Page 1

FlameStopper

™

Thru-Wall & Thru-Floor Fittings

INSTALLATION INSTRUCTIONS

Installation Instruction No.: INS0010R2 – Updated January 2007

Wiremold / Legrand Electrical Systems conform to and should be

installed and properly grounded in compliance with

requirements of the current National Electrical Code, Canadian

Electrical Code or codes administered by local authorities.

All electrical products may represent possible shock or fire

hazard if improperly installed or used. Wiremold / Legrand

electrical products are UL Listed to U.S. and Canadian

safety standards, made for interior use only, and should

be installed in conformance with current local building codes

and/ or the National Electrical Code.

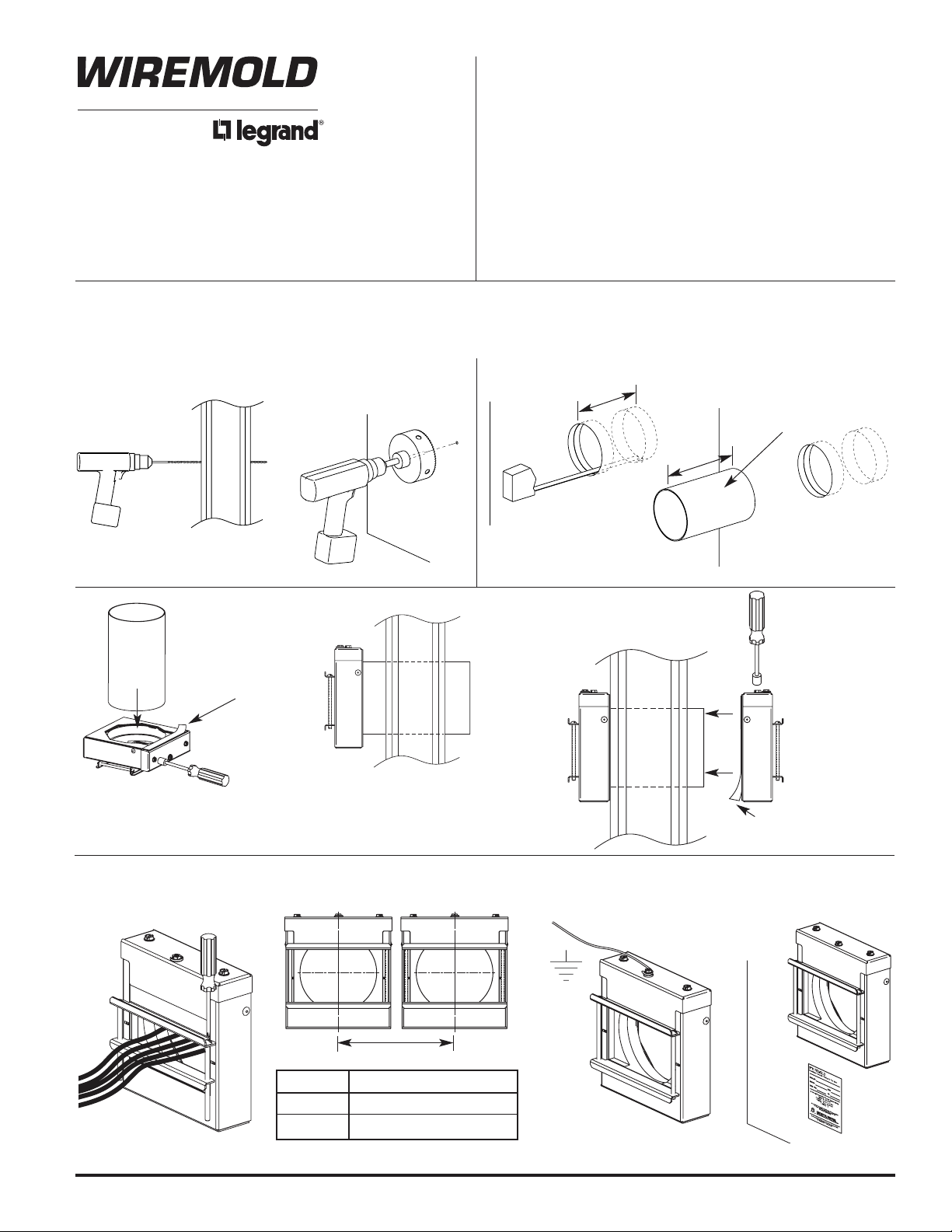

1. Determine location and drill

pilot hole thru wall or floor.

Drill hole using 4 3/4"

[120mm] for FS4R and

2 1/4" [58mm] for FS2R.

NOTE: Use core drill when going

through concrete or

block walls or floors.

2. Measure wall or floor thickness.

Cut EMT Sleeve to length.

3. Peel off backing

for adhesive.

1. Insert EMT

into Box.

Wall or Floor Thickness

Wall or Floor Thickness

+ 1 5/8" [41mm]

4. Stick on Wall or floor (Make

sure wall or floor is clean

and dust-free).

NOTE: Do not force EMT through

intumescent material.

NOTE: Do not over tighten.

2. Tighten Clamp.

5. Install cabling then adjust

sliding doors to be snug

around cables by turning

side screws.

4.

Products Covered: FS2R, FS4R, FS2RHS, FS4RHS, FS2RWP8, FS4RWP12

6. Ground in accordance with

National Electrical Codes.

7. Fill out and place

label on wall or floor

near FlameStopper.

Minimum Spacing

CAT NO. MINIMUM SPACING

FS4R 6 1/8" [155MM]

FS2R 3 7/8" [98MM]

FS2R, FS4R INSTALLATION – Thru-Wall & Thru-Floor:

3.

1. Peel off backing

for adhesive.

2. Stick on Wall

or floor.

3. Tighten Clamp.

Page 2

2

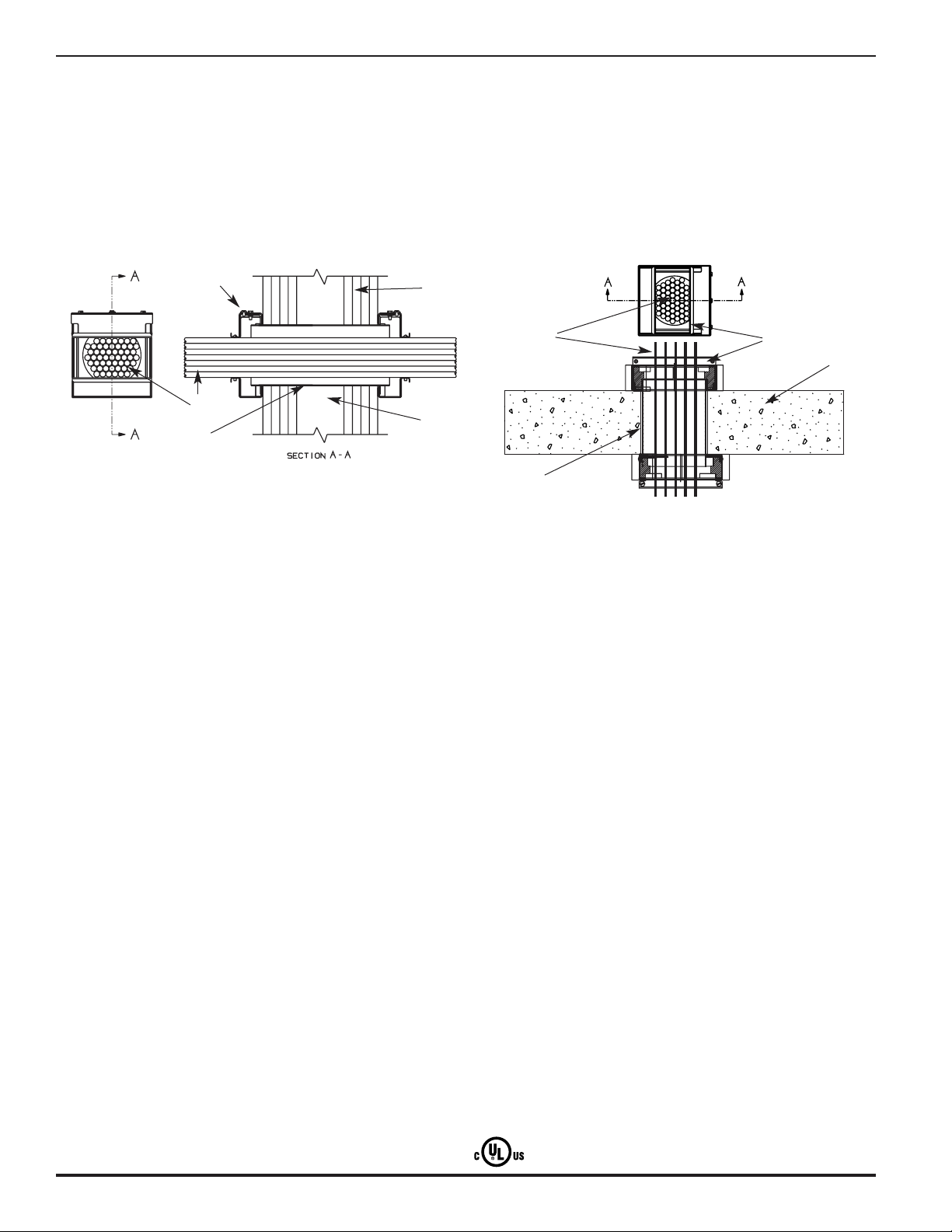

1. Wall Assembly – The 1, 2, 3 or 4 hr fire-rated gypsum board/stud wall assembly shall

be constructed of the materials and in the manner described within the individual U300,

U400 or V400 Series Wall or Partition Designs in the UL Fire Resistance Directory and

shall incorporate the following construction features:

A. Studs – Wall framing shall consist of either wood studs or steel channel studs. Wood

studs to consist of nom 2 by 4 in. [51 by 102 mm] lumber spaced max 16 in. [406 mm]

OC. Steel studs to be min 1-5/8 in. [41 mm] wide and spaced max 24 in. [610 mm] OC.

B. Gypsum Board* – Thickness, type, number of layers and fasteners as specified in the

individual Wall and Partition Design. Diam of opening shall be 2-1/4 in. [57 mm] and 4-3/4 in.

[121 mm] for the nom 2 in. [51 mm] and 4 in. [102 mm] sleeves (Item 2), respectively.

The hourly F Rating of the firestop system is dependent upon the hourly rating of the

wall in which it is installed.

2. Metallic Sleeve – Nom 2 in. [51 mm] or 4 in. [102 mm] diam electrical metallic tubing

(EMT), dependent on the size of the firestop device (Item 4). The sleeve is to extend a nom

3/4 in. beyond both surfaces of wall. The annular space between the sleeve and the

periphery of opening shall be min 0 in. (continuous point contact) to max 1/4 in. [6 mm].

3. Cables – Aggregate cross-sectional area of cables in the EMT sleeve to be 0% to max

60% of the aggregate cross-sectional area of the EMT sleeve. When there is no cable fill,

device cover is to be tightly closed. Cables to be rigidly supported on both sides of the

wall assembly. Any combination of the following types of cables may be used:

A. Single conductor No. 18 AWG (or smaller) RG/U coaxial cable with fluorinated

ethylene insulation and jacketing.

B. Fiber optic cable with polyvinyl chloride (PVC) or polyethylene (PE) jacket and

insulation having a max diameter of 5/8 in. [16 mm].

C. Max 4 pair No. 22 AWG (or smaller) copper conductor data cable with polyvinyl

chloride (PVC) or plenum rated jacketing and insulation.

D. Max 4/C No. 2 AWG (or smaller) copper conductor cable with XLPE/PVX insulation

and PVC jacket.

E. Max 100 pair No. 24 AWG (or smaller) copper conductor telecommunication cable

with polyvinyl chloride (PVC) jacketing and insulation.

F. Max 400 pair No. 24 AWG (or smaller) copper conductor telecommunication cable

with polyvinyl chloride (PVC) jacketing and insulation.

G. Max 8/C 12 AWG (or smaller) copper conductor steel Metal-Clad or Armored-Clad cable.

The hourly T Rating of the firestop system is equal to the F Rating when no cable fill is used

or when cables A or B are used. The hourly T Rating is equal to the F Rating up to 3 hr when

cable C is used. The hourly T Rating is 1 hr when cable D is installed in 2, 3 or 4 hr rated

walls, 1/2 hr in 1 hr rated walls. The hourly T Rating is 1 hr when cable E is installed in 4 hr

rated walls and 0 hr in 1, 2 or 3 hr rated walls. The hourly T Rating is 3/4 hr when cable F is

installed in 2, 3 or 4 hr rated walls, 0 hr in 1 hr rated walls. The hourly T Rating is 1/4 hr

when cable G is installed in 2, 3 or 4 hr rated walls, 0 hr in 1 hr rated walls.

The L Rating at ambient and 400°F with no cable fill is 2.6 CFM and 1.9 CFM, respectively.

The L Rating at ambient and 400°F with cable fill is 2.8 CFM and 1.3 CFM, respectively.

4. Firestop Device – Device to be installed in accordance with the accompanying installation

instructions. Device to be installed and secured to the EMT sleeve both sides of wall.

THE WIREMOLD COMPANY – FS2R FlameStopper, FS4R FlameStopper

*Bearing the UL Classification Mark

1. Floor & Wall Assembly – Min 4-1/2 in. [114 mm] thick reinforced lightweight or normal

weight (100-150 pcf or 1600-2400 kg/m3) concrete floor or wall. Wall may also

be constructed of any UL Classified Concrete Blocks*. Maximum diameter of opening is

4-1/2 in. [114 mm].

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

*4-Hour Rated Assemblies (System No. W-J-3154): for concrete wall installation, minimum

6 in. [152mm] thick, reinforced lightweight or normal weight (100-150 pcf or 1600-2400

kg/m3) concrete wall.

2. Metallic Sleeve – Nom 2 in. [51 mm] or 4 in. [102 mm] diameter electrical metallic tubing

(EMT), dependent on the size of the firestop device (Item 4). The sleeve is to extend a nom

5/8 in. [16mm] beyond both surfaces of floor or wall. The annular space between the sleeve

and the periphery of opening shall be min 0 in. (continuous point contact) to max 1/4 in.

[6 mm].

3. Cables – Aggregate cross-sectional area of cables in the EMT sleeve to be 0% to max 60%

of the aggregate cross-sectional area of the EMT sleeve. When there is no cable fill, device

cover is to be tightly closed. Cables to be rigidly supported on both sides of the wall

assembly. Any combination of the following types of cables may be used:

A. Single conductor No. 18 AWG (or smaller) RG/U coaxial cable with fluorinated ethylene

insulation and jacketing.

B. Fiber optic cable with polyvinyl chloride (PVC) or polyethylene (PE) jacket and insulation

having a max diameter of 5/8 in. [16 mm].

C. Max 4 pair No. 22 AWG (or smaller) copper conductor data cable with polyvinyl chloride

(PVC) or plenum rated jacketing and insulation.

D.

Max 4/C No. 2 AWG (or smaller) copper conductor cable with XLPE/PVX insulation and

PVC jacket.

E. Max 100 pair No. 24 AWG (or smaller) copper conductor telecommunication cable with

polyvinyl chloride (PVC) jacketing and insulation.

F. Max 400 pair No. 24 AWG (or smaller) copper conductor telecommunication cable with

polyvinyl chloride (PVC) jacketing and insulation.

G. Max 8/C 12 AWG (or smaller) copper conductor steel Metal-Clad or Armored-Clad cable.

The hourly T Rating is 3 hr when no cable fill is used or when cables A, B or C are used. The

hourly T Rating is 3/4 hr when cable D is used. the hourly T Rating is 1 hr when cables E

and F are used. The hourly T Rating is 1/4 hr when cable G is used.

4. Firestop Device – Device to be installed in accordance with the accompanying installation

instructions. Device to be installed and secured to the EMT sleeve both sides of wall

or floor.

THE WIREMOLD COMPANY – FS2R FlameStopper, FS4R FlameStopper

*Bearing the UL Classification Mark

u

UL Certification

From UL Fire Resistance Directory

Through-penetration Firestop Systems

System No. W-L-3300

December 28, 2005

Ratings – 1, 2, 3 and 4 Hr (See Item 1)

T Ratings – 0, 1/4, 1/2, 3/4, 1, 2, 3, and 4 Hr (See Item 3)

L Rating at Ambient – 2.6 CFM and 2.8 CFM (See Item 3)

L Rating at 400°F – 1.9 CFM and 1.3 CFM (See Item 3)

Through-penetration Firestop Systems

System No. C-AJ-3271

January 12, 2006

F Rating – 3 Hr*

T Ratings – 1/4, 3/4, 1, & 3 (See Item 3)

L Rating at Ambient – 2.6 CFM and 2.8 CFM (See Item 3)

L Rating at 400°F – 1.9 CFM and 1.3 CFM (See Item 3)

FIRESTOP DEVICE FOR USE IN THROUGH-PENETRATION

FIRESTOP SYSTEMS. SEE UL DIRECTORY OF PRODUCTS

CERTIFIED FOR CANADA AND UL FIRE RESISTANCE DIRECTORY

D

E

I

F

I

S

S

A

L

C

1A

3

2

1B

4

3

2

1

4

Page 3

3

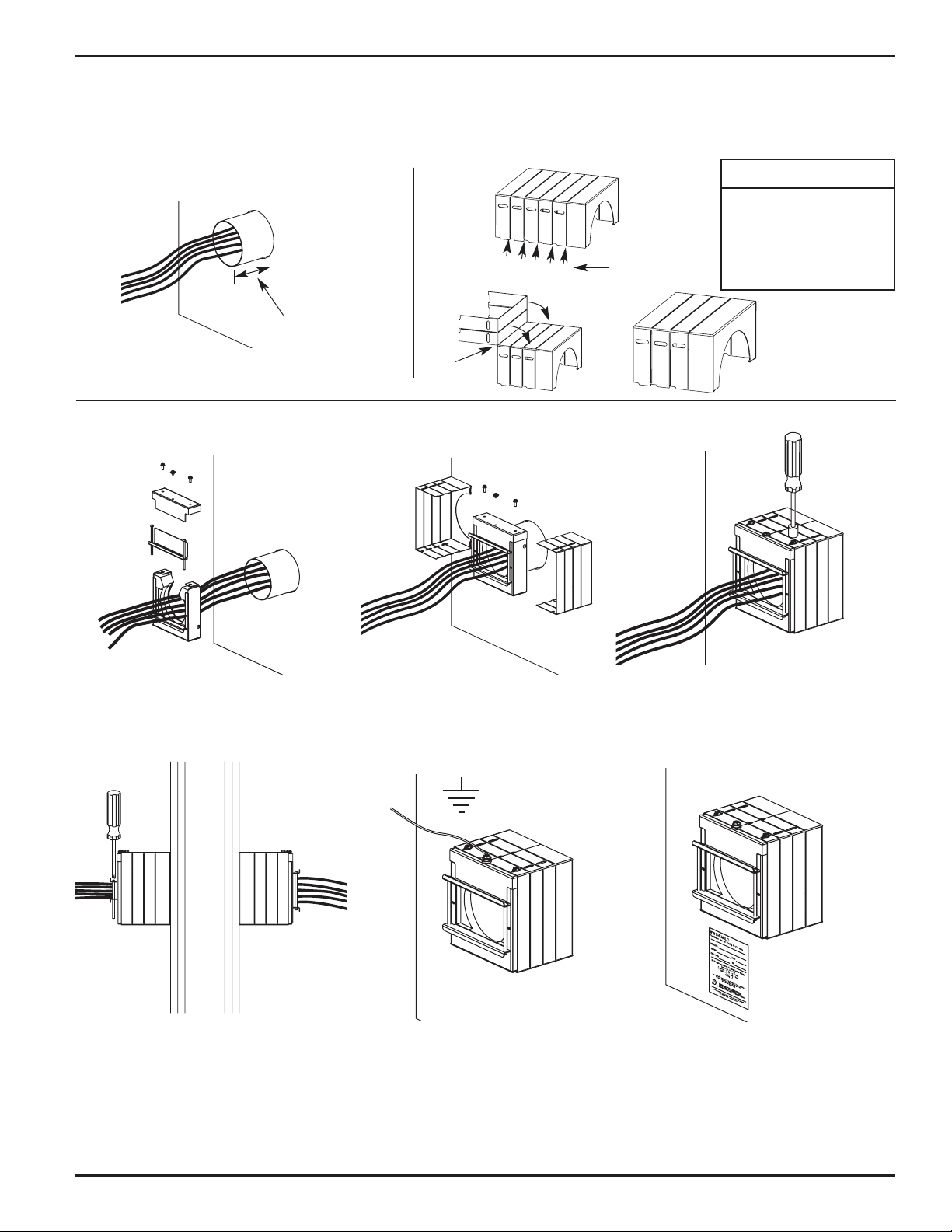

Measure pipe length.

Break Off.

A.

B.

C.

A.

Install Heat Shield around Product.

B. Tighten Clamp.

A.

B.

FS2RHS, FS4RHS HEAT SHIELD INSTALLATION:

NOTE: Heat Shield is only required if conduit extends out from the wall more than 7/8" [22mm].

Add-On Kit used to retrofit Flamestopper Thru-Wall Fitting onto existing 2" trade size or 4" trade size EMT pipe.

Use FS2RHS – 2" trade size EMT with FS2R. Use FS4RHS – 4" trade size EMT with FS4R.

1. Remove any existing firestop material from

within end of EMT Pipe.

3. Remove Top and Front Door and

drop Cables into Fitting.

5. Move Sliding Doors to be snug around

Cables by turning Side Screws.

6.

4.

2.

NOTE: Pipe cannot exceed 6" [152mm].

NOTE: Make sure Heat Shield

is tight to wall.

Ground in accordance with

National Electrical Codes.

Fill out and place label on wall

near FlameStopper.

PIPE HEAT SHIELD

LENGTH CUT LENGTH

1/2" – 7/8" No Shield Needed

7/8" – 1" 1

1" – 2" 2

2" – 3" 3

3" – 4" 4

4" – 5" 5

5" – 6" No EMT

1.

2.

3.

4.

5.

Cut Length

Page 4

4

1. Wall Assembly – The 1, 2, 3 or 4 hr fire-rated gypsum board/stud wall assembly shall be

constructed of the materials and in the manner described within the individual U300, U400

or V400 Series Wall or Partition Designs in the UL Fire Resistance Directory and shall

incorporate the following construction features:

A. Studs – Wall framing shall consist of either wood studs or steel channel studs. Wood

studs to consist of nom 2 by 4 in. [51 by 102 mm] lumber spaced max 16 in. [406 mm]

OC. Steel studs to be min 1-5/8 in. [41 mm] wide and spaced max 24 in. [610 mm] OC.

B. Gypsum Board* – Thickness, type, number of layers and fasteners as specified in the

individual Wall and Partition Design. Diam of opening shall be 2-1/4 in. [57 mm] and 4-3/4

in. [121 mm] for the nom 2 in. [51 mm] and 4 in. [102 mm] sleeves (Item 2), respectively.

The hourly F Rating of the firestop system is dependent upon the hourly rating of the wall

in which it is installed.

2. Metallic Sleeve – Nom 2 in. [51 mm] or 4 in. [102 mm] diam electrical metallic tubing (EMT),

dependent on the size of the firestop device (Item 4). The sleeve is to extend a min 7/8 in. to

a max 6 in. [152 mm] beyond both surfaces of wall. The annular space between the sleeve and

the periphery of opening shall be min 0 in. (continuous point contact) to max 1/4 in. [6 mm].

3. Cables – Aggregate cross-sectional area of cables in the EMT sleeve to be 0% to max 60%

of the aggregate cross-sectional area of the EMT sleeve. When there is no cable fill, device

cover is to be tightly closed. Cables to be rigidly supported on both sides of the wall

assembly. Any combination of the following types of cables may be used:

A. Single conductor No. 18 AWG (or smaller) RG/U coaxial cable with fluorinated ethylene

insulation and jacketing.

B. Fiber optic cable with polyvinyl chloride (PVC) or polyethylene (PE) jacket and insulation

having a max diameter of 5/8 in. (16 mm).

C. Max 4 pair No. 22 AWG (or smaller) copper conductor data cable with polyvinyl chloride

(PVC) or plenum rated jacketing and insulation.

D. Max 4/C No. 2 AWG (or smaller) copper conductor cable with XLPE/PVX insulation and PVC jacket.

E. Max 100 pair No. 24 AWG (or smaller) copper conductor telecommunication cable with

polyvinyl chloride (PVC) jacketing and insulation.

F. Max 400 pair No. 24 AWG (or smaller) copper conductor telecommunication cable with

polyvinyl chloride (PVC) jacketing and insulation.

G. Max 8/C 12 AWG (or smaller) copper conductor steel Metal-Clad or Armored-Clad cable.

The hourly T Rating of the firestop system is equal to the F Rating when no cable fill is used

or when cables A or B are used. The hourly T Rating is equal to the F Rating up to 3 hr when

cable C is used. The hourly T Rating is 1 hr when cable D is installed in 2, 3 or 4 hr rated

walls, 1/2 hr in 1 hr rated walls. The hourly T Rating is 1 hr when cable E is installed in 4 hr

rated walls and 0 hr in 1, 2 or 3 hr rated walls. The hourly T Rating is 3/4 hr when cable F is

installed in 2, 3 or 4 hr rated walls, 0 hr in 1 hr rated walls. The hourly T Rating is 1/4 hr

when cable G is installed in 2, 3 or 4 hr rated walls, 0 hr in 1 hr rated walls.

The L Rating at ambient and 400°F with no cable fill is 3.7 CFM and 2.1 CFM, respectively.

The L Rating at ambient and 400°F with cable fill is 4.6 CFM and 2.0 CFM, respectively.

4. Firestop System – The firestop system shall consist of the following:

A. Firestop Device* – Heat Shield – The heat shield shall be installed in accordance with

the accompanying installation instructions. Device to be installed around the outside of the

EMT sleeve both sides of wall. – THE WIREMOLD CO. – FS2RHS, FS4RHS

B. Firestop Device* – Device to be installed in accordance with the accompanying

installation instructions. Device to be installed and secured to the heat shield (Item 4A) at

the end of the EMT sleeve on both sides of wall. – THE WIREMOLD CO. - FS2R

FlameStopper, FS4R FlameStopper

*Bearing the UL Classification Mark

1. Wall Assembly – Min 4-1/2 in. [114 mm] thick reinforced lightweight or normal weight

(100-150 pcf or 1600-2400 kg/m3) concrete for 1 and 2 hr rated assemblies. Min 6 in. [152

mm] thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3)

concrete for 3 and 4 hr rated assemblies. Wall may also be constructed of any UL Classified

Concrete Blocks. Diam of opening shall be 2-1/4 in. [57 mm] or 4-3/4 in.

[121 mm] for the nom 2 in. [51 mm] and 4 in. [102 mm] sleeves (Item 2).

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

The hourly F Rating of the firestop system is dependent upon the hourly rating of the

wall in which it is installed.

2. Metallic Sleeve – Nom 2 in. [51 mm] or 4 in. [102 mm] diam electrical metallic tubing

(EMT), dependent on the size of the firestop device (Item 4). The sleeve is to extend a min

7/8 in.[22.2mm] to a max 6 in. [152mm] beyond both surfaces of wall. The annular space

between the sleeve and the periphery of opening shall be min 0 in. (continuous point

contact) to max 1/4 in. [6 mm].

3. Cables – Aggregate cross-sectional area of cables in the EMT sleeve to be 0% to max 60%

of the aggregate cross-sectional area of the EMT sleeve. When there is no cable fill, device

cover is to be tightly closed. Cables to be rigidly supported on both sides of the wall

assembly. Any combination of the following types of cables may be used:

A. Single conductor No. 18 AWG (or smaller) RG/U coaxial cable with fluorinated ethylene

insulation and jacketing.

B. Fiber optic cable with polyvinyl chloride (PVC) or polyethylene (PE) jacket and insulation

having a max diameter of 5/8 in. [16 mm].

C. Max 4 pair No. 22 AWG (or smaller) copper conductor data cable with polyvinyl chloride

(PVC) or plenum rated jacketing and insulation.

D.

Max 4/C No. 2 AWG (or smaller) copper conductor cable with XLPE/PVX insulation and PVC jacket.

E. Max 100 pair No. 24 AWG (or smaller) copper conductor telecommunication cable with

polyvinyl chloride (PVC) jacketing and insulation.

F. Max 400 pair No. 24 AWG (or smaller) copper conductor telecommunication cable with

polyvinyl chloride (PVC) jacketing and insulation.

G. Max 8/C 12 AWG (or smaller) copper conductor steel Metal-Clad or Armored-Clad cable.

The hourly T Rating of the firestop system is equal to the F Rating when no cable fill is used

or when cables A or B are used. The hourly T Rating is equal to the F Rating up to 3 hr when

cable C is used. The hourly T Rating is 1 hr when cable D is installed in 2, 3 or 4 hr rated

walls, 1/2 hr in 1 hr rated walls. The hourly T Rating is 1 hr when cable E is installed in 4 hr

rated walls and 0 hr in 1, 2 or 3 hr rated walls. The hourly T Rating is 3/4 hr when cable F is

installed in 2, 3 or 4 hr rated walls, 0 hr in 1 hr rated walls. The hourly T Rating is 1/4 hr

when cable G is installed in 2, 3 or 4 hr rated walls, 0 hr in 1 hr rated walls.

The L Rating at ambient and 400°F with no cable fill is 3.7 CFM and 2.1 CFM, respectively. The

L Rating at ambient and 400°F with cable fill is 4.6 CFM and 2.0 CFM, respectively.

4. Firestop System – The firestop system shall consist of the following:

A. Firestop Device* – Heat Shield – The heat shield shall be installed in accordance

with the accompanying installation instructions. Device to be installed around the outside

of the EMT sleeve both sides of wall. – THE WIREMOLD CO. - FS2RHS, FS4RHS

B. Firestop Device* - Device to be installed in accordance with the accompanying

installation instructions. Device to be installed and secured to the heat shield (Item 4A)

at the end of the EMT sleeve on both sides of wall. – THE WIREMOLD CO. - FS2R

Flamestopper, FS4R Flamestopper

*Bearing the UL Classification Mark

u

UL Certification

From UL Fire Resistance Directory

Through-penetration Firestop Systems

System No. W-L-3301

December 28, 2005

F Ratings – 1, 2, 3 and 4 Hr (See Item 1)

T Ratings – 0, 1/4, 1/2, 3/4, 1, 2, 3 and 4 Hr (See Item 3)

L Rating at Ambient – 3.7 CFM and 4.6 CFM (See Item 3)

L Rating at 400°F – 2.1 CFM and 2.0 CFM (See Item 3)

Through-penetration Firestop Systems

System No. W-J-3155

December 28, 2005

F Ratings – 1, 2, 3 and 4 Hr (See Item 1)

T Ratings – 0, 1/4, 1/2, 3/4, 1, 2, 3 and 4 Hr (See Item 3)

L Rating at Ambient – 3.7 CFM and 4.6 CFM (See Item 3)

L Rating at 400°F – 2.1 CFM and 2.0 CFM (See Item 3)

FIRESTOP DEVICE FOR USE IN THROUGH-PENETRATION

FIRESTOP SYSTEMS. SEE UL DIRECTORY OF PRODUCTS

CERTIFIED FOR CANADA AND UL FIRE RESISTANCE DIRECTORY

D

E

I

F

I

S

S

A

L

C

1A

3

2

1B

4B

4A

4A

3

2

1

4B

4A

4A

Page 5

5

A. B.

A.

FS2RWP8, FS4RWP12 WALL PLATE INSTALLATION:

Add-On Kit used to retrofit Flamestopper Thru-Wall Fitting over holes in the wall cables already installed. Use FS2RWP8 –

8" trade size Wall Covering Plate with FS2R. Use FS2RWP12 – 12" trade size Wall Covering Plate with FS4R.

1.

4.

B. Tighten Screw.

3. Use Insulation as template for holes.

2. Measure Wall thickness.

CAT NO. MAX. HOLE AREA

FS2RWP8 36 IN

2

FS4RWP12 100 IN

2

Wall

Thickness

Cut Split Sleeve to length. Wall

thickness plus 2 3/4" [70mm].

Page 6

6

A.

B.

6. Adjust Sliding Doors to be snug around Cable by turning Side Screws.

7.

FS2RWP8, FS4RWP12 WALL PLATE INSTALLATION (continued):

Ground in accordance with

National Electrical Codes.

Fill out and place label on wall

near FlameStopper.

A.

B. Tighten Clamp.

5.

Page 7

1. Wall Assembly – The 1 or 2 hr fire-rated gypsum board/stud wall assembly shall be

constructed of the materials and in the manner described within the individual U300, U400

or V400 Series Wall or Partition Designs in the UL Fire Resistance Directory and shall

incorporate the following construction features:

A. Studs – Wall framing shall consist of either wood studs or steel channel studs. Wood

studs to consist of nom 2 by 4 in. [51 by 102 mm] lumber spaced max 16 in. [406 mm]

OC. Steel studs to be min 2-1/2 in. [64 mm] wide and spaced max 24 in. [610 mm] OC.

B. Gypsum Board* – Thickness, type, number of layers and fasteners as specified in the

individual Wall and Partition Design. Max area of opening shall be 100 sq in. [645 sq

cm] with a max dimension of 10 in. [254 mm] for the FS4RWP12 device (Item 3B).

Max area of opening shall be 36 sq in. [232 sq cm] with a max dimension of 6 in.

[152 mm] for the FS4RWP12 device (Item 3B).

The hourly F Rating of the firestop system is dependent upon the hourly rating of the

wall in which it is installed.

2. Cables – Aggregate cross-sectional area of cables in the EMT sleeve to be 0% to max 60%

of the aggregate cross-sectional area of the EMT sleeve. When there is no cable fill, device

cover is to be tightly closed. Cables to be rigidly supported on both sides of the wall

assembly. Any combination of the following types of cables may be used:

A. Max 4 pair No. 22 AWG (or smaller) copper conductor data cable with polyvinyl chloride

(PVC) or plenum rated jacketing and insulation.

B. Single conductor No. 18 AWG (or smaller) RG/U coaxial cable with fluorinated ethylene

insulation and jacketing.

C. Fiber optic cable with polyvinyl chloride (PVC) or polyethylene (PE) jacket and insulation

having a max diameter of 5/8 in. (16 mm).

D. Max 8/C 12 AWG (or smaller) copper conductor steel Metal-Clad or Armored-Clad cable.

The hourly T Rating of the firestop system is 1-1/4 hr when no cable fill is used or when

cables A or C are used in 2 hr rated walls, 1/2 hr in 1 hr rated walls. The hourly T Rating is

1 hr when cable B is installed in 2 hr rated walls, 1/2 hr in 1 hr rated walls. The hourly T

Rating is 1/4 hr when cable D is installed in 2 hr rated walls, 0 hr in 1 hr rated walls.

The L Rating at ambient and 400°F with no cable fill is 1.7 CFM and 1.8 CFM, respectively.

The L Rating at ambient and 400°F with cable fill is 3.3 CFM and 2.0 CFM, respectively.

3. Firestop System – The firestop system shall consist of the following:

A. Sleeve – The octagonal, two-piece, 16 gauge (or heavier) galv steel sleeve shall be

installed in accordance with the accompanying installation instructions.

B. Firestop Device* – Wall Covering Plate – The two-piece wall covering plates shall be

installed on both sides of wall in accordance with the accompanying installation

instructions. The plates shall overlap opening a min 1 in. [25 mm] on all sides. The

plates are secured around sleeve and attached to gypsum board with min 1/8 in. [3.2

mm] diam steel toggle bolts. A min 16 gauge, 2-3/4 by 1-1/2 in. [70 by 38 mm] galv

steel plate is secured to the steel plates over the seams between top and bottom plates

with min No. 14 steel sheet metal screws.

THE WIREMOLD CO. – FS2RWP8, FS4RWP12

C. Firestop Device* – Device to be installed in accordance with the accompanying

installation instructions. Device to be installed and secured to the steel sleeve (Item

3A) on both sides of wall.

THE WIREMOLD CO. - FS2R FlameStopper, FS4R FlameStopper

*Bearing the UL Classification Mark

7

u

UL Certification

From UL Fire Resistance Directory

Through-penetration Firestop Systems

System No. W-L-3302

December 28, 2005

F Ratings – 1, and 2 Hr (See Item 1)

T Ratings – 0, 1/4, 1/2, 1 and 1-1/4 Hr (See Item 3)

L Rating at Ambient – 1.7 CFM and 3.3 CFM (See Item 3)

L Rating at 400°F – 1.8 CFM and 2.0 CFM (See Item 3)

FIRESTOP DEVICE FOR USE IN THROUGH-PENETRATION

FIRESTOP SYSTEMS. SEE UL DIRECTORY OF PRODUCTS

CERTIFIED FOR CANADA AND UL FIRE RESISTANCE DIRECTORY

D

E

I

F

I

S

S

A

L

C

3B

3C

2

1A

1B

3A

Page 8

Wiremold / Legrand

U.S. and International:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX 860-232-2062 • Outside U.S. 860-233-6251

Canada:

570 Applewood Crescent • Vaughan, Ontario L4K 4B4

1-800-723-5175 • FAX 905-738-9721

INS0010R2 – Updated January 2007 – For latest specs visit www.wiremold.com

© Copyright 2007 Wiremold / Legrand All Rights Reserved

CABLE O.D. FS2 FS4

TYPE CABLE / WIRE SIZE Inches [mm] 40% FILL 60% FILL 40% FILL 60% FILL

UNSHIELDED 4-pair, 24 AWG Cat 3 0.190 [4.8] 47 71 208 312

TWISTED PAIR 4-pair, 24 AWG Cat 5e 0.210 [5.3] 38 58 170 255

4-pair, 24 AWG Cat 6 0.250 [6.3] 20 30 68 100

TELEPHONE 2-pair, 24 AWG 0.140 [3.6] 87 130 383 574

25-pair, 24 AWG 0.410 [10.4] 10 15 44 67

50-pair, 24 AWG 0.580 [14.7] 5 7 22 33

100-pair, 24 AWG 0.700 [17.8] 3 5 15 22

400-pair, 24 AWG 1.470 [37.3] 0 1 3 5

COAXIAL RG58/U 0.195 [5.0] 45 67 197 296

RG59/U 0.242 [6.1] 29 43 128 192

RG62/U 0.242 [6.1] 29 43 128 192

RG6/U 0.270 [6.9] 21 32 95 140

FIBER OPTIC 2 Count 0.180 [4.6] 52 79 231 347

6 Count 0.210 [5.3] 38 58 170 255

24 Count 0.400 [10.2] 10 16 46 70

48 Count 0.450 [11.4] 8 12 37 55

96 Count 0.560 [14.2] 5 8 23 35

FLAMESTOPPER WIRE FILL CAPACITIES FOR DATA/COMMUNICATIONS

CABLE TYPE CONDUCTORS O.D. FS2 FS4

QUANTITY SIZE Inches [mm] 40% FILL 60% FILL 40% FILL 60% FILL

Copper Conductor Cable 4 2 1.120 [28.45] 1 2 4 6

with XLPE/PVX insulation 3 2 1.020 [25.91] 1 2 5 8

and PVC jacket 4 4 0.975 [24.77] 2 3 6 9

3 4 0.890 [22.61] 2 3 7 11

4 6 0.820 [20.83] 2 3 8 12

3 6 0.745 [18.92] 3 4 10 15

4 8 0.725 [18.44] 3 4 10 15

3 8 0.660 [16.76] 4 5 12 19

0.375 [9.5] 12 18 53 80

Max 8 cond. No. 12 AWG 0.500 [12.7] 6 10 30 45

MC (Metal Clad) Cable 0.625 [15.9] 4 6 19 28

0.655 [16.6] 3 5 17 26

FLAMESTOPPER WIRE FILL CAPACITIES FOR POWER WIRING

Loading...

Loading...