Page 1

General:

NOTE: These devices are intended to be installed as outlined in Article 374 of the National Electrical Code.

1. Compare and coordinate the architectural and electrical drawings with the Walker installation drawings. Contact your local

Wiremold field sales representative immediately if any dimensions or details are incorrect.

2. On arrival, check the shipment for shortages or damage. Contact your local Wiremold field sales representative immediately

if there are any problems. File a freight claim for any damage directly with the carrier. Protect material and cartons from

moisture damage.

3. Trench and accessories are banded and palletized where required. Lifts will weigh up to 3,000 lbs. All equipment and

expendable supplies necessary to install the trench system are to be furnished by the trenchduct installer.

4. Advise all trades that trenchduct is not to be used as a walkway or crosswalk in moving about or storing any construction

material. The trenchduct installer shall coordinate the placement of concrete with the general contractor in accordance with

Section 6 and the Finishing Notes and Details.

5. VA Full Bottom Trench has a one-piece U–shaped bottom pan or a flat bottom with two spot welded sheet metal angles.

VA Bottomless Trench has sheet metal angles held in place with set screws. Both styles utilize aluminum extruded rails and

exterior leveling screws (shipped separately) to adjust the rail and cover plate assembly. Cover plates and bottom pans or

sheet metal angles can be placed at any location along the extruded side rails.

Trenchduct Installation:

1. Layout:

A. Begin trench layout at a tee, elbow, or center of a run. Strike chalk lines to indicate the location of the trench body or

compartment. The inside width of the trench body is 3/4" [19.1mm] less than the cover width. Overall width is approximately 1 3/4" [44mm] greater than cover width.

B. Position all trench components for the entire run. Install leveling feet and support if required, but do not permanently fasten

at this time. Position risers in equipment closets so that they are approximately 1" [25mm] to 2" [51mm] away from existing

or future walls. Field drill openings if required and secure grommets or power drops (see Section 2d).

C. Re-check all dimensions, particularly stub ups into walls and closets. If trench has pre-punched openings, check the hole

alignment by removing a cover plate.

D. For bottomless trench: power compartments, grommets, power drops and other internal components should be installed

before placement of trenchduct cover plates. These items must be installed before partitions are welded together.

2. Coupling and Securing:

A. To couple trench pieces together, slide the combination clips midway across each joint and tighten screws. Position

remaining combination clips as shown on the drawings, or a maximum of 40" [1017mm] on center.

B. For bottomless trench: place metal void closures under bottom flange(s), or on top of outside bottom flange of bottomless

trench side rail assembly and secure to deck and trench side rail. Fastening should occur at two locations (staggered) per

panel intersection and a maximum of 24" [610mm] on center (30" [712mm] on center for 30" [712mm] wide deck panel).

C. After all trench pieces are in position, permanently attach leveling feet to the form, concrete sub slab or precast concrete

pad with suitable fasteners. Review drawings for specific details.

D. Use fillet welds 1/2" [12.7mm] or longer, blind rivets or self-drilling screws that do not penetrate into the raceway to

fasten trenchduct and components. Recommended rivet is Avdel #1693-0613 3/16" [4.8mm] dia. x .062 – .250 [1.58mm –

6.35mm] grip range. Use #8 drill bit [.199 dia – 5.0mm]. Only end closures and trenchduct risers are supplied with

attachment hardware.

E. Cover plate hold-down screws have a #2 Phillips recess, and a special #10-14 thread. Order part #431032-040 from

Walker Systems.

VA Trenchduct –

Full, Intermittent, or Bottomless

INSTALLATION INSTRUCTIONS

Installation Instruction No.: IY0072 R2 – Updated April 2006

Wiremold / Legrand electrical systems conform to and should

be properly grounded in compliance with requirements of

the current National Electrical Code or codes administered by

local authorities.

All electrical products may present a possible shock or fire

hazard if improperly installed or used. Wiremold / Legrand

electrical products may bear the mark as UL Listed and/or

Classified and should be installed in conformance with current

local and/or the National Electrical Code.

IMPORTANT: Please read all instructions

before beginning.

Page 2

4. Height Adjustment:

A. The height adjustment of the trenchduct system is -0" + 5/8". Secure all trench components prior to making adjustments.

Be certain that the trench base will rest on a solid surface or that concrete will be installed under the trench base

so that partitions and support studs will effectively support cover plates.

B. Field install leveling screws only where required. Trenchduct should be set to screed using a laser, and is not adjustable

after the concrete pour.

C. Full bottom VA trench can be adjusted two ways:

1. The entire trench assembly can be adjusted as a unit using the height adjusting screw on the leveling foot. Do not

loosen the set screw on the combination clip. Install one additional set screw into the combination clip and engage the

metal rib to help support the trench bottom pan. The setscrew is a #8-32 x 1/4" self-threading, Taptite brand screw. It is

Walker part #429071-016. Additional screws are shipped separately or packed in a hardware bag with the leveling feet.

2. To raise the aluminum rail and cover assembly only, secure the trench bodies to the form or sub-slab. Loosen and/or

remove the set screw and turn the adjusting screw as required. After leveling is complete, tighten the two combination

clip fastening screws.

5. Final Review and Adjustments:

A.. Inspect all components for gaps or openings where concrete mix may enter the system. Secure these openings with

waterproof sealing compound (Walker part# 290G) or duct tape (Walker part # H296).

B. Witness and check the concrete pour to be certain that the concrete is flush with the top of the cover plate. Refer to

Finishing Notes and Details.

C. After the concrete pour, any partitions shall be adjusted so they bear against the underside of the cover plates when the

final cover leveling is completed. Weld the partitions together with 1/8" [3.2mm] x 1/2" [12.7mm] long fillet welds at each

end and on two foot centers. Paint the welds with a corrosion resistant paint. Clear all debris and deburr any sharp edges

that would interfere with wiring.

D. Any support studs shall be adjusted so they bear against the underside of the cover plate.

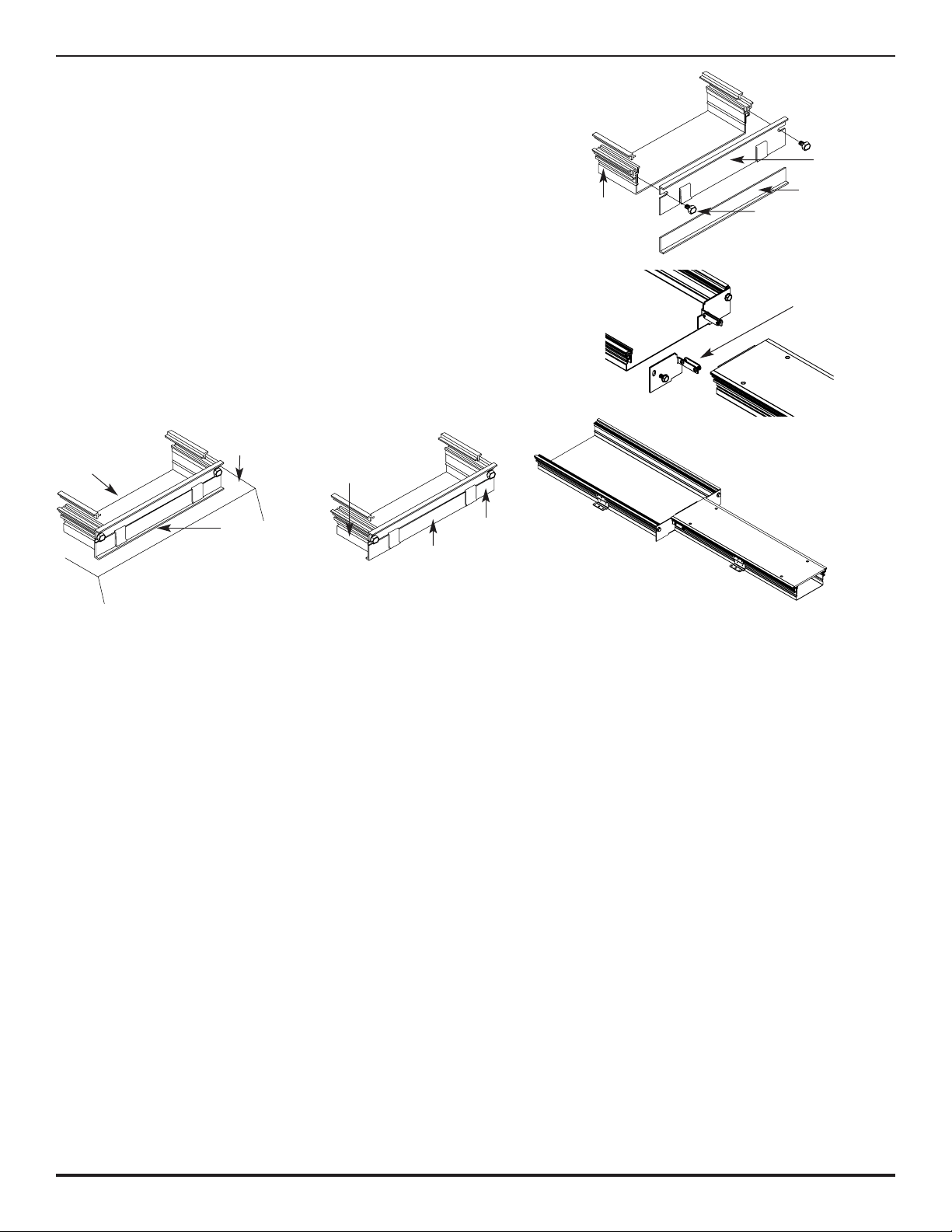

3. End Closure:

A. For full length closure, fasten top part of end closure to

end of trenchduct with two hex head screws provided

(see Figure 1). For partial end closure, fasten closure to

end of wider trenchduct with hex head screws provided

(see Figure 2).

B. Tighten screws into aluminum rail slot until end closure is

secure to trenchduct.

C. For partial closure, slide twin pilot into aluminum rail of

narrow trenchduct and tighten #10-24 hex head screws

(see Figure 2A).

D. Install and adjust bottom part of end closure (maximum 1"

[25mm]) until it is level with bottom of trenchduct.

E. If used on cell or deck, tack weld end closure bottom

flange to top of raceway (see Figure 3).

F. If used on underfloor duct or alone, flip end closure

bottom around so bottom flange is hidden under

trenchduct (see Figure 4).

Top Part

Bottom Part

Trenchduct

Figure 1

Figure 2

Figure 2A

Figure 4

Figure 3

Hex Head Screw

Twin pilot

Top of Raceway

Trenchduct

Tack Weld

Along Here

Bottom Part

(Flip Over)

Top Part

Trenchduct

Page 3

6. Work Subsequent to Trenchduct Installation by Other Contractors:

A. Concrete Placement and Curing:

1. Reinforced concrete design shall be in accordance with American Concrete Institute Specifications for Structural

Concrete for Buildings (ACI301-72) and ACI Building Code Requirements for Reinforced Concrete (ACI318-82),

2. Concrete placement shall follow proper and accepted industry practice and be in accordance with ACI Recommended

Practice for Measuring, Mixing, Transporting, and Placing Concrete (ACI304-73).Concrete must be vibrated at all

trenchducts to insure that the concrete completely fills underneath the system. However, it is imperative that the

concrete not be over vibrated. Over vibration causes segregation of material in the concrete mix which, in turn,

leads to weakening of concrete strength.

3. Concrete curing shall follow proper and accepted industry practice and be in accordance with ACI301-72.

B. After the Concrete Pour:

1. Excess moisture should be removed from inside of the trenchduct within 48 hours after the concrete pour. Remove

cover plates where water may have entered the trenchduct and remove all water from the system. Periodically, check

the trench system for water accumulation or condensation. Depending on job site and weather conditions, a cover

plate removed at several locations along each run will help prevent condensation inside the system. If water is left in

the trench system, it may freeze, causing severe damage to the trench and floor slab.

2. When heavy material or equipment loads will be placed on or moved over the trench system, install temporary planking

that will transfer loads to the adjacent concrete.

NOTE: Cover plates, compartment dividers or other trench components that are damaged during construction must

be replaced by others. This will not be the responsibility of Walker.

3. For BVA Bottomless or IBVA Intermittent Bottomless Trench: Place metal void closures under bottom flange(s)

or on top of outside bottom flange of trench side rail assembly and secure to deck and trench side rail by fillet welds

(1/2" [12.7mm] or longer) and/or blind rivets on 24" [610mm] centers.

4. Floor finish contractor shall clean and prepare cover plates prior to final floor covering installation. Use a suction cup

lifter, Walker part #485, to remove cover plates.

For tile floors: The outside trim extrusion is reversed to the tile position and secured in place

(refer to Finishing Notes and Details).

For carpet floors: The trim extrusion shall remain flush.

5. Consult the carpet supplier for recommendations on installing carpet over the trenchducts.

NOTE: Bottomless trench for use only over UL Listed Cellular Metal Raceway or UL Listed Cellular Metal Floor Raceway

Fluted Section Fittings.

Page 4

Concrete Finishing:

BOTTOMLESS AND FULL BOTTOM VA TRENCH

Figure 1 – Section Thru Trench

Figure 2 – Concrete Finish

Step 3

Depth of Pour

Void Closures as Required –

(Shipped Separately)

Compartments as Required –

(Shipped Separately)

Bottom Required for

Power Cables

Cover Plate as Required

Leveling Screw (Only use when

Adjustments to Screed is Required

and after Trench is Fastened ).

Figure 3 – Tile Finish

Escutcheon

Steps 5 and 6

Step 4

Top of Trenchduct

© Copyright 2006 Wiremold / Legrand All Rights Reserved

Wiremold / Legrand

U.S. and International:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX 860-232-2062 • Outside U.S.: 860-233-6251

Canada:

570 Applewood Crescent • Vaughan, Ontario L4K 4B4

1-800-723-5175 • FAX 905-738-9721

IY0072 R2 0406

1. Trench installer shall set top of trenchduct level with concrete screed line. Concrete installer must maintain top of finished

floor level with top of trenchduct.

2. Make all height adjustments prior to concrete pour. If ponding or other problems are encountered before or during the

concrete pour, re-adjustment shall be made as determined by the general contractor in order to maintain a level floor.

3. See Section 6a for Concrete Placement.

4. Concrete installer to hand trowel concrete level with top of trenchduct a minimum of 18" [457mm] along both sides

of trenchduct.

5. If floor is to have 1/8" [3.2mm] thick tile, tile installer shall remove and prepare covers to receive tile. After tile is installed,

drill and countersink covers to fit hold-down screw escutcheons.

6. Just prior to replacing tiled covers, remove trim and install as shown in Figure 3. Interchange outside mitered trim on flat

ells with inside mitered trim. Replace covers and complete balance of floor tile installations.

Loading...

Loading...