Page 1

Wiremold®electrical systems conform to and should be properly

grounded in compliance with requirements of the current National

Electrical Code or codes administered by local authorities.

All electrical products may present a possible shock or fire

hazard if improperly installed or used. Wiremold®electrical products

may bear the mark of a Nationally Recognized Testing Laboratory

(NRTL) and should be installed in conformance with current local

and/or the National Electrical Code.

FloorPort™Series

Activation Covers & Barrier Kits

I N S T A L L A T I O N I N S T R U C T I O N S

Installation Instruction No.: 1 008 150 R2 – Updated April 2011

Products: FP Series Covers with PKKIT, RFBKIT, RFBCIKIT, NRGKIT Barriers, & Abandonments S3AXPB, PKCAP and NRGCAP.

IMPORTANT: Please read all instructions

before beginning.

CAUTION: Do not operate floor scrubbers, tile strippers, or resurfacing equipment over the top of the cover. This may result in damage

CAUTION: Wash covers with a mild soap solution. Avoid any cleaning solutions with ingredients that may react with the aluminum

to the surface of the product.

construction of the products.

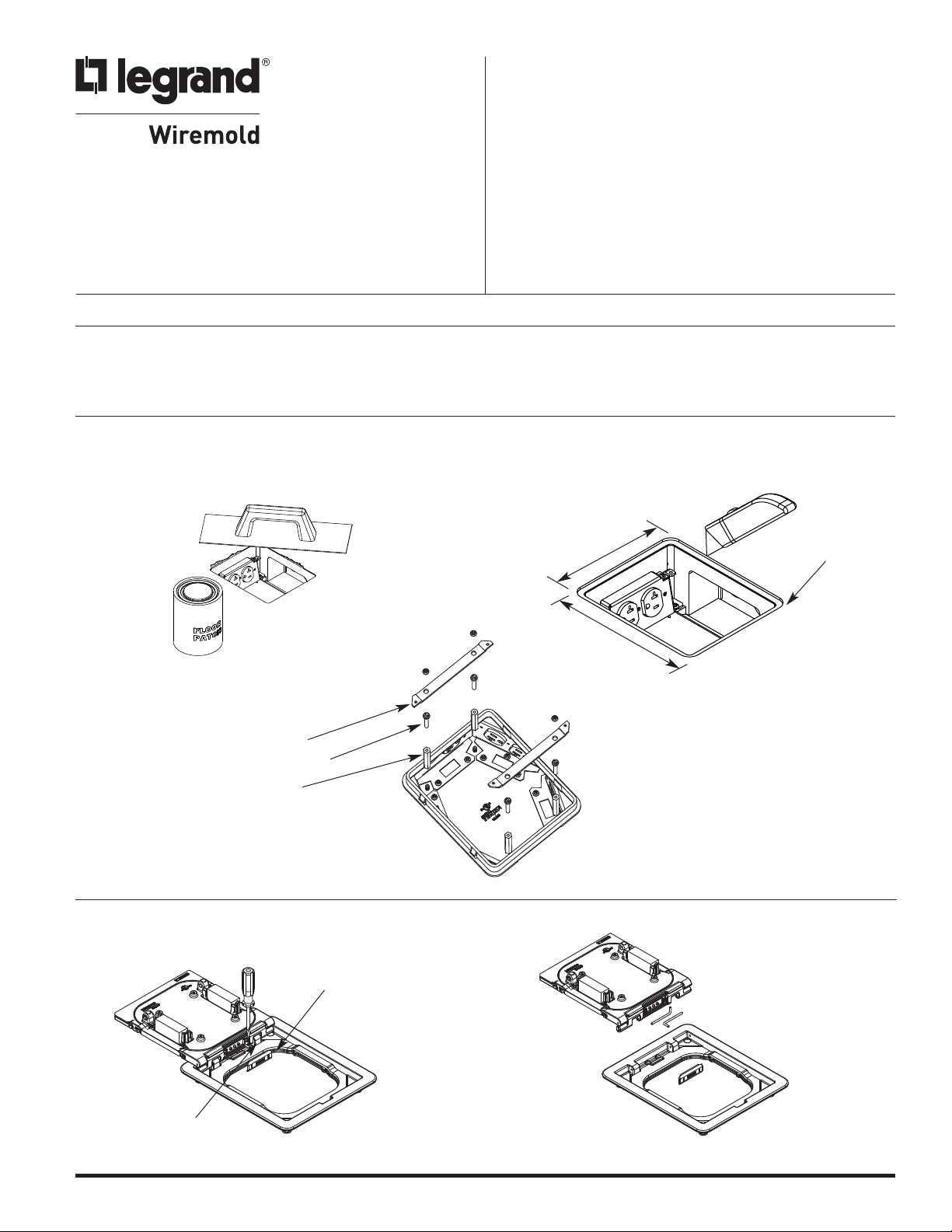

TRIM FLANGE INSTALLATION:

1. PREPARATION: Before installing Cover, repair any

cracks or chips around the Preset or Floor Box

opening using a suitable grout or repair compound.

3. RFB6 Installation Only – Install standoffs,

adjusting screws, and link straps as shown.

Link Strap

Adjusting Screw

Standoff

2. FPCTC, FPBTC & FPFFTC Series – Flanged Carpet

Installation Cut opening in Carpet as indicated in illustration.

6 1/4"

[158mm]

7 7/16"

[188mm]

Radius

1/2" [12.7mm]

1. REMOVING THE LID (FPC & FPB Series): Pry off

Cap from Hinge Clip with small blade screwdriver to

expose “L” Pins. Roll “L” Pin down and slide inward.

Cap

“L” Pin

1a. Remove both “L” Pins and detach Lid.

Page 2

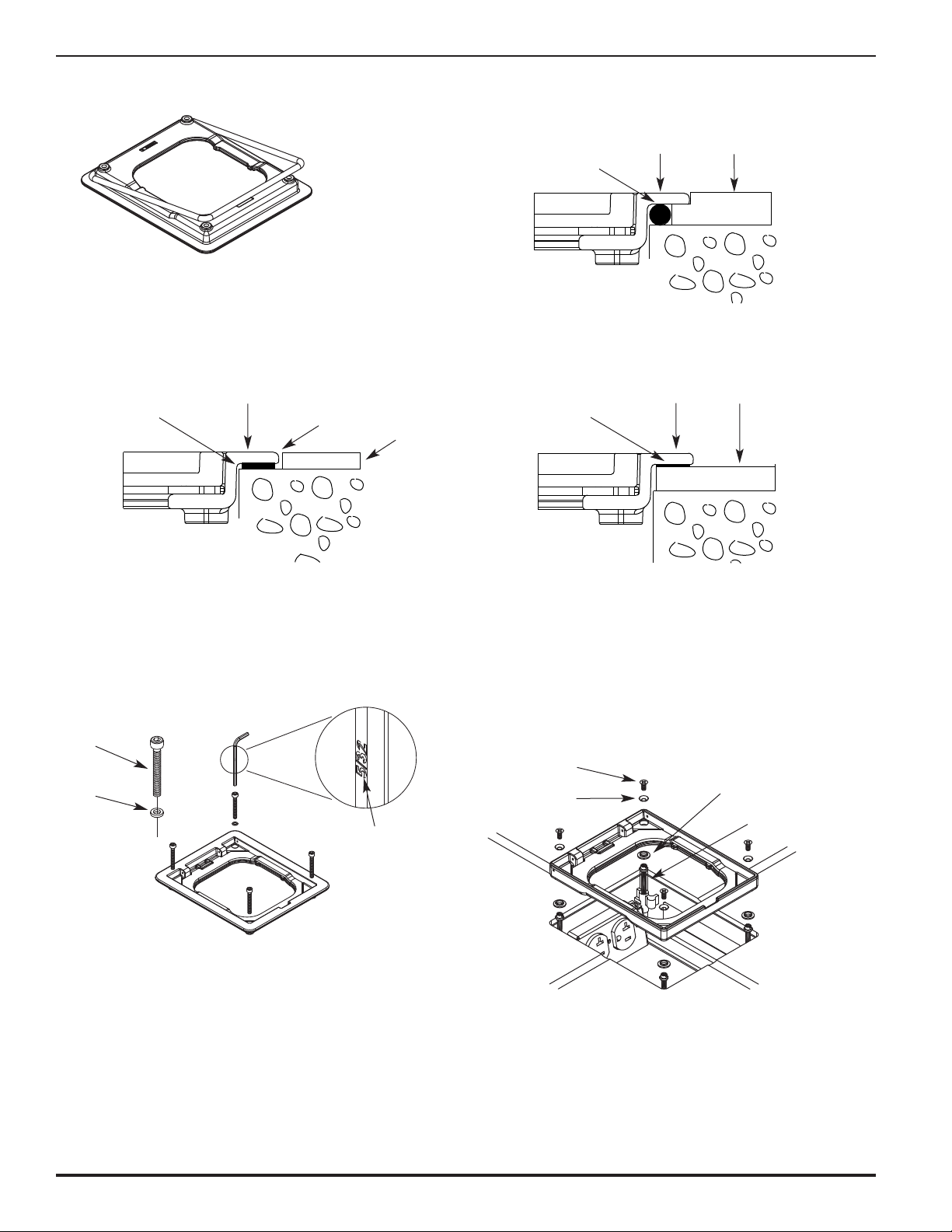

2. INSTALLING GASKET (All Flanged): Place

asket onto the underside of the Trim Ring.

G

2a. Flanged Carpet Installation: Installation view of

ound Gasket and Carpet.

r

2b.Flanged Tile Installation – FLUSH: Place flat Gasket

under Trim Ring prior to positioning on Concrete.

G

lat

F

asket

Flange

Apply Grout or

Silicone Compound

at Joint

ile (1/8"

T

3.2mm])

[

Round

Gasket

Flange

C

arpet

2c. Flanged Tile Installation – SURFACE: Place flat Gasket

under Trim Ring prior to positioning over Tile.

lange

Flat

Gasket

F

Tile

3. ATTACHING THE COVER (Flanged): Slide sealing

Washer over Attachment Screw and mount Flange

to Fitting.

Attachment

Screw (4X)

Sealing

Washer

5/32

4a. ATTACHING THE COVER (Flangeless): Thread adjusting

screws into preset or floor box and place nylon shoulder

washers on screws. Position flange on top and use a slotted

screwdriver to adjust flange elevation flush with floor surface.

#8 Hold-Down

Screw

Beveled

Washer

Nylon Shoulder

Washer

Slotted Adjusting

Screw

2

Page 3

ith Level or Straight Edge.

w

4c. Top of Flange adjusted flush with Floor Covering. 4b.Confirm top edge of Flange is level with Floor Covering

Tile

ylon

N

houlder

S

asher

W

eveled

B

asher

W

A

djusting

crew

S

Hold-Down

Screw

Trim Ring

4d.RFB6 Installation Only – Top of Flange adjusted

flush with Floor Covering.

NON-FLANGED

STYLE FLOOR PORT

TRIM RING

ATTACHMENT

CREW

S

ADJUSTING

SCREW

BEVELED

WASHER

NYLON

SHOULDER

WASHER

5. Re-attach Lid in Trim Ring and re-insert “L” Pins and

Hinge Clip Cap.

4e. Seal edge of Flange with Grout or Silicone.

6. FINISHING (Carpet Installation – FPC Series): Cut

Carpet Insert (see Template on last page) and mount

to Lid with Carpet Tape or Glue.

Carpet

Insert

7. Installation complete.

3

Page 4

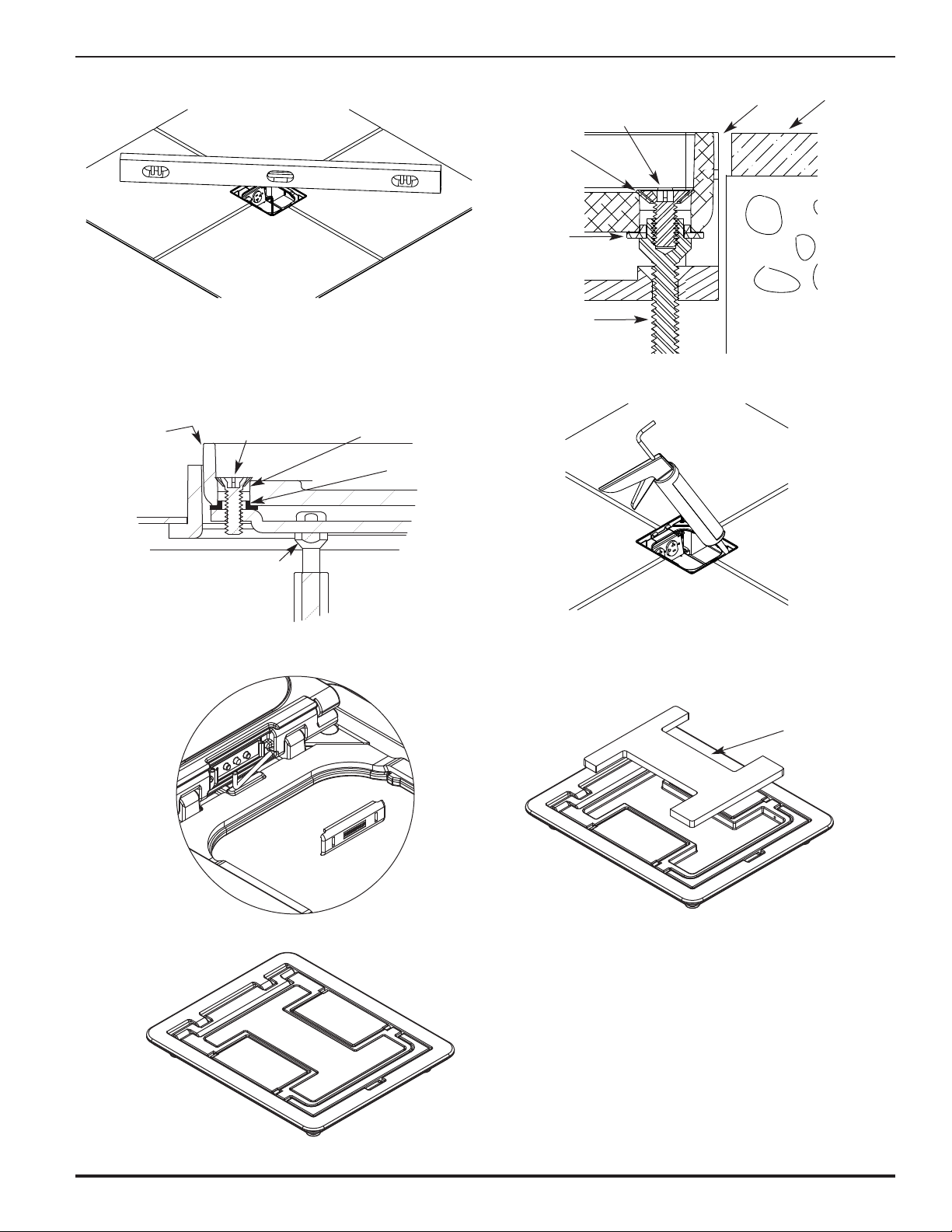

FURNITURE FEED BARRIER KIT – Cat. No. PKKIT

For use on Walkercell & Walkerdeck PK Presets

1. Install power and communication Bend Radius

Grommets as shown. Walkerdeck Presets must

2. Install Barrier Base to Preset Receptacle Mounts as shown

using #10-24 Screws.

have Insulation Blanket inserted on deck surface

o maintain Fire Classification.

t

Communication Bend

Radius Grommet

Power

Grommet

PK Preset

Interior

nsulation

I

lanket

B

FURNITURE FEED BARRIER KIT – Cat. No. RFBKIT

For use on RFB4, RFB4-SS, RFB2, RFB2-SS & RFB2-OG Floor Boxes

1. Install Barrier Base to RFB4 Floor Box Receptacle

Mounts as shown using #10-24 Screws.

2. Install Barrier Base to RFB4-SS or RFB2 Series Floor Box

as shown using Screws provided in Base Plate. Follow

directions on next page to complete installation.

ount Barrier Ears to

M

eceptacle Mounts

R

Mount Barrier Ears to

Receptacle Mounts

RFB4

Interior

FURNITURE FEED BARRIER KIT – Cat. No. RFBCIKIT

For use on RFB4-CI Floor Boxes

1. Install Barrier Base to RFB4-CI Floor Box as shown

using Screws provided in Base Plate.

Mount Barrier Ears at

bottom of Floor Box

RFB4-SS &

RFB2 Series

Interior

Mount Barrier Ears at

bottom of Floor Box

RFB4-CI

Interior

4

Page 5

URNITURE FEED BARRIER KIT – Cat. No. NRGKIT

F

For use with UL Listed KAM Industries LTD, dba Cordeck Cellular Metal Raceway Fittings, catalog number

B or N-R-G Bloc

N

1. Insert lower lip of Grommet into the

communication opening of the Cell.

Push the top of the Grommet inward

until it snaps into the Cell opening.

ommunication Bend

C

adius Grommet

R

-R-G Bloc

N

nterior

I

®

V Series Presets

I

2. Install Barrier Base to N-R-G Deck

as shown using #10-32 Screws.

Follow directions below to

omplete installation.

c

ount Barrier

M

ar at bottom

E

3. Install Cell Closure Plate to N-R-G

Deck as shown using #10-32 Screws.

#10-32 x 5/16" Self

Tap (Phillips Drive)

ell Closure

C

late

P

FURNITURE FEED ACTIVATIONS – FPFF SERIES

1. Select suitable Upper Partition height for concrete

pour depth and position over Lower Partition. Attach

Trim Ring. Mount Upper Partition to Trim Ring with

#8-32 x 1/4 FHMS. Fasten Upper and Lower Partitions

with #8-32 x 3/8 PHMS.

#8-32 x 1/4 FHMS

Trim Ring

2. Place Gasket on Flange and remove necessary

Screw Plugs for intended Conduit Fitting.

#8-32 x 7/8"

FHMS (6X)

Power Plate with

1" Trade Size

NPT Opening

NPT Screw Plug

1 1/4" Trade Size

NPT Screw Plug

1 1/4" x 2" Trade Size

1" Trade Size

NPT Reducer

Upper Partition

Bracket

#8-32 x 1/4 PHMS

Lower Partition

Bracket

FLOORPORT BRACKET COMPATIBILITY

These fittings are for indoor installation on carpet or tile

covered concrete floors that contain a cellular raceway

system that has a minimum of 2-1/2" [64 mm] of concrete

topping over the top of the deck. A typical UL Filer

Classified floor activation will consist of the following

components:

PK Series Preset Inserts

“( )” Maximum Quantity of Units Allowed Inside of Preset Insert

COVER ACTIVATION BARRIER COMMUNICATION

ASSEMBLY ASSEMBLY ASSEMBLY BRACKET

FPBTC

FPCTC (1) WPACR — (2) DTB-2

FPBT

FPCT

FPFFTC — (1) PKKIT (1) DTB-2FP

FPFFT

Trim Ring

Communication Plate

with 2" Trade Size NPT

opening (not listed for

power applications)

Gasket

N-R-G-Bloc®Series Preset Inserts

“( )” Maximum Quantity of Units Allowed Inside of Preset Insert

COVER ACTIVATION BARRIER COMMUNICATION

ASSEMBLY ASSEMBLY ASSEMBLY BRACKET

(1) NPACR — (2) DTB-N3

(2) DTB-N3 or

(1) NPACR-SGL — (1) NRGRT8 or

(1) NRGACT12 or

FPBTC (1) NRGACT8 or

FPCTC (1) NPACR-DD — (1) NRGRT8 or

FPBT (1) NPACR-VDD — (1) NRGACT8 or

FPCT (1) NRGRT8 or

(2) NPACR-VDD — —

FPFFTC (1) NRGACT8 or

FPFFT (1) NRGRT8 or

— (1) NRGKIT (1) NRGACT12 or

(1) NRGACT8 or

(1) NRGRT12

(1) NRGACT12 or

(1) NRGRT12

(1) NRGACT12 or

(1) NRGRT12

(1) NRGRT12

5

Page 6

URNITURE FEED ACTIVATIONS – FPFF SERIES

F

(continued)

3. Attach Fitting and Conduit to Cover Plate. Pull wire &

ables and mount Cover Plate to Trim Ring.

c

Thread Conduit

Fitting into Plate

eep Screw Plug

K

or abandonment

f

lexible

F

onduit

C

CAUTION: Tighten Mounting Plate Screws securely

to maintain system ground continuity.

ABANDONMENT

1. Cat. No. S3AXBP

For abandonment, remove Cover Assembly and install

1/4" [6.4mm] Steel Plate using four Leveling Screws

provided. Top of Plate should be flush with finished Floor.

Apply a bead of silicone caulking around the Bottom

Plate to prevent any water or debris entry.

4. Installation complete.

2. Place 1/8" [3.2mm] aluminum Top Plate over the

Bottom Plate. Install the four Screws provided to

secure the two Plates.

PERMANENT ABANDONMENT

1. Cat. Nos. PKCAP & NRGCAP

For permanent abandonment, remove Cover Assembly

and replace with Mud Cap. Repair the Floor Opening

using a suitable Grout or Concrete fill.

6

Page 7

To maintain UL Classification on cellular deck applications, refer to the tables below for maximum quantity of conductors allowed

to exit activation covers. Refer to the UL Fire Resistance Directory for additional floor design information. Depth of concrete over

top of steel deck must be a minimum of 2 1/2" [64 mm]

CABLE CAPACITY FOR CAT. NO. SERIES PK PRESETS

MANUFACTURED BY WALKER SYSTEMS, INC.

COVER CAT. NO. PRESET USED WITH: POWER COMM

FPBTC 2 Duplex Receptacles 4 (a) 64 (c)

FPCTC 2 Duplex Receptacles 4 (a) 64 (c)

FPFFTC Conduit Feed - Power Only 14 (b) 0

FLANGED

FLANGELESS

FLANGED

FLANGELESS

FPFFTC Conduit Feed - Comm. Only 0 224 (d)(e)

FPFFTC Conduit Feed - Power & Comm. 14 (b) 224 (d)(e)

FPBT 2 Duplex Receptacles 4 (a) 64 (c)

FPCT 2 Duplex Receptacles 4 (a) 64 (c)

FPFFT Conduit Feed - Power Only 14 (b) 0

FPFFT Conduit Feed - Comm. Only 0 224 (d)(e)

FPFFT Conduit Feed - Power & Comm. 14 (b) 224 (d)(e)

CABLE CAPACITY FOR CAT. NO. SERIES NB OR NRG BLOC IV PRESETS

COVER CAT. NO. PRESET USED WITH: POWER COMM

FPBTC 2 Duplex Receptacles 4 (a) 96 (c)

FPBTC 4 Duplex Receptacles 8 (a) 64 (c)

FPCTC 2 Duplex Receptacles 4 (a) 96 (c)

FPCTC 4 Duplex Receptacles 8 (a) 64 (c)

FPFFTC Conduit Feed - Power Only 14 (b) 0

FPFFTC Conduit Feed - Comm. Only 0 224 (d)(e)

FPFFTC Conduit Feed - Power & Comm. 14 (b) 224 (d)(e)

FPBTC 2 Duplex Receptacles 4 (a) 96 (c)

FPBTC 4 Duplex Receptacles 8 (a) 64 (c)

FPCTC 2 Duplex Receptacles 4 (a) 96 (c)

FPCTC 4 Duplex Receptacles 8 (a) 64 (c)

FPFFT Conduit Feed - Power Only 14 (b) 0

FPFFT Conduit Feed - Comm. Only 0 224 (d)(e)

FPFFT Conduit Feed - Power & Comm. 14 (b) 224 (d)(e)

NOTES:

(a) Maximum quantity of three-conductor

power supply cords (3/8" [9.5mm]

maximum diameter).

(b) Maximum quantity of No. 12 AWG

conductors allowed when a 1/2" through

1" trade size liquid tight steel conduit with

cast steel 90º elbow is connected to

access cover. When conductors larger

than No. 12 AWG are used, the aggregate

cross-sectional area of the copper

conductors shall not exceed the aggregate

cross-sectional area of

No. 12 AWG conductors.

(c) Maximum quantity of No. 24 AWG

conductors (4-pair communication

cable has eight conductors; 25-pair

communication cable has 50 conductors).

When conductors larger than No. 24

AWG are used, the aggregate crosssectional area of the copper conductors

shall not exceed the aggregate crosssectional area of No. 24 AWG conductors.

Maximum size of any communication

cable is not to exceed 25-pair (3/8"

[9.5mm] maximum diameter).

(d) Maximum quantity of No. 24 AWG

conductors (4-pair communication

cable has eight conductors; 25-pair

communication cable has 50 conductors)

allowed when a 1/2" through 1- 1/4"

trade size liquid tight conduit with cast

steel 90º elbow is connected to access

cover. When conductors larger than

No. 24 AWG are used, the aggregate

cross-sectional area of the copper

conductors shall not exceed the aggregate

cross-sectional area of No. 24 AWG

conductors. Maximum size of any

communication cable is not to exceed

25-pair (3/8" [9.5mm] maximum diameter).

(e) Where local codes permit, conduit

may be omitted when used for

communication type cables. A steel

conduit fitting or a nipple that extends

a minimum distance of 1" [25.4 mm]

beyond surface of cover assembly must

be utilized. Protect wires from damage by

installing a bushing suitable for use with

the type of fitting used. The diameter of

the conduit fitting opening for the passage

of cables shall be no more than 1/8 in.

larger than the diameter of the cable.

Use a suitable fire-resistive caulking such

as 3M Part No. CP 25WB to seal openings

around cables larger than 1/8 in.

7

Page 8

ARPET INSERT TEMPLATE

C

31/32"

[24.8mm]

7/8"

4

124mm]

[

5/16"

3

[84mm]

9/32"

1

33mm]

[

4 1/8"

[105mm]

19/32"

1

40mm]

[

9/32"

1

33mm]

[

19/32"

[14.7mm]

Radius 3/32"

[2.5mm]

© Copyright 2011 Legrand/Wiremold All Rights Reserved

CAUTION: When printing copies of this template,

please be sure template is scaled correctly

and is the correct size once it is printed.

Wiremold

U.S. and International:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX 860-232-2062 • Outside U.S.: 860-233-6251

Canada:

570 Applewood Crescent • Vaughan, Ontario L4K 4B4

1-800-723-5175 • FAX 905-738-9721

1 008 150 R2 0411

Loading...

Loading...