Page 1

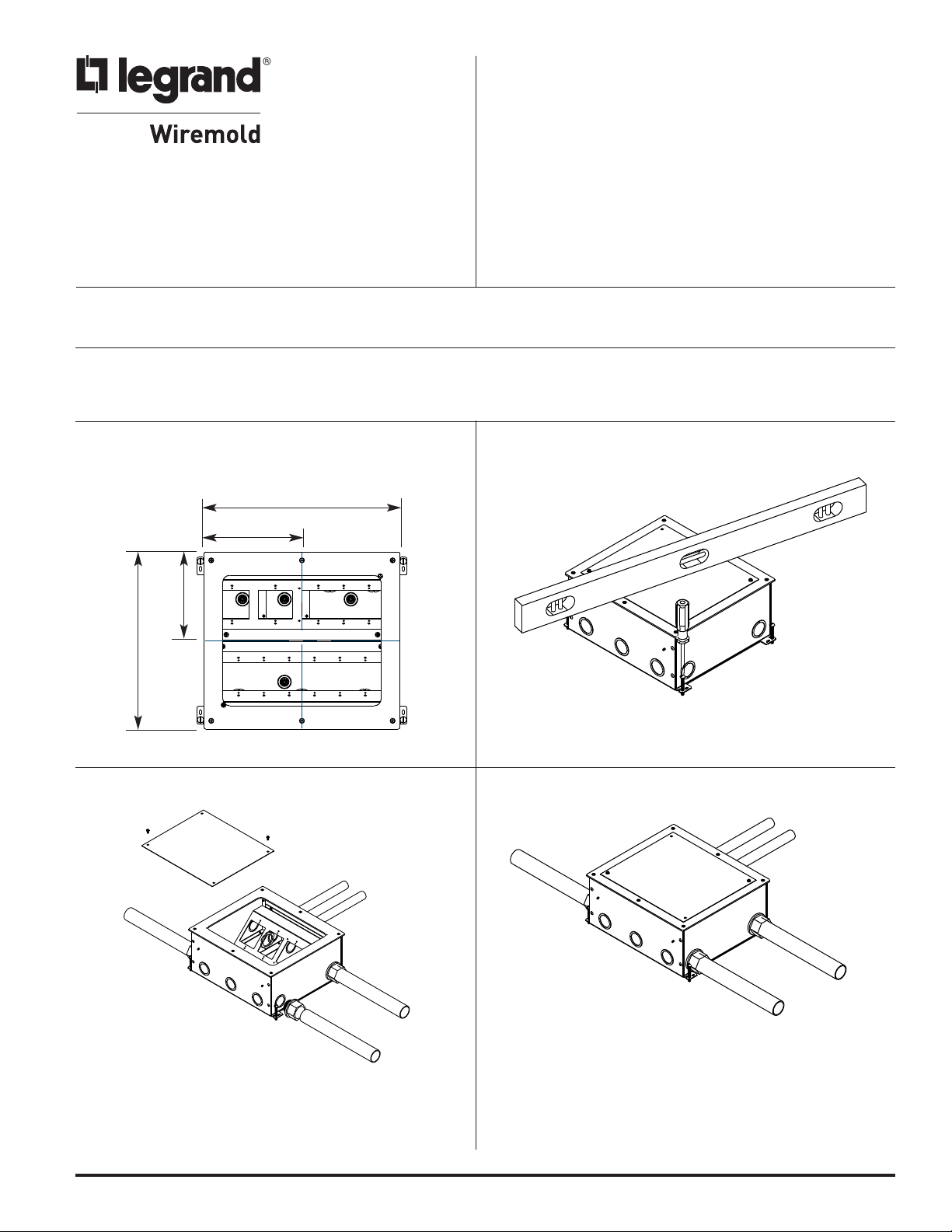

RFB 119 Series Floor Box

I N S T A L L A T I O N I N S T R U C T I O N S

Installation Instruction No.: 1 003 189R1 – Updated April 2011

Legrand/Wiremold electrical systems conform to and should be properly

grounded in compliance with requirements of the current National

Electrical Code or codes administered by local authorities.

All electrical products may present a possible shock or fire

hazard if improperly installed or used. Legrand/Wiremold electrical

products may bear the mark of a Nationally Recognized Testing

Laboratory (NRTL) and should be installed in conformance with current

local and/or the National Electrical Code.

IMPORTANT: Please read all instructions

before beginning.

Products Covered: Floor Box Cat. Nos.: RFB9, RFB11,

CAUTION: Do not operate tile stripper or resurfacing equipment over top of covers. This may result in damage to the surface finish

CAUTION: When used in bare concrete or terrazzo floors, use part number: RFB119-PAN (Sold separately).

Step 1 Locate and position box in accordance to floor

plans or blueprint.

Floor Box Covers: RFB119CTC, RFB119BTC

Floor Box Device Plates: RFB119 (suffix)

of the product.

Step 2 Level & anchor box. Top of box must be flush with

concrete pour. Use screws, nails, or wire to prevent

box from floating during pour.

14"

[356mm]

"

7

178mm]

[

6 5/16"

[161mm]

12 5/8"

[321mm]

CAUTION: Box has no post pour adjustment.

Step 3 Remove mudcap and attach conduit.

Step 4 Reinstall mudcap.

NOTE: For use in bare concrete or terrazzo floors, replace

mudcap with part number: RFB119-PAN. (Sold

separately.) (See Step 19.)

Page 2

Step 5 Screed to top of box surface. Hand troweling

recommended near box edges.

CAUTION: Do not dislodge or shift box with jobsite traffic

or concrete vibrations.

NOTE: If box is over-poured or the top plate is below

the concrete surface, follow these steps:

1. Remove and retain mudcap and mudcap

mounting screws. If mudcap is bent during

removal, flatten within reason.

2. Install one or more 1/8" thick spacers, Cat No.

RFB119-TS (available separately), until the top

one is flush with the concrete surface.

See Step 19 for illustration.

3. Replace mudcap on top of spacers and secure

with mounting screws. Duct tape any cracks or

seams where concrete may enter.

4. Pour concrete patch around the perimeter of

the spacers and level with the concrete floor.

5. Complete installation following the

remaining steps.

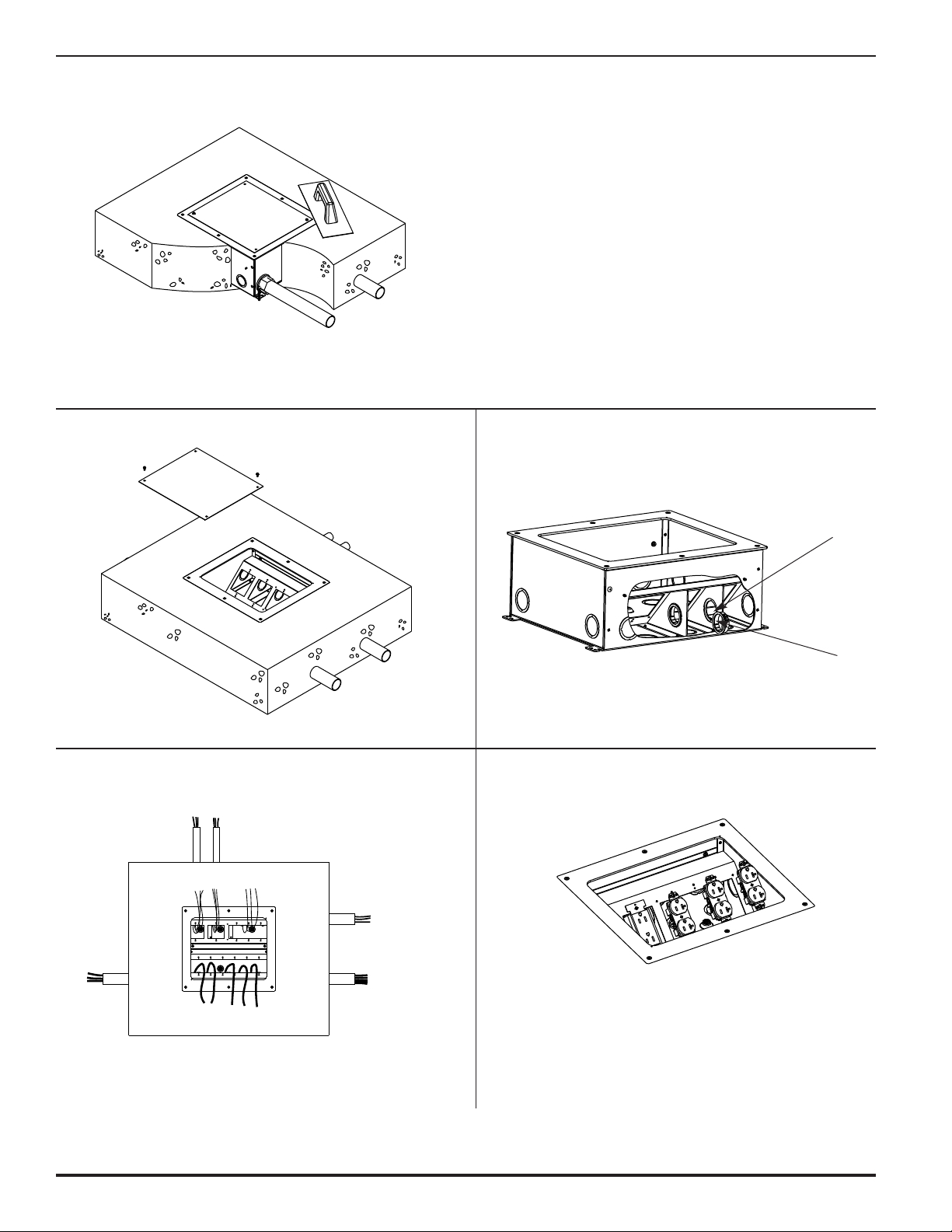

Step 6 Remove mudcap.

Step 8 Locate and pull wires and cables.

Step 7 If service access between adjacent compartments

is required, remove KO between compartments

and add grommet (not included).

O between

K

compartments

Grommet

(not supplied)

Step 9 Terminate and mount devices.

NOTE: Wire devices (not included) in accordance with National

Electrical Code or any local code that applies. Make sure

that any grounding conductors are connected to the

grounding screws.

2

Page 3

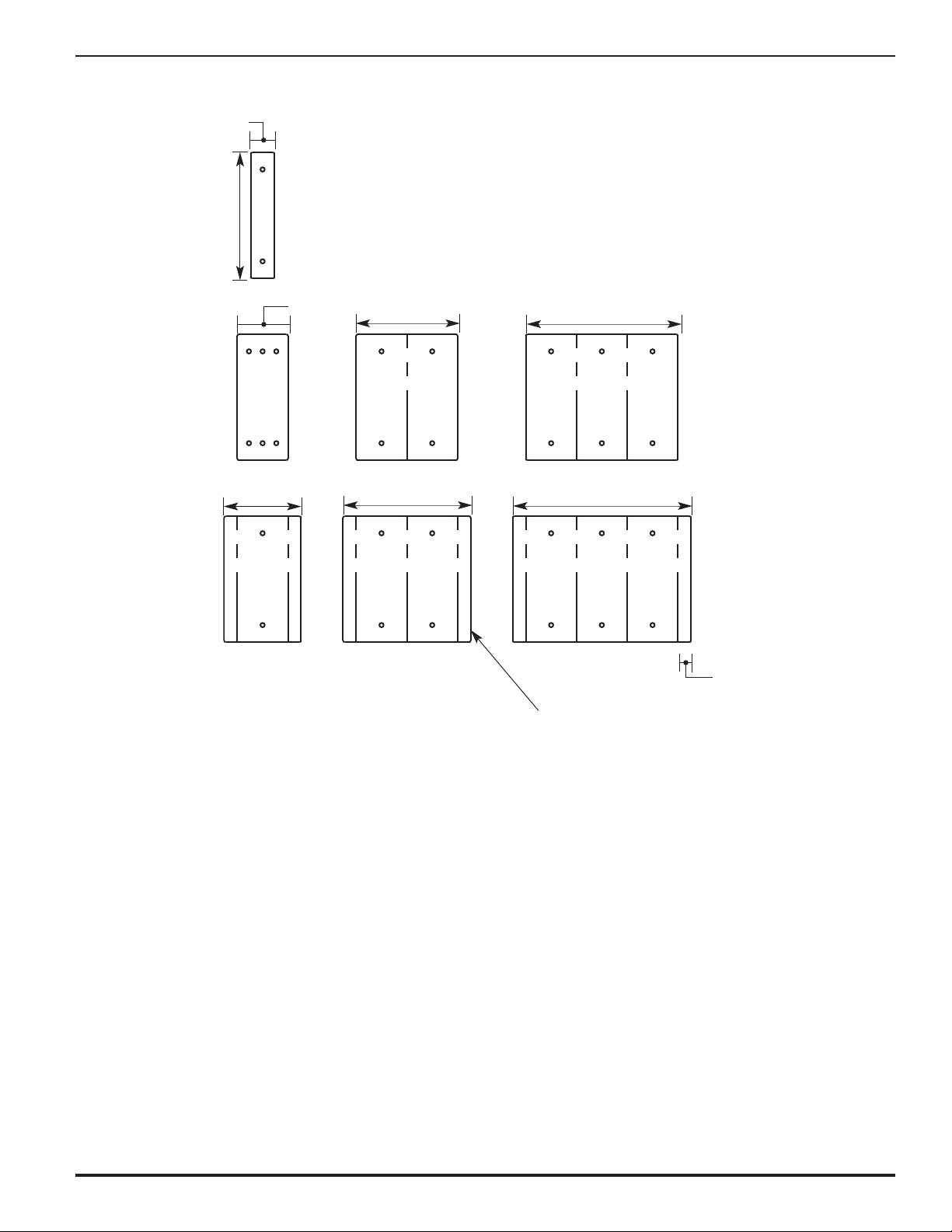

Step 10 Determine device plate selection based on sizes illustrated below.

/8"

7

22mm]

[

Spacer Plate

Cat No. RFB119-SPACER

1/2"

4

114mm]

[

Used to close off space adjacent

to standard plates when used on

multi-gang mounting brackets.

1, 2, and 3 Gang

Sectional Plates

1, 2, and 3 Gang

Standard Plates

2 3/4"

[70mm]

1 13/16"

[46mm]

3 5/8"

[92mm]

4 9/16"

[116mm]

7/16"

5

138mm]

[

3/8"

6

162mm]

[

Standard Plates extend 15/32"

[11.9mm] on each side wider

than sectional plates.

15/32"

[11.9mm]

3

Page 4

Step 11 Determine device plate required to close off wiring compartments. Sectional (1-13/16" [46mm] wide) or standard device

plates may be used with multi-gang mounting plates.

NOTE: Standard width device plates extend into adjacent gangs, preventing the mounting of other device

plates. Resulting gap should be closed with a spacer plate or single gang sectional plate.

7/8"

[22mm]

6-Gang Mounting Bracket

3-Gang & (2) Single Gangs (Vertical)

Mounting Bracket (RFB11)

1/2"

4

114mm]

[

13/16" [46mm]

1

pacing between gangs

s

1 13/16" [46mm] wide

sectional device plate

(3) Single Gangs (Horizontal)

Mounting Bracket (RFB9)

2 7/16"

[62mm]

6"

[152mm]

4

Page 5

Step 12 Mount blanking plates and spacers between standard size plates to close off any gaps or openings. Typical layouts are

illustrated below.

6-GANG MOUNTING BRACKETS USED WITH STANDARD DEVICE PLATES

3-Gang Standard Plate

(6 3/8" x 4 1/2"

[162mm x 114m])

Cat. No. RFB119-SPACER

Used to close gap between standard

single and multi-gang plates

1-Gang Standard Plate

(2 3/4" x 4 1/2"

[70mm x 114m])

Cat. No. RFB119-SB

Single-gang Sectional Blank

Plate (mounted off-center)

2-Gang Standard Plate

(4 9/16" x 4 1/2"

[116mm x 114m])

6-GANG MOUNTING BRACKETS USED WITH SECTIONAL DEVICE PLATES

Cat. No. RFB119-SPACER

Used to close gap between standard

single and multi-gang plates

Existing opening when not covered

with Cat. No. RFB119-SPACER

(6) 1-Gang Sectional Plates

(1 13/16" x 4 1/2"

[46mm x 114m])

Cat. No. RFB119-SPACER

5

Page 6

CARPET INSTALLATIONS

tep 13 Install carpet and cut 12 1/16" x 10 5/16" [262mm

S

x 306mm] rectangular opening over box opening.

12 1/16"

[306mm]

6"

[153mm]

1/8"

5

131mm]

[

10 5/16"

[262mm]

tep 14 Open cover lid and position in box opening.

S

Position (2) mounting brackets under box opening

as shown in Step 15 and secure lid to brackets.

Mounting

Bracket

Step 15 Tighten mounting bracket screws securing flange

into box top cover plate.

Cover

Flange

Carpet

(Lid insert)

Mounting

Bracket Screw

Flange

Gasket

Mounting

Bracket

Carpet

Box Top

Cover Plate

Concrete

Step 16 Cut carpet insert and mount inside lid. Use

enclosed template for dimensions.

Carpet

Insert

6

Page 7

1 3/8"

35mm]

[

2 1/2"

64mm]

[

5 1/16"

129mm]

[

iameter

D

1 7/16"

37mm]

[

adius

R

1/4"

7mm]

[

9 5/8"

[219mm]

CARPET INSERT TEMPLATE

CAUTION: When printing copies of

this template please be

sure template is scaled

correctly and is the

correct size once it

is printed.

7

Page 8

TILE INSTALLATIONS

tep 17 Cover flange is 1/4" thick. Use 1/8" spacer, Cat.

S

No. RFB119-TS, for 3/8" tile installations. Use two

spacers for 1/2" tile installations. Mount cover to

box as shown in Steps 14 and 15. See illustration

in Step 20

Cat. No.

RFB119-BTC

Cover

Cat. No.

RFB119-TS

(1/8" Thick)

Sold Separately.

Not required for

1/4" tile.

3/8" Tile

BARE CONCRETE & TERRAZZO INSTALLATIONS

Step 19 Install pan prior to pouring floor. Pan is 1/4" tall.

Use in conjunction with spacers to obtain 3/8"

and 1/2" heights.

Original mudcap and

(2) mounting screws

Cat. No. RFB119-PAN

(sold Separately) 1/4"

tall. Used to dam

opening for installation

of cover during terrazzo

pour. Use RFB119-TS

spacers for floors

greater than 1/4" thick

tep 18 Use grout and/or silicone caulk between edges

S

of flange and tile.

Step 20 After concrete or terrazzo has cured, mount cover

to box as shown in Steps 14 and 15. Apply

sealing compound around perimeter of cover, as

shown in Step 18.

DETAIL VIEW OF FINISHED INSTALLATION

Seal edge of

cover with

silicone or caulk

Cover Flange

Terrazzo/Tile

Cat. No.

RFB119-PAN

1/4" tall

Original mudcap

placed inside

terrazzo pan

Cat. No.

RFB119-TS

1/8" thick

Cat. No. RFB119-TS

(sold Separately) 1/8"

thick. Not required for

1/4" terrazzo. Use (1)

for 3/8" and (2) for 1/2"

thick floors.

Top of box

(flush with

concrete)

1/8"

WIREMOLD

U.S. and International:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX 860-232-2062 • Outside U.S.: 860-233-6251

Canada:

570 Applewood Crescent • Vaughan, Ontario L4K 4B4

1-800-723-5175 • FAX 905-738-9721

3/8"

1/4"

Cover

Mounting

Bracket

NOTE: Remains in place during

cover installation

3/8"

1/8" Spacer

© Copyright 2011 Legrand/Wiremold All Rights Reserved

1 003 189R1 0411

Loading...

Loading...