Page 1

Wattstopper

Ceiling

30 20 10 0102030

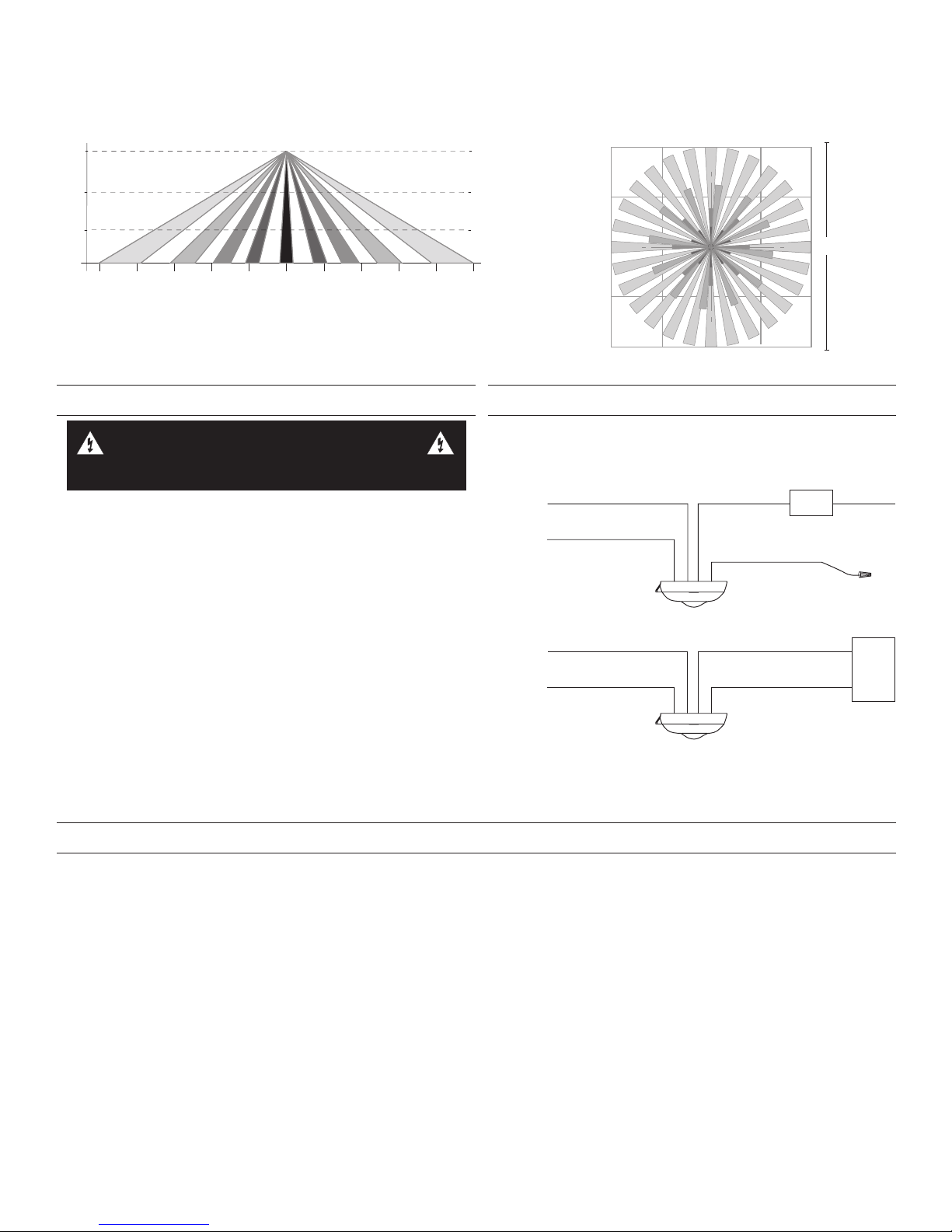

HBL1 Coverage Side View

40 30 20 10 010203040

20

10

10

20

20 ft

HBL1 Coverage Top View

&HLOLQJ

&RYHUDJH6LGH9LHZ

Coverage Top View

12 60612

®

High Bay • Line Voltage • Passive Infrared • Occupancy Sensor

No: 24162 – 2/17 rev. 1

Installation Instructions • Instructions d’Installation • Instrucciones de Instalación

Catalog Number • Numéro de Catalogue • Número de Catálogo: HB340B-L1, HB340B-L3, HB340B-L7

Country of Origin: Made in China • Pays d’origine: Fabriqué en Chine • País de origen: Hecho en China

SPECIFICATIONS

HB340B-Lx

Voltages ........................................................ 347/480VAC, 60Hz

Load requirementst

@347VAC, 60Hz ...............................................0-1200W ballast

@480VAC, 60Hz ................................................0-1200W ballas

HB340B-L1

HB340B-L3

HB340B-L7

@120VAC, 60Hz ...............................................................1/6 hp

Lens

L1 40 ft. mounting height, 60 ft. x 20 ft.

L3 20 ft. mounting height, 24 ft. diameter

L7 40 ft. mounting height, 100 ft. diameter

US Patent: ........................................... 5,640,113 and 5,804,991

DESCRIPTION AND OPERATION

The HB340B-Lx occupancy sensors are designed for automatic lighting control in warehouse high bay applications. All models contain a

passive infrared sensor (PIR). The HB340B-Lx series sensors are modular and are made up of a Power Module and a Lens. The coverage

area is determined by the lens module. There are three different lens available. See the Coverage section for more information.

All models in the HB340B-Lx series use a set of DIP switches to set the time delay and PIR sensitivity, as explained on page 3.

COVERAGE

Coverage patterns, density and range, are determined by the type of Lens attached to the HB340B-Lx.

HB340B-L1 and HB340B-L1M

The L1 Lens offers linear patterns best suited

for high bay aisleway applications. The

Fresnel lens is designed to detect walking

motion when mounted at or around 40’. In

optimal conditions, the lens has a 60’ linear

detection range.

Identical to the HBL1, the HBL1M comes

with opaque adhesive tape applied to the

interior of the lens, cutting off 1/2 of the

coverage pattern. This customized coverage

is ideal for the beginning of aisle ways where

cross traffic could be an issue.

HB340B-L3

The L3 Lens offers 360° coverage and is best suited

for open area and aisleway coverage in high bay

applications. The L3 is a multi-cell, multi-tier Fresnel

lens offering a high density coverage pattern that

spreads over a 24’ diameter area at a height of 20’.

0

10

20

30

40

0

Top View

12

6

6

0

24 ft

12

Page 2

e

HB340

HB340B-L7

50' 25' 0' 25' 50'

50'

25'

25'

50'

0'

0'

50'

The HBL7 lens is designed for higher mounting than the HBL3. The HBL7 has a lens that covers a 100’ diameter area at a height of 40’.

Ceiling

15'

27'

40'

50'

10' 10'20' 20'30' 30'40' 40'

Side View

INSTALLATION

WARNING

TURN THE POWER OFF AT THE CIRCUIT

BREAKER BEFORE INSTALLING THE SENSOR.

1. Determine the mounting location appropriate to the features

of the power module and the coverage area. Careful

consideration must be given to sensor placement. Avoid

placing the sensor where the edge of the fixture, shelving or

other obstructions may block the sensor’s line of sight. Mount

the sensor below the edge of the fixture and away from the

fluorescent lamps so that the heat from the lamps does not

affect the sensor.

2. Make sure that you have the appropriate accessories for the

sensor mounting configuration. (See Mounting Options.)

3. Assemble any necessary mounting accessories and attach

them to the power module, making sure that the flying leads

from the power module are accessible.

4. Connect the line voltage and load wires to the sensor leads as

shown in the Wiring Diagram for the unit’s application.

• Do not allow bare wire to show.

• Make sure all connections are secure.

5. Restore power from the circuit breaker.

347VAC Wiring

Line

Neutral

Black with White Stripes

480VAC Wiring

Phase A

Phase B

Black with White Stripes

Top View

0'

100'

WIRING

Black

Black

Red (Load A)

Red with White Stripes (Load B)

Red (Load A)

Red w/White Stripes (Load B)

Load

Cap the wir

Neutral

Load

The HB340B-Lx can be attached to the fixture or junction box using the back box and chase nipple or directly to the fixture surface via

the two screw holes provided in the Power Module (see Surface mounting below). The Extender Module (HBEM3) allows attaching the

sensor to the side of the fixture in a number of configurations using provided chase nipples.

Back box mounting requires a standard 1/2” knockout for the chase nipple. The Power Module mounts to the back box with a bayonet

type fitting requiring a slight twist of the units to separate them or lock them into place. The box comes ready for side mounting. It can

be modified for rear mounting as follows:

1. Pop out the cap in the rear knockout.

2. Un-snap the chase nipple from the side mount and snap into the rear mounting hole.

3. Use the cap to close the side mount hole.

4. The chase nipple provided can be pushed into a standard 1/2” knockout in a metal fixture [max of 1 mm (0.04”) thick metal] without

the need for the included internal nut. The nut can be used for added security if necessary.

The HBEM3 extender module allows threading the wires through its chase nipples and into the fixture for connection. The two sides of

the HBEM3 are then snapped together to protect the wires. The short chase nipple is designed to snap into the HBNB3 connection box

while the longer chase nipple snaps into any metal fixture or connection box with a standard knockout. The caps on the HBEM3 can be

removed in various configurations to allow moving the chase nipples and adjusting the height of the sensor on the fixture

Surface mounting requires holes in the fixture to pass wires and attach two #6-32 screws through the surface mounting screw holes on

the component side of the Power Module as shown.

MOUNTING OPTIONS

2

Page 3

HB340

HBLx

Lens

(do not touch)

Sensor

Module

Back

Box

HBEM3

Extender

Module

or

E

S

O

L

C

O

P

E

N

DIP Switches

Alignment Guides

Light Level

Adjustment

Trimpot

Using the back box and HBEM3 Extender Module

ADJUSTMENTS

Sensor factory pre-sets are as follows (default settings are bold):

Factory Switch Settings (N/A = not applicable, no effect)

1 2 3 4 5 6 7 8 9 10

ON OFF OFF OFF OFF ON ON OFF N/A N/A

PIR Sensitivity (switches 1&2) ........... Medium 85%

Time Delay (switches 3-7) ....................15 minutes

Override (switch 8) ........ Controlled by occupancy

PIR Sensitivity (Switches 1-2)

The factory setting (Normal) is suitable for most

applications, but it may be necessary to adjust the PIR

sensitivity if there is any environmental interference

causing false triggers or if sensitivity needs to be

increased for your particular application. Use DIP

switches 1 & 2 to adjust sensitivity.

Surface

Mounting

Screw Hole

Surface

Mounting

Screw Hole

PIR Sensor

Detection

Indicator LED

Time Delay (Switches 3-7)

Use DIP switches 3 to 7 to adjust the time delay.

Switch 3 4 5 6 7 TIME DELAY

ON ON ON ON ON 15 seconds

OFF ON ON ON ON 5 minutes

OFF OFF ON ON ON 10 minutes

OFF OFF OFF ON ON 15 minutes

OFF OFF OFF OFF ON 20 minutes

OFF OFF OFF OFF OFF 30 minutes

PIR Override (Switch 8)

A value of OFF enables occupancu control. A value of ON sets

the load ON all the time (used for testing load).

NOTE: Switches 9 and 10 are not used in this model.

Switch 1 2 PIR SENSITIVITY

OFF OFF 100% High

ON OFF 85% (MEDIUM)

OFF ON 75% (LOW)

ON ON 60% (LOW)

3

Page 4

IMPORTANT START-UP INFORMATION

A 60-second start-up period occurs during initial installation and after a power failure of 5 minutes or more. After applying power to the

sensor wait at least 60 seconds for the sensor to begin detecting occupancy and the load to turn ON. It may turn ON during the start-up

period, depending on the state of the relay when power was off.

• If the sensor detects occupancy during the start-up, when the load turns ON it stays ON as long as the sensor continues to detect

motion, plus the Time Delay.

• If no occupancy is detected during the 60-second start-up, the load may come on anyway during the start-up. If no occupancy is

detected by the time the start-up is complete, the relay opens and the load turns OFF.

TROUBLESHOOTING

If you suspect improper operation, review the Start-Up information. After start-up, the sensor will open or close the relay to correspond to

the occupancy status of the area. When power to the sensor is lost, the relay(s) close, turning on the load if the load still has power.

To quickly test the unit, set the time delay to minimum. Wait for the start-up period to end. Move out of the sensor’s view. Lights should

turn OFF after 15 seconds. Move into the sensor’s view. The sensor’s Red LED should blink and the lights should turn ON.

Red LED on power module does not blink:

Check sensor wire connections. Verify the neutral wire is tightly secured.

Red LED blinks but lights do not turn ON:

1. Make sure that power to the sensor has been ON continuously for at least one minute, then

a. Turn OFF power to the sensor. The relay will close.

b. Turn ON power to the sensor. The load should come ON. If not, continue with step 2.

2. Check power connections to the light fixture.

3. Check all sensor wire connections. Verify the load wire is tightly secured.

4. Make sure the sensor is not continuously triggered (LED Flashing) during the time delay duration.

Lights will not turn OFF:

1. If there is no motion from people or equipment in the sensor’s view but the red LED blinks, look for any nearby source of infrared

energy (heat) in motion, such as turbulent air from a heating or cooling supply, or other sources such as heat from the fluorescent

lamps in the fixture.

• Mount the sensor so that it’s lens is below the edge of the fixture and does not directly view the lamps.

• Divert the air supply away from the sensor, or move the sensor.

2. Verify time delay set in switches 3-7. The time delay can be set from 15 seconds to 30 minutes. Ensure that the time delay is set to

the desired delay and that there is no movement within the sensor’s view for that time period.

3. Check PIR and Light Level Override DIP switch settings. If all control functions are overridden the load stays ON.

4. Check sensor wire connections. Verify load and neutral wires are secure.

ORDERING INFORMATION

Catalog # Description

HB340B-L1 High Bay Sensor 347/480 VAC with coverage @ 40’ mounting height, 60’ x 20’.

HB340B-L3 High Bay Sensor 347/480 VAC with coverage @ 20’ mounting height, 24’ diameter.

HB340B-L7 High Bay Sensor 347/480 VAC with coverage @ 40’ mounting height, 100’ diameter.

HB3EM3 Extender module with 2 chase nipples and nuts 1 short (0.88”) for connection to plastic, 1 long (1.24”) for

connection to metal

All units are White.

WARRANTY INFORMATION INFORMATIONS RELATIVES À LA GARANTIE INFORMACIÓN DE LA GARANTÍA

Wattstopper warranties its products to be free

of defects in materials and workmanship for a

period of five (5) years. There are no obligations

or liabilities on the part of Wattstopper for

consequential damages arising out of, or in

connection with, the use or performance of this

product or other indirect damages with respect

to loss of property, revenue or profit, or cost of

removal, installation or reinstallation.

No. 24162 – 2/17 rev. 1

© Copyright 2017 Legrand All Rights Reserved.

© Copyright 2017 Tous droits réservés Legrand.

© Copyright 2017 Legrand Todos los derechos reservados.

Wattstopper garantit que ses produits sont

exempts de défauts de matériaux et de fabrication

pour une période de cinq (5) ans. Wattstopper

ne peut être tenu responsable de tout dommage

consécutif causé par ou lié à l’utilisation ou

à la performance de ce produit ou tout autre

dommage indirect lié à la perte de propriété, de

revenus, ou de profits, ou aux coûts d’enlèvement,

d’installation ou de réinstallation.

Wattstopper garantiza que sus productos

están libres de defectos en materiales y mano

de obra por un período de cinco (5) años. No

existen obligaciones ni responsabilidades por

parte de Wattstopper por daños consecuentes

que se deriven o estén relacionados con el

uso o el rendimiento de este producto u otros

daños indirectos con respecto a la pérdida

de propiedad, renta o ganancias, o al costo

de extracción, instalación o reinstalación.

800.879.8585

www.legrand.us/wattstopper

Loading...

Loading...