessary to adjust the PIR sensitivity if there is any

environmental interference causing false triggers or if sensitivity

needs to be increased for your particular application. Use DIP

switches 1 & 2 to adjust sensitivity.

Switch 1 2 PIR SENSITIVITY

OFF OFF High

ON OFF NORMAL

OFF ON Medium

ON ON Low

Time Delay (Switches 3-7)

Use DIP switches 3 to 7 to adjust the time delay.

Switch 3 4 5 6 7 TIME DELAY

ON ON ON ON ON 15 seconds

OFF ON ON ON ON 5 minutes

OFF OFF ON ON ON 10 minutes

OFF OFF OFF ON ON 15 minutes

OFF OFF OFF OFF ON 20 minutes

OFF OFF OFF OFF OFF 30 minutes

Override (Switch 8)

The override disables the occupancy control feature of the HB300W

sensor module. When occupancy control is disabled, the load

remains ON as long as the sensor is powered.

Switch 8 Load Effect

OFF Controlled by Occupancy

ON PIR override. Load always ON

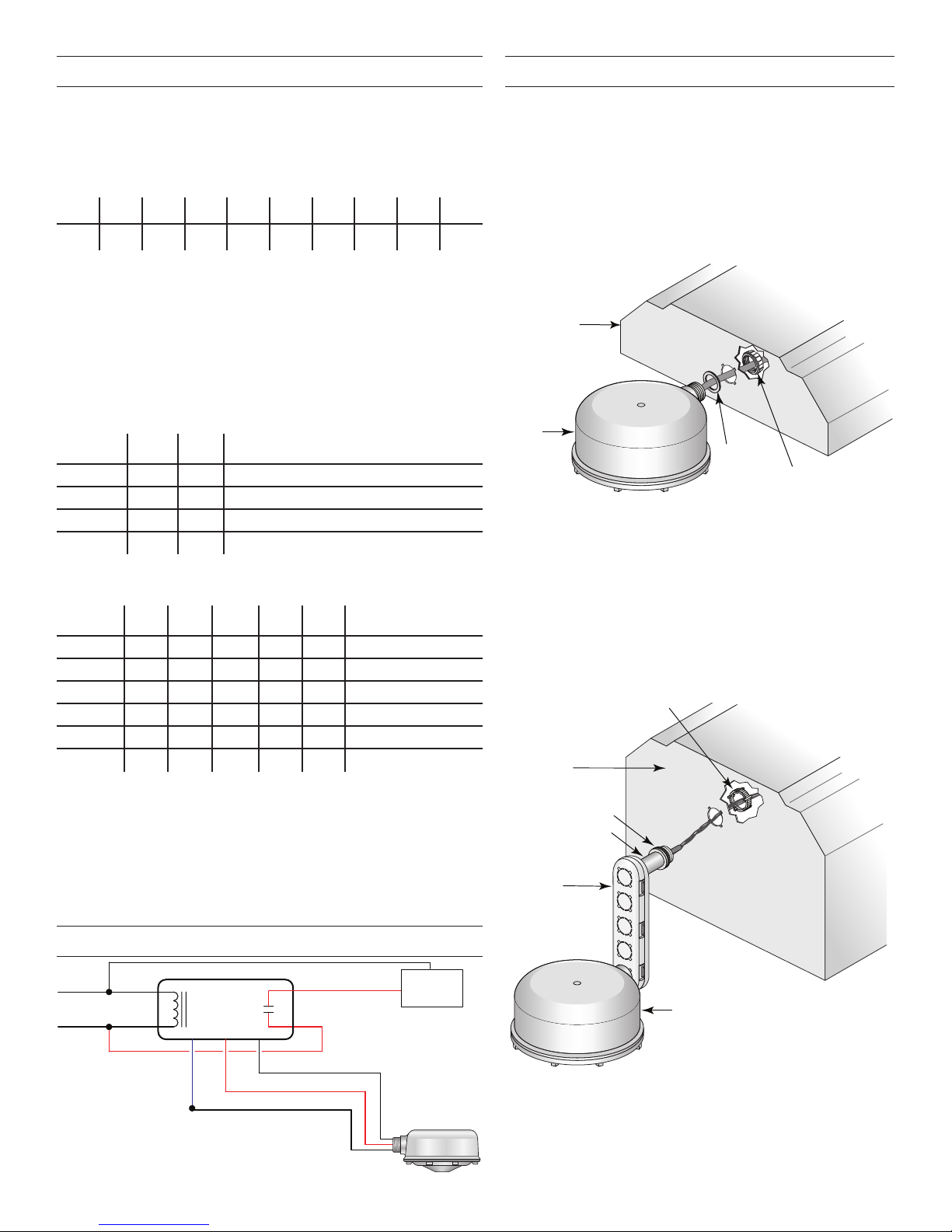

Punch or drill a 0.825” (21 mm) hole in the luminaire housing

from the exterior of the fixture assembly of the standard

module. The wiring cable is threaded through it and into the

fixture for connection. Hand tighten with a threaded nut.

As shown in the illustration below, the HB300W can be

attached directly to a watertight fixture or junction box that is

equipped with a threaded nipple. The center of the threaded

nipple should be no more than approximately one inch (1”)

from the bottom of the fixture to avoid blocking the sensor’s

view.

Wet location

light fixture

(supplied by

others)

HB300W

sensor

Rubber

Gasket

HB300W attached to a watertight light xture

Threaded nut

The HBEM3W extender module allows attaching the sensor to

the side of the fixture so that the lens can be positioned below

the bottom edge of the fixture. The two sides of the HBEM3W

snap together to protect the cable.

The extender housing is not watertight, but the inner flange

rings on the chase nipple and the HB300W housing fit into

grooved rubber rings on the the cable. This keeps moisture

from entering the fixture and sensor at those locations.

Wet location

light fixture

(supplied by others)

Rubber washer

Chase nipple

HBEM3W

Extender

housing

WIRING

(Common)

Blk

(+24VDC)

(Control Output)

Red

Red

Neutral

Hot

Wht

Blk

Power

Pack

Blu

Red

Load

HB300W sensor

HB300W attached to a watertight light xture using HBEM3W

Wht

Red

Blk

HB300W

2

Loading...

Loading...