Page 1

NP800 Series

Jumbo Tele-Power®Pole

INSTALLATION INSTRUCTIONS

Installation Instruction No.: INS00006R1 – Updated April 2005

Wiremold Electrical Systems conform to and should be

installed and properly grounded in compliance with

requirements of the current National Electrical Code, Canadian

Electrical Code or codes administered by local authorities.

All electrical products may represent possible shock or fire

hazard if improperly installed or used. Wiremold electrical

products are UL Listed to U.S. and Canadian safety

standards, made for interior use only, and should be installed

in conformance with current local and/or the National

Electrical Code.

NP800 Series Tele-Power Poles are provided standard with an anodized aluminum finish or may be painted any number of color

selected from a full array of powder coat finishes. Standard poles have two channels of different depths. These channels may be

divided at various locations by snap-in dividers to form additional channels. All channels may enclose either power or

communication wiring. Wire fill capacities are outlined below, followed by illustrations of standard pole hardware, and instructions

for a typical installation (over). Poles may be supplied with box ends of various sizes. Walkerflex™ Manufactured Wiring System

Connectors or with 10' [3.04m] cord ends (cUL only).

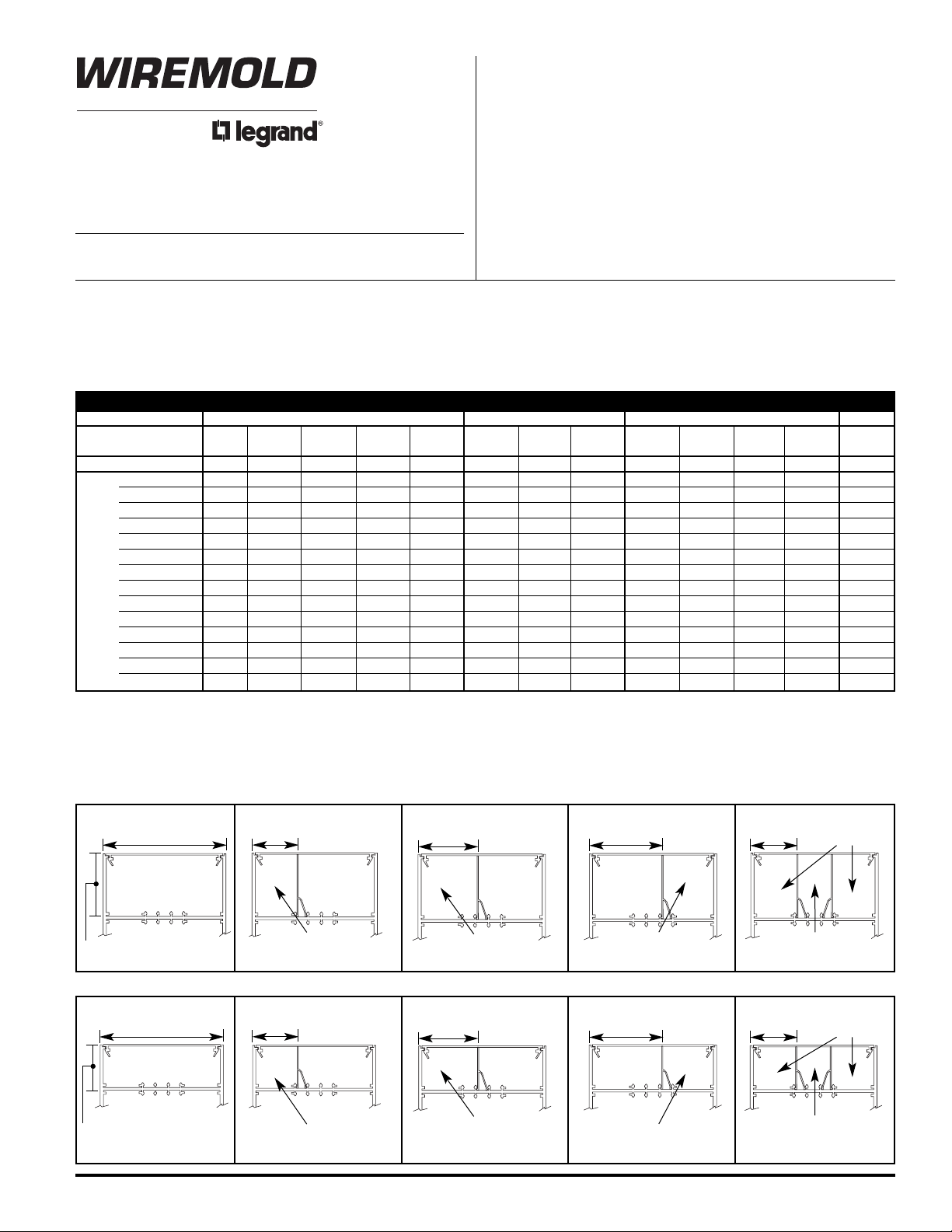

CABLE TYPE UNSHIELDED TWISTED PAIR SHIELDED TWISTED PAIR COAX TWINAX

DESCRIPTION CAT 3 CAT3 CAT5e CAT5 CAT6 TYPE 1 TYPE 2 TYPE 9 RG58/U RG59/U RG62 RG6U 100 OHM

4 PAIR 25 PAIR 4 PAIR 25 PAIR 4 PAIR 22 AWG 22 AWG 22 AWG 20 AWG 22 AWG 22 AWG 18 AWG

NOMINAL O.D. (In.) 0.19 0.36 0.21 0.337 0.25 0.39 0.465 0.275 0.195 0.242 0.242 0.27 0.24

2.4 25.0 7.0 20.0 8.0 14.0 6.0 4.0 12.0 24.0 15.0 15.0 12.0 15.0

2.8 29.0 8.0 24.0 9.0 17.0 7.0 4.0 14.0 28.0 18.0 18.0 14.0 18.0

3.2 33.0 9.0 27.0 10.0 19.0 8.0 5.0 16.0 32.0 20.0 20.0 16.0 21.0

4.2 44.0 12.0 36.0 14.0 25.0 10.0 7.0 21.0 42.0 27.0 27.0 22.0 27.0

4.3 45.0 12.0 37.0 14.0 26.0 10.0 7.0 21.0 43.0 28.0 28.0 22.0 28.0

4.8 50.0 14.0 41.0 16.0 29.0 12.0 8.0 24.0 48.0 31.0 31.0 25.0 31.0

5 52.0 14.0 43.0 16.0 30.0 12.0 8.0 25.0 50.0 32.0 32.0 26.0 33.0

5.2 55.0 15.0 45.0 17.0 31.0 13.0 9.0 26.0 52.0 33.0 33.0 27.0 34.0

5.8 61.0 17.0 50.0 19.0 35.0 14.0 10.0 29.0 58.0 37.0 37.0 30.0 38.0

6.2 65.0 18.0 53.0 20.0 37.0 15.0 10.0 31.0 62.0 40.0 40.0 32.0 41.0

7 74.0 20.0 60.0 23.0 42.0 17.0 12.0 35.0 70.0 45.0 45.0 36.0 46.0

7.7 81.0 22.0 66.0 25.0 47.0 19.0 13.0 38.0 77.0 50.0 50.0 40.0 51.0

8 84.0 23.0 69.0 26.0 48.0 20.0 14.0 40.0 80.0 52.0 52.0 41.0 52.0

12 126.0 35.0 103.0 40.0 73.0 30.0 21.0 60.0 120.0 78.0 78.0 62.0 79.0

DATA/COMMUNICATION: MAXIMUM WIRE FILLS FOR UL AND cUL LISTED TELE-POWER POLES

CAPACITY OF CROSS SECTION (In

2

)

SNAP-IN DIVIDERS AREAS OF CROSS SECTIONS

Large Compartment

Small Compartment

5"

[127mm]

2 13/16"

[71mm]

12 sq. in.

[7742mm

2

]

1 5/8"

[41mm]

4.3" sq. in.

[2774mm

2

]

7.7 sq. in.

[4698mm

2

]

2 3/16"

[71mm]

5.8" sq. in.

[3742mm

2

]

6.2 sq. in.

[4000mm

2

]

3 1/8"

[79mm]

5" sq. in.

[3226mm

2

]

7 sq. in.

[4516mm2]

1 5/8"

[41mm]

3.4" sq. in.

[2194mm

2

]

4.3 sq. in.

[2774mm

2

]

5"

[127mm]

1 15/16"

[49mm]

8 sq. in.

[5161mm

2

]

1 5/8"

[41mm]

2.8" sq. in.

[1806mm

2

]

5.2 sq. in.

[3355mm

2

]

2 3/16"

[71mm]

3.8" sq. in.

[2452mm2]

4.2 sq. in.

[2710mm

2

]

3 1/8"

[79mm]

3.2" sq. in.

[2065mm

2

]

4.8 sq. in.

[3097mm

2

]

1 5/8"

[41mm]

2.4" sq. in.

[1548mm

2

]

2.8 sq. in.

[1806mm

2

]

NOTE: Capacity range is calculated at 30% of raceway areas as stated in the Commercial Buildings Standard for Telecommunication Pathways

and Spaces, EIA/TIA-569.

These are the approximate diameter and cross-sectional areas for typical cables in each category. Check with the cable manufacturer for

more accurate dimensions.

Page 2

Wiremold / Legrand

U.S. and International:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX 860-232-2062 • Outside U.S. 860-233-6251

Canada:

570 Applewood Crescent • Vaughan, Ontario L4K 4B4

1-800-723-5175 • FAX 905-738-9721

INS00006R1 – Updated April 2005 – For latest specs visit www.wiremold.com

© Copyright 2005 The Wiremold Company All Rights Reserved

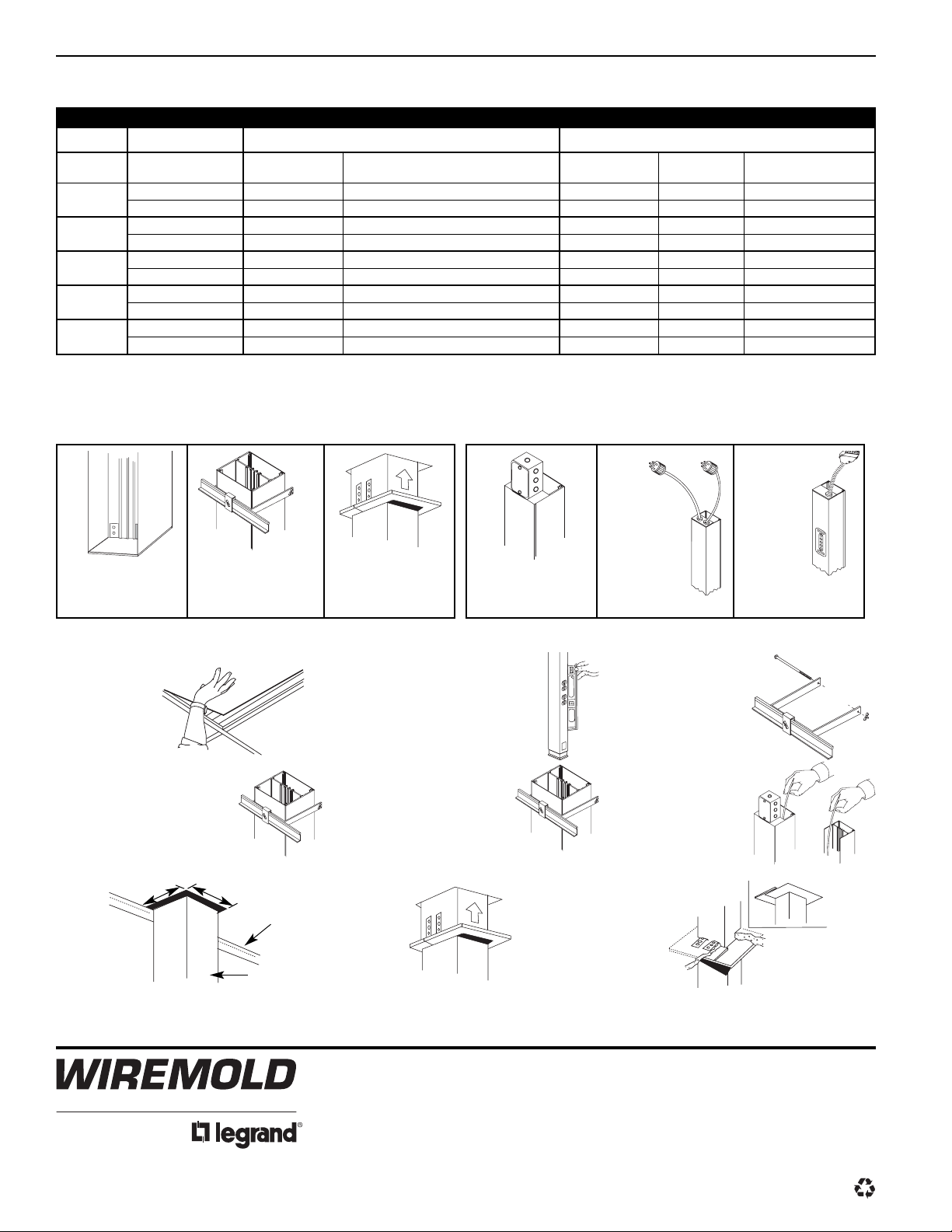

NP800 Series Tele-Power Poles are provided with a maximum of four 4" x 2 3/8" x 1 7/8" or two 4 11'16" x 4 11/16" x 2 1/8" utility

boxes. Various box configurations can be made to accommodate different numbers of circuits. Figures shown below are per utility box.

WIRE

NO. OF CONDUCTORS

UL LISTED POLE cUL LISTED POLE

GAUGE

& CIRCUITS

(Complies with the National Electrical Code) (Complies with the Canadian Electrical Code)

4" x 2 3/8" x 1 7/8" 4" x 4" x 2 1/8" 4 11/16" x 4 11/16" x 2 1/8" 4" x 2 3/8" x 1 7/8" 4" x 4" x 2 1/8" 4 11/16" x 4 11/16" x 2 1/8"

BOX (16.5 cu. in.) BOX (30 cu. in.) BOX (42 cu. in.) BOX (16.5 cu. in.) BOX (30 cu. in.) BOX (42 cu. in.)

14 Conductors 6 15 21 10 20 28

3 Wire CCTS 2 5 7 3 6 9

12 Conductors 5 13 18 9 17 24

3 Wire CCTS 1 4 6 3 5 8

10 Conductors 5 12 16 7 13 18

3 Wire CCTS 1 4 5 2 4 6

8 Conductors 4 10 11 5 10 11

3 Wire CCTS 1 3 3 1 3 3

6 Conductors 2 6 6 3 6 8

3 Wire CCTS 0 2 2 1 2 2

POWER: MAXIMUM WIRE FILLS FOR UL AND cUL LISTED TELE-POWER POLES (BOX ENDED)

NOTE: Wires per channel are limited by wire fill in the utility box.

15A, 125V Tele-Power Poles UL listed by Underwriters’ Laboratories will be constructed with 12-gauge wire, and poles that are cUL Listed

may be constructed with 14-gauge or 12-gauge wire. Higher amperage poles will be wired to meet applicable codes.

STANDARD POLE HARDWARE

Pole Foot – Non-adjustable

foot with velcro

®

supplied

on base to secure pole to

carpet.

Tee Bar Clamp – Clamp is

used for quick and secure

fastening of the top of the

pole.

Ceiling Tile trim – The

trim provides a finished

appearance where pole

passes through ceiling panel.

WIRING OPTIONS

Utility Box –

Box is

mechanically fastened to pole

and hard wired to receptacles.

Box ended pole only.

10' Cord End –

Cord is hard wired

to receptacles in

pole. Maximum

of three cords per

compartment.

Cord-ended

pole only.

Walkerflex –

The Walkerflex

Manufactured

Wiring System

can be used to

feed receptacles

in the power

pole or to feed

subsequent

systems at ground level.

Make all necessary connections

to complete the

circuit.

STANDARD POLE HARDWARE

1. Remove ceiling tile. 2.

Align pole vertically (using a level) with top

of pole resting against ceiling T-bar. After

aligning pole, anchor to the floor using the

velcro pad. For carpeted floors, use a

single swatch of velcro attached to the

bottom of the foot. For tile, fasten the

second swatch to the floor.

3.

Assemble the pole mounting

bracket on the ceiling T-bar

at approximate location as

shown. Tighten bracket

locking thumb screw

loosely so bracket is free

to slide on T-bar.

4. Place pole in the mounting

bracket, checking that receptacle

orientation is as desired. Align

ole vertically (using level) and

tighten both pole and bracket

locking thumb screws.

Figure 1

5. Remove utility box cover and

connect power leads from pole

to overhead wiring system, using

wiring methods of applicable

electrical codes. Hook up cord

ends, or Walkerflex Connectors

to adjoining wiring systems.

6. Install low potential cables

by fishing them down

through the opening in

the top of the pole or by

removing the cover,

laying the cables in and

replacing the cover.

Notch Panel

Pole

beside

T-bar

Pole

T-bar

Pole away

from T-bar

Engage two Trim

Plates on Pole

Trim Plates

on ceiling

Figure 2

Figure 3

7. Notch ceiling panel (Figure 1). Install ceiling panel (Figure 2). Engage ceiling trim and slide up to finish installation (Figure 3).

NOTE: Velcro

®

is a registered trademark of Velcro Industries.

Loading...

Loading...