Page 1

Wiremold electrical systems conform to and should be properly

grounded in compliance with requirements of the current National

Electrical Code or codes administered by local authorities.

All electrical products may present a possible shock or fire

hazard if improperly installed or used. Wiremold electrical products

may bear the mark as UL Listed and/or Classified and

should be installed in conformance with current local and/or the

National Electrical Code.

Convia®Enabled

Walkerflex®System

I N S T A L L A T I O N I N S T R U C T I O N S

Installation Instruction No.: 1 008 478 – August 2009

roducts Covered: NVHUB, LVHUB, NRD1, NRD2, LRD1, LRD2, NPM12, NPM22, NPM24, NPM44, NPM24PF,

P

NPM44PF, CNDU, CLDU, CNWC, CLWC, CNPA, CLPA, CNCS, CLCS, CNCBS, CLCBS, CNCW,

CLCW, CAP3456 & CAP810

NOTE: Label on product indicates which products are suitable for use in air handing spaces

GENERAL INFORMATION

1. Each Convia®Enabled Walkerflex®System connector

2. Disconnect power from source prior to wiring any Walkerflex

3. Installer to determine the maximum power cable length

4. Installer to ensure adequate overload protection based on

5. Refer to appropriate Wiring Diagram and System Key

in accordance with Sec. 300-22(C) of the National Electric Code.

contains a color coded key that indicates rating, conductor

location and orientation. Only like colored keys can be

mated. See Key Configuration and Color Chart on page 11

for available options. Each key is comprised of one or more

configurations.

component into the building’s electrical power system.

based on wire gauge and circuit load.

the system key, rating and circuit load.

Configuration Conductor Location Chart for field connections

of Cat. Nos. CNWC/CLWC (Wire Connector) and

CNCW/CLCW (Cable Whips). Refer to wiring diagram

supplied with CNDU/CLDU (Distribution Unit) for field

termination.

IMPORTANT: Please read all instructions

before beginning.

6. Securing and Supporting of Cables and Components: Refer

to NEC Article 604, Manufacturing Wiring Systems and any

local codes.

7. Cap all unused connector openings with Cat. No. CAP3456

(for 3 through 6 wire system) or Cat. No. CAP810 (for 8 and

10 wire system).

8. All Convia Enabled accessories are available in a 3-6 wire

and 8-10 wire system and are rated 20A, 120V.

9. 277V Convia Enabled Walkerflex components are only

available in 3-6 wire configurations.

10.The Convia Enabled Walkerflex system is compatible with

the standard Walkerflex system of the same configuration

and key.

Page 2

ONVIA ENABLE WALKERFLEX SYSTEM INSTALLATION

C

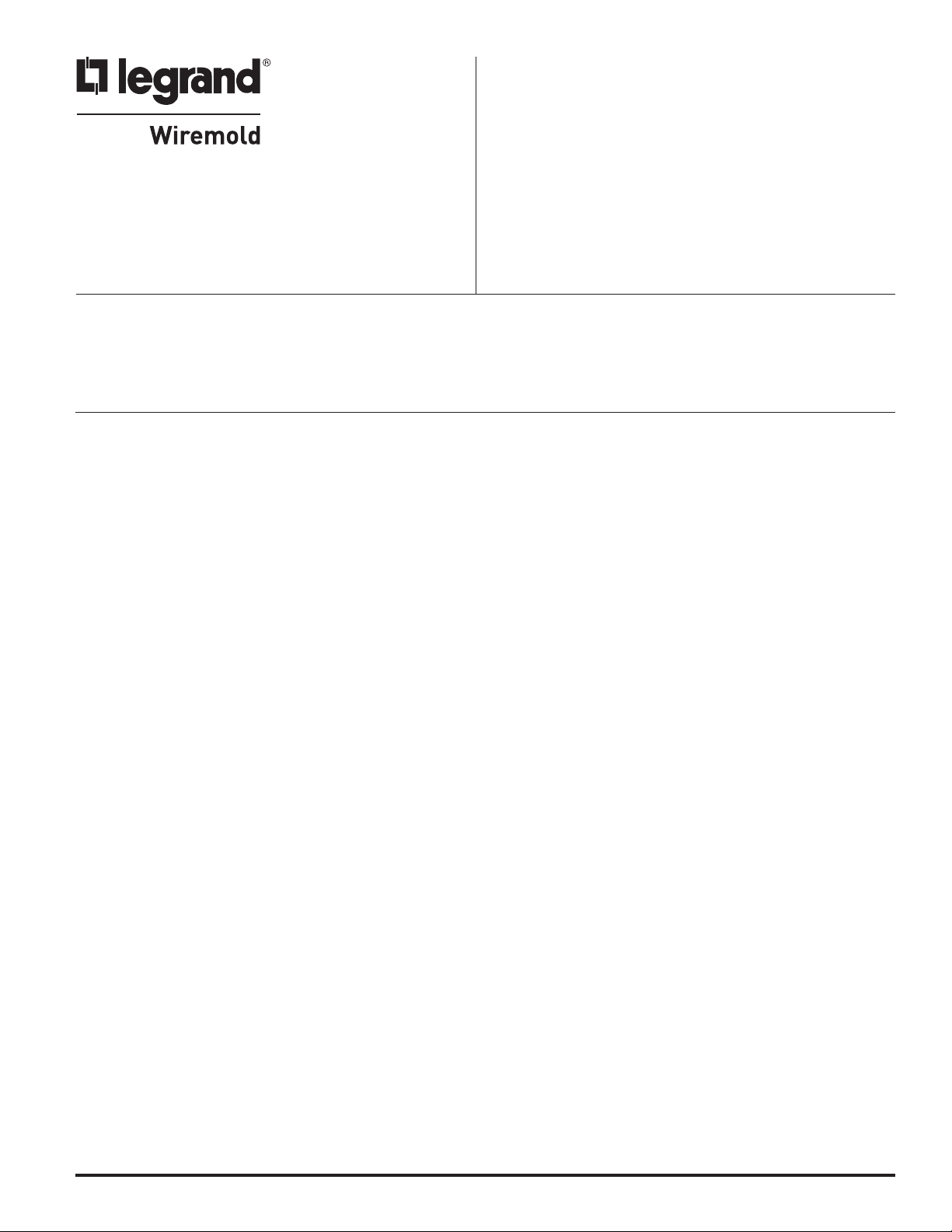

CNDU and CLDU Module & Flex Cables:

The CNDU and CLDU (CLDU is available for 3-6 wire configurations only) module is the main power source and interface to

the Convia Enabled Walkerflex System. It is to be fed from a distribution panel outfitted with appropriate circuit breakers to

rotect wiring.

p

NOTE: Cap Unused Connectors

NDU & CLDU Distribution Unit:

C

P

ow

e

r

O

ut

On All Power Out Modules.

Current Flow

Direction

Pow

e

r

In

Secure Box

in Place

Cat. No. CNWC & CLWC

(Wire Connector)

Cat. No. CNPA & CLPA

(Power Adapter)

Cat. No. CNCS & CLCS

(Cable Set)

F

eed

Pow

Ou

er

t

Connected to

Protected Circuit(s)

Cat. No. CAP3456 End Cap

(for 3-6 wire configurations)

P

ow

e

r

I

n

Cat. No. CAP810 End Cap

(for 8-10 wire configurations)

Pow

er

Ou

t

Cat. No. CNCS &CLCS

(Cable Set)

Current Flow

Direction

Current Flow

Direction

CAUTION: Do not make or break

connections while

circuits are energized.

Current Flow

Direction

Cat. No. CNCBS & CLCBS

(Splitter)

Mate only identical Keys

and Configurations.

Cat. No. CNCW & CLCW

(Cable Whip)

2

Page 3

ONVIA ENABLE WALKERFLEX SYSTEM INSTALLATION

C

(continued)

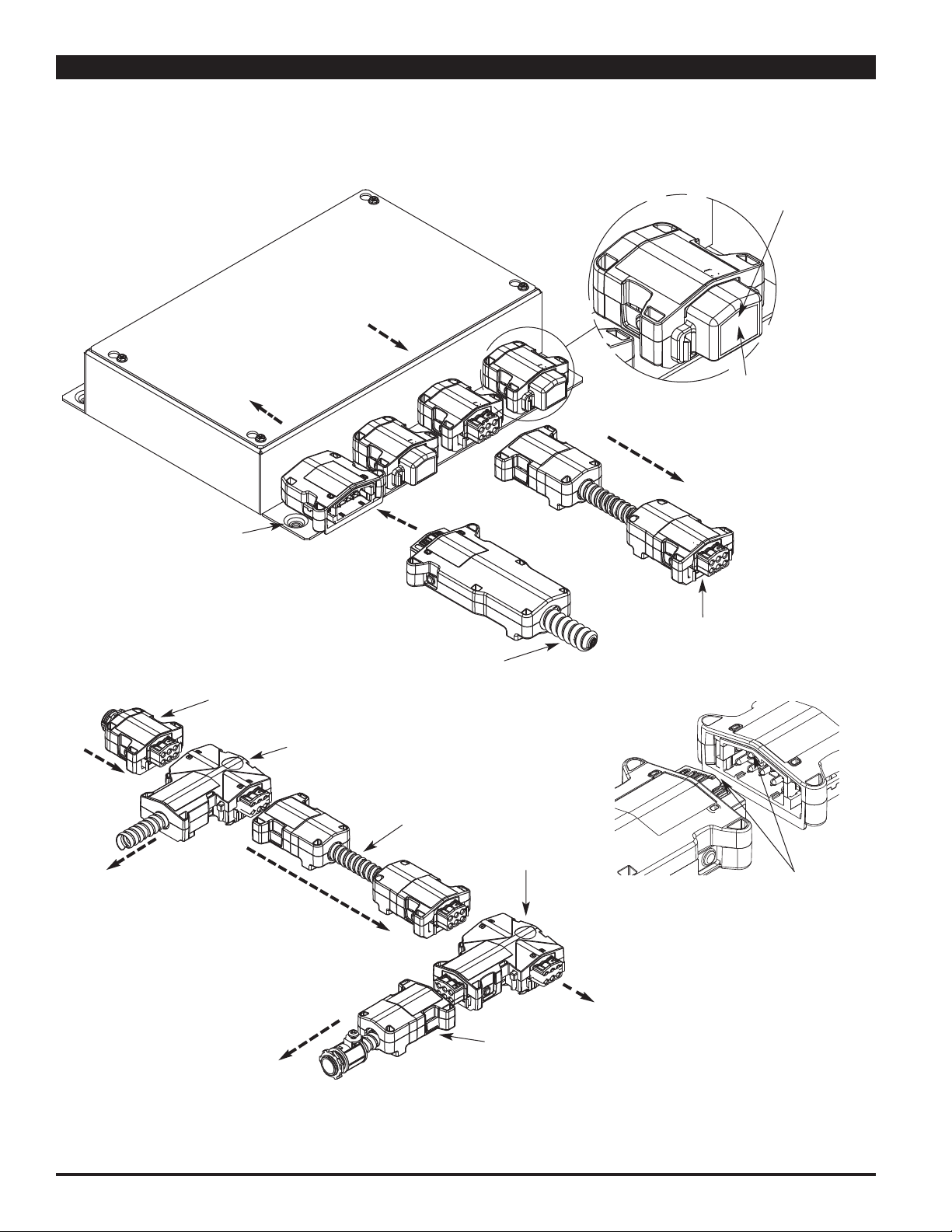

Network Hubs

The Network Hub module makes up the

backbone or Main Bus of the network. Multiple

Network Hubs can be configured to increase the

size of the network or to increase the number of

available ports in an installation location. Up to 50

etwork Hubs can be connected on a single

N

network with a patch cable length of up to 2000

feet. Refer to the ConviaNet Design Guide for

more information.

Step 1: Mount Network Hub securely using

Mounting Holes

Step 2: Connect Power to Network Hub.

appropriate screws and anchors.

For Modular Connection: Connect Convia

Enable Walkerflex Modular Cable

to modular input.

Prewired 5-Port Network Hub

Table A – NETWORK HUB POWER CONFIGURATIONS

120V SYSTEM

Part Walkerflex

umber Phase Configurations

N

VHUBA A 111, 211, 311

N

NVHUBB B 211, 311

VHUBC C 311

N

VHUBD 222

N

NVHUBF Field Wired

J11 Jack for Main

R

us Connections

B

J45 Jacks for Node

R

us Connections

B

RJ11 Jack for Main

Bus Connections

For Field Wired Units: Connect conduit to appropriate

conduit opening and wire per the National Electric

Code. (See Wiring Schematic below or on product

Power input coming

from Distribution Box

or main panel

Current Flow

Direction

label for connections.

3/4" Trade Size

Knockout

277V SYSTEM

art Walkerflex

P

Number Phase Configurations

VHUBA A 111, 211, 311

L

VHUBB B 211, 311

L

LVHUBC C 311

VHUBF Field Wired

L

VHUBF Field Wired

L

Field Wired 5-Port Network Hub

Hub Wiring Schematic

Step 3: Connect Wiremold Convia Enabled pre-terminated

RJ11 cables between the Network Hubs. Install

Communication Loop Closures into RJ11 ports at the

beginning and end of the network run (Main Bus).

Communications Loop

Closure – 2 required

for each network

Wiremold Convia

Enabled Pre-terminated

RJ11 Cable to next

Network Hub in network

NOTE: To ensure proper network functioning, Communication

Loop Closures need to be installed into the beginning

and end of the Main Bus of the network. If there is

only one Network Hub in the installation, then

Communication Loop Closures must be installed in

both RJ11 ports on the Network Hub.

1/2" Trade Size

Knockout

Step 4: Install Wiremold Convia Enabled pre-terminated

RJ45 cables between the Network Hubs and the

Relay Dimmers, Power Modules, Sims, Switches,

and Scene Controllers.

Wiremold Convia Enabled Preterminated RJ45 Cables going

to Relay Dimmers, Power

Modules, Sims, Switches and

Scene Controllers

Step 5: Move on to the installation of Relay Dimmers

and Power Modules.

3

Page 4

CONVIA ENABLE WALKERFLEX SYSTEM INSTALLATION

(continued)

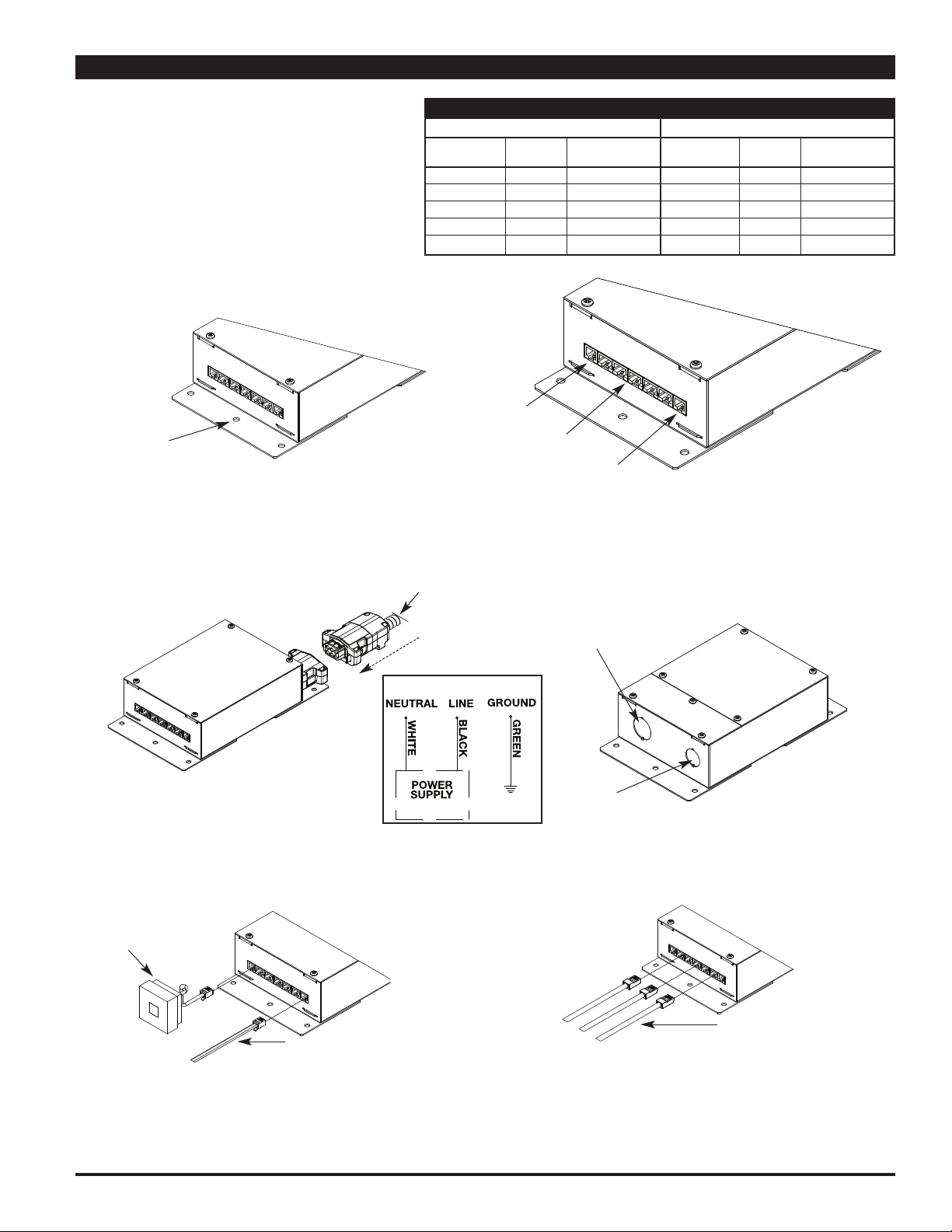

Relay Dimmer

he Relay Dimmer Modules are used to

T

control lighting and other devices, (maximum

20A load) via the Convia Enabled Walkerflex

System. They connect to the Network Hub

to create the Node Bus of the network. Up

to 25 nodes can be connected on a single

Node Bus with a maximum patch cable

length of 1000 feet. Refer to the ConviaNet

Design Guide for more information.

RD1A, NRD2A A 111, 211, 311

N

RD1B, NRD2B B 211, 311

N

NRD1C, NRD2C C 311

NRD1F, NRD2F Field Wired

RD1/LRD1 has one (1) controlled Walkerflex 111 output.

N

NRD2/LRD2 has two (2) controlled Walkerflex 111 outputs.

Table B –RELAY DIMMER POWER CONFIGURATIONS

120V SYSTEM

art Walkerflex

P

Number Phase Configurations

NOTE: For proper dimming function, use only approved dimming ballasts.

Additional ballasts are being added as they become available. For

updated ballast information, visit www.wiremold.com. If a qualified

0-10 VDC dimming ballast is not on the list, please contact your

sales representative for verification.

Step 1: Mount Relay Dimmer securely using

appropriate screws and anchors.

Convia Net

(RJ45) Jack for

Accessory Bus

Connections

Convia Net

(RJ45) for

Mounting Holes

Node Bus

Connections

277V SYSTEM

Part Walkerflex

umber Phase Configurations

N

LRD1A, LRD2A A 111, 211, 311

LRD1B, LRD2B B 211, 311

RD1C, LRD2C C 311

L

RD1F, LRD2F Field Wired

L

APPROVED DIMMING BALLASTS

Manufacturer Name

Advanced Transformer Mark

sram Sylvania Quiktronic

O

niversal Technologies SuperDim

U

General Electric UltraMax

onviaIR (RJ11)

C

ack for IR

J

Connections

Step 2: Connect Power to Relay Dimmers.

For Modular Connection: Connect Convia

Enabled Walkerflex Modular Cable

to modular input and output.

Power input coming

from Distribution Box

or main panel

Current Flow

Direction

Power Output going to

light fixture ballasts

Current Flow

Direction

NRD1 Wiring Schematic

For Field Wired Units: Connect conduit to appropriate

conduit opening and wire per the National

Electric Code. (See Wiring Schematic below

or on product label for connections.

1/2" Trade Size

Knockout

3/4" Trade Size

Knockout

NRD2 Wiring Schematic

4

Page 5

ONVIA ENABLE WALKERFLEX SYSTEM INSTALLATION

C

(continued)

Step 3: Connect Wiremold Convia Enabled Pre-terminated

J45 cables between the Network Hub and the

R

Relay Dimmers to create the Node Bus. The top

ConviaNet RJ45 jack is IN, the bottom ConviaNet

RJ45 jack is OUT.

n from Network

I

ub or upstream

H

elay Dimmer or

R

ower Module

P

Out to downstream

Relay Dimmer or

Power Module

Step 5: Install End Terminators in all ConviaNet RJ45

Node Bus Terminals not being used.

Step 4: Connect Wiremold Convia Enabled Pre-terminated

J45 cables between the Relay Dimmers and the

R

Sims, Sensors, Switches, and Scene Controllers

to create the Accessory Bus. An Accessory Bus

can contain up to 50 devices with a maximum

patch cable length of 500 feet.

Out to Sim, Switch

or Scene Controller

Step 6: Install IR Sensors into ConviaIR RJ11 Port.

R Sensor

I

NOTE: To ensure proper network functioning, End

Terminators need to be installed in all unused

Node ports, and Inline Terminators need to be

installed at the end of all Accessory Bus Runs.

Step 7: Connect Class 2 cable to Dimming Terminal Block.

See Product Label for dimming connections.

0-10VDC Dimmer

Terminal Block

NOTE: Connect appropriate Class 2 cable (Plenum rated

if installed in an Air Handling Space) to terminals

on the Relay Dimmer Modules in accordance with

Article 725 of the National Electric Code.

NOTE: IR Sensor can be installed using a RJ11 In-Line

Connector (PNRJ11LC) and a Wiremold Convia

Enabled pre-terminated RJ11 Cable when

necessary. IR Sensors are needed in all boxes for

commissioning and are recommended to aid in

reconfiguring or troubleshooting network setups.

Step 8: Connect system to light fixtures per the National

Electric Code.

5

Page 6

ONVIA ENABLE WALKERFLEX SYSTEM INSTALLATION

C

(continued)

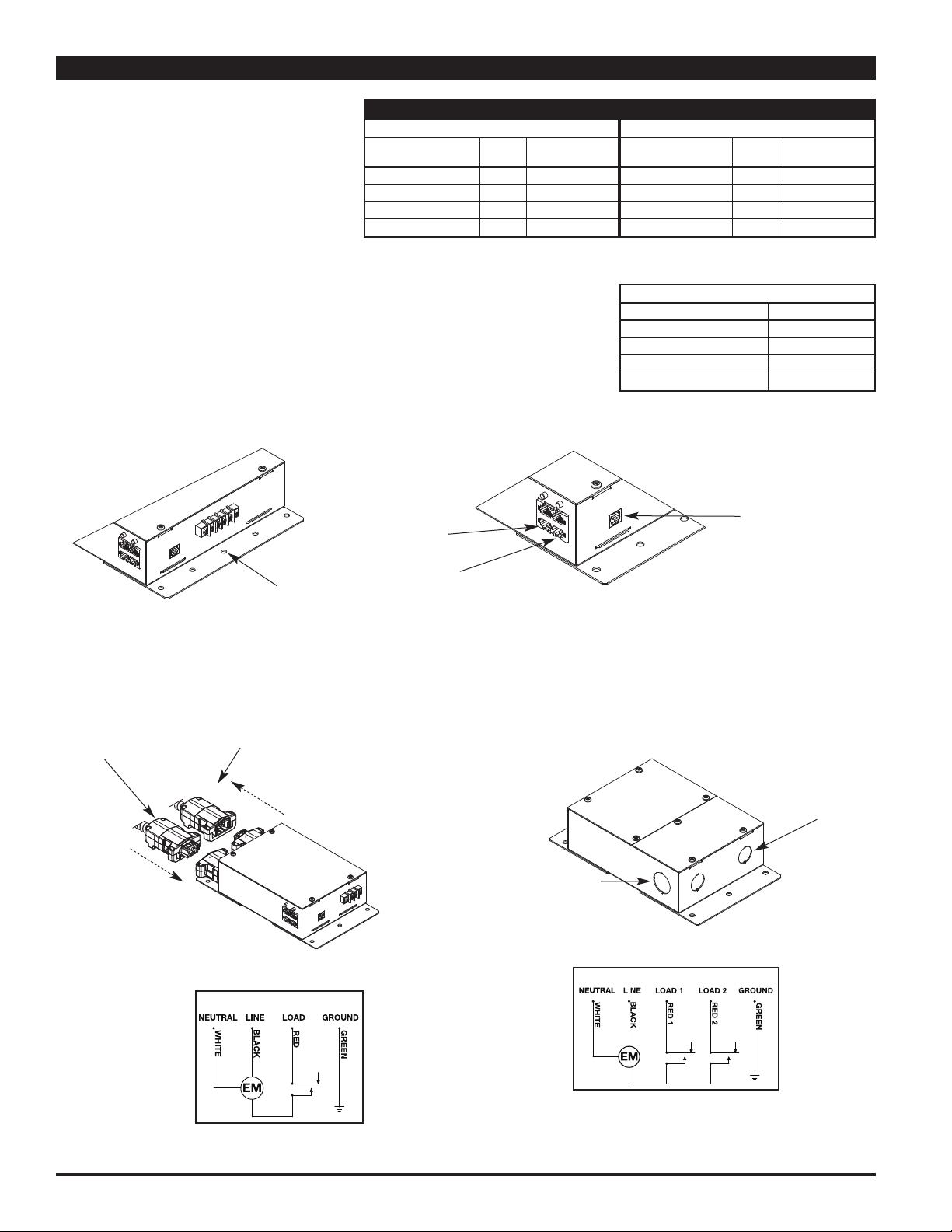

Power Modules

The Power Modules are used to control

general purpose loads, (maximum 20A load)

via the Convia Enabled Walkerflex System.

They connect to the Network Hub to create

the Node Bus of the network. Up to 25

odes can be connected on a single Node

n

Bus with a maximum patch cable length of

1000 feet. Refer to the ConviaNet Design

Guide for more information.

Step 1: Mount Power Modules securely using

appropriate screws and anchors.

Mounting Holes

Table C – POWER MODULE CONFIGURATIONS

art Number of Number of Walkerflex Walkerflex

P

Number Controlled Circuits Total Circuits Input(s) Output(s)

NPM12 12222 222

PM22 22222 222

N

PM12F 12 Field Wired

N

NPM22F 22 Field Wired

NPM24 24422 (2) 222

PM44 44422 (2) 222

N

PM24F 24 Field Wired

N

NPM44F 44 Field Wired

NPM24PF 24422 422

NPM44PF 44422 422

ConviaNet

(RJ45) Jack for

ccessory Bus

A

onnections

C

onviaNet (RJ45)

C

ack for Node

J

us Connections

B

onviaIR (RJ11)

C

ack for IR

J

Connections

Step 2: Connect Power to Power Modules.

For Modular Connection: Connect Convia Enabled Walkerflex Modular

Cable to modular input and output(s).

Two Circuit Power Modules

Pow

er

Out

put

goi

ng t

Pow

f

r

om

or

m

er

i

nput

com

Di

st

r

i

but

ai

n panel

Current Flow

Dire

c

tion

i

ng

i

on Box

Fl

oor

Boxes,

Dev

i

ces,

Cur

Di

r

ect

Pow

from Distribu

or ma

et

c.

r

ent

Fl

i

on

e

r in

in

pa

Poke-

ow

pu

t c

n

e

omin

tion

l

Thr

o

u

Four Circuit Partition Feed Modules

g

Box

Pow

er

i

nput

f

r

om

Di

st

or

m

ai

n panel

Current Flow

Direction

Four Circuit Power Modules

com

i

ng

r

i

but

i

on Box

Cur

r

ent

Fl

Di

Power Output going to

Floor Boxes, Poke-Thru

Devices, etc.

Current Flow

Direction

ow

r

ect

i

on

Pow

Fl

oor

Dev

er

Out

Boxes,

i

ces,

et

put

Poke-

c.

goi

ng t

Thr

o

u

Current Flow

Direction

6

Page 7

ONVIA ENABLE WALKERFLEX SYSTEM INSTALLATION

C

(continued)

Step 2 (continued):

For Field Wired Units: Connect conduit to appropriate conduit opening and wire per the National

Electric Code. (See Wiring Schematic below or on product label for connections).

Four Circuit Power Modules – Field Wired

3

/

4

"

Tr

ade

Si

z

Kn

ockou

e

t

3

Kn

Two Circuit Power Modules – Field Wired

/

4

"

Tr

ade

Si

z

ockou

e

t

NPM12 Wiring Schematic NPM24 Wiring Schematic

NPM22 Wiring Schematic NPM44 Wiring Schematic

1

Kn

/

2

"

ockou

Tr

ade

Si

z

e

t

1

Kn

/

2

"

ockou

Tr

ade

Si

z

e

t

Step 3: Connect Wiremold Convia Enabled pre-terminated

RJ45 cables between the Network Hubs and the

Power Modules to create the Node Bus. The top

ConviaNet RJ45 jack is IN, the bottom ConviaNet

RJ45 jack is OUT.

I

n f

r

om

Net

w

or

upst

m

M

m

odul

r

eam

er

k

or

e

Ou

t to dow

n

s

Dimme

tream

r or

le

Relay

Power Modu

Hub or

Rel

ay

Pow

Di

er

Step 5: Install End Terminators in all ConviaNet RJ45

Node Bus terminals not being used.

NOTE: To ensure proper network functioning, End Terminators

need to be installed in all unused Node ports, and End

Terminators or Inline Terminators need to be installed

at the end of all Accessory Bus Runs.

Step 4: Connect Wiremold Convia Enabled pre-terminated

RJ45 cables between the Power Modules and the

Sims, Switches, and Scene Controllers to create

the Accessory Bus. An Accessory Bus can contain

up to 50 devices with a maximum patch cable

length of 500 feet.

Out

t

o Si

m

,

Sw

i

t

or

Scene Cont

ch

r

ol

l

er

Step 6: Install IR Sensors into ConviaIR RJ11 Port.

IR Sensor

NOTE: IR Sensor can be installed using a RJ11 In-Line

Connector (PNRJ11LC) and a Wiremold Convia Enabled

pre-terminated RJ11 Cable when necessary. IR Sensors

are needed in all boxes for commissioning and are

recommended to aid in reconfiguring or troubleshooting

network setups.

7

Page 8

ALKERFLEX SYSTEM ACCESSORIES

W

TYPICAL PREWIRED ACCESS FLOOR BOX INSTALLATIONS

Access

Floor Box

Cat. No. CNCS

(Cable Set)

Cat. No. CNPA

(Power Adapter)

Cat. No. CNCS

(Cable Set)

CE6STCP222PA

Cat. No. CNCW

(Cable Whip)

CE3ATCAL111PA

CE4ATCAL222PA

CE4FFATCAL422CW

8

Page 9

ALKERFLEX SYSTEM WIRING DIAGRAMS

L1 Black

W

120V 20A SYSTEM FOR 1, 2, 3 OR 4 LINE CONDUCTORS

ONNECTED TO A GROUNDED THREE-PHASE WYE

C

120V 20A SYSTEM FOR 1 OR 2 LINE CONDUCTORS

CONNECTED TO A DUAL NEUTRAL GROUNDED

THREE-PHASE WYE

120V 20A SYSTEM FOR 1 OR 2 LINE CONDUCTORS

ONNECTED TO A DUAL NEUTRAL GROUNDED

C

THREE-PHASE WYE AND ISOLATED GROUND

120V 20A SYSTEM FOR 1 OR 2 LINE CONDUCTORS

CONNECTED TO A GROUNDED THREE-PHASE WYE

AND ISOLATED GROUND

277V 20A SYSTEM FOR 1, 2, OR 3 LINE CONDUCTORS

CONNECTED TO A GROUNDED THREE-PHASE WYE

277V 20A SYSTEM FOR 1 OR 2 LINE CONDUCTORS

CONNECTED TO A DUAL NEUTRAL GROUNDED

THREE-PHASE WYE

277V 20A SYSTEM FOR 1 OR 2 LINE CONDUCTORS

CONNECTED TO A DUAL NEUTRAL GROUNDED

THREE-PHASE WYE AND ISOLATED GROUND

277V 20A SYSTEM FOR 1 OR 2 LINE CONDUCTORS

CONNECTED TO A GROUNDED THREE-PHASE WYE

AND ISOLATED GROUND

9

Page 10

ALKERFLEX SYSTEM WIRING DIAGRAMS

W

(continued)

120V 20A SYSTEM FOR 4 LINE CONDUCTORS & 2

EUTRALS CONNECTED TO AN ISOLATED GROUND

N

THREE-PHASE WYE

120V 20A SYSTEM FOR 3 LINE CONDUCTORS & 3

NEUTRALS CONNECTED TO AN ISOLATED GROUND

THREE-PHASE WYE

120V 20A SYSTEM FOR 6 LINE CONDUCTORS & 2

EUTRALS CONNECTED TO AN ISOLATED GROUND

N

THREE-PHASE WYE

120V 20A SYSTEM FOR 4 LINE CONDUCTORS & 4

NEUTRALS CONNECTED TO AN ISOLATED GROUND

THREE-PHASE WYE

120V 20A SYSTEM FOR 6 LINE CONDUCTORS & 3

NEUTRALS CONNECTED TO A THREE-PHASE WYE

10

Page 11

6

7

8

5

4

3

9

10

2

G

6

7

8

5

4

3

9

10

2

G

6

7

8

5

4

3

9

10

2

G

6

7

8

5

4

3

9

10

2

G

6

7

8

5

4

3

9

10

2

G

6

7

8

5

4

3

9

10

2

G

6

7

8

5

4

3

9

10

2

G

6

7

8

5

4

3

9

10

2

G

6

7

8

5

4

3

9

10

2

G

6

7

8

5

4

3

9

10

2

G

G

5

6

1

2

3

G

5

6

1

2

3

G

5

6

1

2

3

G

5

6

1

2

3

G

5

6

1

2

3

G

5

6

1

2

3

ALKERFLEX SYSTEM WIRING CONFIGURATIONS

W

WALKERFLEX 3-6 KEY CONFIGURATIONS

ERMINAL

T

LOCK

YSTEM COLOR KEY POWER OUT POWER IN

S

20A, 120V Black A

20A, 120V, Orange B

IG

20A, 120V, Clear C

2N

20A, 277V Yellow D

20A, 277V, Green E

IG

20A, 277V, Blue F

2N

B

WALKERFLEX 8-10 KEY CONFIGURATIONS

ERMINAL

T

LOCK

YSTEM COLOR KEY POWER OUT POWER IN

S

20A, Black 422

120V,

4H/2N/IG

20A, Orange 442

120V,

4H/4N/IG

20A, Natural 332

120V,

3H/3N/IG

20A, Blue 631

120V,

6H/3N/G

20A, Ivory 622

120V,

6H/2N/IG

B

8-10 SYSTEM KEYING CONFIGURATIONS & COLORS

TERMINAL

SYSTEM COLOR KEY CONFIG COLOR COLOR COLOR

BLOCK WIRE WIRE WIRE

CONDUCTOR

120V Black 422 422 7 Line 1: Black 2 Neutral 1: White 1 Equip Gnd: Green

4H/2N/IG 8 Line 2: Red 3 Neutral 2: Wht/Red 6 ISO Gnd: Grn/Yel

9 Line 3: Blue

10 Line 4: Blk/Wht

120V Orange 442 442 7 Line 1: Black 2 Neutral 1: White 1 Equip Gnd: Green

4H/4N/IG 8 Line 2: Red 3 Neutral 2: Wht/Red 6 ISO Gnd: Grn/Yel

9 Line 3: Blue 4 Neutral 3: Wht/Blu

10 Line 4: Blk/Wht 5 Neutral 4: Wht/Blk

120V Natural 332 332 7 Line 1: Black 2 Neutral 1: White 1 Equip Gnd: Green

3H/3N/IG 8 Line 2: Red 3 Neutral 2: Wht/Red 6 ISO Gnd: Grn/Yel

9 Line 3: Blue 4 Neutral 3: Wht/Blu

120V Blue 631 631 5 Line 1: Black 2 Neutral 1: White 1 Equip Gnd: Green

6H/3N/G 6 Line 2: Red 3 Neutral 2: Wht/Red

7 Line 3: Blue 4 Neutral 3: Wht/Blu

8 Line 4: Blk/Wht

9 Line 5: Red/Wht

10 Line 6: Blu/Wht

120V Ivory 622 622 4 Line 1: Black 2 Neutral 1: White 1 Equip Gnd: Green

6H/2N/IG 5 Line 2: Red 3 Neutral 2: Wht/Red 6 ISO Gnd: Grn/Yel

7 Line 3: Blue

8 Line 4: Blk/Wht

9 Line 5: Red/Wht

10 Line 6: Blu/Wht

HN G

LOCATION

LOCATION

CONDUCTOR

LOCATION

CONDUCTOR

11

Page 12

ALKERFLEX SYSTEM WIRING CONFIGURATIONS

W

(continued)

3-6 SYSTEM KEYING CONFIGURATIONS & COLORS

TERMINAL

BLOCK WIRE WIRE WIRE

COLOR KEY CONFIG COLOR COLOR COLOR

Black A 111 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

211 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

311 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

411 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

Orange B 112 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

212 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

222 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

Clear C 221 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

Yellow D 111 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

211 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

311 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

411 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

Green E 112 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

212 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

222 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

Blue F 221 1 Line 1: Black 6 Neutral 1: White 4 Equip Gnd: Green

HN G

LOCATION

CONDUCTOR

LOCATION

CONDUCTOR

LOCATION

CONDUCTOR

2 Line 2: Red

2 Line 2: Red

3 Line 3: Blue

2 Line 2: Red

3 Line 3: Blue

5 Line 4: Blk/Wh

5 ISO Gnd: Grn/Yel

2 Line 2: Red 5 ISO Gnd: Grn/Yel

2 Line 2: Red 3 Neutral 2: Wht/Red 5 ISO Gnd: Grn/Yel

2 Line 2: Red 5 Neutral 2: Wht/Red

2 Line 2: Red

2 Line 2: Red

3 Line 3: Blue

2 Line 2: Red

3 Line 3: Blue

5 Line 4: Blk/Wh

5 ISO Gnd: Grn/Yel

2 Line 2: Red 5 ISO Gnd: Grn/Yel

2 Line 2: Red 3 Neutral 2: Wht/Red 5 ISO Gnd: Grn/Yel

2 Line 2: Red 3 Neutral 2: Wht/Red 5

© Copyright 2009 Legrand All Rights Reserved

WIREMOLD

U.S. and International:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX 860-232-2062 • Outside U.S.: 860-233-6251

Canada:

570 Applewood Crescent • Vaughan, Ontario L4K 4B4

1-800-723-5175 • FAX 905-738-9721

1 008 478 0809

Loading...

Loading...