Page 1

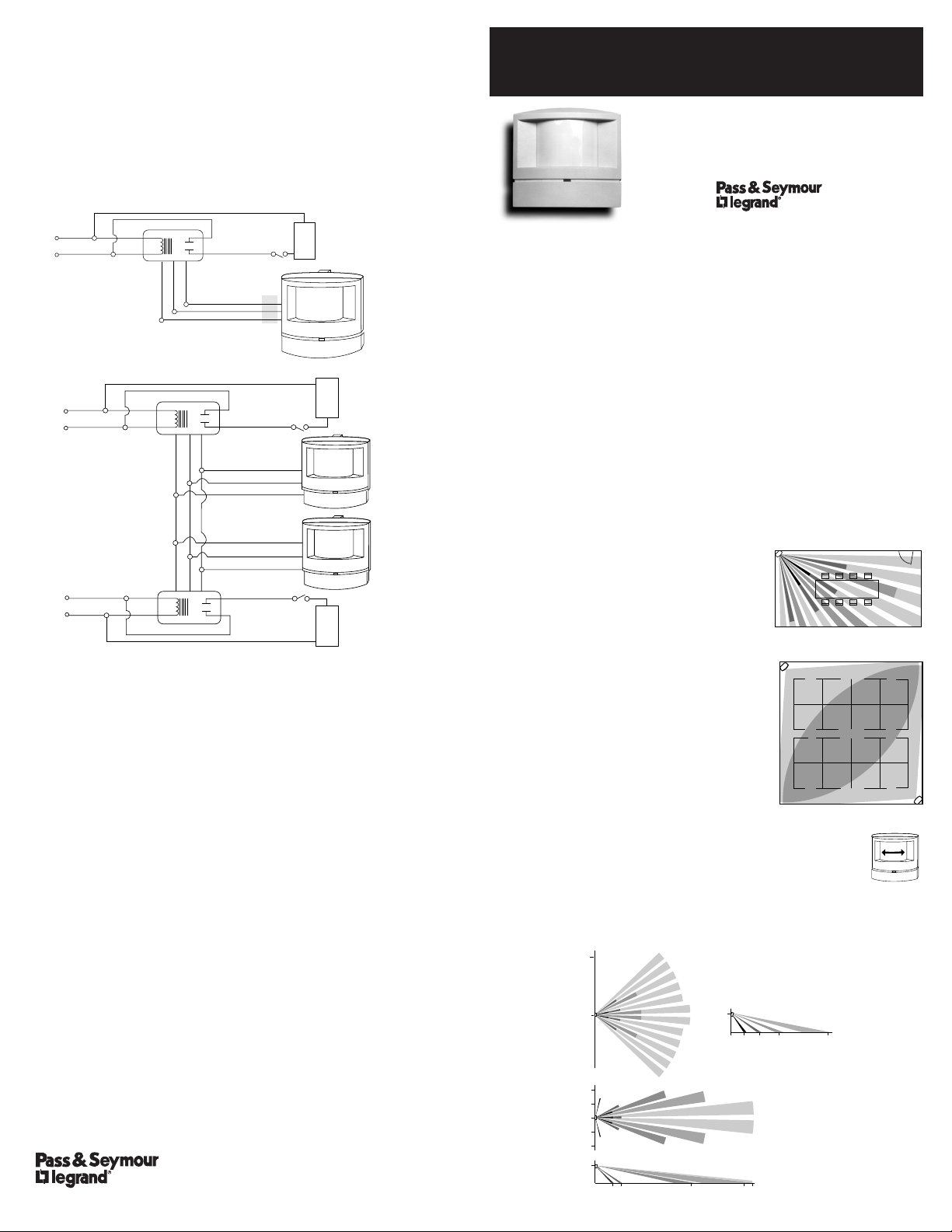

WIRING DIRECTIONS

C

ontrol Output 24VDC

C

ommon

+

24VDC

L

ighting

L

oad

W

hite / Neutral

R

ed (Load)

R

ed (Line)

W

hite

B

lackHot

Neutral

P

ower Pack

Red

Black

Blue

Switch

Blue

Red

Black

Blue (Control Output 24VDC)

Red (+24VDC)

White (Neutral)

Red (Load)

Red (Line)

White

BlackHot

N

POWER PACK

Red

Black

Blue

Switch

Black (Control Return)

Blue (Control Output 24VDC)

Red (+24VDC)

Lighting

Load

Lighting

Load

White (Neutral)

Red (Load)

R

ed (Line)

White

Black

H

ot

N

POWER PACK

Red

Black

Blue

Switch

Black (Control Return)

Lens-plane

10ft

0

8ft

8ft

16ft

16ft

0

10 15ft 55ft 85 90ft

33ft

0ft

7ft

10ft

3

15ft 25ft 50ft

0

WARNING – Turn power off at the circuit breaker before installing power pack

or sensors.

Note: Each power pack can supply power for up to eight sensors. If using

more than eight sensors, multiple power packs are required.

For normal installation, connect:

BLUE wire from power pack to BLUE wire from sensor.

RED wire from power pack to RED wire from sensor.

and BLACK wire from power pack to BLACK wire from sensor.

ingle Sensor Wiring

S

Multiple Sensors Wiring

LIMITED FIVE YEAR WARRANTY

Pass & Seymour will remedy any defect in workmanship or material in Pass &

Seymour products which may develop under proper and normal use within

five (5) years from date of purchase by a consumer:

(1) by repair or replacement, or, at Pass & Seymour’s option, (2) by

return of an amount equal to consumer’s purchase price. Such remedy is

IN LIEU OF ANY AND ALL EXPRESSED OR IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Such

remedy by Pass & Seymour does not include or cover cost of labor for

removal or reinstallation of the product. ALL OTHER FURTHER ELEMENTS

OF DAMAGE (INCIDENTAL OR CONSEQUENTIAL DAMAGES) FOR BREACH

OF ANY AND ALL EXPRESSED OR IMPLIED WARRANTIES INCLUDING

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE ARE EXCLUDED HEREBY. (Some states do not allow disclaimer or

exclusion or limitation of incidental or consequential damages, so the above

disclaimers and limitation or exclusion may not apply to you.) ANY IMPLIED

WARRANTIES INCLUDING WHERE REQUIRED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE SHALL BE

LIMITED TO THE FIVE YEAR PERIOD SET FORTH ABOVE. (Some states do

not allow limitations on how long an implied warranty lasts, so the above

limitation may not apply to you.)

To insure safety, all repair to Pass & Seymour products must be made by

Pass & Seymour, or under its specific direction. Procedure to obtain

performance of any warranty obligation is as follows: (1) Contact Pass &

Seymour, Syracuse, New York 13221, for instructions concerning return or

repair, (2) return the product to Pass & Seymour, postage paid, with your

name and address and a written description of the installation or use of the

Pass & Seymour product, and the observed defects or failure to operate, or

other claimed basis for dissatisfaction.

This warranty gives you specific legal rights and you may also have other

rights which vary from state to state.

P.O. Box 4822

Syracuse, NY 13221

(800) 223-4185

Part No. 340400 Rev. D

Printed in U.S.A.

INSTALLATION & OPERATING INSTRUCTIONS

WA1001/HS1001

IR OCCUPANCY SENSOR

P

S Patent No.:

U

,787,722

4

UNIT DESCRIPTION

The WA1001/HS1001 are 24VDC passive infrared (PIR) occupancy sensors

which control lighting or HVAC systems based on occupancy.

PIR sensing systems are passive systems which react to changes in infrared

energy (moving body heat) within the coverage area. PIR sensors must

directly “see” motion of an occupant to detect them, so careful consideration

must be given to sensor placement.

SPECIFICATIONS

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24VDC

Power Supply . . . . . . . . . . . Pass & Seymour Power Pack

Current Consumption . . . . . . . . . . . . . . . . . . . 8mA Typical

Time Adjustment . . . . . . . . . . . . . 15 seconds–30 minutes

Sensitivity Adjustment . . . . . . . . . . . . Minimum–Maximum

APPLICATION

Coverage may be slightly less than the maximum sensing distance depending

upon obstacles such as furniture or partitions. This must be considered

when planning the number of sensors and their placement. Also, total

coverage area will be smaller for lower mounting heights.

Enclosed office applications

The best location to install the WA1001 is in a

corner which does not face a door. Avoid placing

the sensor so that it can see out an open door

where it may be able to sense people walking by.

Also, avoid placing the sensor where obstacles

will block its view—the sensor must “see” the

occupants in order to detect them.

Conference Rooms, Large

Office Areas, and Classrooms

For these applications, the WA1001 is best. Place

sensor in the corner facing into the room. To

obtain maximum coverage in a partitioned work

area, use the sensors to create coverage zones

that overlap each other. As a general rule, you

should be able to view the sensor clearly from

each desk in the coverage area.

Aisleways, Hallways and Shelving Areas

In these types of applications, the HS1001 is used.

The HS1001 lens has a narrow, long-range view and should be

installed on a wall or ceiling at the end of an aisleway. It works

best when mounted at 10 ft.

COVERAGE PATTERNS

Coverages shown are maximum and represent coverage for half-step,

walking motion.

TOP

TOP

SIDE

Dense Wide Angle Lens (WA1001)

up to 1200 sq ft

SIDE

Long Range Lens (HS1001)

up to 90 linear ft

Page 2

SELECTING SENSOR LOCATION

0°

9

1

8

2

7

J

unction Box

=18°

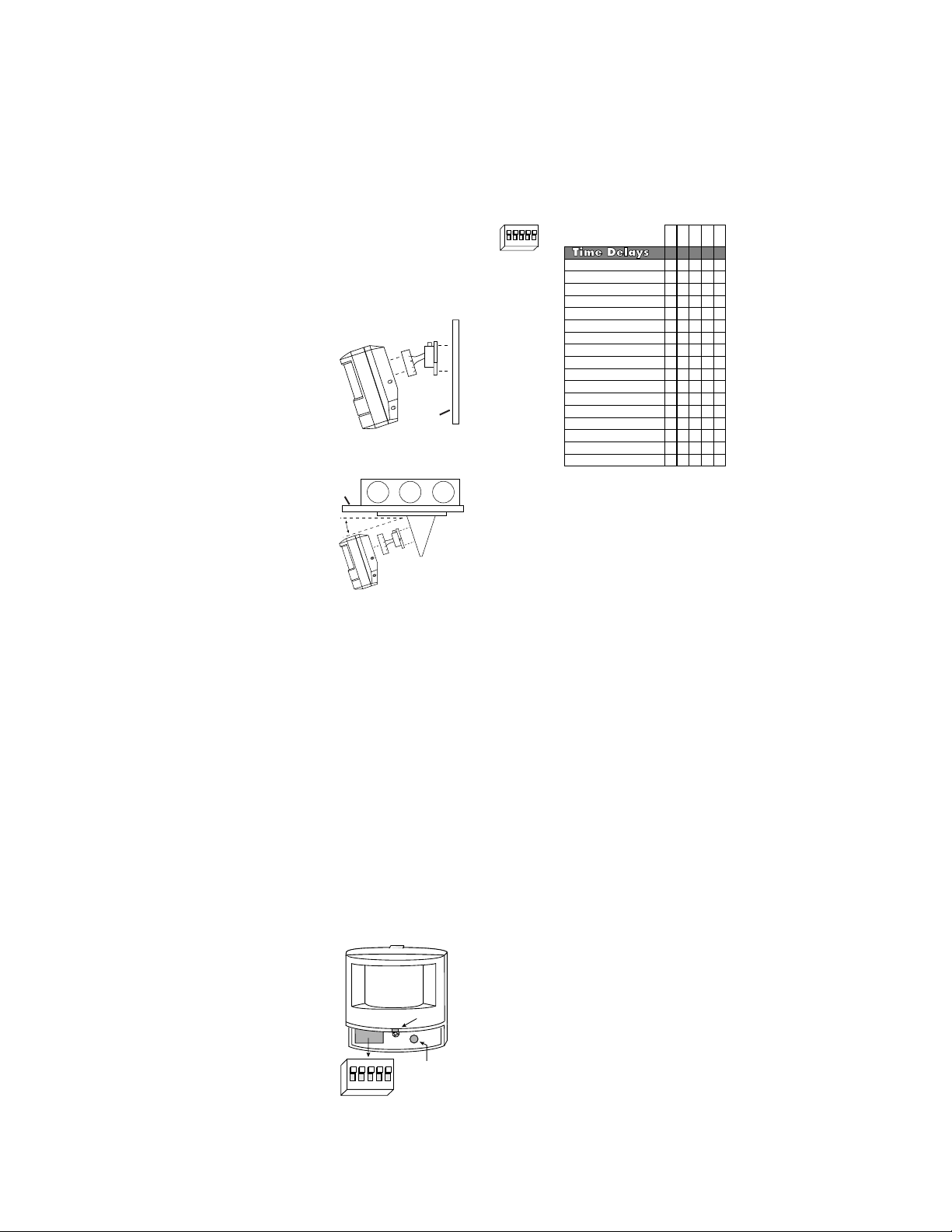

Sensitivity

Adjustment

Time-Delay

DIP Switch

on

25431

LED

DIP Switch #

15 seconds

4

minutes

6 minutes

8

minutes

1

0 minutes

12 minutes

1

4 minutes

2

minutes

16 minutes

20 minutes

22 minutes

2

4 minutes

2

6 minutes

28 minutes

30 minutes

O

verride

1

8 minutes

1

2345

X

=on O=off

X

X

X

X

X

X

X

X

X

X

XXX

X

X

X

X

X

X

O

O

O

O

XX

X

X

X

X

X

X

X

O

O

O

OOO

O

OOO

O

O

O

X

X

X

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

OOO

O

O

O

O

O

X

X

O

O

O

O

O

O

O

O

Time-Delay

DIP Switch

on

25431

2

7

9

1

8

°

0

Proper placement of the sensor is critical in achieving maximum performance

of the device. Passive infrared sensors respond to movement of heat

sources, such as humans, through their direct viewing area. Use the following

rules when selecting the location of the sensors:

• Do not place sensors where viewing area contains direct air currents, or

concentrated, direct reflected light.

• Sensor viewing is line-of-sight, therefore, do not place sensors where

desired coverage is obstructed by walls, columns or other objects.

• Do not place sensors directly above baseboard heaters or forced air

outlets.

• Use sensors only with lighting loads.

• Sensors should be used in dry, indoor locations.

INSTALLATION

The WA1001 and HS1001 can be mounted to a wall or ceiling. Brackets

are available that give flexibility for positioning the sensor.

Swivel Mount Bracket

The swivel mounting bracket gives the angle

Swivel Mount Bracket

adjustment flexibility needed in some

applications, especially for low or very high

mounting heights, or when mounting to a wall.

This is achieved by aligning the angle markings

on the sensor mount with the alignment mark on

the wall mount. The swivel mounting bracket can

be used with or without the ceiling mount bracket.

Ceiling Mount Bracket

The ceiling and swivel mounting brackets can be

used together when mounting the WA1001 or

C

eiling

HS1001 to the ceiling. This arrangement gives

angle adjustment flexibility.

Align the angle marks on the

swivel mount bracket to the angle desired. Note

that the ceiling mount bracket adds 18° to the

angle set with the swivel mount bracket.

The ceiling mount bracket is designed to

wivel

S

Mount

Bracket

connect to a standard 3-0 Mud/Plaster Ring.

1. Use provided screws to secure ceiling mount bracket plate

to mud ring.

2. Connect the swivel mount bracket to the sensor and to the

V-bracket of the ceiling mount bracket with Phillips head

screws.

3. Run wire through slots in V-bracket (two slots are provided

for flexibility) and snap bracket to the ceiling plate, taking

precautions to prevent wires from getting pinched. Connect

wire leads coming out of sensor as described in wiring diagram.

Sensor Angle Adjustment

When adjusting, have a person walk toward the sensor in a zig-zag pattern

from the far end of the desired coverage area. Increase or decrease mounting

angle as needed until the PIR sensor detects them (red LED flashes).

SENSOR ADJUSTMENT

After sensor is installed, it should be set so the lights will stay on whenever the

coverage area is occupied. Before starting the adjustment process, make

sure the office furniture is installed, lighting circuits are turned on, and the

HVAC systems are in the overridden/on position. VAV systems should be set

to their highest air flow.

Note: There is up to a one and a half minute

warm-up after power is restored to the sensor, before

the sensor works properly.

1. Set the time delay to minimum, 15 seconds.

2. Set the sensitivity to maximum, fully clockwise.

3. Move out of the coverage area. The lights should turn

4. Set the desired time delay with the DIP switches.

5. Readjust the angle of the sensor if necessary

See table under DIP Switch Settings for time

delay adjustments.

off after approximately 15 seconds. If not, see

Troubleshooting. If needed, decrease sensitivity to

reduce coverage in the area.

(see Installation).

✆Call (800) 223-4185 for Technical Support ✆

Wall

Ceiling

Mount

Bracket

DIP SWITCH SETTINGS

Recommended time delay settings:

Offices and conference rooms: . . . . . . . . . . . . . . .10-16 min.

Open office spaces: . . . . . . . . . . . . . . . . . . . . . . .10-16 min.

Classrooms: . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-16 min.

Warehouses: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10 min.

Hallways: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-16 min.

Note: Frequent cycling of lights can reduce

lamp life; use caution when setting the time

delay below 8-10 min.

TROUBLESHOOTING

WARNING – Turn off power at the circuit breaker before working with

high voltage.

The lights do not turn on with occupancy:

LED does NOT flash:

1. Check the sensitivity settings. Increase (clockwise) as needed.

2. Check all sensor and power pack wire connections.

3. Check for 24VDC at sensor (red & black).

• If 24VDC is present, replace the sensor.

• If 24VDC is not present, check that high voltage (120 or 277VAC) is

present to power pack. If it is, replace power pack.

4. Call (800) 223-4185 for technical support.

LED does flash:

1. Check all sensor and power pack wire connections.

2. Check for 24VDC at the power pack’s blue wire connection to sensor while

someone moves in front of sensor to activate the LED. If there is no

voltage, replace the sensor. If there is voltage, replace the power pack.

3. Call (800) 223-4185 for technical support.

The lights do not turn off automatically:

1. Check the sensitivity settings. Decrease (counterclockwise) as needed.

2. Check all sensor and power pack wire connections.

3. Disconnect power pack’s blue wire:

If the lights do not turn off, replace power pack.

If the lights turn off, the problem may be in the sensor, to check:

• Turn sensitivity and time delay to minimum and allow the sensor to time

out. If the lights turn off, the sensor is working properly. The lights may

be staying on because the sensor is detecting motion or some type of

interference. Go through the sensor adjustment process again.

4. If sensor still does not operate properly, call (800) 223-4185 for

technical support.

Override Function:

In the event of unit failure or if it is necessary to leave the lights on, set DIP

switch #5 to ON. This will bypass the automatic function of the sensor to

allow manual on/off control of circuits.

Loading...

Loading...